A kind of 32.5 mixed Portland cement for rural township and anti-crack concrete and its preparation method

A portland cement, township technology, applied in rural townships and 32.5 mixed Portland cement for anti-crack concrete and its preparation field, can solve problems such as insufficient sulfate ions, shortage, and impact on concrete performance, and achieve reduction of alkali bone Feed reaction, reduce the amount of clinker, and promote the effect of energy saving, consumption reduction, emission reduction and waste utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

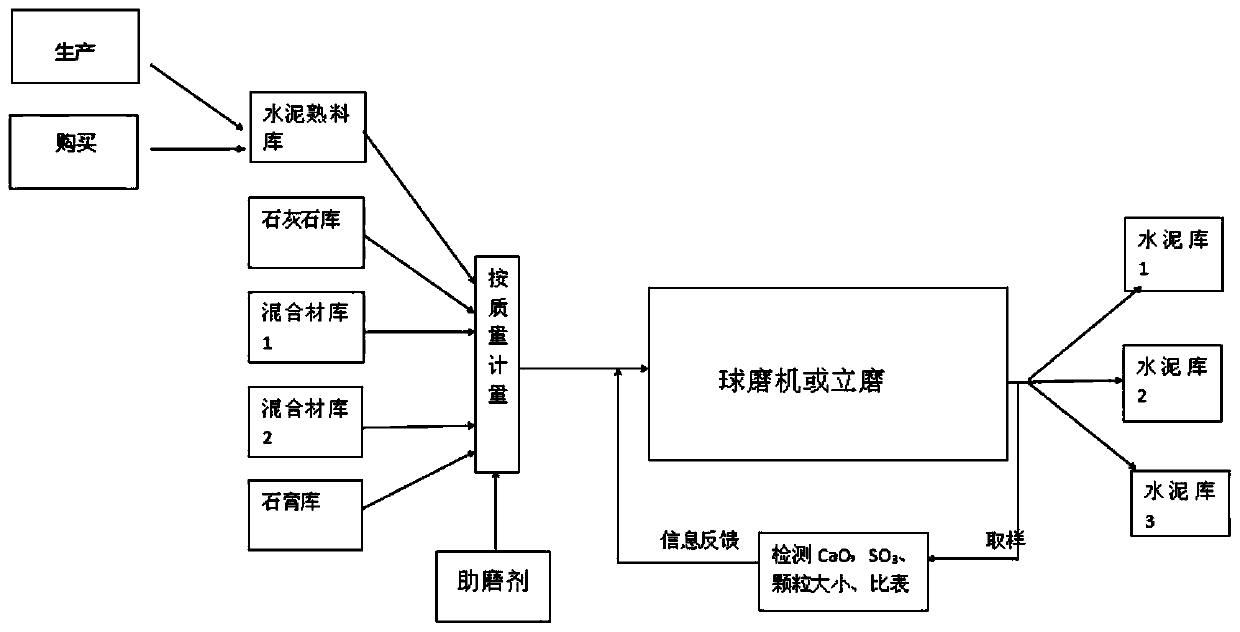

Method used

Image

Examples

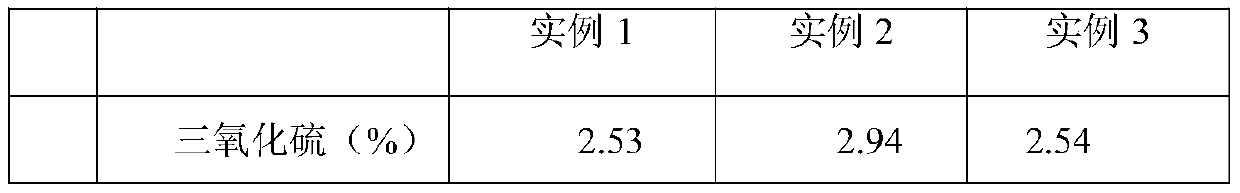

Embodiment 1

[0055] A kind of 32.5 mixed Portland cement for rural townships and anti-crack concrete, the proportion of which is: 65% of Portland cement clinker, 6% of gypsum, 15% of limestone, and 13.95% of mixed materials (slag, granulated blast furnace slag) , Grinding aid 0.05%.

[0056] The Portland cement clinker is precalcined kiln calcined clinker, and the control parameters of the Portland cement clinker: 1-day compressive strength ≥ 12MPa, 3-day compressive strength ≥ 28MPa, 28-day compressive strength ≥ 55MPa, The mass content of tricalcium aluminate ≤ 8%, the mass content of silicate minerals ≥ 68%, the mass content of tricalcium silicate ≤ 58%, the mass content of magnesium oxide 2 O+Na2 O) <0.6%.

[0057] 32.5 Mixed Portland cement also includes mixed materials including granulated blast furnace slag, slag, calcined coal gangue, and fly ash, and 8% of the mixed materials meet the requirements of other waste residues such as sandstone, phosphorus slag, kiln dust, and steel sla...

Embodiment 2

[0068] A kind of 32.5 mixed Portland cement for rural township and anti-crack concrete, the proportion of which is: Portland cement clinker 40%, gypsum 3%, limestone 25%, mixed materials (fly ash, granulated blast furnace slag) 31.5%, grinding aid 0.5%. Component materials meet relevant standards and requirements.

[0069] Others are the same as example 1.

Embodiment 3

[0071] A kind of 32.5 mixed portland cement for rural township and anti-crack concrete, its proportion is: Portland cement clinker 52.5%, gypsum 5%, limestone 10%, admixture material (granulated blast furnace slag) 32%, help Abrasive 0.5%. The component materials meet the relevant standards and the aforementioned requirements. Others are the same as example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com