Metal-based ceramic coating and preparation method of same

A ceramic coating, metal-based technology, applied in metal material coating process, coating, liquid chemical plating and other directions, can solve the problems of low coating thickness, thin coating, long time consumption, etc., to achieve adhesion Good, high purity, long shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

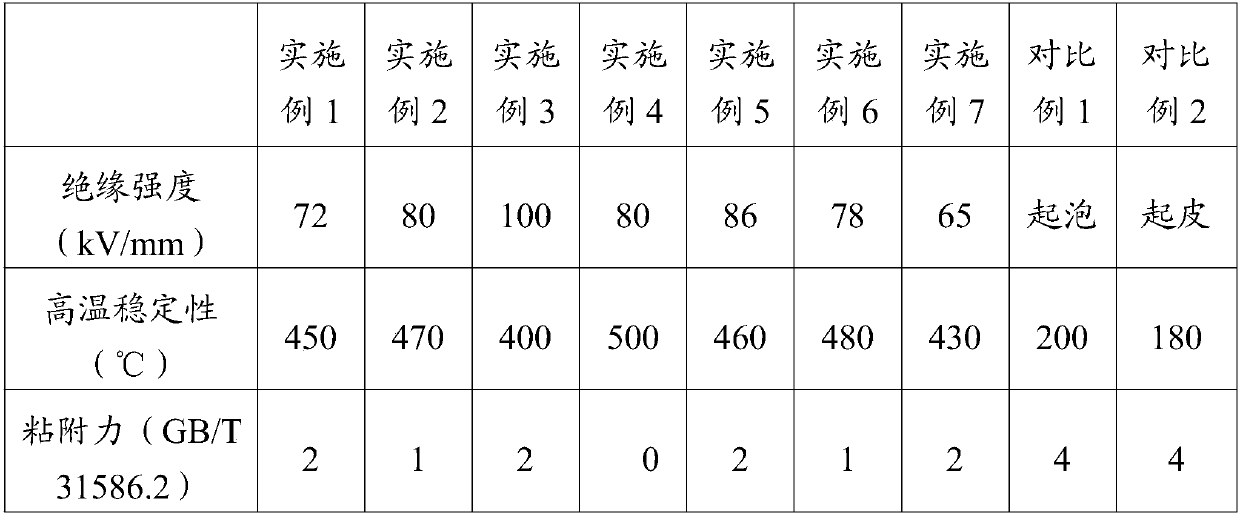

Examples

Embodiment 1

[0031] Step 1, steel substrate surface pretreatment: First, the surface of the steel substrate workpiece was ultrasonically cleaned with acetone for 30 minutes, then ultrasonically degreased with sodium hydroxide solution (mass fraction 2-8%) for 10 minutes, and finally polished with 120-mesh sandpaper ( provide a cleaner, rougher, more reactive surface for subsequent coatings);

[0032] Step 2, preparation of high-purity aluminum dihydrogen phosphate binder: Pour a phosphoric acid solution with a mass fraction of 65% into a three-necked flask, then add aluminum hydroxide powder (purity is 99.99%), mix and stir evenly at 120°C Carry out the oil bath for 1h to obtain the liquid aluminum dihydrogen phosphate finished product, and the molar ratio of phosphoric acid to aluminum hydroxide is 2.14:1;

[0033] Step 3, preparation of alumina insulating coating: 30g of aluminum dihydrogen phosphate binder, 60g of water, and 90g of nano-alumina are mixed uniformly and ball-milled for 5 ...

Embodiment 2

[0035] Step 1, steel substrate surface pretreatment: First, the surface of the steel substrate workpiece was ultrasonically cleaned with acetone for 30 minutes, then ultrasonically degreased with sodium hydroxide solution (mass fraction 2-8%) for 10 minutes, and finally polished with 120-mesh sandpaper ( provide a cleaner, rougher, more reactive surface for subsequent coatings);

[0036] Step 2, preparation of high-purity aluminum dihydrogen phosphate binder: Pour a phosphoric acid solution with a mass fraction of 65% into a three-necked flask, then add aluminum hydroxide powder (purity is 99.99%), mix and stir evenly, and heat at 130°C Carry out the oil bath for 1h to obtain the liquid aluminum dihydrogen phosphate finished product, and the molar ratio of phosphoric acid to aluminum hydroxide is 2.16:1;

[0037] Step 3, preparation of alumina insulating coating: 8g of aluminum dihydrogen phosphate binder, 16g of water, 23.8g of nano-alumina, 2.0g of nano-magnesium oxide were ...

Embodiment 3

[0039]Step 1, steel substrate surface pretreatment: First, the surface of the steel substrate workpiece was ultrasonically cleaned with acetone for 30 minutes, then ultrasonically degreased with sodium hydroxide solution (mass fraction 2-8%) for 10 minutes, and finally polished with 120-mesh sandpaper ( provide a cleaner, rougher, more reactive surface for subsequent coatings);

[0040] Step 2, preparation of high-purity aluminum dihydrogen phosphate binder: Pour a phosphoric acid solution with a mass fraction of 65% into a three-necked flask, then add aluminum hydroxide powder (purity is 99.99%), mix and stir evenly, and heat at 140°C Carry out oil bath 1h, promptly make liquid aluminum dihydrogen phosphate finished product, and the molar ratio of phosphoric acid and aluminum hydroxide is 3.12:1;

[0041] Step 3, preparation of alumina insulating coating: 9g of aluminum dihydrogen phosphate binder, 27g of water, 36g of nano-alumina, and 1.5g of nano-magnesia were uniformly mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com