Patents

Literature

77results about How to "Improve dielectric breakdown strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

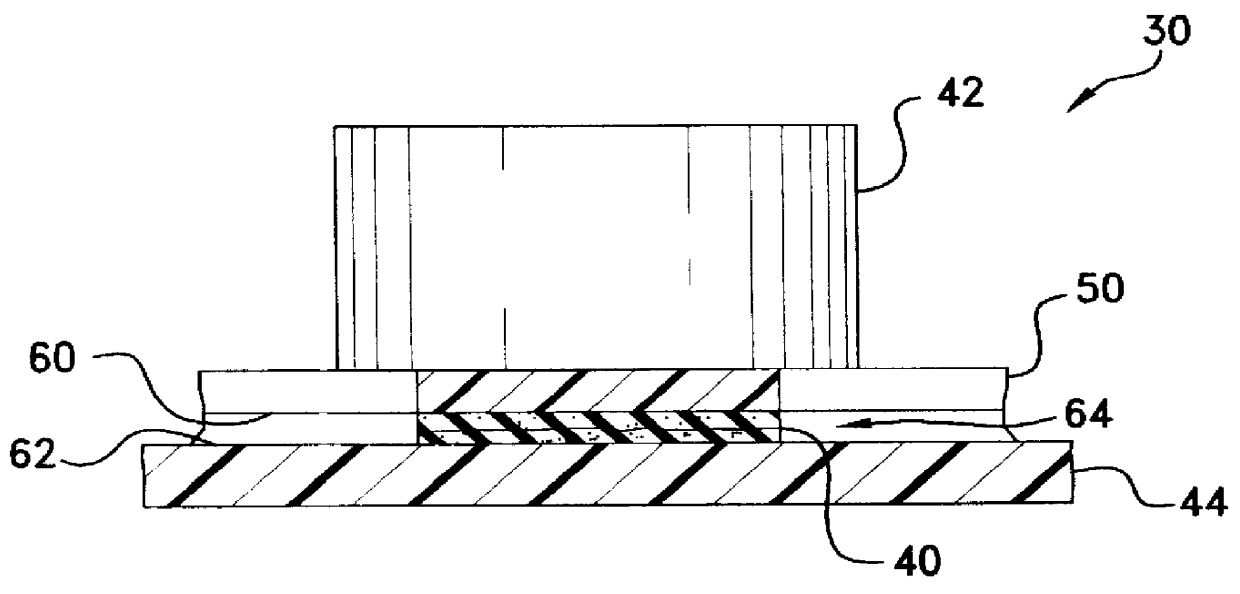

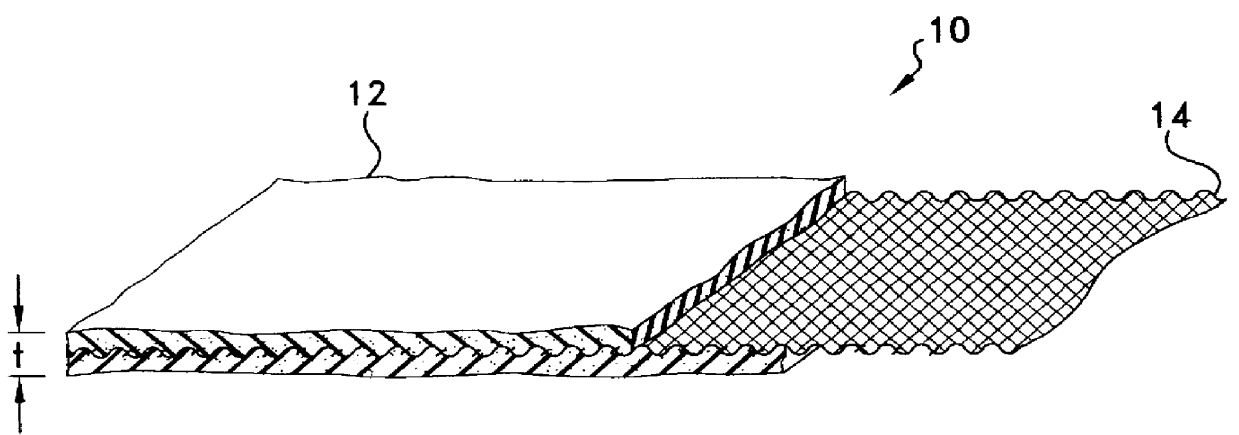

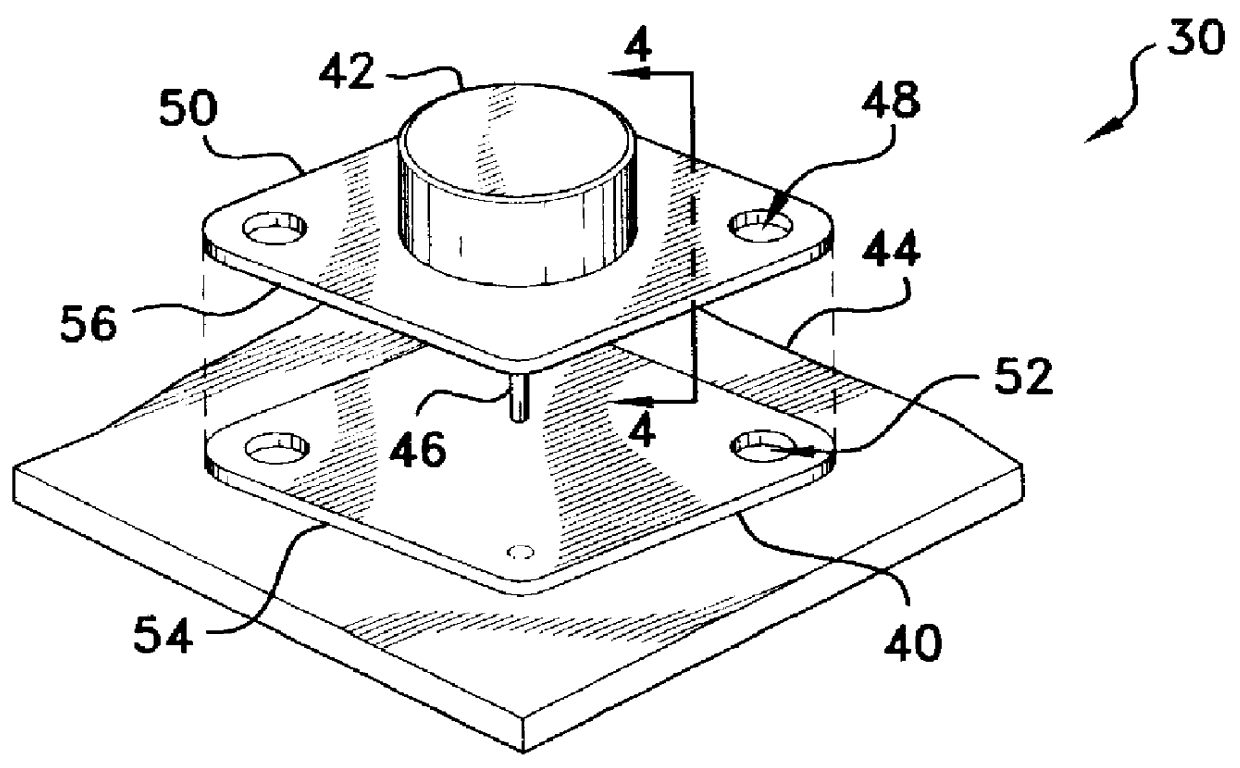

High dielectric strength thermal interface material

InactiveUS6096414AImprove performanceMaintain good propertiesOther chemical processesSynthetic resin layered productsThermal conductivityThermal transmittance

A thermally-conductive, electrically insulative interface for conductively cooling a heat-generating source, such as an electronic component, having an associated thermal dissipation member such as a heat sink. The interface is provided as a cured sheet of a curable material formulated as a blend of a curable silicone binder, and a particulate alumina, i.e., aluminum oxide (Al2O3), filler. The interface is observed to exhibit a thermal conductivity of at least about 0.8 W / m-K and a wet dielectric breakdown strength of at least about 475 Vac / mil.

Owner:PARKER INTANGIBLES LLC

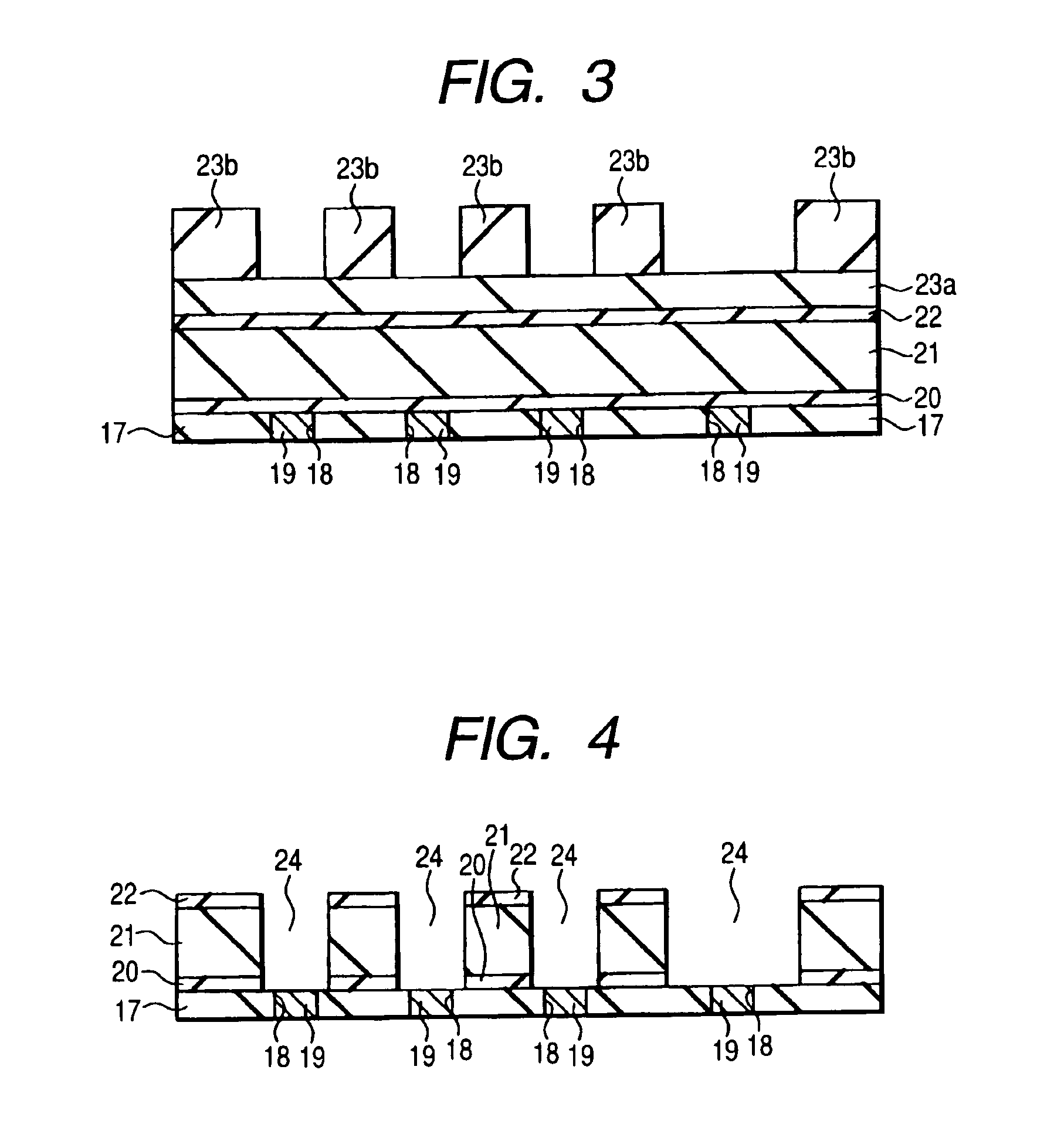

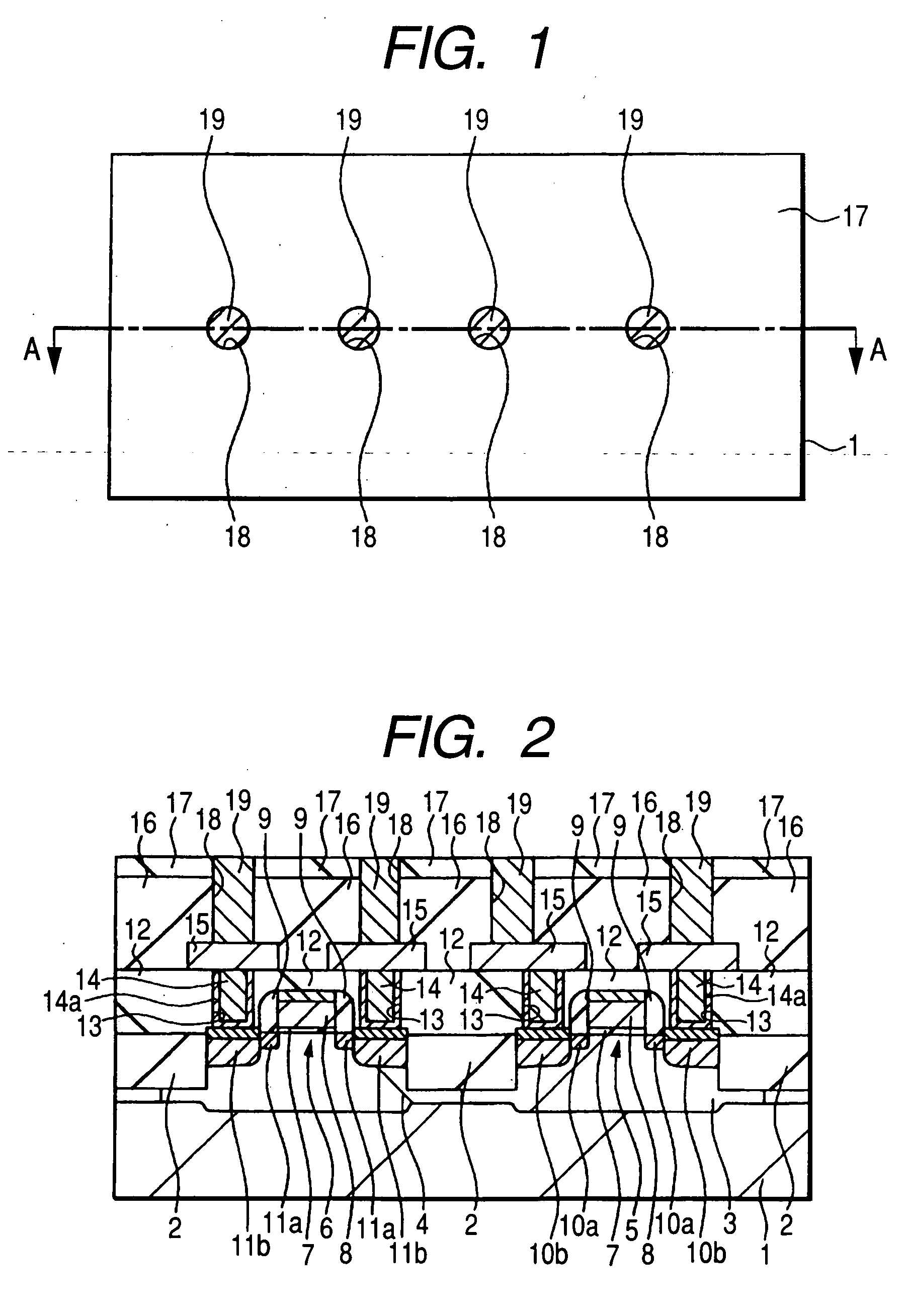

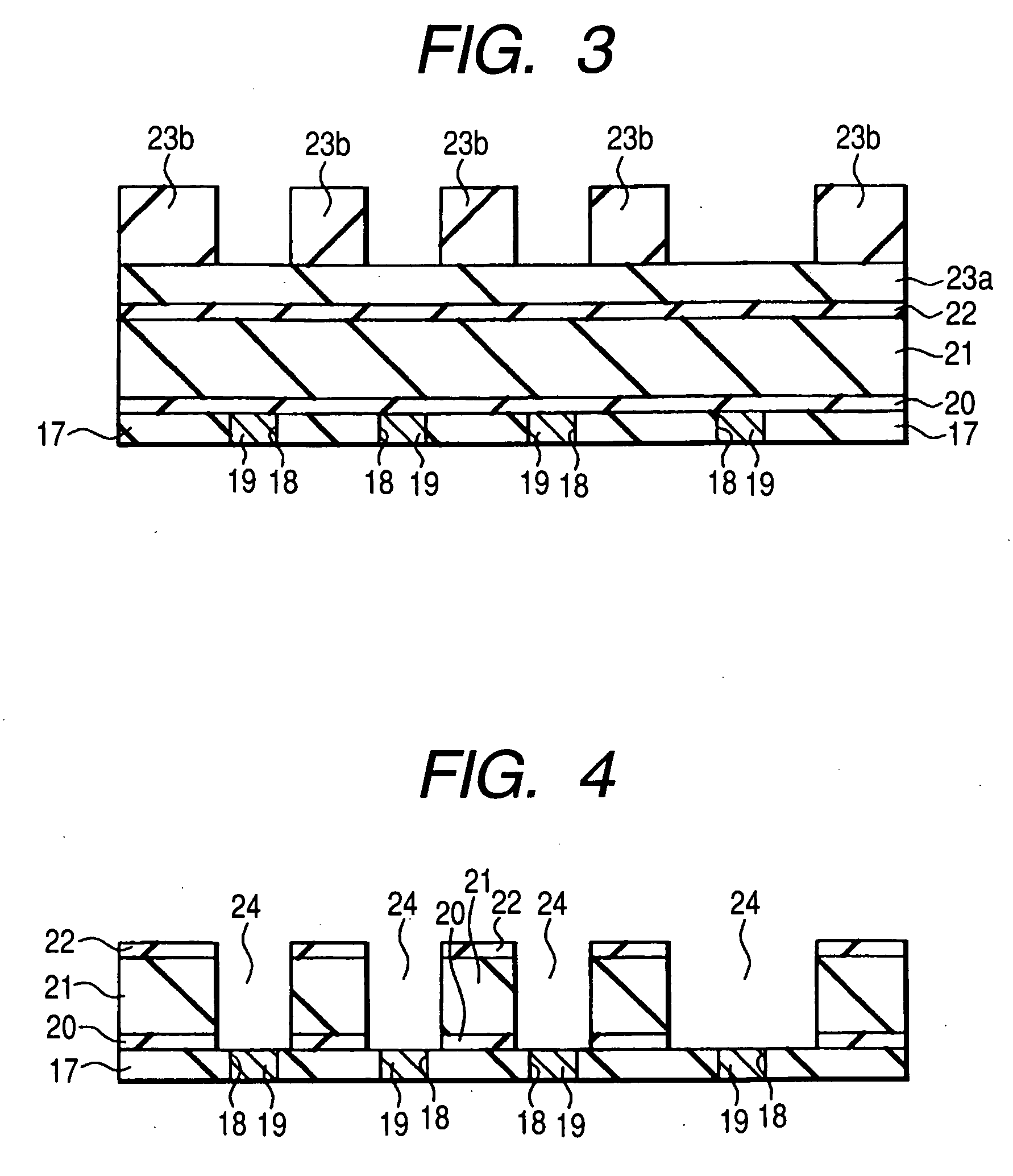

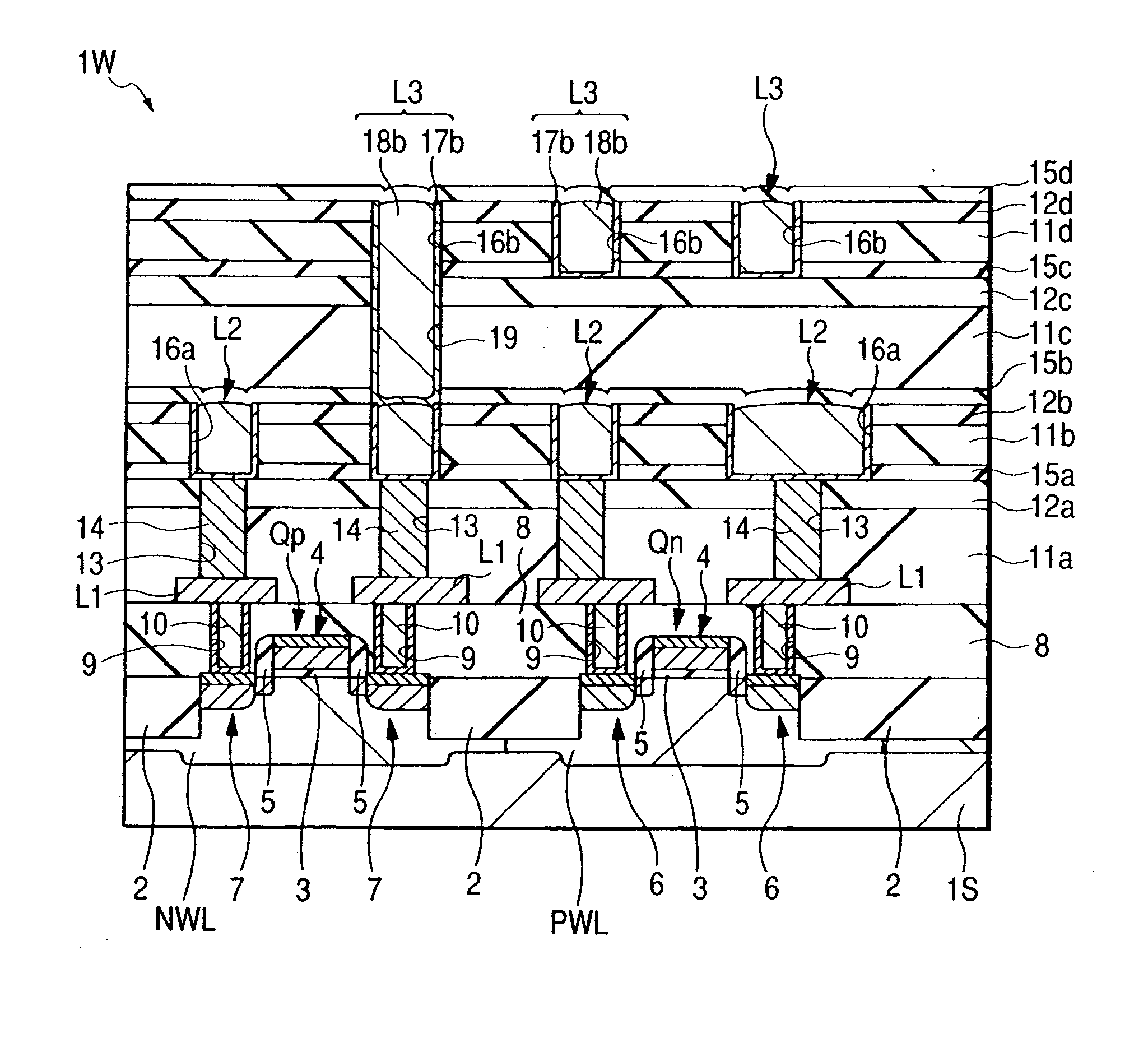

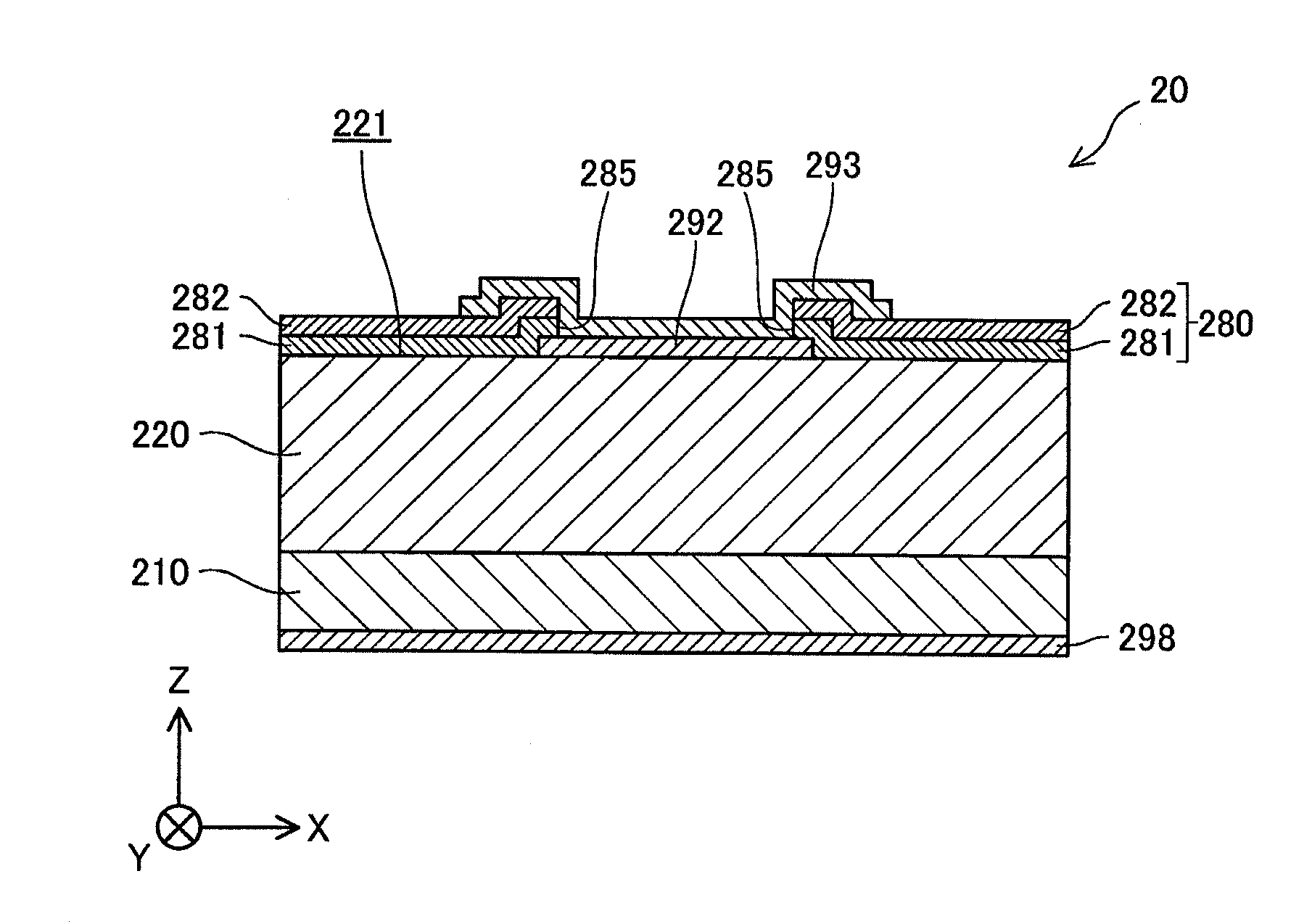

Semiconductor device including an interconnect having copper as a main component

InactiveUS7042095B2Improve dielectric breakdown strengthReduce capacitanceSemiconductor/solid-state device detailsSolid-state devicesCapacitanceCopper interconnect

Provided are a semiconductor device comprising a semiconductor substrate, a first insulating film formed thereover, interconnects formed over the first insulating film and having copper as a main component, a second insulating film formed over the upper surface and side surfaces of each of the interconnects and over the first insulating film and having a function of suppressing or preventing copper diffusion, and a third insulating film formed over the second insulating film and having a dielectric constant lower than that of the second insulating film; and a method of manufacturing the semiconductor device. This invention makes it possible to improve dielectric breakdown strength between copper interconnects and reduce capacitance between the copper interconnects.

Owner:TESSERA ADVANCED TECH

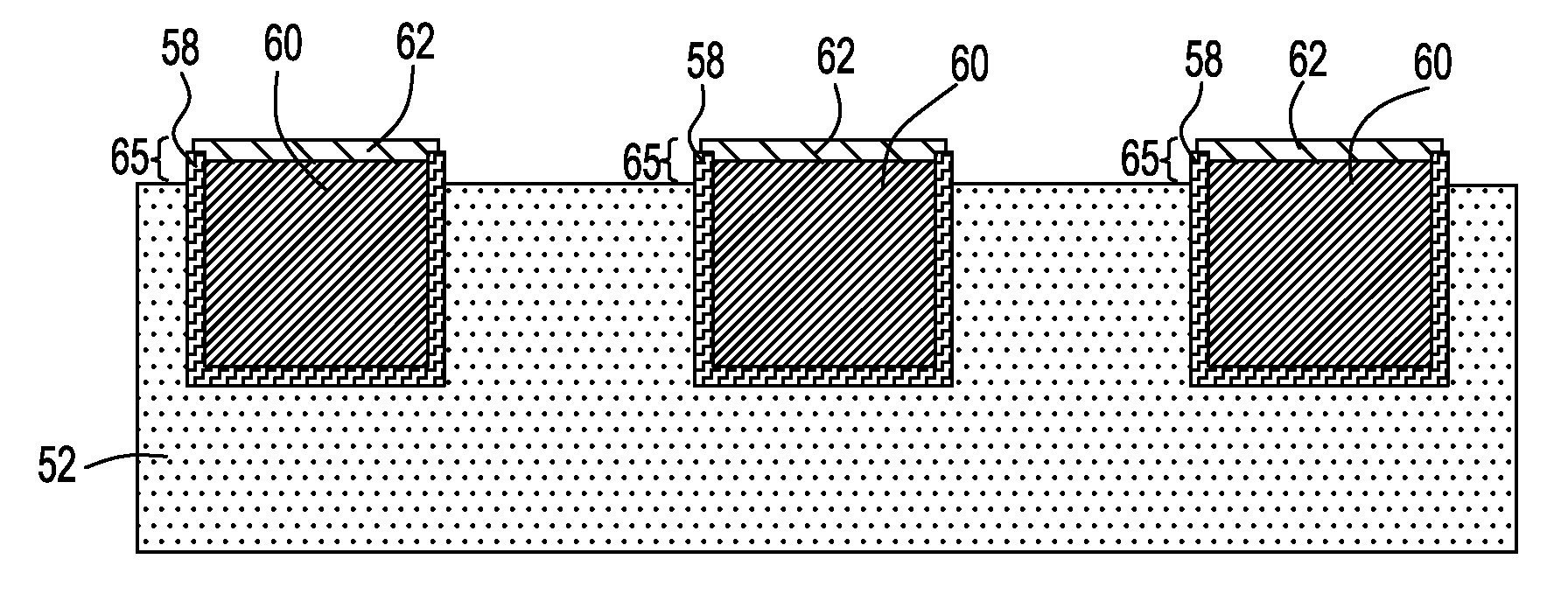

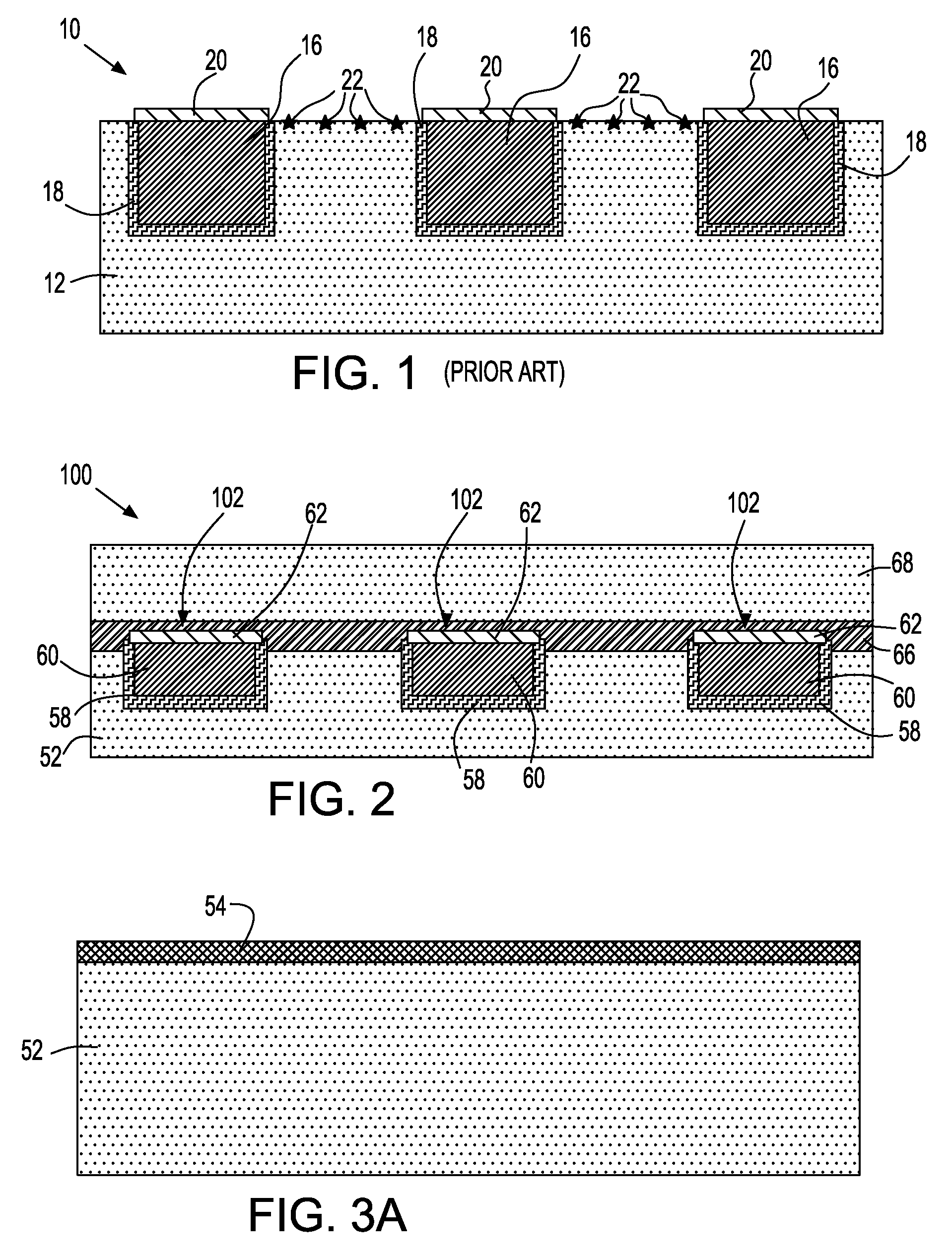

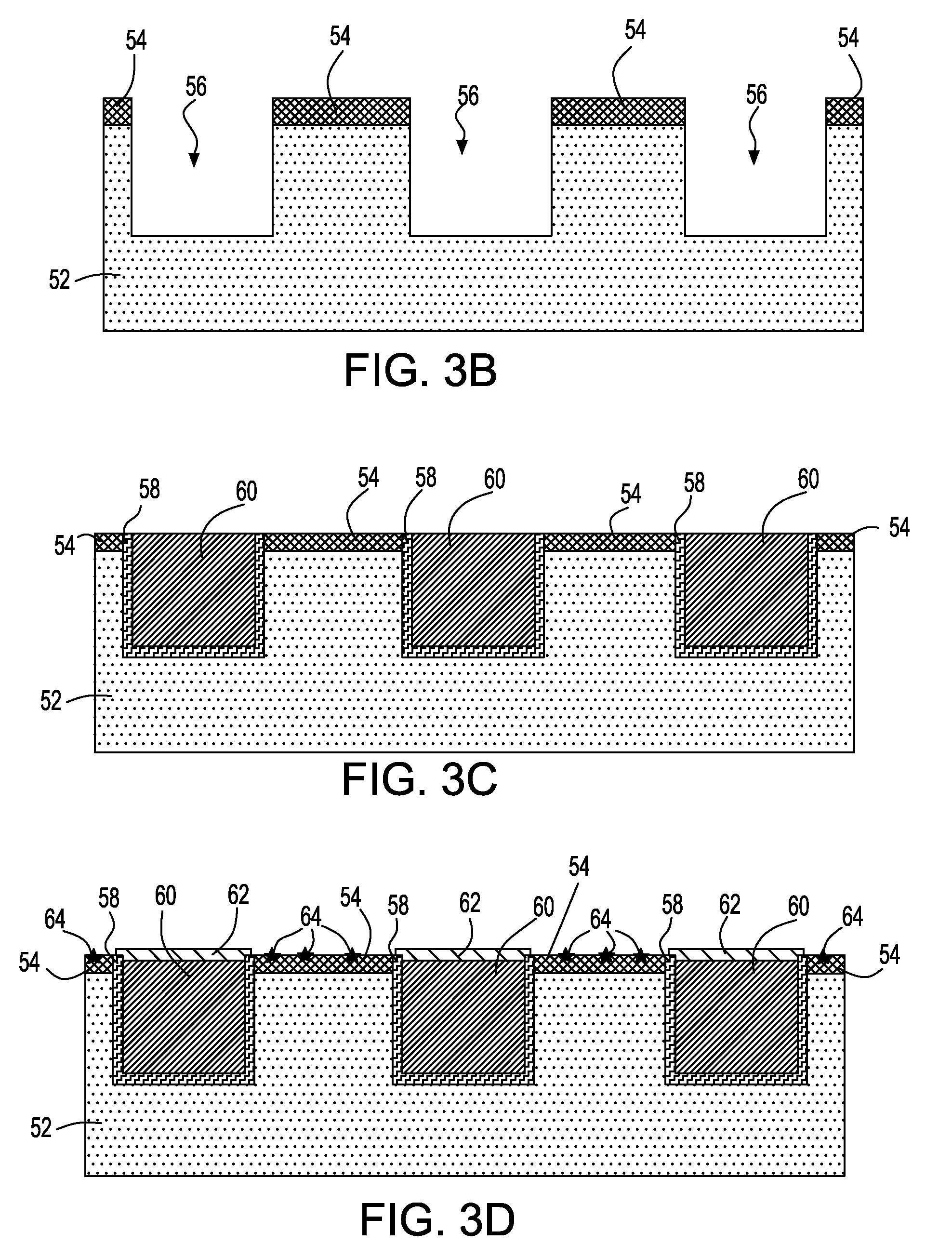

Structure for metal cap applications

InactiveUS20080197499A1Improve dielectric breakdown strengthImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesState of artDielectric breakdown strength

An interconnect structure is provided in which the conductive features embedded within a dielectric material are capped with a metallic capping layer, yet no metallic residue is present on the surface of the dielectric material in the final structure. The inventive interconnect structure has improved dielectric breakdown strength as compared to prior art interconnect structures. Moreover, the inventive interconnect structure has better reliability and technology extendibility for the semiconductor industry. The inventive interconnect structure includes a dielectric material having at least one metallic capped conductive feature embedded therein, wherein a top portion of said at least one metallic capped conductive feature extends above an upper surface of the dielectric material. A dielectric capping layer is located on the dielectric material and it encapsulates the top portion of said at least one metallic capped conductive feature that extends above the upper surface of dielectric material.

Owner:GLOBALFOUNDRIES INC

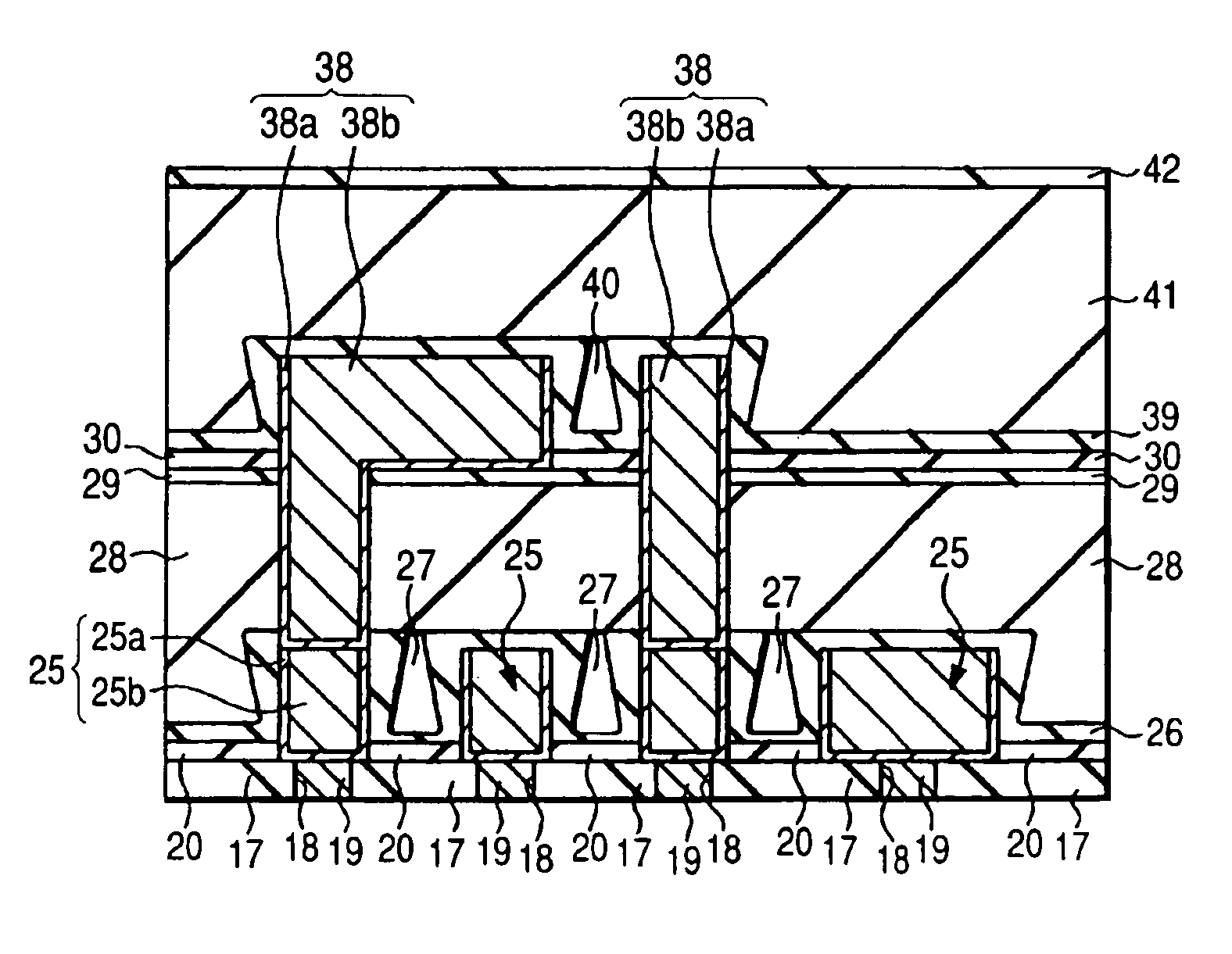

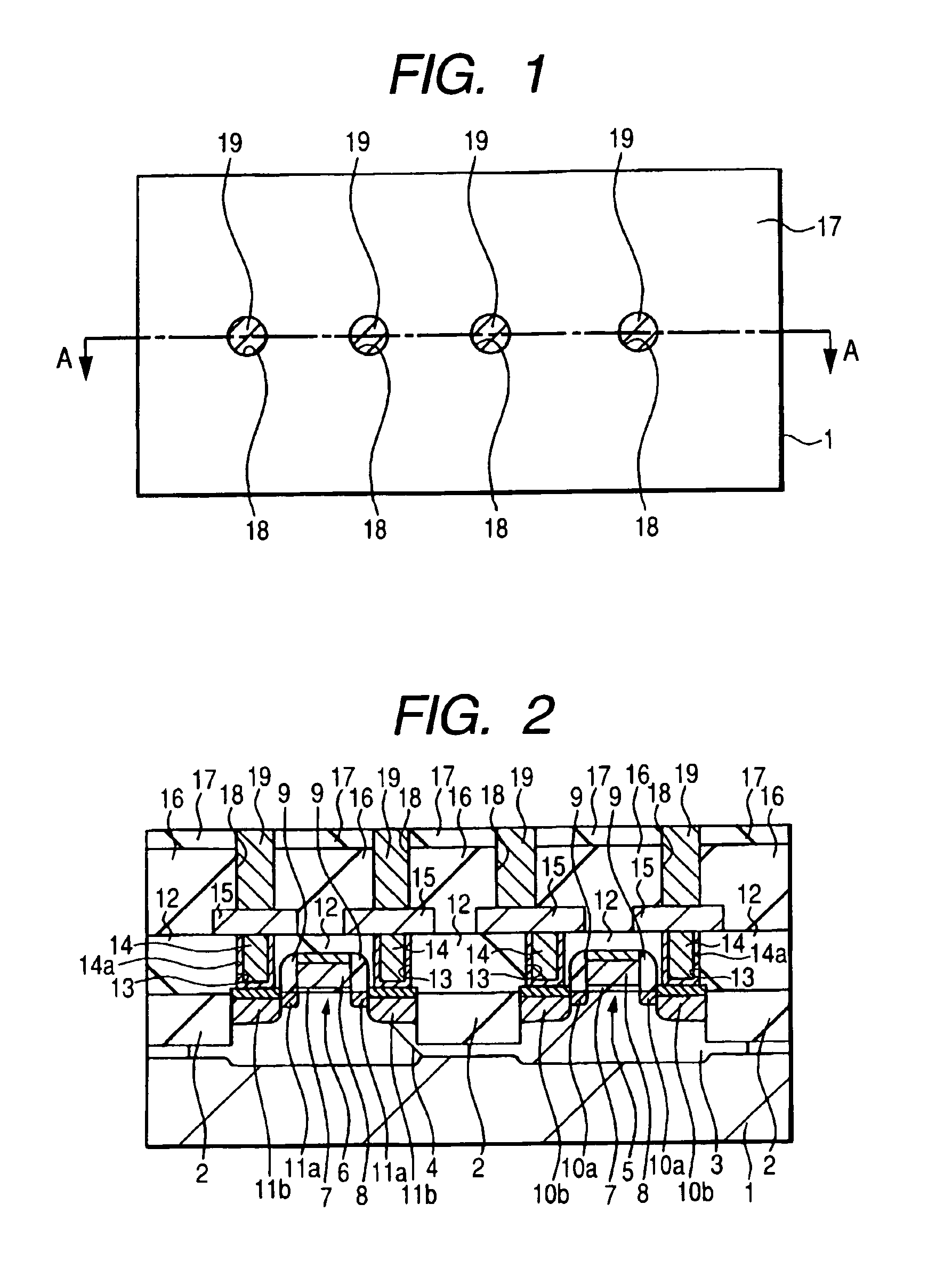

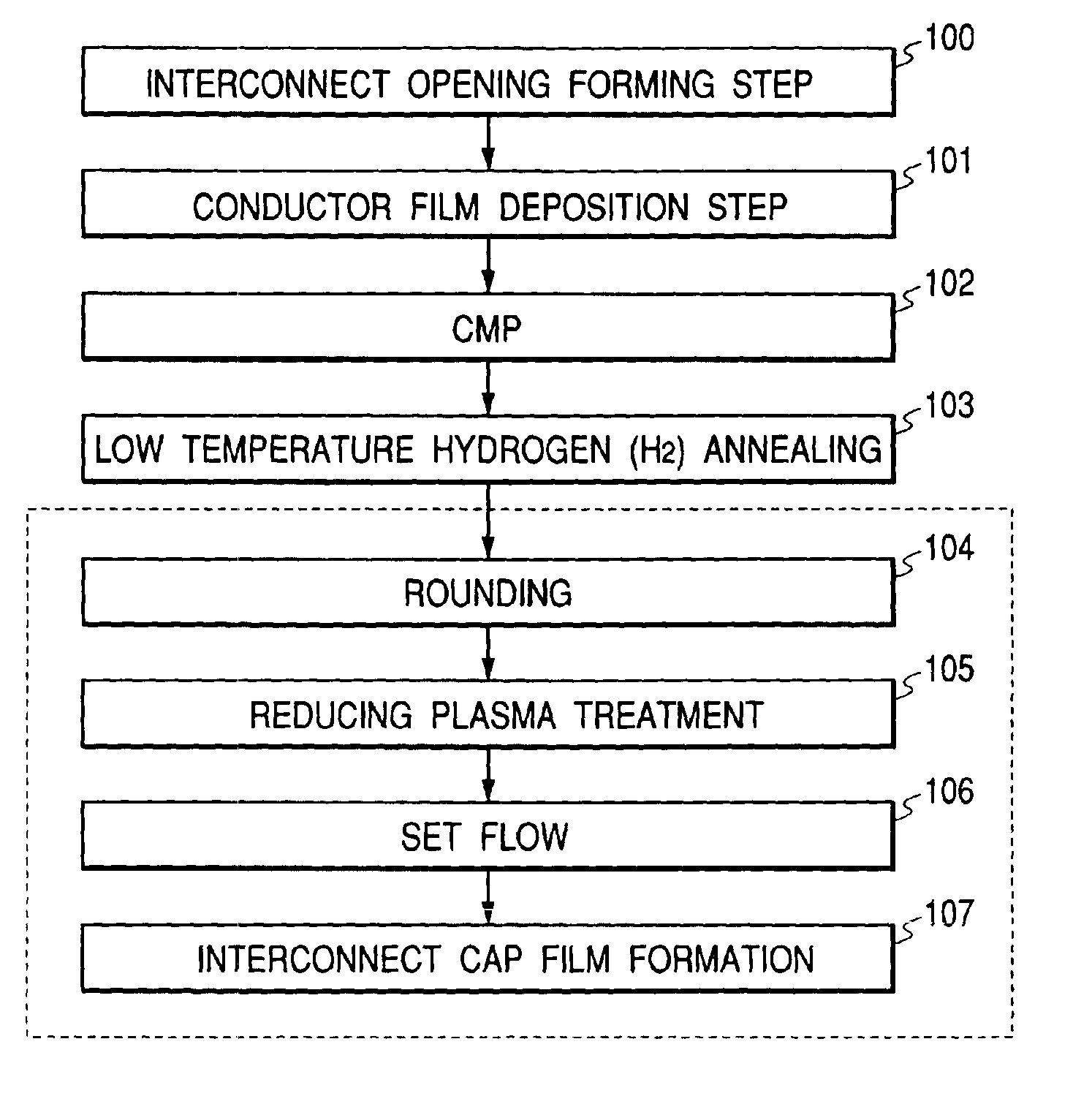

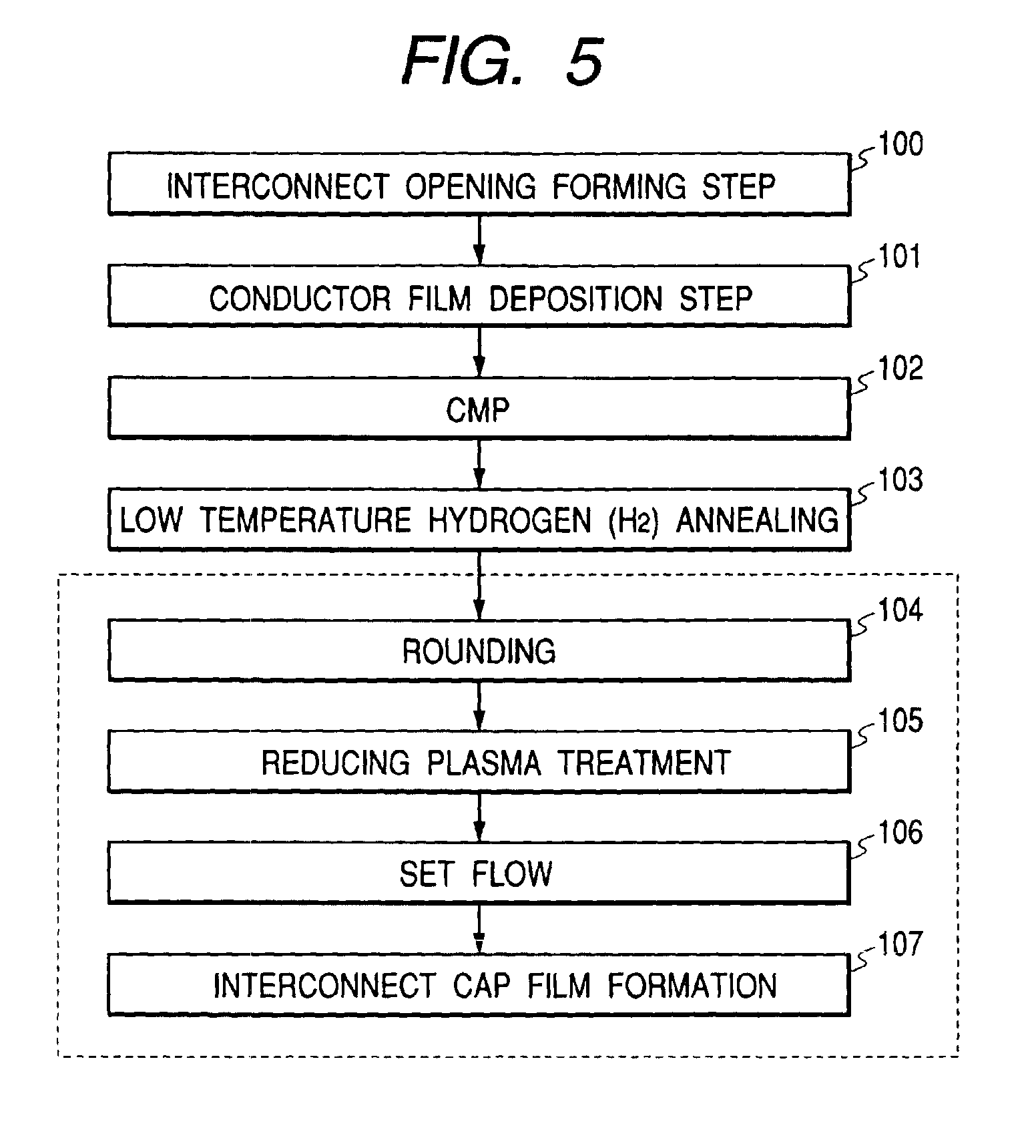

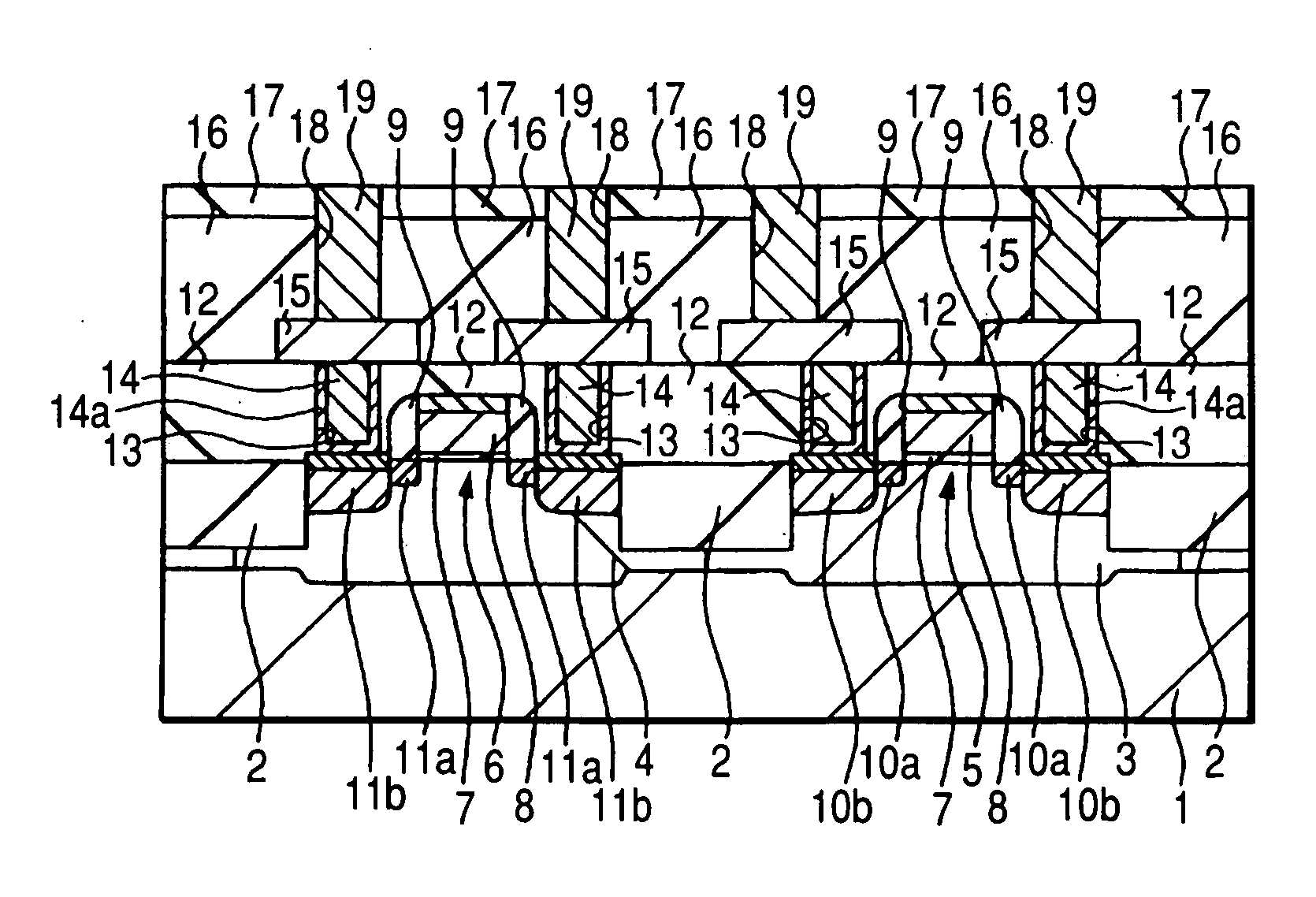

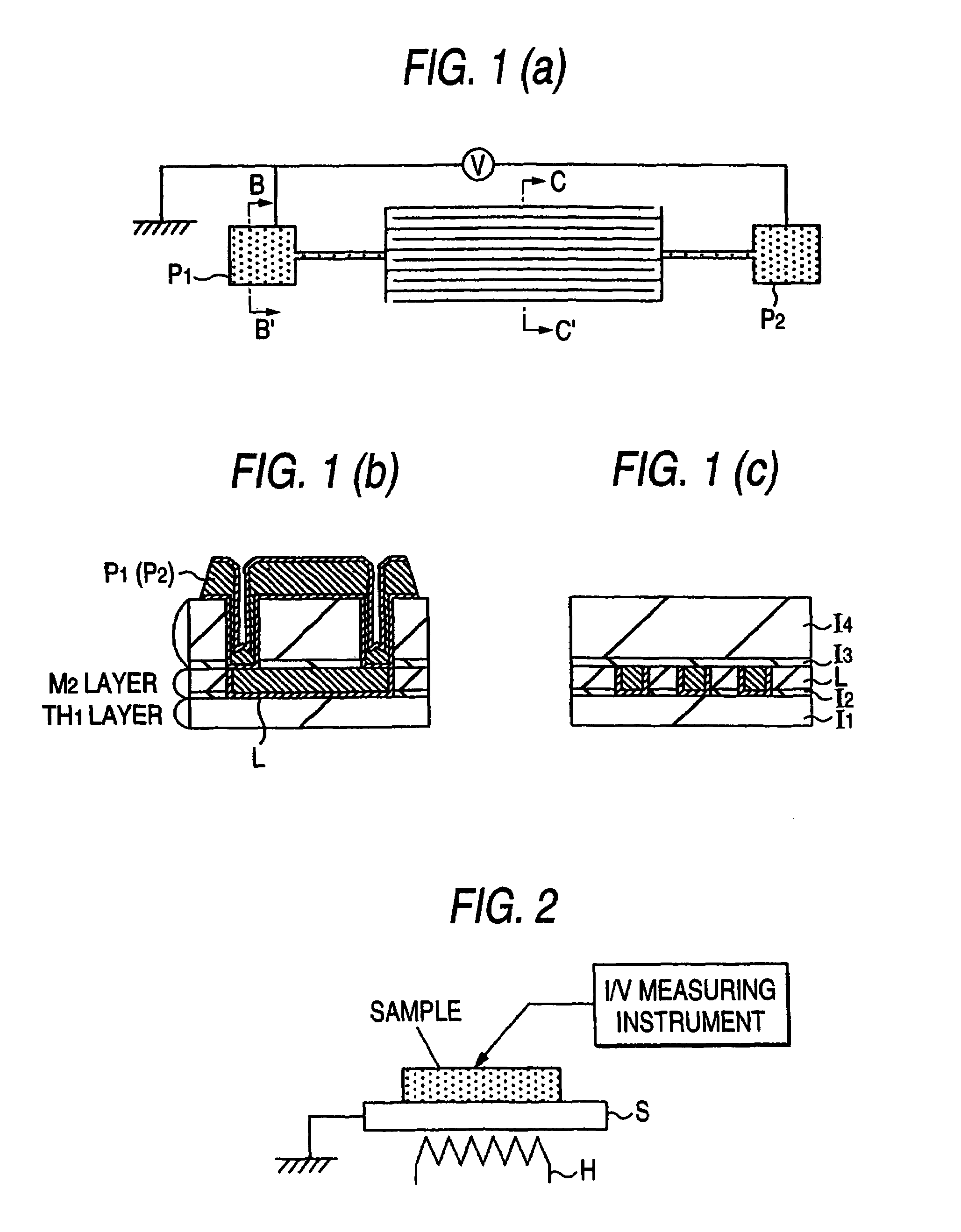

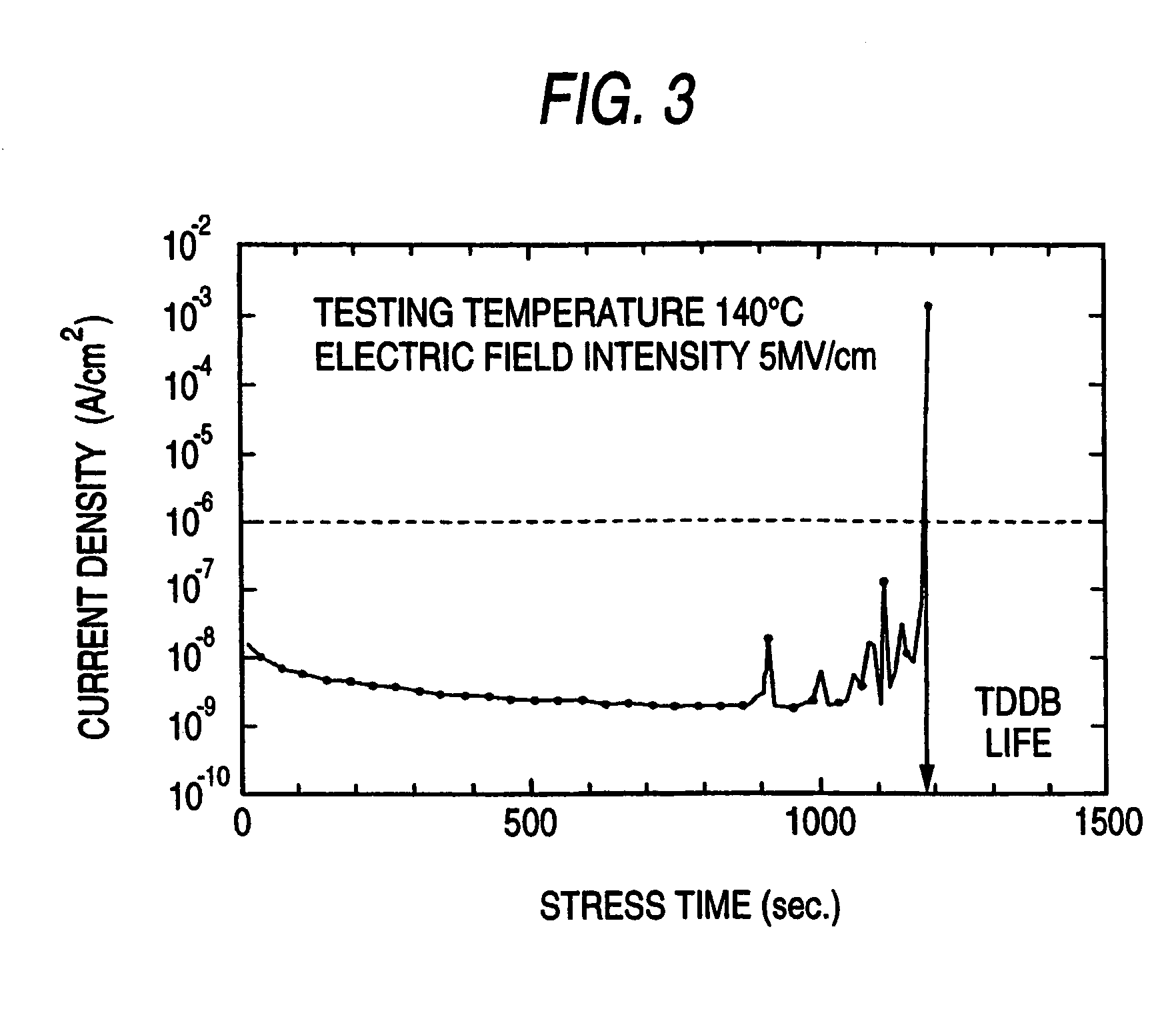

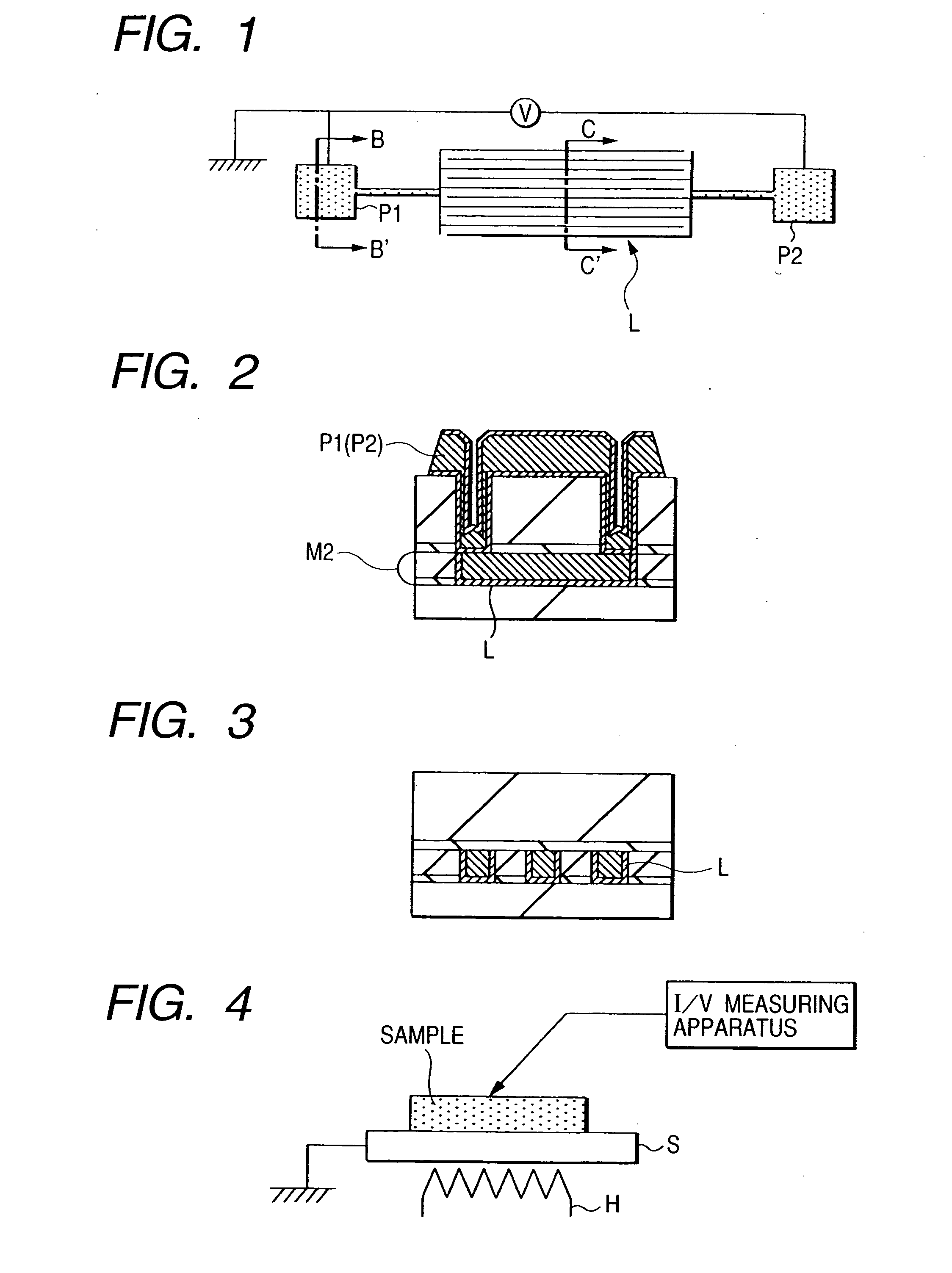

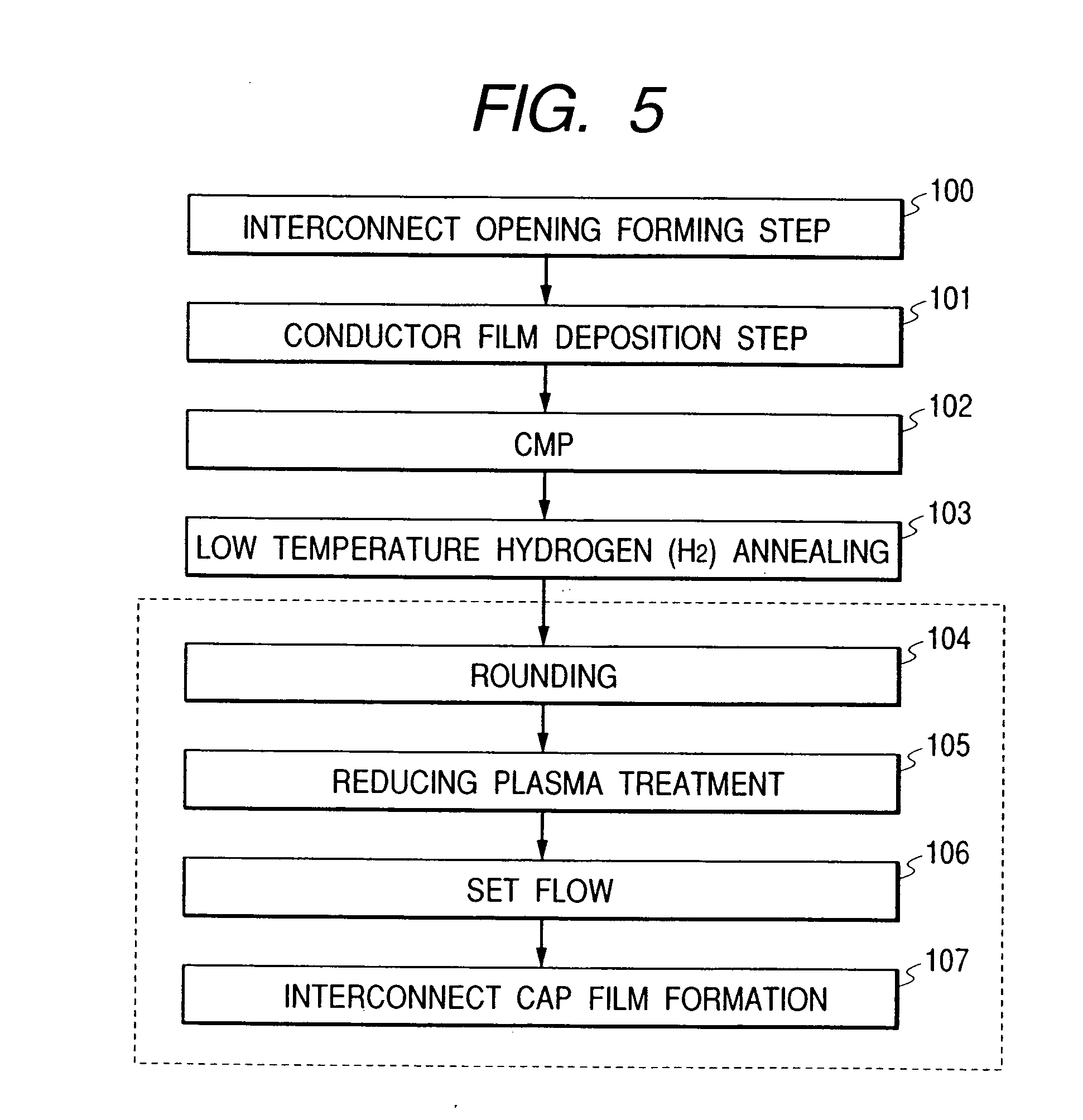

Method for manufacturing semiconductor integrated circuit device

InactiveUS6890846B2Improve dielectric breakdown strengthSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDielectric breakdown strength

Provided is a manufacturing method of a semiconductor device which comprises (a) depositing a first insulating film over a wafer, (b) forming an interconnect opening in the first insulating film, (c) forming, in the interconnect opening, an interconnect having a conductor film comprised mainly of copper, (d) forming a taper at a corner of said conductor film on the opening side of the interconnect opening, and (e) depositing a second insulating film over the first insulating film and interconnect. The present invention makes it possible to improve dielectric breakdown strength between interconnects each having a main conductor film comprised mainly of copper.

Owner:RENESAS ELECTRONICS CORP

Semiconductor device and a method of manufacturing the same

InactiveUS20060183317A1Improve dielectric breakdown strengthReduce capacitanceSemiconductor/solid-state device manufacturingCapacitanceCopper interconnect

Provided are a semiconductor device comprising a semiconductor substrate, a first insulating film formed thereover, interconnects formed over the first insulating film and having copper as a main component, a second insulating film formed over the upper surface and side surfaces of each of the interconnects and over the first insulating film and having a function of suppressing or preventing copper diffusion, and a third insulating film formed over the second insulating film and having a dielectric constant lower than that of the second insulating film; and a method of manufacturing the semiconductor device. This invention makes it possible to improve dielectric breakdown strength between copper interconnects and reduce capacitance between the copper interconnects.

Owner:NOGUCHI JUNJI +1

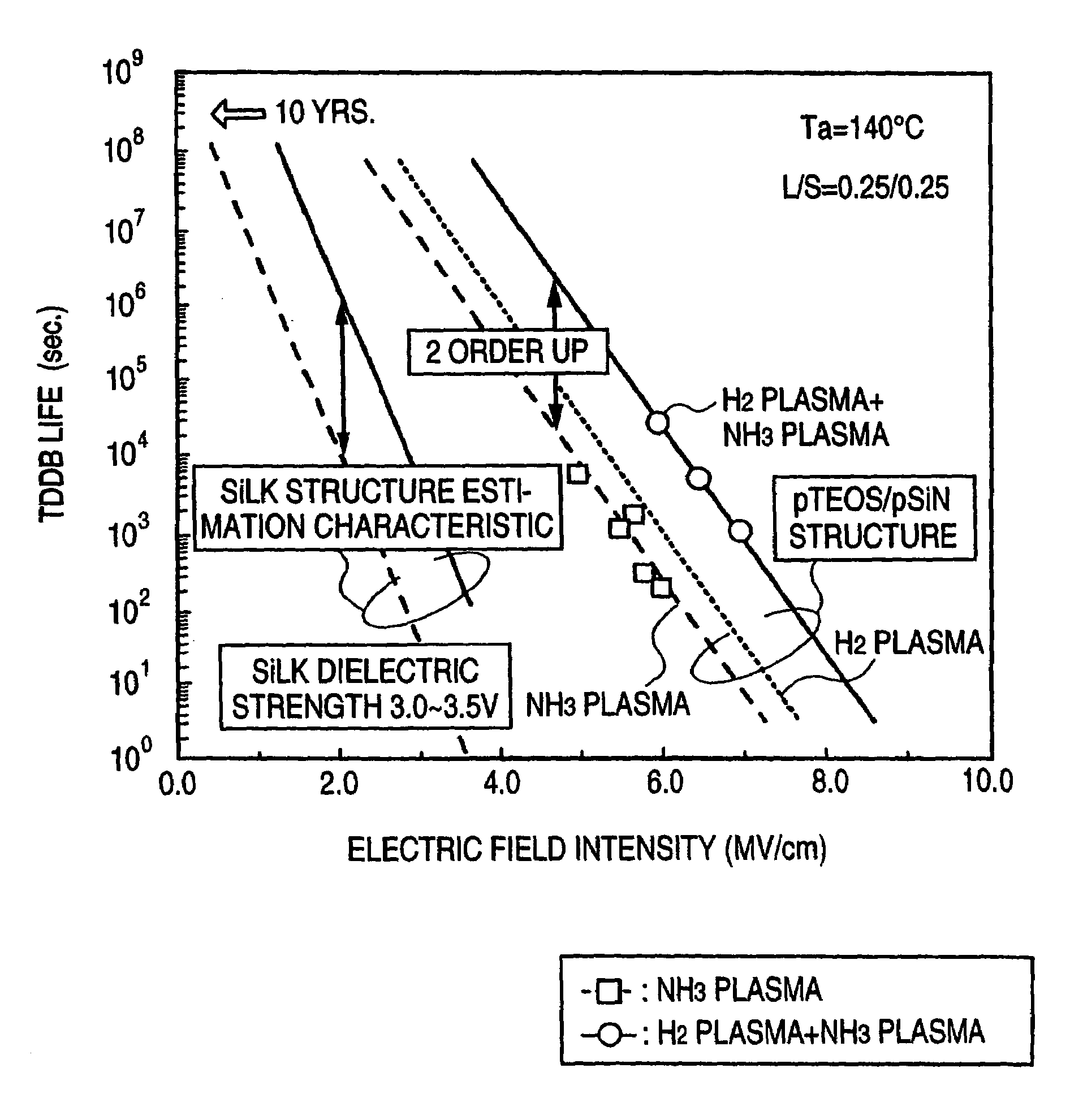

Fabrication method of semiconductor integrated circuit device

InactiveUS7084063B2Improve dielectric breakdown strengthIncrease resistanceTransistorSemiconductor/solid-state device detailsCopper interconnectDielectric breakdown strength

The copper interconnect formed by the use of a damascene technique is improved in dielectric breakdown strength (reliability). During post-CMP cleaning, alkali cleaning, a deoxidizing process due to hydrogen annealing or the like, and acid cleaning are carried out in this order. After the post-CMP cleaning and before forming an insulation film for a cap film, hydrogen plasma and ammonia plasma processes are carried out on the semiconductor substrate. In this way, a copper-based buried interconnect is formed in an interlayer insulation film structured of an insulation material having a low dielectric constant.

Owner:HITACHI LTD

Method for manufacturing semiconductor integrated circuit device

InactiveUS20050196954A1Improve dielectric breakdown strengthSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDevice material

Provided is a manufacturing method of a semiconductor device which comprises (a) depositing a first insulating film over a wafer, (b) forming an interconnect opening in the first insulating film, (c) forming, in the interconnect opening, an interconnect having a conductor film comprised mainly of copper, (d) forming a taper at a corner of said conductor film on the opening side of the interconnect opening, and (e) depositing a second insulating film over the first insulating film and interconnect. The present invention makes it possible to improve dielectric breakdown strength between interconnects each having a main conductor film comprised mainly of copper.

Owner:RENESAS TECH CORP

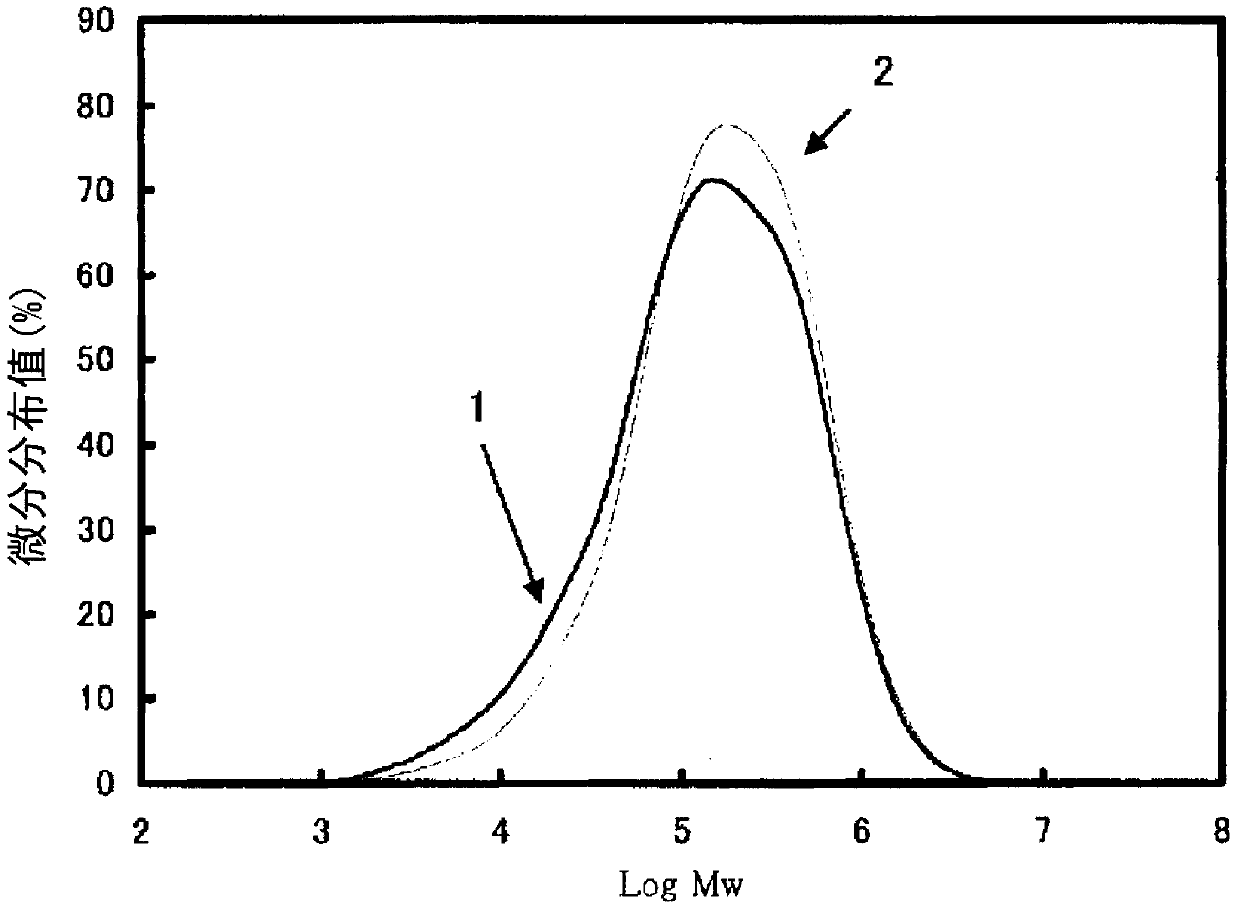

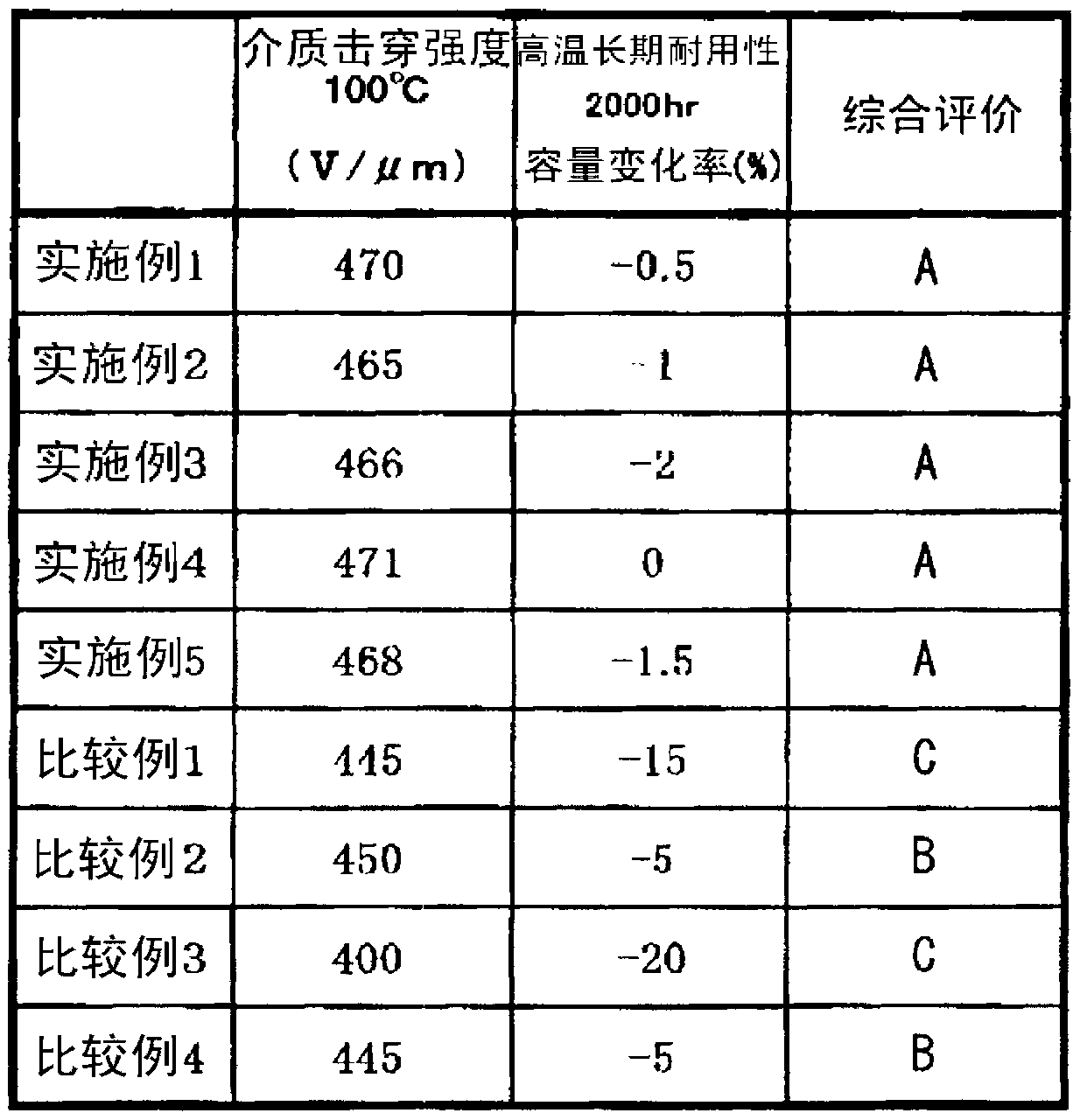

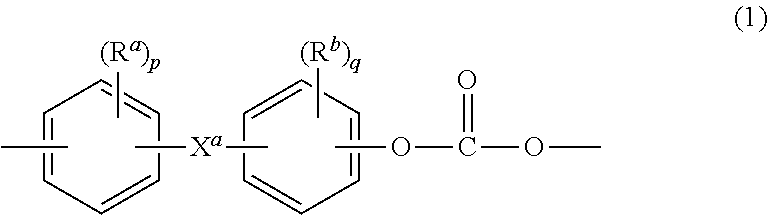

Polypropylene film for capacitor

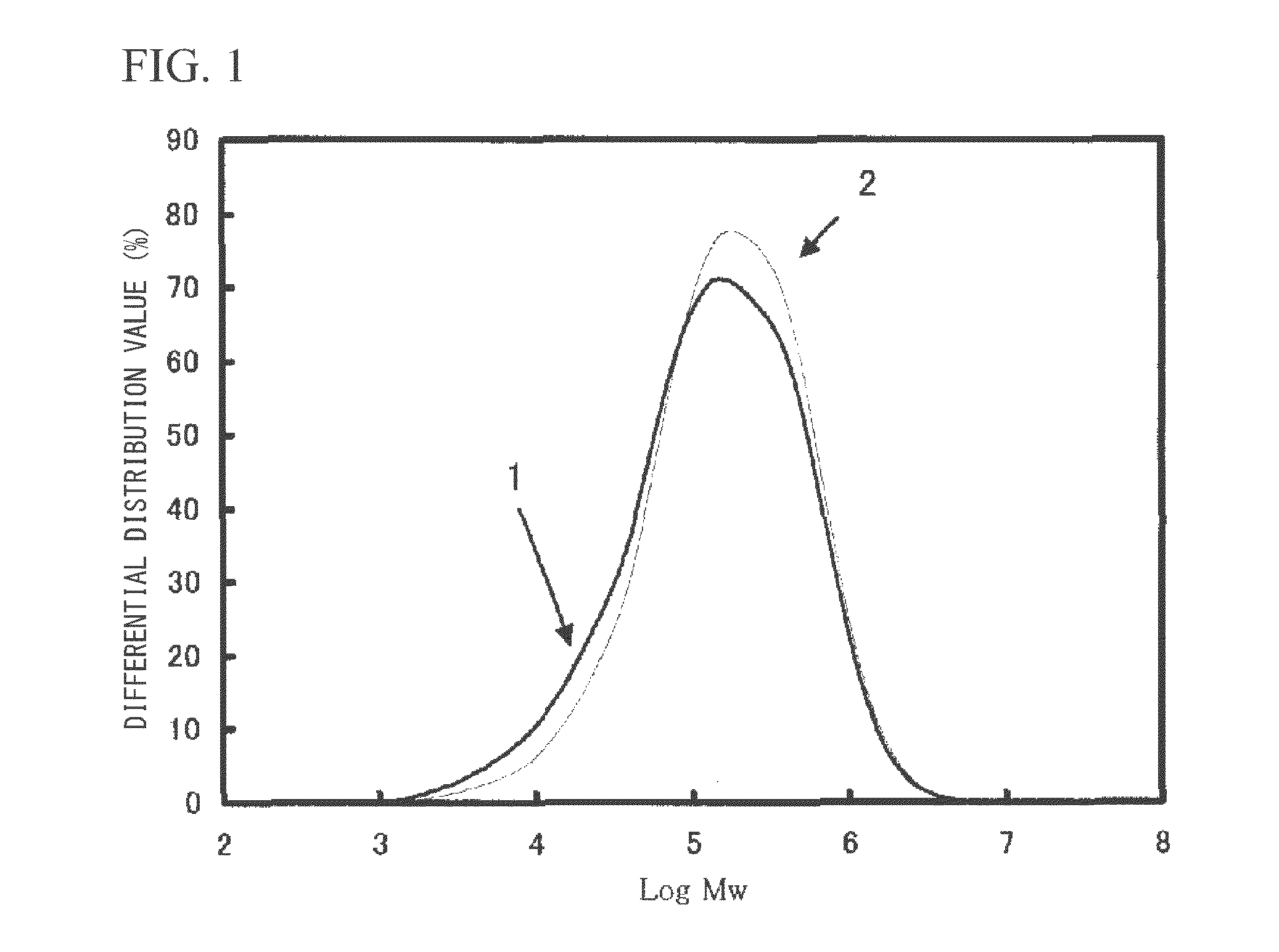

ActiveCN103329226AImprove dielectric breakdown strengthImprove patienceFixed capacitor dielectricThin material handlingNMR - Nuclear magnetic resonanceHeat resistance

Provided is a biaxially stretched polypropylene film for capacitors which is ultrathin and is excellent in terms of heat resistance, withstand voltage performance, and long-term durability. The biaxially stretched polypropylene film has such a degree of stereoregularity that the mesopentad content ([mmmm]), determined by high-temperature nuclear magnetic resonance (high-temperature NMR) spectroscopy, is 94% or greater but less than 98%. This film, in an examination by gel permeation chromatography (GPC), has a weight-average molecular weight (Mw) of 250,000-450,000 and a molecular-weight distribution (Mw / Mn) of 4-7 and gives a molecular-weight distribution curve in which the difference obtained by subtracting the differentiated distribution value corresponding to a logarithmic molecular weight, Log(M), of 6 from the differentiated distribution value corresponding to a Log(M) of 4.5 is 9-15%. The film is produced using a raw polypropylene resin in which the constitution concerning molecular-weight distribution has been regulated by degrading the polypropylene resin with a peroxide.

Owner:OJI HLDG CORP

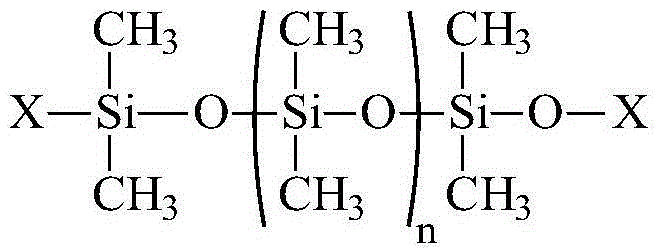

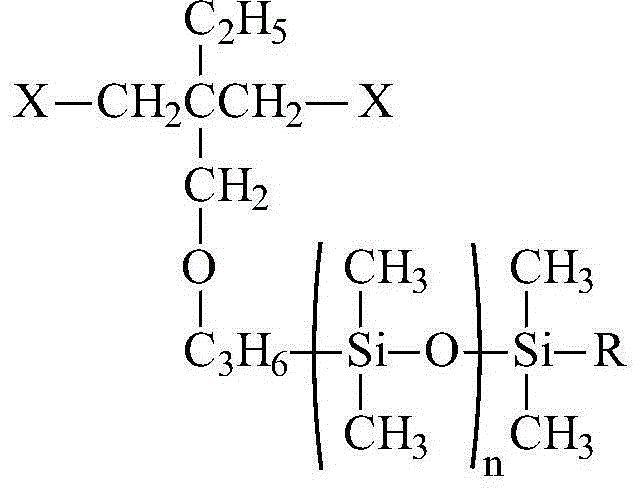

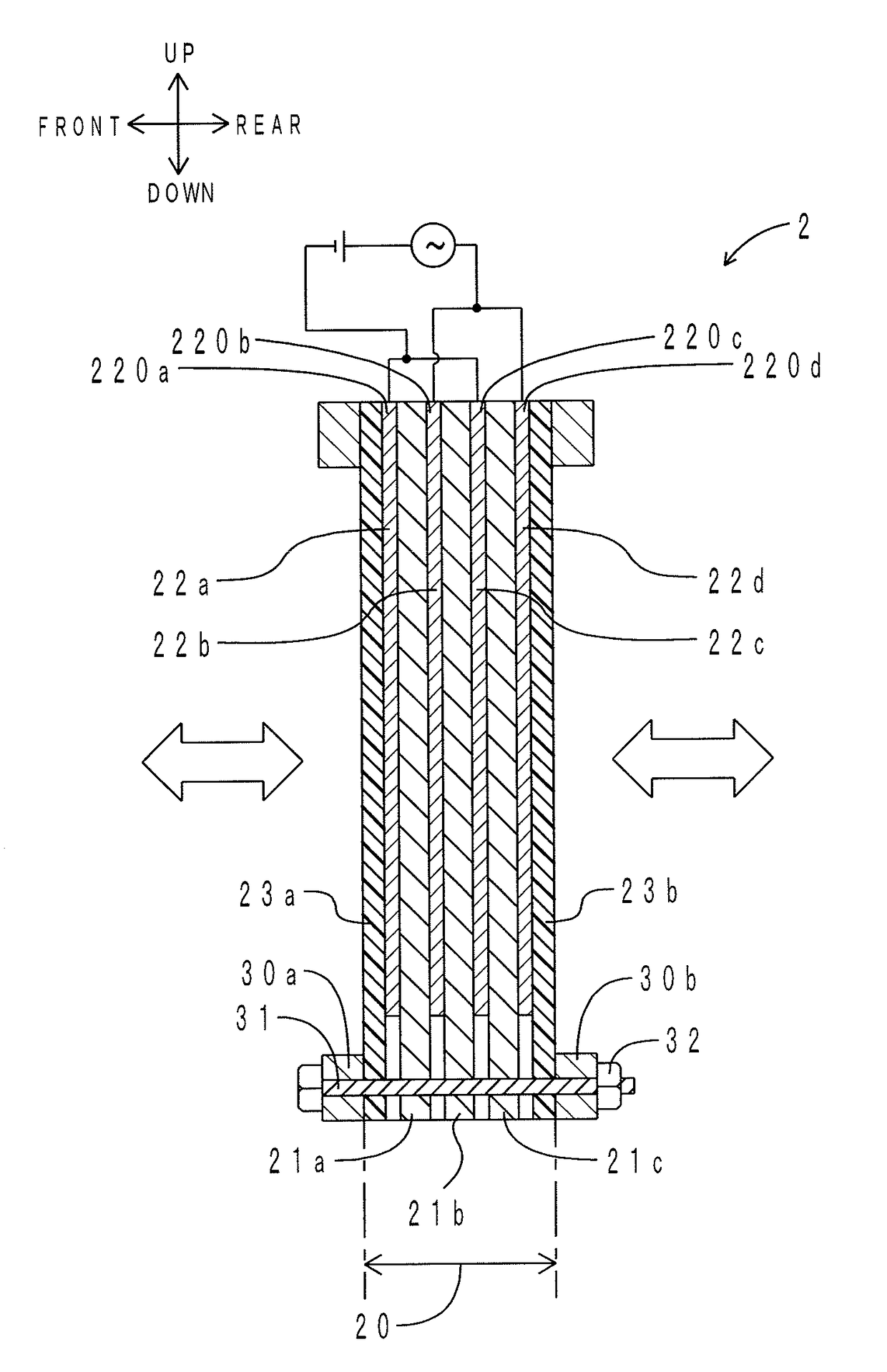

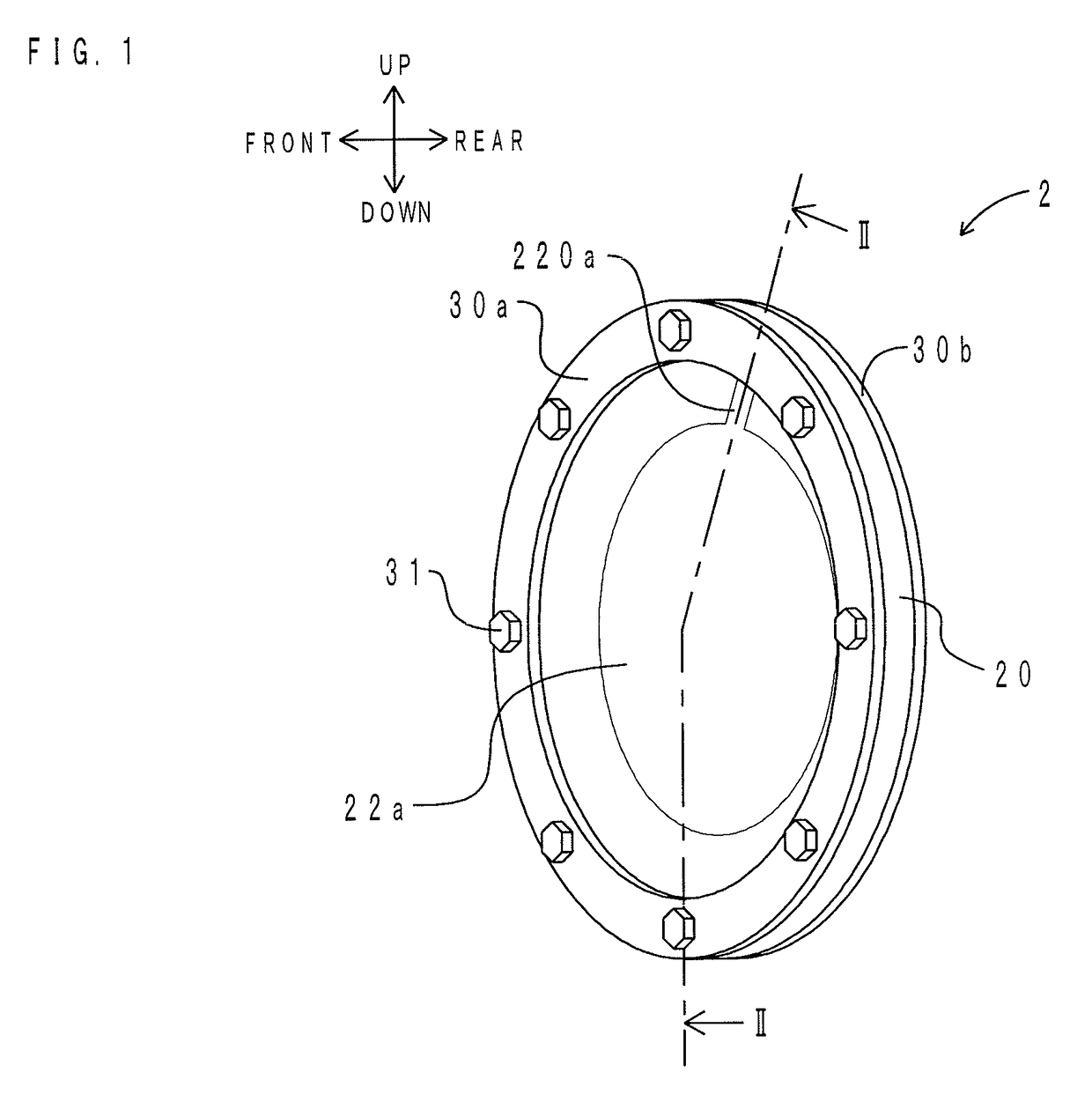

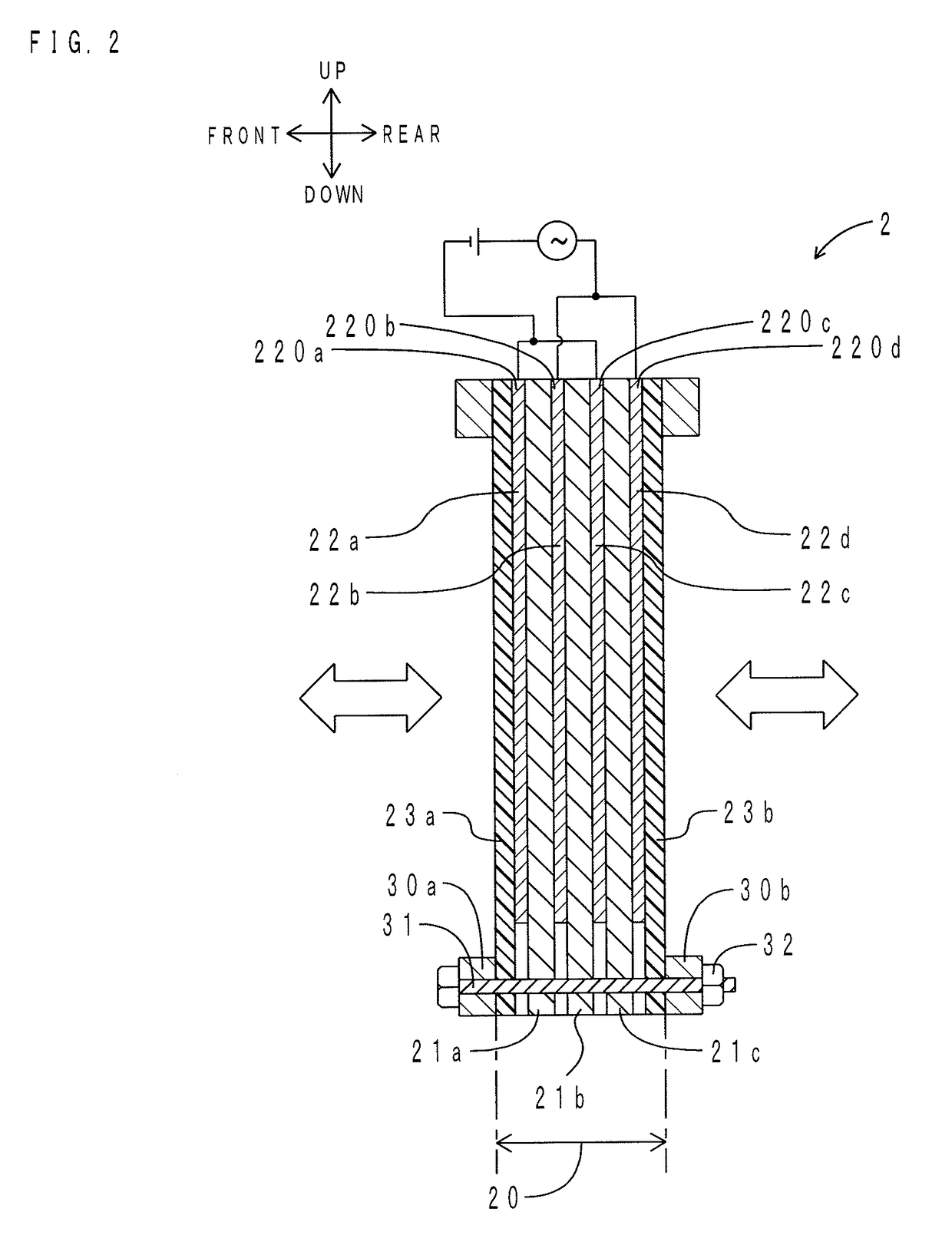

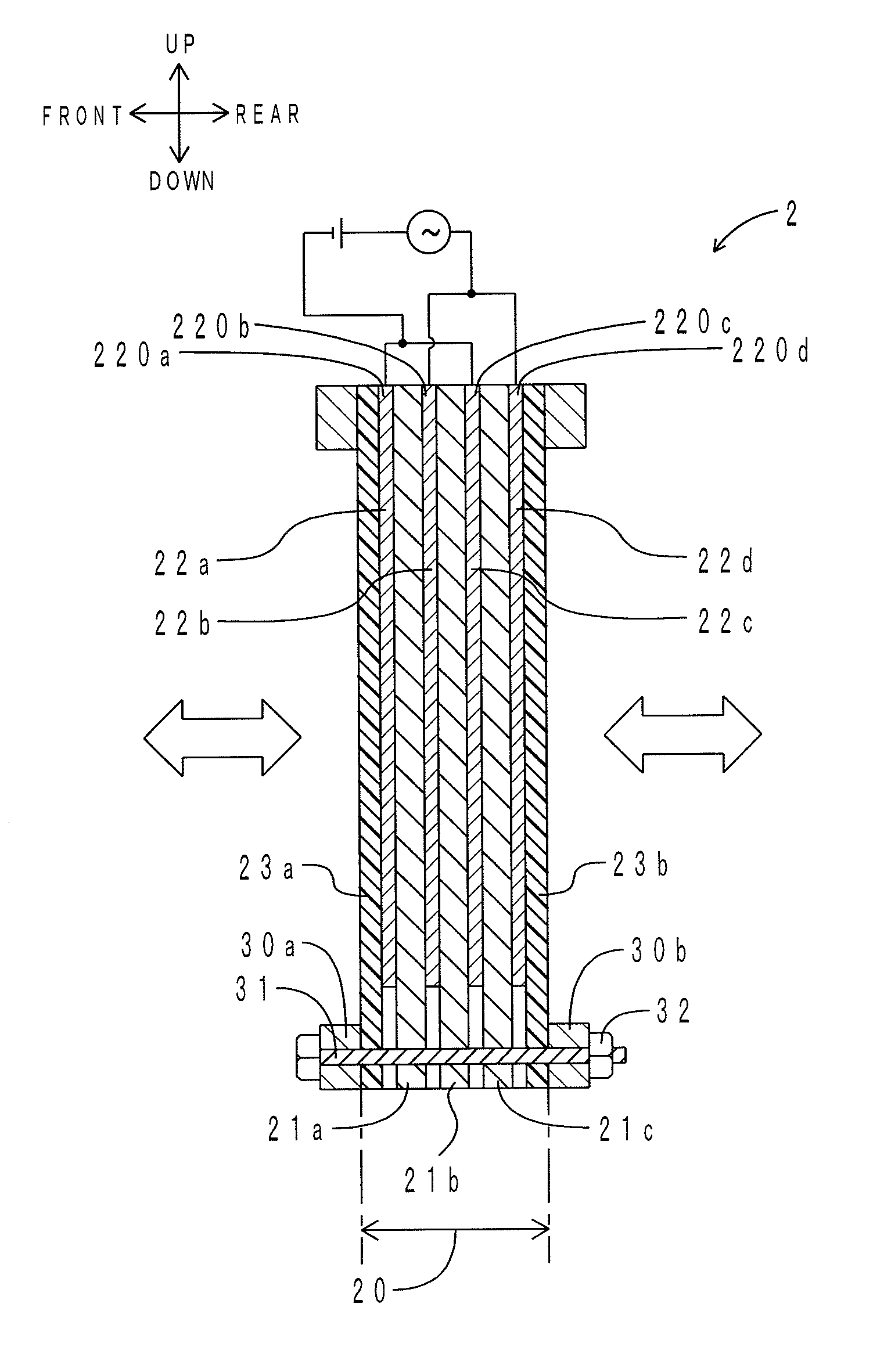

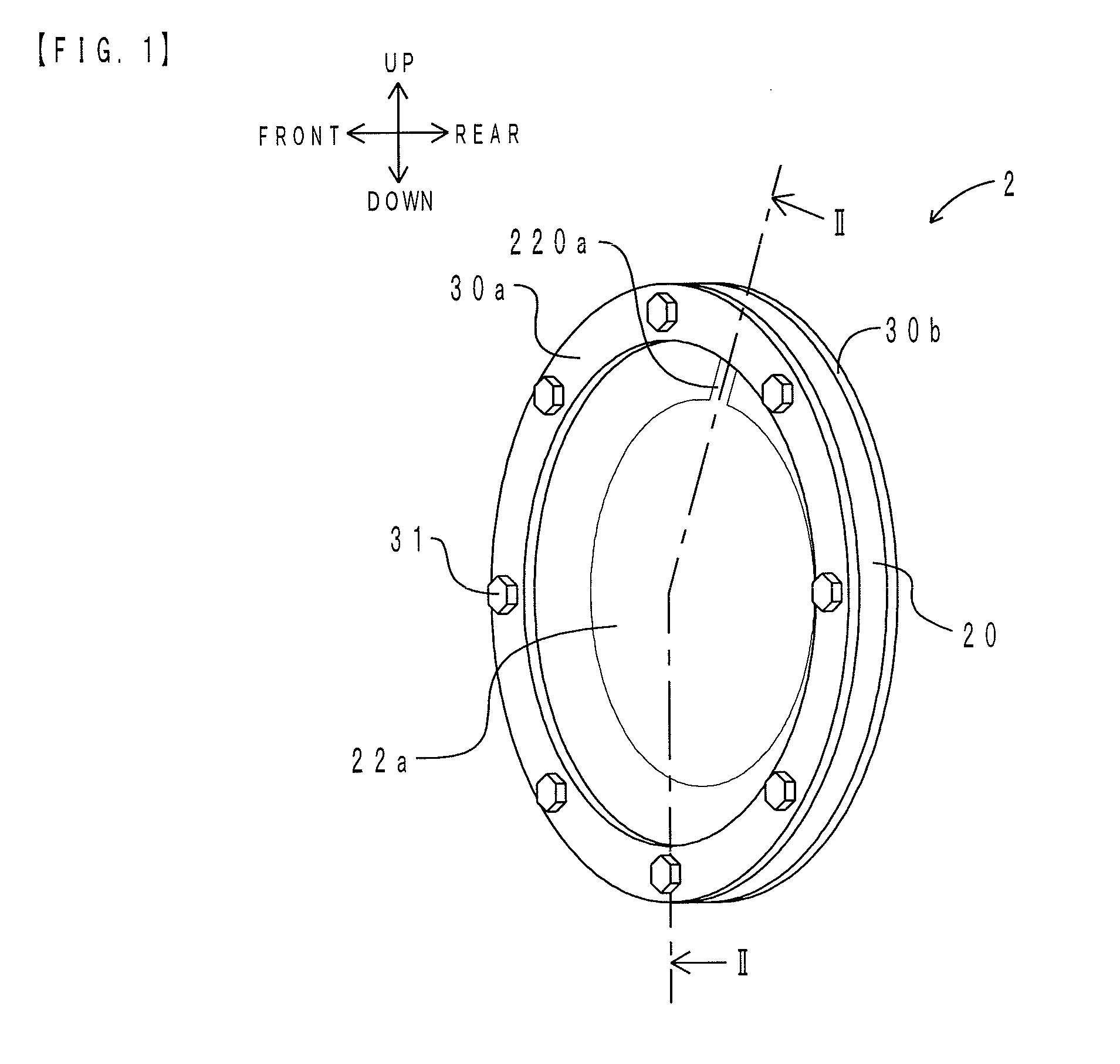

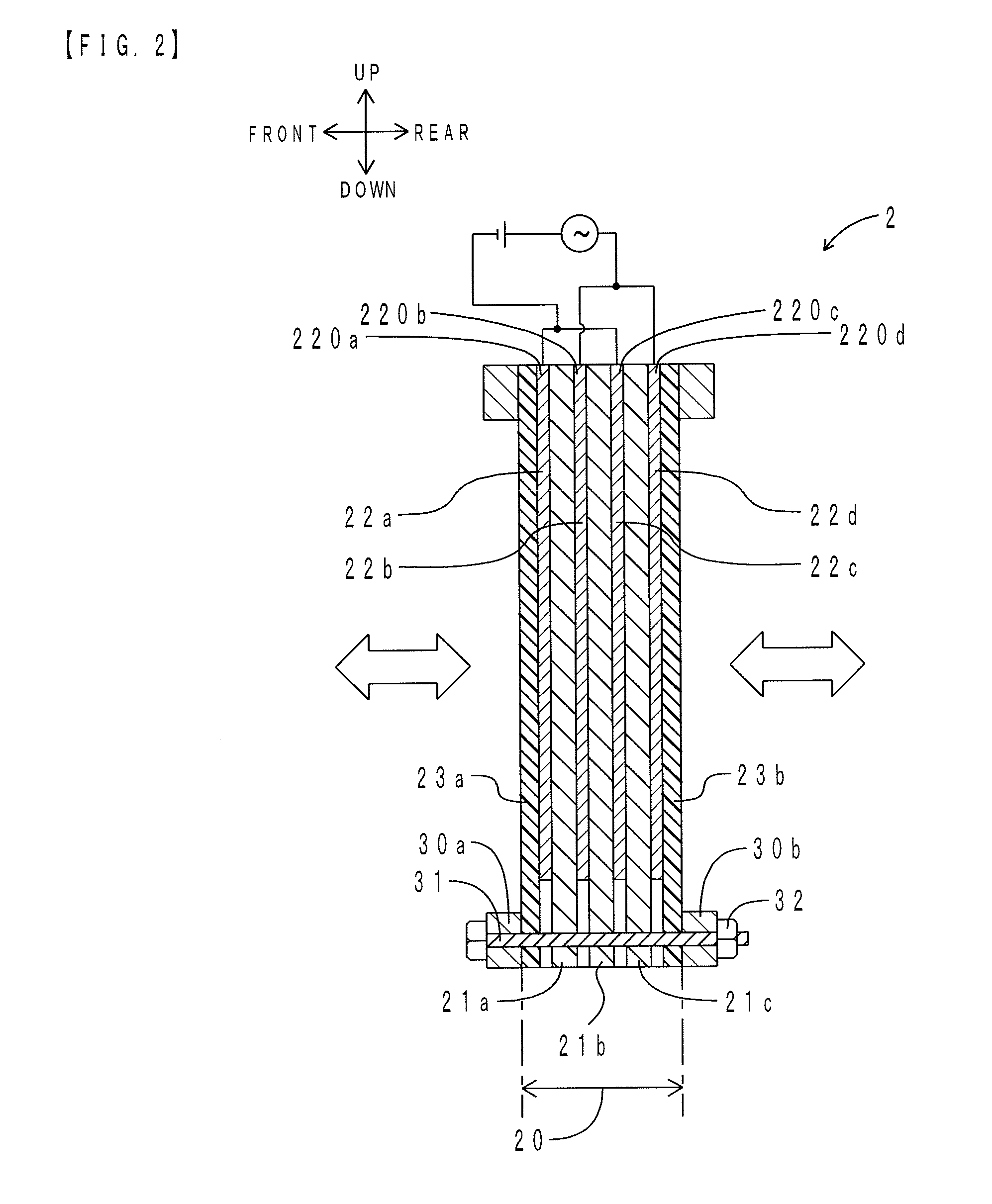

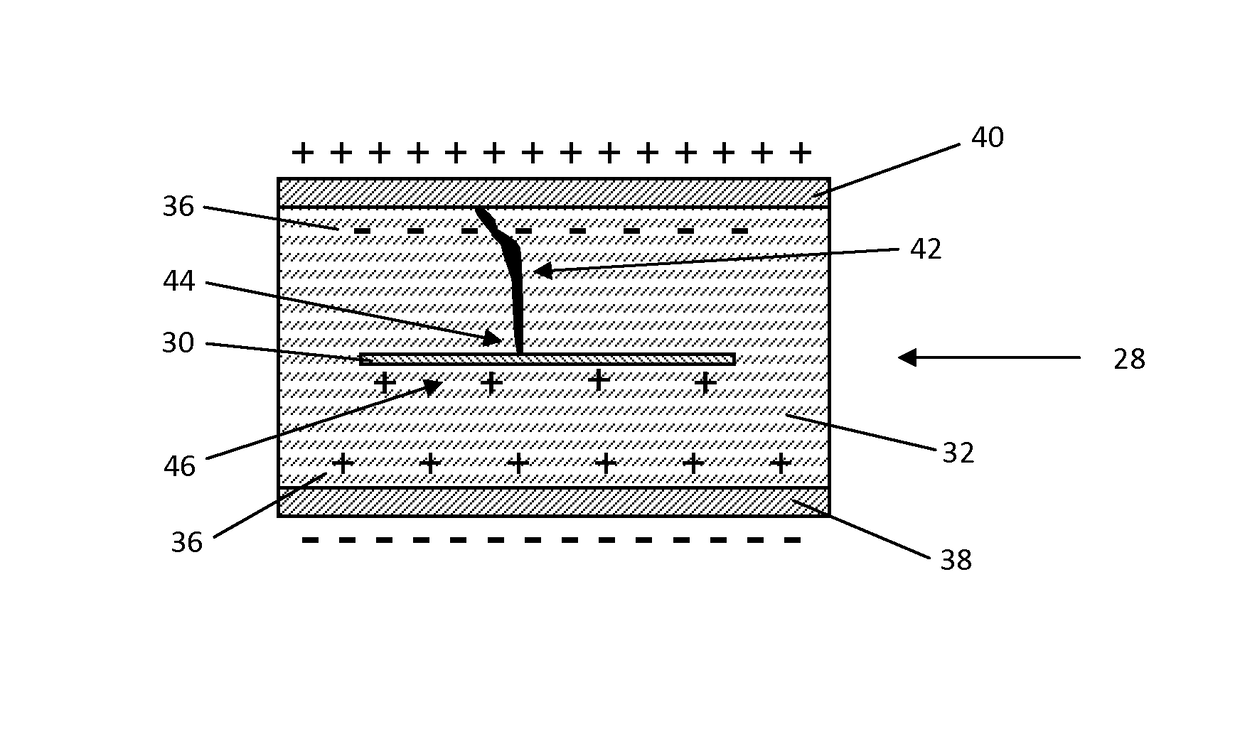

Curable Organopolysiloxane Composition For Transducers And Applications Of Such Curable Silicone Composition For Transducers

ActiveUS20150344671A1Increase energy densityImprove featuresPiezoelectric/electrostriction/magnetostriction machinesSkin careTransducerSilicone

The present invention provides a curable organopolysiloxane composition capable of producing a cured article that can be used as a transducer and provided with excellent mechanical characteristics and / or electrical characteristics. The present invention also relates to a novel curable organopolysiloxane composition for transducer use comprising a curable organopolysiloxane composition and a compound having a highly dielectric functional group.

Owner:DOW TORAY CO LTD +1

Nanolaminate thin films and method for forming the same using atomic layer deposition

InactiveUS20060216548A1High quality nanolaminate thin film have been substantially reduced or eliminatedImprove dielectric breakdown strengthLiquid surface applicatorsSemiconductor/solid-state device manufacturingOptoelectronicsSilicon dioxide

A nanolaminate thin film and a method for forming the same using atomic layer deposition are disclosed. The method includes forming an aluminum oxide layer having a first thickness on at least a portion of a substrate surface by sequentially pulsing a first precursor and a first reactant into an enclosure containing the substrate. A layer of silicon dioxide is formed on at least a portion of the aluminum oxide layer by sequentially pulsing a second precursor and a second reactant into the enclosure to form a nanolaminate thin film.

Owner:VEECO INSTR +1

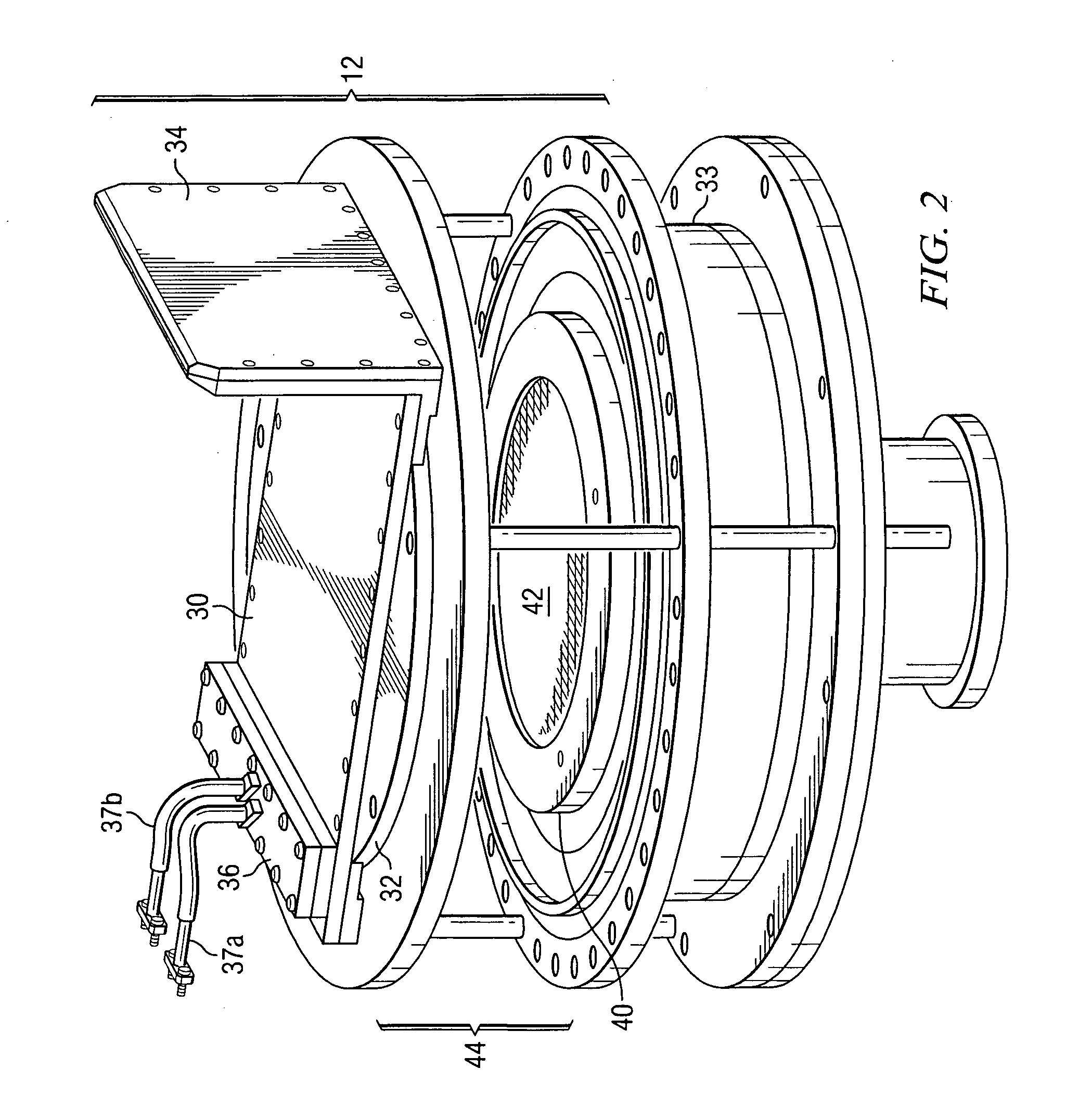

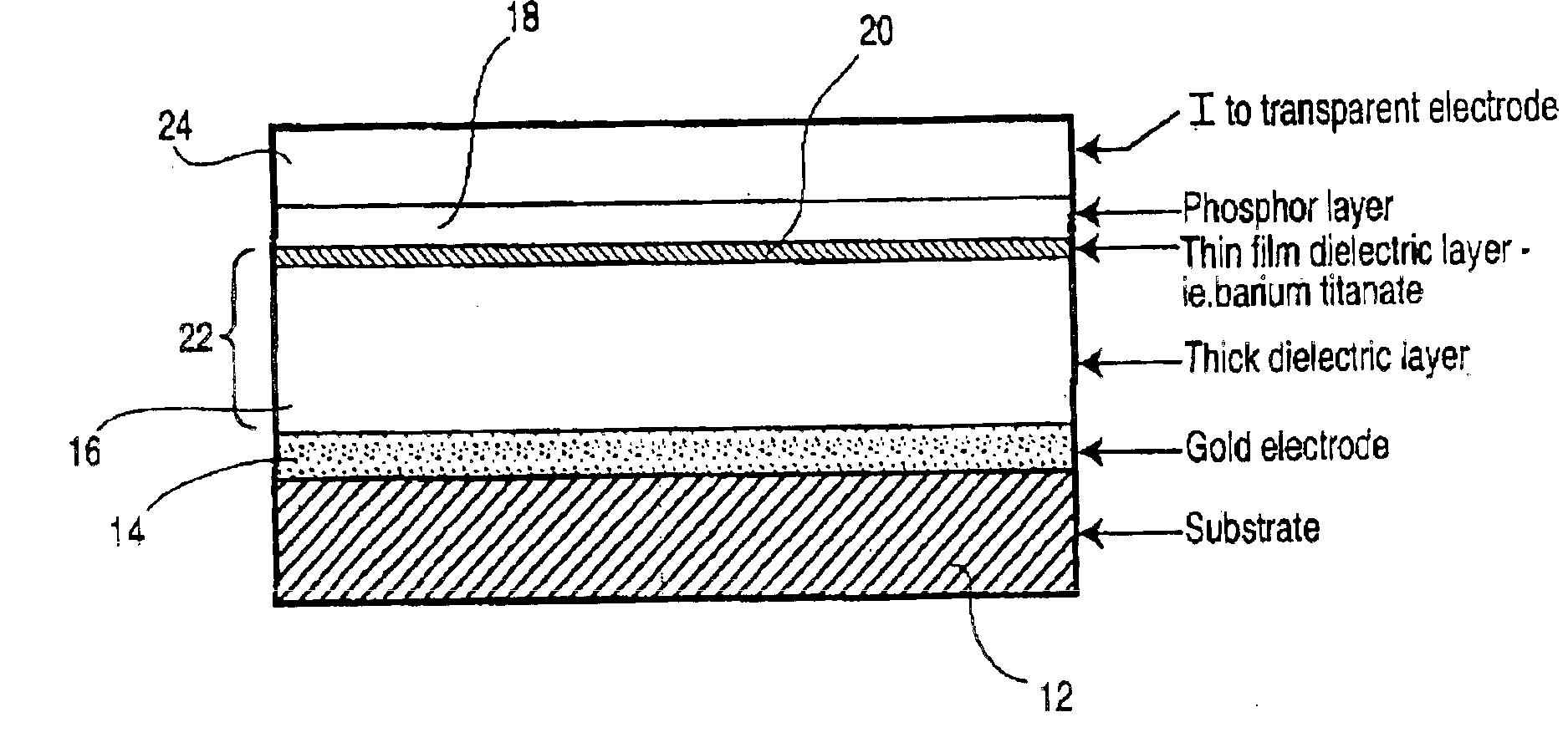

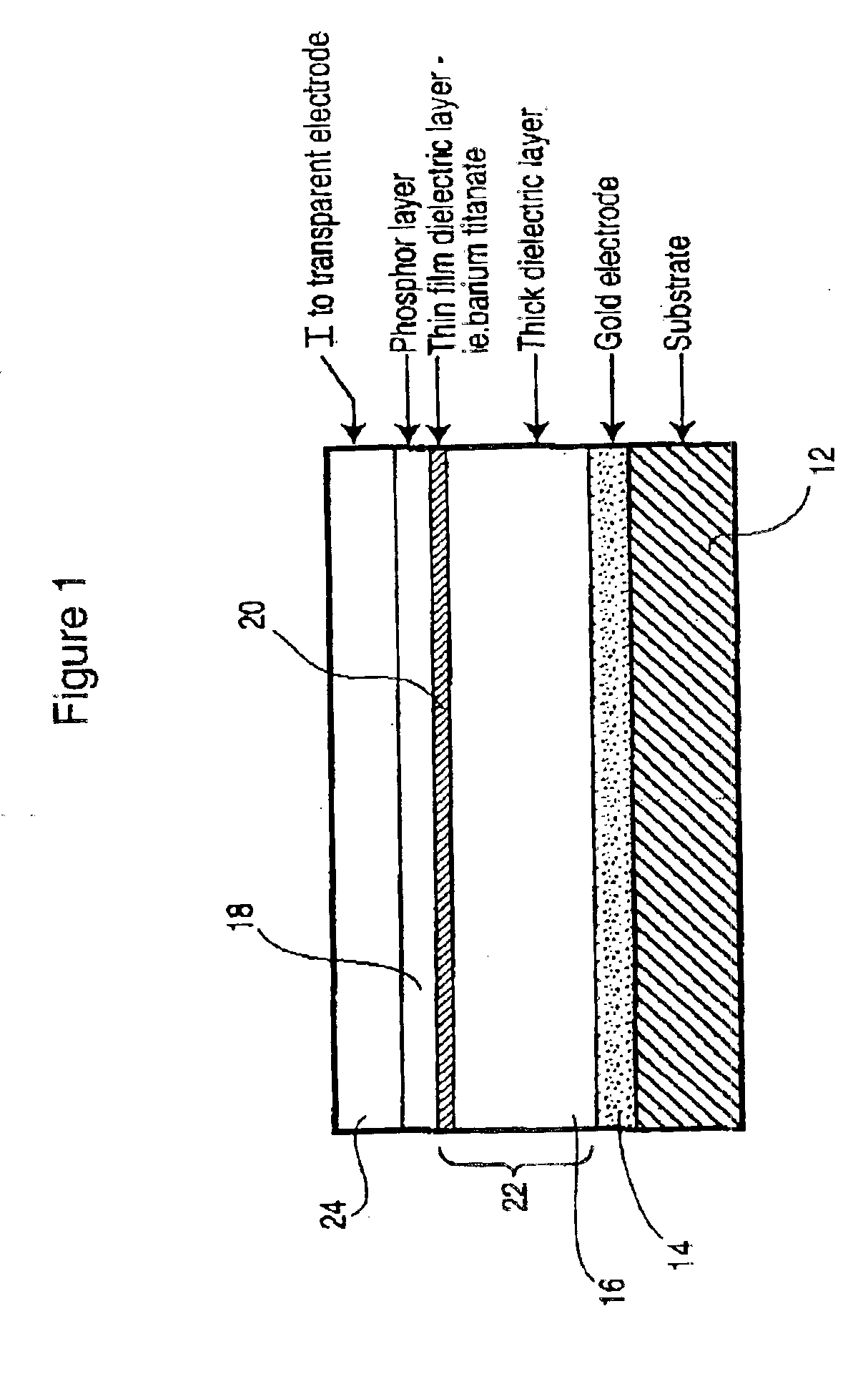

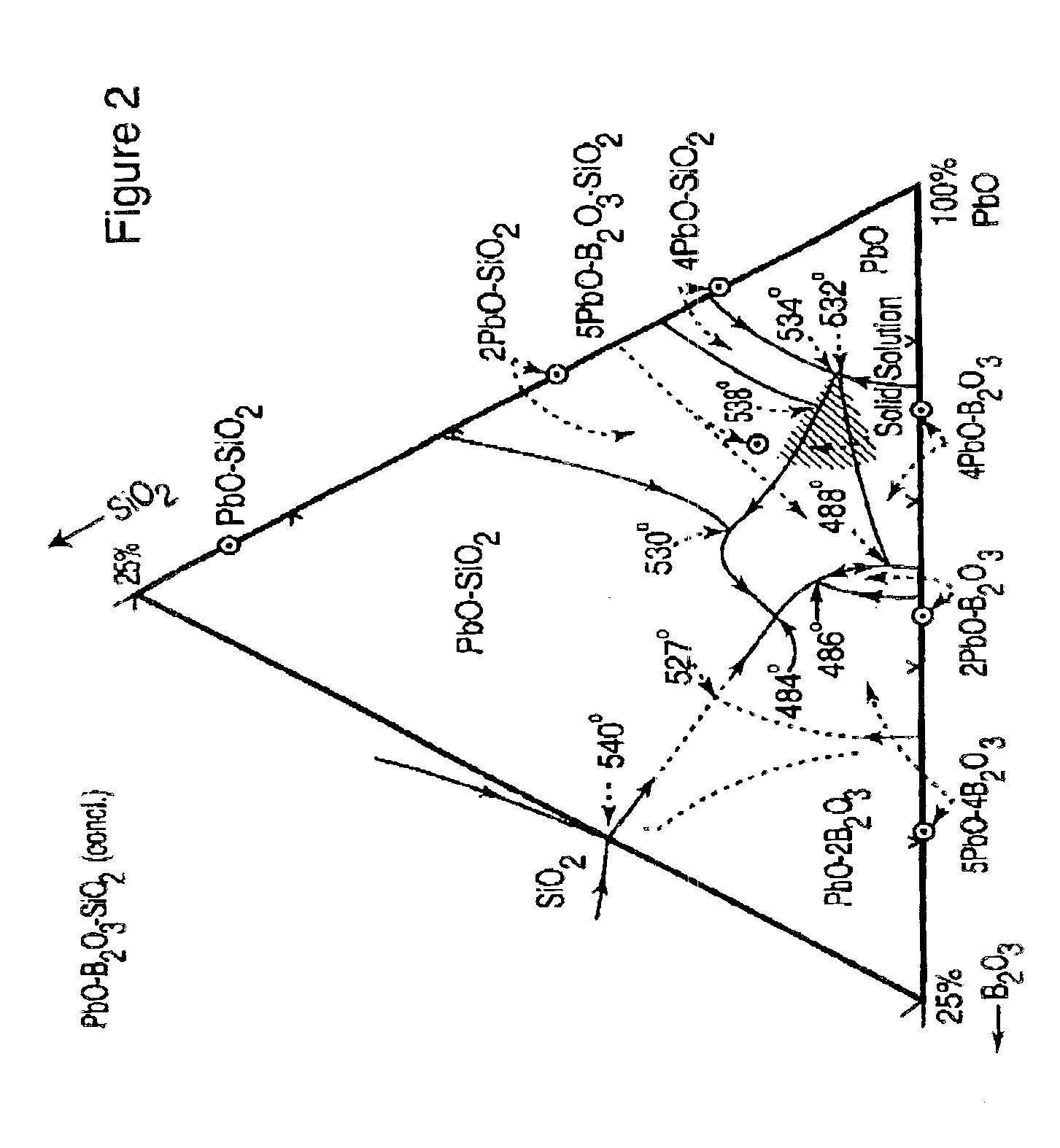

Low firing temperature thick film dielectric layer for electroluminescent display

InactiveUS6919126B2Increasing residual porosityEasy to useElectroluminescent light sourcesPretreated surfacesLead zirconate titanateBarium titanate

The present invention is a low firing temperature, composite thick film dielectric layer for an electroluminescent display. The composite thick film dielectric layer comprises;(a) a lower zone layer of a thick film composition comprising;one or more of lead magnesium niobate (PMN), lead magnesium niobate-titanate (PMN-PT), lead titanate, barium titanate and lead oxide; anda glass frit composition comprising lead oxide, boron oxide and silicon dioxide;(b) an upper zone comprising at least one layer of lead zirconate titanate (PZT) and / or barium titanate; and(c) an intermediate composite zone comprising a composite of (a) and (b).

Owner:IFIRE IP CORP

Electrical insulation system

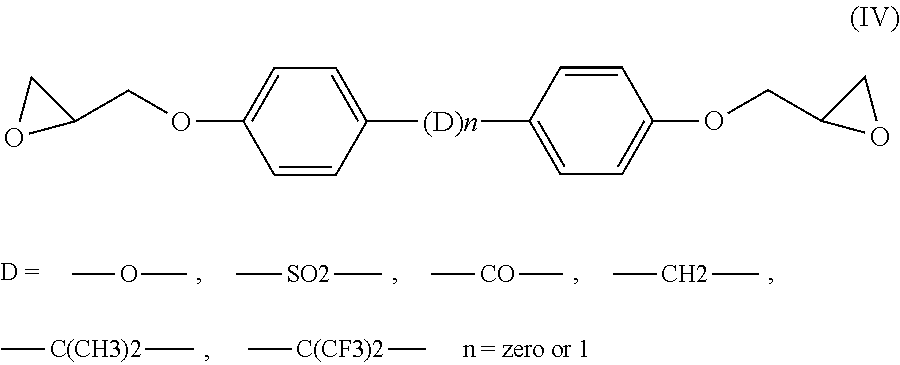

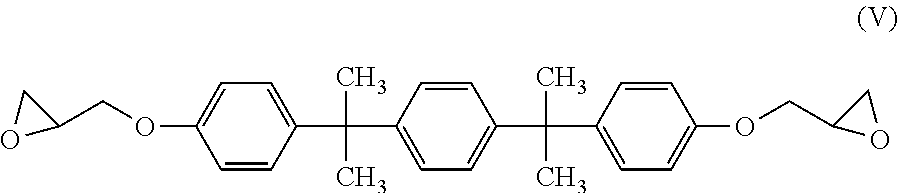

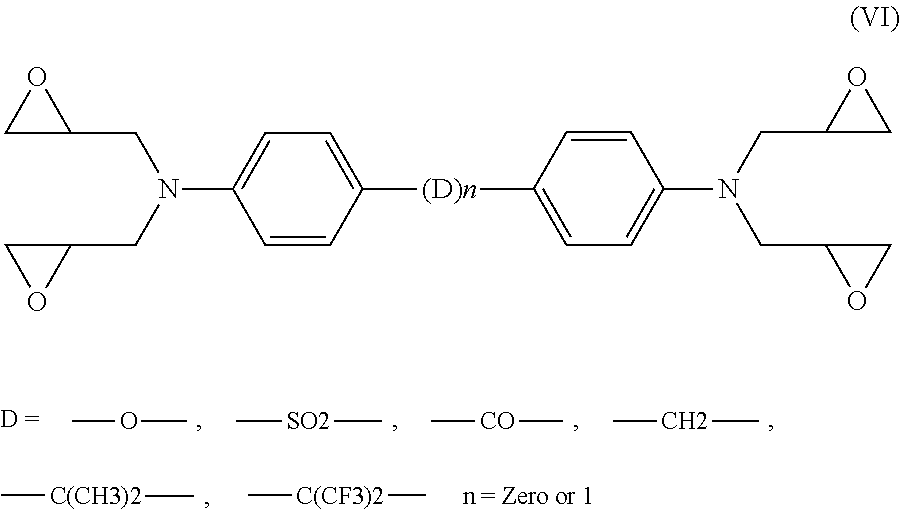

InactiveUS20130203897A1Good dispersionSimple mixing methodMaterial nanotechnologyPlastic/resin/waxes insulatorsPolytetramethylene terephthalateEpoxy

Electrical insulation system with improved electrical breakdown strength, including a hardened polymer component having incorporated therein a filler material and a nano-scale sized filler material. The hardened polymer component is selected from epoxy resin compositions, polyesters, polyamides, polybutylene terephthalate, polyurethanes and polydicyclo-pentadiene. The filler material has an average particle size within the range of 1 μm-500 μm, and is present in a quantity within the range of 40%-65% by weight, calculated to the total weight of the insulation system. The nano-scale sized filler material is a pretreated nano-scale sized filler material, having been produced by a sol-gel process. The nano-scale sized filler material is present within the electrical insulation system in an amount of about 1%-20% by weight, calculated to the weight of the filler material present in the electrical insulation system.

Owner:ABB RES LTD

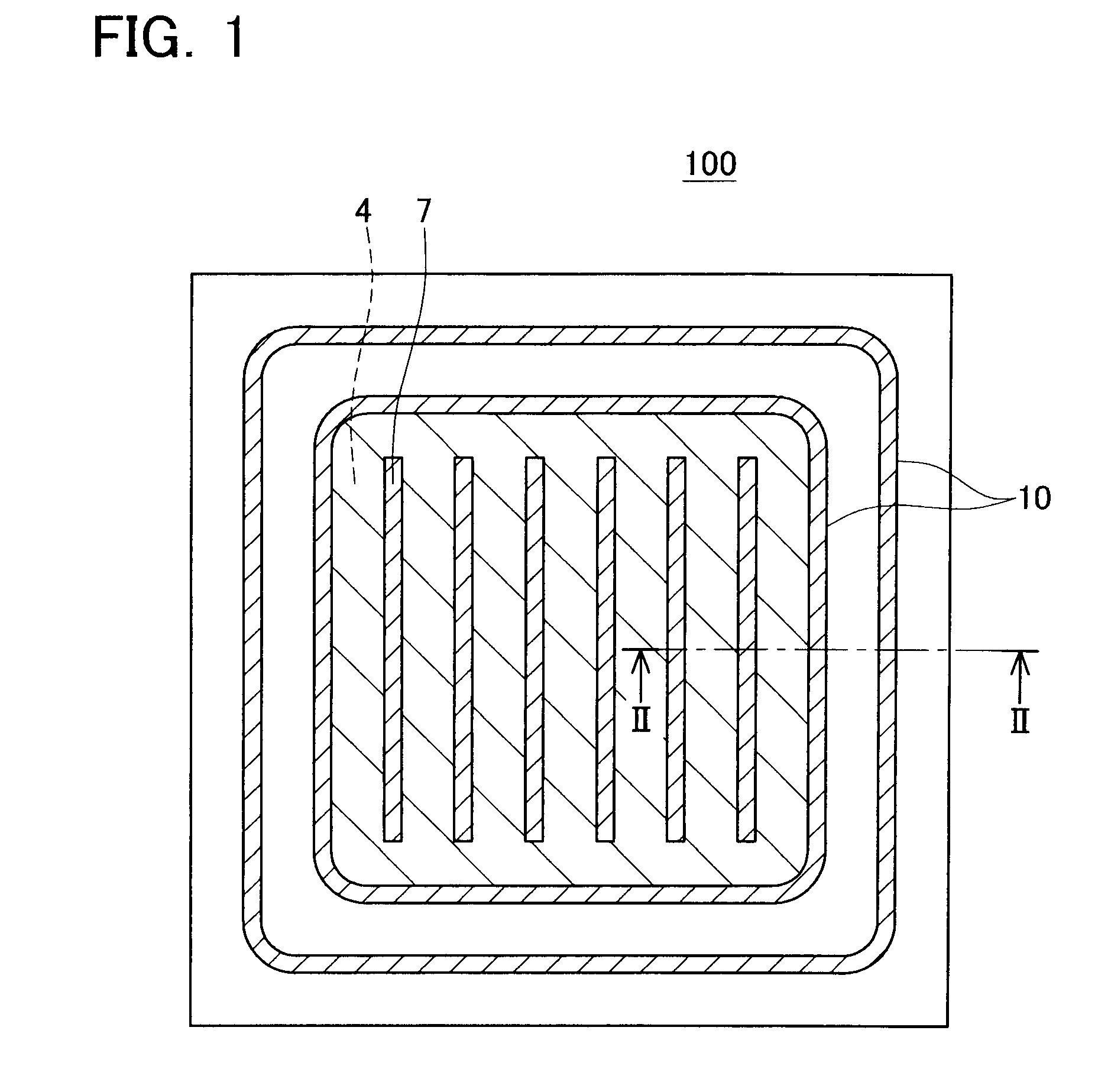

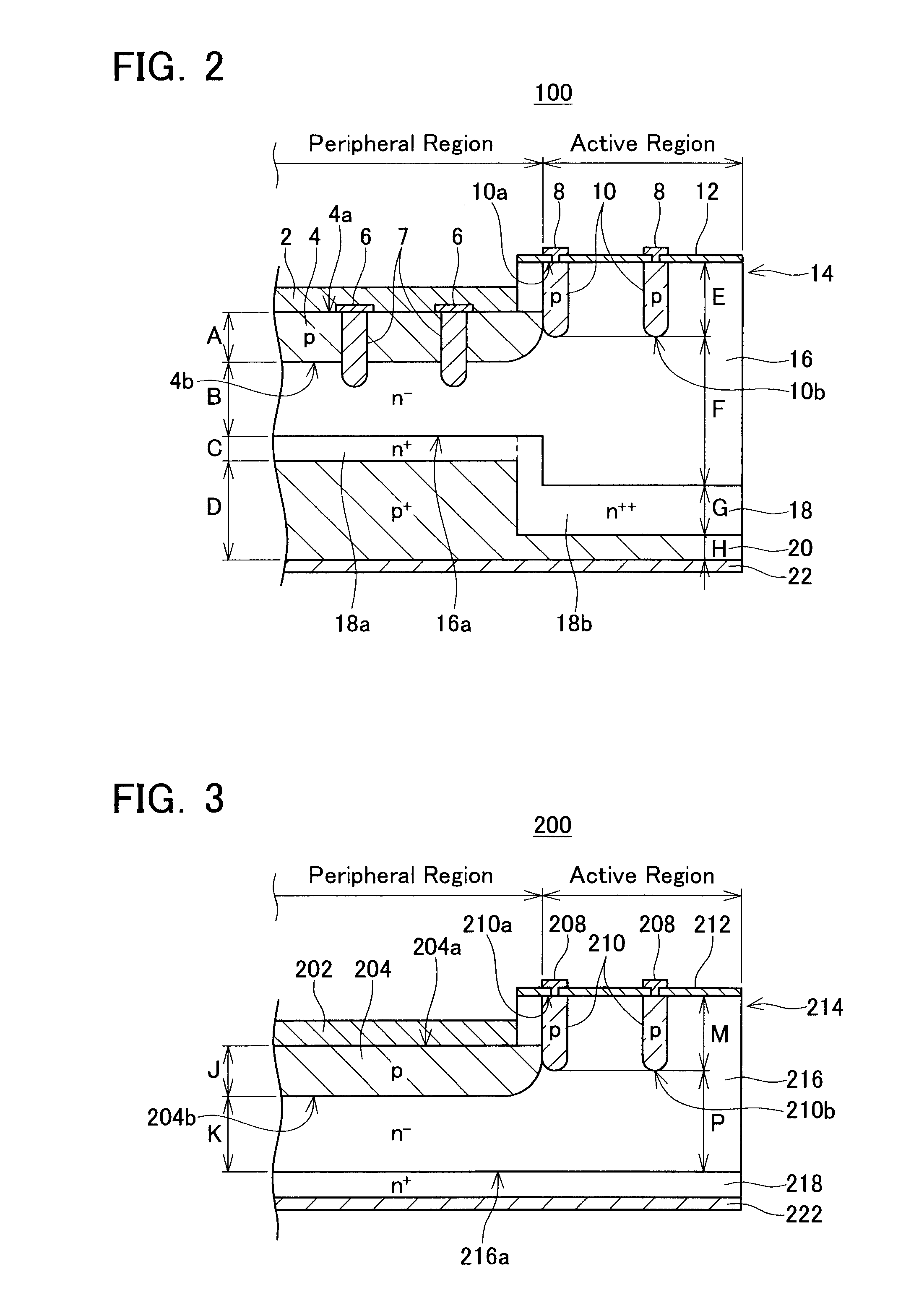

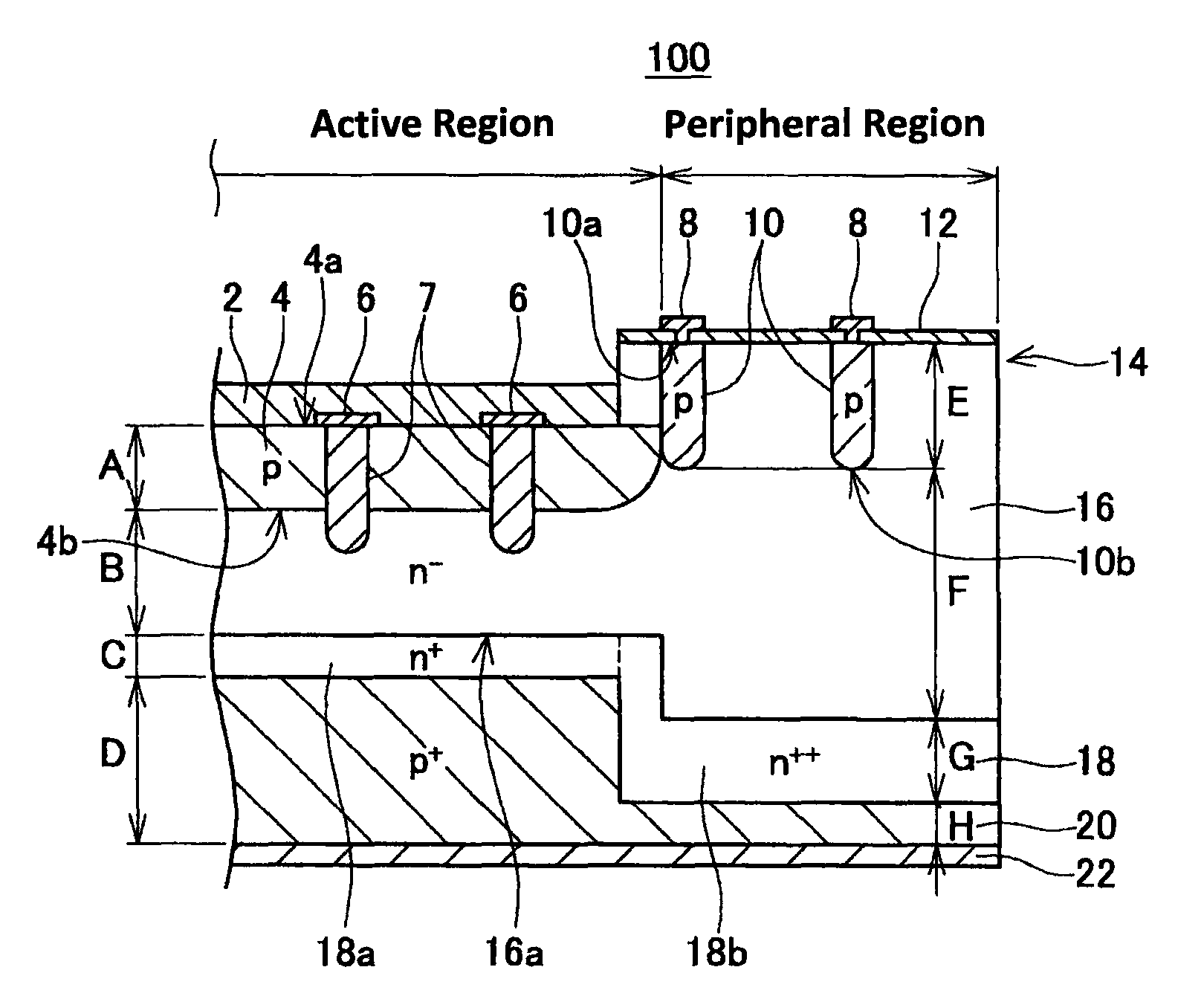

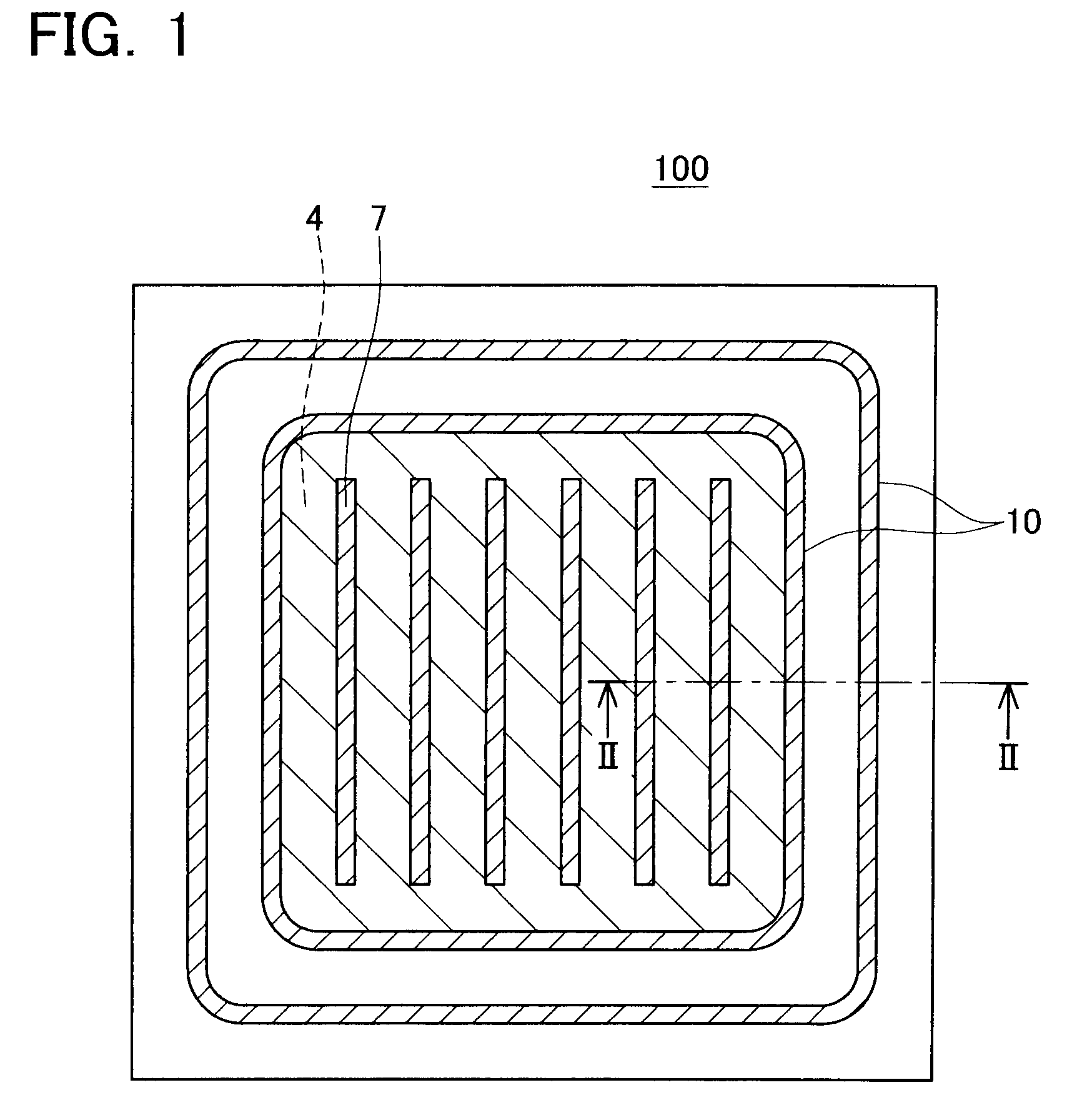

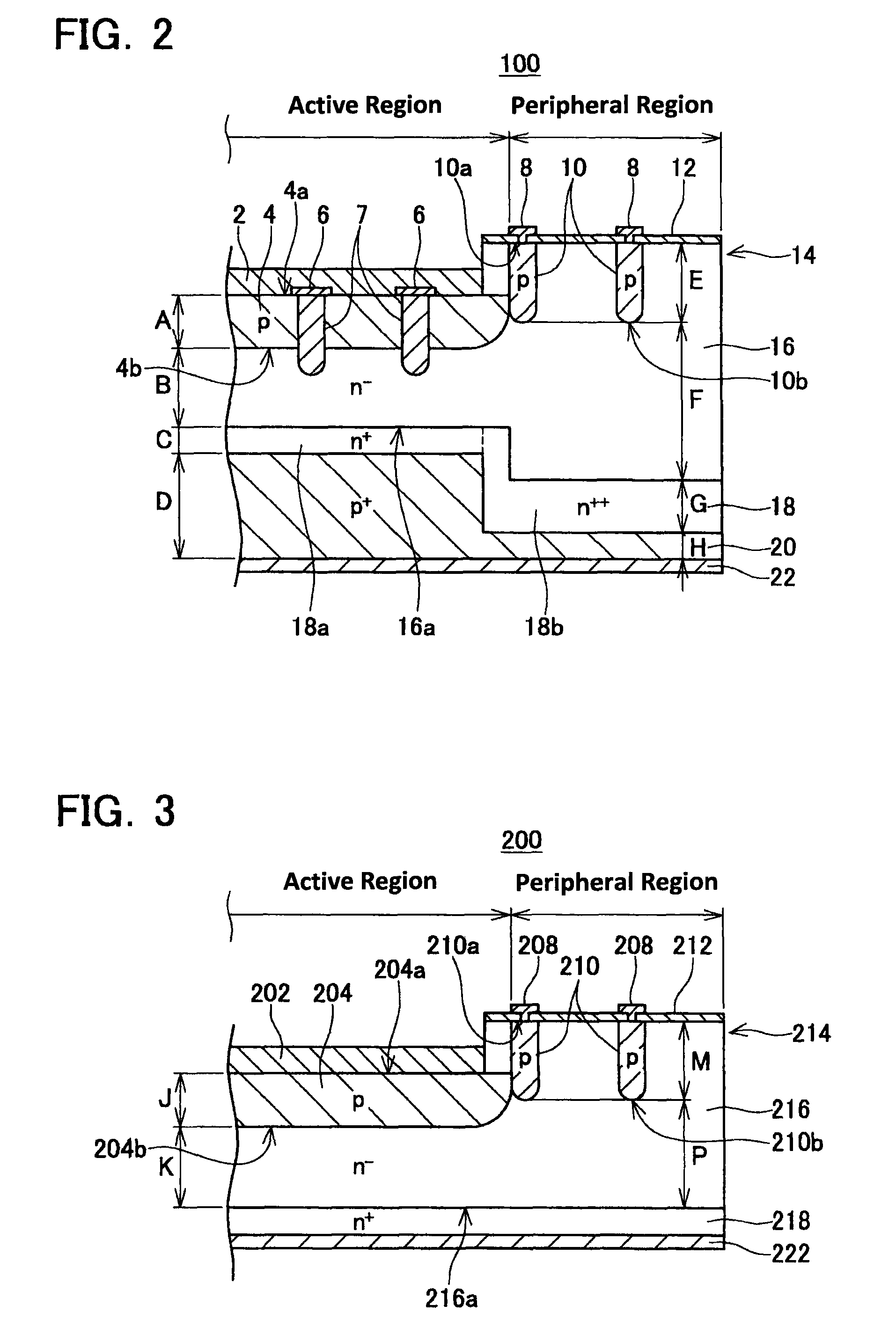

Semiconductor device

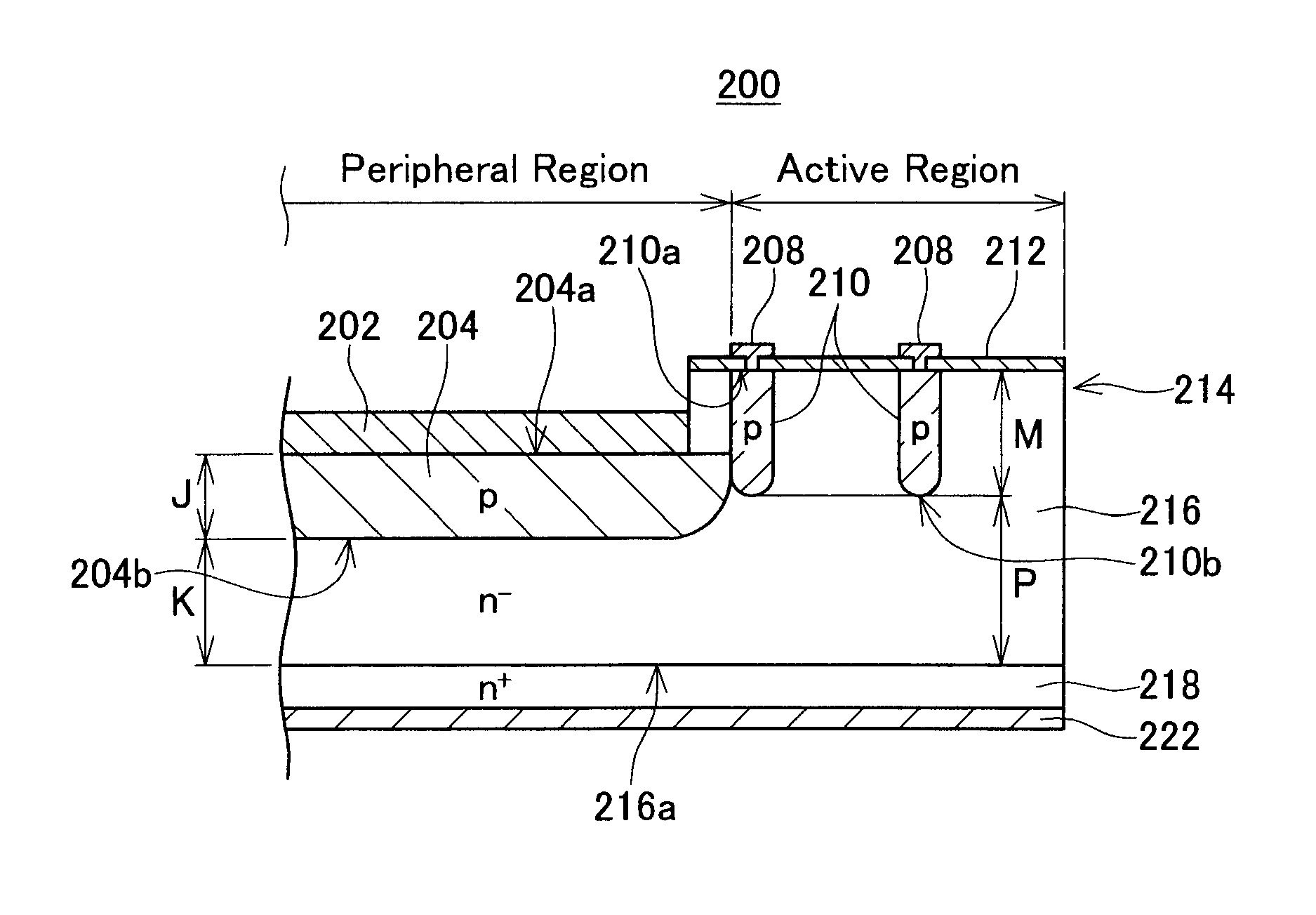

ActiveUS20100224907A1Improve dielectric breakdown strengthIncrease the on-resistanceSemiconductor/solid-state device detailsSolid-state devicesBody regionPhysics

To provide a semiconductor device in which dielectric breakdown strength in a peripheral region is increased without increasing on-resistance. An IGBT comprises a body region, guard ring, and collector layer. The body region is formed within an active region in a surface layer of a drift layer. The guard ring is formed within a peripheral region in the surface layer of the drift layer, and surrounds the body region. The collector layer is formed at a back surface side of the drift layer, and is formed across the active region and the peripheral region. A distance F between a back surface of the guard ring and the back surface of the drift layer is greater than a distance between a back surface of the body region and the back surface of the drift layer. A thickness H of the collector layer in the peripheral region is smaller than a thickness D of the collector layer in the active region.

Owner:DENSO CORP

IGBT semiconductor device

ActiveUS7973363B2Increasing the thicknessLow efficiencyThyristorSemiconductor/solid-state device detailsPower semiconductor deviceSurface layer

To provide a semiconductor device in which dielectric breakdown strength in a peripheral region is increased without increasing on-resistance. An IGBT comprises a body region, guard ring, and collector layer. The body region is formed within an active region in a surface layer of a drift layer. The guard ring is formed within a peripheral region in the surface layer of the drift layer, and surrounds the body region. The collector layer is formed at a back surface side of the drift layer, and is formed across the active region and the peripheral region. A distance F between a back surface of the guard ring and the back surface of the drift layer is greater than a distance between a back surface of the body region and the back surface of the drift layer. A thickness H of the collector layer in the peripheral region is smaller than a thickness D of the collector layer in the active region.

Owner:DENSO CORP

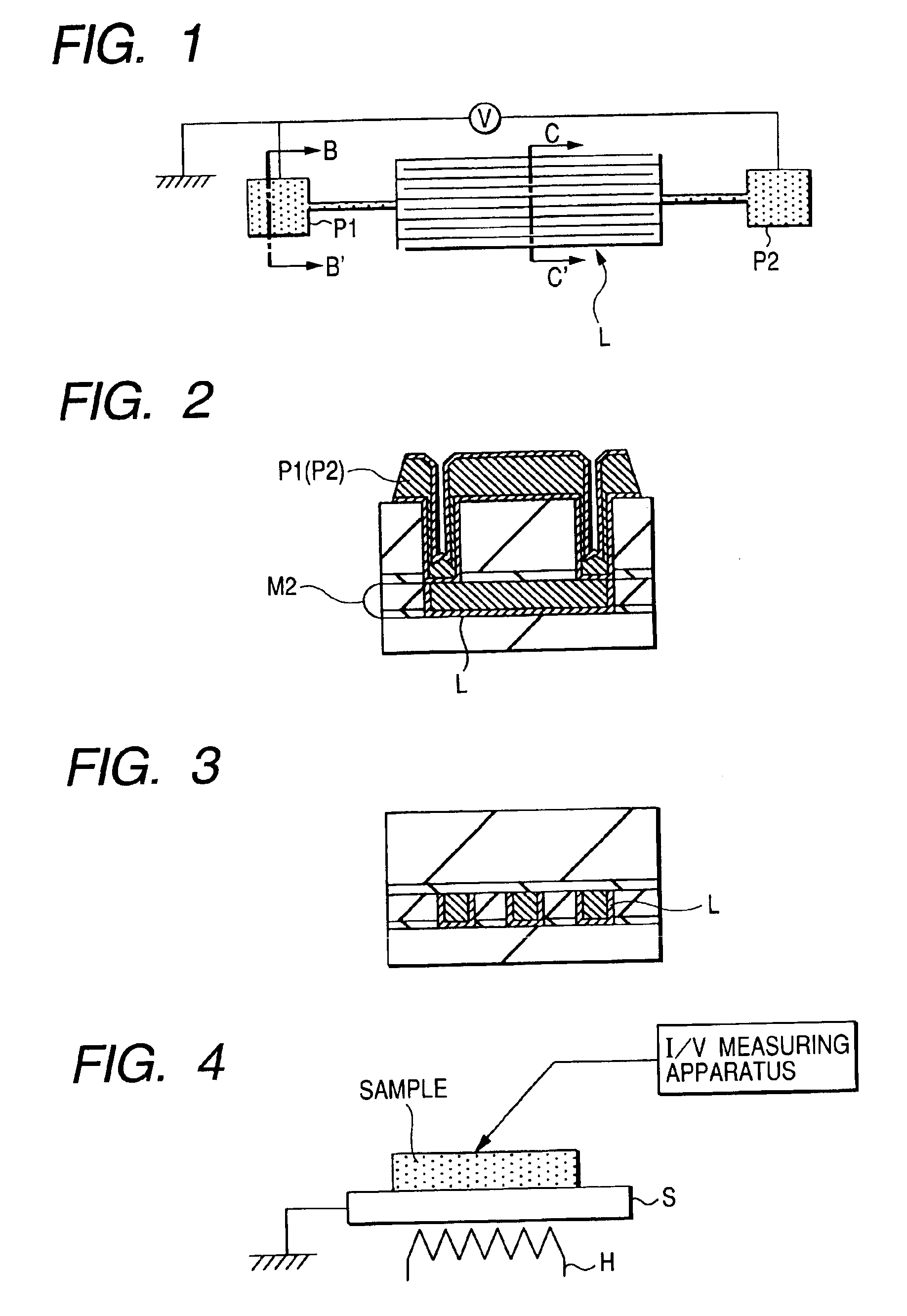

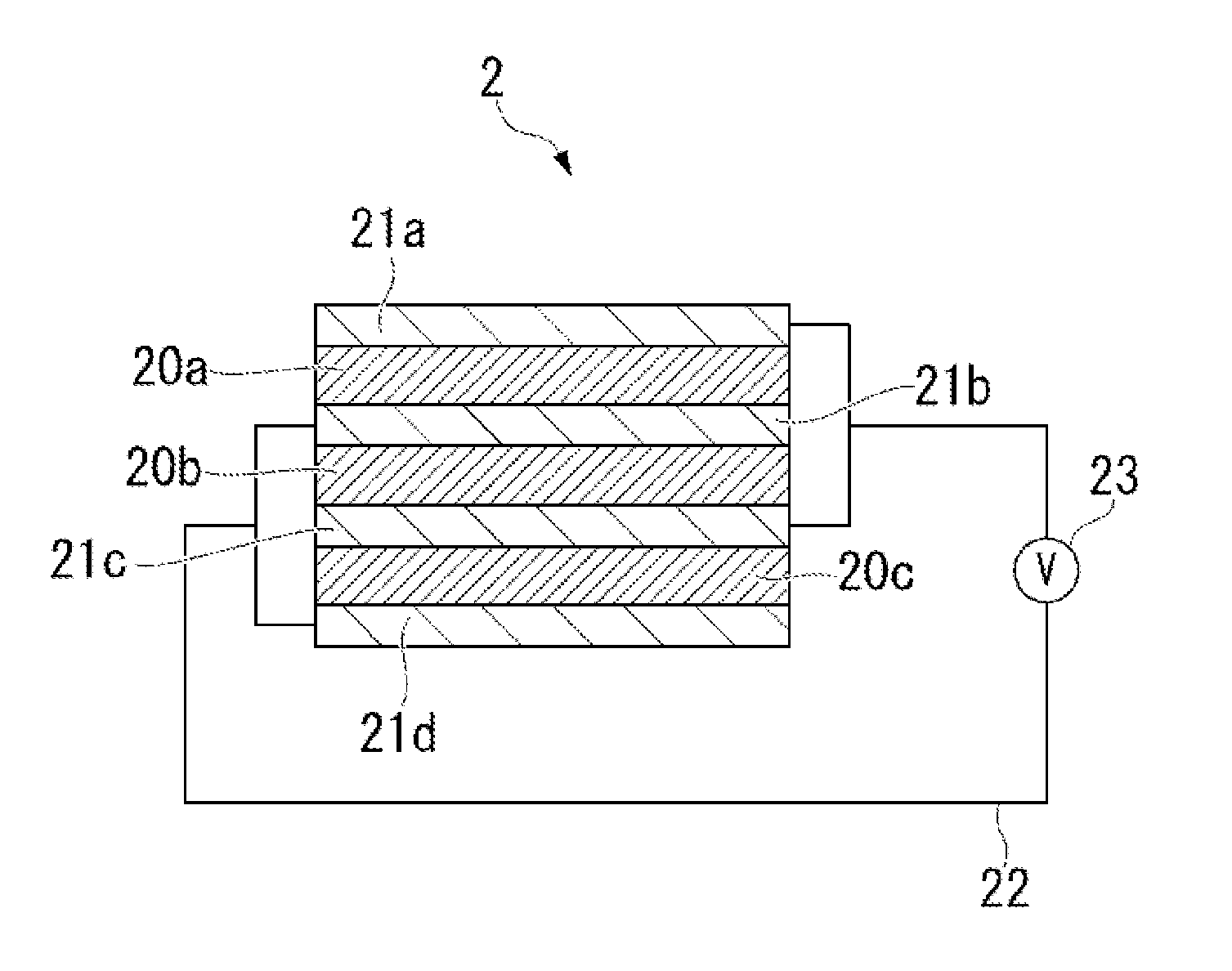

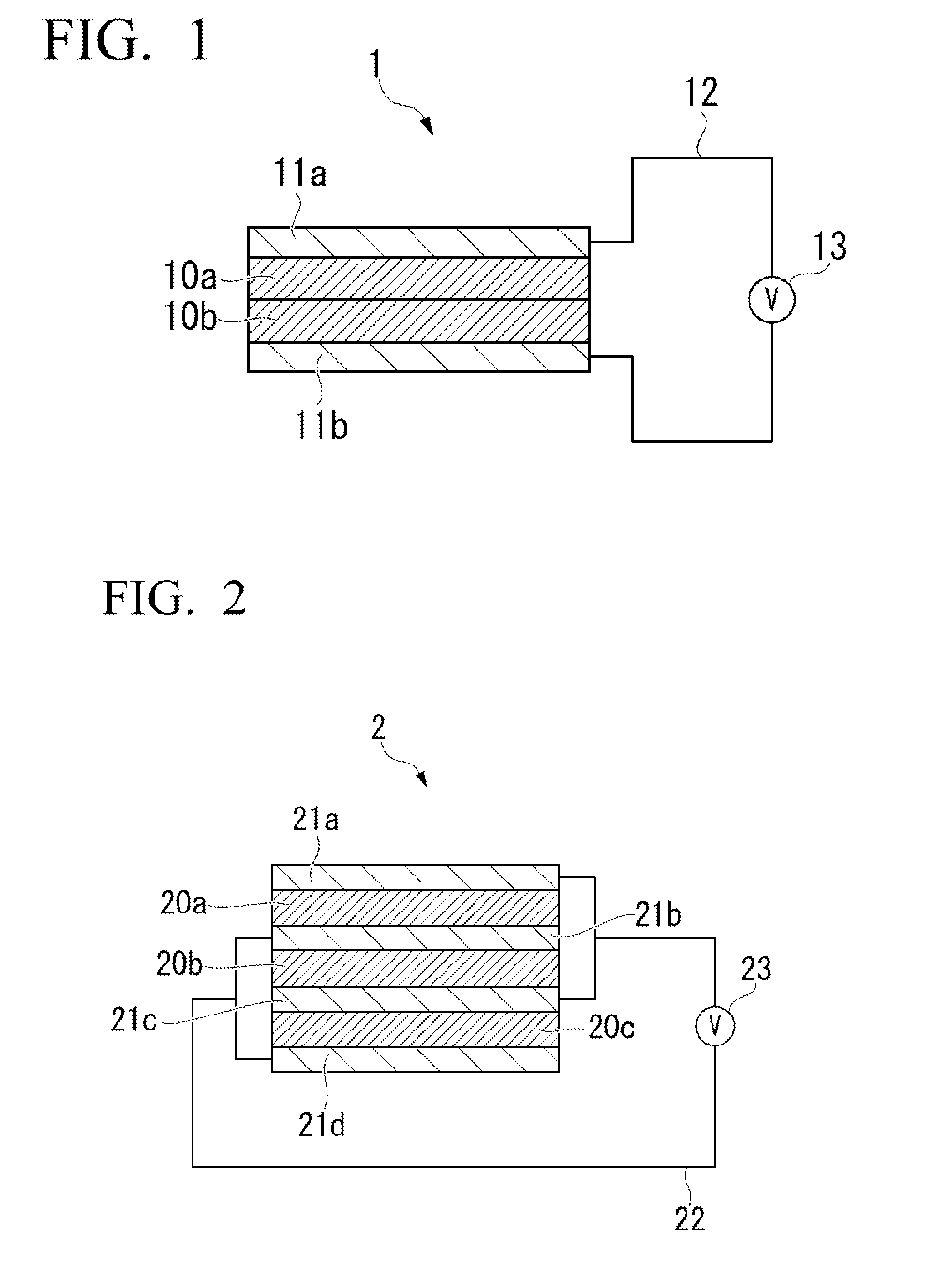

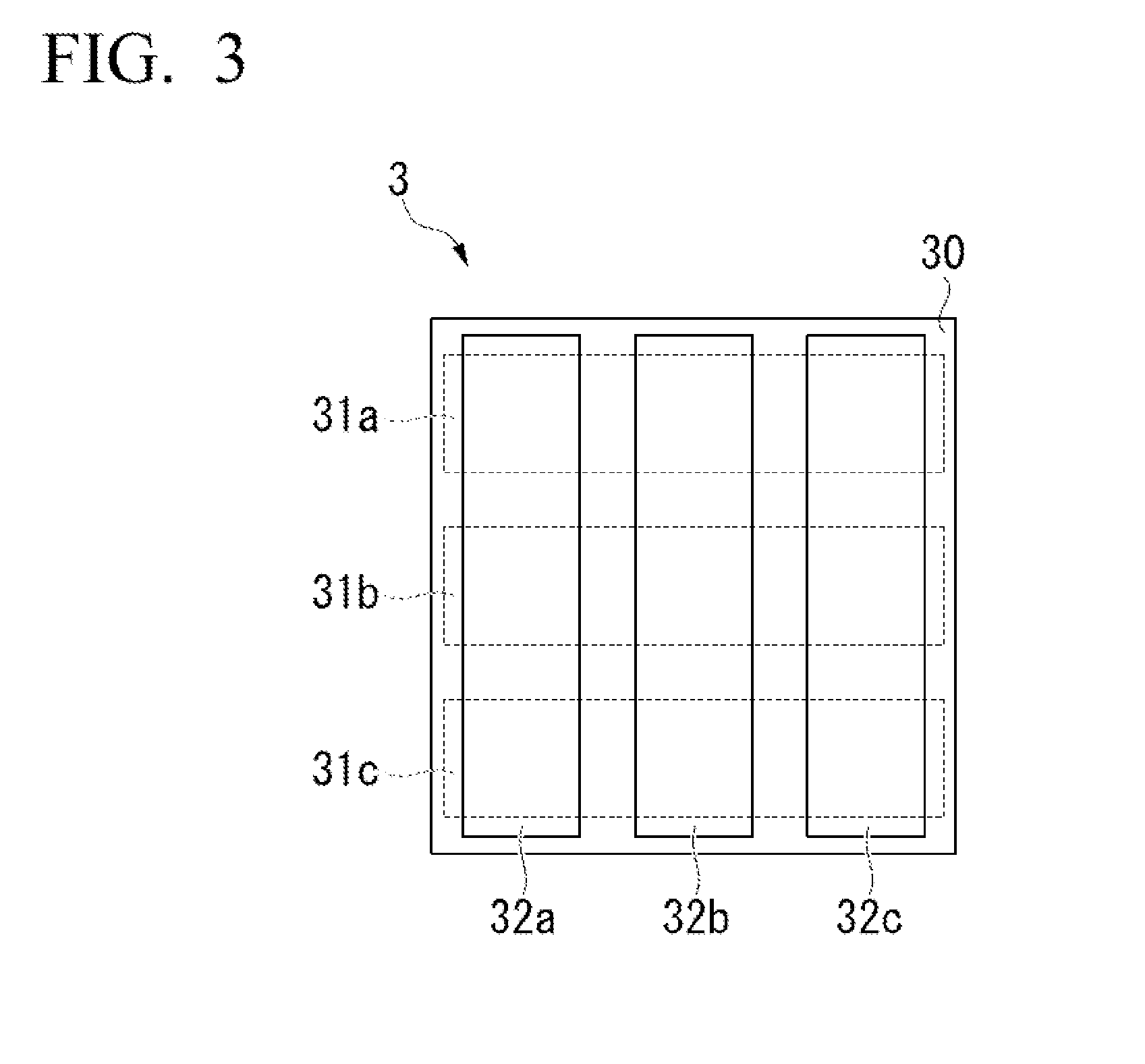

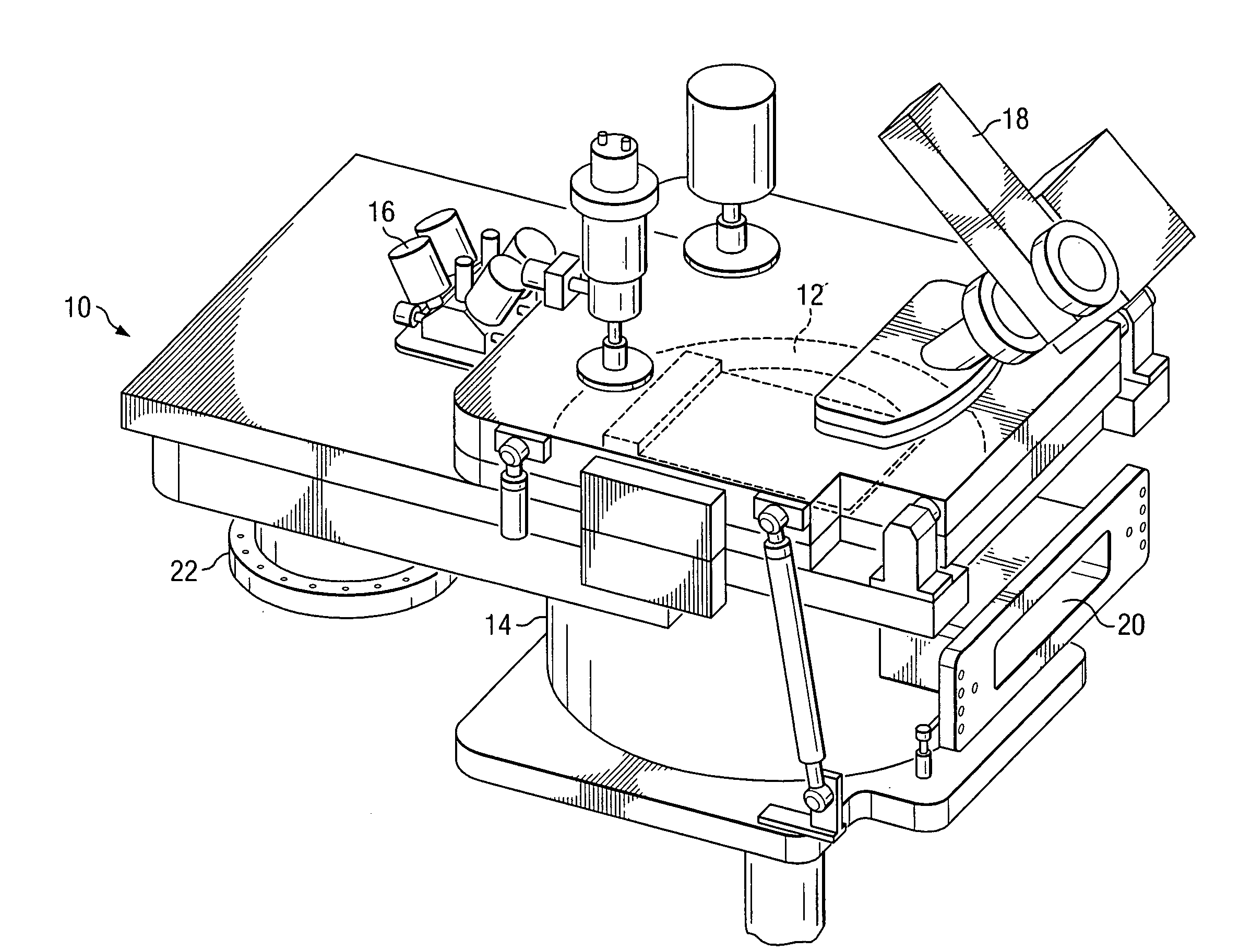

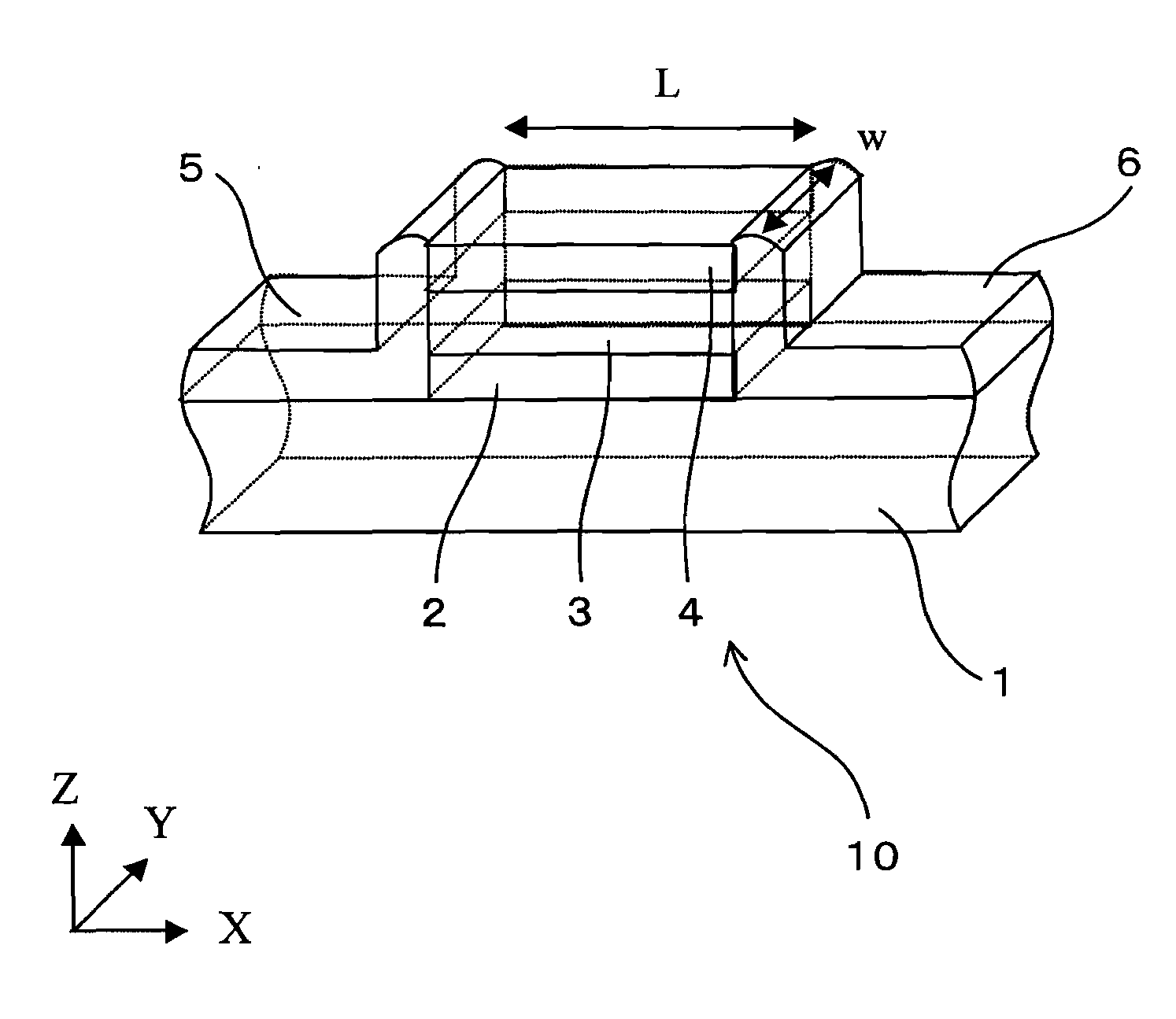

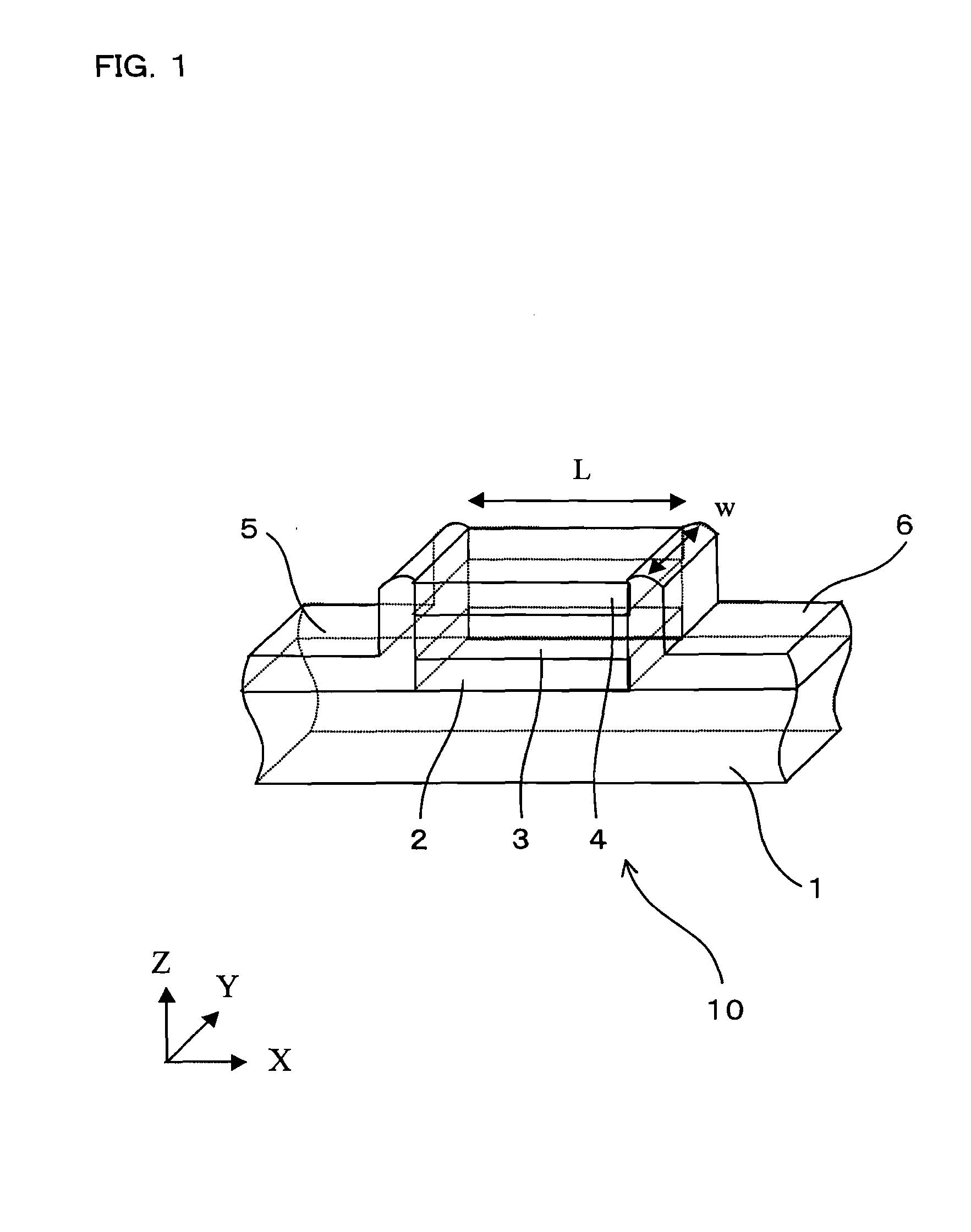

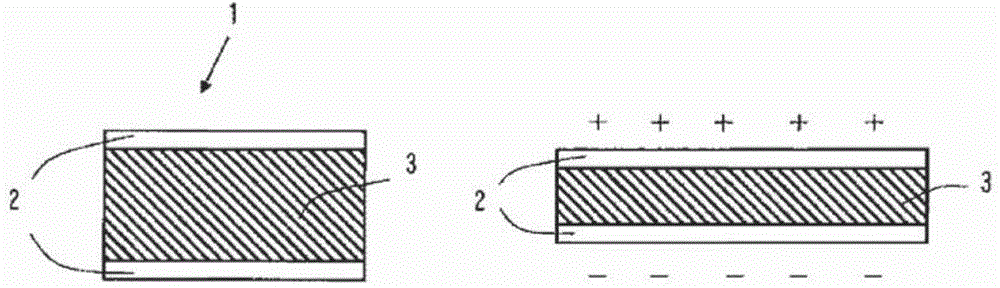

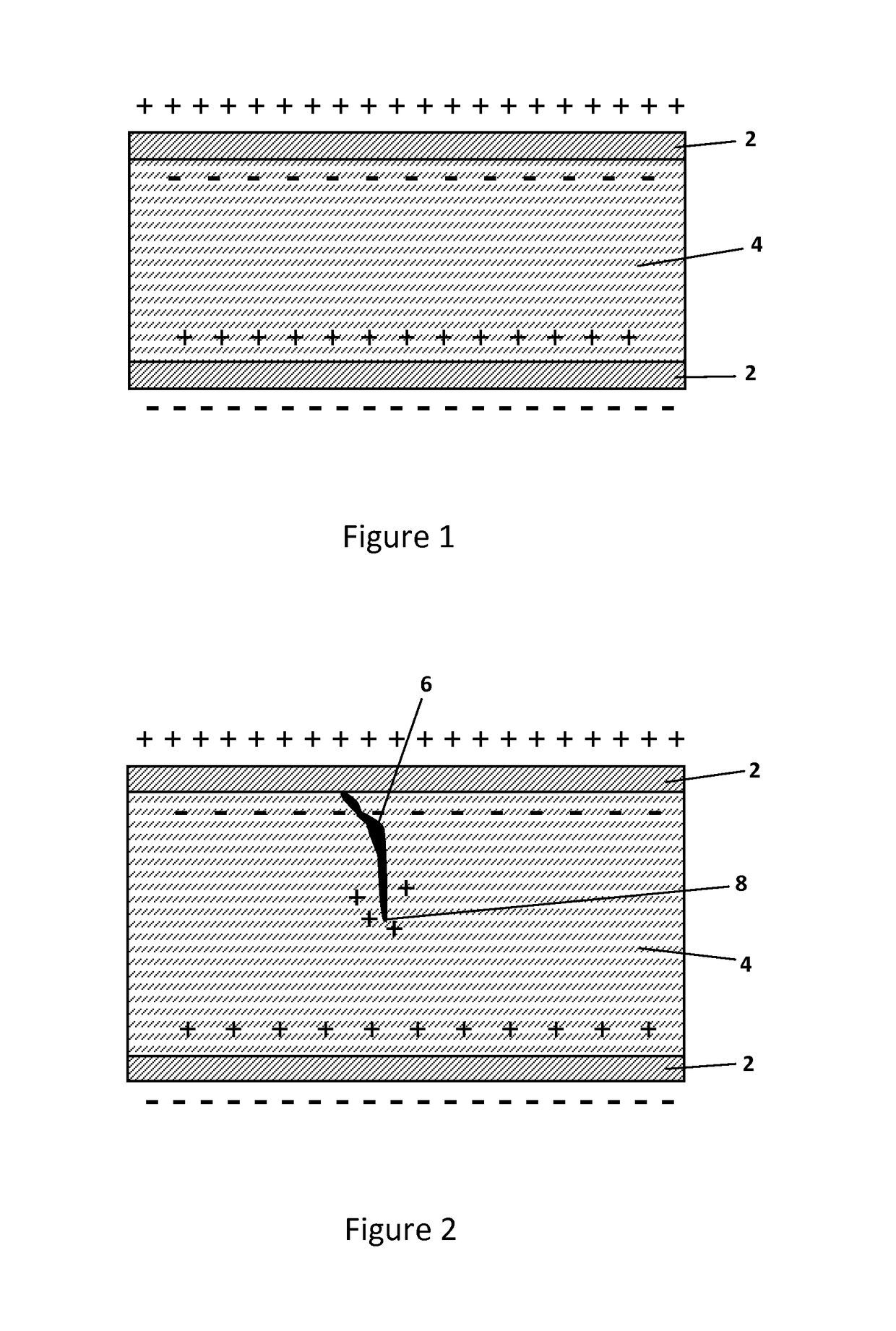

Electromagnetic field detecting element and device using same

InactiveUS20090296258A1Improve dielectric breakdown strengthEfficient detectionNanomagnetismMagnetic measurementsInsulation layerRoom temperature

An electromagnetic field detecting element 10 includes a lamination of three insulation layers 2, 3, and 4. The dielectric breakdown strength of the insulation layer 3 is greater than the dielectric breakdown strengths of insulation layers 2 and 4. The three insulation layers 2, 3, and 4 are disposed between a pair of electrodes 5 and 6. Boundaries 7 and 8 on both ends of an overlapping region of the opposing surfaces 5a and 6a in a Z direction are apart from the insulation layer 3 by thicknesses t1 and t3 of the insulation layers 2 and 4, respectively. Between the pair of electrodes 5 and 6, ballistic current paths interposing therebetween the insulation layer 3 are formed by applying, between the pair of electrodes 5 and 6, an electric field having a magnitude which causes dielectric breakdown in the insulation layers 2 and 4 while causing no dielectric breakdown in the insulation layer 3. Thus, it is possible to perform at a room temperature a highly efficient electromagnetic field detection utilizing AB effect or AC effect.

Owner:SHARP KK

Polypropylene film for capacitor

ActiveUS20130288000A1Improve dielectric breakdown strengthIncreased durabilityFixed capacitor dielectricSynthetic resin layered productsNMR - Nuclear magnetic resonanceHeat resistance

A biaxially-oriented polypropylene film for an ultra-thin capacitor that has superior heat resistance, withstand voltage performance and long-term durability. The film has a stereoregularity in which mesopentad fraction (mmmm) as determined by measurement of high temperature nuclear magnetic resonance (high temperature NMR) is between 94% and 98%, a weight average molecular weight (Mw) of 250,000 to 450,000, a molecular weight distribution (Mw / Mn) of 4 to 7, and on a molecular weight distribution curve, a difference determined by subtracting the differential distribution value when the logarithm of molecular weight Log(M)=6 from the differential distribution value when Log(M)=4.5 that is 9% to 15%. The film is fabricated using a polypropylene raw material resin in which the composition of the aforementioned molecular weight distribution has been adjusted by peroxidative decomposition treatment of a polypropylene resin.

Owner:OJI HLDG CORP

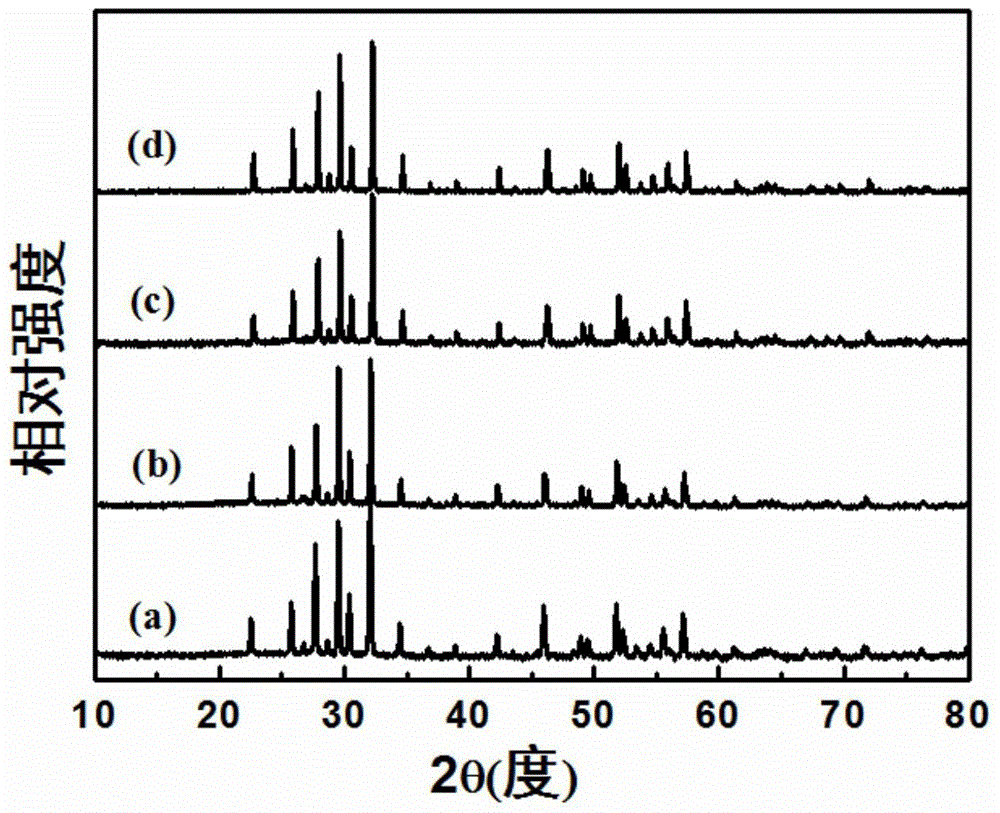

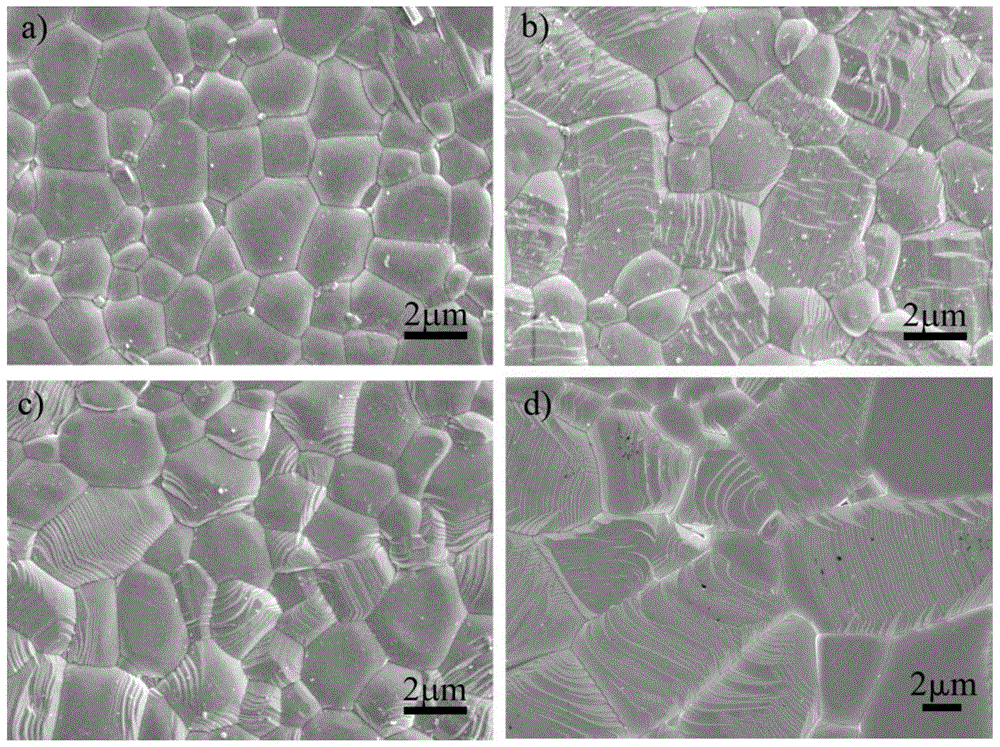

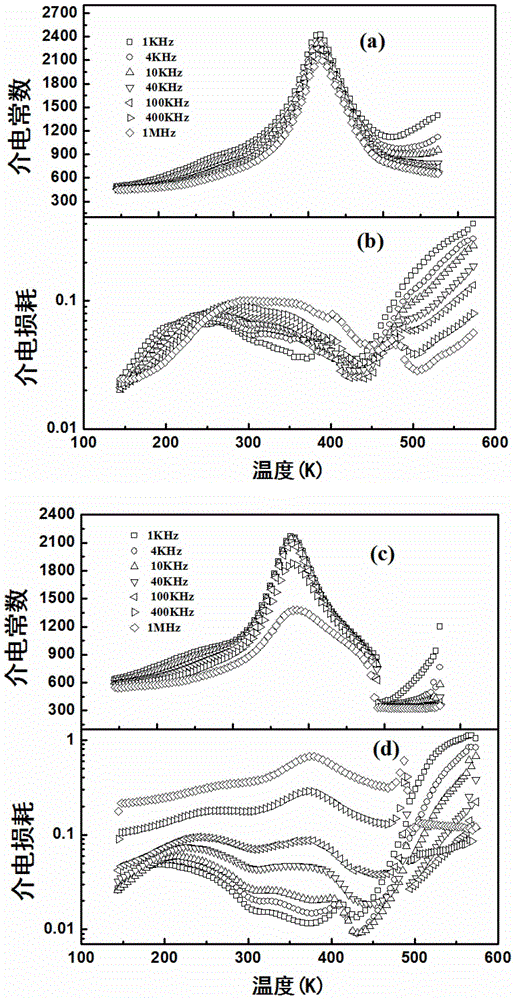

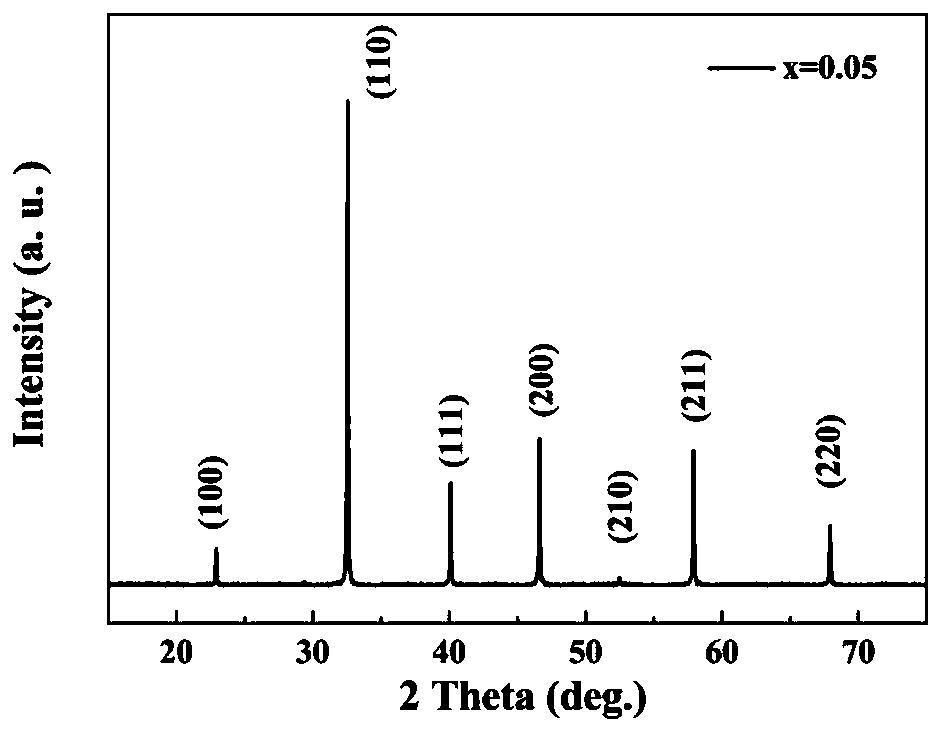

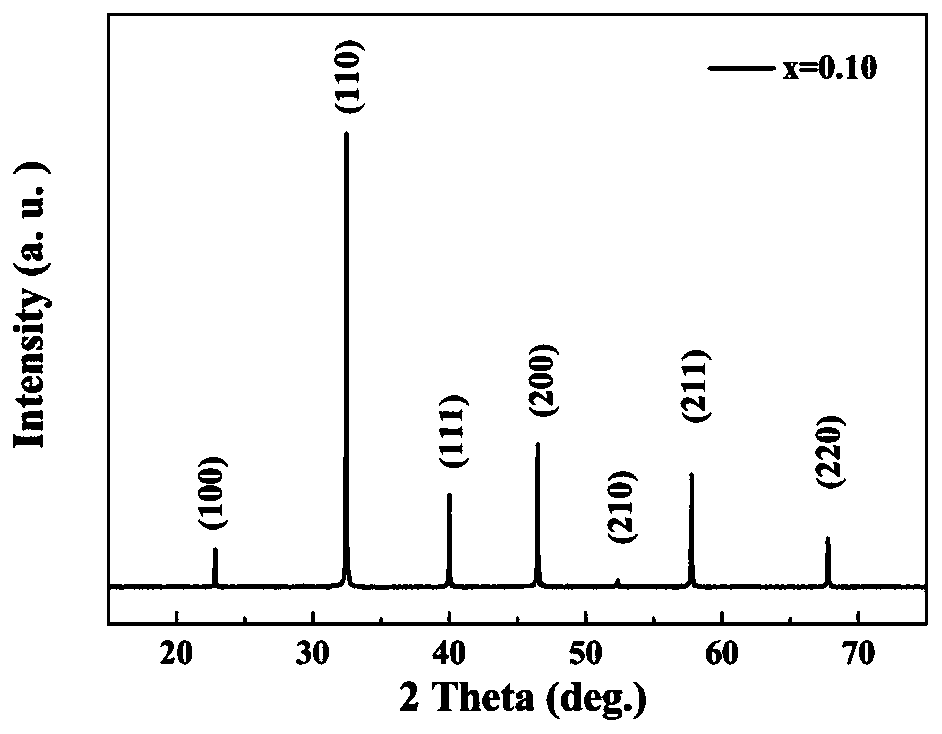

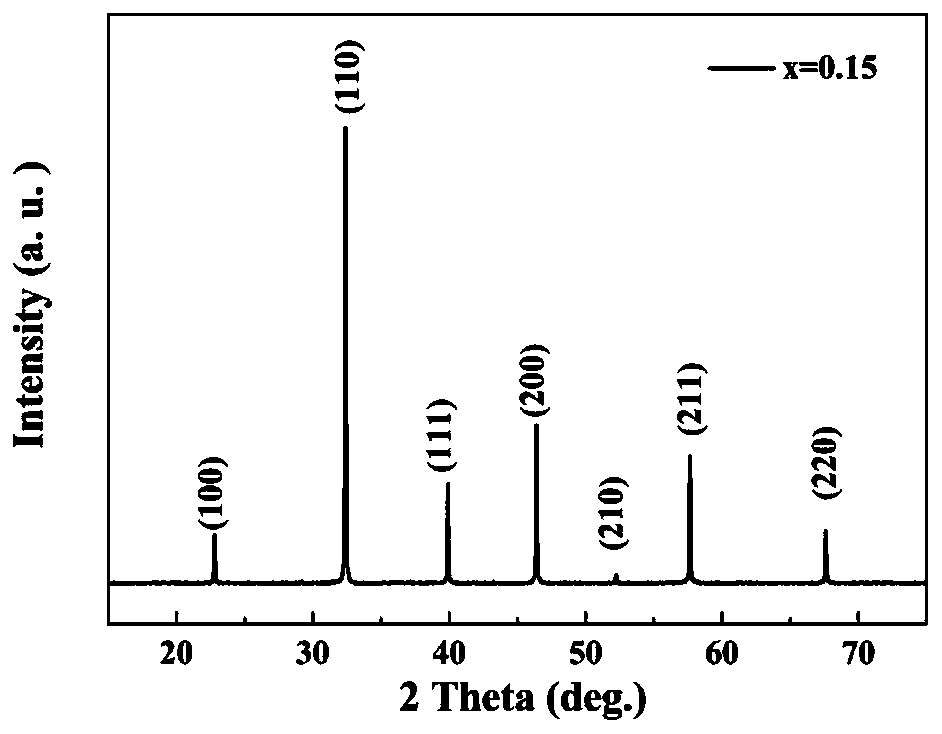

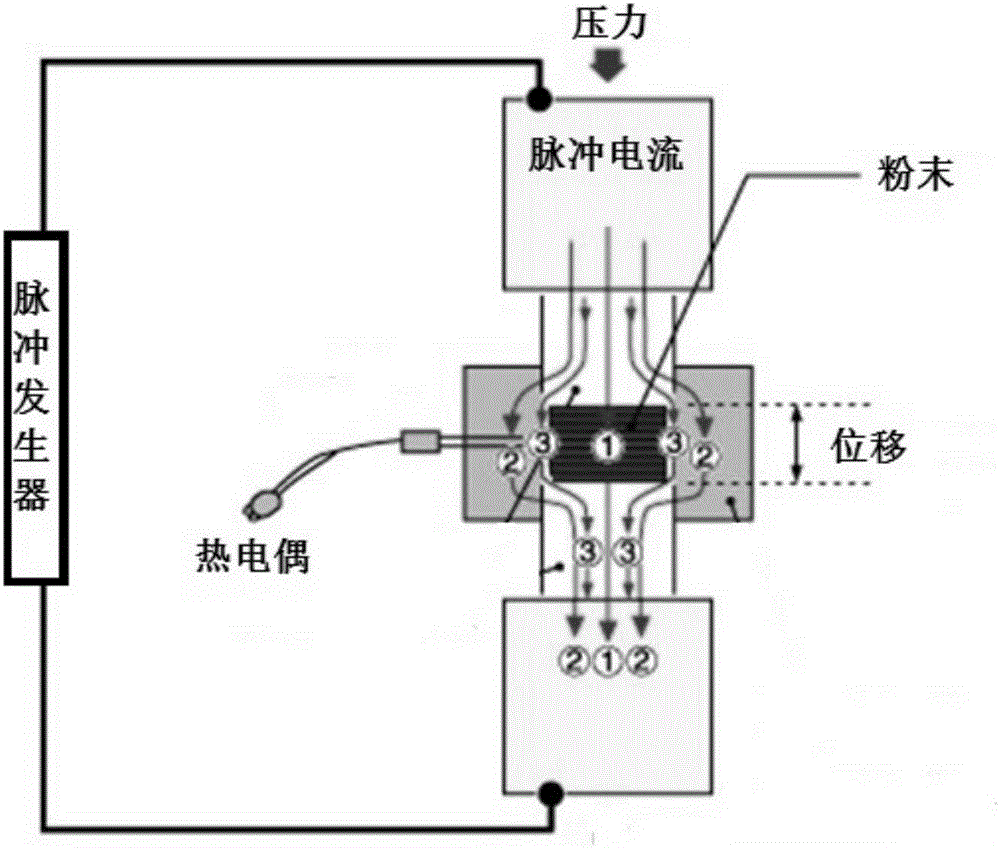

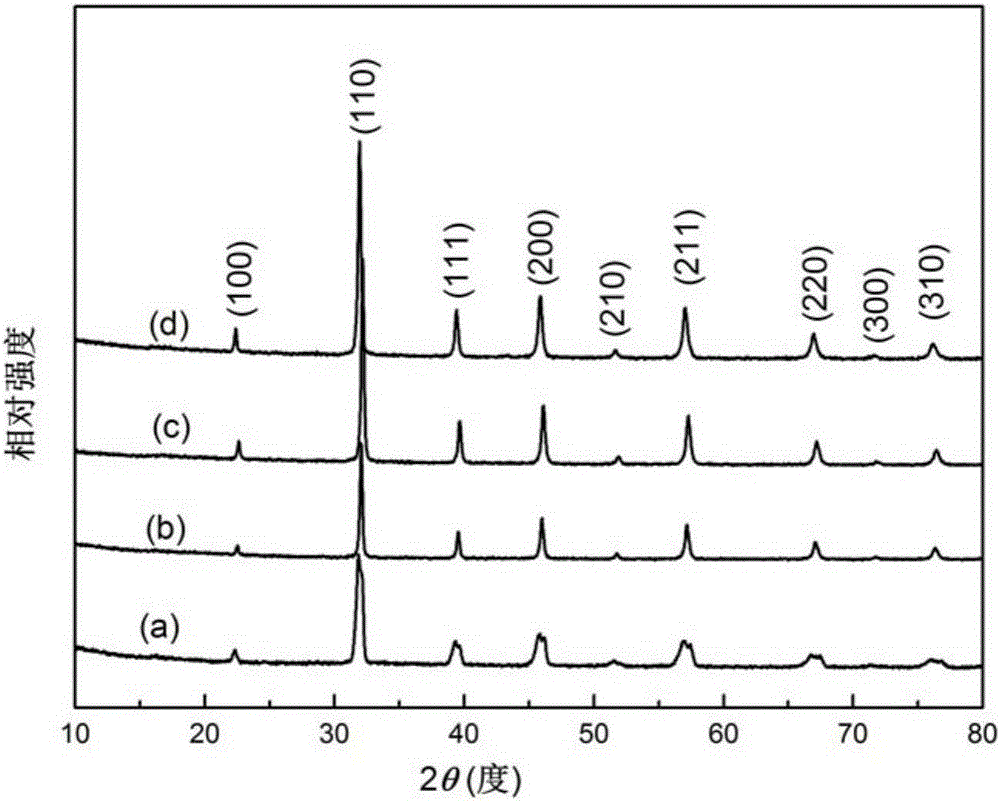

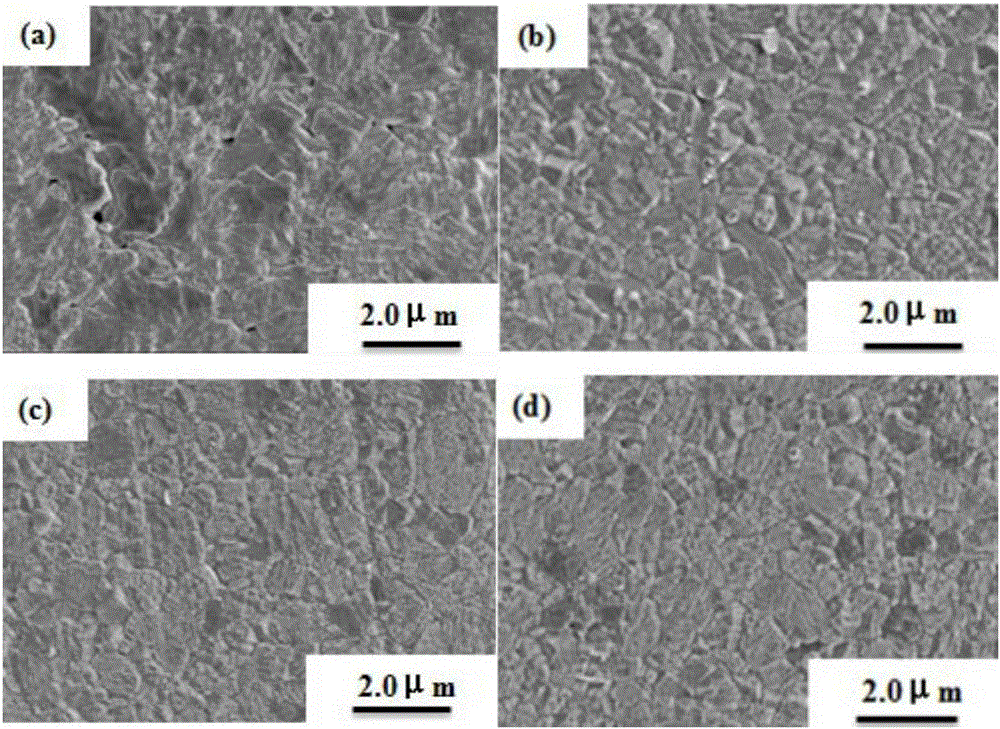

Method for preparing strontium barium niobate ceramics with high pyroelectric effects

ActiveCN105753471ASmall and uniformImprove dielectric breakdown strengthDielectricStrontium barium niobate

The invention discloses a method for preparing strontium barium niobate ceramics with high pyroelectric effects.The method includes mixing raw materials BaCO<3>, SrCO<3> and Nb<2>O<5> according to a chemical formula of Sr<x>Ba<1-x>Nb<2>O<6> to obtain Sr<x>Ba<1-x>Nb<2>O<6> powder; sintering the Sr<x>Ba<1-x>Nb<2>O<6> powder by the aid of a spark plasma sintering system in a vacuum environment at the temperature of 1000-1050 DEG C to prepare ceramic sintered bodies and thermally treating the ceramic sintered bodies in the air at the temperature of 965-980 DEG C for 3 hours to obtain the strontium barium niobate ceramics with the high pyroelectric effects.The x can be equal to 0.4 or 0.5 or 0.6.The method has the advantages that the strontium barium niobate ceramics with the high pyroelectric effects have small crystal grain sizes and are high in density, the dielectric breakdown field strength is improved, accordingly, the strontium barium niobate ceramics hopefully can be used for solid-state refrigerating systems, and various currently confronted climatic environmental problems due to the fact that ozone layers are destructed by Freon which is used as a refrigerants can be solved.

Owner:ZHEJIANG UNIV

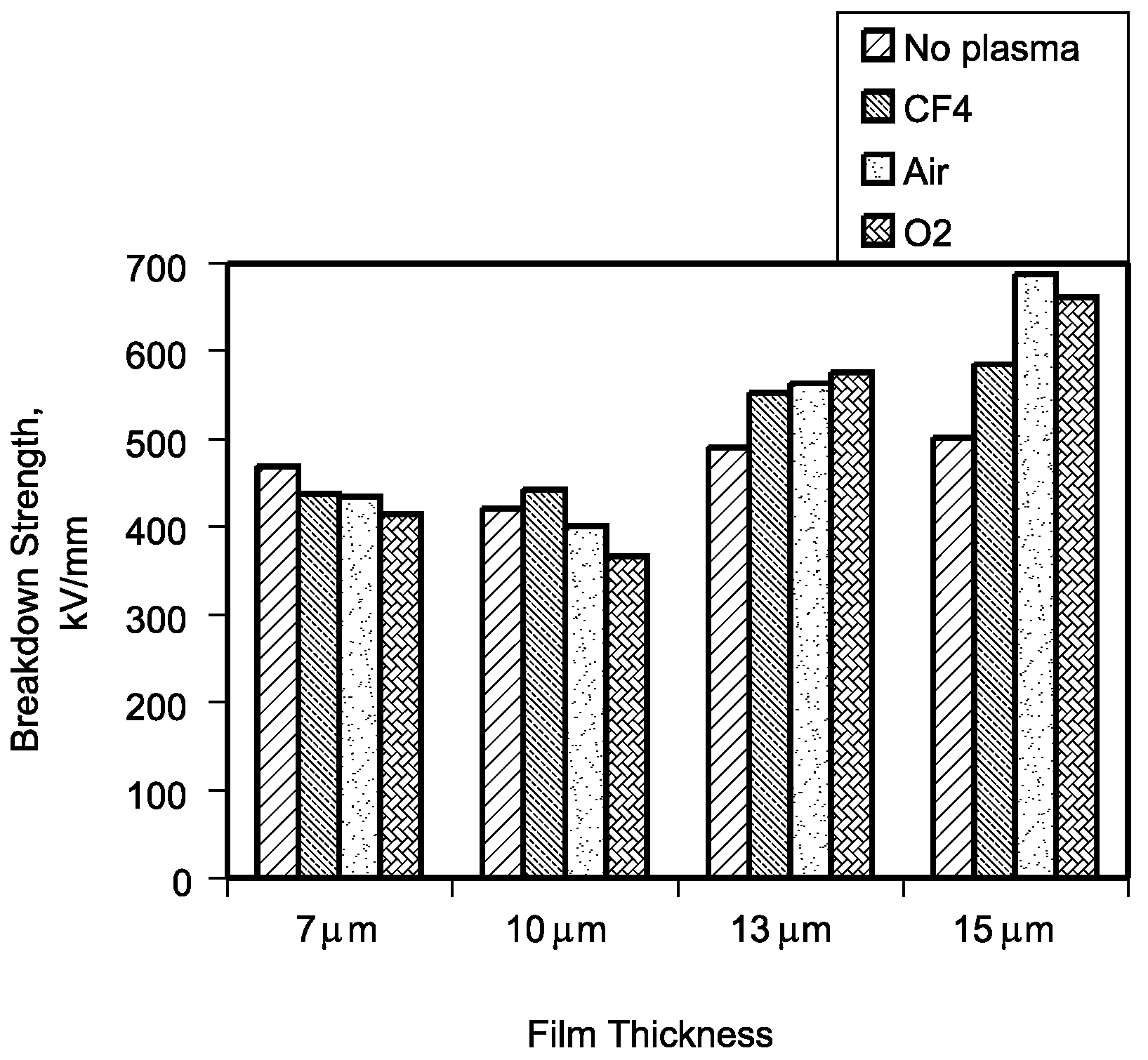

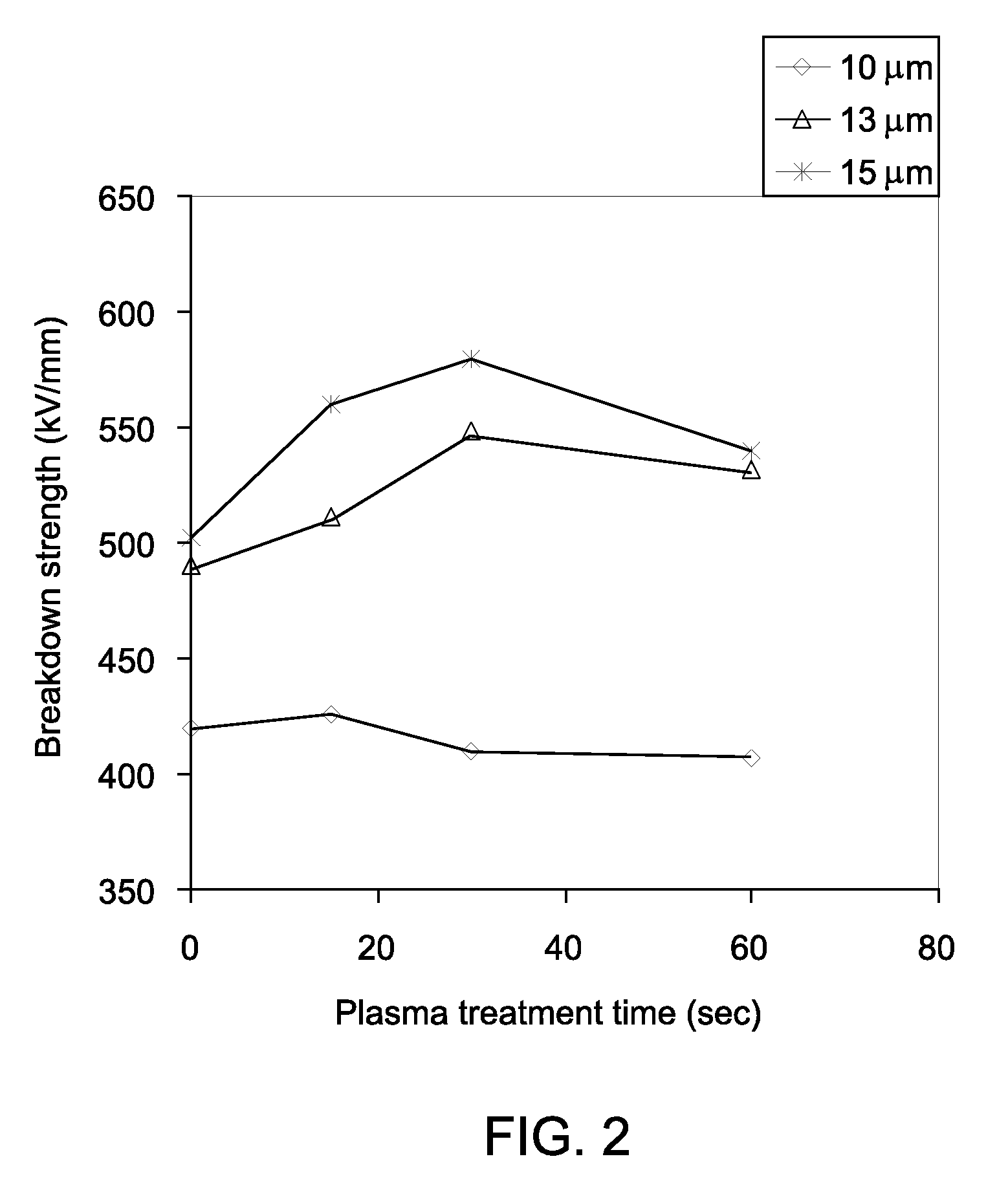

Methods for improving the dielectric properties of a polymer, and related articles and devices

InactiveUS20100246094A1Improve dielectric breakdown strengthLiquid surface applicatorsElectrolytic capacitorsVitrificationPolymeric surface

In one aspect of the present invention, a method for increasing the dielectric breakdown strength of a polymer is described. The method comprises providing the polymer and contacting a surface of the polymer in a reaction chamber with a gas plasma, under specified plasma conditions. The polymer is selected from the group consisting of a polymer having a glass transition temperature of at least about 150° C., and a polymer composite comprising at least one inorganic constituent. The contact with the gas plasma is carried out for a period of time sufficient to incorporate additional chemical functionality into a surface region of the polymer film, to provide a treated polymer. Also provided are an article and method of manufacture.

Owner:GENERAL ELECTRIC CO

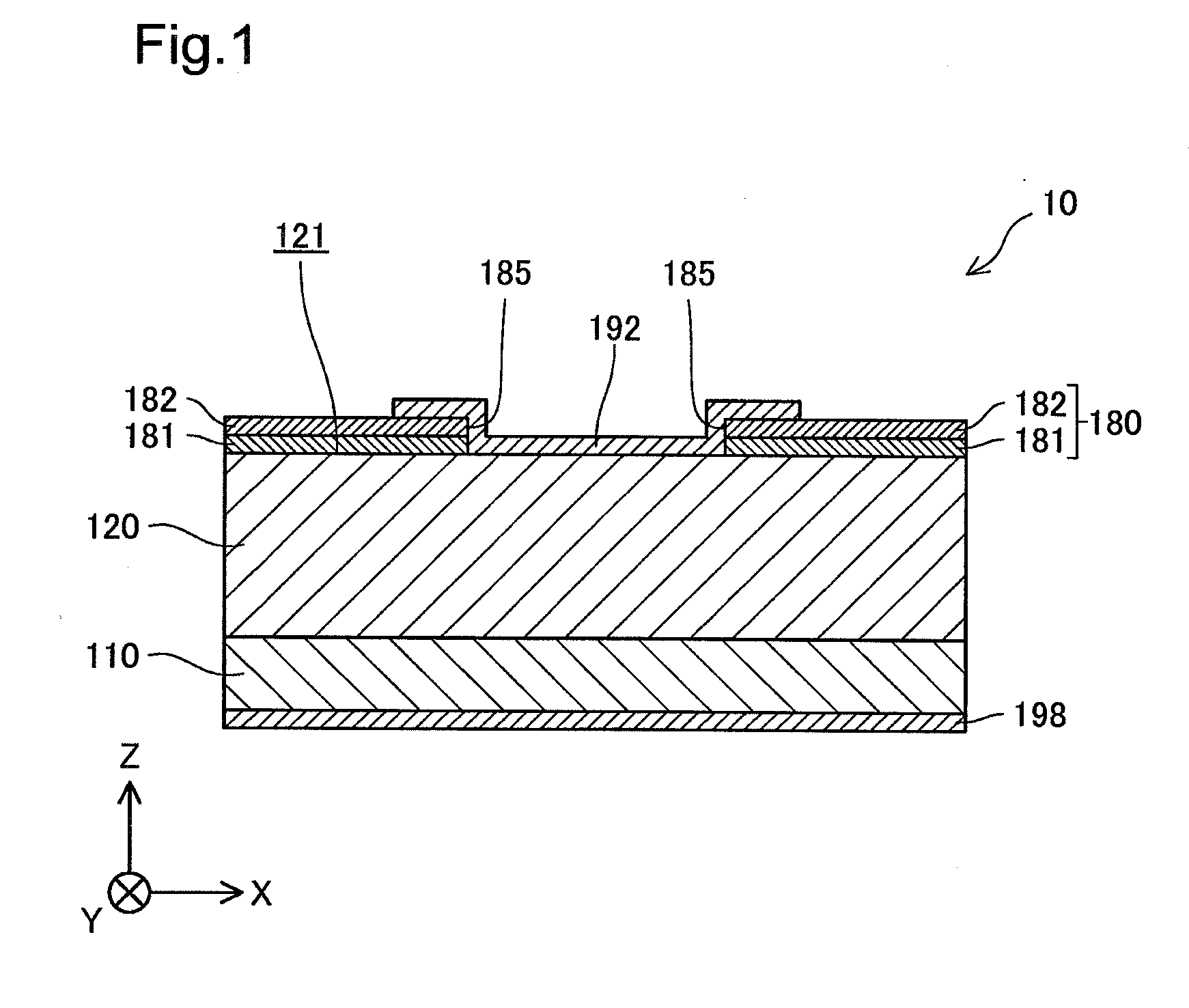

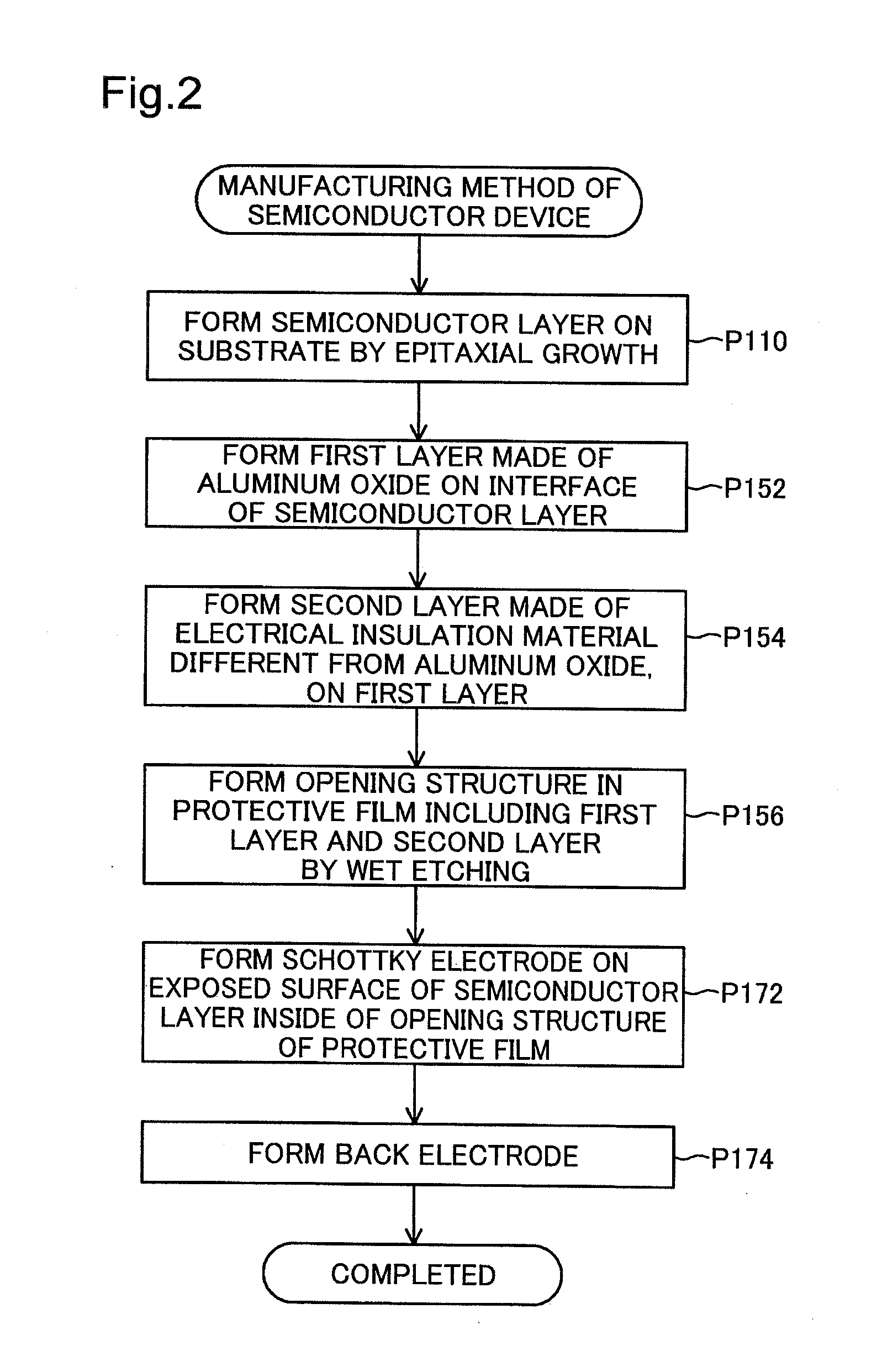

Semiconductor device

ActiveUS20150021617A1Total current dropImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor

A semiconductor device includes; a semiconductor layer mainly made of GaN; a protective film provided to have electrical insulation property and configured to coat the semiconductor layer; and an electrode provided to have electrical conductivity and configured to form a Schottky junction with the semiconductor layer. Tthe protective film includes: a first layer made of Al2O3 and arranged adjacent to the semiconductor layer; a second layer made of an electrical insulation material different from Al2O3 and formed on the first layer; and an opening structure formed to pass through the first layer and the second layer. The electrode is located inside of the opening structure.

Owner:TOYODA GOSEI CO LTD

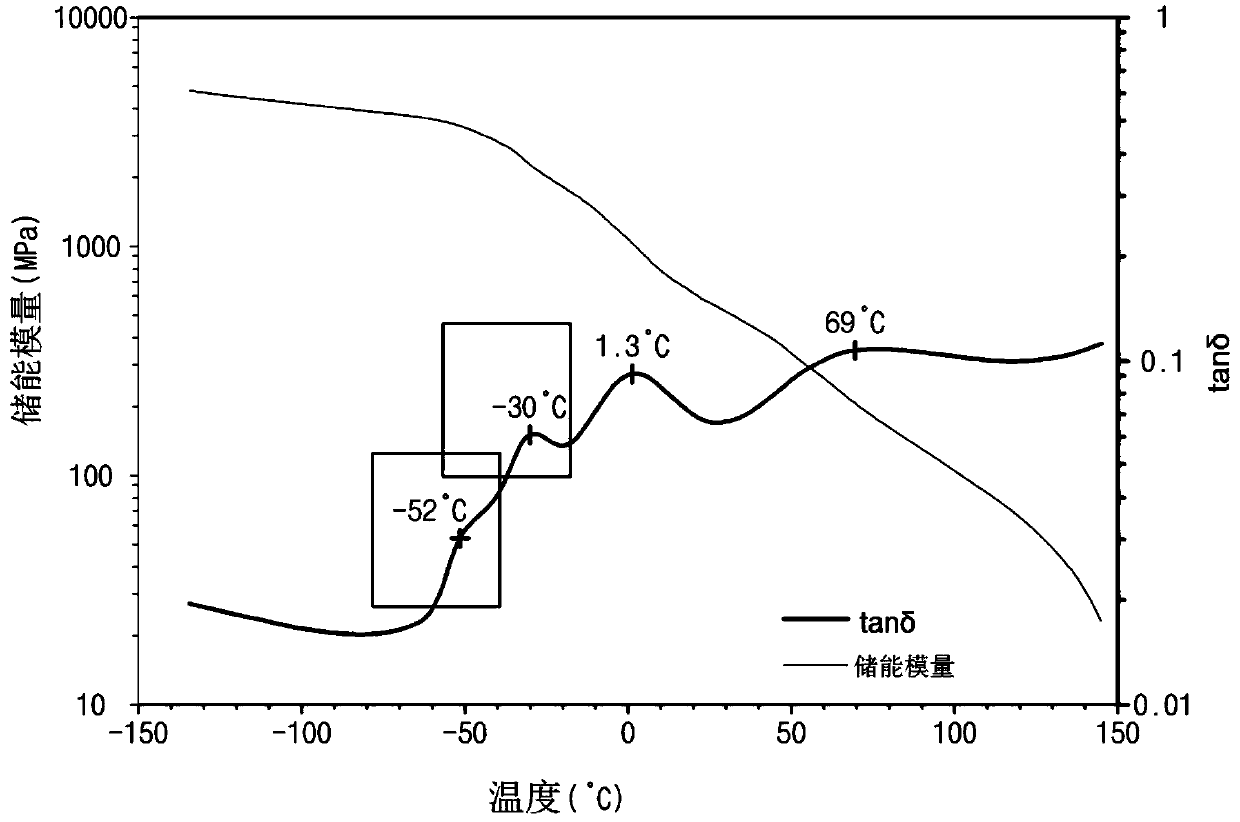

Polymer actuator

InactiveCN104937735AImprove flexibilityHigh elongationGenerators/motorsPiezoelectric/electrostrictive devicesDynamic viscoelasticityEngineering

The present invention provides a polymer actuator which has excellent flexibility, excellent tensibility and high dielectric breakdown strength, while having low temperature dependence of characteristics such as elastic modulus, and which can be driven even by low electric field. The present invention relates to a polymer actuator which is characterized in that: the storage modulus (E'(20°C)) as determined by dynamic viscoelasticity measurement at a frequency of 1 Hz at a temperature of 20°C is 0.5 MPa or less; the ratio of the storage modulus (E'(-20°C)) as determined by dynamic viscoelasticity measurement at a frequency of 1 Hz at a temperature of -20°C relative to the storage modulus (E'(20°C)), namely E'(-20°C) / E'(20°C) is 5.0 or less; and the ratio of the storage modulus (E'(40°C)) as determined by dynamic viscoelasticity measurement at a frequency of 1 Hz at a temperature of 40°C relative to the storage modulus (E'(20°C)), namely E'(40°C) / E'(20°C) is 0.5 or more.

Owner:TOYO TIRE & RUBBER CO LTD

Ceramic material with high energy storage performance and ultrafast discharge rate and preparation method thereof

The invention provides a ceramic material with high energy storage performance and ultrafast discharge rate and a preparation method thereof, the chemical formula of the ceramic material is (1-x) (Na0.5Bi0.5) 0.7 Sr0.3TiO3-xBi (Mg2 / 3Nb1 / 3) O3, and x is more than or equal to 0.05 and less than or equal to 0.20. The preparation method comprises the following steps: (1) uniformly mixing SrCO3, Na2CO3, TiO2, Bi2O3, MgO and Nb2O5 to obtain raw material powder, briquetting, presintering, crushing and sieving to obtain presintered powder; (2) carrying out ball milling on the presintered powder to obtain raw material powder; and (3) tabletting and molding the raw material powder, and sintering into porcelain to obtain the ceramic material with high energy storage performance and ultrafast discharge rate. The ceramic material has high energy storage performance and excellent charging and discharging performance, is a promising high-performance dielectric candidate material, and has the characteristics of environmental friendliness, high practicability and the like.

Owner:SHAANXI UNIV OF SCI & TECH

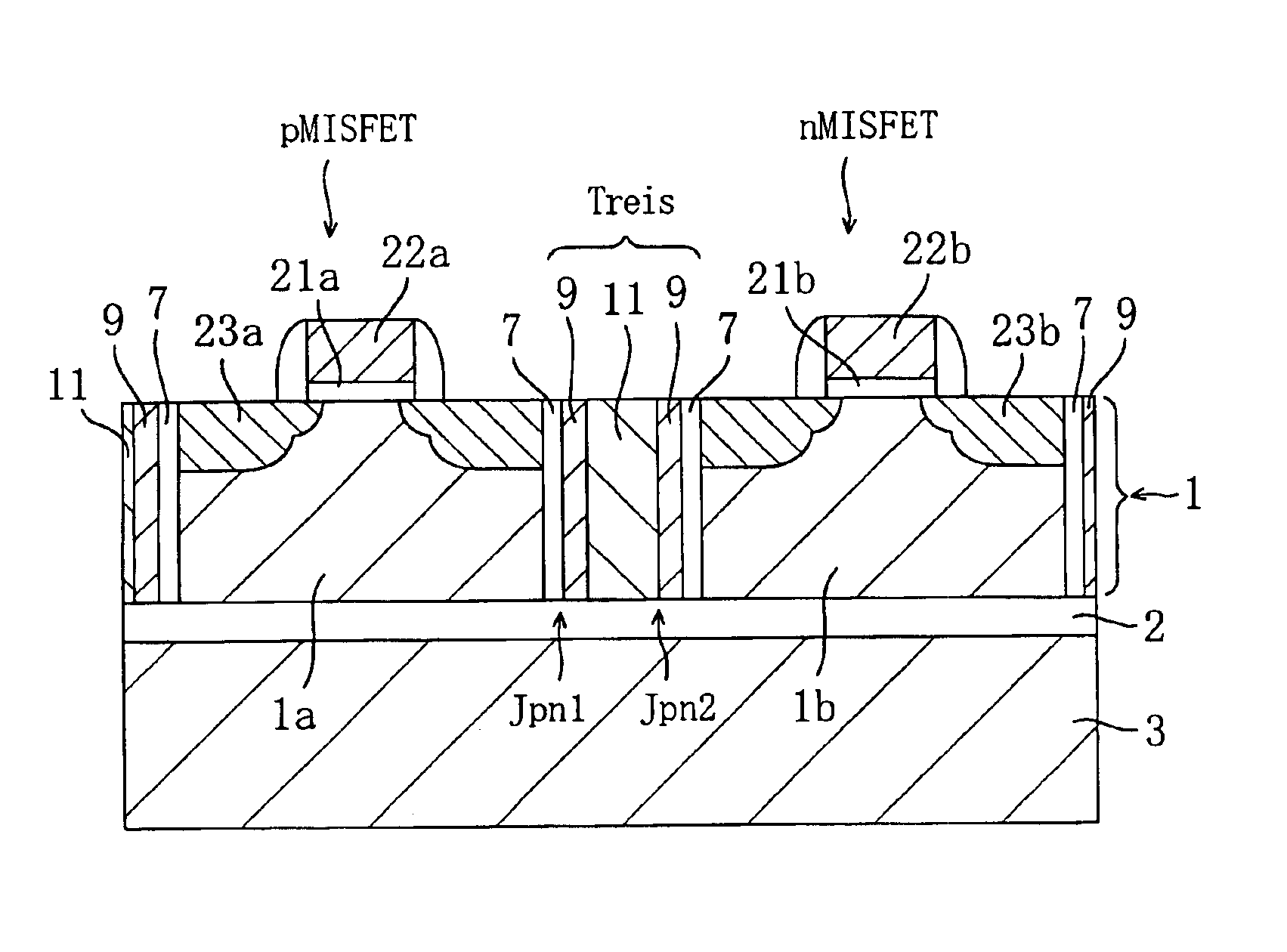

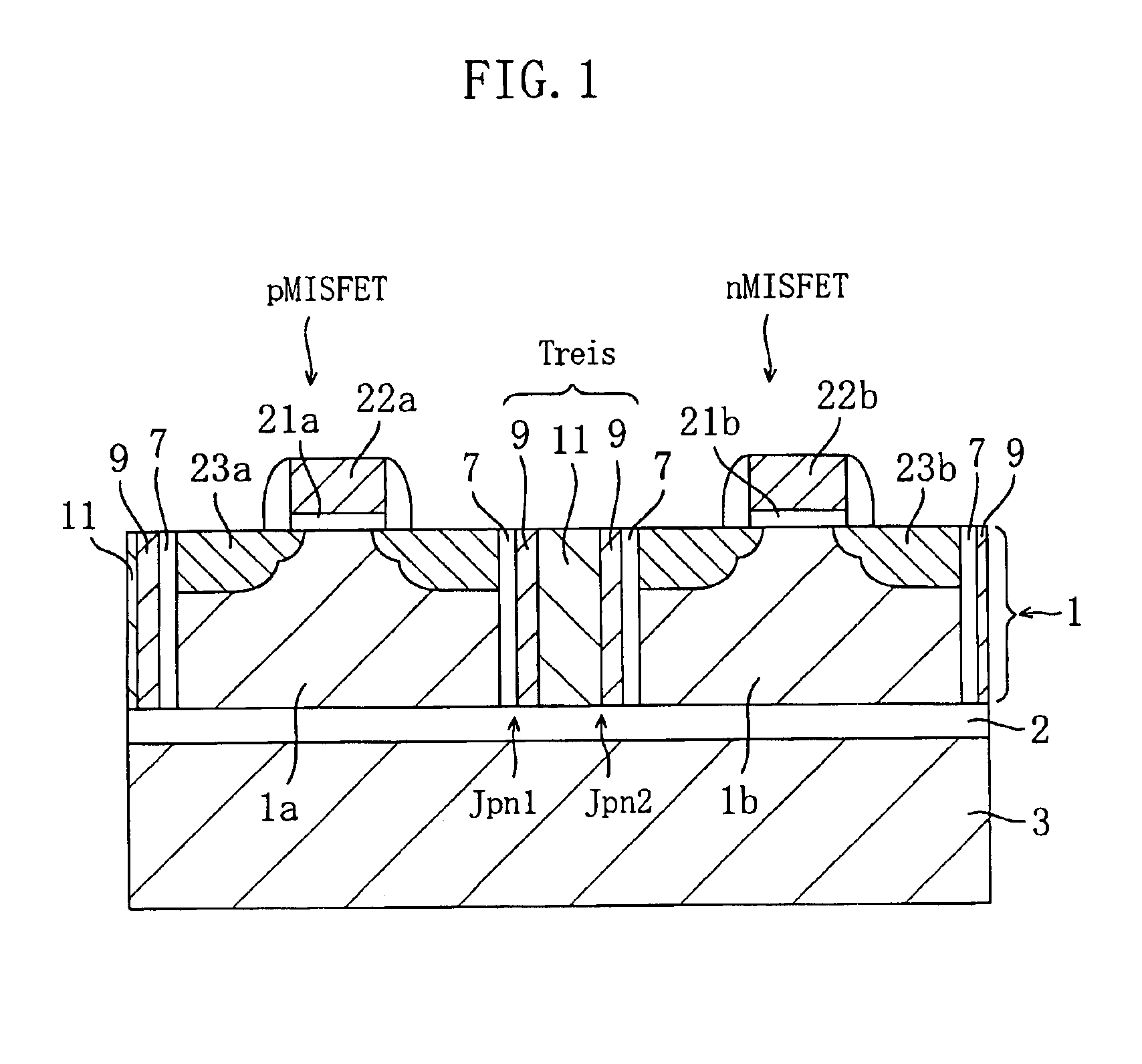

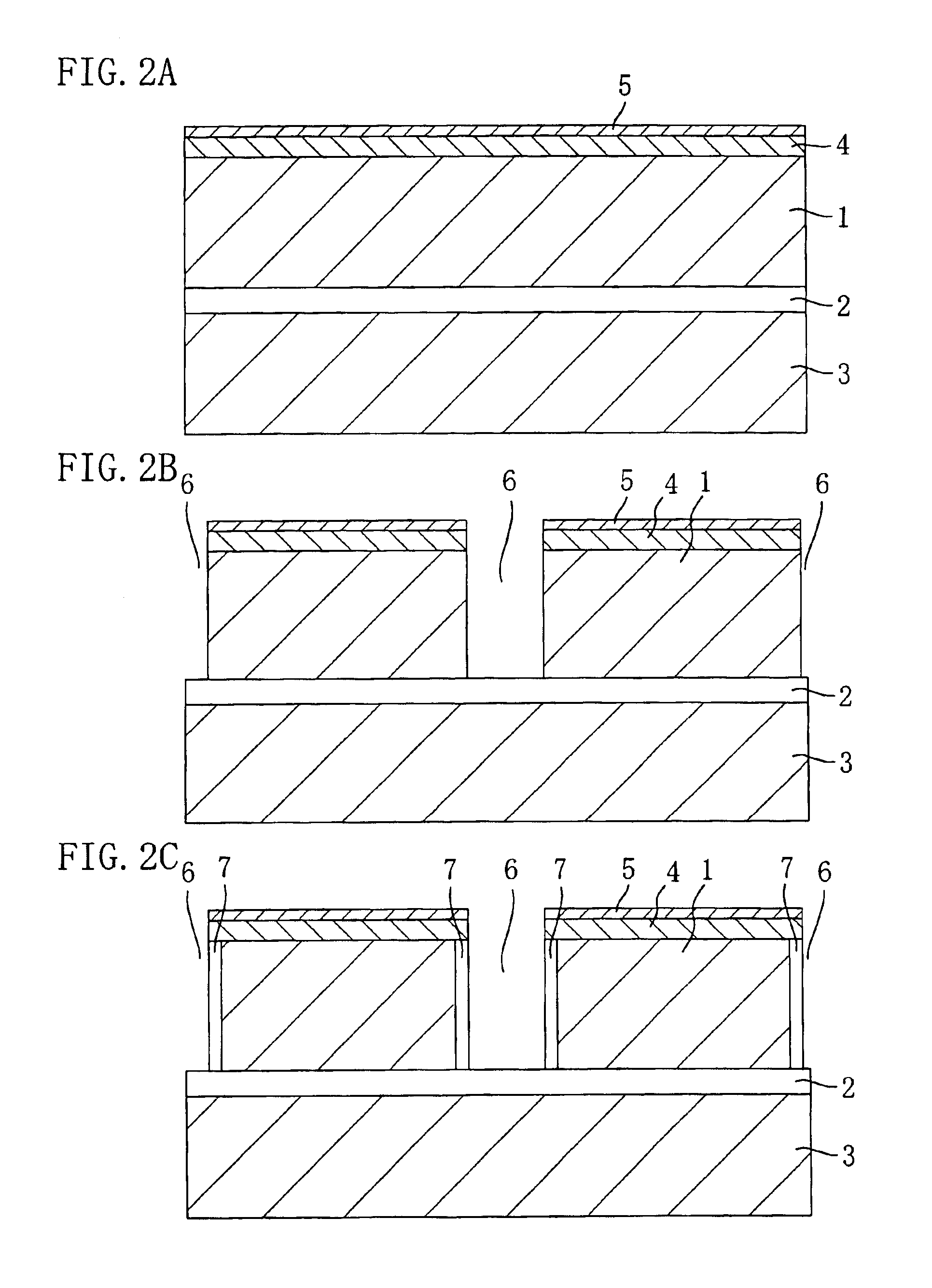

Semiconductor device using an SOI substrate and having a trench isolation and method for fabricating the same

InactiveUS6867462B2Improve dielectric breakdown strengthSuppressing generation of stressTransistorSolid-state devicesSoi substrateDepth direction

A trench isolation region separating active regions in which MISFETs are formed includes: side insulating films covering the sides of a trench; polycrystalline semiconductor layers of a first conductivity type covering the respective sides of the side insulating films; and a polycrystalline semiconductor layer of a second conductivity type filling a gap between the polycrystalline semiconductor layers of the first conductivity type. Two pn junctions extending along the depth direction of the trench are formed between each of the polycrystalline semiconductor layers of the first conductivity type and the polycrystalline semiconductor layer of the second conductivity type. Upon application of a voltage between the active regions, a depletion layer expands in one of the pn junctions, so that the voltage is also partly applied to the depletion layer. As a result, the concentration of electric field in the side insulating films is relaxed.

Owner:PANASONIC CORP

Capacitor films with high temperature performance, methods of manufacture, and articles thereof

ActiveUS20190153217A1Improve electrical performanceImprove dielectric breakdown strengthFixed capacitor electrodesFixed capacitor dielectricPolymer scienceMicrometer

A film including 70 to 99 weight percent of an amorphous, high heat copolycarbonate having a glass transition temperature of at least 170° C., preferably 170 to 230° C., more preferably 175 to 200° C., and 1 to 30 weight percent of a cyclic olefin copolymer each based on the total weight of polymers in the film; wherein the film has a dielectric breakdown strength of greater than 700 Volts / micrometer, preferably 700 to 1250 Volts / micrometer at 150° C., is provided. Methods for the manufacture of the film and articles including the films are provided.

Owner:SHPP GLOBAL TECH BV

Multi-layer dielectric film with nanostructured block copolymer

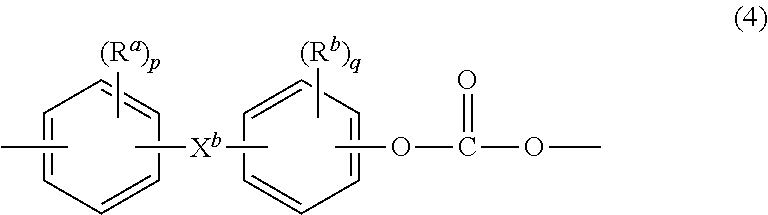

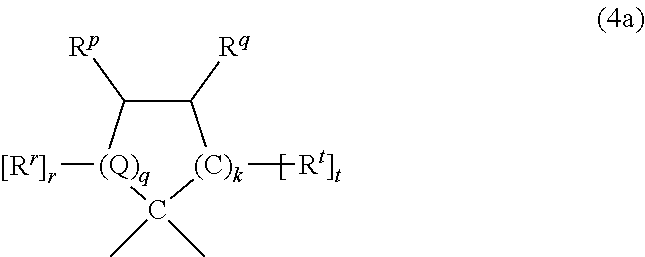

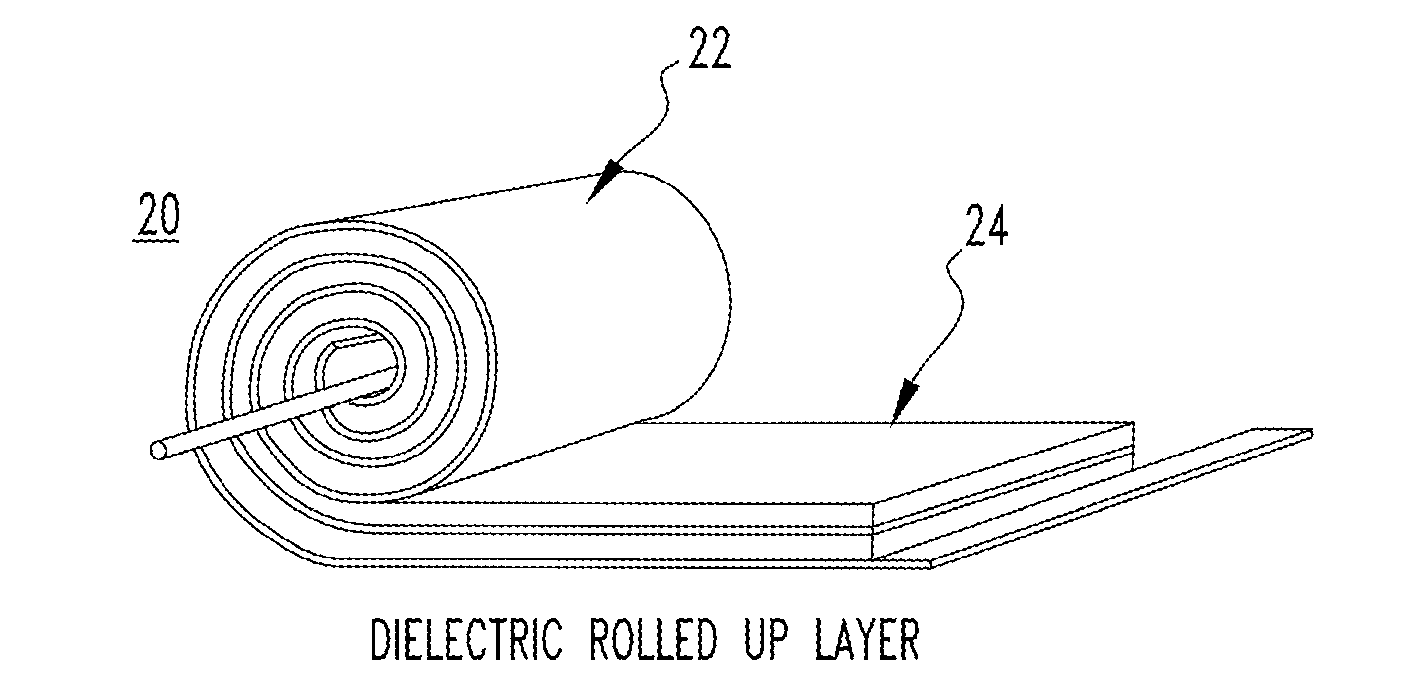

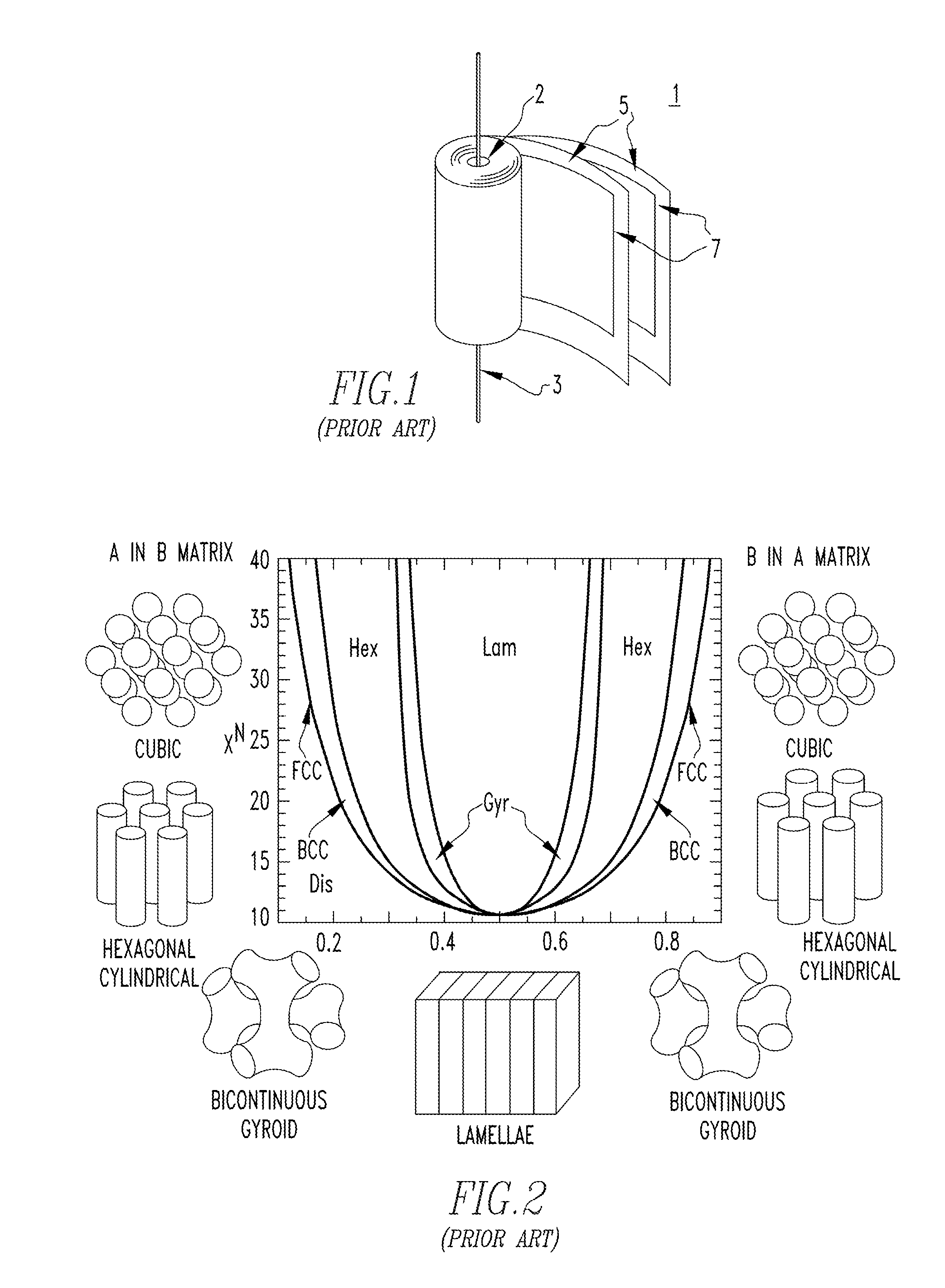

InactiveUS20160260545A1High dielectric strengthImprove performanceFixed capacitor dielectricWound capacitorsDielectricElectricity

The disclosed concept relates to multi-layer dielectric film with nano- or micro-structured block copolymers, such as, but not limited to, di-block copolymers and tri-block copolymers, and, more particularly, to capacitors constructed from the film. More particularly, the disclosed concept provides the ability to tune or control one or more characteristics of the dielectric film and capacitors formed therefrom, by selecting and combining blocks that exhibit different electrical and / or mechanical properties.

Owner:EATON INTELLIGENT POWER LTD

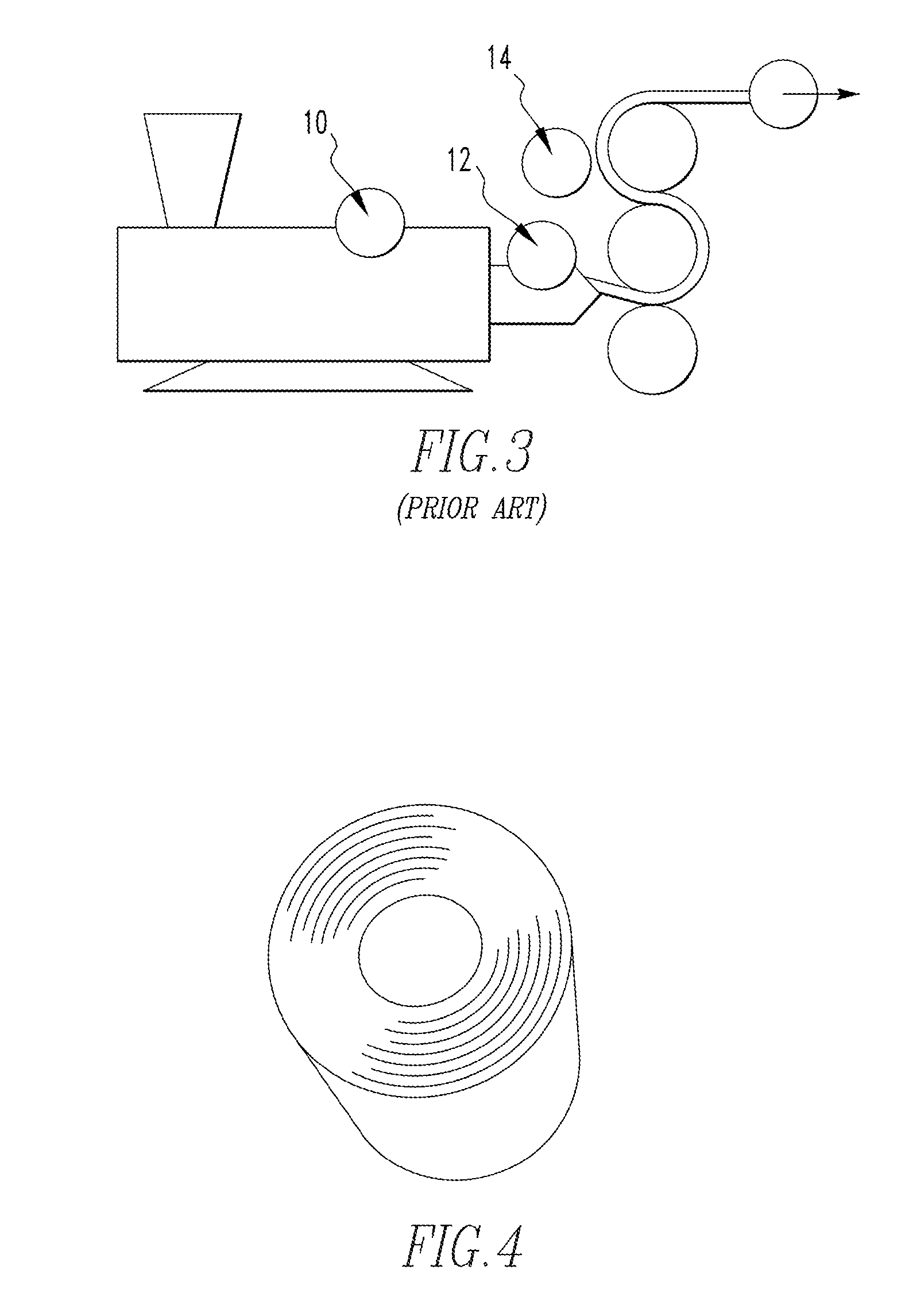

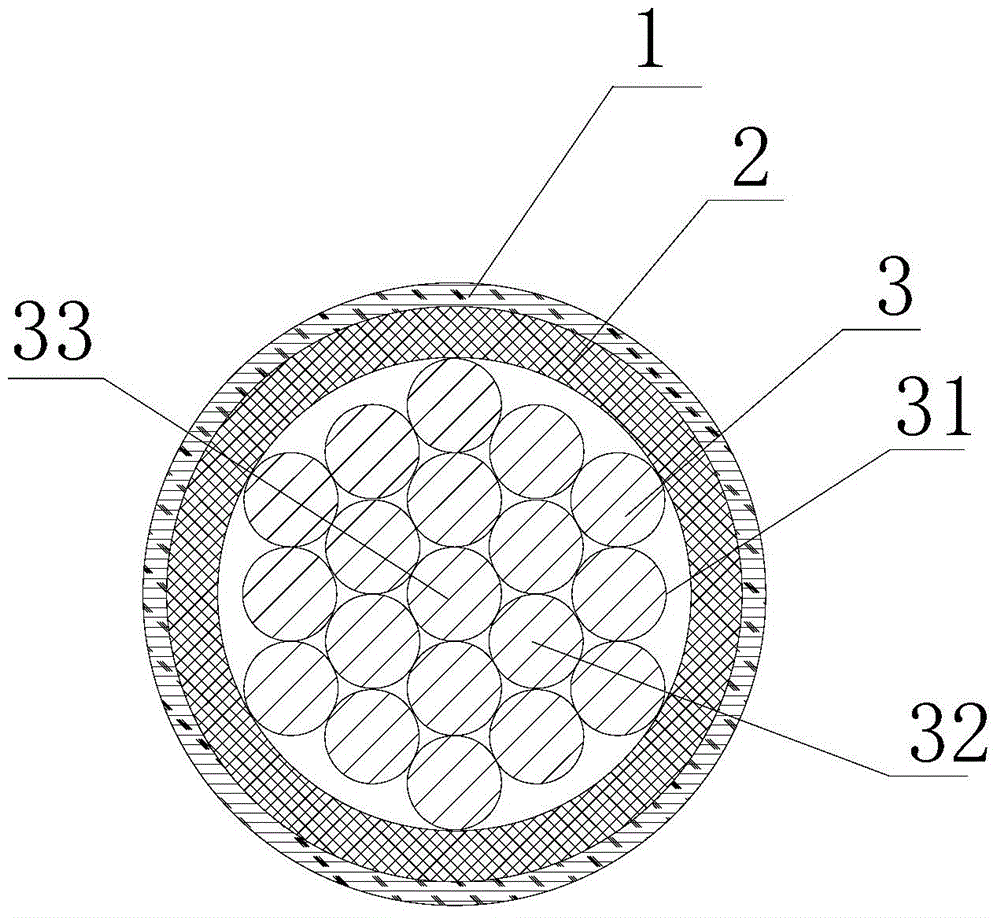

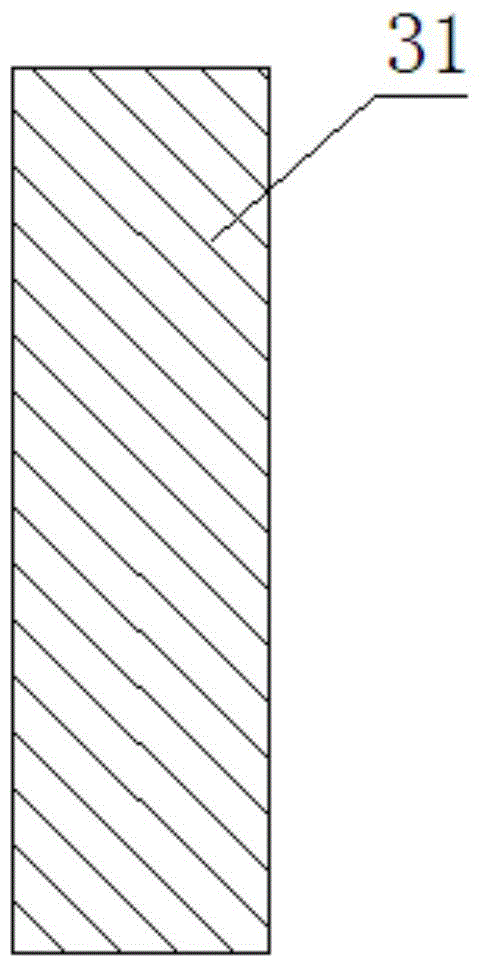

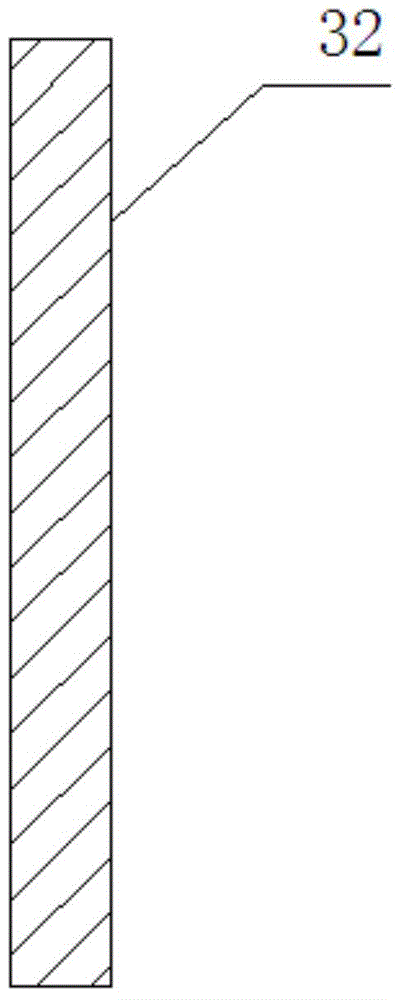

Production process for photovoltaic cable with high electric conductivity

InactiveCN104900345AGuaranteed service lifeGood weather resistanceConductor/cable markingInsulating conductors/cablesStrong acidsCorrosion

The invention discloses a production process for a photovoltaic cable with high electric conductivity. The production process comprises conductor core processing, insulating layer processing, packaging, cooling, character printing and forming a cable, and package examining. Particularly, the production process comprises the following steps: (a) conductor core processing: preparing a multilayer conductor core through intertwisting by a wire twisting machine; (b) insulating layer processing: forming an insulating layer through high-temperature extruding and flowing out of a fluorine adding mold port; (c) protecting layer processing: mixing polytetrafluoroethene with extrusion assisting agent, preparing a product after procedures such as extrusion, (d) packaging: packaging the conductor core by the insulating layer; (e) cooling: cooling the insulating layer, and extruding the protecting layer on the insulating layer; (f) character printing and forming the cable: printing characters on the surfaces of wires, and preparing the cable through the wires; and (g) package examining: performing quality examining on the cable, and warehousing the packaged products. The solar photovoltaic cable prepared according to the method of the invention has advantages of excellent corrosion resistance, high oil resistance, high strong-acid and strong-base resistance, and high oxidation resistance. Furthermore the specific intertwisted structure of the conductor core realizes more stable use performance and longer service life of the cable.

Owner:ZHEJIANG QINSHAN CABLE

Dielectric film, method for manufacturing the same, and transducer including the same

ActiveUS9685254B2Lower resistanceHigh dielectric constantRubber insulatorsPiezoelectric/electrostrictive device manufacture/assemblyDielectricElastomer

A dielectric film includes an elastomer and nanoparticles dispersed in the elastomer while chemically bound to the elastomer. The nanoparticles have cyano groups and are manufactured by a sol-gel process using an organometallic compound. A method for manufacturing a dielectric film includes: producing a chelate compound of an organometallic compound; producing a sol of metallic oxide particles having cyano groups by adding a silane coupling agent having a cyano group, an organic solvent, and water to the chelate compound; preparing a mixed solution by mixing the sol of the metallic oxide particles having cyano groups and a polymer solution containing a rubber polymer having a functional group capable of reacting with a hydroxy group; and forming a dielectric film by applying the mixed solution to a substrate and by curing a coating film.

Owner:SUMITOMO RIKO CO LTD +1

Barium strontium titanate based aluminum oxide composite ceramic with high energy storage density and preparation method of barium strontium titanate based aluminum oxide composite ceramic

ActiveCN105272217AImprove dielectric breakdown strengthHigh energy storage densityAir atmosphereCeramic sintering

The invention discloses a preparation method of barium strontium titanate based aluminum oxide composite ceramic with high energy storage density. According to the method, firstly, raw materials, BaCO3, SrCO3 and TiO2 are prepared according to the chemical formula Ba0.4Sr0.6TiO 3, then ground, dried, sieved and calcined for 3 hours at the temperature of 1,150 DEG C, and Ba0.4Sr0.6TiO 3 powder is prepared; secondarily, the Ba0.4Sr0.6TiO 3 powder and Al2O3 powder are prepared in the mass ratio being (100-x):x, wherein x ranges from 1 to 5, the powder is ground, dried and sieved, and ceramic powder is prepared; the ceramic powder is put in a mold and sintered in a vacuum environment at the temperature of 1,000 DEG C through a discharge plasma sintering system, and a ceramic sintered body is prepared; the ceramic sintered body is subjected to thermal treatment for 3 hours at the temperature of 1,100 DEG C in the air atmosphere, and the barium strontium titanate based aluminum oxide composite ceramic with high energy storage density is prepared. The dielectric breakdown strength of the prepared composite ceramic can reach 300 kV / cm at the room temperature, and the energy storage density can reach 1.69 J / cm<3> at the room temperature. The prepared barium strontium titanate based aluminum oxide composite ceramic with high energy storage density can be used for components such as a high-density energy storage capacitor and the like and has great application value in the high-power and impulse-power fields.

Owner:ZHEJIANG UNIV

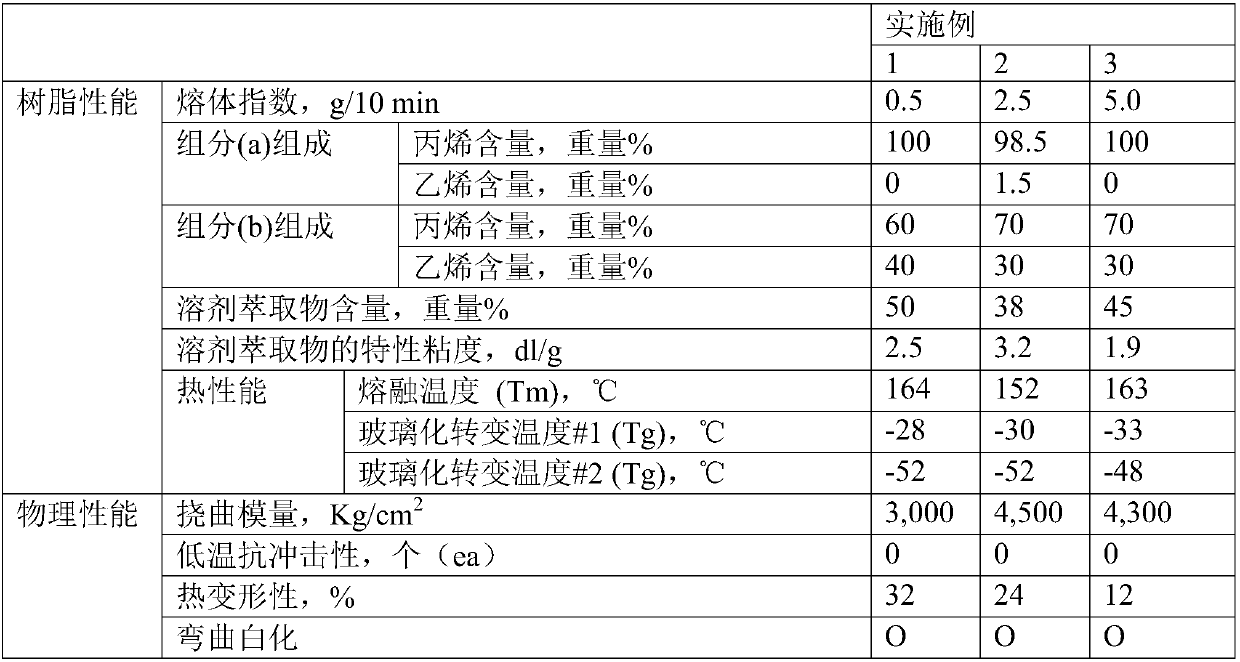

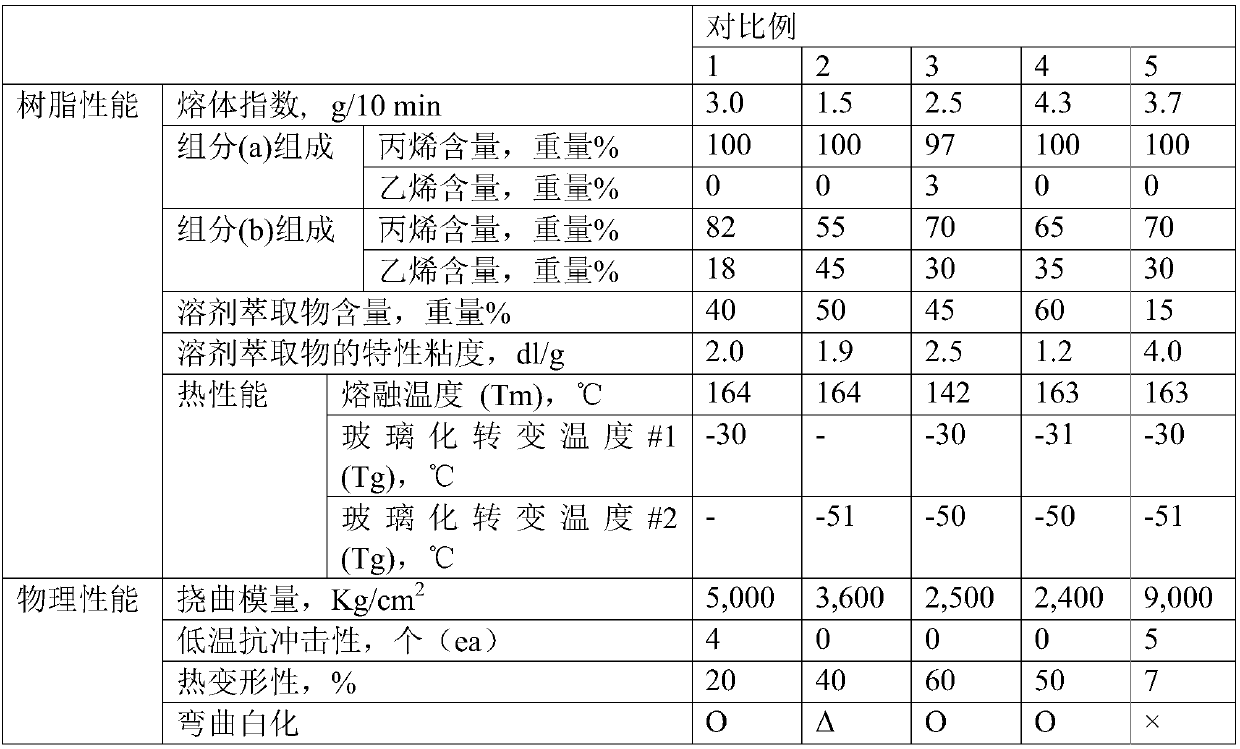

Polypropylene for insulation layer of power cable

ActiveCN109651698AGood flexibilityImprove thermal deformationPower cablesInsulatorsBreakdown strengthInsulation layer

Provided is a polypropylene resin for an insulation layer of a power cable, which has excellent flexibility, heat distortion and low-temperature impact resistance and a high insulation breakdown strength to be suitably used for an insulation layer of an electrical power cable. In an exemplary embodiment, the polypropylene resin includes an ethylene-propylene impact copolymer consisting of a propylene homopolymer or an ethylene-propylene random copolymer (a), and ethylene-propylene copolymer rubber (b) polymerized therein, wherein the ethylene-propylene impact copolymer has a melting temperature (Tm) in a range of 145 DEG C to 170 DEG C, the content of a rubber component, measured by the content of a solvent extract (xylene solubles, room temperature) in the ethylene-propylene impact copolymer, is in a range of 35 wt% to 55 wt%, and the rubber component has two glass transition temperatures (Tg) in ranges of -25 DEG C to -35 DEG C and -45 DEG C to -55 DEG C.

Owner:HANWHA TOTAL ENERGIES PETROCHEMICAL CO LTD

Dielectric film, method for manufacturing the same, and transducer including the same

ActiveUS20160155532A1Lower resistanceHigh dielectric constantRubber insulatorsGroup 4/14 element organic compoundsDielectricElastomer

A dielectric film includes an elastomer and nanoparticles dispersed in the elastomer while chemically bound to the elastomer. The nanoparticles have cyano groups and are manufactured by a sol-gel process using an organometallic compound. A method for manufacturing a dielectric film includes: producing a chelate compound of an organometallic compound; producing a sol of metallic oxide particles having cyano groups by adding a silane coupling agent having a cyano group, an organic solvent, and water to the chelate compound; preparing a mixed solution by mixing the sol of the metallic oxide particles having cyano groups and a polymer solution containing a rubber polymer having a functional group capable of reacting with a hydroxy group; and forming a dielectric film by applying the mixed solution to a substrate and by curing a coating film.

Owner:SUMITOMO RIKO CO LTD +1

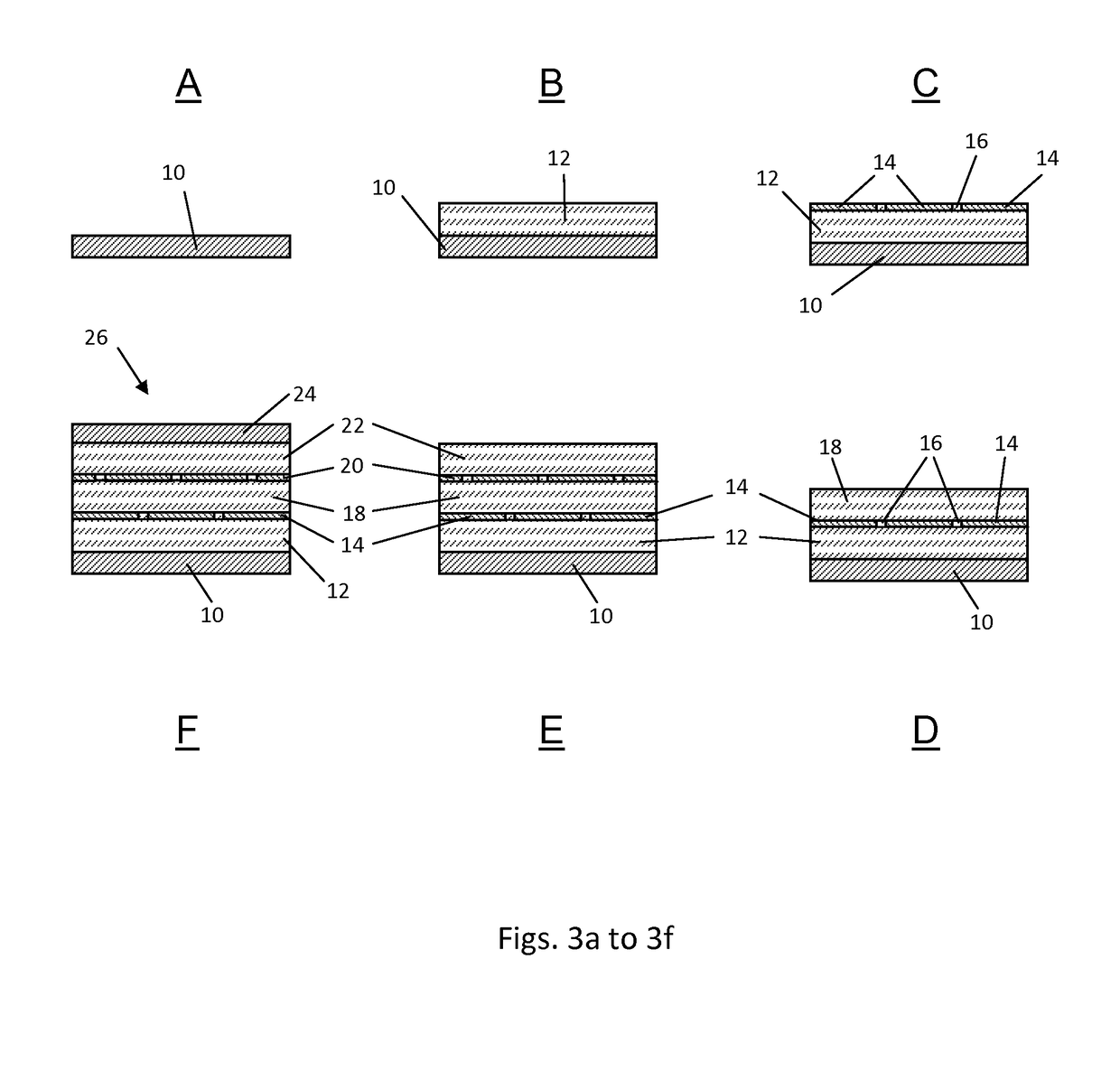

Method of making dielectric capacitors with increased dielectric breakdown strength

ActiveUS9646766B2Increase energy densityReduce mechanical strainFixed capacitor electrodesFixed capacitor dielectricBreakdown strengthMicro fracture

The invention is directed to a process for making a dielectric ceramic film capacitor and the ceramic dielectric laminated capacitor formed therefrom, the dielectric ceramic film capacitors having increased dielectric breakdown strength. The invention increases breakdown strength by embedding a conductive oxide layer between electrode layers within the dielectric layer of the capacitors. The conductive oxide layer redistributes and dissipates charge, thus mitigating charge concentration and micro fractures formed within the dielectric by electric fields.

Owner:UCHICAGO ARGONNE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com