Preparation method of high-temperature-resistant, high-strength and rigid thermal insulation material

A thermal insulation material and high-strength technology, which is applied in the field of preparation of inorganic composite materials, can solve the problems that are not conducive to the use of large-scale kiln insulation bricks, high material density, and limited use, and achieve good anti-scouring performance, short production cycle, The effect of good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

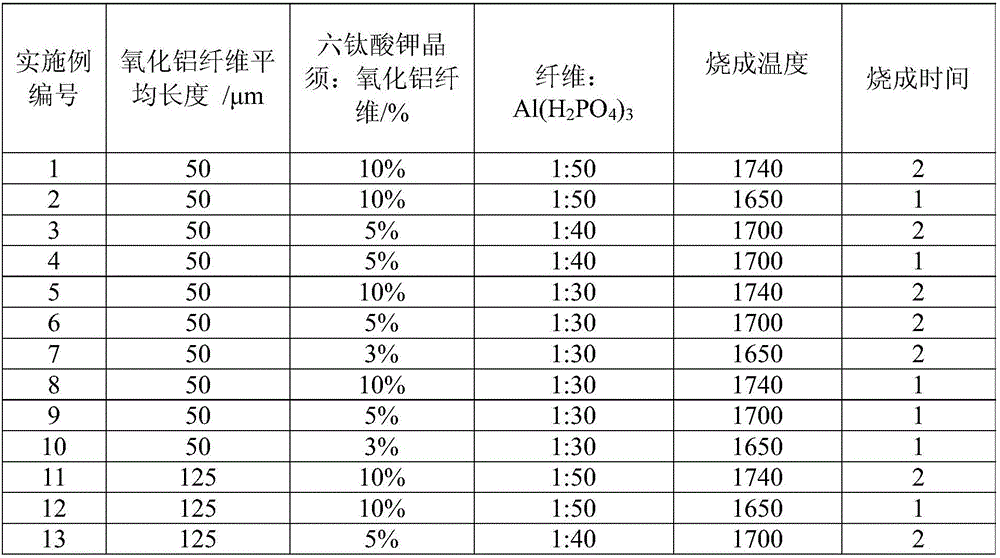

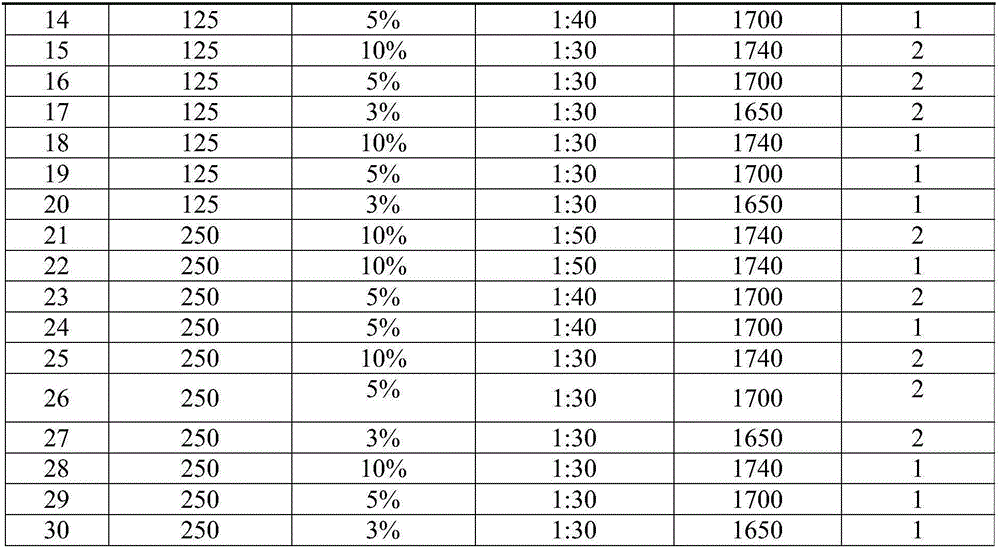

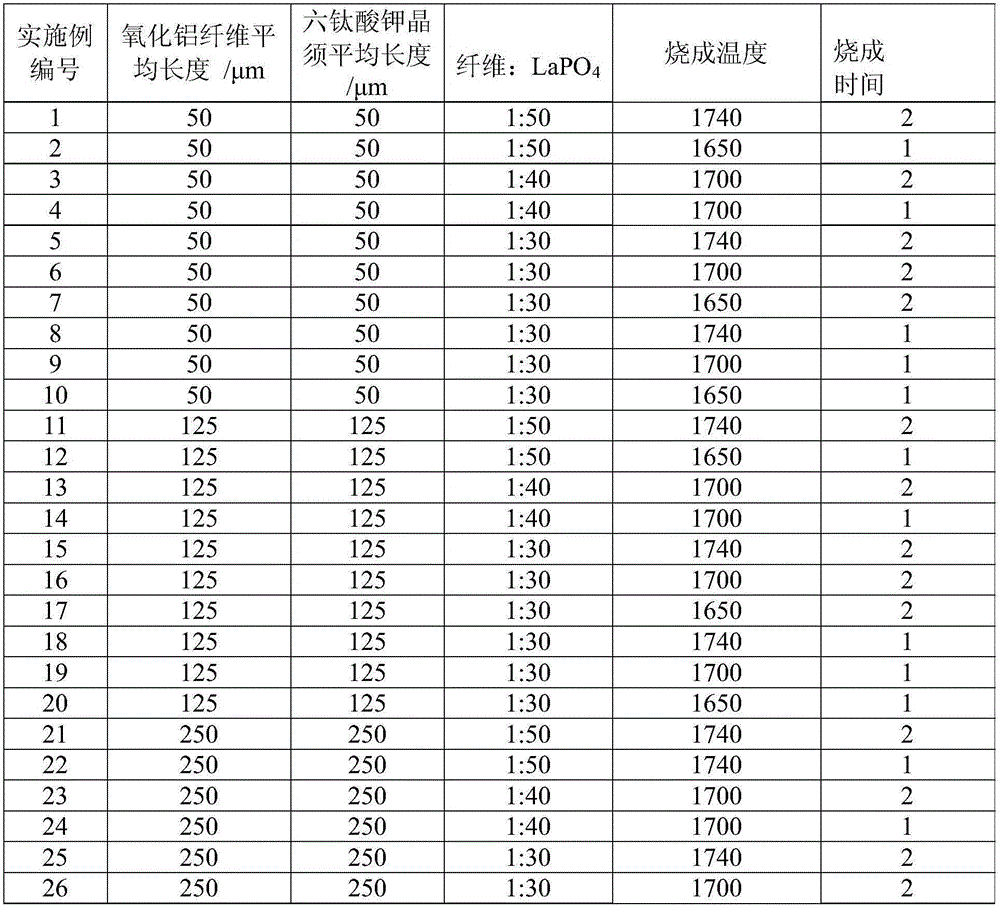

Examples

Embodiment 1

[0032] (1) Weigh 100 g of alumina fiber, and cut the fiber with a shearing device so that the average length of the fiber is 50 μm. Weigh 10 g of potassium hexatitanate whiskers (diameter 5-12 μm, length 50-250 μm).

[0033] (2) According to Al(OH) 3 :H 3 PO 4 :H 2 Al(H 2 PO 4 ) 3 Solution, preparation steps are as follows, weigh a certain amount of aluminum hydroxide (Al(OH) 3 ) slowly into deionized water, mix evenly, and under the condition of 70°C, slowly add concentrated phosphoric acid (H 3 PO 4 ), stirring while adding, to obtain a clear and transparent solution, take 5000gAl(H 2 PO 4 ) 3 solution.

[0034] (3) Mix the alumina fiber and potassium hexatitanate whisker in step (1) with the prepared solution in step (2), and stir evenly to completely disperse the fiber into the solution to obtain fiber slurry.

[0035] (4) Adjust the vacuum degree of the vacuum tank to -0.1 MPa, and the vacuum filtration treatment time is 10 minutes, and the vacuum filtration ...

Embodiment 2

[0040] (1) Weigh 100 g of alumina fiber, and cut the fiber with a shearing device so that the average length of the fiber is 50 μm. Weigh 3 g of potassium hexatitanate whiskers (diameter 5-12 μm, length 50-250 μm).

[0041] (2) According to Al(OH) 3 :H 3 PO 4 :H 2 Al(H 2 PO 4 ) 3 Solution, preparation steps are as follows, weigh a certain amount of aluminum hydroxide (Al(OH) 3 ) slowly into deionized water, mix evenly, and under the condition of 70°C, slowly add concentrated phosphoric acid (H 3 PO 4 ), stirring while adding, to obtain a clear and transparent solution, take 3000gAl(H 2 PO 4 ) 3 solution.

[0042] (3) Mix the alumina fiber and potassium hexatitanate whisker in step (1) with the prepared solution in step (2), and stir evenly to completely disperse the fiber into the solution to obtain fiber slurry.

[0043] (4) Adjust the vacuum degree of the vacuum tank to -0.1 MPa, and the vacuum filtration treatment time is 10 minutes, and the vacuum filtration i...

Embodiment 3

[0048] (1) Weigh 100 g of alumina fiber, and cut the fiber with a shearing device so that the average length of the fiber is 125 μm. Weigh 5 g of potassium hexatitanate whiskers (diameter 5-12 μm, length 50-250 μm).

[0049] (2) According to Al(OH) 3 :H 3 PO 4 :H 2 Al(H 2 PO 4 ) 3 Solution, preparation steps are as follows, weigh a certain amount of aluminum hydroxide (Al(OH) 3 ) slowly into deionized water, mix evenly, and under the condition of 70°C, slowly add concentrated phosphoric acid (H 3 PO 4 ), stirring while adding, to obtain a clear and transparent solution, take 4000gAl(H 2 PO 4 ) 3 solution.

[0050] (3) Mix the alumina fiber and potassium hexatitanate whisker in step (1) with the prepared solution in step (2), and stir evenly to completely disperse the fiber into the solution to obtain fiber slurry.

[0051] (4) Adjust the vacuum degree of the vacuum tank to -0.1 MPa, and the vacuum filtration treatment time is 10 minutes, and the vacuum filtration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com