Antioxidant nickel paste and preparation method and application thereof

An anti-oxidation and nickel paste technology, which is applied to the parts of fixed capacitors, fixed capacitor electrodes, fixed capacitor dielectrics, etc., can solve the problem of limited effect on reducing the residual carbon rate, so as to reduce the residual carbon rate, promote decomposition, broaden the The effect of the upper limit of the debinding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In some embodiments, the preparation method of anti-oxidation nickel slurry comprises the following steps:

[0033] (1) The binder is dissolved in part of the solvent to obtain a binder solution;

[0034] (2) Mix the ceramic powder, dispersant and remaining solvent, stir evenly, grind in a sand mill for 6-8 hours, add the binder solution obtained in step (1), stir evenly, grind in a sand mill for 2-4 hours, and disperse To no agglomeration, the first slurry is obtained;

[0035] (3) Add nickel powder (nickel oxide) to the first slurry obtained in step (2), stir for 2 to 4 hours with a planetary mixer, and then grind for 6 to 10 times in a three-roll mill, and disperse until there is no agglomeration to obtain Antioxidant nickel paste. It should be noted that the preparation method of the anti-oxidation nickel slurry of the present invention is not limited to this process.

[0036] When the anti-oxidation nickel slurry of the present invention is used as the internal ...

Embodiment 1~5

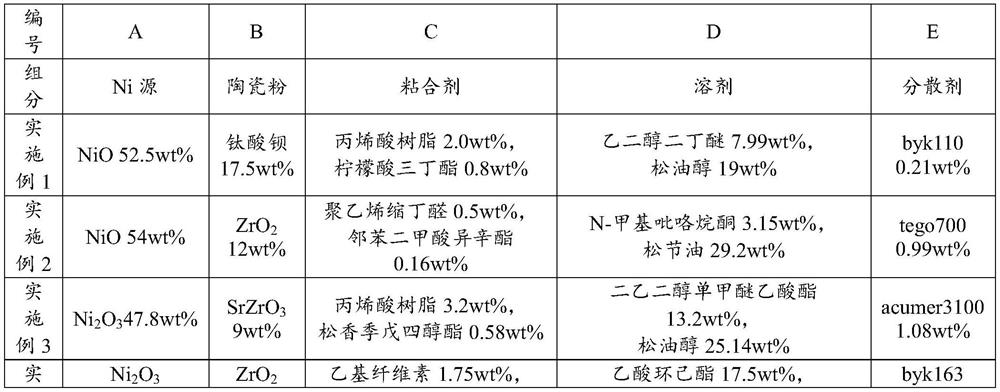

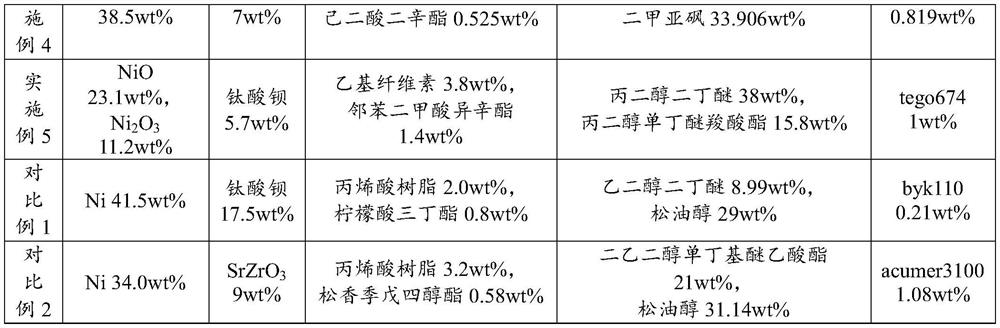

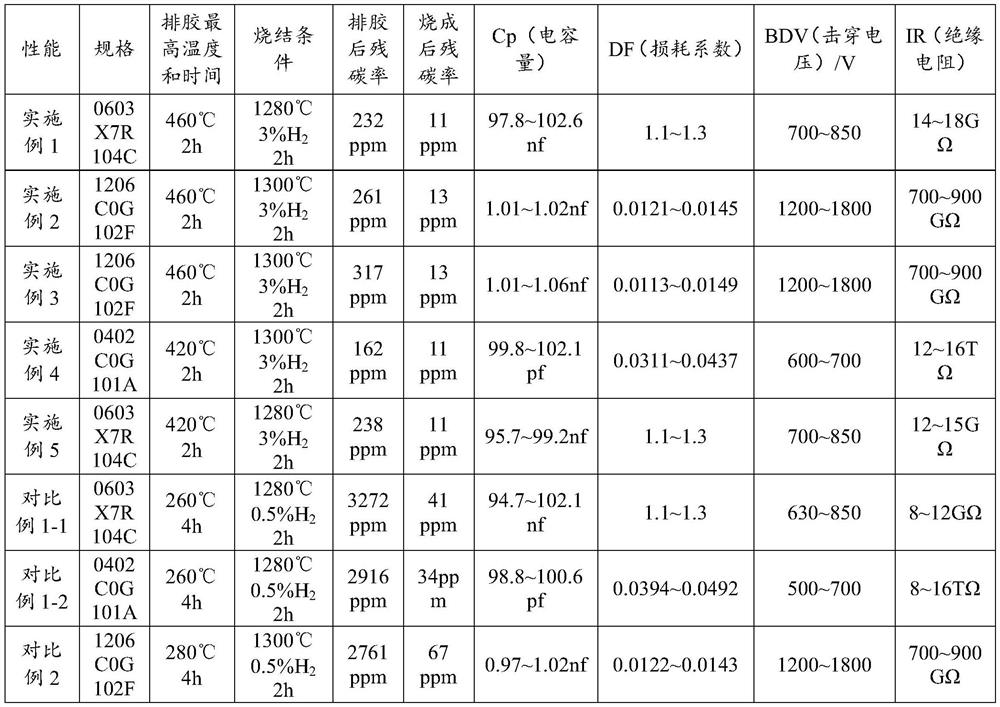

[0042] Embodiment 1~5 and comparative example 1~2

[0043] Embodiment 1~5 and comparative example 1~2 provide a kind of nickel paste respectively, and the composition and weight content thereof of these nickel pastes are as shown in table 1, wherein the nickel source (i.e. nickel oxide powder) that 1206 specification adopts or elemental nickel powder) average particle diameter is 600nm, and the nickel source (i.e. nickel oxide powder or elemental nickel powder) average particle diameter that 0402 and 0603 specifications adopt is 400nm, and the ceramic powder used in all embodiments and comparative examples The average particle size is 100nm, the acrylic resin is b-66 produced by Dow Chemical, the polyvinyl butyral is b30t produced by Japan Kuraray, and the ethyl cellulose is dt- produced by Guangzhou Daojun Biotechnology Co., Ltd. n-50, the dispersant is German BYK byk110, German BYK byk163, German tego700, German tego674 or American Rohm and Haas acumer3100. The preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com