Preparation and production process of pitaya stem gel juice extract

A technology of pitaya stem and production process, which is applied to the preparation of pitaya stem gel juice extract and the field of production technology, can solve the problems of inconvenient extraction of pitaya stem gel juice, low production efficiency and high cost, and achieves reduction of Dry and chapped skin, high productivity and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

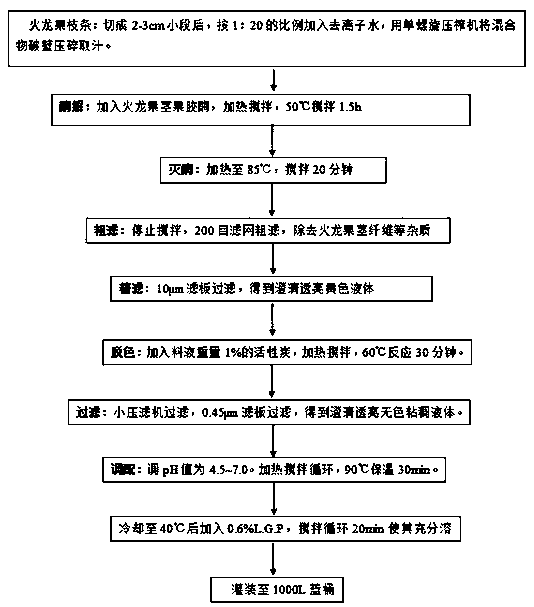

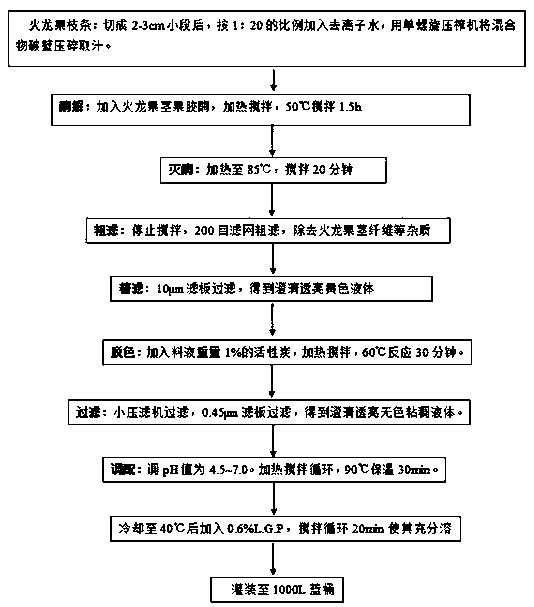

[0028] Embodiment one, the preparation of a kind of pitaya stem gel juice extract and production technology thereof, comprises the steps:

[0029] Step 1: using dragon fruit branches as raw materials, cleaning, crushing and cutting into small branches;

[0030] Step 2: Add deionized water in an appropriate proportion, and use a single screw press to break the wall to make a slurry.

[0031] Step 3: Add pectinase, stir at 50°C for 1.5 hours to carry out enzymatic hydrolysis, and pass through 200 mesh coarse filtration and 10 μm fine filtration to obtain a clear and translucent yellow liquid.

[0032] Step four: decolorization;

[0033] Step 5: filter out the clear liquid, and press filter with a filter press to obtain a clear, translucent, colorless liquid.

[0034] Step 6: Add 0.6% L.G.P (Sangpu cosmetics preservative), stir for 20 minutes until fully dissolved to obtain gel juice extract;

[0035] Step 7: Fill it into a 1000L container to obtain a finished product; finishe...

Embodiment 2

[0042] Embodiment two, the preparation of a kind of dragon fruit stem gel juice extract and its production technology, comprise the steps:

[0043] Step 1: using dragon fruit branches as raw materials, cleaning, crushing and cutting into small branches;

[0044] Step 2: Add deionized water in an appropriate proportion, and use a single screw press to break the wall to make a slurry.

[0045] Step 3: Add pectinase, stir at 50°C for 1.5 hours to carry out enzymatic hydrolysis, and pass through 200 mesh coarse filtration and 10 μm fine filtration to obtain a clear and translucent yellow liquid.

[0046] Step four: decolorization;

[0047] Step 5: filter out the clear liquid, and press filter with a filter press to obtain a clear, translucent, colorless liquid.

[0048] Step 6: Add 0.6% L.G.P (Sangpu cosmetics preservative), stir for 20 minutes until fully dissolved to obtain gel juice extract;

[0049] Step 7: Fill it into a 1000L container to obtain the finished product; fini...

Embodiment 3

[0056] Embodiment three, the preparation of a kind of pitaya stem gel juice extract and production technology thereof, comprise the steps:

[0057] Step 1: using dragon fruit branches as raw materials, cleaning, crushing and cutting into small branches;

[0058] Step 2: Add deionized water in an appropriate proportion, and use a single screw press to break the wall to make a slurry.

[0059] Step 3: Add pectinase, stir at 50°C for 1.5 hours to carry out enzymatic hydrolysis, and pass through 200 mesh coarse filtration and 10 μm fine filtration to obtain a clear and translucent yellow liquid.

[0060] Step four: decolorization;

[0061] Step 5: filter out the clear liquid, and press filter with a filter press to obtain a clear, translucent, colorless liquid.

[0062] Step 6: Add 0.6% L.G.P (Sangpu cosmetics preservative), stir for 20 minutes until fully dissolved to obtain gel juice extract;

[0063] Step 7: Fill it into a 1000L container to obtain a finished product; finished...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com