Efficient production and manufacturing machine for granulated feed

A pellet feed and production machine technology, which is applied in feed, mold extrusion pelletization, cocoa, etc., can solve the problems of being easily polluted by mold, magnetic induction oxygen bacteria, spoilage bacteria, etc., economic loss, and low compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

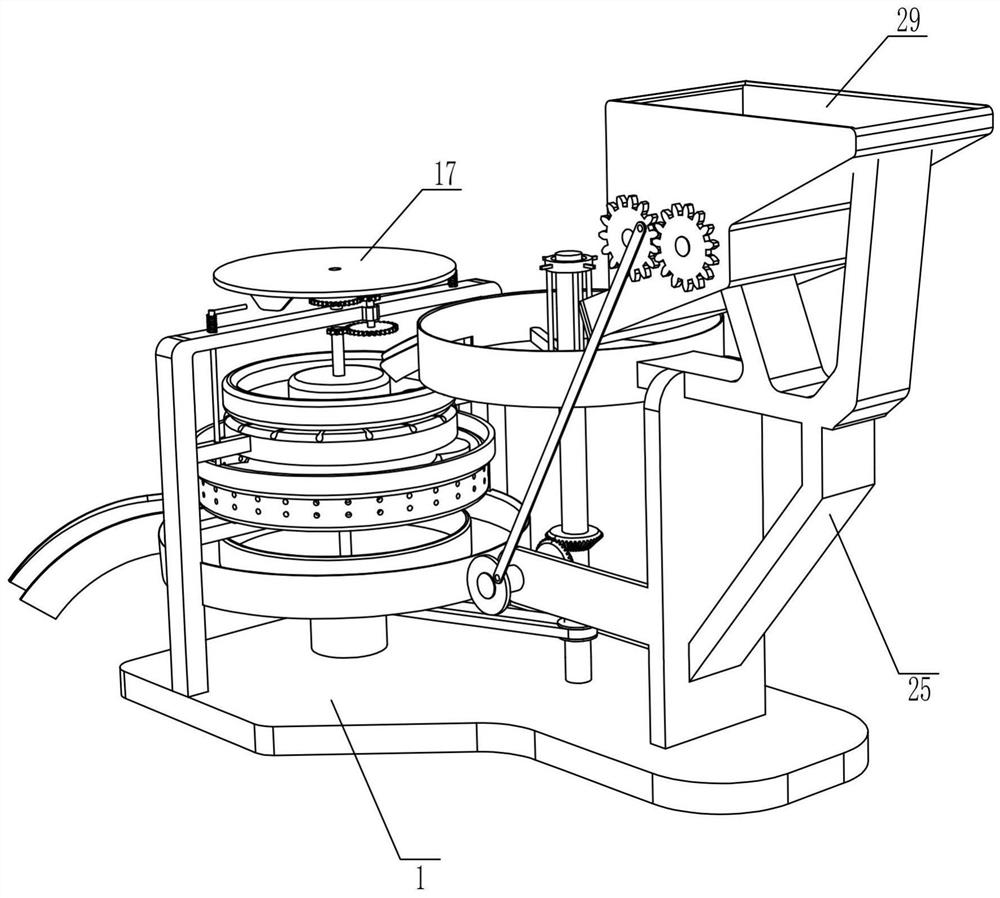

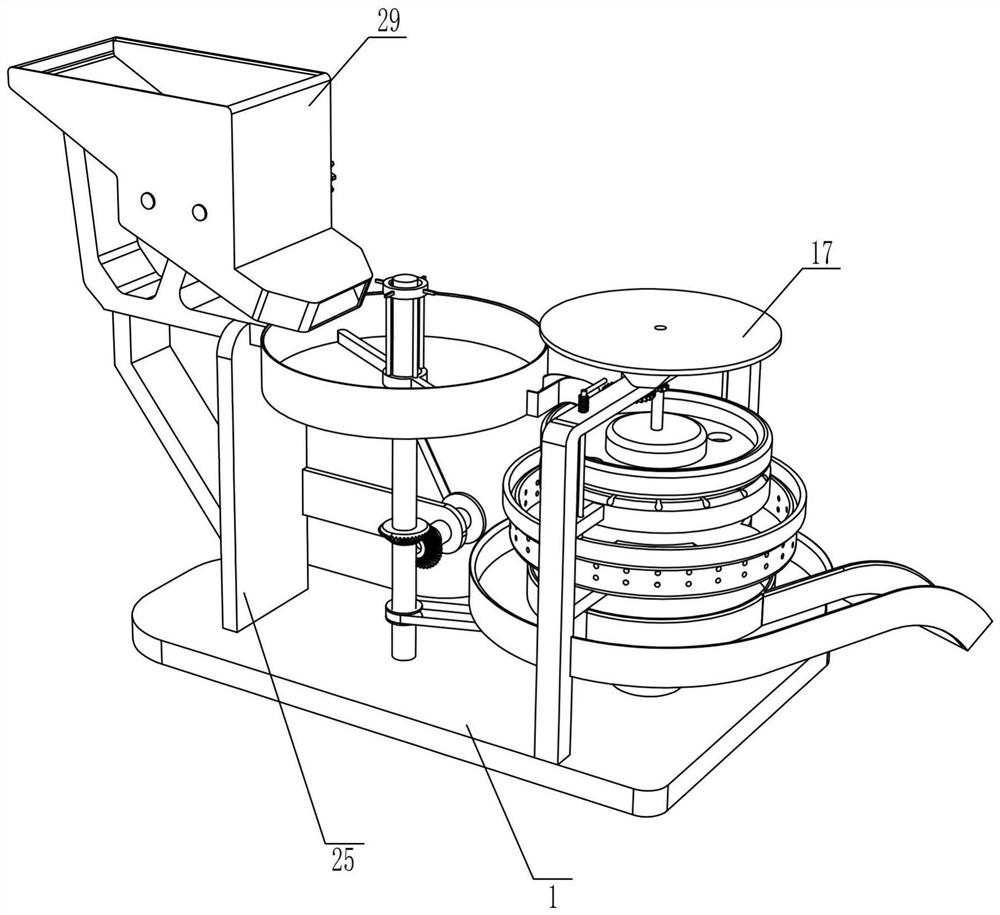

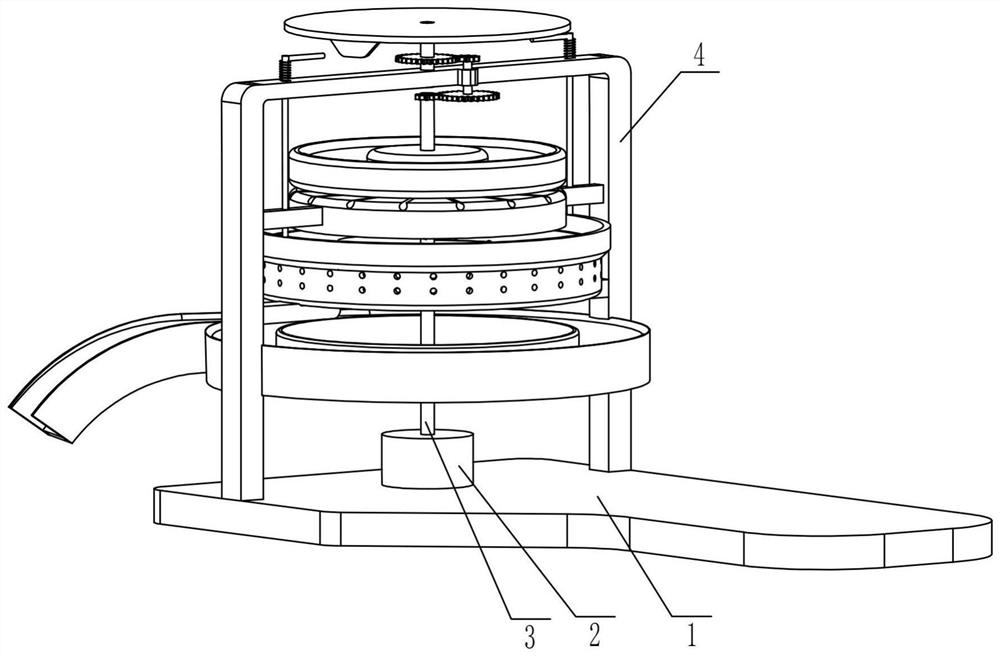

[0025] A pellet feed high-efficiency production machine, such as Figure 1-9 As shown, it includes a base 1, a motor 2, a rotating shaft 3, a support frame 4, a turntable 5, a blanking rack 6, a forming mechanism, a pinion 11, a rotating shaft 12, a large gear 13, a pinion 2 14, Rotating shaft three 15, gear two 16 and cutting mechanism, the motor 2 that plays a driving role is fixedly installed on the base 1, the lower end of the rotating shaft one 3 is fixedly connected with the output end of the motor 2, and the support frame 4 that plays a supporting role It is fixedly installed on the base 1 and is close to the motor 2. The turntable one 5 for transmission is fixedly installed on the rotating shaft one 3 and located above the motor 2. The blanking frame 6 used for discharging is fixedly installed on the support frame 4. and in contact with the turntable one 5, the extrusion molding mechanism capable of extruding the powdered feed raw materials is installed on the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com