Patents

Literature

119 results about "Phosphate binder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphate binders are medications used to reduce the absorption of dietary phosphate; they are taken along with meals and snacks. They are frequently used in people with chronic kidney failure (CKF), who are less able to excrete phosphate, resulting in an elevated serum phosphate.

Molecularly imprinted phosphate binders for therapeutic use

InactiveUS20050276781A1Increase surface areaSpecific binding capacityOrganic dyesSynthetic polymeric active ingredientsPhosphateCalcium Binder

Methods for synthesizing molecularly imprinted polymers (MIP) having an affinity for dietary phosphates, resulting polymers, pharmaceutical compositions and modes of administration are disclosed. The MIP compounds are useful for binding excess dietary phosphates in a patient in need thereof.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Phosphate binder with reduced pill burden

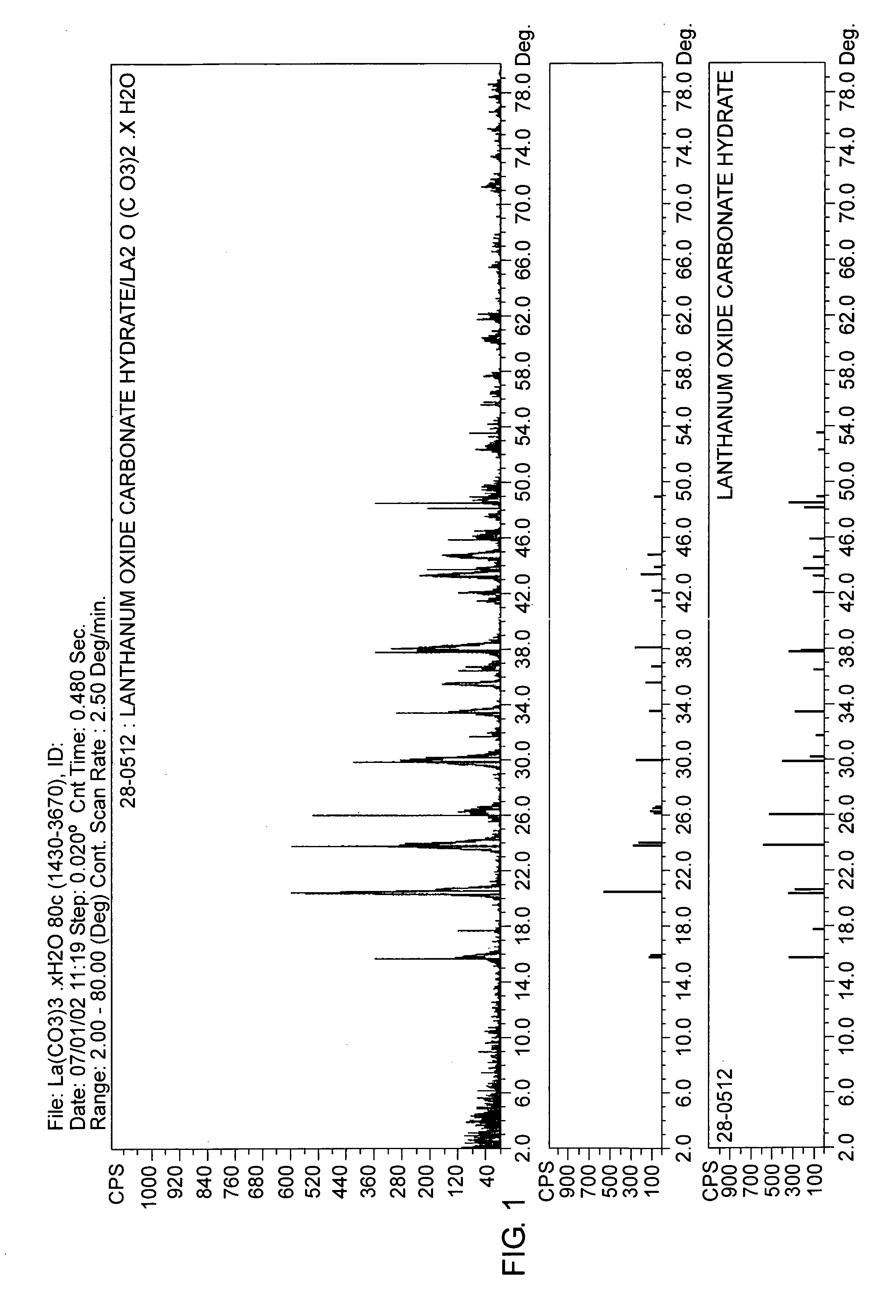

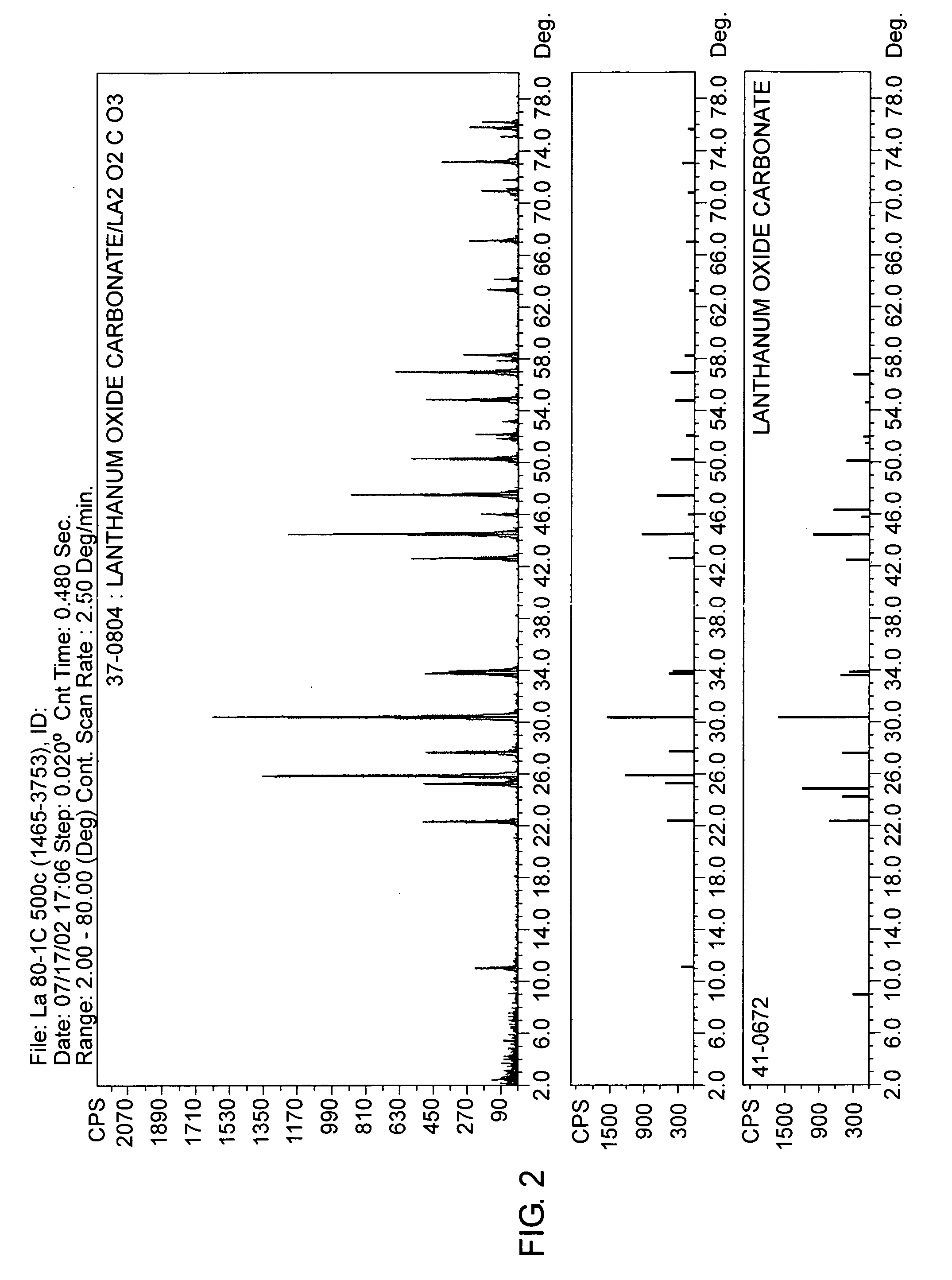

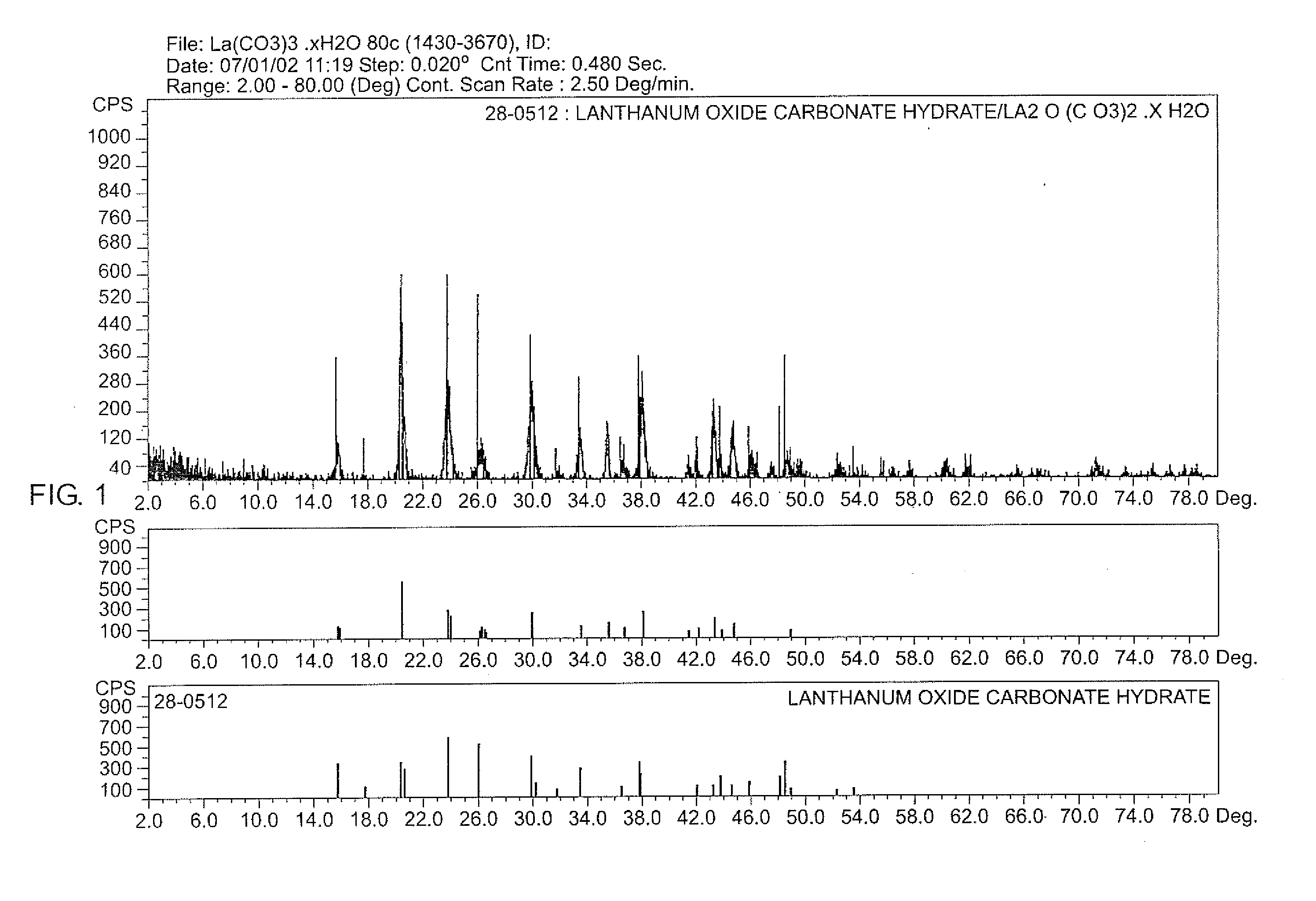

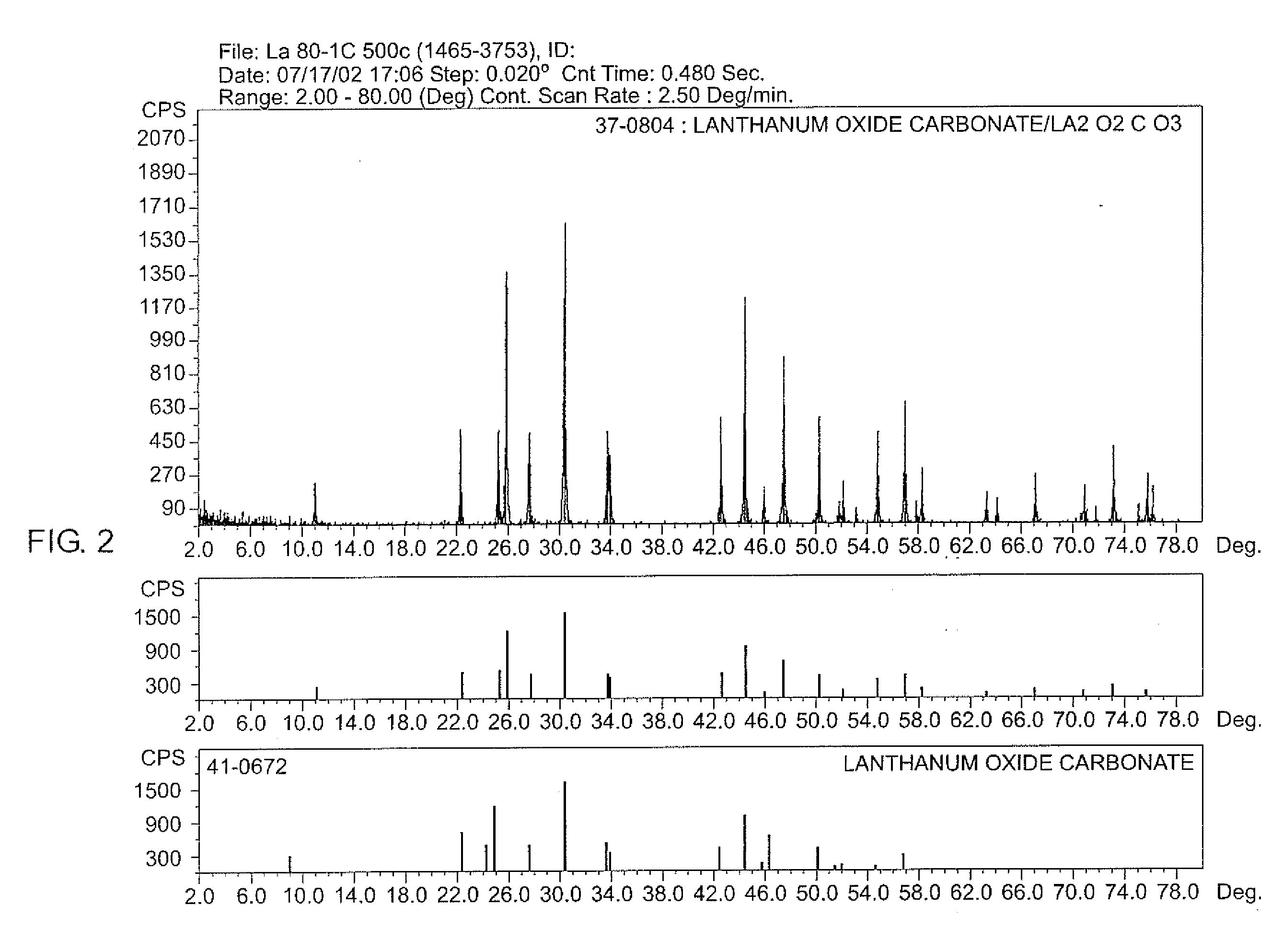

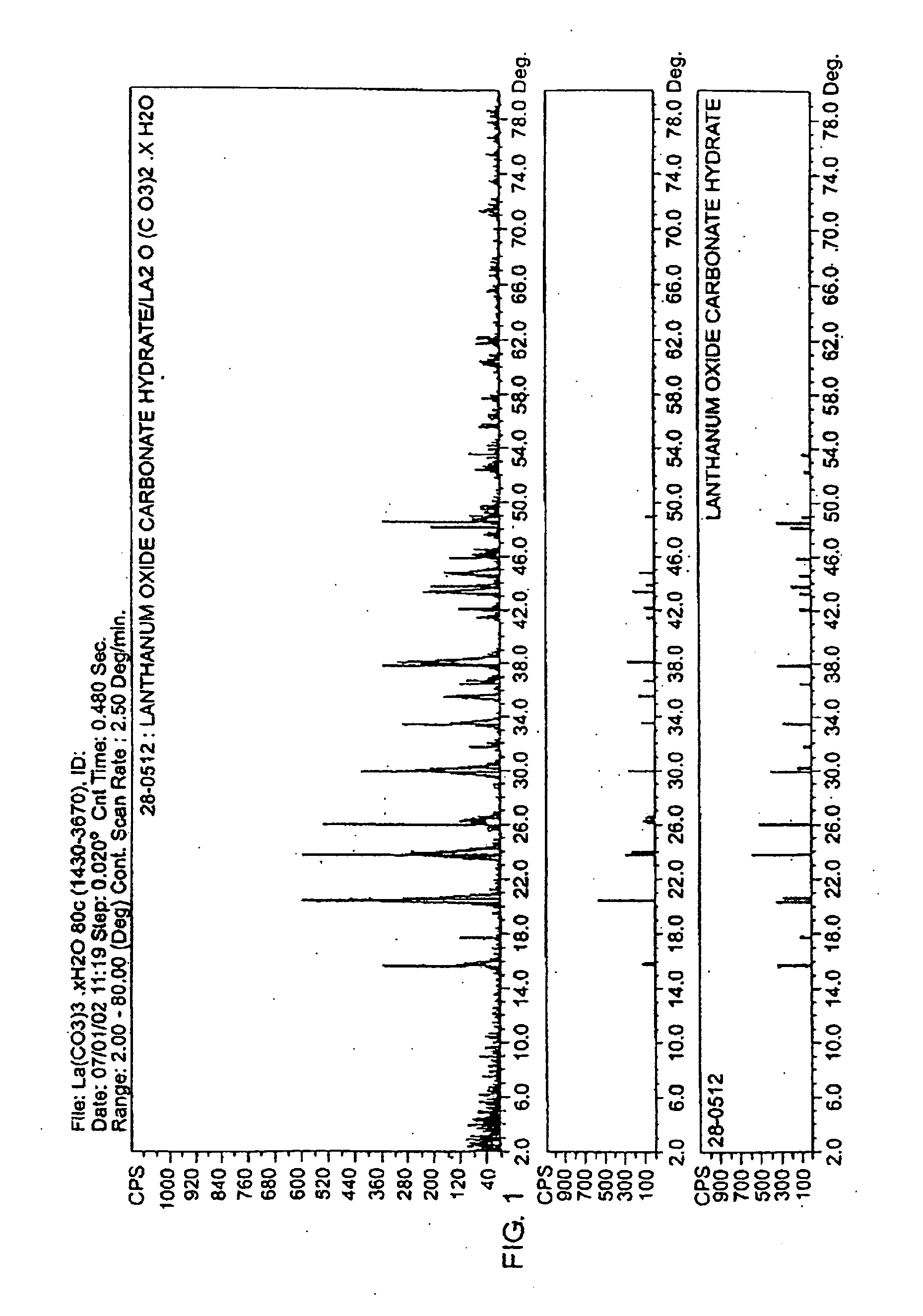

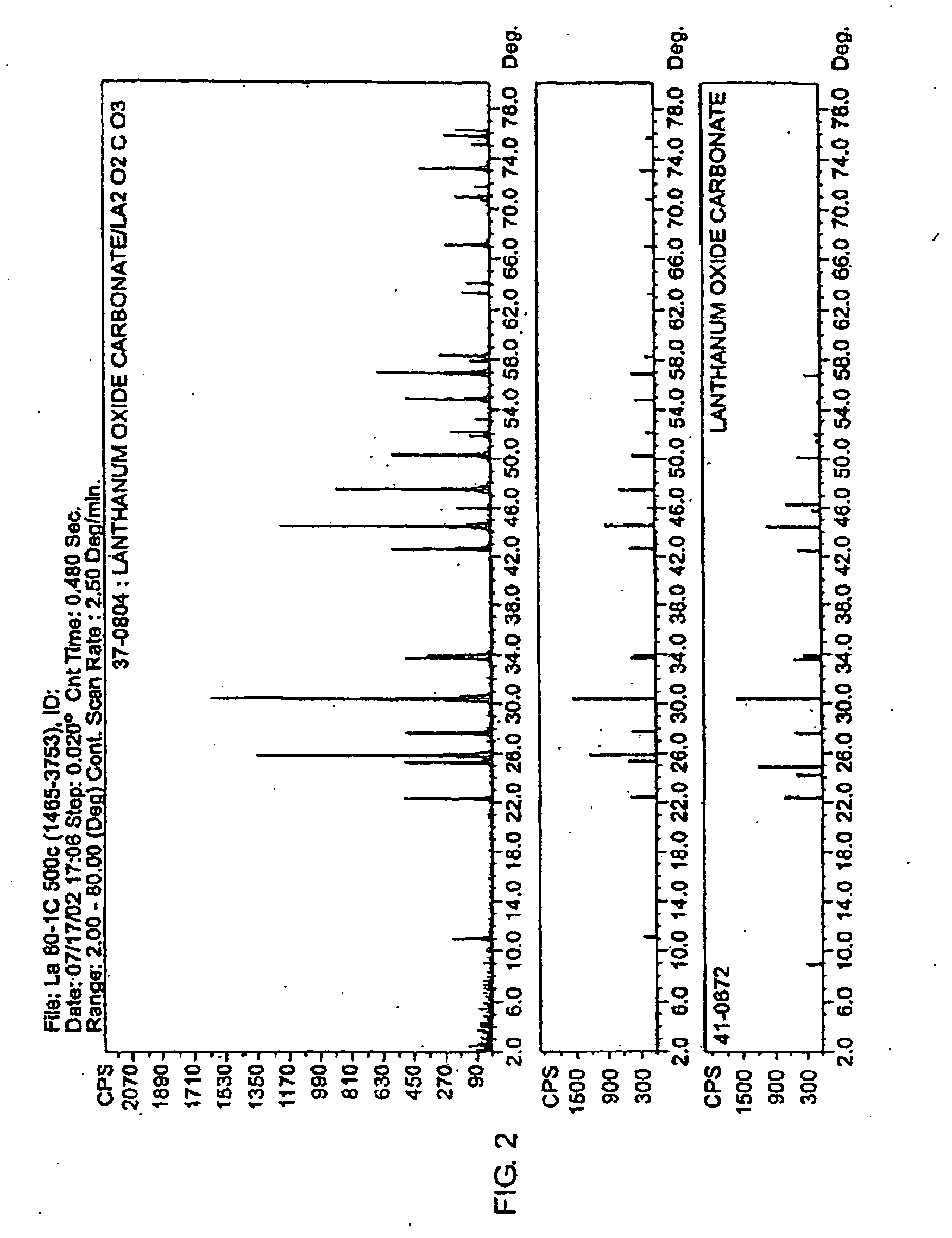

The present invention is generally directed to compositions and formulations that can be used for the treatment of diseases such as End Stage Renal Disease (“ESRD”) and Chronic Renal Insufficiency (“CRI”). Specifically, it is directed to lanthanum-based compounds that bind phosphate and that can be formulated to provide for a reduced pill burden relative to other phosphate binders. In a formulation aspect of the present invention, a formulation is provided the includes a lanthanum-based, phosphate binder. The formulation is typically characterized in that in may be swallowed without chewing. Formulations of the present invention, along with a lanthanum-based compound, may optionally include the following: mass diluting agents; binders; coatings; compression / encapsulation aids; disintegrants; lubricants; plasticizers; slip / anti-electrostatic agents; powder lubricants; and, sweeteners. Where the formulation is in the form of a tablet, it typically has a volume between 0.3 cm3 and 1.2 cm3, preferably between 0.35 cm3 and 0.50 cm3. Each tablet typically includes enough phosphate binder such that only 3 or less tablets need to be ingested each day for a patient suffering from ESRD.

Owner:SPECTRUM PHARMA INC

Formation of chemically bonded ceramics with magnesium dihydrogen phosphate binder

InactiveUS6776837B2Reduce solubilityLess energySludge treatmentSolid waste managementFiberSolubility

Owner:UCHICAGO ARGONNE LLC +1

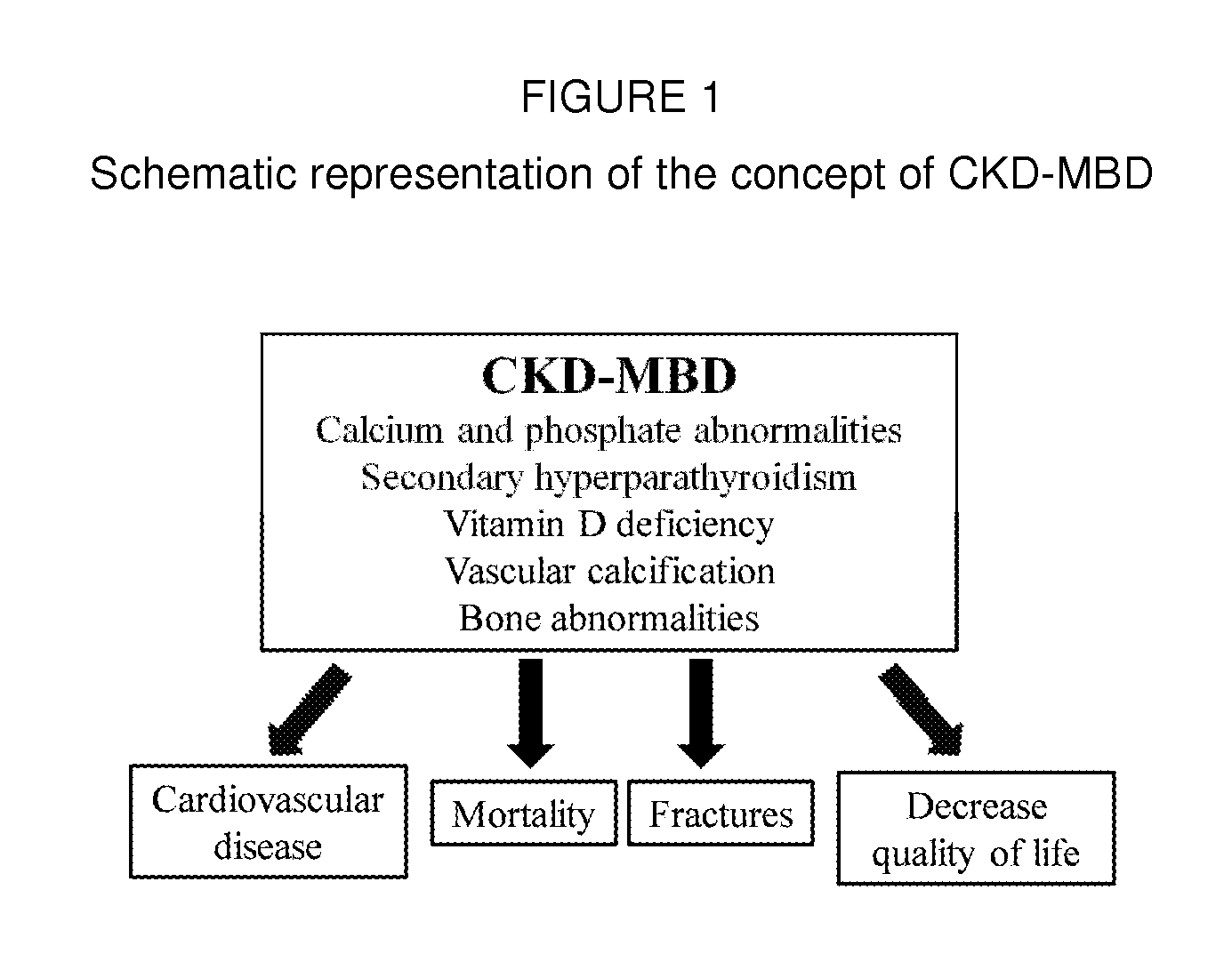

Pharmaceutical compositions comprising phosphate binder, calcium receptor-active compound and/or active vitamin d

InactiveUS20130085121A1Maintain good propertiesImprove bioavailabilityOrganic active ingredientsBiocideMineral bone diseaseCalcium Binder

The present invention is an oral solid pharmaceutical compositions for the treatment of kidney diseases and mineral bone disorder including a phosphate binder, a calcium receptor-active compound and at least one pharmaceutically acceptable excipient, the invention further including a method for preparing the pharmaceutical compositions including the steps of granulating cinacalcet and / or sevelamer and / or vitamin D by one of a wet and a dry granulation process, each with at least one pharmaceutically acceptable excipient to form cinacalcet granules and / or sevelamer granules and / or vitamin D granules, mixing at least two of the cinacalcet granules, sevelamer granules and vitamin D granules to form a granules mixture and compressing the granules mixture to tablets or encapsulating the granules mixture into capsules or pulverizing the granules mixture into a dispersion powder.

Owner:WEIFANG SYNERPHARM

Light weight phosphate cements

A sealant having a specific gravity in the range of from about 0.7 to about 1.6 for heavy oil and / or coal bed methane fields is disclosed. The sealant has a binder including an oxide or hydroxide of Al or of Fe and a phosphoric acid solution. The binder may have MgO or an oxide of Fe and / or an acid phosphate. The binder is present from about 20 to about 50% by weight of the sealant with a lightweight additive present in the range of from about 1 to about 10% by weight of said sealant, a filler, and water sufficient to provide chemically bound water present in the range of from about 9 to about 36% by weight of the sealant when set. A porous ceramic is also disclosed.

Owner:UCHICAGO ARGONNE LLC

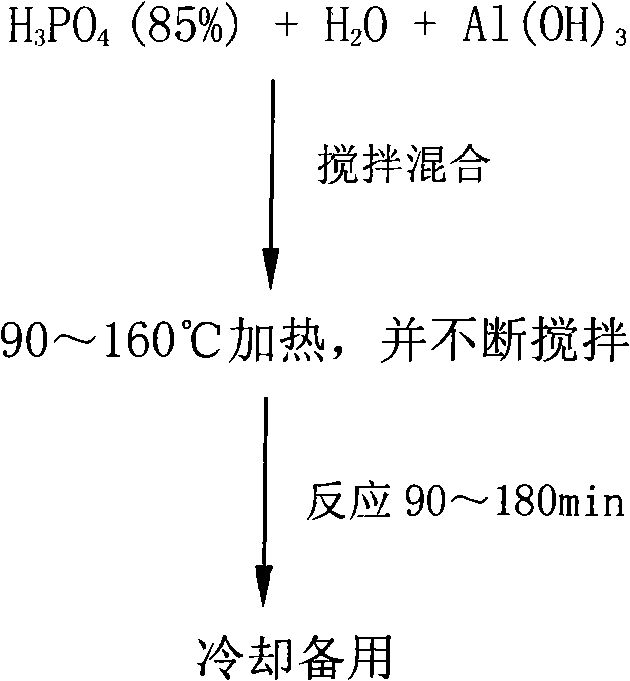

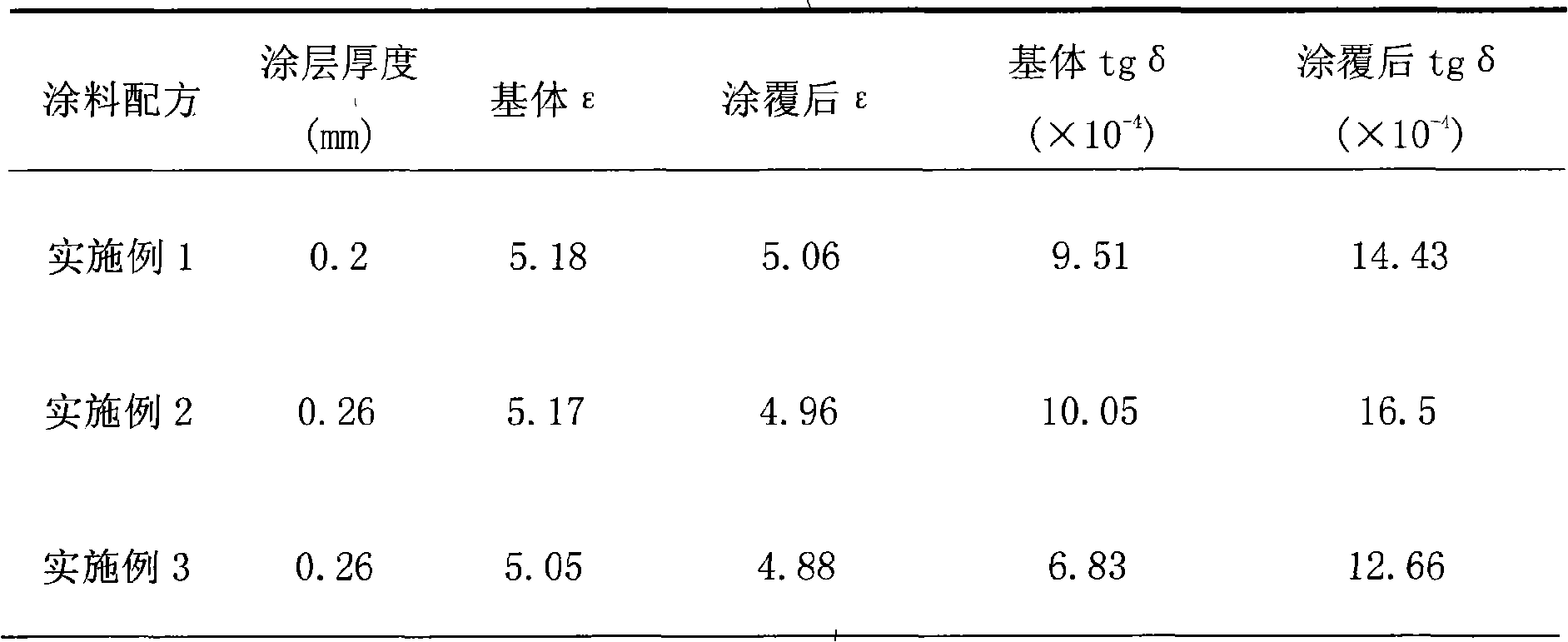

Phosphate-silicon dioxide low-dielectric high temperature-resistant coating and preparation thereof

The invention discloses a low-dielectric high-temperature-resistant phosphate-silicon dioxide coating, with the mass percentage content between the components and the raw material as follows: 50-80% of percentage content of inorganic compound binder, 15-50% of high-temperature filler, 0.5-1.5 wt% of curing agent, 2-5 wt% of thickener, and 0.3-1.5wt% of surfactant; the inorganic compound binder is the mixture of aluminum phosphate or aluminium-chromium phosphate and silicon collosol; the high-temperature resistant filler is the mixture of fused quartz powder and refined quartz powder or alpha-Al2O3 power; the curing agent is MgO; the thickener is fumed silica; the surfactant is non-ionic surfactant. The phosphate binder is firstly prepared, followed by phosphate / silicon collosol compound binder; then the non-ionic surfactant and the high-temperature resistant filler are added to the compound binder, followed by the thickener and the curing agent, then the mixture is evenly mixed. The invention can be used for the surface protection of porous inorganic materials or non-porous inorganic materials and is typically used as wave-transparent material for aerospace crafts.

Owner:TIANJIN UNIV

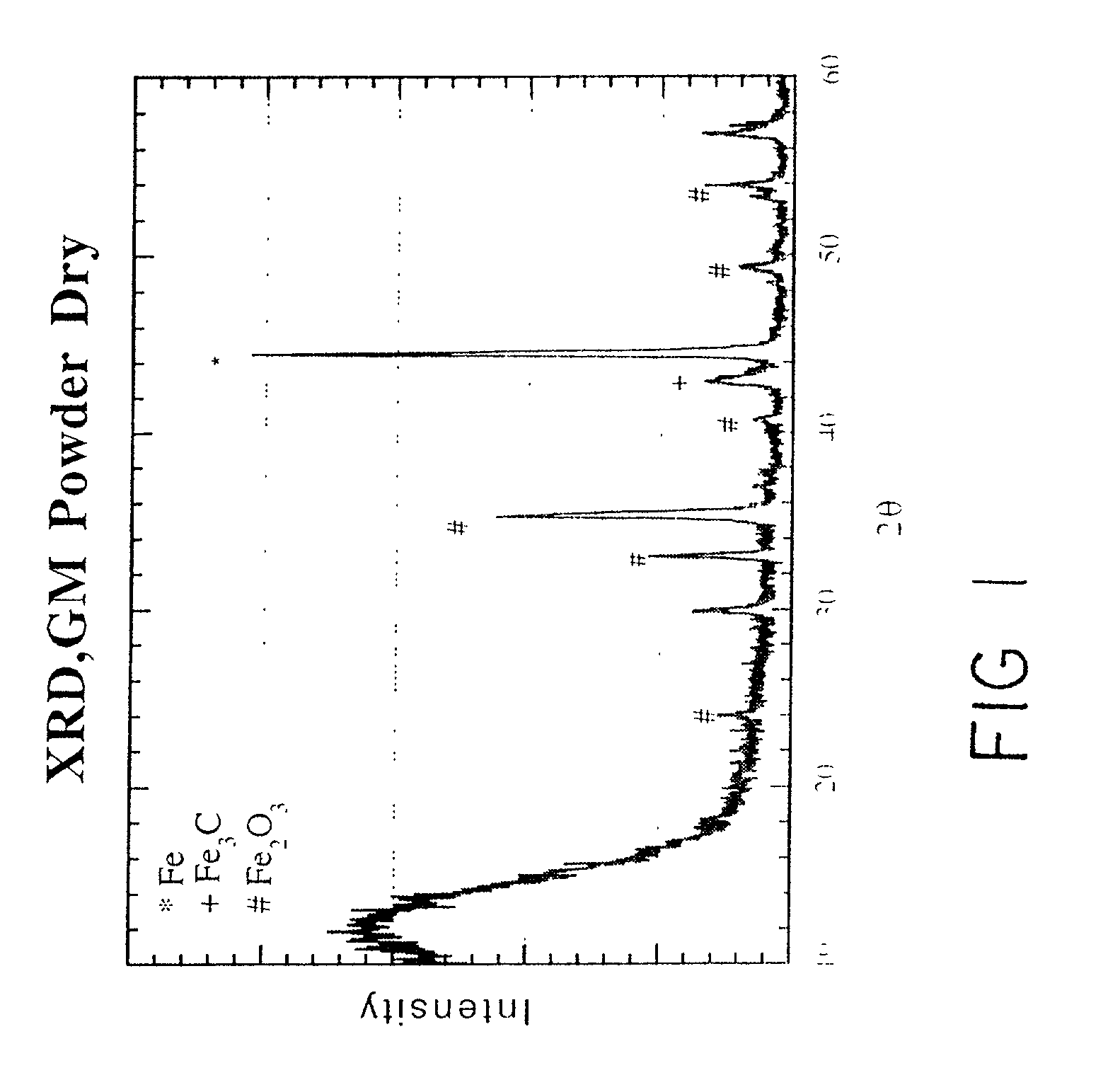

Formation of chemically bonded ceramics with magnesium dihydrogen phosphate binder

InactiveUS20030092554A1Reduce solubilityLess energySludge treatmentSolid waste managementFiberSolubility

A new method for combining magnesium oxide, MgO, and magnesium dihydrogen phosphate to form an inexpensive compactible ceramic to stabilize very low solubility metal oxides, ashes, swarfs, and other iron or metal-based additives, to create products and waste forms which can be poured or dye cast, and to reinforce and strengthen the ceramics formed by the addition of fibers to the initial ceramic mixture.

Owner:UCHICAGO ARGONNE LLC +1

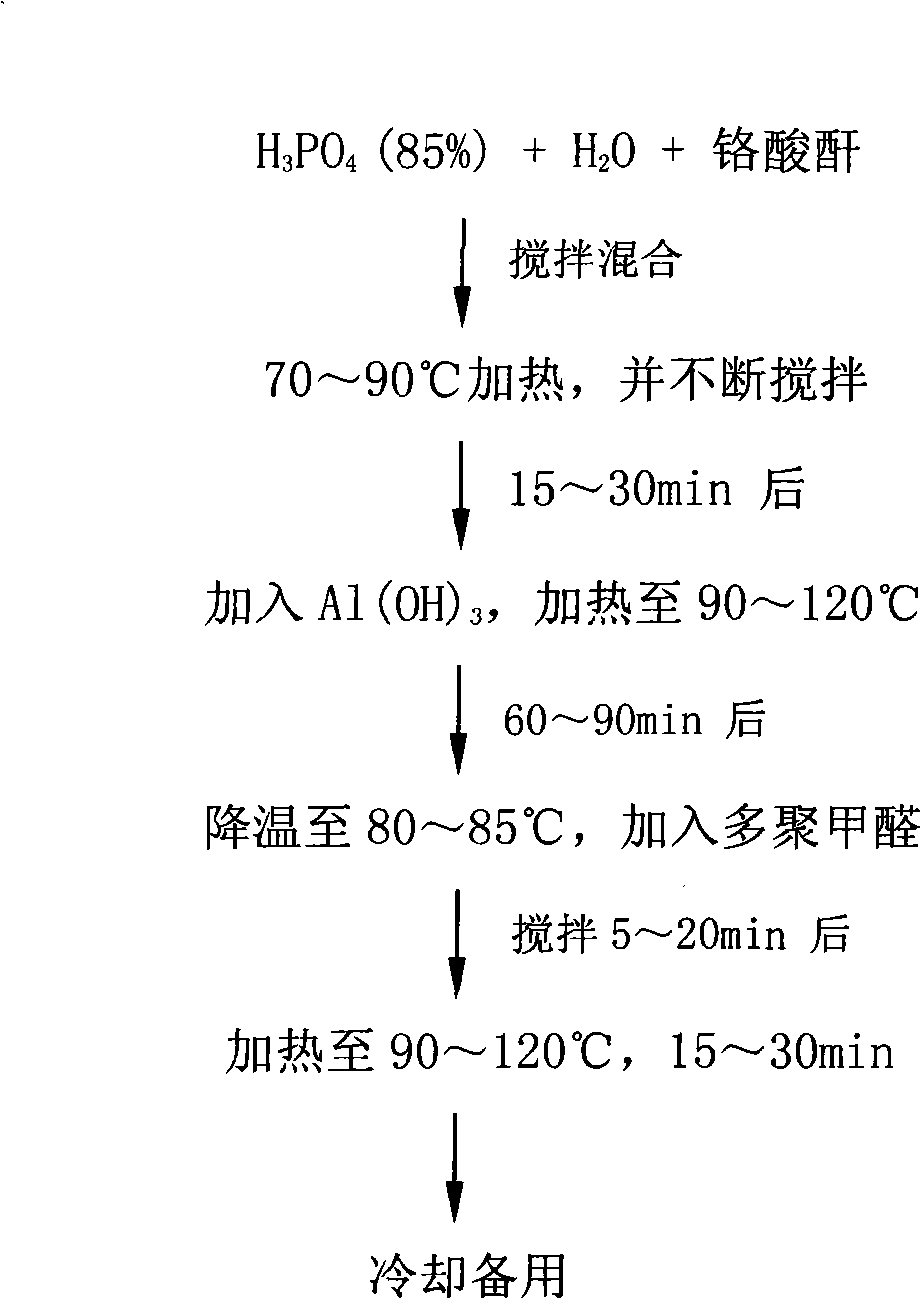

Phosphate based steel rebar anticorrosive coating

ActiveCN104404502AConvenient coatingImprove protectionMetallic material coating processesThermal insulationAluminium hydroxide

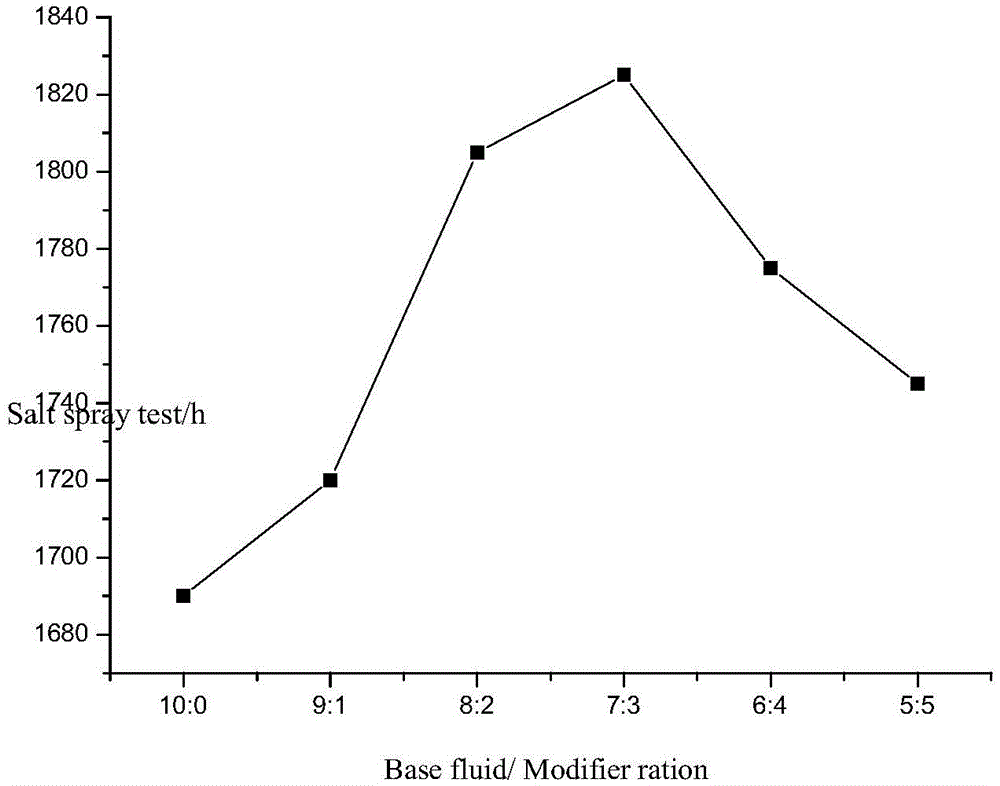

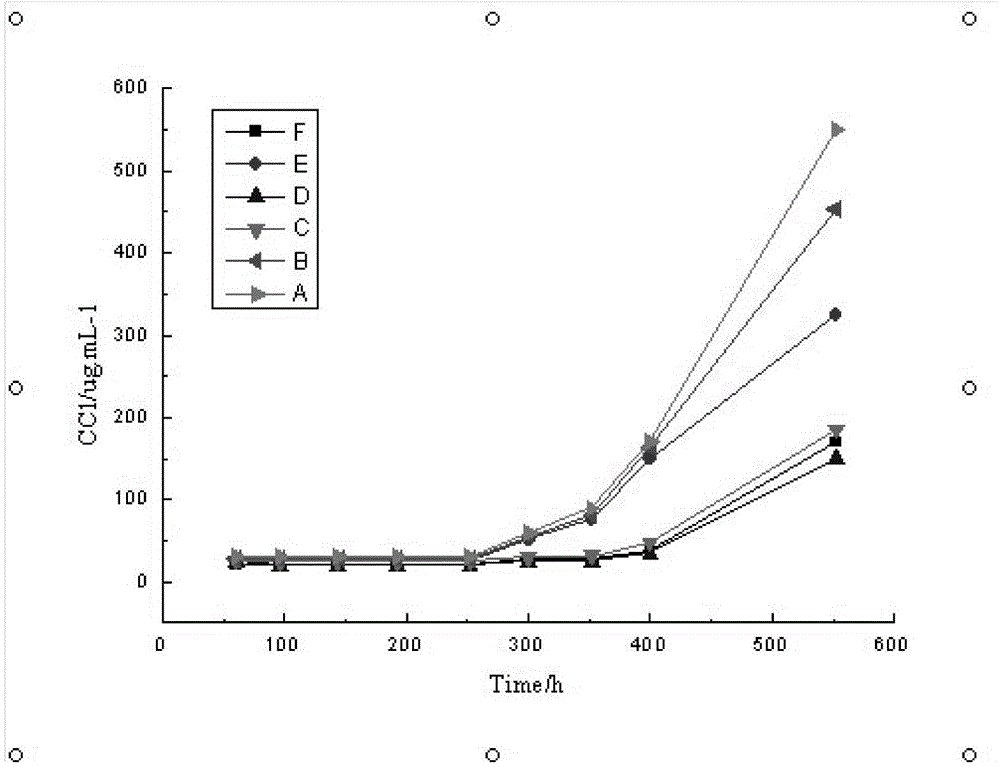

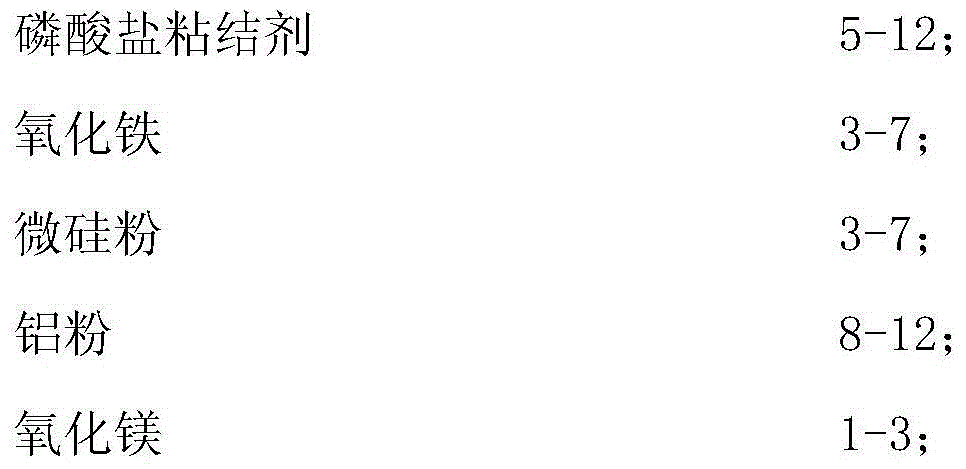

The invention discloses a steel rebar anticorrosive coating material for marine reinforced concrete. The steel rebar anticorrosive coating material is prepared by the following steps: adding aluminium hydroxide into phosphoric acid, heating and carrying out thermal insulation at 70-90 DEG C for 3-5 h so as to obtain a phosphate binder; and using the phosphate binder as a base solution, adding an aldehyde resin modifier, chrome oxide, iron oxide, macro-silicon powder, aluminium powder and magnesium oxide, grinding and uniformly stirring to obtain a phosphate coating. The steel rebar anticorrosive coating material comprises the following ingredients, by weight, 5-12 parts of the phosphate binder, 3-7 parts of iron oxide, 3-7 parts of macro-silicon powder, 8-12 parts of aluminium powder, 1-3 parts of magnesium oxide and 1-3 parts of aldehyde resin. The anticorrosive phosphate based coating material can be cured at normal temperature, and curing time can be adjusted according to requirements. Application of the phosphate coating is popularized. After cured, the coating material has high strength and compact structure and can stably be combined with a concrete structure. By the use of the coating material, a steel rebar can be protected well.

Owner:上海宇砼建筑科技股份有限公司

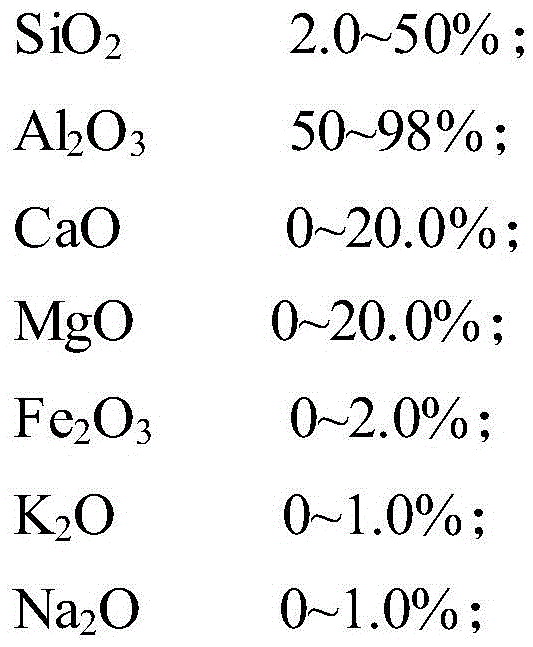

Low-porosity chrome corundum brick and preparation method thereof

The invention discloses a low-porosity chrome corundum brick and a preparation method thereof. The low-porosity chrome corundum brick is prepared from the following raw materials in percentage by mass: 18-28 percent of corundum with the raw material granularity being 5-3mm, 30-40 percent of corundum with the raw material granularity being 3-1mm, 10-20 percent of corundum with the raw material granularity being 1-0mm, 10-20 percent of corundum with the raw material granularity being smaller than 0.088mm, 1-15 percent of high-content chromium ore or fused chrome oxide with the raw material granularity being 1-0mm and 2-15 percent of high-purity chromium oxide with the raw material granularity being smaller than 0.088mm; and in addition, a phosphate binder accounting 2-5 percent for the total mass of all the raw materials is added. According to the low-porosity chrome corundum brick and the preparation method, a product is prepared by material mixing, forming, sintering, impregnating with a nanometer oxide suspension and microwave drying according to burdening of the low-porosity chrome corundum brick, can lower the apparent porosity and the porosity aperture of a chrome corundum material, and reacts with permeated molten slag to form a high melting point substance, increases the viscosity of the molten slag, and slows down permeation of the molten slag.

Owner:河南瑞泰耐火材料科技有限公司

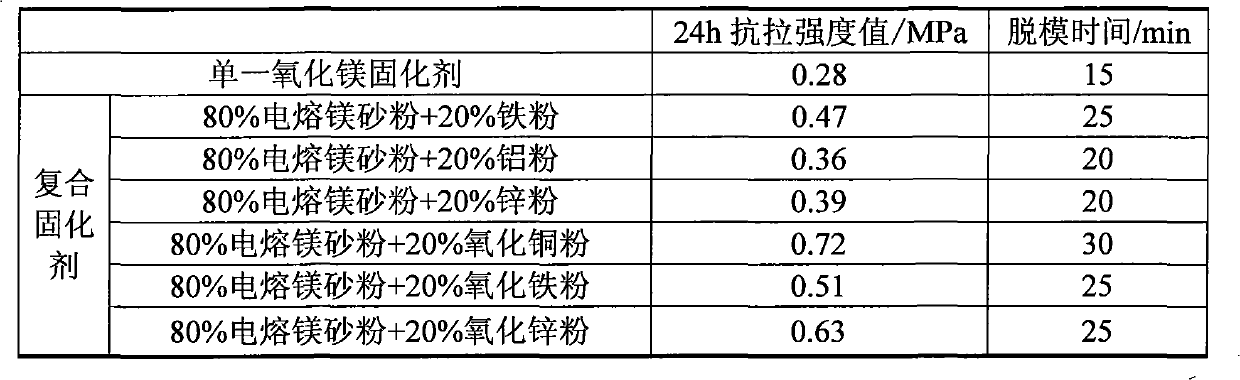

Composite curing agent for phosphate casting binder and preparation method of composite curing agent

InactiveCN102085561AThe demoulding time is suitableModerate demoulding timeFoundry mouldsFoundry coresPhosphateCalcium Binder

The invention provides a composite curing agent for a phosphate casting binder. Fused magnesia powder is utilized as the main component of the composite curing agent, metal element powder or metal oxide powder is added, and stirring and ball-milling are carried out on the fused magnesia powder and the metal element powder or metal oxide powder, thus the composite curing agent is prepared, whereinthe added quantity of the fused magnesia powder is 70-90wt% of the composite curing agent; and the added quantity of the metal element powder or metal oxide powder is 10-30wt% of the composite curingagent. The no-bake phosphate binder of the composite curing agent provided by the invention has the advantages of moderate demoulding time, high sand mould (core) strength and good recyclability of moulding sand, prevents any environmental pollution during the usage, and can completely meet the requirements of casting production.

Owner:HUBEI UNIV OF TECH

Low temperature process for making radiopac materials utilizing industrial/agricultural waste as raw material

ActiveUS20060066013A1Saving on accountConsiderable heat energyCeramic shaping apparatusNon-woven fabricsPyrophyllitePhosphate binder

Owner:COUNCIL OF SCI & IND RES

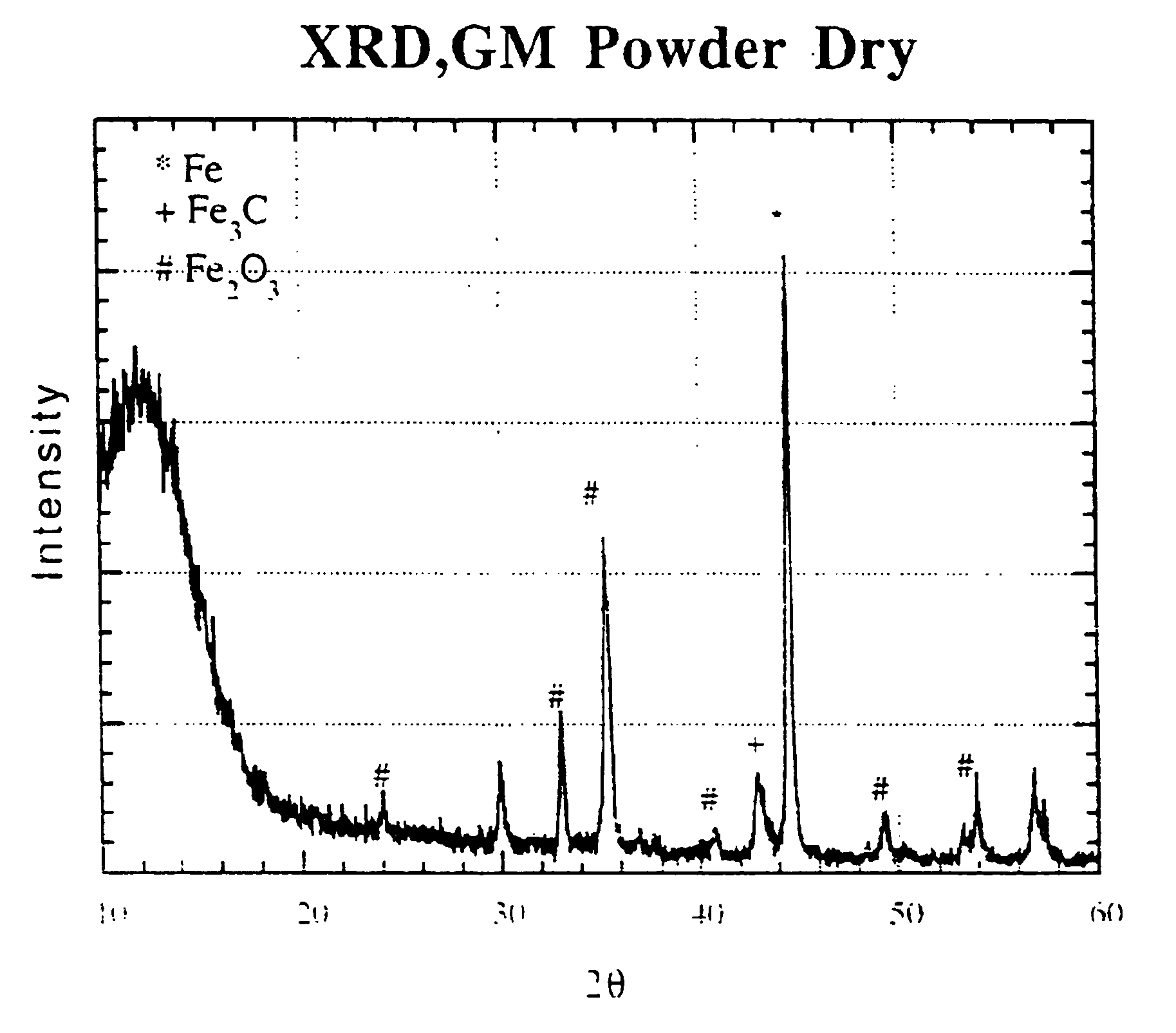

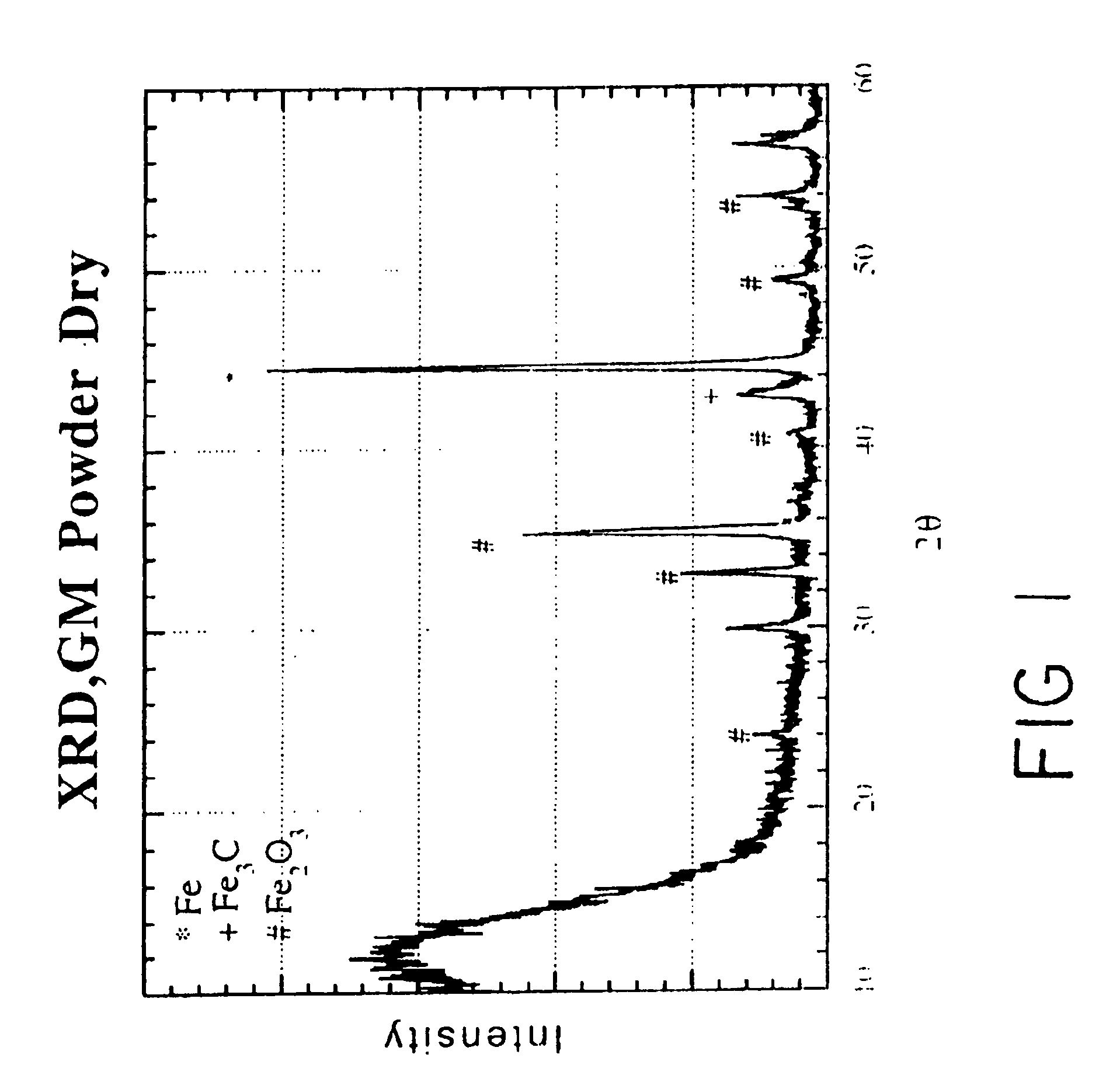

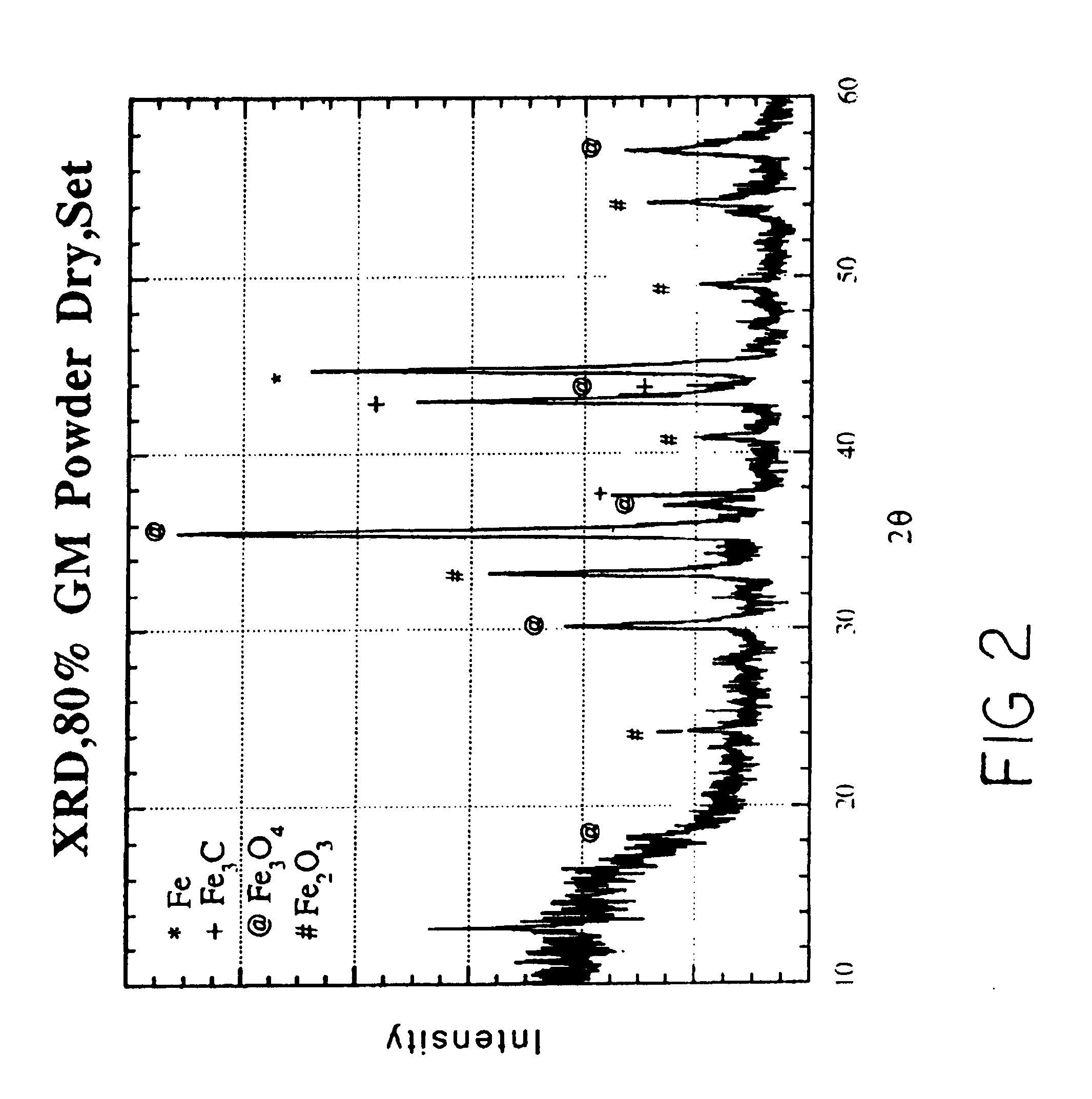

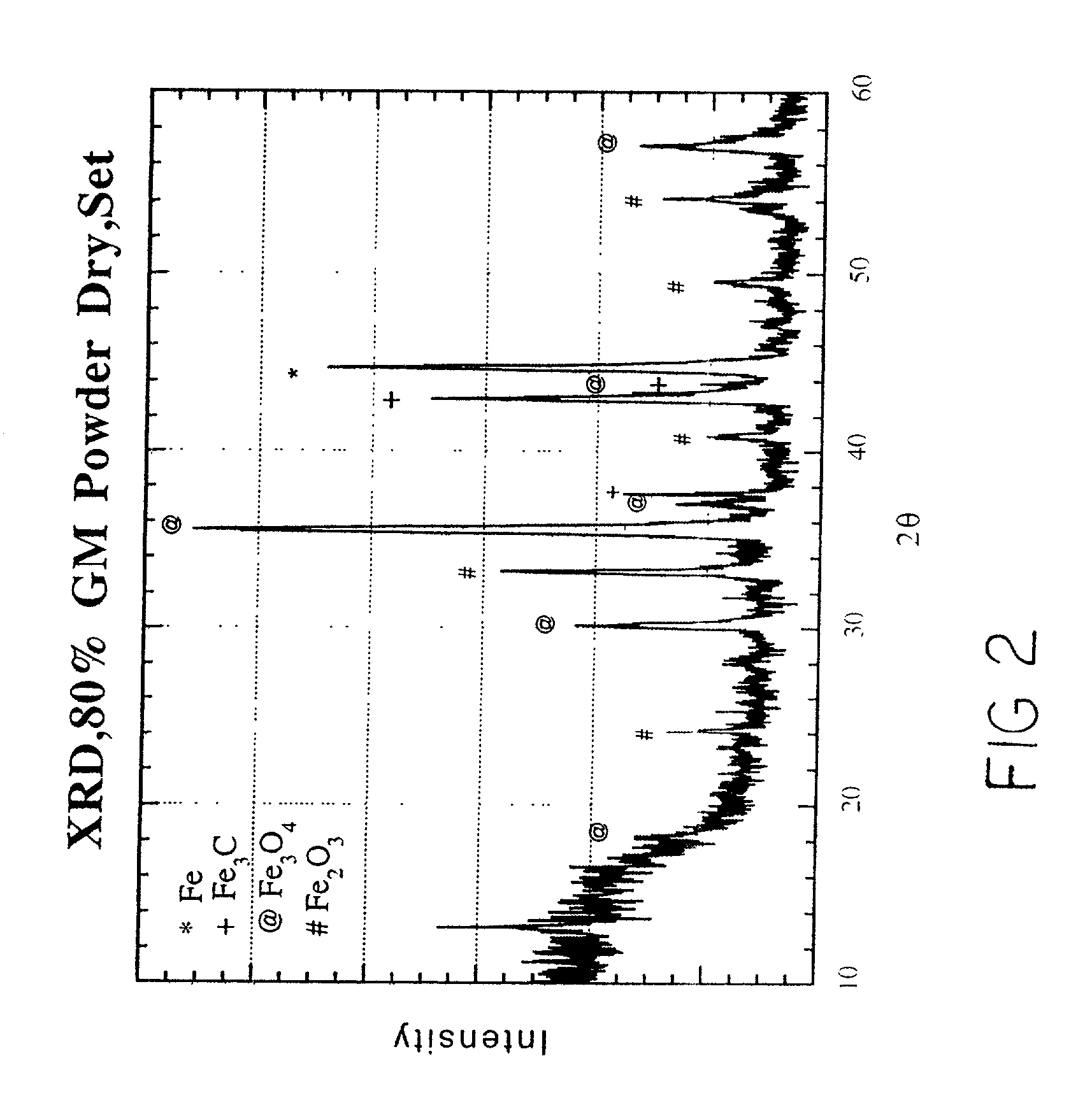

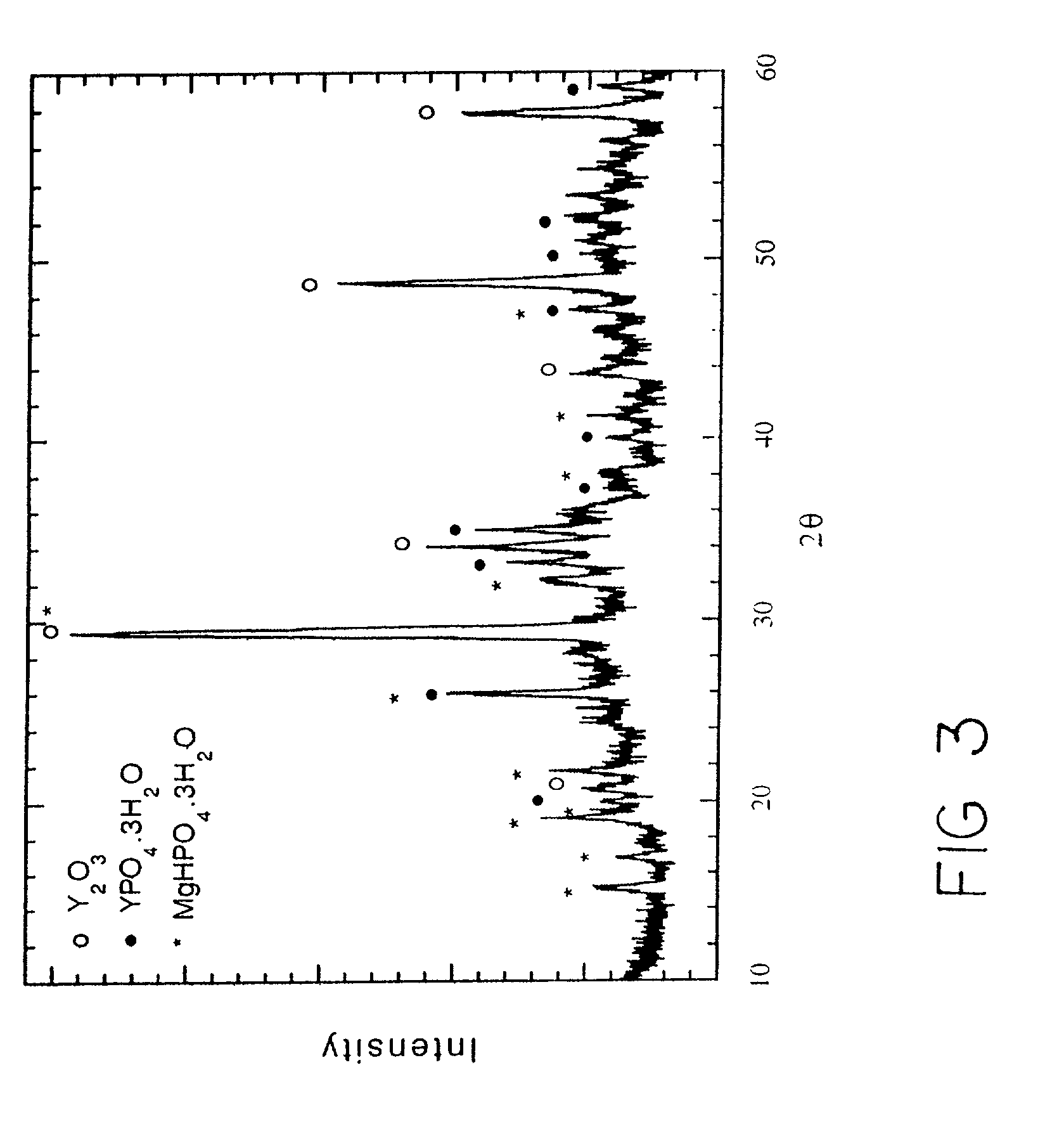

Method of waste stabilization with dewatered chemically bonded phosphate ceramics

ActiveUS20060235258A1Prevent volatilizationImprove the immunitySolid waste managementSolid waste disposalBound waterPhosphate

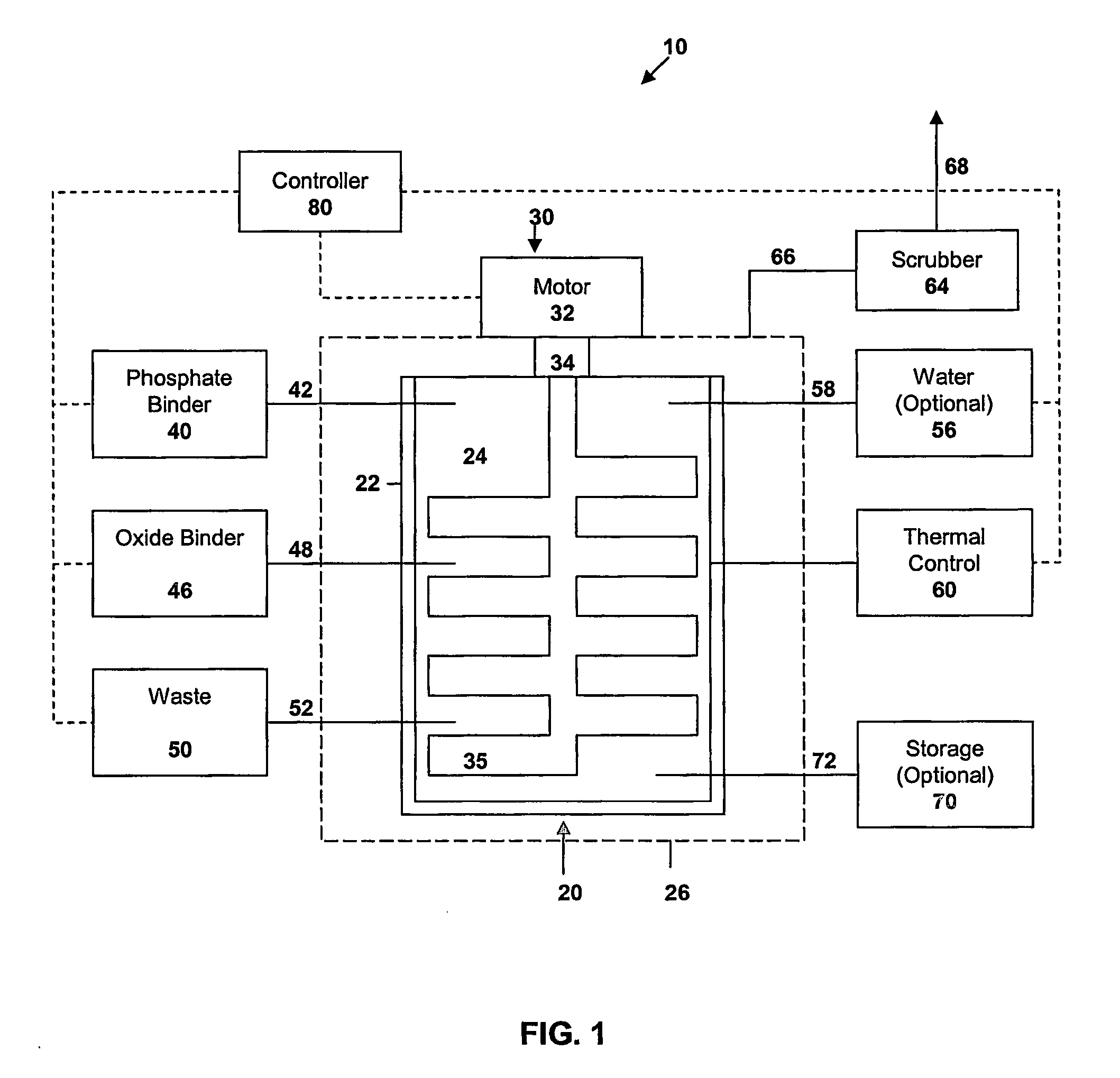

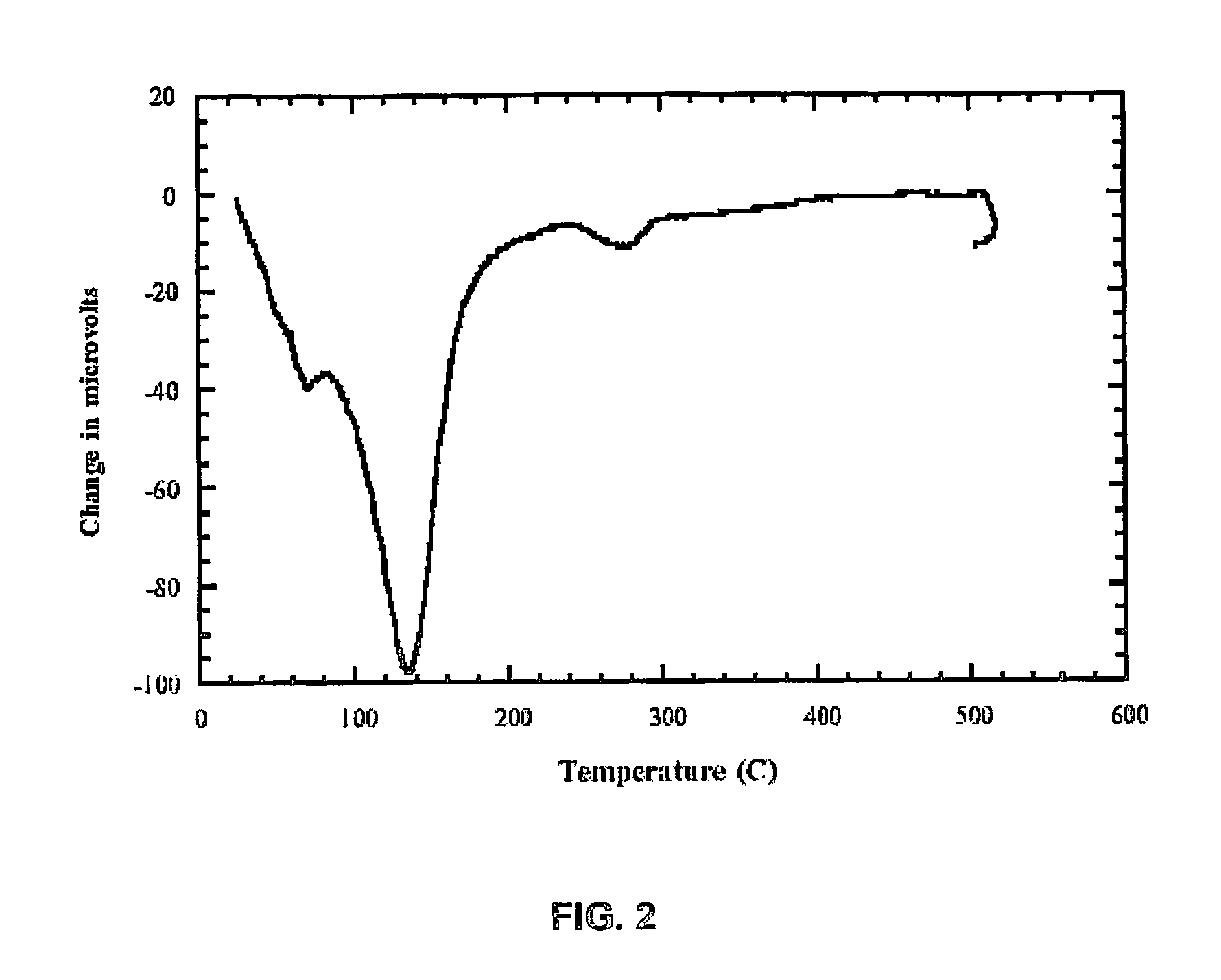

A method of stabilizing a waste in a chemically bonded phosphate ceramic (CBPC). The method consists of preparing a slurry including the waste, water, an oxide binder, and a phosphate binder. The slurry is then allowed to cure to a solid, hydrated CBPC matrix. Next, bound water within the solid, hydrated CBPC matrix is removed. Typically, the bound water is removed by applying heat to the cured CBPC matrix. Preferably, the quantity of heat applied to the cured CBPC matrix is sufficient to drive off water bound within the hydrated CBPC matrix, but not to volatalize other non-water components of the matrix, such as metals and radioactive components. Typically, a temperature range of between 100° C.-200° C. will be sufficient. In another embodiment of the invention wherein the waste and water have been mixed prior to the preparation of the slurry, a select amount of water may be evaporated from the waste and water mixture prior to preparation of the slurry. Another aspect of the invention is a direct anyhydrous CBPC fabrication method wherein water is removed from the slurry by heating and mixing the slurry while allowing the slurry to cure. Additional aspects of the invention are ceramic matrix waste forms prepared by the methods disclosed above.

Owner:CH2M HILL +2

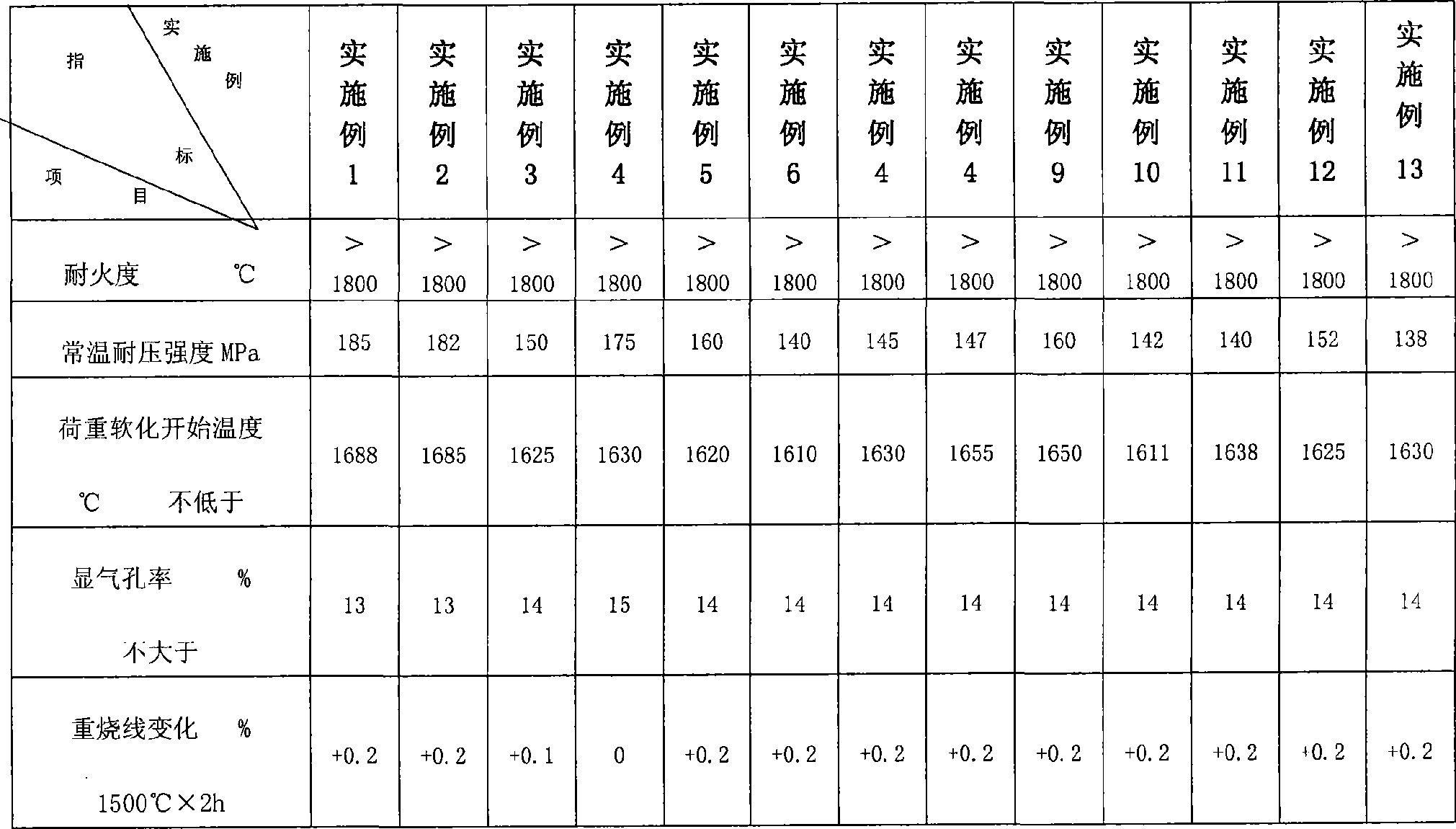

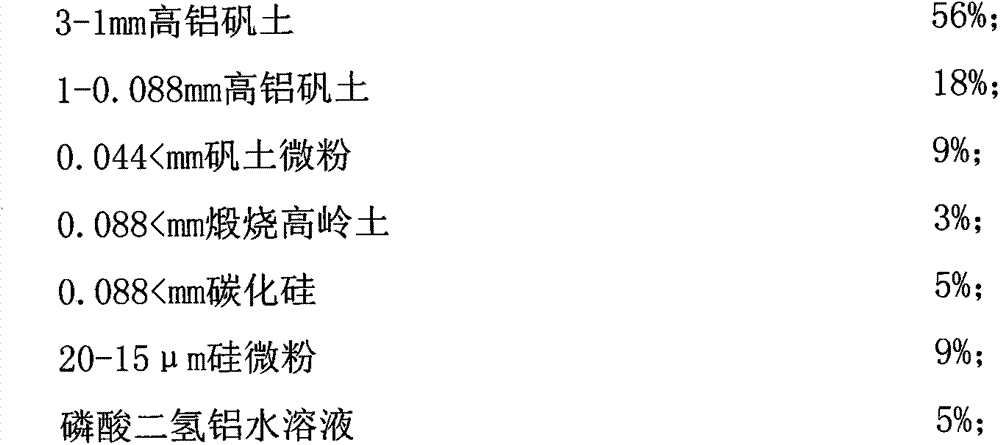

Phosphate-bonded aluminum silicon carbide brick and preparation method thereof

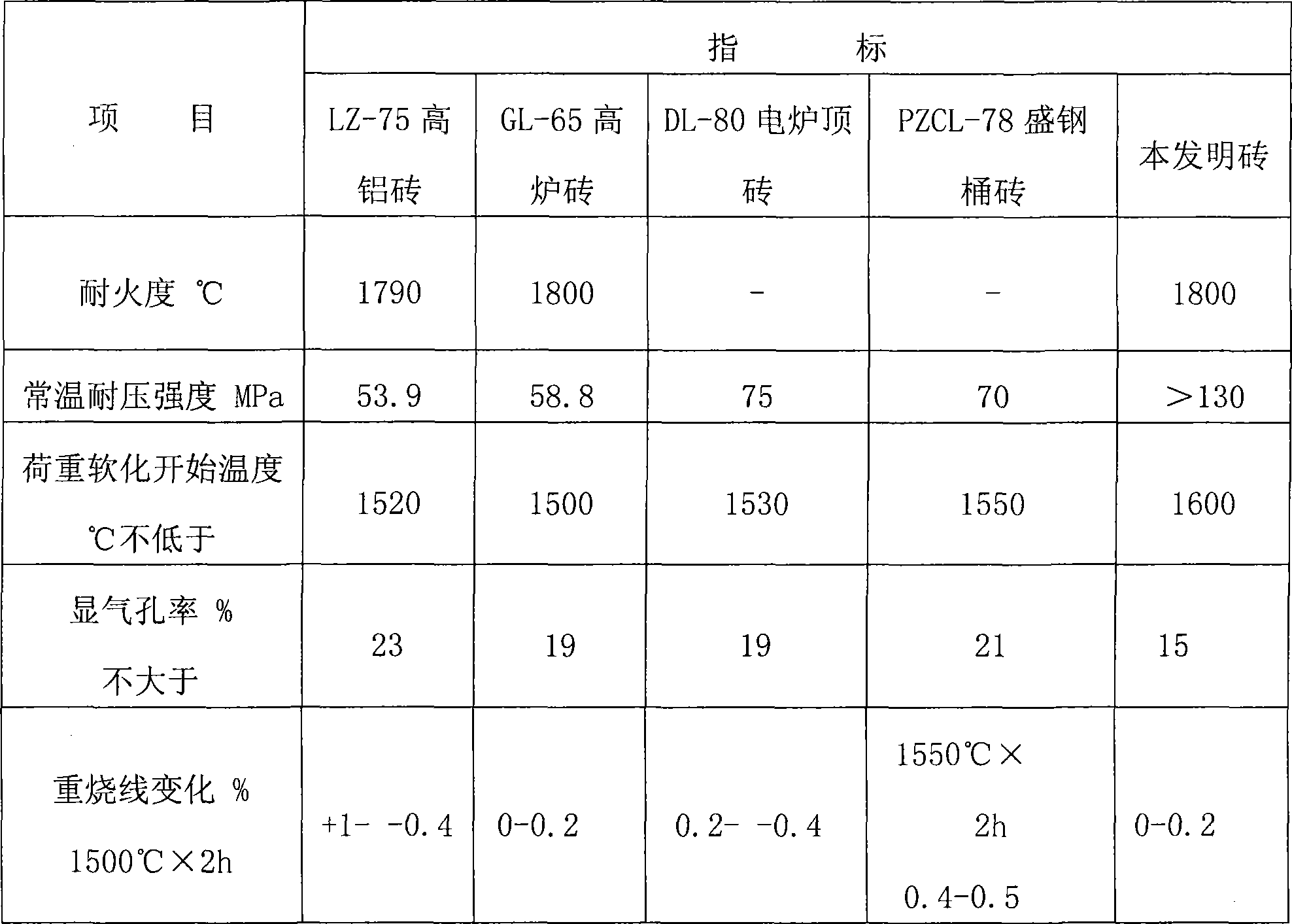

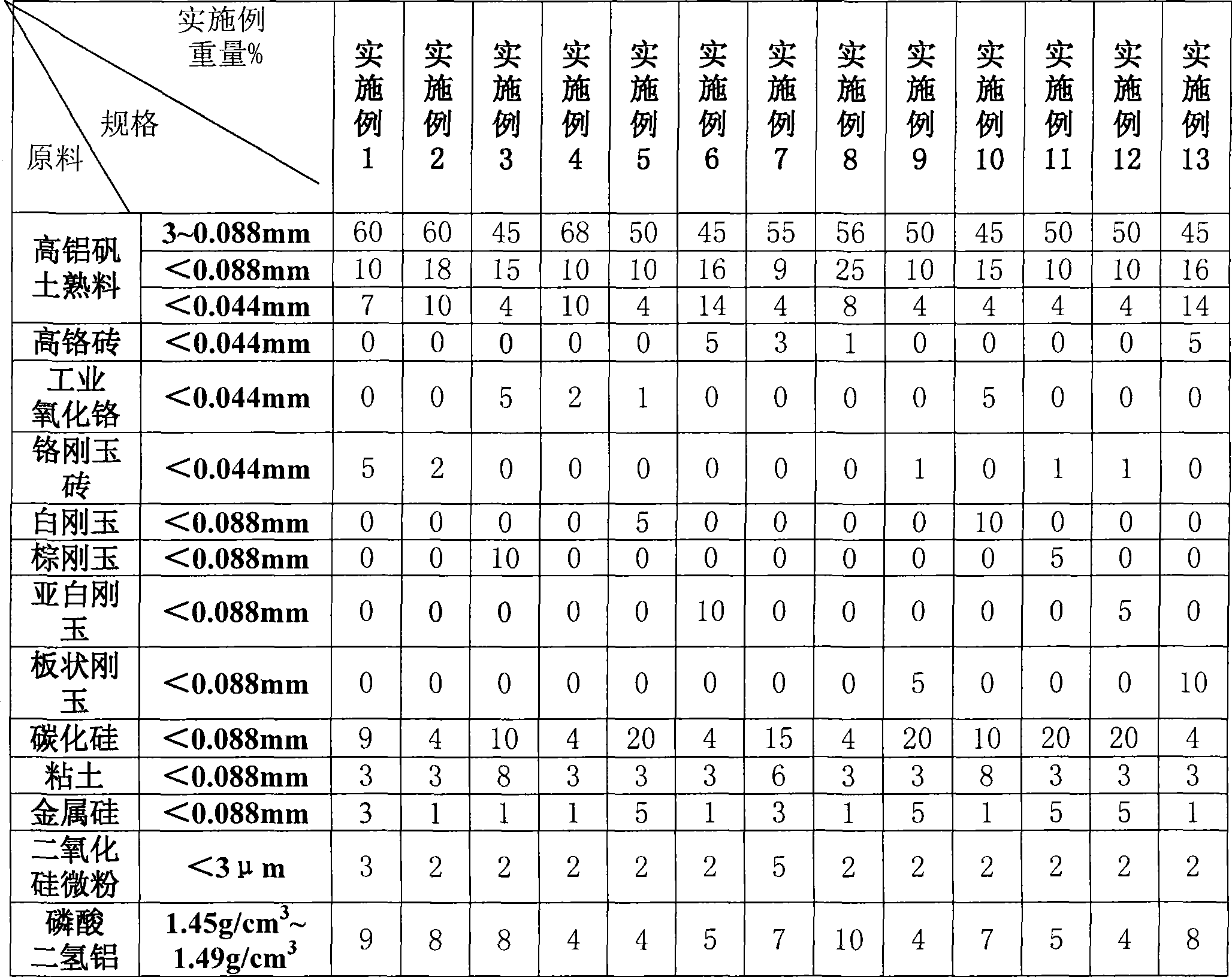

The invention discloses a phosphate-bonded aluminum silicon carbide brick, which is characterized by comprising main ingredients and a phosphate binder, wherein the main ingredients comprise the following raw materials by weight percentage: 45 to 68 percent of bauxite chamotte with a granularity of 3 to 0.088 mm, 10 to 25 percent of bauxite chamotte with a granularity of less than 0.088 mm, 4 to 14 percent of bauxite chamotte with a granularity of less than 0.044 mm, 0 to 10 percent of corundum, 1 to 5 percent of a chromic oxide-containing material, 4 to 20 percent of silicon carbide, 3 to 8 percent of clay, 2 to 5 percent of silicon dioxide micro powder, and 1 to 5 percent of metallic silicon; and the phosphate binder is added in an amount which is 4 to 10 percent of the weight of the main ingredients. The aluminum silicon carbide brick is made into high quality aluminum silicon carbide brick which has an apparent porosity of less than 15 percent, a cold crushing strength of more than 130MPa, a starting refractoriness under load of more than 1,600 DEG C and high inoxidability by ageing mixture, back rolling, forming, drying and baking.

Owner:巩义市金岭耐火材料有限公司

Phosphate binder for casting

InactiveCN101417315AHigh heat intensityLow collapsibilityFoundry mouldsFoundry coresPhosphatePhosphoric acid

The invention relates to a phosphate binder used for casting, which comprises the components by weight ratio: 45 to 55 percent of phosphoric acid, 33 to 45 percent of aluminium dihydrogen phosphate, 5 to 15 percent of boric acid and 6 to 12 percent of citric acid. The binder can also be mixedly matched with 0.5 to 2 percent of magnesium oxide curing agent by weight ratio. The binder adopts the phosphoric acid and the aluminium dihydrogen phosphate as a binder main body, and is added with the boric acid and citric acid for improving the bonding property, thus being one phosphate binder with good property used for casting. The binder has the advantages of low cost, little environmental pollution, high hot strength, good collapsibility and the like, can improve working environment to the utmost extent, and reduce production cost.

Owner:大连核心铸造技术工程研究所

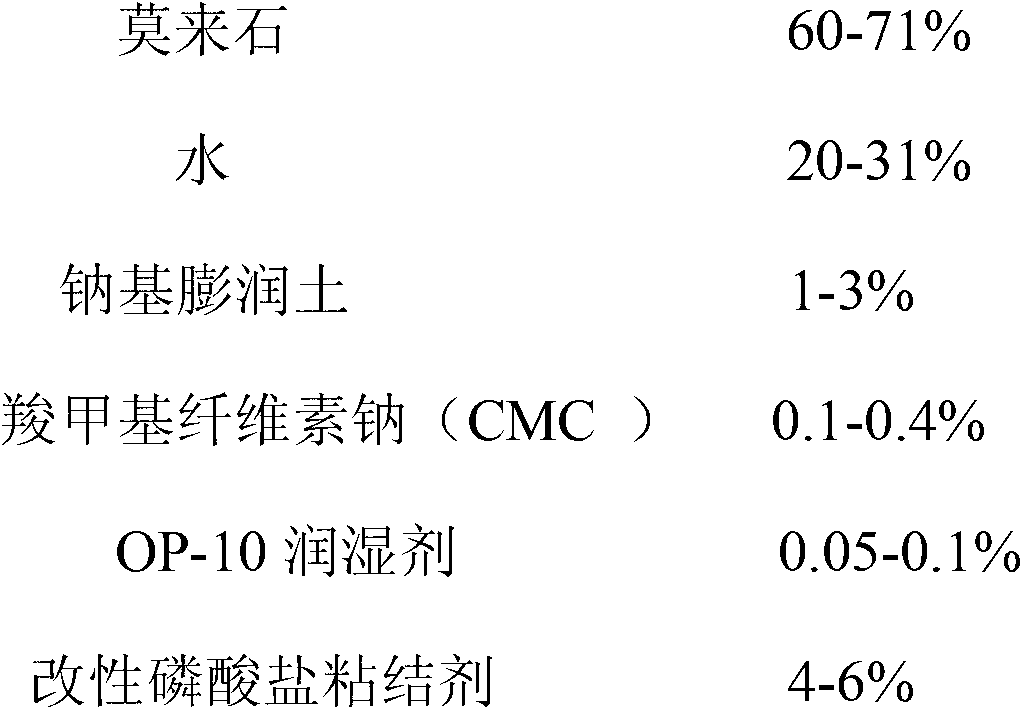

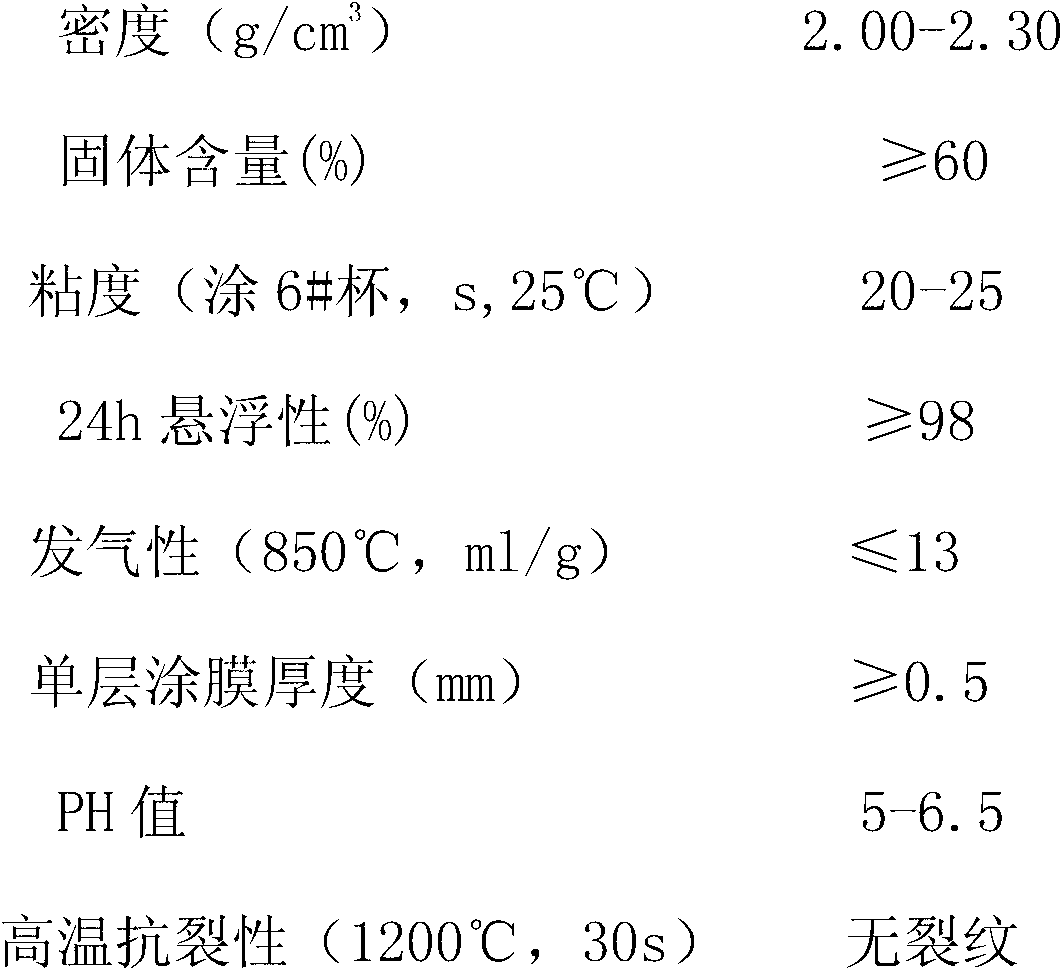

Water-based self-drying casting paint, and preparation method and application method

InactiveCN103223458ATightly boundImprove rheologyFoundry mouldsFoundry coresWater basedSodium Bentonite

The invention provides a water-based self-drying casting paint, and a preparation method and an application method. According to the invention, 1-3% of sodium-based bentonite and water 1-1.5 times the weight of bentonite are uniformly stirred with high speed; the mixture is added in a sealed container and is subjected to standing, where the mixture is sufficiently wetted and activated, such that a liquid A is prepared; 0.1-0.4% of sodium carboxymethyl cellulose is dispersed by using ethanol with a concentration no lower than 95% according to a weight ratio of 1:1; water with an amount 30-50 times that of the mixture is added; the mixture is uniformly stirred and is subjected to standing and sufficient initiation; the mixture is mixed with the liquid A; the obtained mixture is stirred with a proper amount of water; a composite suspension is prepared by grinding by using a colloid mill; the suspension is mixed and grinded with 60-71% of mullite, 0.05-0.1% of a wetting agent, and 4-6% of a modified phosphate binder, such that a pasty paint is prepared; and the pasty paint is diluted by using water, such that the paint is obtained. After a reaction with an alcohol-based paint comprising magnesia powder, the paint can be self-dried. Therefore, cost of independent use of an alcohol-based paint or a water-based paint is greatly reduced, and the influence to the environment is greatly ameliorated.

Owner:HUBEI UNIV OF TECH

Treatment of chronic renal failure and other conditions in domestic animals: compositions and methods

InactiveUS20080058250A1BiocideHeavy metal active ingredientsAge related diseaseCombined Modality Therapy

The present invention generally concerns the management of age-related diseases in domestic animals. Specifically, the present invention is directed to combination therapies for the treatment of progressive renal diseases (e.g., Chronic Renal Failure) and their accompanying secondary disease states. In a composition aspect, the present invention provides a composition comprising a phosphate binder and another pharmaceutically active ingredient. The other pharmaceutically active ingredient is selected from a group consisting of antihypertensives, calcitrol, vitamin D analogues, lipid restriction products, potassium salts, treatments for anemia and alkalization compounds.

Owner:SPECTRUM PHARMA INC

Composition comprising a phosphate binder and its preparation

InactiveUS20040234595A1Good lookingImprove propertiesSolid waste managementAlkali metal silicate coatingsInorganic phosphateCalcium silicate

A binder, a composition, a product and a kit, as well as a process for preparing the binder and composition, are directed to a composition useful as an inorganic phosphate binder, which binder is characterized as having calcium silicate sites which are connected the one with the other by alumina-silica phosphate bonds, and a filler.

Owner:XEXOS

High-fluidity phosphate inorganic binder sand and preparation method thereof

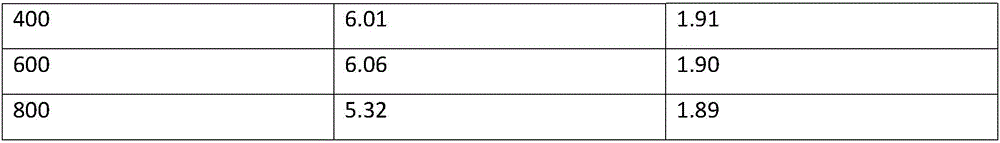

The invention belongs to the field of casting and particularly relates to high-fluidity phosphate inorganic binder sand and a preparation method thereof. The high-fluidity phosphate inorganic binder sand comprises, by mass, 2500 parts of burnt sand, 100 parts of a phosphate inorganic binder, 8 parts of a metallic oxide curing agent and 5 parts of an addition agent. The addition agent comprises a solution prepared by one or more nonionic surface active agents such as alkyl glycoside, 1-61, 1-62, S-80 and MOA-9P, and silicon dioxide with the granularity at 400-1200 meshes and mixed with the solution; and the weight ratio of the nonionic surface active agents to the silicon dioxide is 1:5-1:3. According to the high-fluidity phosphate inorganic binder sand and the preparation method thereof, while the inherent advantages of cleanliness and environment protection, good collapsibility, high strength and the like of the phosphate binder sand are maintained, the fluidity of the phosphate binder sand is greatly improved, and requirements for novel green casting materials and a casting method in modern casting production are met.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

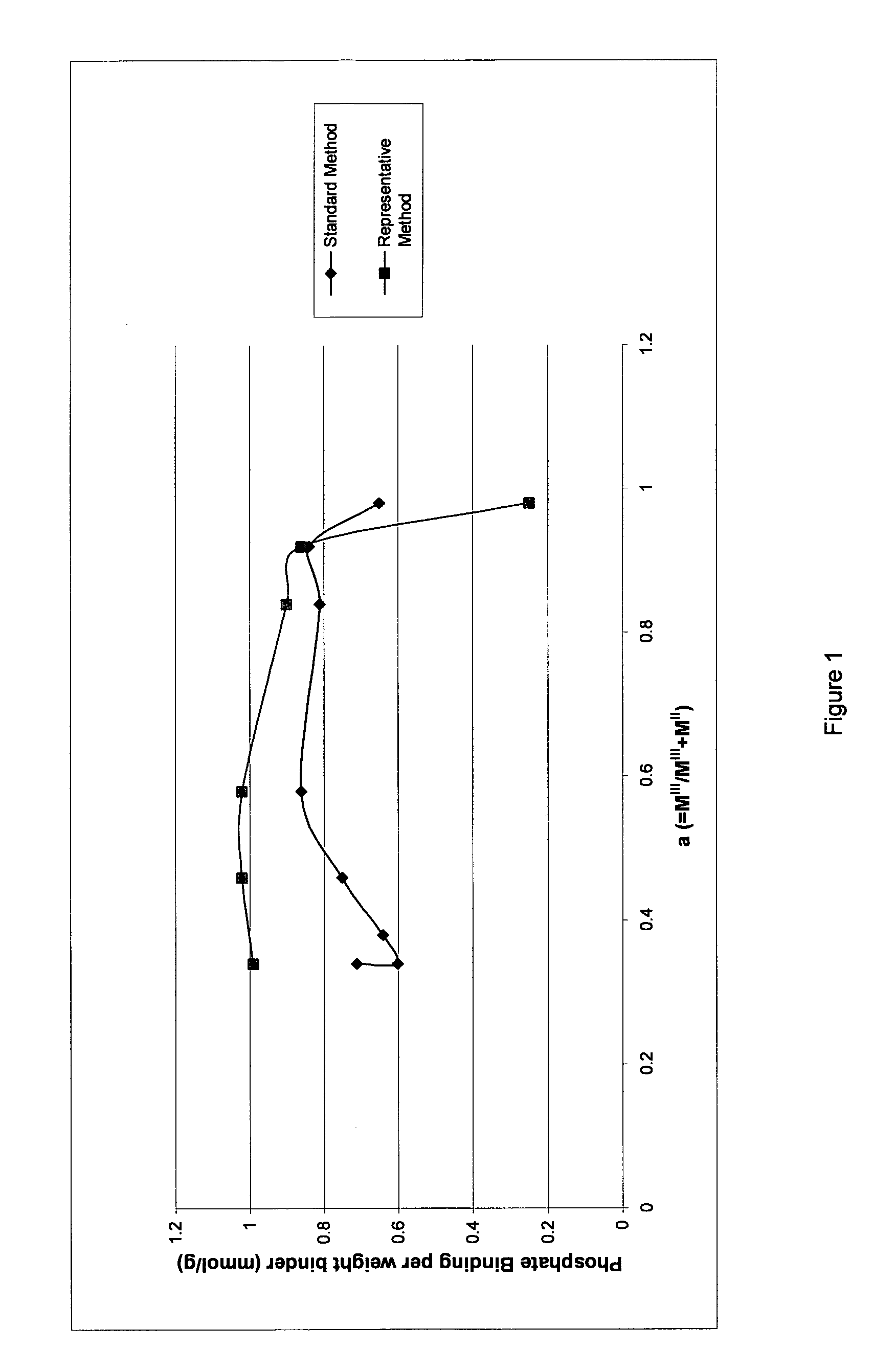

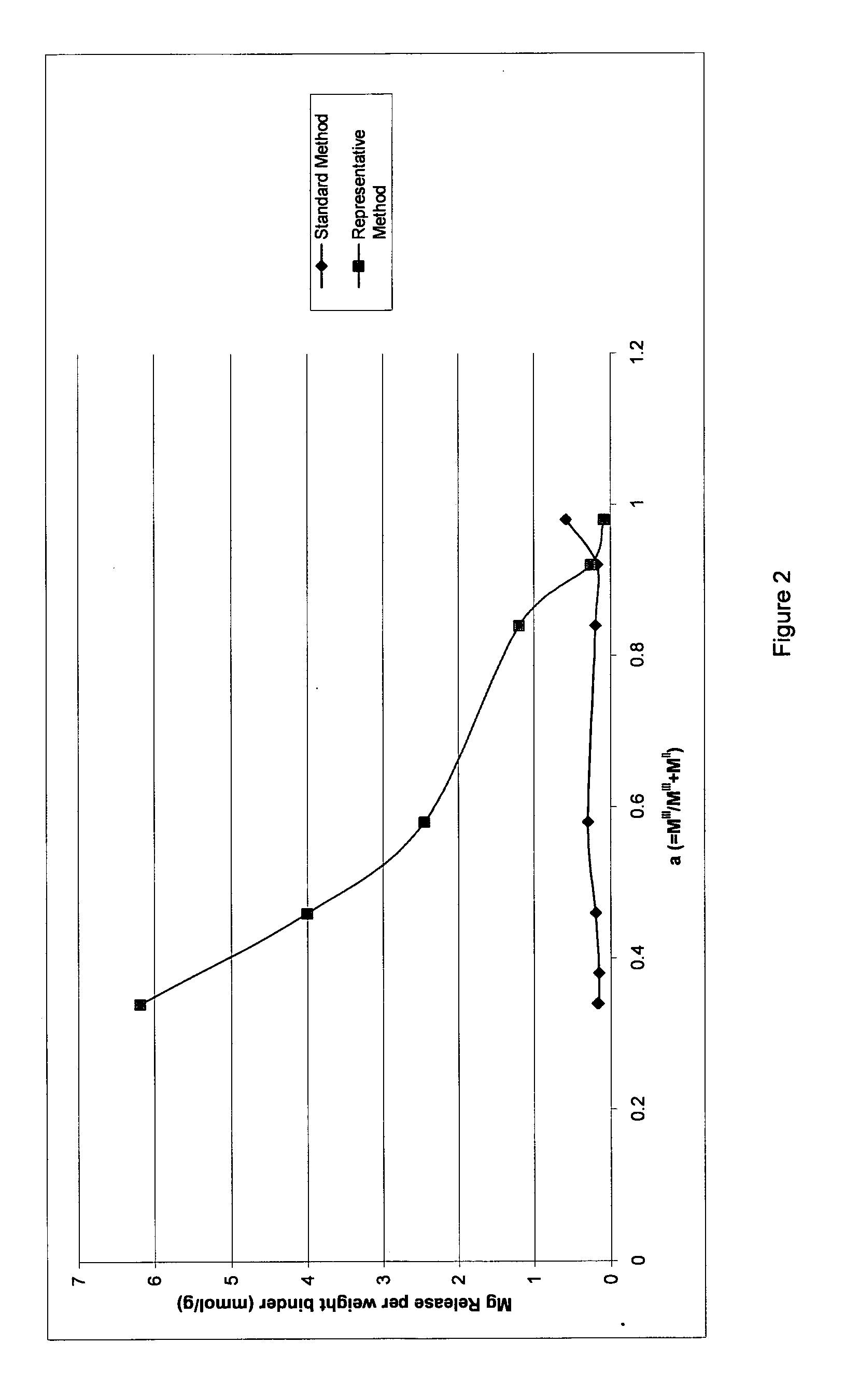

Mixed metal compounds for treatment of hyperphosphataemia

The present invention relates to mixed metal compounds having pharmaceutical activity, especially as phosphate binders. It also extends to methods of manufacture of those compounds, as well as to pharmaceutical compositions containing such compounds. It further relates to their pharmaceutical use. In particular, the present invention relates to use of compounds of Formula (I): MII1-aMIIIa wherein M is at least one bivalent metal (i.e. with two positive charges); M1 is at least one trivalent metal (i.e. with three positive charges); and 1>a>0.4.

Owner:OPKO IRELAND GLOBAL HLDG LTD

Aluminum magnesium chromium composited spinel brick

The invention belongs to the field of fire resistant materials, and particularly relates to an aluminum magnesium chromium composited spinel brick. The brick comprises the following raw materials in percentage by weight: 30 to 50 percent of tabular corundum with a granularity of 5 mm to 3 mm, 15 to 35 percent of tabular corundum with a granularity of 3 mm to 1 mm, 5 to 15 percent of tabular corundum with a granularity less than 0.088 mm, 2 to 15 percent of aluminum magnesium spinel with a granularity less than 0.088 mm, 5 to 30 percent of high chromium ore with a granularity of 1 mm to 0 mm, 1 to 10 percent of chrome green with a granularity less than 0.088 mm, and phosphate binder of which the weight is 2 to 5 percent of the total weight of the above materials. According to the invention, the aluminum magnesium chromium composited spinel brick has a high melting point, high hardness, low porosity, good thermal shock resistance and excellent slag resistance especially for ferrosilicon slag erosion and seepage, can meet the usage requirements of harsh working condition parts in a high temperature colored copper melting furnace, an electric furnace for cleaning slag, an anode furnace and a flash furnace, and has remarkable economical benefit.

Owner:河南瑞泰耐火材料科技有限公司

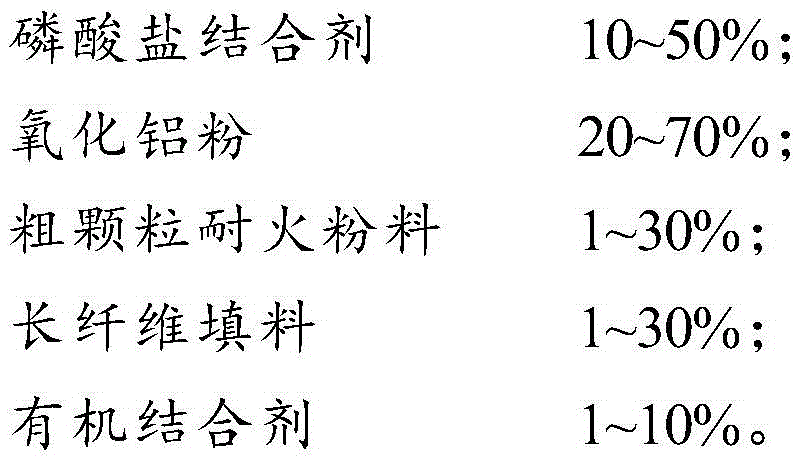

Novel composite coating layer and preparation method thereof

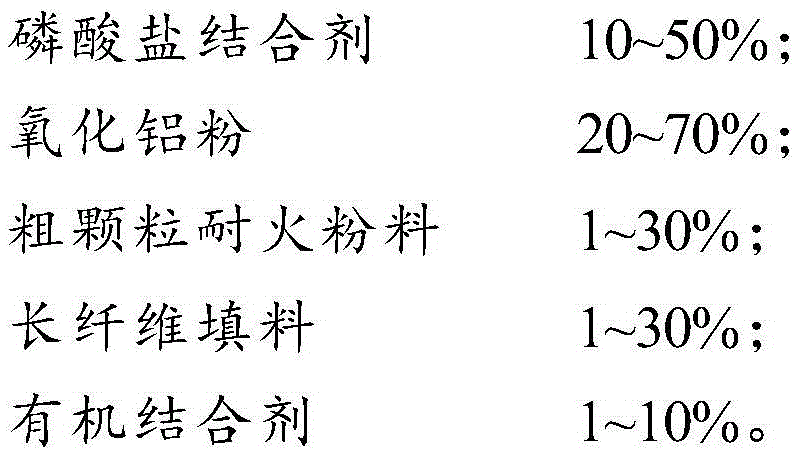

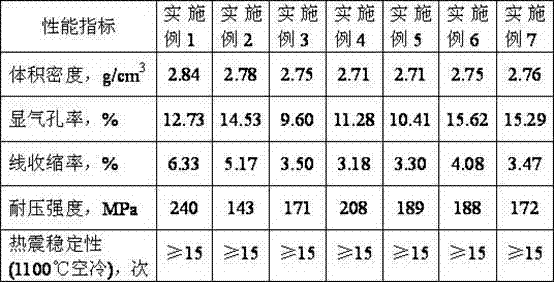

The invention provides a novel composite coating layer; a selected binder is high-temperature-resistant phosphate, and a filler is selected from a high-temperature refractory powder and fibers (including high-temperature-resistant inorganic silicate fibers and related organic fibers); the novel composite coating layer comprises, by the weight percentage, 10-50% of a phosphate binder, 20-70% of an alumina powder, 1-30% of a coarse-particle refractory powder, 1-30% of a long fiber filler, and 1-10% of an organic binder. The novel composite coating layer comprises the following main performance indexes: the volume weight after the novel composite coating layer is dried at room temperature is 1500-2500 kg / m<3>, the compressive strength is 1-26 MPa, the breaking strength is 1-15 MPa, the heating linear shrinkage is 0-3%, the solid content is 60-95%, the discretionary reduction is 2-30%, the viscosity is 10000-100000 MPa*s, and the using temperature is 800-1400 DEG C. The novel composite coating layer has the advantages of excellent thermal shock resistance and air flow scouring resistance, prevents a fiber furnace lining in a high temperature furnace from directly making contact with a severe environment in the furnace, so as to prolong the service life of the furnace lining, and improve furnace heat-preservation and heat-insulation effects.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Preparation method of plasma sprayed ceramic composite coating for ceramic pot

InactiveCN105060941AImprove densification performanceImprove wear resistanceCeramic compositeCalcium Binder

The invention relates to a preparation method of a plasma sprayed ceramic composite coating for a ceramic pot. The plasma sprayed ceramic composite coating comprises a nanometer oxide, a magnesium oxide, silicon carbide ceramic, nanometer silver nitrate, titanium carbide, a yttrium oxide, zirconium silicate, water glass, glass fiber, graphite, expanded vermiculite, sorbic acid, an organo-siloxane coupling agent, a phosphate binder, polymethacrylate emulsion, JFC and deionized water. The preparation method has the advantages that an obtained coating material replaces an existing non-sticky Teflon coating and has good mechanical property, high strength, abrasion resistance, heat resistance and antibacterial property and is non-toxic and environmentally-friendly.

Owner:WENZHOU HONGCHENGXIANG TECH

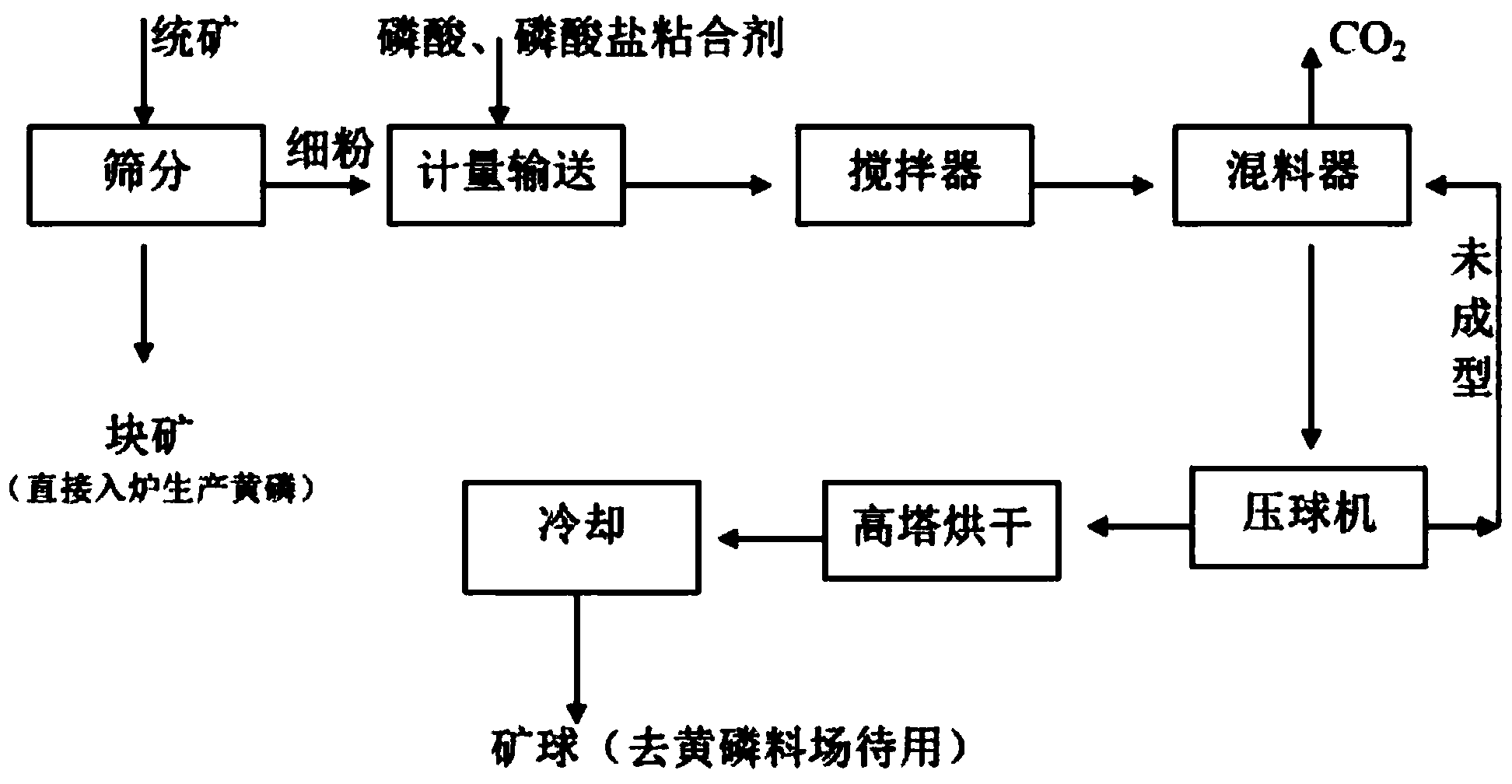

Method for producing powdered rock phosphate balls by using powdered rock phosphate

ActiveCN103964404AIncrease contentRaise the gradeRaw phosphate material treatmentCO2 contentCalcium Binder

The invention relates to the technical field of mineral processing, in particular to a method for producing powdered rock phosphate balls by using powdered rock phosphate screened out by enterprises or mineral powder left after mine production with low-concentration phosphoric acid. The method comprises the steps of screening, batching, mixing, ball pressing, drying and cooling; in the method, the content of P2O5 in phosphate rock is increased as a phosphate acid and phosphate binder is adopted and the P2O5 in the binder ultimately enters a furnace and participates the phosphorus producing reaction, and the quality of phosphate rock is improved; carbonate impurities in the added phosphoric acid and phosphate rock are subjected to chemical replacement reaction, and mixing is carried out by a double-roll mixer, so that carbon dioxide and organic matters harmful to the electric furnace during production can be fully released; in the production of yellow phosphor, the power consumption of the electric furnace can be reduced by 190 kilowatt hour as long as 1% of CO2 content is reduced, the consumption of coke can be reduced by 29 kilograms, and the production costs of the enterprises can be greatly reduced.

Owner:贵州福泉川东化工有限公司

Method for preparing corundum mullite crucible

The invention relates to a crucible applied to the fields of ceramic industry, metal smelting, powder high-temperature calcination and the like, in particular to a method for preparing a corundum mullite crucible. The corundum mullite crucible takes mullite particles with the particle size being 2-0.1mm and fine mullite powder with the particle size being 0.061-0.075mm as aggregates, and a matrix part comprises sintered alumina micro powder with the particle size being 0.003mm at most and also comprises mullite micro powder with the particle size being 0.045mm at most or adds clay with the particle size being 0.045mm at most at the same time. A binder is a phosphate binder or adds an aluminate binder, magnesium oxide micro powder with the particle size being at most 0.045mm is adopted as a coagulant, and a water reducer adopts a high-efficiency water reducer or sodium tripolyphosphate. According to the method, the deformation and the yield of the casting crucible products sintering processing are improved and increased, and the purposes of cost reducing, efficiency increasing, energy saving and consumption reducing are achieved.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Phosphate combined low-aluminum Guimo brick and preparation method thereof

The invention relates to a phosphate combined low-aluminum Guimo brick and a preparation method thereof. The brick comprises 30-59% of 3-1mm high-aluminum bauxite, 11-28% of 1-0.088mm high-aluminum bauxite, 0-20% of 0.044<mm bauxite micropowder, 0-18% of 0.088<mm alumina micropowder, 5-19% of 0.088<mm calcined kaolin, 5-16% of 0.088<mm silicon carbide, 8-22% of 20-15mu m silicon micropowder and 3-10% of phosphate binder. The preparation technique comprises the following steps: proportionally mixing the raw materials, adding the phosphate binder, aging, grinding, mechanically forming, drying, heating the dried green brick to 450-600 DEG C, and keeping the temperature for 2-8 hours. The phosphate combined low-aluminum Guimo brick can utilize the low-grade raw material, and has the advantages of favorable alkali resistance and better high-temperature resistance.

Owner:ZAOZHUANG GAIZE FURNACE ENG

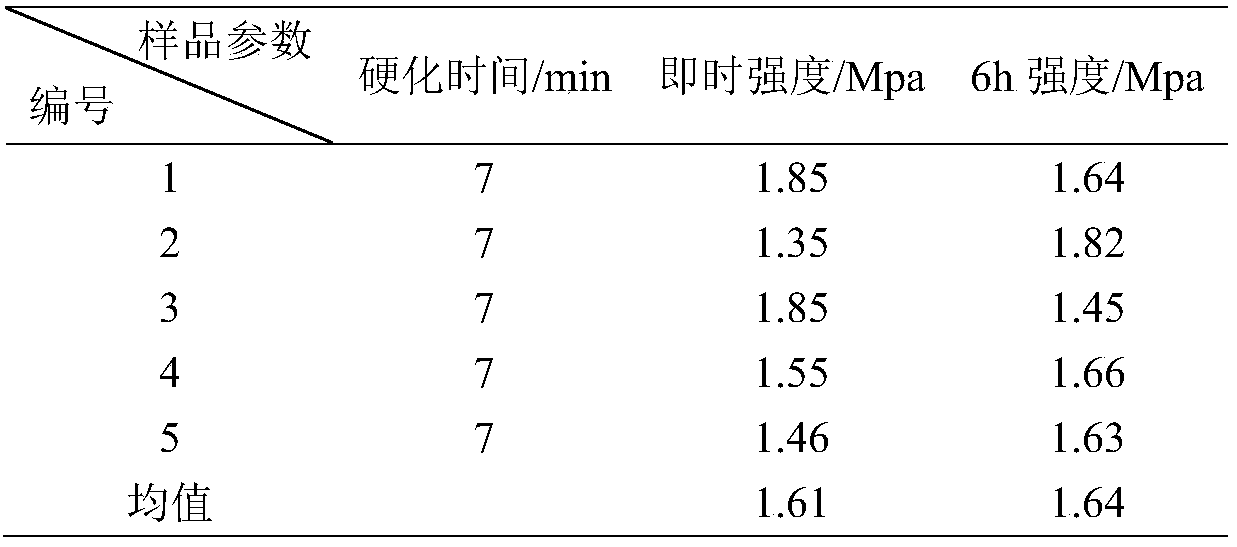

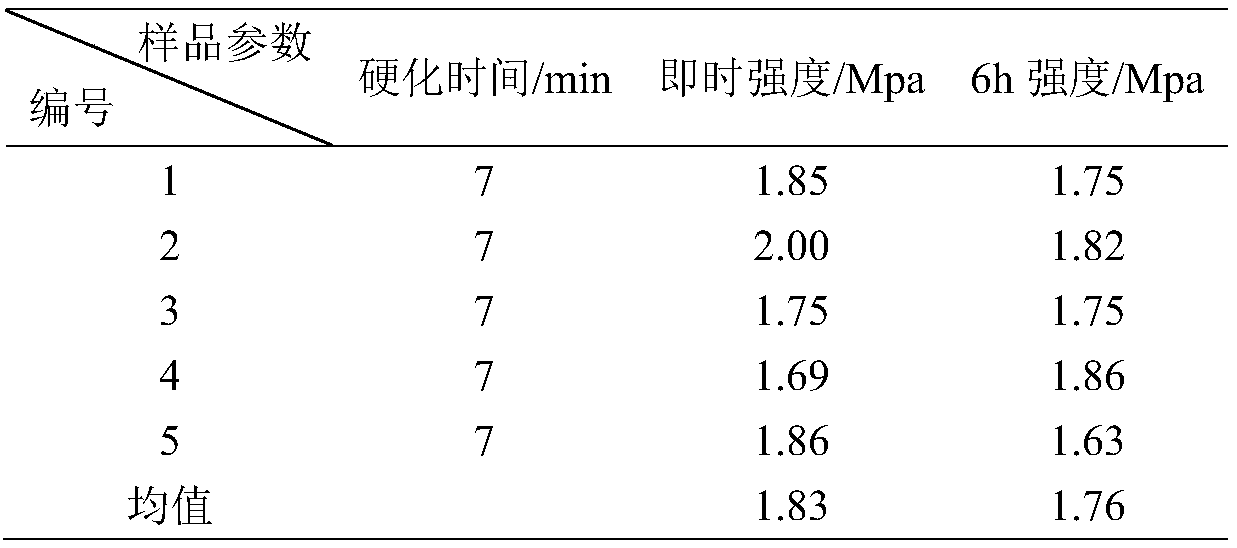

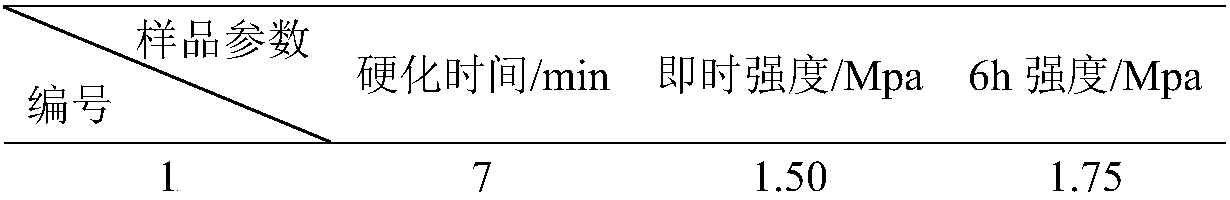

Ferrous sulfate modified phosphate binder and preparation method thereof

ActiveCN108907069AImprove mechanical propertiesImprove moisture resistanceFoundry mouldsFoundry coresSilicic acidAluminium hydroxide

The invention discloses a ferrous sulfate modified phosphate binder and a preparation method thereof. The ferrous sulfate modified phosphate binder is prepared from raw materials as follows: 53.74%-53.81% of phosphoric acid for industrial use, 10.81%-10.83% of aluminium hydroxide powder, 1.908%-1.910% of boric acid, 0.318% of silicic acid, 1.272%-1.274% of magnesium oxide, 0.02%-0.159% of ferroussulfate and 31.8%-31.84% of water. The preparation method comprises following steps: the raw materials are added in specific sequence, and with addition of ferrous sulfate, a macromolecular compound with constitution water can be formed in a reaction process, so that the finally prepared phosphate binder has higher stability and higher moisture absorption performance. A test indicates that a sandmold prepared from the binder has higher instant strength and constant-humidity room (RH40%) 6h strength, the maximum instant strength can reach 1.86 MPa, and the maximum constant-humidity room (RH40%) 6h strength can reach 1.76 MPa.

Owner:HUBEI UNIV OF TECH +1

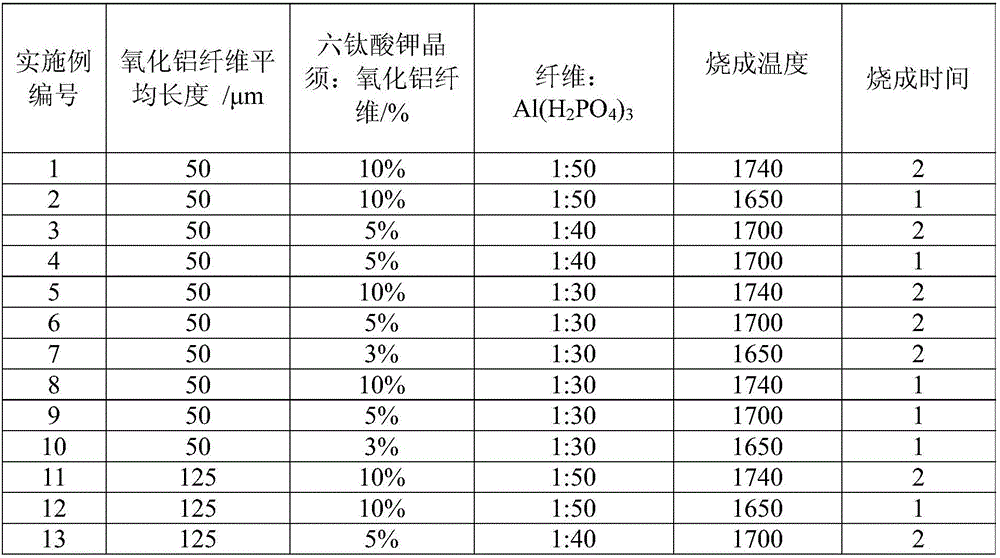

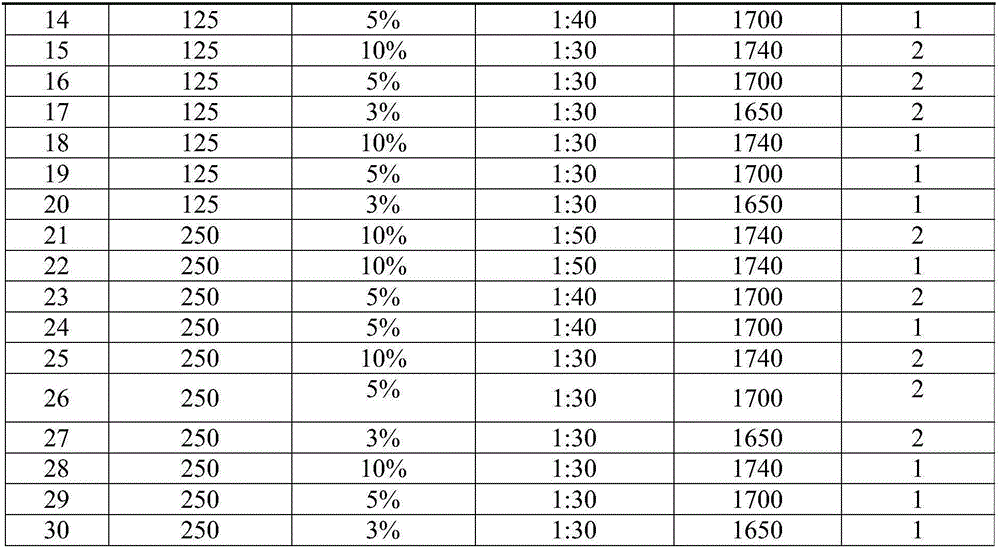

Preparation method of high-temperature-resistant, high-strength and rigid thermal insulation material

ActiveCN106587901AImprove mechanical propertiesImprove insulation performanceCeramicwareFiberPorosity

The invention relates to a preparation method of a high-temperature-resistant, high-strength and rigid thermal insulation material and belongs to the technical field of preparation of inorganic composite materials. The preparation method comprises steps as follows: (1) pretreatment: alumina fibers and potassium hexatitanate whiskers are chopped; (2) one of an aluminum dihydrogen phosphate binder or a lanthanum phosphate binder is selected as a binder; (3) suction filtration forming: the chopped alumina fibers and potassium hexatitanate whiskers prepared in step (1) are placed in the binder prepared in step (2) in the mass ratio and mixed, slurry obtained through mixing is stirred, subjected to suction filtration forming, demolding and transferred to a constant-temperature drying oven; (4) heat treatment: a material prepared in step (3) is placed in a kiln for heat treatment. The preparation method is simple to operate and easy to implement, and the obtained target product has high mechanical properties and thermal insulation performance on the premise that the high porosity is guaranteed and has good anti-scouring performance and thermal shock resistance.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

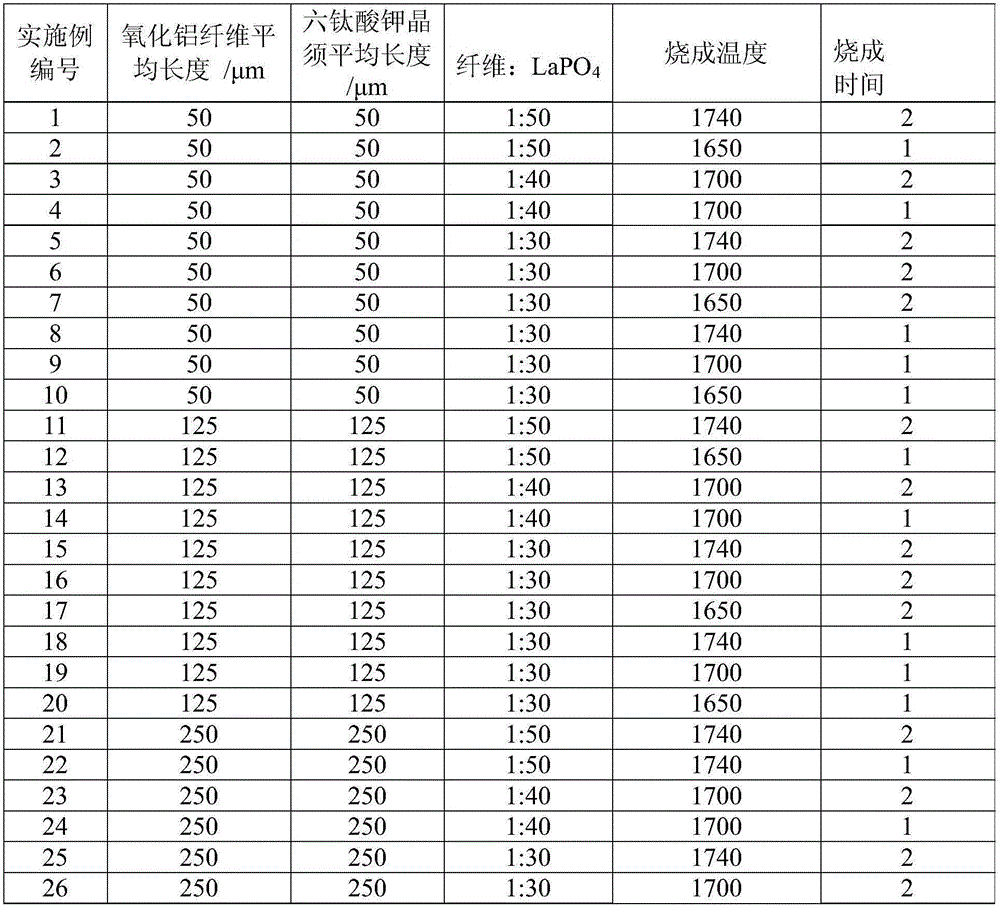

Curing agent for inorganic phosphate binder precoated sand and application thereof

ActiveCN112453314AUniform particle sizeImprove liquidityFoundry mouldsFoundry coresInorganic phosphateCalcium Binder

The invention discloses a curing agent for inorganic phosphate binder precoated sand. The curing agent for the inorganic phosphate binder precoated sand comprises the following components: 2 to 6 parts of coupling agent; 25 to 40 parts of a phosphate binder; 2 to 6 parts of an organic weak acid aqueous solution; 25 to 30 parts of crystalline hydrate; and 30 to 50 parts of PVP coated magnesia powder. According to the curing agent for the inorganic phosphate binder precoated sand provided by the invention, the inorganic phosphate binder and the crystalline hydrate are attached to the surfaces ofsand grains, hot air is introduced to enable the binder to be dried, the crystalline hydrate is wrapped in the binder, dry precoated sand is obtained, and the dry precoated sand has excellent flowability; and after sand shooting, the hydrate is decomposed into water molecules through mold heating so as to wet the binder, and the wetting binder and the sand grains are bonded and formed with each other and then rapidly cured to form strength.

Owner:保定保蒙新型材料科技有限公司

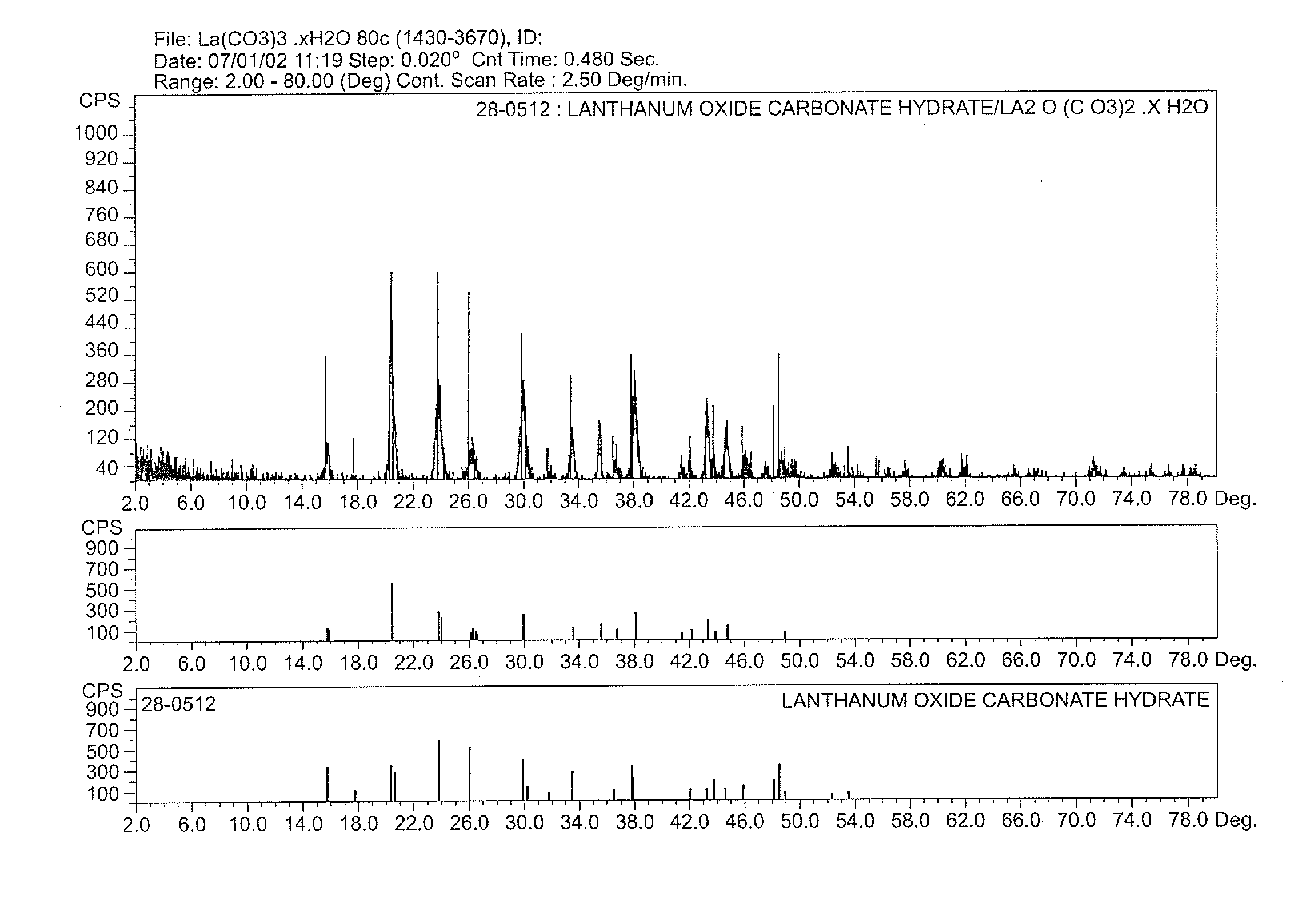

Hyperphosphatemia in domestic animals: compositions and methods of treatment

The present invention is generally related to the treatment of hyperphosphatemia in domestic animals. It is specifically directed to compositions containing phosphate binders that are palatable to domestic animals and methods using such compositions. In a composition aspect, the present invention provides a composition that includes: a rare earth compound (e.g., lanthanum oxycarbonate or lanthanum carbonate hydroxide), calcium salts (e.g, calcium carbonate or calcium acetate), aluminum salts (e.g., aluminum hydroxide or a hydrophilic exchange resin; and an ingredient of domestic animal food, wherein the ingredient is selected from a group consisting of chicken, beef, lamb, chicken meal or lamb meal, corn, rice, bone meal, fish meal, fish, egg product, beef, beef meal, corn gluten meal, poultry by-product meal, wheat flour, beef tallow, maple syrup, honey, apple, flaxseed, flaxseed meal, rice bran and germ, oats, barley, and wheat bran.

Owner:SPECTRUM PHARMA INC

Method of calculating a phosphorus-protein ratio

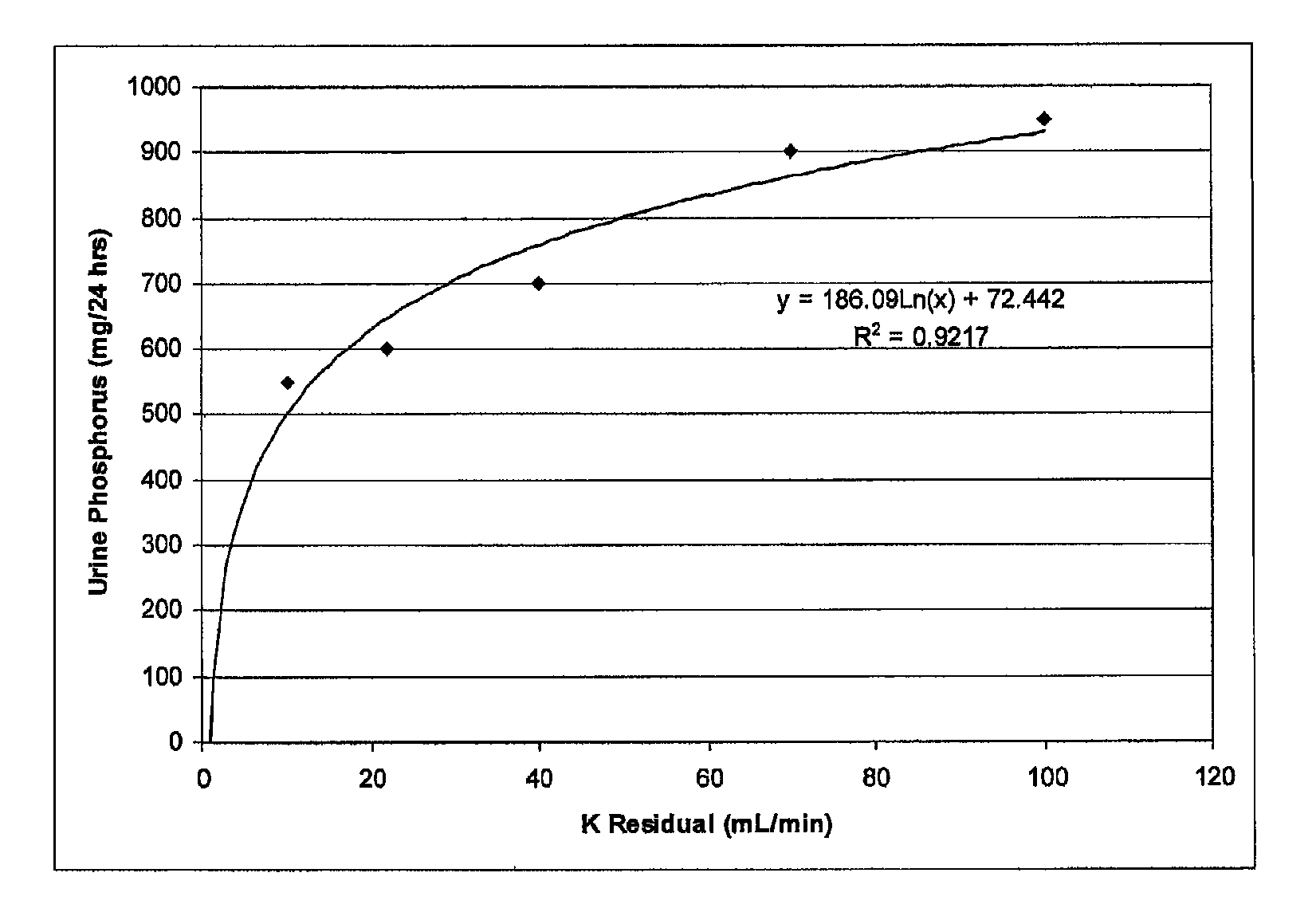

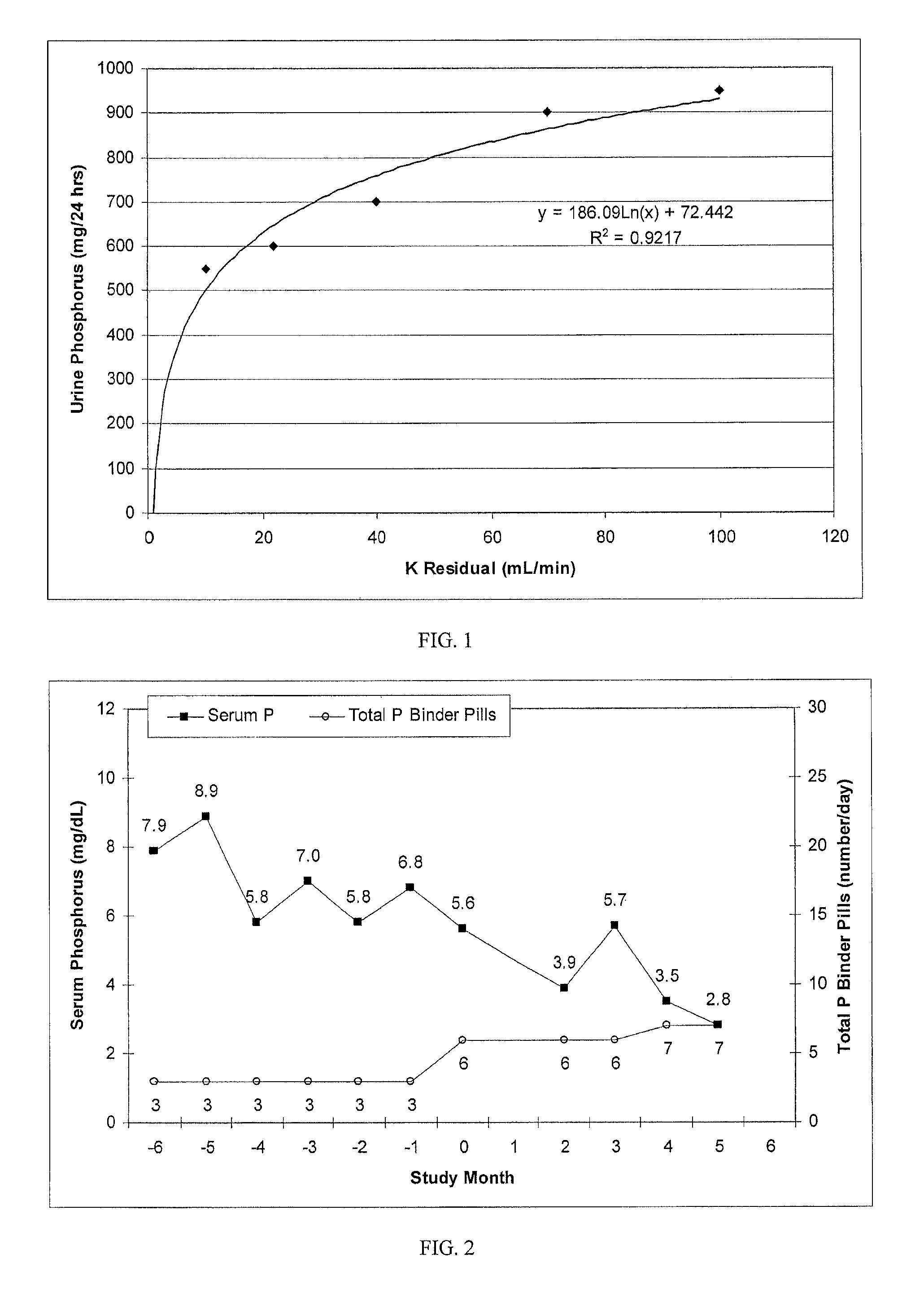

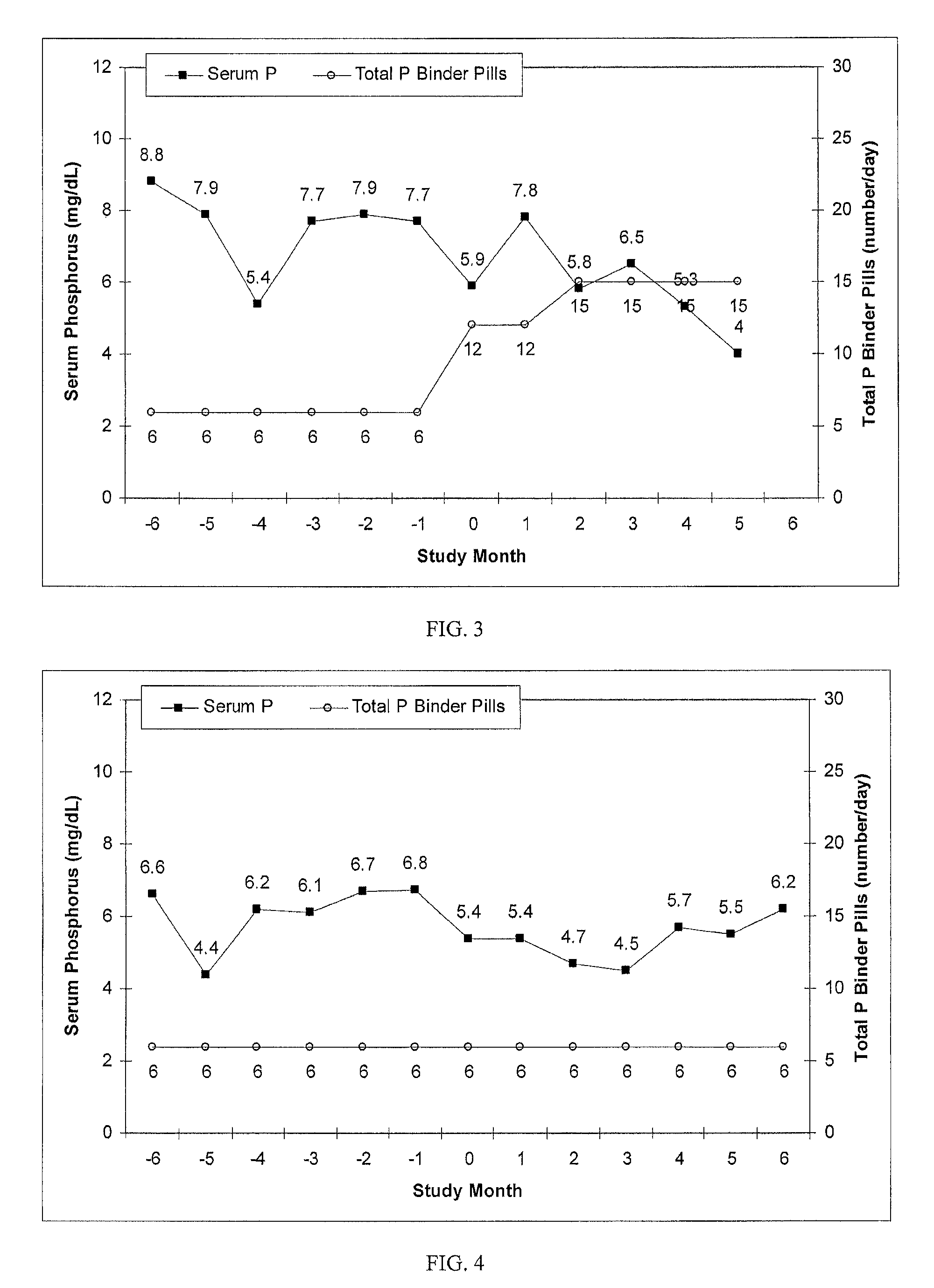

A method of identifying a patient who is non-compliant with prescribed diet and / or phosphate binder regimen calculates a phosphorus-protein ratio (PPR) by calculating the patient's protein intake, measuring the patient's serum phosphorus concentration, and estimating the amount of phosphorus removed by the patient's kidneys from measured residual urea clearance. The PPR is the ratio between the total amount of phosphorus removed from the patient and the patient's protein intake. The method enables identifying a patient that is non-compliant with prescribed diet and / or phosphate binder regimen if the PPR is outside of an acceptable range.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com