Viscosity regulator for pre-mixed high-strength concrete

A high-strength concrete and viscosity modifier technology, applied in the field of viscosity modifiers and concrete admixtures, can solve the problems of uneven quality of raw materials, inability to reduce concrete viscosity, and large differences, so as to increase fluidity and avoid coarse aggregate sedimentation. Bottom, the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

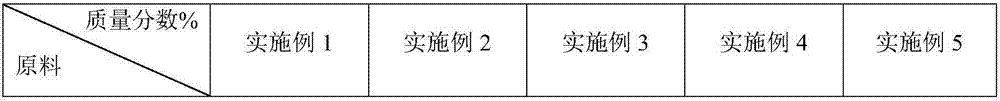

[0023] A viscosity regulator for high-strength concrete, mixed and stirred evenly according to the mass fraction in the following table, and formulated into a viscosity regulator:

[0024]

[0025]

[0026] The viscosity modifier prepared according to the above table is mixed with concrete respectively, and the concrete viscosity is judged by measuring the time for the concrete to pass through the V-shaped funnel with reference to CECS203-2006 "Technical Regulations for the Application of Self-Compacting Concrete".

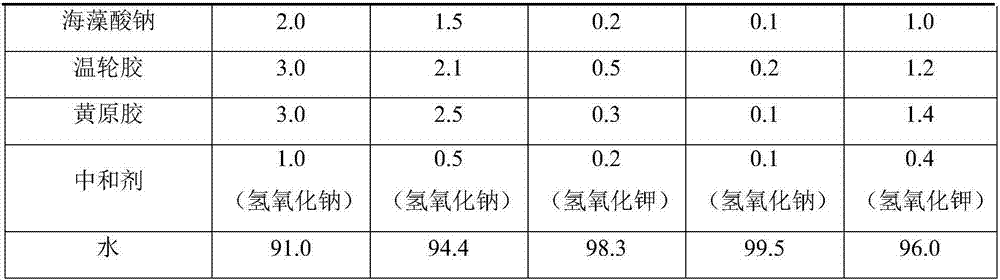

[0027] The mix ratio of the concrete used is shown in the table below:

[0028]

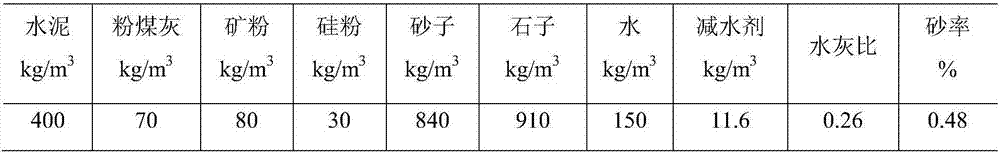

[0029] The measured concrete properties are shown in the table below:

[0030]

[0031] It can be seen from the above table that the viscosity modifier of the present invention can effectively reduce the viscosity of concrete by as much as 33.3% to 39.1%, and at the same time, it does not have much influence on the strength of concrete at 3d, 7d, and 28d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com