Method for increasing yield of super-thick material layer sintering

A technology of yield rate and material layer, which is applied in the field of improving the sintering yield of ultra-thick material layer and the field of material distribution device, can solve the problems of high return rate of sintered ore at the edge, large heat loss of edge material, and low yield, so as to reduce sintering The effect of returning ore, reducing internal stress, and reducing chapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

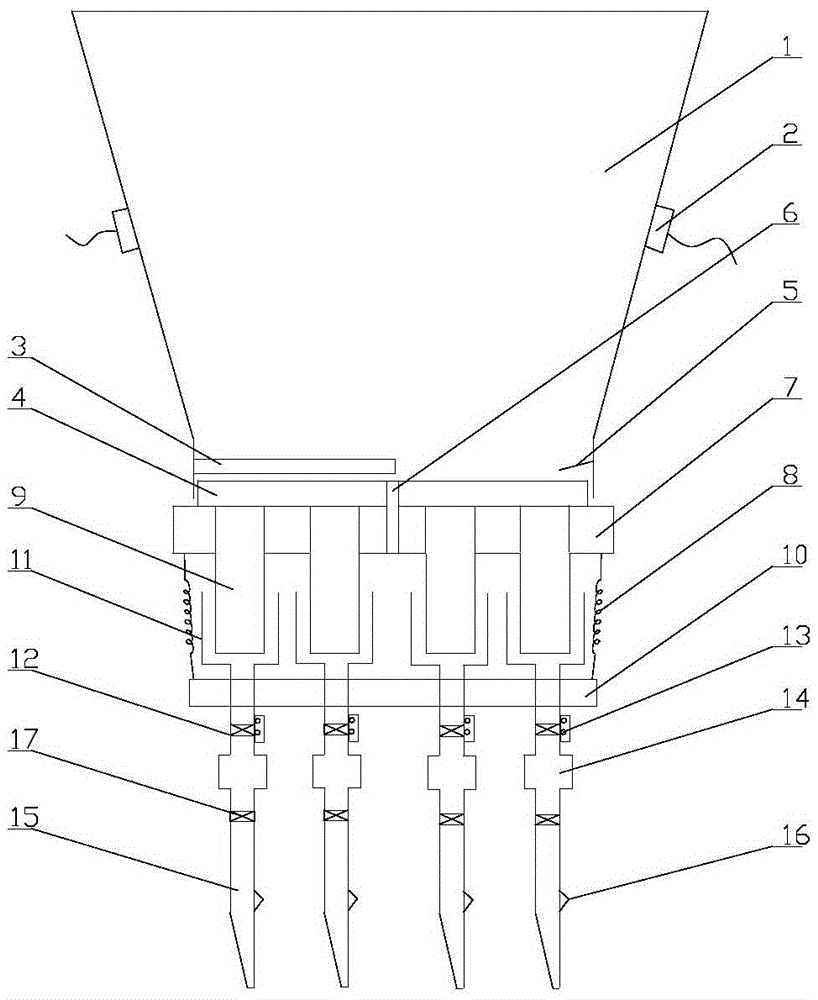

Embodiment 1

[0038] Fully mix 55 parts by weight of iron concentrate and 45 parts by weight of bituminous coal, and then add quicklime to it to form a mixture; adjust the amount of quicklime added so that the binary basicity of the mixture is the same as the basicity of the sintering mixture, CaO / SiO 2 is 2.0; the bituminous coal is a mixture of fat coal and gas fat coal at a ratio of 1:1, and the particle size is less than 180 mesh; the mixture is mixed with 3 parts by weight of water and fully stirred in a mixer. The mixed material after mixing is hot-pressed by a briquetting machine, wherein the molding pressure is 25MPa; the hot-pressing temperature is 400° C.; the hot-pressing time is 10min; The above-mentioned hot-pressed pellets are distributed into the sintered mixture material layer through a distribution device arranged between the sintered distributor and the igniter, wherein the amount of hot-pressed pellets distributed into the edge sintered mixture is 1.5 times that of the i...

Embodiment 2

[0043] Fully mix 65 parts by weight of iron concentrate and 35 parts by weight of bituminous coal, and then add quicklime to it to form a mixture; adjust the addition amount of quicklime so that the binary basicity of the mixture is the same as the basicity of the sintering mixture, and CaO / SiO 2 is 2.2; the bituminous coal is fat coal, and the particle size is less than 180 mesh; the mixture is added with 5 parts by weight of water, and the mixture is fully stirred and mixed in a mixer. The mixed material is hot-pressed by a briquetting machine, wherein the molding pressure is 22MPa; the hot-pressing temperature is 450° C.; the hot-pressing time is 12min; Distribute the above-mentioned hot-pressed pellets into the sintered mixture material layer through a distribution device arranged between the sintered distributor and the igniter, wherein the amount of hot-pressed pellets distributed into the edge sintered mixture is twice that of the intermediate sintered mixture ; The d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com