Ceramic material with high energy storage performance and ultrafast discharge rate and preparation method thereof

A discharge rate and ceramic material technology, applied in the field of ceramic materials with high energy storage performance and ultra-fast discharge rate and its preparation, can solve the problems of low dielectric breakdown field, hindering practical application, and large dielectric loss. Achieve good temperature stability and frequency stability, excellent energy storage density and efficiency, and small back-shaped area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the ceramic material with high energy storage performance and ultra-fast discharge rate of the present invention comprises the following steps:

[0048] (1) According to chemical formula (1-x) (Na 0.5 Bi 0.5 ) 0.7 Sr 0.3 TiO 3 -xBi(Mg 2 / 3 Nb 1 / 3 )O 3 will analyze pure SrCO 3 、Na 2 CO 3 、TiO 2 、 Bi 2 o 3 , MgO and Nb 2 o 5 The ingredients, where x represents the mole fraction, and 0.05≤x≤0.20, use absolute ethanol as the medium, mix evenly through ball milling for 22 to 24 hours, then dry at 100°C, pass through a 120-mesh sieve, briquette, and pass through 800 Pre-calcined at ~900°C for 3-5 hours to obtain a block solid, then crush the block solid and pass through a 120-mesh sieve to obtain a pre-calcined powder;

[0049] (2) The calcined powder obtained in step (1) is ball-milled for 22 to 24 hours with absolute ethanol as the medium, then dried at 100° C., and passed through a 120-mesh sieve to obtain the raw material powder;

...

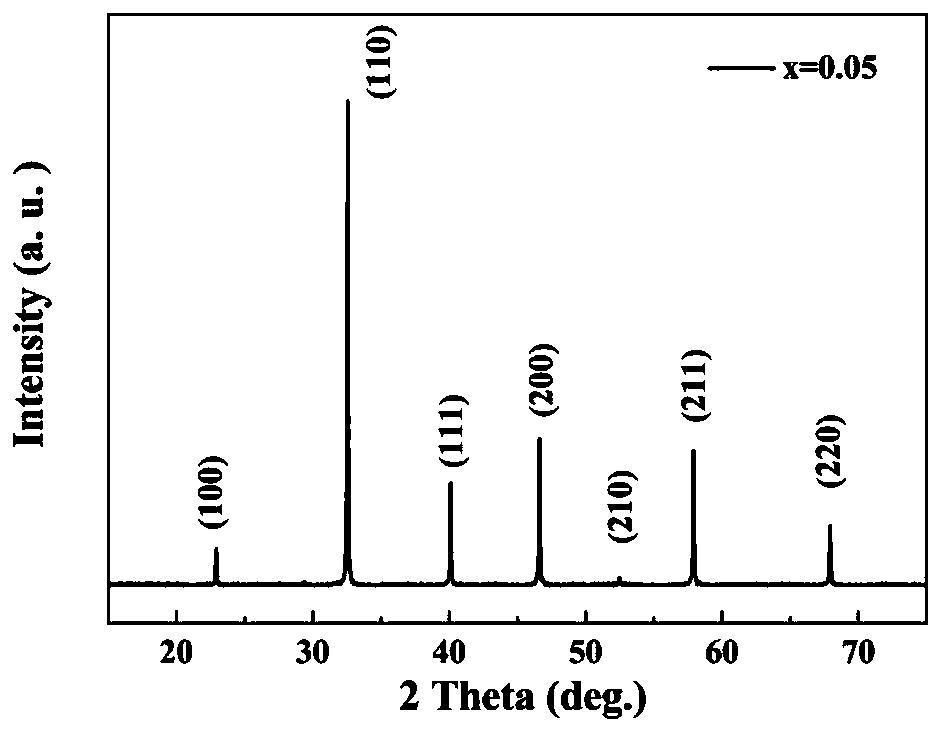

Embodiment 1

[0066] The chemical formula of the ceramic material in this case is: (1-x)(Na 0.5 Bi 0.5 ) 0.7 Sr 0.3 TiO 3 -xBi(Mg 2 / 3 Nb 1 / 3 )O 3 , wherein x represents the mole fraction, and x=0.05.

[0067] The preparation method of the above-mentioned ceramic material with high energy storage performance and ultra-fast discharge rate comprises the following steps:

[0068] (1) According to chemical formula (1-x) (Na 0.5 Bi 0.5 ) 0.7 Sr 0.3 TiO 3 -xBi(Mg 2 / 3 Nb 1 / 3 )O 3 will analyze pure SrCO 3 、Na2 CO 3 、TiO 2 、 Bi 2 o 3 , MgO and Nb 2 o 5 The ingredients, where x represents the mole fraction, and x=0.05, use absolute ethanol as the medium, mix uniformly by ball milling for 22 hours, then dry at 100°C, pass through a 120-mesh sieve, briquette, and then pre-calcined at 900°C for 3 hours, block solids were obtained, and then the block solids were pulverized and passed through a 120-mesh sieve to obtain calcined powder;

[0069] (2) The calcined powder obtained in ste...

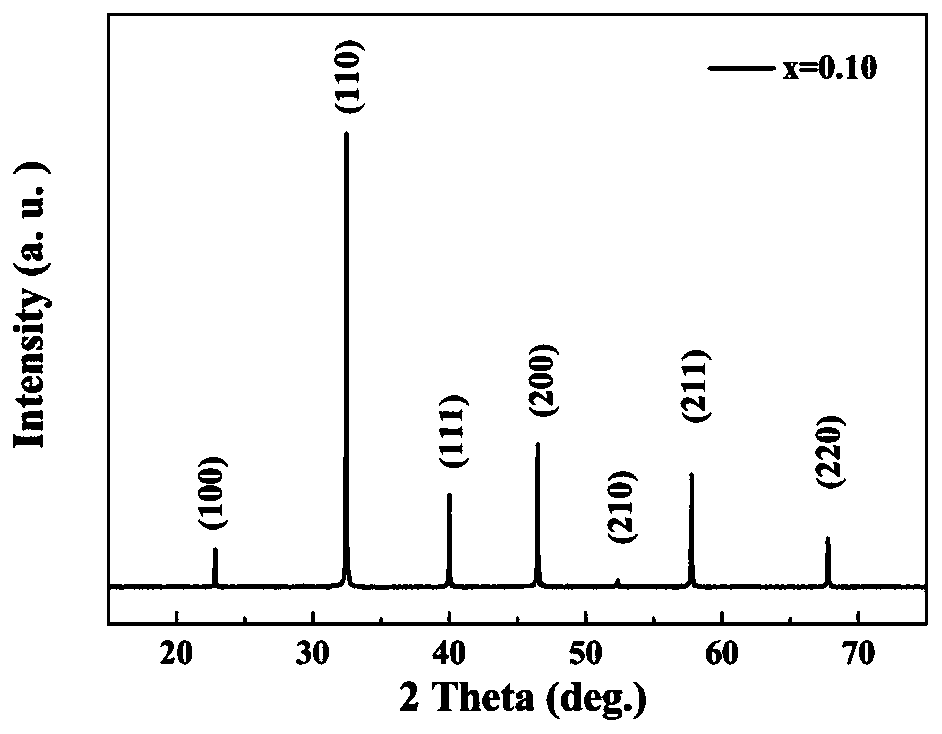

Embodiment 2

[0074] The chemical formula of the ceramic material in this case is: (1-x)(Na 0.5 Bi 0.5 ) 0.7 Sr 0.3 TiO 3 -xBi(Mg 2 / 3 Nb 1 / 3 )O 3 , wherein x represents the mole fraction, and x=0.10.

[0075] The preparation method of the above-mentioned ceramic material with high energy storage performance and ultra-fast discharge rate comprises the following steps:

[0076] (1) According to chemical formula (1-x) (Na 0.5 Bi 0.5 ) 0.7 Sr 0.3 TiO 3 -xBi(Mg 2 / 3 Nb 1 / 3 )O 3 will analyze pure SrCO 3 、Na 2 CO 3 、TiO 2 、 Bi 2 o 3 , MgO and Nb 2 o 5 The ingredients, where x represents the mole fraction, and x=0.10, use absolute ethanol as the medium, mix uniformly by ball milling for 23 hours, then dry at 100°C, pass through a 120-mesh sieve, briquette, and then pre-calcined at 850°C for 4 hours, block solids were obtained, and then the block solids were pulverized and passed through a 120-mesh sieve to obtain calcined powder;

[0077] (2) The calcined powder obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com