Lightweight plastering mortar and construction method thereof

A plastering mortar and light-weight technology, which is applied in the field of construction mortar, can solve the problems of not having the function of shielding and absorbing electromagnetic waves, self-heavy, and light-weight walls that do not match, so as to reduce thermal bridge effects, reduce specific gravity, and reduce seepage. The effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

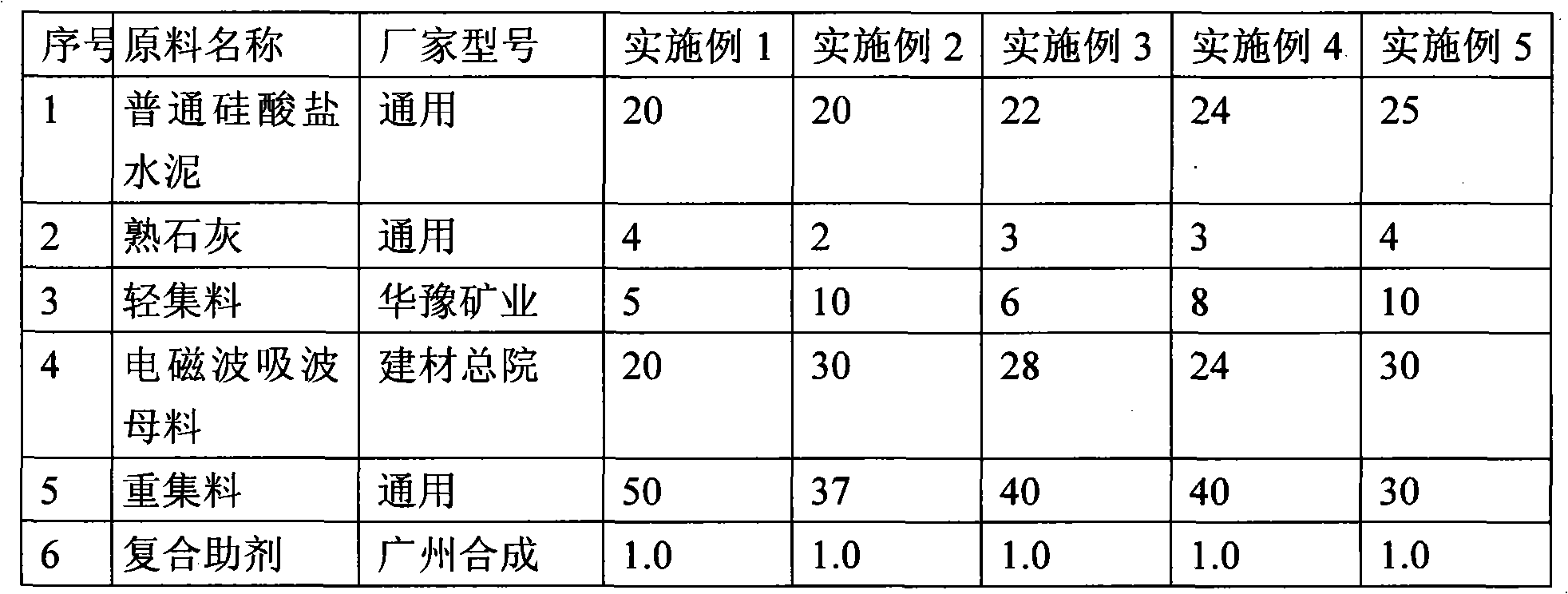

[0037] Take each component according to the weight shown in Example 1 in Table 1, and the production process is as follows: mix ordinary Portland cement, slaked lime, light aggregate, electromagnetic wave absorbing masterbatch, heavy aggregate and compound additives according to the above-mentioned specific gravity, Stir evenly with machinery to obtain the lightweight plastering mortar of Example 1, which can be packaged in paper bags or packed in bulk.

[0038] Construction method: Take 100 kg of light-weight plastering mortar with the function of shielding and absorbing electromagnetic waves obtained in Example 1 above, add 30 kg of water to dilute, stir mechanically or manually until the mixture is uniform, and the viscosity suitable for mechanical spraying or manual construction can be carried out Mechanized spraying or manual work.

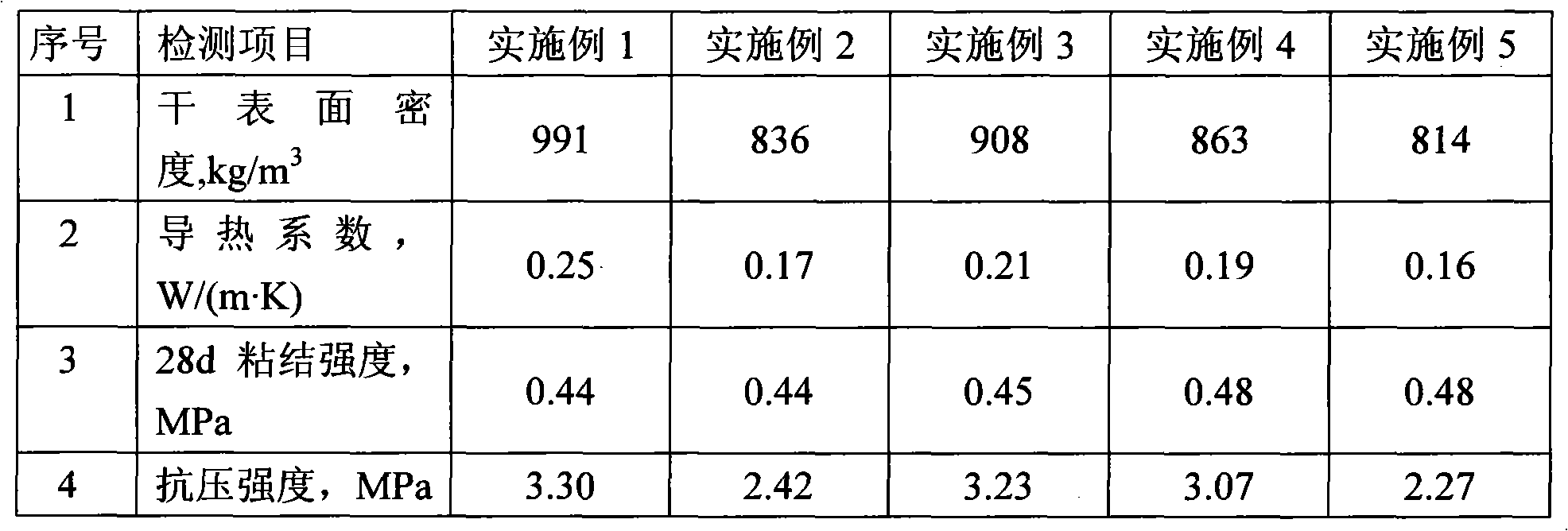

[0039] Perform performance testing according to national standards or industry standards. The testing basis for dry surface density, thermal...

Embodiment 2

[0041]With each component weight of embodiment 2 specified in table 1, repeat the production technology described in embodiment 1 (only each component weight changes) obtain the lightweight plastering mortar of embodiment 2; Repeat the construction method in embodiment 1 , Take 100 kg of mortar and add 35 kg of water to dilute it, stir it mechanically or manually until it is evenly mixed, and then carry out mechanized spraying or manual operation. Perform performance testing with each standard described in Example 1, and the results are as shown in the corresponding data of Example 2 in Table 2.

Embodiment 3

[0043] With each component weight of embodiment 3 specified in table 1, repeat the production process described in embodiment 1 (only each component weight changes) obtain the lightweight plastering mortar of embodiment 3; Repeat the construction method in embodiment 1 , Take 100 kg of mortar and add 40 kg of water to dilute it, stir it mechanically or manually until it is evenly mixed, and then carry out mechanized spraying or manual work. Perform performance testing with each standard described in Example 1, and the results are as shown in the corresponding data of Example 3 in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com