Patents

Literature

105 results about "Dielectric breakdown strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dielectric strength is calculated by dividing the breakdown voltage by the thickness of the sample. Most plastics have good dielectric strengths (in the order of 100 to 300 kV/cm). Factors Affecting Dielectric Strength. It is approximately inversely proportional to the absolute temperature.

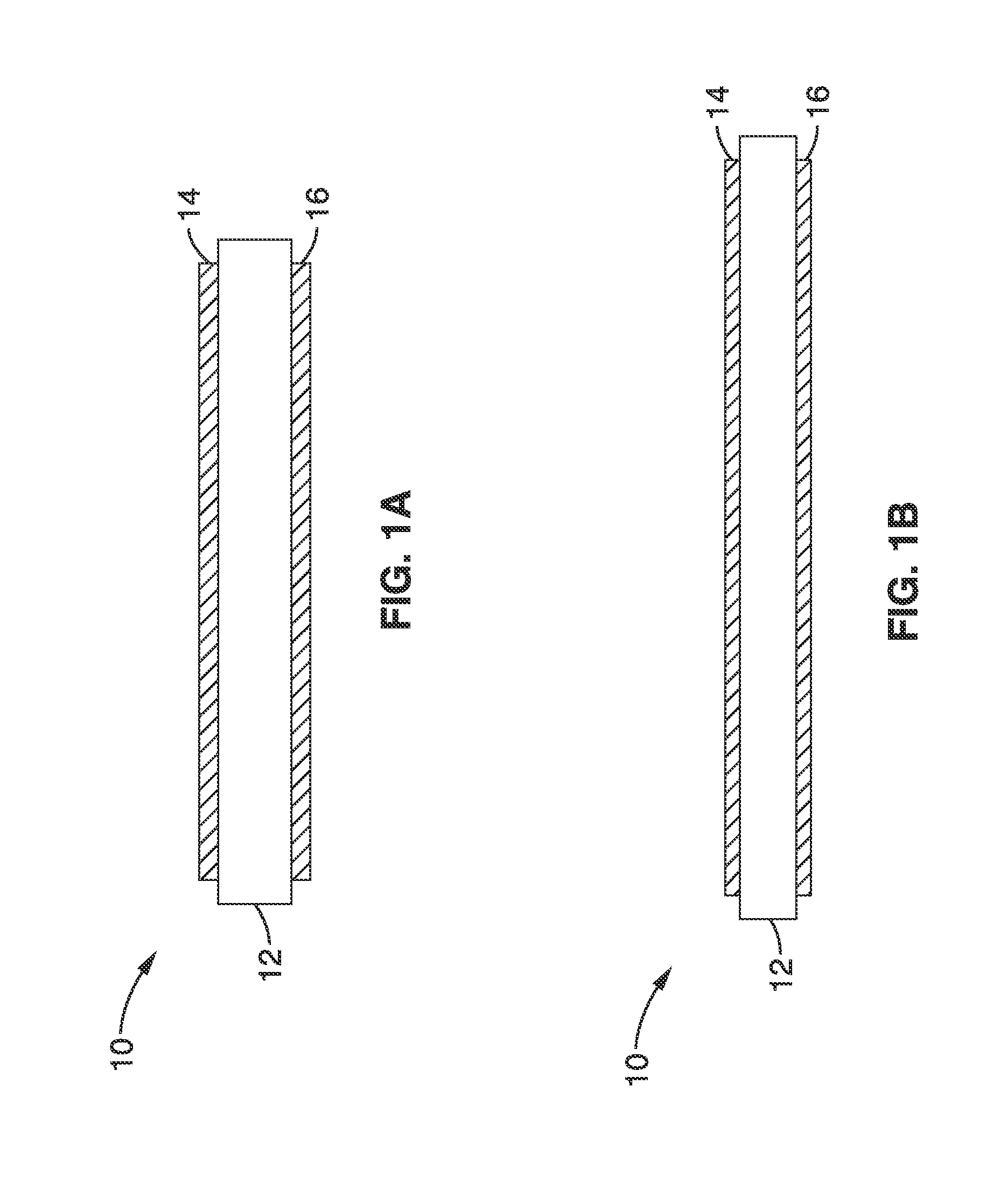

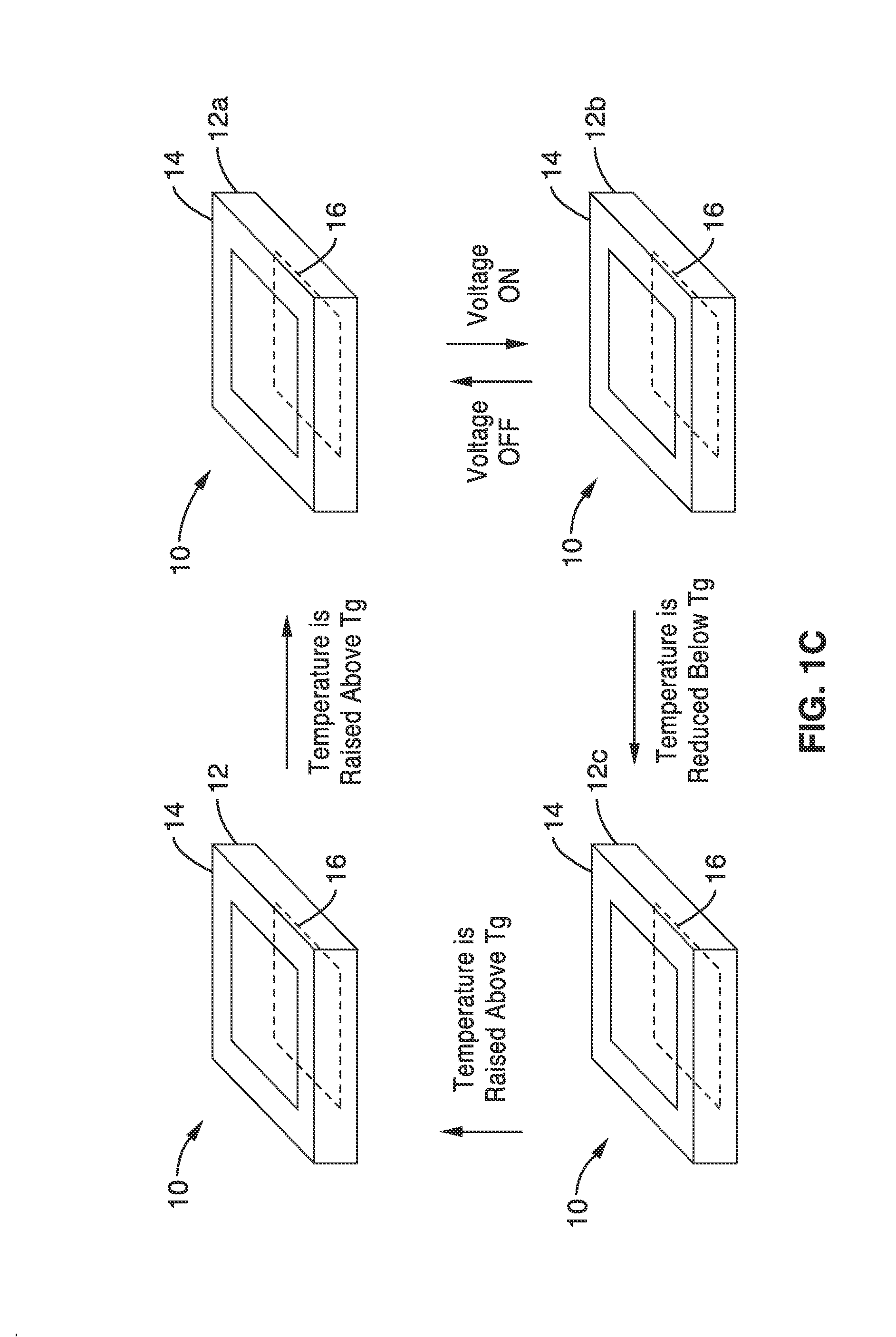

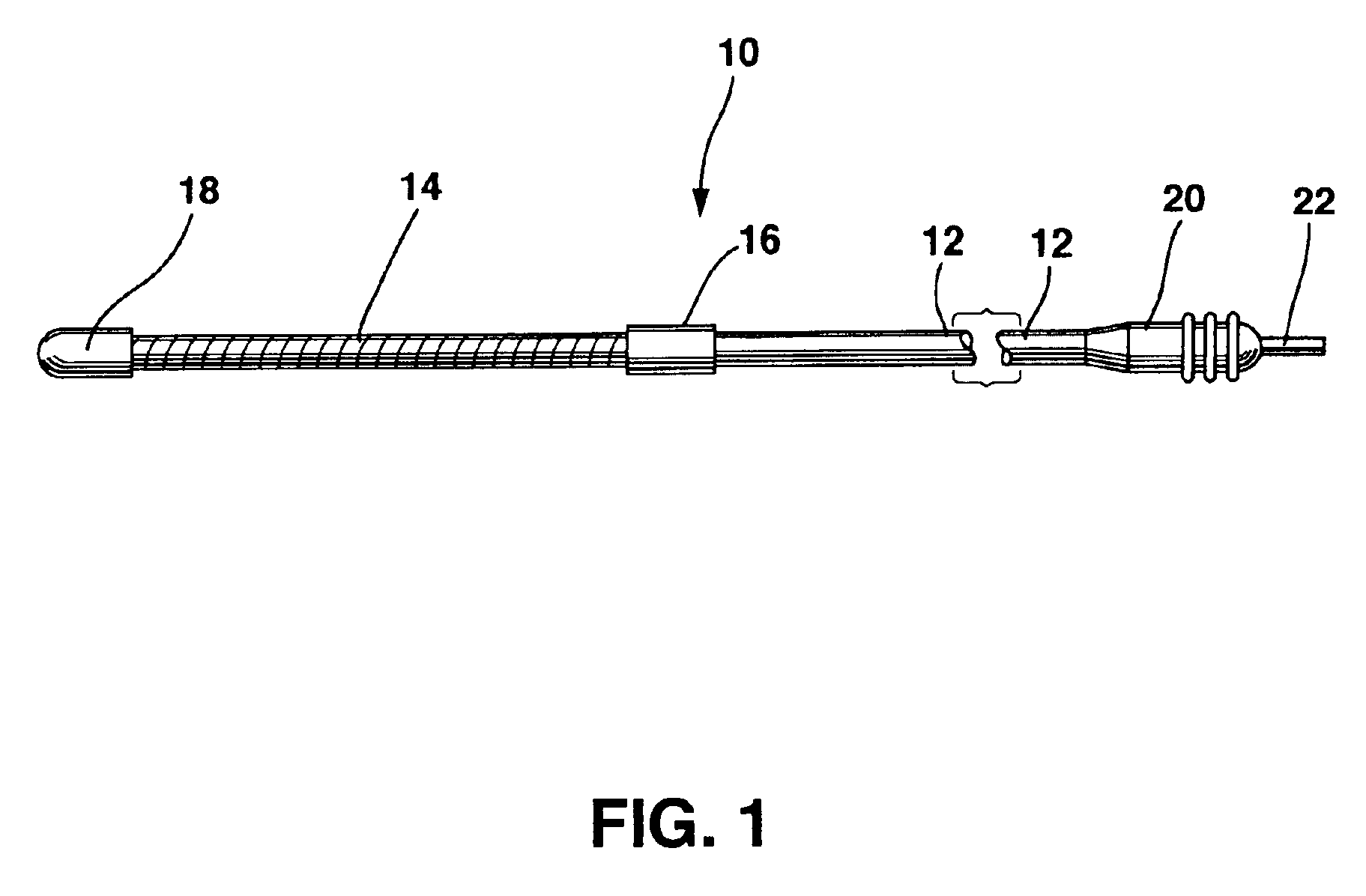

Bistable electroactive polymers

ActiveUS20100171393A1Improve mechanical energySpeed up the conversion processPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionHigh energyShock resistance

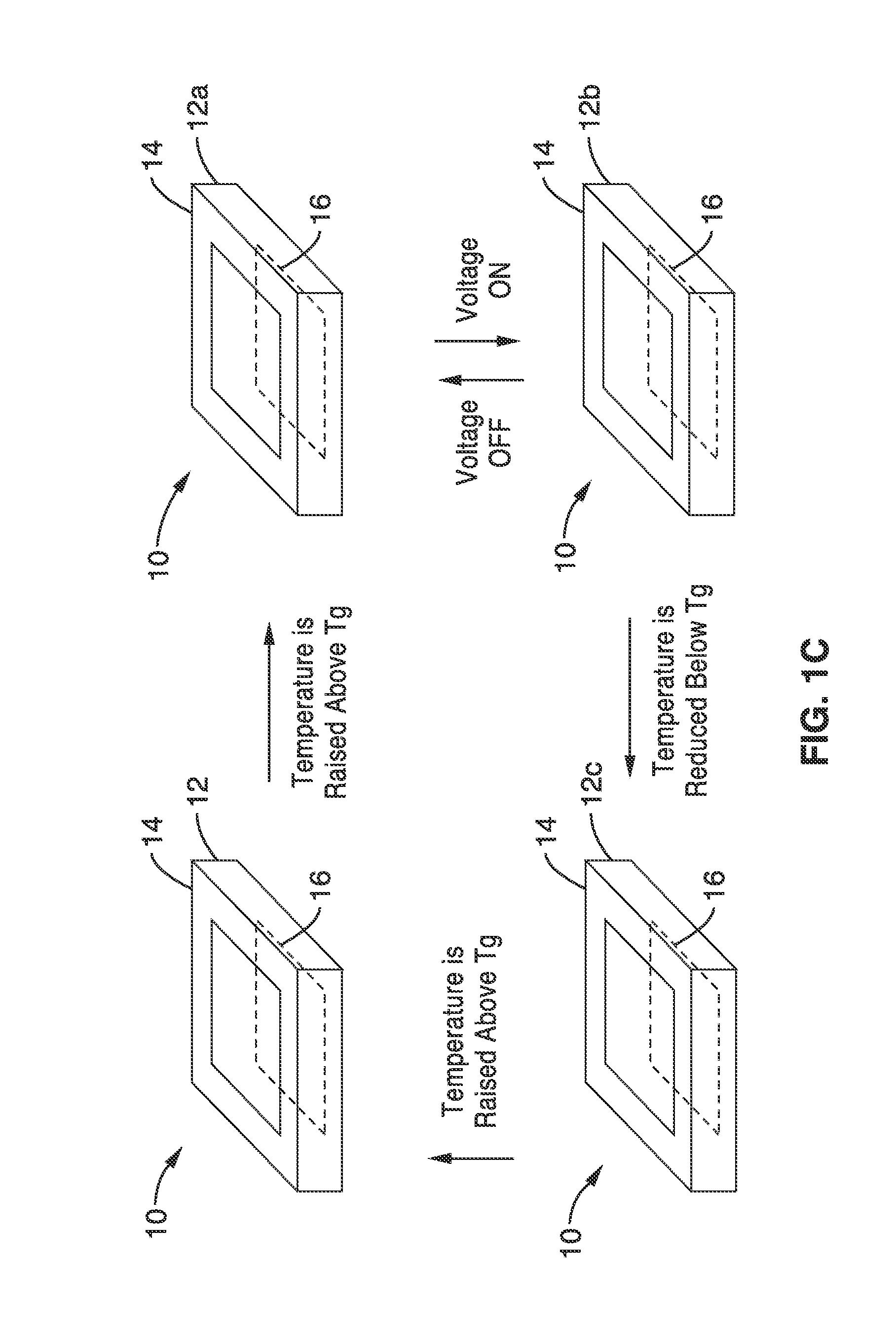

A bistable electroactive polymer transducer is provided for electrically actuated deformation of rigid electroactive polymer members. The polymers have glass transition temperatures (Tg) above ambient conditions and turn into rubbery elastomers above Tg and have high dielectric breakdown strength in the rubbery state. They can be electrically deformed to various rigid shapes with maximum strain greater than 100% and as high as 400%. The actuation is made bistable by cooling below Tg to preserve the deformation. The dielectric actuation mechanism includes a pair of compliant electrodes in contact with a dielectric elastomer which deforms when a voltage bias is applied between the pair of electrodes. In some of the transducers of the present invention, the dielectric elastomer is also a shape memory polymer. The deformations of such bistable electroactive polymers can be repeated rapidly for numerous cycles. The polymer transducers have such advantages as high energy and power densities, quietness, mechanical compliancy (for shock resistance and impedance matching), high efficiency, lightweight, and low cost.

Owner:RGT UNIV OF CALIFORNIA

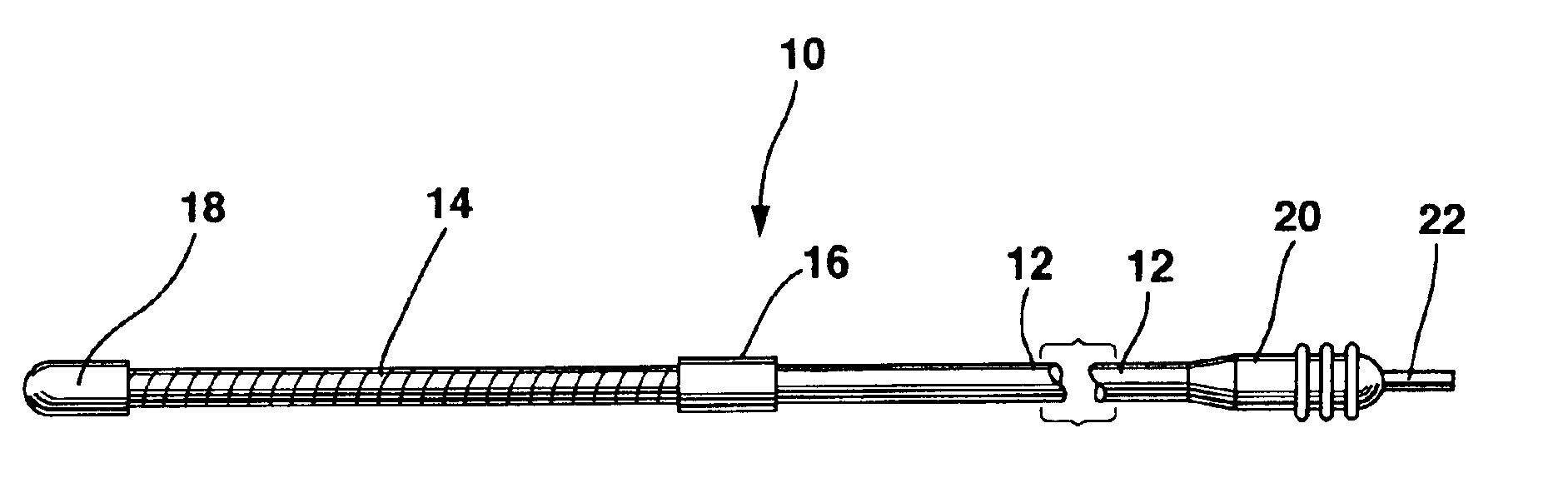

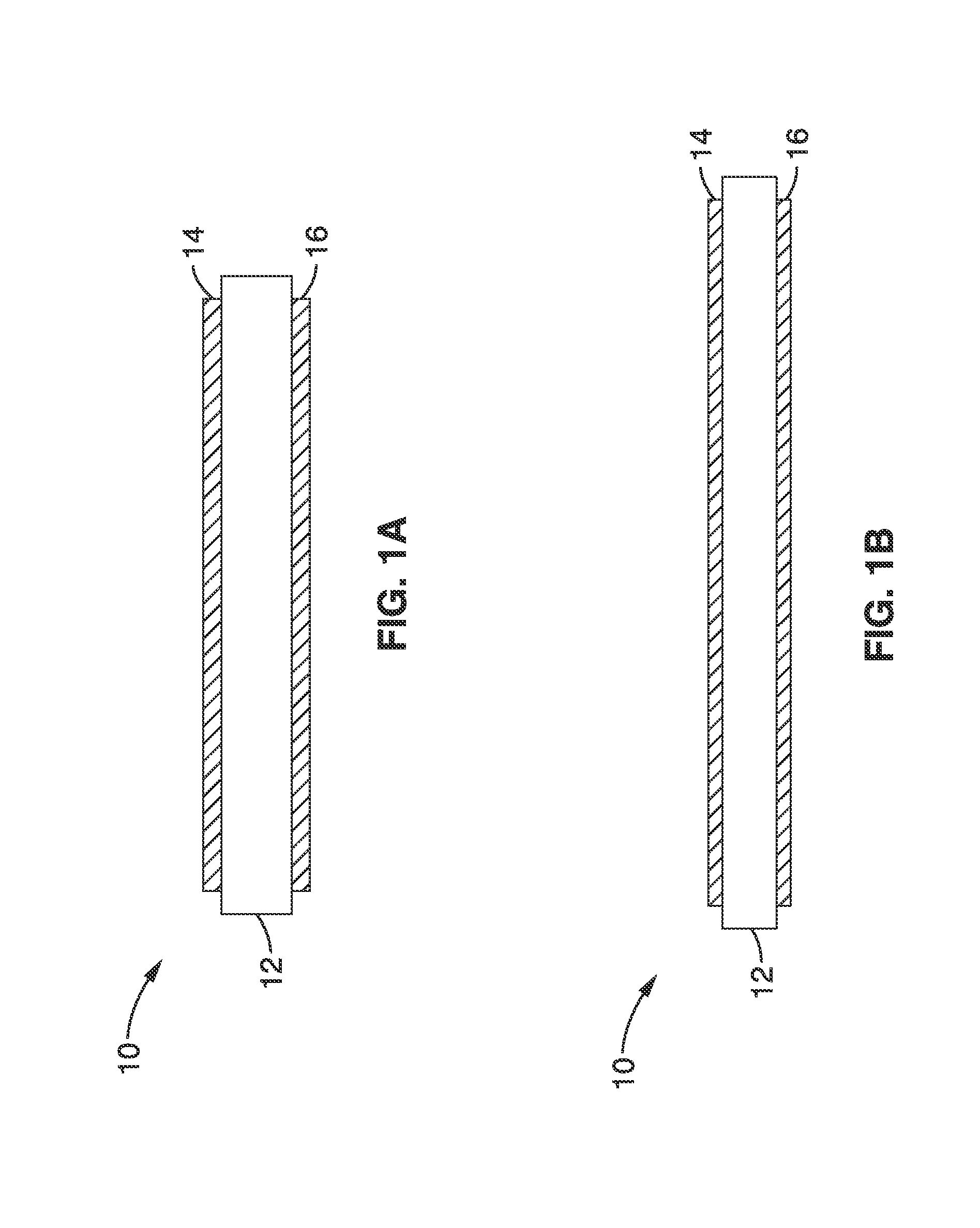

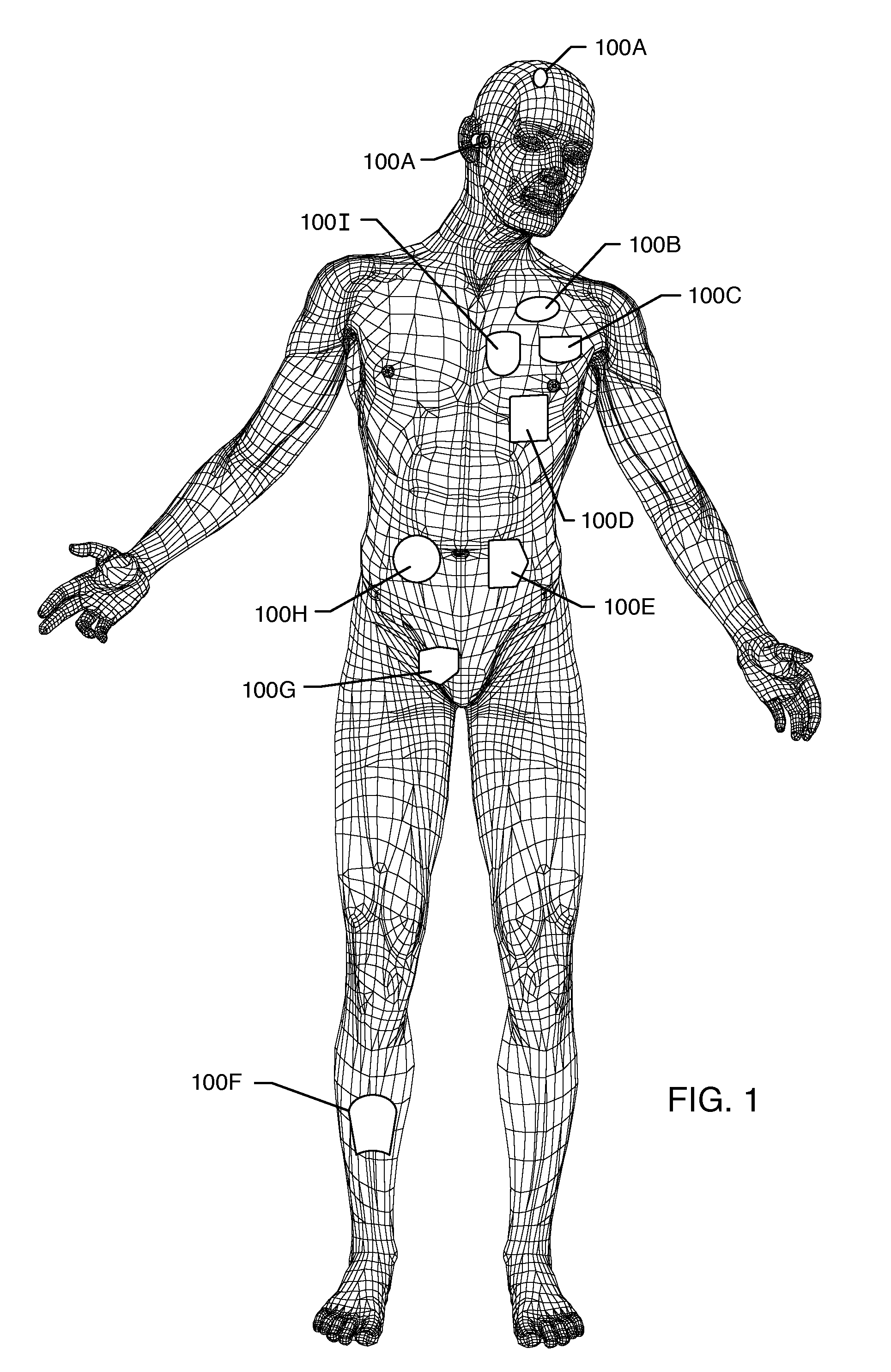

Polymeric materials with improved dielectric breakdown strength

InactiveUS6879861B2Plastic/resin/waxes insulatorsHeart defibrillatorsDielectric breakdown strengthUltimate tensile strength

A novel polymeric electrically insulating material that includes a linked voltage stabilizing agent. Also provided are methods of making the novel material and articles and devices that incorporate the novel material, particularly implantable medical devices.

Owner:MEDTRONIC INC

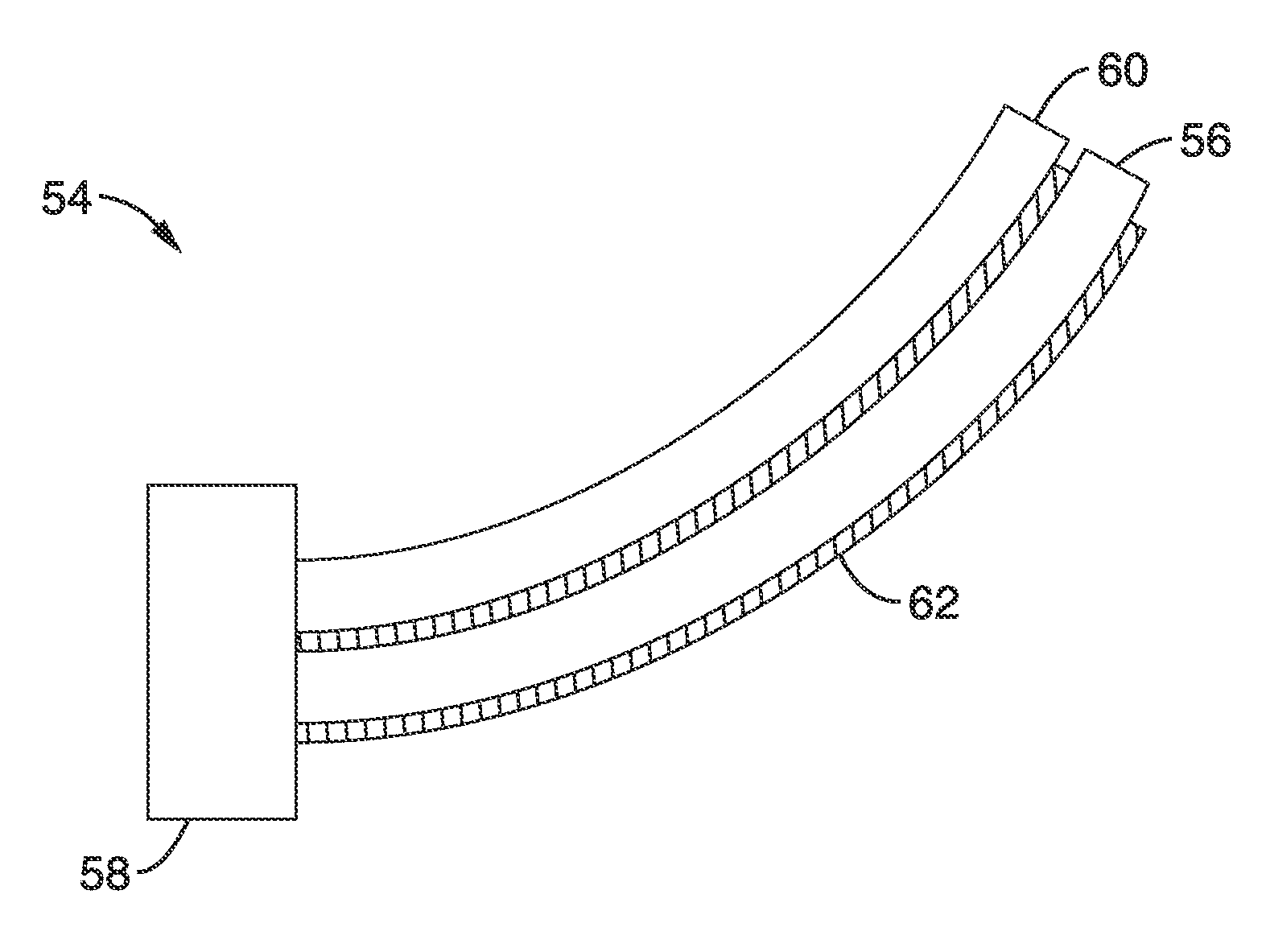

Bistable electroactive polymers

ActiveUS8237324B2Improve mechanical energySpeed up the conversion processPiezoelectric/electrostriction/magnetostriction machinesMachines/enginesVitrificationActive polymer

Owner:RGT UNIV OF CALIFORNIA

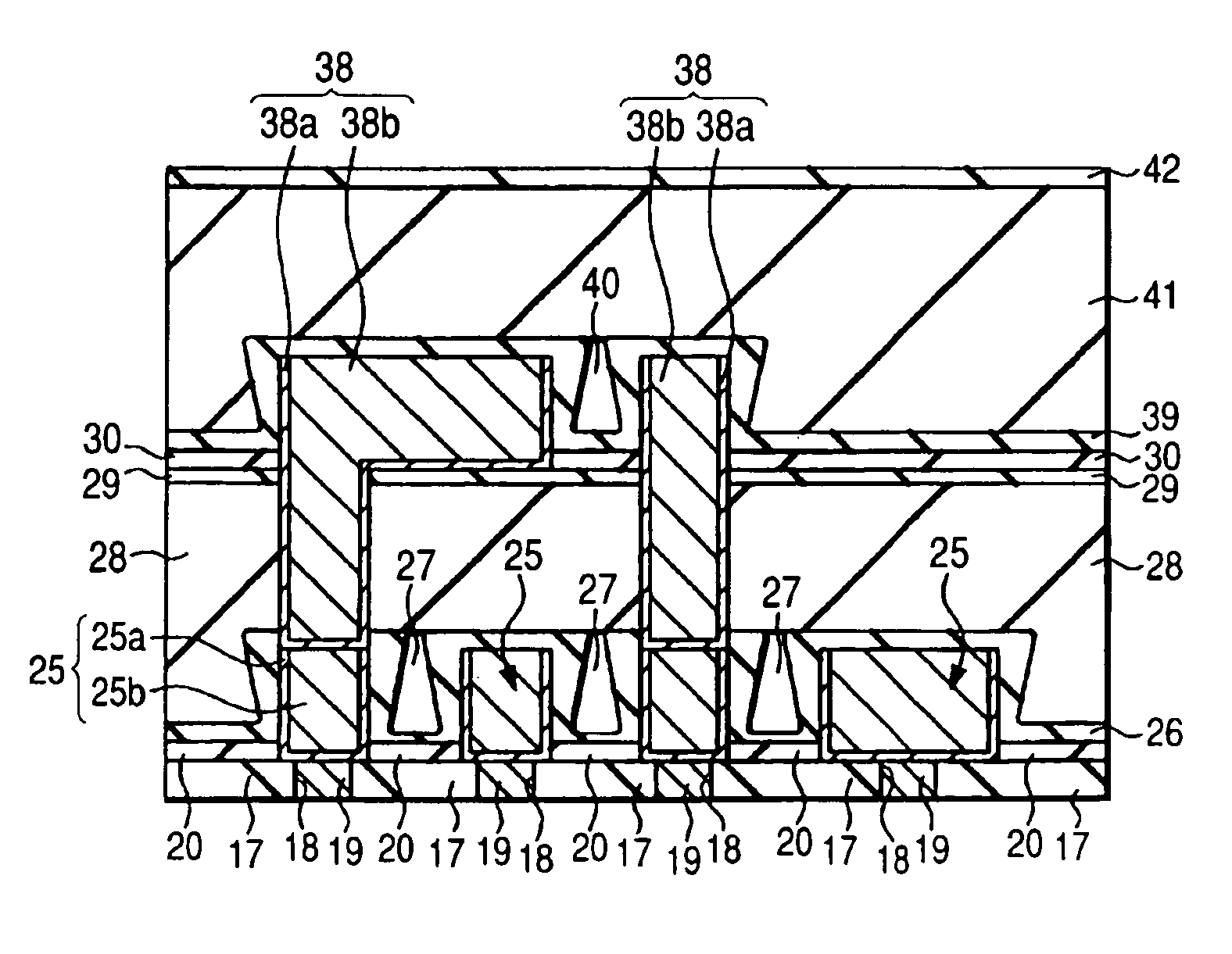

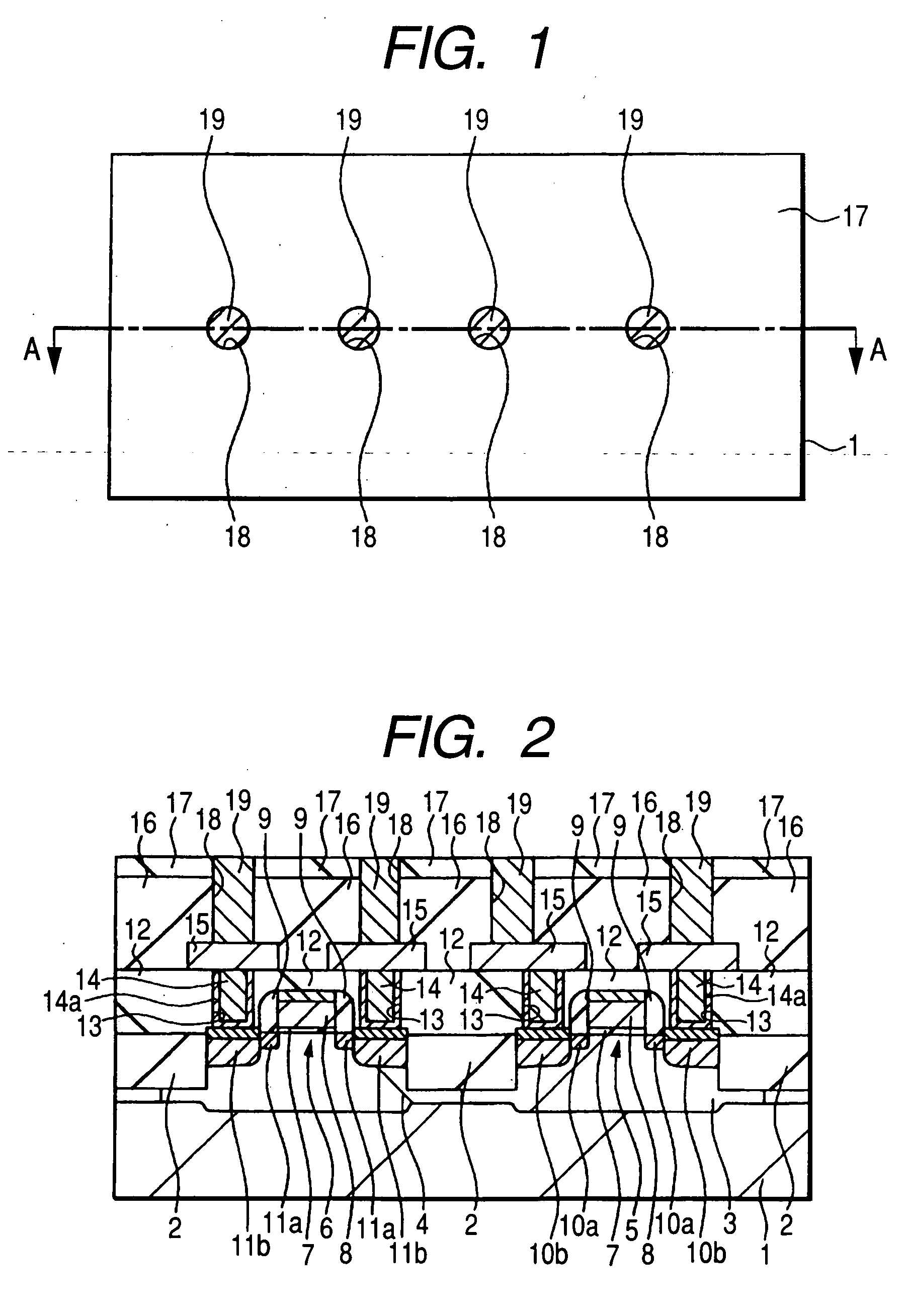

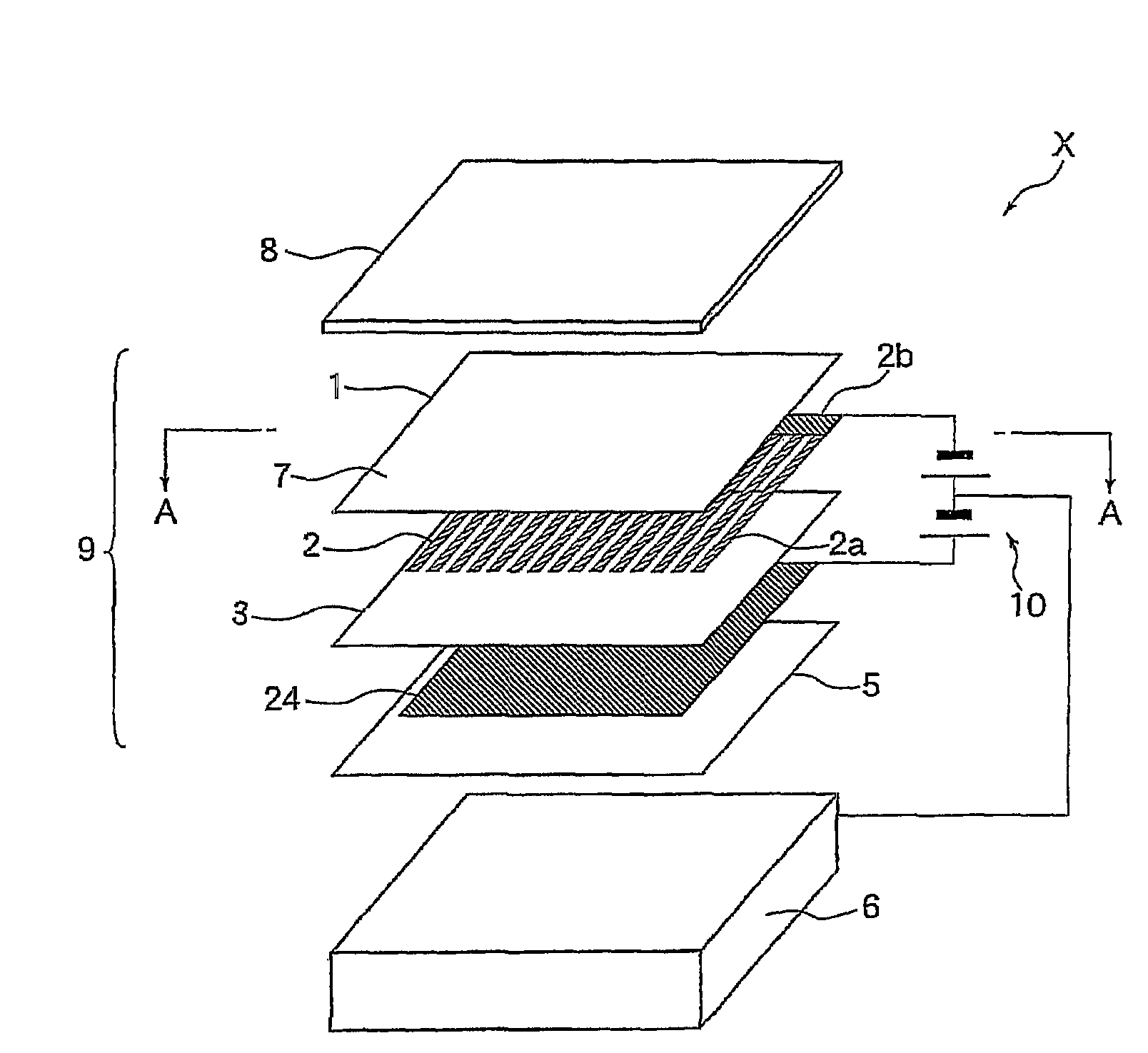

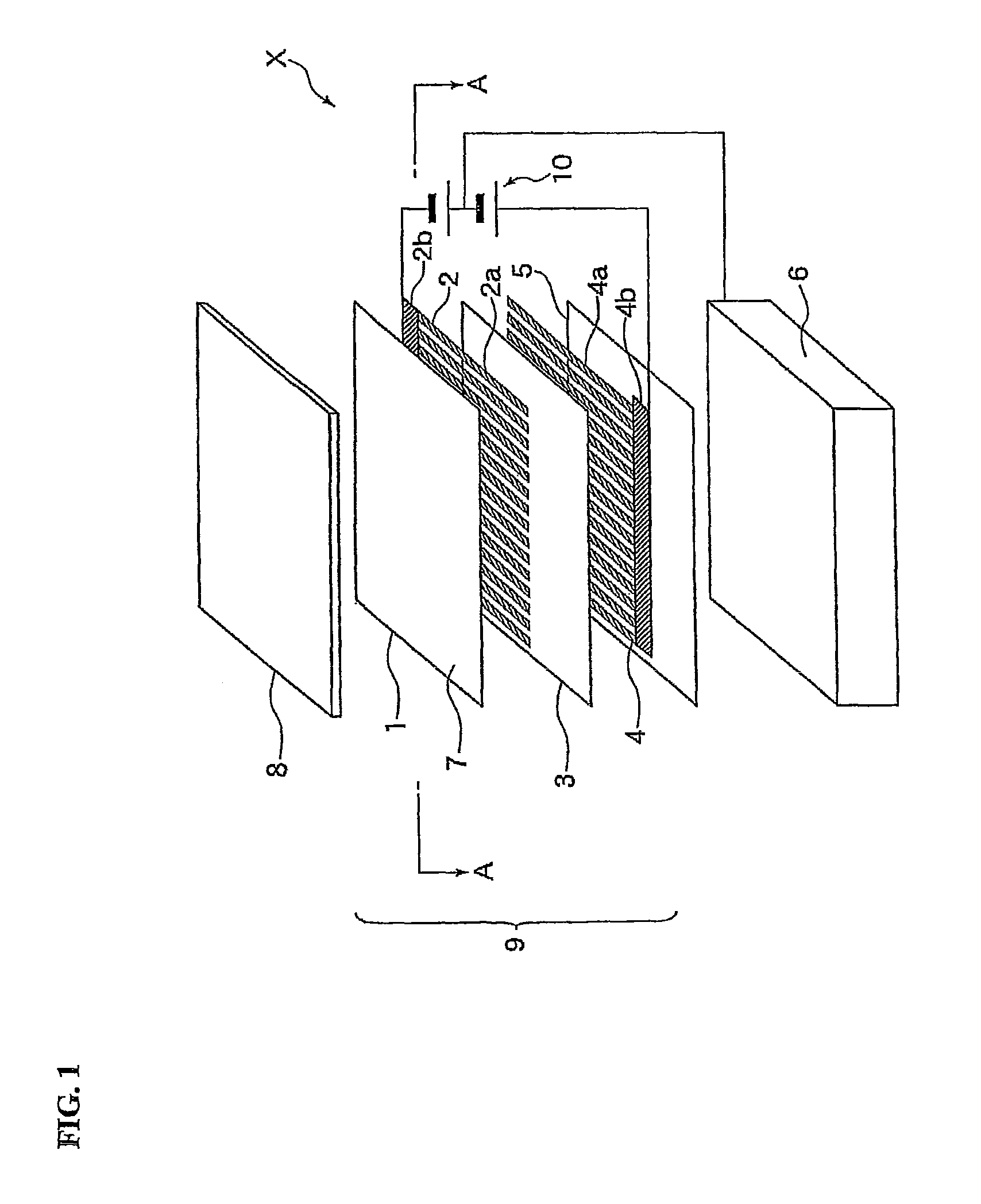

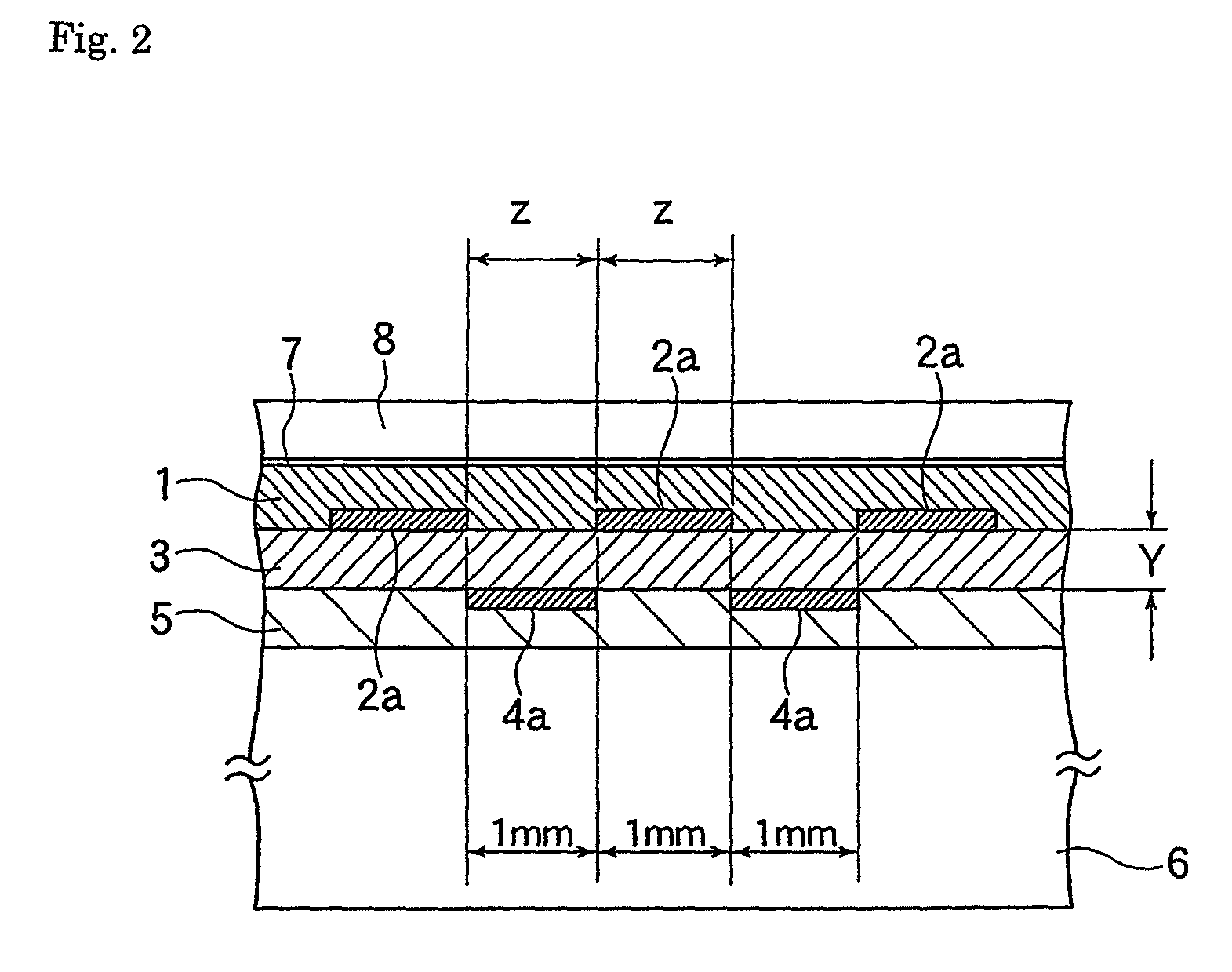

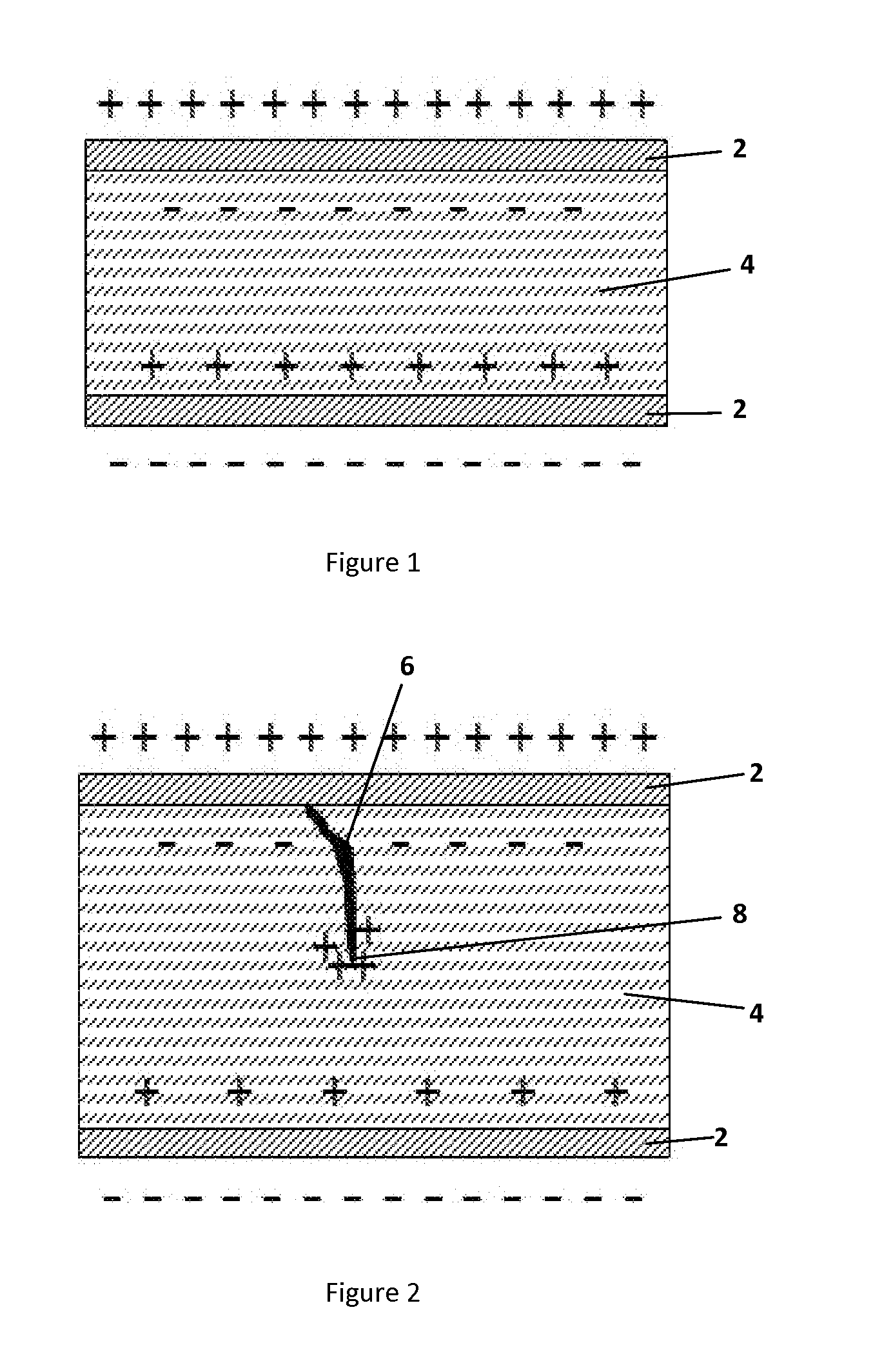

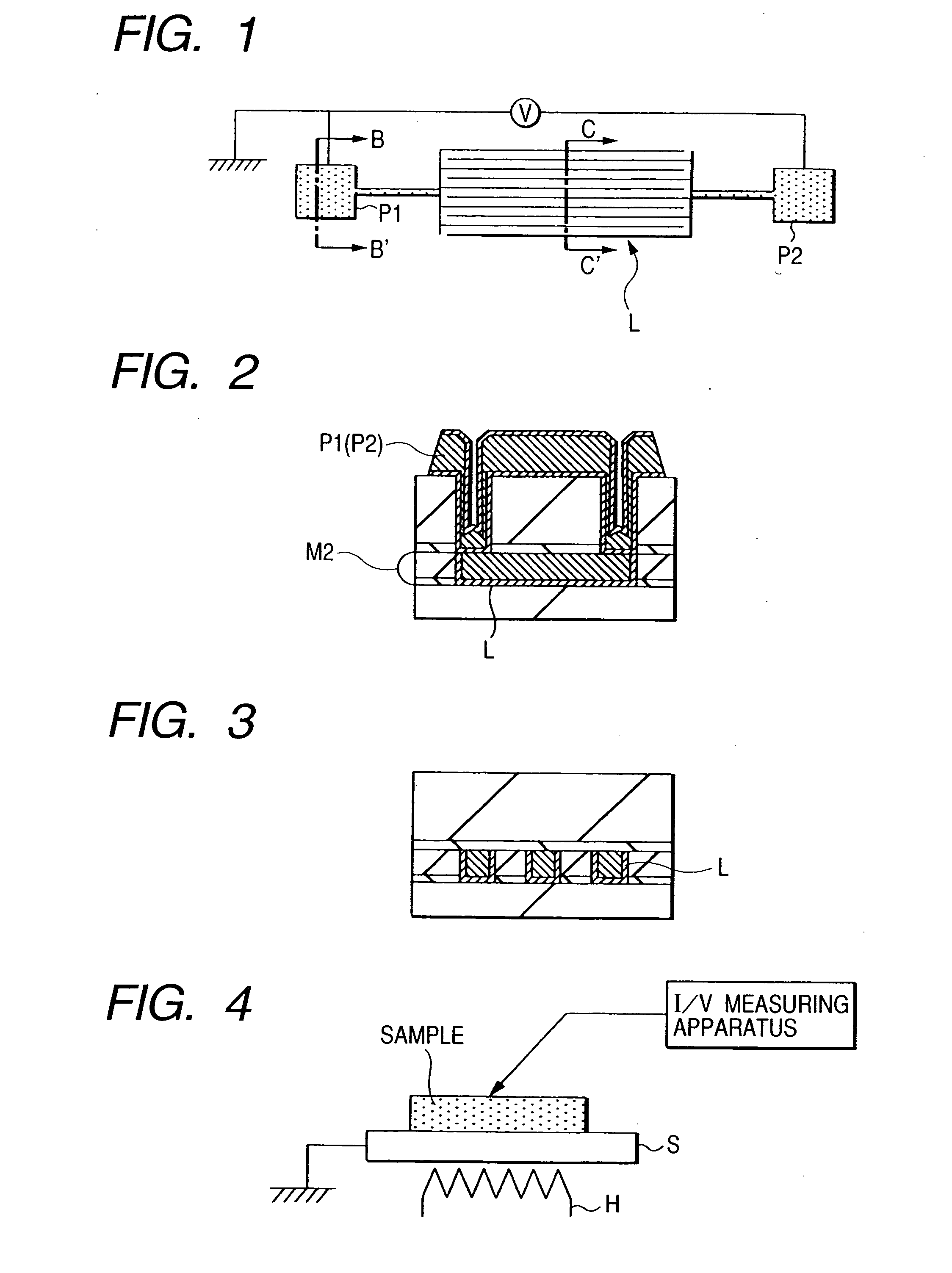

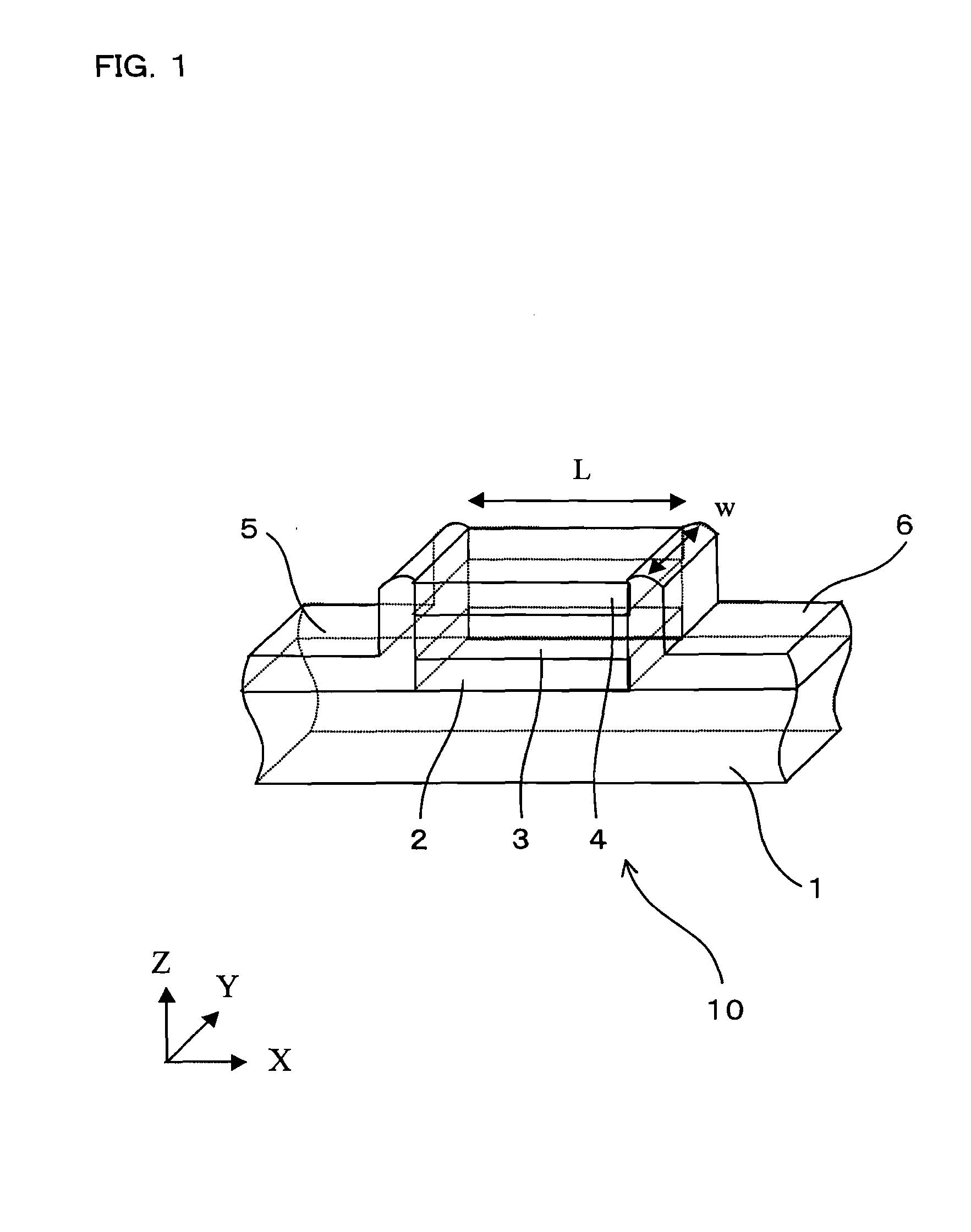

Bipolar Electrostatic Chuck

InactiveUS20070223173A1Sufficient performanceEliminate dischargeSemiconductor/solid-state device manufacturingElectrostatic holding devicesDielectric breakdown strengthDepth direction

A bipolar electrostatic chuck which has excellent dielectric breakdown strength and provides excellent attracting performance. The bipolar electrostatic chuck eliminates difficulty in dismounting a sample from a sample attracting plane as much as possible after application of a voltage to electrodes is finished. The bipolar electrostatic chuck is provided with a first electrode and a second electrode in an insulator and permits a surface of the insulator to be the sample attracting plane. The insulator has the first electrode, an interelectrode insulating layer and the second electrode in this order from the sample attracting plane in the depth direction. The second electrode has a region not overlapping with the first electrode in a normal line direction of the sample attracting plane.

Owner:CREATIVE TECH CORP

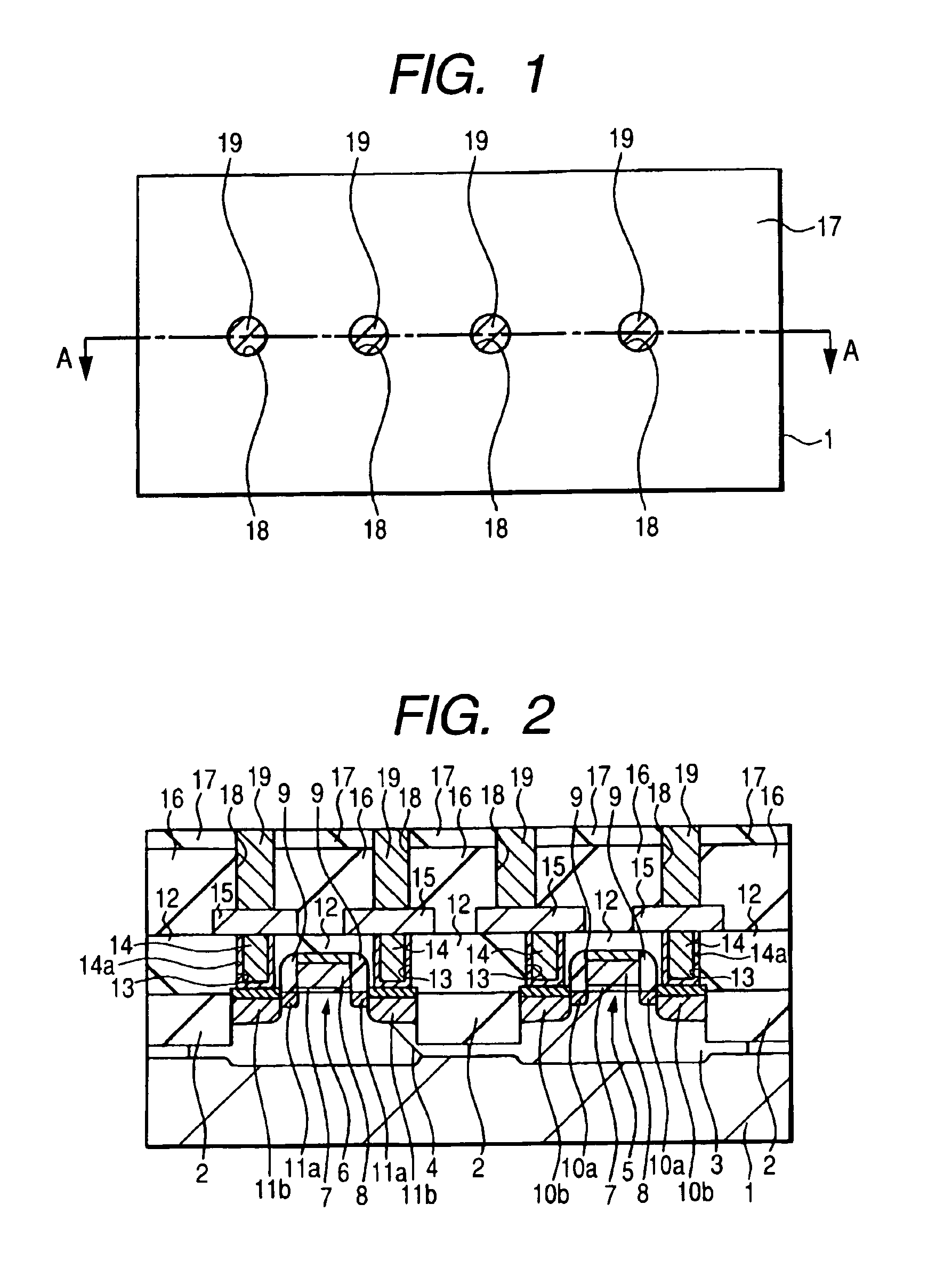

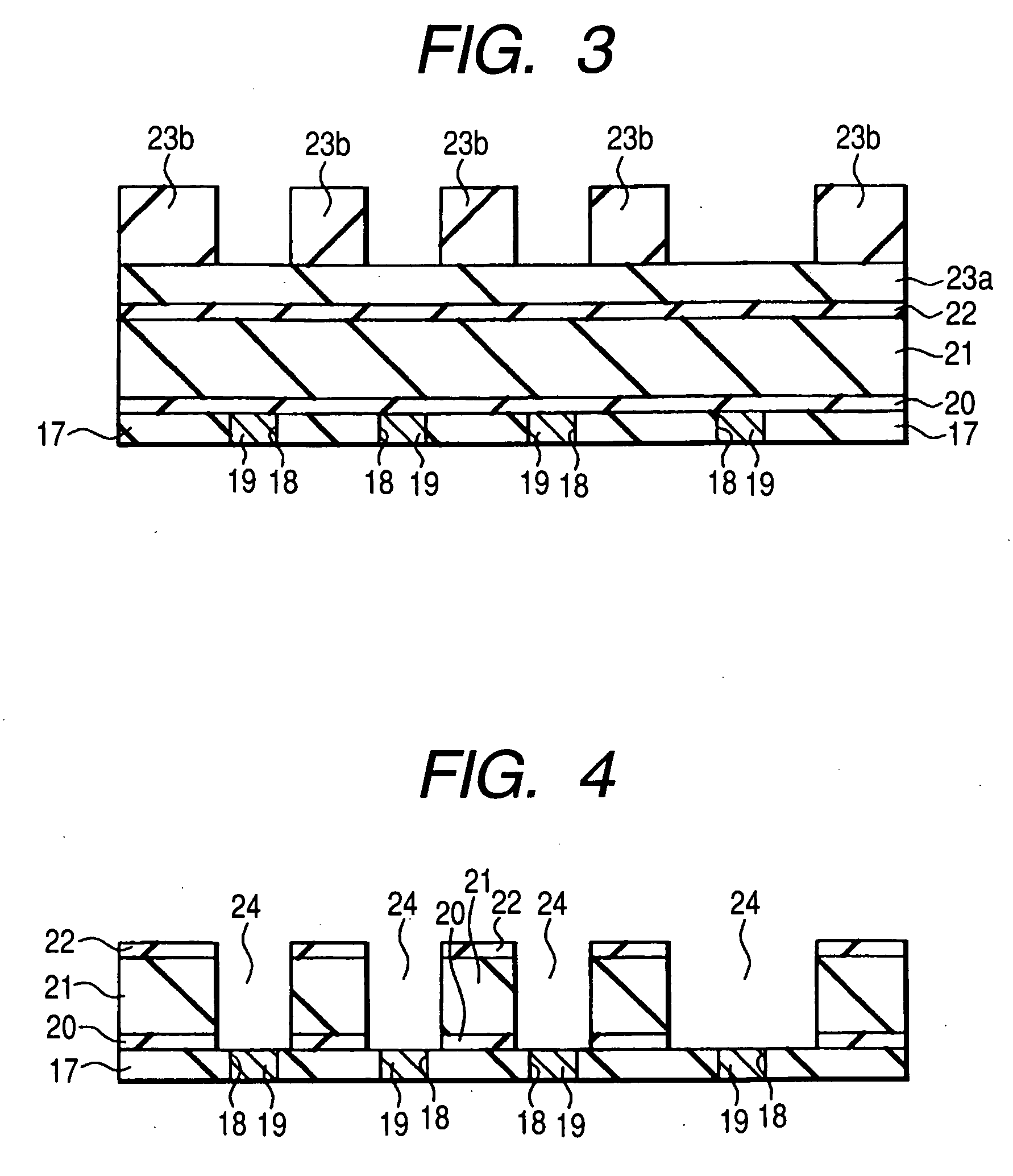

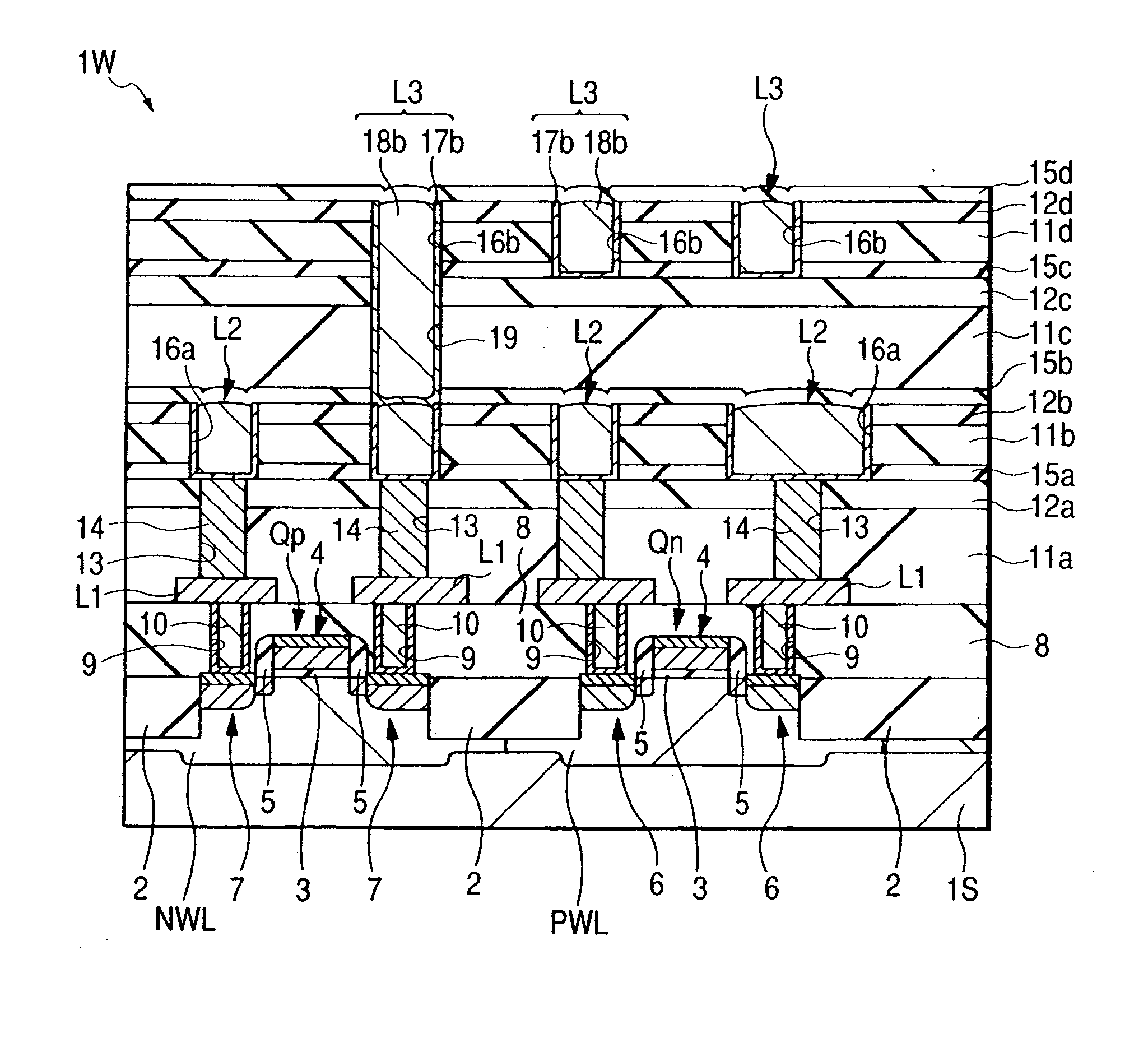

Semiconductor device including an interconnect having copper as a main component

InactiveUS7042095B2Improve dielectric breakdown strengthReduce capacitanceSemiconductor/solid-state device detailsSolid-state devicesCapacitanceCopper interconnect

Provided are a semiconductor device comprising a semiconductor substrate, a first insulating film formed thereover, interconnects formed over the first insulating film and having copper as a main component, a second insulating film formed over the upper surface and side surfaces of each of the interconnects and over the first insulating film and having a function of suppressing or preventing copper diffusion, and a third insulating film formed over the second insulating film and having a dielectric constant lower than that of the second insulating film; and a method of manufacturing the semiconductor device. This invention makes it possible to improve dielectric breakdown strength between copper interconnects and reduce capacitance between the copper interconnects.

Owner:TESSERA ADVANCED TECH

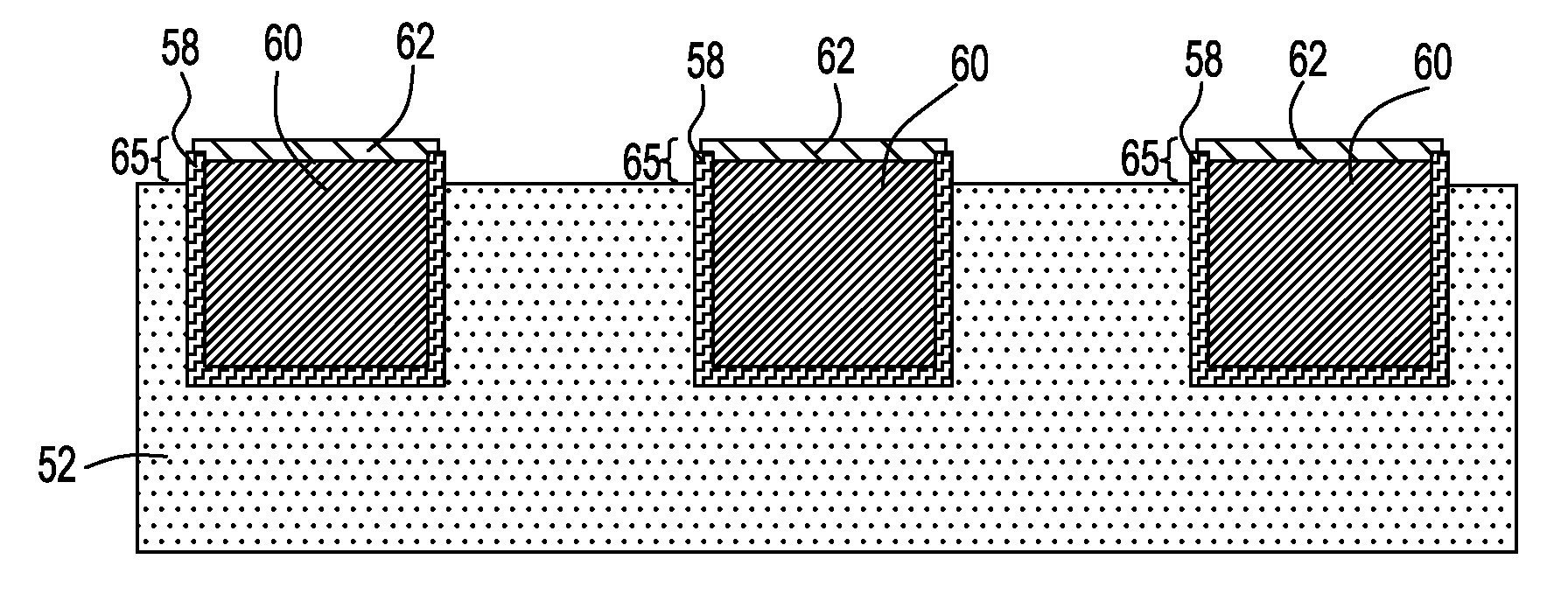

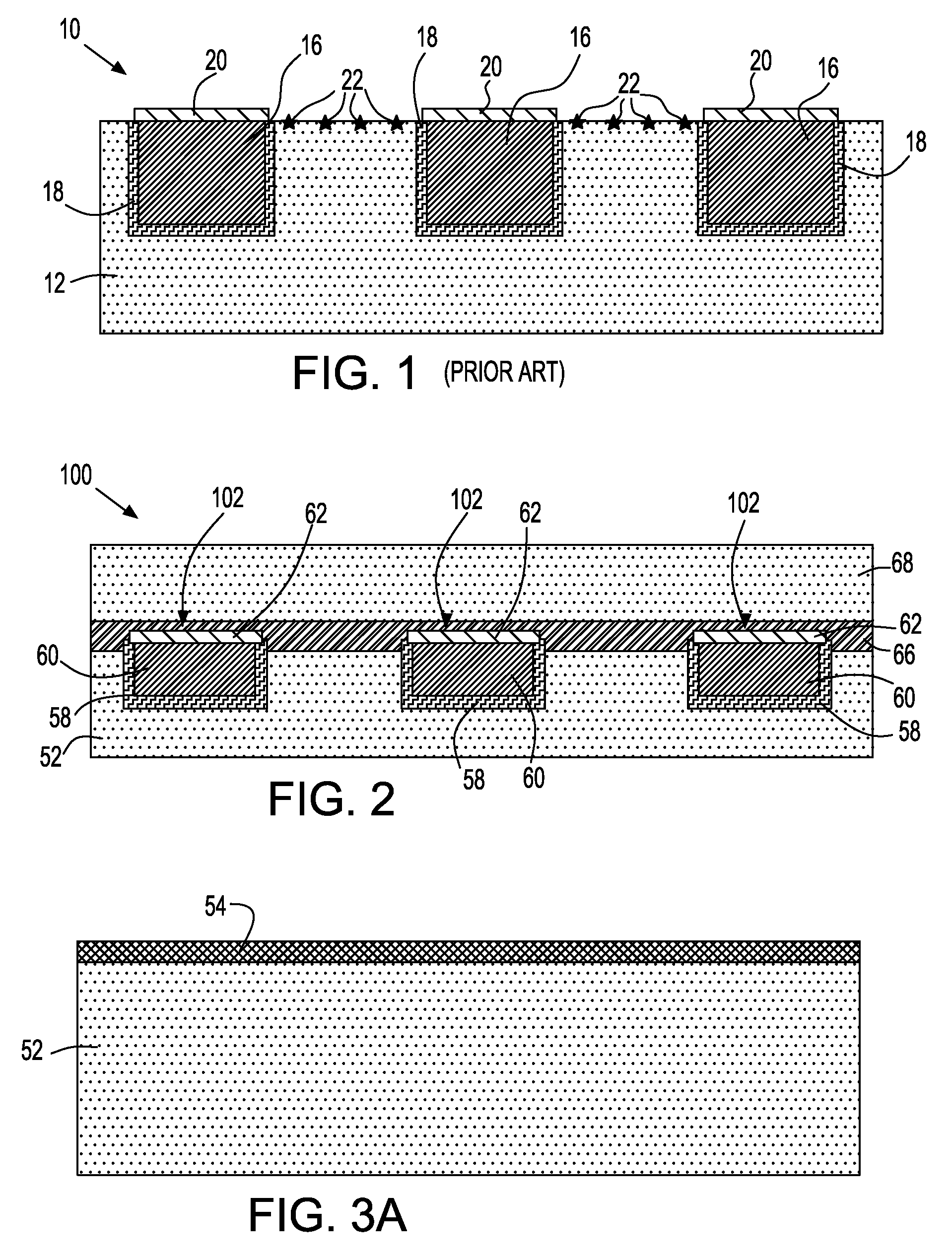

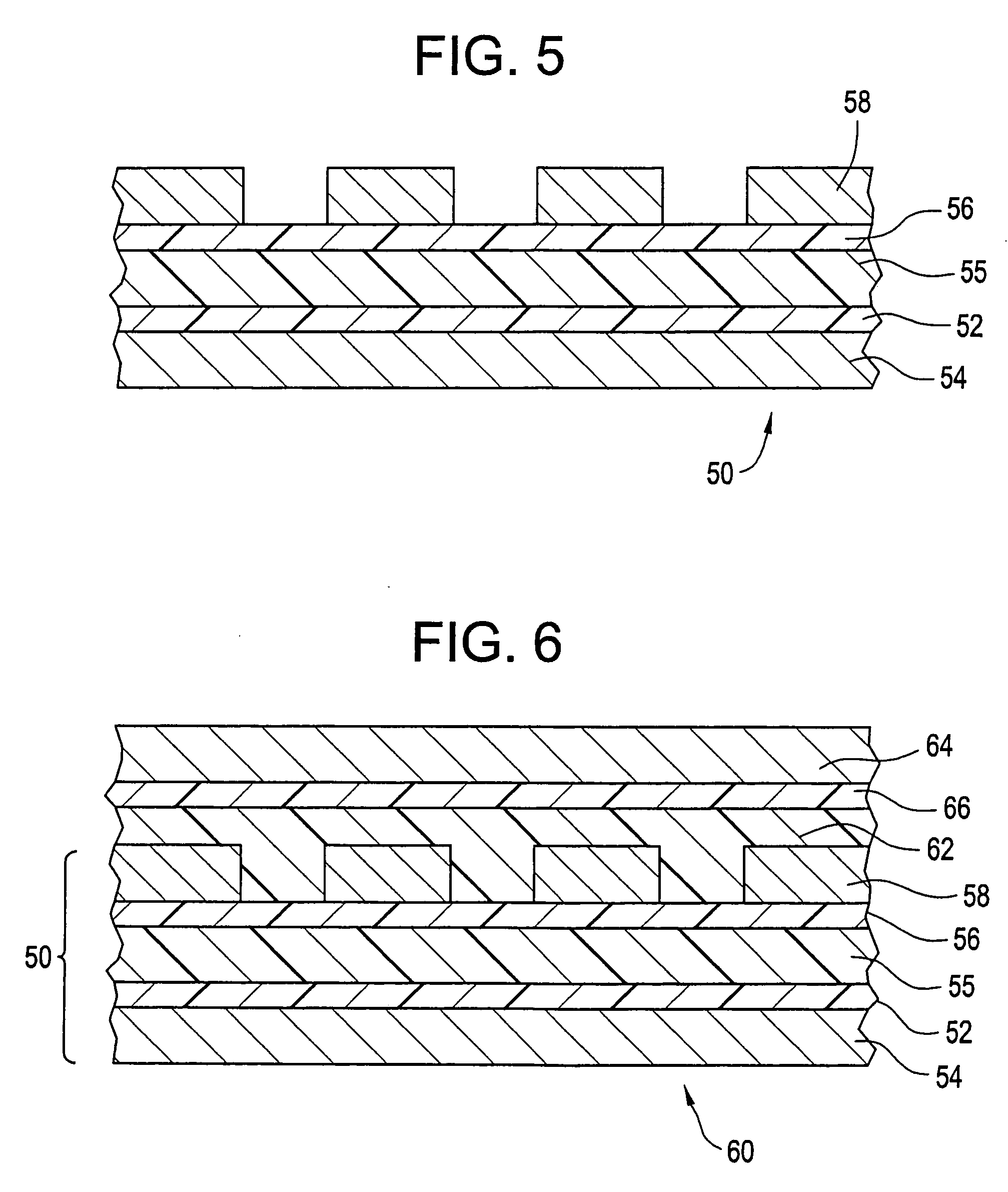

Structure for metal cap applications

InactiveUS20080197499A1Improve dielectric breakdown strengthImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesState of artDielectric breakdown strength

An interconnect structure is provided in which the conductive features embedded within a dielectric material are capped with a metallic capping layer, yet no metallic residue is present on the surface of the dielectric material in the final structure. The inventive interconnect structure has improved dielectric breakdown strength as compared to prior art interconnect structures. Moreover, the inventive interconnect structure has better reliability and technology extendibility for the semiconductor industry. The inventive interconnect structure includes a dielectric material having at least one metallic capped conductive feature embedded therein, wherein a top portion of said at least one metallic capped conductive feature extends above an upper surface of the dielectric material. A dielectric capping layer is located on the dielectric material and it encapsulates the top portion of said at least one metallic capped conductive feature that extends above the upper surface of dielectric material.

Owner:GLOBALFOUNDRIES INC

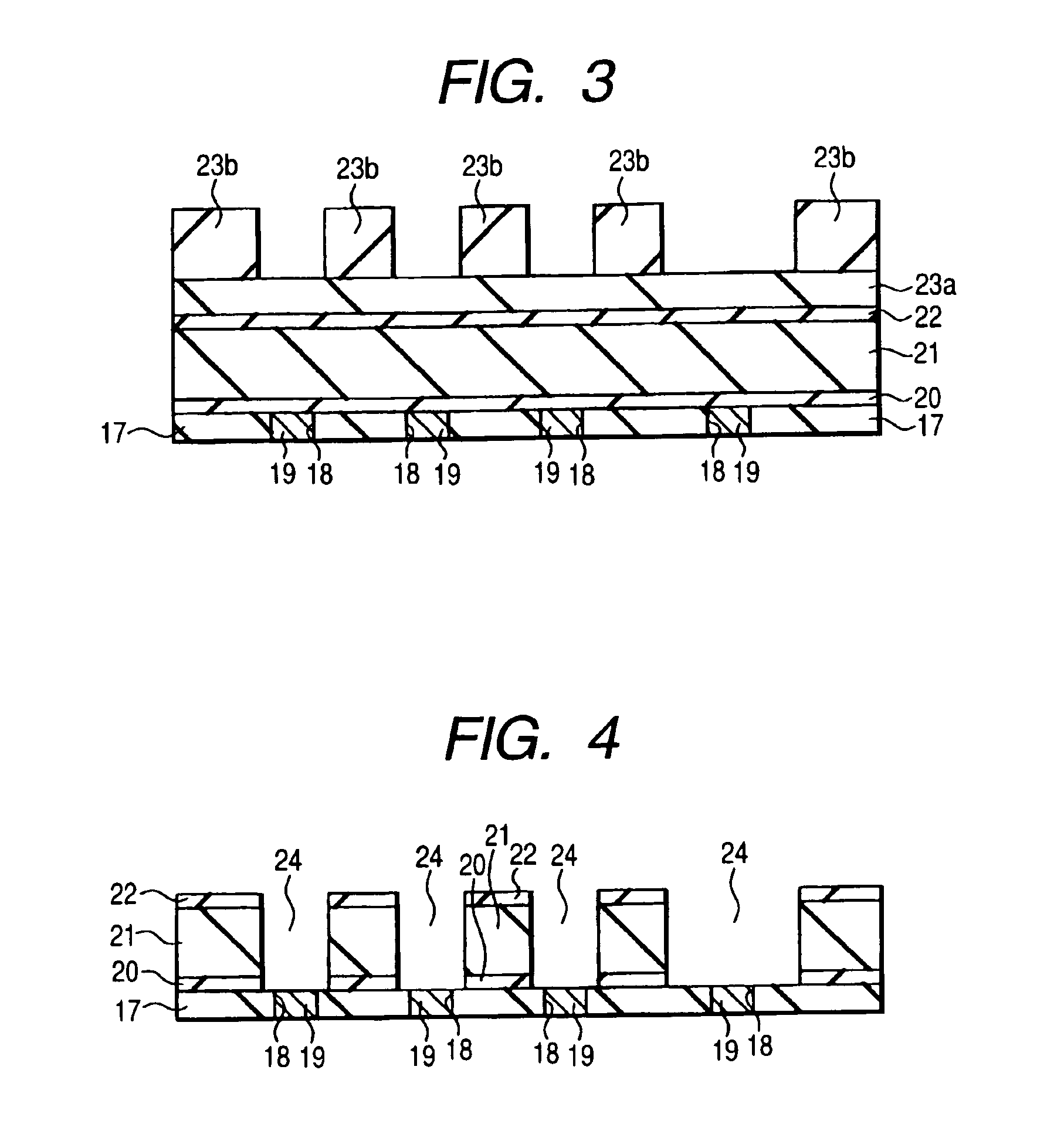

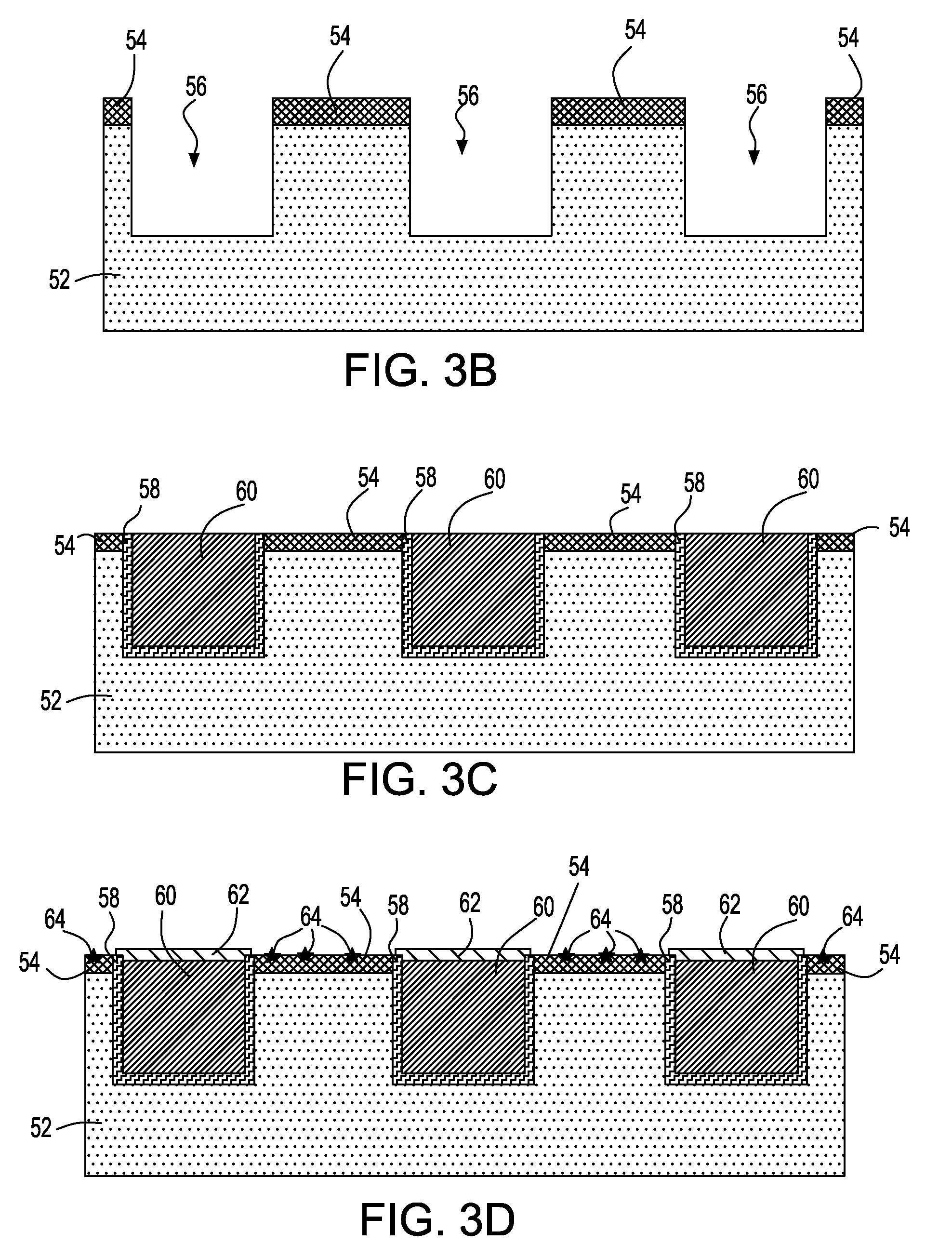

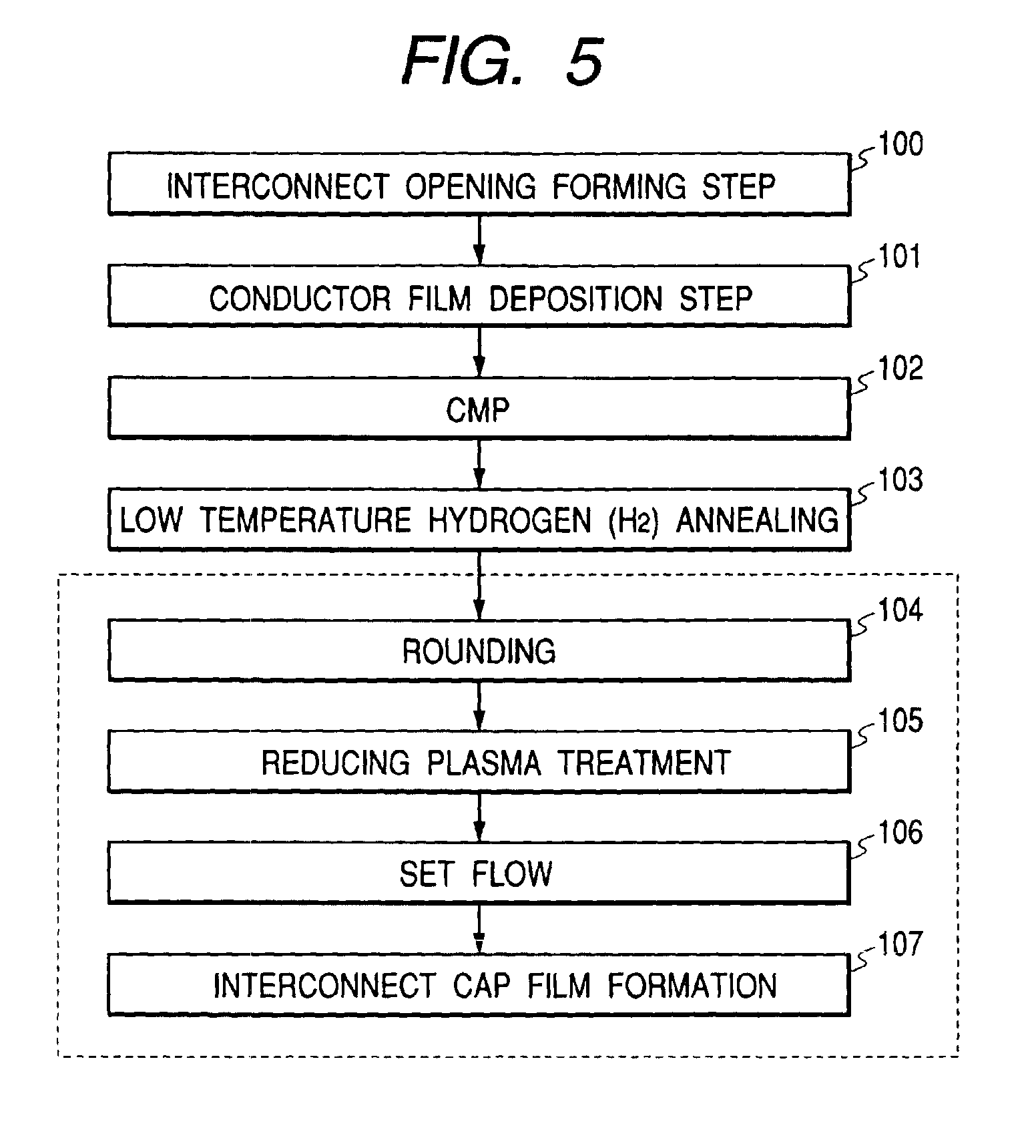

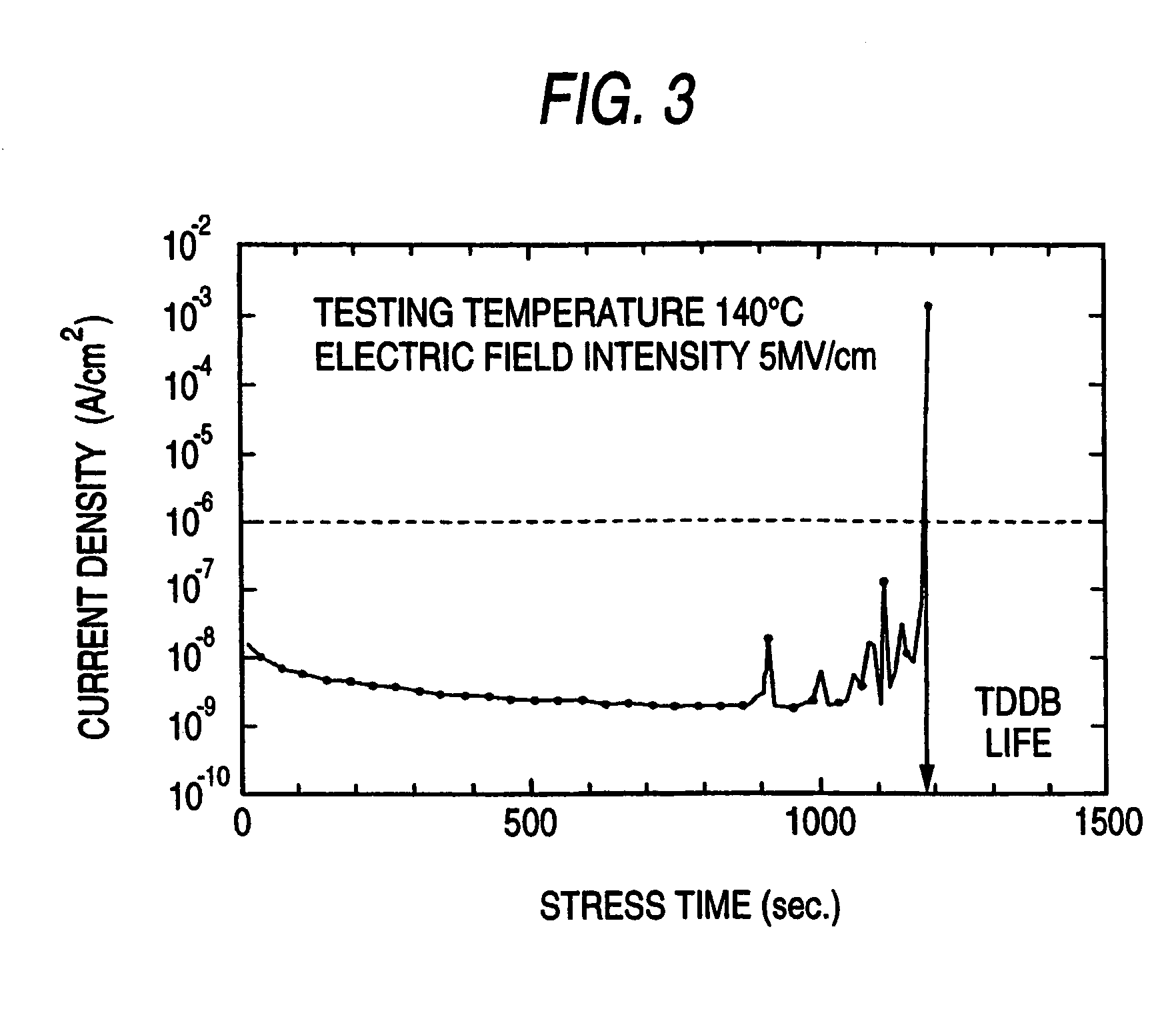

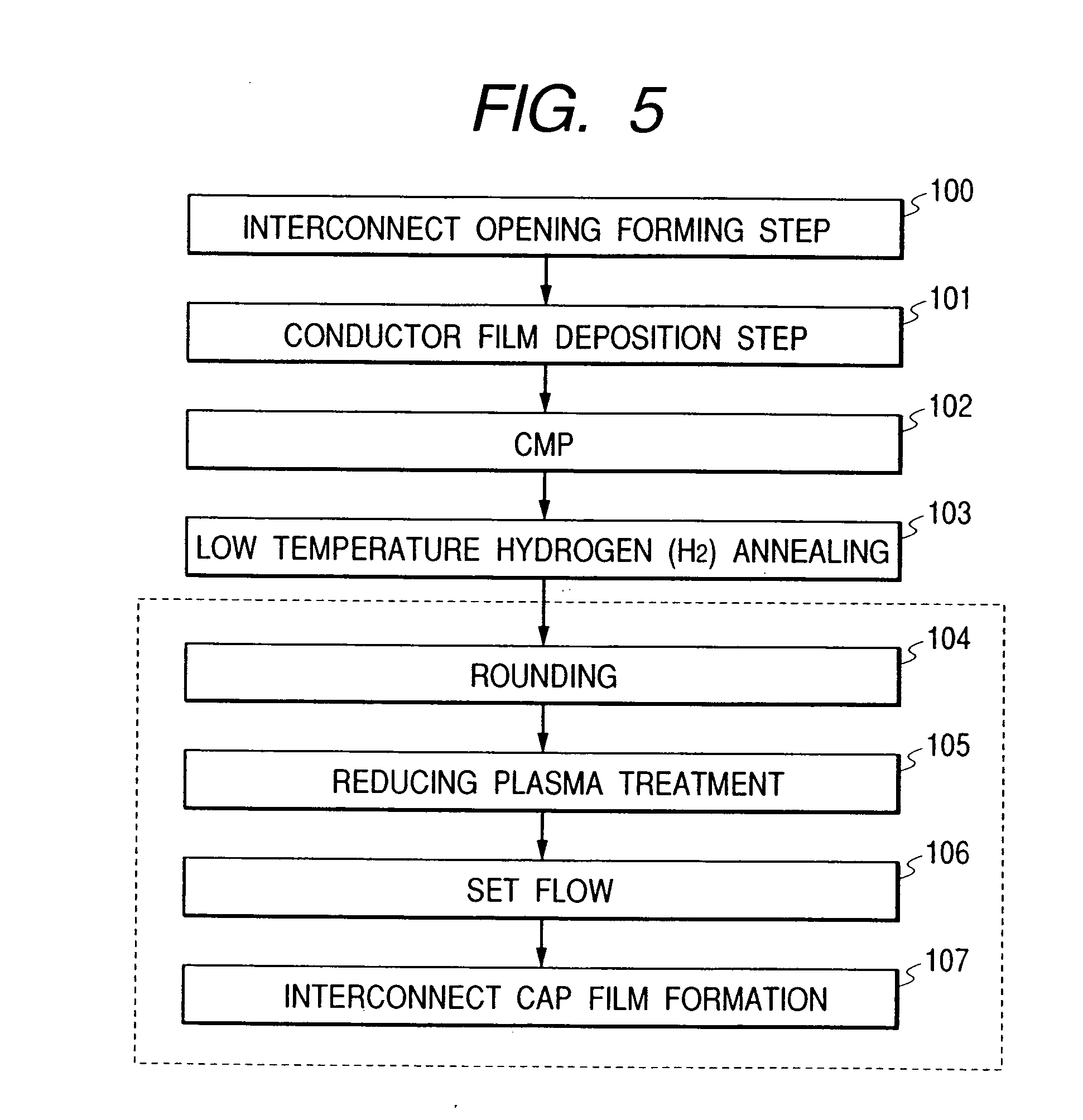

Method for manufacturing semiconductor integrated circuit device

InactiveUS6890846B2Improve dielectric breakdown strengthSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDielectric breakdown strength

Provided is a manufacturing method of a semiconductor device which comprises (a) depositing a first insulating film over a wafer, (b) forming an interconnect opening in the first insulating film, (c) forming, in the interconnect opening, an interconnect having a conductor film comprised mainly of copper, (d) forming a taper at a corner of said conductor film on the opening side of the interconnect opening, and (e) depositing a second insulating film over the first insulating film and interconnect. The present invention makes it possible to improve dielectric breakdown strength between interconnects each having a main conductor film comprised mainly of copper.

Owner:RENESAS ELECTRONICS CORP

Bipolar electrostatic chuck

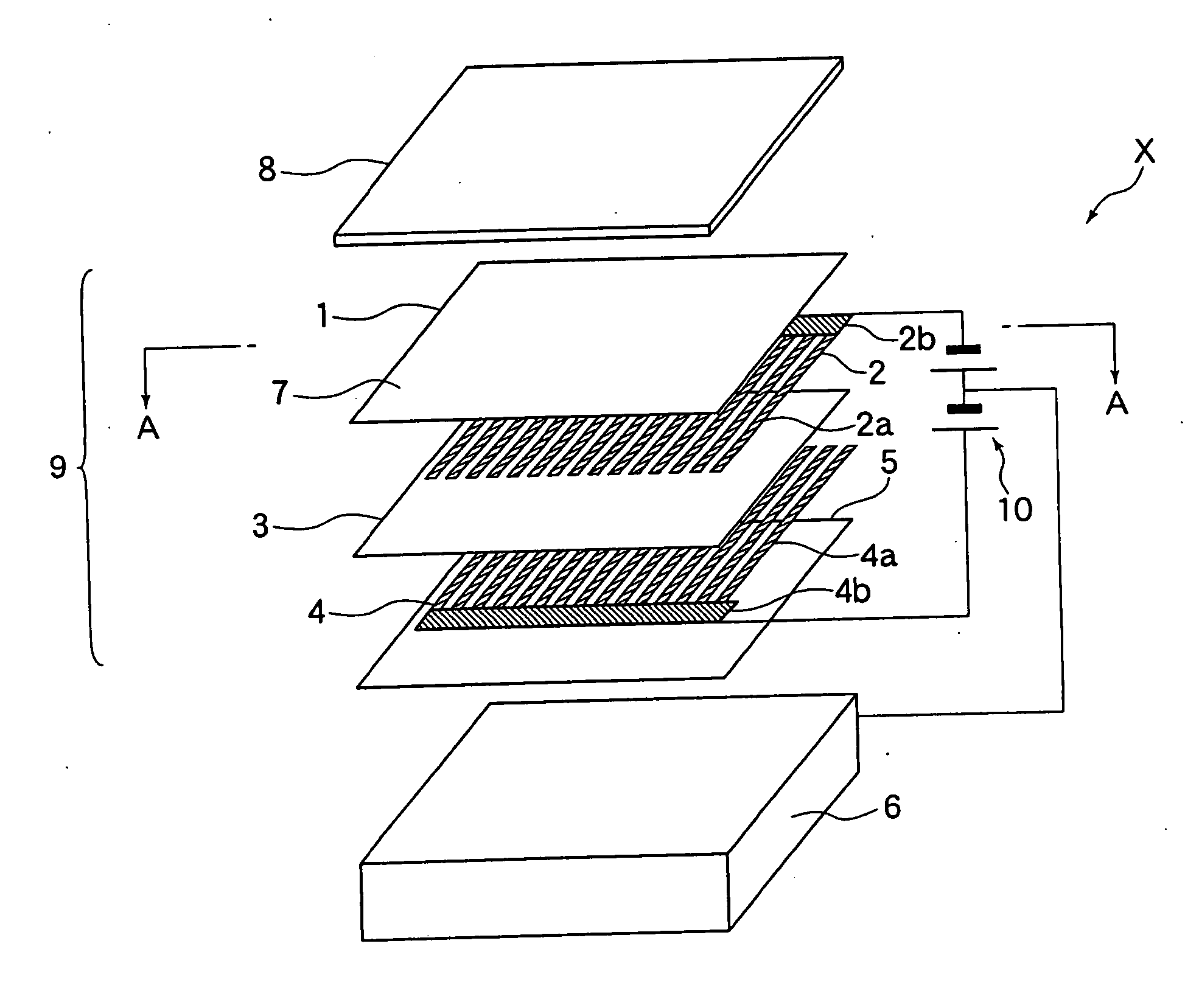

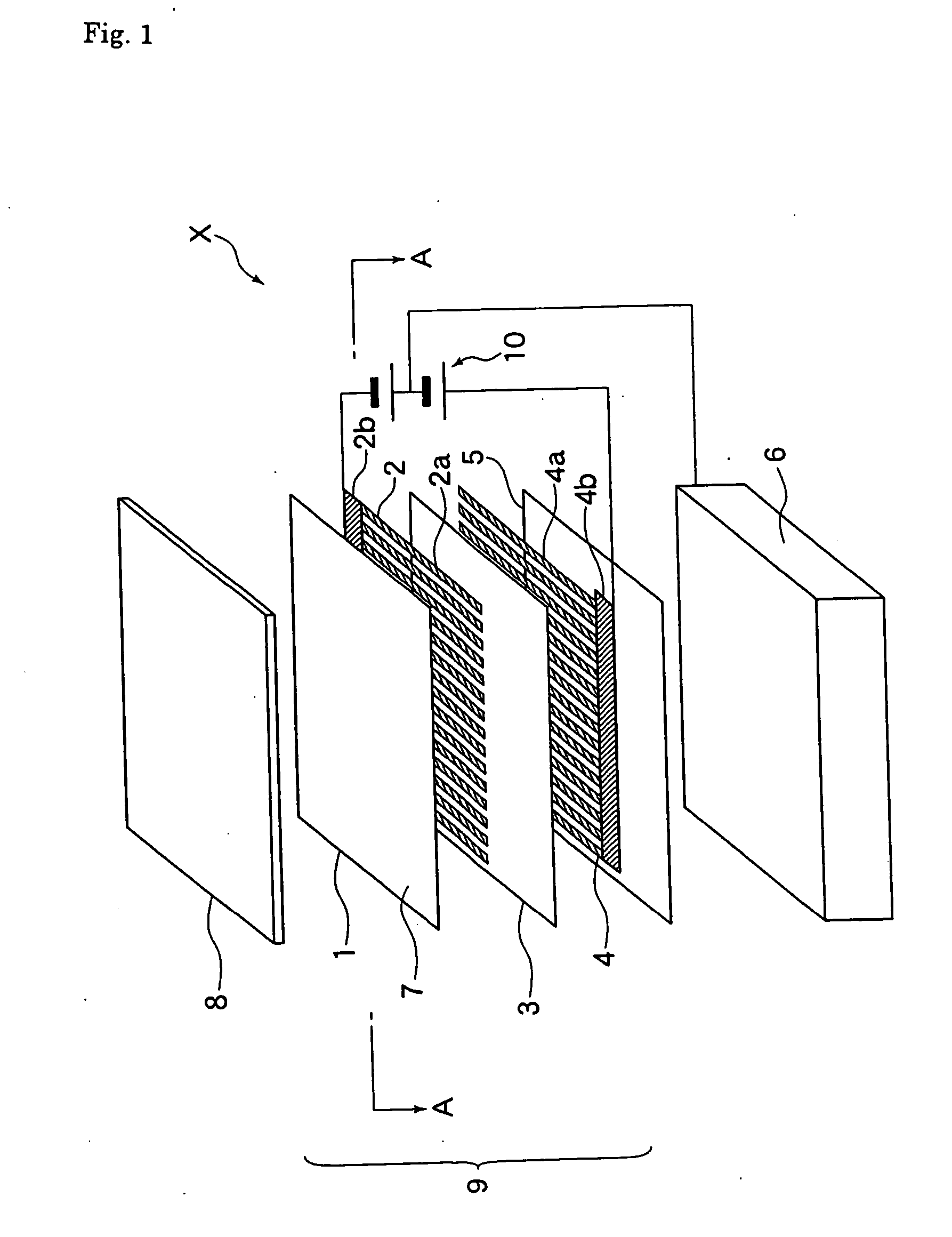

ActiveUS20100149720A1Improve flatnessImprove reliabilitySemiconductor/solid-state device manufacturingElectrostatic holding devicesDielectric breakdown strengthDepth direction

A bipolar electrostatic chuck which has excellent dielectric breakdown strength and provides excellent attracting performance. The bipolar electrostatic chuck eliminates difficulty in dismounting a sample from a sample attracting plane as much as possible after application of a voltage to electrodes is finished. The bipolar electrostatic chuck is provided with a first electrode and a second electrode in an insulator and permits a surface of the insulator to be the sample attracting plane. The insulator has the first electrode, an interelectrode insulating layer and the second electrode in this order from the sample attracting plane in the depth direction. The second electrode has a region not overlapping with the first electrode in a normal line direction of the sample attracting plane.

Owner:CREATIVE TECH CORP

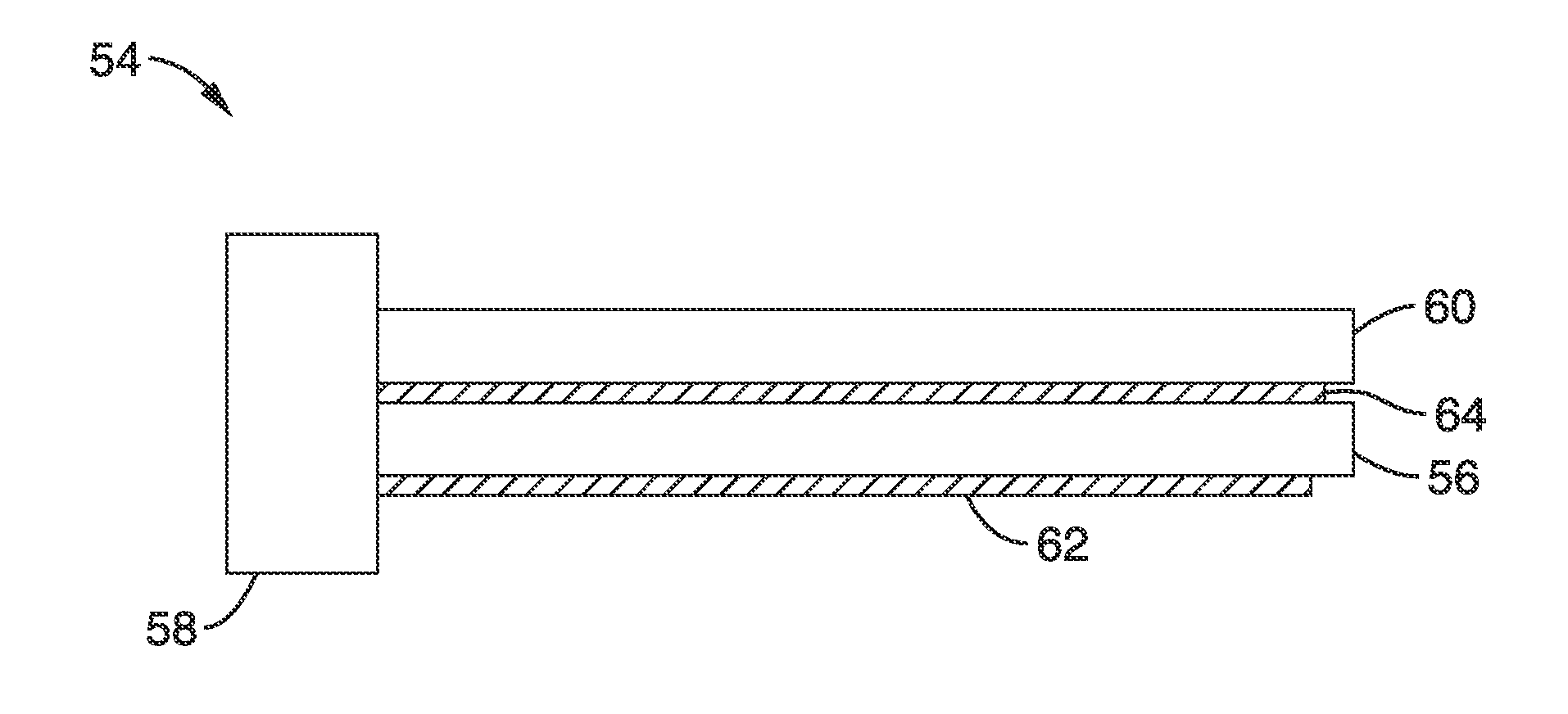

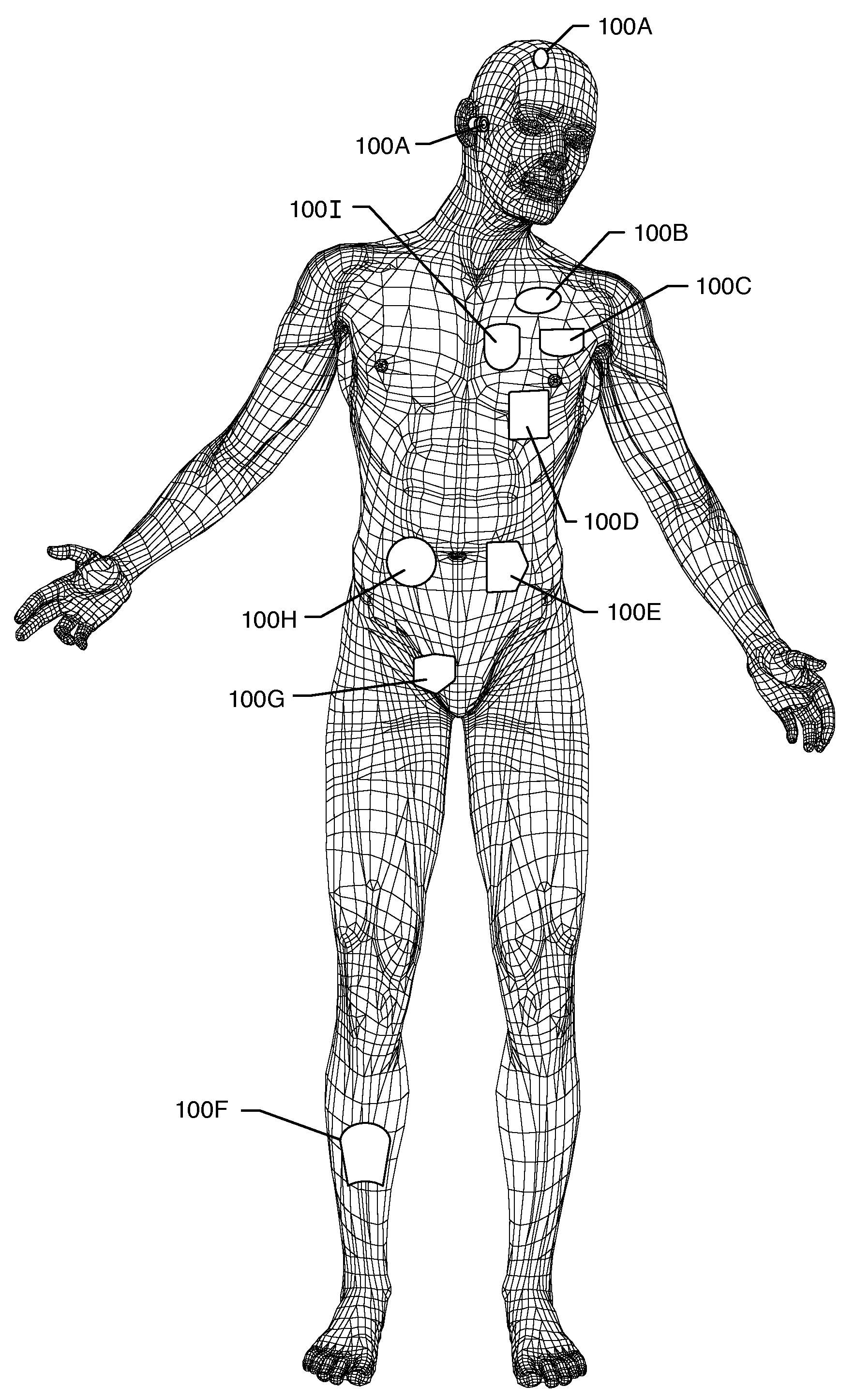

Dielectric fluid filled active implantable medical devices

InactiveUS20090312835A1Increase the volts-per-mil breakdown strengthDigital data processing detailsHeart defibrillatorsDielectricNitrogen

Active implantable medical devices (AIMDs) are backfilled with a dielectric fluid to increase the volts per mil dielectric breakdown strength between internal circuit elements. In a method for backfilling the AIMD with dielectric fluid, substantially all air and moisture is evacuated from the AIMD housing prior to backfilling the AIMD housing with a dielectric fluid having a dielectric breakdown strength greater than air, nitrogen or helium. The AIMD is constructed to accommodate volumetric expansion or contraction of the dielectric fluid due to changes of pressure or temperature of the dielectric fluid to maintain integrity of the AIMD.

Owner:WILSON GREATBATCH LTD

Semiconductor device and a method of manufacturing the same

InactiveUS20060183317A1Improve dielectric breakdown strengthReduce capacitanceSemiconductor/solid-state device manufacturingCapacitanceCopper interconnect

Provided are a semiconductor device comprising a semiconductor substrate, a first insulating film formed thereover, interconnects formed over the first insulating film and having copper as a main component, a second insulating film formed over the upper surface and side surfaces of each of the interconnects and over the first insulating film and having a function of suppressing or preventing copper diffusion, and a third insulating film formed over the second insulating film and having a dielectric constant lower than that of the second insulating film; and a method of manufacturing the semiconductor device. This invention makes it possible to improve dielectric breakdown strength between copper interconnects and reduce capacitance between the copper interconnects.

Owner:NOGUCHI JUNJI +1

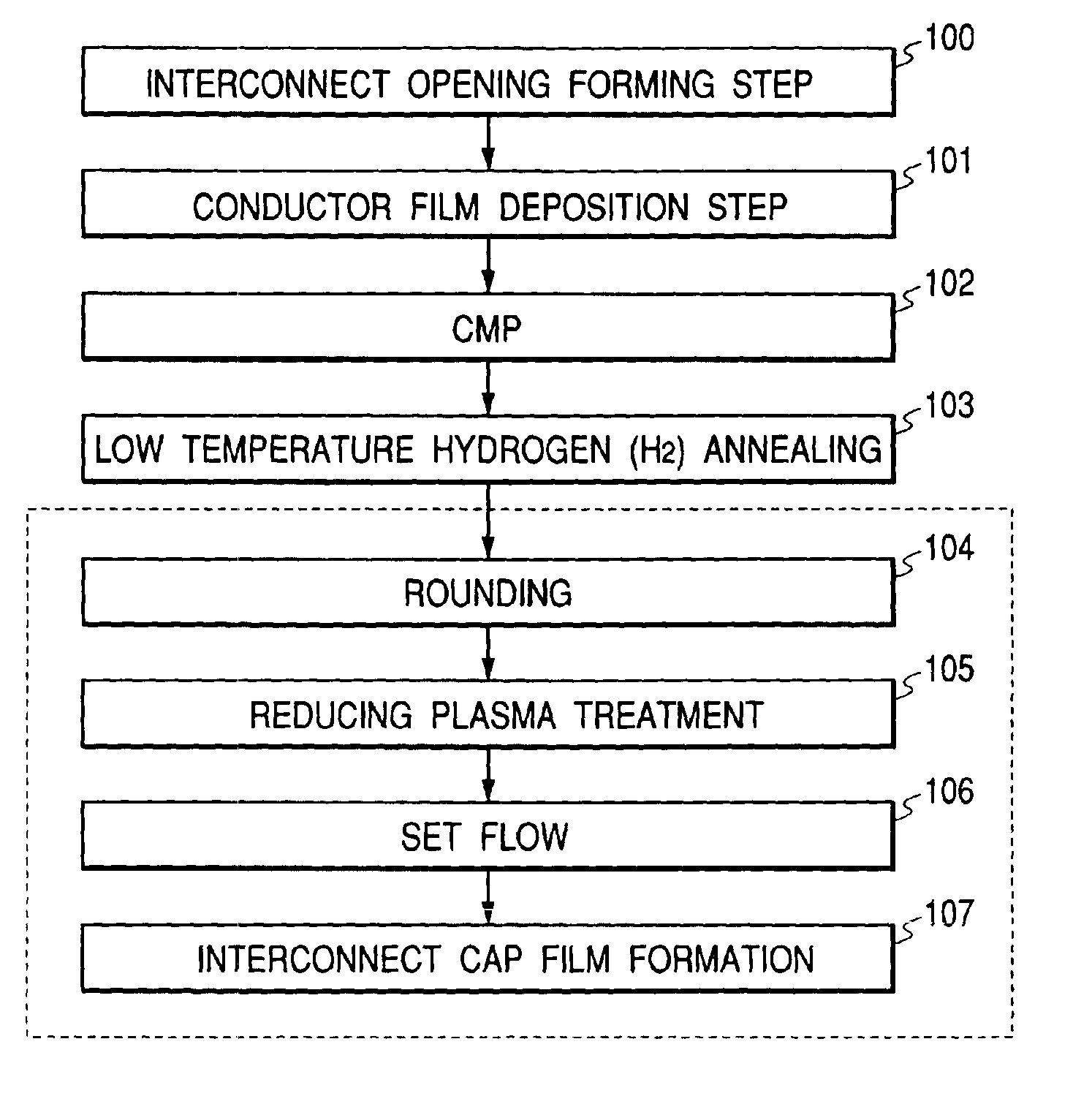

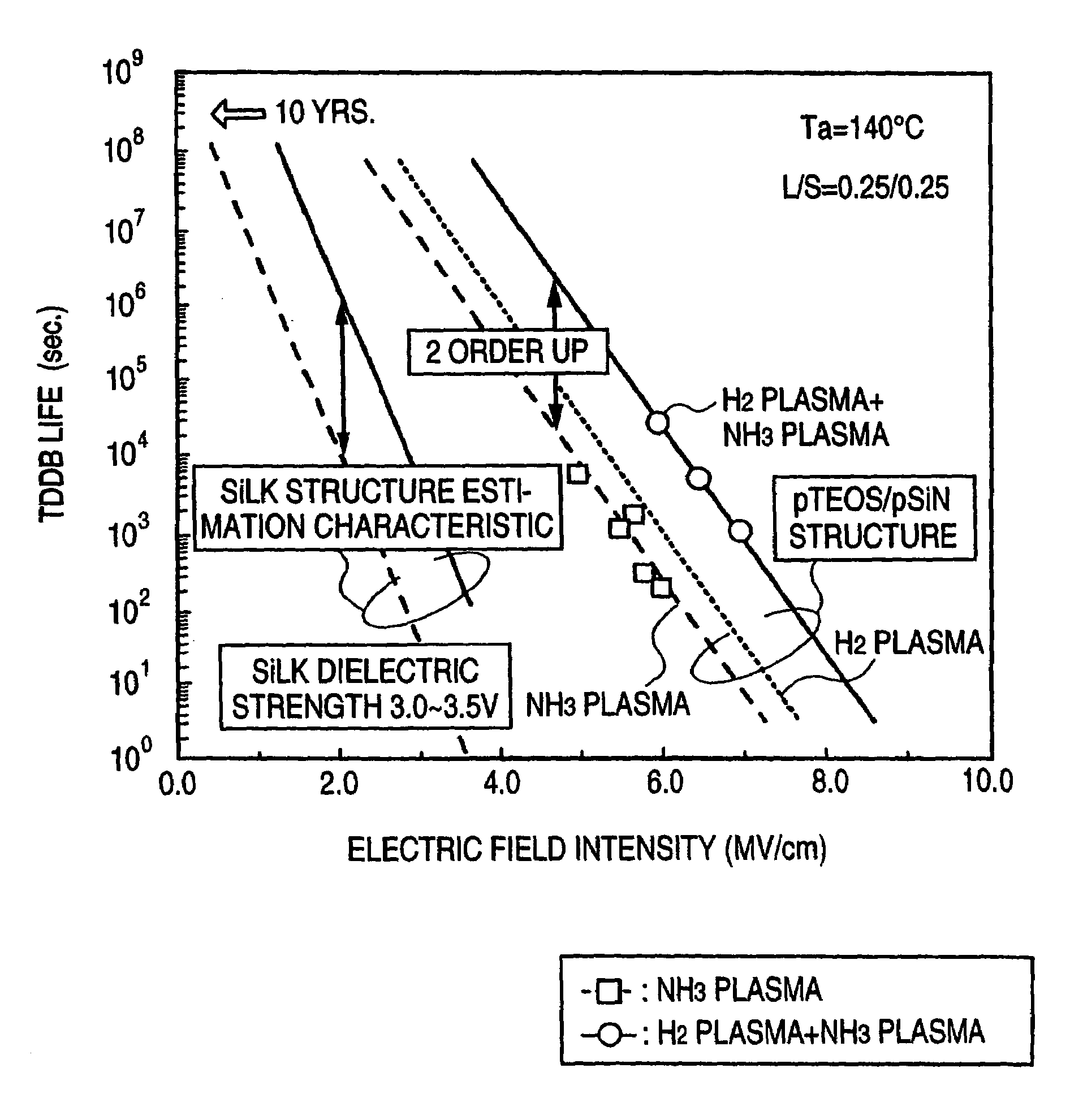

Fabrication method of semiconductor integrated circuit device

InactiveUS7084063B2Improve dielectric breakdown strengthIncrease resistanceTransistorSemiconductor/solid-state device detailsCopper interconnectDielectric breakdown strength

The copper interconnect formed by the use of a damascene technique is improved in dielectric breakdown strength (reliability). During post-CMP cleaning, alkali cleaning, a deoxidizing process due to hydrogen annealing or the like, and acid cleaning are carried out in this order. After the post-CMP cleaning and before forming an insulation film for a cap film, hydrogen plasma and ammonia plasma processes are carried out on the semiconductor substrate. In this way, a copper-based buried interconnect is formed in an interlayer insulation film structured of an insulation material having a low dielectric constant.

Owner:HITACHI LTD

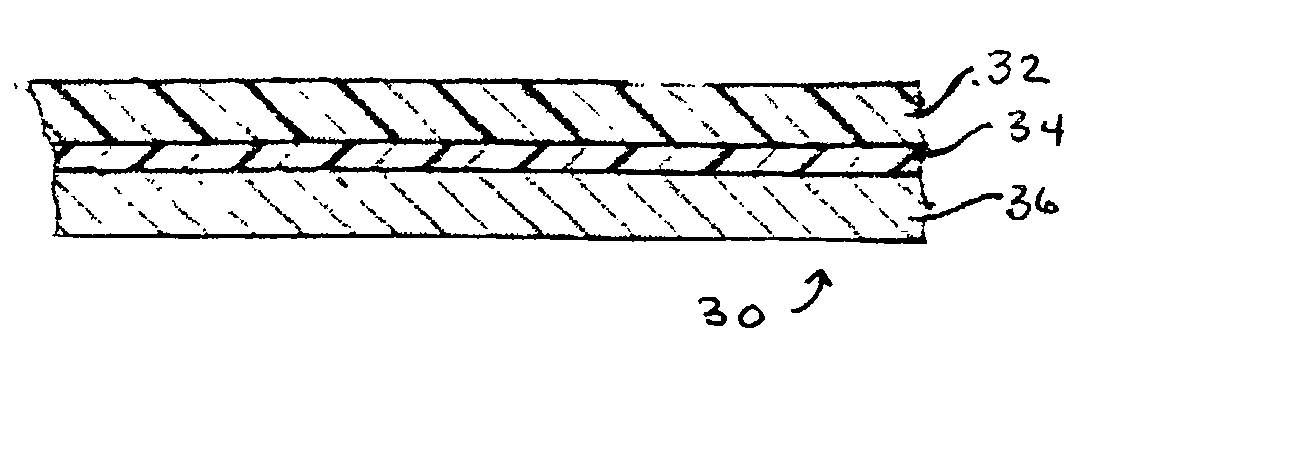

Method for improving bonding of circuit substrates to metal and articles formed thereby

InactiveUS20030075270A1Maintain good propertiesHigh bonding strengthInsulating substrate metal adhesion improvementSynthetic resin layered productsElastomerDielectric breakdown strength

A method of forming a circuit material comprises disposing an adhesion promoting elastomer composition between a conductive copper foil and a thermosetting composition; and laminating the copper foil, adhesion promoting composition, and thermosetting composition to form the circuit material. The adhesion promoting layer may be uncured or partially cured before contacting with the curable thermosetting composition. Preferably the adhesion promoting layer has electrical characteristics such as dissipation factor, dielectric breakdown strength, water absorption, and dielectric constant that are similar to and / or compatible with the electrical characteristics of the thermosetting composition.

Owner:WORLD PROPERTIES

Air core motor-generator

InactiveUS7525230B1Improve efficiencyLong reliable operating lifeWindingsMagnetic circuit rotating partsBrushless motorsMagnetic tension force

A brushless motor-generator includes a rotor having a ferromagnetic tube with radially polarized, alternating polarity permanent magnet poles, and an air core armature that magnetically exerts torque upon the rotor. The magnetic poles drive magnetic flux across a radial magnetic air gap inside of the tube and through windings of the armature that are located in the air gap. The windings utilize wire that is comprised of multiple individually insulated strands that are bundled together and sheathed in an outer electrically insulating serve that separates adjacent windings and provides a higher dielectric breakdown strength than the insulation on the individually insulated strands. A thin circumferentially tensioned band is wrapped around the outer diameter of the axially traversing portions of the windings where located inside the magnetic air gap, imparting radial compression and structural integrity to the windings and increasing the circumferential structural strength of the air core armature for torque production.

Owner:REVOLUTION ELECTRIC MOTOR

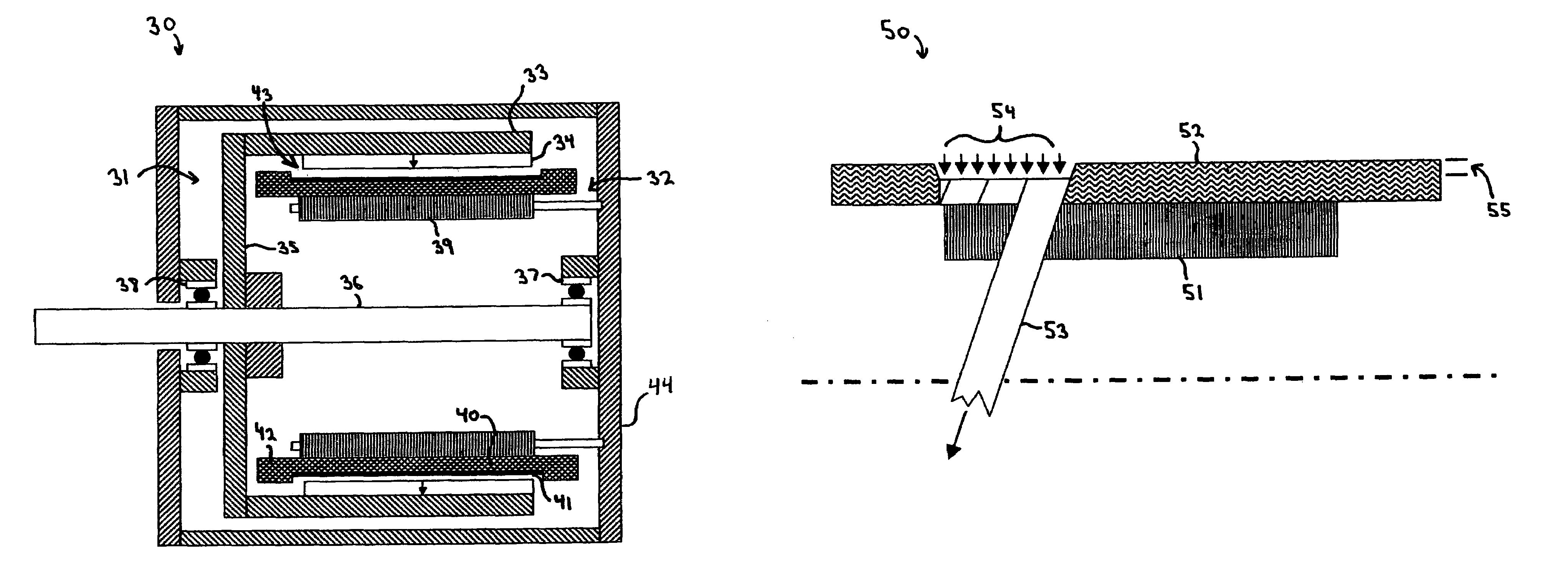

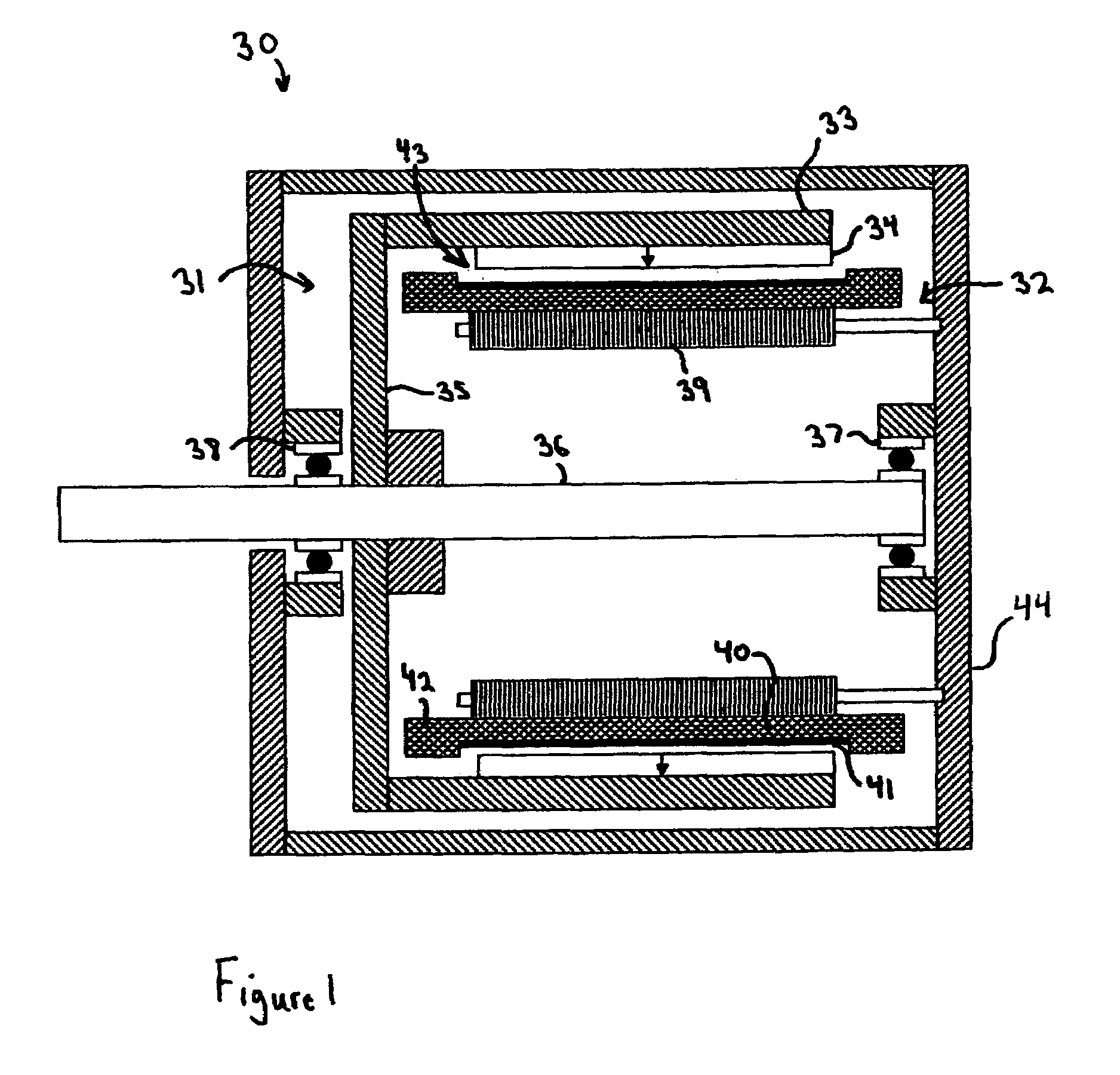

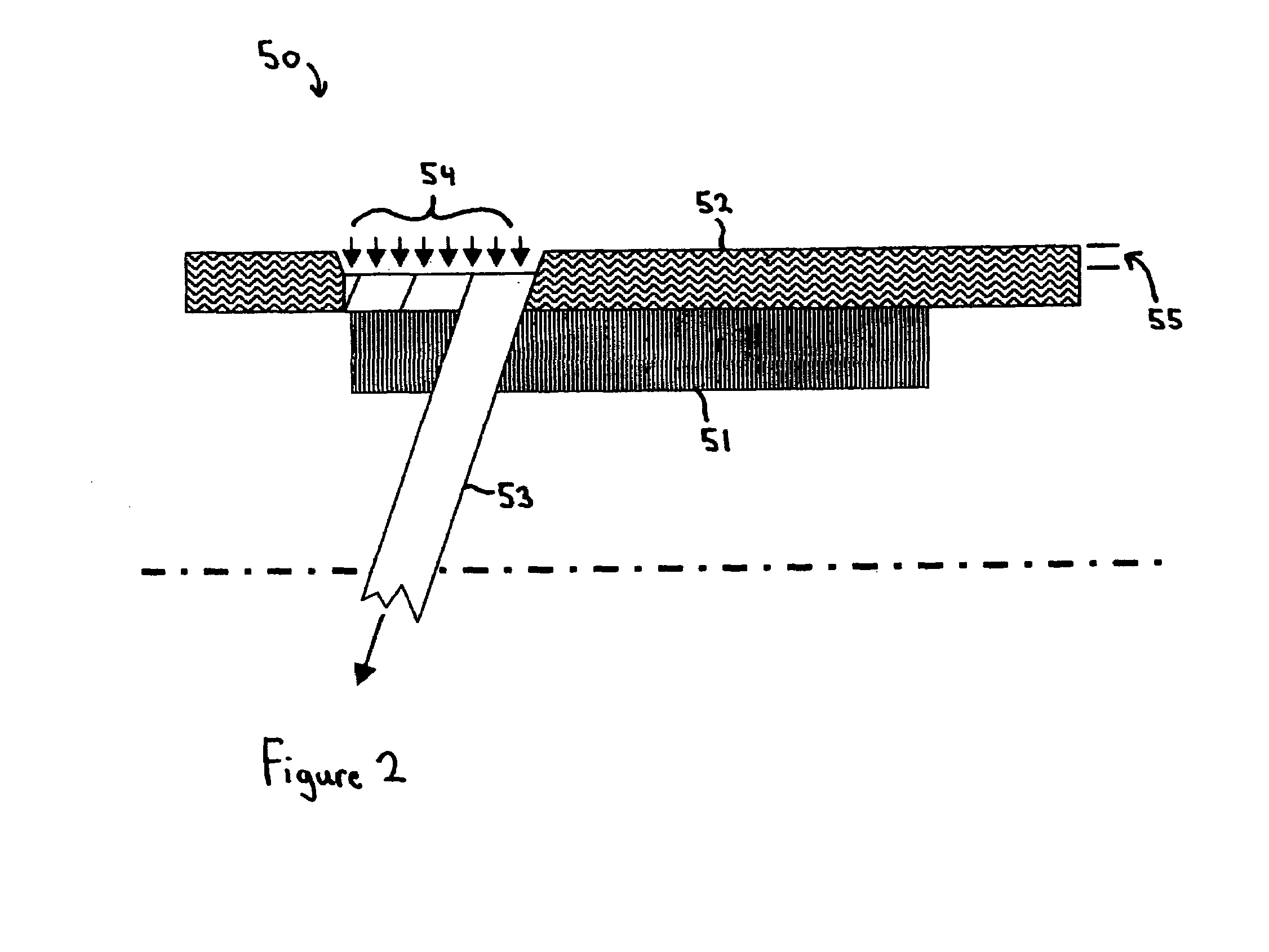

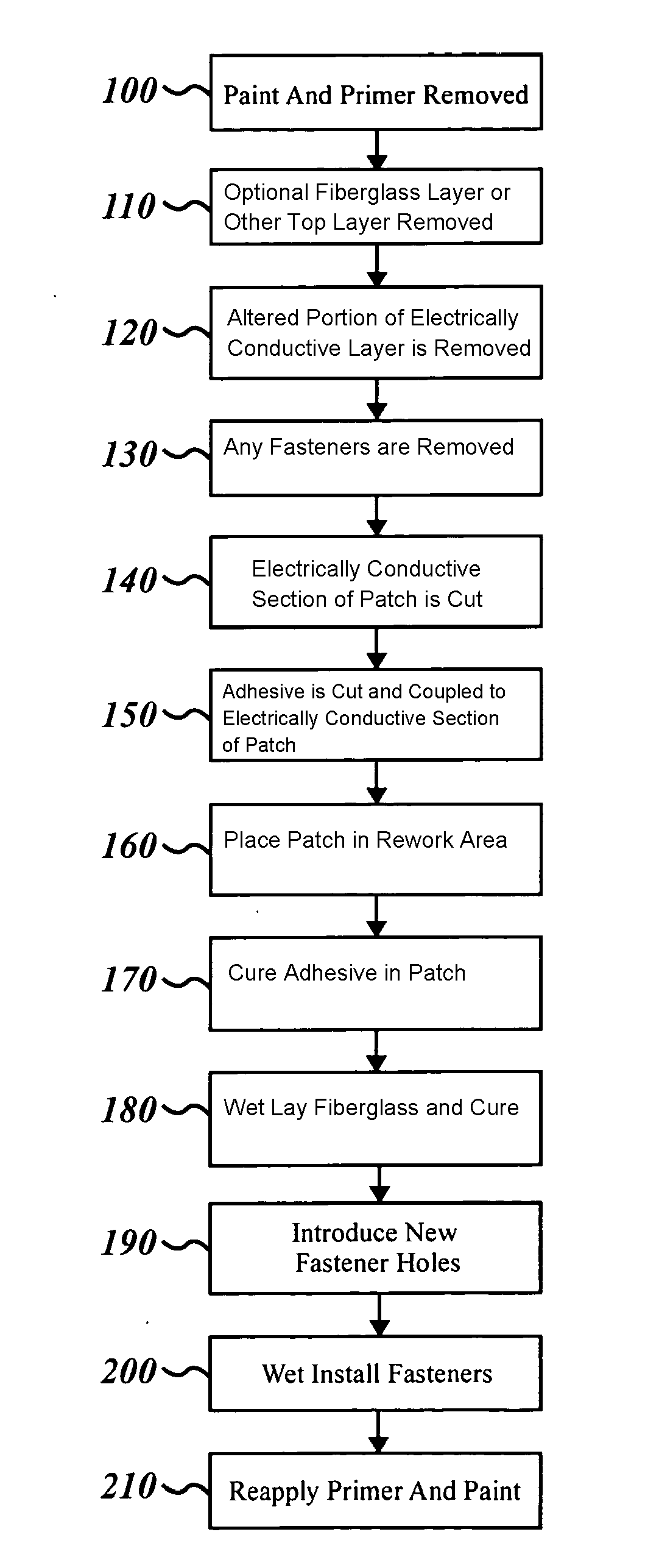

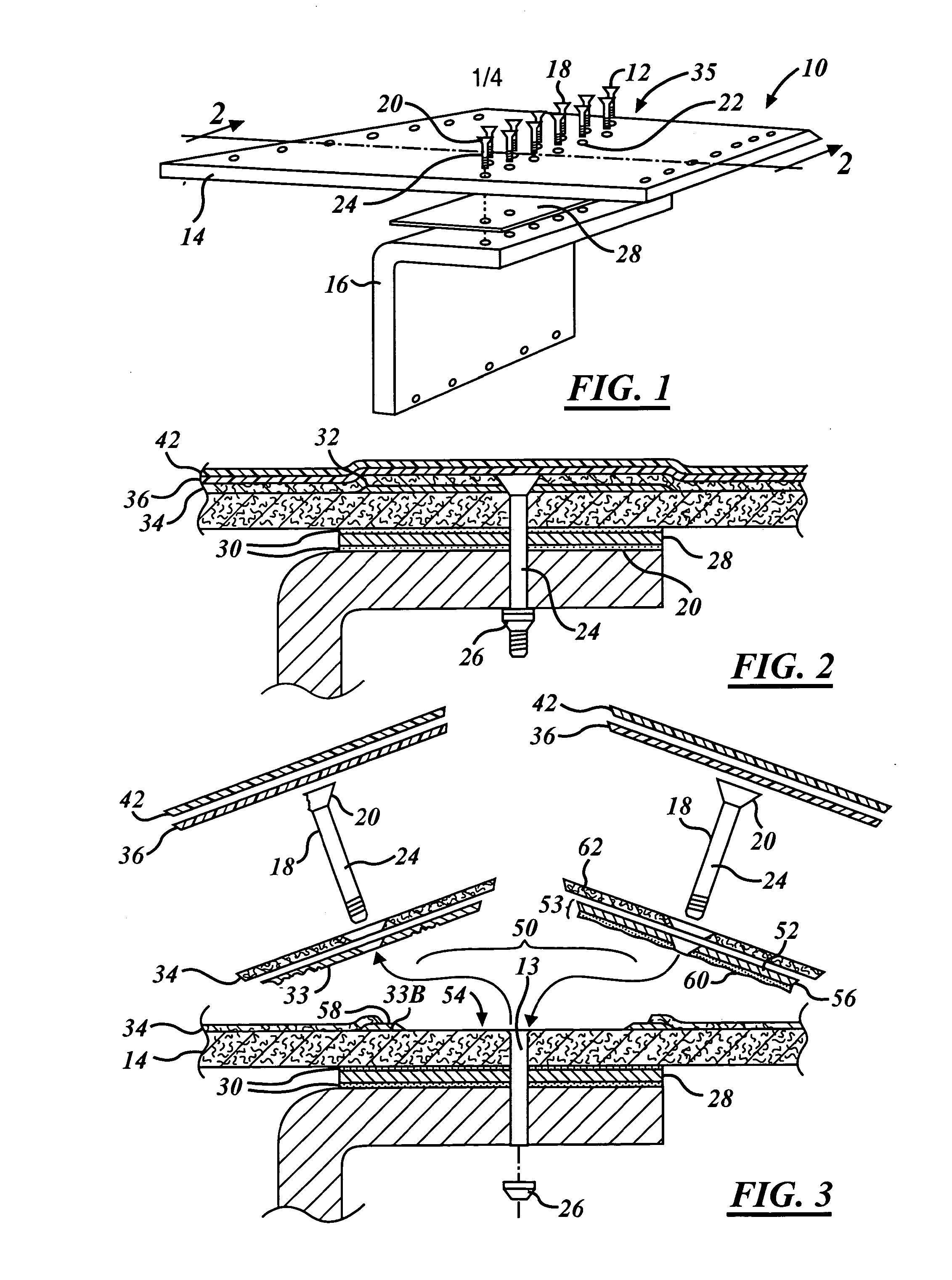

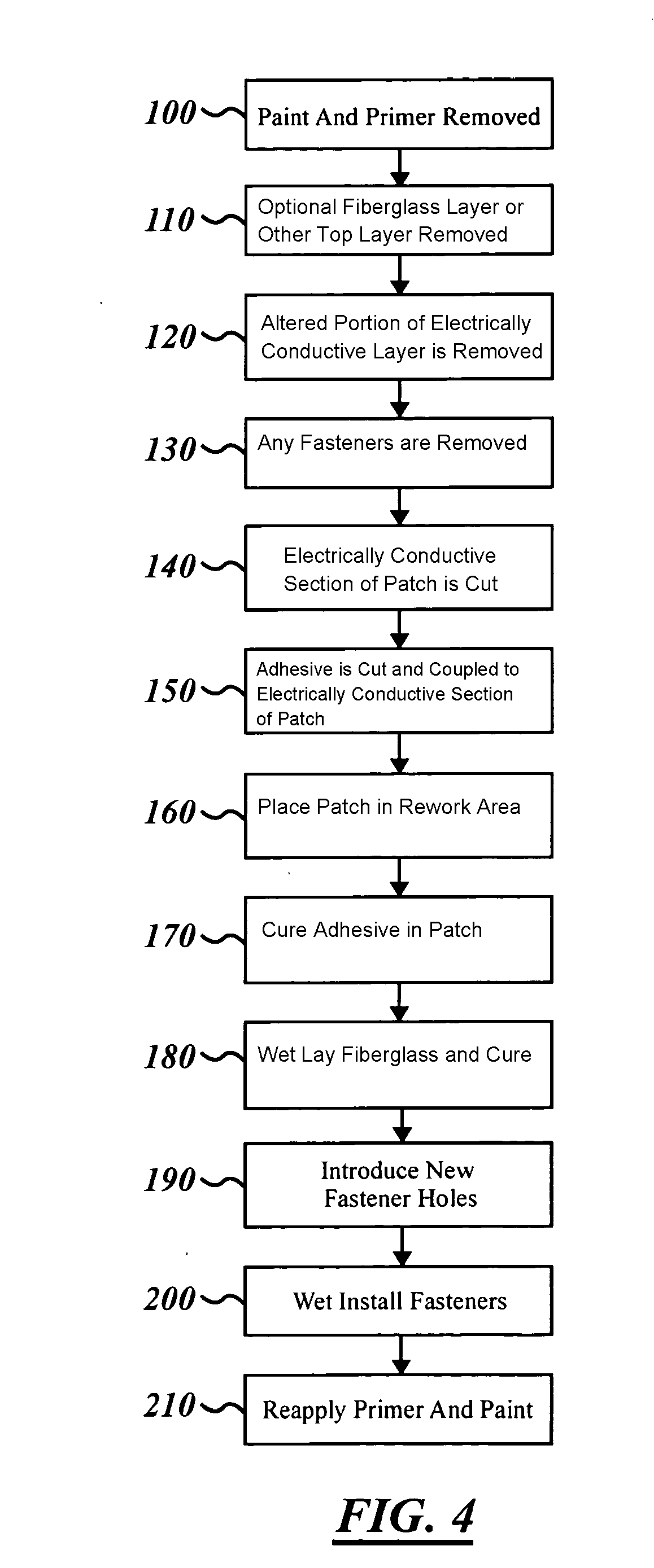

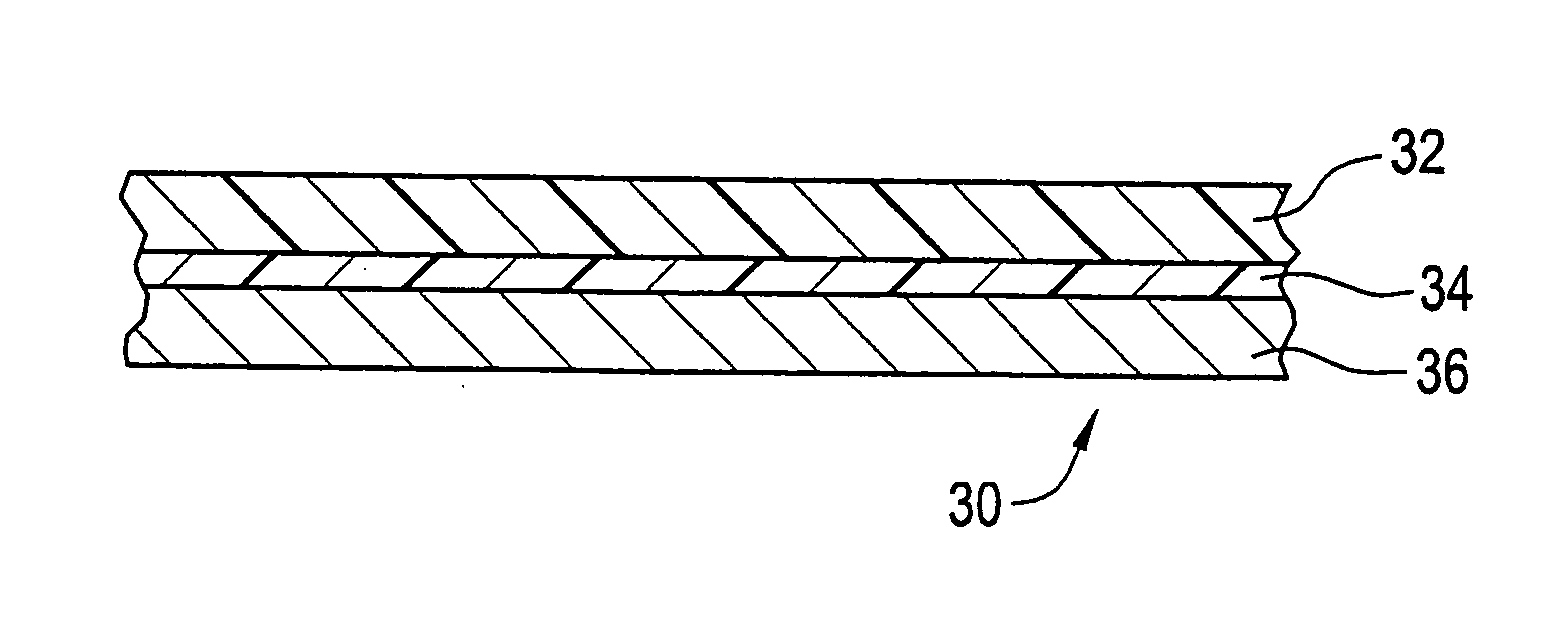

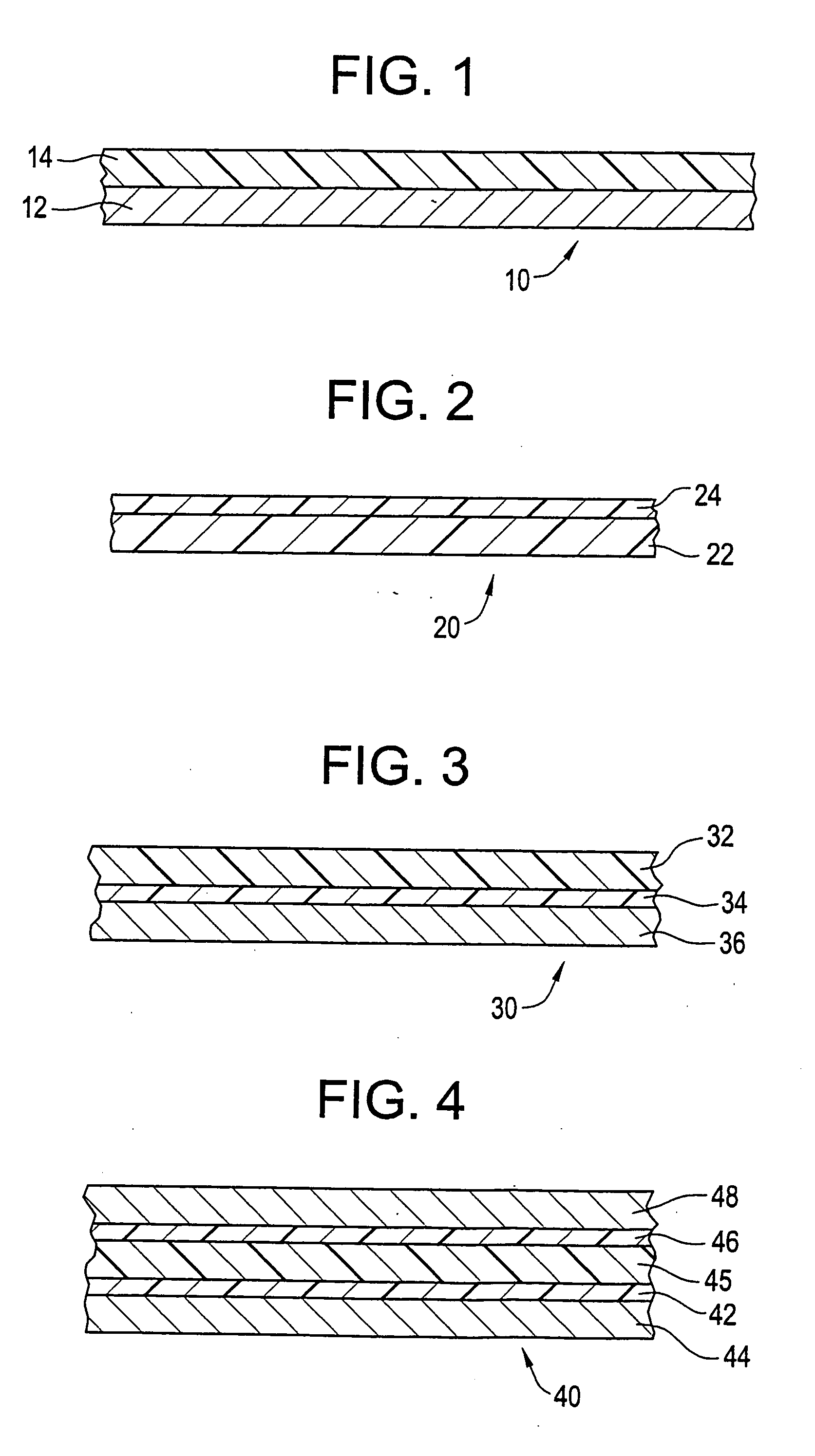

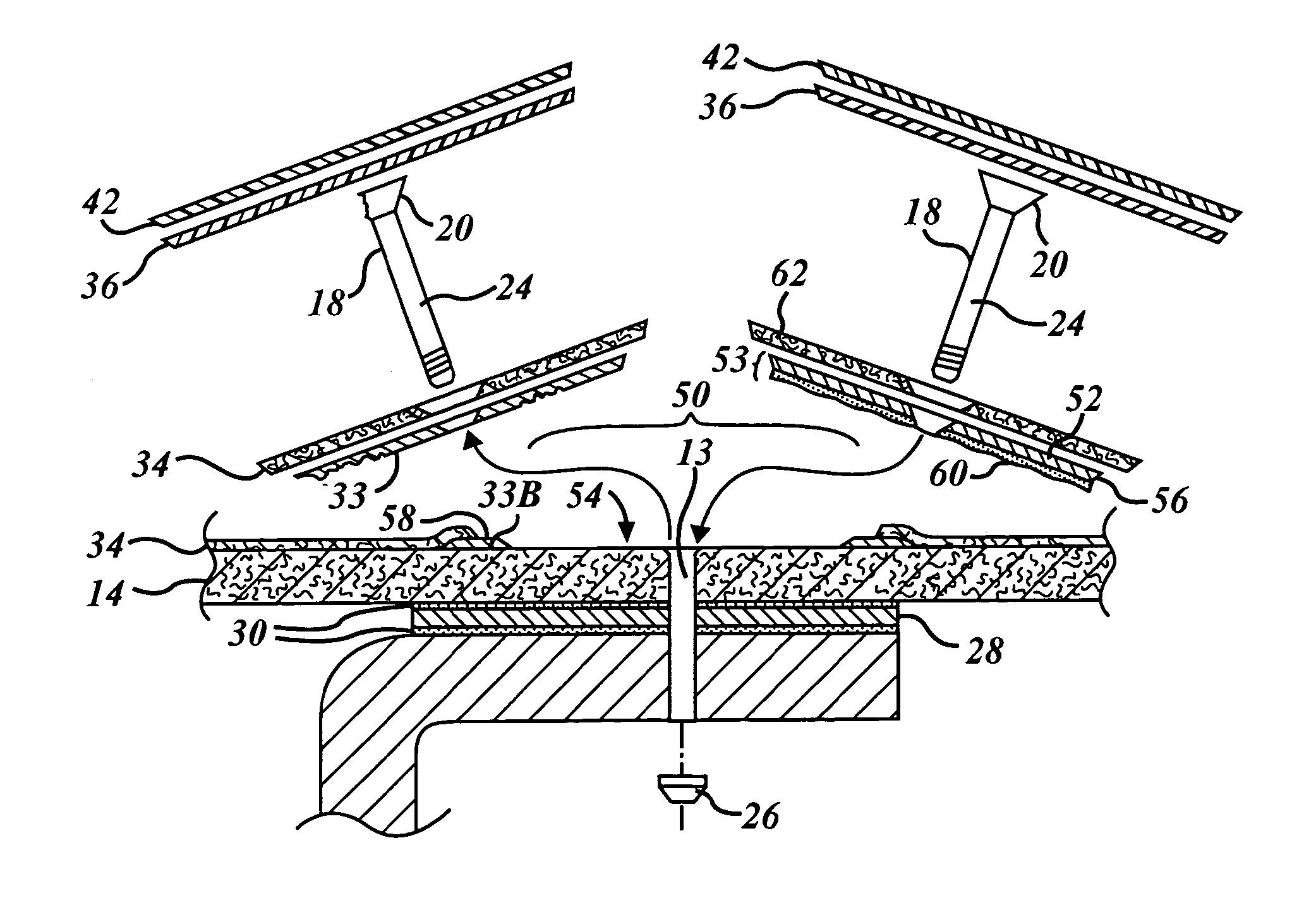

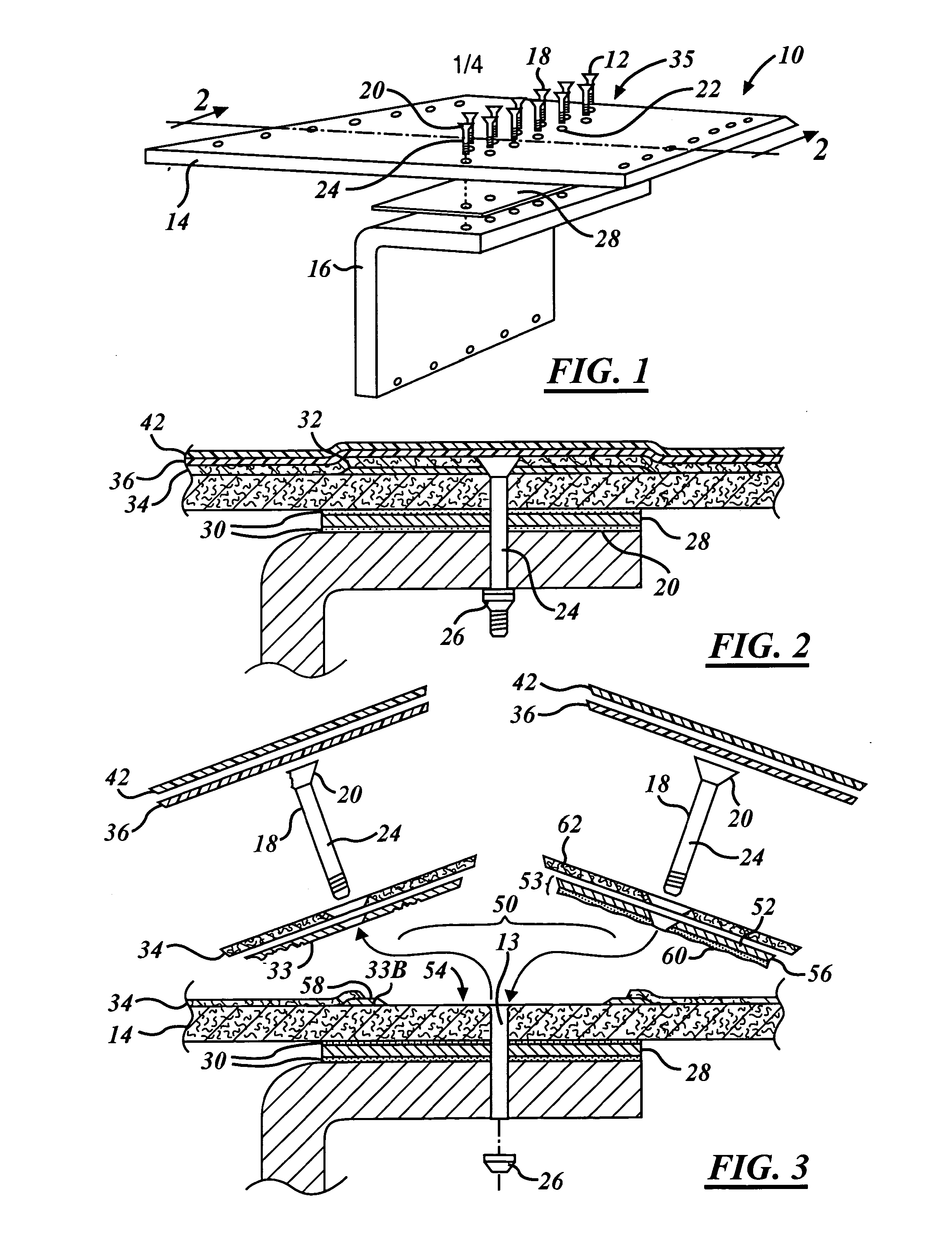

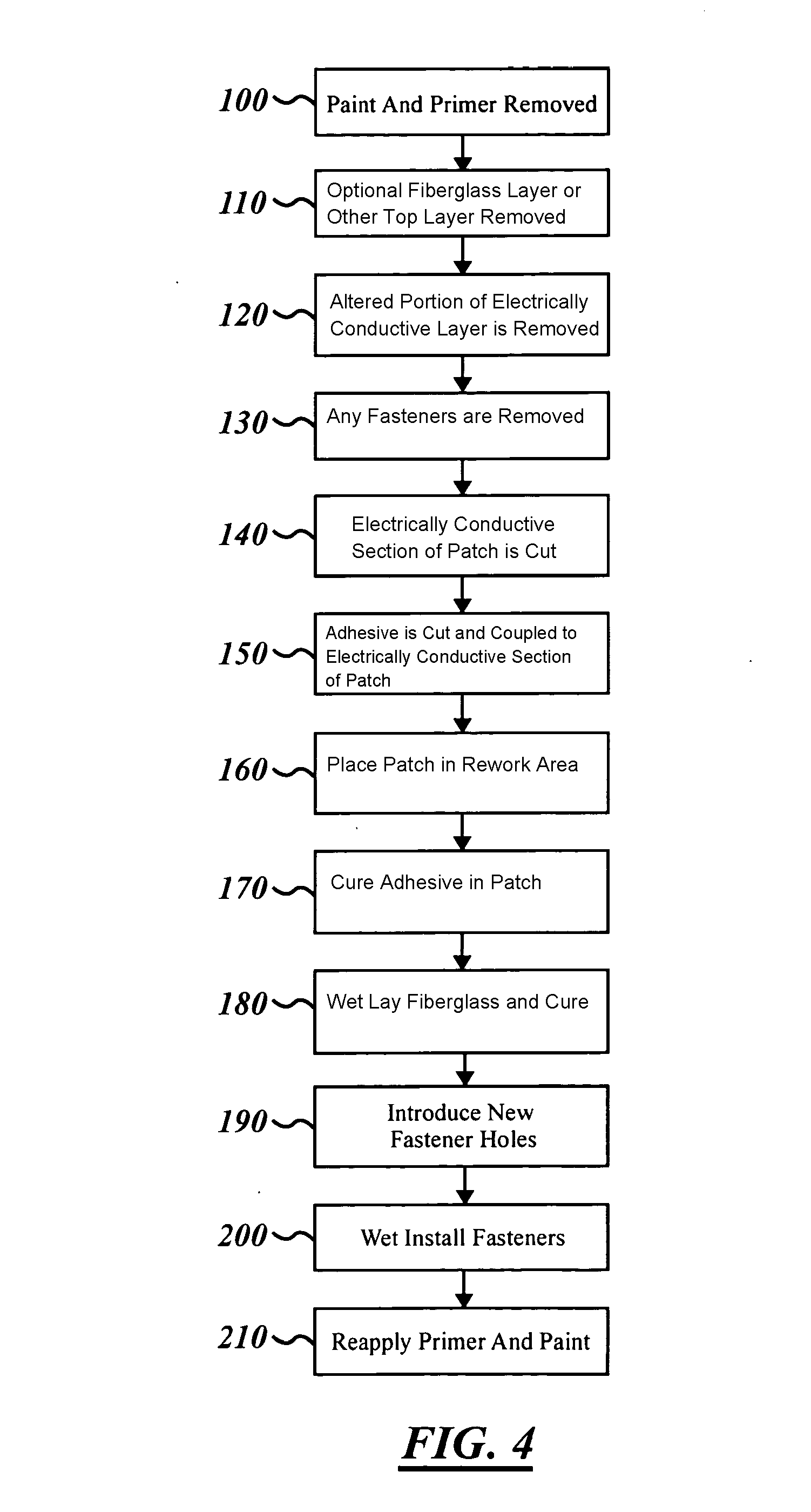

Copper grid repair technique for lightning strike protection

ActiveUS20110186206A1Low densityImprove dielectric breakdown strengthLamination ancillary operationsLaminationElectricityLightning strike

A method for reworking an electrically conductive layer of a composite skin is disclosed in which a patch replaces the altered section of the electrically conductive layer. The method is performed by removing a portion of the electrically conductive layer to reveal the underlying composite skin. A patch is formed, having an electrically conductive section coupled to an adhesive having a low dielectric breakdown strength, and is then introduced over the underlying composite skin such that the adhesive layer covers the underlying composite skin and overlaps an unremoved portion of the electrically conductive layer. The patch is applied such that the electrically conductive section within the patch covers the adhesive layer and overlaps the unremoved section of the electrically conductive layer. The adhesive layer preferably has a low dielectric breakdown strength, so that electricity from lightning which strikes the composite skin may be conducted through the adhesive.

Owner:THE BOEING CO

Method for improving bonding of circuit substrates to metal and articles formed thereby

InactiveUS20050208278A1Improve adhesionHigh bonding strengthInsulating substrate metal adhesion improvementAdhesive processes with surface pretreatmentElastomerCopper foil

A method of forming a circuit material comprises disposing an adhesion promoting elastomer composition between a conductive copper foil and a thermosetting composition; and laminating the copper foil, adhesion promoting composition, and thermosetting composition to form the circuit material. The adhesion promoting layer may be uncured or partially cured before contacting with the curable thermosetting composition. Preferably the adhesion promoting layer has electrical characteristics such as dissipation factor, dielectric breakdown strength, water absorption, and dielectric constant that are similar to and / or compatible with the electrical characteristics of the thermosetting composition.

Owner:WORLD PROPERTIES

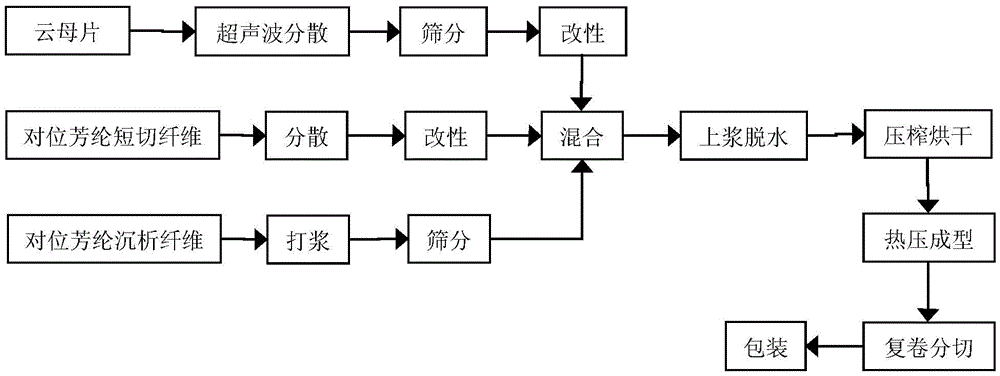

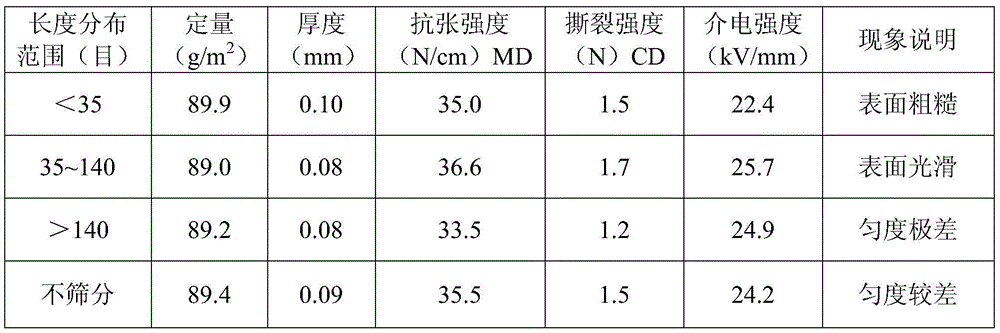

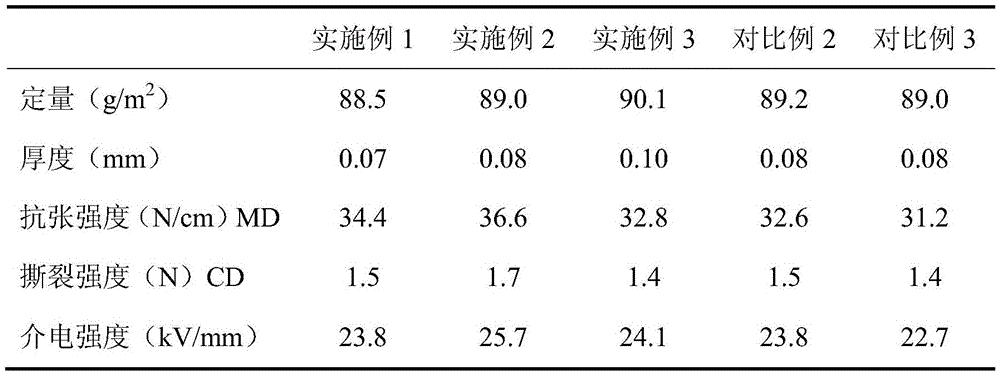

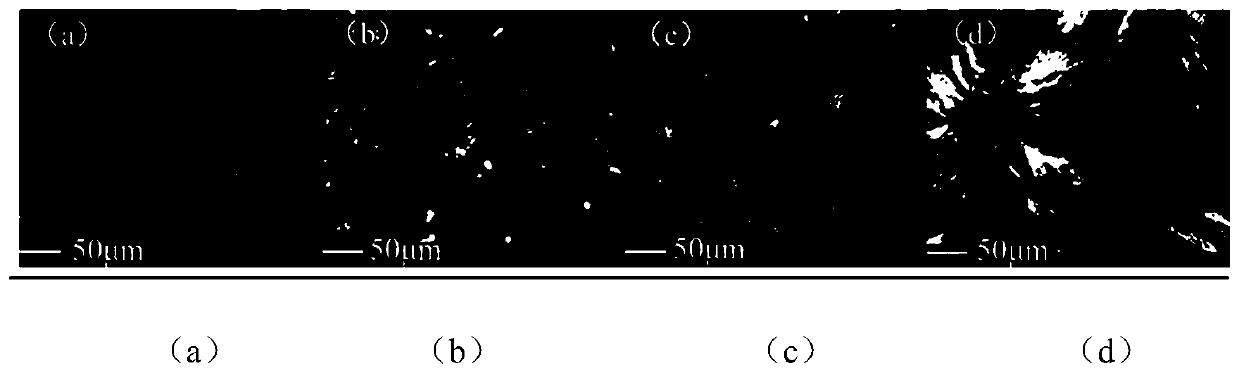

Preparation method of p-aramid fiber-mica paper

ActiveCN105544286AHigh strengthImprove evennessInorganic fibres/flakesPhysical paper treatmentDielectric breakdown strengthSlurry

The invention relates to a preparation method of a p-aramid fiber-mica paper. The preparation method comprises defibering and dispersing silane coupling agent-modified p-aramid chopped fibers to obtain slurry A, carrying out screening on the p-aramid fibrids with a beating degree of 40-65 degrees SR to obtain slurry B, modifying mica plates through an ionic starch solution to obtain modified mica plates, mixing the slurry A, the slurry B and the modified mica plates to obtain uniform mixed slurry, wherein the uniform mixed slurry comprises, by mass, 10-20% of p-aramid chopped fibers, 20-40% of the p-aramid fibrids and 40-70% of the mica plates, carrying out sizing, dehydration and formation on the mixed slurry, carrying out squeezing and drying and carrying out hot press molding to obtain the p-aramid fiber-mica paper. The p-aramid fiber-mica paper obtained through fiber screening and modification, wet method paper making and hot pressing molding has good evenness, excellent mechanical strength, excellent dielectric breakdown strength and high temperature resistance stability.

Owner:YANTAI METASTAR SPECIAL PAPER

Bipolar electrostatic chuck

ActiveUS8238072B2Improve flatnessImprove reliabilitySemiconductor/solid-state device manufacturingElectrostatic holding devicesDielectric breakdown strengthDepth direction

A bipolar electrostatic chuck which has excellent dielectric breakdown strength and provides excellent attracting performance. The bipolar electrostatic chuck eliminates difficulty in dismounting a sample from a sample attracting plane as much as possible after application of a voltage to electrodes is finished. The bipolar electrostatic chuck is provided with a first electrode and a second electrode in an insulator and permits a surface of the insulator to be the sample attracting plane. The insulator has the first electrode, an interelectrode insulating layer and the second electrode in this order from the sample attracting plane in the depth direction. The second electrode has a region not overlapping with the first electrode in a normal line direction of the sample attracting plane.

Owner:CREATIVE TECH CORP

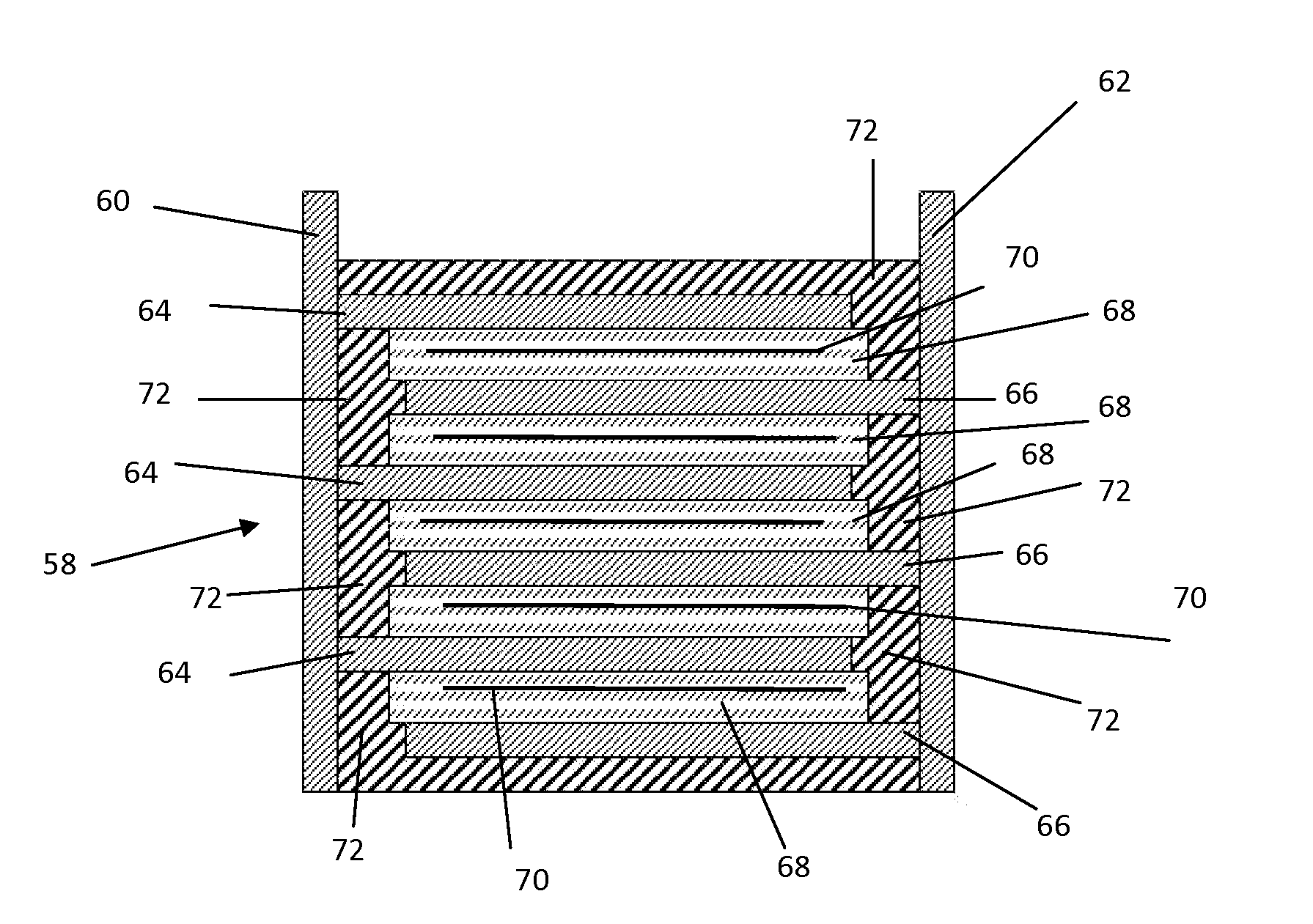

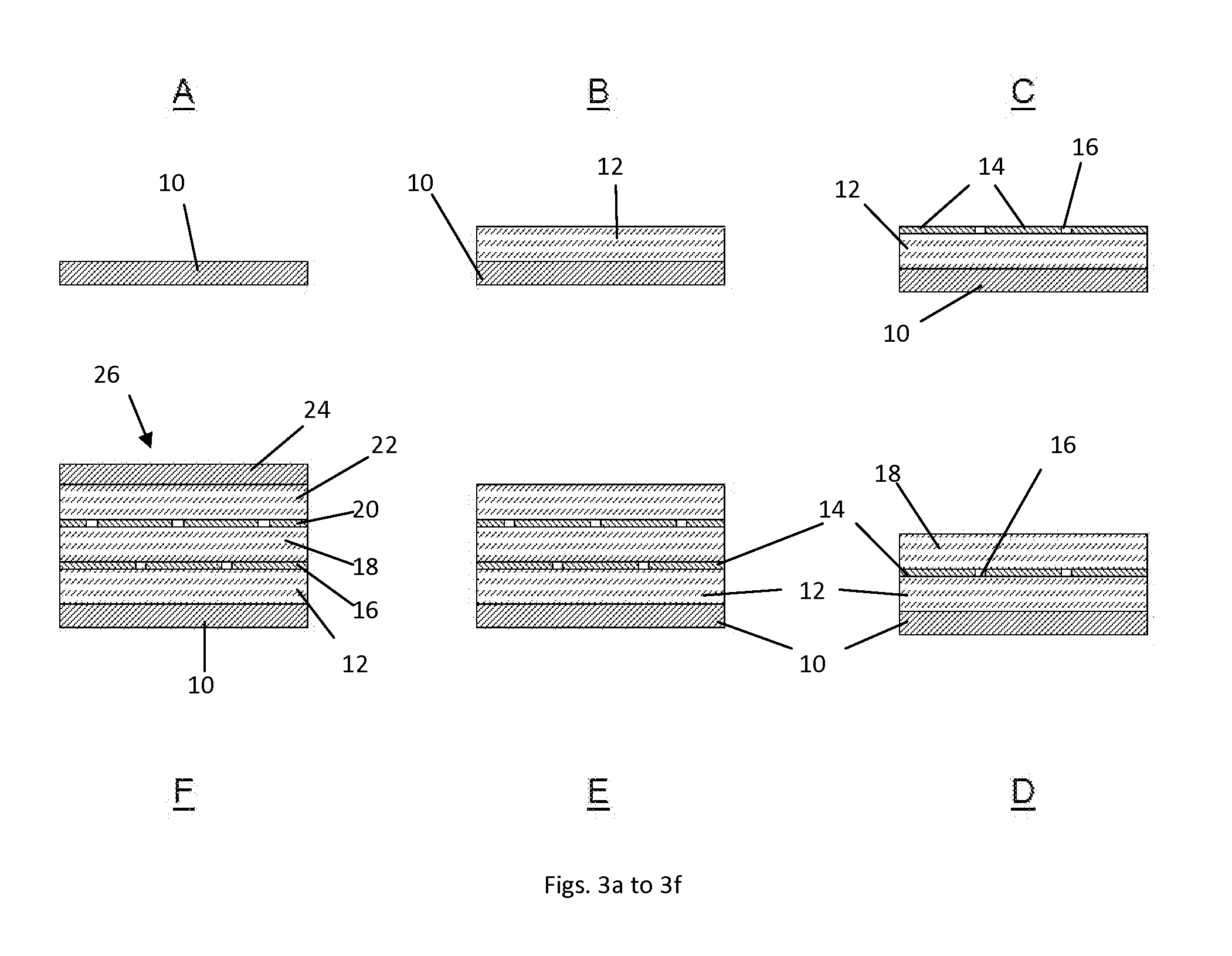

Method of making dielectric capacitors with increased dielectric breakdown strength

ActiveUS20130335882A1Minimize impactBlock and slow down growthFixed capacitor electrodesFixed capacitor dielectricBreakdown strengthMicro fracture

The invention is directed to a process for making a dielectric ceramic film capacitor and the ceramic dielectric laminated capacitor formed therefrom, the dielectric ceramic film capacitors having increased dielectric breakdown strength. The invention increases breakdown strength by embedding a conductive oxide layer between electrode layers within the dielectric layer of the capacitors. The conductive oxide layer redistributes and dissipates charge, thus mitigating charge concentration and micro fractures formed within the dielectric by electric fields.

Owner:UCHICAGO ARGONNE LLC

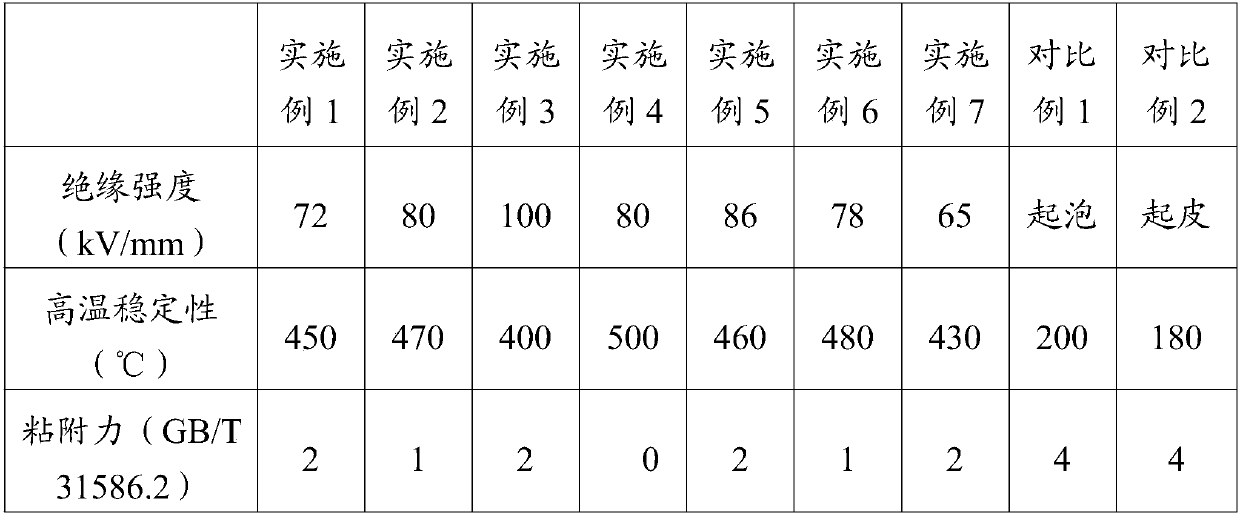

Metal-based ceramic coating and preparation method of same

ActiveCN107747083AHigh purityFine foamLiquid/solution decomposition chemical coatingCeramic coatingPhosphate

The invention provides a metal-based ceramic coating and a preparation method of same. In the method, a dip-coating process is employed, wherein dense-phase ceramic coating having a certain thicknessis produced through the steps of: employing dip-coating process with self-made aluminum dihydrogen phosphate as a binder, a ceramic aggregate as a main base material and a nano-curing agent as an auxiliary base material, wherein the ratios of the components in the slurry are adjusted to reach the optimum ratio in the dip-coating process; and finally performing high-temperature curing treatment. The ceramic coating can reach 100 kV / mm in dielectric breakdown strength, can reach 500 DEG C in maximum available temperature, and can reach 0-grade (GB / T 31586.2) in adhesion force. The metal-based ceramic coating has controllable thickness, is high-temperature-resistant, acid-resistant, corrosion-resistant, wear-resistant and anti-radiation, has high compactness and insulation strength, is toxic-free and zero-pollution, is low in cost and simple in preparation method, and is suitable for large-scale production.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for manufacturing semiconductor integrated circuit device

InactiveUS20050196954A1Improve dielectric breakdown strengthSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDevice material

Provided is a manufacturing method of a semiconductor device which comprises (a) depositing a first insulating film over a wafer, (b) forming an interconnect opening in the first insulating film, (c) forming, in the interconnect opening, an interconnect having a conductor film comprised mainly of copper, (d) forming a taper at a corner of said conductor film on the opening side of the interconnect opening, and (e) depositing a second insulating film over the first insulating film and interconnect. The present invention makes it possible to improve dielectric breakdown strength between interconnects each having a main conductor film comprised mainly of copper.

Owner:RENESAS TECH CORP

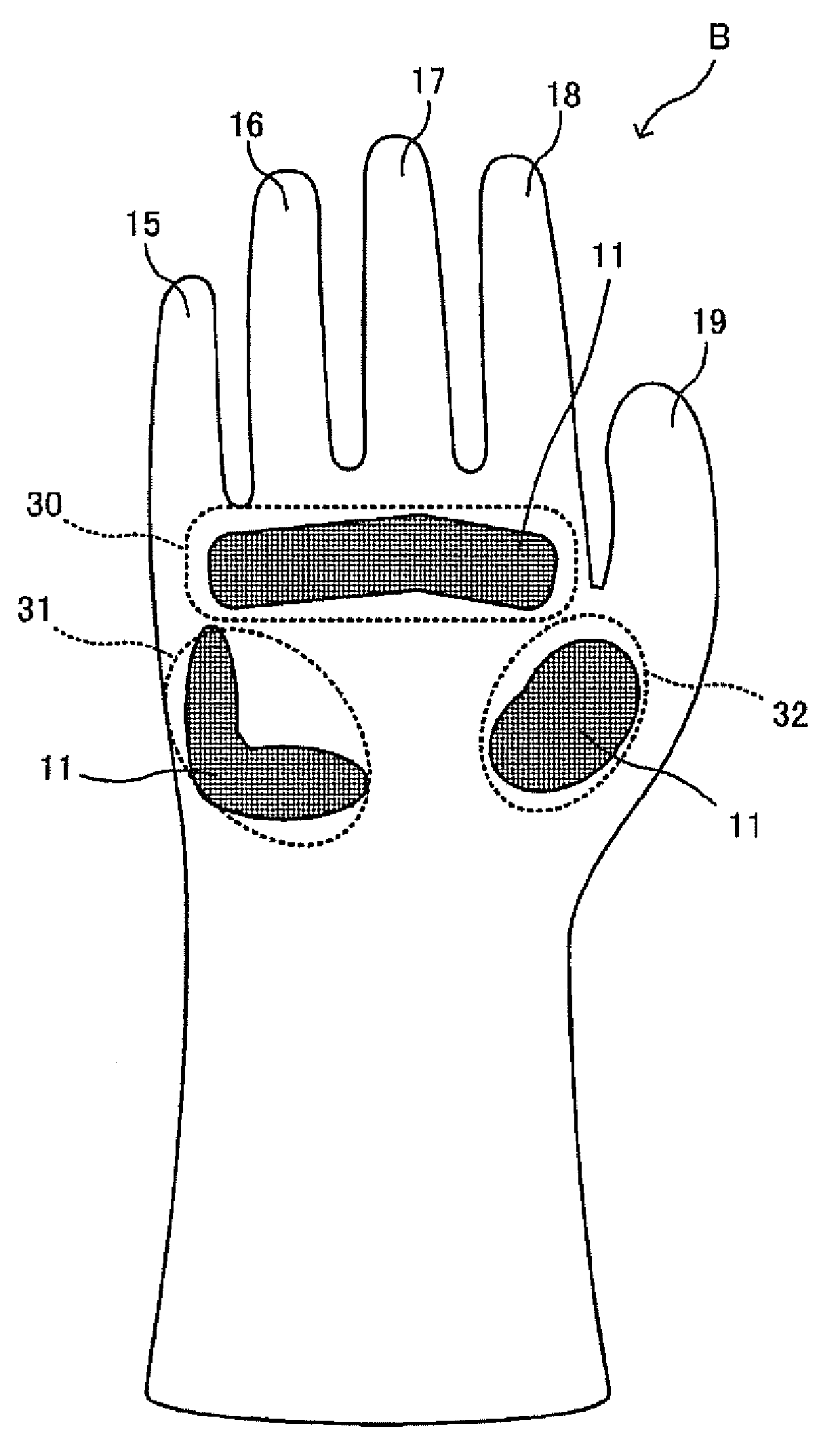

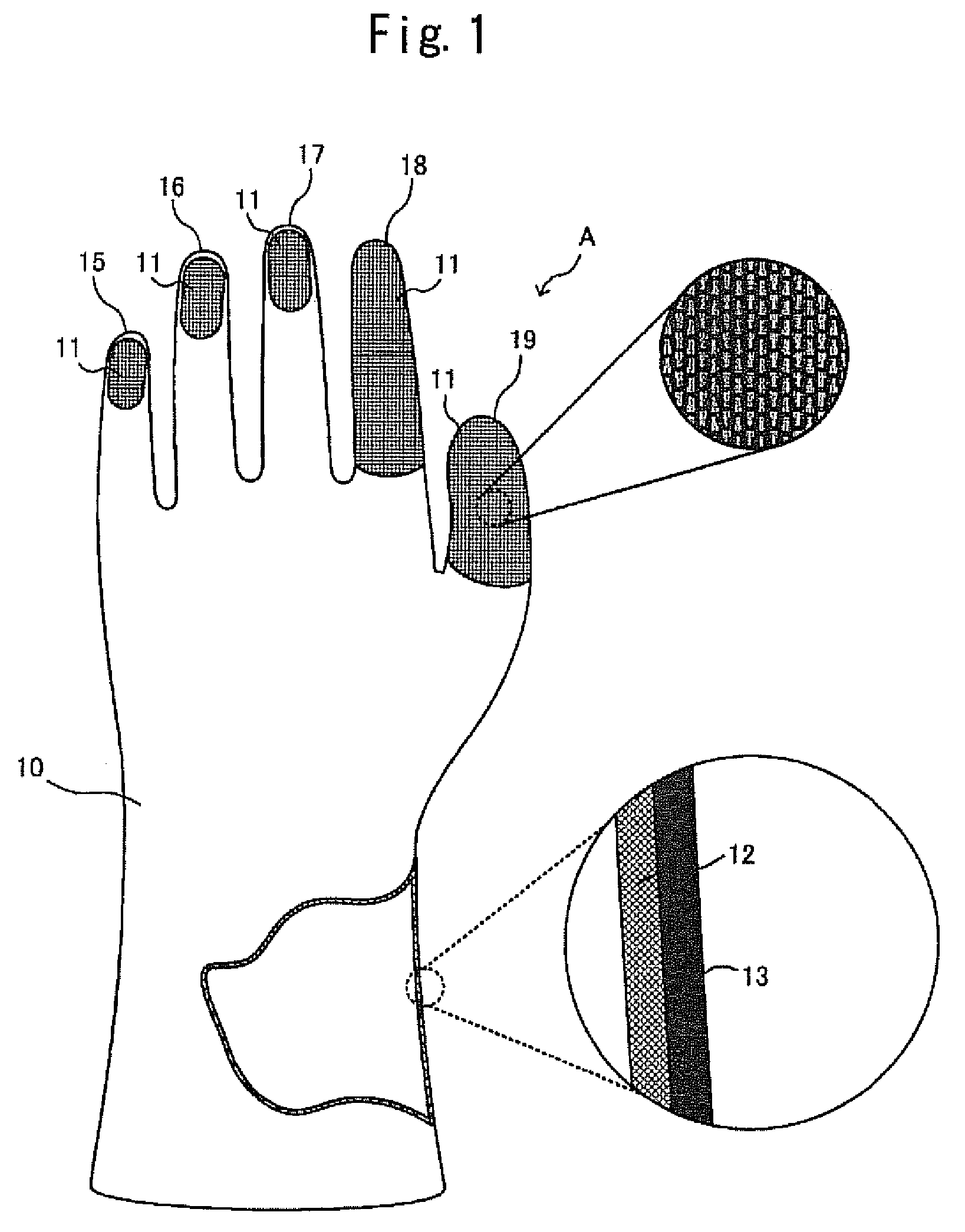

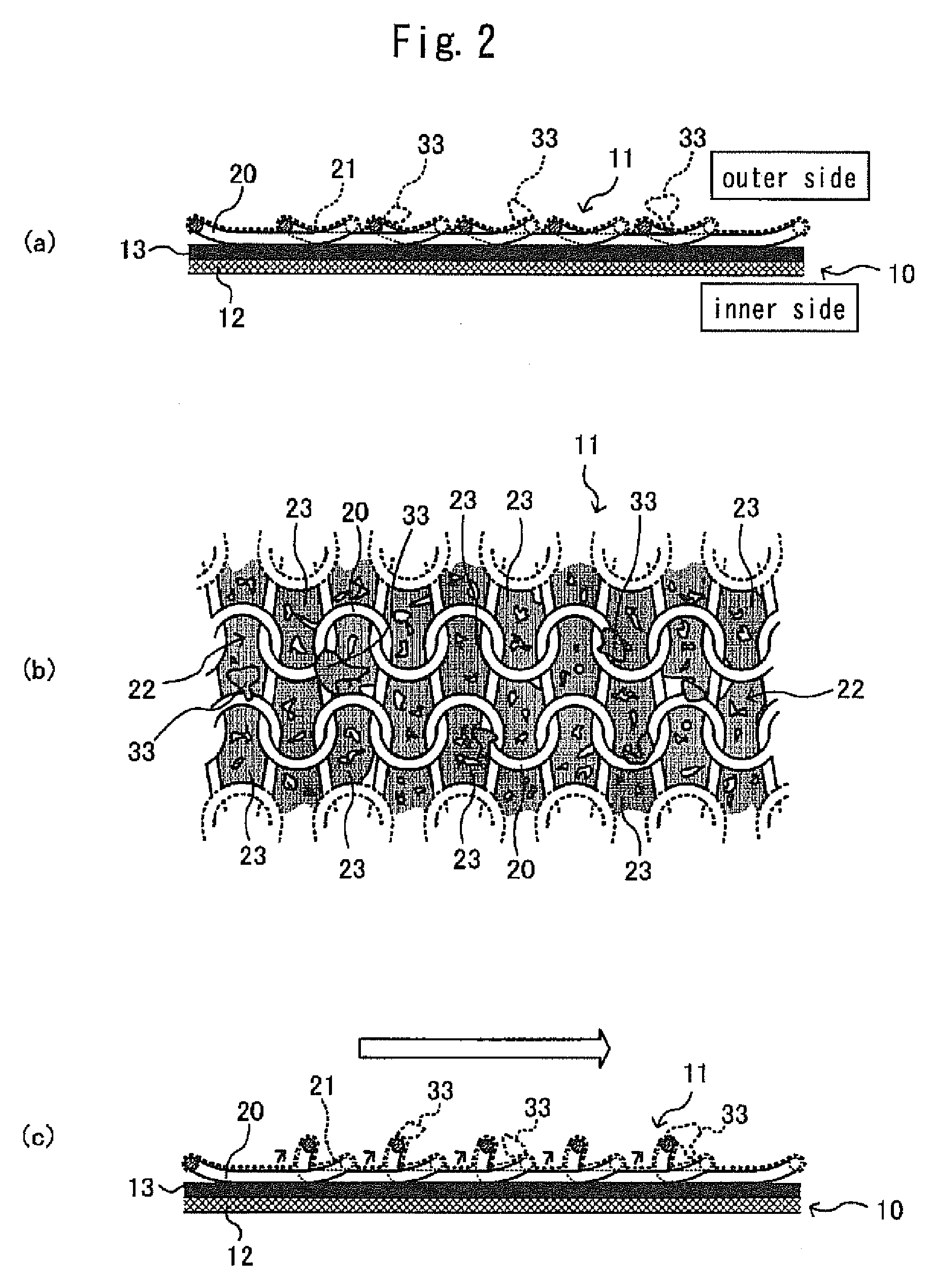

Work glove

InactiveUS8863317B2Increase coefficient of frictionExcellent mounting and dismounting propertyGlovesSport apparatusDielectric breakdown strengthEngineering

Provided is a work glove which has further improved wear resistance and workability while ensuring functions such as dielectric breakdown strength and water proofing. In such a work glove, a fabric material, which is formed of one selected from cloth, knitted fabric and meshed fabric and has a predetermined area, is affixed to an outer surface of a glove base which is made of an elastic material, and a coating film having a higher friction coefficient than the fabric material is formed on a surface of the fabric material.

Owner:TOWA

Copper grid repair technique for lightning strike protection

ActiveUS20100132875A1Low densityImprove dielectric breakdown strengthFuselage bulkheadsAircraft static dischargersElectricityLightning strike

A method for reworking an electrically conductive layer of a composite skin is disclosed in which a patch replaces the altered section of the electrically conductive layer. The method is performed by removing a portion of the electrically conductive layer to reveal the underlying composite skin. A patch is formed, having an electrically conductive section coupled to an adhesive having a low dielectric breakdown strength, and is then introduced over the underlying composite skin such that the adhesive layer covers the underlying composite skin and overlaps an unremoved portion of the electrically conductive layer. The patch is applied such that the electrically conductive section within the patch covers the adhesive layer and overlaps the unremoved section of the electrically conductive layer. The adhesive layer preferably has a low dielectric breakdown strength, so that electricity from lightning which strikes the composite skin may be conducted through the adhesive.

Owner:THE BOEING CO

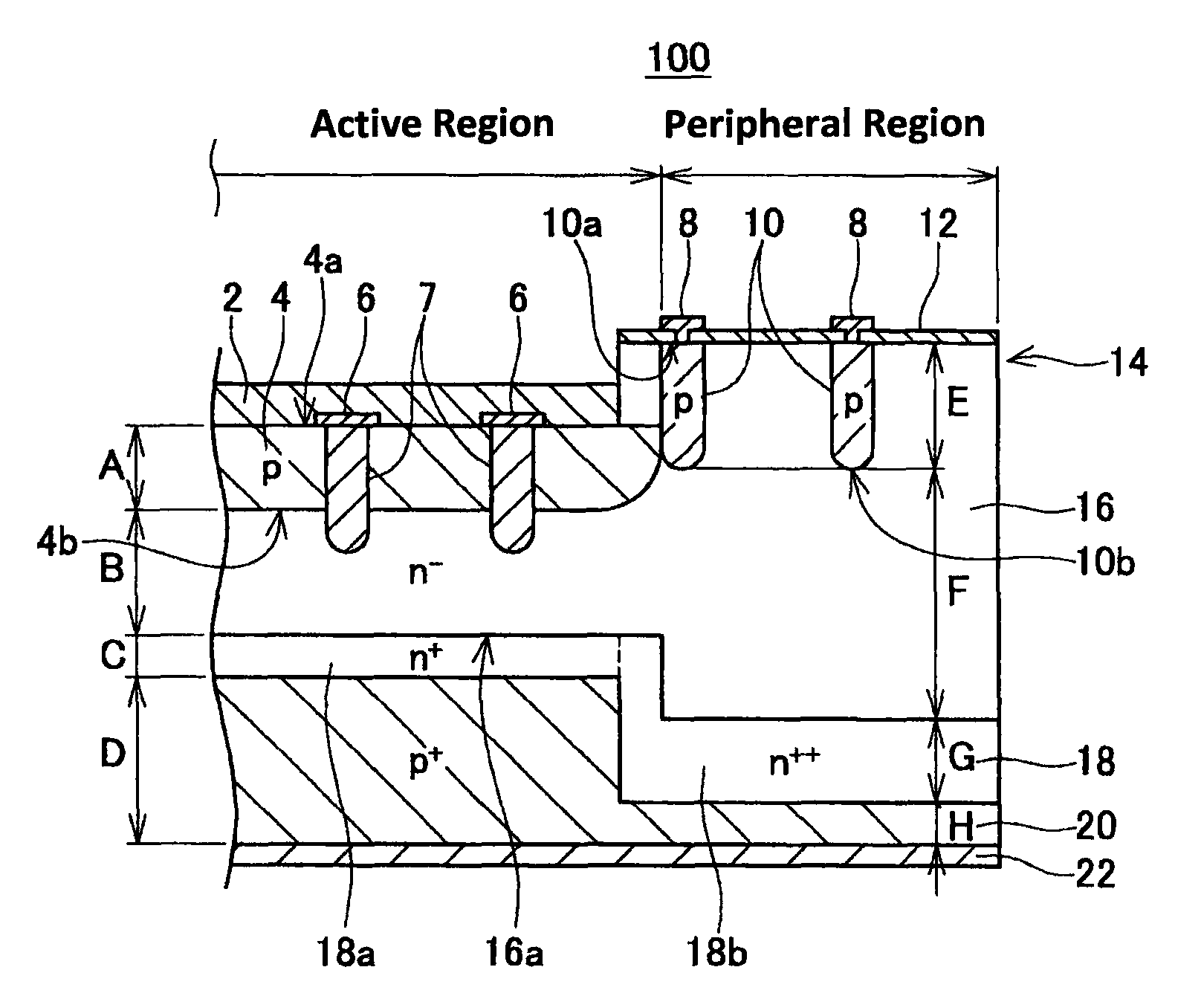

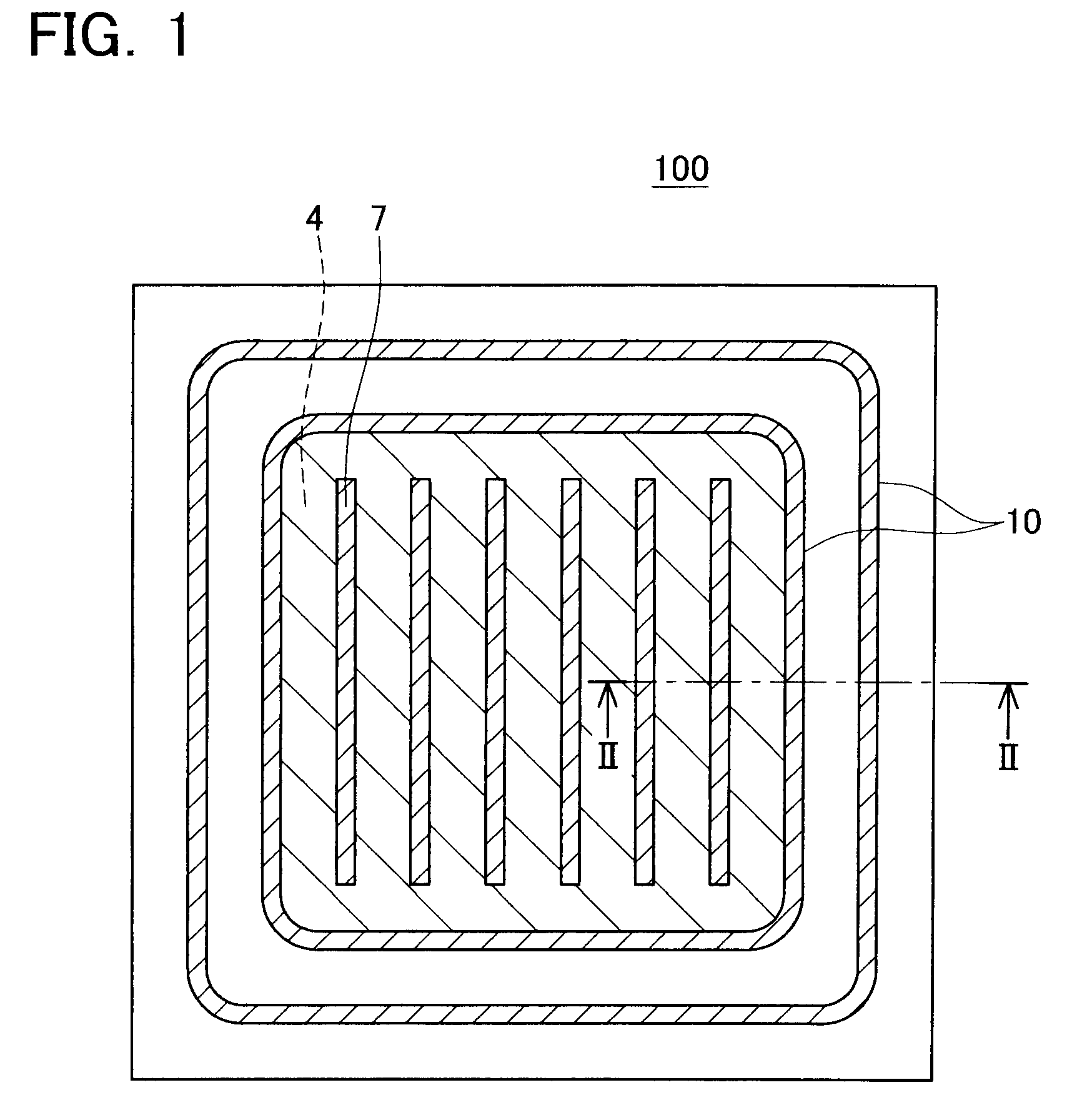

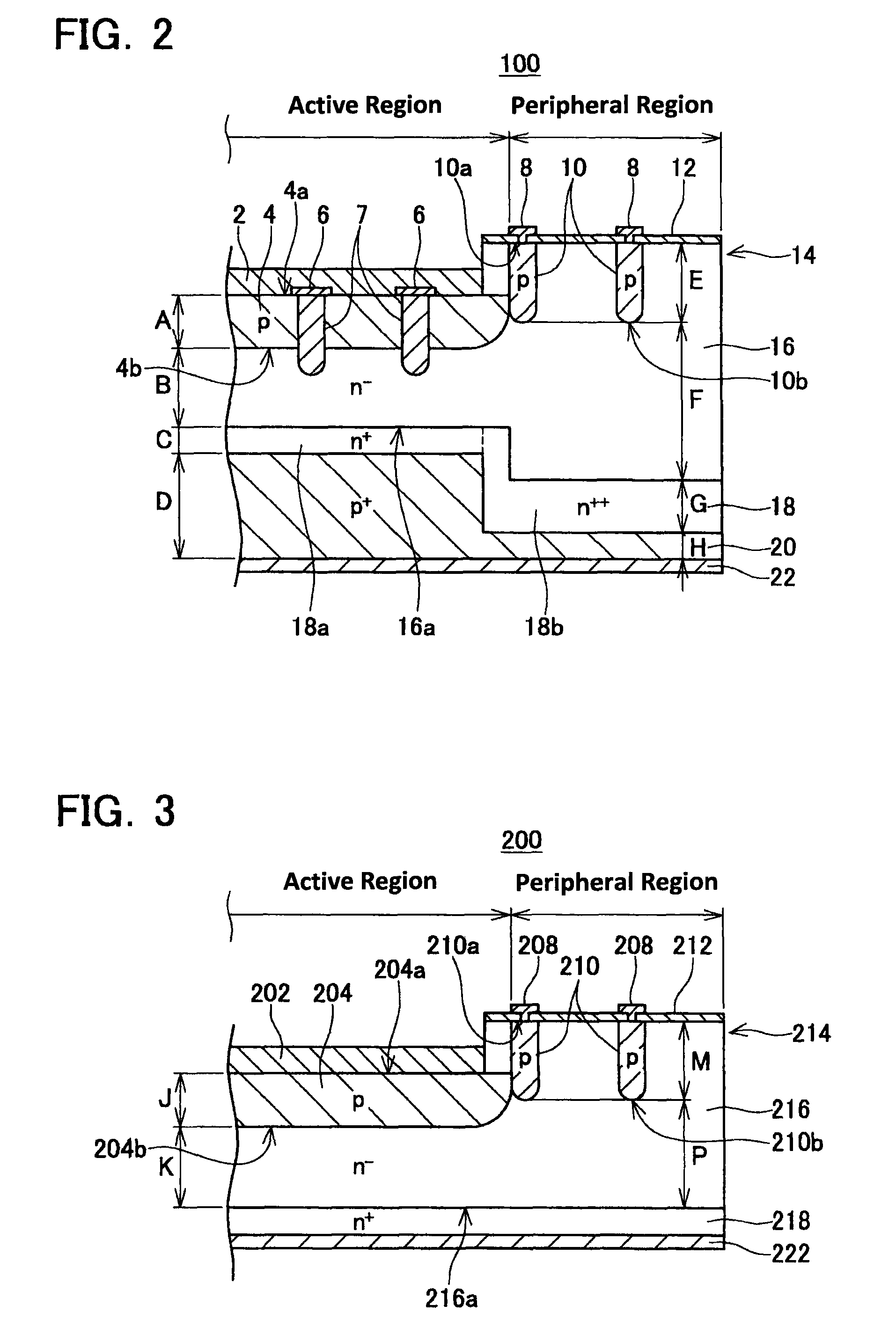

IGBT semiconductor device

ActiveUS7973363B2Increasing the thicknessLow efficiencyThyristorSemiconductor/solid-state device detailsPower semiconductor deviceSurface layer

To provide a semiconductor device in which dielectric breakdown strength in a peripheral region is increased without increasing on-resistance. An IGBT comprises a body region, guard ring, and collector layer. The body region is formed within an active region in a surface layer of a drift layer. The guard ring is formed within a peripheral region in the surface layer of the drift layer, and surrounds the body region. The collector layer is formed at a back surface side of the drift layer, and is formed across the active region and the peripheral region. A distance F between a back surface of the guard ring and the back surface of the drift layer is greater than a distance between a back surface of the body region and the back surface of the drift layer. A thickness H of the collector layer in the peripheral region is smaller than a thickness D of the collector layer in the active region.

Owner:DENSO CORP

Method for manufacturing copper-chromium alloy through laser additive manufacturing technology

InactiveCN107931607AImprove performancePrecision manufacturingAdditive manufacturing apparatusIncreasing energy efficiencyMetallic materialsDielectric breakdown strength

The invention provides a method for manufacturing a copper-chromium alloy through a laser additive manufacturing technology, and belongs to the field of metal materials. Comprehensive performance of aCu-Cr contact material is hopefully comprehensively improved through microstructure refinement and super-refinement of the Cu-Cr contact material, insulating strength of a vacuum arc extinguish chamber is improved, and particularly, dielectric breakdown strength and electric erosive resistance of the alloy are improved and a chopping current value of the alloy is decreased through refinement of Cr phases; and refinement of the Cr phases and uniform dispersed distribution of Cr in cooper are hard to achieve through traditional preparation technologies like fusion casting and a powder metallurgy method. According to the method, an entire block of Cu-Cr alloy material is prepared through the laser additive manufacturing technology, the Cr phases can be refined, comprehensive performance of the alloy is improved, parts of arbitrary complex shapes can be manufactured quickly and precisely, free manufacturing of the parts is achieved, the forming problem of a number of parts of complex shapes is solved, processing procedures are greatly decreased, and the processing cycle is shortened.

Owner:UNIV OF SCI & TECH BEIJING

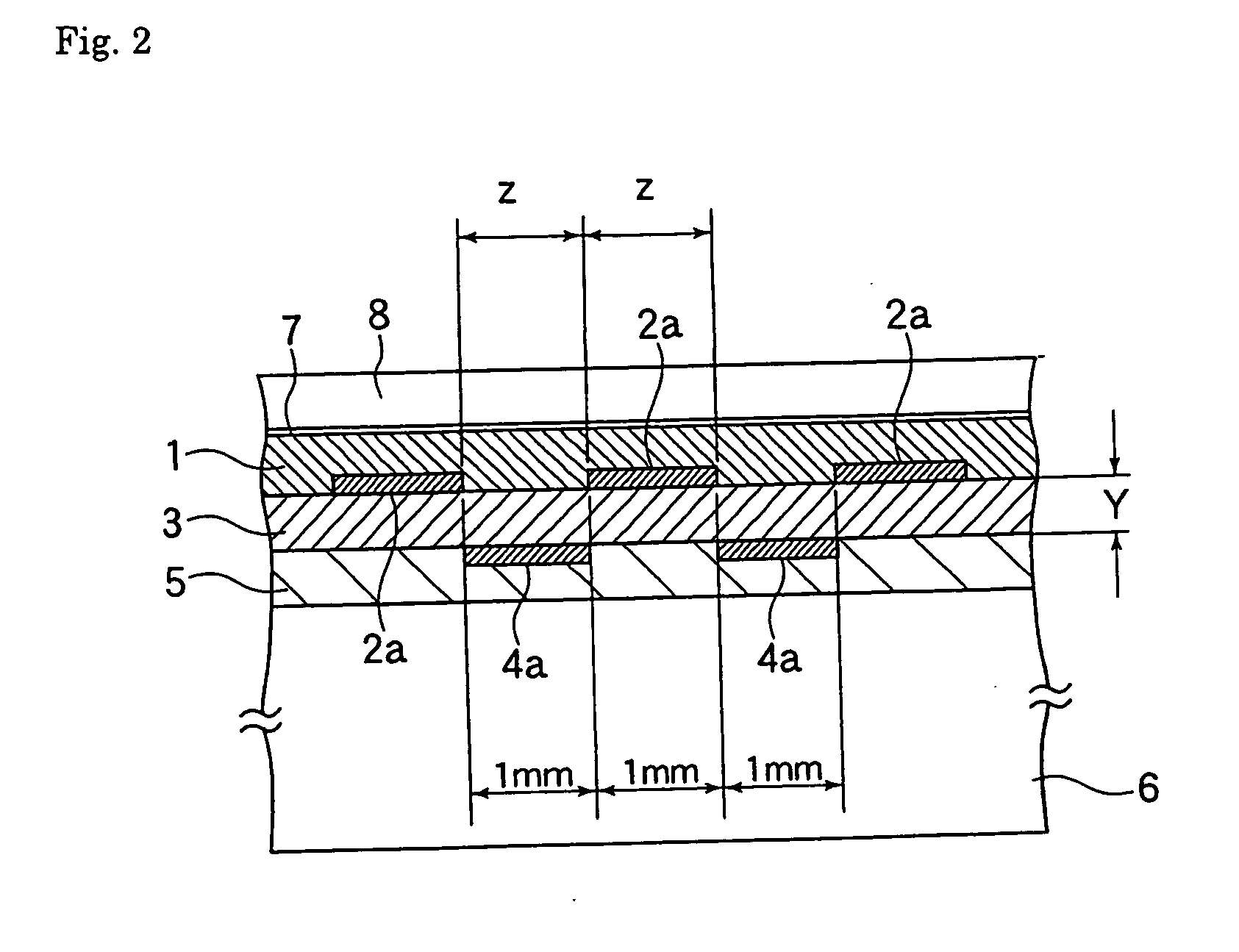

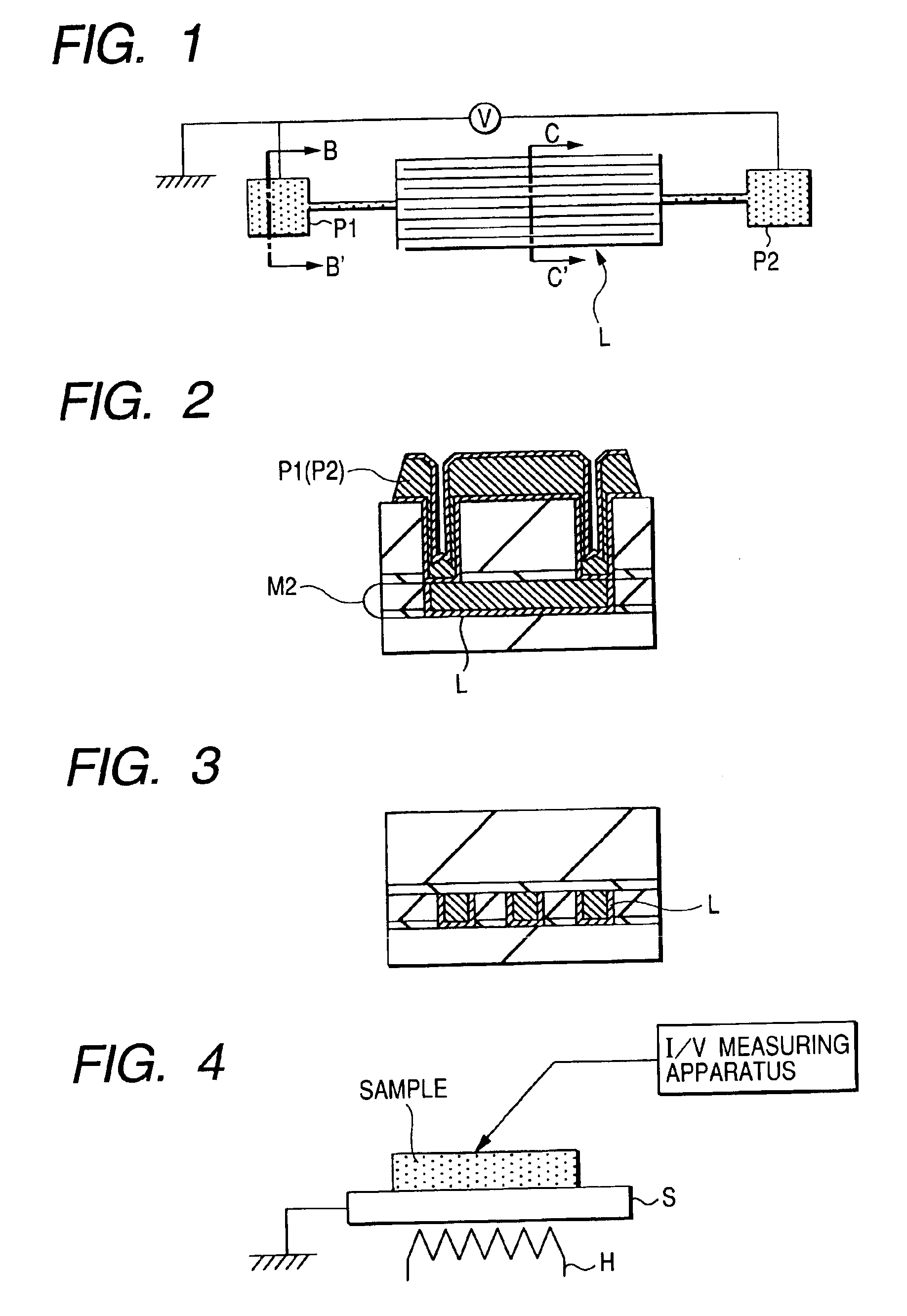

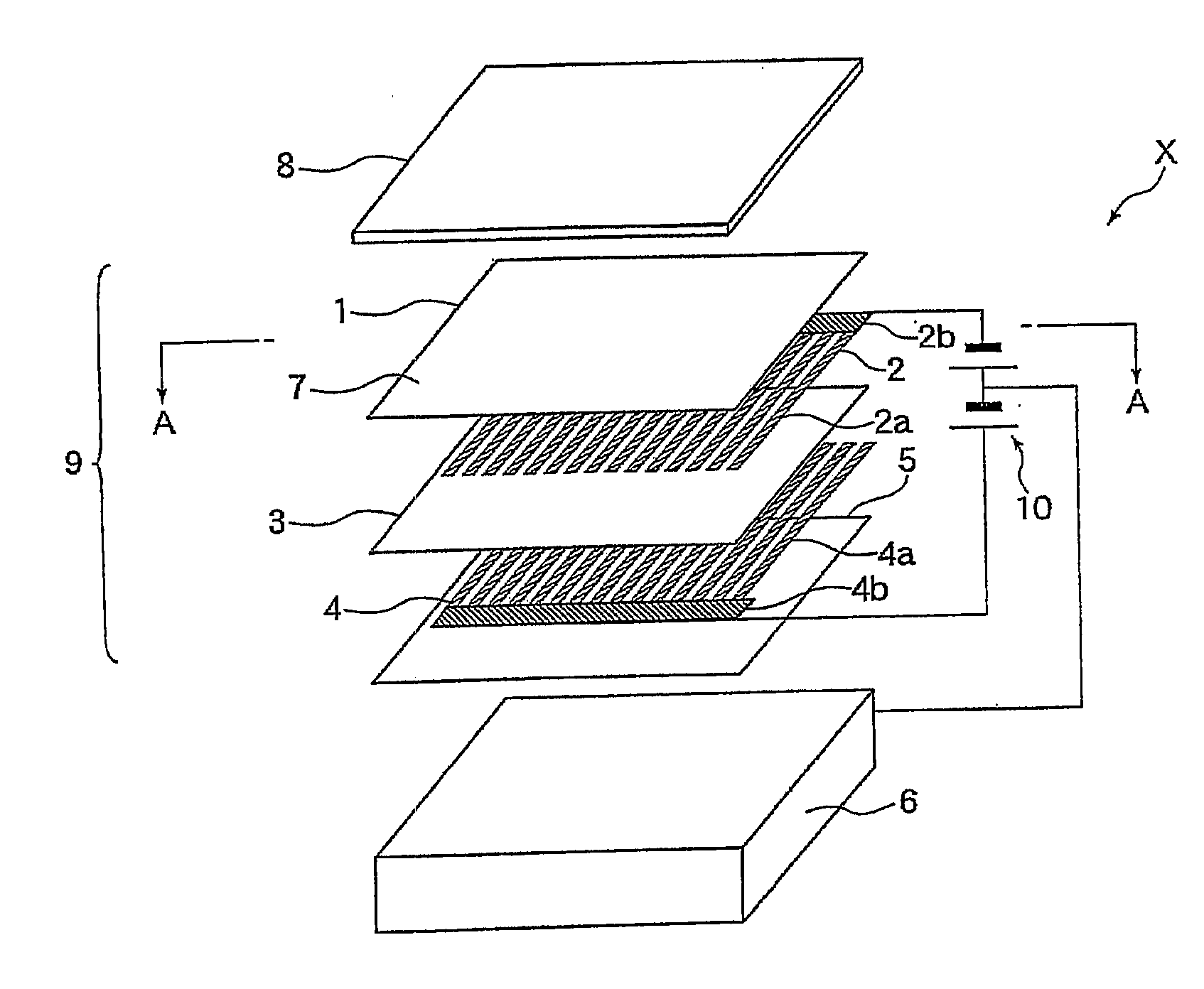

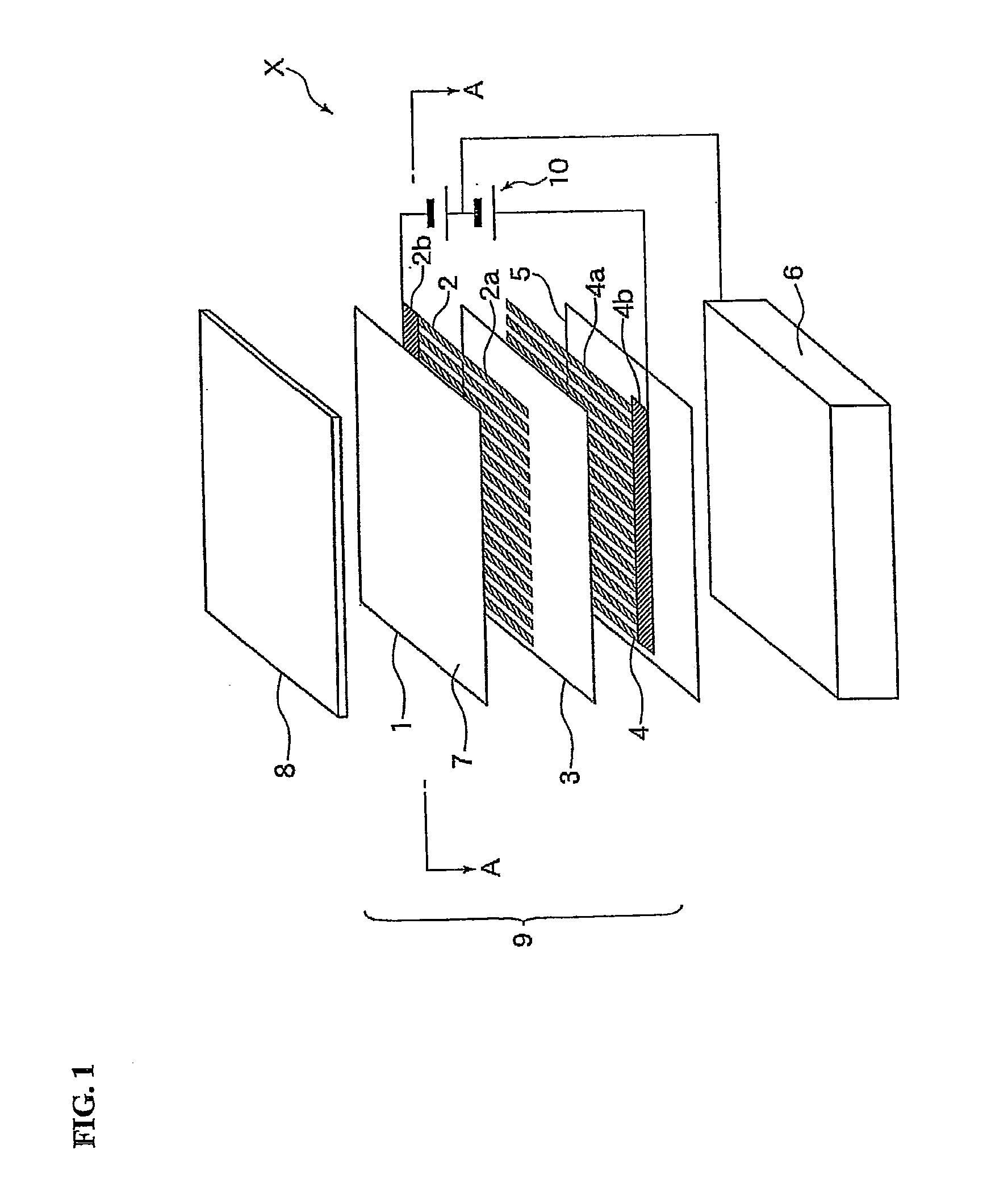

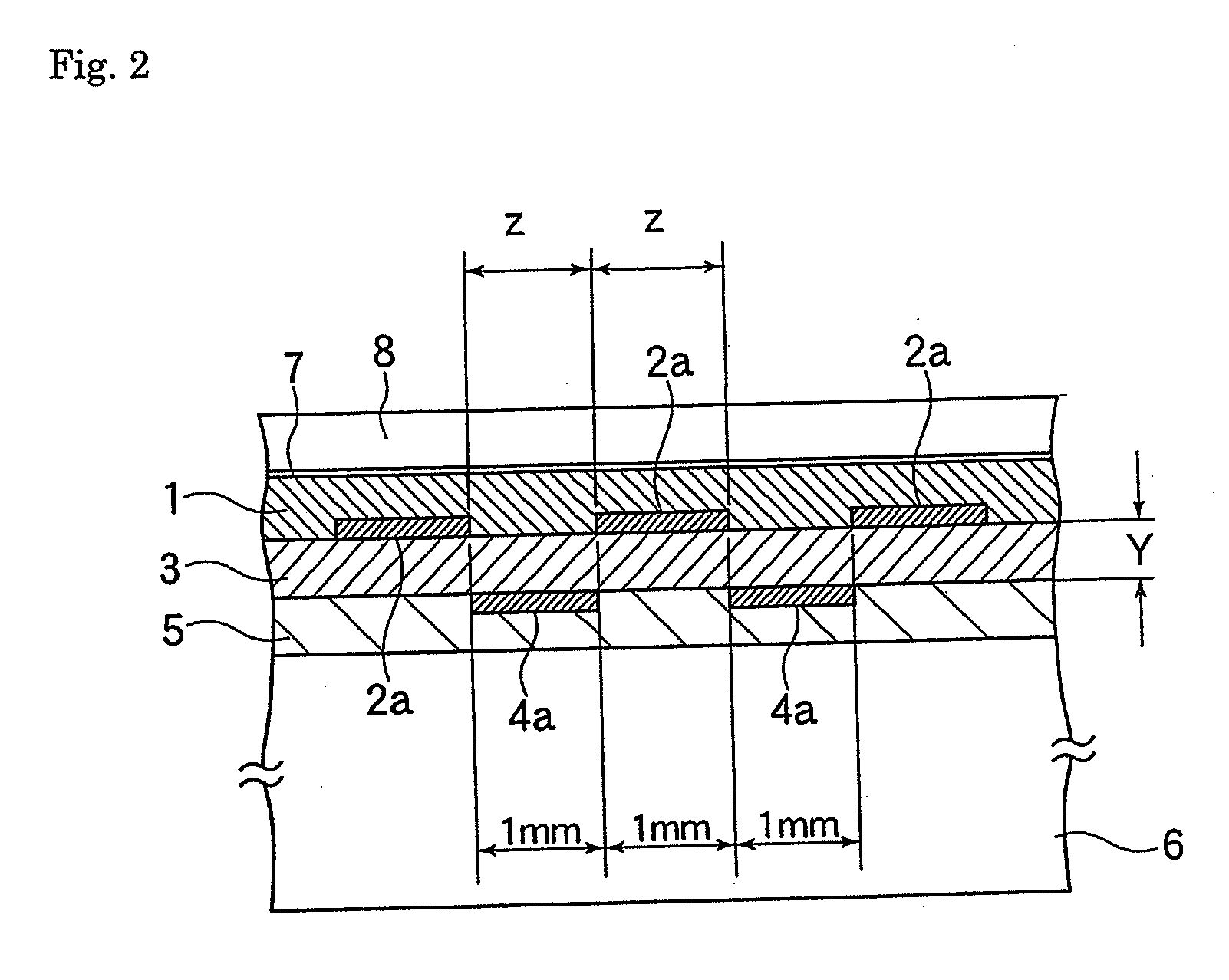

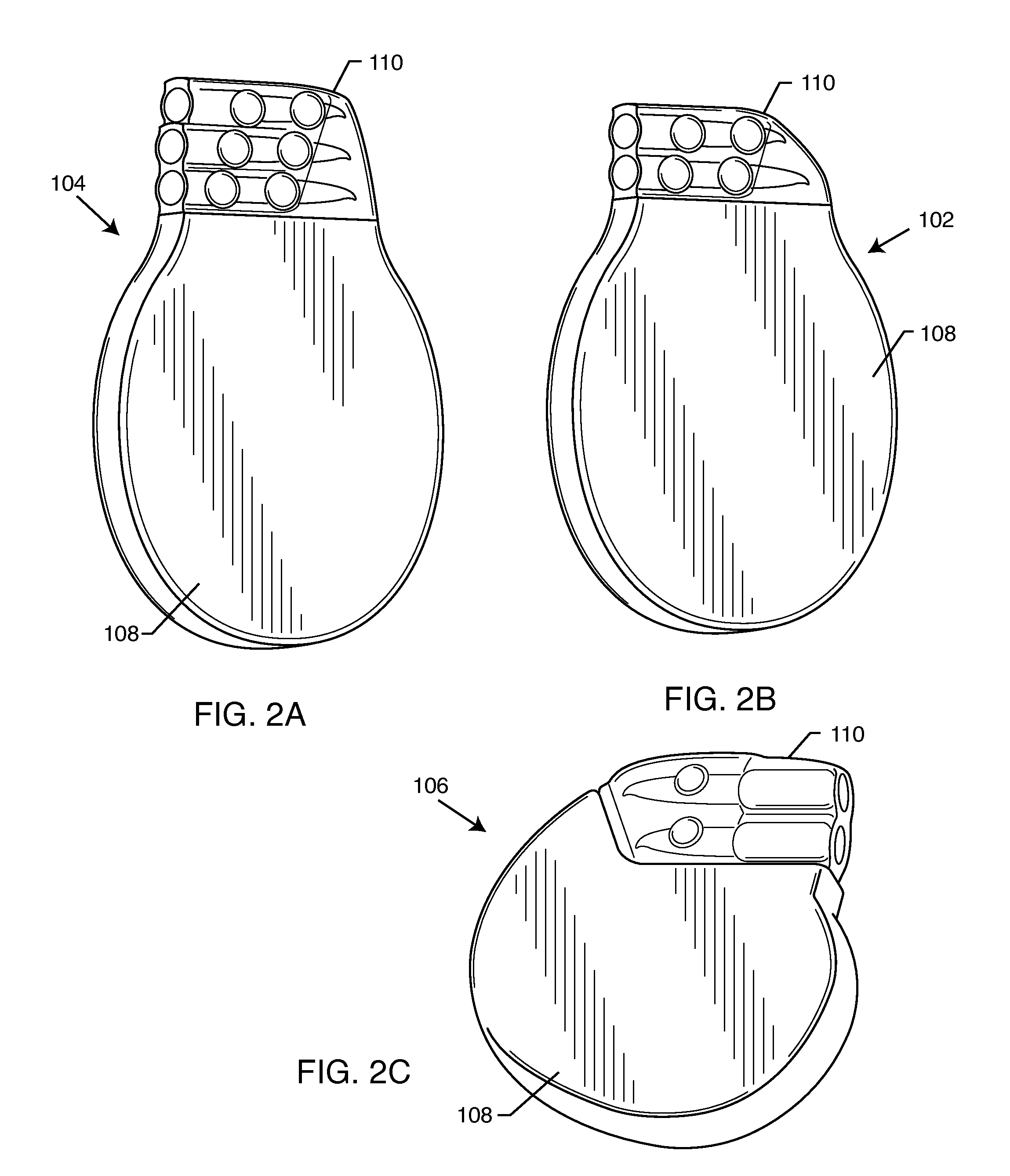

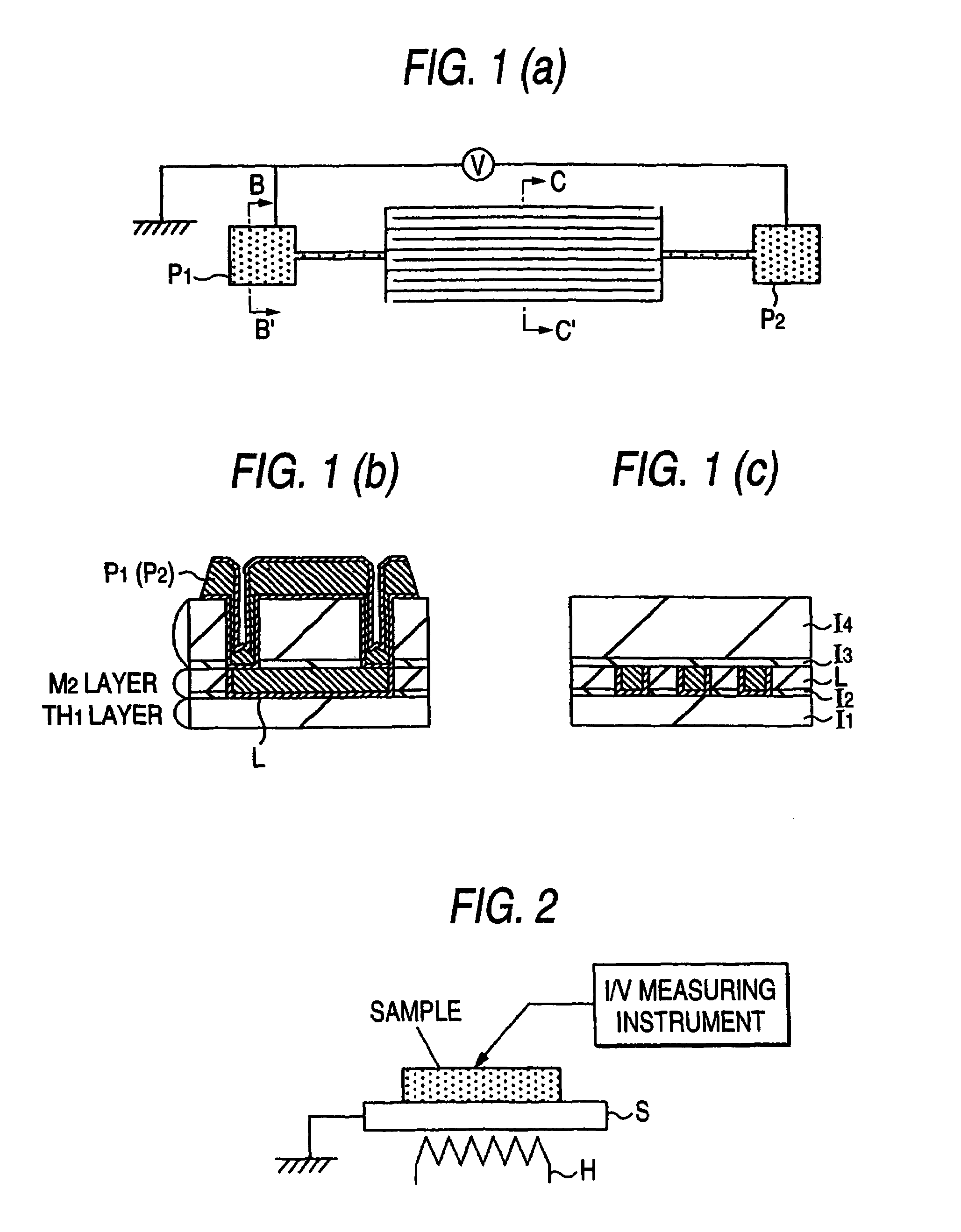

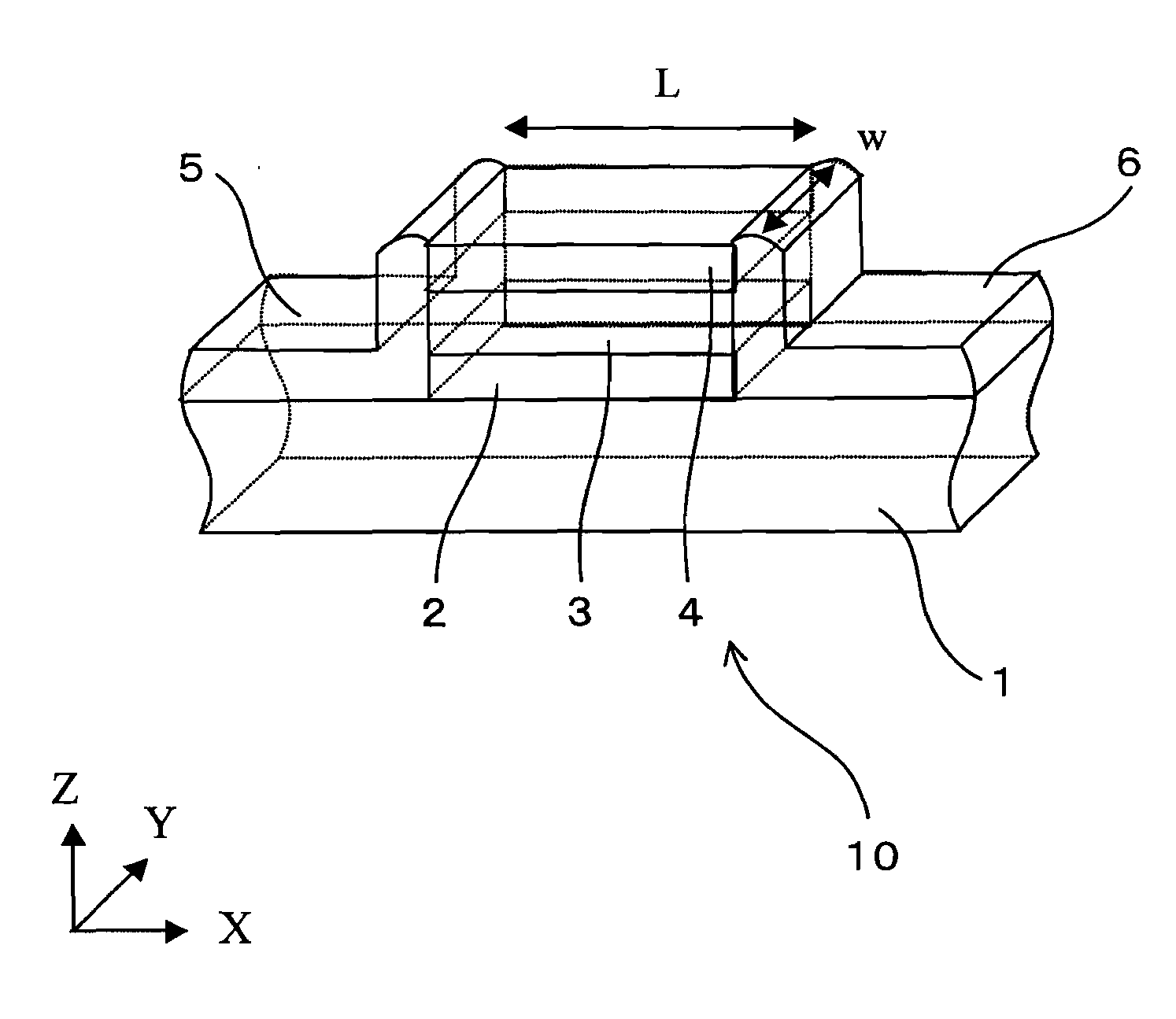

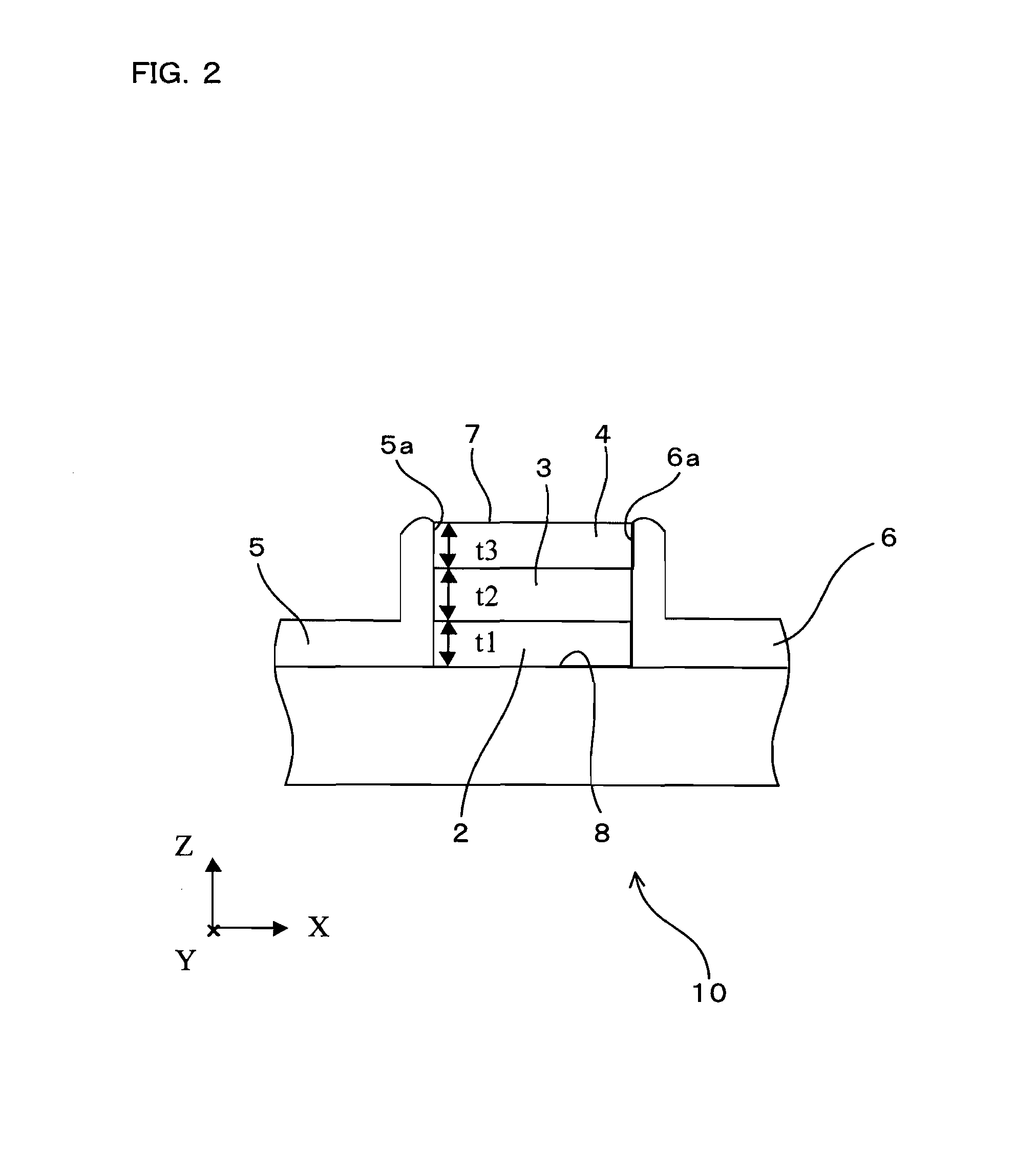

Electromagnetic field detecting element and device using same

InactiveUS20090296258A1Improve dielectric breakdown strengthEfficient detectionNanomagnetismMagnetic measurementsInsulation layerRoom temperature

An electromagnetic field detecting element 10 includes a lamination of three insulation layers 2, 3, and 4. The dielectric breakdown strength of the insulation layer 3 is greater than the dielectric breakdown strengths of insulation layers 2 and 4. The three insulation layers 2, 3, and 4 are disposed between a pair of electrodes 5 and 6. Boundaries 7 and 8 on both ends of an overlapping region of the opposing surfaces 5a and 6a in a Z direction are apart from the insulation layer 3 by thicknesses t1 and t3 of the insulation layers 2 and 4, respectively. Between the pair of electrodes 5 and 6, ballistic current paths interposing therebetween the insulation layer 3 are formed by applying, between the pair of electrodes 5 and 6, an electric field having a magnitude which causes dielectric breakdown in the insulation layers 2 and 4 while causing no dielectric breakdown in the insulation layer 3. Thus, it is possible to perform at a room temperature a highly efficient electromagnetic field detection utilizing AB effect or AC effect.

Owner:SHARP KK

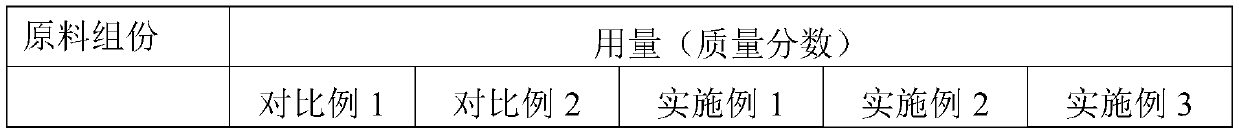

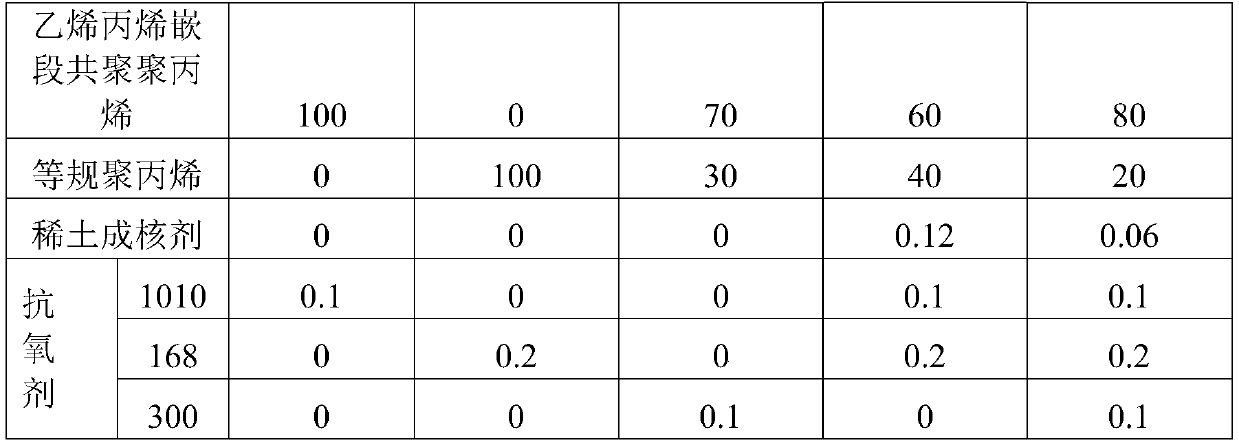

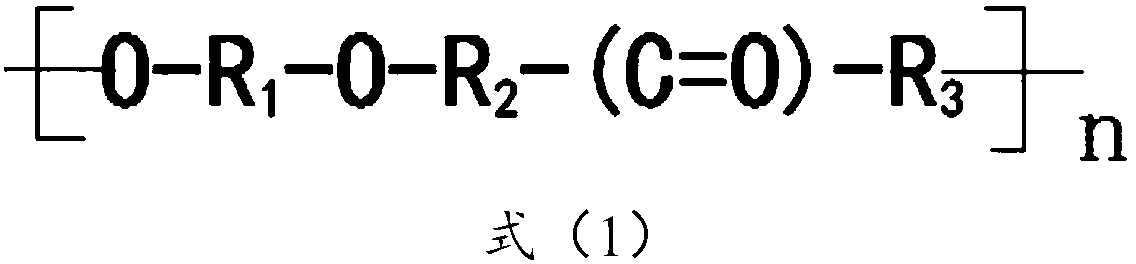

Polypropylene-based high-voltage direct-current cable material and preparation method thereof

ActiveCN110498997AImprove mechanical propertiesLess than obvious accumulationPlastic/resin/waxes insulatorsAntioxidantHigh-voltage direct current

The invention relates to a polypropylene-based high-voltage direct-current cable material and a preparation method thereof. The polypropylene-based high-voltage direct-current cable material comprisesthe following components in parts by mass: 10-50 parts of beta nucleating agent-containing isotactic polypropylene, 50-90 parts of ethylene propylene block co-polypropylene and 0.1-0.5 part of an antioxidant, wherein the sum of the mass parts of the beta nucleating agent-containing isotactic polypropylene and the ethylene propylene block co-polypropylene is 100 parts, and the mass percentage of the beta nucleating agent in the beta nucleating agent-containing isotactic polypropylene is 0.3-1%. According to the invention, the method of adding the beta nucleating agent and the isotactic polypropylene for carrying out mixing with the block polypropylene to prepare the beta crystal-containing blended polypropylene material, and the problems of large brittleness and poor low-temperature impactof isotactic polypropylene, and low dielectric breakdown strength of ethylene propylene block co-polypropylene (EPC) are solved by blending of the EPC and the beta nucleating agent-containing isotactic polypropylene (beta-iPP). The invention provides the polypropylene-based direct-current high-voltage cable material which is green and recyclable, has excellent mechanical and electrical properties, and can replace cross-linked polyethylene (XLPE).

Owner:XI AN JIAOTONG UNIV

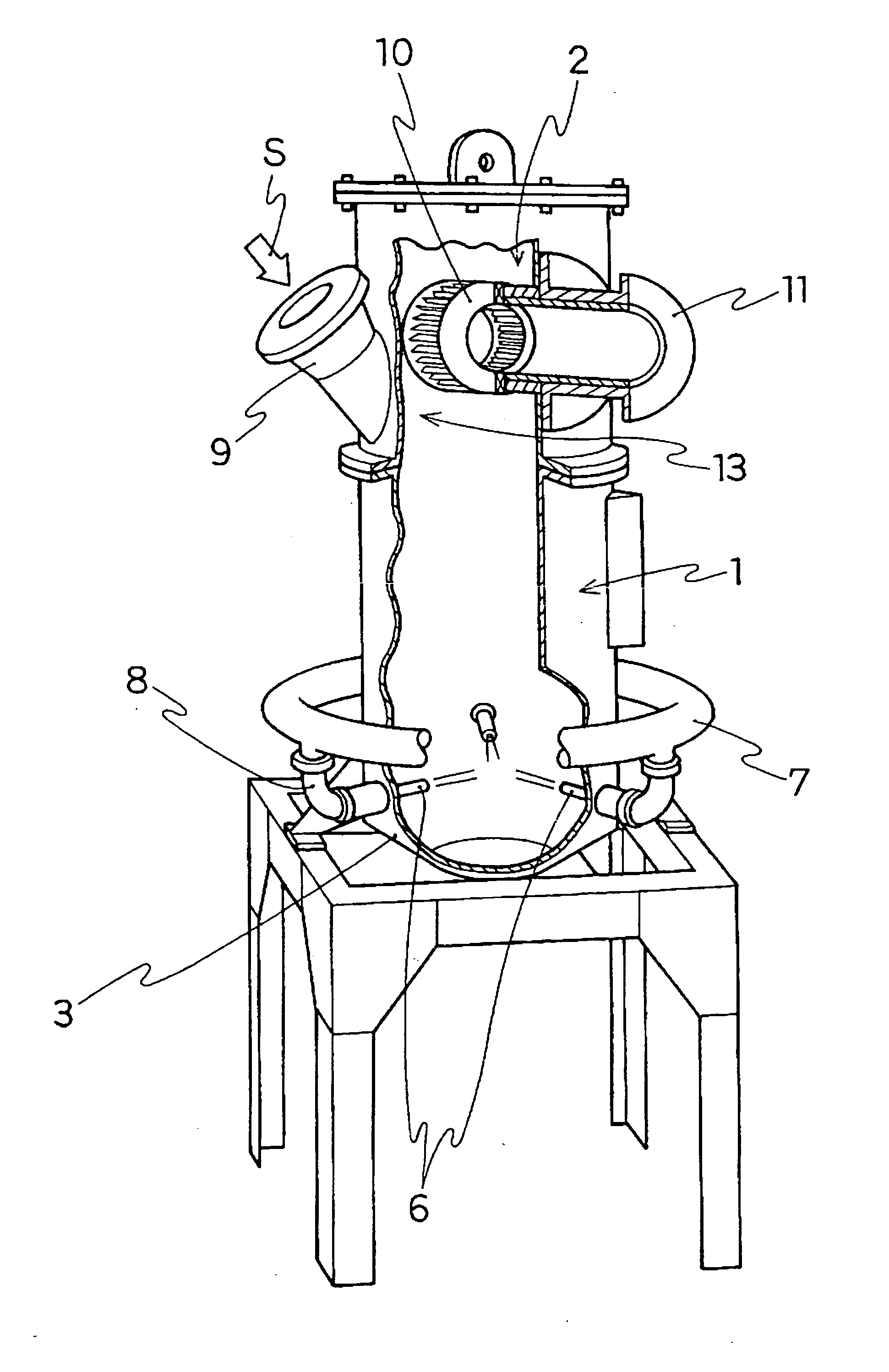

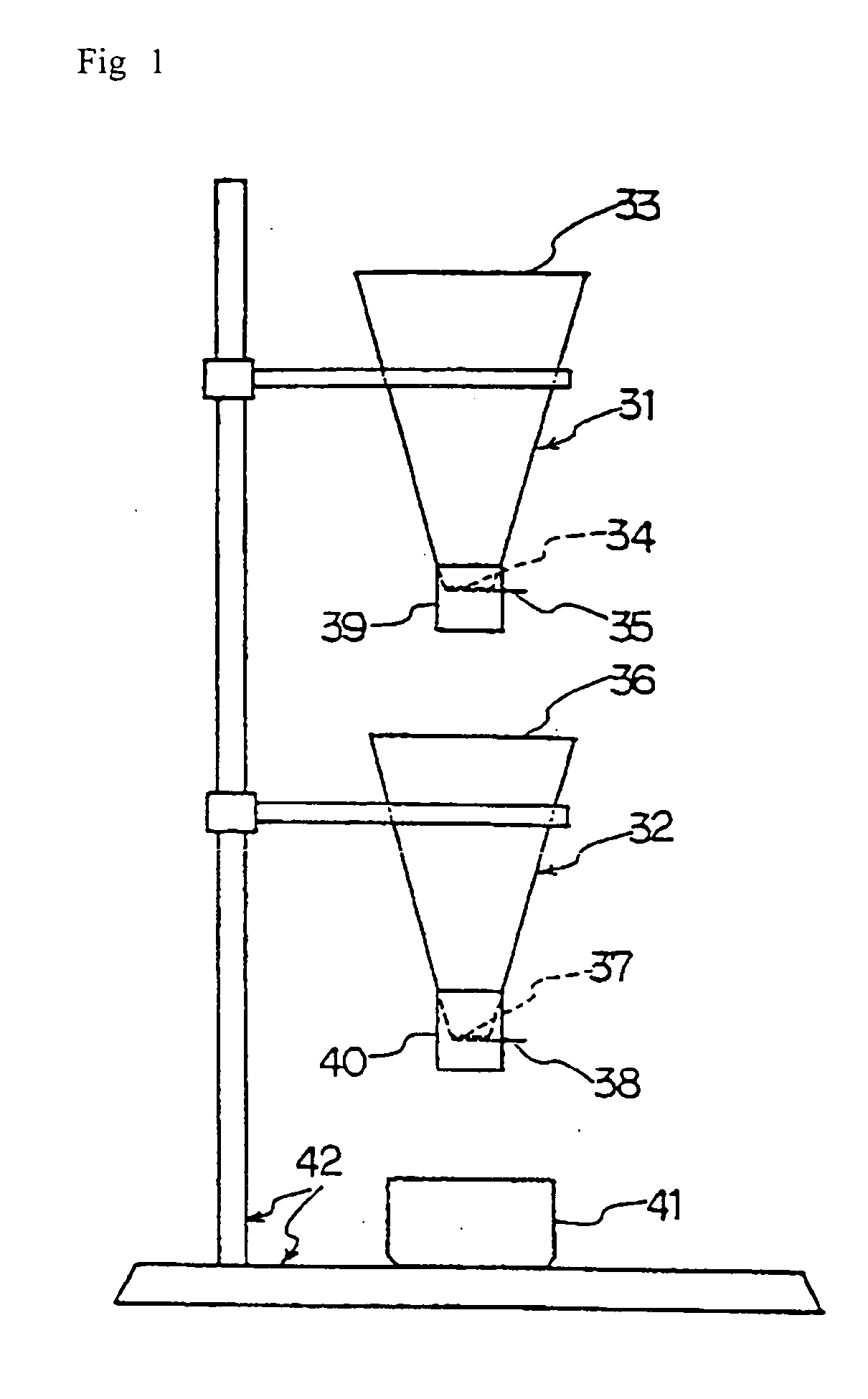

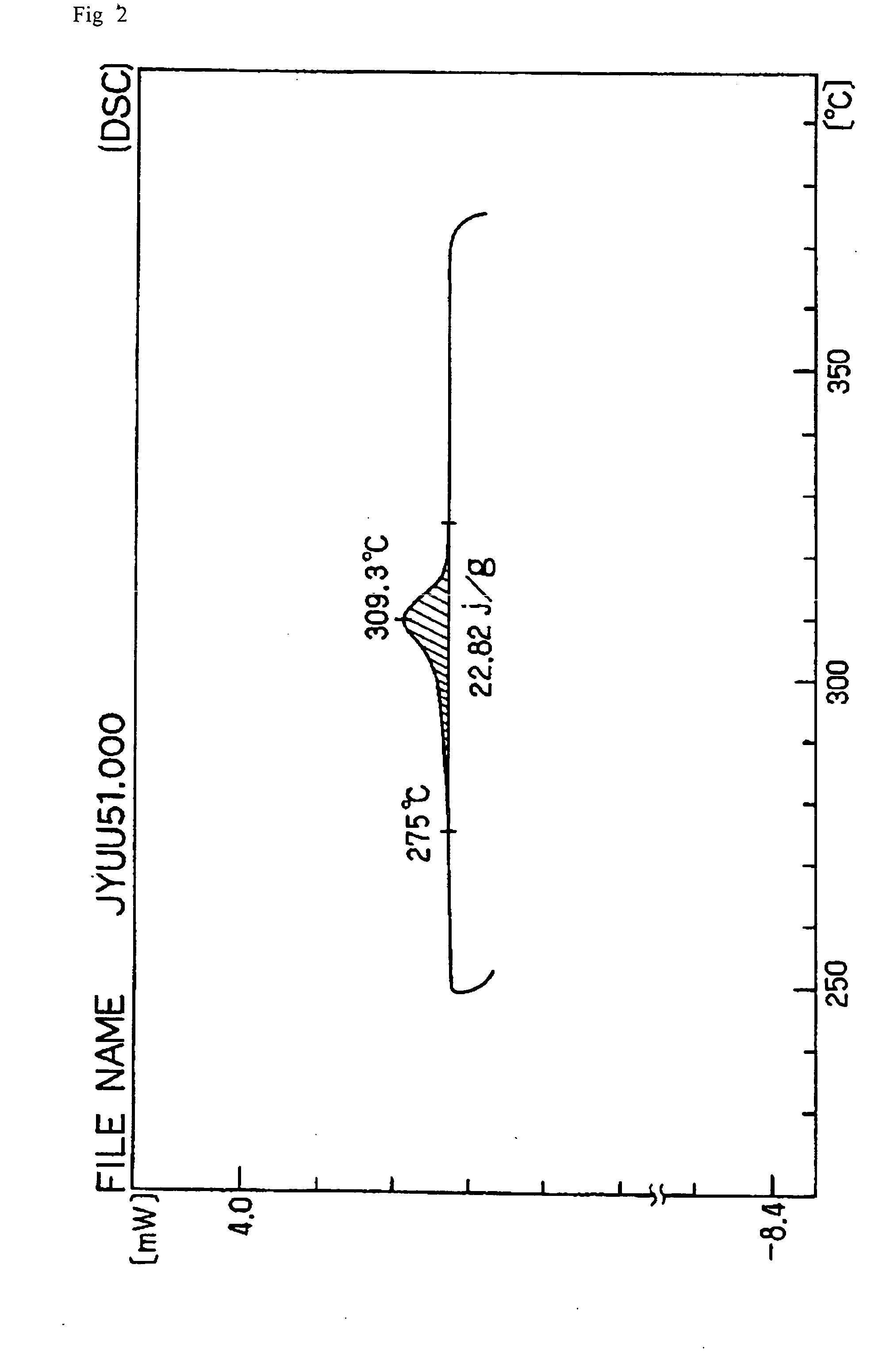

Ptfe powder and method of producing ptfe powder for molding

InactiveUS20050010007A1Improve surface roughnessSuppresses reduction in tensile elongationThin material handlingApparent densityShell molding

This invention provides a polytetrafluoroethylene powder capable of giving moldings which are improved in surface roughness Ra, tensile strength and / or tensile elongation as compared with the prior art ones and can be excellent in dielectric breakdown strength and, further, can be excellent, if desired, in apparent density and / or powder flowability as well, and a method of producing a polytetrafluoroethylene molding powder. The present invention is a PTFE powder wherein a surface roughness Ra of molded articles a1 for measurement is less than 0.92 μm.

Owner:DAIKIN IND LTD

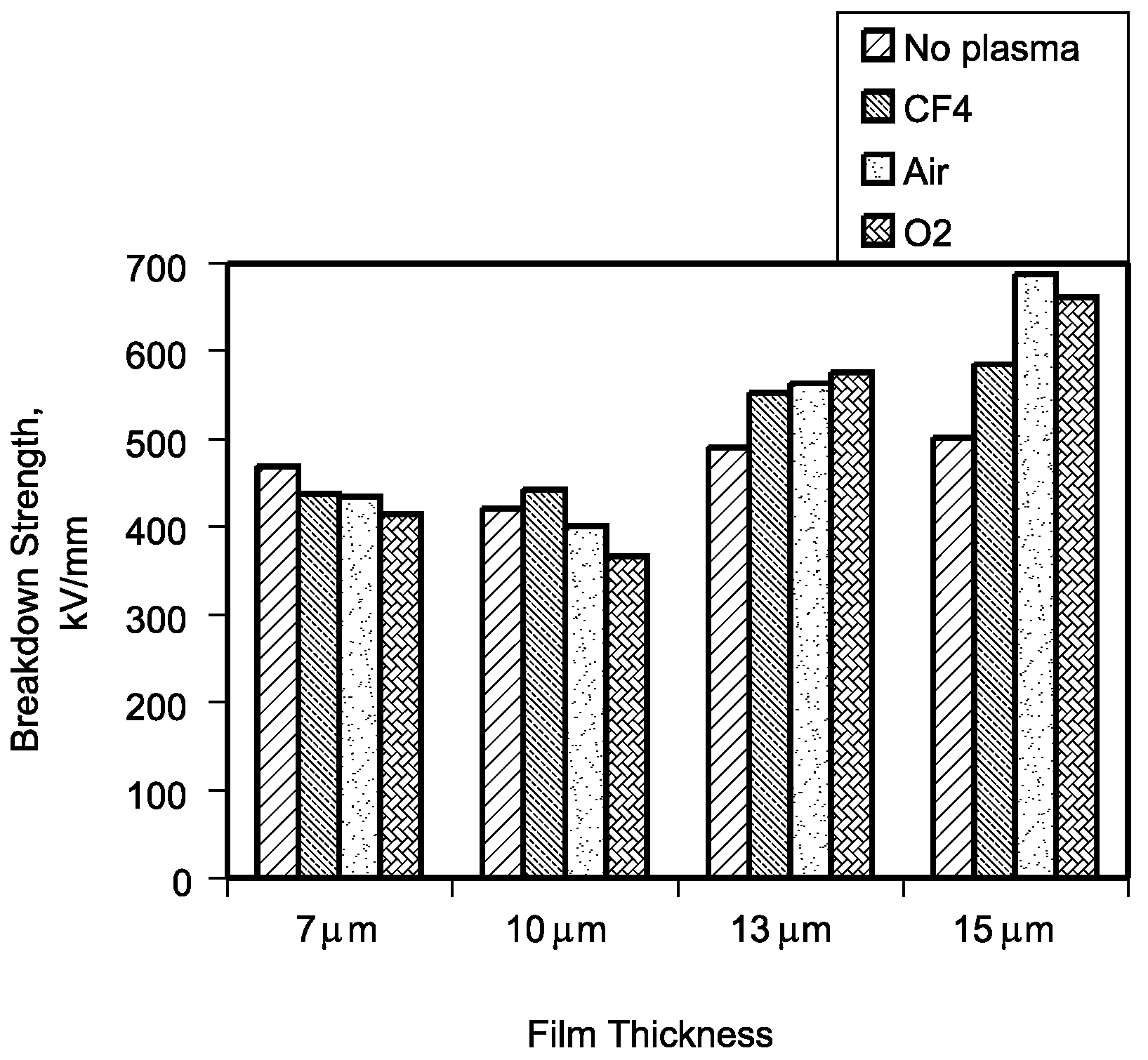

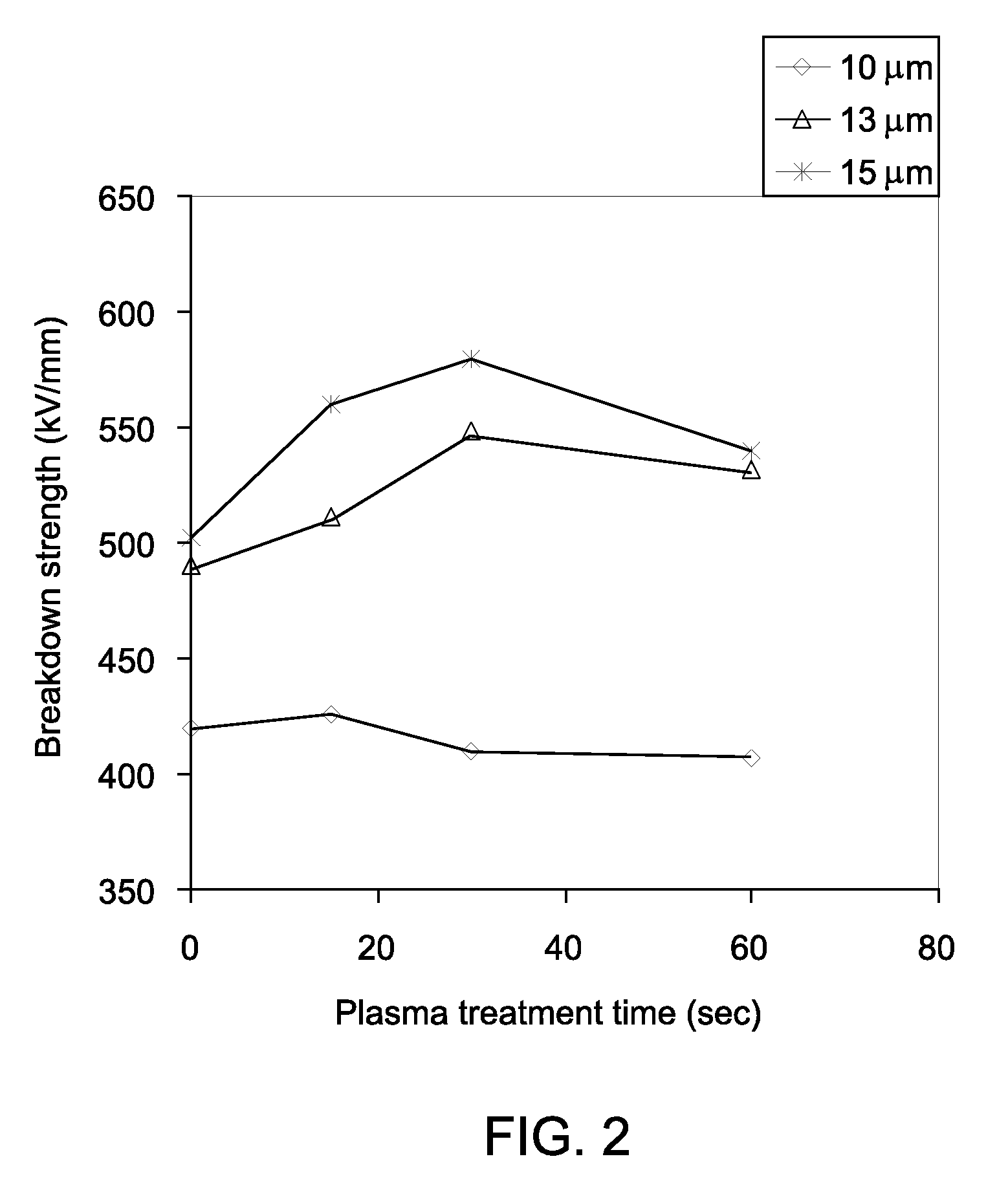

Methods for improving the dielectric properties of a polymer, and related articles and devices

InactiveUS20100246094A1Improve dielectric breakdown strengthLiquid surface applicatorsElectrolytic capacitorsVitrificationPolymeric surface

In one aspect of the present invention, a method for increasing the dielectric breakdown strength of a polymer is described. The method comprises providing the polymer and contacting a surface of the polymer in a reaction chamber with a gas plasma, under specified plasma conditions. The polymer is selected from the group consisting of a polymer having a glass transition temperature of at least about 150° C., and a polymer composite comprising at least one inorganic constituent. The contact with the gas plasma is carried out for a period of time sufficient to incorporate additional chemical functionality into a surface region of the polymer film, to provide a treated polymer. Also provided are an article and method of manufacture.

Owner:GENERAL ELECTRIC CO

Non-crosslinked polyethylene composition for power cable

ActiveUS8981007B2Improve distributionEasy to processPlastic/resin/waxes insulatorsPower cablesPower cableDielectric breakdown strength

Owner:SK INNOVATION CO LTD +1

High-strength lithium battery separator and production technology thereof

InactiveCN107611322AHigh purityGood chemical stabilityLi-accumulatorsCell component detailsKetoneDielectric breakdown strength

The invention discloses a high-strength lithium battery separator and a production technology thereof. The technology comprises the steps of putting a halogenated ketone compound and a dihydroxy compound into a solvent to synthesize polyetheretherketone under the action of carbonate; and stretching a polyetheretherketone nanofiber membrane obtained through melting extrusion at a high temperature to form the high-strength lithium battery separator. According to the polyetheretherketone, the thermal distortion temperature under load can reach 316 DEG C, the instantaneous service temperature canreach 300 DEG C, the polyetheretherketone has excellent chemical stability and can meet the requirements of the lithium battery separator on chemical corrosion resistance and high strength performance, the service life of the lithium battery separator can be well prolonged, and meanwhile, the security is improved; and the prepared high-strength lithium battery separator has the advantages of a relatively small aperture, relatively large specific surface area, high tearing strength, high anti-puncture strength, high dielectric breakdown strength and good chemical stability.

Owner:JIESHOU CITY TIANHONG PACKAGING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com