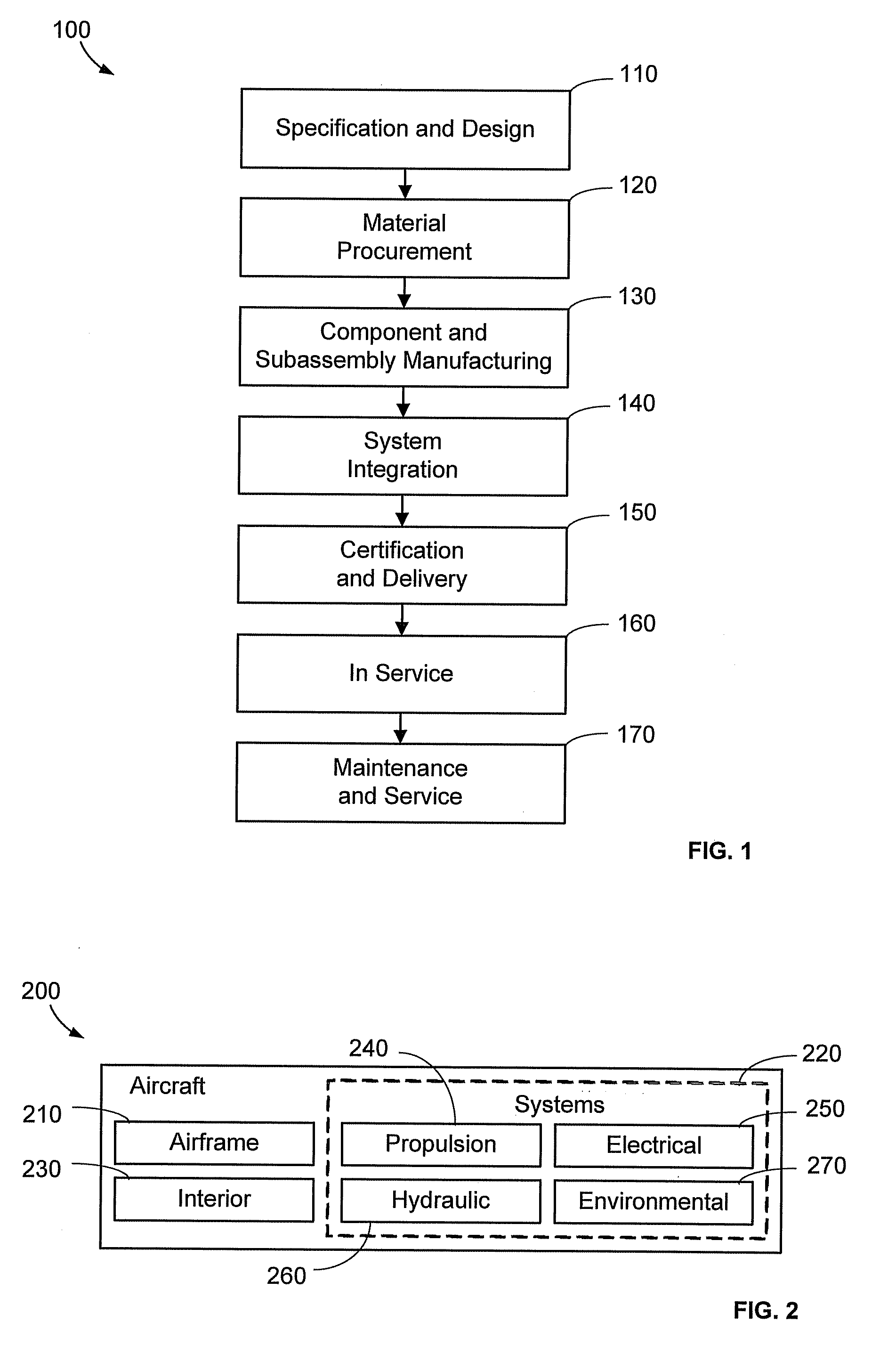

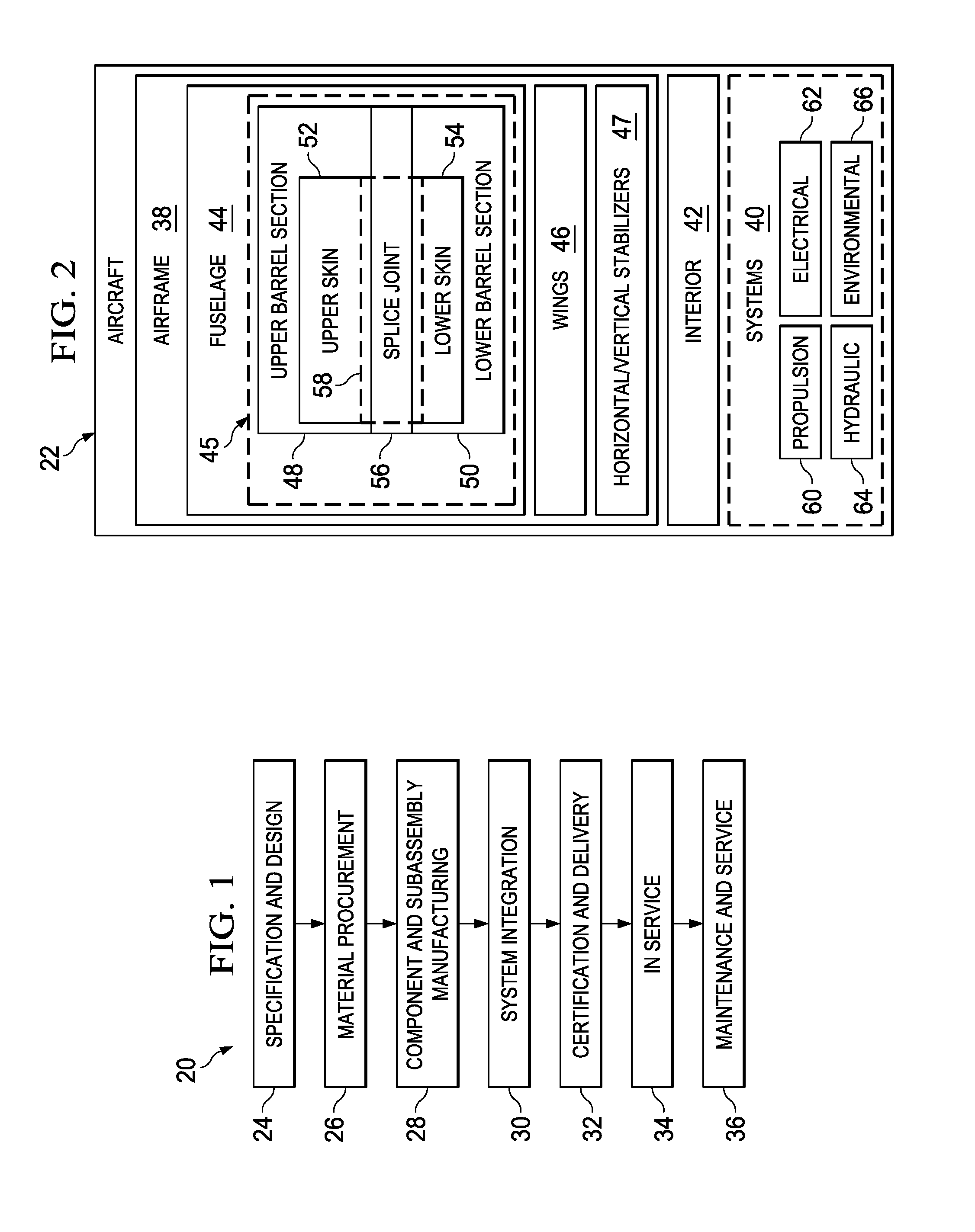

Patents

Literature

216 results about "Composite skin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

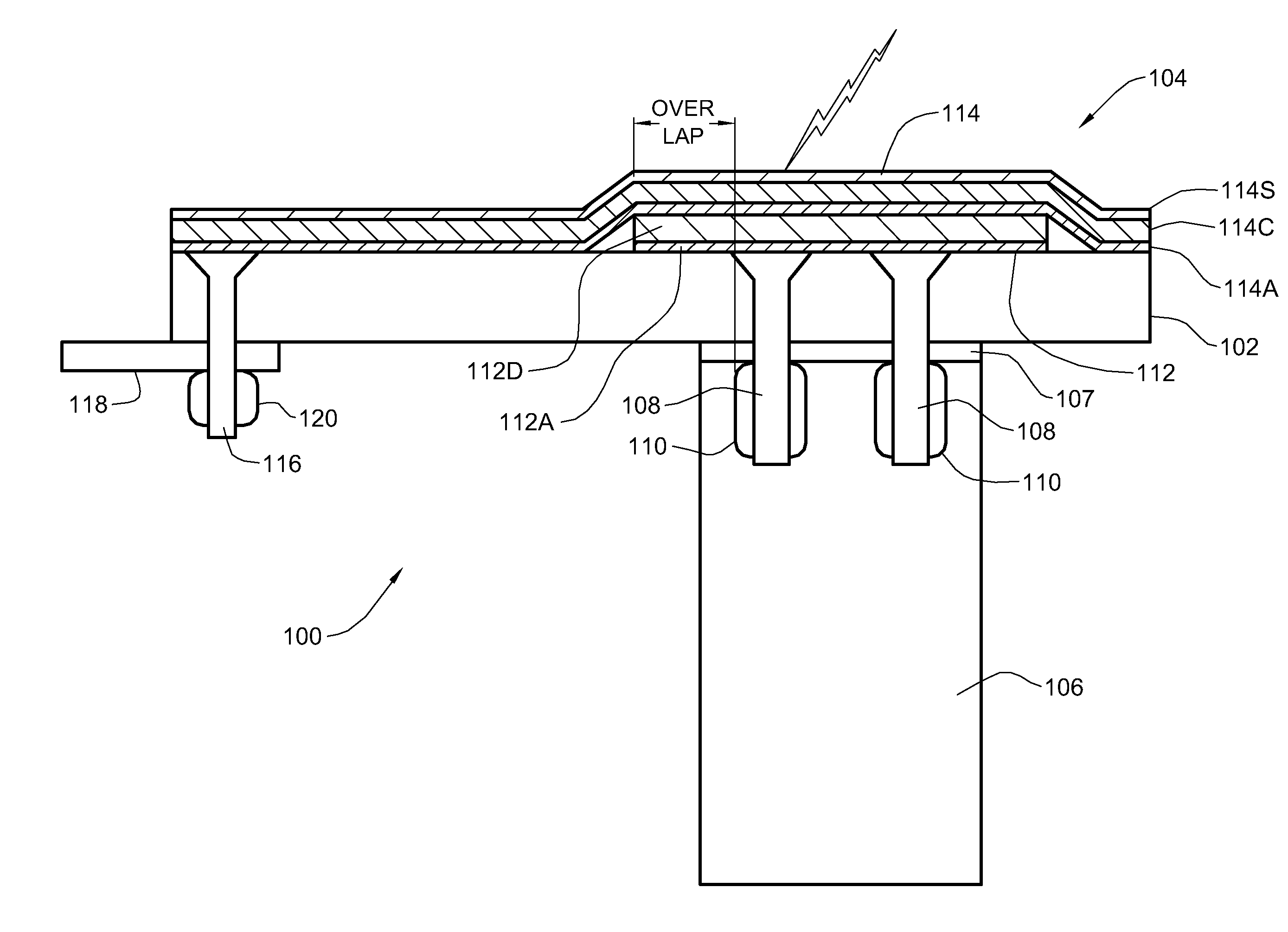

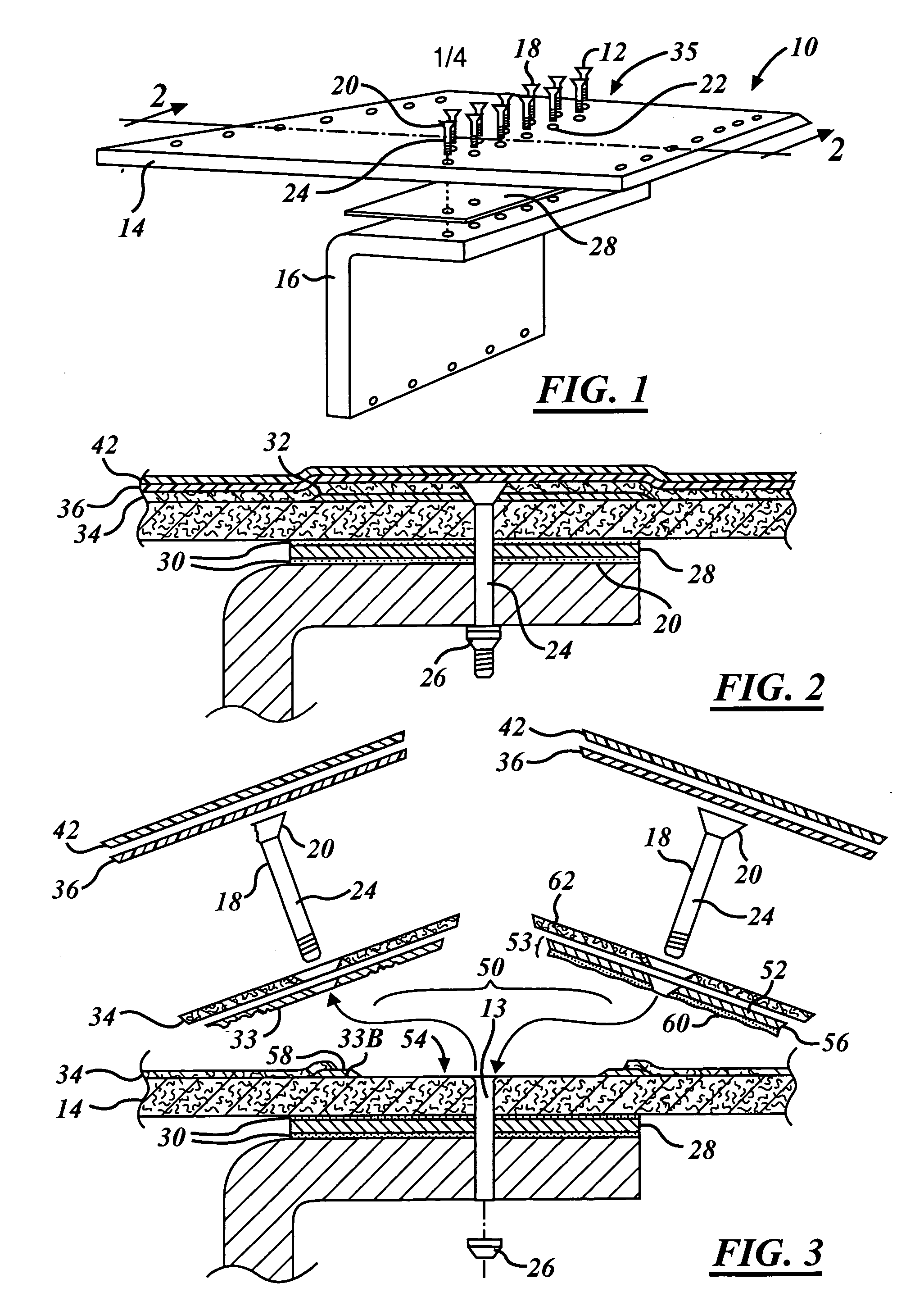

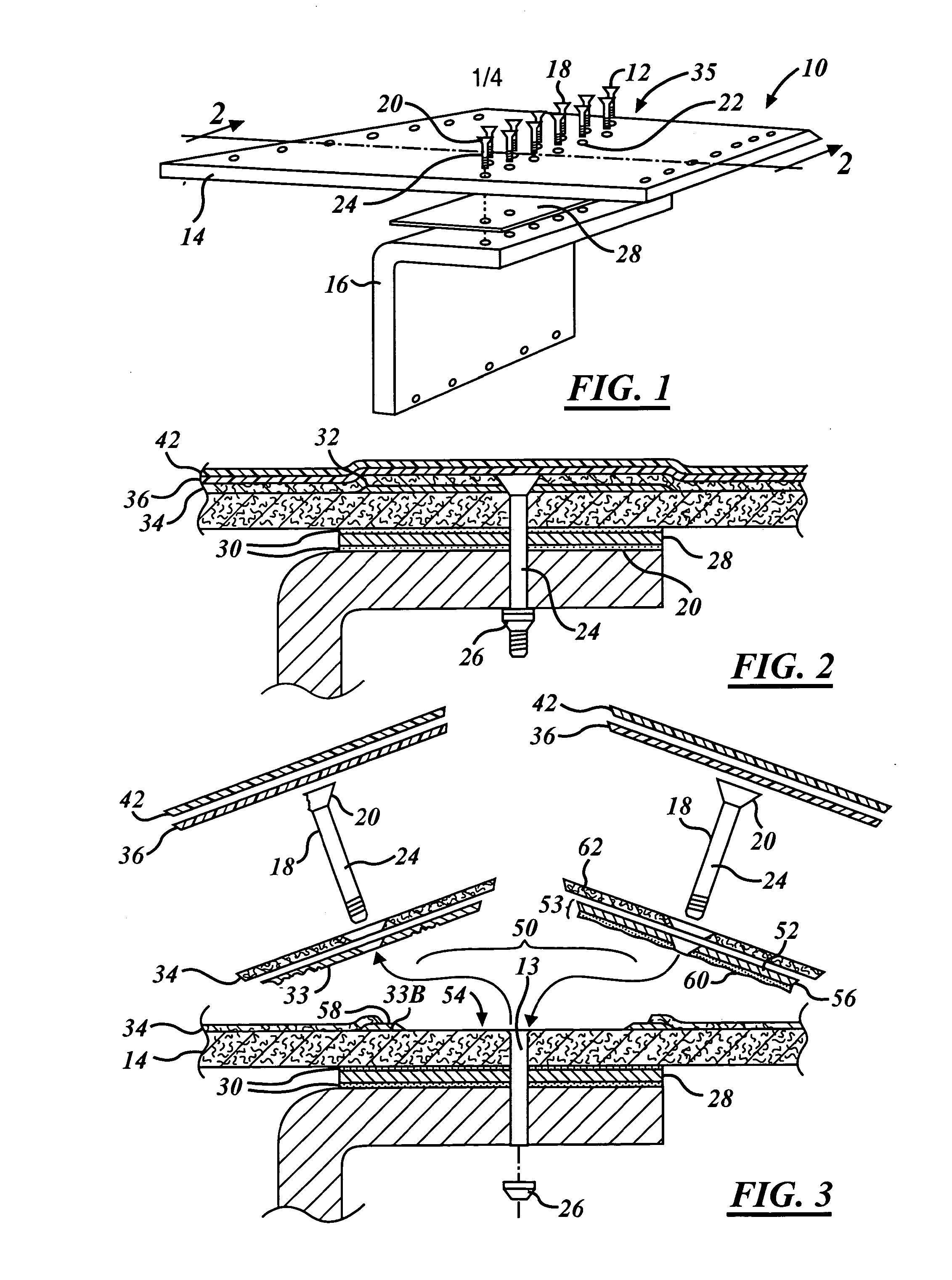

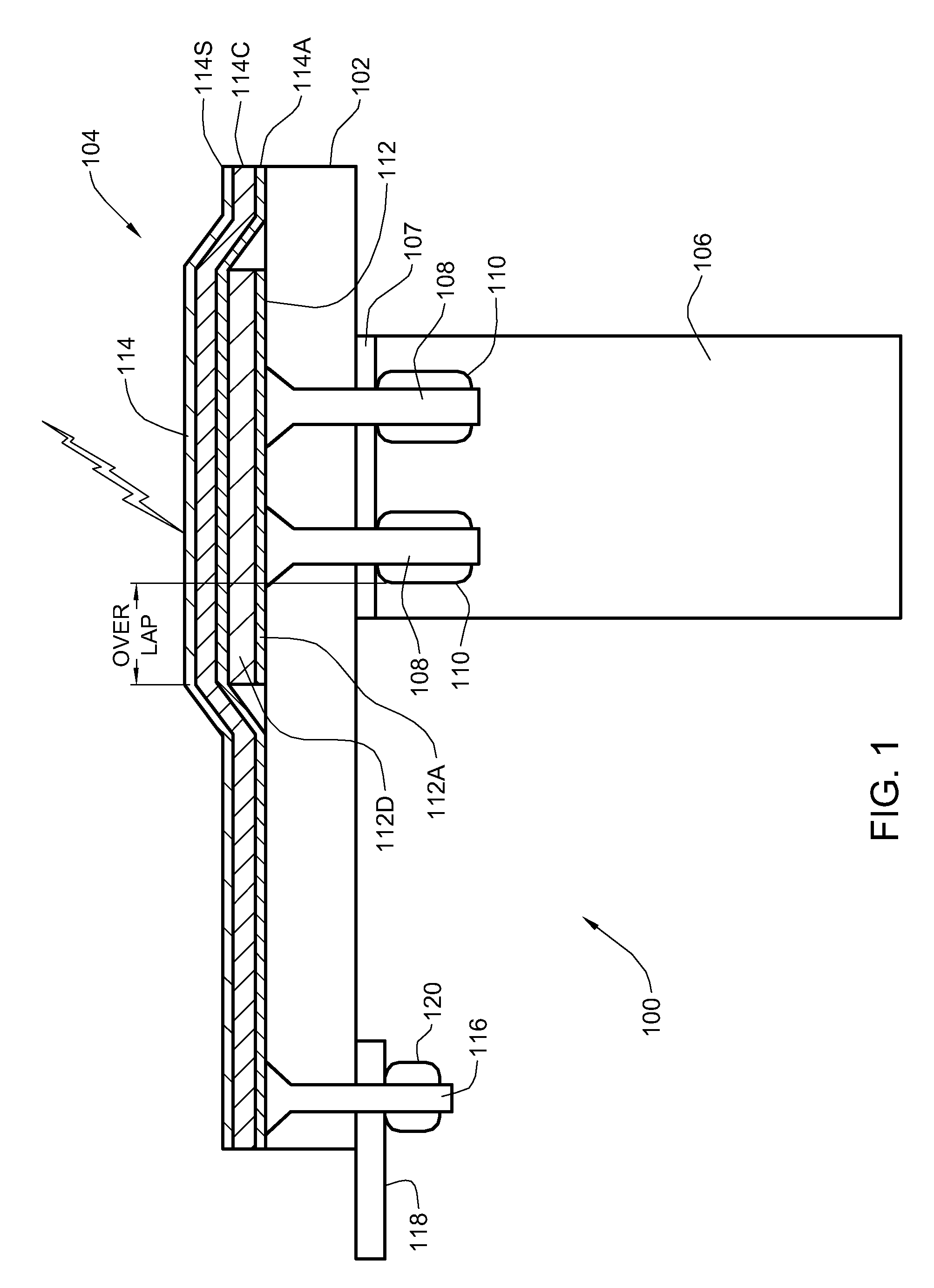

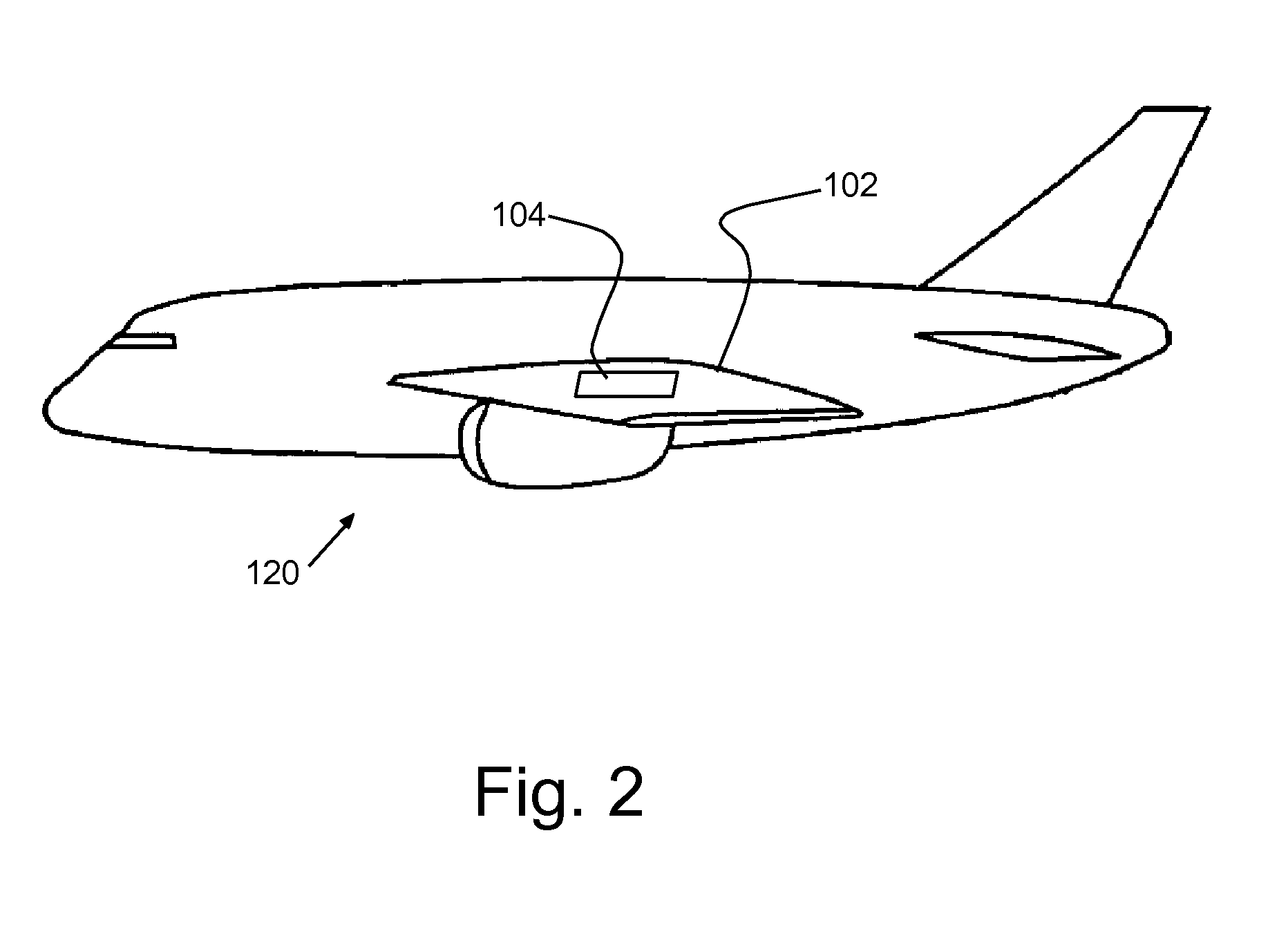

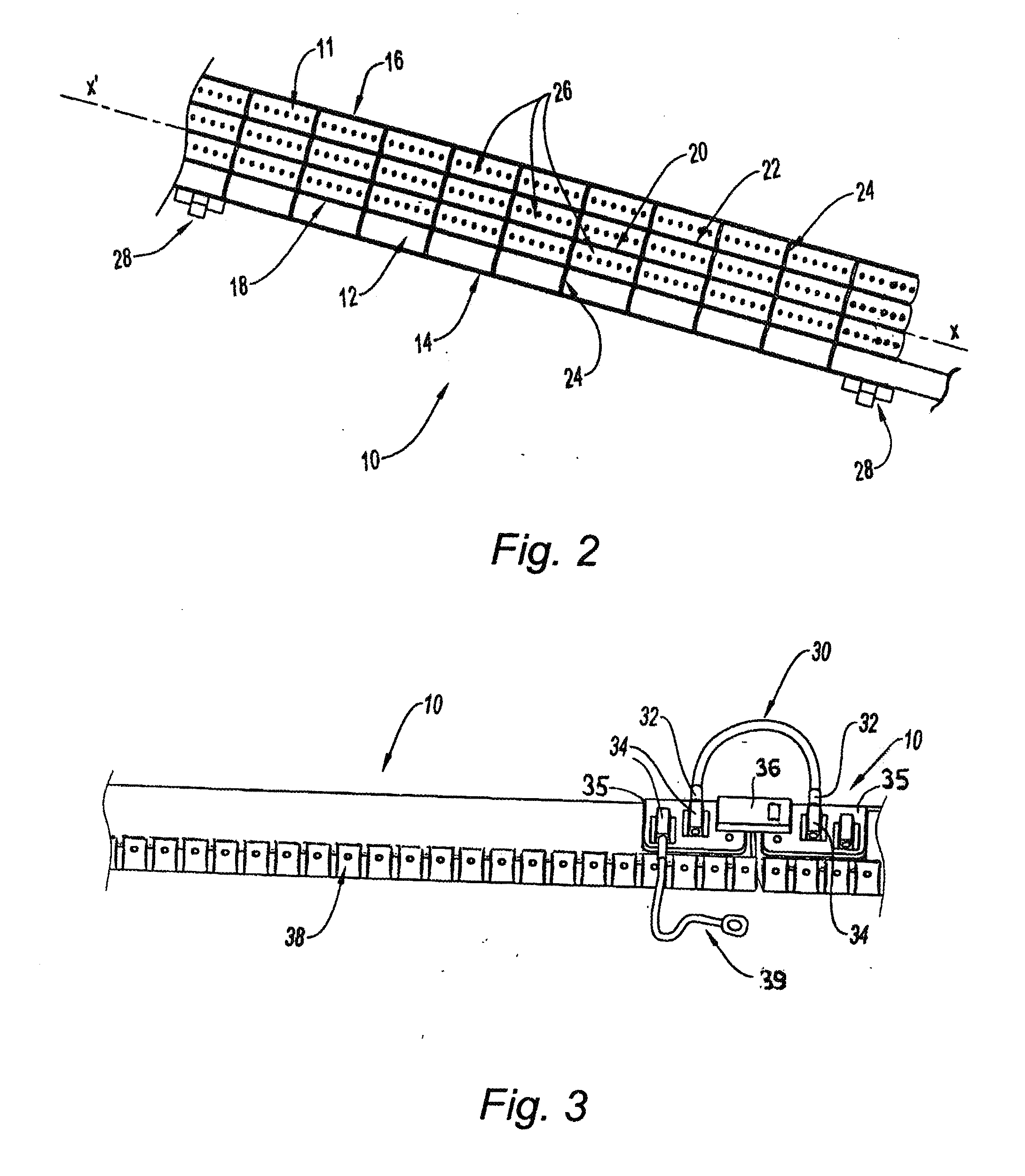

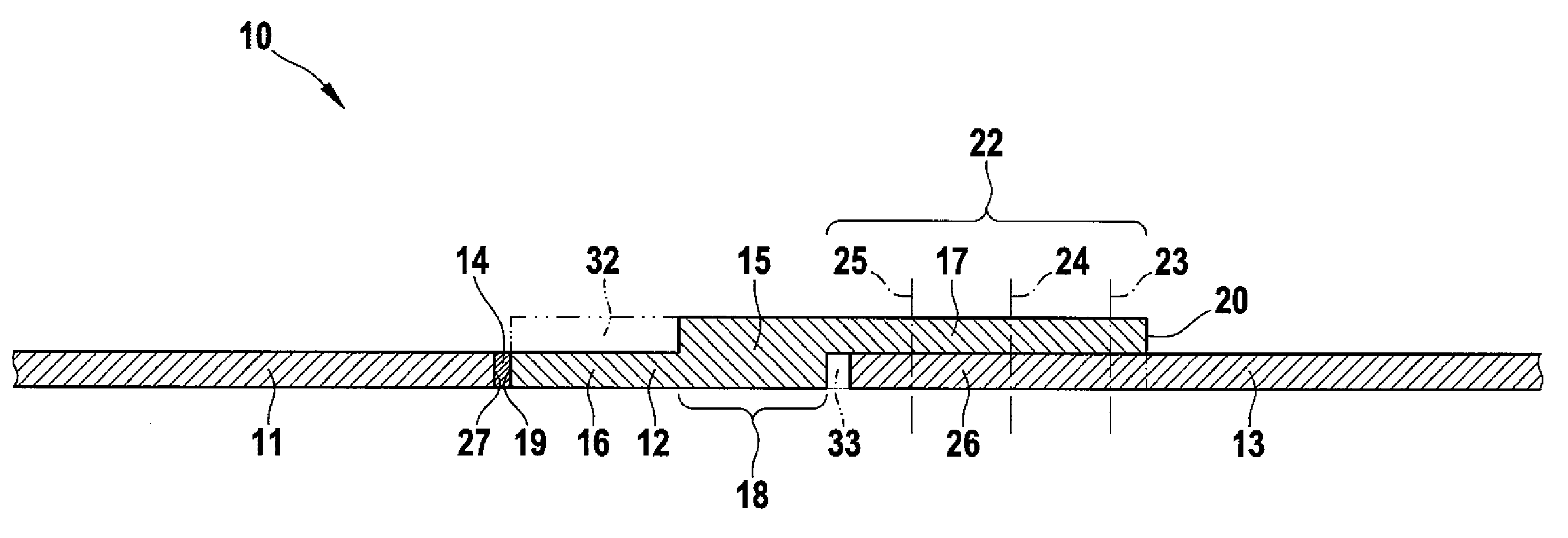

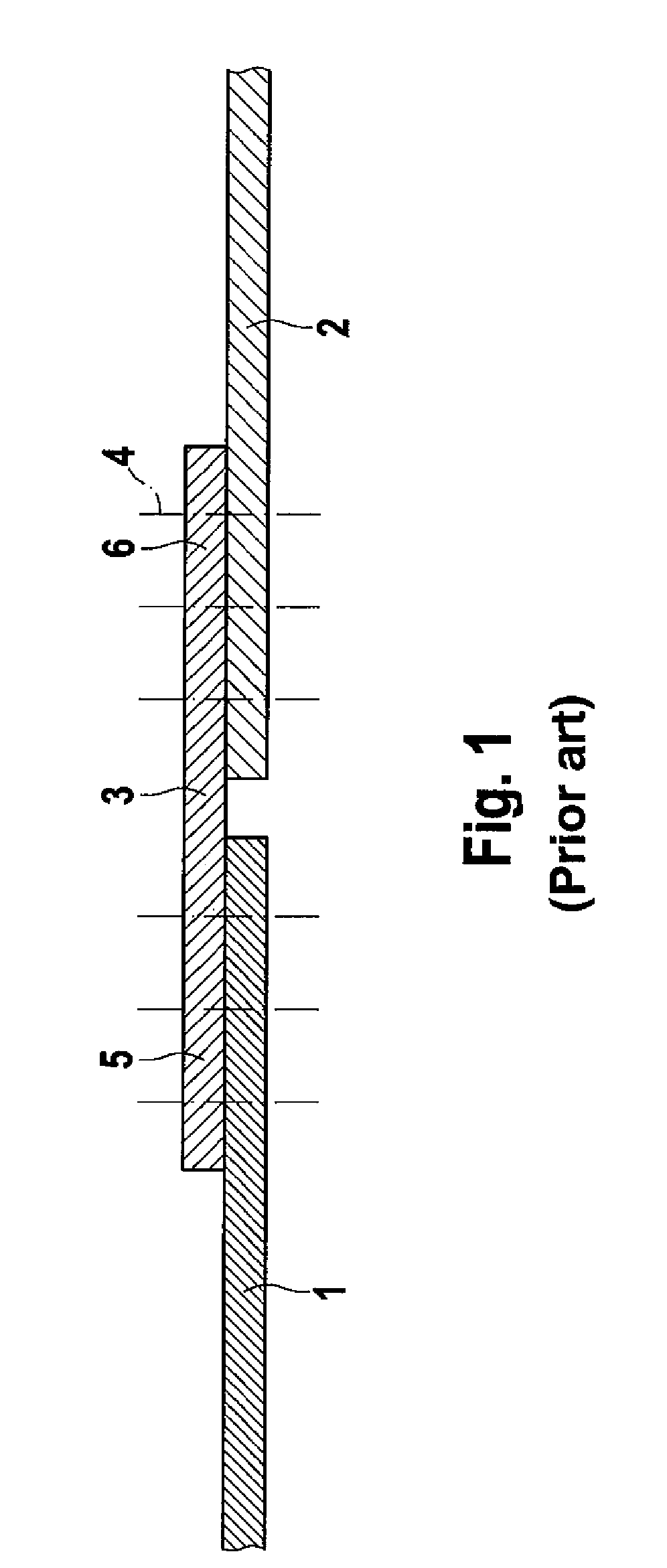

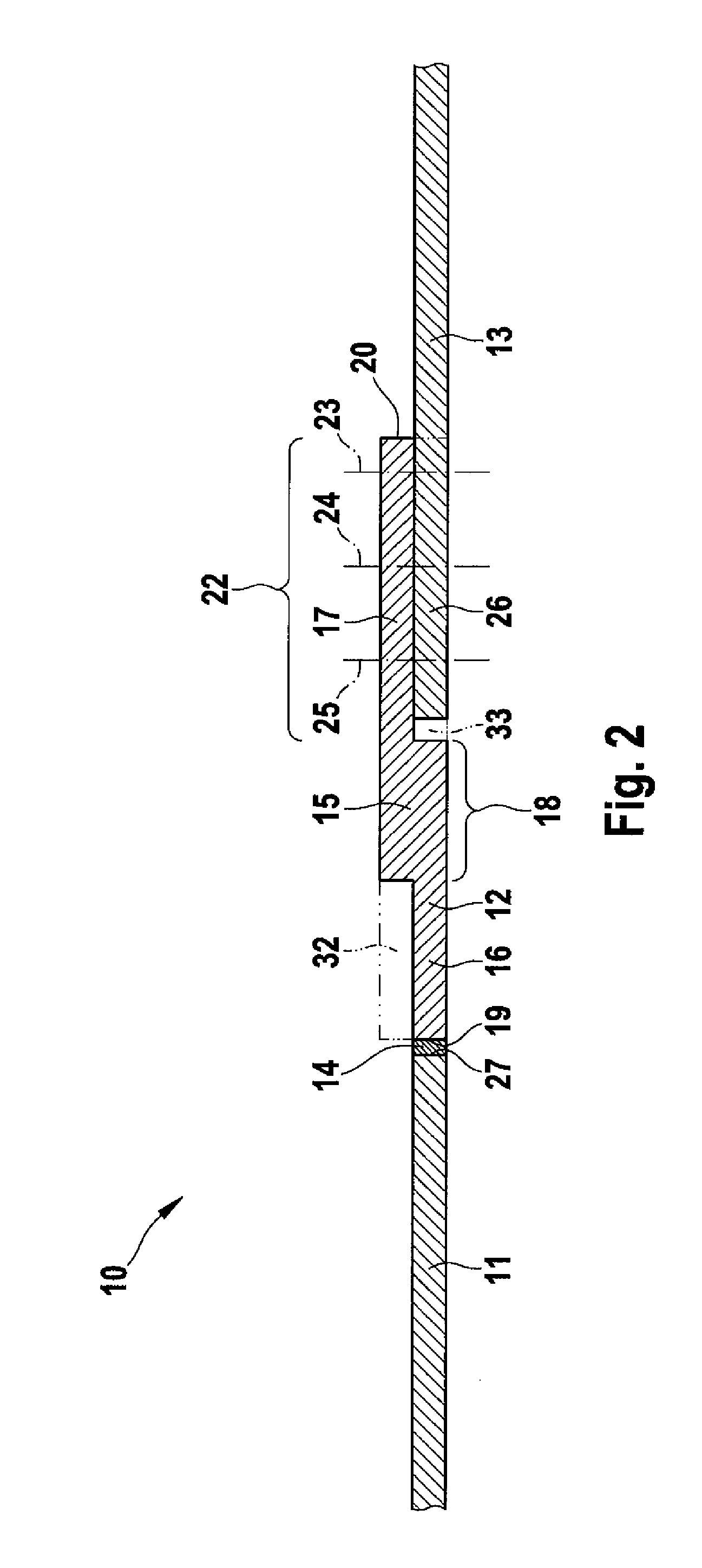

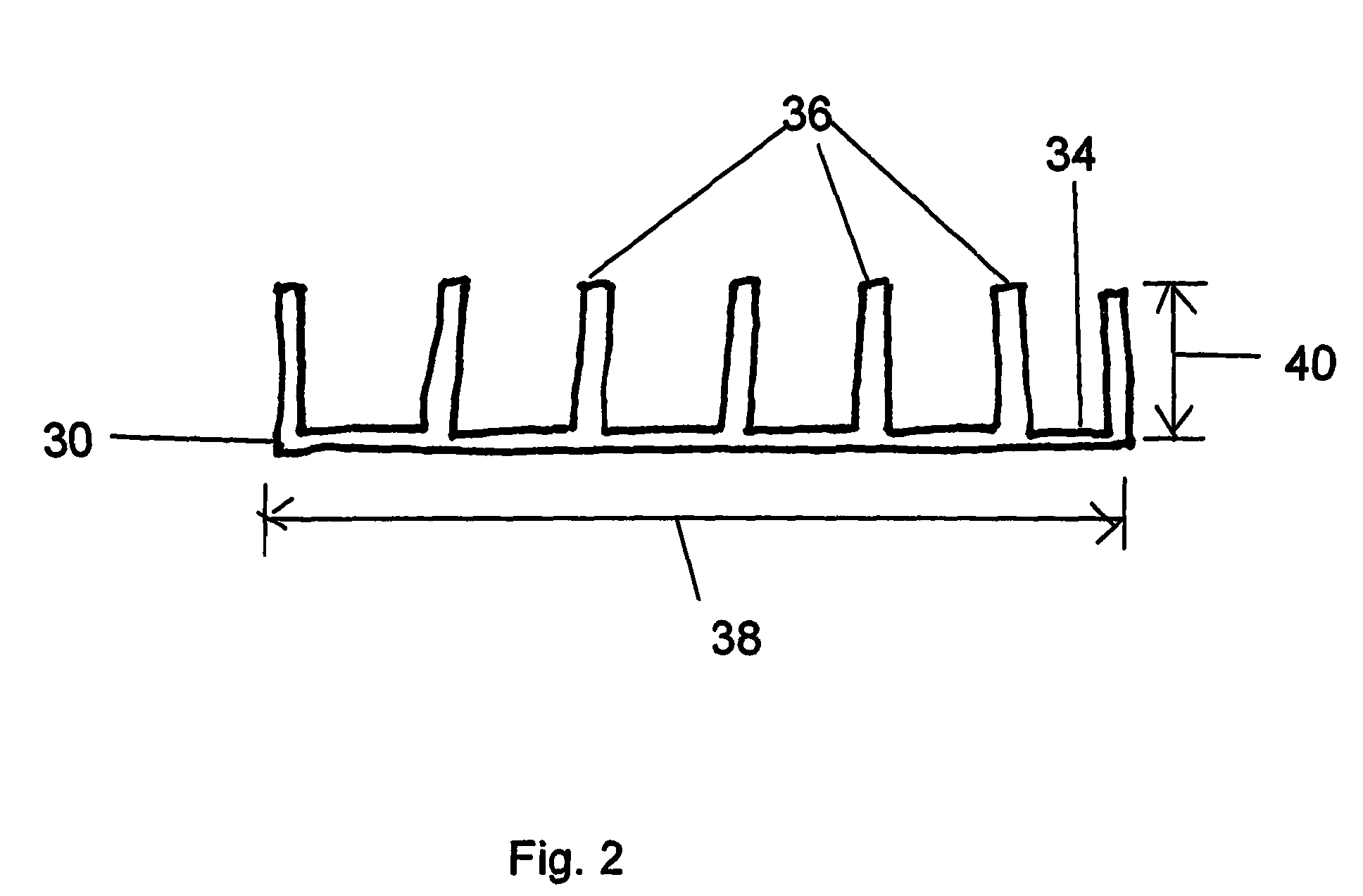

Lightning protection system for composite structure

ActiveUS7277266B1Flexibility in lightning protection designIncreasing aircraft weightAircraft lighting protectorsEmergency protective arrangement detailsElectricityLightning strike

A lightning protection system for protecting composite structures and a method of protecting composite structures from lightning strikes. A dielectric ply is fixed above and completely covers metal surface features, e.g., skin fasteners through a composite skin to a wing fuel tank. A conductive ply is fixed above and completely covers the dielectric ply and extends to an external connection to a platform ground. The conductive ply directs current from lightning strikes away from metal surface features, e.g., to the platform ground. Both plies may be adhesively backed and sequentially pressed into place.

Owner:THE BOEING CO

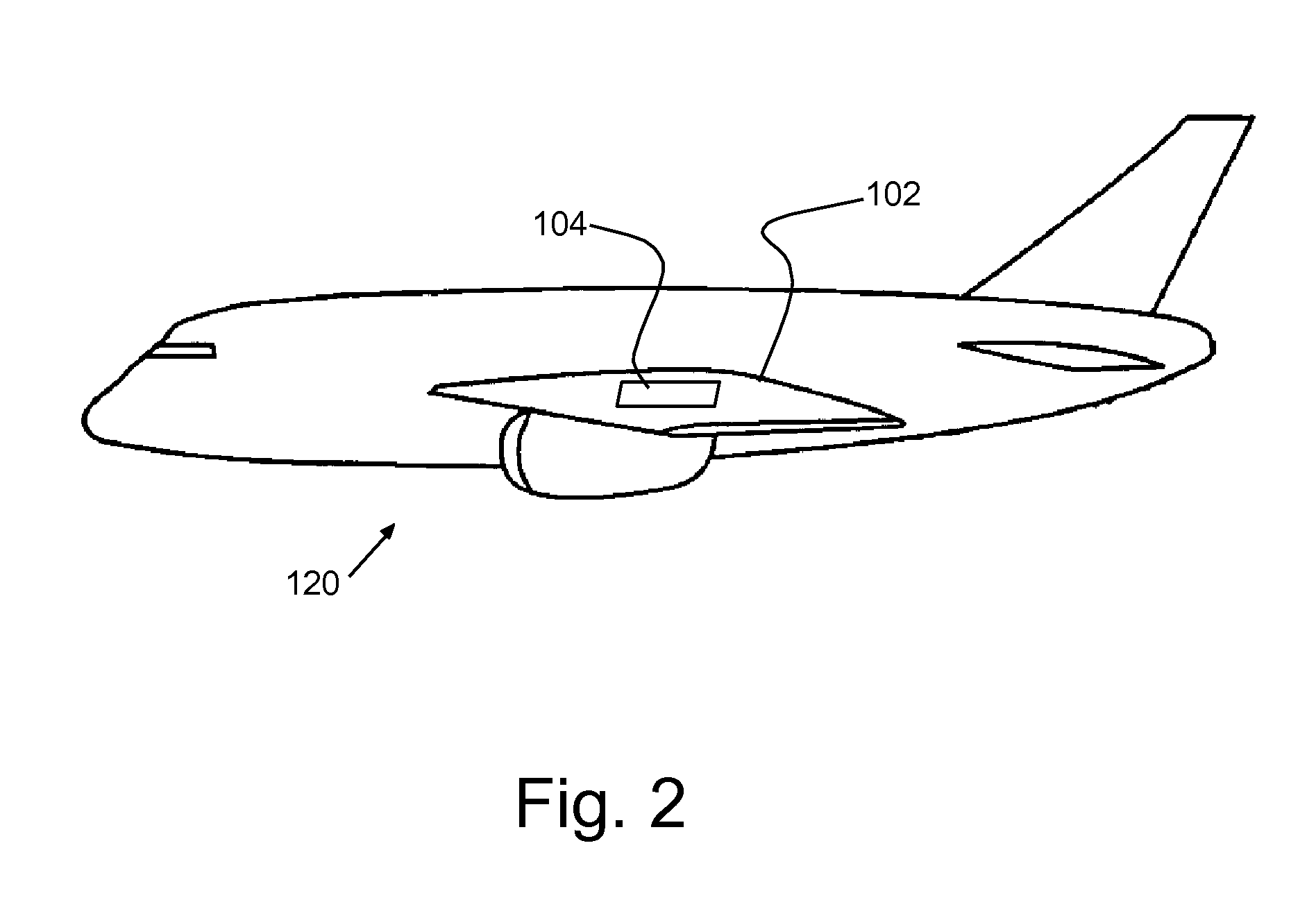

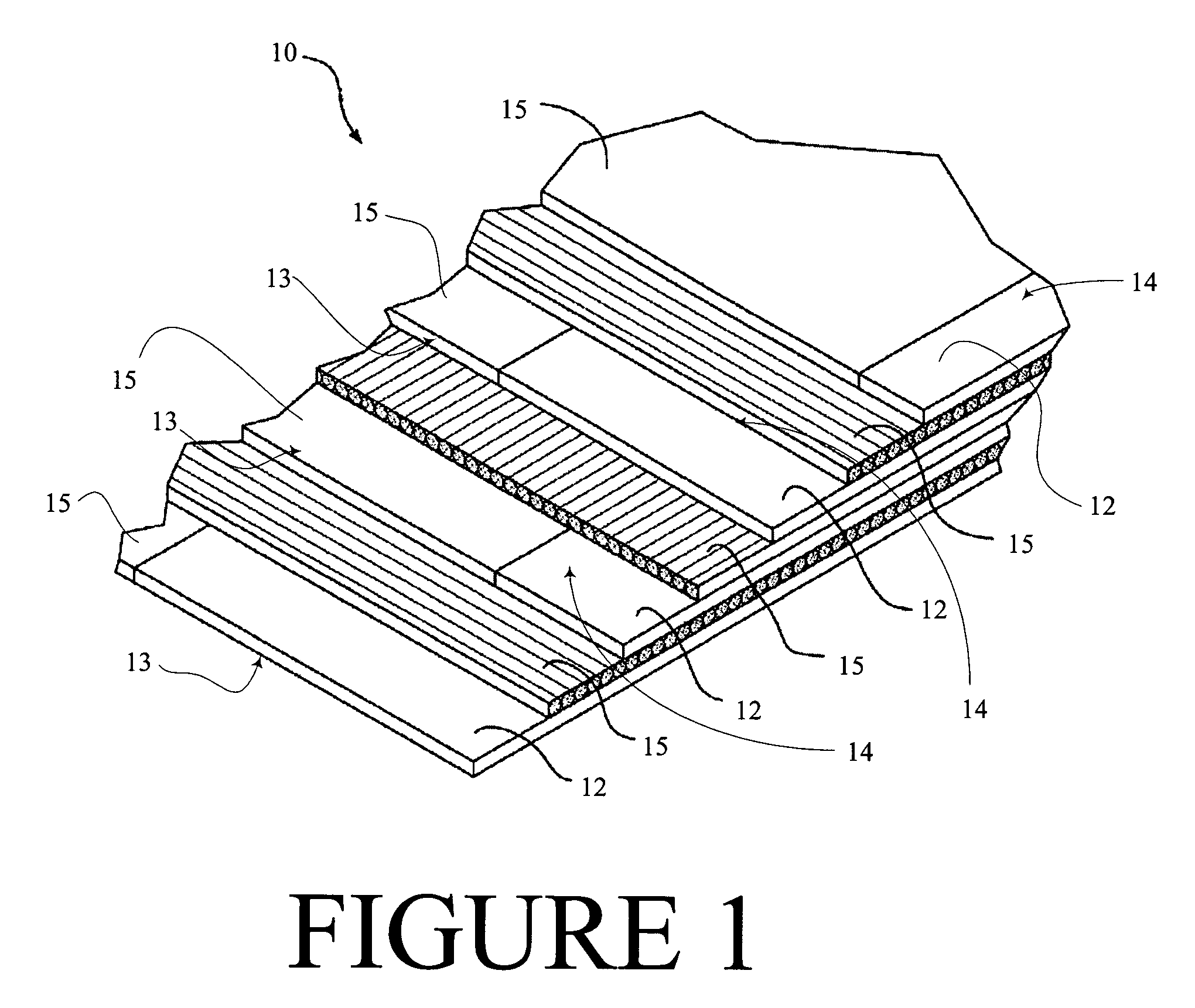

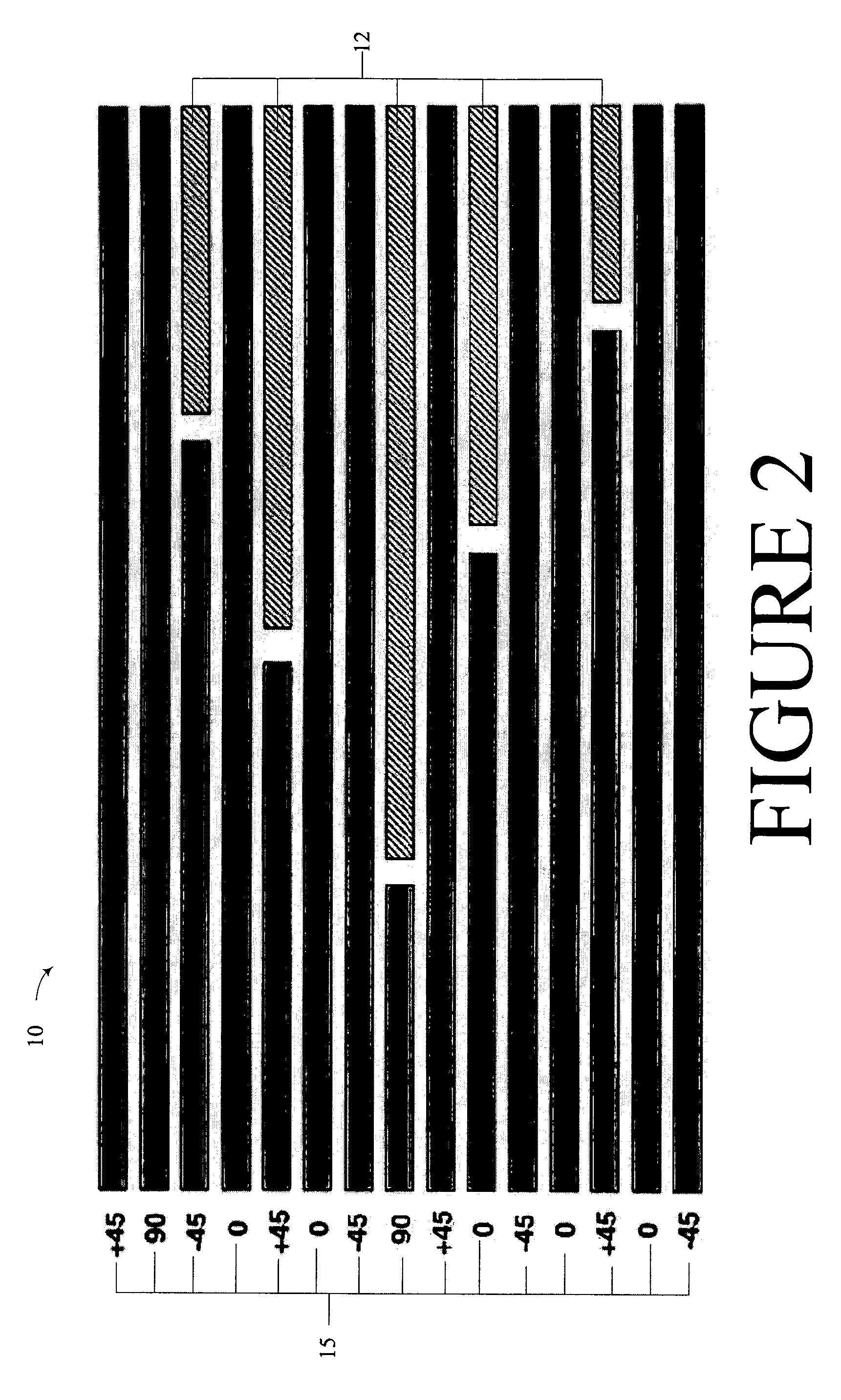

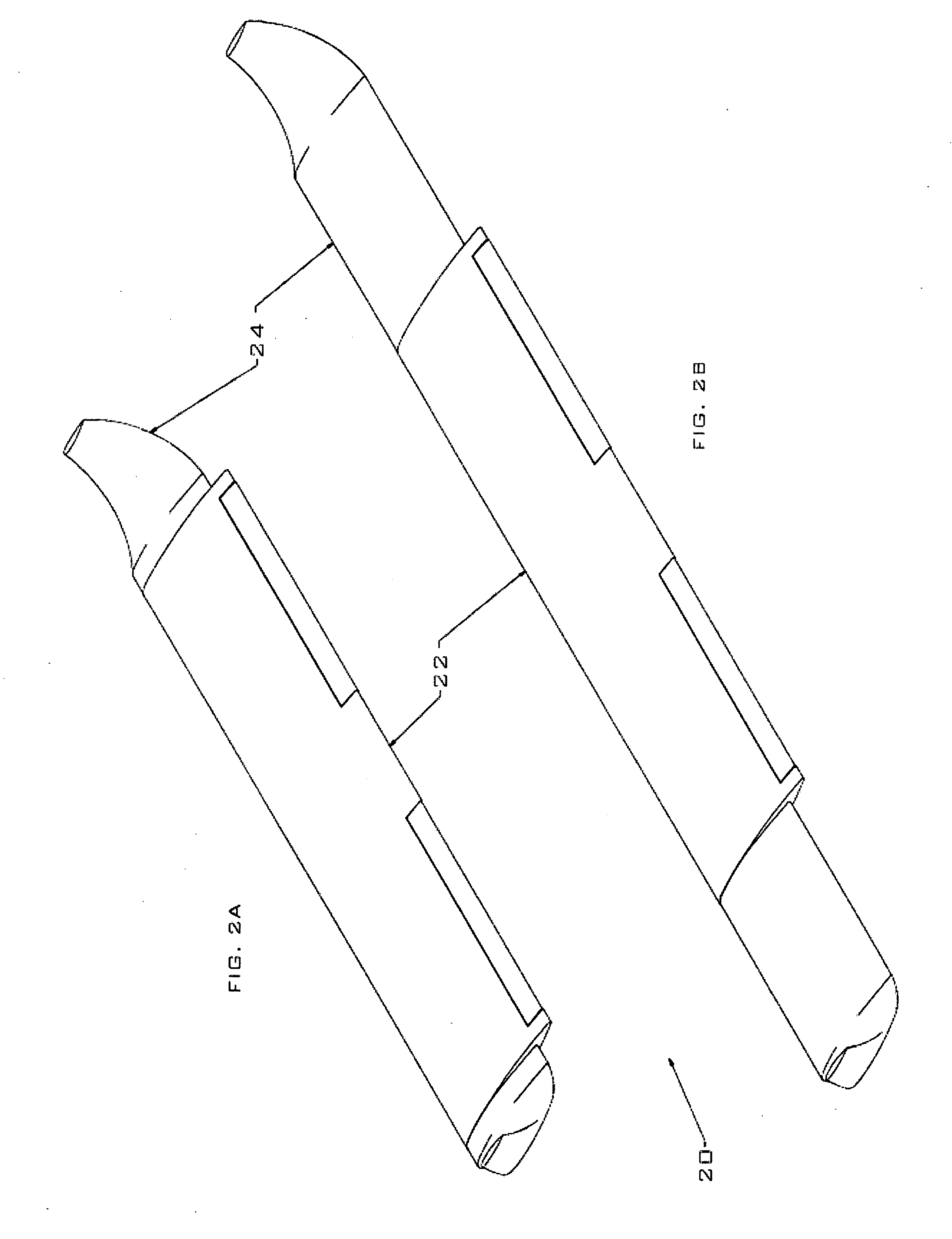

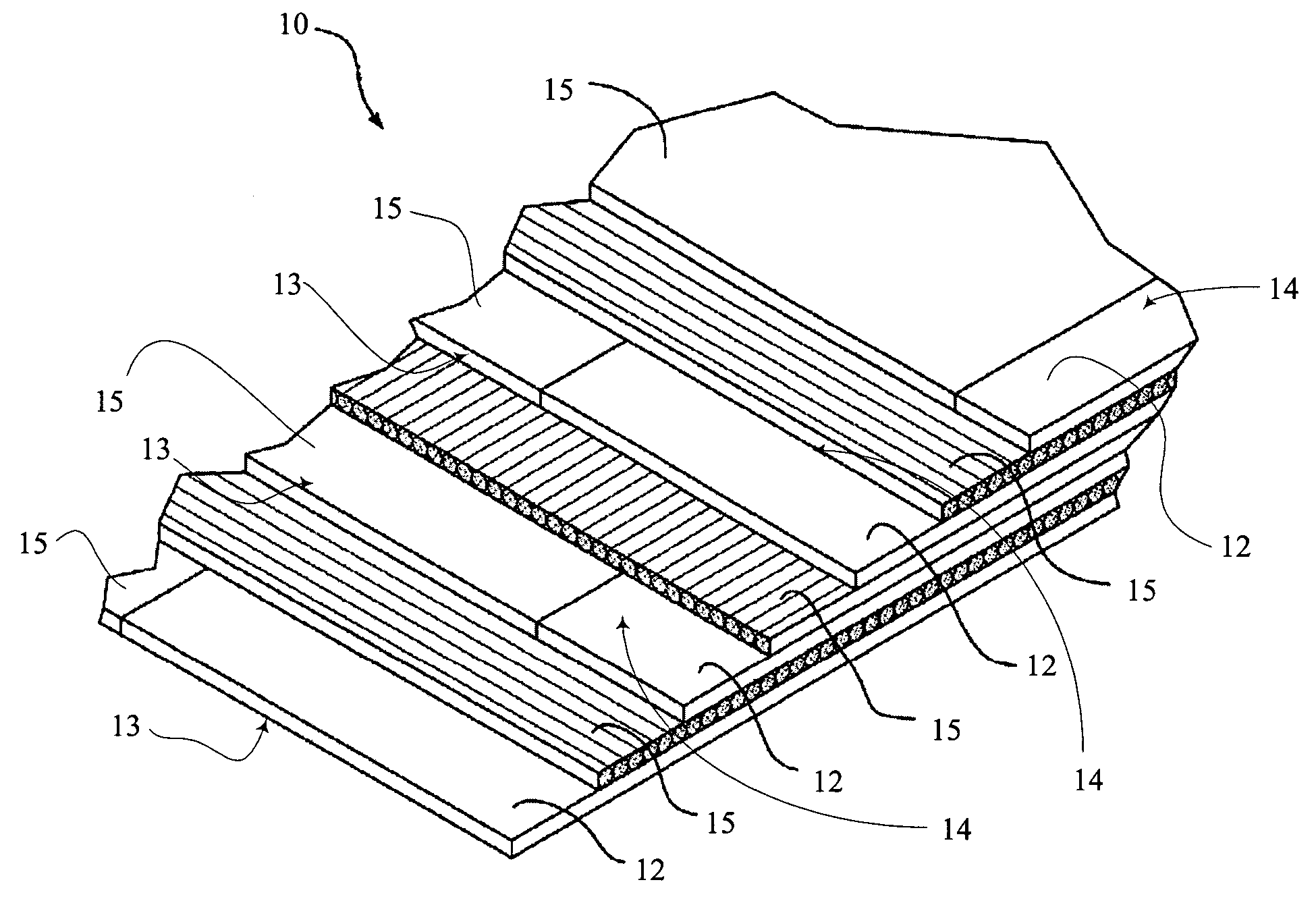

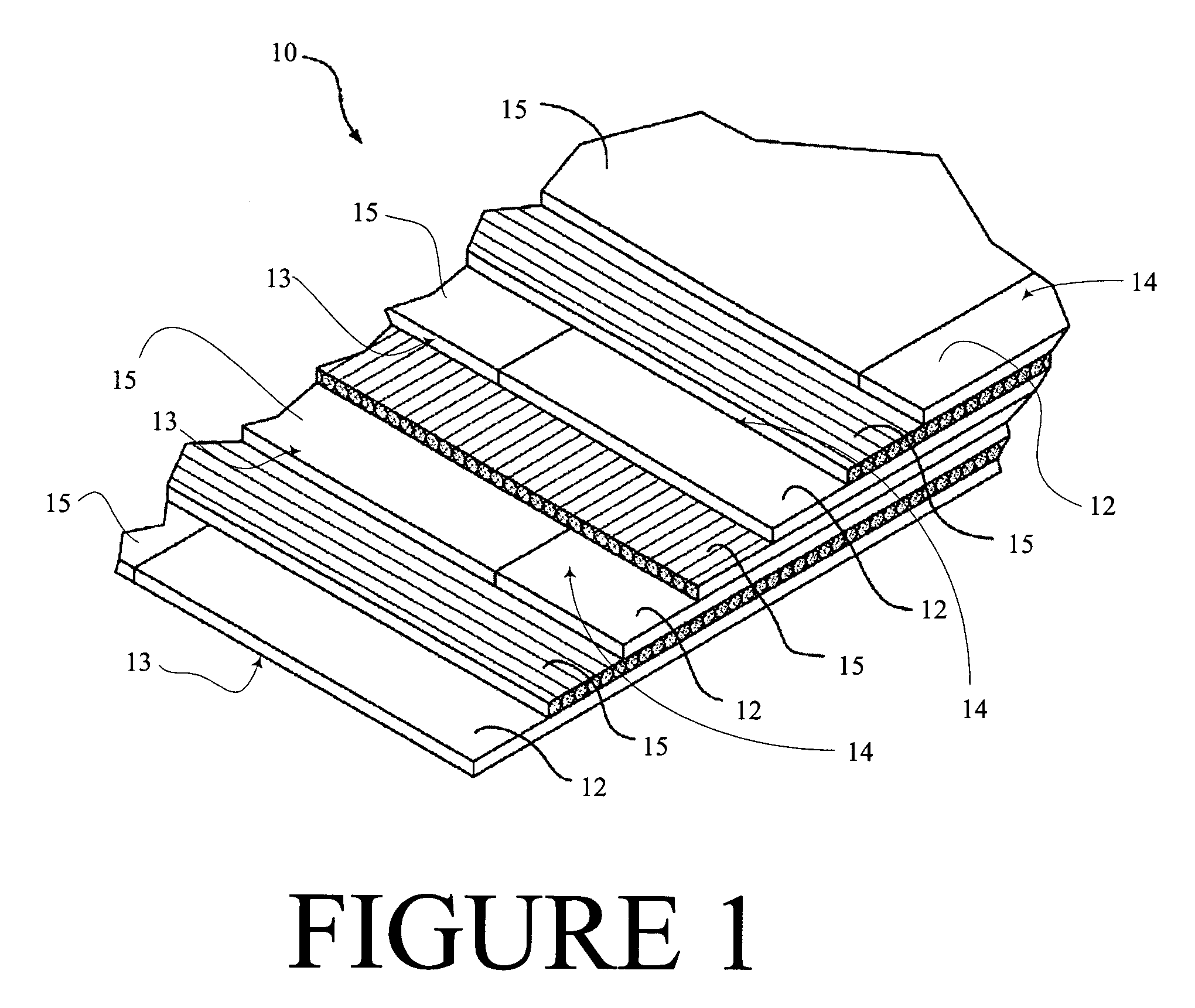

Titanium foil ply replacement in layup of composite skin

Laminate structures and methods for forming same are disclosed. In one embodiment, a laminate structure includes a metal-polymer composite lamina. The metal-polymer composite lamina has a first face and a second face spaced apart, and extends to a terminal edge. The lamina includes a ply of fiber-reinforced polymer that extends between the first face and the second face and has an interior edge. The interior edge defines at least one cutout. A ply of metal foil extends between the first face and the second face substantially from the interior edge filling the at least one cutout.

Owner:THE BOEING CO

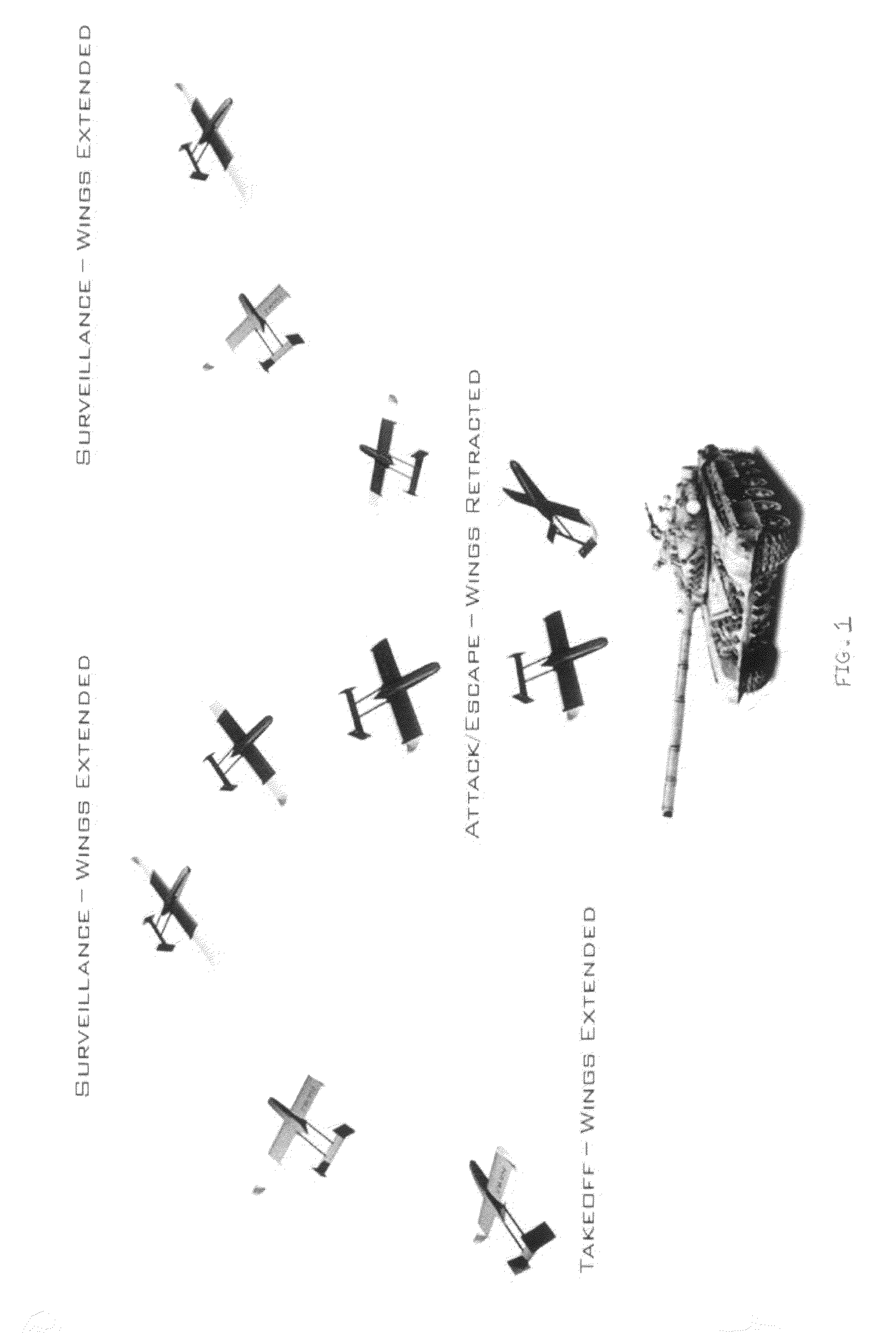

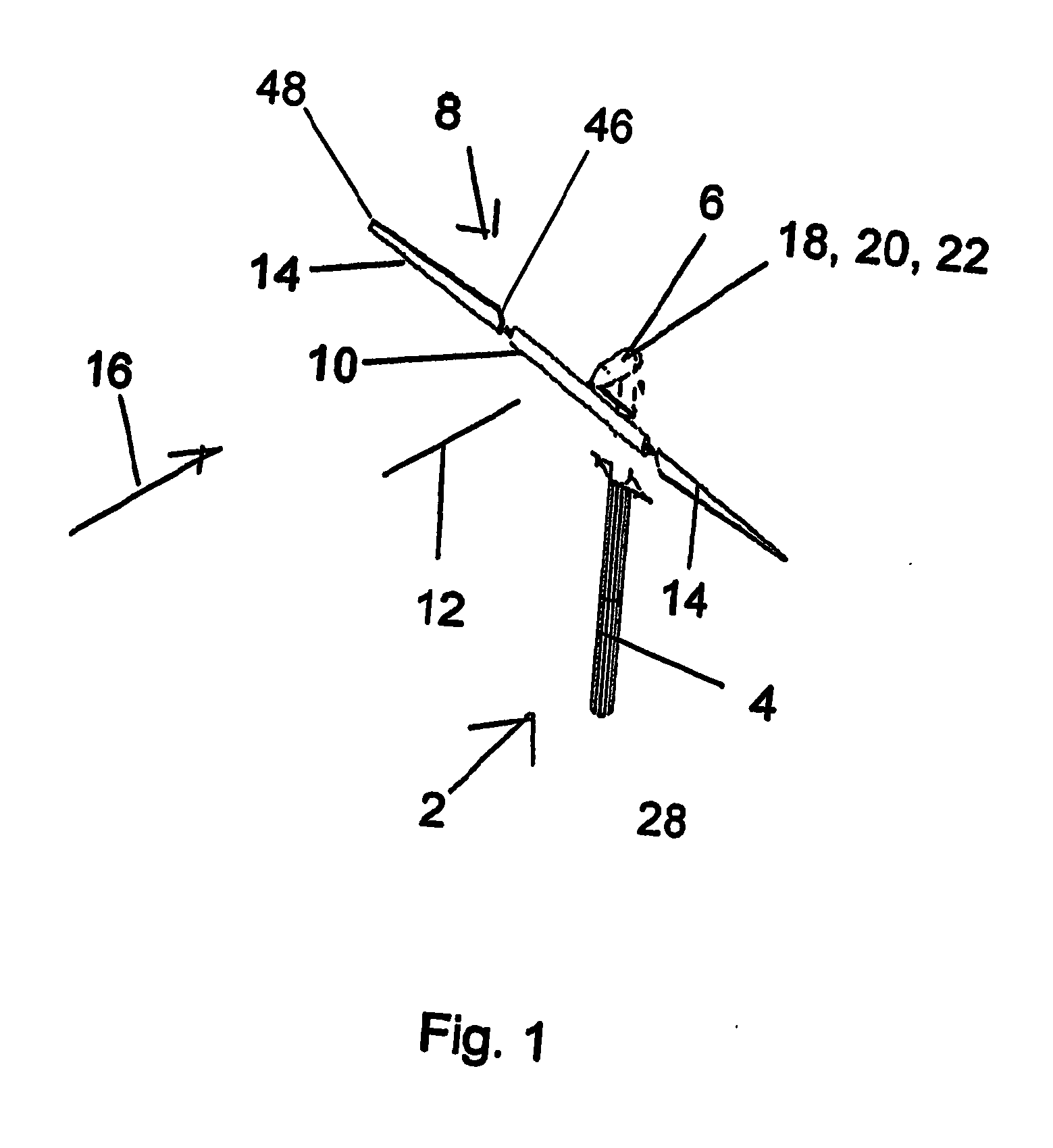

Telescoping and sweeping wing that is reconfigurable during flight

InactiveUS20110001016A1Encourage facilitate wider useEasy maintenancePower plant fuel tanksUnmanned aerial vehiclesComposite skinExtremity Part

Owner:SKILLEN ROBERT STEWART +2

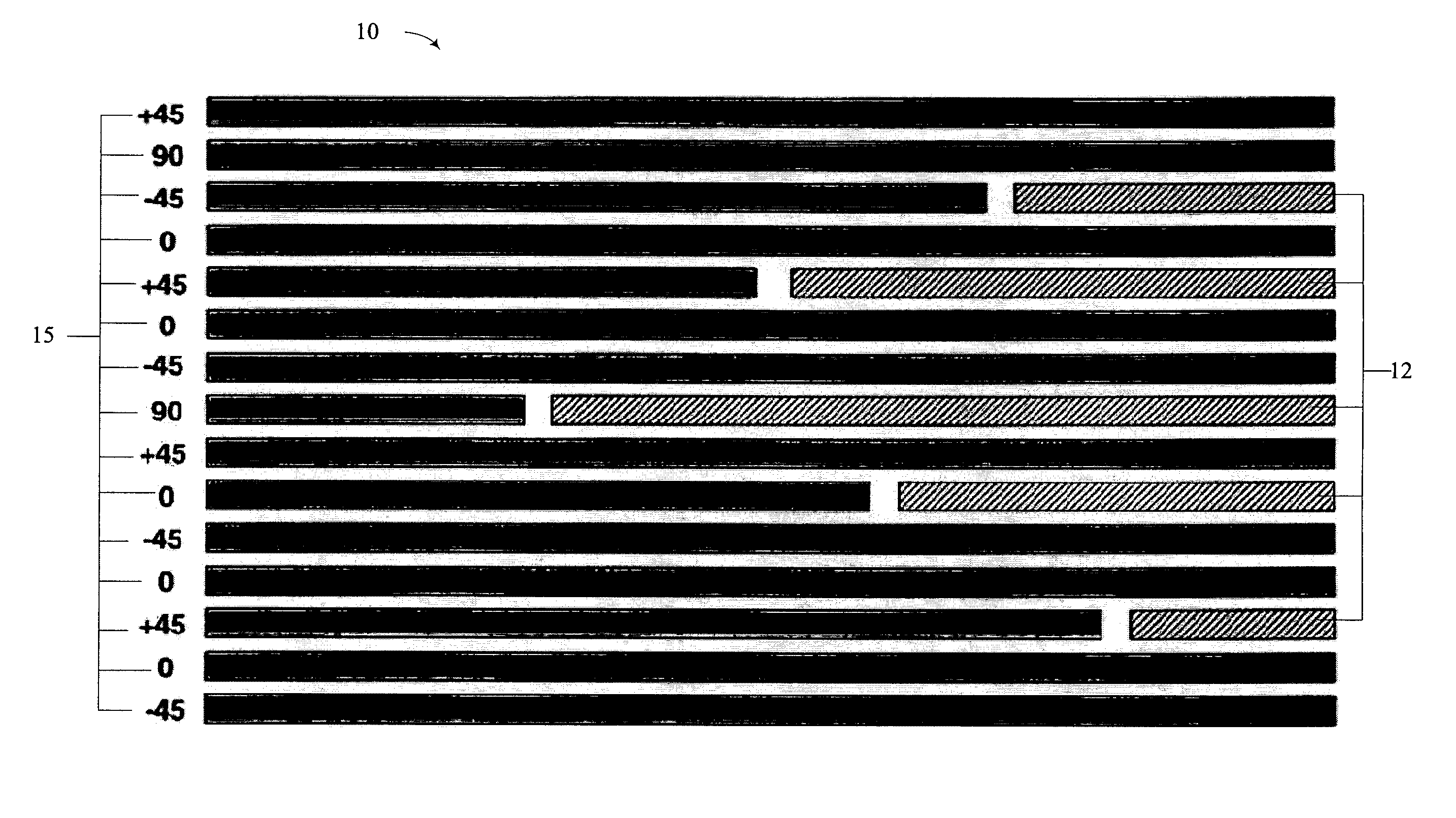

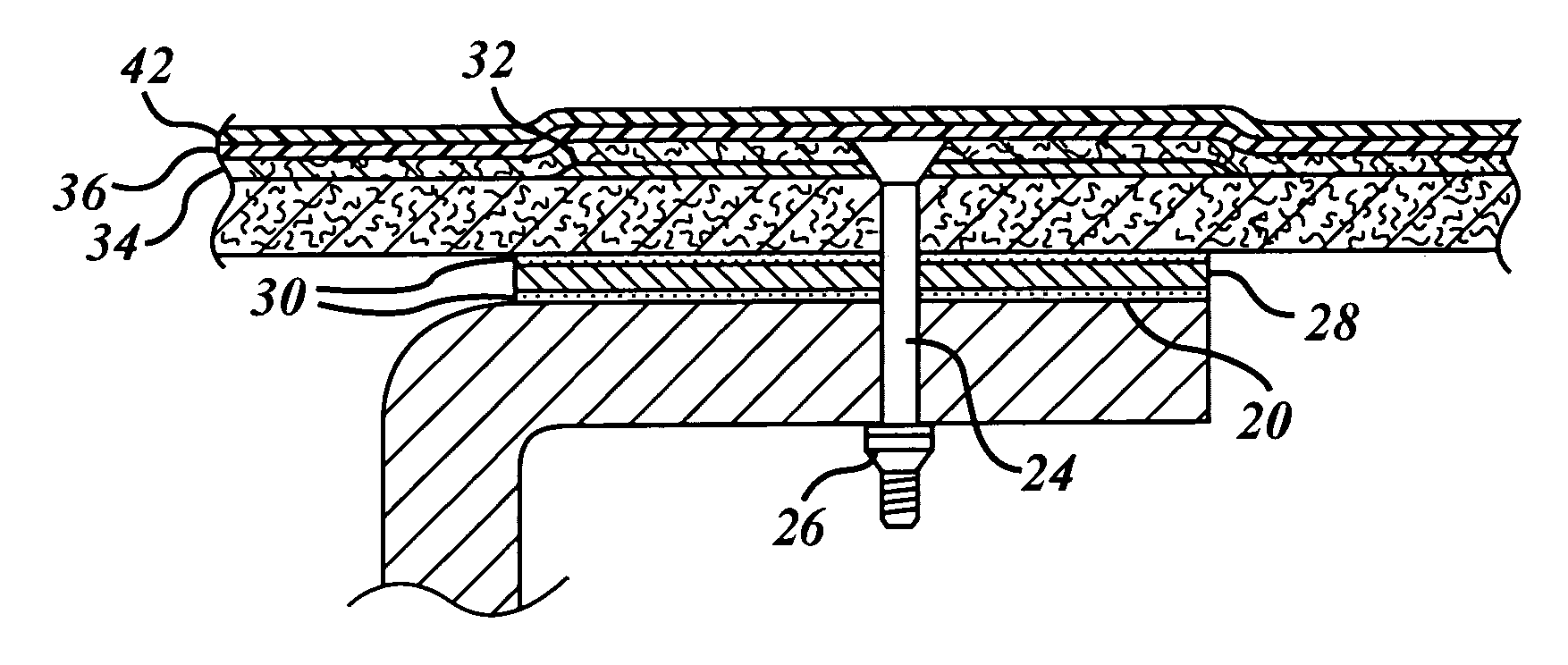

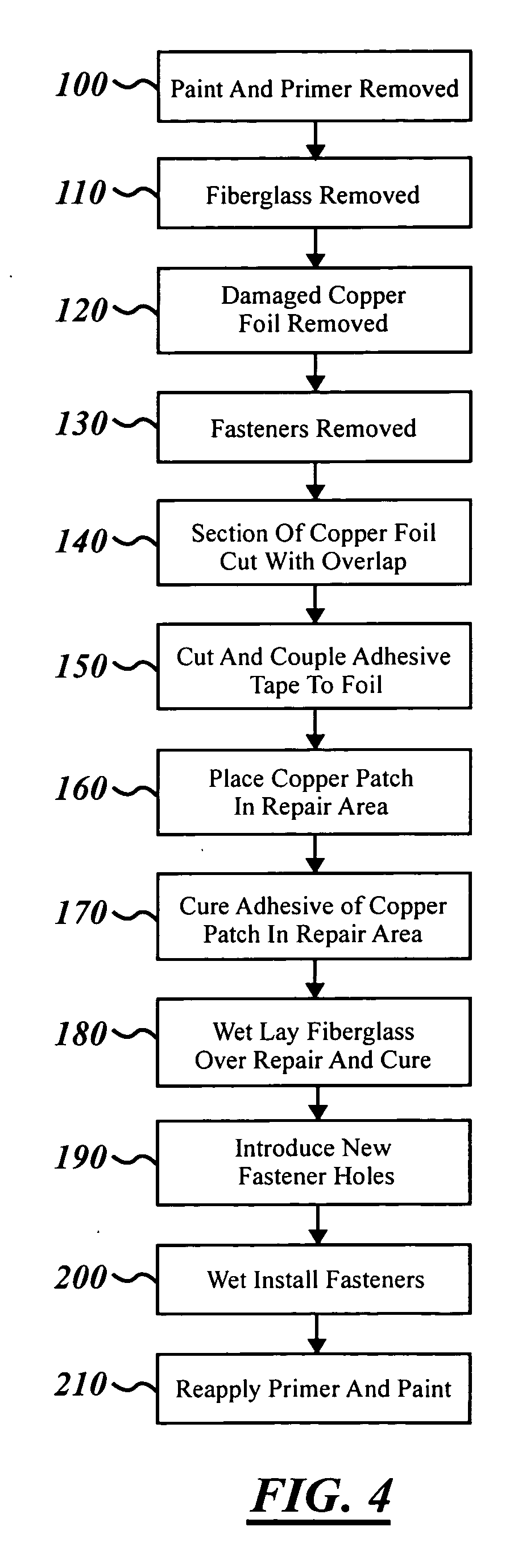

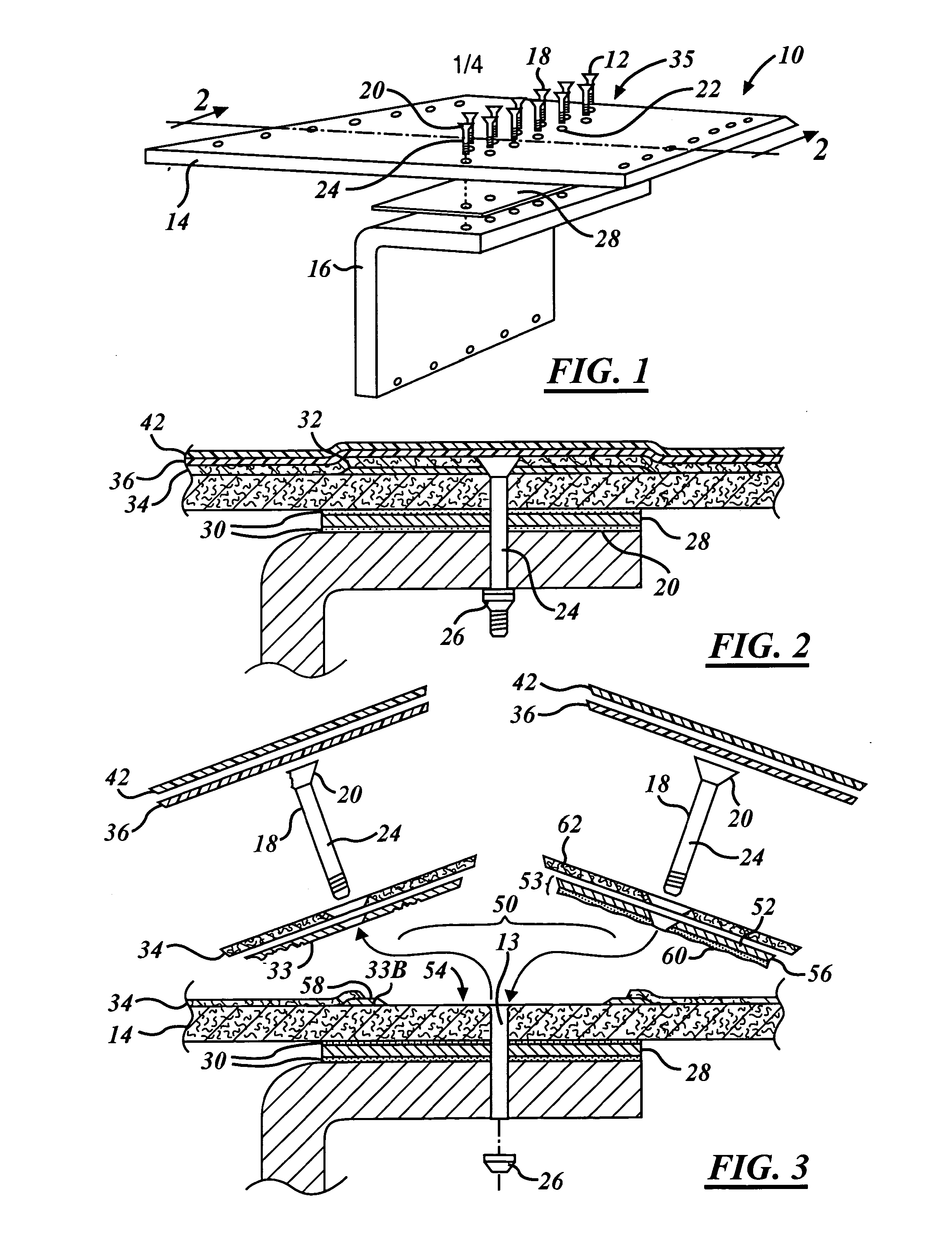

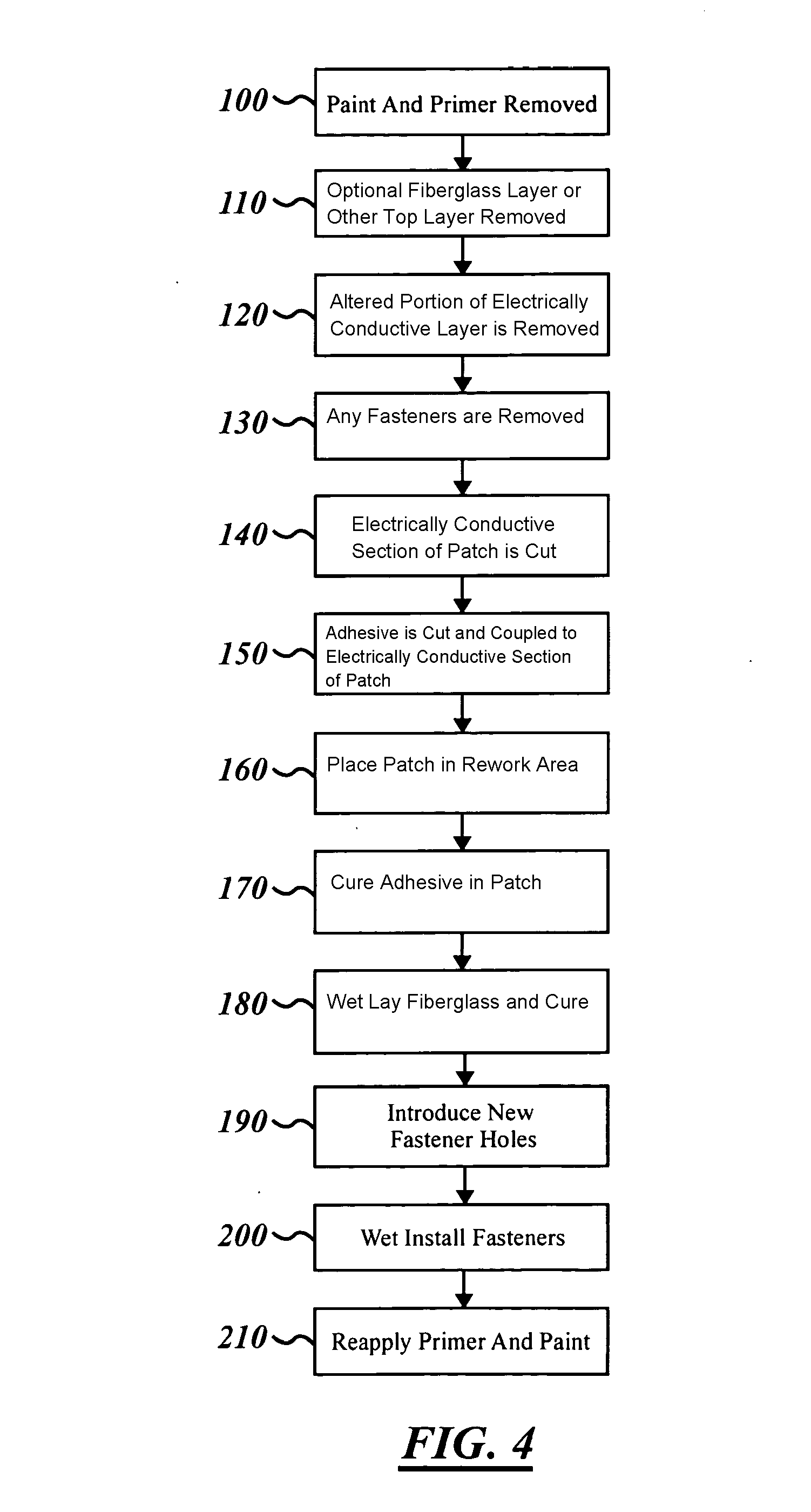

Copper grid repair technique for lightning strike protection

ActiveUS20070177330A1Quick and cost-effective repairMaintain integrityFuselage framesAircraft lighting protectorsGlass fiberLightning strike

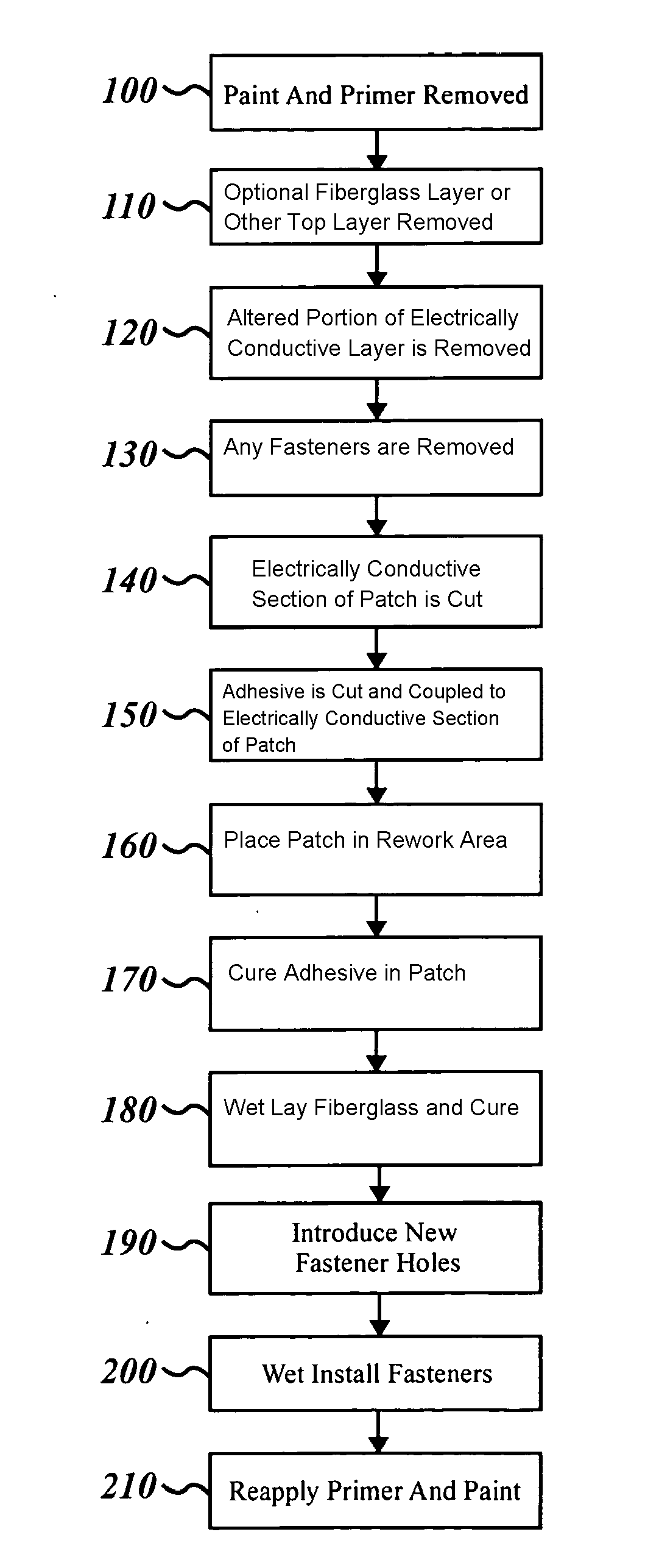

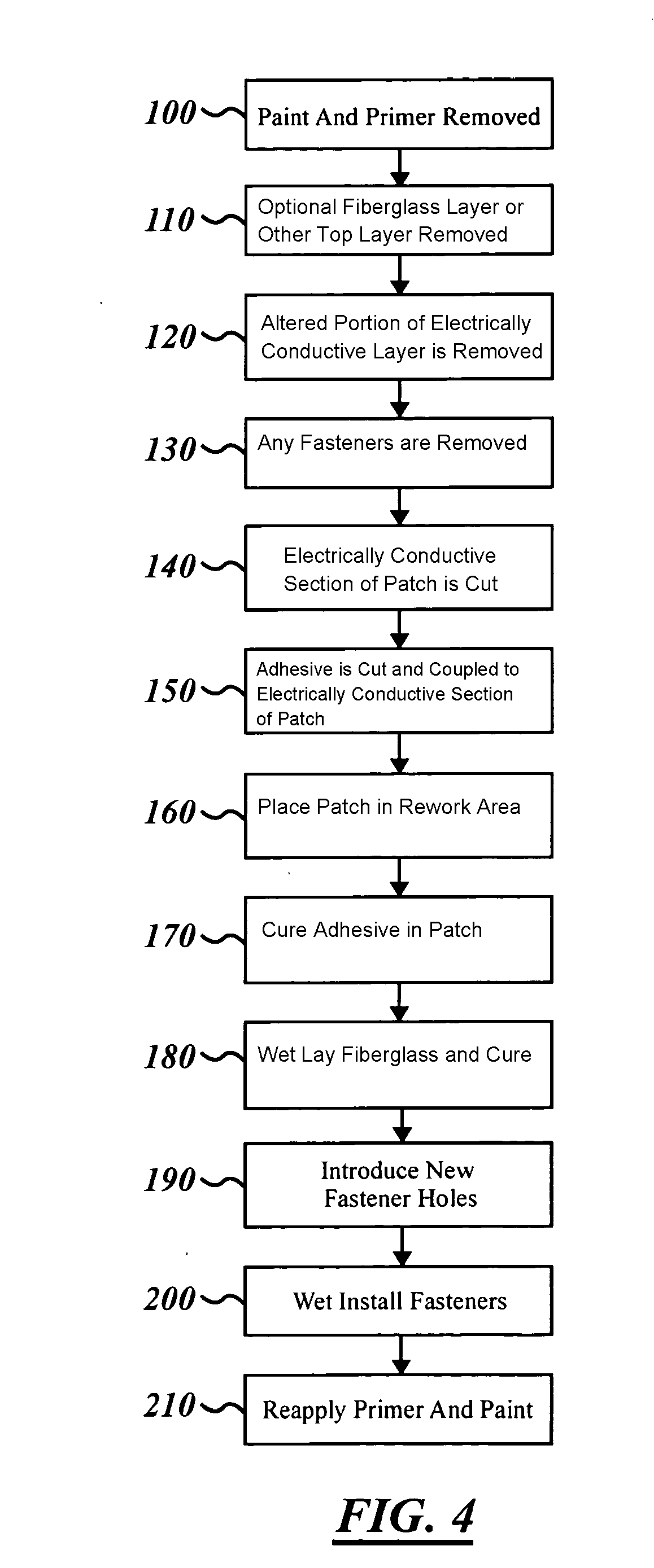

A method for reestablishing the electrical continuity of an electrically conductive layer of a composite aircraft wing damaged by a lightning strike or other mechanical event is disclosed in which a copper patch replaced the damaged section of the electrically conductive layer contained. The repair is performed by first removing any surfacers, fasteners, and damaged electrically conductive layer to expose a portion of the underlying composite skin. A copper patch having a copper foil section coupled to an unsupported film adhesive is then introduced onto an underlying composite skin opening contained within an undamaged section of a copper foil grid and covered with resin-impregnated fiberglass material. The film adhesive and resin-impregnated fiberglass material are then cured and fasteners are then reinserted within the fiberglass material, copper patch and underlying composite skin. The surface of the composite wing is then reprimed and repainted to complete the repair.

Owner:THE BOEING CO

Composite Manufacturing Method

InactiveUS20100239865A1Low costMinimize damageEngine sealsLamination ancillary operationsComposite skinBiomedical engineering

A method of manufacturing a panel, the panel comprising a composite skin and at least one composite stiffener, the method comprising: positioning first and second mandrels on opposite sides of the stiffener; positioning first and second compaction tools on opposite sides of the skin; and compacting the skin between the first and second compaction tools by moving one or both of the compaction tools, wherein the movement of the compaction tool(s) causes the first and second mandrels to move towards the stiffener along inclined paths so as to compact the stiffener between the mandrels.

Owner:AIRBUS OPERATIONS LTD

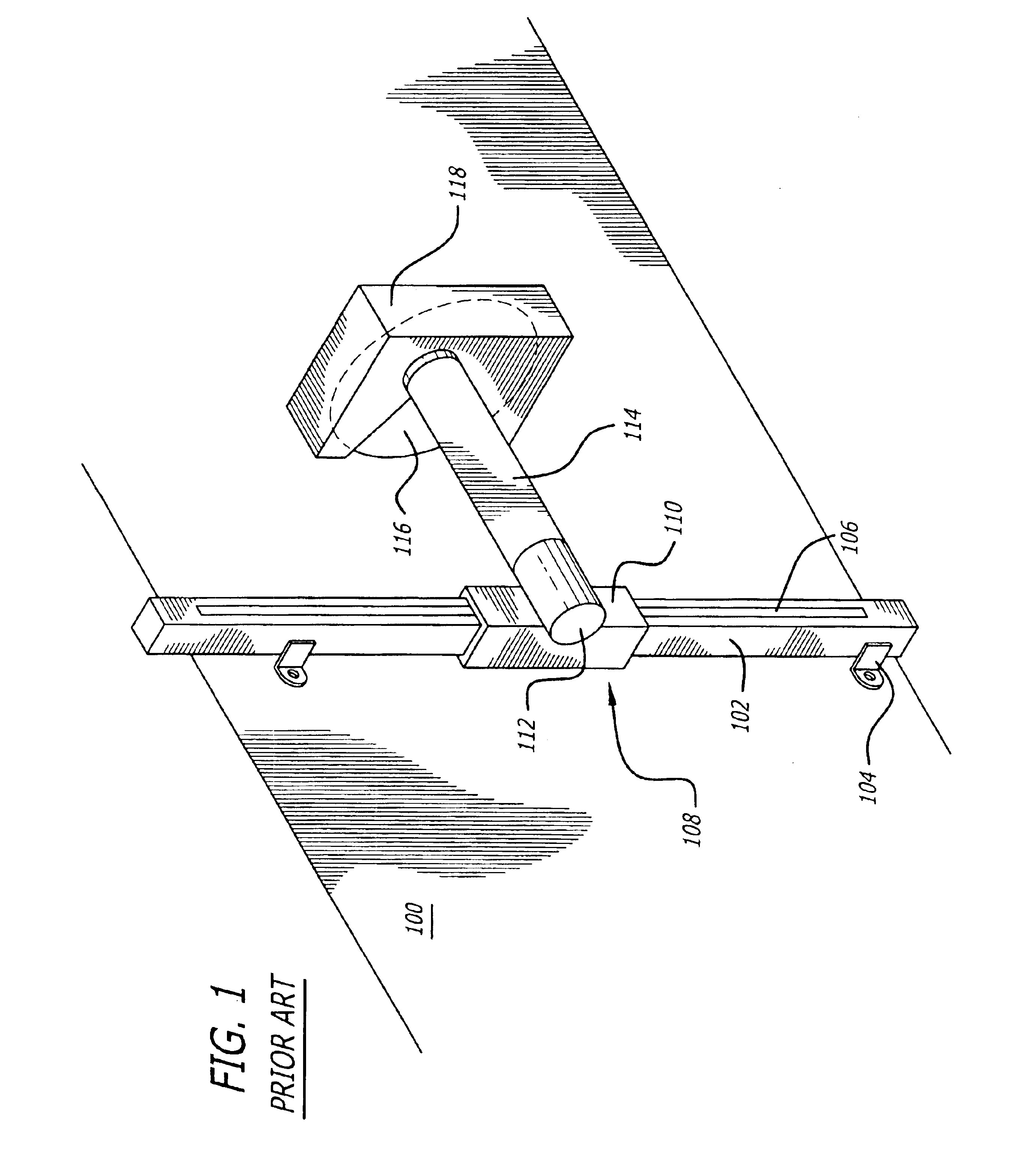

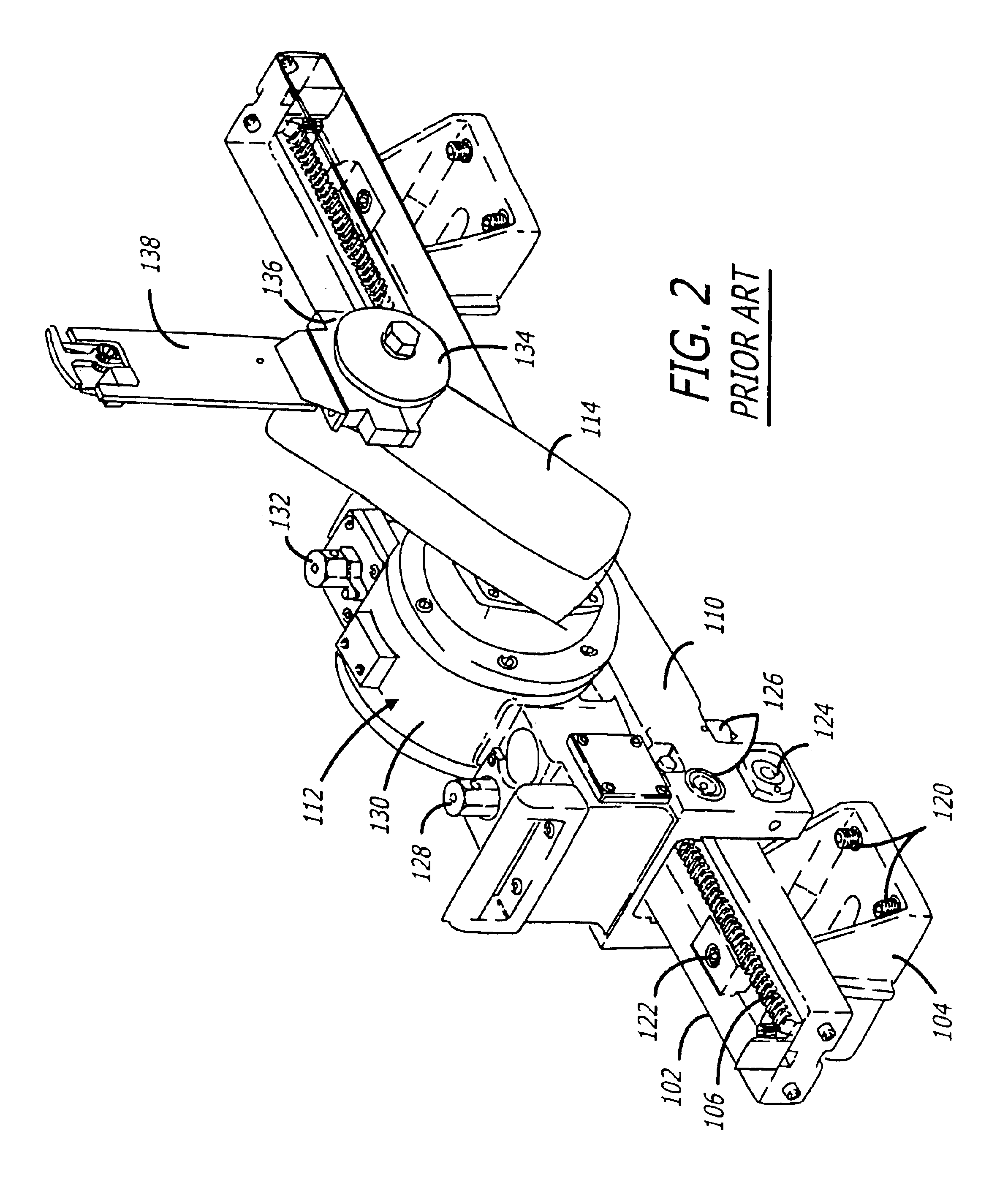

Pavement working apparatus and methods of making

InactiveUS6955167B2Versatile and easy to useHigh strengthMetal sawing devicesPortable power-driven toolsRoad surfaceComposite skin

A portable machine, for example a saw, has a light construction using composite materials such as fiber reinforced resins and a closed cell foam. The saw may have a housing formed from multiple skins of the composite materials in which in the closed cell foam. Metallic inserts may be used to bond to either or both of the foam and the composite skin to accept working components. A saw is also described which uses gears sharing the same support element.

Owner:HUSQVARNA AB

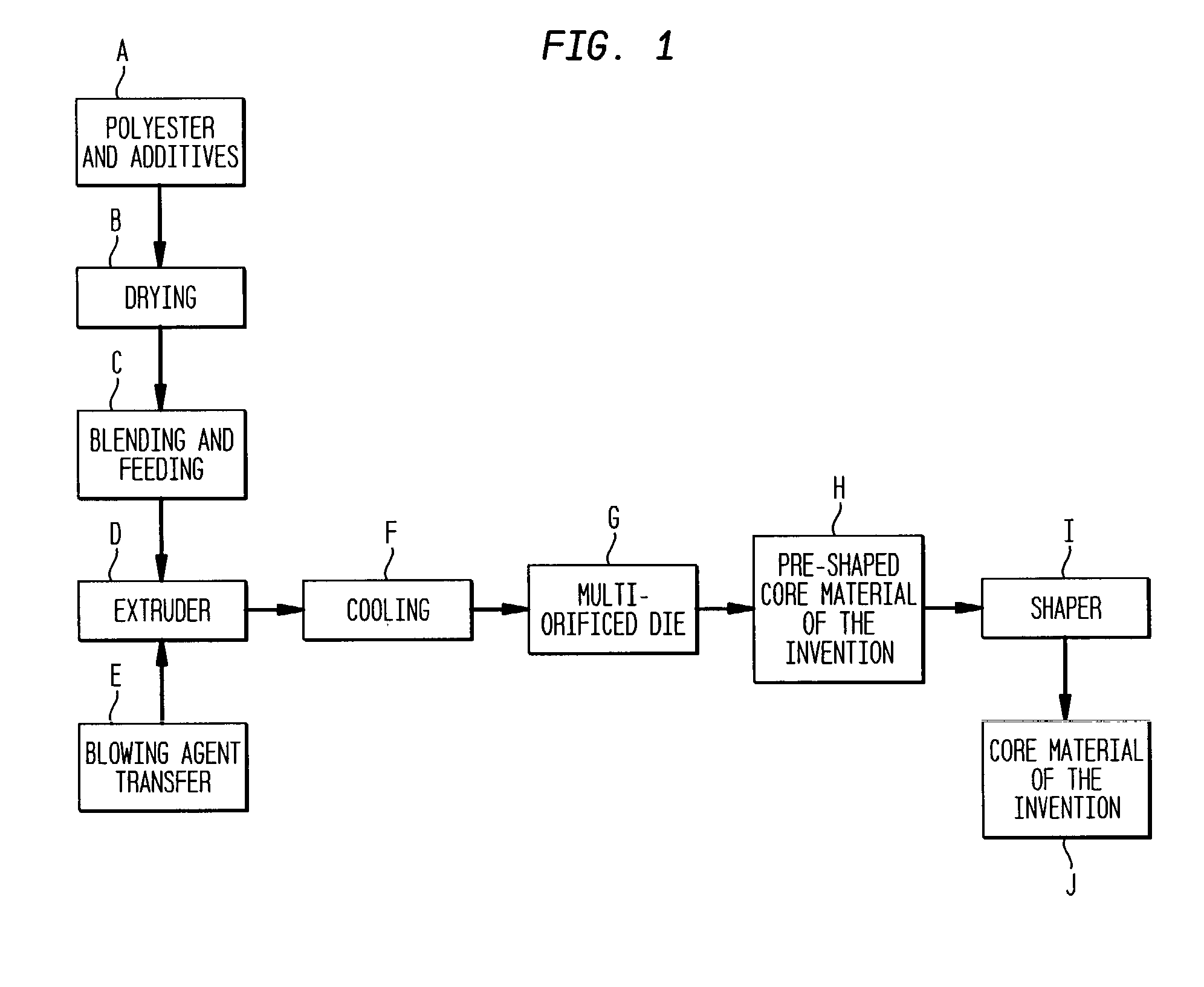

Polyester core materials and structural sandwich composites thereof

ActiveUS20040001946A1Increase resistanceImprove pressure resistanceSynthetic resin layered productsBuilding componentsPolyesterHigh intensity

High-strength, chemically and thermally stable, closed-cell foams, useful as structural core materials in sandwich composites. The core materials of the invention display anisotropic properties. The core materials of the invention are amenable to vacuum-mediated resin bonding to composite skins to provide lightweight, high-strength structural sandwiches suitable for use in a variety of applications, such as marine applications, construction, aviation, rapid transit, and recreational vehicles.

Owner:AIREX

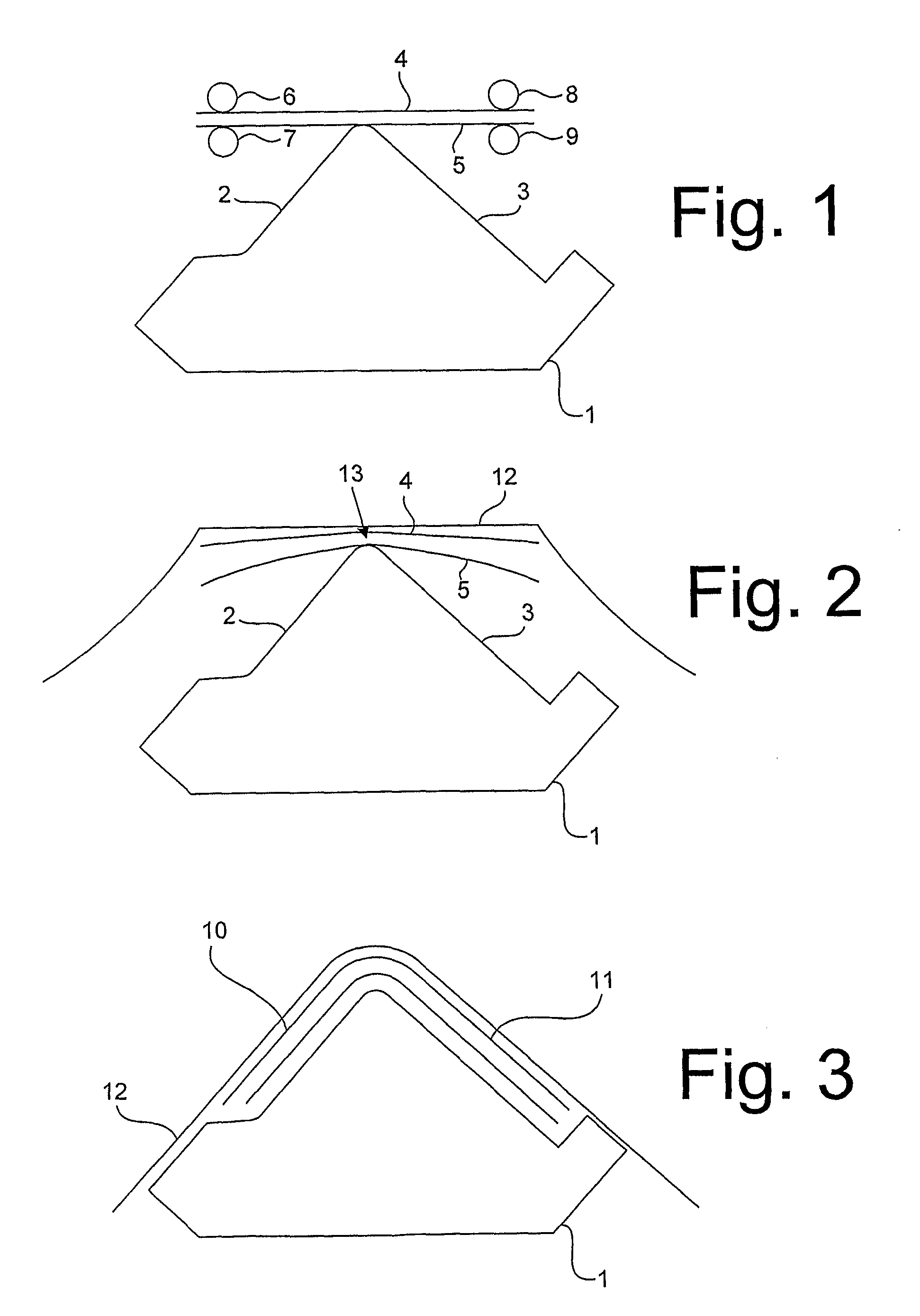

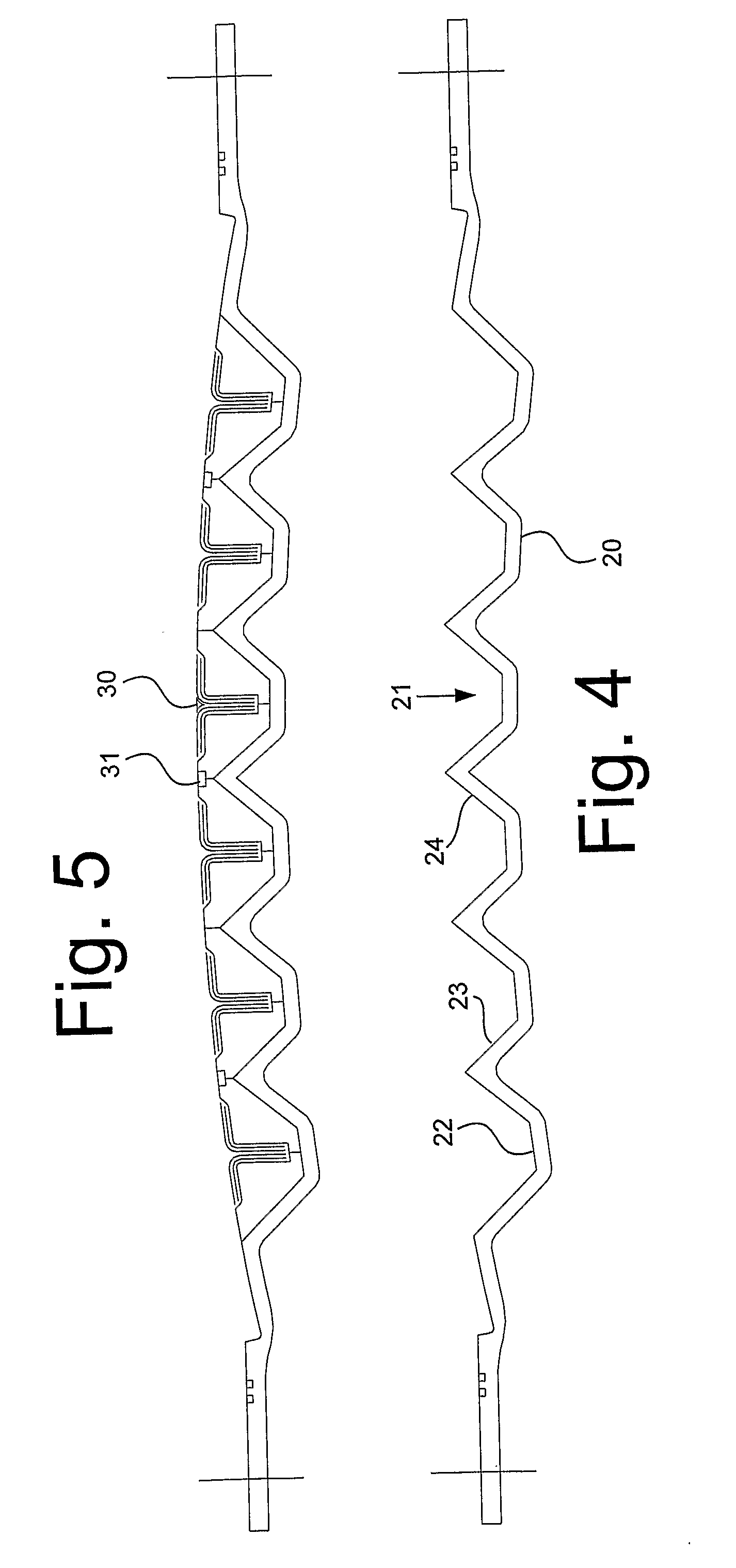

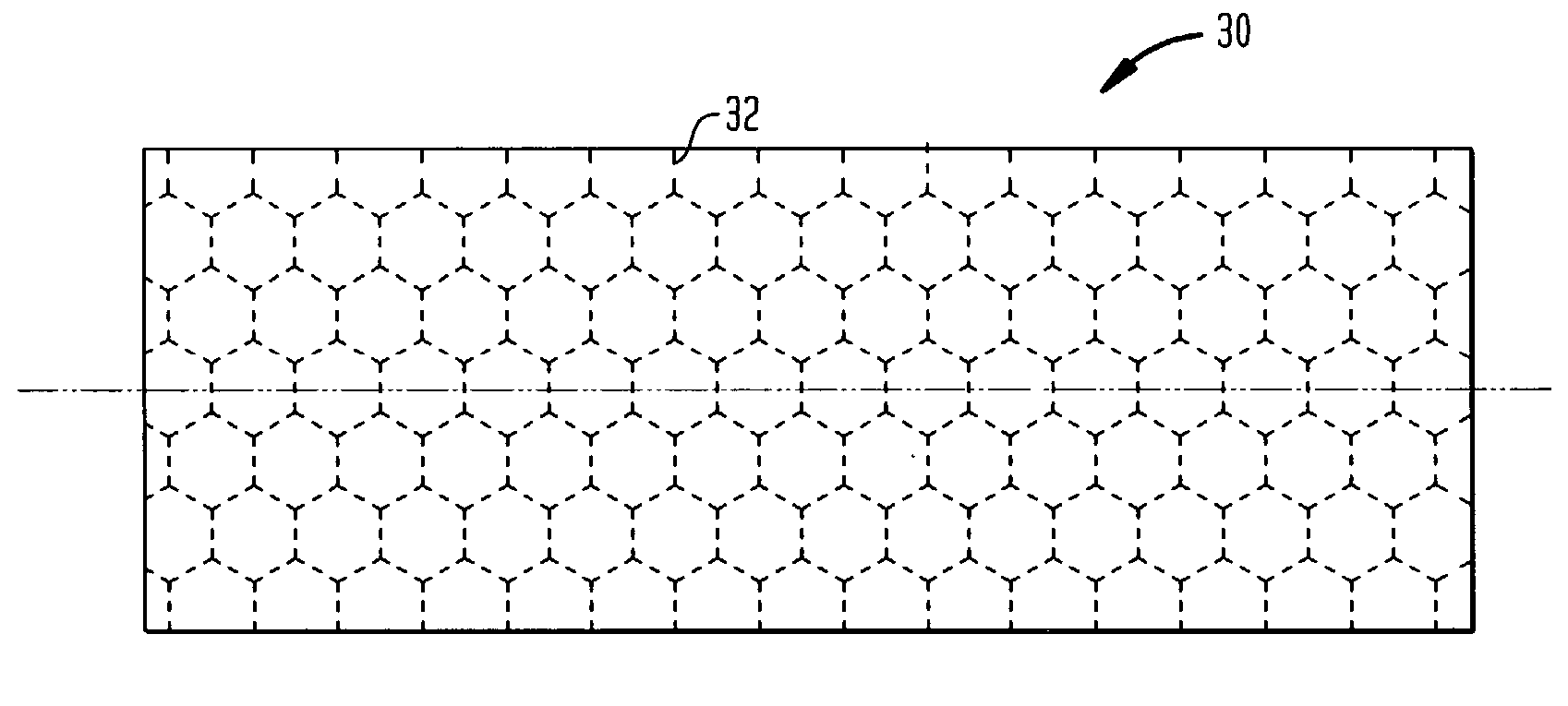

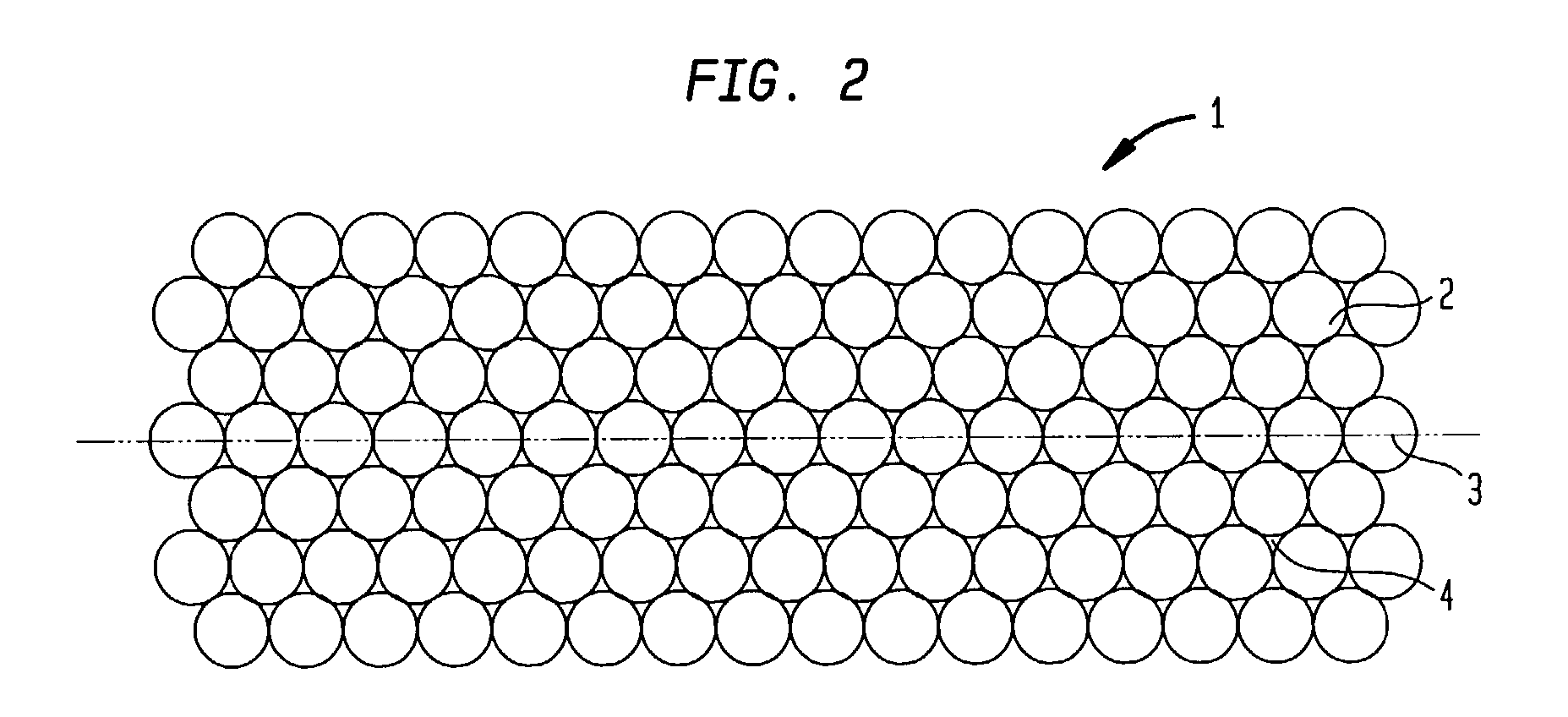

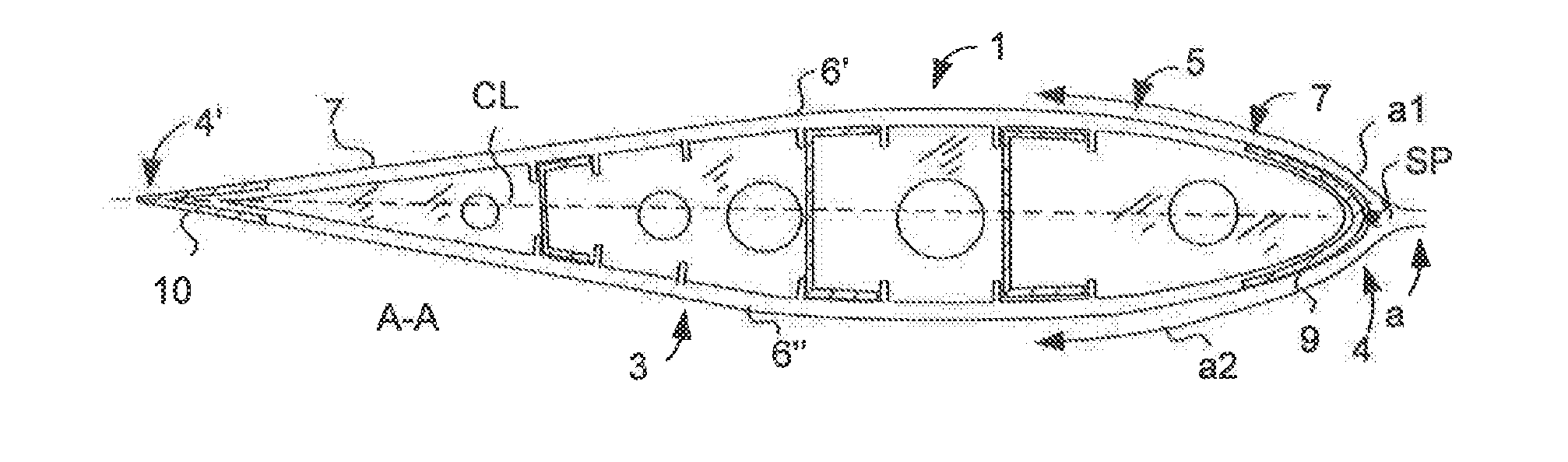

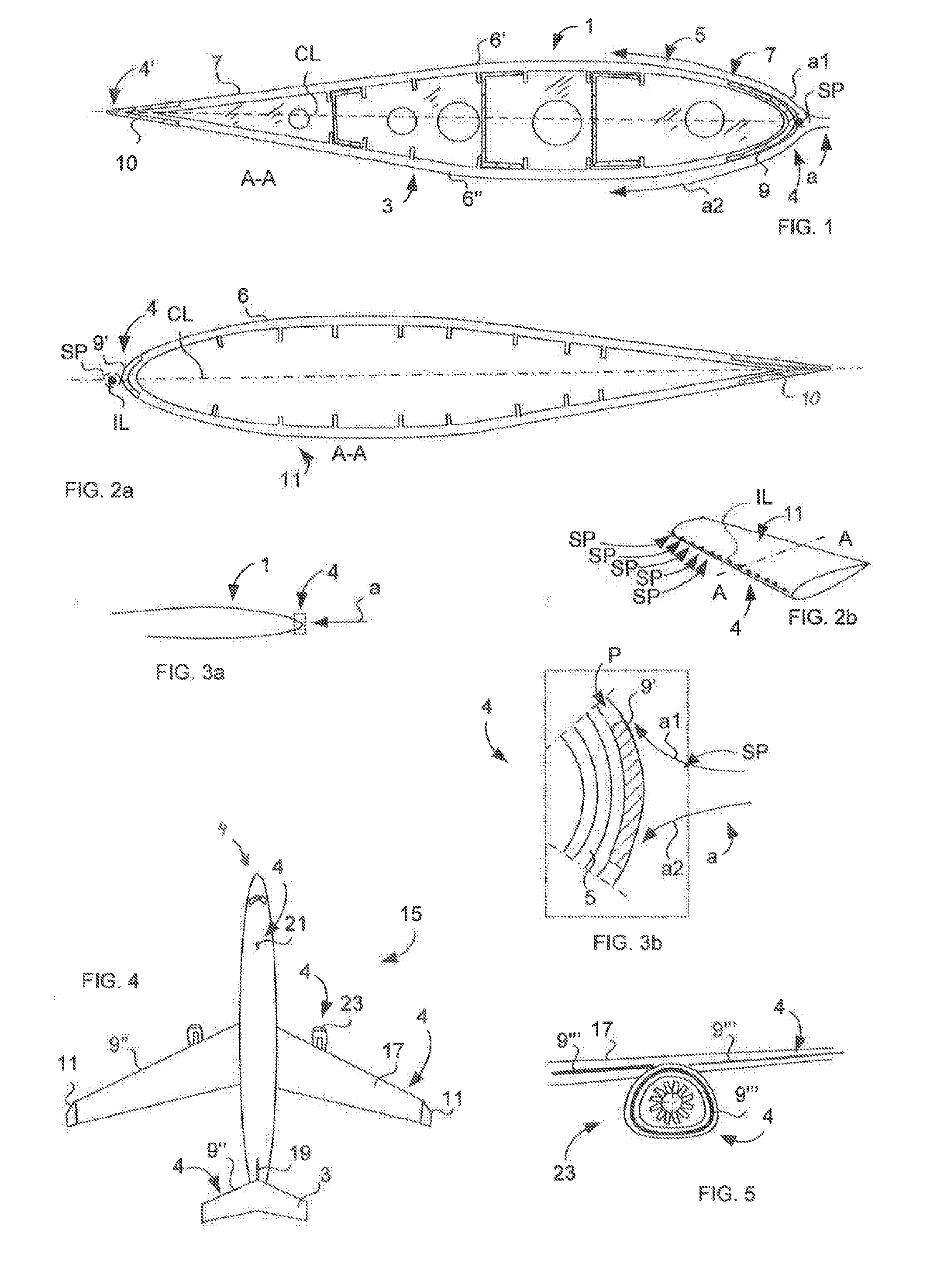

Adaptive composite skin technology (ACTS)

InactiveUS20050151015A1Large deflectionMaintain rigidityMilitary adjustmentEfficient propulsion technologiesEngineeringComposite skin

A tailorable elastic skin is provided for covering shape-changing, or “morphable,” structures. The skin comprises a two-dimensional “planar spring” embedded in an elastomeric material. The invention provides a smooth aerodynamic covering capable of global elongation exceeding 20% with a low input force. The design can be tailored for light-weight, lightly loaded applications, or for more heavily loaded aerodynamic or hydrodynamic conditions.

Owner:UNITED STATES OF AMERICA AS REPRESENTED BY

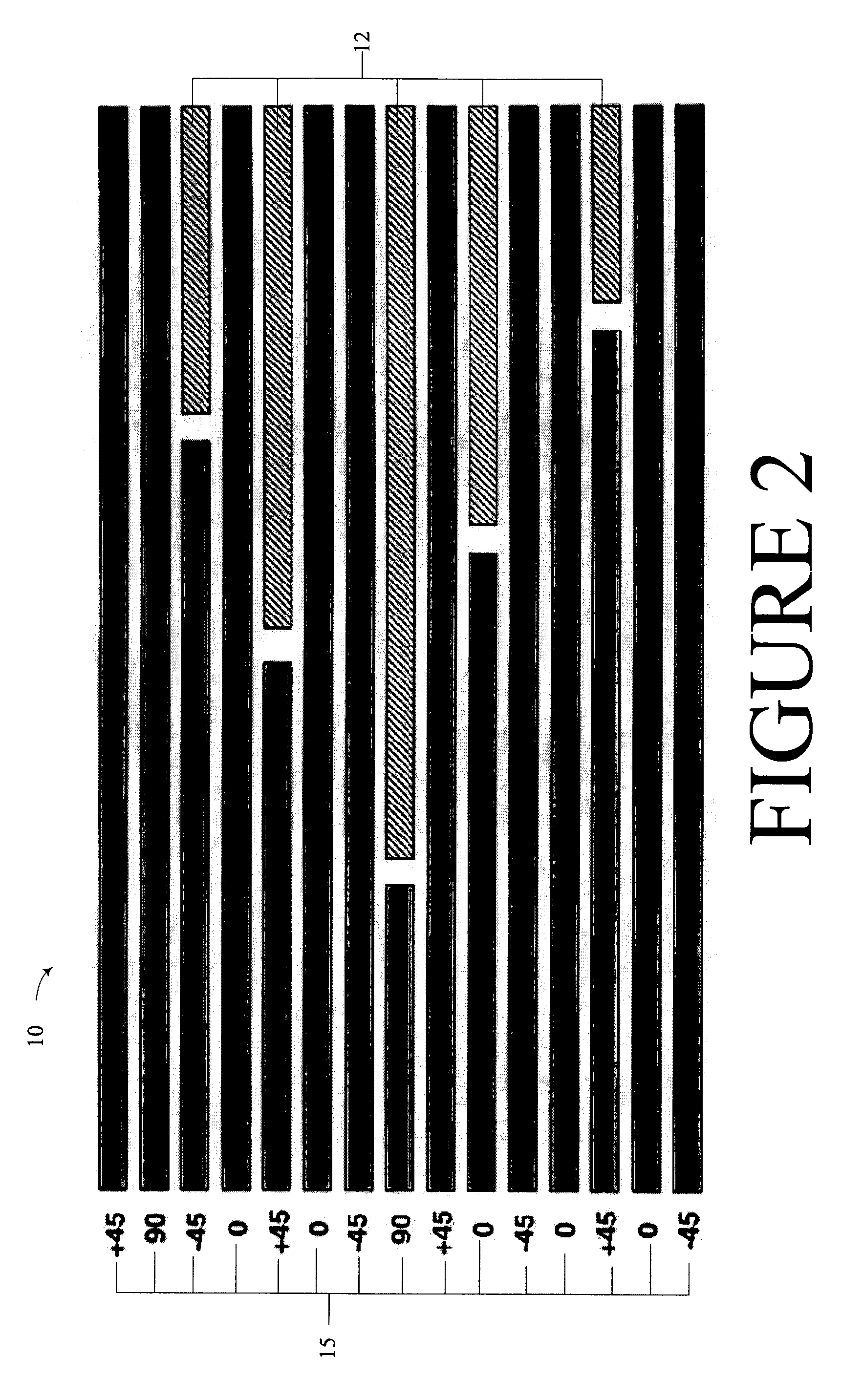

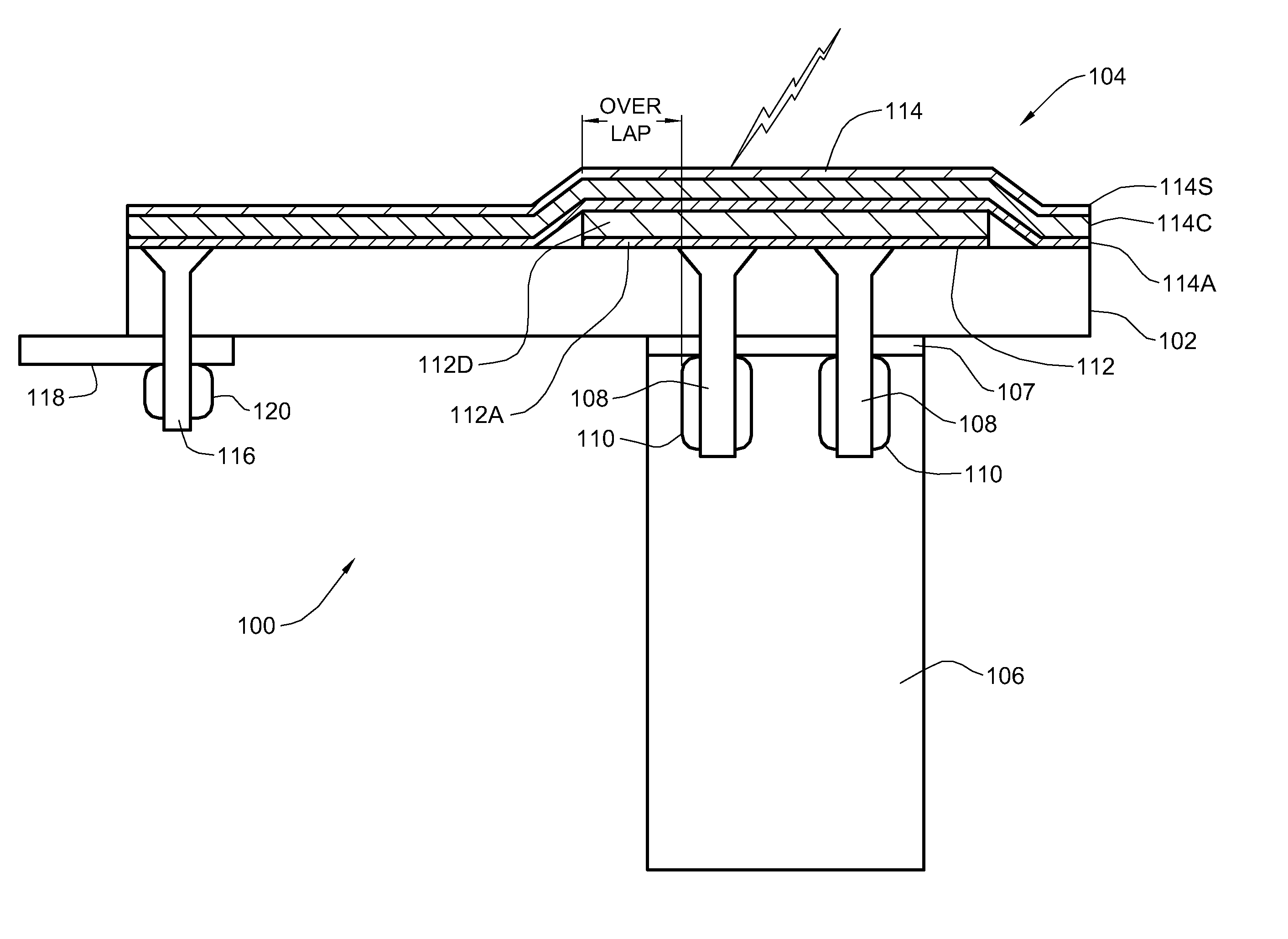

Copper grid repair technique for lightning strike protection

ActiveUS20110186206A1Low densityImprove dielectric breakdown strengthLamination ancillary operationsLaminationElectricityLightning strike

A method for reworking an electrically conductive layer of a composite skin is disclosed in which a patch replaces the altered section of the electrically conductive layer. The method is performed by removing a portion of the electrically conductive layer to reveal the underlying composite skin. A patch is formed, having an electrically conductive section coupled to an adhesive having a low dielectric breakdown strength, and is then introduced over the underlying composite skin such that the adhesive layer covers the underlying composite skin and overlaps an unremoved portion of the electrically conductive layer. The patch is applied such that the electrically conductive section within the patch covers the adhesive layer and overlaps the unremoved section of the electrically conductive layer. The adhesive layer preferably has a low dielectric breakdown strength, so that electricity from lightning which strikes the composite skin may be conducted through the adhesive.

Owner:THE BOEING CO

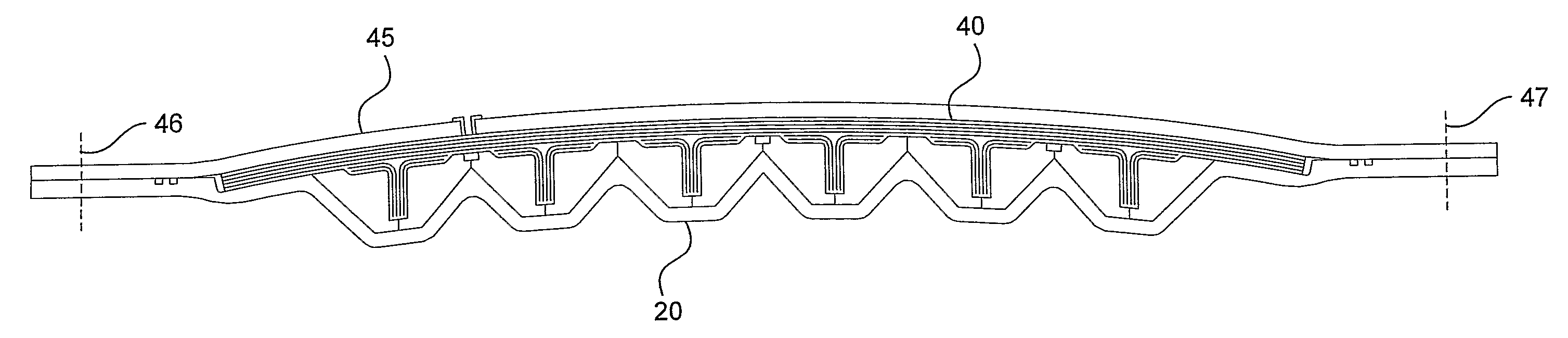

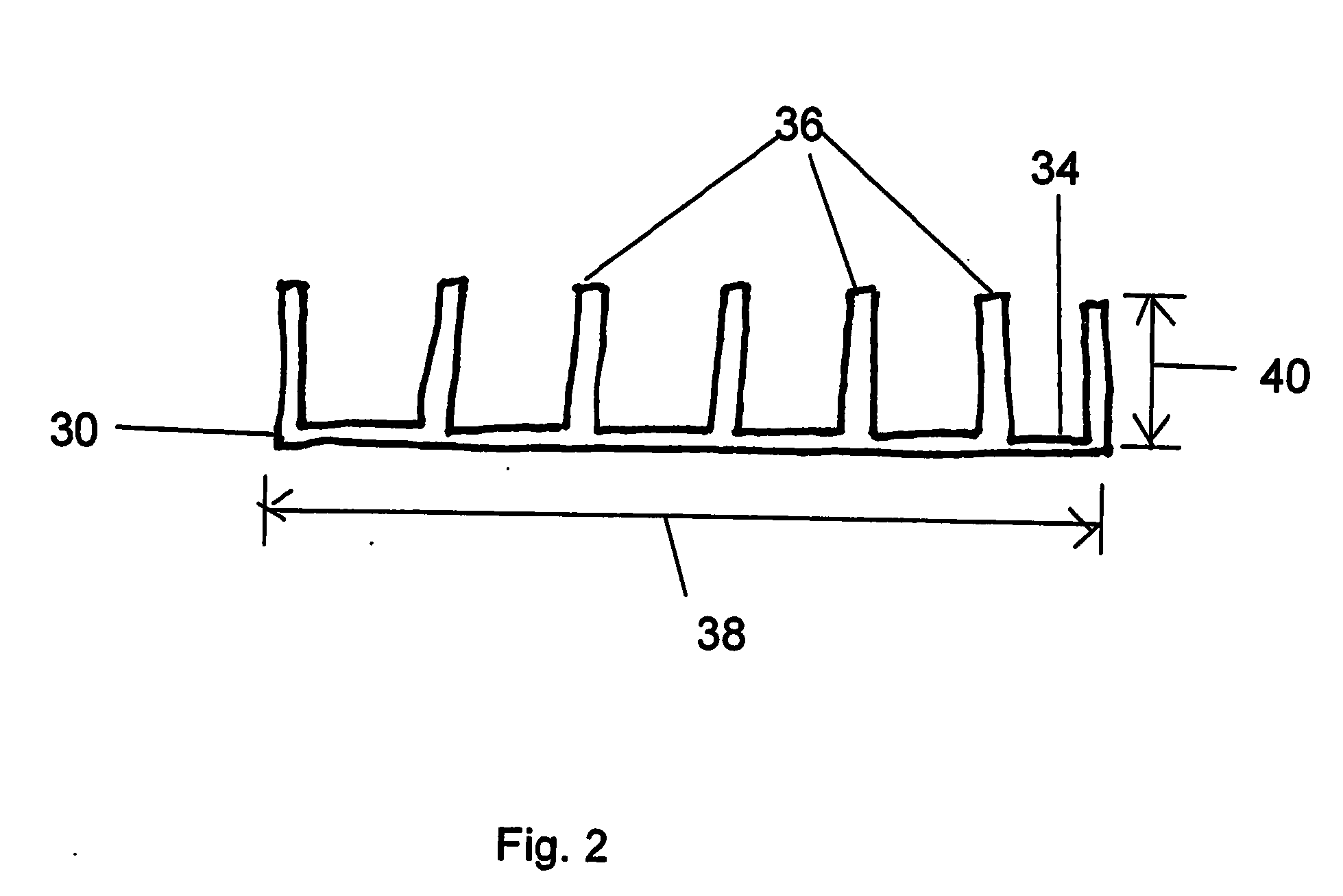

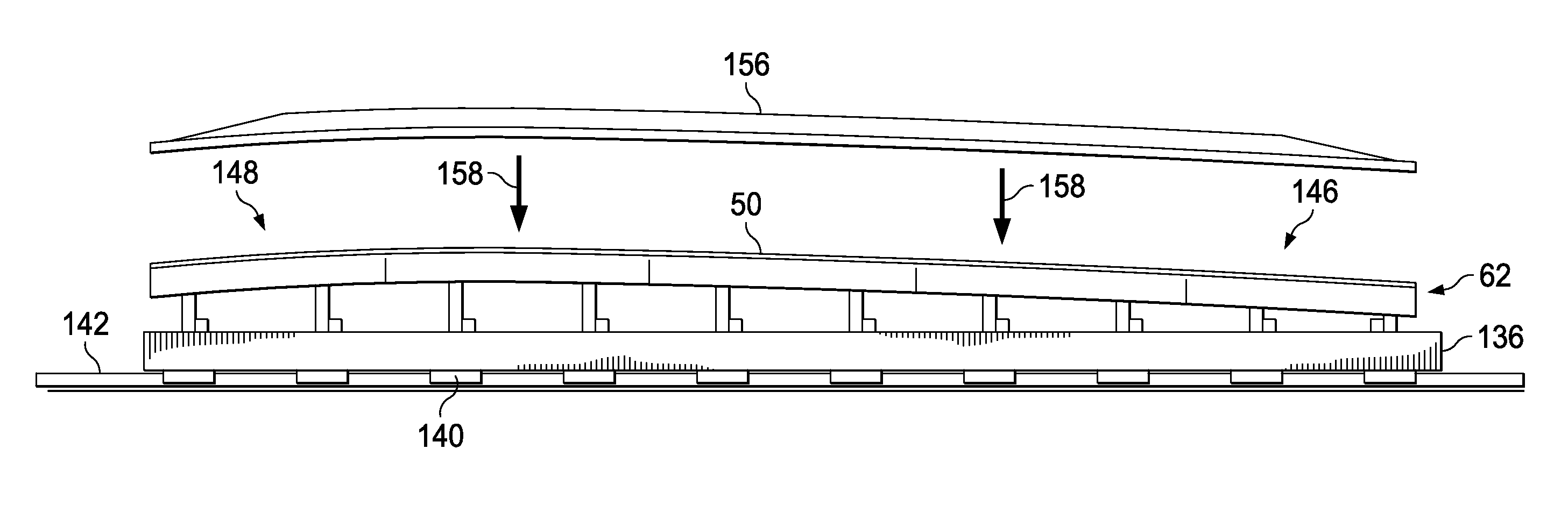

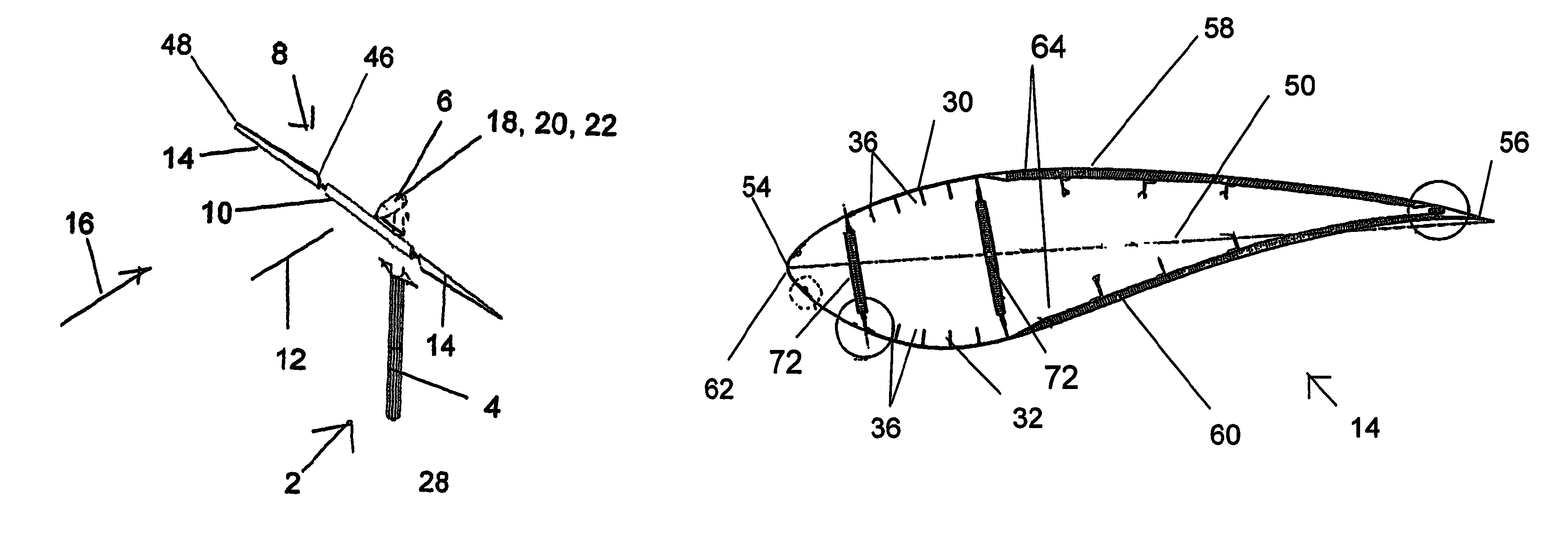

Highly Reliable, Low Cost Wind Turbine Rotor Blade

A wind turbine rotor blade and a wind turbine incorporating the rotor blade include a first and second composite skin. A first and a second spar pultrusion having a base and a plurality of integral ribs generally normal to the base are attached to the inside surface of the first and second composite skins and extend the span of the rotor blade. At least one shear web connects a rib of the first spar pultrusion to a corresponding rib of the second spar pultrusion. The width of the spar pultrusions decreases in a step-wise fashion along the span of the rotor blade from the root to the tip. The leading or trailing edge of the rotor blade may be selectably opened for inspection and repair.

Owner:PIASECKI AIRCRAFT CORP

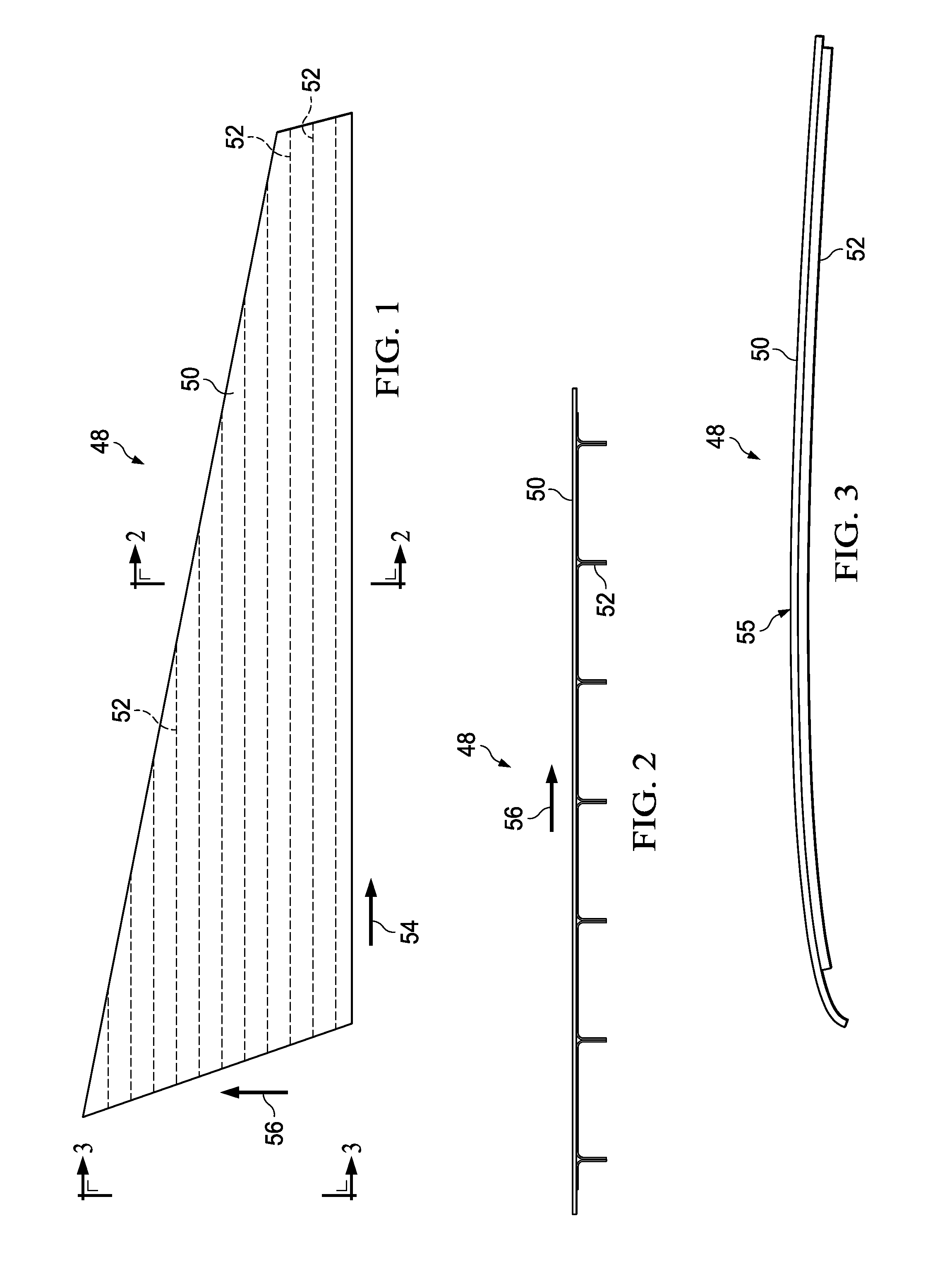

Bonded Composite Airfoil and Fabrication Method

ActiveUS20130320142A1Quality improvementEasy to produceAircraft stabilisationLaminationEngineeringComposite skin

An airfoil includes at least one precured composite spar having a web and at least one flange integrated with an end of the web. A precured composite skin is attached to the spar by adhesive bonding the skin to the flange.

Owner:THE BOEING CO

Composition Based on Plasticized PVC Thermoplastic Resins for the Production of Composite Skins for Vehicle Passenger Compartment Parts

The present invention relates to a composition based on plasticized polyvinyl chloride (PVC) thermoplastic resins for producing a layer of a composite structure or skin, said layer being provided on its outer surface with a coating, characterized in that the composition comprises, expressed as percent by weight: —from 40% to 60% of one or more PVC resins with a K value of between 50 and 80. —from 30% to 50% of one or more types of plasticizers, at least one of which is polymeric in nature, or is a heavy monomeric plasticizer, —from 1% to 20% of additives, such as pigments or fillers, stabilizers, antioxidants, processing additives and lubricants. The invention also provides the process for producing these composite skins by moulding, and their use for parts of the passenger compartment of automotive vehicles, such as, in particular, airbag-equipped dashboards.

Owner:ARKEMA FRANCE SA

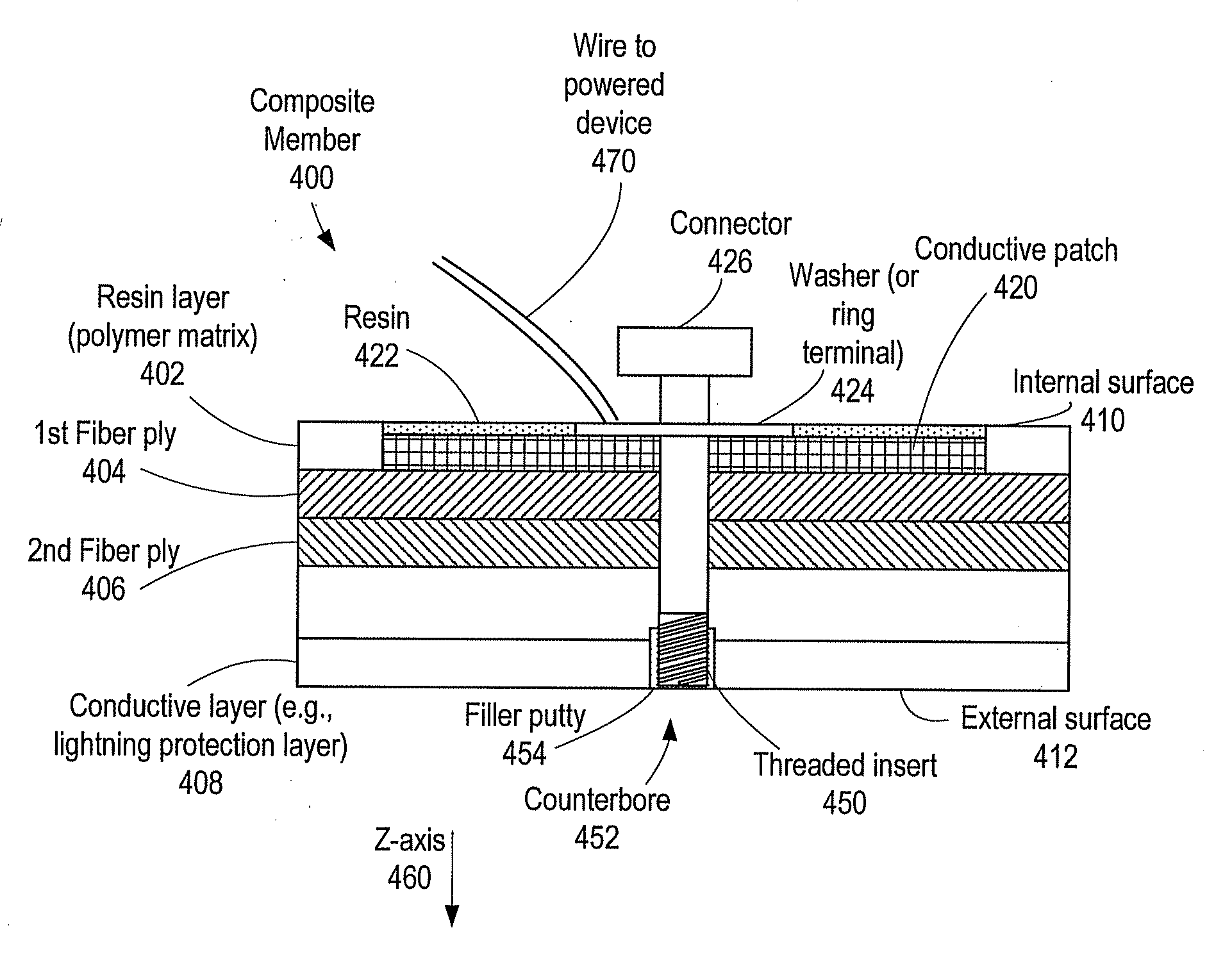

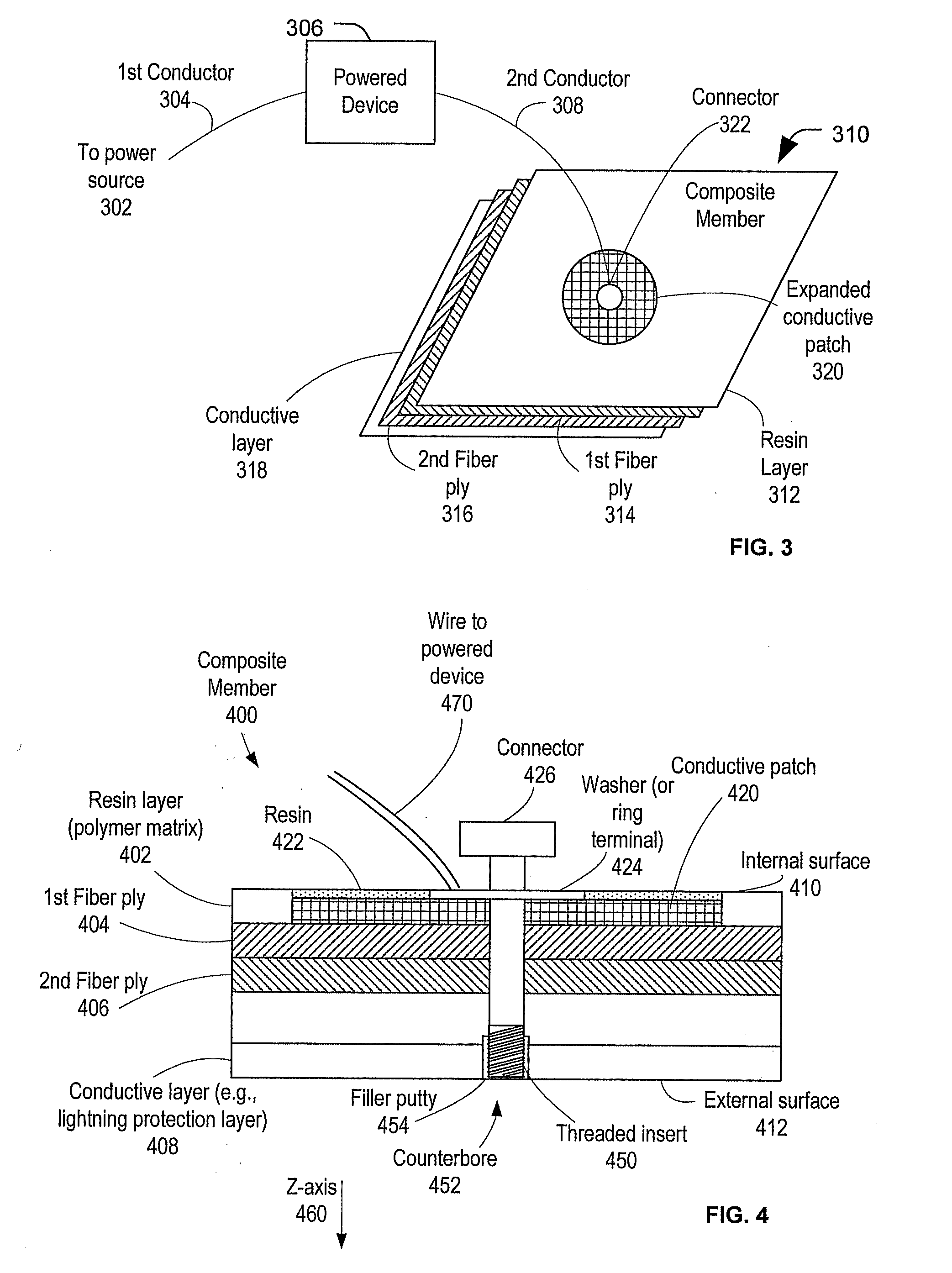

Distributing Power in Systems Having a Composite Structure

Systems and methods to distribute power in a system having a composite structure are provided. A particular aircraft includes a fuselage having a composite skin. The composite skin includes a first resin and a plurality of fibers. The fuselage also includes an expanded conductive patch bonded to an interior surface of the composite skin by a second resin. The expanded conductive patch is in electrical contact with the plurality of fibers. The fuselage also includes a connector in electrical contact with the expanded conductive patch.

Owner:THE BOEING CO

Titanium foil ply replacement in layup of composite skin

Laminate structures and methods for forming same are disclosed. In one embodiment, a laminate structure includes a metal-polymer composite lamina. The metal-polymer composite lamina has a first face and a second face spaced apart, and extends to a terminal edge. The lamina includes a ply of fiber-reinforced polymer that extends between the first face and the second face and has an interior edge. The interior edge defines at least one cutout. A ply of metal foil extends between the first face and the second face substantially from the interior edge filling the at least one cutout.

Owner:THE BOEING CO

Lightning protection system for composite structure

ActiveUS20070236855A1Reduce lightning damageImprove protectionAircraft lighting protectorsEmergency protective arrangement detailsLightning strikeFuel tank

A lightning protection system for protecting composite structures and a method of protecting composite structures from lightning strikes. A dielectric ply is fixed above and completely covers metal surface features, e.g., skin fasteners through a composite skin to a wing fuel tank. A conductive ply is fixed above and completely covers the dielectric ply and extends to an external connection to a platform ground. The conductive ply directs current from lightning strikes away from metal surface features, e.g., to the platform ground to preventing sparking in the fuel tank. Both plies may be adhesively backed and sequentially pressed into place.

Owner:THE BOEING CO

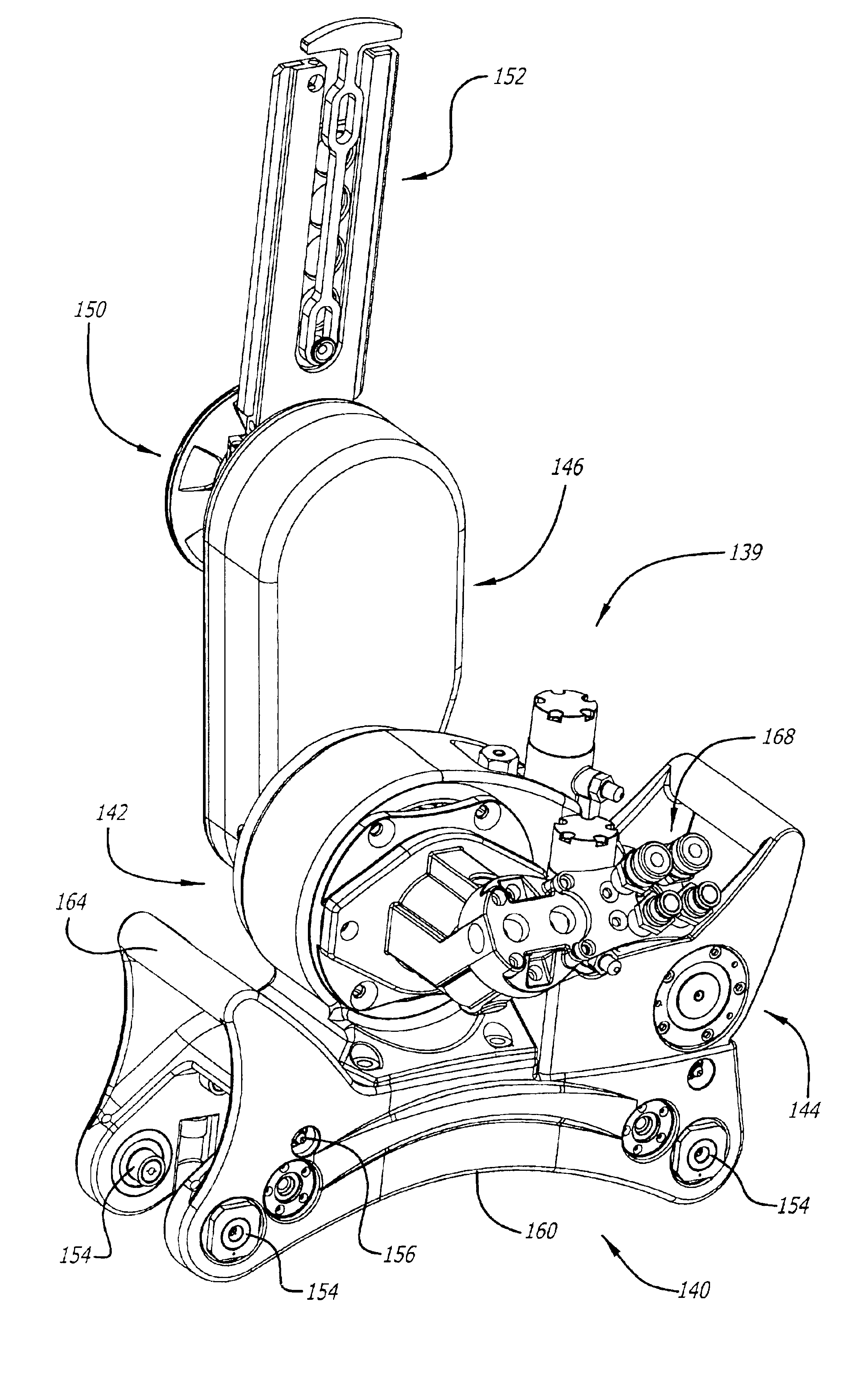

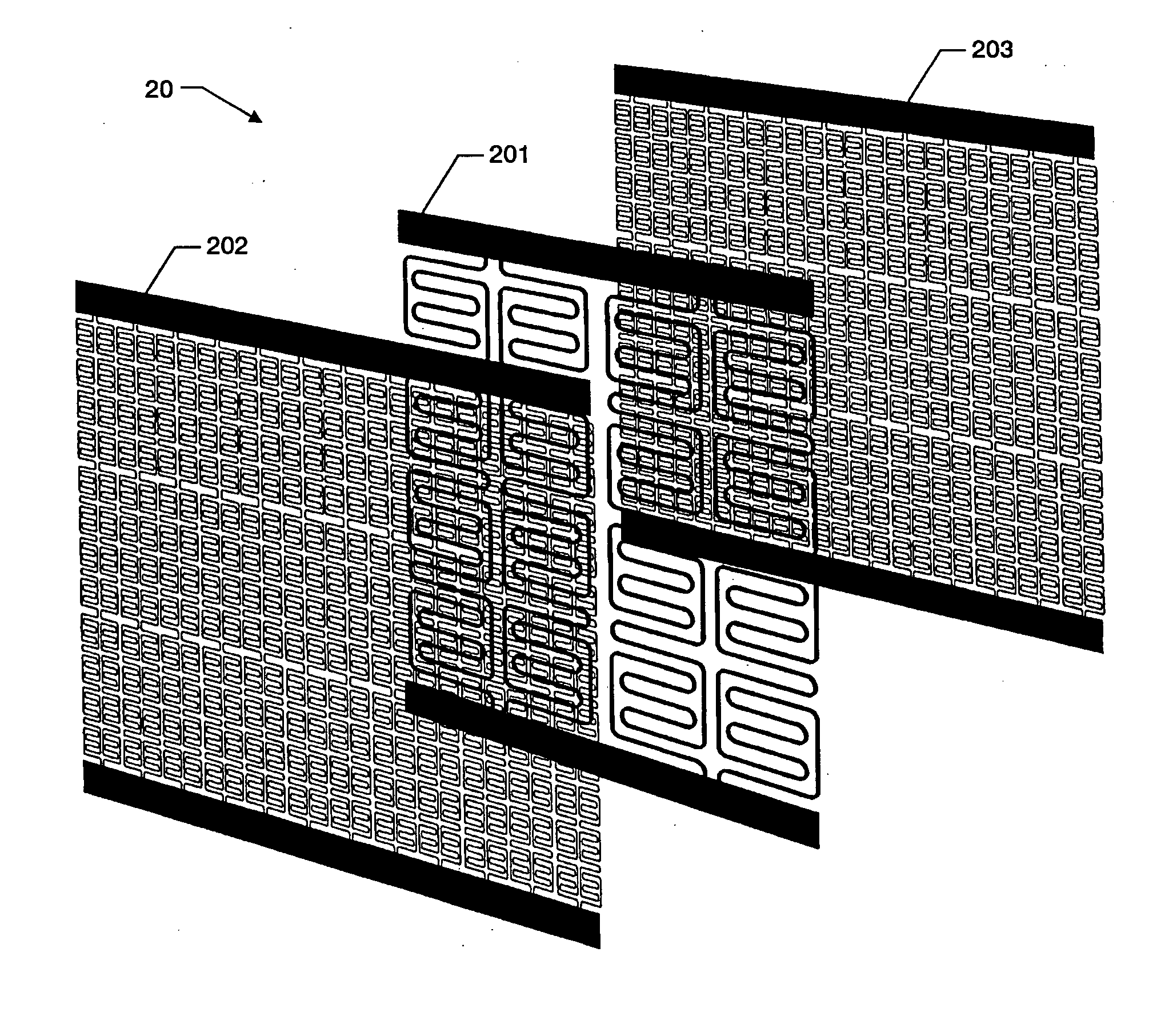

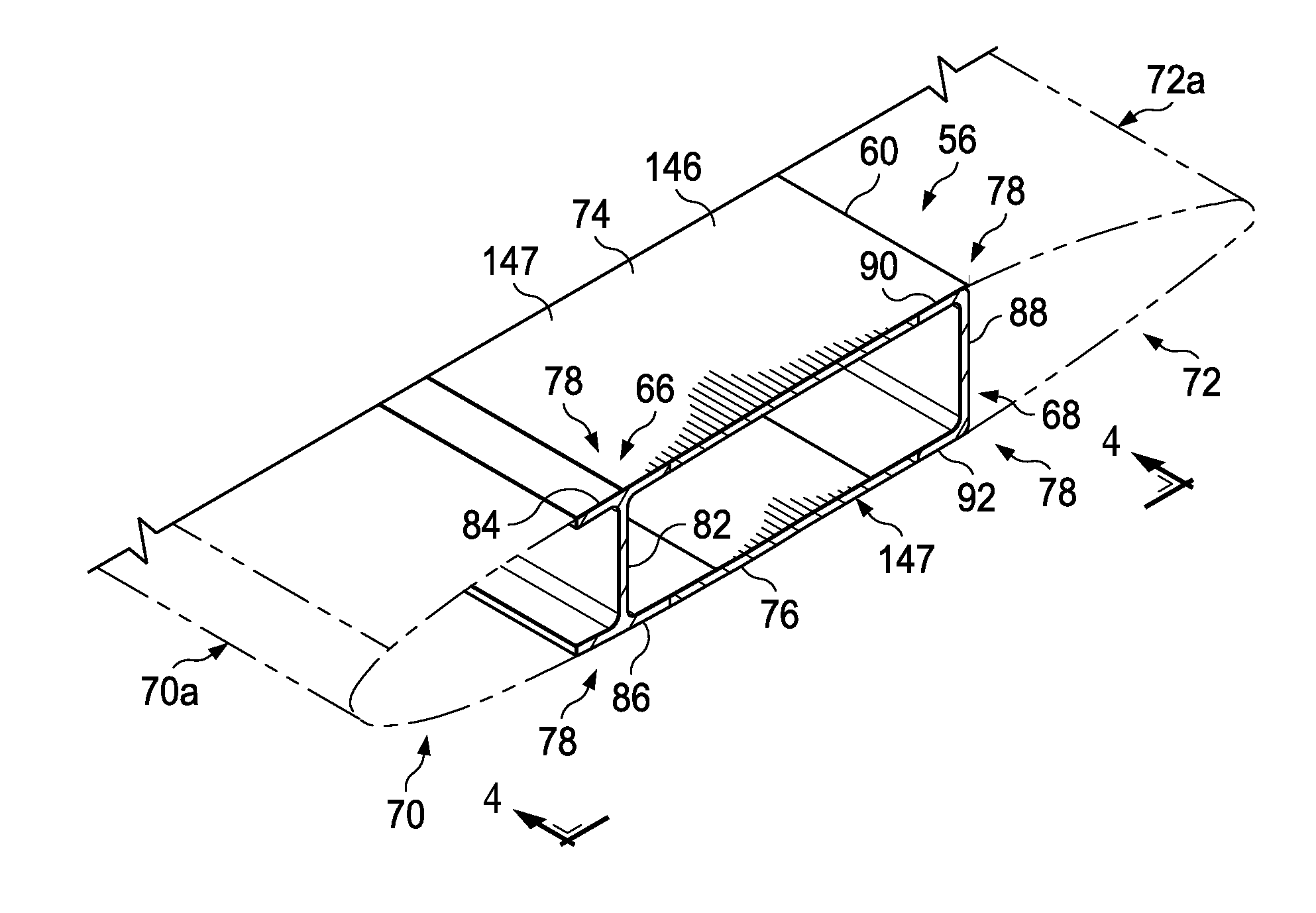

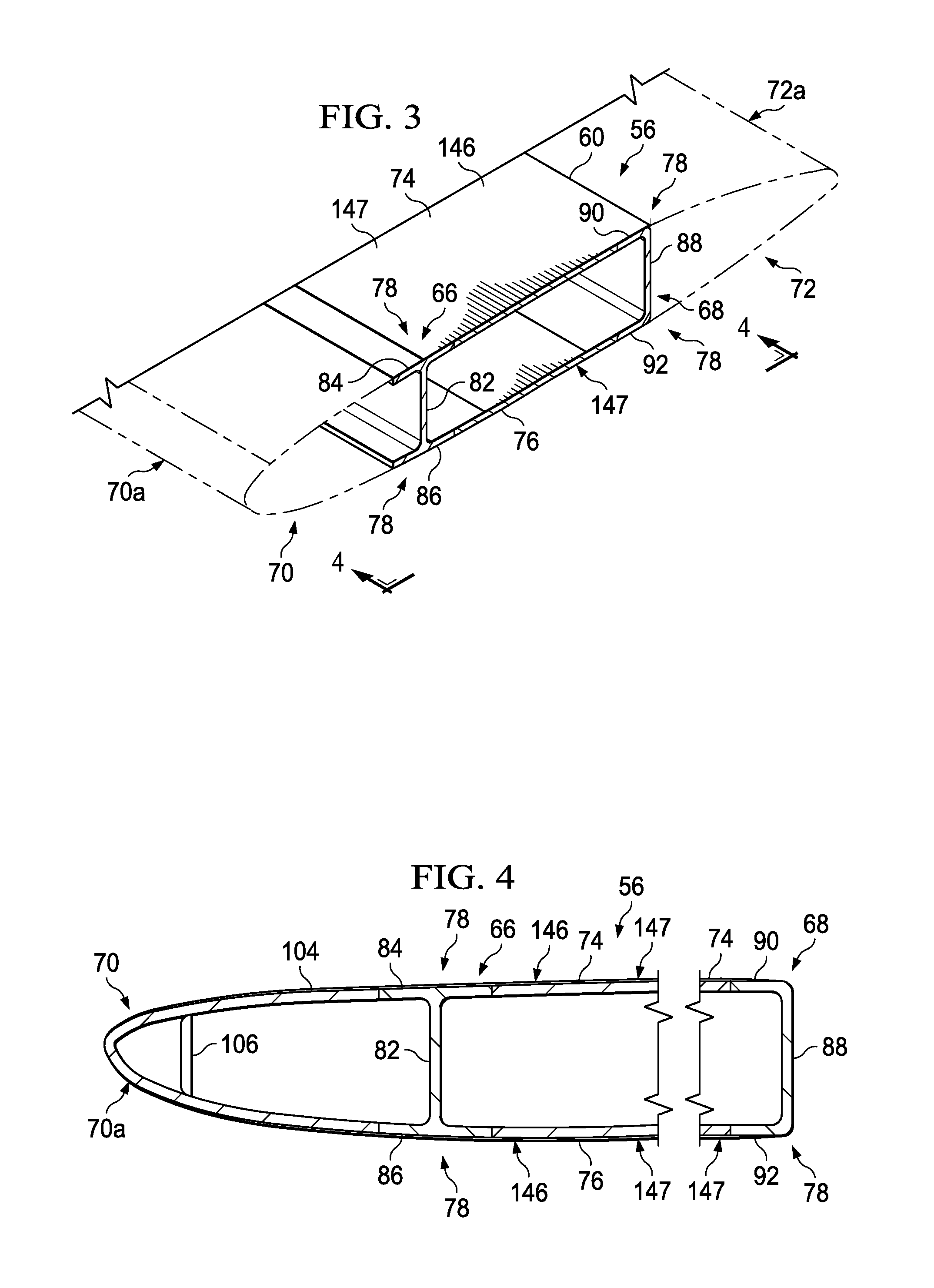

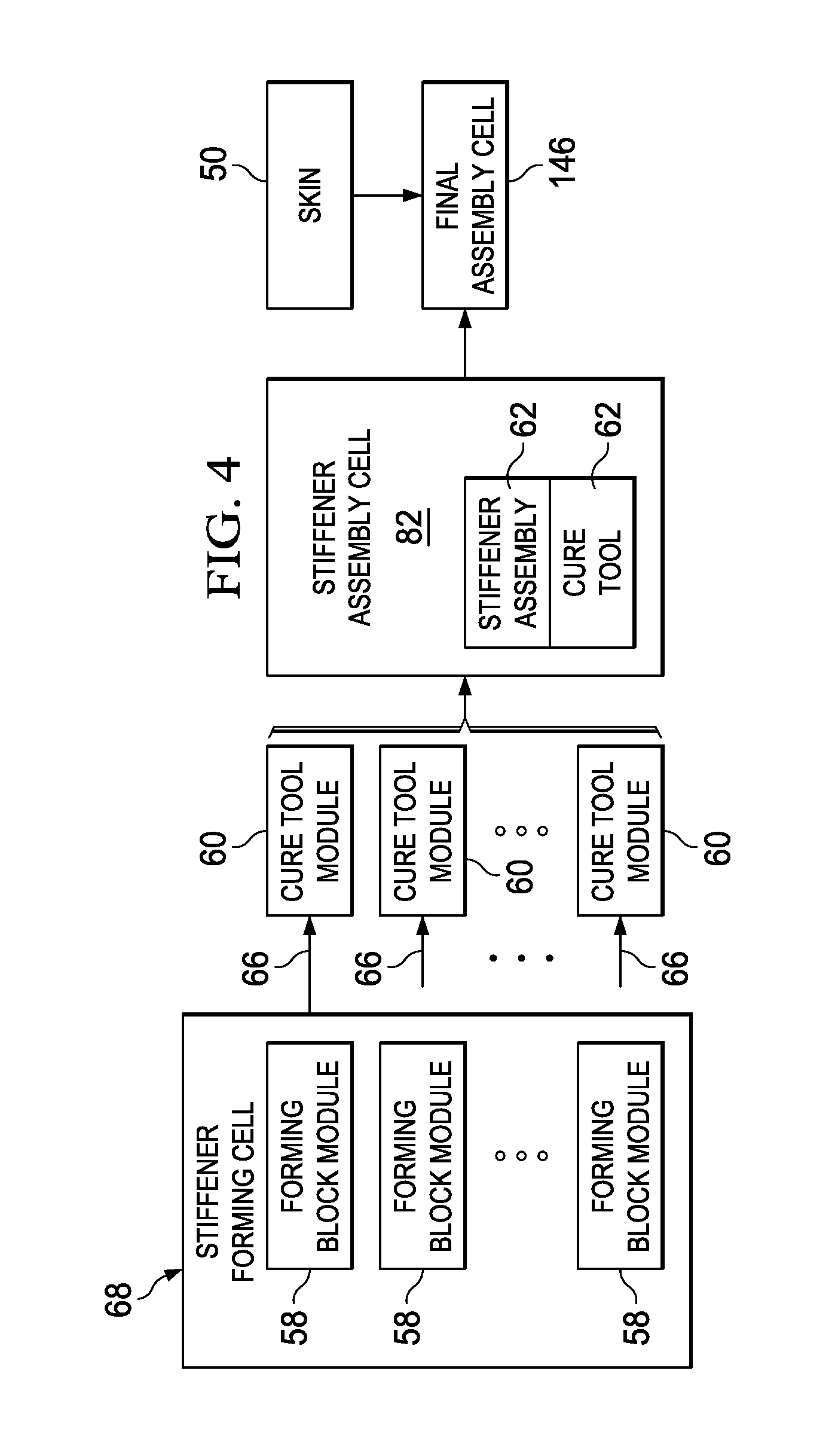

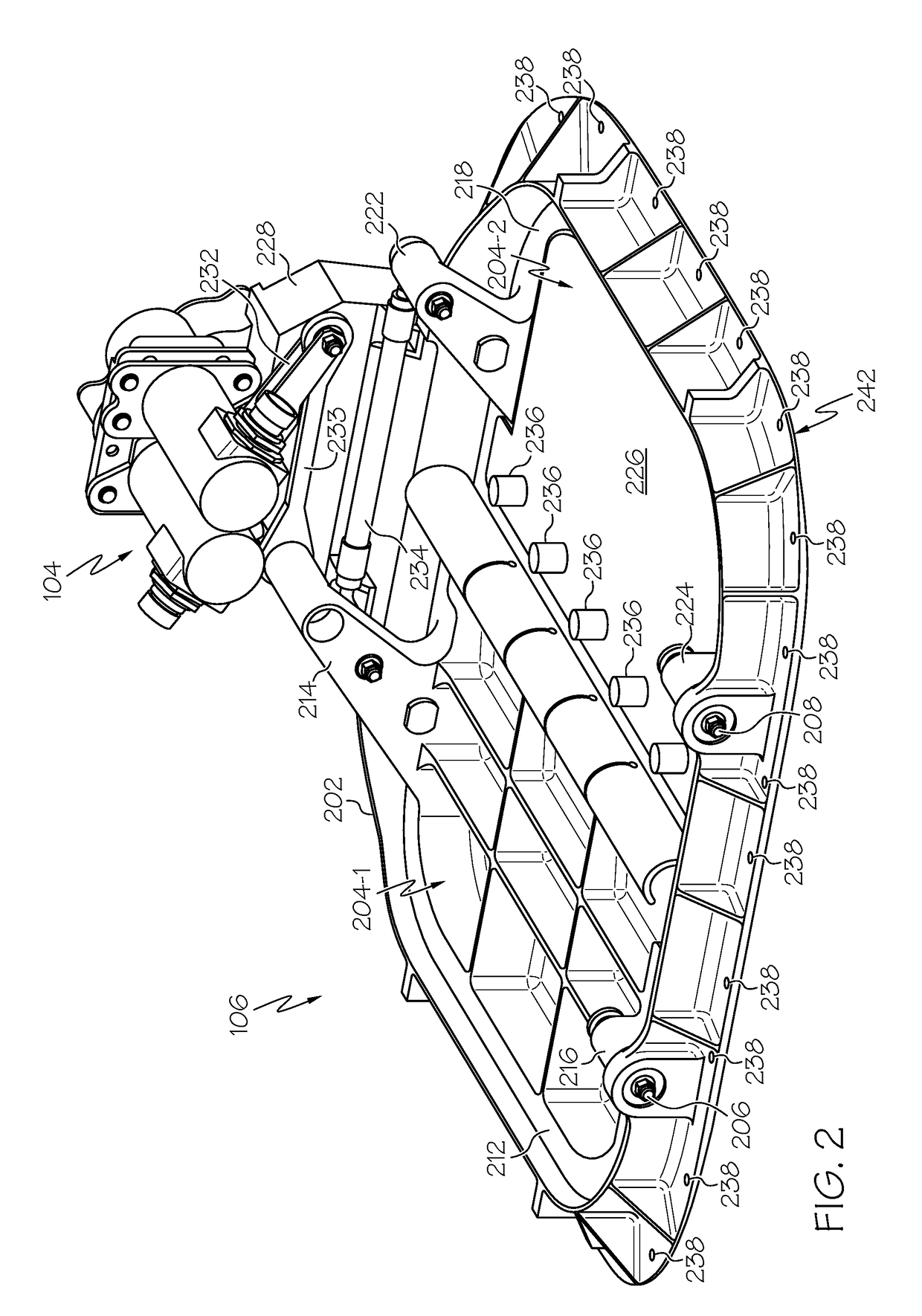

Fabrication of Stiffened Composite Panels

ActiveUS20140374013A1Reduce tooling costsReduce assembly floor space requirementLaminationLamination apparatusComposite skinMechanical engineering

A stiffened composite panel is fabricated using modular tooling. Composite pre-preg is laid up and formed over forming block modules each of which is assembled by co-linearly arranging a plurality of forming block segments. The formed stiffeners are respectively transferred to individual cure tool modules that are assembled by co-linearly arranging a plurality of cure tool module segments. The stiffeners are assembled by arranging the cure tool modules side-by-side, and a composite skin is placed on the assembled stiffeners. The panel is vacuum bagged using a segmented vacuum bag.

Owner:THE BOEING CO

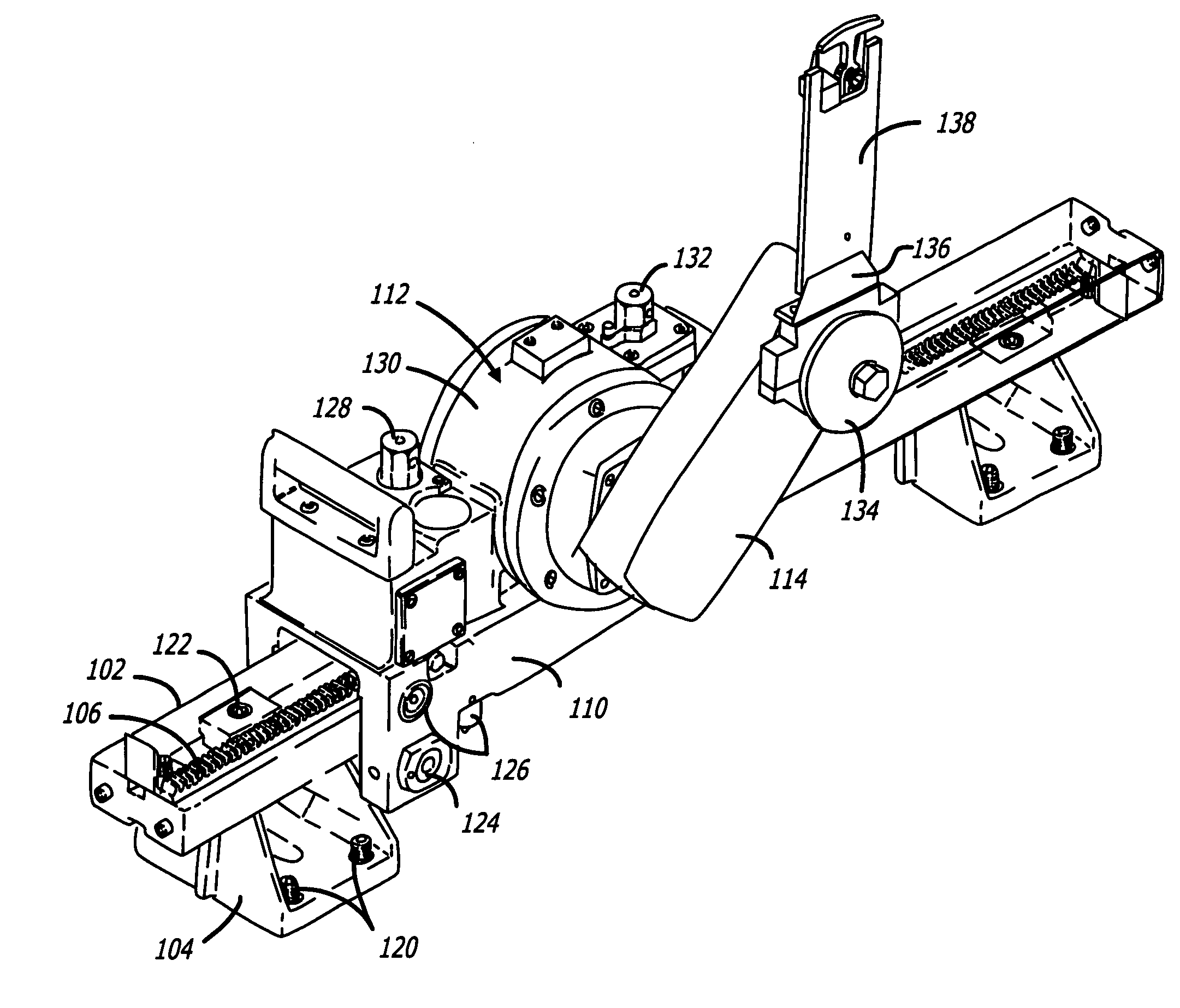

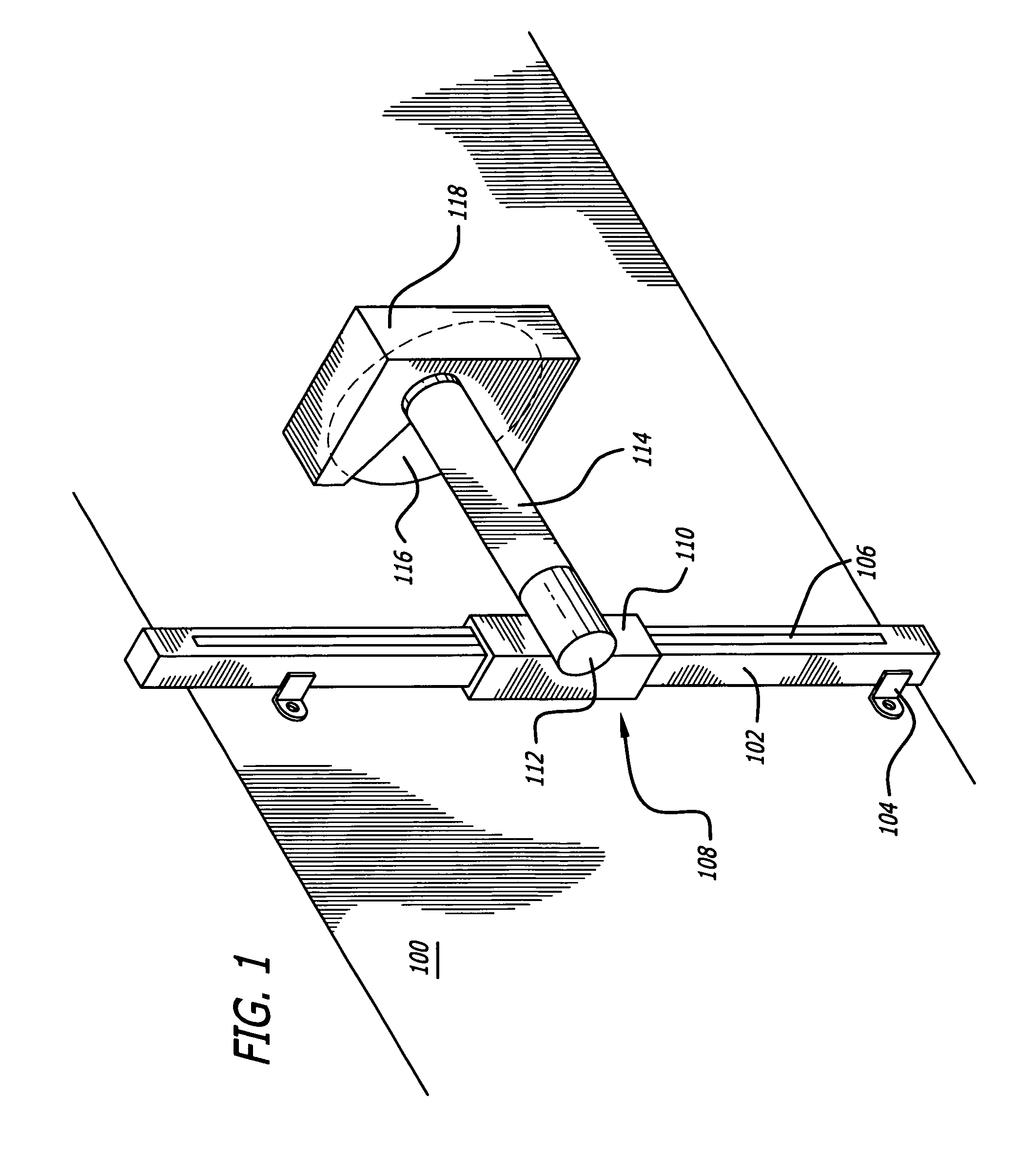

Movable machinery, including pavement working apparatus and methods of making

InactiveUS20060169269A1Easy to useHigh strengthMetal sawing devicesPortable grinding machinesEngineeringRoad surface

Owner:ELECTROLUX PROFESSIONAL OUTDOOR PROD

Composite Columnar Structure Having Co-Bonded Reinforcement and Fabrication Method

ActiveUS20130156979A1Improve abilitiesReduce weightEnvelopes/bags making machineryConnecting rodsComposite skinBiomedical engineering

A columnar structure comprises a generally hollow laminate core, an outer composite skin, and a sleeve-like reinforcement. The sleeve-like reinforcement surrounds the laminate core and is sandwiched between the laminate core and the outer composite skin for reacting compressive loads imposed on the columnar structure.

Owner:THE BOEING CO

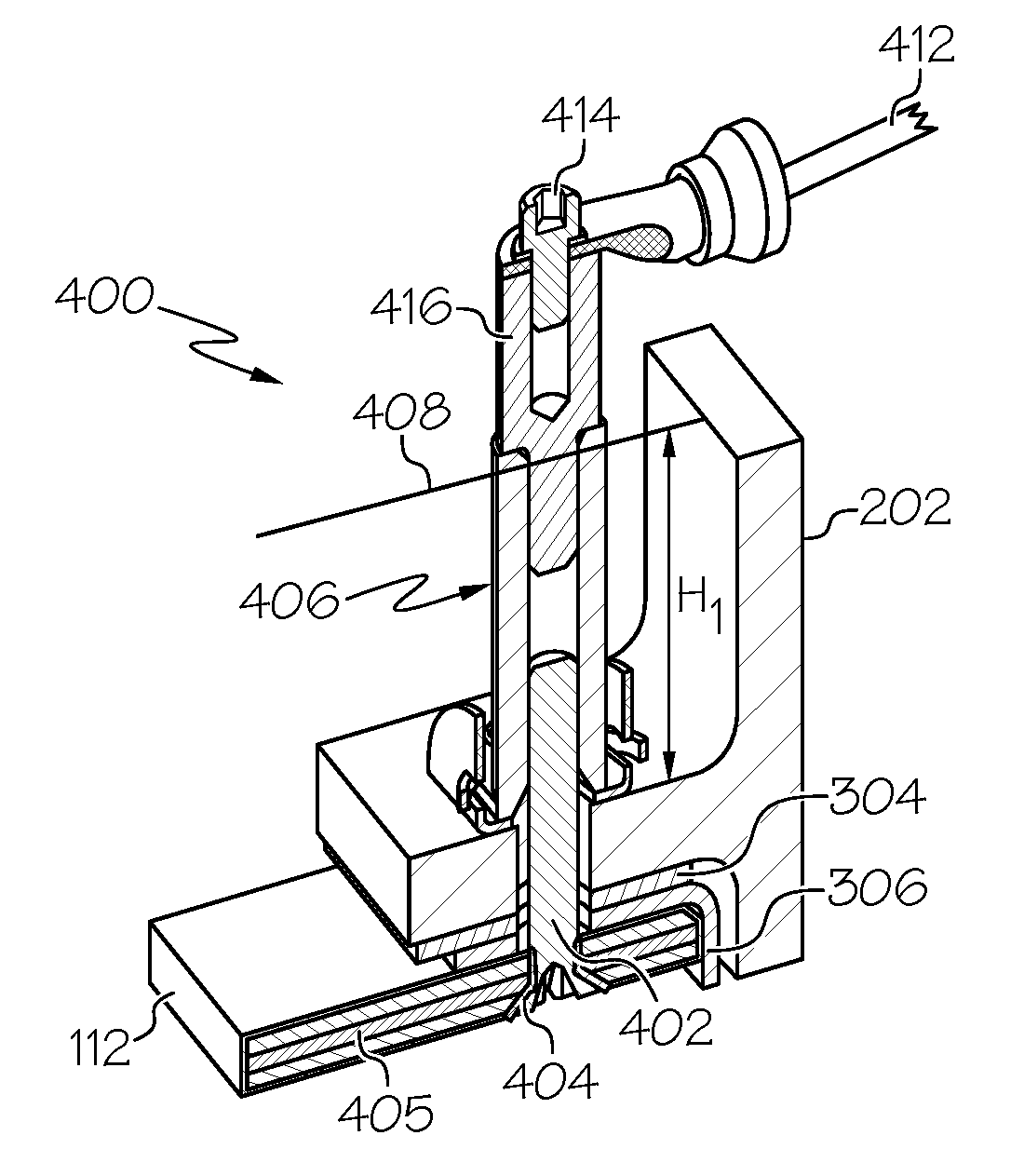

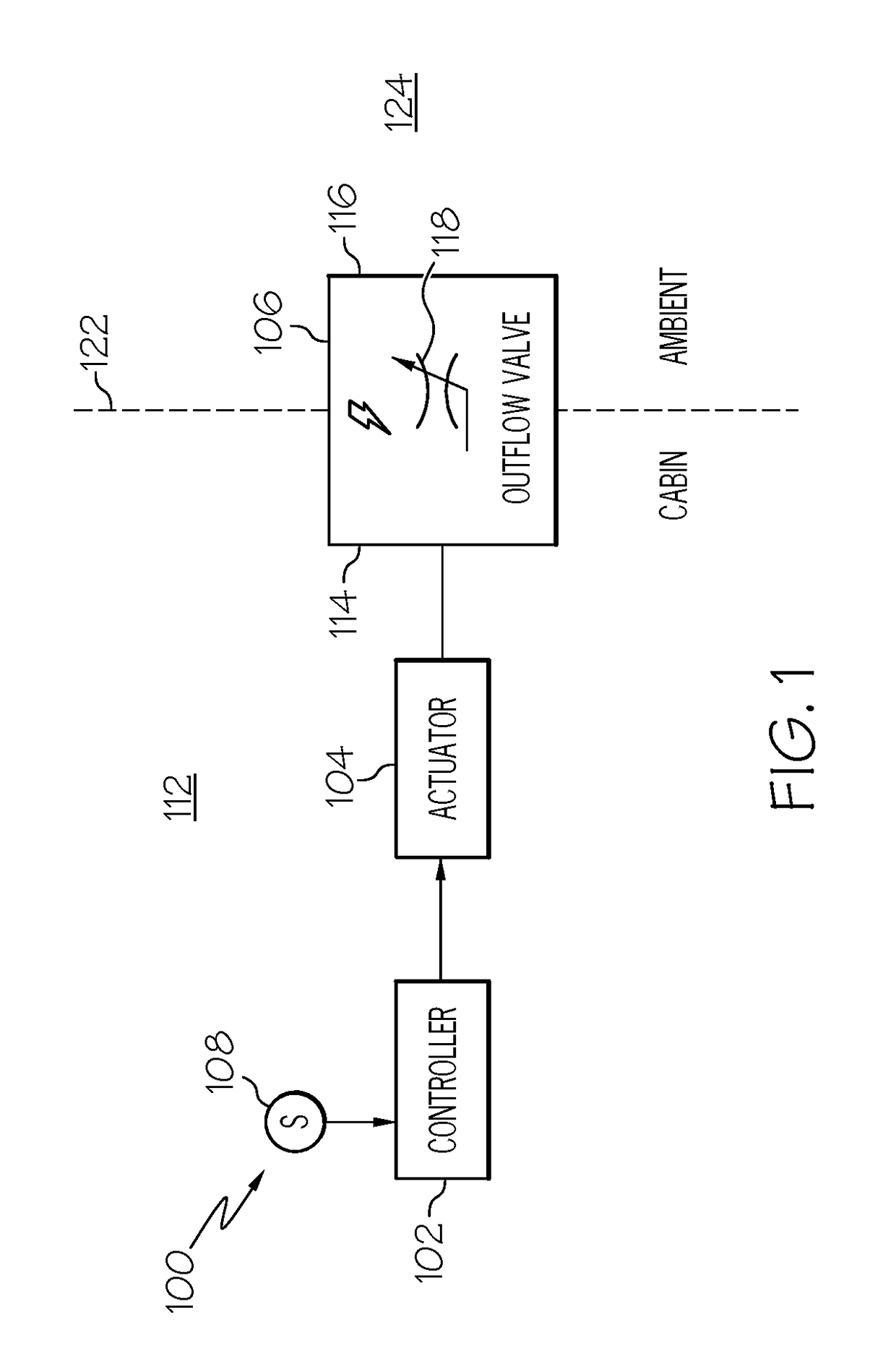

Device for electrically grounding aircraft components mounted on a composite skin fuselage

ActiveUS20170217604A1Increased complexityIncrease costAir-treatment apparatus arrangementsAircraft lighting protectorsMetal frameworkComposite skin

A component mounting assembly includes a non-metallic frame, a nut plate, and a grounding strap. The non-metallic frame is adapted for mounting to an aircraft fuselage. The non-metallic frame includes an outer peripheral portion having one or more fastener openings formed therein, and extends to a first height above the outer peripheral portion. The nut plate is coupled to the outer peripheral portion and extends therefrom to a second height that is at least 50% of the first height. The grounding strap is coupled, via a threaded fastener, to the nut plate.

Owner:HONEYWELL IFL PATENT SERVICES

Method And System For Detecting And Locating By Reflectometry Electrical Faults In Metal Structures

ActiveUS20120223720A1Testing electric installations on transportFault location by pulse reflection methodsElectrical conductorReturn current

The invention aims to provide for detecting and locating by reflectometry electrical faults in a network of metal structures able to receive electrical cables and perform the return-current function of these cables. The invention consists in injecting a probe signal into a conductor, associated with the structures, then in analyzing the reflected signal by comparison with a reference signal.According to one example implementation, an insulated conducting element is held at a distance by fasteners fitted to supports secured to a wall of the metal structure.Application to raceways in composite-skin aeroplanes.

Owner:AIRBUS OPERATIONS (SAS)

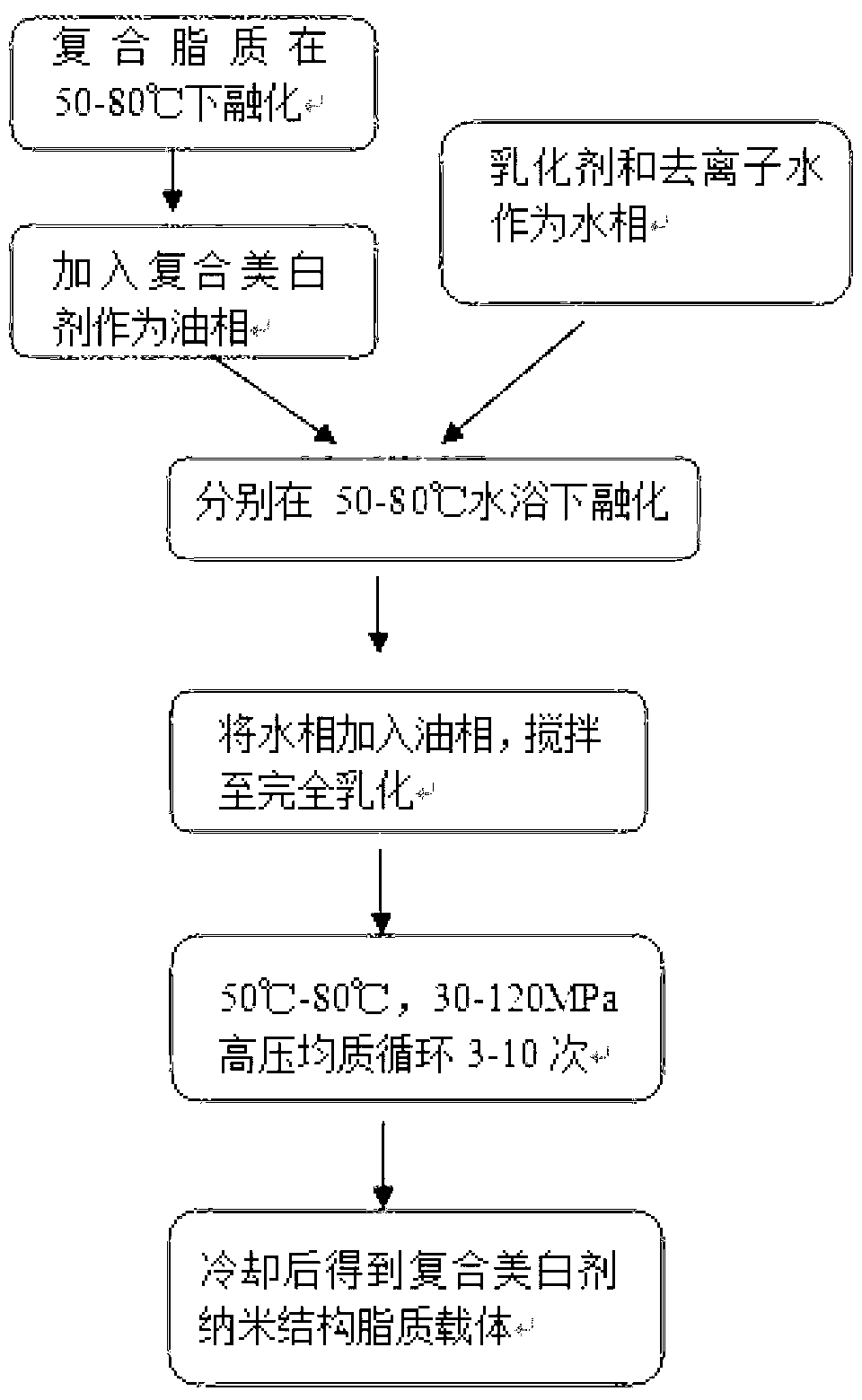

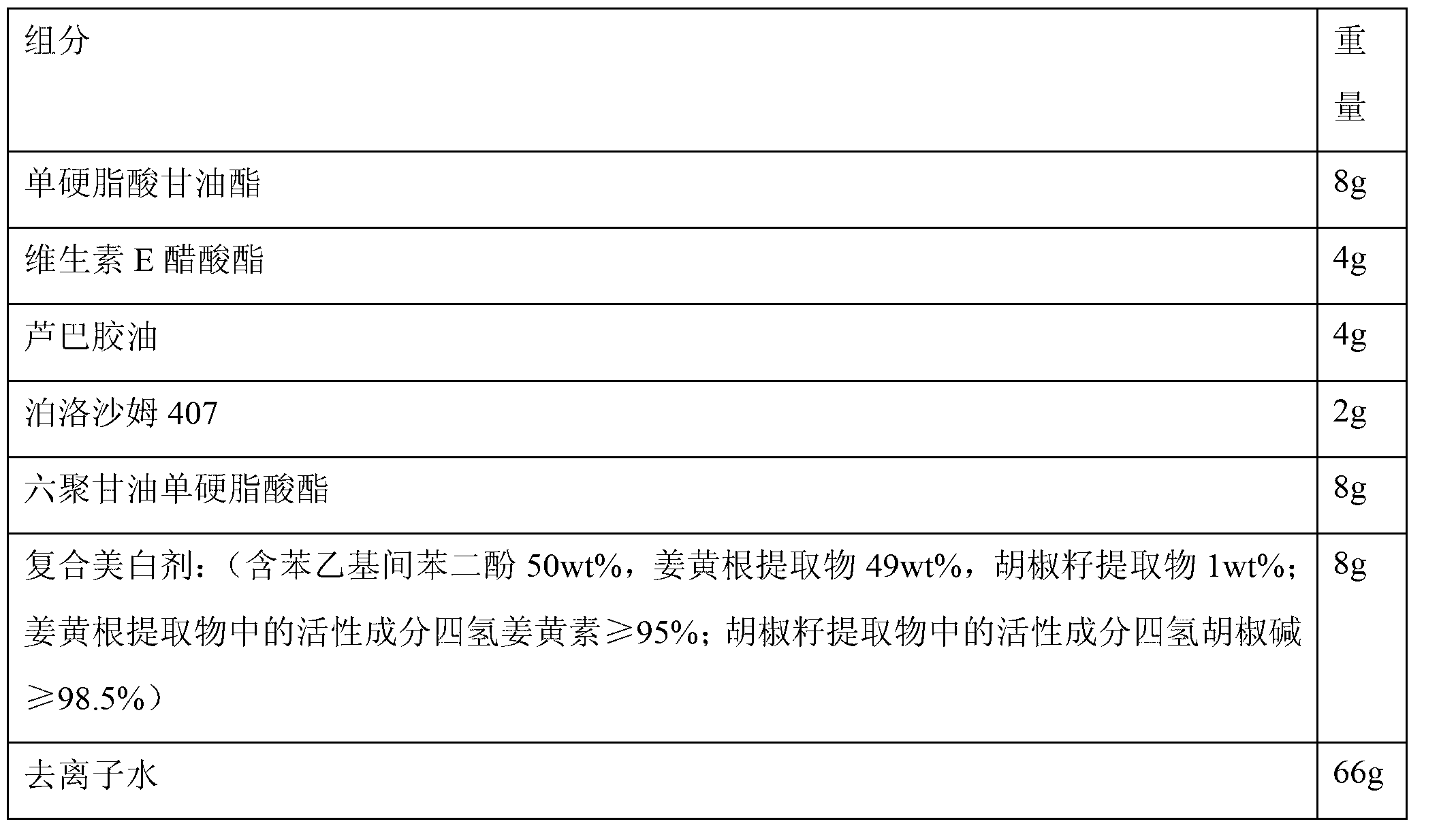

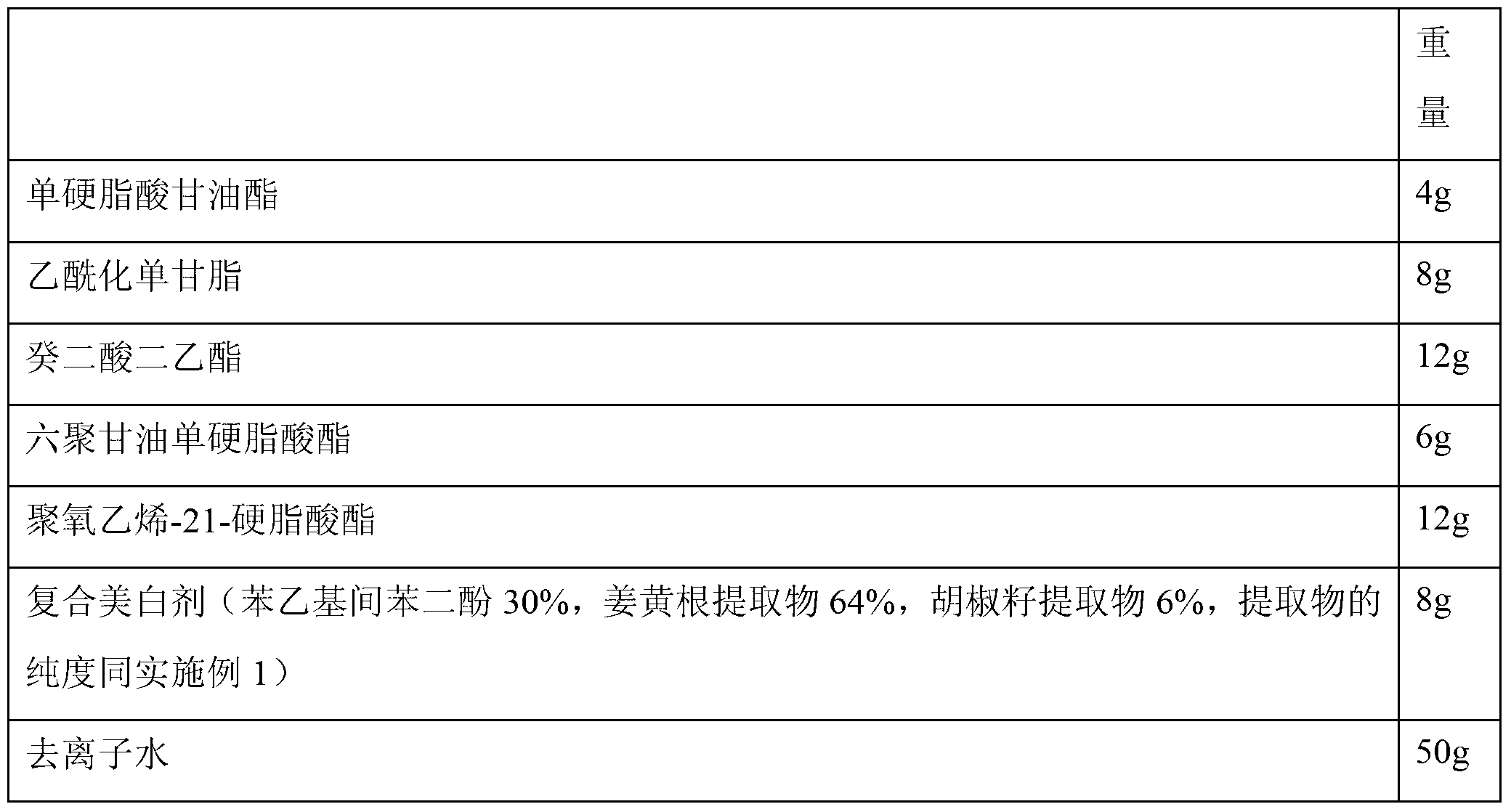

Nanostructured lipid carrier for composite skin lightener and preparation method of composite skin lightener

ActiveCN103251539APromote hydrationClosed system is goodCosmetic preparationsToilet preparationsWhitening AgentsMedicine

The invention relates to a nanostructured lipid carrier (NLC) for a composite skin lightener. The composite skin lightener is loaded on the carrier and comprises the following three active ingredients in percentage by weight: 1-50% of phenylethyl resorcinol, 40-89% of turmeric extract, and 1-10% of pepper seed extract; the carrier further comprises an NLC composite lipid material and an emulsifying agent; and the content of the composite skin lightener in percentage by weight is 1-15%. The composite skin lightener is enveloped by using the NLC; and the enveloping process is simple, controllable, and good in repeatability, and overcomes the application bottlenecks that the active substances are not soluble in water, and easily degrades on meeting light to cause color change, and rapid content decease.

Owner:SHANGHAI ZHONGYI DAILY CHEM CO LTD

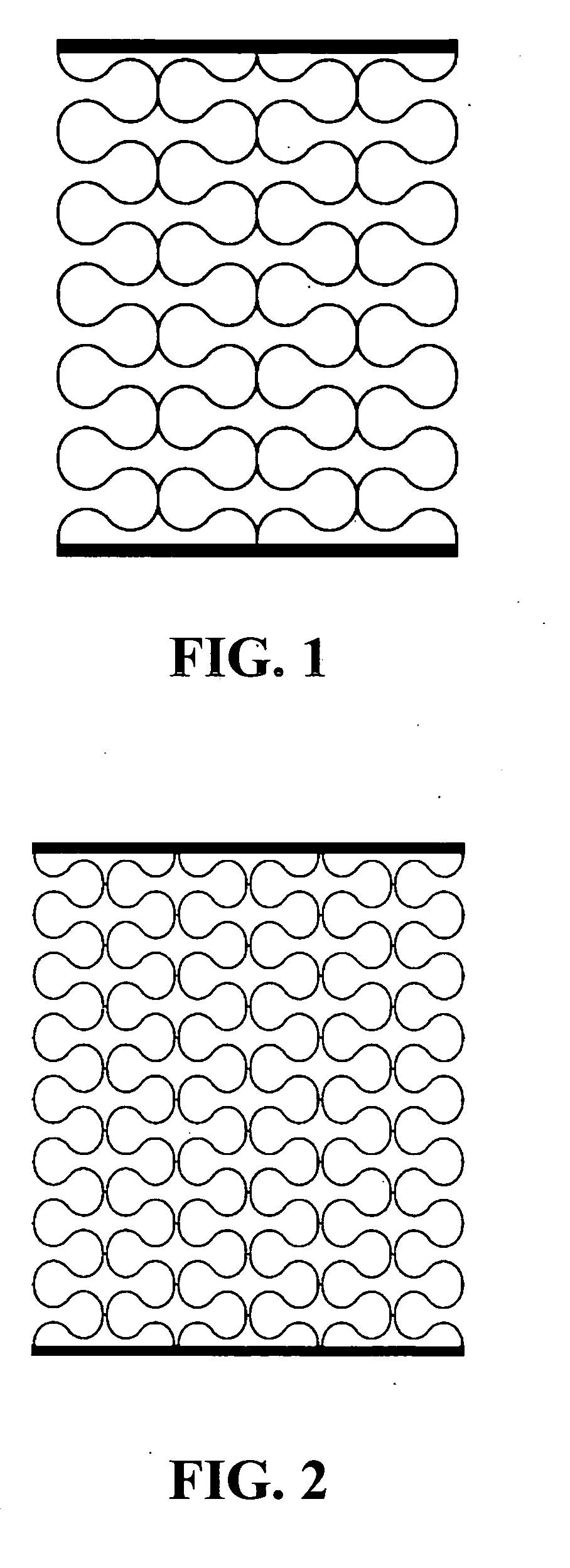

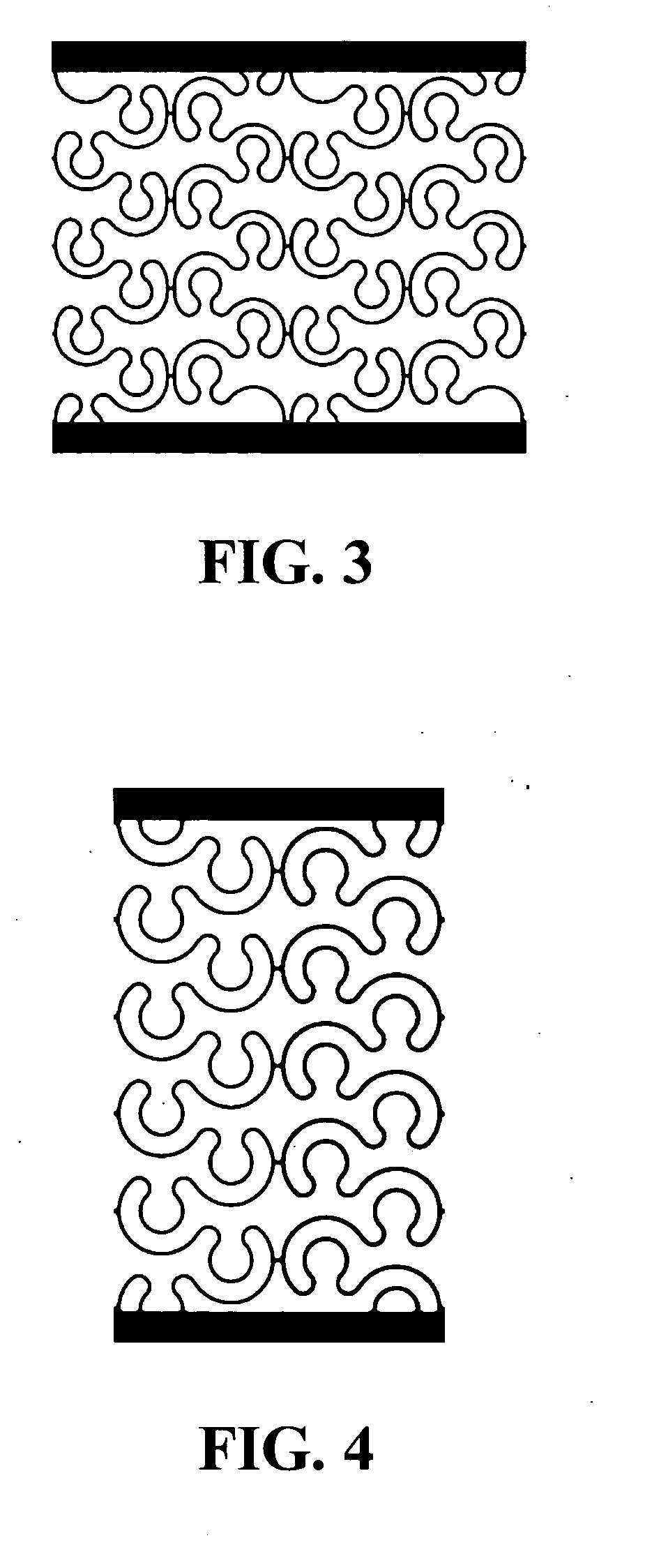

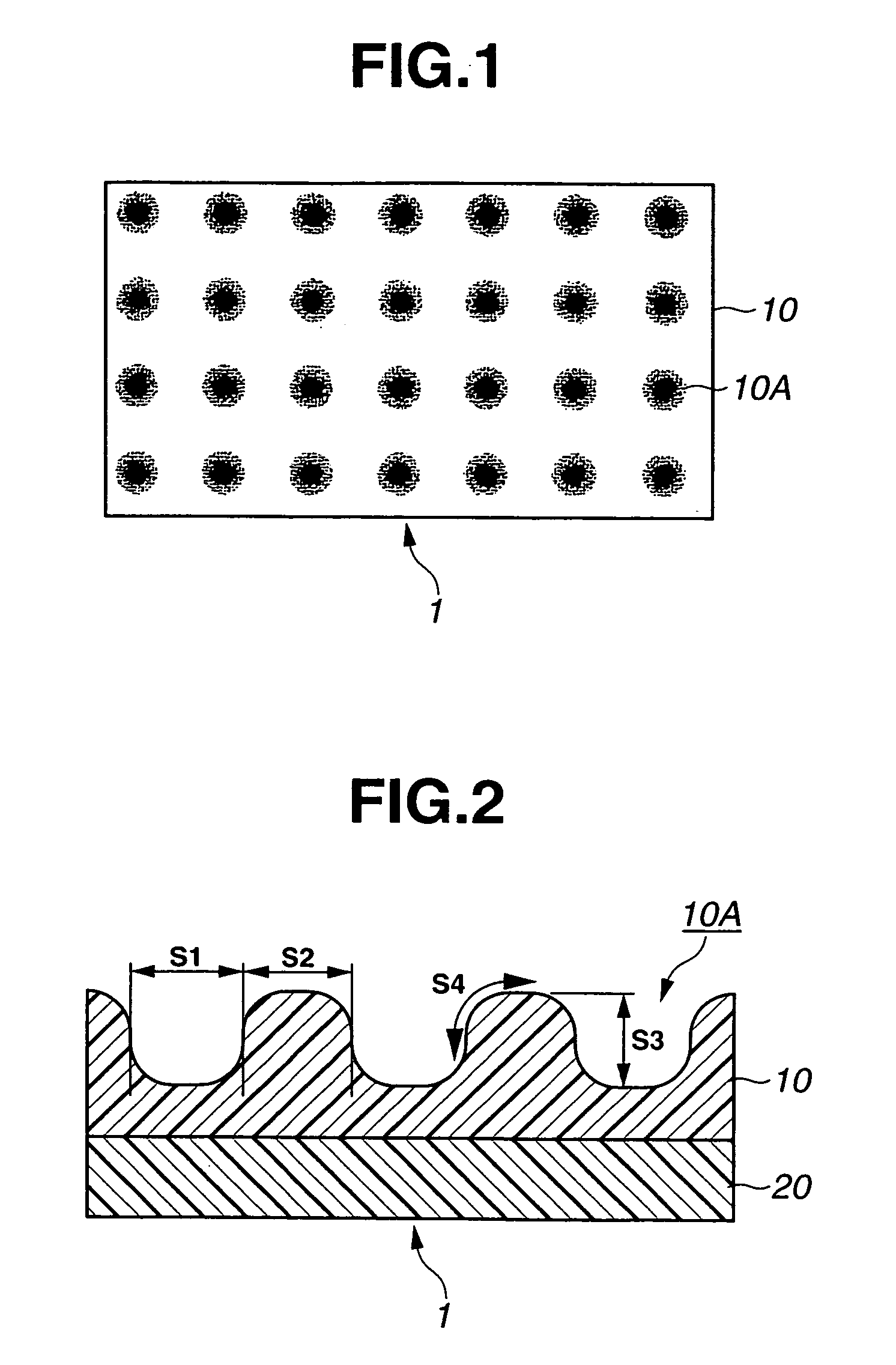

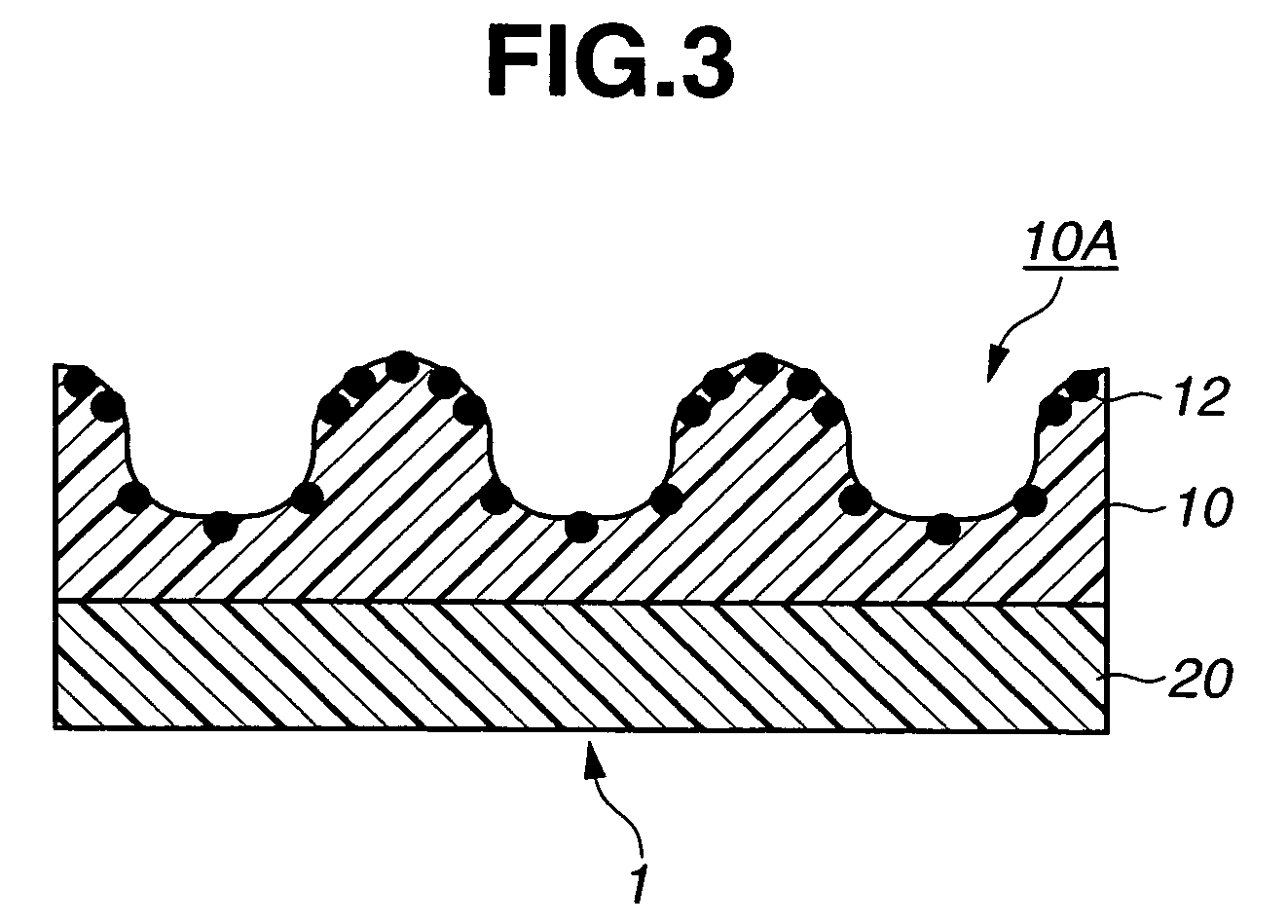

Skin material, skin material production method and composite skin for automotive interior trim

InactiveUS20080305305A1Uniform thicknessGood touchLayered productsVehicle componentsProject areaComposite skin

There is provided a skin material with a substrate and a polymeric layer. The polymeric layer has a first surface adhering to the substrate and a second surface being exposed to the outside and formed with fine recesses. The fine recesses have a depth of 30 to 130 μm and a projected area ratio of 5 to 20% with respect to the total projected area of the second surface of the polymeric layer.

Owner:NISSAN MOTOR CO LTD

Composite collagen-base rack material and its pepn and use

InactiveCN1526764AGood tissue compatibilityPromote degradationAbsorbent padsBandagesCelluloseCarrageenan

The present invention relates to one kind of composite collagen-base rack material and its preparation and use. The material includes collagen and water soluble polysaccharide, and the polysaccharide is at least one of chitosan, salt of algal polysaccharide, proteoglycan, cellulose, carrageenan, acacia and starch. Collagen has natural 3D fiber network structure. The preparation process of the rack material with skin of mammal as material includes elimination of subcutaneous tissue with splitting machine, water soaking, defatting, ash soaking, deashing, splitting, softening, compounding, and Co-60 irradiation to sterilize. Functional material may be added into the composite collagen-base rack material for preparing biological dressing, artificial epidermis, artificial corium and artificial composite skin, and the composite collagen-base rack material may be used together with corollary ointment. The rack material has excellent water and steam penetrability and absorption.

Owner:SHANDONG UNIV

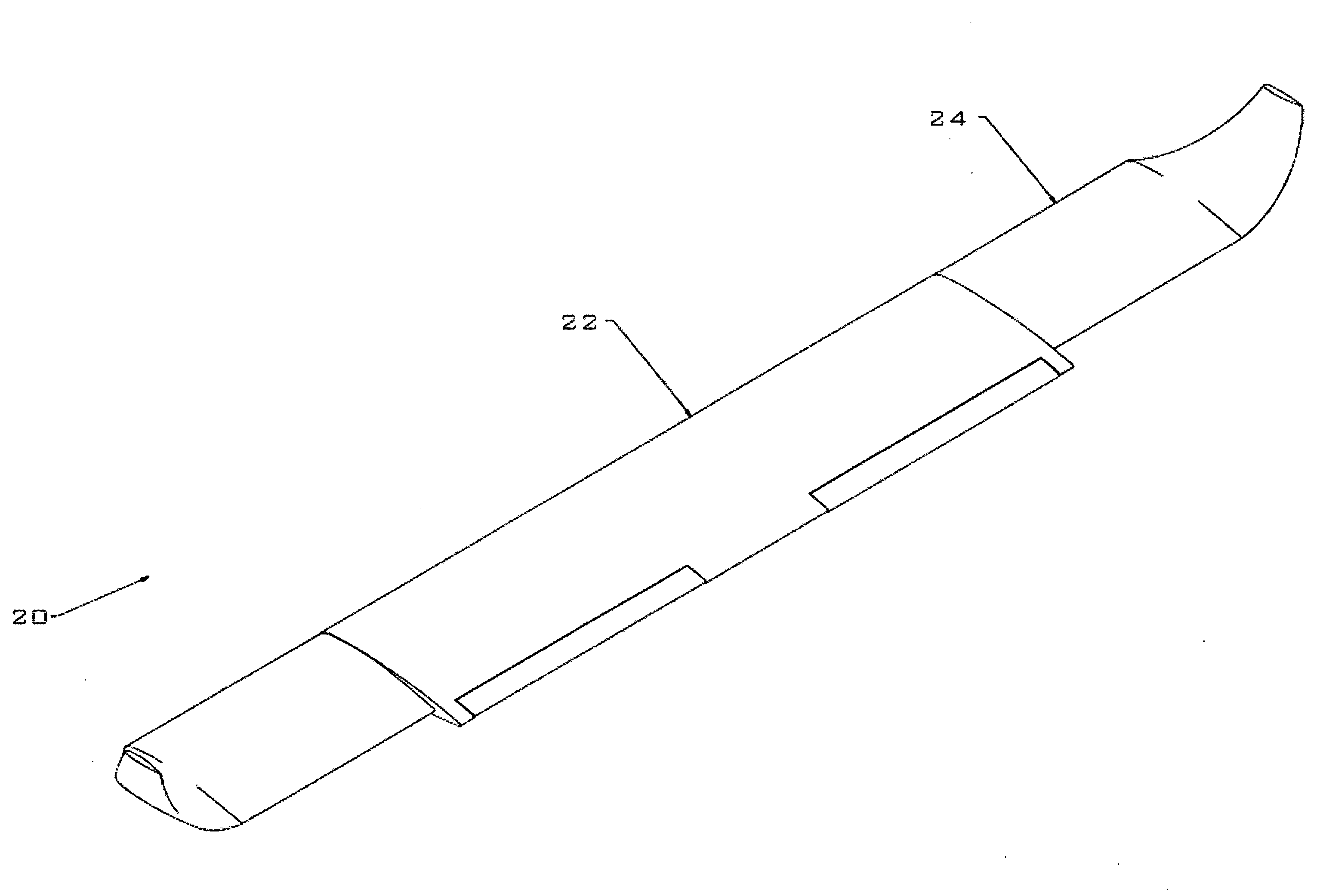

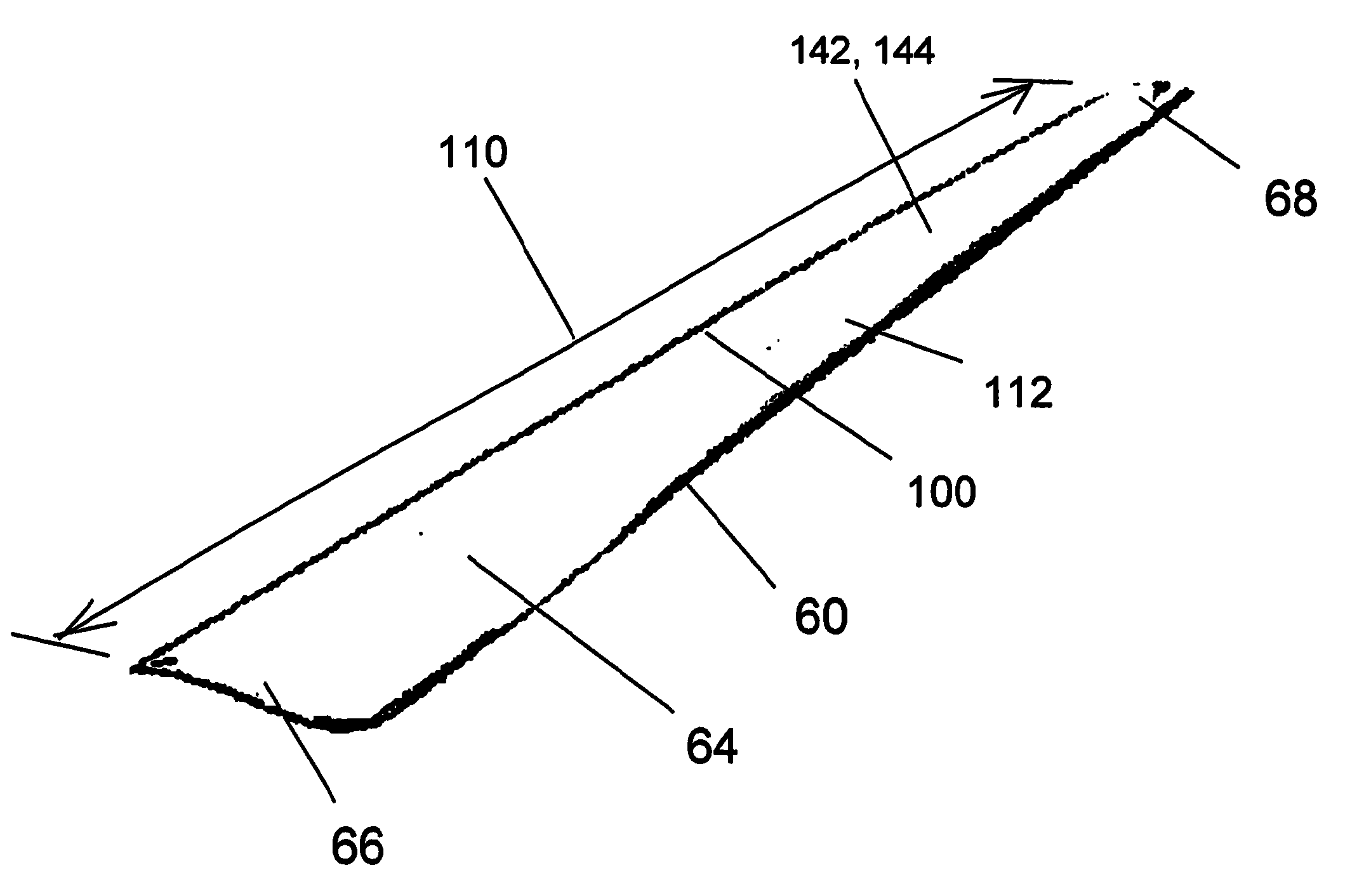

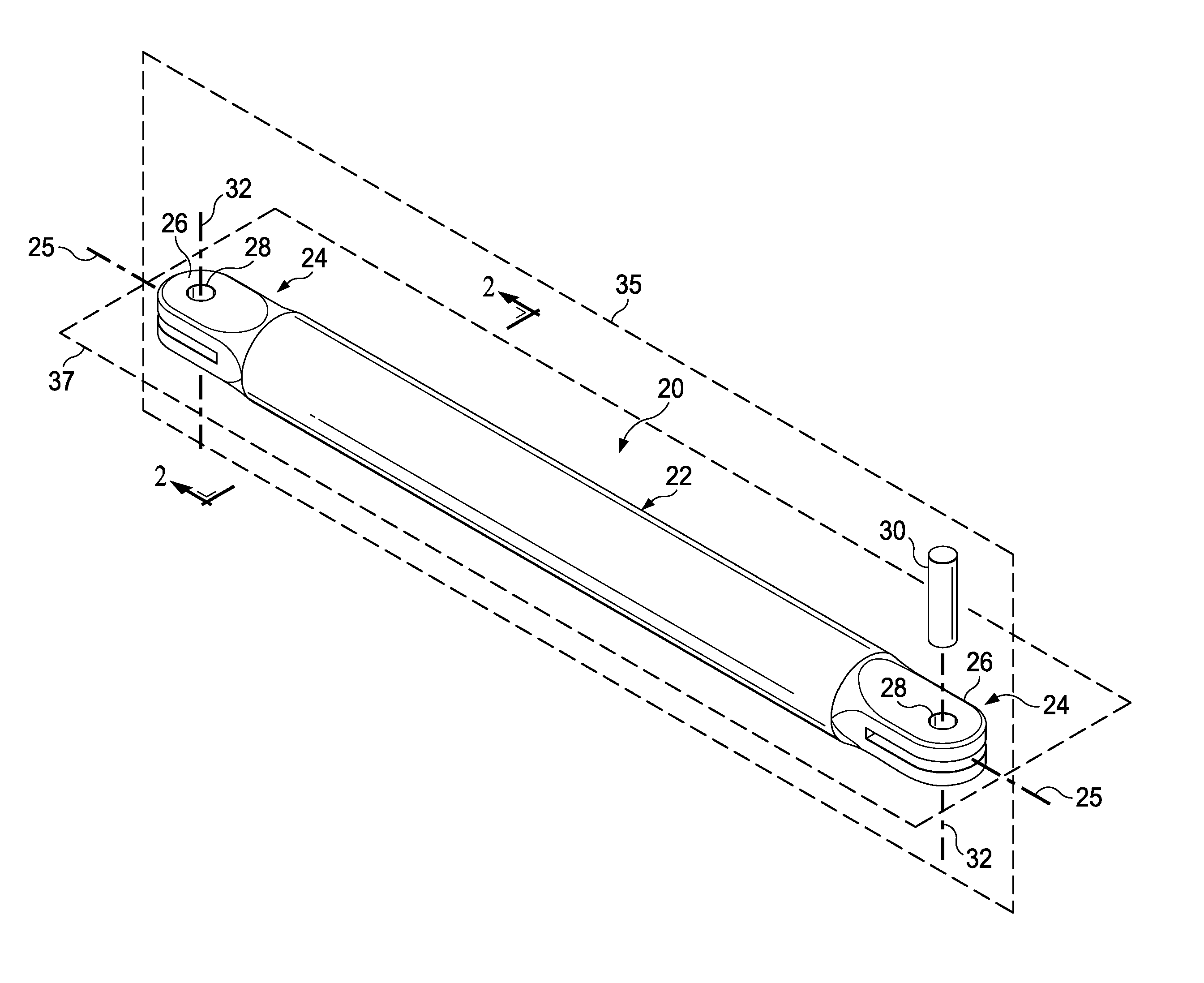

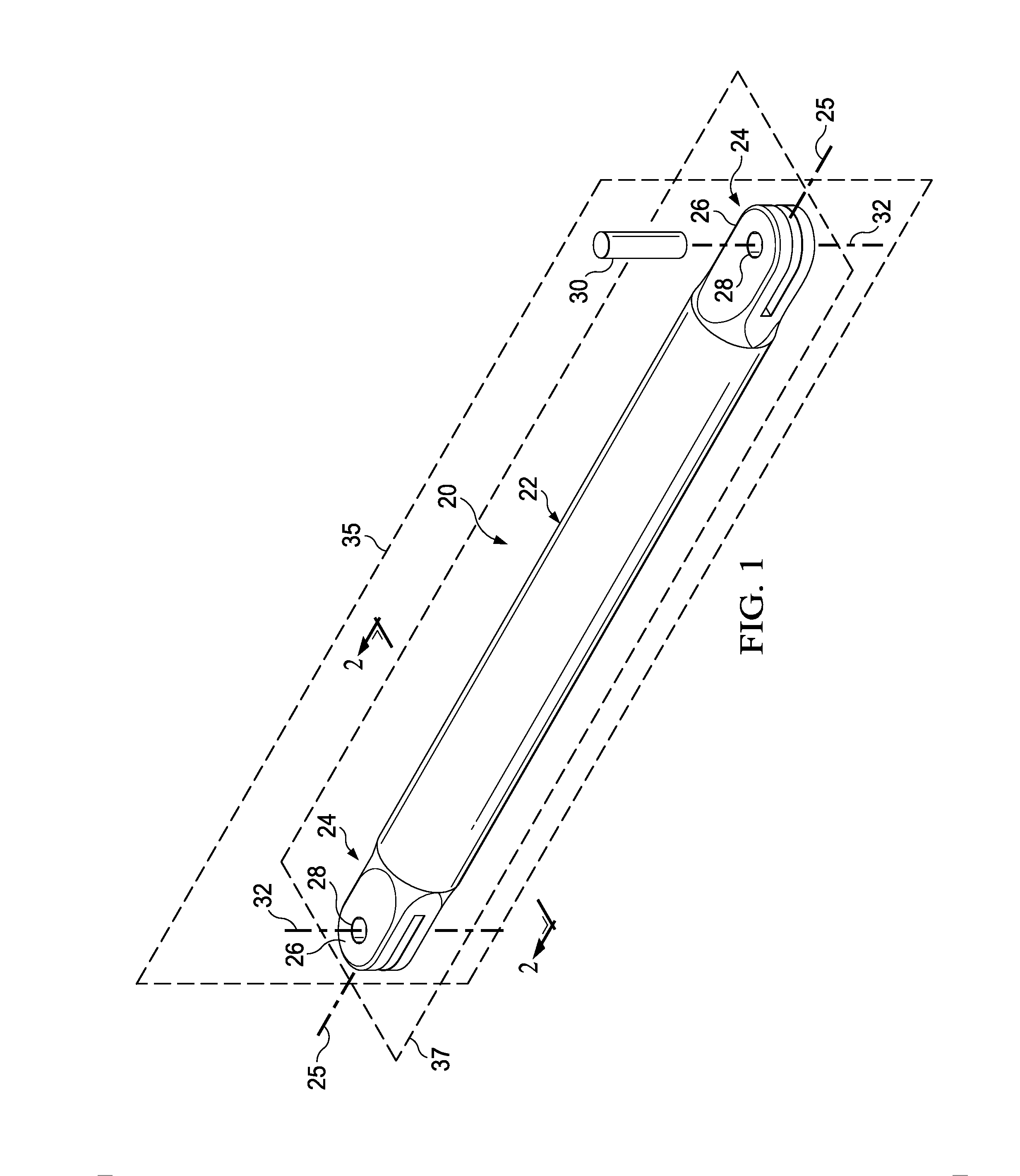

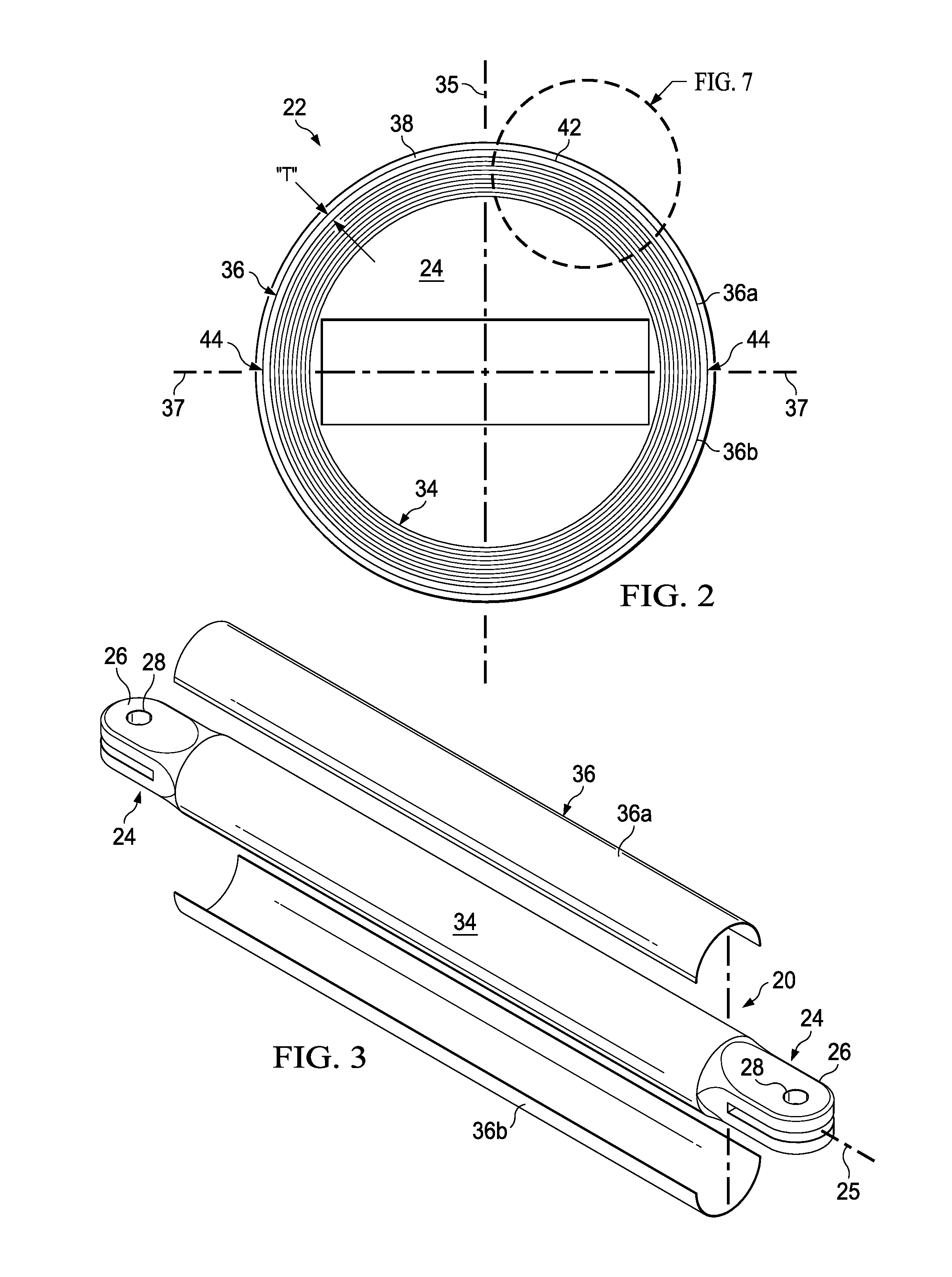

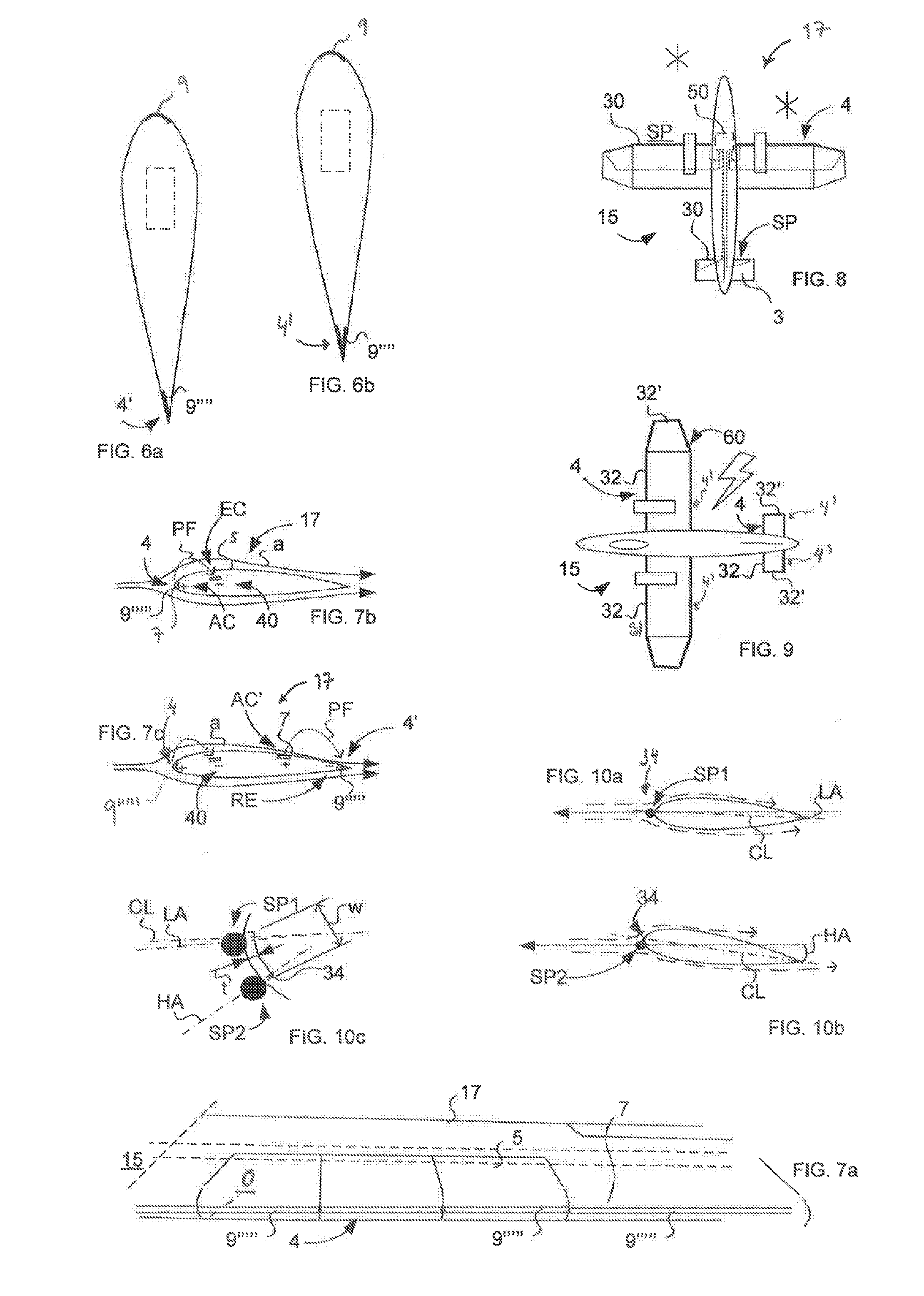

Multifunctional erosion protection strip

ActiveUS20150298791A1Reduce weightAvoid erosionAircraft lighting protectorsBlade accessoriesStagnation pointLeading edge

An airfoil article including a composite skin having a first surface and a second surface opposite first surface, forming a leading edge. The leading edge is during use subjected to an airflow meeting the leading edge at stagnation points. The leading edge includes an elongated member. The outer surface of the elongated member is arranged flush with the first surface of the composite skin such that an essentially smooth aerodynamic surface of the leading edge is formed. The elongated member is adapted to serve as an erosion protection of the leading edge and to function as an electrode of a plasma generating system.

Owner:SAAB AB

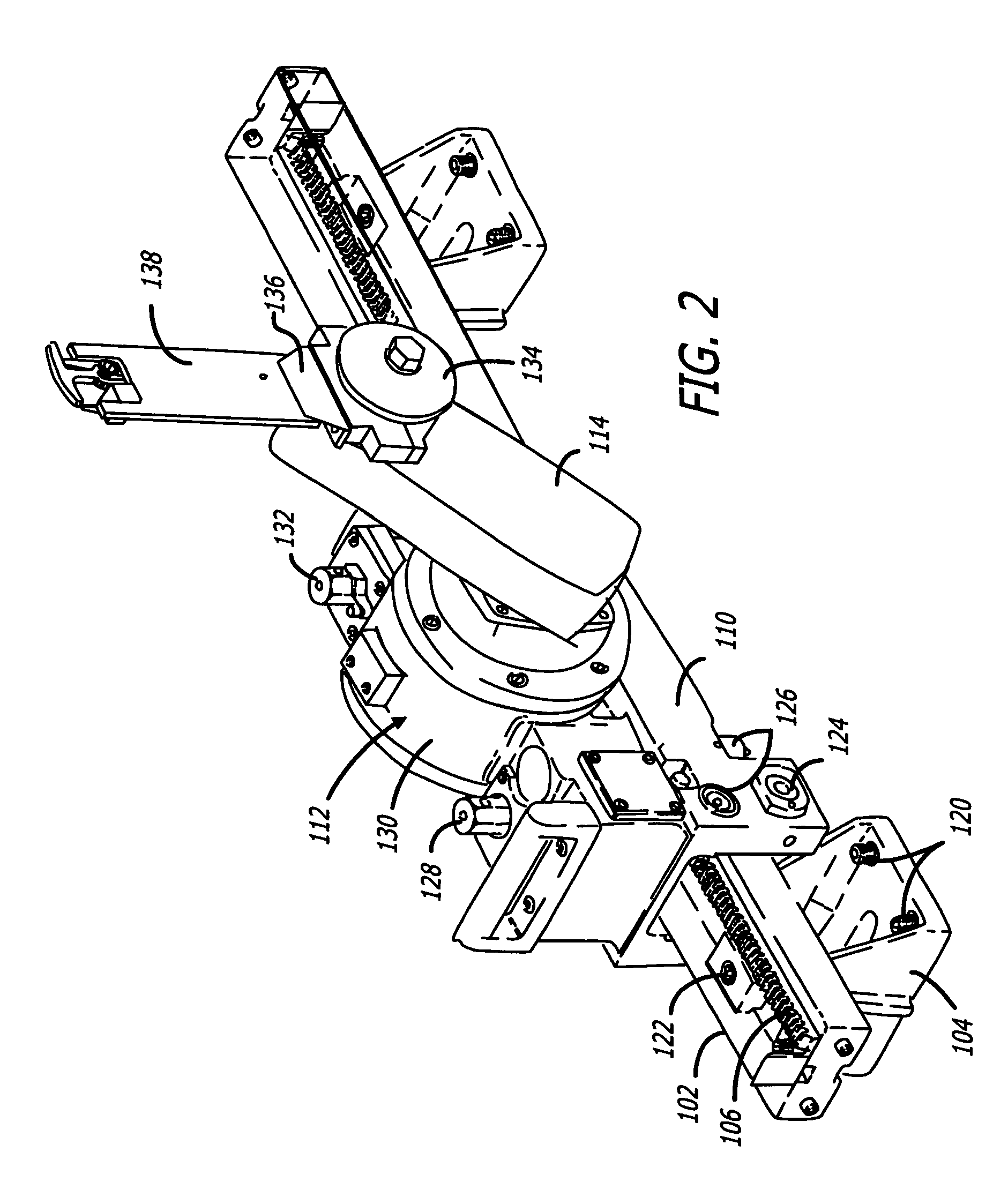

Movable machinery, including pavement working apparatus and methods of making

InactiveUS7018279B2Easy to useHigh strengthMetal sawing devicesPortable grinding machinesRoad surfaceEngineering

A movable machine, for example a saw, has a light construction using composite materials such as fiber reinforced resins and a closed cell foam. The saw may have a housing formed from multiple skins of the composite materials in which is located the closed cell foam. Metallic inserts may be used to bond to either or both of the foam and the composite skin to accept working components. A saw is also described which uses gears sharing the same support element.

Owner:HUSQVARNA AB

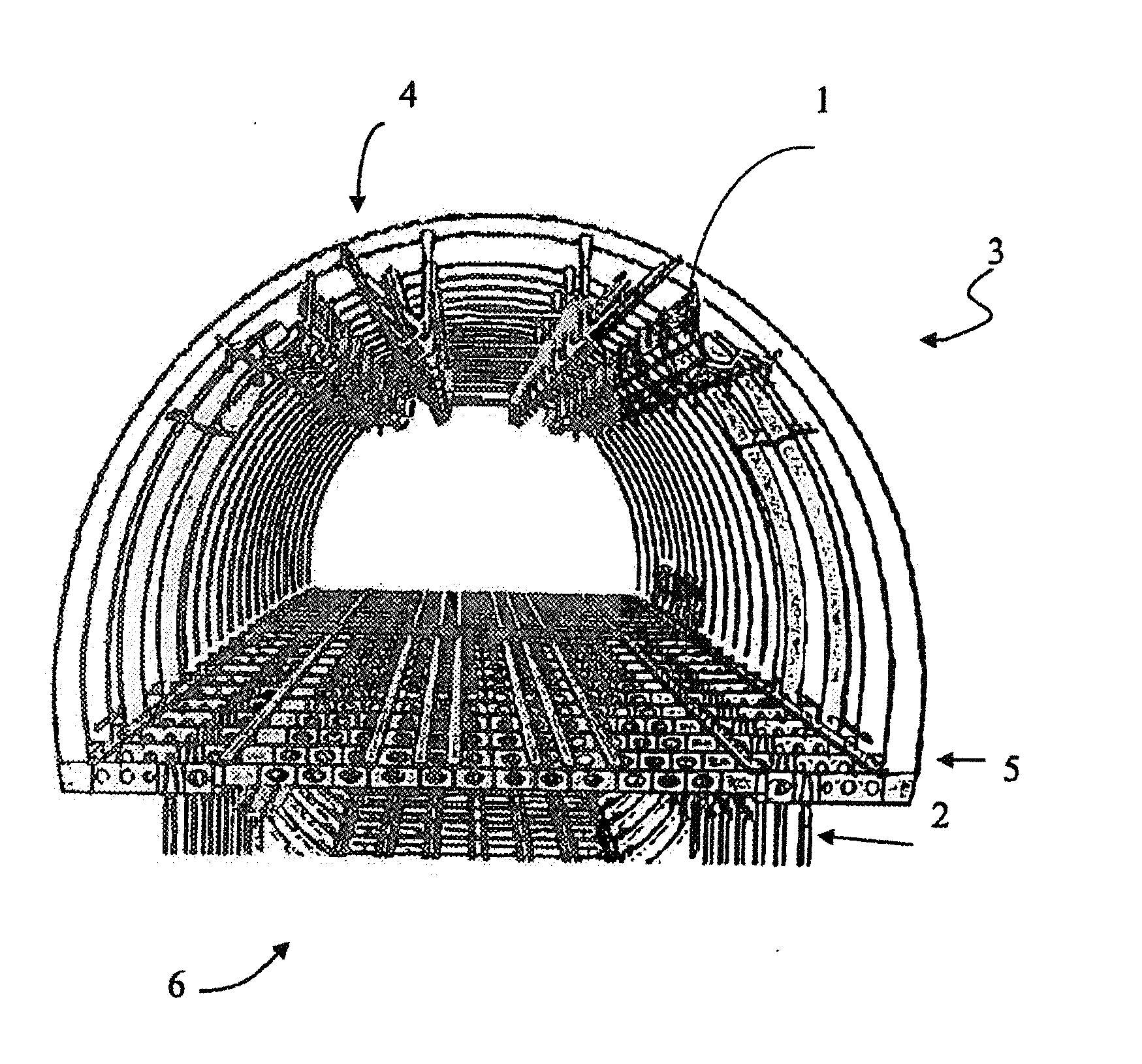

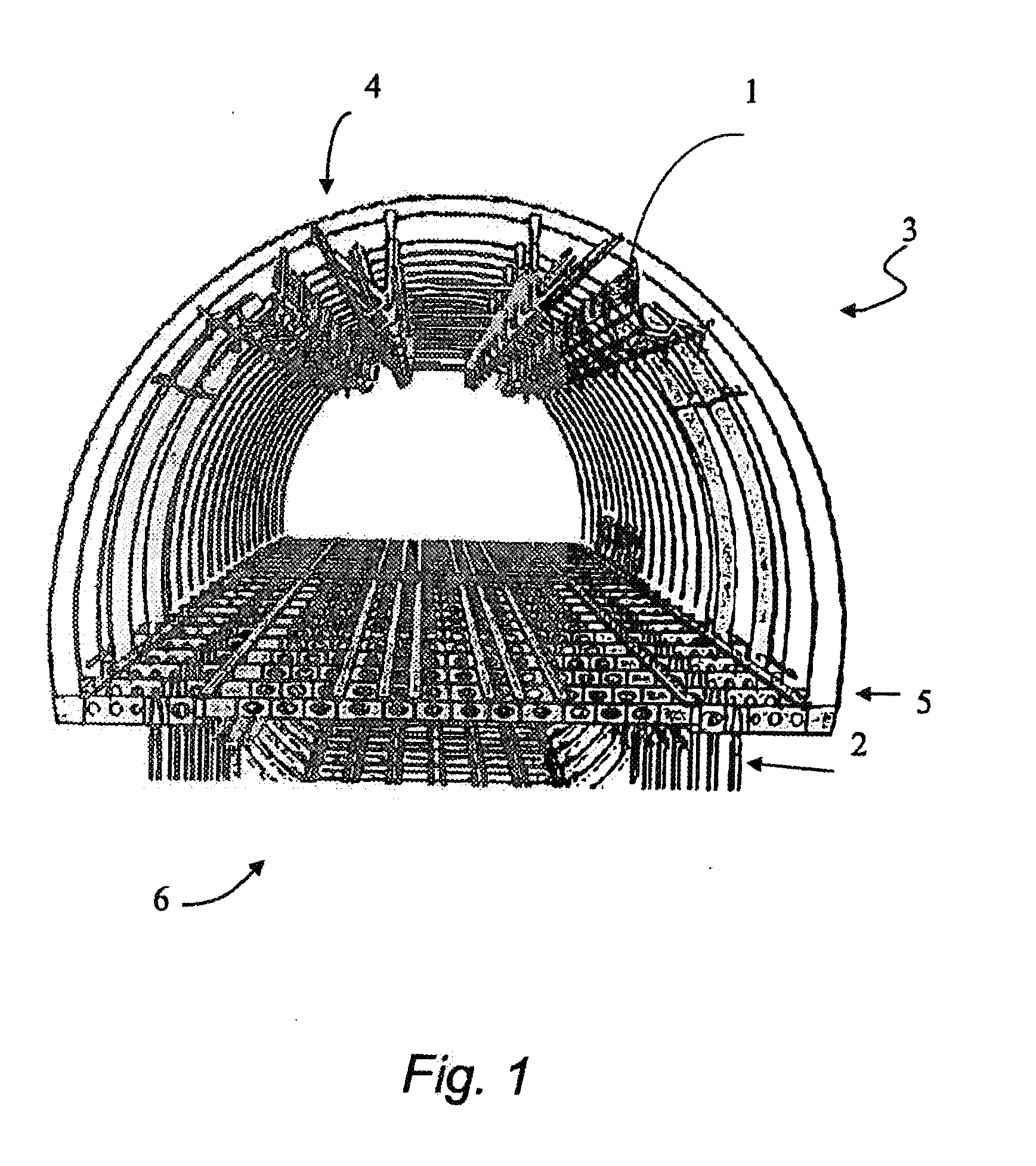

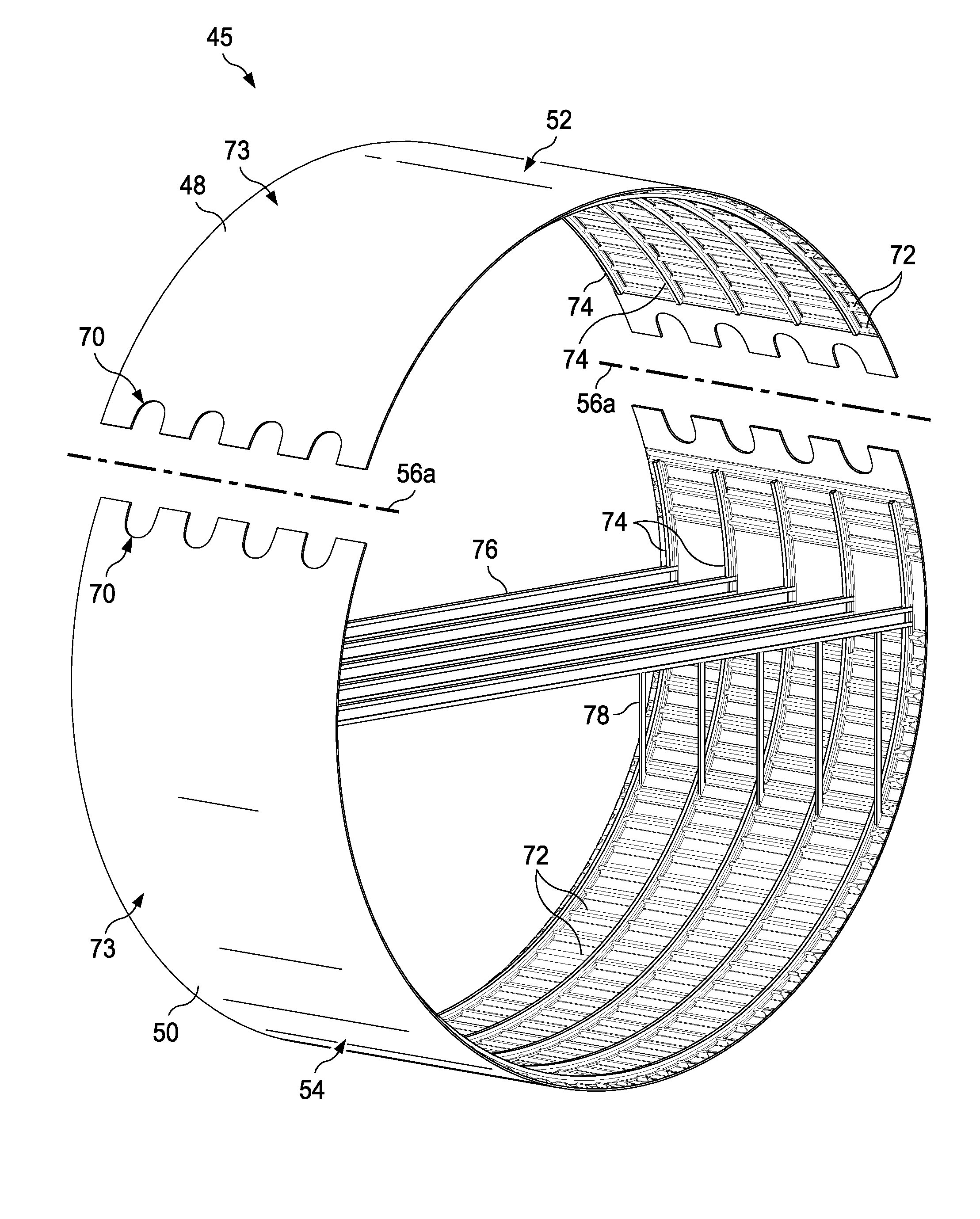

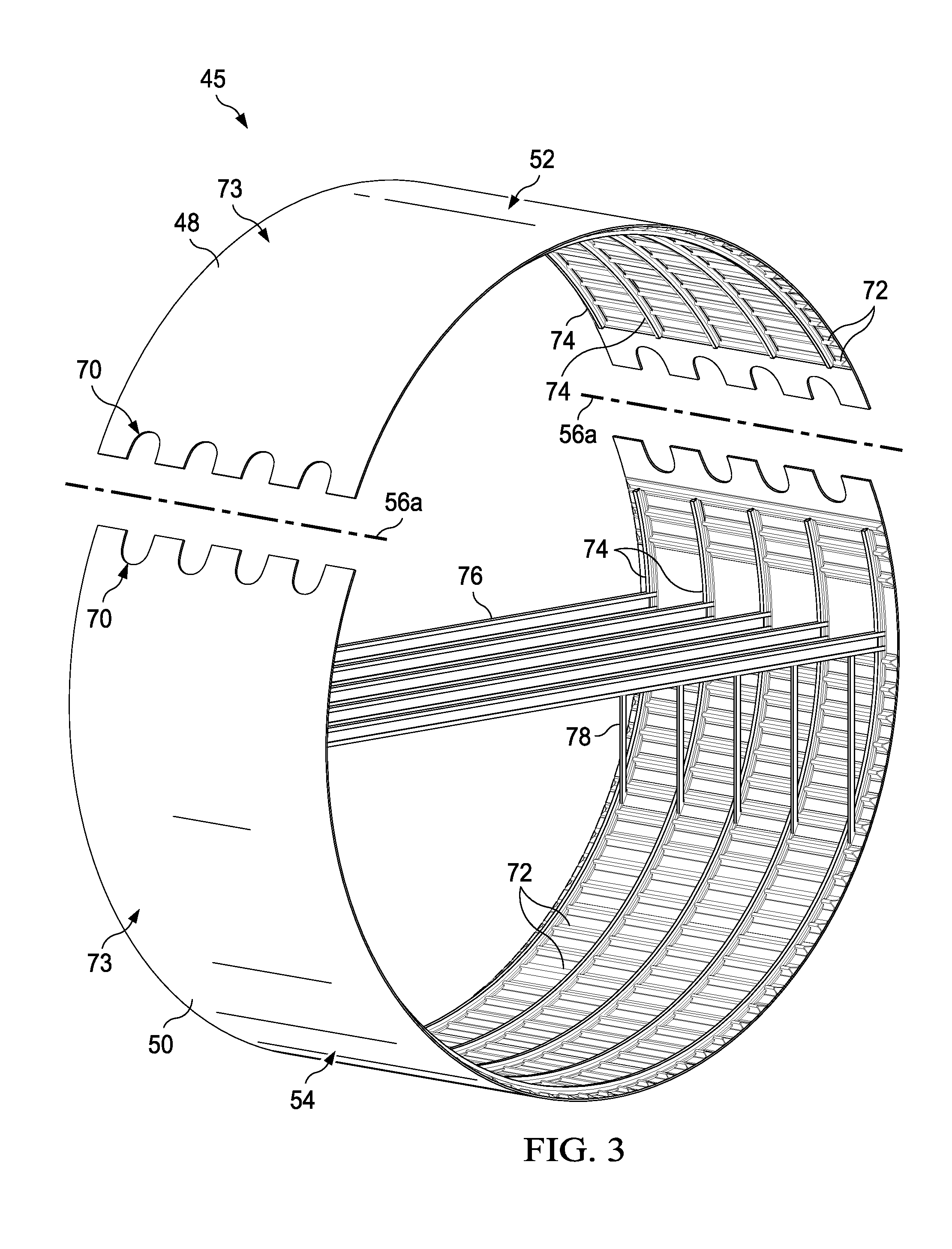

Joining Composite Fuselage Sections Along Window Belts

ActiveUS20140001311A1Improves production flow timeShorten assembly timeLamination ancillary operationsLaminationWindow openingEngineering

A fuselage having a longitudinal window belt has a composite outer skin including upper and lower composite skin sections. The skin includes at least one window opening located at the window belt. The upper and lower skin sections are joined together by a longitudinal splice joint located at the window belt.

Owner:THE BOEING CO

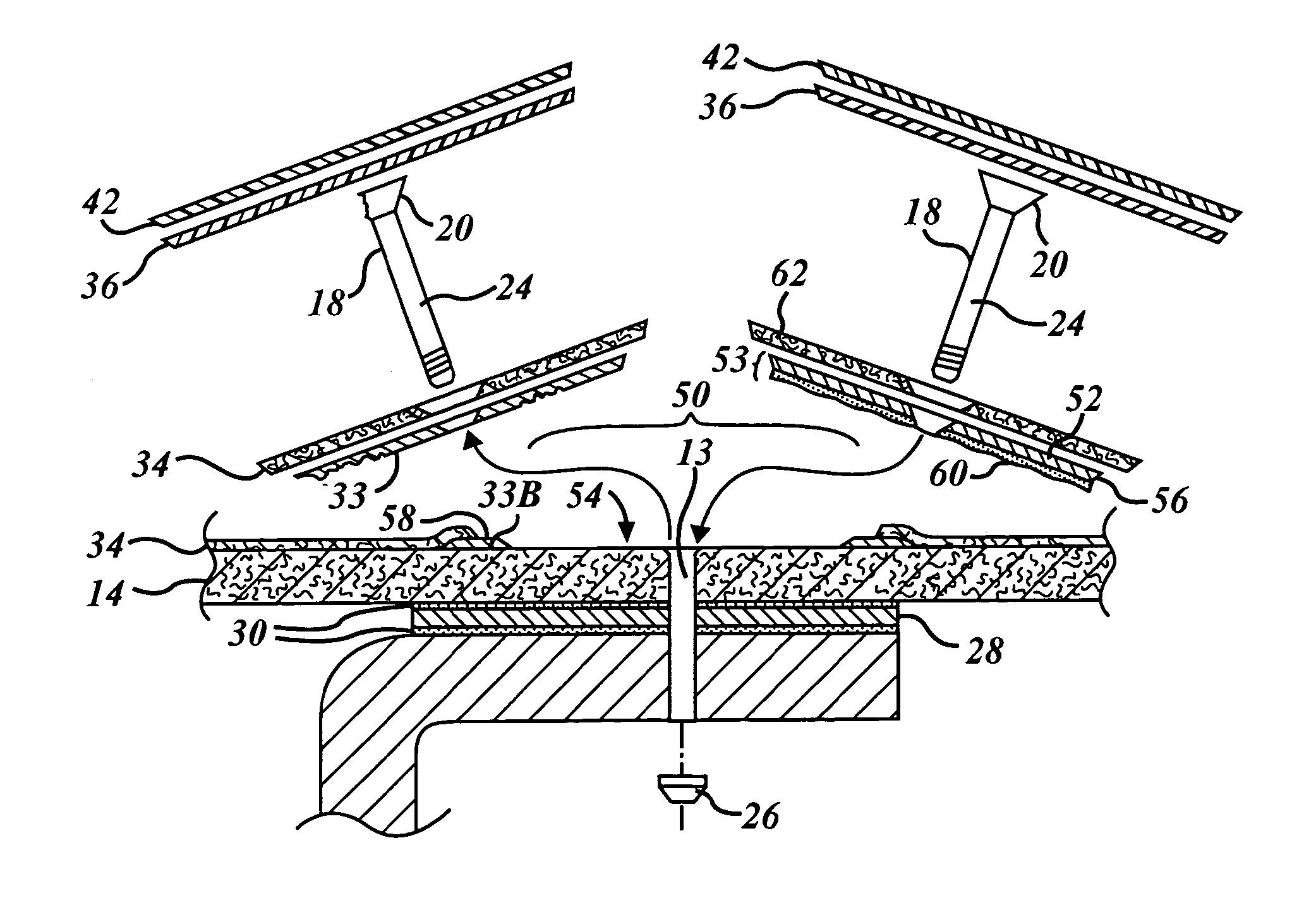

Method for producing a composite skin in the field of aeronautics and astronautics

ActiveUS9314875B2Reduce weightEasy to produceFuselage framesEfficient propulsion technologiesComposite skinEngineering

A composite skin for the aeronautics and astronautics industries, and also a method for producing a composite skin of this type is provided. The method comprises the following method steps: removing excess material from a butt plate to form a butt strap at one end thereof, subsequently connecting the other end of the butt plate to a skin plate with a substance-to-substance bond, and then fastening a further skin plate to the butt strap to form the composite skin. The idea behind the invention involves replacing a rivet connection with a substance-to-substance bond. This provides the advantage that the weight of the composite skin and the production costs for the composite skin are reduced.

Owner:AIRBUS OPERATIONS GMBH

Copper grid repair technique for lightning strike protection

ActiveUS20100132875A1Low densityImprove dielectric breakdown strengthFuselage bulkheadsAircraft static dischargersElectricityLightning strike

A method for reworking an electrically conductive layer of a composite skin is disclosed in which a patch replaces the altered section of the electrically conductive layer. The method is performed by removing a portion of the electrically conductive layer to reveal the underlying composite skin. A patch is formed, having an electrically conductive section coupled to an adhesive having a low dielectric breakdown strength, and is then introduced over the underlying composite skin such that the adhesive layer covers the underlying composite skin and overlaps an unremoved portion of the electrically conductive layer. The patch is applied such that the electrically conductive section within the patch covers the adhesive layer and overlaps the unremoved section of the electrically conductive layer. The adhesive layer preferably has a low dielectric breakdown strength, so that electricity from lightning which strikes the composite skin may be conducted through the adhesive.

Owner:THE BOEING CO

Highly reliable, low cost wind turbine rotor blade

A wind turbine rotor blade and a wind turbine incorporating the rotor blade include a first and second composite skin. A first and a second spar pultrusion having a base and a plurality of integral ribs generally normal to the base are attached to the inside surface of the first and second composite skins and extend the span of the rotor blade. At least one shear web connects a rib of the first spar pultrusion to a corresponding rib of the second spar pultrusion. The width of the spar pultrusions decreases in a step-wise fashion along the span of the rotor blade from the root to the tip. The leading or trailing edge of the rotor blade may be selectably opened for inspection and repair.

Owner:PIASECKI AIRCRAFT CORP

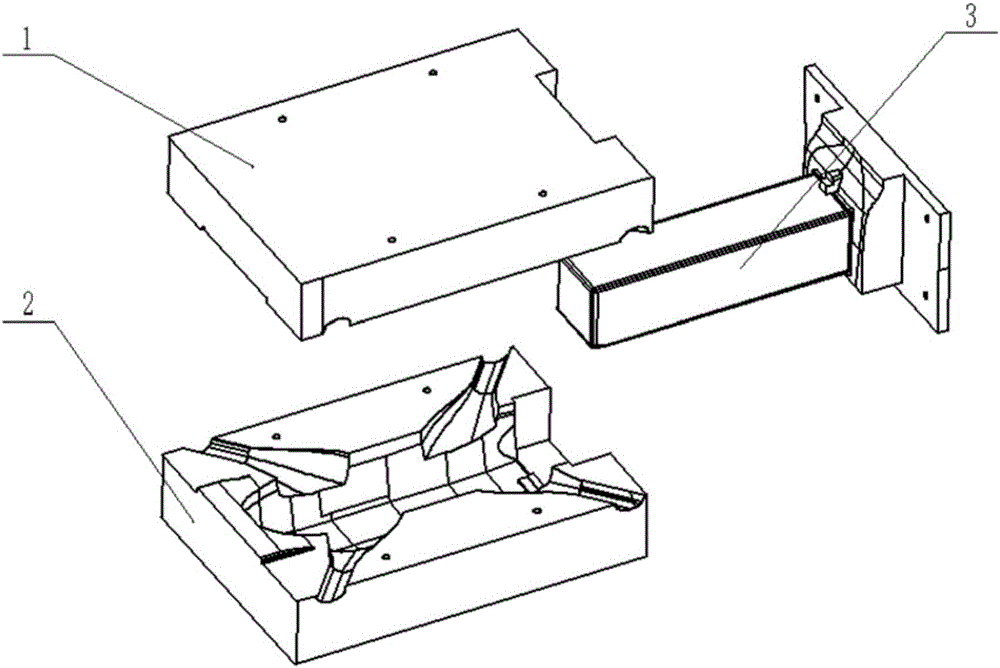

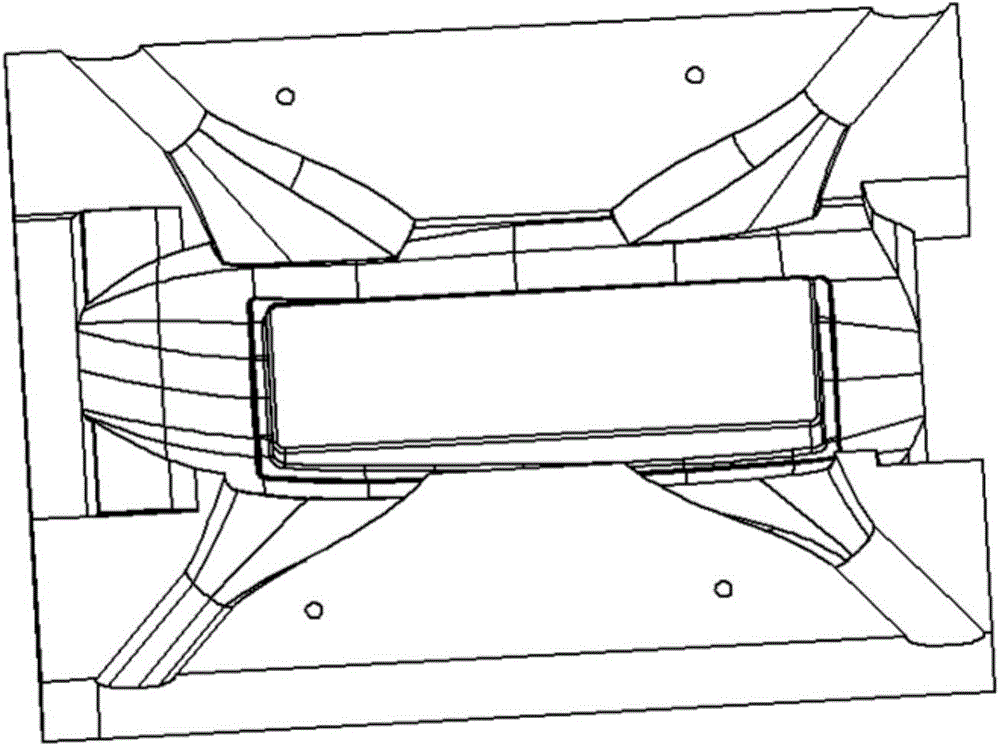

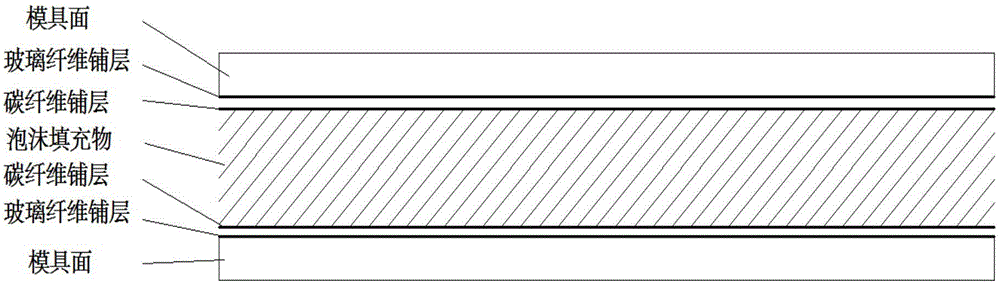

Manufacturing method for full-height multi-rotor unmanned aerial vehicle of foam structure

The invention discloses a full-height multi-rotor unmanned aerial vehicle of a foam structure and a manufacturing method thereof. A body of the unmanned aerial vehicle is made through an integrated forming mode and comprises a composite skin, a foam core body interlayer and a plastic frame body skeleton. The composite skin wraps the foam core body interlayer and the plastic frame body skeleton in an adhesive mode, so that the body of the unmanned aerial vehicle is formed. According to the manufacturing method, low-density PMI foam, carbon fibers good in rigidity and strength and a glass fiber reinforced epoxy resin skin are connected together by combining an upper mold with a lower mold, so that a multi-rotor unmanned aerial vehicle body structure good in performance and complex in appearance is formed, and help is offered to the electric multi-rotor unmanned aerial vehicle with large loads during long-endurance flying.

Owner:AEROSPACE SHENZHOU AIRCRAFT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com