Lime sulphur by-product painting reagent and preparation process thereof

A technology of lime sulfur and lime sulfur crystals, applied in botany equipment and methods, chemicals for biological control, biocides, etc., to achieve good product stability, excellent use effect, and strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

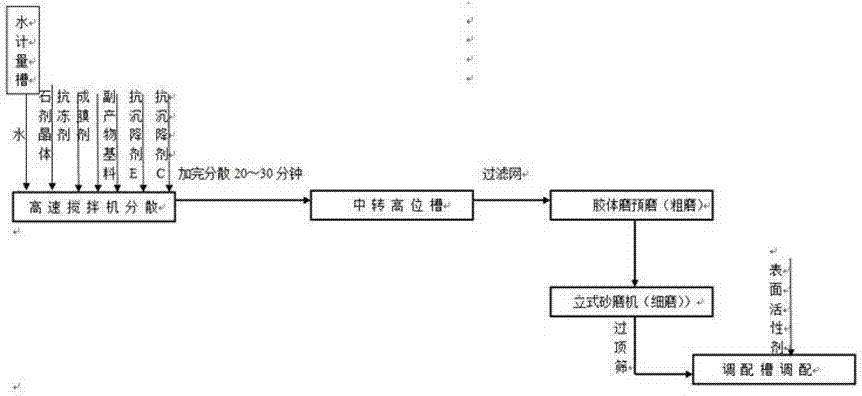

[0029] The process of producing smear by the by-product of lime-sulfur mixture, with the help of the production process of pesticide suspending agent, uses the by-product of lime-sulfur mixture as the main base material, and adds a certain proportion of lime-sulfur crystal as the active ingredient and high-speed dispersion, stirring and mixing of various additives Evenly, after a rough grinding by the screen, it is guided by the pump to the sand mill for fine sand grinding, and then the material is discharged from the top screen of the sand mill cylinder and poured into the blending tank for preparation.

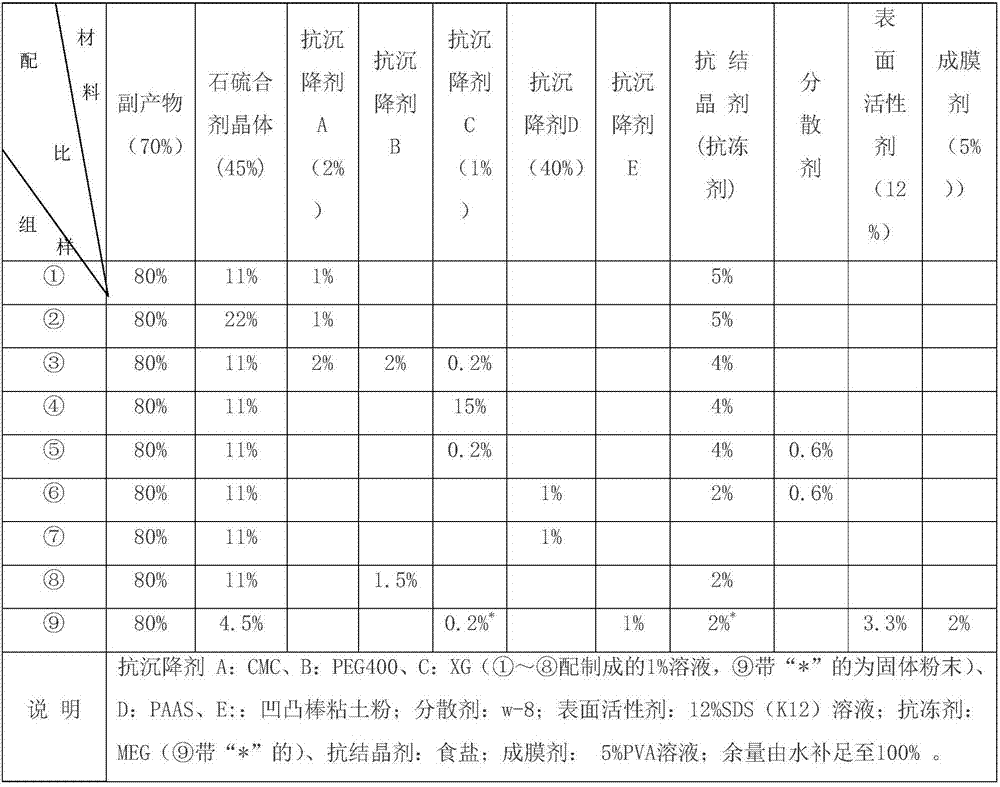

[0030] For the screening of formulas, the total mass percentage is 100%, and % means mass percentage unless otherwise specified.

[0031]

[0032] The above 9 groups of samples were stored at -10°C for 24 hours for comparison: ①~⑧ had different degrees of crystallization and agglomeration, and the group sample ⑨ had no obvious crystallization and agglomeration; stored at r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com