Hand sanitizer and preparation method thereof

A hand sanitizer and solution technology, applied in the field of washing products, can solve the problems of wasting water, not easy to rinse, unable to achieve sterilization and moisturizing, etc., and achieve the effect of small irritation, rich foam and mild performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

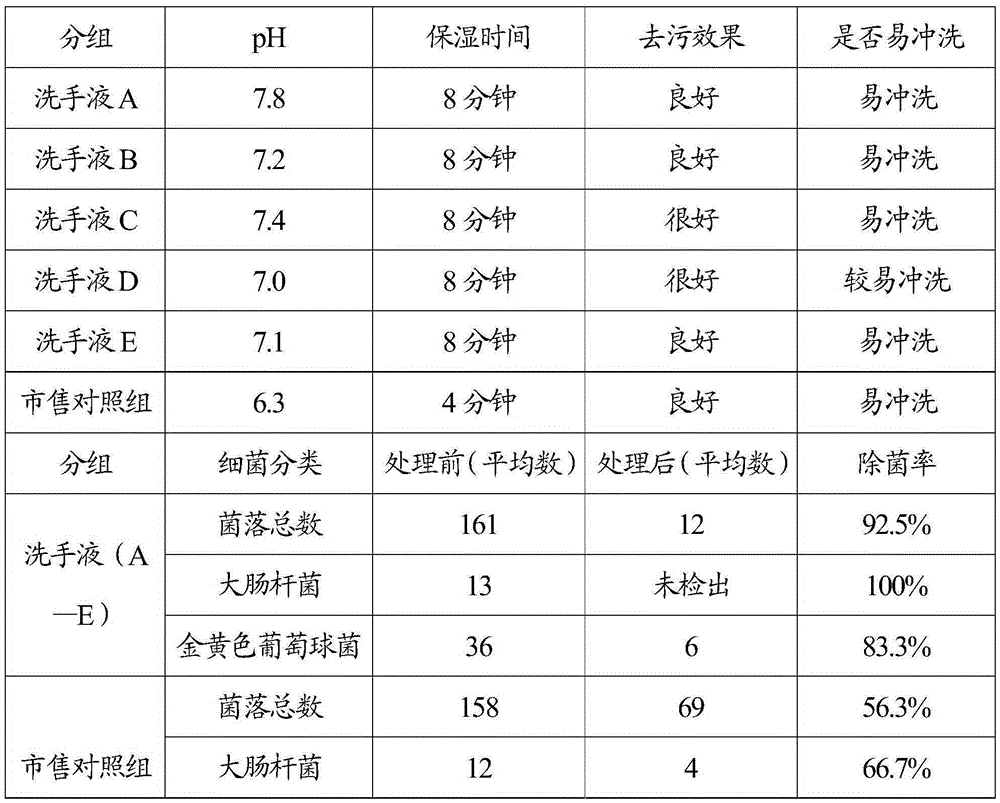

Embodiment 1

[0025] Hand sanitizer A-E described in the present embodiment:

[0026] In parts by weight, it includes: 3 parts of refined salt, 11 parts of sodium fatty alcohol polyoxyethylene ether sulfate, 6 parts of cocamidopropyl betaine, 1.5 parts of coconut oil fatty acid diethanolamide, 87 parts of deionized water, and the number is Hand sanitizer A.

[0027] In parts by weight, it includes: 1 part of refined salt, 5 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 2 parts of cocamidopropyl betaine, 0.5 part of coconut oil fatty acid diethanolamide, 75 parts of deionized water, and the code is Hand sanitizer B.

[0028] In parts by weight, it includes: 2 parts of refined salt, 7 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 4 parts of cocamidopropyl betaine, 1 part of coconut oil fatty acid diethanolamide, 81 parts of deionized water, and the number is Hand sanitizer C.

[0029] In parts by weight, it includes: 2.5 parts of refined salt, 9 parts of sodiu...

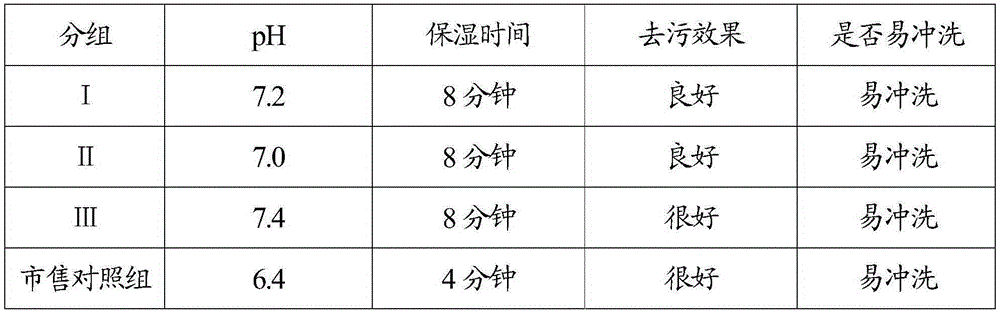

Embodiment 2

[0042] Hand sanitizer I, II, III described in the present embodiment:

[0043] In parts by weight, it comprises: 2 parts of refined salt, 7 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 4 parts of cocamidopropyl betaine, 1 part of coconut oil fatty acid diethanolamide, and 81 parts of deionized water.

[0044] The above-mentioned hand sanitizers I, II, and III are prepared through the following steps:

[0045] (1) Add sterile deionized water to the stirring pot;

[0046] (2) adding the refined salt into the deionized water described in step (1) twice, heating to 75° C., dissolving, and stirring evenly to obtain a refined salt solution;

[0047] (3) cooling the refined salt solution described in step (2), adding sodium fatty alcohol polyoxyethylene ether sulfate, cocamidopropyl betaine, coconut oil fatty acid diethanolamide, cooling and discharging after insulated and stirred for 20 minutes, Aging for another 24 hours, packaging after passing the inspection.

...

Embodiment 3

[0055] Hand sanitizer 1,2,3,4 described in the present embodiment:

[0056] In parts by weight, it comprises: 2 parts of refined salt, 7 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 4 parts of cocamidopropyl betaine, 1 part of coconut oil fatty acid diethanolamide, and 81 parts of deionized water.

[0057] The above-mentioned hand sanitizers 1, 2, 3, 4 are prepared and formed through the following steps:

[0058] (1) Add sterile deionized water to the stirring pot;

[0059] (2) adding the refined salt into the deionized water described in step (1) twice, heating to 75° C., dissolving, and stirring evenly to obtain a refined salt solution;

[0060](3) Cool down the refined salt solution described in step (2) to 45°C, add sodium fatty alcohol polyoxyethylene ether sulfate, cocamidopropyl betaine, and coconut oil fatty acid diethanolamide, heat and stir, then cool and discharge , then aged for 24 hours, and then packed after passing the inspection.

[0061] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com