Bacteriostatic detergent containing plant surfactant and preparation method of bacteriostatic detergent

A surfactant and detergent technology, applied in the field of antibacterial detergent and its preparation, can solve the problems of unsatisfactory foaming ability and foam-stabilizing ability, insufficiently rich and durable foam, unsatisfactory foaming power, and the like. Good bactericidal effect, reduced skin irritation, good washing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, the preparation of acidic oxidized tea polyphenols

[0030] Weigh tea polyphenols and dissolve them in deionized water to form a tea polyphenols aqueous solution, keep warm with circulating water at 20°C, stir, add 0.01mol / L acetic acid solution to make the pH of the reaction solution 2.9, and oxidize for 30 minutes. After the end, add ethyl acetate twice the amount of the reaction solution, centrifuge and separate layers, take the supernatant, concentrate under reduced pressure to form an extract, and spray dry to obtain acidic oxidized tea polyphenols.

[0031] Wherein, in the above preparation process, the concentration of tea polyphenols in the tea polyphenols aqueous solution is 5 g / L; the ventilation rate is 0.5 L / min.

Embodiment 2

[0032] Embodiment 2, preparation of enzymatically oxidized tea polyphenols

[0033] Weigh tea polyphenols and dissolve them in deionized water to form an aqueous solution of tea polyphenols (use a pH regulator to adjust the pH to 5.5), keep warm with circulating water at 37°C, add polyphenol oxidase while stirring, and feed air during the reaction process to enzymatically Oxidation reaction was carried out for 50 minutes. After the reaction was completed, the enzyme was inactivated, ethyl acetate was added to the reaction solution twice as much, centrifuged and separated, the supernatant was taken, concentrated under reduced pressure to form an extract, and spray-dried to obtain enzymatically oxidized tea polyphenols.

[0034] Wherein, the concentration of tea polyphenols in the aqueous solution of tea polyphenols may be 3 g / L; the concentration of the polyphenol oxidase in the reaction solution is 1.5 g / L; the ventilation rate is 0.6 L / min.

Embodiment 3~5

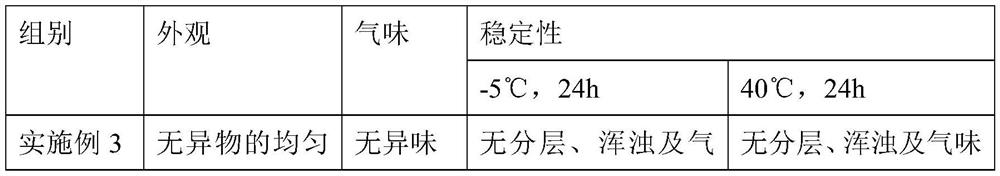

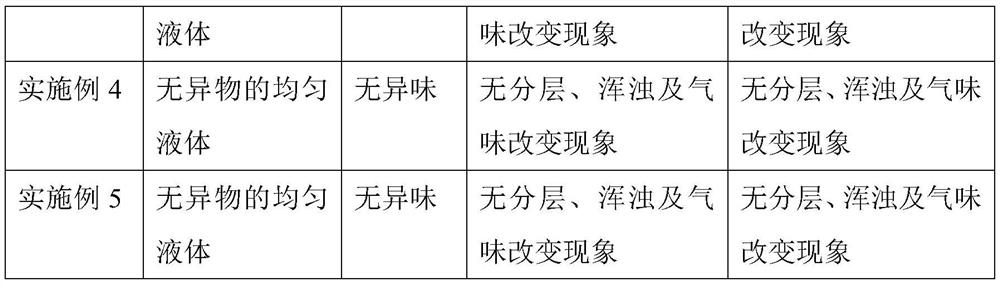

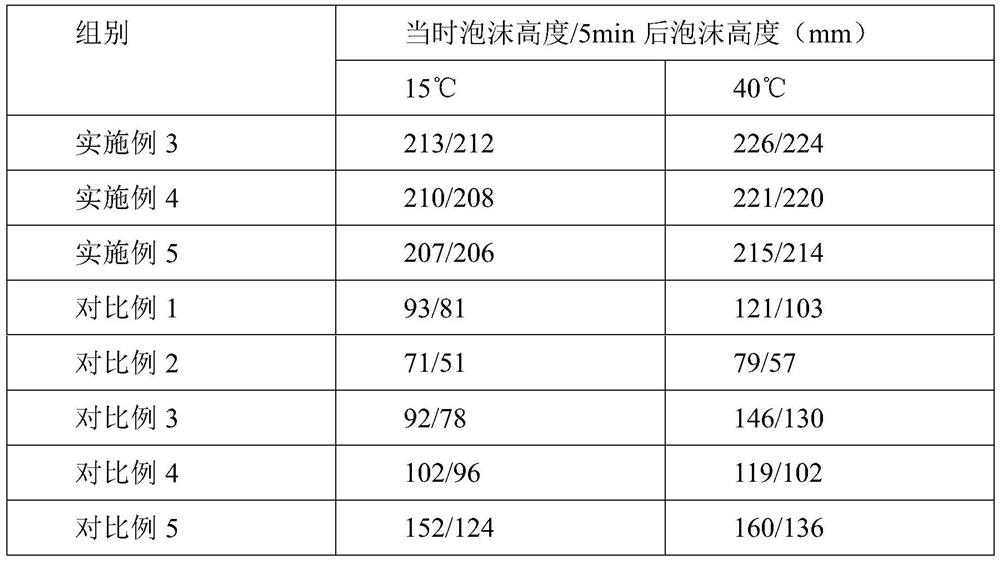

[0035] Embodiment 3-5 A kind of antibacterial detergent formula containing plant surfactant and its preparation (quality score)

[0036] components Example 3 Example 4 Example 5 Sapinberry Extract 22% 25% 20% Enzymatic Oxidation of Tea Polyphenols 5% 3% 5% Acidic Oxidized Tea Polyphenols 2% 0.6% 1% Aloe Vera Extract 1% 0.5% 1.5% Honeysuckle Extract 1.5% 1% 3% Lemongrass Extract 0.5% 0.5% 0.5% Sodium chloride 1.0% 1.5% 2% EDTA-2Na 0.05% 0.05% 0.05% Methylisothiazolinone 0.1% 0.1% 0.1% Methylchloroisothiazolinone 0.1% 0.1% 0.1% Deionized water margin margin margin

[0037] Embodiment 3~5 detergent preparation method

[0038] Take the amount of deionized water in the formula, add it to the stirring pot, heat to 45°C, add compound oxidized tea polyphenols, and stir evenly; continue to heat to 65°C, add Sapindus chinensis extract and chelating agent, stir evenly; cool dow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com