A kind of modified mixed Portland cement and preparation method thereof

A Portland cement and modification technology, applied in cement production and other directions, can solve problems affecting project quality, energy, resource waste, isolation, etc., and achieve the effects of facilitating construction, reducing water consumption, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

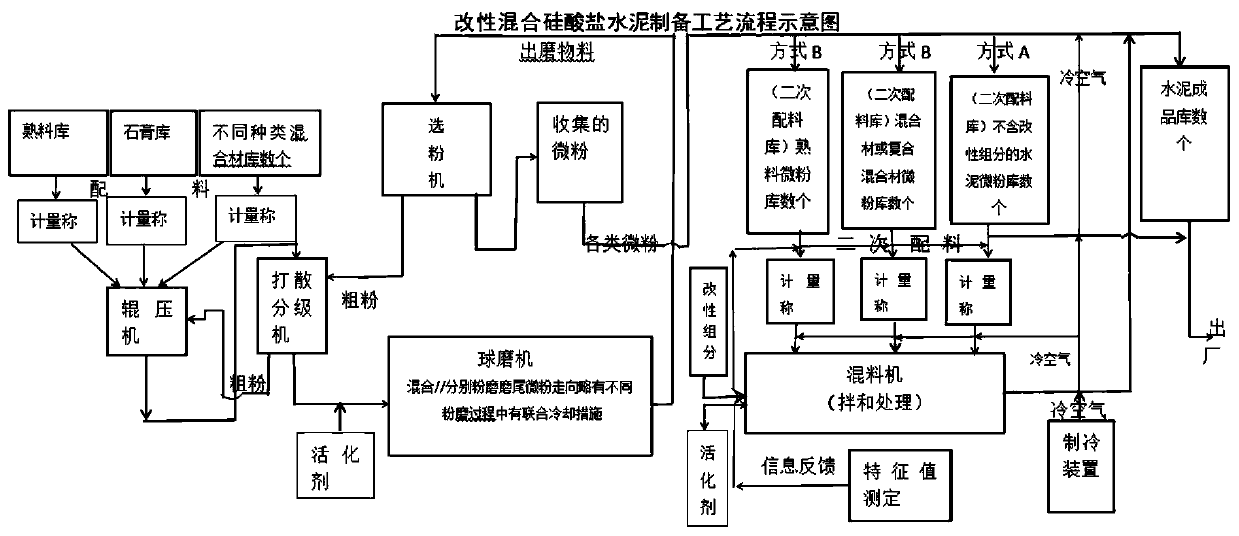

Image

Examples

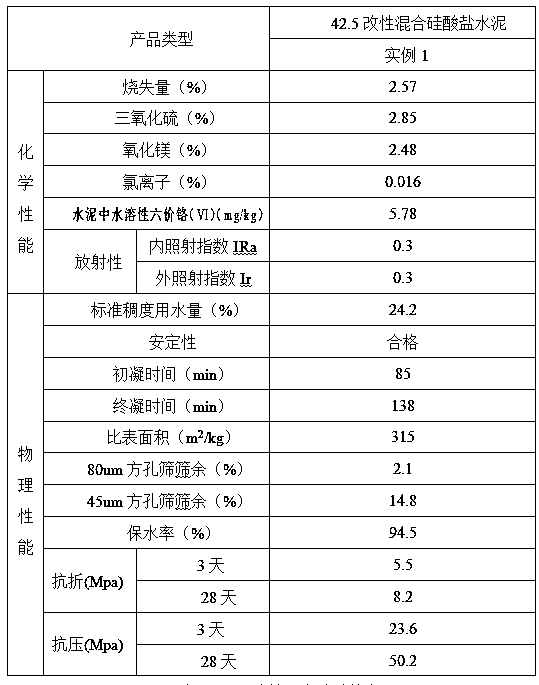

Embodiment 1

[0045] A 42.5 modified mixed portland cement, the raw material ratio of each component is: clinker 78.5%, gypsum 6.0%, limestone 5.0%, granulated blast furnace slag 7.48%, activator 0.02% and mineral colorant (coal Gangue) 3.0%. The activator uses 2,5-dihydroxyethylpiperazine mother liquor, and the component materials meet the relevant standards and the aforementioned requirements.

[0046] The preparation method of the 42.5 modified mixed Portland cement, the specific steps are as follows:

[0047] Step 1: Select the above-mentioned raw materials, adopt the pre-homogenization measures of flat laying and vertical cutting and use in combination, and store them in clinker warehouse, gypsum warehouse, and multiple warehouses of different types of mixed materials. The activator is stored in a storage tank for standby;

[0048] Step 2: adopt mixed grinding method A, after measuring the ingredients of clinker, gypsum, limestone, granulated blast furnace slag, activator, and coal ga...

Embodiment 2

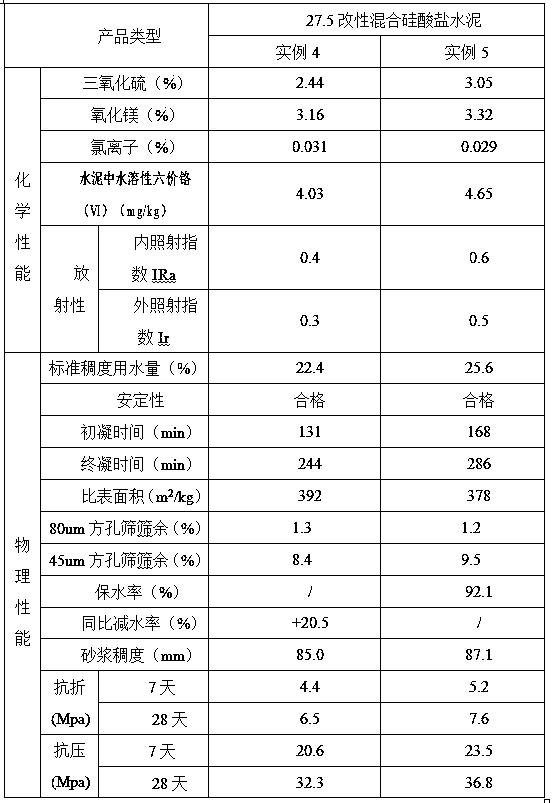

[0051] A 32.5 modified mixed portland cement, the raw material ratio of each component is: clinker 55.0%, gypsum 5.0%, limestone 10.0%, granulated blast furnace slag 5.48%, fly ash 10.5%, pozzolanic mixed material 9.0% %, coal gangue (mineral coloring agent) 3.0%, activator 0.02% and composite water reducer 2.0%. The activator uses 2,5-dihydroxyethylpiperazine mother liquor, the composite water reducer uses polycarboxylate powder, and the component raw materials meet the relevant standards and the aforementioned requirements.

[0052] The preparation method of the 32.5 modified mixed Portland cement, the specific steps are as follows:

[0053] Step 1: Select the above-mentioned raw materials, take the measures of flat laying, vertical cutting and pre-homogenization, and put them into the clinker warehouse, gypsum warehouse, and multiple warehouses of different types of mixed materials, and store the modified components and activators separately in storage tanks ,spare;

[00...

Embodiment 3

[0058] A 32.5 modified mixed portland cement, the raw material ratio of each component is: clinker 55.0%, gypsum 5.0%, limestone 10.0%, granulated blast furnace slag 5.5%, fly ash 9.3%, slag (pozzolanic Mixed material) 8.0%, carbon black (mineral colorant) 3.0%, activator 0.10%, cellulose ether 0.1% and redispersible latex powder 4.0%. The activator used is composed of 2,5-dihydroxyethylpiperazine mother liquor and tetrahydroxyethylethylenediamine, the cellulose ether uses hydroxypropyl methylcellulose ether, and the redispersible latex powder uses ethylene- Vinyl acetate copolymer. The component raw materials meet the relevant standards and the aforementioned requirements.

[0059] The preparation method of the 32.5 modified mixed Portland cement, the specific steps are as follows:

[0060] Step 1: Select the above-mentioned raw materials, take the measures of flat laying, vertical cutting and pre-homogenization, and put them into the clinker warehouse, gypsum warehouse, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com