Patents

Literature

613 results about "Aromatic agent" patented technology

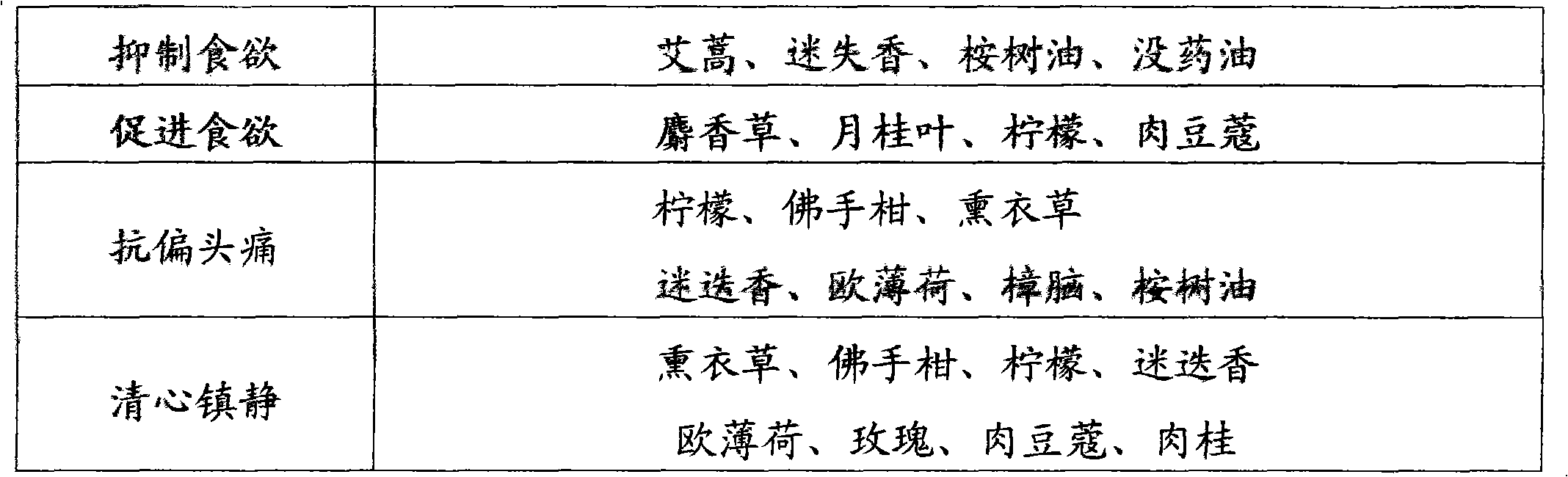

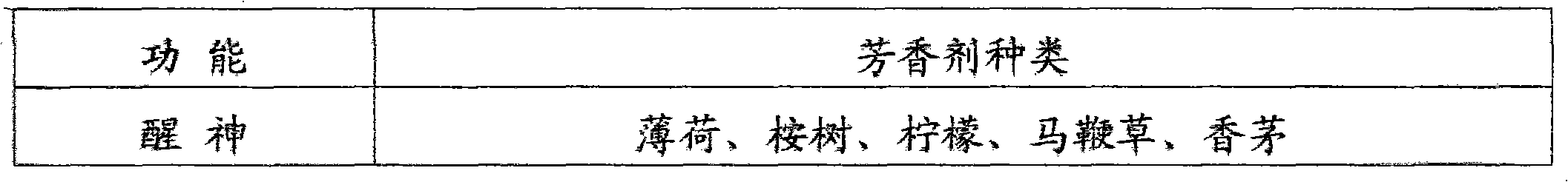

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Controlled release formulations coated with aqueous dispersions of acrylic polymers

InactiveUS6143353ADissolution stabilityIncrease weight gainPretreated surfacesMedical devicesWater insolubleActive agent

A stable solid controlled release formulation having a coating derived from an aqueous dispersion of a hydrophobic acrylic polymer includes a substrate including an active agent selected from the group consisting of a systemically active therapeutic agent, a locally active therapeutic agent, a disinfecting and sanitizing agent, a cleansing agent, a fragrance agent and a fertilizing agent, overcoated with an aqueous dispersion of the plasticized water-insoluble acrylic polymer. The formulation provides a stable dissolution of the active agent which is unchanged after exposure to accelerated storage conditions.

Owner:PURDUE PHARMA LP

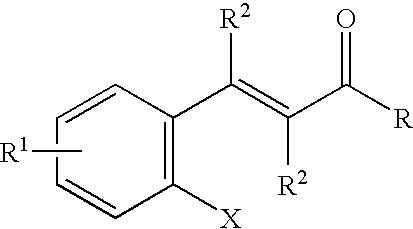

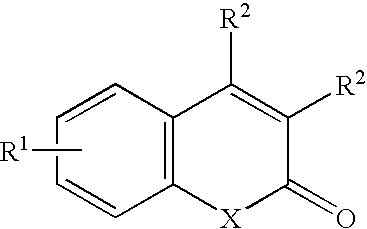

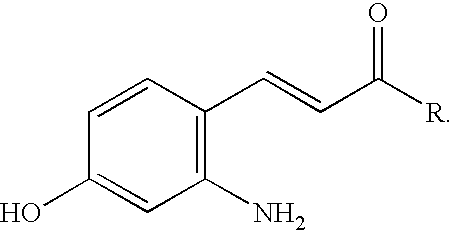

Photo-labile pro-fragrance conjugates

The present invention relates to photo-labile pro-fragrance conjugates comprising:a) a photo-labile unit which upon exposure to electromagnetic radiation is capable of releasing a pro-fragrance unit; andb) a pro-fragrance unit, which when so released is eitheri) a pro-fragrance compound capable of releasing a fragrance raw material; orii) a fragrance raw material.The present invention relates to systems for delivering fragrances to a situs, and to laundry detergent compositions, fine fragrances, personal care and hair care compositions comprising said systems.

Owner:PROCTER & GAMBLE CO

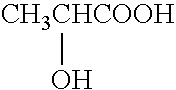

Fragranced Therapeutic Delivery System

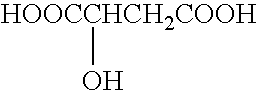

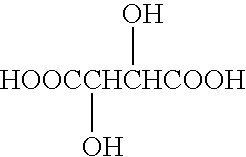

The present invention relates to multi-functional topical delivery systems for providing long-lasting delivery of fragrance as. well as skin-supporting and / or pharmaceutically active ingredients comprising (i) an oil phase; (ii) an aqueous phase; (iii) phenoxyethanol at a concentration of from about 2.0% to about 2.7% based on the total weight of the composition; (iv) an effective exfoliating amount of a hydrophobic hydroxycarboxylic acid selected from the group consisting of orthohydroxybenzoic acid, hydroxycarboxylic acids containing a C12-C24 fatty acid esterified to the alpha carbon hydroxyl group, hydroxycarboxylic acids containing a C12-C24 fatty alcohol esterified to a carboxyl group; (v) a non-ionic emulsifier having an HLB of from about 7 to about 10; (vi) a fragrance composition; and (vii) at least one skin-supporting or dermatopharmaceutically active agent.

Owner:TREMO TEC GMBH

Viscose fiber with plant source anti-bacterial function and aromatic smell, and preparation method thereof

ActiveCN103225123ANo side effectsComfortable to takeArtificial thread manufacturing machinesArtificial filaments from viscoseSide effectMint extract

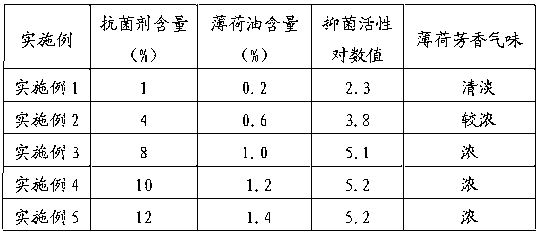

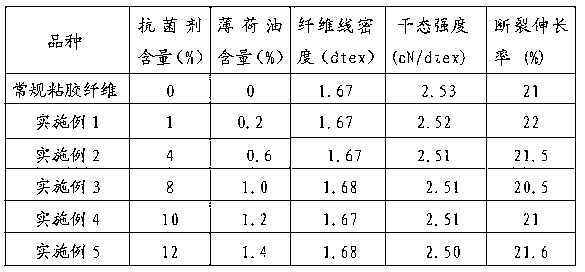

The invention discloses a viscose fiber with a plant source anti-bacterial function and aromatic smell. The viscose fiber is composed of a viscose spinning solution, an anti-bacterial agent and an aromatic agent, wherein the anti-bacterial agent is mixed powder of a mint extract and a isatis root extract, wherein the weight percentage of the mint extract accounts for 40%-80%; and the weight percentage of the isatis root extract accounts for 60%-20%; the aromatic agent is mint oil coated by microcapsules; the anti-bacterial agent accounts for 1%-8% of the mass of methyl cellulose in the viscose spinning solution; the mint oil accounts for 0.2%-1% of the mass of methyl cellulose in the viscose spinning solution; and the viscose fiber is prepared by adopting a wet spinning method by using the viscose spinning solution, the anti-bacterial agent and the aromatic agent. The plant source extracts and the plant source essential oil are used as the anti-bacterial agent and the aromatic agent; and the anti-bacterial agent and the aromatic agent are uniformly distributed in the fiber, so that the anti-bacterial function and the aromatic smell of the fiber are durable. Since the plant source extracts and the aromatic agent are natural substances extracted from the plants, so that the viscose fiber has no side effect to human body.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Synergistic medicament containing flavoring agents and having an antagonistic regenerative and/or protagonist decontamination effect

InactiveUS20050014827A1Reduce toxinsPositive improvementAntibacterial agentsBiocideMicroorganismMedicine

The invention relates to medicaments comprising a microbicidal composition consisting of at least two GRAS (Generally Recognized As Safe) aromatic agents or derivatives thereof, and to the use of these compositions for producing decontamination and / or regenerative agents for treating humans and animals.

Owner:SCHUR JORG P

Aromatherapy delivery system

ActiveUS7427417B2Safe releasePleasing effectCosmetic preparationsBiocideAromatherapistOlfactory system

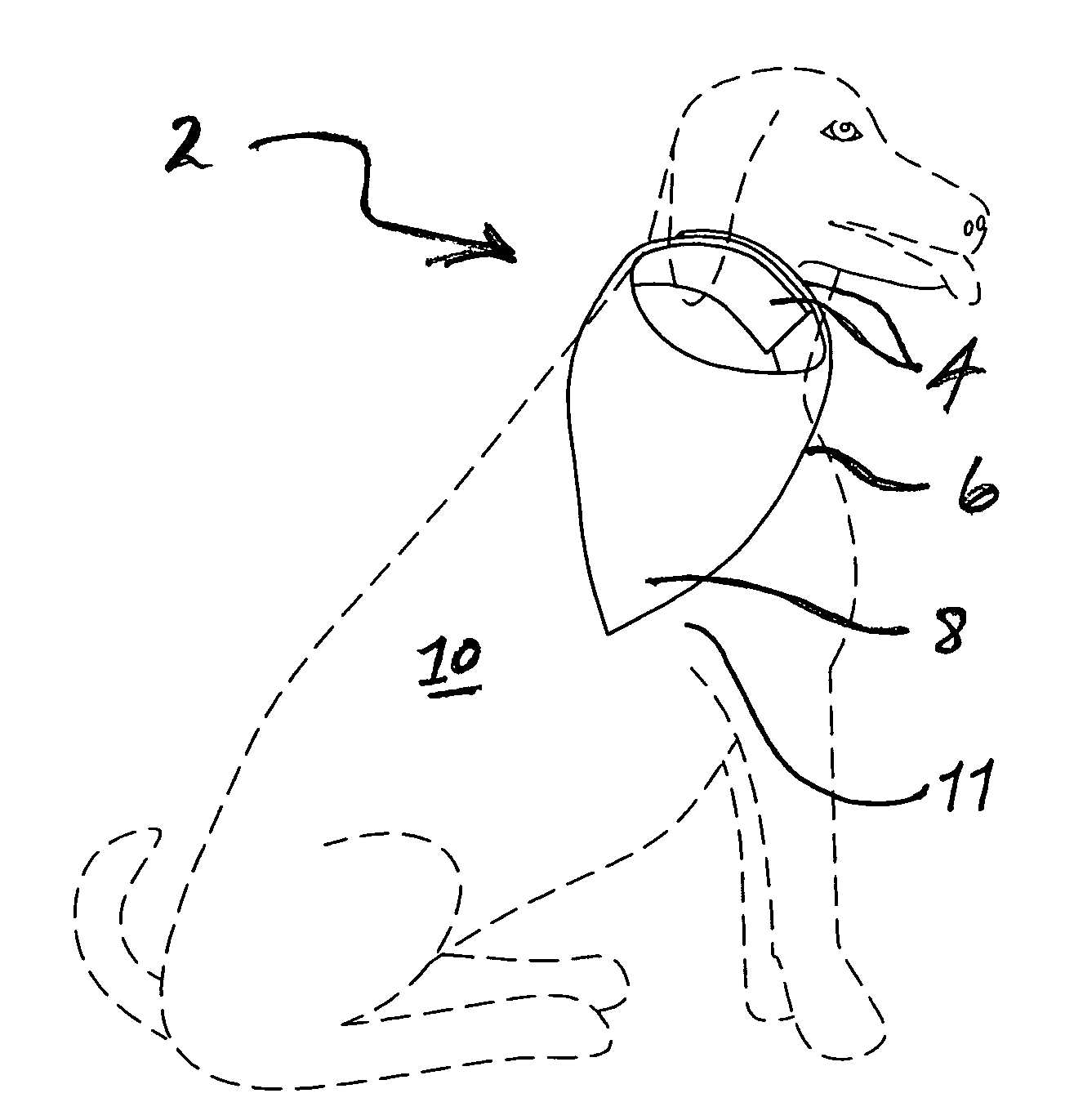

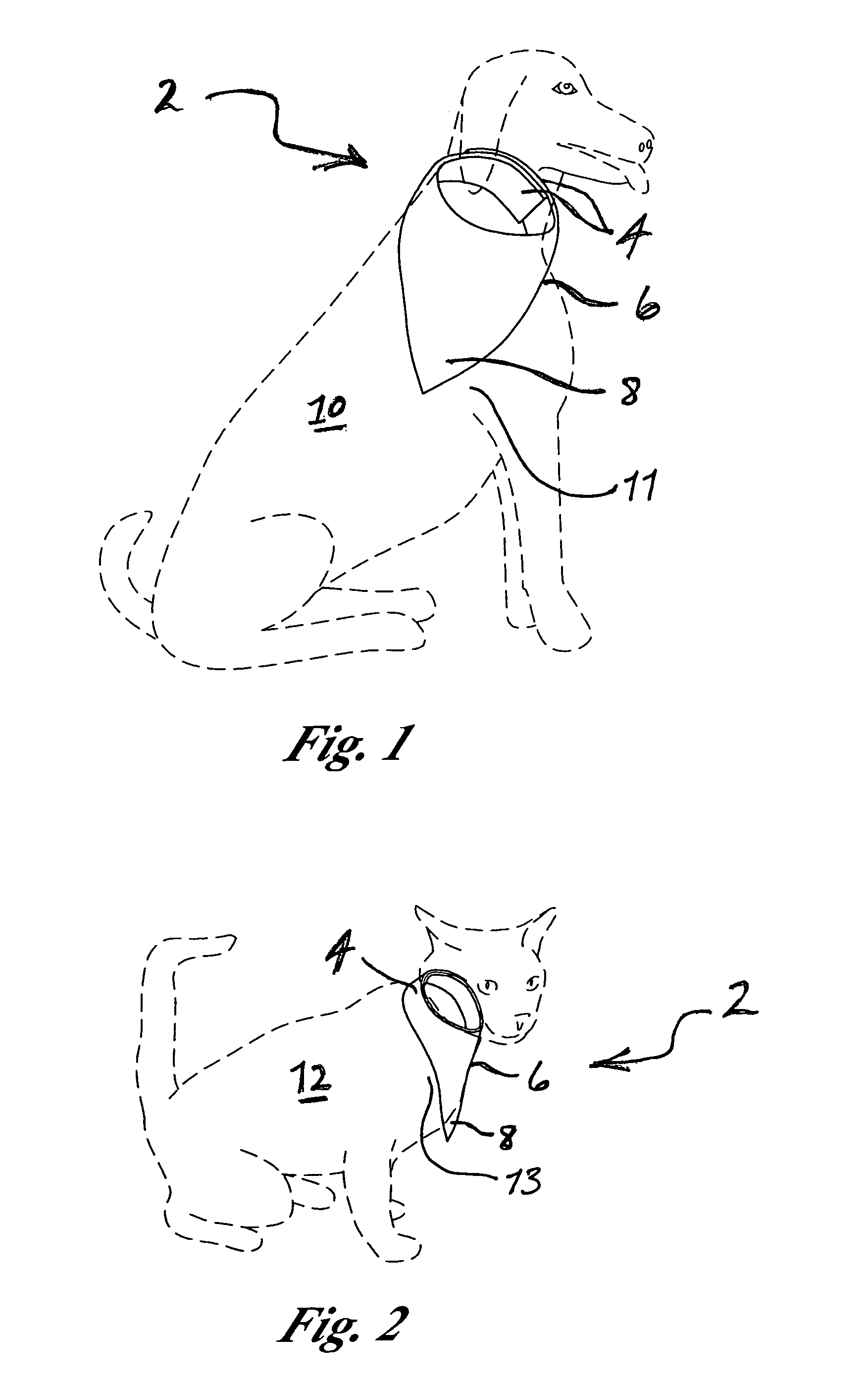

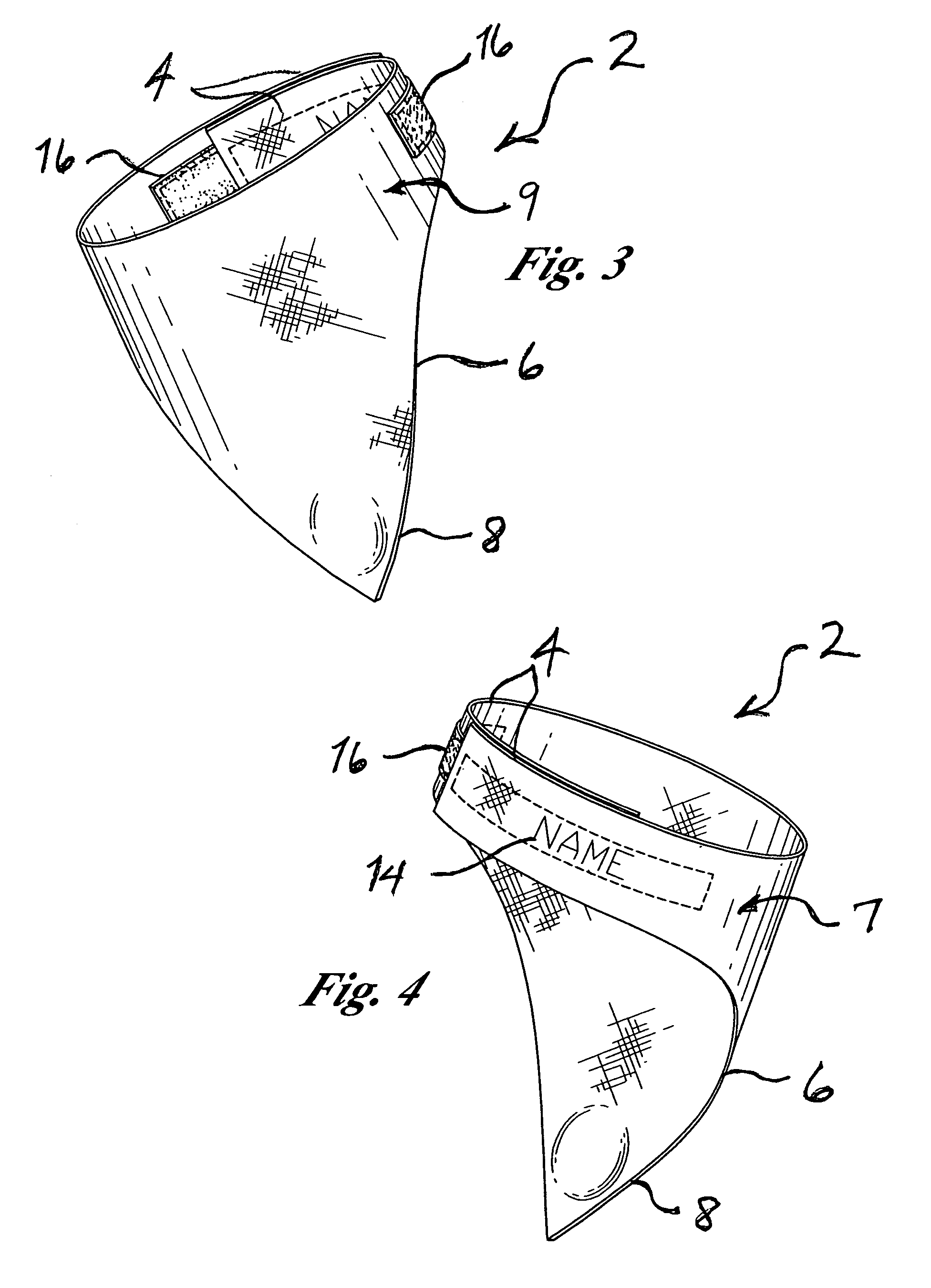

An aromatherapy delivery system for people and animals allows targeted placement of scents in close proximity to the olfactory system to provide the continuous, stimulating, relaxing, therapeutic and / or medicinal effects desired by the aromatherapist. The inventive system comprises a sewn, double-layered pouch of vapor-permeable material with sealable opening for inserting aromatic sachet materials, either loose or contained in a small bag. The device thus filled with aromatics is worn around the neck, wrist or leg, and is retained in place by suitable attachment device such as hook and loop strips. The preferred bandana-shaped embodiment is generally triangular with elongated tabs extending from opposed apexes in which the third (depending) apex of the pouch contains the replaceable sachet mixture. Aromatic vapors are diffused through the air at normal temperatures or activated through other means, such as through body heat generated by exercise or by manual kneading or squeezing of the pouch.

Owner:SEQUIM LAVENDER

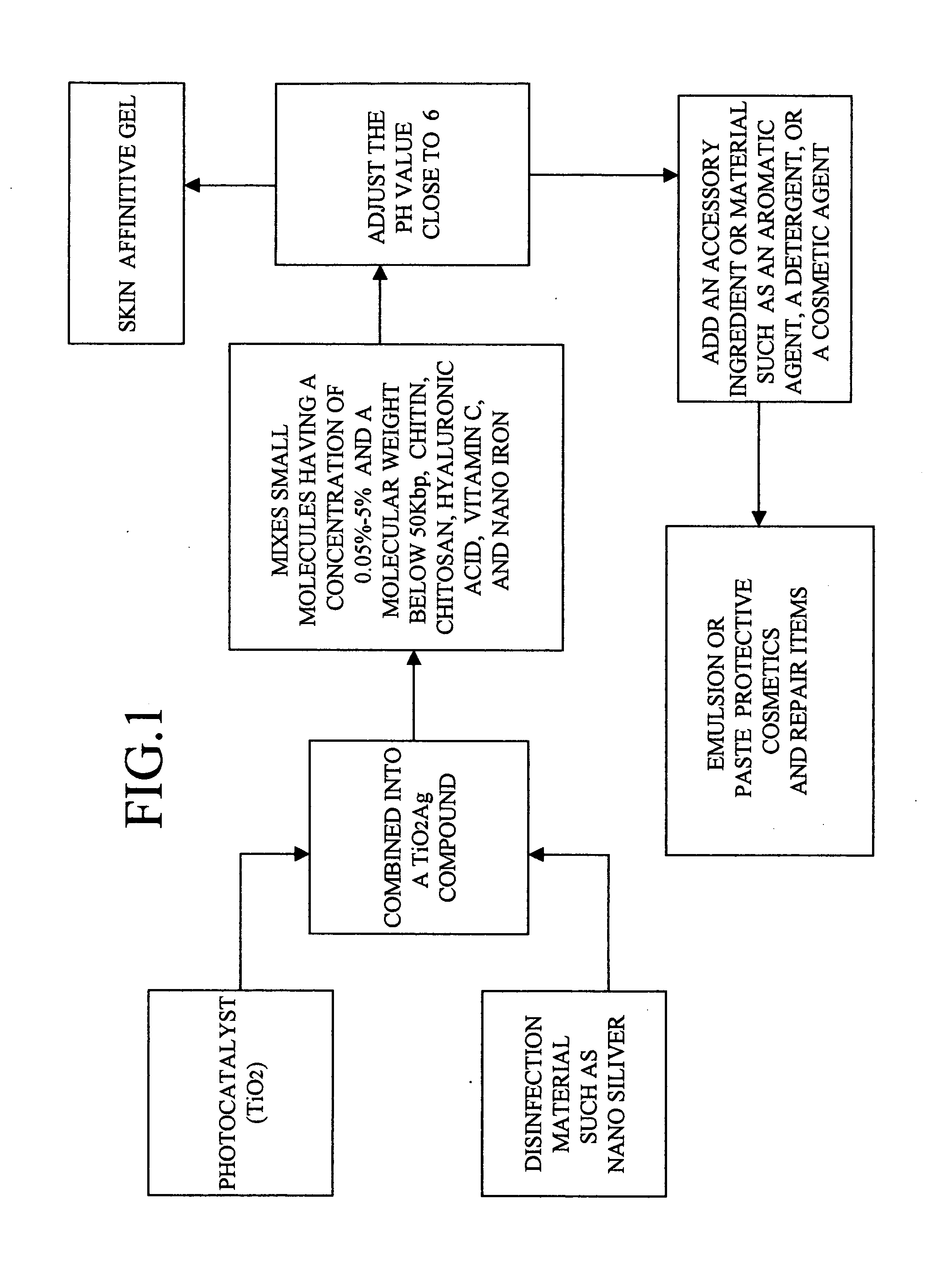

Human body affinitive lubricating protective and repair gel

InactiveUS20050249760A1Stop the bleedingClean skinCosmetic preparationsHeavy metal active ingredientsTectorial membraneRepair tissue

The present invention discloses a human body affinitive lubricating protective and repair gel, which combines photocatalyst (TiO2) particles with a disinfection material such as nano silver to produce a TiO2Ag compound, and mixes the compound with a filtered natural biological organism with a molecular weight below 50 Kbp and a concentration of 0.05˜5% including small molecules of collagen, chitin, chitosan, hyaluronic acid, vitamin C, and nano iron, and its pH value is adjusted to 6 which is close to the pH value of our skin, and thus the mixture constitutes a gel affinitive to human skins and non-toxic to human cells. An accessory ingredient such as an aromatic agent, a detergent, or a cosmetic agent is added in the manufacturing process to produce an emulsion or a paste for coating or spraying, which is used as a health or sanitation item such as a hand liquid soap, a cosmetic, a shampoo, or a disinfectant. The feature of the small diameter of the particles (1˜100 n / m) can penetrate the cuticle of our skin and remain at the derma inside the skin pores to produce a protective film, and the collagen can be absorbed by the skin to give the effects of repairing tissues, stopping bleeding, and lubricating skins. With the cyclic disinfection effect of the TiO2Ag compound, a deeper clean skin to prevent germs is obtained and a disinfection effect is achieved to eliminate acnes and pimples. The present invention also makes use of an oxidation-reduction mechanism of the photocatalyst (TiO2) to achieve long-hour disinfection and naturally remove germs.

Owner:SHIN CHING SUN +1

Freeze-dried coffee tablets

ActiveUS20060024420A1Creating pore structureSmooth shapeMilk preparationConfectioneryFreeze-dryingFlavouring agent

The present invention relates to a coffee tablet which is obtainable by molding and freeze-drying a solution of coffee solids into a desired shape and which has improved dissolution properties and an appealing smooth and / or shiny surface appearance. The coffee tablet also has a closed surface pore structure and an internal pore structure wherein a majority of the pores in the pore structure are interconnected and have a size of between 5 and 50 micrometers. The coffee tablet can also include a coating of a coffee, a flavorant, a colorant or an aroma. The coffee tablet is packaged in an environment of an aroma to form a product that exhibits fresh and strong flavor and aroma characteristics when a beverage is prepared from the tablet even after long term storage of the tablet.

Owner:SOC DES PROD NESTLE SA

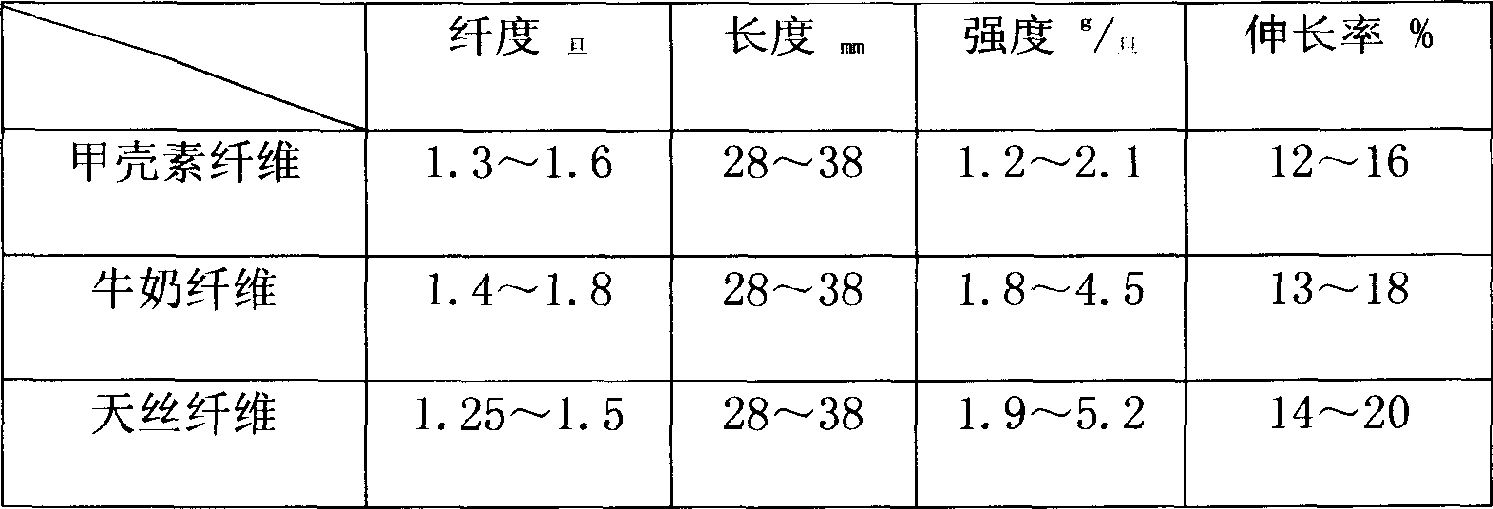

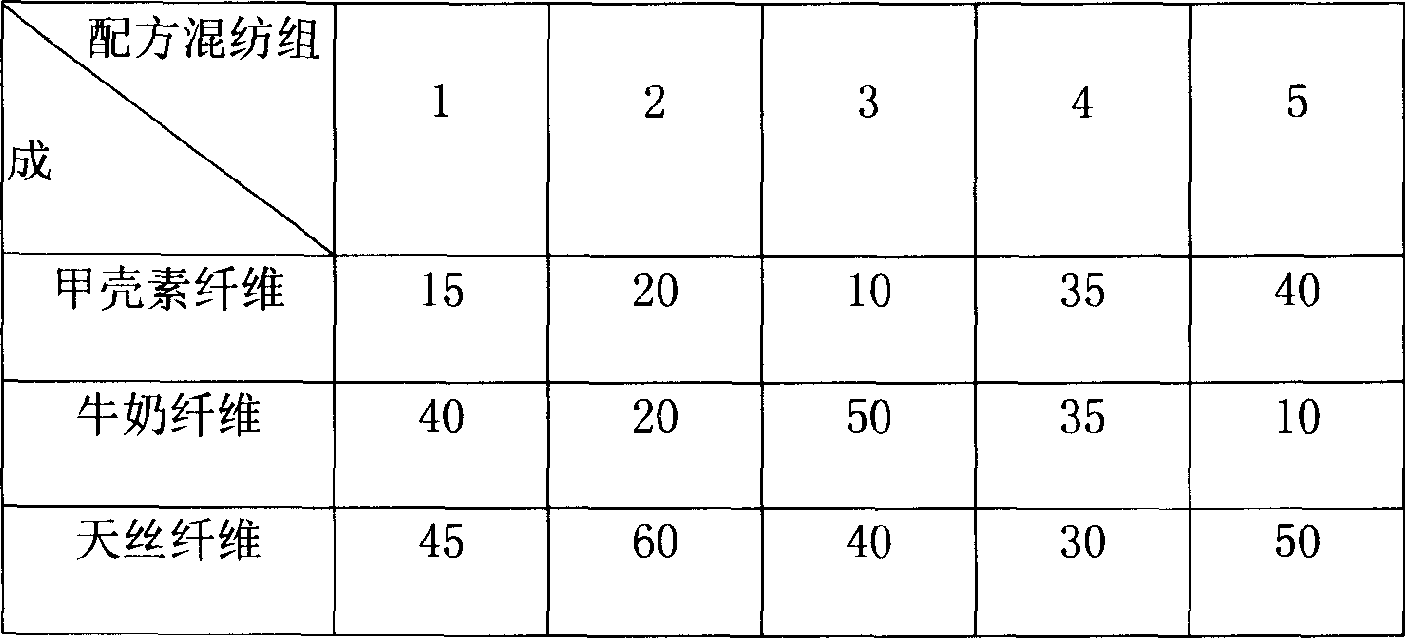

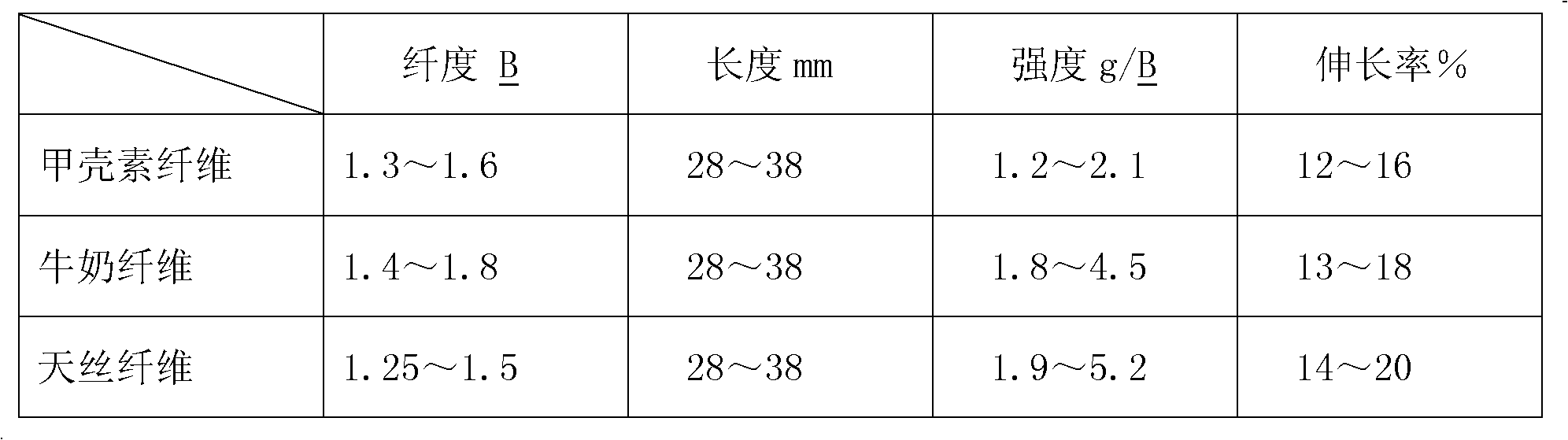

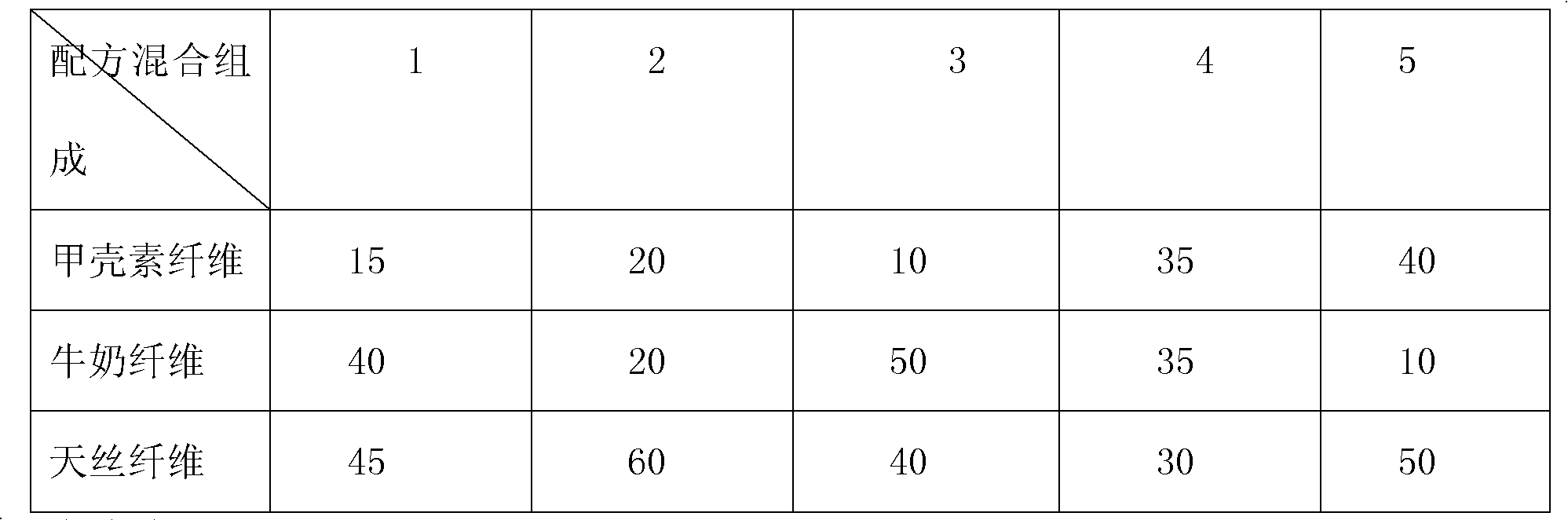

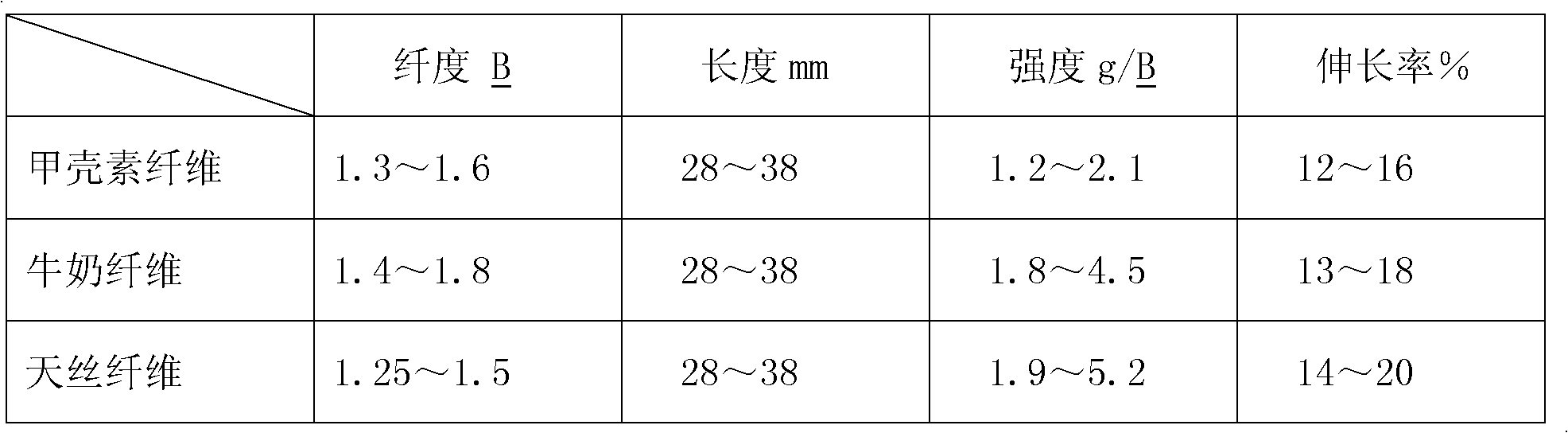

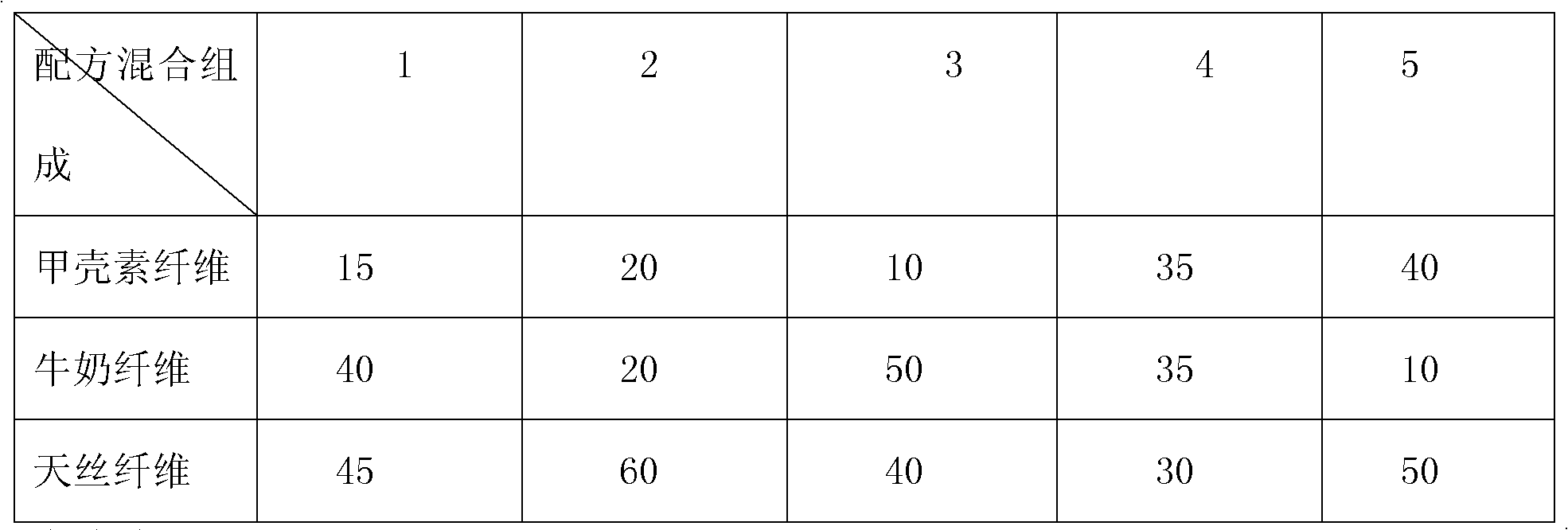

Multe-function skin-protective aromatic spinning material and mfg method thereof

InactiveCN1483874AImprove immunityImprove the quality of living environmentFibre treatmentWoven fabricsYarnEngineering

The present invention relates to a multifunctional skin-protecting aromatic spinning material and its making method. Said multifunctional spinning material is made from chitin fibre, milk protein fibre and tencel fibre, and blended spinning them into yarn according to blending ratio of 10-40:10-50:40-60, then knitting or weaving said material into face fabric, and making the face fabric undergo the process of micapsule aromatic after-finishing treatment to obtain the invented product.

Owner:SHANGHAI JIERUNSI TEXTILE

Degradable interlayer material for screen window capable of purifying air

InactiveCN103691206APlay a beautifying effectImprove adsorption capacityInsect protectionFiltration separationPorosityElectrospinning

The invention discloses a degradable interlayer material for a screen window capable of purifying air, belonging to the field of air purification. The degradable interlayer material mainly consists of two supporting layers and an electrostatic spinning non-woven fabric, wherein the electrostatic spinning non-woven fabric is placed between the two supporting layers. An ultrathin nanofiber filter layer is prepared by an electrostatic spinning method, and a MnO2 catalyst, an aromatic agent, fluorescent powder and the like are added into the layer. The fiber diameter ranges from 500nm to 5 microns, the aperture ranges from 300nm to 30 microns, the thickness ranges from 20 microns to 2mm, and the porosity is greater than 75%. The ultrathin nanofiber filter layer can filter PM2.5 and decompose toxic matters, and the prepared filter material is integrated with the existing screen window, so that the degradable interlayer material is suitable for various occasions. According to the degradable interlayer material for the screen window capable of purifying air disclosed by the invention, functional assistants can be added according to demand, and the prepared filter material can be further used as a filter membrane for an air conditioner or other filter equipment, and the material is efficient and convenient.

Owner:BEIJING UNIV OF CHEM TECH

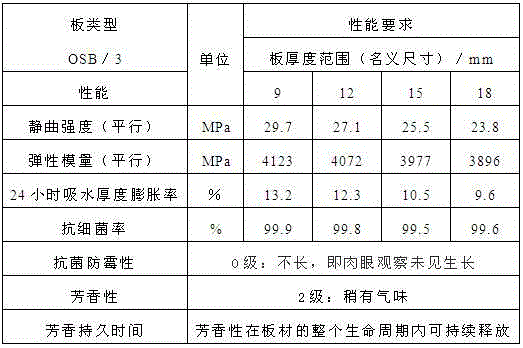

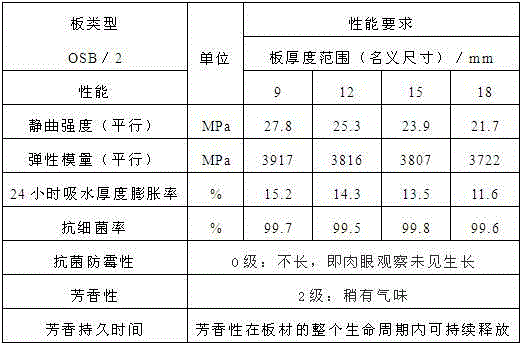

Anti-bacteria mould-proof fragrant directional shaving board and manufacturing process thereof

ActiveCN104608228AReasonable preparation processSimple preparation processNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSide effectSurface layer

The invention relates to an anti-bacteria mould-proof fragrant directional shaving board and a manufacturing process of the anti-bacteria mould-proof fragrant directional shaving board. The anti-bacteria mould-proof fragrant directional shaving board comprises a core layer and a surface layer. The surface layer is provided with a surface layer adhesive agent layer. The effective ingredients of the surface layer adhesive agent layer comprise, by weight, 10 parts of adhesive agents and 0.5-1 part of anti-bacteria mould-proof aromatic. The weight ratio of anti-bacteria mould-proof agents and aromatic of the anti-bacteria mould-proof aromatic is 2:1. The anti-bacteria mould-proof agents are a mixture of mint extractive and radix isatidis extractive. The adhesive agents are melamine adhesive agents. The aromatic is mint oil wrapped by microcapsules. The anti-bacteria rate of the manufactured directional shaving board reaches over 99.5%, the mould-proof rate reaches the zero level stipulated by the industrial standard JC / T 2039-2010, the aromaticity reaches the second level, the fragrance can be released during the whole service life of the board continuously, and no side effect exists for a human body.

Owner:寿光市鲁丽木业股份有限公司

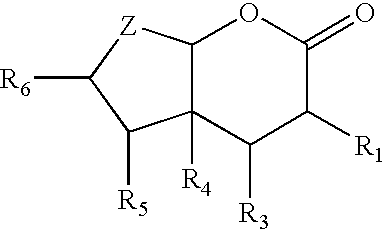

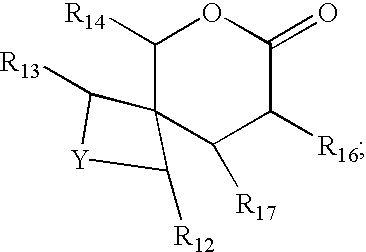

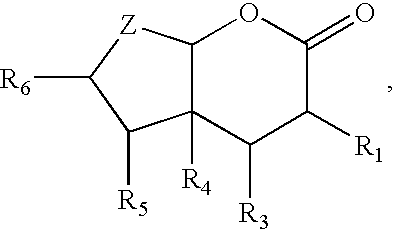

Bicyclic lactones, perfumery uses thereof, processes for preparing same and intermediates therefor

InactiveUS6462015B1Increase aromaEnhance intense and substantiveCosmetic preparationsOrganic chemistryHydrogenAromatic agent

Described are bicyclic lactones, both fused ring lactones defined according to the generic structure:and spiro lactones defined according to the generic structure:uses thereof in augmenting, enhancing or imparting aromas in or to perfume compositions, perfumed articles, colognes and perfumed polymers; processes for preparing such bicyclic lactones and intermediates therefor.In the structure:Z is one of the moieties:one of R1 or R3 is methyl and the other is hydrogen; and R4, R5, R6, R7, R8 and R9 are hydrogen or nonadjacent C1-C3 alkyl. In the structure:Y represents C2-C12 substituted or unsubstituted alkylidenyl, alkenylidenyl or alkadienylidenyl having the structure:and completes a C5-C15 cycloalkyl, cycloalkadienyl or cycloalkenyl ring moiety; and wherein R12, R13, R14, R16, R17, R28, R29, R30 and R31 represent hydrogen or nonadjacent alkyl; wherein s is an integer of from 0 up to 10; t is an integer of from 0 up to 10; and v is an integer of 1 or 2; with the proviso that the sum of s and t is between 0 and 10 according to the inequalities: 0<=s+t<=10;0<=s<=; 10; and 0 <=t<=10.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

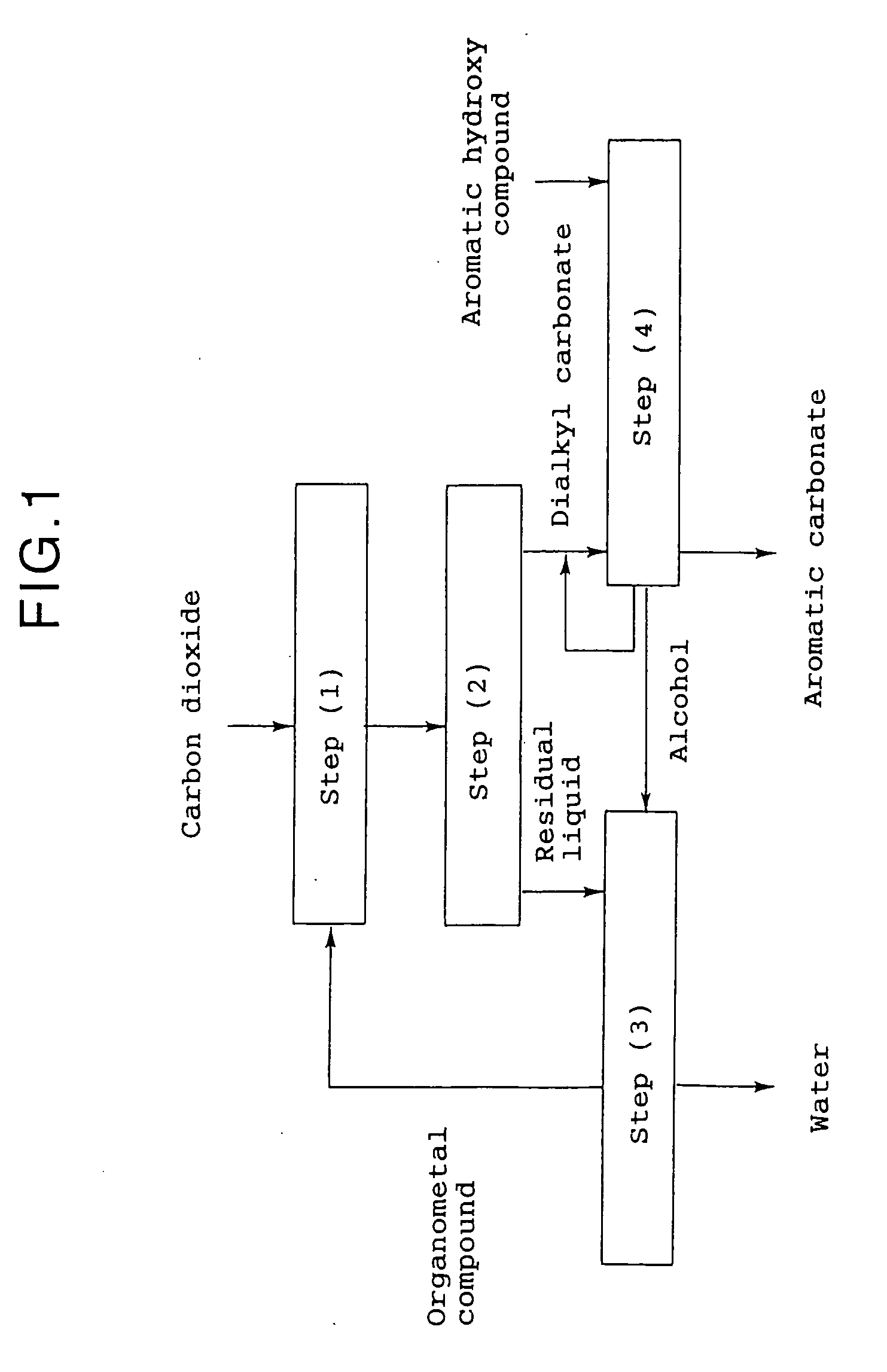

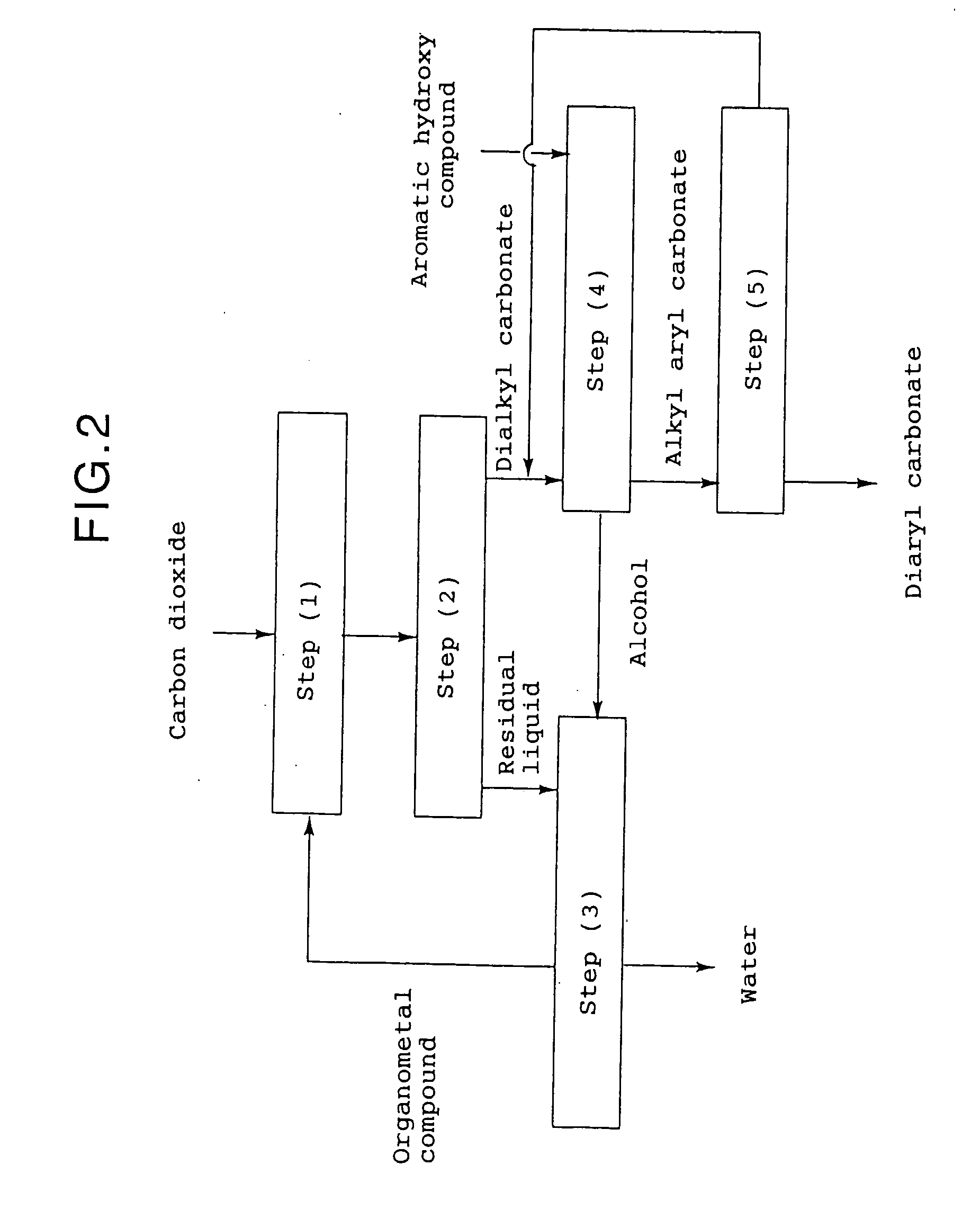

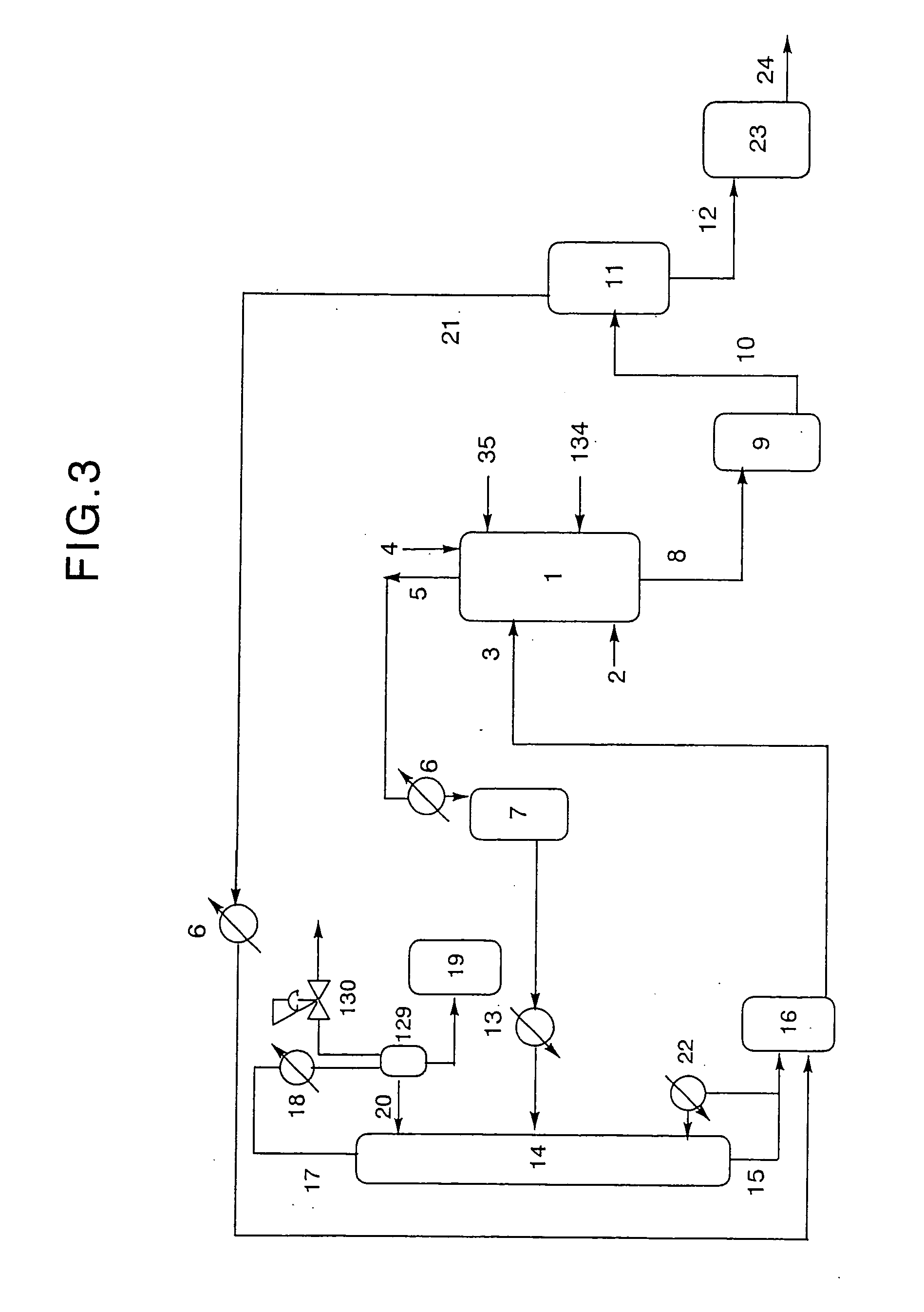

Method for producing an aromatic carbonate

ActiveUS20070055042A1Simple and efficient productionHigh purityPreparation from organic carbonatesPreparation from carbon dioxide or inorganic carbonatesAlcoholAromatic agent

A method for producing an aromatic carbonate, comprising: (1) performing a reaction between an organometal compound and carbon dioxide to obtain a reaction mixture containing a dialkyl carbonate formed by the reaction, (2) separating the dialkyl carbonate from the reaction mixture to obtain a residual liquid, (3) reacting the residual liquid with an alcohol to form at least one organometal compound and form water and removing the water from the organometal compound, and (4) reacting the dialkyl carbonate separated in step (2) with an aromatic hydroxy compound to obtain an aromatic carbonate.

Owner:ASAHI KASEI KK

Multifunctional aromatic antibiosis viscose fiber and preparation method thereof

InactiveCN101935893AEasy to takeContinuous regenerationArtificial filaments from viscoseWet spinning methodsAntibiosisEmulsion

The invention discloses a multifunctional aromatic antibiosis viscose fiber and a preparation method thereof. The preparation method comprises the following steps of: (1) crushing silver zeolite into silver zeolite micropowder with the fineness not larger than 0.4mm, placing the silver zeolite micropowder and a diepersant into water, stirring and mixing uniformly to obtain a silver zeolite aqueous emulsion; (2) preparing viscose by using cellulose pulp as a raw material, adding the silver zeolite aqueous emulsion and a microcapsule aromatizer in a dissolution step, mixing and grinding, and then defoaming and filtering to obtain a spinning solution; and (3) subjecting the spinning solution to spinning molding in a spinning coagulating bath, and refining to obtain the multifunctional aromatic antibiosis viscose fiber, wherein the spinning speed is 20-60m / min. The multifunctional viscose fiber prepared with the method contains microcapsule aromatizer and silver zeolite antibacterial agent, and the weight content proportion of cellulose to the microcapsule aromatizer to the silver seolite antibacterial agent is 86+98.5:0.5-5:1-9.

Owner:CHTC HELON

Skincare aromatic textile material and manufacturing method thereof

InactiveCN103147195AImprove immunityImprove the quality of living environmentFibre treatmentYarnAromatherapyHuman body

The invention provides a skincare aromatic textile material, which is characterized in that the skincare aromatic textile material is formed by blending chitosan fibers, milk protein fibers and tencel fibers, wherein the weight percent of the blended fibers is (10-40): (50-40):(40-60), and the blended fiber at least comprises fragrance. The skincare aromatic textile material has the advantages that after the three fibers are blended, the advantages of the three kinds of fibers can be adequately played, so that a product can have functions of bacteriostasis, deodorization, skin moistening, skin nourishing, humidity absorption, softness and comfort. Meanwhile, through post-treatment of microcapsules containing the fragrance, fabric becomes a best carrier of the microcapsules containing the fragrance, and the aromatherapy can be realized by slowly releasing the fragrance of the microcapsules by the fabric, so that the immunity of the human body can be enhanced, the quality of a living environment of people is improved, and a certain auxiliary treatment effect can be realized for the health of the human body.

Owner:青岛同盈家纺有限公司

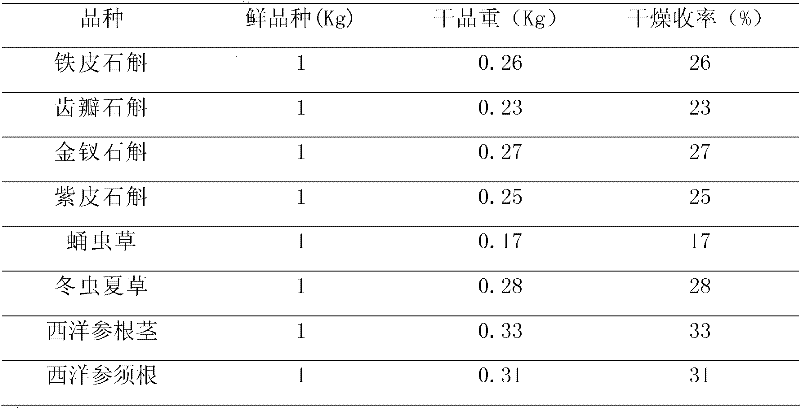

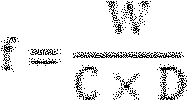

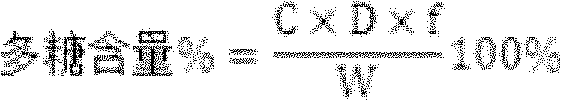

Dendrobium health product composition, preparation method thereof and purpose thereof

The invention discloses a dendrobium health product composition, a preparation method thereof and a purpose thereof. The formula of the composition comprises dendrobium, American ginseng and cordyceps. The compatibility of above traditional Chinese medicines allows the body immunity to be enhanced and taboos of yang deficiency people to dendrobium health products to be eliminated; the direct fresh product usage in the preparation process allows the peculiar flavor of plants and the slimy mouthfeel of the plant protoplasm to be reserved, and no perfumes are added; crushing immersion and membrane concentration which are adopted in the processing process avoid the efficacy component destroy under high temperatures; and general waste American ginseng fibrous roots are added to the composition to substitute American ginseng rhizomes, so the characteristic that the content of effective components in the fibrous roots is high is fully utilized, and American ginseng plantation benefits are improved.

Owner:杭州美澳生物技术有限公司

One-time forming high-strength decorative slab and manufacturing process thereof

InactiveCN101602223AHigh strengthImprove toughnessDomestic articlesFlat articlesULTRAMARINE BLUETemperature resistance

The invention discloses a one-time forming high-strength decorative slab and a manufacturing process thereof. The slab comprises the following compositions in portion by weight: 100 portions of 40-to-120-mesh wood powder, 8 to 25 portions of melamine, 0.5 to 2.0 portions of titanium pigment, 0.1 to 1.2 portions of ultramarine blue powder, 0 to 12 portions of active carbon, 0 to 62 portions of fire retardant, 0 to 13.5 portions of aromatizer and 0 to 12 portions of antistatic agent. The manufacturing process comprises the following steps: (1) weighing and respectively storing the compositions according to the weight portions in the formula; (2) setting the temperature of a stirrer between 80 and 110 DEG C, and drying wood powder in the stirrer for 30 to 120 minutes; (3) then, adding the melamine, the titanium pigment, the ultramarine blue powder and auxiliary materials including the fire retardant and / or the aromatizer and / or the antistatic agent to stir again for 15 to 30 minutes, and finally adding active carbon to stir continuously for 10 minutes; (4) obtaining a mixture after heat preservation at a temperature of between 20 and 80 DEG C; (5) maintaining the temperature of the mixture, paving the mixture in a die cavity and covering a decorative film before and after paving the mixture; (6) carrying out sulfuration for 15 to 35 minutes by a flat sulfuration machine at a temperature of between 160 and 170 DEG C under a clamping pressure ranging from 1.4 to 2.6MPa; and (7) transferring the mixture to a cooling machine to cool down the mixture to less than 40 DEG C. The one-time forming high-strength decorative slab has the characteristics of high strength, high toughness, high temperature resistance, aging resistance, waterproofness, environmental protection, no deformation, and the like.

Owner:SUZHOU GOODTIME TECH DEV

Controlled release formulations coated with aqueous dispersions of acrylic polymers

A stable solid controlled release formulation having a coating derived from an aqueous dispersion of a hydrophobic acrylic polymer includes a substrate including an active agent selected from the group consisting of a systemically active therapeutic agent, a locally active therapeutic agent, a disinfecting and sanitizing agent, a cleansing agent, a fragrance agent and a fertilizing agent, overcoated with an aqueous dispersion of the plasticized water-insoluble acrylic polymer. The formulation provides a stable dissolution of the active agent which is unchanged after exposure to accelerated storage conditions.

Owner:PURDUE PHARMA LP

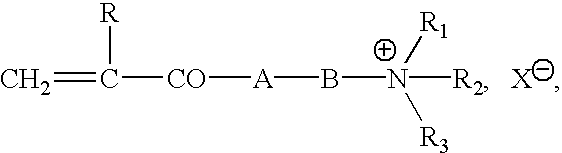

Quick water-dissolving film containing cosmetic, aromatic, pharmaceutical or food substances

InactiveUS7612048B2Good dimensional stabilityEasy to insertCosmetic preparationsBiocideSolubilityCellulose

Film with high solubility in water, comprising a starch, a cellulose and a cosmetic, aromatic, pharmaceutical and / or food substance in a quantity exceeding 10% on the total film weight.

Owner:BIOFARMITALIA SPA

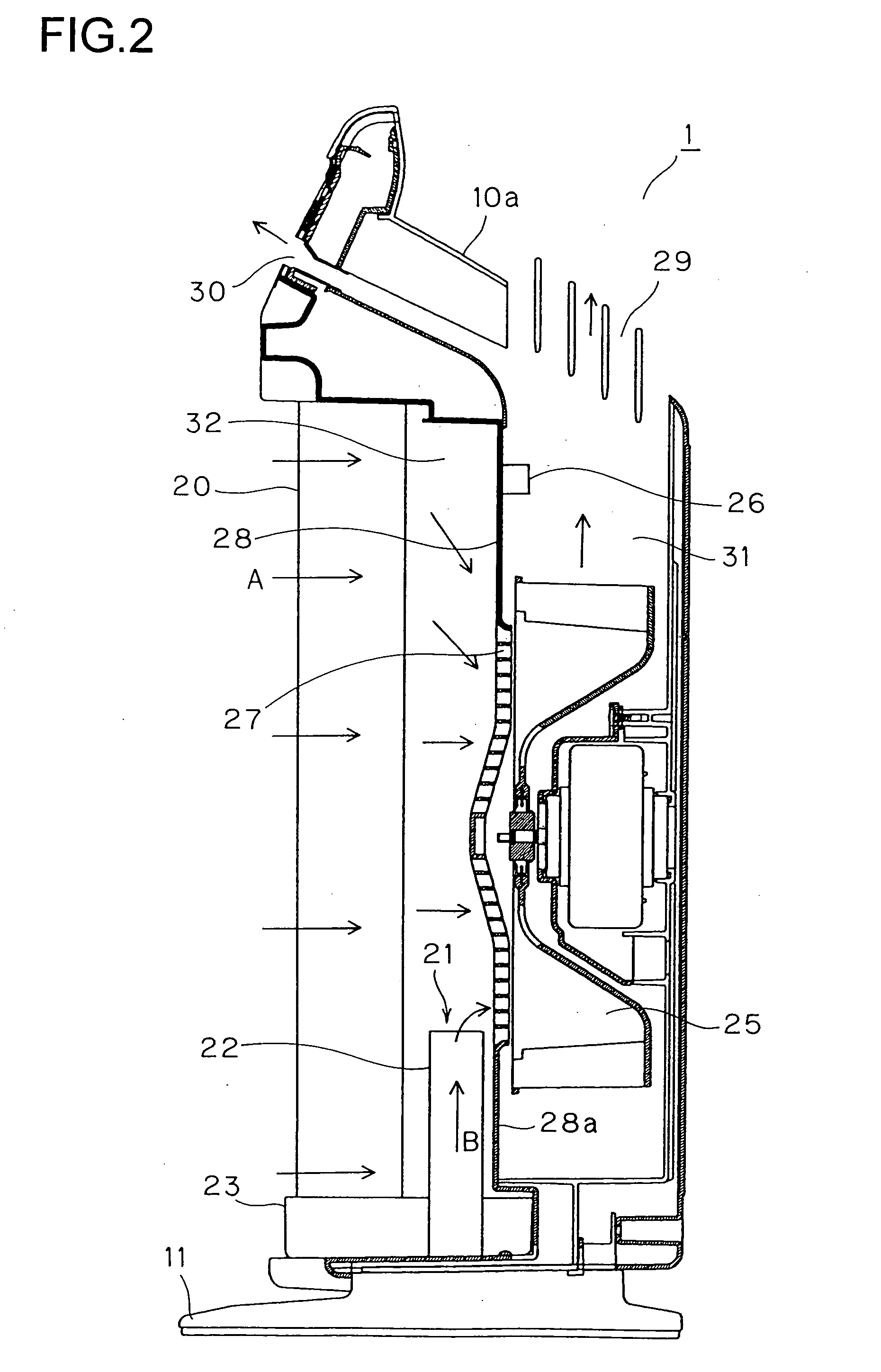

Air Cleaner Using Dust Collecting Filter

InactiveUS20080083337A1Low costGuaranteed functionCombination devicesMechanical apparatusHEPAAromatic agent

There are provided: an air blower 25 that introduces indoor air from an air inlet 13 and delivers the air through air outlets 29 and 30; and a dust collecting filter 55 that collects dust contained in air. The dust collecting filter 55 carries a porous microcapsule 37 impregnated with an aromatic agent, and is formed of an HEPA filter having a filtering material 55a impregnated with an antiviral agent. On the surface of the dust collecting filter 55, there is provided a breathable antibacterial sheet 37 impregnated with an antiallergenic agent.

Owner:SHARP KK

Fabric nano post-treatment reagent with durable antibiotic fragrance effect and mfg. technique thereof

A method for preparing post finishing nanoreagent of fabric product with persistant aromatic and antibiotic effect includes using high adhesion material as wall material and mixture of aromatics and germicide as core material of microcapsule, forming 25% core material solution by mixing aromatics and germicide with volume ratio as 4:1-2:1 and then diluting it by pure water, forming A solution by mixing oily emulsifier with high adhesion material and toluene solution in volume ratio as 5:12:20, forming B solution by mixing liquid phase curing agent with core solution in volume ratio as 1.5:6 and forming said nanoreagent by mixing A solution with B solution in volume ratio as 1:1.

Owner:GUANGDONG PENGYUN IND

Chlorine dioxide air disinfectant and preparation method thereof

InactiveCN104012571AEffective disinfectionEasy to useBiocideDisinfectantsChlorine dioxideDisinfectant

The invention discloses a chlorine dioxide air disinfectant which comprises the following components in parts by weight: 5-10 parts of chlorite, 5-10 parts of an acid form agent, 70-85 parts of an auxiliary agent and 5-10 parts of an aromatic; a method for preparing the chlorine dioxide air disinfectant comprises the steps of S1, respectively drying the chlorite, the acid form agent, the auxiliary agent and the aromatic by a hot air drier; S2, grinding and sieving the dried chlorite, acid form agent, auxiliary agent and aromatic; and S3, evenly mixing according to a formula in an oxygen-free environment, and respectively packaging by boxes. The chlorine dioxide air disinfectant is box-packed powder; after being contacted with air, the chlorine dioxide air disinfectant is capable of continuously releasing chlorine dioxide gas, so that the continuous dynamic purification is carried out on the air, and harmful chemical substances in the air can be decomposed; the chlorine dioxide air disinfectant prepared by adopting the method is convenient to use and fragrant in smell, and has the effects of efficient sterilization and deodorization.

Owner:四川裕霖环境工程有限公司

Skin care natural textile material and manufacturing method thereof

InactiveCN103103665AImprove immunityImprove the quality of living environmentFibre treatmentYarnHuman bodyFiber

The invention provides a skin care natural textile material and a manufacturing method of the skin care natural textile material. The skin care natural textile material and the manufacturing method thereof is characterized in that chitin fiber, milk protein fiber, and tencel fiber are blended to form the skin care natural textile material and weight percentage of blending is 10-40 : 10-50 : 40-60, and the blending fiber at least contains aromatic. The skin care natural textile material and the manufacturing method thereof have the advantages that the three kinds of fiber are blended, the advantages of three kinds of fiber can be fully played, and thus products have functions of being anti-bacterial, moistening and caring skin, absorbing moisture, soft, and comfortable. At the same time, with processing of microcapsules containing aromatic, the fabric becomes the best carrier of microcapsules containing aromatic, fabric with slow release of microcapsule aromatic can conduct an aromatic function therapy, an immune ability of a human body is strengthened, quality of the human living environment is improved, and certain supportive therapeutic effect on human body health is realized.

Owner:ZHONGDI HOME TEXTILES

Efficient laundry detergent

InactiveCN103881855AEfficient decontaminationEfficient sterilizationSurface-active non-soap compounds and soap mixture detergentsSoftened waterSolvent

The invention provides an efficient laundry detergent. The laundry detergent is prepared from following components in parts by weight: 20-60 parts of cation alkyl polyglucoside, 5-12 parts of fatty acid polyoxyethylene ester, 0.5-5 parts of alpha olefin sodium sulfonate, 5-30 parts of fatty alcohol-polyoxyethylene ether sodium sulfate, 4-12 parts of alkanolamide, 5-10 parts of natural soap powder, 0.01-6 parts of bio-enzyme, 2-12 parts of enzyme stabilizer, 2-10 parts of cosolvent, 0.01-2.5 parts of preservative, 4-8 parts of herbal extract solution, 0.1-2 parts of aromatic, 5-50 parts of softened water, and proper amount of citric acid. The laundry detergent has the beneficial effects of having efficient decontamination, degerming and anti-static capacities, well protecting hands and hardly hurting the hands in washing by hands due to the herbal extract solution, and having pleasant smell due to the aromatic.

Owner:李新琴

Polyvinyl chloride (PVC) cable sheath material and preparation method thereof

InactiveCN102250435AExcellent low temperature/high temperature performanceIncrease char formationPlastic/resin/waxes insulatorsInsulated cablesAluminium hydroxidePolyvinyl chloride

The invention discloses a polyvinyl chloride (PVC) cable sheath material and a preparation method thereof. The PVC cable sheath material comprises 100 parts of PVC resin, 30-50 parts of plasticizer, 3-7 parts of compound stabilizer, 20-40 parts of active calcium carbonate, 5-15 parts of kaolin, 5-15 parts of aluminum hydroxide, 3-6 parts of antimony trioxide, 3-5 parts of zinc borate and 0.5-1.5 parts of aromatizer. In the cable sheath rubber disclosed by the invention, through the optimal combination of aluminum hydroxide, antimony trioxide and zinc borate, the carbonization amount is improved by approximate 50%; the smoke generation amount during naked flame combustion is reduced by 30-50%, and the limiting oxygen index (LOI) is improved to 33; by selecting a proper plasticizer, the material has excellent low-temperature and high-temperature resistance at the same time, and the use temperature of the material is (-30)-90 DEG C; and a mint-flavored essential oil aromatizer is added to the material, so that the obtained product has aromatic odor and has the actions of eliminating nausea, nervousness and tension headache and dispelling mosquito.

Owner:WUXI MINGZHU CABLE

Disinfectant health-care aromatic hand paper towel and preparation method thereof

ActiveCN104846685ALow costReduce manufacturing costCosmetic preparationsToilet preparationsAntibacterial agentAntibacterial property

The invention discloses a disinfectant health-care aromatic hand paper towel and a preparation method thereof. The hand paper towel comprises the following components: softwood sulfite pulp, bamboo-pulp paper fiber, straw pulp, a cationic starch solution, a wet strength agent, a powerful antibacterial agent, an aromatic agent and titanium dioxide, wherein the wet strength agent is polyethylene ethylamine resin, the powerful antibacterial agent is composed of pure-oxygen-based quaternary ammonium salt, Sophora flavescens, common cnidium fruit, honeysuckle, borneol, isatis root, ethanol and distilled water, and the aromatic agent is composed of chitosan, ethanol, essence extract, deionized water, glycerin and triphosphoric acid. The prepared disinfectant health-care aromatic hand paper towel in the invention has the characteristics of no toxicity, harmlessness, environmental protection, highly-efficient antibacterial property and emission of aroma, can efficiently avoid contact-type cross infection with bacteria in public places and is safer and more secure to use.

Owner:ZHEJIANG HUACHUAN IND GRP

Sustained-release mosquito expelling aromatic agent and preparation method thereof

InactiveCN102233143AImprove solubilityUniform release rateBiocidePest repellentsAntioxidantPreservative

The invention relates to an aromatic agent, in particular to a sustained-release mosquito expelling aromatic agent and a preparation method thereof. The sustained-release mosquito expelling aromatic agent consists of the following components in percentage by weight: 1-6 percent of mosquito expelling medicament, 2-8 percent of nonionic surfactant, 2-30 percent of ethanol, 0.2-0.5 percent of preservative, 0.05-0.1 percent of complexing agent, 0.1-0.3 percent of antioxidant, 1-5 percent of essence, 2-10 percent of pearl particles and the balance of deionized water. According to the description, compared with the prior art, the sustained-release mosquito expelling aromatic agent and the preparation method thereof have the advantages that: because the mosquito expelling medicament is added into the aromatic agent, the aromatic agent has a mosquito expelling effect; and because the pearl particles are used as carriers, the production cost is relatively low, the release time of the medicament is short and controllable, and the using cost is reduced.

Owner:福建省金鹿日化股份有限公司

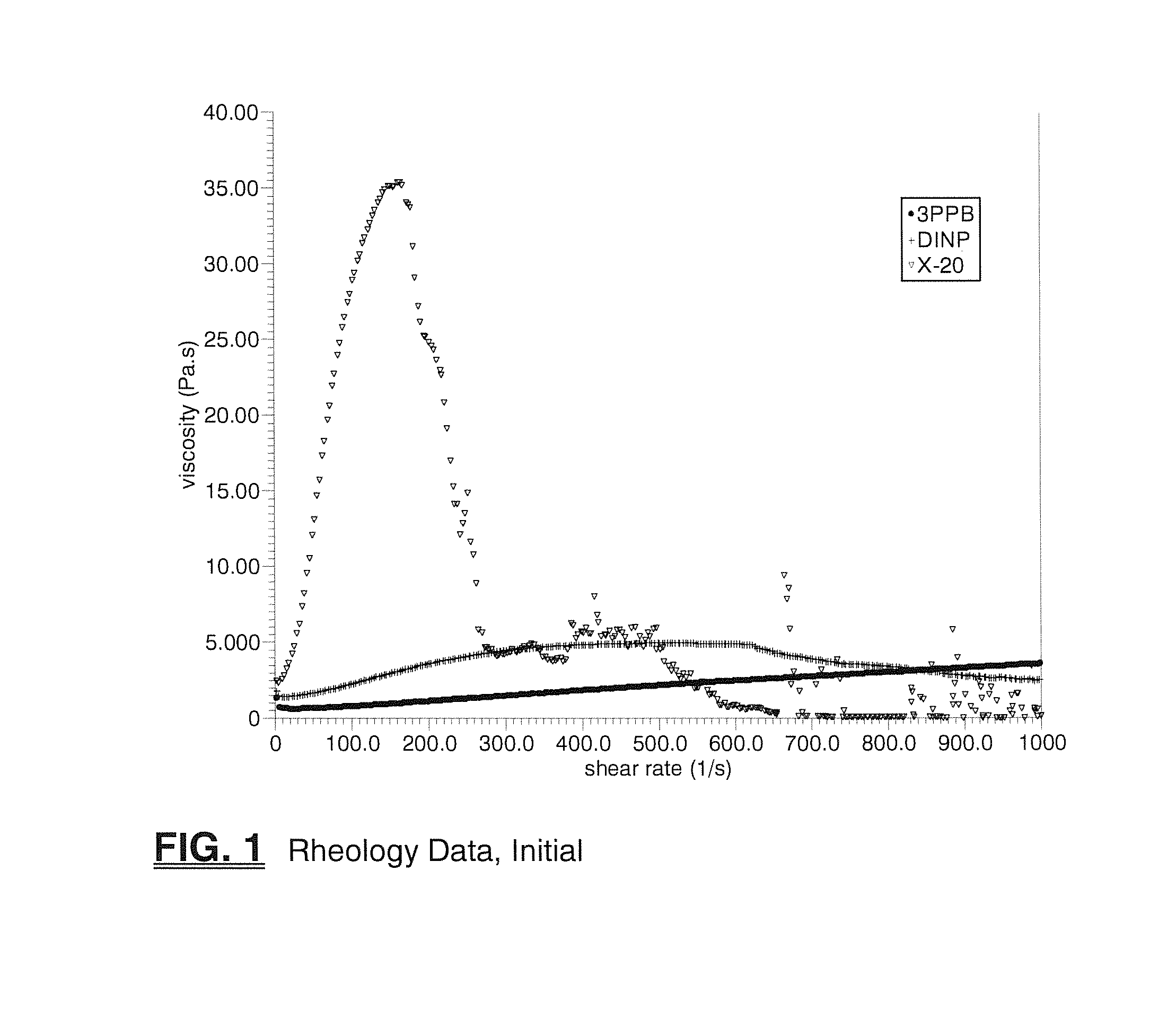

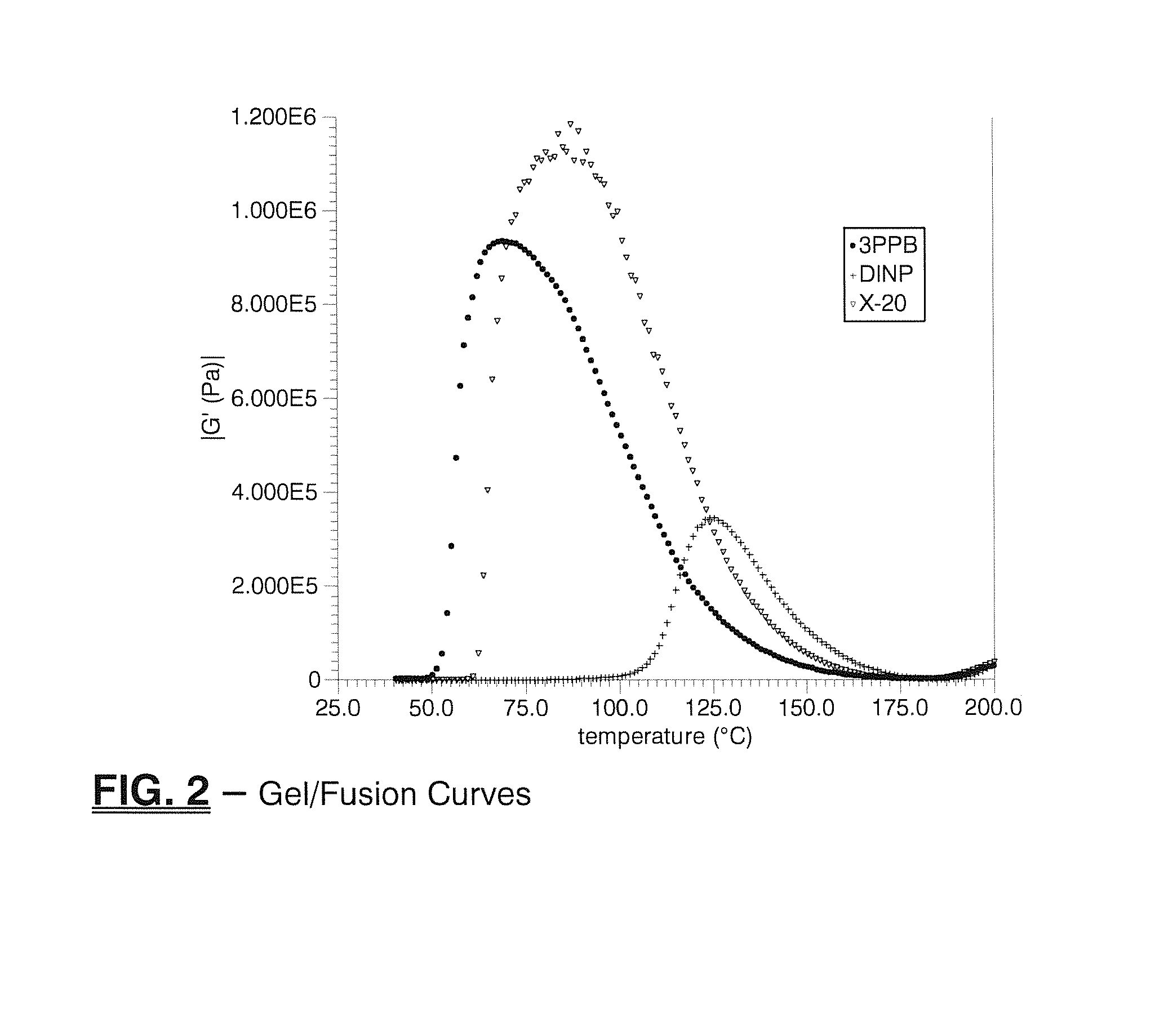

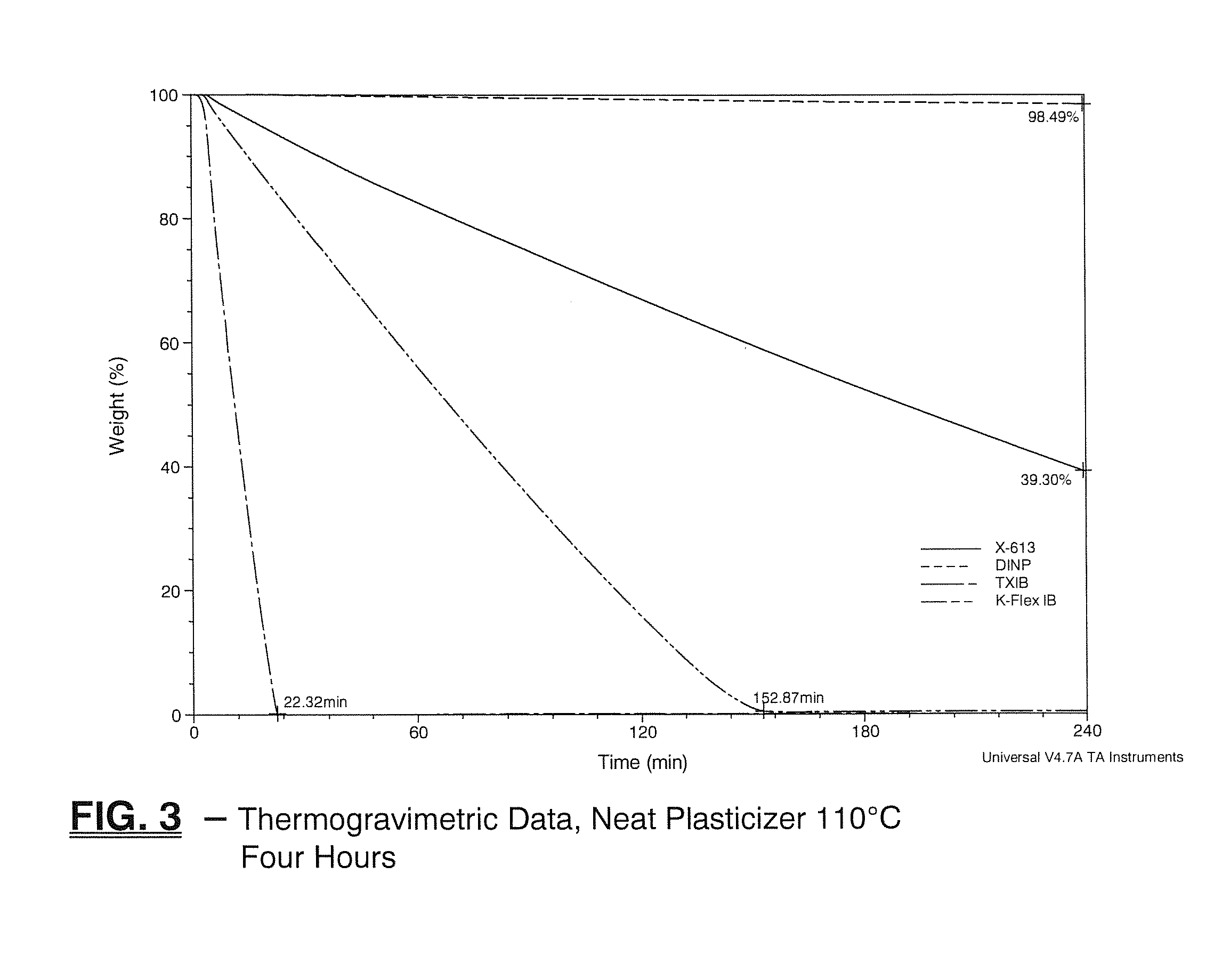

Monobenzoate useful as a plasticizer in plastisol compositions

ActiveUS20140275376A1Low VOC contentMonocarboxylic acid ester polymer adhesivesOrganic chemistryPropyl benzoateAromatic agent

A unique monobenzoate useful as a plasticizer in polymeric dispersions, such as plastisols and melt compounds. The monobenzoate comprises 3-phenyl propyl benzoate, a benzoate ester heretofore known as a flavoring and fragrance agent, but not previously utilized as a plasticizer in polymeric applications. Depending on the application, the advantages rendered by the use of the inventive monobenzoate include, among other things, excellent solvating properties, low viscosity, viscosity stability, and improved rheology, as well as health, safety and environmental advantages over traditional plasticizers. The monobenzoate may be used alone or in combination with a variety of plasticizers, including but not limited to phthalates, terephthalates, dibenzoates, other monobenzoates, or 1,2-cyclohexane dicarboxylate esters, and mixtures thereof.

Owner:EMERALD KALAMA CHEM

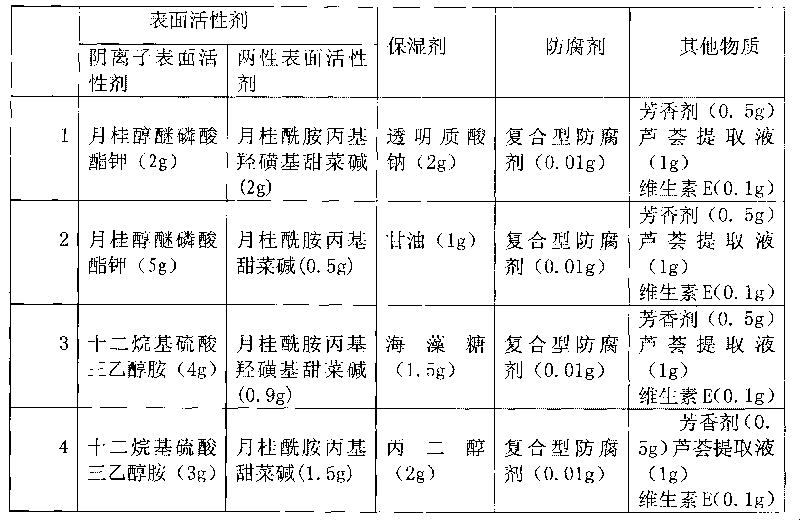

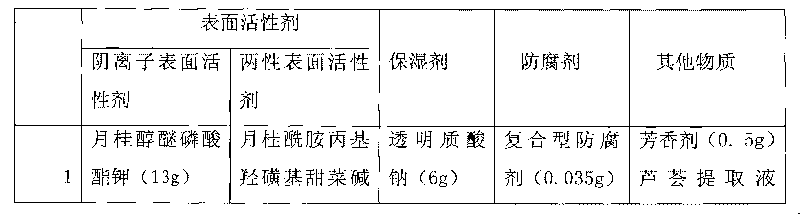

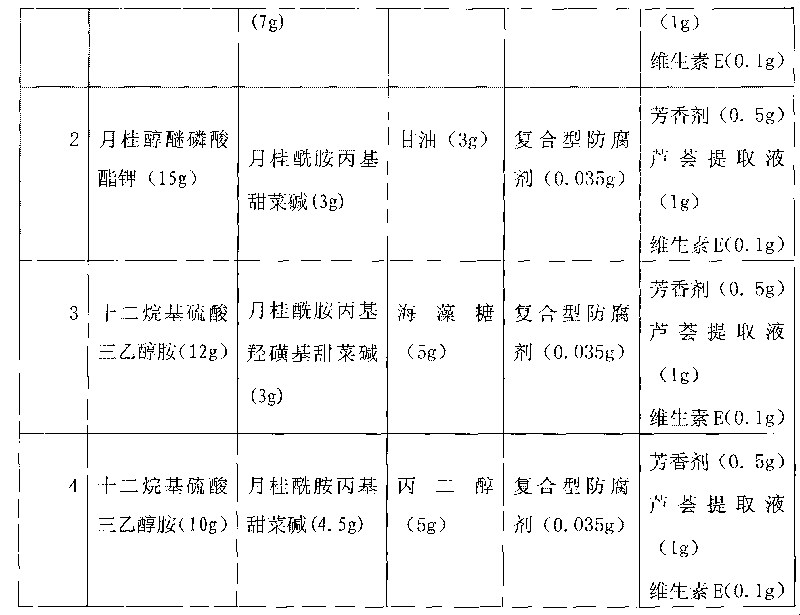

Washing-free bath lotion and preparation method thereof

InactiveCN101721341ALess irritatingNon-toxicCosmetic preparationsToilet preparationsPreservativePolar exploration

The invention discloses a washing-free bath lotion. On the basis of total weight, every 100g of the bath lotion comprises the following components by weight: 2-15g of anion surface active agent, 0.5-10g of amphoteric surface active agent, 0.1-6g of wet preserving agent, 0.005-0.035g of preservative, 0.3-0.8g of aromatic agent, 0.05-0.15g of vitamin E, 0.5-1.5g of asparagus extracting solution and the balance of deionized water, wherein the pH value of the components is adjusted with citric acid within a range of 5-7 . The washing-free bath lotion has the characteristics of small pungency, no poison, less residue, high biological degradability, skin cleaning and no need of being washed with clear water after use, is suitable for the special environment of difficult water supply, hostile environment, easy dirty and dreggy body and hair of a person and difficult realization of bath with water, such as patients, mountain climbing, polar exploration, navigation, spaceflight, and the like and is simple and convenience for use.

Owner:NAVY MEDICINE RES INST OF PLA

PVC cable insulating material and preparation method thereof

InactiveCN102153825AExcellent low temperature/high temperature performanceIncrease char formationPlastic/resin/waxes insulatorsAluminium hydroxidePolyvinyl chloride

Owner:WUXI MINGZHU CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com