Method for preparing corundum mullite crucible

A mullite and crucible technology, applied in the field of corundum mullite crucibles, can solve the problems of poor thermal stability and acid and alkali resistance, high cost of crucibles, easy cracking and peeling, etc., to improve yield and thermal stability, improve Yield and erosion resistance, effect of improving sintering yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

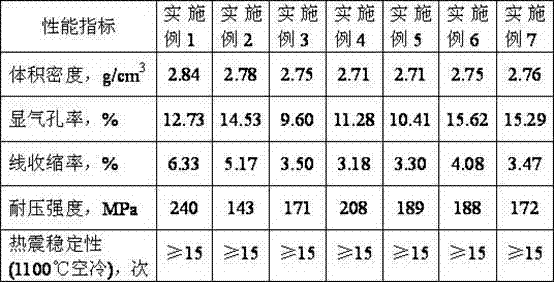

Examples

Embodiment 1

[0035] Example 1: The mass percent of each component is: 29% of sintered mullite particles with a particle size of 2 to 0.1mm, 14% of fused mullite fine powder with a particle size of 0.061mm to 0.075mm, and 14% of fused mullite fine powder with a particle size of ≤0.045mm 6% clay, 35% alumina micropowder with particle size ≤ 3μm, 2.1% pure calcium aluminate cement, 6.48% aluminum dihydrogen phosphate, 0.08% naphthalene-based superplasticizer (FDN-300), 0.08% magnesia micropowder, water 7.26%.

[0036] The preparation method of corundum mullite crucible specifically comprises the following steps:

[0037] (1) First mix the micropowder, dispersant and coagulant in a ball mill tank for about 40 minutes in a certain proportion, so that the micropowder, dispersant and coagulant are fully dispersed and mixed evenly, and then put the mixed matrix powder into the belt Sealed in a woven bag of plastic film;

[0038] (2) Put the mullite particles, premixed fine powder and mullite fin...

Embodiment 2

[0042] Example 2: The mass percent of each component is: 31% of sintered mullite particles with a particle size of 2 to 0.1mm, 13% of fused mullite fine powder with a particle size of 0.061mm to 0.075mm, and 13% of fused mullite fine powder with a particle size of ≤0.045mm Sintered mullite micropowder 10%, alumina micropowder ≤3μm 27%, pure calcium aluminate cement 2.48%, aluminum dihydrogen phosphate 7.42%, magnesia micropowder 0.72%, sodium tripolyphosphate 0.11%, water 8.27%. The preparation method is the same as in Example 1.

Embodiment 3

[0043]Example 3: The mass percentage of each component is: 32% of fused mullite particles with a particle size of 2 to 0.1mm, 9% of fused mullite fine powder with a particle size of 0.061mm to 0.075mm, and a particle size of ≤0.045mm 5% of fused mullite powder, 33% of alumina powder with particle size ≤ 3μm, 4.8% of pure calcium aluminate cement, 10.74% of aluminum dihydrogen phosphate, 0.87% of magnesium oxide powder, 0.16% of sodium tripolyphosphate, and 4.43% of water %. The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com