Patents

Literature

80results about How to "Improve sintering yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High performance strontium-calcium permanent magnetic ferrite magnet and preparation method thereof

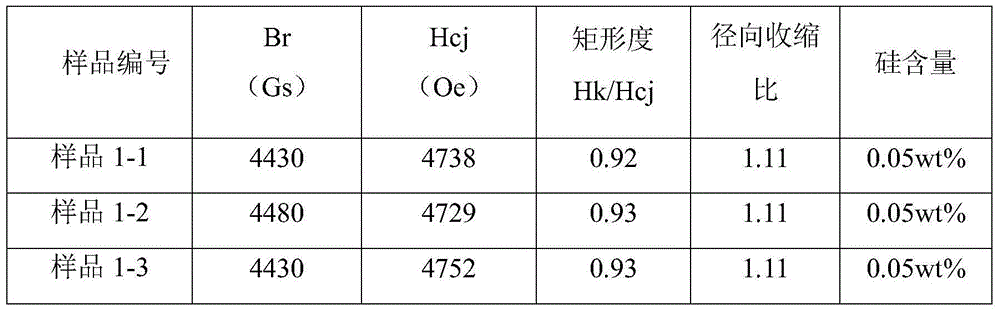

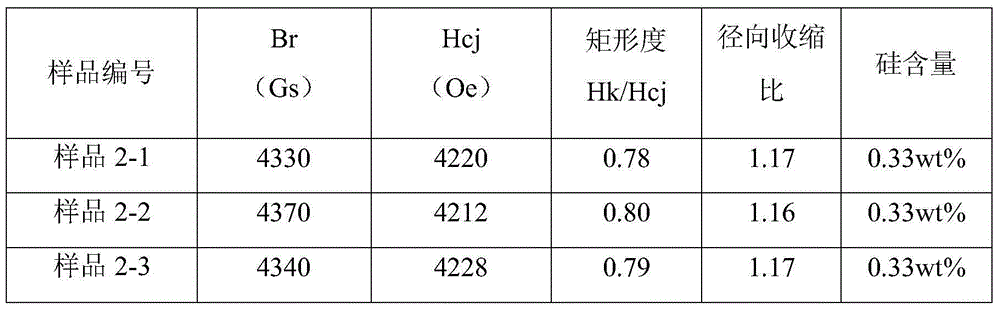

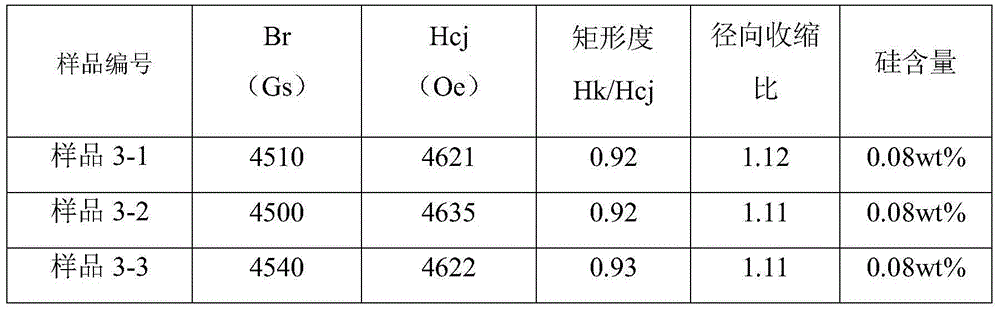

The invention provides a high performance strontium-calcium permanent magnetic ferrite magnet and a preparation method thereof; and the invention belongs to the field of permanent magnetic materials. The magnet has a principal phase of a hexagonal crystal structure. The principal phase of the hexagonal crystal structure consists of metal elements represented by a formula of Sr(x)Ca(y)La1-x-yFe(z)Co(m), and the formula satisfies the conditions that: x is greater than or equal to 0.2 and less than or equal to 0.8; y is greater than or equal to 0.1 and less than or equal to 0.4; z is greater than or equal to 9.0 and less than or equal to 11.0; m is greater than or equal to 0.1 and less than or equal to 0.2; and y / m is greater than or equal to 1.5 and less than or equal to 2.0; meanwhile, by the cooperative use of a secondary additive, the magnet has a high magnetic performance that Br: 4200 Gs - 4600 Gs, Hcj: 4000 Oe - 5600 Oe, and a rectangle degree Hk / Hcj higher than 0.90. In the high performance strontium-calcium permanent magnetic ferrite magnet and the preparation method thereof, a radial shrinkage ratio of a sintered magnet is ranging from 1.10 to 1.12 by controlling the content of silicon in a primary pre-sintering powder material and the secondary additive, thus increasing the production efficiency of the sintering process, reducing the production cost, and meeting the requirements of a massive industrial production.

Owner:马鞍山市鑫洋永磁有限责任公司

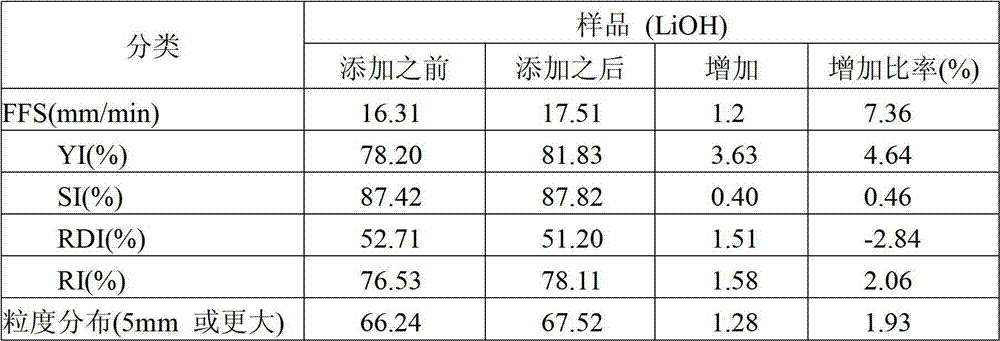

Method for treating iron-bearing dust using sintering process

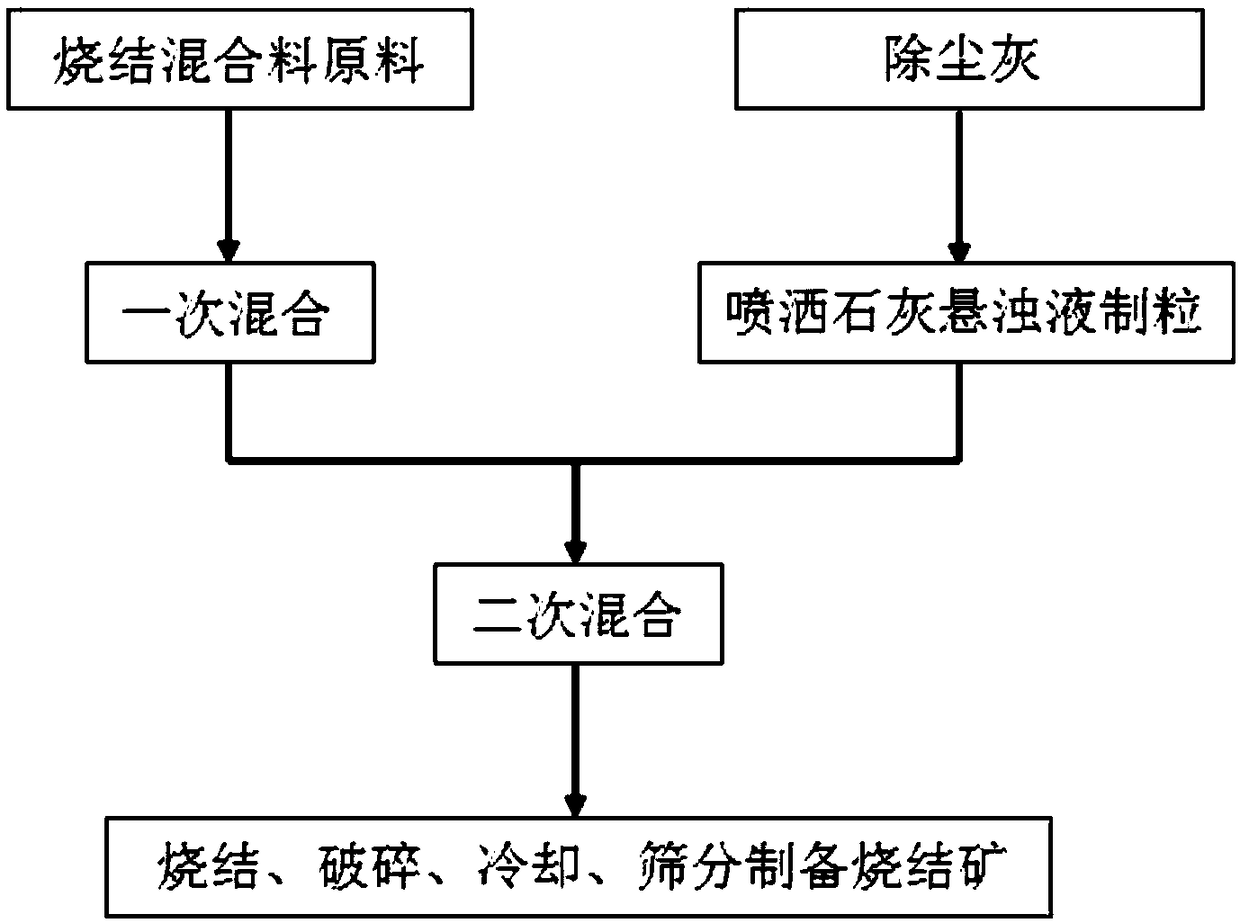

The invention discloses a method for treating iron-bearing dust using a sintering process. The method includes the steps that lime suspension liquid is sprayed in dedusting ash, granulating is carriedout to obtain dedusting ash particles; the dedusting ash particles are added into a sintered mixture, and a sintered mixing material is obtained by mixing and granulating; and the sintered mixing material is distributed, sintered, broken, cooled and screened to prepare a sinter. According to the method for treating the iron-bearing dust using the sintering process, by spraying slaked lime suspension liquid on the surface of the dedusting ash with fine particle size and poor granulability, and the dedusting ash is agglomerated into dedusting ash small particles using viscosity and wettabilityof the slaked lime suspension liquid; the dedusting ash particles are added into the sintered mixture, after mixing and granulating, dedusting ash particles coated with iron ore powder on the externalare formed, separate combustion and mineralization are carried out in the sintering process, and influence of the dedusting ash particles on the composition of a sintered liquid phase is avoided; during the cooling process, the internal cooling speed of the particles is low, the bonding phase strength is improved advantageously, thus the sinter strength and average particle size are improved, low-temperature reduction pulverization of the sinter is obviously inhibited, and the quality of the sinter is obviously improved.

Owner:BEIJING SHOUGANG CO LTD

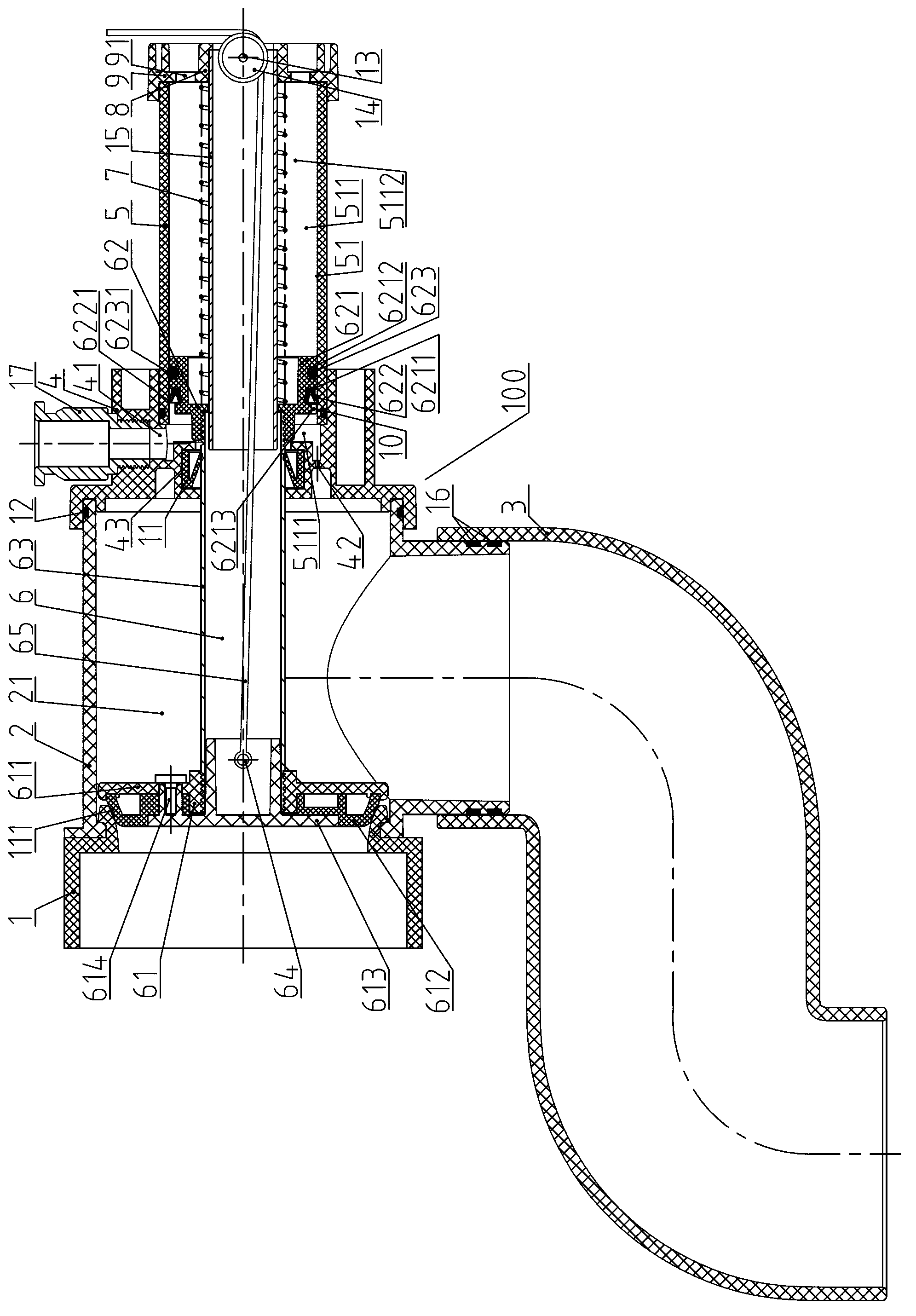

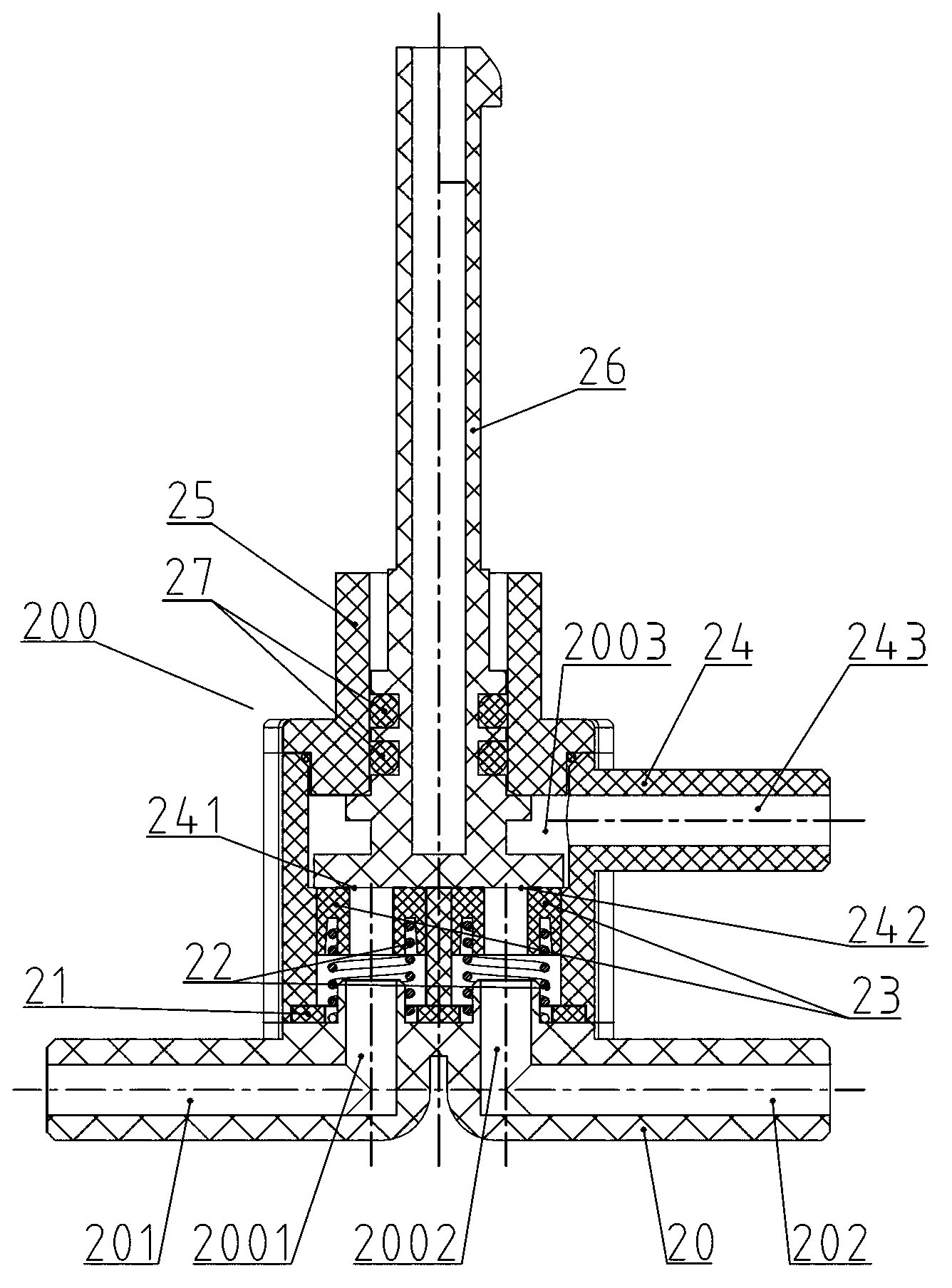

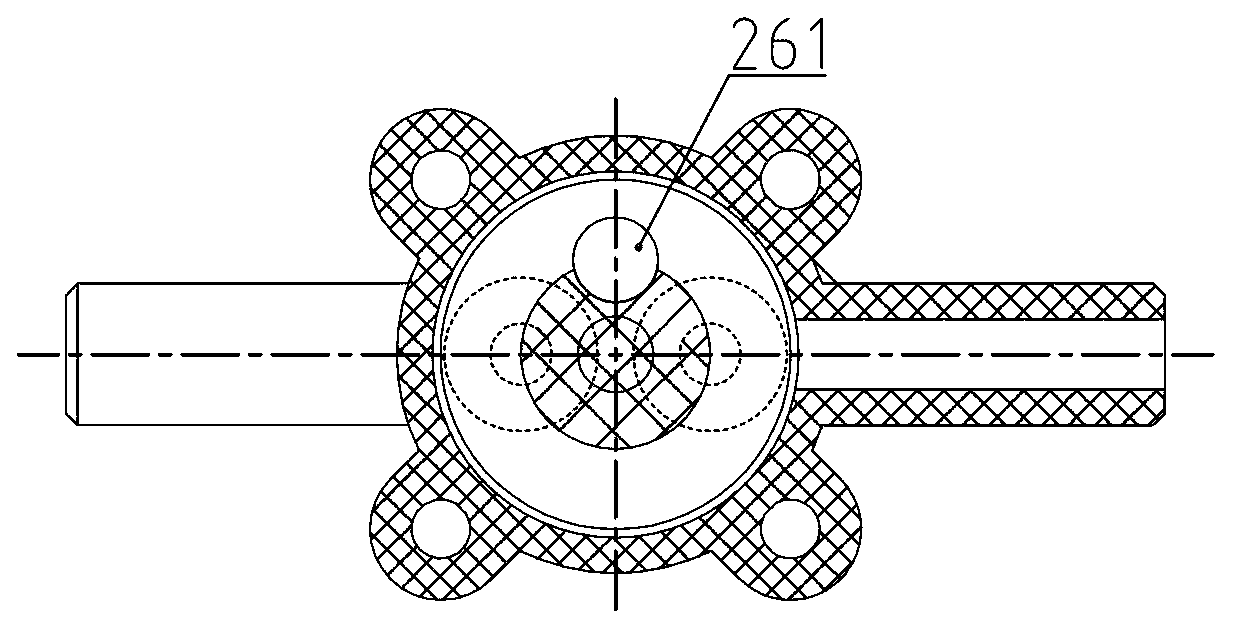

Novel direct-discharging type closestool blowdown system and novel non-water-tank closestool flushing system

The invention discloses a novel direct-discharging type closestool blowdown system and a novel non-water-tank closestool flushing system. The novel direct-discharging type closestool blowdown system comprises a blowdown outlet connecting sealing ring, a blowdown pipe I, a cylinder cover I, a cylinder body, piston components, a spring and a spring supporting part, wherein the piston components comprise a blowdown opening piston component, a cylinder piston component and a piston connecting pipe. The novel direct-discharging type closestool blowdown system replaces a ceramic internal blowdown pipeline (a siphon pipeline) with a zigzag pipe in an existing pedestal closestool, the structure of the pedestal closestool is made to be simpler, manufacturing and sintering yield of the pedestal closestool is improved, and energy is saved and emission is reduced in the production of pedestal closestools.

Owner:ZHEJIANG VIVI ELECTRONIC SANITARY WARE CO LTD

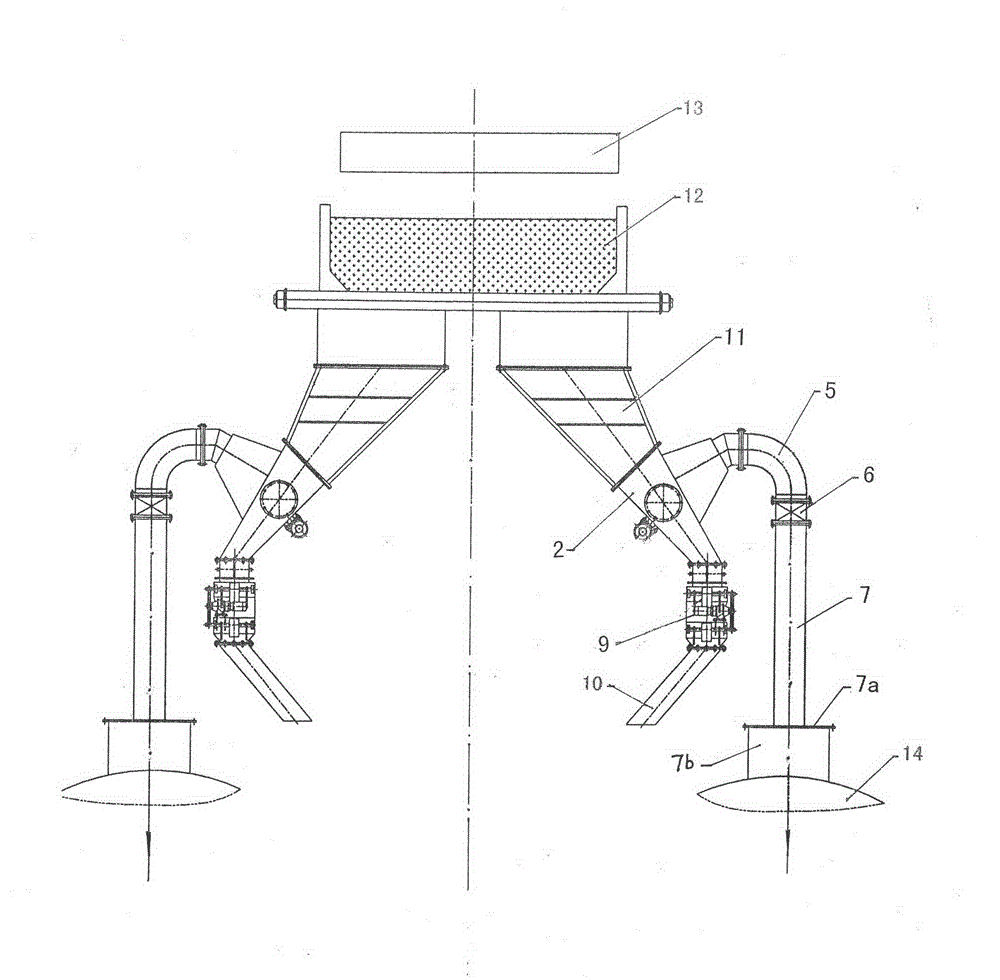

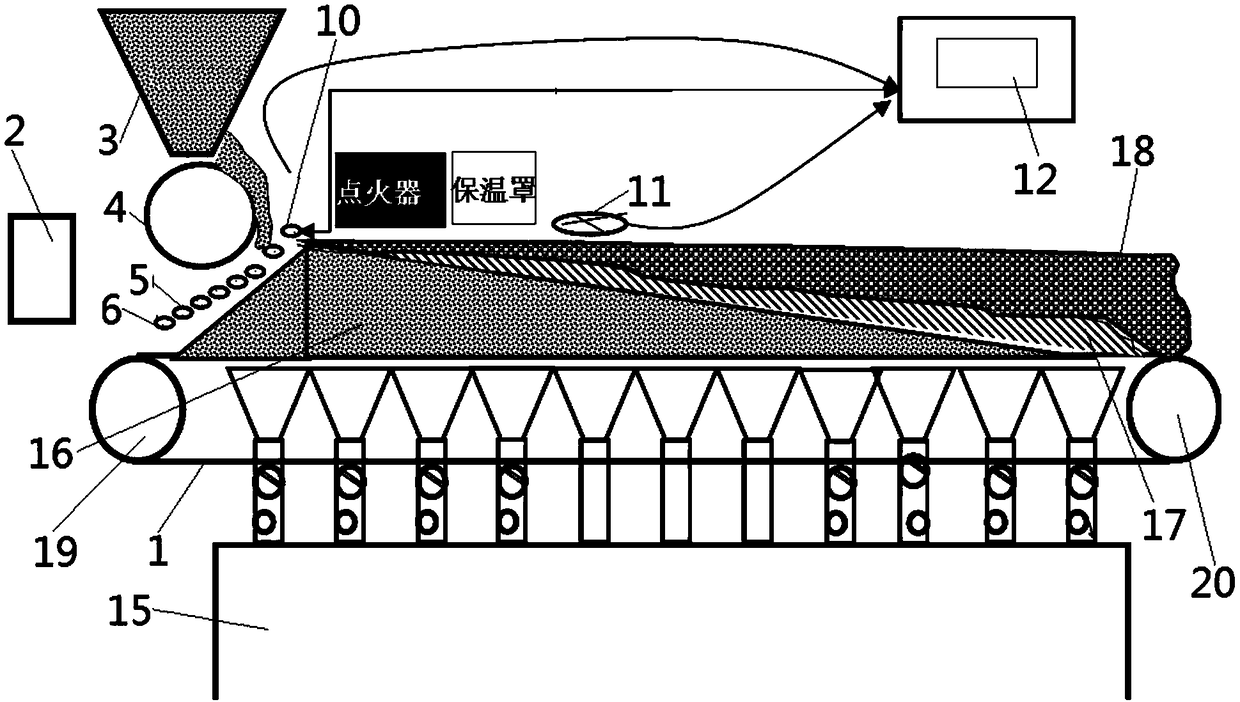

Negative micropressure ignition system for sintering machine bellows

The invention discloses a negative micropressure ignition system for a sintering machine bellows. A trolley is located over the upper end of the bellows, an igniter is separately arranged over the top of the trolley, the upper part of the bellows is opposite to the lower end of the trolley via a duct, and the lower part of the bellows is connected with the upper part of a bellows pipe through a first graphite packing. A vibrating motor is mounted on one sidewall of the bellows pipe, an observation hole with an observation hole cover is arranged at the middle of the bellows pipe, the upper end of a double-layered cindervalve is connected with the lower end of the bellows pipe through a second graphite packing, and the lower end of the double-layered cindervalve is connected with a discharge pipe through a third graphite packing. A wear-resistant bellows-connecting pipe which communicates with the cavity of the bellows pipe is mounted on the other sidewall of the bellows pipe, and is connected with one end of a wear-resistant elbow through connecting flanges, the other end of the wear-resistant elbow is connected with the upper end of a vertical connecting pipe through a resistance balance valve, and the lower end of the vertical connecting pipe is connected with an axial air duct and a big flue through a cover. The negative micropressure ignition system can realize gas-material separation, effectively control the sintering thickness of sinter, increase the grade of sinter and reduce the production cost.

Owner:LOUDI LINGYI MECHANICAL & ELECTRICAL EQUIP

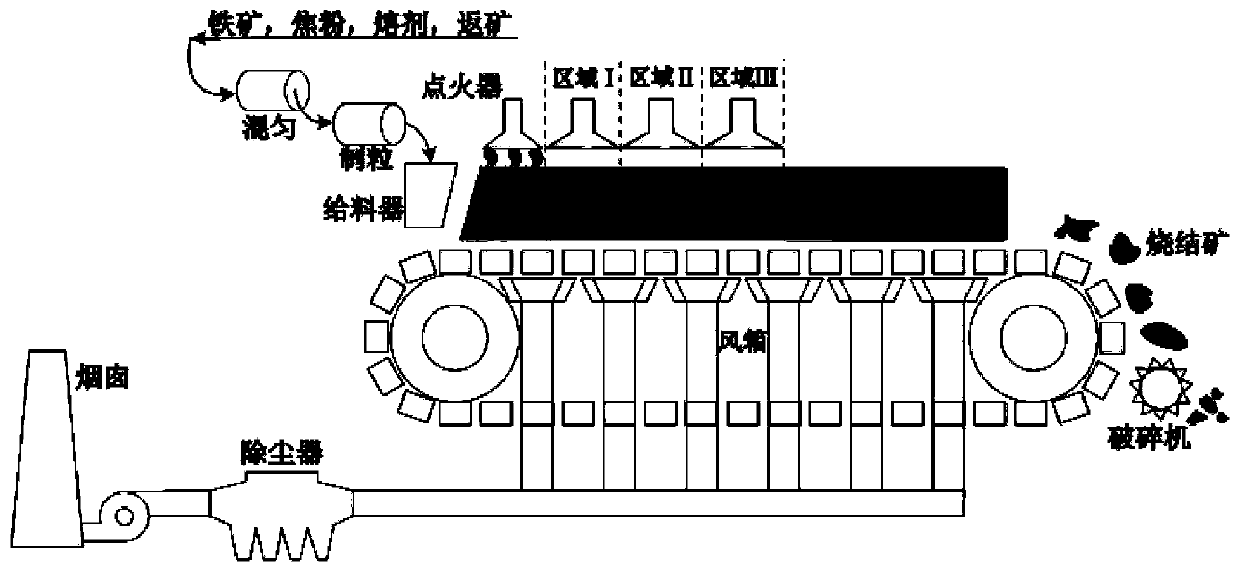

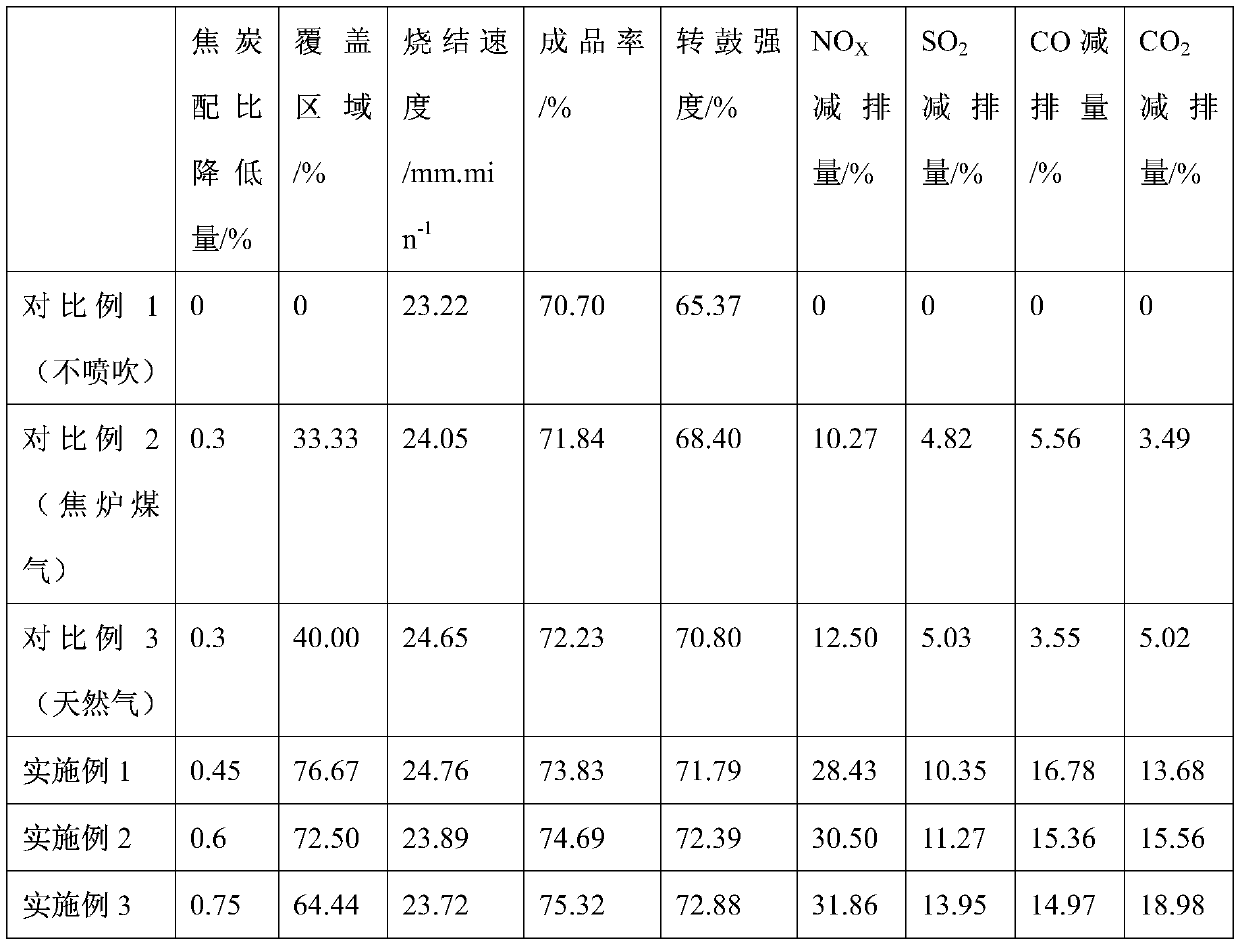

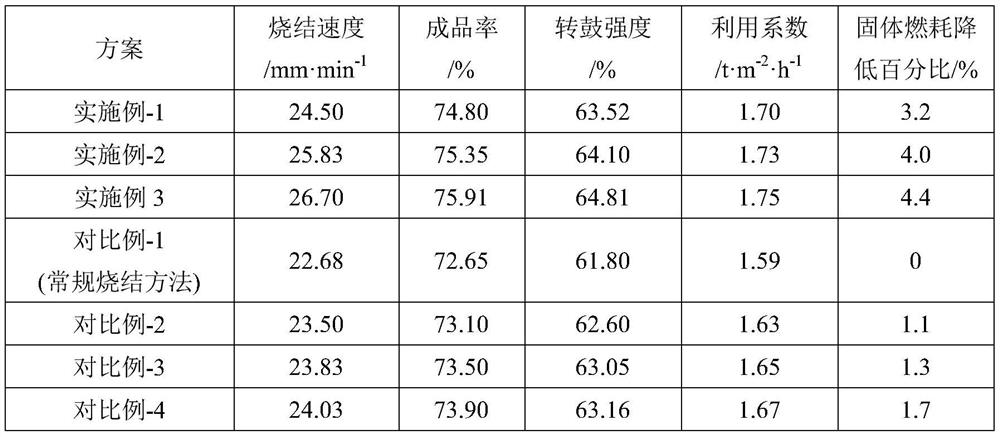

Low-carbon low-emission sintering method based on coupled injection of multiple gases

The invention discloses a low-carbon low-emission sintering method based on coupled injection of multiple gases. Based on the difference of heat storage capacities of parts at the heights of differentmaterial layers, areas from thermal insulation completion to a waste gas temperature rising point of a material surface of a sintering machine are sequentially divided into a low heat storage capacity area, an intermediate heat storage capacity area and a high heat storage capacity area according to the temperature intervals smaller than 1250 DEG C, 1250-1300 DEG C and 1300-1350 DEG C, and high heating value gas with the injection heating value being larger than 30 MJ / Nm<3>, an intermediate heating value gas with the injection heating value being 15-30 MJ / Nm<3> and low heating value gas withthe injection heating value being smaller than 15 MJ / Nm<3> are separately injected to the three areas. The low-carbon low-emission sintering method effectively couples the differences between the heating capacity requirements and the gas quality of different areas of the sintering material layer, realizes heating capacity balanced distribution of the material layers at different heights, forms a beneficial ore-forming condition, greatly improves the sintering quality and the quality index, meanwhile, effectively expands the coverage area of gas injection, further reduces the solid fuel consumption, increases the emission reduction ratio of pollutants such as NOX, SO2 and COX, and realizes the low-carbon low-emission sintering.

Owner:CENT SOUTH UNIV

Method for manufacturing high-power annular inductor

ActiveCN102930971AGuaranteed demandSimple processTransformers/inductances magnetic coresCoils manufactureInductorEngineering

The invention relates to a method for manufacturing a high-power annular inductor, comprising the following steps: manufacturing an annular magnetic core, manufacturing an inductance coil and assembling to obtain a finished product. The high-power annular inductor manufactured by adopting the method comprises the annular magnetic core and the inductance coil. The annular magnetic core comprises more than three semi-arc shaped magnetic blocks along the circumference, wherein each semi-arc shaped magnetic block is equally divided into upper and lower halves; the surface of each semi-arc shaped magnetic block is coated with an insulating layer with a thickness of 0.2-0.5mm; the joints of the combined upper and lower semi-arc shaped magnetic blocks are arrayed in a mutual staggered way; the inductance coil is a spiral ring coil winded from a hard wire; the spiral ring coil is combined together with the semi-arc shaped magnetic blocks; and the annular magnetic core is sleeved coaxially and impregnated and cured into the whole product. The method overcomes the problems that the powdery magnetic core of the traditional annular inductor is restricted in size and can not be made from the large-area hard wire, the annular inductor is enabled to develop towards high power, and the requirement on the inductance inductor in the modern power electronics field is met.

Owner:NINGXIA YINLI ELECTRICAL CO LTD

Encapsulation method and encapsulation equipment for OLED display panel

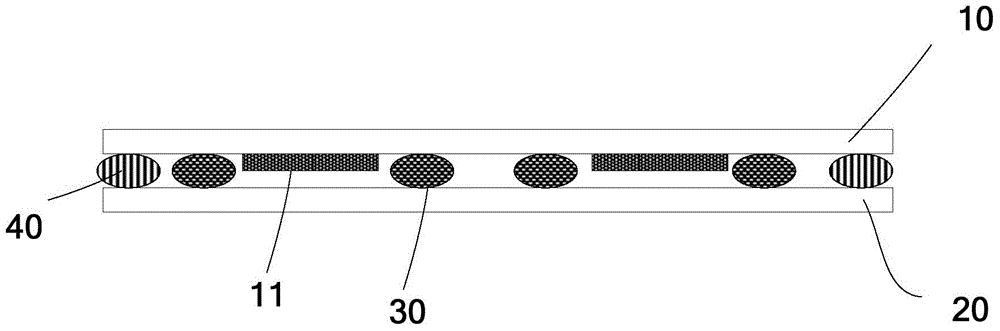

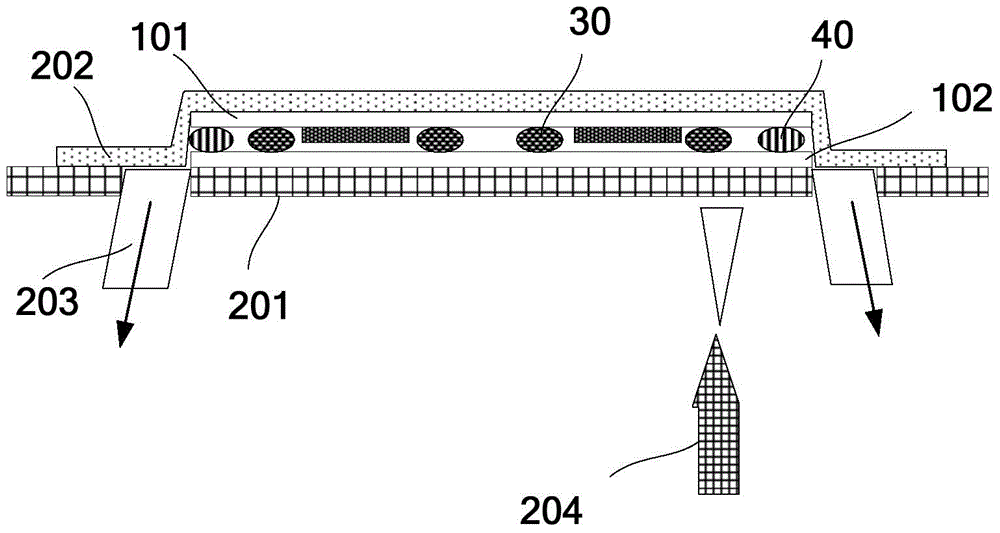

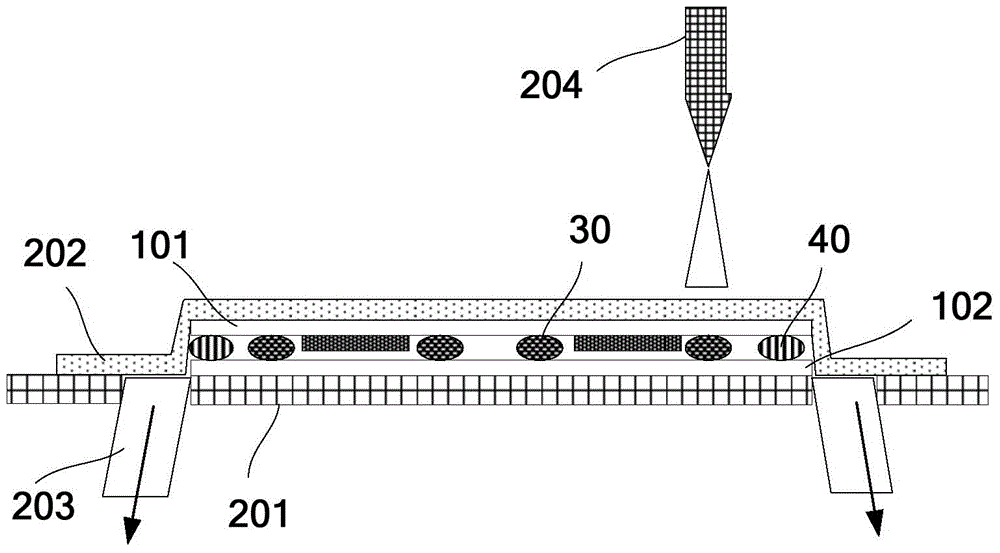

ActiveCN104362104AHigh strengthIncrease contact areaSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLaser

The invention provides an encapsulation method and encapsulation equipment for an OLED display panel. The encapsulation method is used for encapsulating the OLED display panel. The display panel comprises a first substrate and a second substrate adhered with glass glue; the glass glue is positioned between the first substrate and the second substrate. The encapsulation method comprises the steps of arranging the display panel between a supporting base table and a soft thin film, wherein the size of the soft thin film is greater than that of the display panel; extracting air between the supporting base table and the soft thin film, wherein the soft thin film is attached to the display panel and the supporting base table, and a closed space is formed between the soft thin film and the supporting base table, furthermore, the soft thin film pressurizes the display panel in the closed space to enlarge the contact area between the glass glue and the first substrate; heating the glass glue with laser. According to the encapsulation method and the encapsulation equipment, the soft thin film is used for pressurizing the display panel, so that the contact area between the glass glue and the first substrate can be enlarged; therefore, when the glass glue is heated by laser, the sintering yield can be increased.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

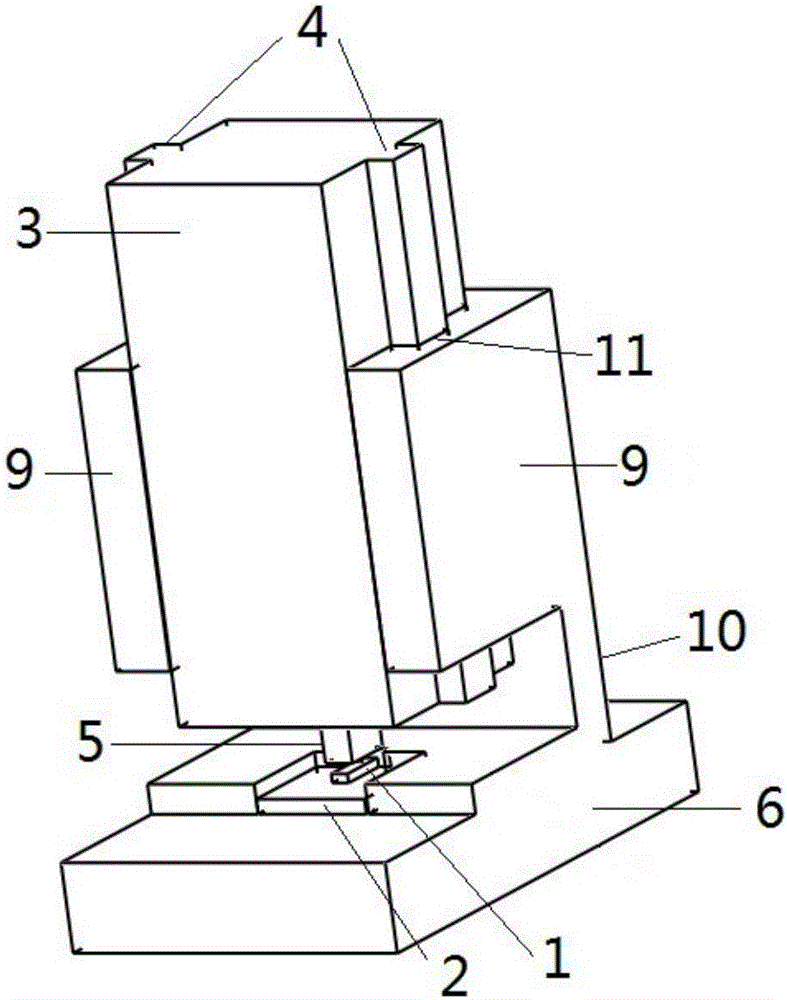

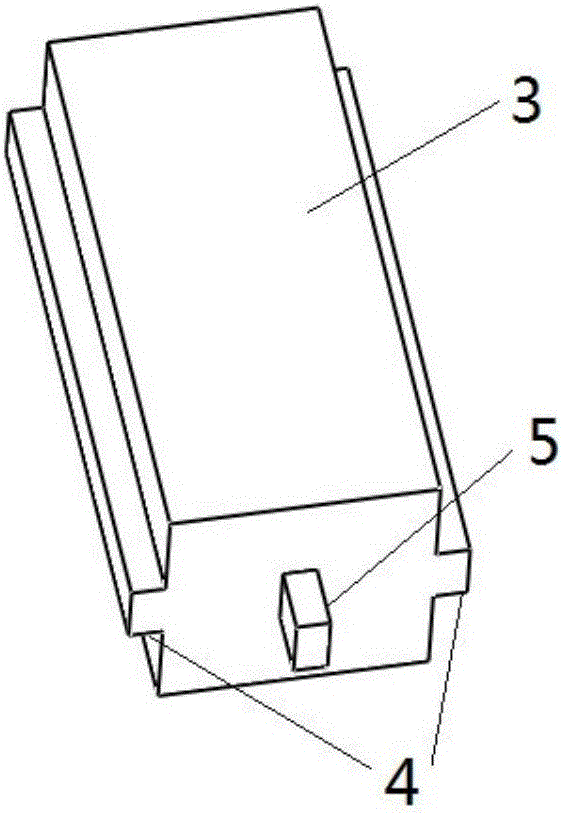

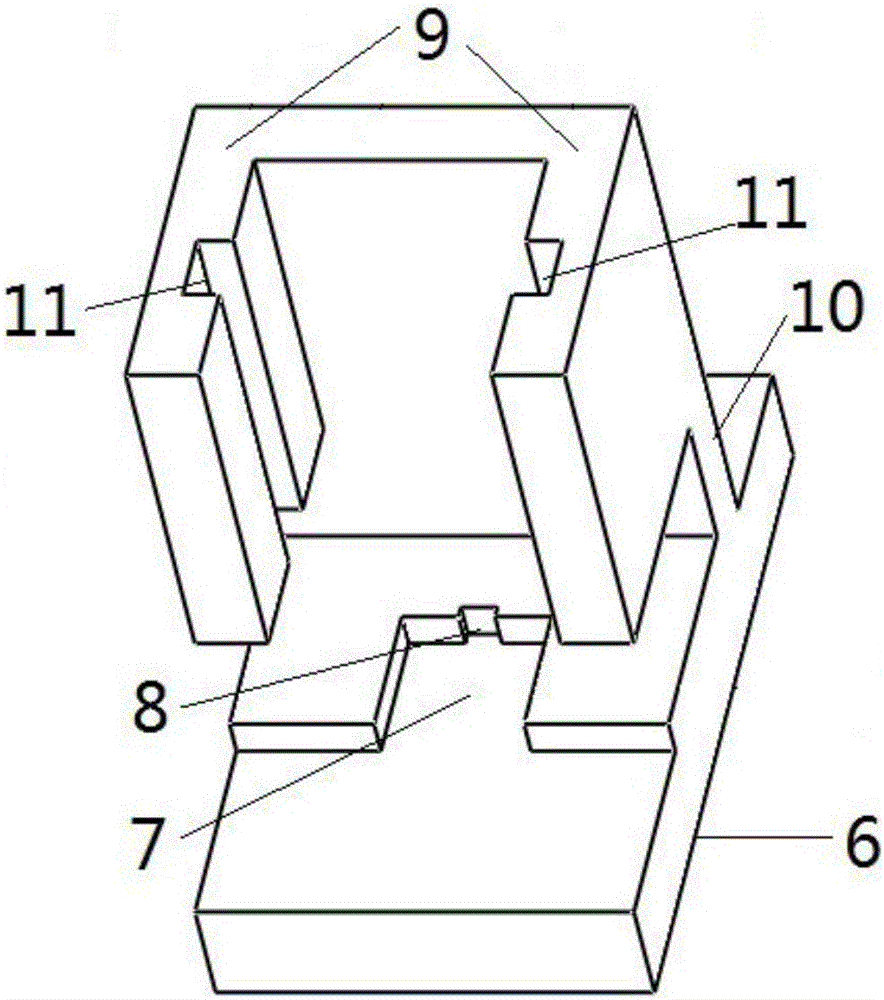

Self-aligning sintering clamp and method for semiconductor laser chip

ActiveCN105896307ASimple structureLow costLaser detailsSemiconductor lasersSemiconductor chipEngineering

The invention relates to a self-aligning sintering clamp and method for a semiconductor laser chip. The clamp comprises a pedestal, a guide rail support, and a press block. The pedestal is provided with a positioning card slot matched with a heat sink. Two sides of the press block are provided with symmetric positioning racks. The guide rail support is vertically disposed on the pedestal, and is provided with symmetric suspension arms. The interior of each suspension arm is provided with a positioning guide rail. The positioning racks of the press block can be sleeved by the positioning guide rails, and move up and down in the positioning guide rails. The bottom end of the press block is provided with a press column. When the press block moves downwards, the press column compresses a chip on the heat sink. The invention also provides the method for sintering the semiconductor laser chip through the above clamp. The clamp is simple in structure, is low in cost, can achieve the self-aligning, and is convenient for operation and observation. The method can achieve the quick batch sintering of the semiconductor laser chips and heat sinks, and remarkably improves the sintering yield of the clamp.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

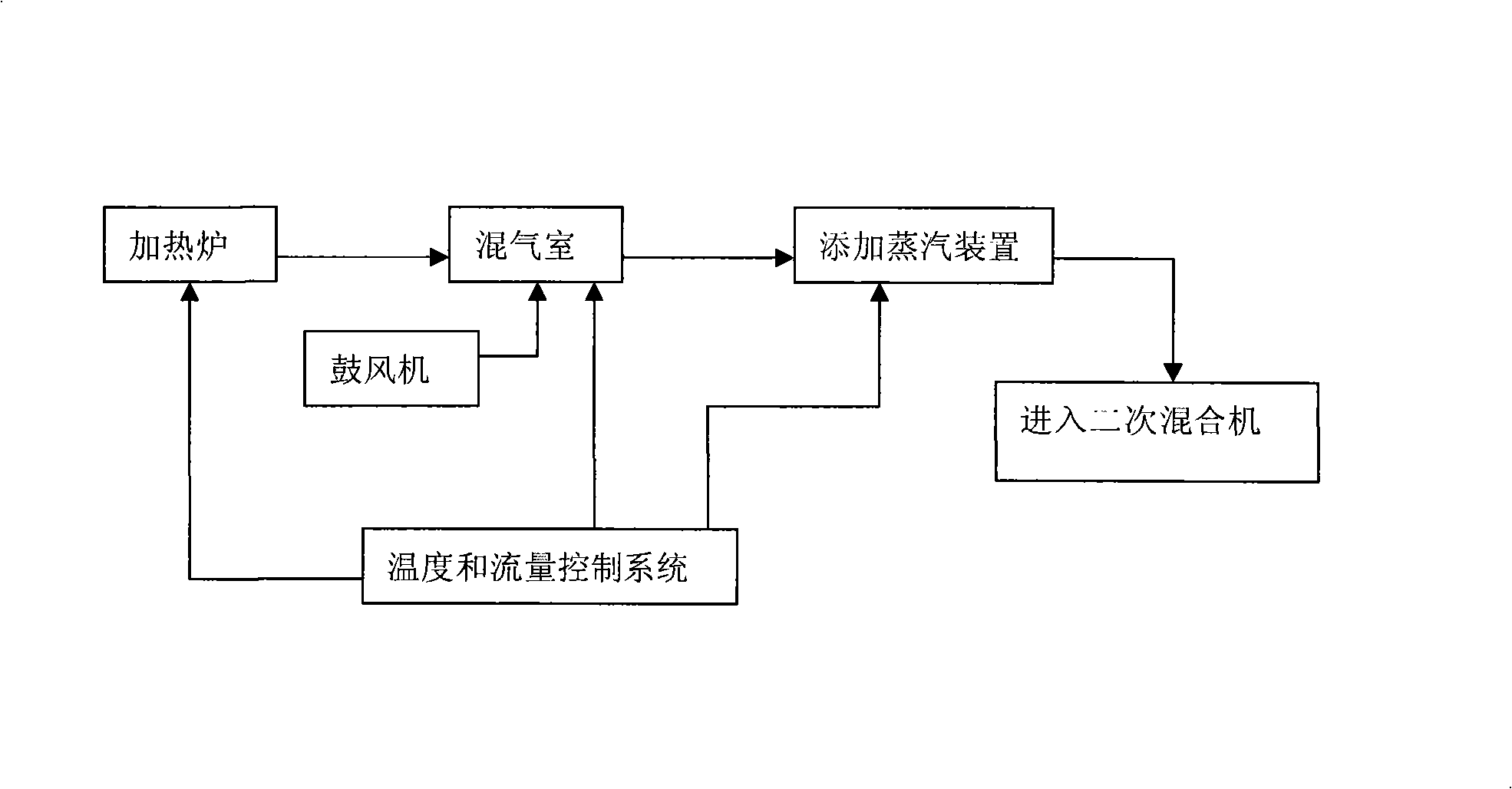

Preheating sintered mixture process utilizing heating furnace hot waste gas

InactiveCN101349509AReduce the temperatureIncrease temperatureIncreasing energy efficiencyPreheating chargesCold airControl system

The invention discloses a process for preheating sintered mixed material through utilizing hot waste gas of a heating furnace, wherein an add-on steam device, a gas mixing chamber and a gas-fired furnace are connected on a secondary mixing machine of a sintering device in turn, wherein the gas-fired furnace, the gas mixing chamber and the add-on steam device are all provided with temperature and flow sensors inside, wherein each temperature and flow sensor is connected with a temperature and flow control system through wires. High temperature hot waste gas which is generated by burning coal gas in the gas-fired furnace enters into the gas mixing chamber which is provided with a blower, and blower can blow a certain amount of cold air into the gas mixing chamber to appropriately regulate the temperature of hot waste gas, hot waste gas which is mixed in the gas mixing chamber is further added into the steam device to mix and humidify with steam to the saturation, then the hot waste gas which is humidified enters into the secondary mixing machine, and is blown to the mixed material along the opposite direction to the material flow of the sintered mixed material. The invention not only has simple technology flow, but also can effectively increase the temperature of sintered mixed material, and has high sintered yield.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

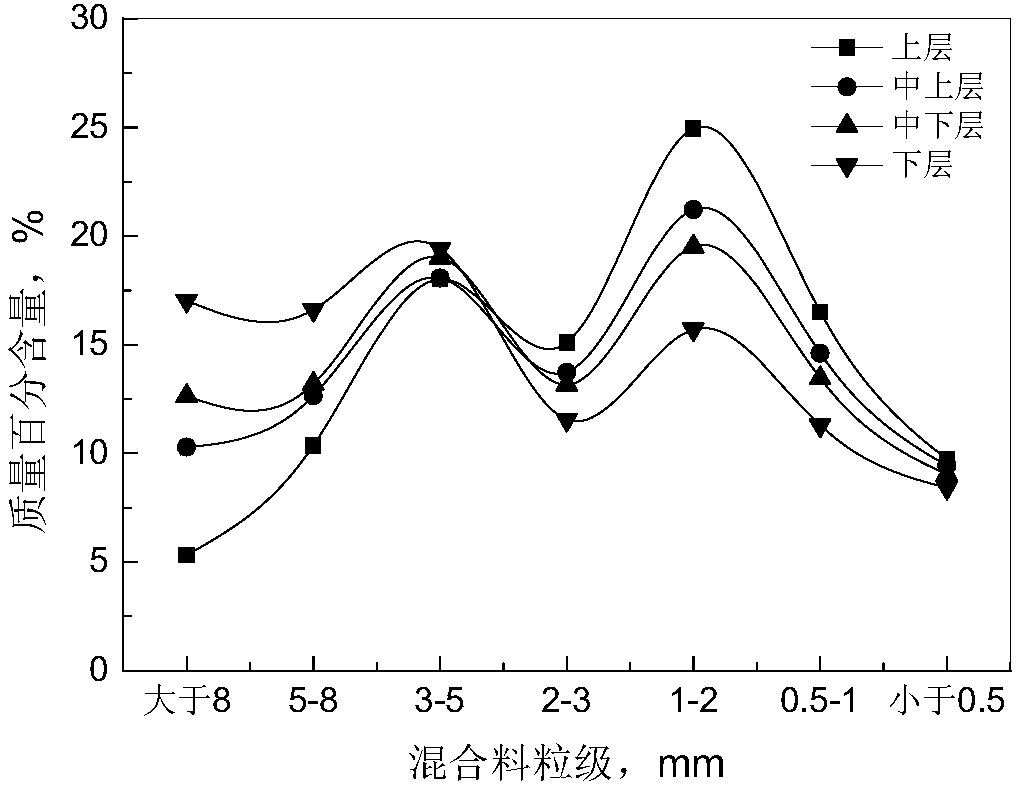

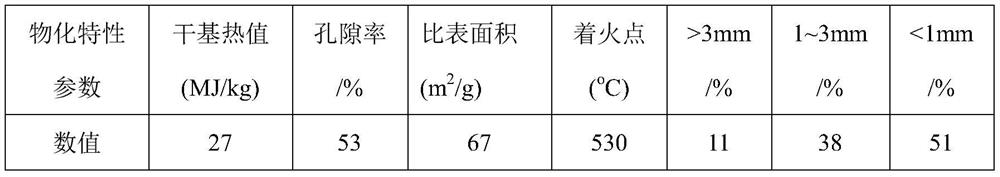

Method for improving reduction of agglomerate and reducing fuel consumption

The invention discloses a method for improving reduction of agglomerate and reducing fuel consumption. The method comprises the following steps: 1. pretreatment: granulating the solid fuel for sintering, and respectively controlling the mass percentage and the average granularity of each of the particles of greater than 3 mm, 1 to 3 mm, 0.5 to 1 mm, and less than 0.5 mm; and 2, granulation: blending iron ore, a flux, returning ore, iron-containing dust and a solid fuel according to the set agglomerate composition and quality index, and then performing primary and secondary mixed granulation in order, adding the solid fuel during primary or secondary mixed granulation of the other sintering raw materials to adjust the primary and secondary mixed granulation time T1 and T2 of the solid fuel, controlling the average particle size increase value of the solid fuel during the whole granulation process to 0.04 to 0.43 mm, wherein the average particle size after granulation is 1.4 to 2.0 mm;and 3. burden distribution and sintering.

Owner:BAOSHAN IRON & STEEL CO LTD

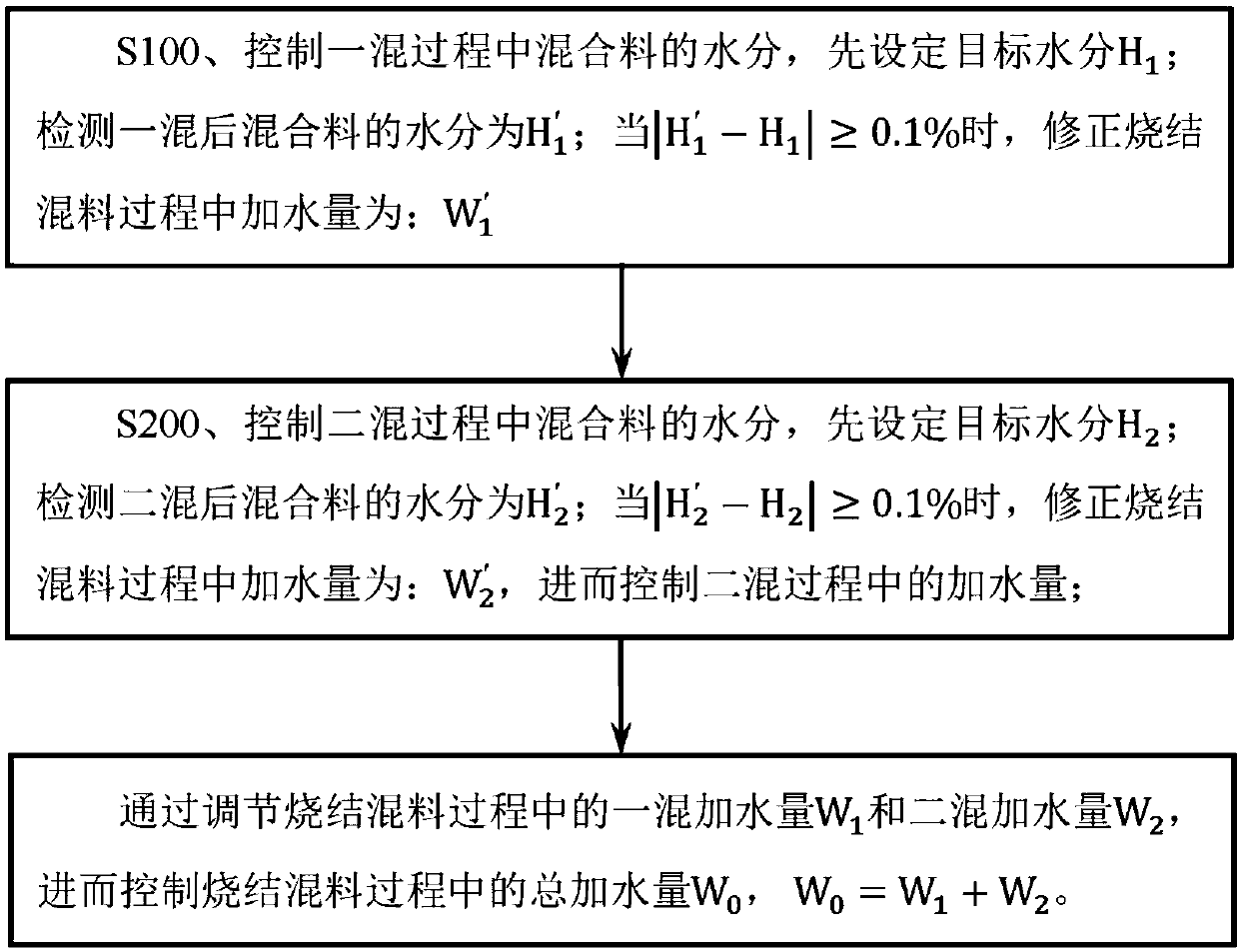

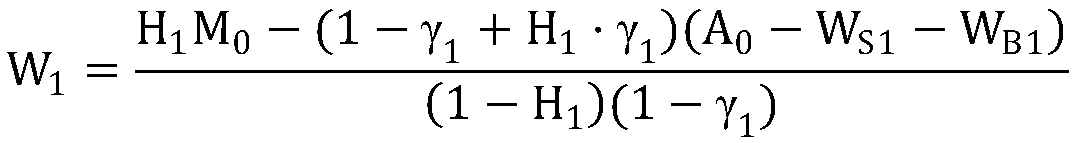

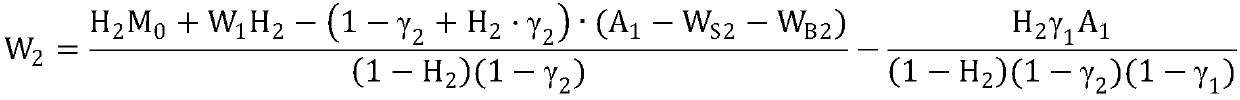

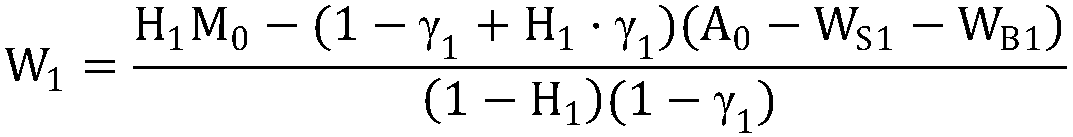

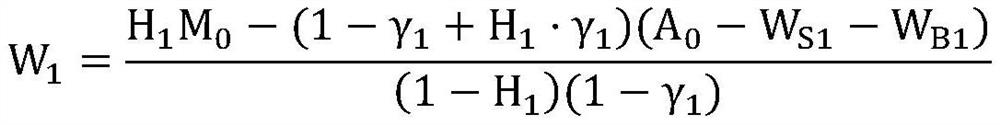

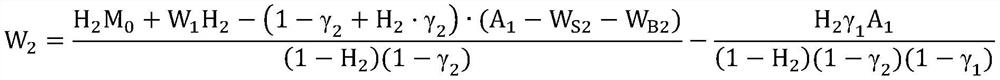

Automatic control method for water content of sintering mixture

ActiveCN108130417AImprove the accuracy of adding waterMoisture fluctuationsSpecial data processing applicationsAutomatic controlWater content

The invention discloses an automatic control method for the water content of a sintering mixture and belongs to the technical field of sintering. The automatic control method includes the specific steps that S100, the water content of a mixture in the first mixing process is controlled, and a target water content H1 is firstly set; it is detected that the water content of the mixture after first mixing is H'1; and when |H'1-H1|>=0.1%, the water adding amount in the mixture sintering correcting process is W'1; and S200, the water content of the mixture in the second mixing process is controlled, and a target water content H2 is firstly set; it is detected that the water content of the mixture after second mixing is H'2; and when |H'2-H2|>=0.1%, the water adding amount in the mixture sintering correcting process is W'2. By adjusting the water adding amount W1 during first mixing and the water adding amount W2 during second mixing in the mixture sintering process, the total water adding amount W0 in the mixture sintering process is controlled. According to the automatic control method for the water content of the sintering mixture, the accuracy and objectivity of operation are improved, and the water distribution precision of the sintering mixture is improved.

Owner:山东诺德能源科技有限公司

Cutter blank forming technology of ceramic surgical blade

InactiveCN105503182AThickness is easy to controlQuality improvementIncision instrumentsOther manufacturing equipments/toolsSurgical bladeHardness

The invention discloses a cutter blank forming technology of a ceramic surgical blade. The cutter blank forming technology of the ceramic surgical blade sequentially includes the following execution steps that firstly, slurry is ground, ball milling frequency is 30 Hz, and ball milling time is 24 hours; secondly, tape-casting slurry is prepared, and the viscosity is required to be 8000-12000 MPa.s; thirdly, a blank strip is prepared, the rotation speed of a tape-casting machine is 20 mm / min, and the thickness of the generated blank strip is 0.35+ / -0.02 mm; fourthly, lamination isostatic pressing forming is conducted, multiple laminations are stacked at equal thickness, isostatic pressure is 25-30 MPa, and the water temperature is required to be 85+ / -3 DEG C; fifthly, punching forming and sintering are carried out, sintering temperature is 1350-1380 DEG C, and sintering time is 2 hours; sixthly, appearance inspection is conducted. The cutter blank forming technology of the ceramic surgical blade is high in production efficiency, high in density, bending strength and Vickers hardness of the formed cutter blank, high in sintering yield and high in cutting edge sharpness.

Owner:ZHUHAI LUCKYMAN TECH CO LTD

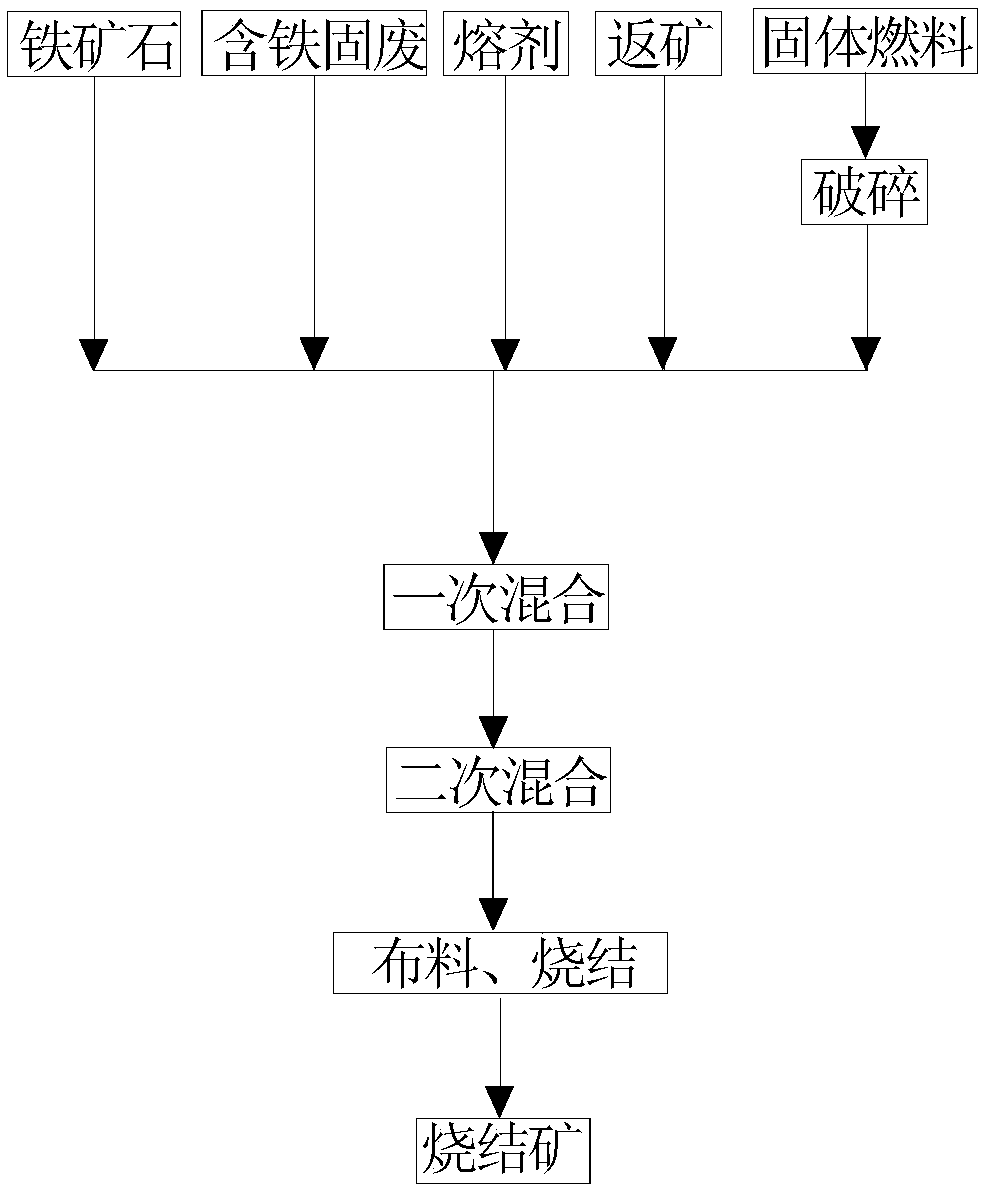

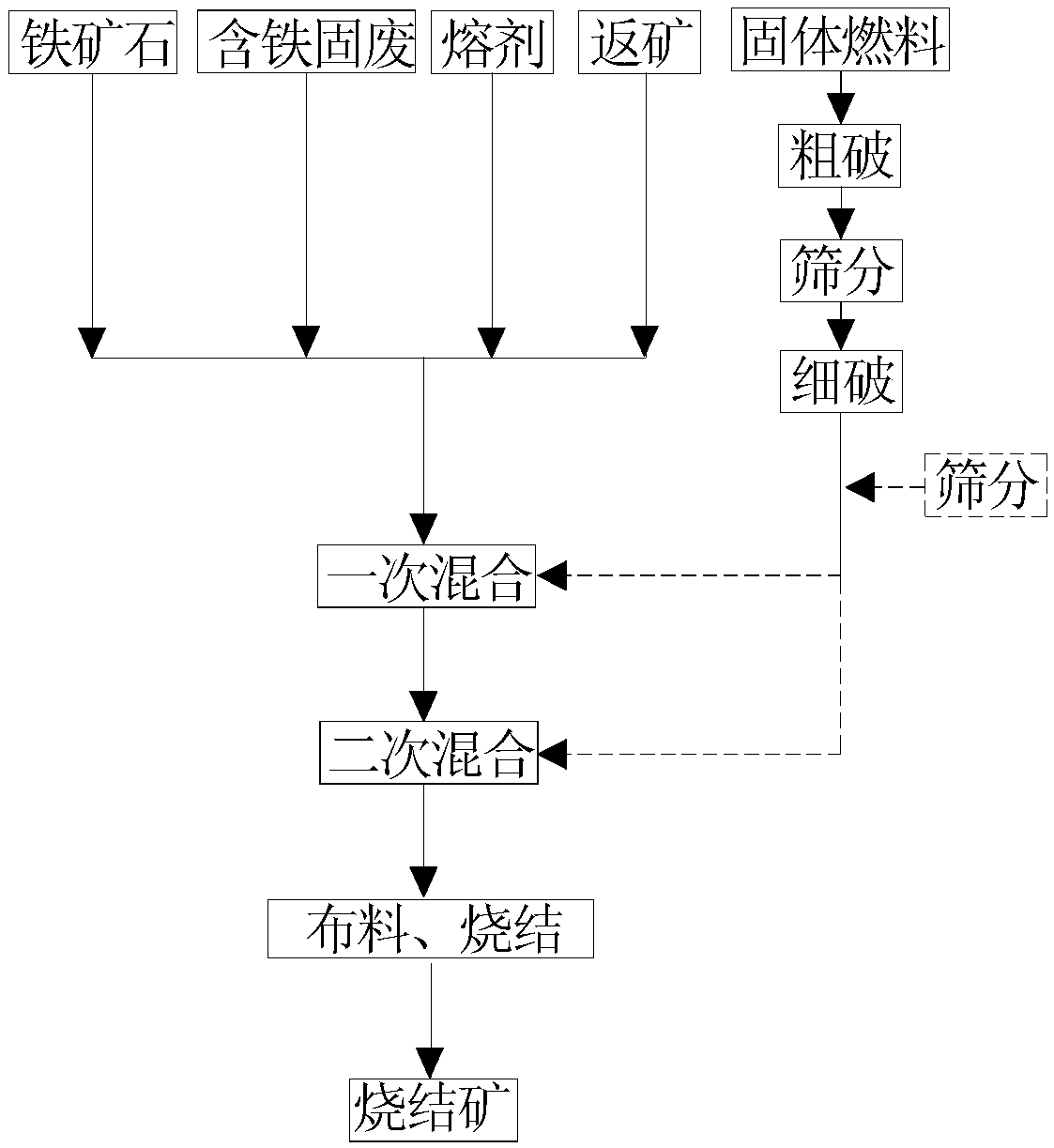

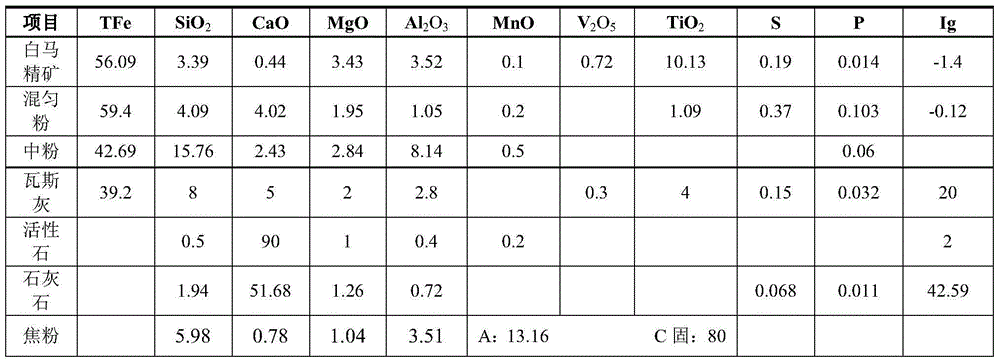

Method for producing sintering ore with iron ore concentrate as main iron materials

InactiveCN105714103AImproved particle size compositionImprove breathabilityGranularityMaterial distribution

The invention provides a method for producing sintered ore with iron concentrate as the main iron material. The iron concentrate, the returned ore with a particle size of 3-5 mm, and coke powder, limestone, magnesium stone, and quicklime with a particle size of less than 1 mm are added with water and then mixed vigorously. Machine-made mixture ball A; after adding water with iron concentrate, returned ore with a particle size of less than 3mm, coke powder with a particle size of 1-5mm, limestone with a particle size of 1-2mm, magnesium stone with a particle size of 1-2mm and quicklime, it is made by a strong mixer Mixture ball B: Mix mixture ball A, mixture ball B and coke powder with a particle size of less than 1mm evenly to form sinter mixture C, which is distributed on sintering equipment and sintered to obtain a finished sintered ore. The invention can improve the gas permeability and sintering speed of the sintering material layer, thereby increasing the output of iron concentrate sintering and reducing the fuel consumption of iron concentrate sintering; at the same time, it is beneficial to strengthen the mineralization performance of iron-containing raw materials and the generation of calcium ferrite, Improve the strength and yield of sintered ore.

Owner:ANGANG STEEL CO LTD

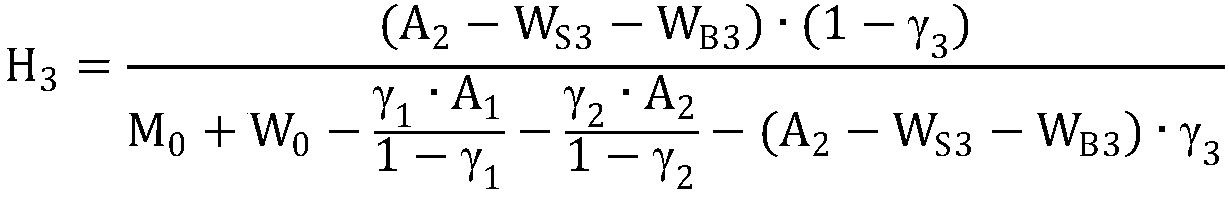

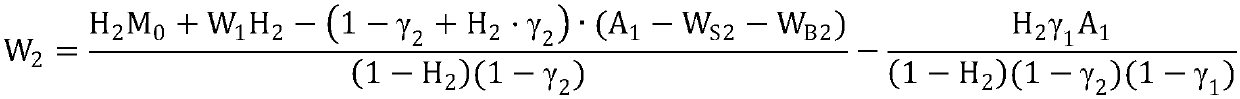

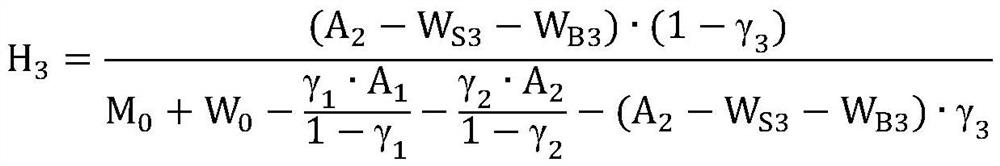

Method for estimating moisture content of mixture on sintering machine according to water addition volume

ActiveCN108133106AWater adjustmentEasy to add waterDesign optimisation/simulationSpecial data processing applicationsProcess conditionsMoisture

The invention discloses a method for estimating the moisture content of a mixture on a sintering machine according to the water addition volume, and belongs to the technical field of sintering. The estimated moisture content of the mixture on the sintering machine is H3 which is calculated according to a formula which is shown in the description. By means of the method, the moisture content of themixture on the sintering machine in the later period can be estimated according to the water addition volume of the mixing process in the former period, operating personnel conveniently adjust the water addition volume in the sintering and mixing process according to the technological conditions of the moisture content of the sintering mixture, and then the water addition volume is conveniently optimized in the sintering and mixing process.

Owner:山东诺德能源科技有限公司

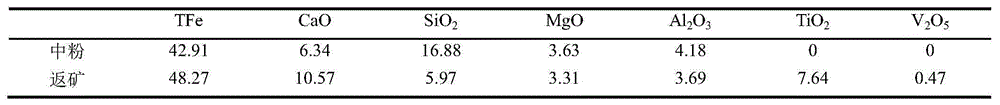

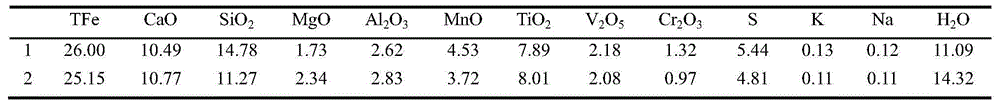

Vanadium tailings large-scale utilization and production method

ActiveCN104694743ASimple structureImprove sintering yieldBlast furnace detailsMoistureLow melting point

The invention discloses a vanadium tailings large-scale utilization and production method. The method includes the following steps that a, sintering raw materials are prepared; b, material mixing is conducted, wherein the prepared sintering raw materials are evenly mixed; c, pelletizing is conducted; d, the mixed sintering raw materials are distributed on a sintering pallet to be ignited and sintered, and sintered ores are made; e, a CaC12 solution is sprayed on the produced finished sintered ores through a spray system; f, the finished sintered ores are transported into a blast furnace to be smelt. Compared with an existing method, by means of the method, a low-melting-point sintering phase can be formed in the sintering process, the sintered ore phase structure is improved, the sinter product ratio is increased, the problems that it is difficult to conduct discharging, and discharging is uneven due to the fact that vanadium tailings are small in bulk specific weight and large in moisture can be effectively solved, the sintering material mixing accuracy is improved, the harmful element sulphur in the vanadium tailings can be removed in the sintering process, and secondary solid waste resource circulating and recycling are guaranteed. The problem of environmental pollution brought by long-time stacking of the vanadium tailings is further solved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Pre-dechlorinating-sintering treatment technology for high-chlorine metallurgical waste and incineration fly ash

ActiveCN110465538AReduce corrosionEfficient use ofSolid waste disposalTransportation and packagingSludgeResource utilization

The invention discloses a pre-dechlorinating-sintering treatment technology for high-chlorine metallurgical waste and incineration fly ash. The technology comprises the processes that high-chlorine metallurgical dust sludge, waste incineration fly ash and carbonaceous fuel are mixed uniformly and then pressed into block masses after the water content is balanced by adopting chlorine-containing wastewater; the obtained block masses are arranged in an oxygen-deficient atmosphere to be subjected to roasting pretreatment, and roasting block masses are obtained; and the roasting block masses serveas an iron ore sintering bottoming material to participate in sintering. According to the technology, pollution of chlorine and dioxin in the solid waste sintering process is reduced through roastingpretreatment, resource utilization of components such as Fe, Ca and C in the solid waste such as the high-chlorine metallurgical dust sludge and the waste incineration fly ash is achieved, and meanwhile reuse of the chlorine-containing wastewater is achieved.

Owner:CENT SOUTH UNIV +1

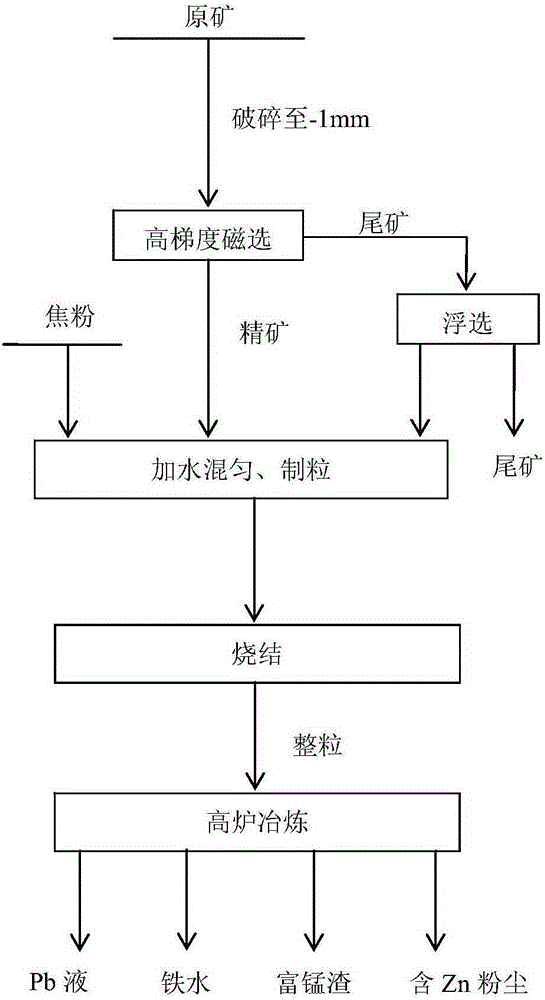

Comprehensive utilization method for low-grade complex ferromanganese ore

ActiveCN105296747ARaise the gradeReduce processingBlast furnace detailsFlotationMaterials scienceMagnetic separation

The invention discloses a comprehensive utilization method for low-grade complex ferromanganese ore. The comprehensive utilization method comprises the steps that raw ore is crushed to a certain particle size, and magnetic separation is conducted through a high-gradient magnetic separator; valuable elements such as Pb and Zn in tailings are recycled through flotation; sintering is conducted after flotation concentrate and magnetic concentrate are mixed uniformly; the sintered ore enters a blast furnace for smelting; and in the blast furnace smelting process, Pb deposits at the bottom of the blast furnace as liquid phases, Pb and molten iron are separated and recycled, Zn is enriched in blast furnace dust, Fe enters the next working procedure as molten iron, and Mn enters the slag phase and forms manganese-rich slag. In this way, various valuable elements in the complex refractory ferromanganese ore are utilized sufficiently. The method is easy to implement and reliable, energy consumption is low, various valuable elements in the raw ore can be recycled, and accordingly the economic benefits of mineral products are greatly increased. By means of the comprehensive utilization method, a feasible method and a reliable theoretical foundation are provided for the development and utilization of the low-grade ferromanganese ore.

Owner:CENT SOUTH UNIV

High-performance strontium permanent magnetic ferrite preparation method

The invention discloses a high-performance strontium permanent magnetic ferrite preparation method. The method comprises 1, adding nanometer bismuth oxide, nanometer cobaltous oxide, nanometer zinc oxide and nanometer germanium oxide into nanometer strontium carbonate, nanometer ferric oxide, nanometer calcium carbonate and nanometer silica as raw materials, and carrying out sanding, 2, carrying out pre-sintering, 3, adding nanometer lanthana oxide, nanometer cerium oxide, nanometer gadolinium oxide, nanometer bismuth oxide, nanometer cobalt oxide, nanometer germanium oxide, nanometer zinc oxide, a grain boundary modifier, a dispersant, a coupling agent, nanometer cesium carbonate, nanometer aluminum oxide, nanometer calcium carbonate and nanometer silica into the pre-sintered product, carrying out mixing to obtain a uniform mixture, replacing strontium by lanthanum, cerium, gadolinium and bismuth, replacing iron ions by cobalt, zinc or germanium and carrying out sanding, 4, carrying cooling molding, and 5, carrying out sintering in a combustion furnace. The method greatly improves permanent magnetic ferrite saturation magnetization, magnet coercive force, remanent magnetism and stability.

Owner:安吉县科声磁性器材有限公司

Synchronous sintering method of titanium alloy or pure titanium product in powder injection molding

The invention relates to a synchronous sintering method of a titanium alloy or a pure titanium product in powder injection molding. The synchronous sintering method comprises the following steps: S1,an injection blank of the titanium alloy or pure titanium is prepared; S2, a sintering jig injection blank is prepared, wherein, A, powder is mixed, specifically, ceramic powder and a low-temperaturesintering aid are uniformly mixed; B, feed is prepared, specifically, the uniformly mixed powder is prepared into feed particles; and C, the feed particles are subjected to injection molding through an injection molding machine to obtain the sintering jig injection blank; S3, placing is conducted, specifically, the injection blank of the titanium alloy or the pure titanium is placed on the sintering jig injection blank; S4, catalyzing is conducted, specifically, a catalytic blank is obtained; S5, thermal desorption is conducted, specifically, a thermal desorption blank is obtained; and S6, sintering is conducted, specifically, a sintered blank is obtained. According to the synchronous sintering method of the titanium alloy or the pure titanium product in powder injection molding, the product and a sintering jig are synchronously sintered, thus synchronous shrinkage of the sintering jig and the product is achieved, the sintering jig has a good supporting effect on the product, and therefore sintering deformation of the titanium alloy or the pure titanium product is effectively improved, and the sintering yield is increased.

Owner:CHANGZHOU GIAN TECH

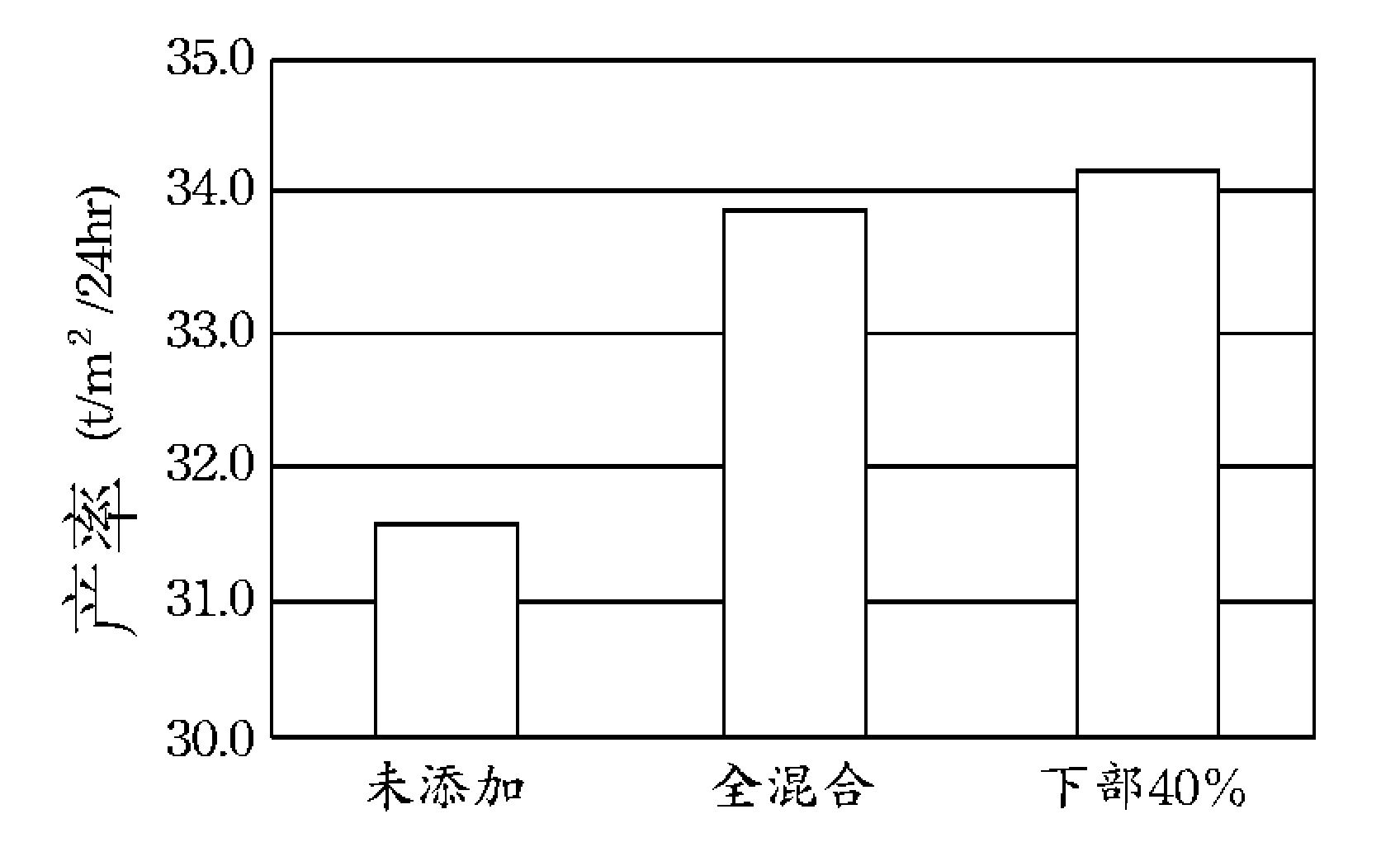

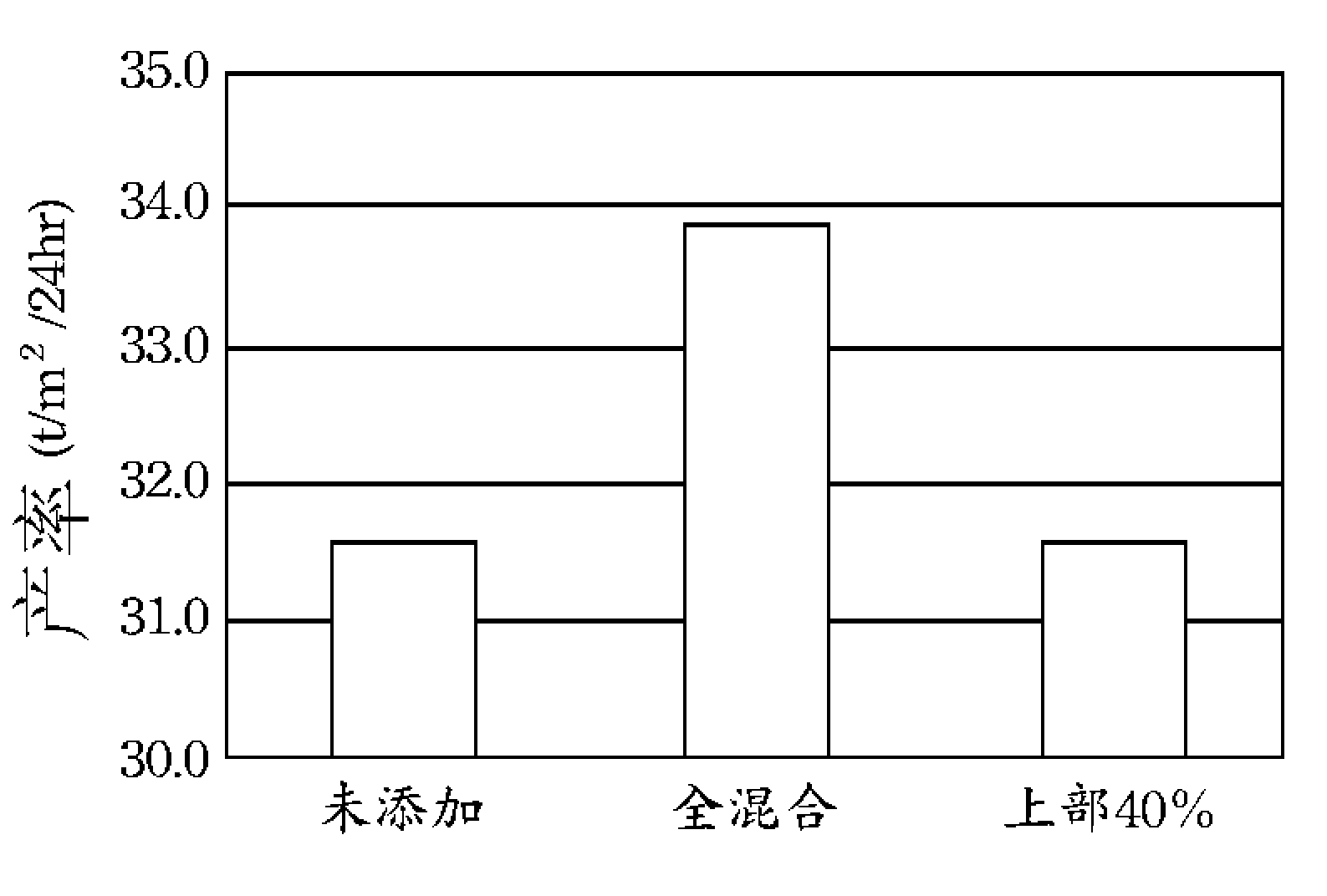

Method for increasing output of sintering process

A method for increasing the output of a sintering process comprises the following steps: dividing a sintering mixture into a first part and a second part; mixing quicklime with the first part to form a quicklime doped sintering mixture; laying the quicklime doped sintering mixture on a sintering support table to form a first sintering subbed on the sintering support table; laying the second part on the first sintering subbed to form a second sintering subbed on the first sintering subbed; and sintering a sintering bed formed through the stacking of the first sintering subbed and the second sintering subbed.

Owner:CHINA STEEL

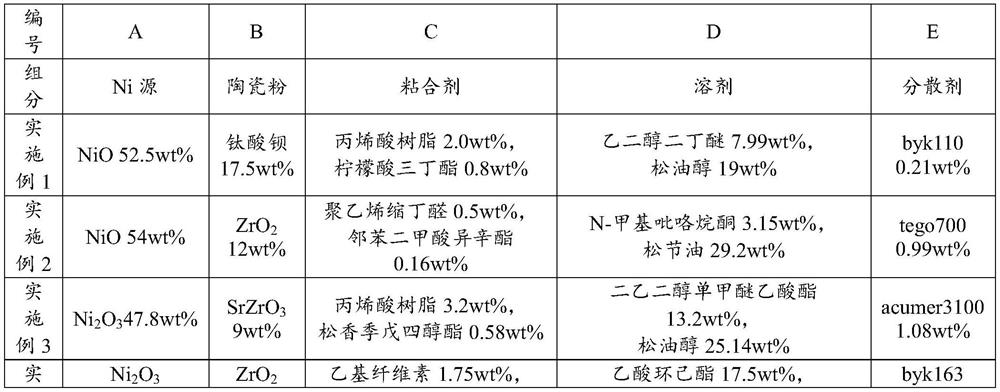

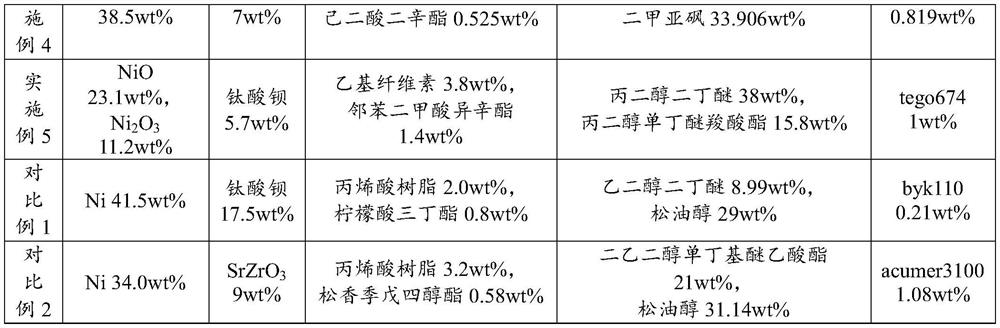

Antioxidant nickel paste and preparation method and application thereof

ActiveCN113270270AReduce carbon residue ratePromote decompositionFixed capacitor electrodesFixed capacitor dielectricAdhesiveResidual carbon

The invention discloses antioxidant nickel paste as well as a preparation method and application thereof. The anti-oxidation nickel paste comprises nickel powder, ceramic powder, an adhesive, a dispersing agent and a solvent, wherein the nickel powder is nickel oxide. According to the present invention, the nickel oxide is used for replacing nickel metal in the MLCC inner electrode slurry, so that on one hand, the problem that base metal is prone to oxidation is not considered, the upper limit value of the glue discharging temperature is widened, the high-temperature glue discharging is achieved, and decomposition of organic additives is promoted, so that the residual carbon rate after glue discharging of the MLCC is reduced, the oxidation problem in the glue discharging process of an inner electrode is reduced, and internal defects are reduced, an obvious positive effect on the improvement of the subsequent sintering yield and the improvement of the reliability is realized; and on the other hand, a finally obtained MLCC product can still keep good electrical performance.

Owner:广东省先进陶瓷材料科技有限公司

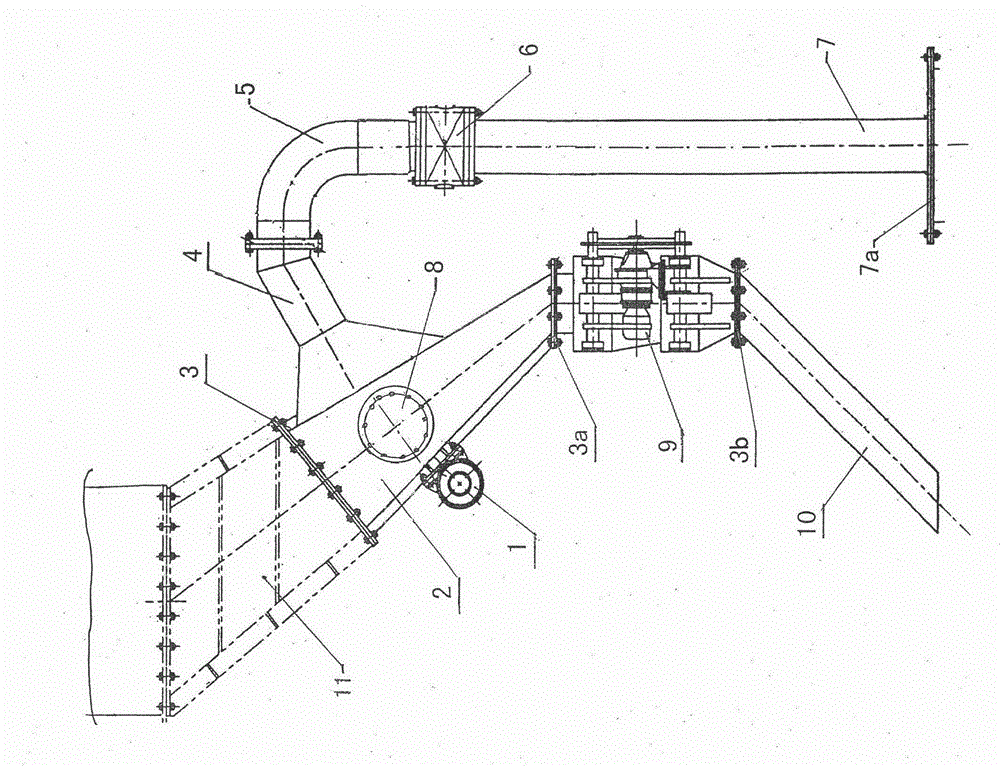

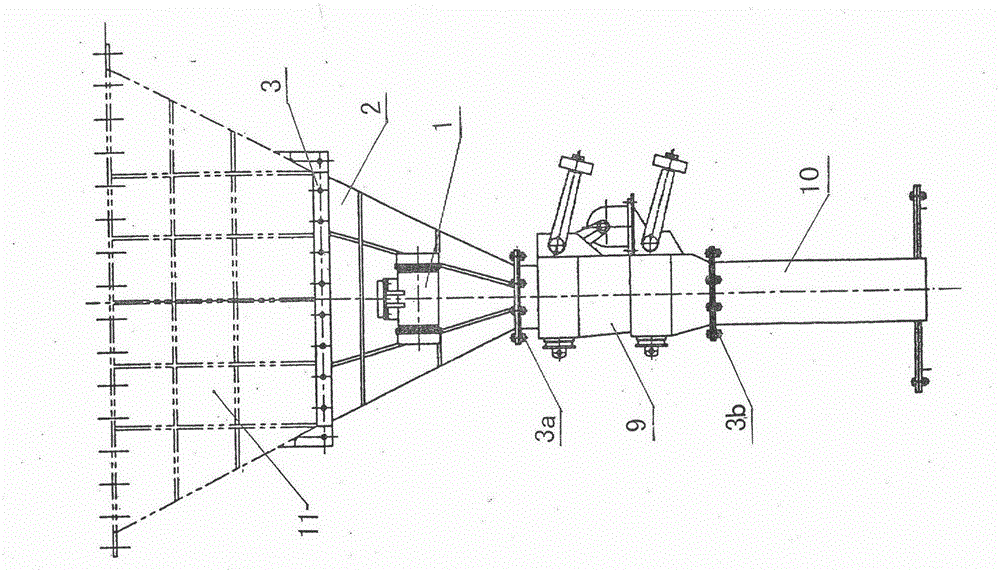

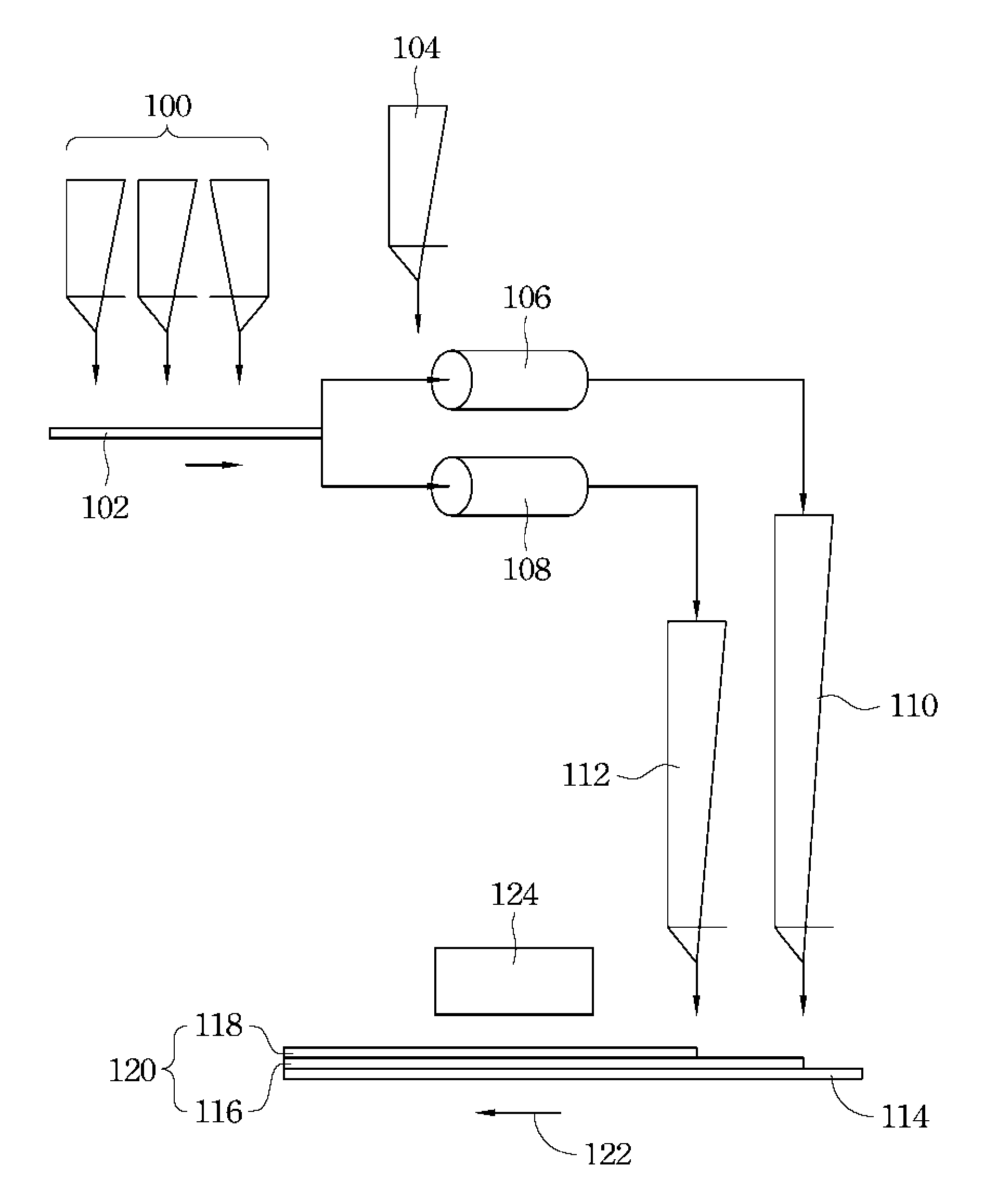

Distributor for sintering machine and method for distributing material using the distributor for sintering machine

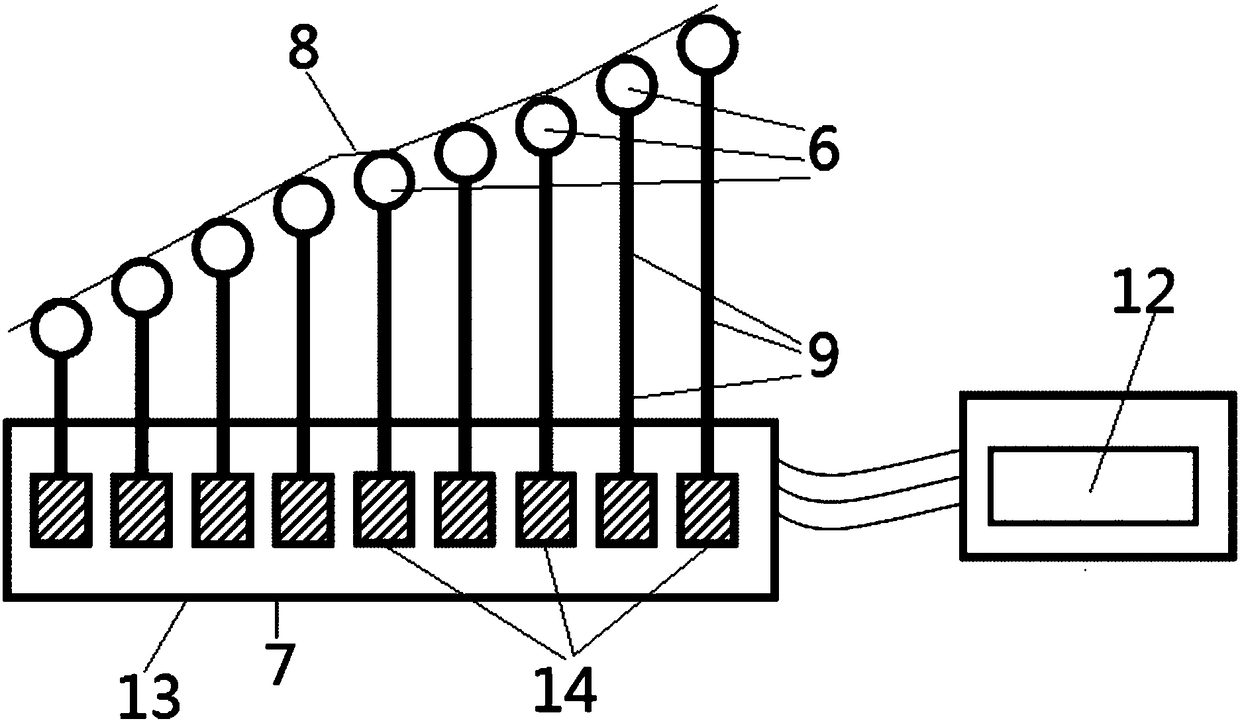

ActiveCN106959012BSimple structurePromote sinteringCharge treatment typeFurnace typesDistributorMixing tank

The invention provides a sintering machine distributing device applied to the technical field of iron and steel smelting equipment parts, and further relates to a distributing method using the sintering machine distributing device. A sintering mixing tank (3) is arranged on the upper portion of one side of a sintering machine body (1) of a sintering machine. A round roller feeder (4) is arranged under the sintering mixing tank (3). A distributing device body (5) is arranged under the round roller feeder (4) and composed of a plurality of distributing rollers (6). A distributing face (8) is formed by the upper surfaces of the multiple distributing rollers (6). The bottom of each distributing roller (6) is connected with an adjusting part (7) through a connecting base (9). According to the distributing device and the distributing method, particle segregation and sinter bed particle uniformity of a sinter mixture are achieved advantageously, the bed breathability is improved, sintering solid fuel consumption is reduced advantageously, and the sintering production cost is reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

Sintered ore containing sintered fly ash balls and preparation method

The invention relates to sintered ore containing sintered fly ash balls. The sintered ore containing the sintered fly ash balls comprises the following raw materials in percentage by weight: 65 to 75percent of uniformly mixed ore, 15 to 20 percent of return ore, 3 to 6 percent of fuel, 5 to 10 percent of flux, 1 to 15 percent of sintered fly ash balls with the particle size being more than or equal to 3mm, and 0.05 to 0.98 percent of adhesive. The preparation method comprises the following steps of rolling sintered fly ash; preparing the sintered fly ash balls; uniformly mixing the uniformlymixed ore, the return ore, the fuel, the flux and the sintered fly ash balls with the particle size being not less than 3mm; sintering; conventionally cooling and screening; and preparing the sinteredore for later use. According to the sintered ore containing the sintered fly ash balls and the preparation method provided by the invention, the sintering fly ash can be comprehensively utilized, nopollution is caused to the environment, the cost is low, and the performance of the prepared sintered ore can meet the use requirement.

Owner:武汉钢铁有限公司

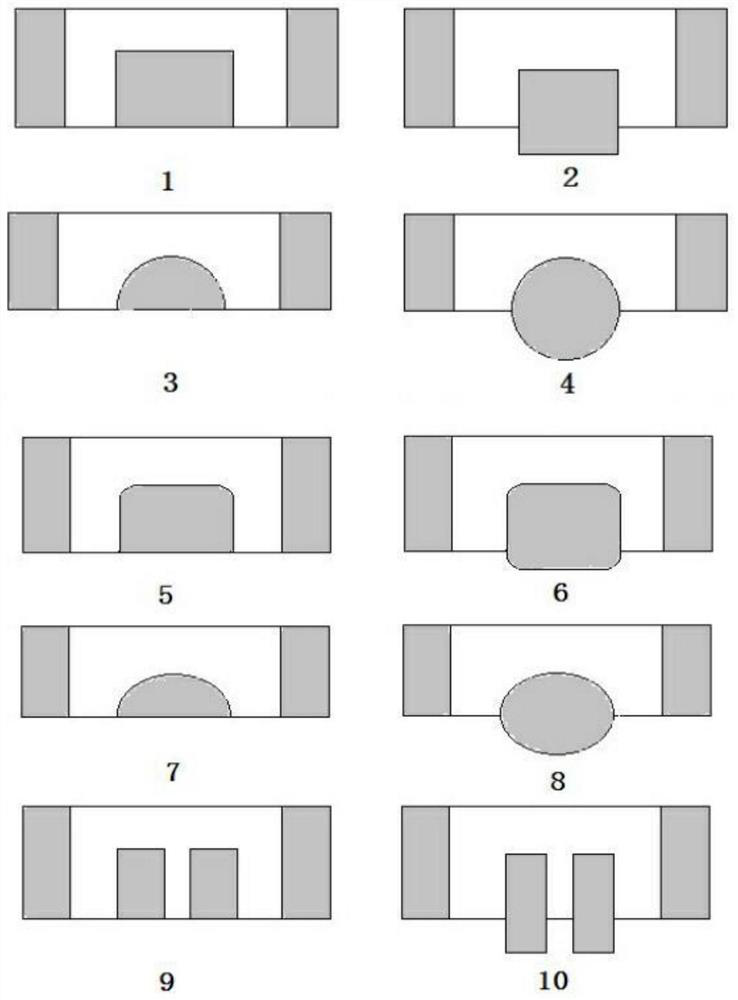

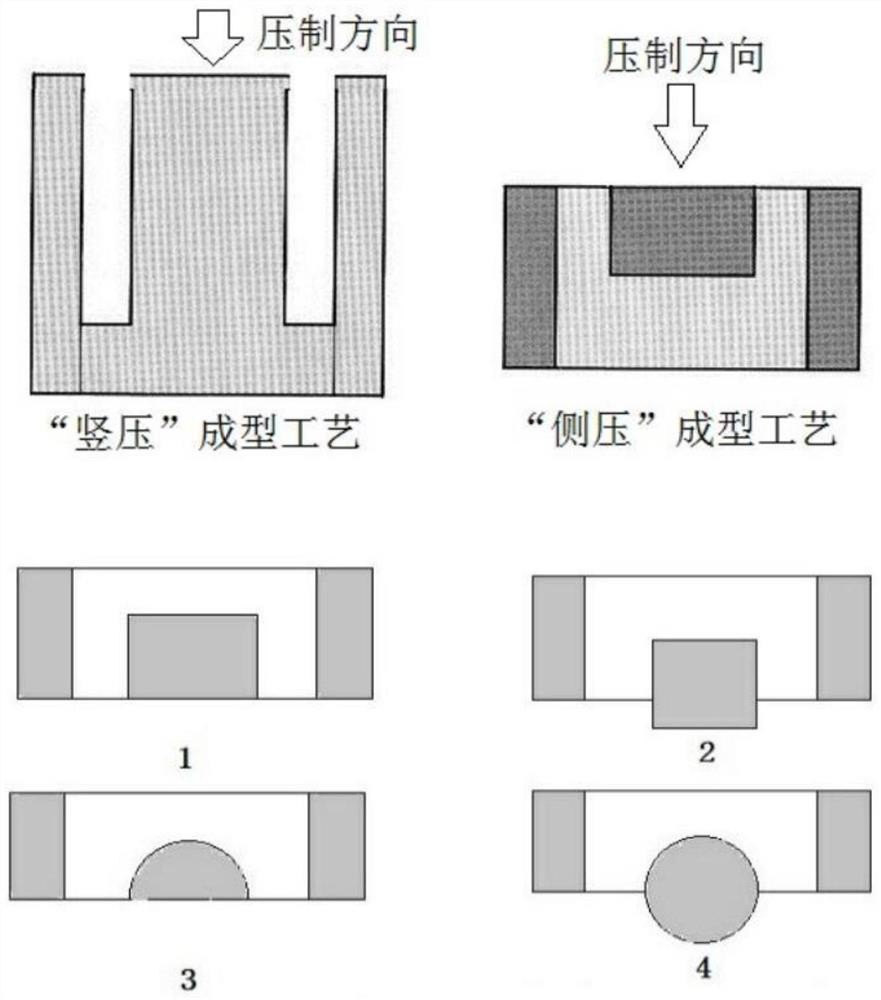

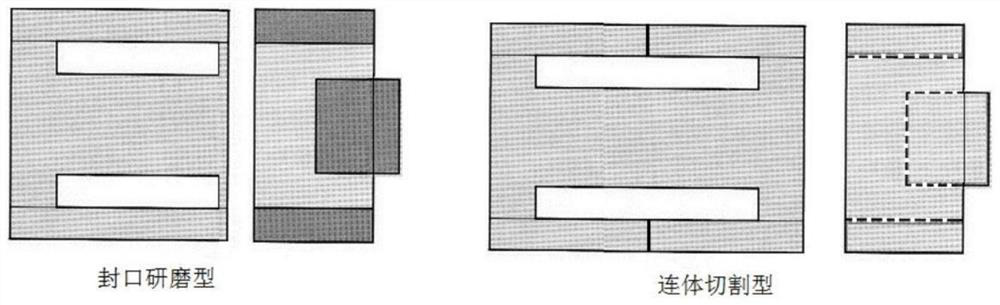

Manufacturing process of special-shaped ferrite magnetic core

PendingCN114005669AHigh dimensional accuracyOvercome the phenomenon that easily leads to product deformationMagnetic core manufactureManufacturing technologyPunching

The invention belongs to the technical field of ferrite, and particularly relates to a manufacturing process of a special-shaped ferrite core. The manufacturing process comprises the steps of (1) conducting punch forming, specifically, selecting soft magnetic ferrite particle powder, and preparing a sealed blank or a connected blank designed by the process on a vertical forming machine or a high-speed rotary forming machine by adopting a mold in a bidirectional punching manner; (2) sintering; (3) cutting and grinding; (4) carrying out ultrasonic cleaning; and (5) inspecting. According to the process, the phenomenon that a conventional preparation method for preparing the special-shaped magnetic core element is prone to causing product deformation can be overcome, the thinking frame that the special-shaped magnetic core element can only be formed in a vertical pressing mode but cannot be formed in a side pressing mode is broken through, and the process is achieved through a density compensation method. The manufacturing process is easy to operate, convenient to process and easy to industrialize, the special-shaped magnetic core element with high dimensional precision can be manufactured, the percent of pass is greatly increased, the cost is saved, and the manufacturing process has high industrial utilization value and is worthy of popularization and application.

Owner:江西尚朋电子科技有限公司

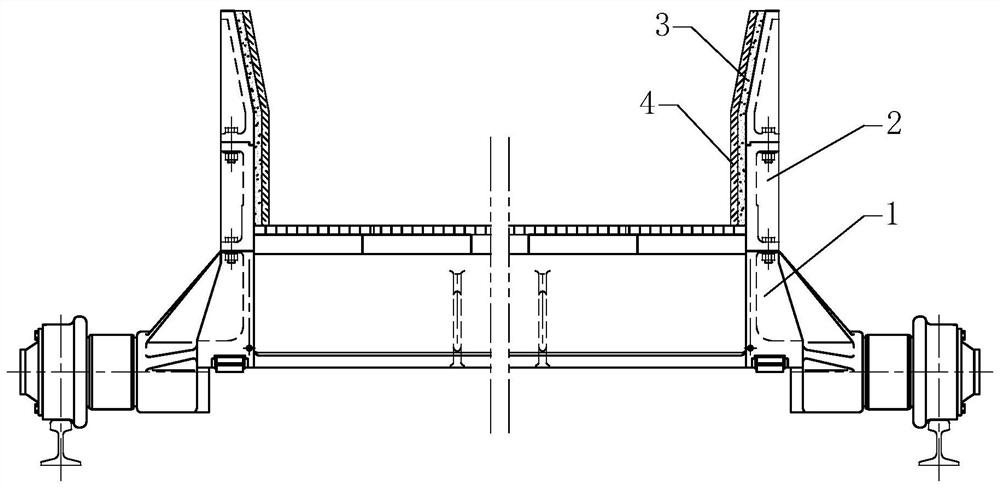

A sintering machine trolley

ActiveCN109556406BReduce heat dissipationNot easy to crack and deformMolten spray coatingCharge treatment typeThermal insulationThermal dissipation

The invention discloses a sintering pallet. The sintering pallet comprises a pallet body and pallet baffles arranged on two sides of the pallet body, wherein the inner surfaces of the pallet baffles are coated with thermal insulation coatings, and the surfaces of the thermal insulation coatings are coated with wear-resistant anti-corrosive coatings. According to the sintering pallet, the thermal dissipation of the trolley can be reduced, the energy is saved, and meanwhile the sintering yield is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

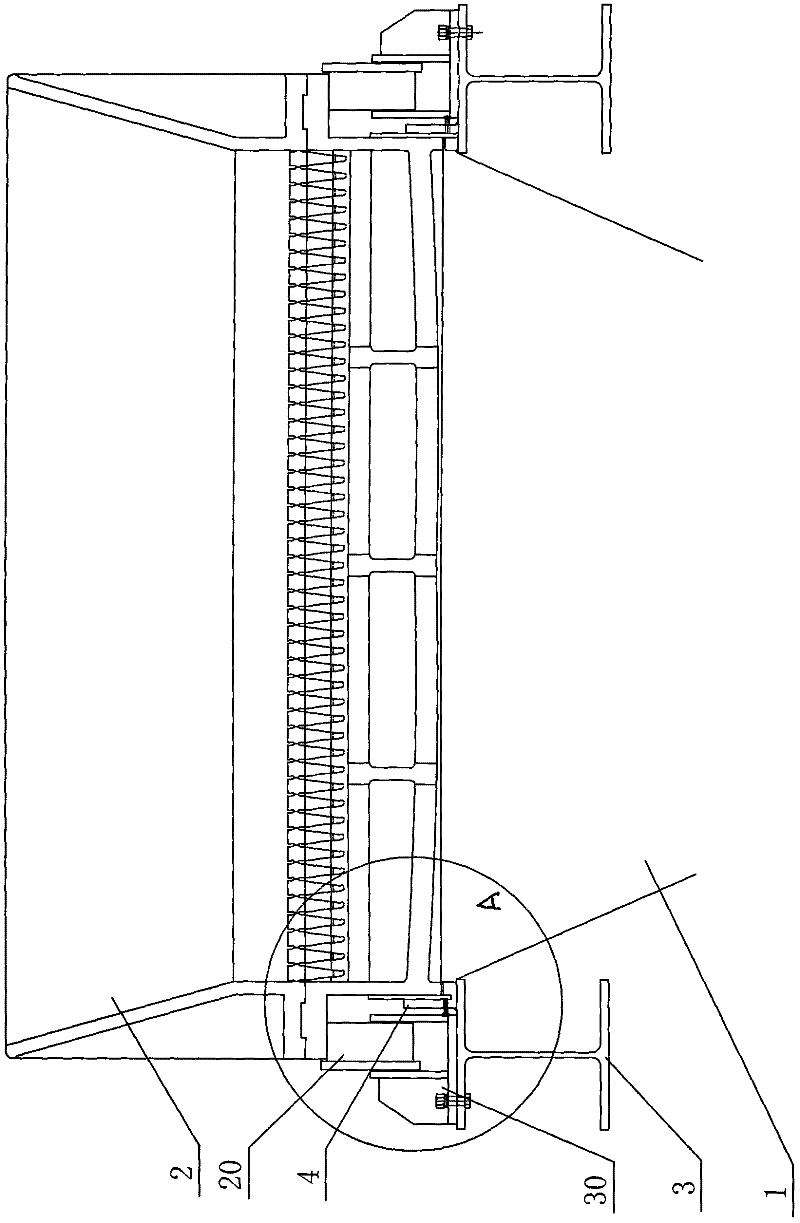

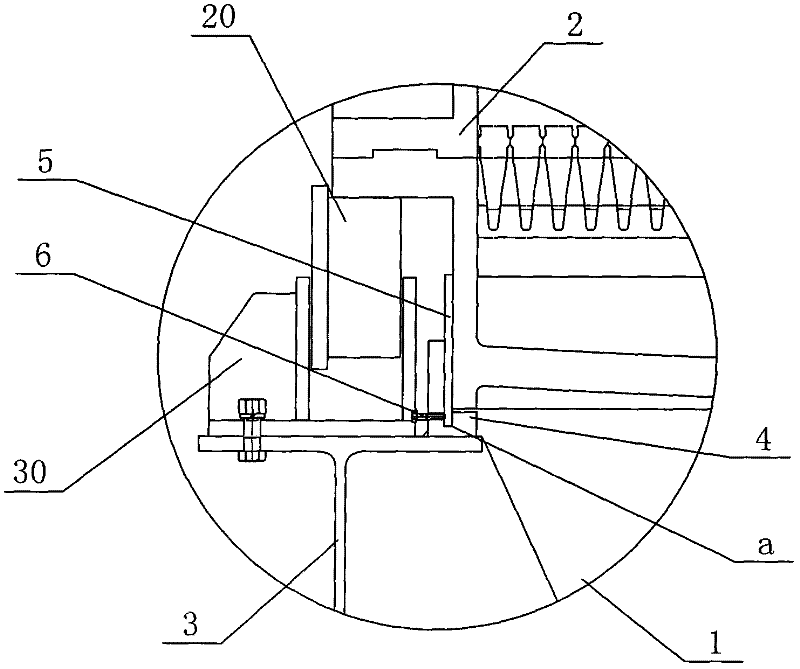

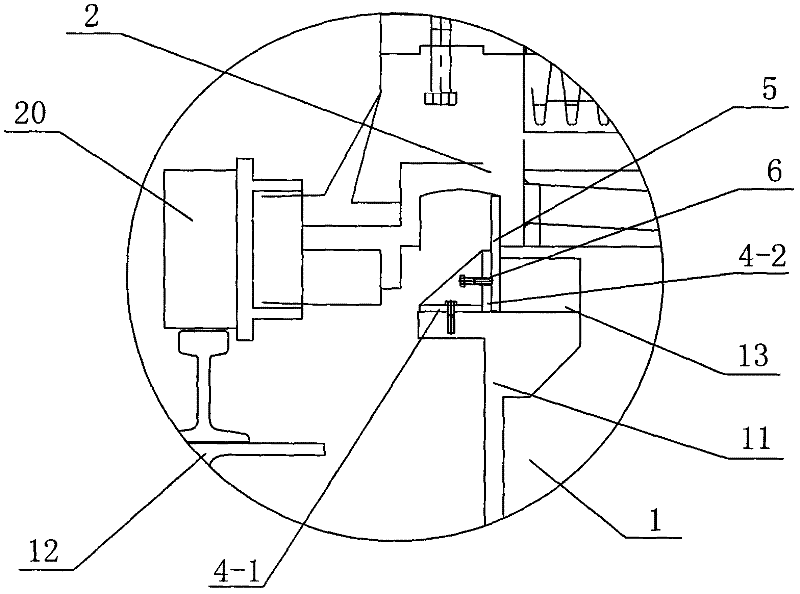

Sealing device for sintering machine trolley and air box

ActiveCN102121793BOvercoming the lack of wear and tearAvoid enteringEngine sealsFurnace typesEngineeringUtilization rate

The invention discloses a sealing device for a sintering machine trolley and an air box. The sealing device comprises a sealing plate and a sealing plate mounting member, wherein the sealing plate is arranged on the outer side surface of the lower part of the sintering machine trolley so as to seal a clearance between the bottom of the sintering machine trolley and the top of the air box; and thesealing plate mounting member is used for mounting the sealing plate on a mounting bracket at the outer side of the top of the air box. According to the sealing device disclosed by the invention, as the clearance between the sintering machine trolley and the air box is sealed from the side surface, the air leakage rate is low, the airflow utilization rate is improved by 30%, the sintering yield is increased by 20%, the total power of the motor is reduced by 30%, the production cost is low, the equipment operation rate is high, and the maintenance is convenient. By adopting the sealing device disclosed by the invention, the investment in civil engineering is saved by about 40%, the investment in sintering is saved, and the operation cost is low.

Owner:宝鸡市晋旺达机械设备有限公司

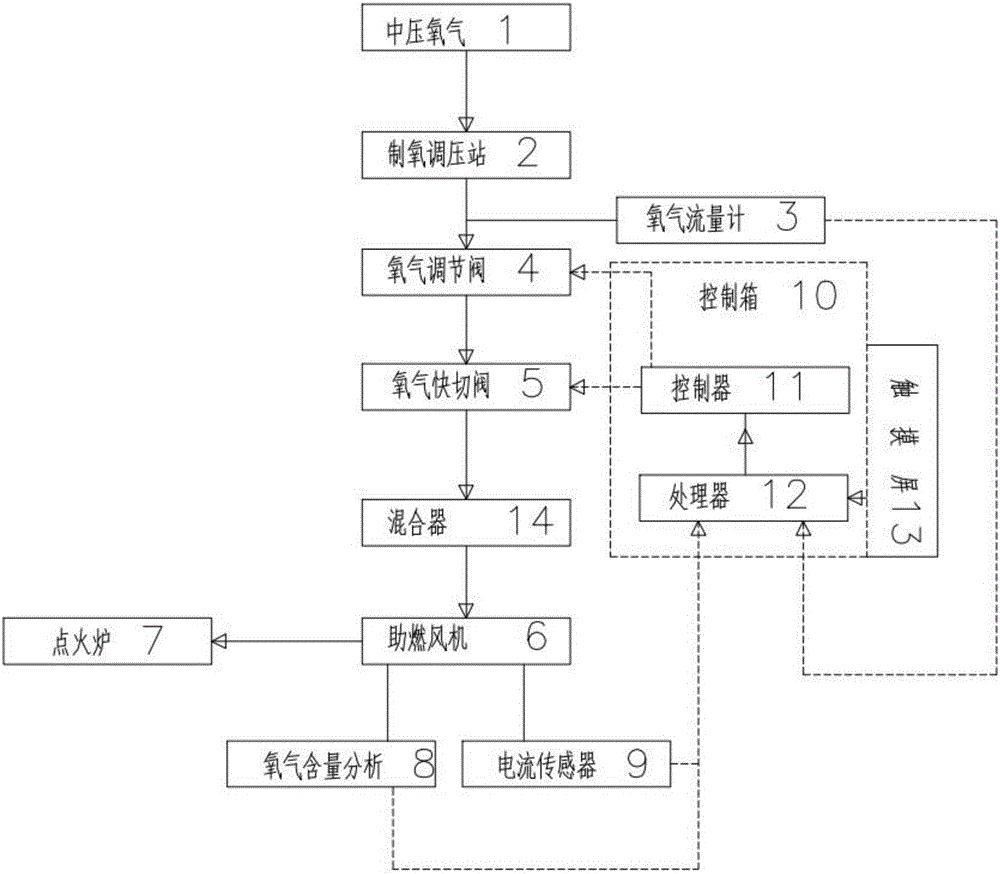

Sintering oxygen enrichment system

PendingCN106595309AReduce internal circulation reversion rateImprove sintering yieldCharge treatment typeFurnace typesMetallurgyHot blast

The invention discloses a sintering oxygen enrichment system. The sintering oxygen enrichment system comprises an oxygen production pressure adjusting station; medium-pressure oxygen is fed to a sintering factory through a pipe network after being adjusted the pressure by the oxygen production pressure adjusting station, and is conveyed to an oxygen adjusting valve through a pipe at the sintering factory; an oxygen flow meter is mounted in front of the oxygen adjusting valve; and then, the oxygen is conveyed to an oxygen quick cutting valve through a pipe, is conveyed to a gas mixer through a pipe, and is fed in two combustion assisting fans through pipes. The sintering oxygen enrichment system has the following beneficial effects: the sintering oxygen enrichment system facilitates to reduce the internal circulation reverse ore rate and increase the sintering yield, and can increase the sintering yield by above 10%; meanwhile, an oxygen-enriched ignition process is adopted to prominently improve the sintering ignition quality and to achieve obvious effects on increment of sintering ores, energy conservation and improvement of the product quality; and in addition, for sintering factories using blast furnace gas and difficult to obtain other calorific value gas to ignite, the oxygen-enriched ignition technology is adopted to also achieve prominent improvement effects.

Owner:孔祥旭

A method for estimating the moisture content of a sintering machine mixture according to the amount of water added

ActiveCN108133106BWater adjustmentEasy to add waterDesign optimisation/simulationSpecial data processing applicationsMetallurgyMoisture

The invention discloses a method for estimating the moisture content of a sintering machine mixture according to the amount of water added, and belongs to the technical field of sintering. The invention relates to a method for estimating the moisture content of the sintering machine mixture according to the amount of water added. It is estimated that the moisture content of the mixture on the sintering machine is H 3 , H 3 Calculated by the following formula: the present invention can estimate the moisture content of the mixture on the later sintering machine according to the amount of water added in the previous mixing process, which is convenient for the operator to adjust the sintering mixing process according to the technological conditions of the moisture content of the sintering mixture The amount of water added in the process is convenient to optimize the amount of water added in the process of sintering and mixing.

Owner:山东诺德能源科技有限公司

Method for strengthening sintering of high-proportion fine-grained material through multi-medium gas injection

The invention discloses a method for strengthening sintering of a high-proportion fine-grained material through multi-medium gas injection. The method comprises the following steps that uniform mixing, granulation, distribution, ignition and sintering are sequentially conducted on raw materials such as fine-grained iron ore, a fluxing agent, high-combustion-activity fuel, conventional fossil fueland return mines, and a mixed gas medium formed by fuel gas and water vapor is sprayed to the surface of a sintered material in the sintering process. According to the method, the permeability and thethermal state of a material layer are optimized by regulating and controlling the characteristic parameters and the addition proportion of the high-combustion-reaction-activity fuel and regulating and controlling the injection concentration and the coverage range of multi-medium gas and the relative volume percentage of fuel gas and water vapor in a coupling manner, so that the sintering of high-proportion fine-grained material is strengthened.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com