Patents

Literature

59results about How to "Reduce chapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nursing type disinfecting liquid soap

ActiveCN102085159AReduce chappingReduce irritant dermatitisCosmetic preparationsToilet preparationsIrritant dermatitisAlcohol

The invention relates to nursing type disinfecting liquid soap which is a water solution containing the following components in proportion by weight: 0.1-5.0% of disinfectant, 1.0-30.0% of surfactant, 0.5-40.0% of thickener, 0.1-25.0% of nursing agent, 0.05-2.0% of pH regulator for regulating the pH of the solution to be 5-7, and 0.0-30.0% of lipophilic solvent. The nursing type disinfecting liquid soap provided by the invention has a homogeneous formula and a very low content of alcohol components, and skin protecting factors are added, thus reducing skin dryness or cracking and irritant dermatitis caused by frequent hand washing, and achieving multiple effects of washing, disinfecting and protecting skin. Therefore, the nursing type disinfecting liquid soap is a novel mild hand washing disinfectant with an efficient disinfecting action.

Owner:CHANGSHA YOUWEI BIOTECH

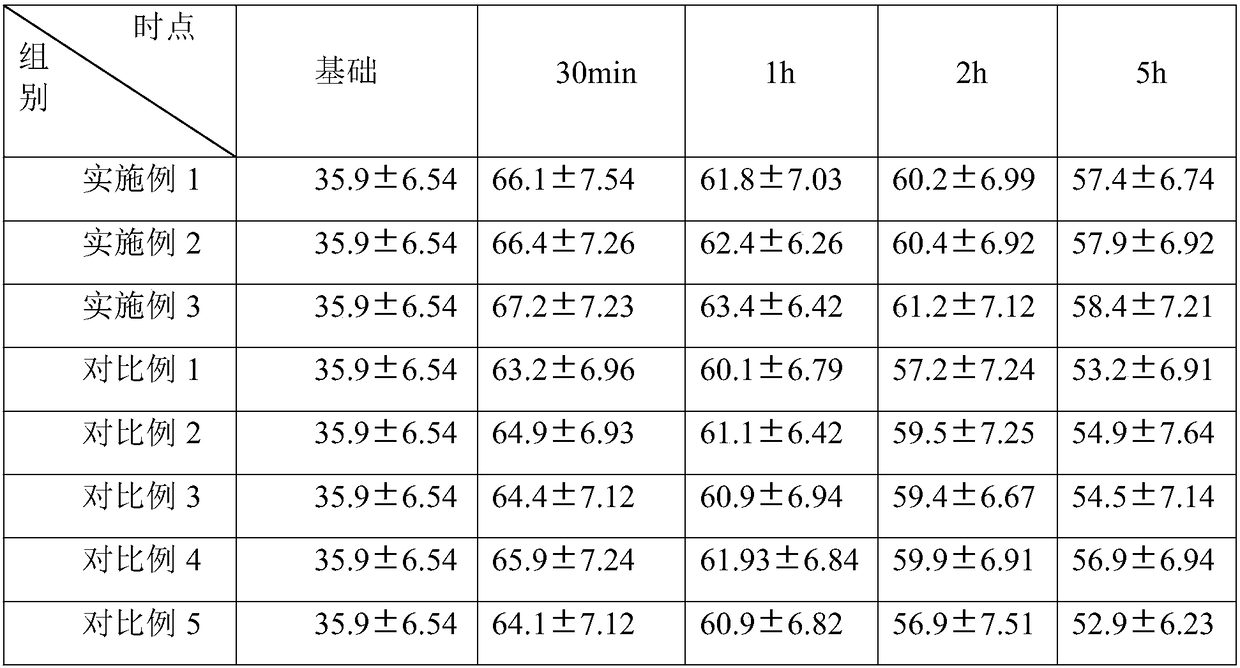

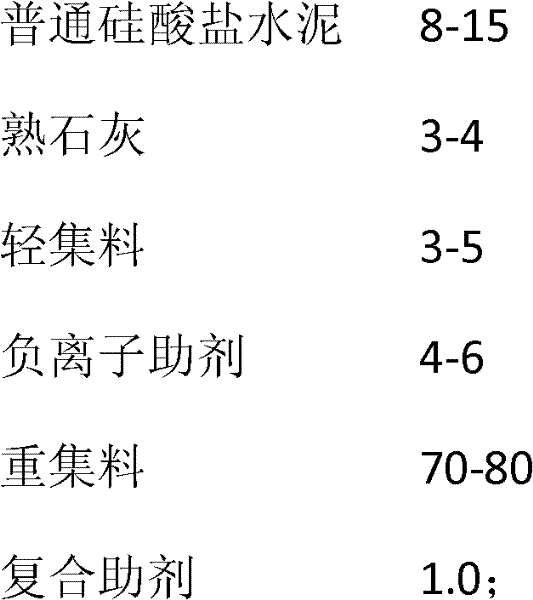

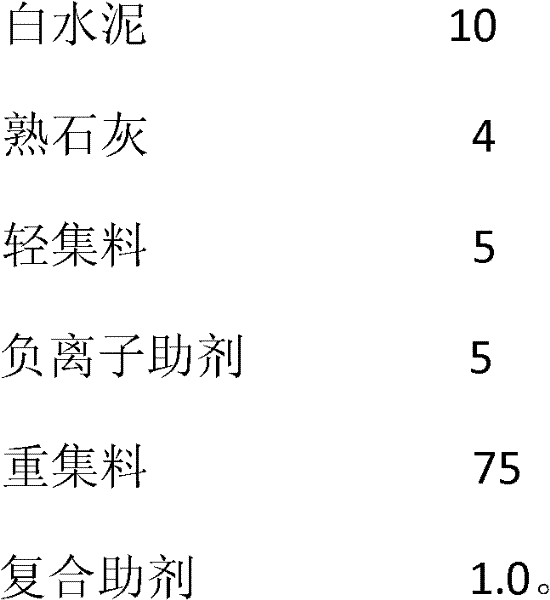

Interior wall plastering mortar and construction method thereof

InactiveCN101712545AHigh tensile strengthReduce stretchCovering/liningsSolid waste managementRiver sandFineness

The invention provides interior wall plastering mortar, which is prepared by mixing the following components in part by weight: 30 to 35 parts of ordinary Portland cement, 4 to 5 parts of hydrated lime, 5 to 10 parts of light aggregate, 50 to 60 parts of heavy aggregate, and 1.0 part of C-type composite auxiliary, wherein the light aggregate is an inorganic vitrified hollow cellular material of which the fineness is lower than 100 meshes; the heavy aggregate is ordinary river sand; and the C-type composite auxiliary is sold by Guangzhou Hecheng Trading Company. The construction method for the interior wall plastering mortar comprises the following steps: diluting the light energy-saving interior wall plastering mortar with water accounting for 30 to 50 percent of the weight of the mortar; and mechanically or manually stirring the diluted mortar until the mortar is mixed uniformly to achieve the viscosity suitable for mechanical spraying or manual construction. Therefore, the mortar can be sprayed mechanically or constructed manually. The interior wall plastering mortar has light weight and energy conservation, can prevent hollowness, cracking and falling off by being matched with a light wall body, can effectively reduce cracking of the mortar, ensures the quality of construction work, has the advantages of heat insulation and noise reduction, low cost of unit area, good grain composition, good peaceability, mechanical construction contribution and simple process.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Acne-removing compound essential oil

InactiveCN103705423AHas pain reliefAntidepressantCosmetic preparationsToilet preparationsJuniperBase oil

The invention relates to a cosmetic and skincare product, and particularly relates to acne-removing compound essential oil. The acne-removing compound essential oil comprises the following raw materials: needle juniper essential oil, sandalwood essential oil, chamomile essential oil, rose essential oil, lavender essential oil and base oil. The needle juniper essential oil is helpful for oily congestive skins and can improve sebum of scalp, and can improve acne, pore block and dermatitis due to the characteristic of purification. The sandalwood essential oil has the effect of promoting skin cells to grow, so that the skin is elastic and constrictive. Therefore, the compound essential oil provided by the invention has a very good acne-removing effect and further can maintain sensitive skins, increase skin elasticity and improve dried and hydropenic skins, so that the compound essential oil is excellent acne-removing skin care compound essential oil.

Owner:QINGDAO YONGTONG ELEVATOR ENG

High-flow-state anti-cracking concrete and preparation method thereof

InactiveCN111484282AImprove crack resistanceImprove impermeabilitySolid waste managementEpoxyWater reducer

The invention relates to high-flow-state anti-cracking concrete comprising the following components in parts by weight: 220-430 parts of cement, 130-200 parts of water, 30-90 parts of fly ash, 70-130parts of mineral powder, 550-880 parts of a fine aggregate, 1100-1350 parts of a coarse aggregate, 6-15 parts of a super absorbent resin particles, 20-60 parts of sponge rubber particles, 3-15 parts of steel fibers, 2-8 parts of epoxy resin and 4-10 parts of a water reducing agent, wherein the sponge rubber particles are formed by crushing sponge rubber. The preparation method comprises the steps:S1, uniformly mixing the super absorbent resin particles with the sponge rubber particles; S2, adding the mixture obtained in the step S1 into water to enable the super absorbent resin particles andthe sponge rubber particles to pre-absorb water, so as to obtain a pre-water-absorbing mixture; and S3, mixing the cement, the fly ash, the mineral powder, the fine aggregate, the coarse aggregate, the steel fibers, the epoxy resin, the water reducing agent, water and the pre-water-absorbing mixture, and uniformly stirring to obtain the high-flow-state anti-crack concrete. The high-flow-state anti-cracking concrete is good in anti-cracking performance and has the effect of improving the durability of the concrete.

Owner:上海练定新材料科技有限公司

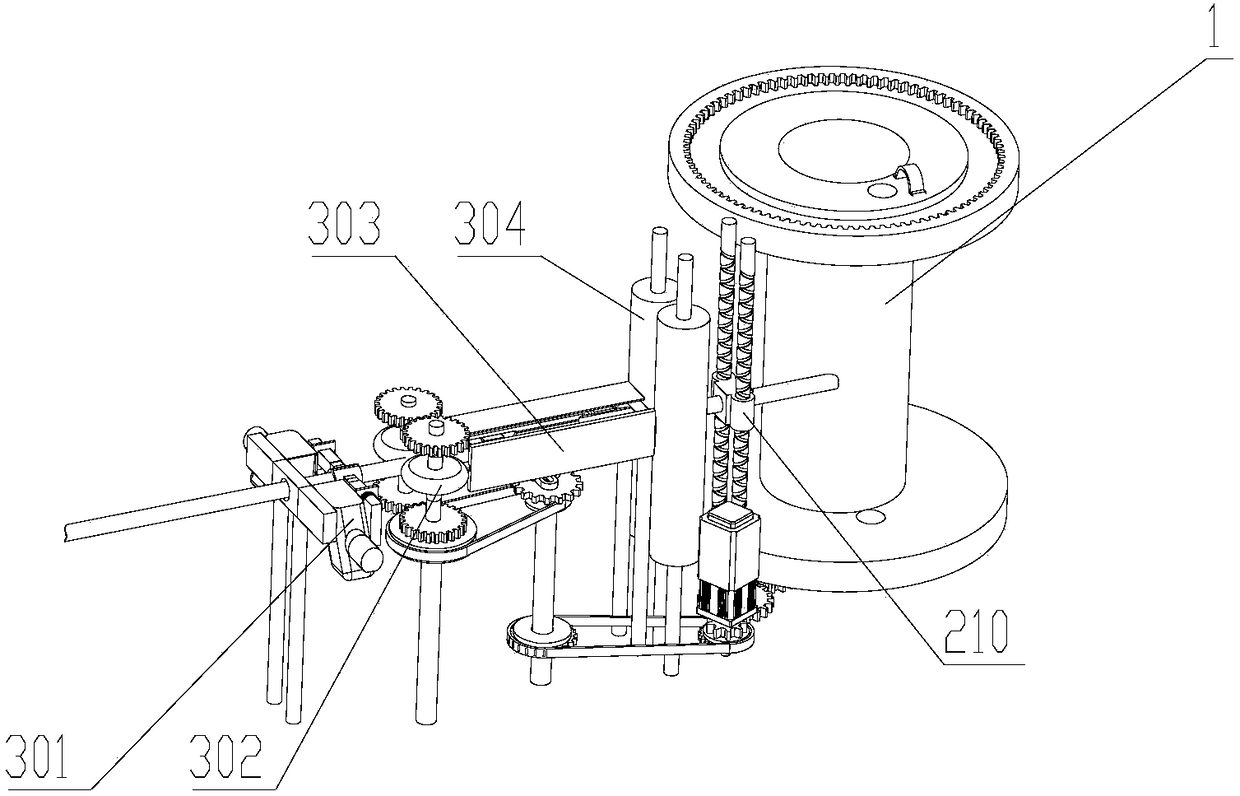

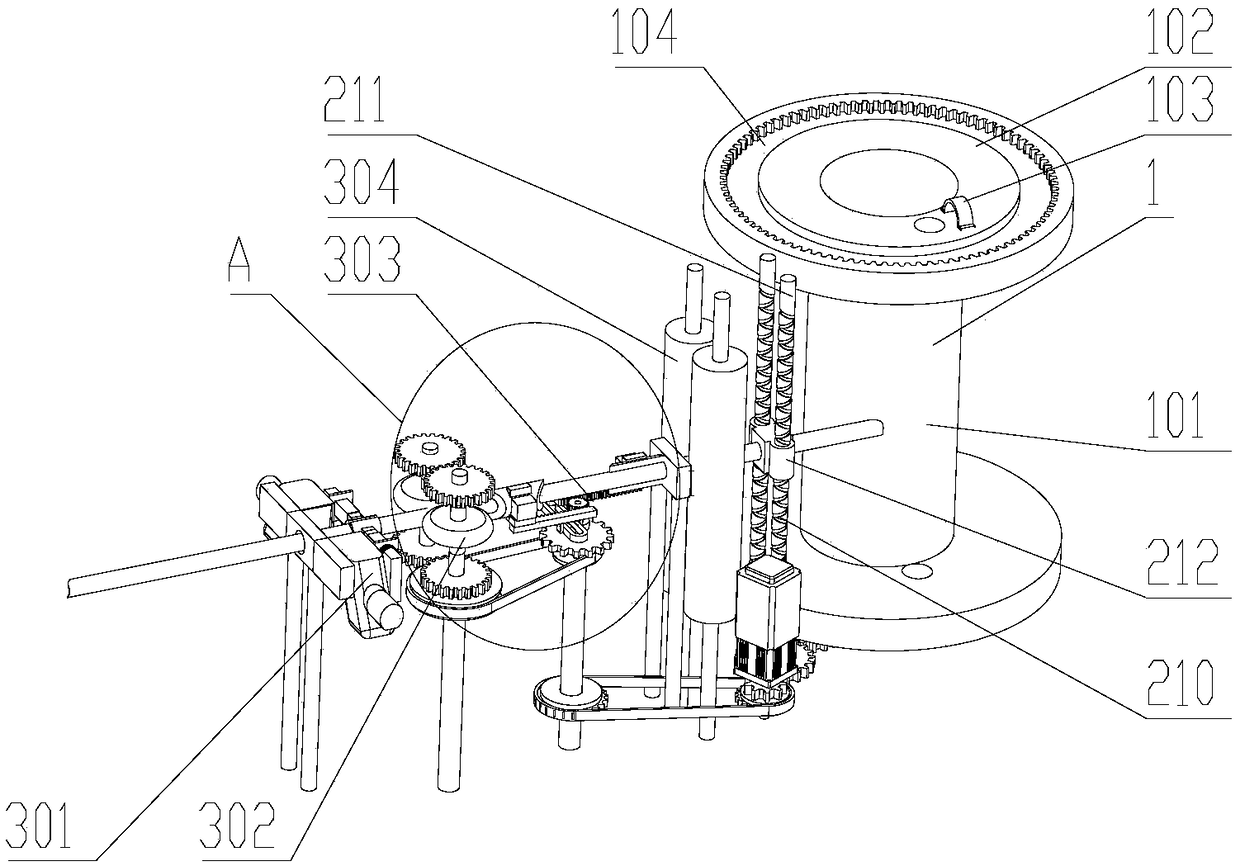

Water pipe automatic storage device

ActiveCN108516405AEasy and flexible operationGuaranteed pullFilament handlingEngineeringSeason cracking

The invention discloses a water pipe automatic storage device and relates to the field of agricultural equipment. According to the technical scheme, the water pipe automatic storage device comprises apipe storing mechanism arranged on a vehicle body; the pipe storing mechanism comprises a pipe winding mechanism and a pipe pulling mechanism arranged on one side of the pipe winding mechanism and used for pulling a water pipe; the pipe winding mechanism comprises a base and a pipe shaft, and the pipe shaft is inserted in the base; a driving mechanism is arranged at the end, close to the base, ofthe pipe shaft; and the pipe pulling mechanism comprises an inlet and an outlet, and air heaters are arranged on the two sides of the inlet. The water pipe automatic storage device has the beneficialeffects that by arranging the air heaters, softening of the water pipe in winter is facilitated, so that when the water pipe is subjected to winding storage, season crack of the wound water pipe dueto the fact the temperature is excessively low and consequently the water pipe is hardened is reduced; unique extrusion discs serve as the pulling device of the water pipe, thus pulling of the water pipe with elasticity is ensured, and the water pipe is further not liable to be damaged; and sundried on a water pipe body can be effectively cleared away by a cleaning cylinder, and then through rotating of the pipe shaft and up-down moving of a pipe arranging device on two-way lead screws, the purpose of automatically storing the water pipe is achieved.

Owner:SHANDONG INST OF POMOLOGY

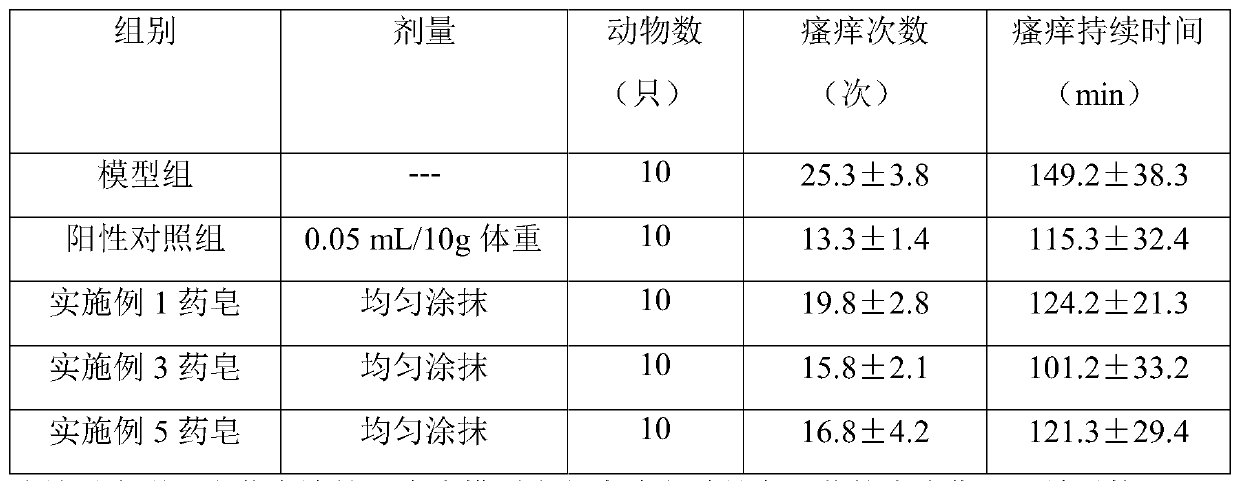

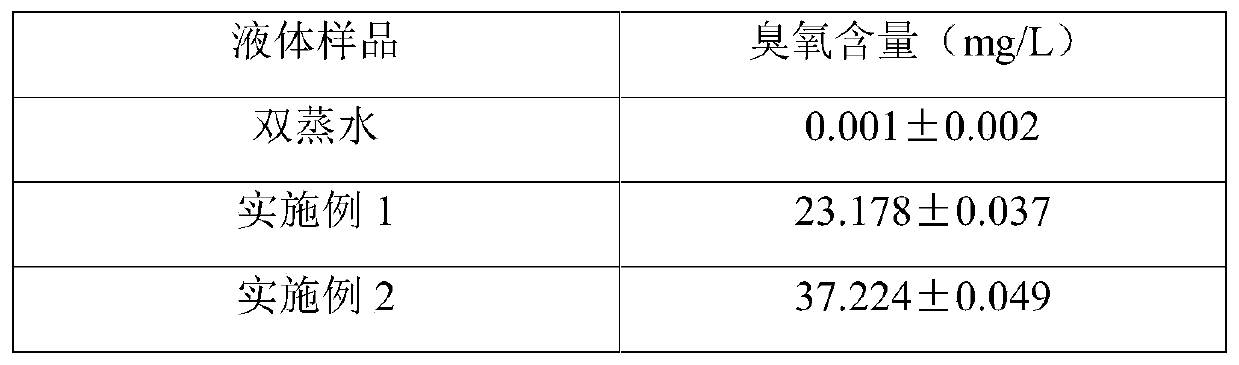

Bactericidal and anti-itching medicated soap and preparation method thereof

InactiveCN110029026AHigh hardnessImprove wear resistanceSurface-active non-soap compounds and soap mixture detergentsSkin careGiant salamanderSea salt

The invention discloses a bactericidal and anti-itching medicated soap and a preparation method thereof. The medicated soap achieves bactericidal and bacteriostatic effects by fixing ozone to ozone salt and utilizing the efficient bactericidal action of the ozone; meanwhile, itching caused by skin allergy is reduced through a variety of Chinese herbal medicines and essential oil with the anti-itching effect; in addition, through mutual cooperation with a giant salamander mucus protein extract, horse oil, badger fat and ambergris, skin is nourished and itching and cracking caused by dryness areprevented. Through adoption of a formula of a neutral soap and supplemented by a foaming agent, during using, the medicated soap is smooth, delicate, non-irritant to the skin and good in skin friendliness; in addition, through addition of large-grained sea salt, the hardness and the plasticity of the medicated soap can be better and industrial production is more facilitated. Through protease digestion and use of natural plant raw materials during preparation, the safer factor of the medicated soap is higher and allergic risks are eliminated.

Owner:张慧君

Drying method for processing wood board raw materials

ActiveCN112254449ASpeed up water evaporationAvoid crackingWood treatment detailsDrying gas arrangementsPulp and paper industryWood plank

The invention discloses a drying method for processing wood board raw materials, and relates to the technical field of wood board processing. The drying method comprises the steps that 1, the wood board raw materials are cut and processed, particles attached to the edges and the surfaces of the cut wood board raw materials are removed, and a raw material A is obtained; 2, dust on the surface of the raw material A is removed through an air gun, then the raw material A is soaked in a treatment solution for 5 min, and then the raw material A is taken out and aired; and 3, the raw material A is placed in a drying device to be dried, the drying time is 0.5-1 h, and the drying temperature is 50-55 DEG C; According to the drying method for processing the wood board raw materials, before a wood board is dried, the surface of the wood board can be cleaned and pretreated, two cleaning processes are set, the surface of the wood board can be ground to be flat through grinding, and therefore the wood board can be pressed conveniently during drying, attached particles can be removed through grinding, and the particles are prevented from affecting the surface of the wood board during drying.

Owner:安徽金福瑞家具股份有限公司

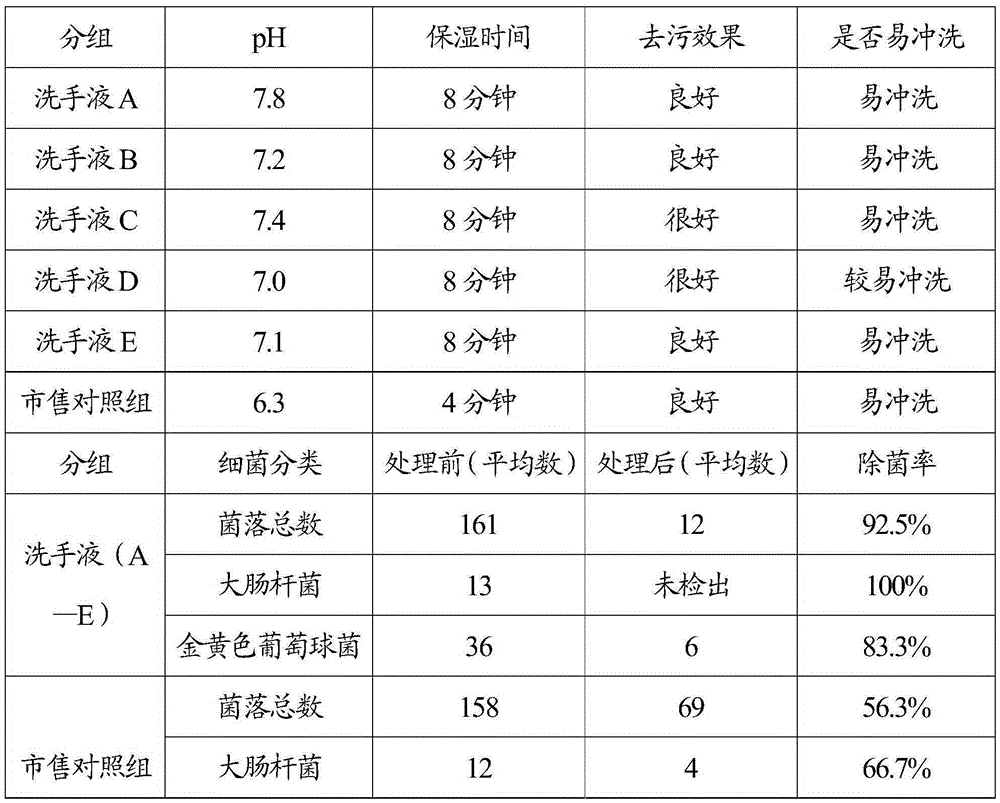

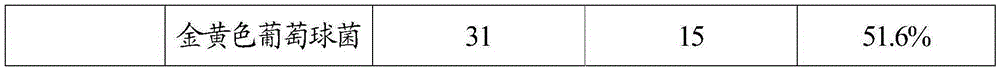

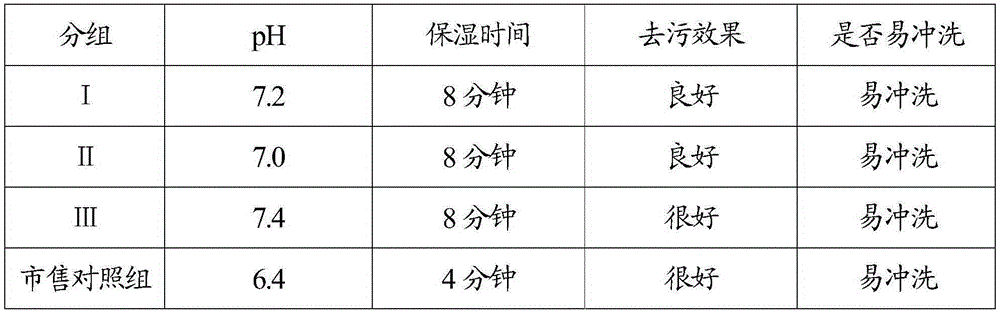

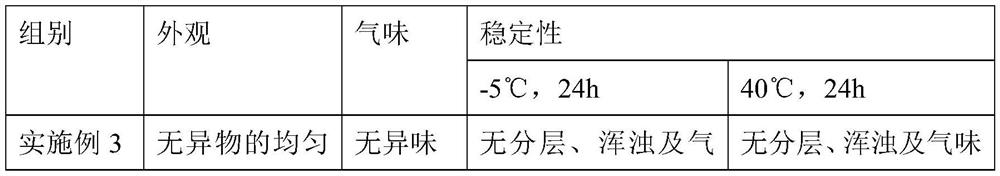

Hand sanitizer and preparation method thereof

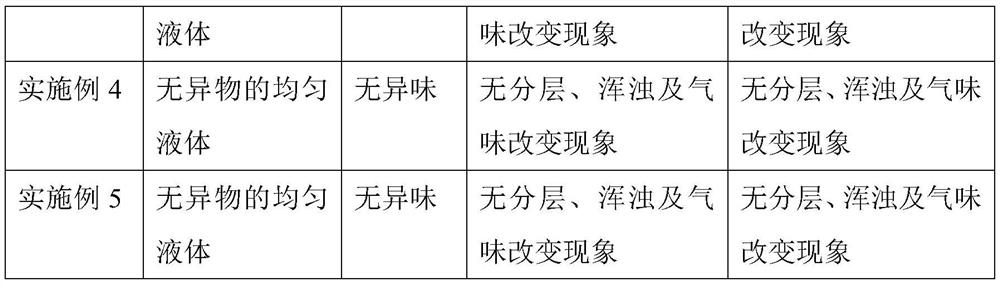

InactiveCN105287249AMild performanceLess irritatingCosmetic preparationsToilet preparationsHand sanitizerCocamidopropyl betaine

The invention discloses a hand sanitizer and a preparation method thereof. The hand sanitizer comprises the following components in parts by weight: 1-3 parts of refined salt, 5-11 parts of polyoxyethylene fatty alcohol sodium sulfate, 2-6 parts of cocamidopropyl betaine, 0.5-1.5 parts of cocoanut fatty acid diethanolamide and 75-87 parts of deionized water. The hand sanitizer has an effect of rinsing easily while having a certain viscosity, and also has a moisture preserving function and can relieve hand chaps and promote chap healing while achieving the effects of decontaminating, cleaning, eradicating odors and killing bacteria.

Owner:CHENGDU BAIWEIFANG TRADE

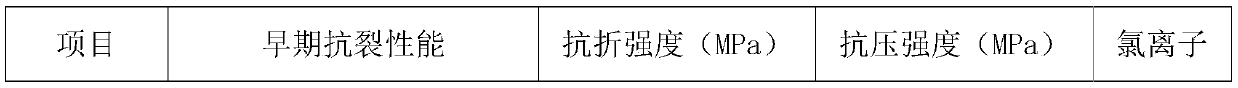

Mortar for decorating external wall

The invention discloses a natural aeolian sand mortar for decorating an external wall, which is mixed by the following components in parts by weight: 10-20 of ordinary portland cement, 2-3 of slaked lime, 3-5 of lightweight aggregate, 71-84 of heavy aggregate (aeolian sand), 1.0 of complex additive, wherein the lightweight aggregate is an inorganic vitrified hollow micropore material; the heavy aggregate is the aeolian sand; the preferred fineness of the inorganic vitrified hollow micropore material is 80-100 mesh, the weight content of the aeolian sand with 50-70 mesh preferred fineness is more than 90 percent, and the rest aeolian sand has more than 100-mesh fineness. The invention has the advantages that the mortar has prominent stereo texture, endurance and stability, light weight, saved energy and good crack- resistant and anti-drop properties, and exhibits natural and rich European style customs decoration effect; and the mortar also has good smear workability and simple process, and is suitable for mechanization construction. The construction method is as follows: the mortar is diluted by adding water based on 30-50 percent of the mortar by weight, mechanical agitation or hand stirring is carried out to be evenly mixed to reach a proper viscosity for mechanical spray or hand construction.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

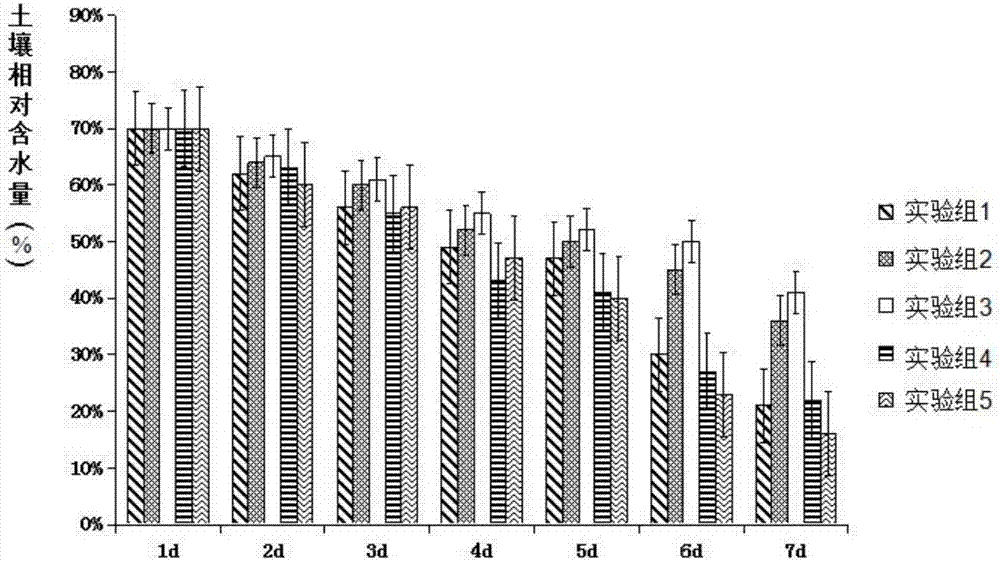

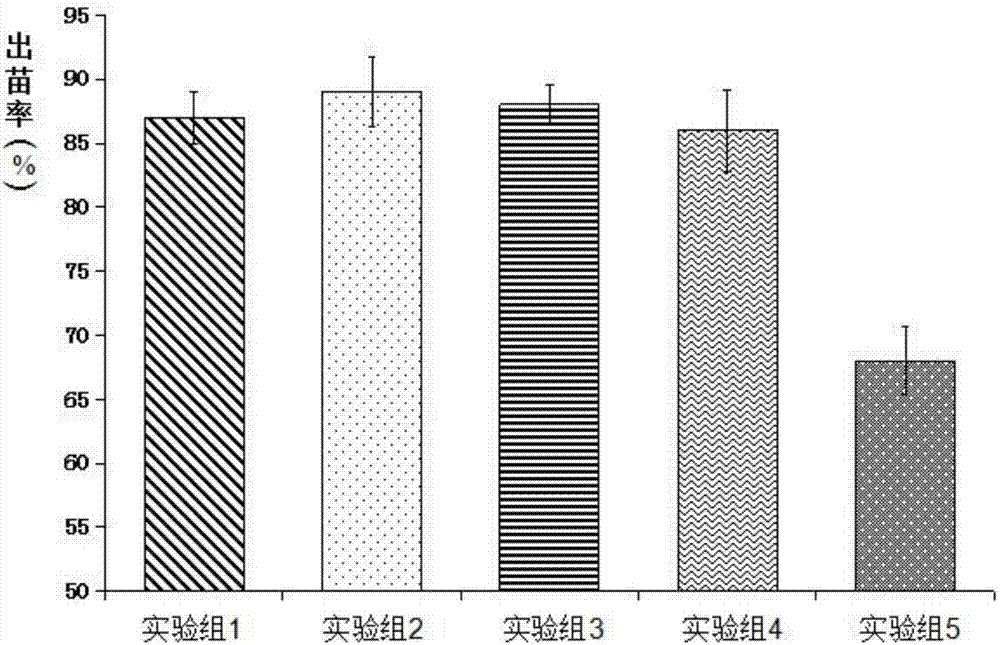

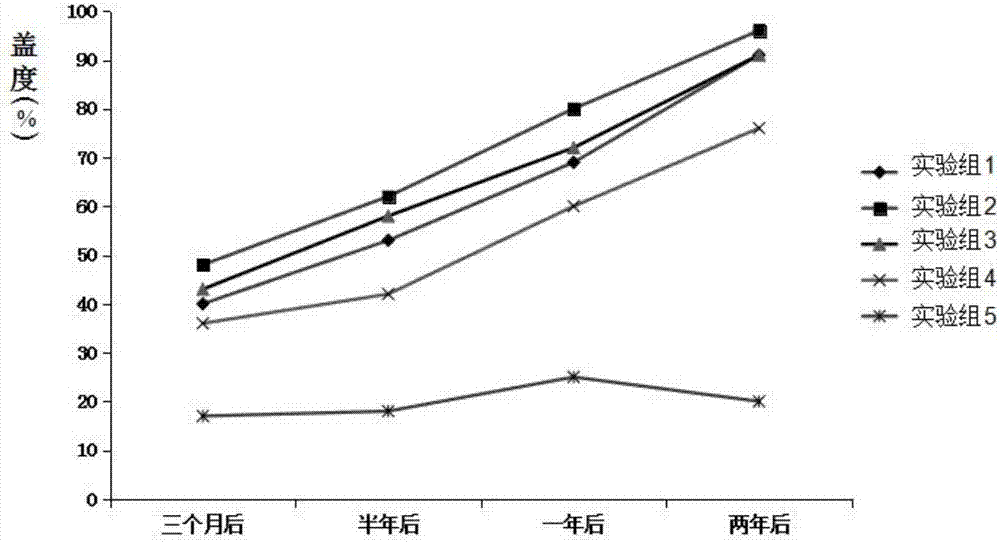

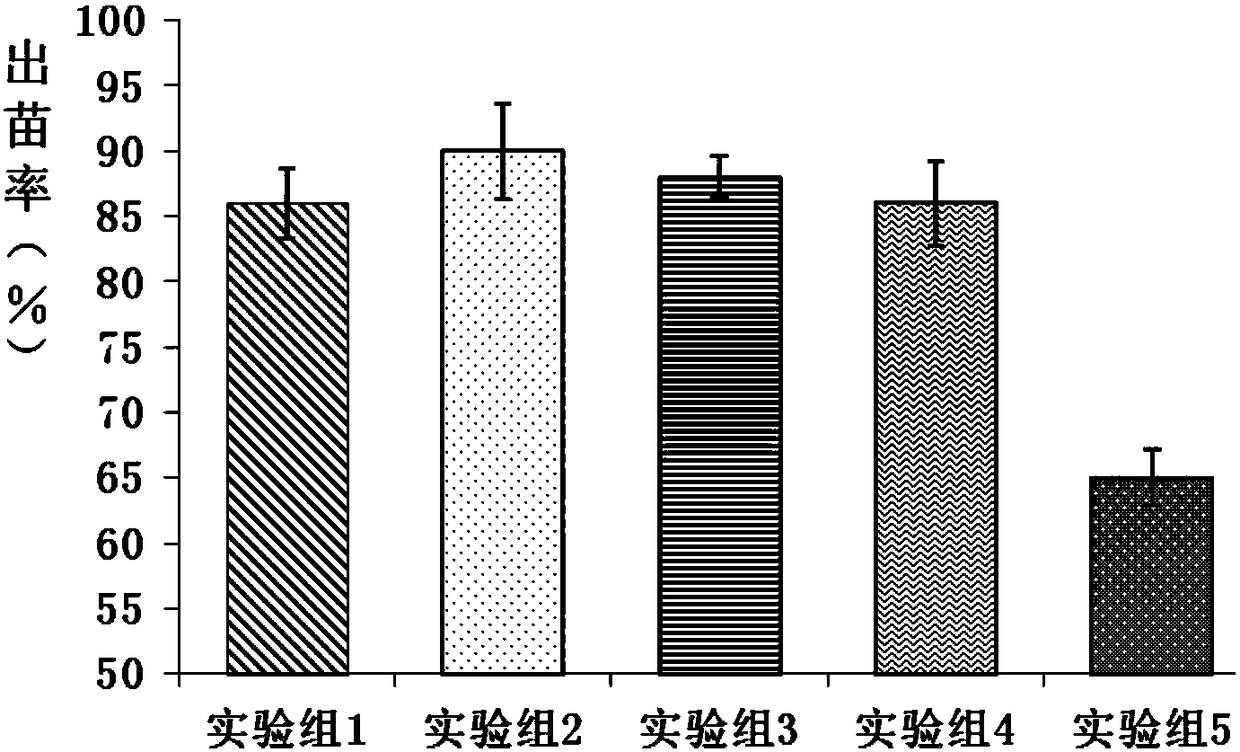

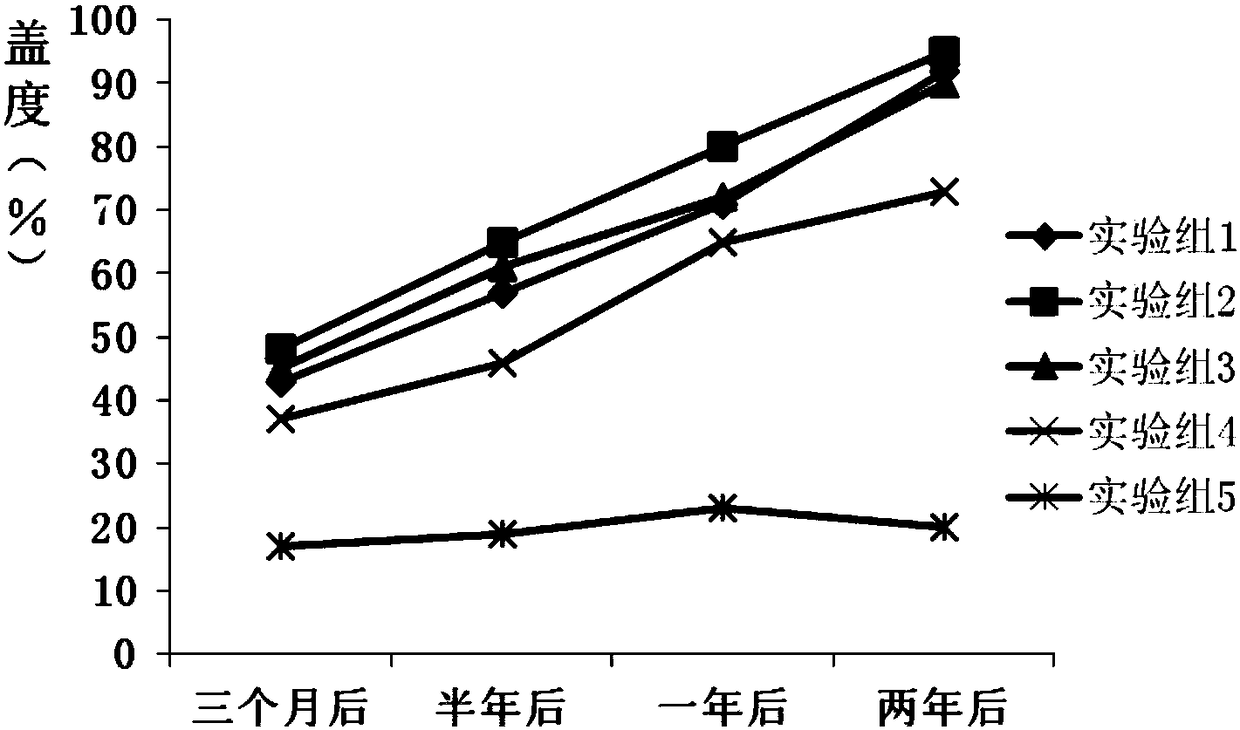

Spray seeding matrix for regreening of bare side slope adapted to soil in arid and semi-arid zones and preparation method of spray seeding matrix

InactiveCN106866230AReduce chappingImprove fertilityGrowth substratesCulture mediaFiberSodium Bentonite

The invention relates to the technical field of environment protection and greening of side slopes, and provides a spray seedling matrix for regreening of bare side slope adapted to soil in arid and semi-arid zones and a preparation method of the spray seeding matrix. The spray seedling matrix provided by the invention is prepared from the following raw materials in parts by weight: 25 to 40 parts of composted organic wastes, 30 to 40 parts of side slope loess, 5 to 15 parts of kaolin, 0.5-0.8 part of potassium fulvate, 5 to 15 parts of bentonite clay, 3 to 4 parts of flour sticky glue and 5 to 10 parts of plant fibers. According to the spray seedling matrix, intensive aboveground parts and developed root systems of plants can be quickly formed on the long-term arid and bare side slope, regreening of the side slope can be effectively carried out, the soil is consolidated, and surface runoff and soil washing can be prevented and controlled. The preparation method provided by the invention comprises the steps of mixing the composted organic wastes, the side slope loess, the kaolin, the potassium fulvate and the bentonite clay and pulverizing into particles; then mixing the particles with the plant fibers to obtain a mixture; successively, adding water and stirring the mixture to form a viscous state; then mixing the viscous product with the flour sticky glue. The preparation method has the advantages of simple technology, strong operability and benefit to industrial production.

Owner:LANZHOU UNIVERSITY

Body-care skin-care face-beautifying compound essential oil

InactiveCN103705422APromotes skin cell growthBalances and softens skinCosmetic preparationsToilet preparationsInjury mouthDry skin

The invention relates to a cosmetic and health care product, and particularly relates to body-care skin-care face-beautifying compound essential oil. The body-care skin-care face-beautifying compound essential oil comprises the following raw material components: sandalwood essential oil, chamomile essential oil, rose essential oil, jasmine essential oil and base oil, wherein the sandalwood essential oil can fast rehabilitate a wound or a scar so as to have elasticity and shrinkage effects, balance and soften skin and improve dry and dehydrated skin; the chamomile essential oil can relieve stress, calm mood and repair sensitive, inflamed and eczematous skin; the rose essential oil has very good face-beautifying and skin-care effects and can improve skin dryness and restore skin elasticity; the jasmine essential oil has the outstanding effects of conditioning dry and sensitive skin, increasing the skin elasticity and delaying skin aging. Thus, the compound essential oil disclosed by the invention can be used for slimming the body, repairing the sensitive skin, increasing the skin elasticity, delaying the skin aging and softening the skin, and has very good body-care skin-care face-beautifying effects.

Owner:QINGDAO YONGTONG ELEVATOR ENG

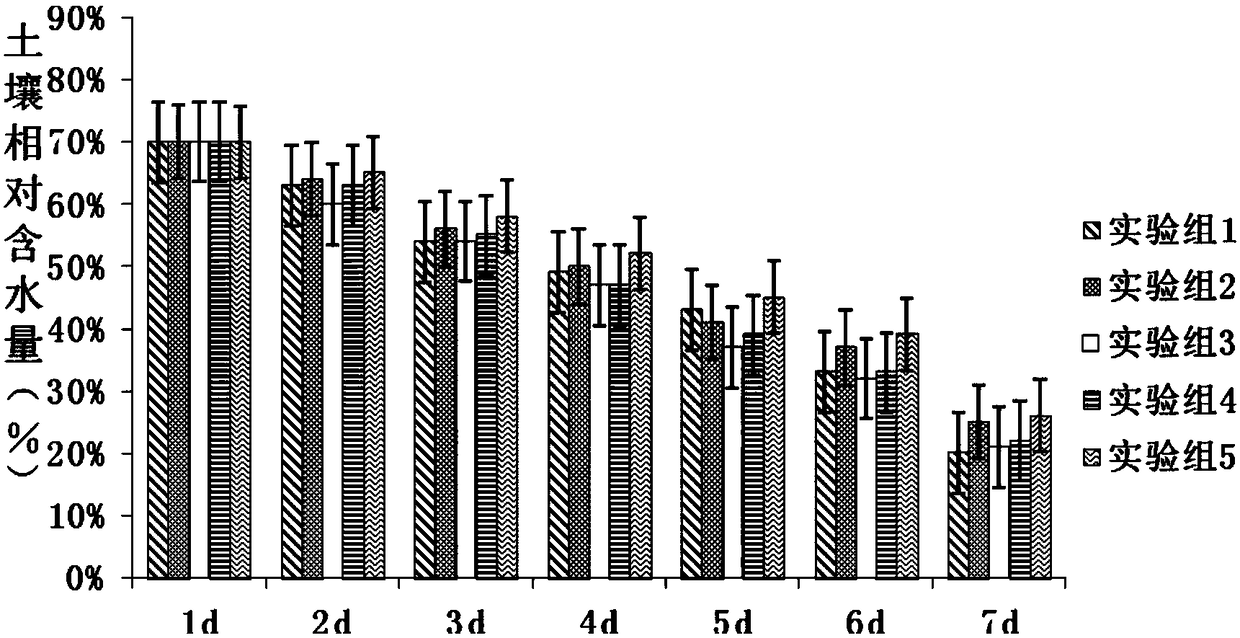

Spray-seeding matrix for regreeening of slopes of droughty saline and alkaline land, and preparation method thereof

InactiveCN108610208ALow costImprove fertilityExcrement fertilisersBioloigcal waste fertilisersSodium BentoniteAlkali soil

The invention provides a spray-seeding matrix applicable to regreeening of slopes of droughty saline and alkaline land, and a preparation method thereof, belonging to the technical fields of improvement of saline and alkaline land and greening matrixes for slopes. The spray-seeding matrix comprises the following raw materials by weight: 30-40 parts of decomposed organic waste, 35-45 parts of alienearth, 5-15 parts of bentonite, 5-10 parts of vegetable fibers, 0.5-0.8 part of halophilic and basophilic microbial agents, and 3-4 parts of a flour paste adhesive. The spray-seeding matrix allows plants to rapidly form dense aerial parts and developed roots on the slopes of droughty saline and alkaline land, thereby effectively realizing slope regreening, consolidating soil and preventing and treating surface runoff and soil erosion. The preparation method for the spray-seeding matrix provided by the invention comprises the following steps: mixing and pulverizing the decomposed organic waste, the alien earth and the bentonite so as to form particles, then mixing the particles with the plant fibers, adding water, carrying out stirring to allow the obtained mixture to be in a viscous state, and then mixing the mixture with the flour paste adhesive and the halophilic and basophilic microbial agents. The preparation method is simple technology, good in operability and favorable for industrial production.

Owner:LANZHOU UNIVERSITY

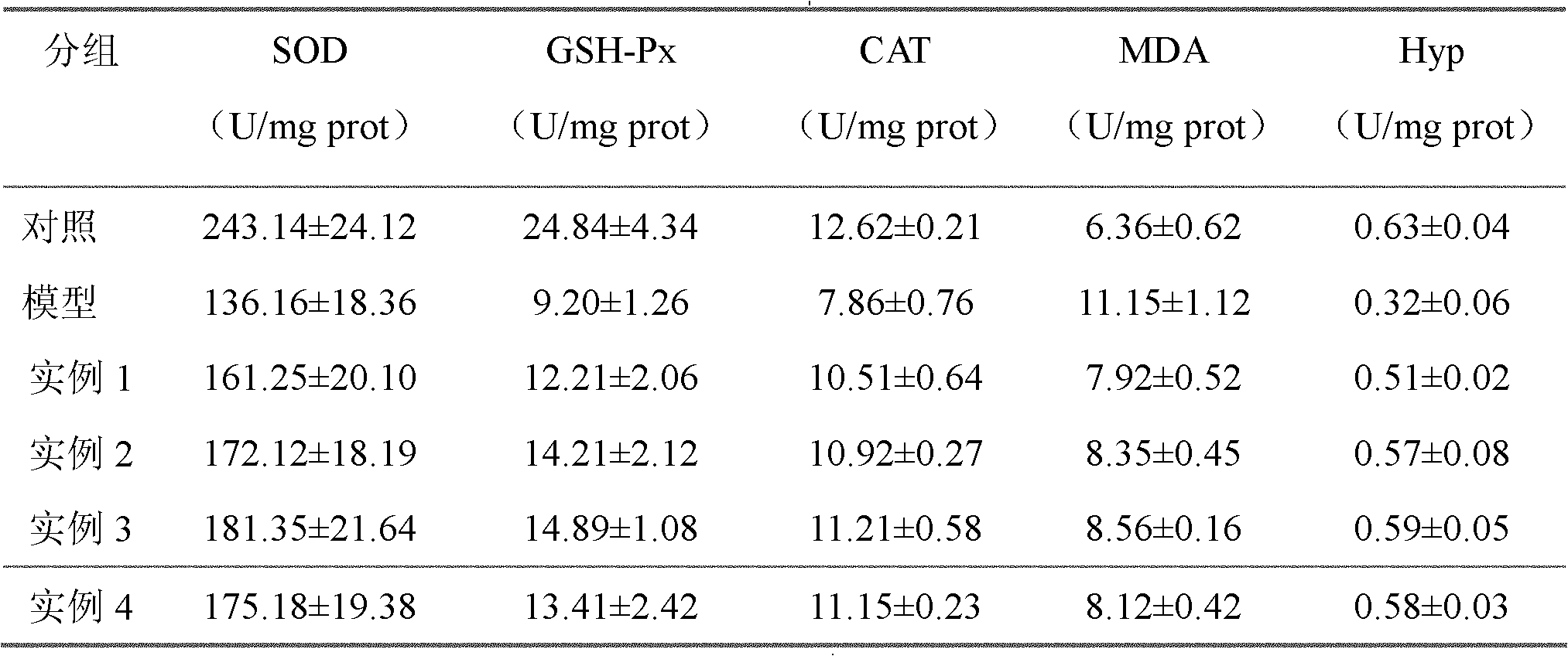

Wet tissue special for sports

InactiveCN101869447AImprove antioxidant capacityDelay agingCosmetic preparationsToilet preparationsRoom temperatureThermal water

The invention relates to the field of hygienic products, in particular to a wet tissue special for sports. The invention aims to provide the wet tissue special for sports with advantages of sterilization, deodorization and strong water absorbability. The wet tissue is manufactured by the following steps of: adding aloe, lactic acid, olive oil essence, chamomile and vitamin E into 30 to 60 DEG C hot water in an amount which is several times that of the components, stirring and dissolving; adding a proper amount of propylene glycol and essence into the mixture, stirring and dissolving the mixture, and cooling the solution to room temperature; complementally adding RO purified water into the solution to obtain medicinal liquid; and soaking cotton jacquard spun-laced cloth with thickness between 1.5 and 2.5 millimeters and specification of 250 millimeters * 250 millimeters into the medicinal liquid.

Owner:DALIAN OUPAI TECH

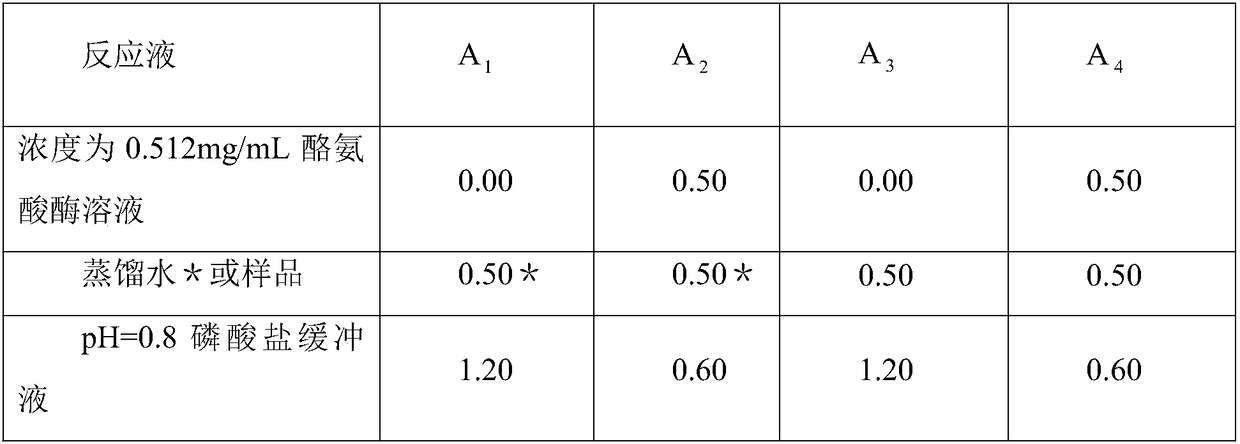

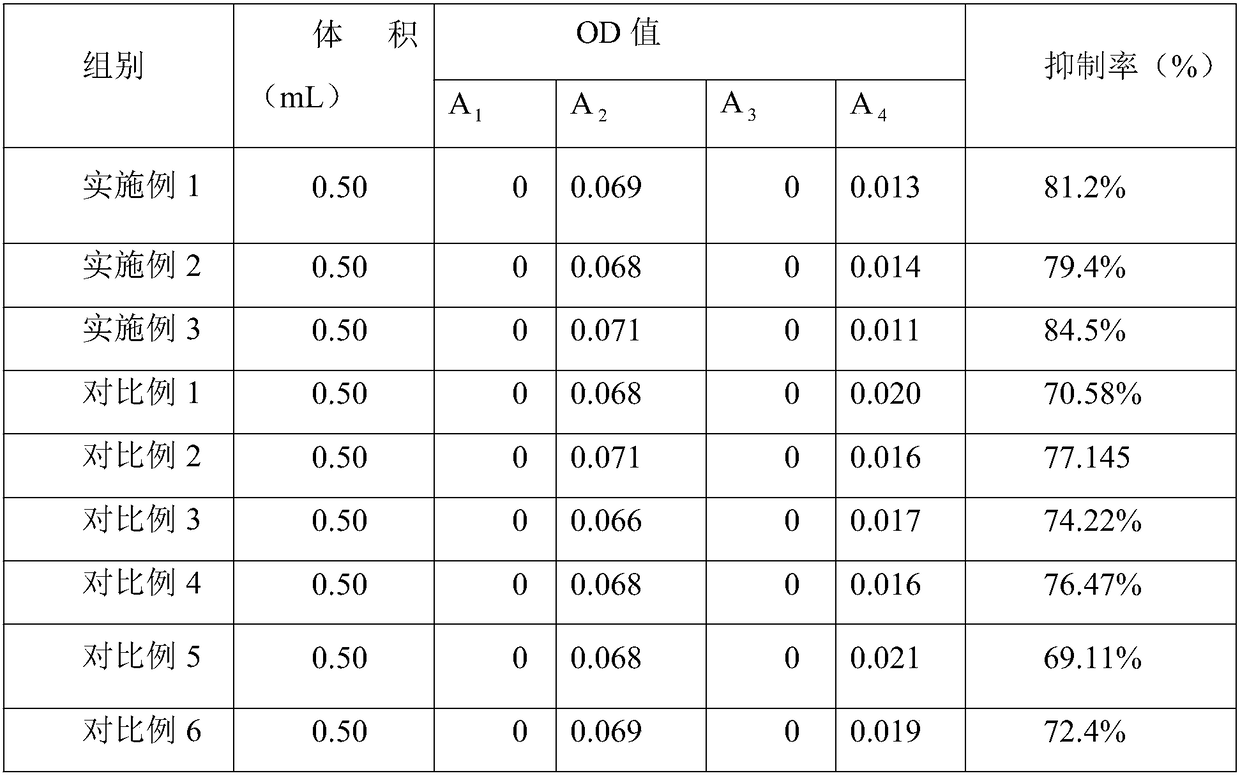

Preparation method of whitening and moisturizing facial mask based on purple rice extract liquid

ActiveCN108403574AHigh extraction ratePromote absorptionCosmetic preparationsToilet preparationsHydroxyethyl celluloseRaw material

The invention discloses a preparation method of a whitening and moisturizing facial mask based on a purple rice extract liquid, wherein the preparation method comprises the following steps: step 1, weighing the following corresponding raw materials in parts by weight: 32-38 parts of the purple rice extract liquid, 16-22 parts of a mica dispersion liquid, 10-14 parts of persimmon pectin, 6-10 partsof squalane, 4-8 parts of tea seed oil, 2-6 parts of hydroxyethyl cellulose, 1-3 parts of methylparaben and 14-18 parts of deionized water. The preparation method of the whitening and moisturizing facial mask based on the purple rice extract liquid adopts a two-aqueous phase extraction method and microwave-assisted collaborative ultrasonic extraction, so the extraction rate of polysaccharides andprocyanidins is improved, and the polysaccharides and procyanidins are extracted simultaneously to be applied to the facial mask. The procyanidins have a multi-hydroxyl structure and are easy to absorb, also can inhibit tyrosinase activity and play a whitening effect.

Owner:TAOYUAN COUNTY XINGLONG RICE TECH DEV

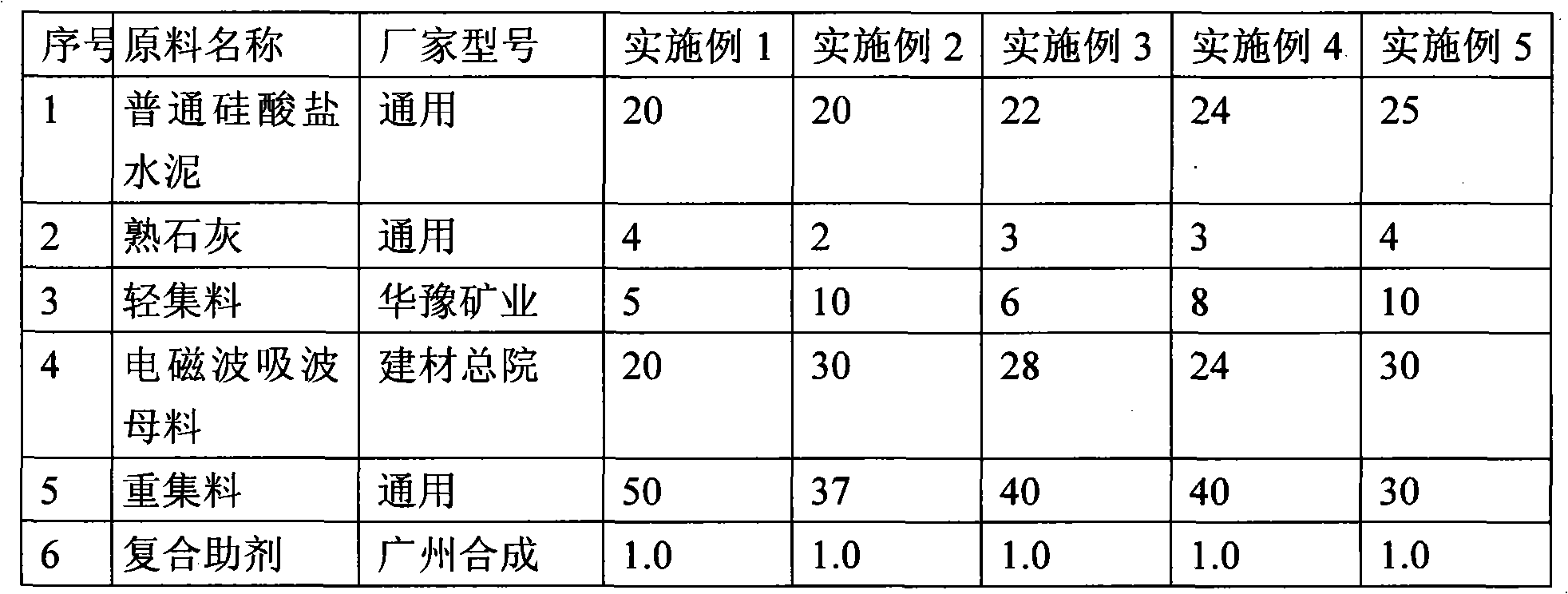

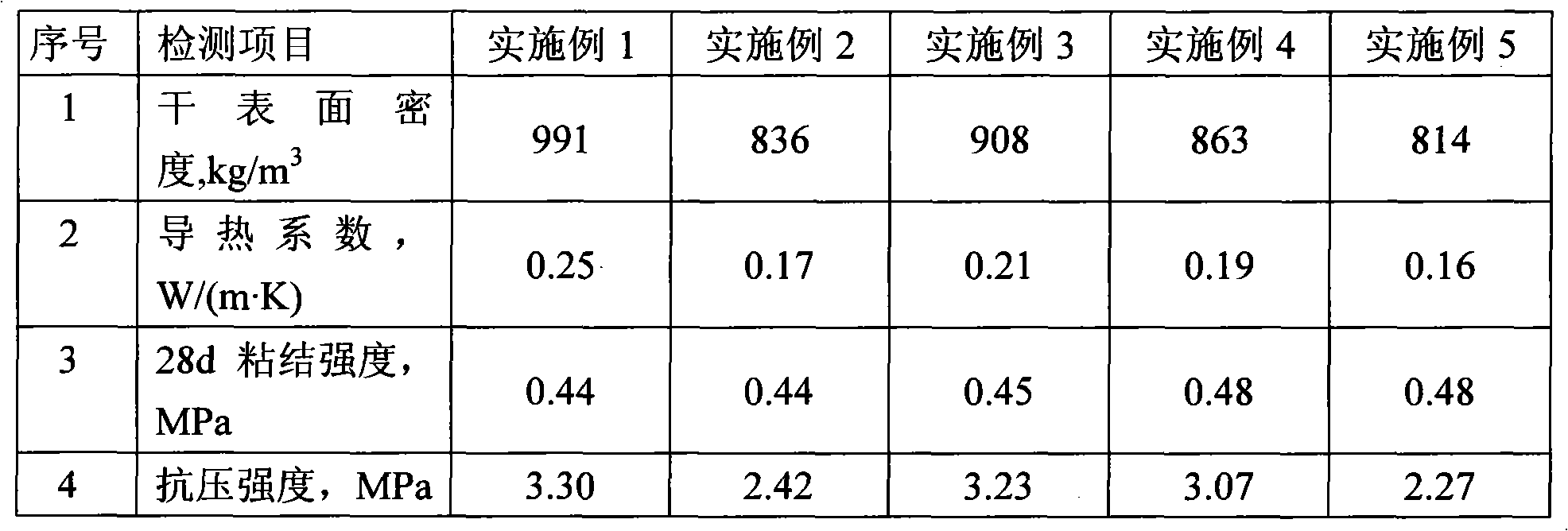

Lightweight plastering mortar and construction method thereof

The invention discloses lightweight plastering mortar, which is characterized in that the mortar is formed by mixing the following components in part by weight: 20 to 25 parts of common silicate cement, 2 to 4 parts of slaked lime, 5 to 10 parts of light aggregate, 20 to 30 parts of electromagnetic wave absorption master batch, 30 to 50 parts of heavy aggregate and 1.0 part of composite auxiliaryagent, wherein the light aggregate is an inorganic vitrified hollow micropore material with fineness of less than 100 meshes, and the heavy aggregate is common river sand. The construction method comprises the following steps of: diluting the lightweight plastering mortar by adding water in an amount which is 30 to 50 percent of the weight of the mortar, mechanically or manually stirring the mortar till the mortar is mixed uniformly, and mechanically coating the mortar or manually constructing the mortar when the mortar reaches the viscosity suitable for mechanical coating or manual construction. The lightweight plastering mortar with function of shielding and absorbing electromagnetic wave can shield and absorb the outdoor electromagnetic wave, absorb the indoor electromagnetic wave and reduce the diffuse reflection of the indoor electromagnetic wave, is light and energy-saving, reduces the consumption of unit area material and has low unit area manufacturing cost; and when used for a lightweight wall, the lightweight plastering mortar can prevent hollowing, cracking and dropping, is favorable for mechanized construction, and has simple process.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

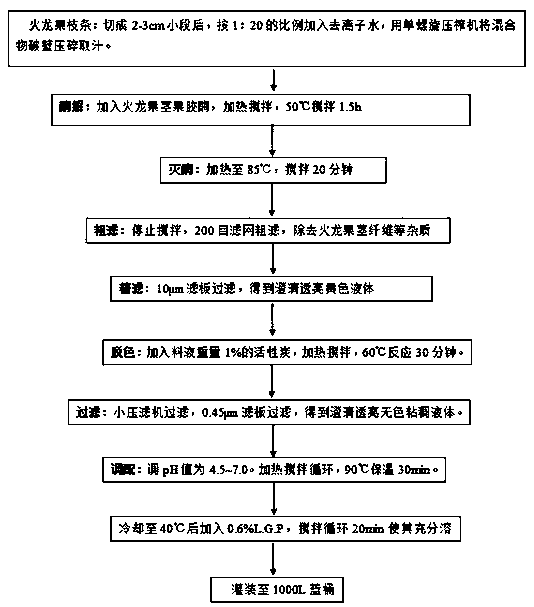

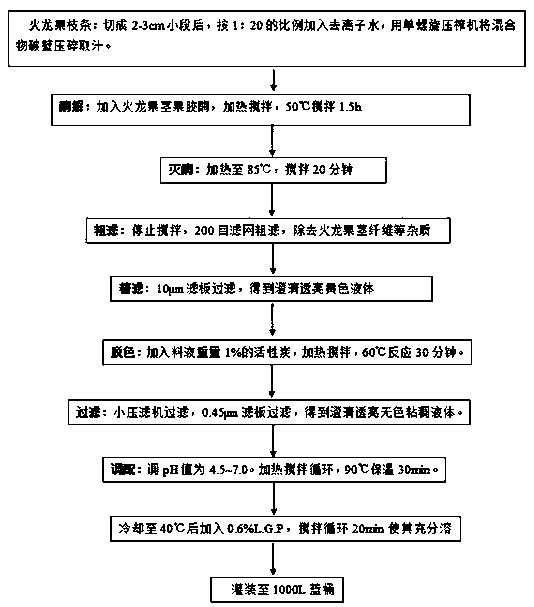

Preparation and production process of pitaya stem gel juice extract

InactiveCN109998107AIncrease productivityLow costNatural extract food ingredientsFood ingredient functionsWater soluble polymersSmall branch

The invention discloses a preparation and production process of a pitaya stem gel juice extract. The process includes the following steps that firstly, pitaya branches adopted as the raw material arewashed and then smashed and cut into small branches; secondly, deionized water is added according to an appropriate proportion, and a single-screw press is adopted for cell wall breaking to make pulp;thirdly, pectinase is added, stirring is performed for 1.5 hours at 50 DEG C for enzymolysis. The preparation and production process of the pitaya stem gel juice extract is high in production efficiency and low in cost; the main ingredient of the gel juice extract produced with the pitaya branches as the raw material is SPPS which is a mixture containing acetylated beta-D-pyranmannan, is a natural, mild and non-irritant water-soluble polymer and can improve the stability of an emulsion system, reduce the transdermal loss of moisture and reduce the dryness or cracking of skin; by studying thebiological effects of the SPPS in oxidation resistance, skin whitening and moisturizing, it is found that the SPPS has a significant moisturizing effect.

Owner:广东美辰生物科技有限公司

Inner wall decoration mortar and construction method thereof

ActiveCN101857408BAvoid crackingAvoid hollowingSolid waste managementBuilding constructionsHeat conductingHuman health

Owner:SHENZHEN GRANDLAND DECORATION GROUP

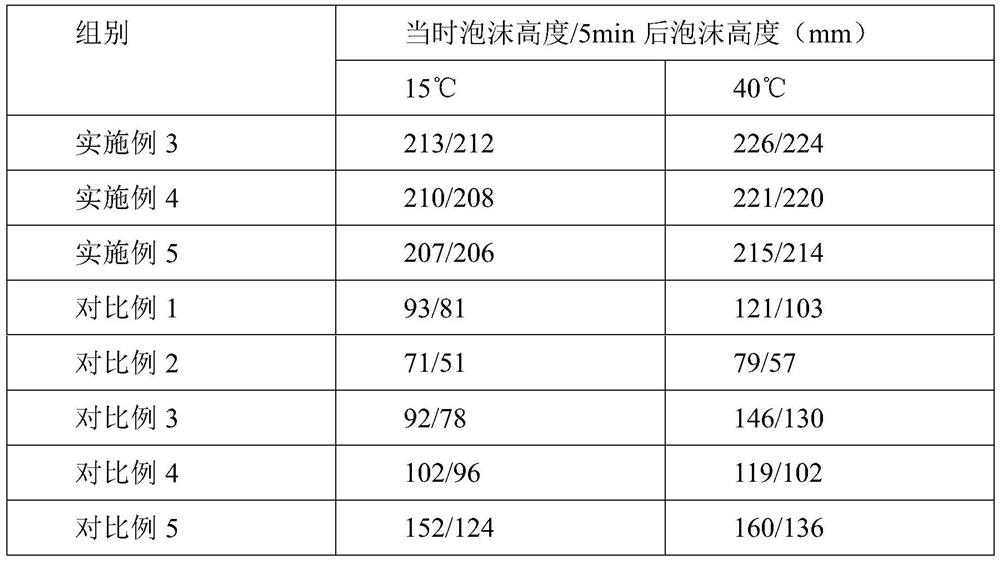

Bacteriostatic detergent containing plant surfactant and preparation method of bacteriostatic detergent

ActiveCN112430510AReduce stimulationGood antibacterial effectInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsBiotechnologyPhenolic content in tea

The invention belongs to the technical field of washing products, and particularly relates to a bacteriostatic detergent containing a plant surfactant and a preparation method of the bacteriostatic detergent. The bacteriostatic detergent containing the plant surfactant comprises the following components in percentage by mass: 10-25% of Chinese soapberry seed extract, 1-8% of compound oxidized teapolyphenol, 1-3% of antibacterial agent, 0.5-1.5% of emollient, 0.1-1% of aromatic, 0.1-4% of thickener, 0.01-0.1% of chelating agent, 0.1-0.3% of preservative and the balance of water. According to the detergent, the Chinese soapberry seed extract is compounded with two types of oxidized tea polyphenol to serve as a surfactant system, so that the prepared detergent has excellent high-temperatureand low-temperature foaming capacity and foam stabilizing capacity, the detergency is obviously improved, the overall washing performance is good, and the performance is excellent.

Owner:广州振华生物科技有限公司

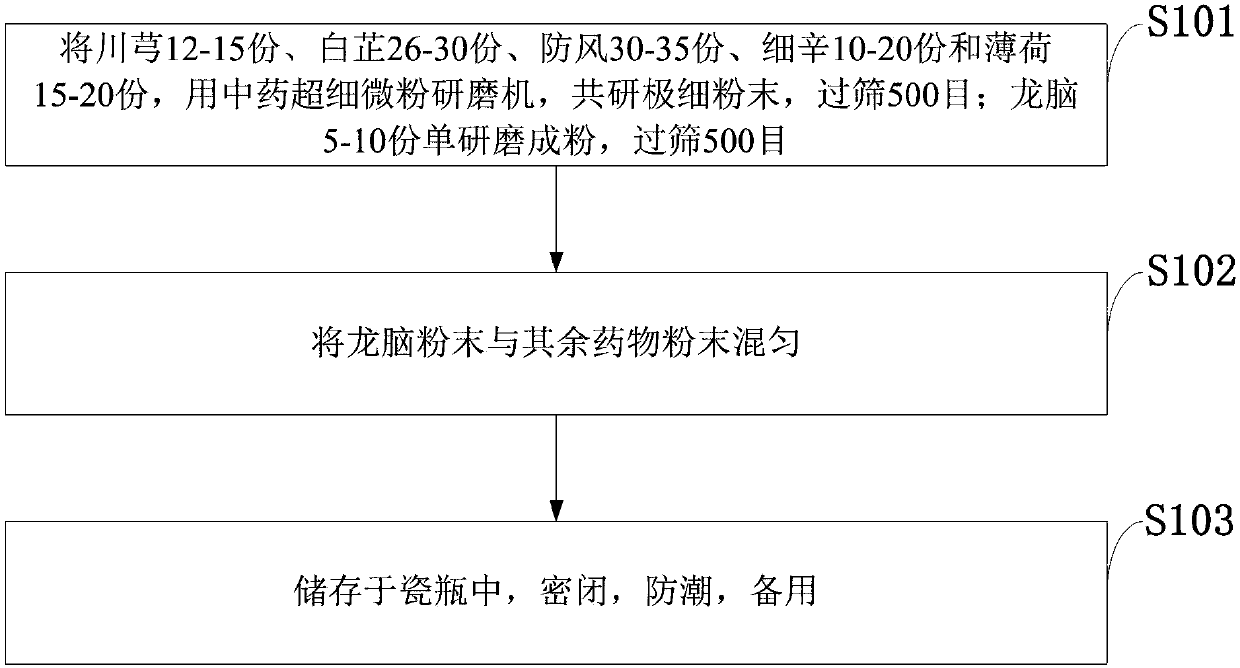

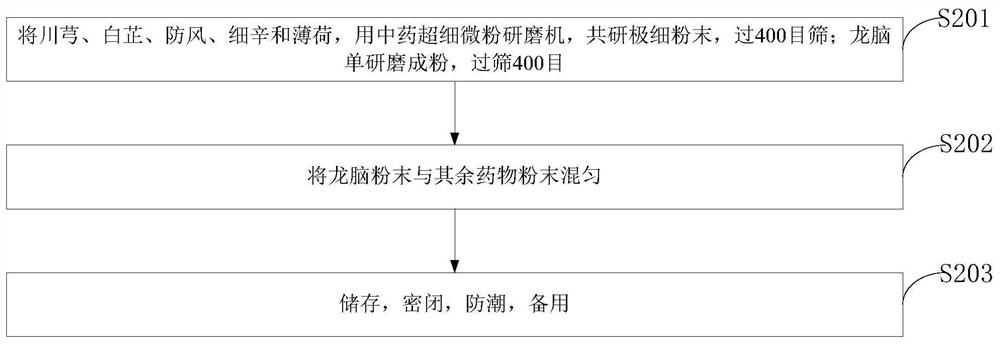

External-use medicine for treating beriberi and preparation method thereof

InactiveCN107669735AImprove complianceStrong targetingPowder deliveryAntimycoticsBeriberiSide effect

The invention belongs to the technical field of traditional Chinese medicine and discloses external-use medicine for treating beriberi and a preparation method thereof. The external-use medicine comprises, by weight, 12-15 parts of rhizoma chuanxiong, 26-30 parts of radix angelicae dahuricae, 30-35 parts of radix sileris, 10-20 parts of asarum, 15-20 parts of mentha haplocalyx and 5-10 parts of borneol. The external-use medicine has the advantages that the external-use medicine is evident in curative effect on the beriberi, the effective rate of the external-use medicine reaches 100%, the external-use medicine can take effect on the same day when the external-use medicine is used, and the symptoms of the beriberi are relieved even eliminated when the external-use medicine is continuously used for a week; the locally-acting external-use medicine can avoid a liver first-pass effect and kidney burden, is safe, reliable, free of side effects when being used for a long time, capable of improving foot environments, capable of effectively inhibiting and eliminating fungi, viruses and bacteria, economical, practical, convenient to use and fragrant, and does not affect normal movement at all.

Owner:TIANJIN UNIV OF TRADITIONAL CHINESE MEDICINE

Preparation method of medicine for treating beriberi and athlete's foot

InactiveCN105287628AGood for treating beriberiShort course of treatmentSalicyclic acid active ingredientsAntimycoticsSalicylic acidBiology

The invention discloses a preparation method of a medicine for treating beriberi and athlete's foot. The medicine is prepared from the following raw materials by weight: A: 50-80 parts of salicylic acid, 10-50 parts of boric acid, 1-5 parts of menthol and 1-8 parts of talcum powder; B: 0.1-5 parts of potassium permanganate powder; C: 0.1-20 parts of glacial acetic acid; the raw materials A, B and C can be separately prepared into medicine powder for sub-packaging; the raw materials A and B can be separately pressed into medicine blocks. The medicine has a good treating effect on beriberi, has the efficacies that the treating course is short and the treating efficiency is high, can reduce dry cracking and peeling at an affected part, can relieve pain of a patient, and has the advantages that a lubricous and cool feeling is achieved, beriberi can be thoroughly cured once, and recurrence is avoided.

Owner:阮少康

Drink containing pumpkin enzymes and preparation method thereof

InactiveCN106036269AImprove immunityAvoid damageFood ingredient functionsFine lineBULK ACTIVE INGREDIENT

The present invention discloses drink containing pumpkin enzymes and a preparation method thereof. The drink containing the pumpkin enzymes is prepared from peach gums, pumpkins, maca, fructus corni, herba gynostemmatis pentaphylli, American ginsengs, siraitia grosvenorii, and water as active ingredients in certain parts by weight. The raw materials of the drink containing the pumpkin enzymes are complementary in advantages, and the mutual synergic or resistant functions of the raw materials are utilized to improve curative effects, so that the drink has common efficacies of benefiting qi and supplementing blood, clearing heart and moistening lungs, strengthening spleen and benefiting middle warmer, and nourishing liver and supplementing kidneys, can reduce the damages of harmful free radicals on cells in body, improves skin metabolism, discharges harmful toxins, enables the human body to be full in qi and blood, and moderate in liver, kidneys, spleen and lungs, relieves fatigues, improves body functions, and has functions of improving human body immunity, preventing aging, removing freckles and beautifying features, reducing skin fine lines and dry cracks, enabling facial skins to be moist and shiny, and full of elasticity, and beautifying features and nourishing skins.

Owner:JIAXING TIANTENG AGRI LEISURE CO LTD

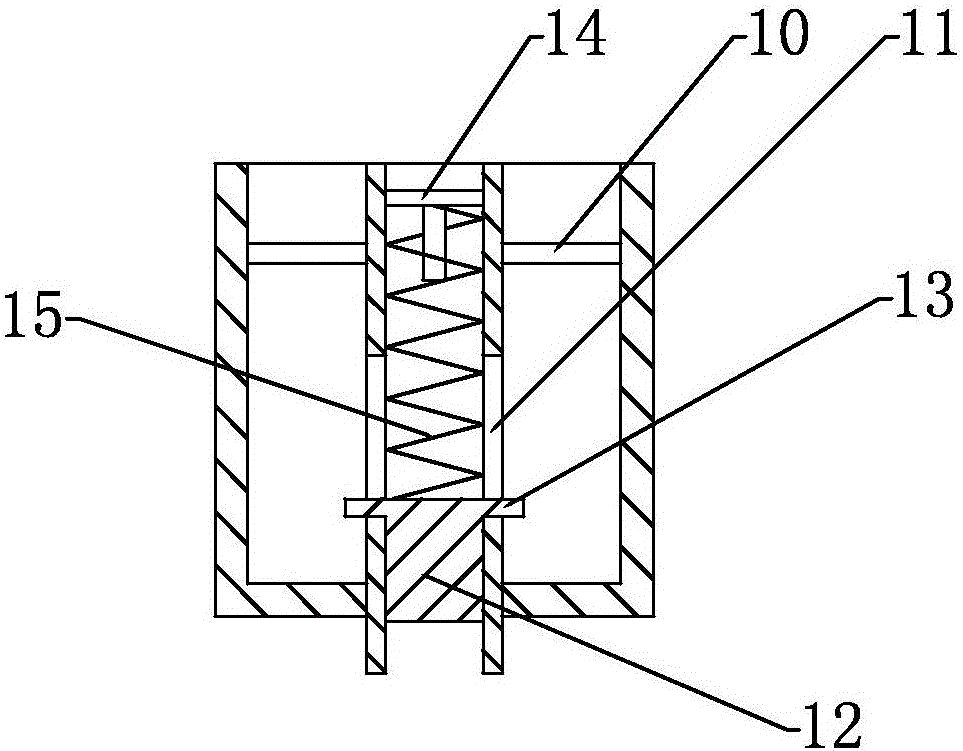

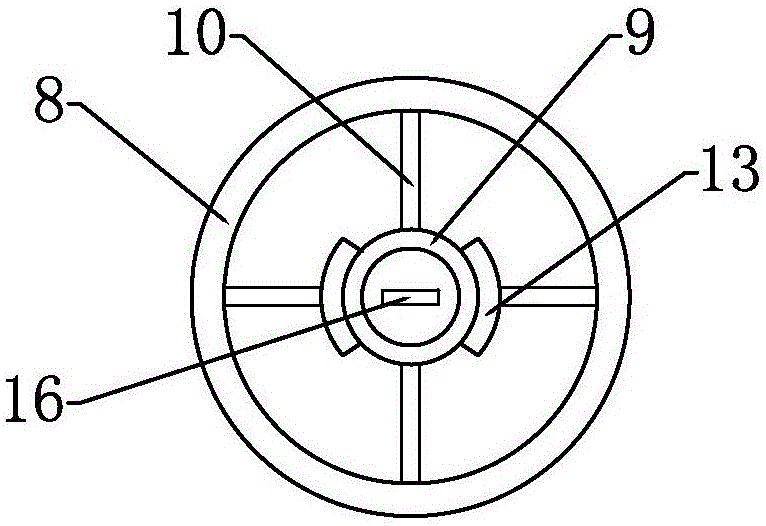

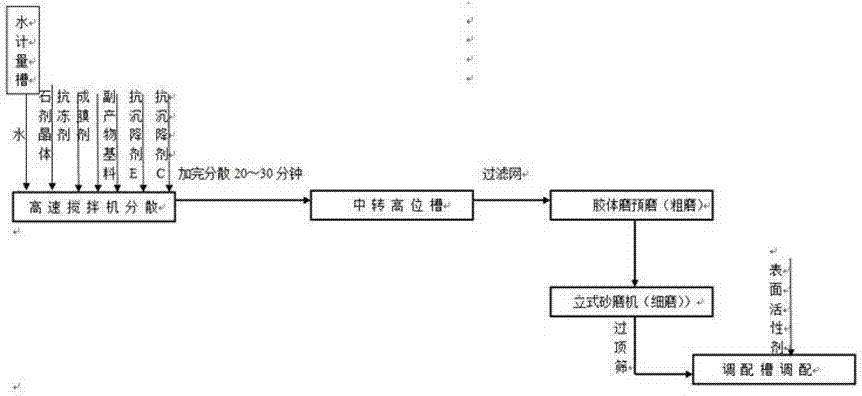

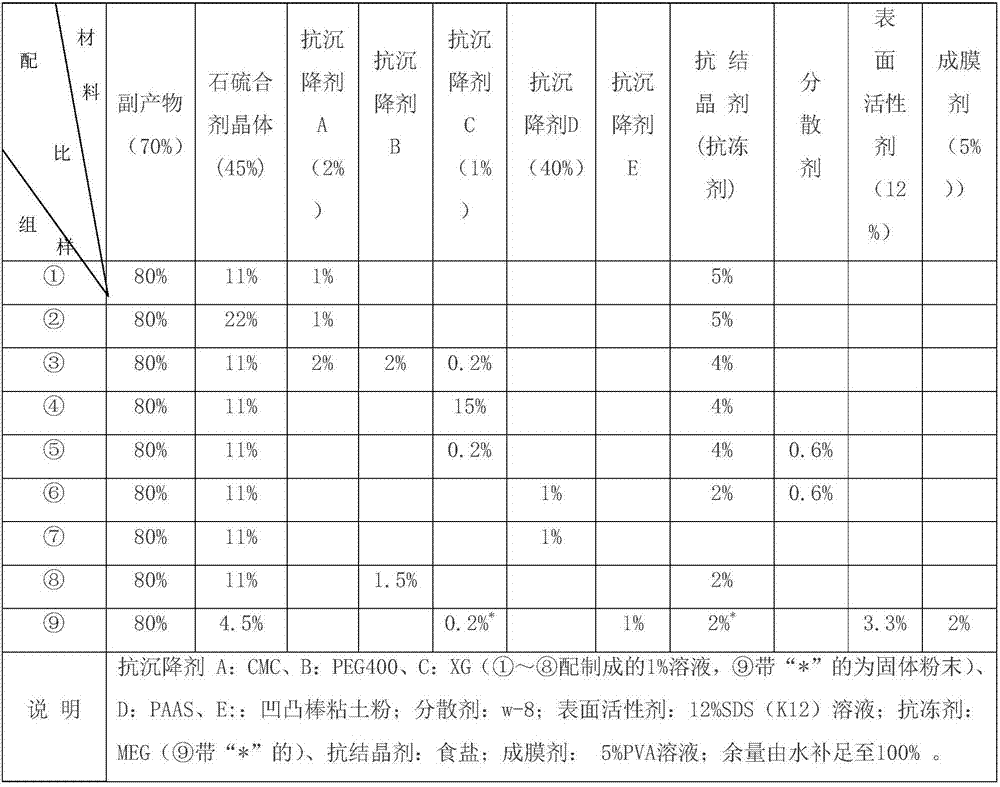

Lime sulphur by-product painting reagent and preparation process thereof

InactiveCN106900742AWith suspension stabilityThe formula is fine and scientific and reasonableBiocideAntifouling/underwater paintsWhitening AgentsSuspending Agents

The invention discloses a process for producing a painting reagent by using a lime sulphur by-product. According to the process, a by-product is taken as a main base material, supplemented lime sulphur is taken as an active ingredient, in the process of formula development and manufacturing, anti-sinking agents, an antifreeze agent, a film-forming agent and a surface active agent are added, and a process for producing a farm chemical suspending agent is adopted to manufacture. The painting reagent comprises the following raw materials in percentage by mass: 75-80% of a by-product base material, 4.4-5.0% of lime sulphur crystal, 0.2-0.3% of an anti-sinking agent C, 1.0-2.0% of an anti-sinking agent E, 2.0-5.0% of the antifreeze agent, 1.5-2.5% of the film-forming agent, 3.0-5.0% of the surface active agent and 100% of supplemented water. The painting reagent not only has the characteristics of a whitening agent used in abundance on the market, but also has suspension stability which is specially owned by the farm chemical suspending agent.

Owner:宜宾北方川安化工有限公司

Method for increasing yield of super-thick material layer sintering

The invention relates to a method for increasing the yield of super-thick material layer sintering. Hot pressing pellets with the alkalinity being the same as that of a sintering mixture are distributed into the sintering mixture, so that ventilation holes are formed in an upper sintering material layer during ignition sintering. The method comprises the steps that 55-70 wt% of iron concentrate and 30-45 wt% of soft coal are fully uniformly mixed, then quick lime is added into the iron concentrate and the soft coal to form a mixture, the binary alkalinity of the mixture is made to be the same as the alkalinity of the sintering mixture, the ratio of CaO to SiO2 is 1.8-2.4, 2-5 wt% of water is added into the mixture, and the mixture is fully stirred and uniformly mixed in a mixer; a uniformly mixed mixture is subjected to hot pressing forming through a ball press machine, wherein the forming pressure is 20-30 MPa, the hot pressing temperature is 350-550 DEG C, the hot pressing time is 8-15 min, and the diameters of obtained hot pressing pellets are 8-12 mm; and the hot pressing pellets are distributed into the sintering mixture layer through a distribution device arranged between a sintering distributor and an ignitor, wherein the amount of the hot pressing pellets distributed into the edge sintering mixture is 1-2.5 times that of the hot pressing pellets distributed into the middle sintering mixture, and the depth of the hot pressing pellets distributed into the sintering material layer is 20-200 mm.

Owner:ANGANG STEEL CO LTD

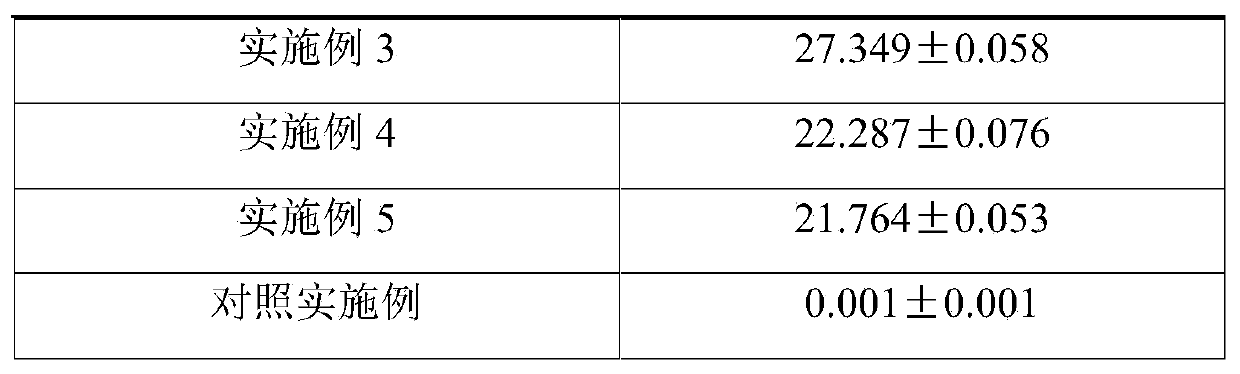

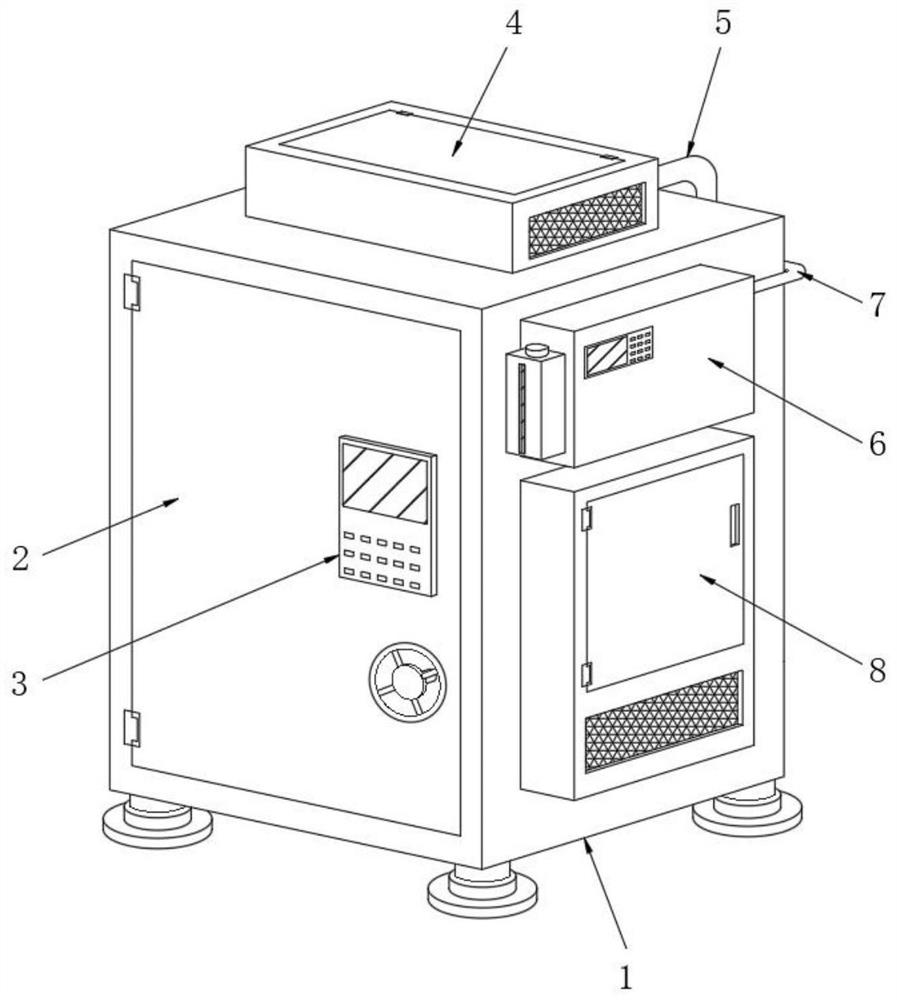

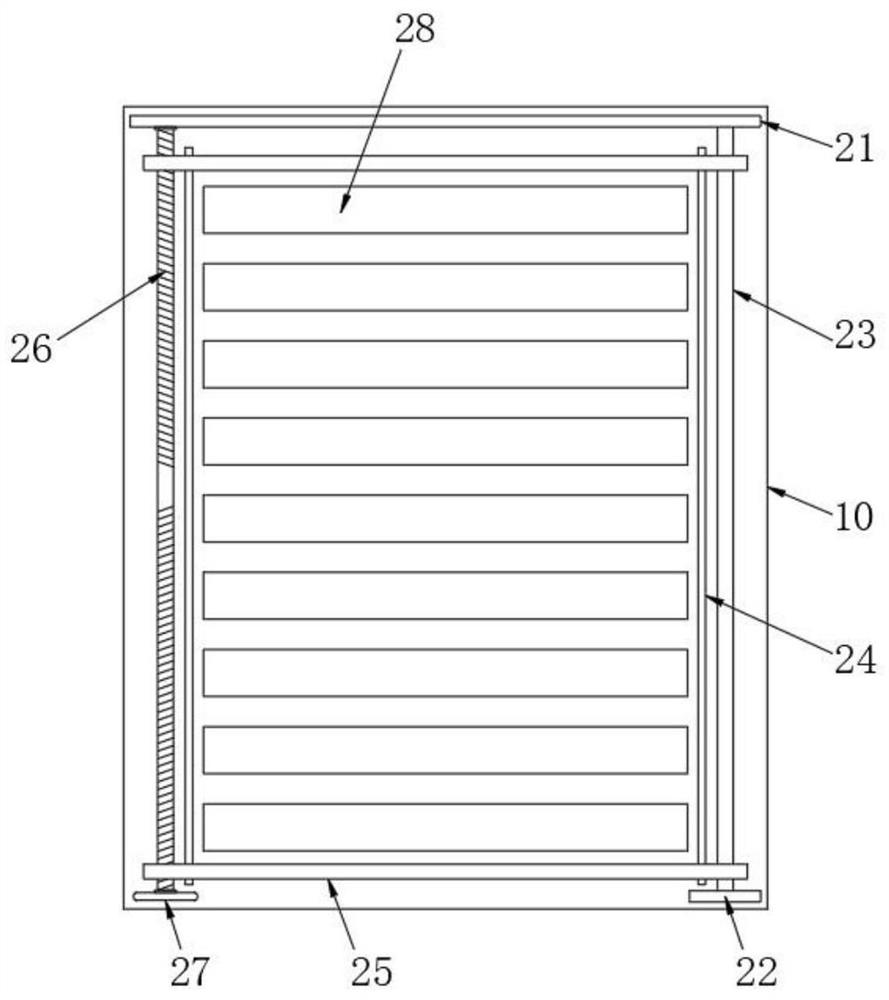

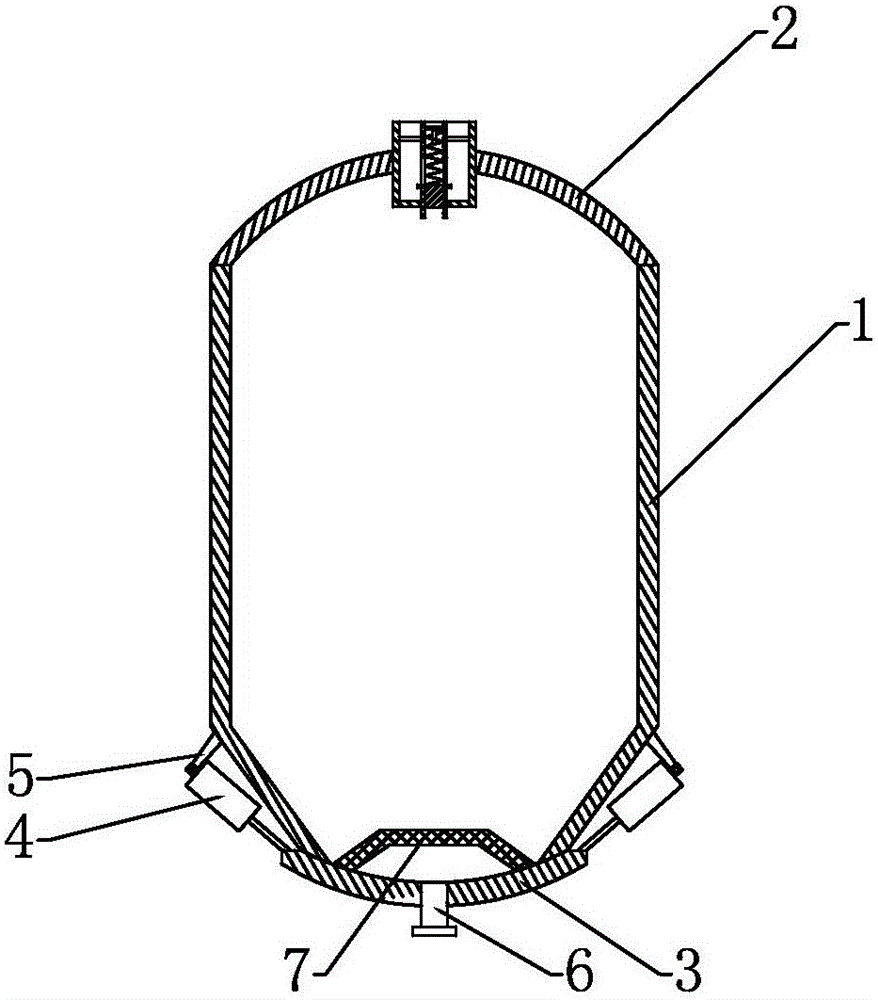

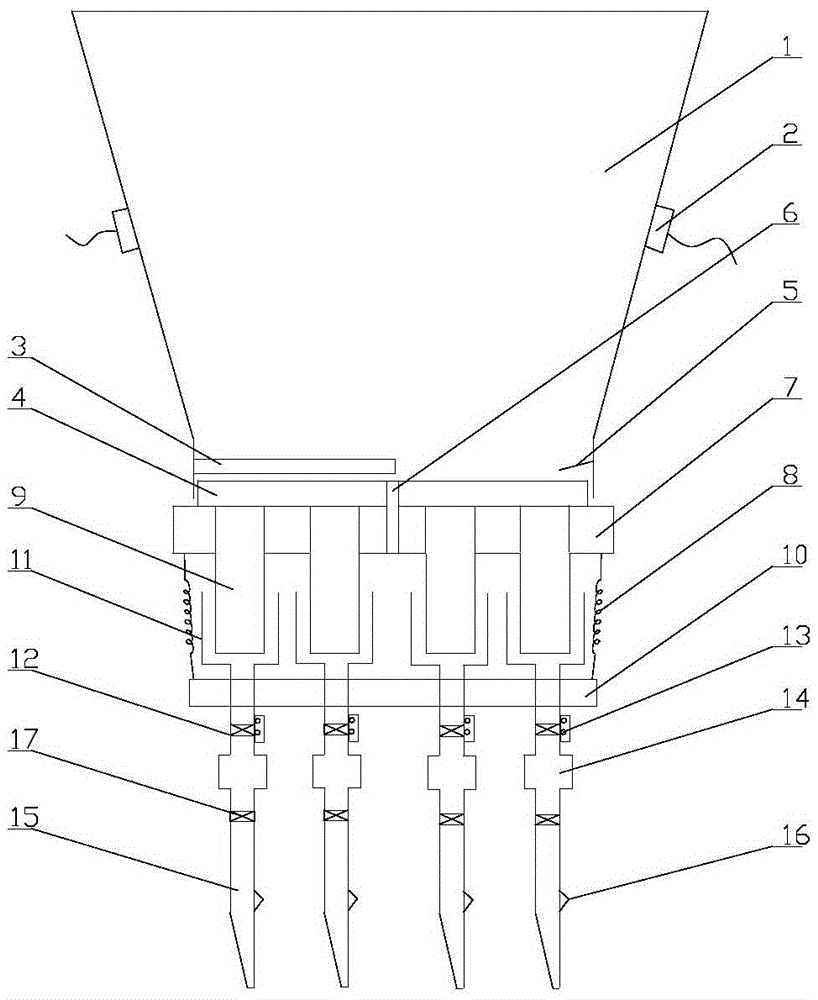

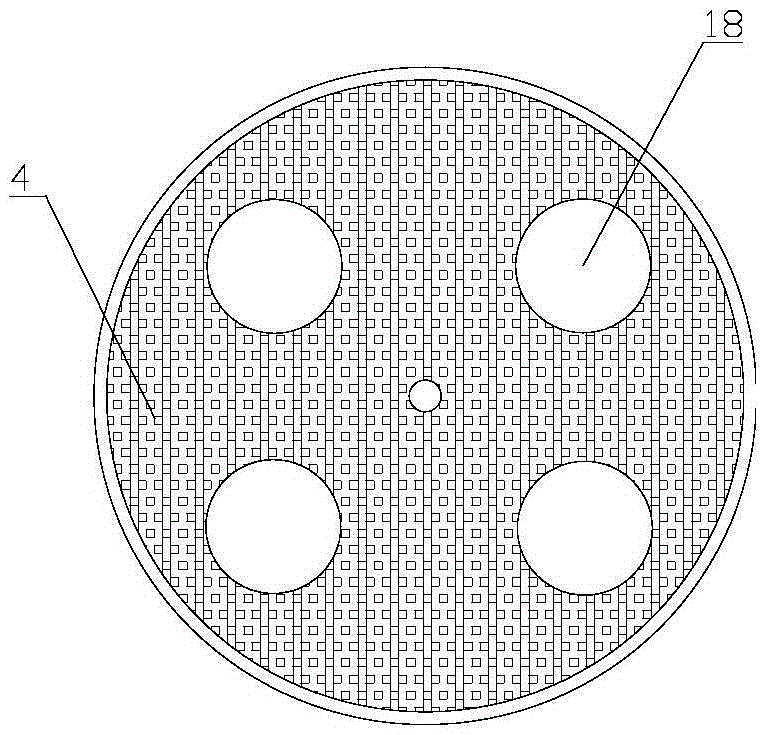

Cleaning light-resisting airing box for immunohistochemical stain experiment

InactiveCN108106912AReduce the chance of fluorescence quenchingReduce chappingPreparing sample for investigationFluorescence/phosphorescenceFluorescenceQuenching

The invention belongs to the technical field of bioexperiments, and particularly relates to a cleaning light-resisting airing box for the immunohistochemical stain experiment. The cleaning light-resisting airing box comprises an outer shell, a control panel, a hatching cleaning device, an airing device, a moisturizing layer and an electric plate layer, wherein the outer shell is a rectangular boxbody, the hatching cleaning device, the airing device, the moisturizing layer and the electric plate layer are arranged in the box body of the outer shell, the control panel is arranged on one side ofthe upper surface of the box body of the outer shell, a cover plate used for sealing and covering the box body is arranged adjacent to the control panel on the upper surface of the box body of the outer shell; an on-off key and a temperature and humidity regulating button are arranged on the control panel; a display screen is further arranged to display time, temperature and humidity. The cleaning light-resisting airing box integrates the three functions of resisting light, cleaning and airing, the probability of fluorescence quenching is reduced, the dust pollution is reduced, a sheet is prevented from cracking, the degree of cleanliness of the sheet is improved, and the experiment effect of the immunofluorescence is guaranteed.

Owner:FUDAN UNIV

Liquid medicine capable of treating beriberi

InactiveCN104324202ALow costReduce chappingAntimycoticsHydroxy compound active ingredientsBeriberiAlcohol

The invention discloses a liquid medicine capable of treating beriberi. The liquid medicine capable of treating the beriberi is prepared from 20 parts of rice vinegar, 25 parts of aloe, 10 parts of medicinal alcohol, 5 parts of garlic and 10 parts of water. The liquid medicine can be prepared easily; raw materials are cheap; and the liquid medicine has a short course of treatment, is fast in effectiveness, and can treat both the symptoms and root causes.

Owner:黄心诚

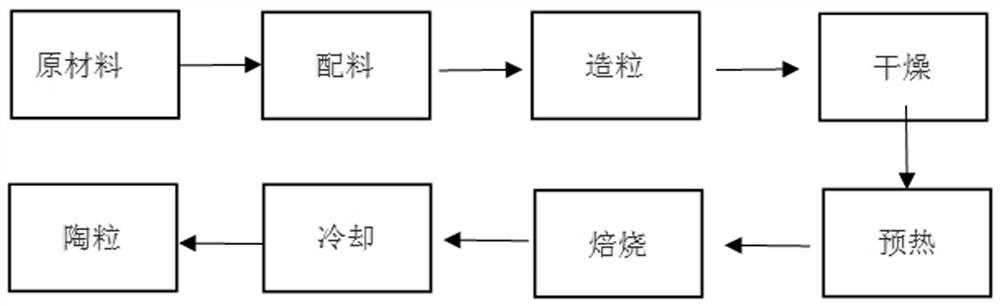

Ceramsite fired by doping high-silicon iron tailings and preparation method thereof

PendingCN112811926ARealize the utilization of solid waste resourcesImprove liquidityCeramic materials productionCeramicwareSilicon ironBuilding material

The invention belongs to the field of comprehensive utilization of building materials and solid wastes, and particularly relates to a method for firing ceramsite by doping high silicon iron tailings and other solid wastes. The invention relates to ceramsite fired by doping high-silicon iron tailings, wherein the ceramsite is prepared from the following raw materials in parts by mass: 60-70 parts of high-silicon iron tailings, 10-15 parts of red mud, 5-12 parts of montmorillonite, 5-8 parts of pulverized coal and 5-10 parts of kitchen garbage. Various performance index values of the ceramsite prepared only in the north provided by the invention meet the standard requirements of GBT17431.1-2010 "Lightweight Aggregate and Test Method Thereof". According to the invention, in the ceramsite doped with the high-silicon iron tailings for firing, the high-silicon iron tailings are used as main raw materials; so that from the perspective of treatment of a large amount of solid waste, the problem that a large amount of tailings are accumulated is efficiently solved, solid waste resource utilization is achieved, waste is turned into wealth, and the influence of the solid waste such as the tailings on the environment is reduced. The technical scheme has certain ecological benefits and social benefits.

Owner:SHENYANG POLYTECHNIC UNIV

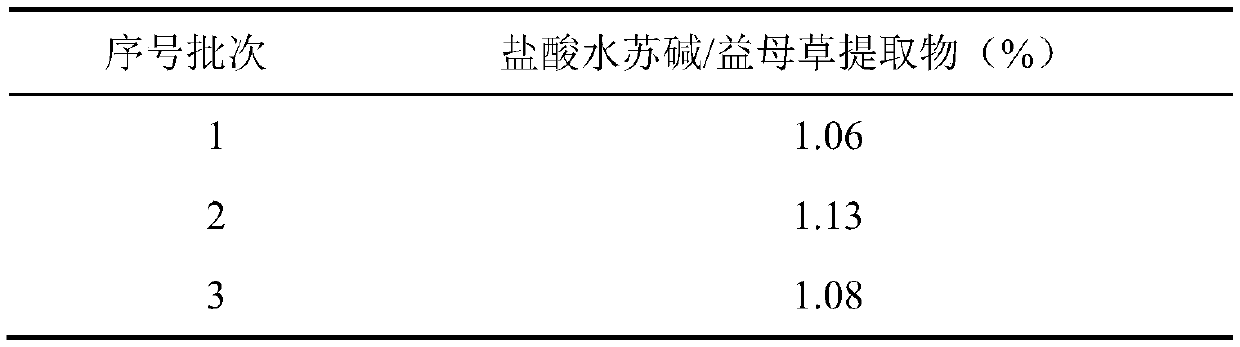

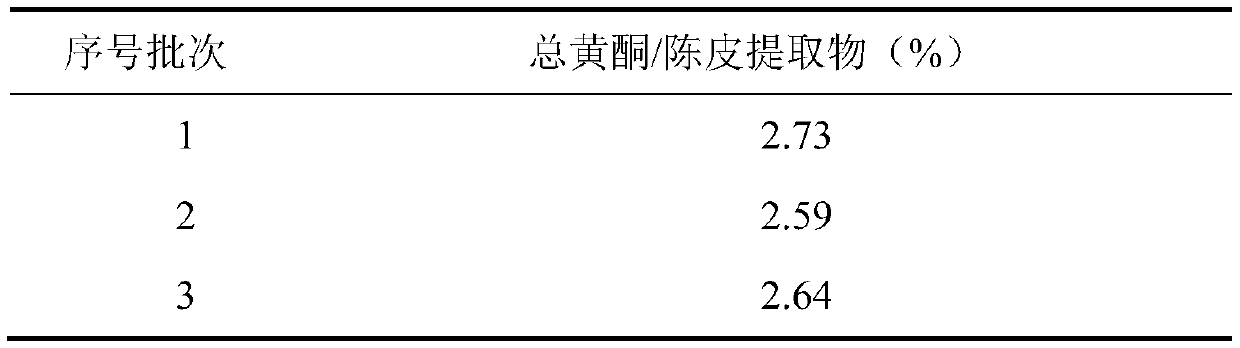

Composite skin care cream with moisturizing property and preparation method thereof

InactiveCN109730957AHigh activityEasy to synthesizeCosmetic preparationsToilet preparationsAdditive ingredientComposite skin

The invention discloses a composite skin care cream with a moisturizing property and a preparation method thereof. The composite skin care cream with the moisturizing property is prepared from, by weight, 37-43 parts of an extract of herba leonuri, 17-23 parts of an extract of pericarpium citri reticulatae, 27-33 parts of an extract of herba houttuyniae, 8-12 parts of an extract of rhizoma alismatis, 18-22 parts of olive oil, 18-22 parts of squalane, 6-10 parts of silicone, 10-14 parts of glyceride stearate, 18-22 parts of triethanolamine, 14-18 parts of 1,3-butanediol, 4-8 parts of plant essence and 80-120 parts of purified water. The composite skin care cream with the moisturizing property can permeate into the surface of the skin, remove the free radicals of human body cells and have ananti-aging effect. Because the skin care cream contains a variety of effective ingredients of Chinese herbal medicine, the skin care cream also has the effects of moisturizing and whitening.

Owner:陕西中医药大学附属医院

Ointment for treating beriberi and preparation method thereof

InactiveCN105920279AShort course of treatmentQuick resultsAntimycoticsAnthropod material medical ingredientsLicorice rootsDictamnus dasycarpus

The invention relates to an ointment for treating beriberi and a preparation method thereof. The ointment is prepared from the following traditional Chinese medicines by mass: 10 to 25 parts of phellodendron, 5 to 10 parts of Chinese gall, 15 to 25 parts of plantain herb, 8 to 15 parts of Sophora flavescens, 10 to 20 parts of clove, 5 to 15 parts of root of kudzu vine, 15 to 25 parts of common cnidium fruit, 10 to 18 parts of patrinia herb, 3 to 9 parts of Fructus Forsythiae, 10 to 18 parts of safflower, 10 to 25 parts of Dictamnus dasycarpus, 18 to 25 parts of wild chrysanthemum flower, 15 to 35 parts of Radix Astragali, 5 to 10 parts of gentian, 3 to 8 parts of Tokyo violet herb, 2 to 8 parts of aloe, 3 to 6 parts of mint and 1 to 5 parts of licorice root. The ointment provided by the invention has good effect, short treatment course and fast action and can reduce cracks on an affected part and relieve pain of patients; and the preparation method is simple.

Owner:SUZHOU TIANLING CHINESE TRADITIONAL MEDICINE SLICE

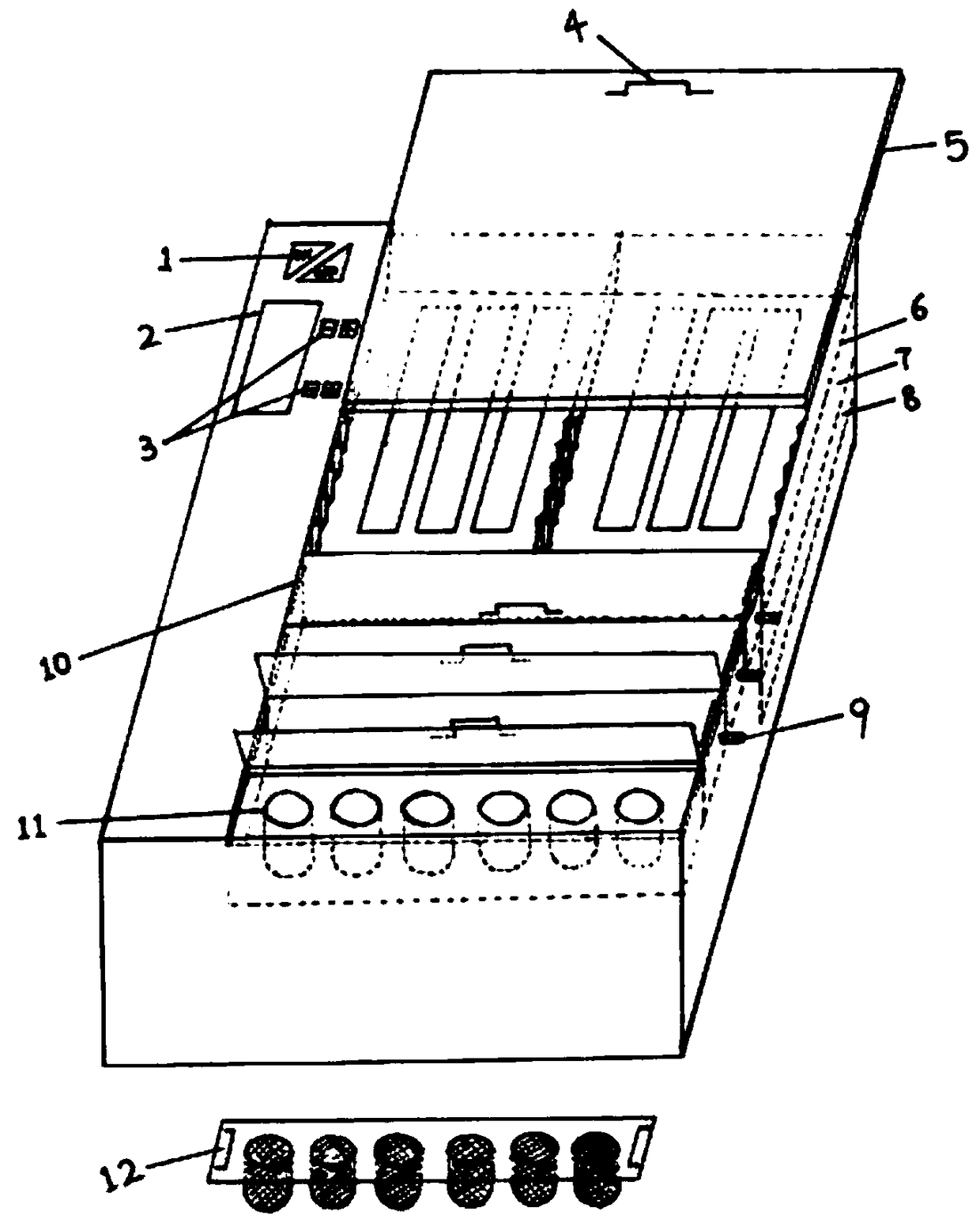

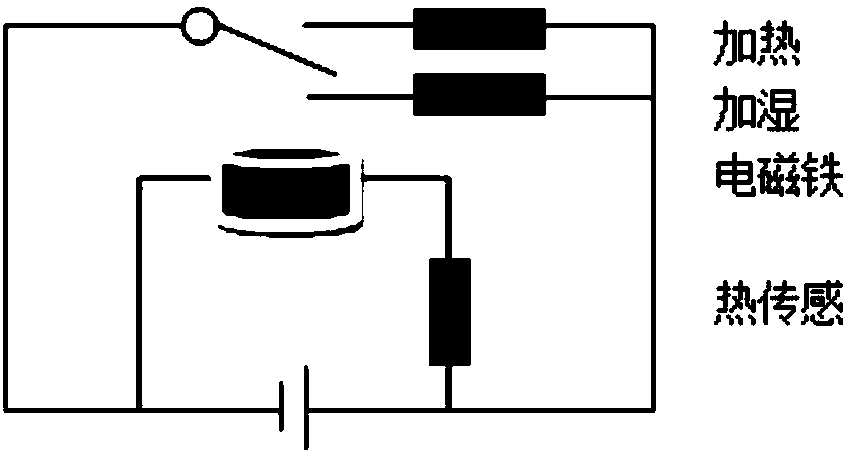

Humidified and dried citrus tea preparation method

ActiveCN107927241AGuaranteed qualityKeep active ingredientsPre-extraction tea treatmentDrying gas arrangementsHesperidiumHeat sensitive

The invention discloses a humidified and dried citrus tea preparation method, which comprises a citrus processing, tea leaf filling, first-step drying, second-step drying, third-step drying, packagingand storage and other steps. In the steps of citrus tea drying, air temperature, humidity and wind speed are controlled, consequently, the quality of citrus tea is increased, quality deterioration reaction occurring in the conventional hot air drying process, such as active ingredient oxidation and destruction of volatile oil and other heat-sensitive substances, is reduced, so that the active ingredients of the citrus tea are kept to the max, and thereby the health-care effect of the citrus tea is increased.

Owner:广西国茗金花茶科技有限公司

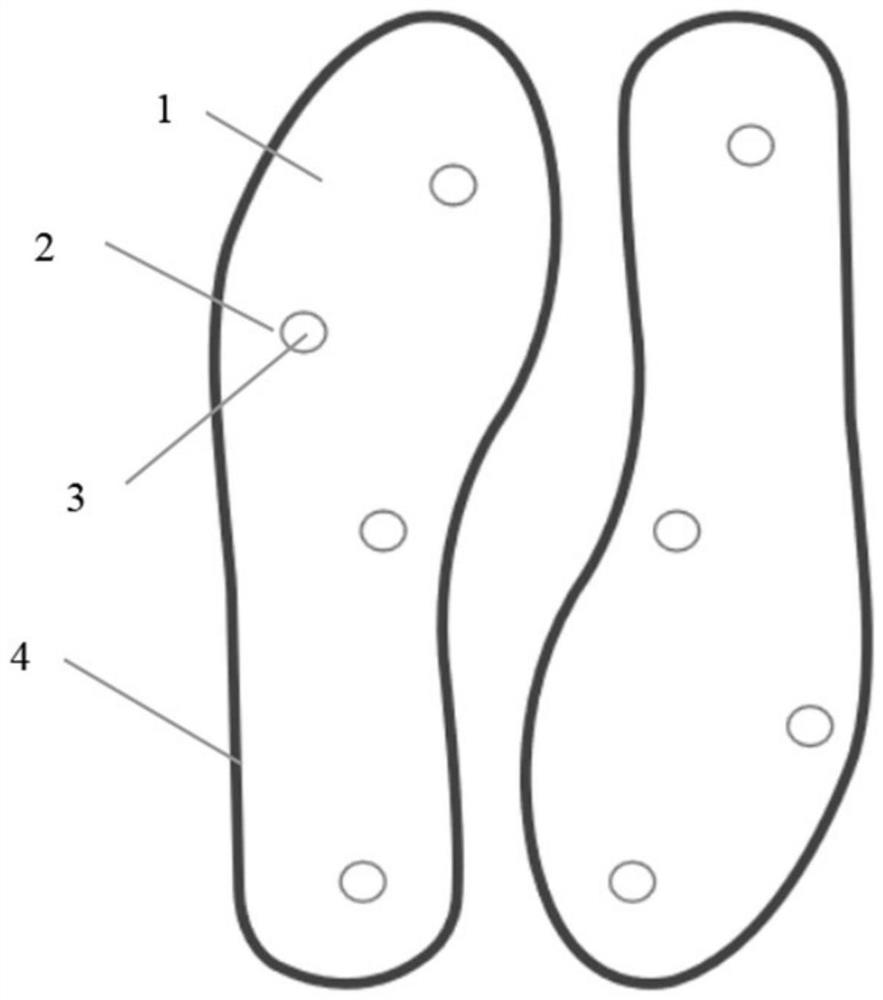

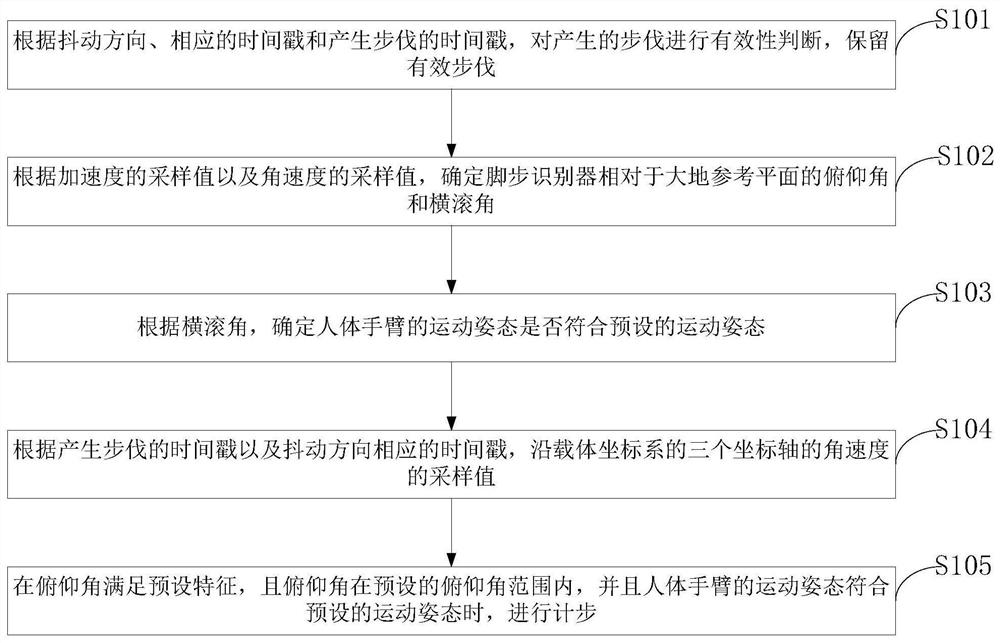

Artemisia argyi insole and health care shoe with health care effects

InactiveCN113180328ARelieve sore throatRelieve dry throatHydroxy compound active ingredientsInsolesFoot solesTraditional medicine

The invention belongs to the technical field of health-care insoles, and discloses an artemisia argyi insole and a health care shoe with health care effects. The artemisia argyi insole with health care effects comprises an insole body, and a plurality of raised massage beads are adhered to different positions of the insole body; wormwood balls are placed in the massage beads; and vent holes are formed in the massage beads. An elastic layer is adhered to the lower part of the insole body; and a plurality of grid holes are formed in the insole body. The health care shoe is provided with a shoe body, a footstep recognizer is embedded in the rear end of the shoe body, and the artemisia argyi insole with health-care effects is arranged on the upper portion of the shoe body. The positions of the massage beads are arranged according to the main acupuncture points of the foot sole, the acupuncture points have the health care effects, on the basis that the basic insole function is provided, the foot can be massaged, foot fatigue is relieved to a certain degree, and meanwhile the deodorization effect is achieved.

Owner:深圳市川崎运动用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com