Patents

Literature

348results about How to "Improve burnout rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

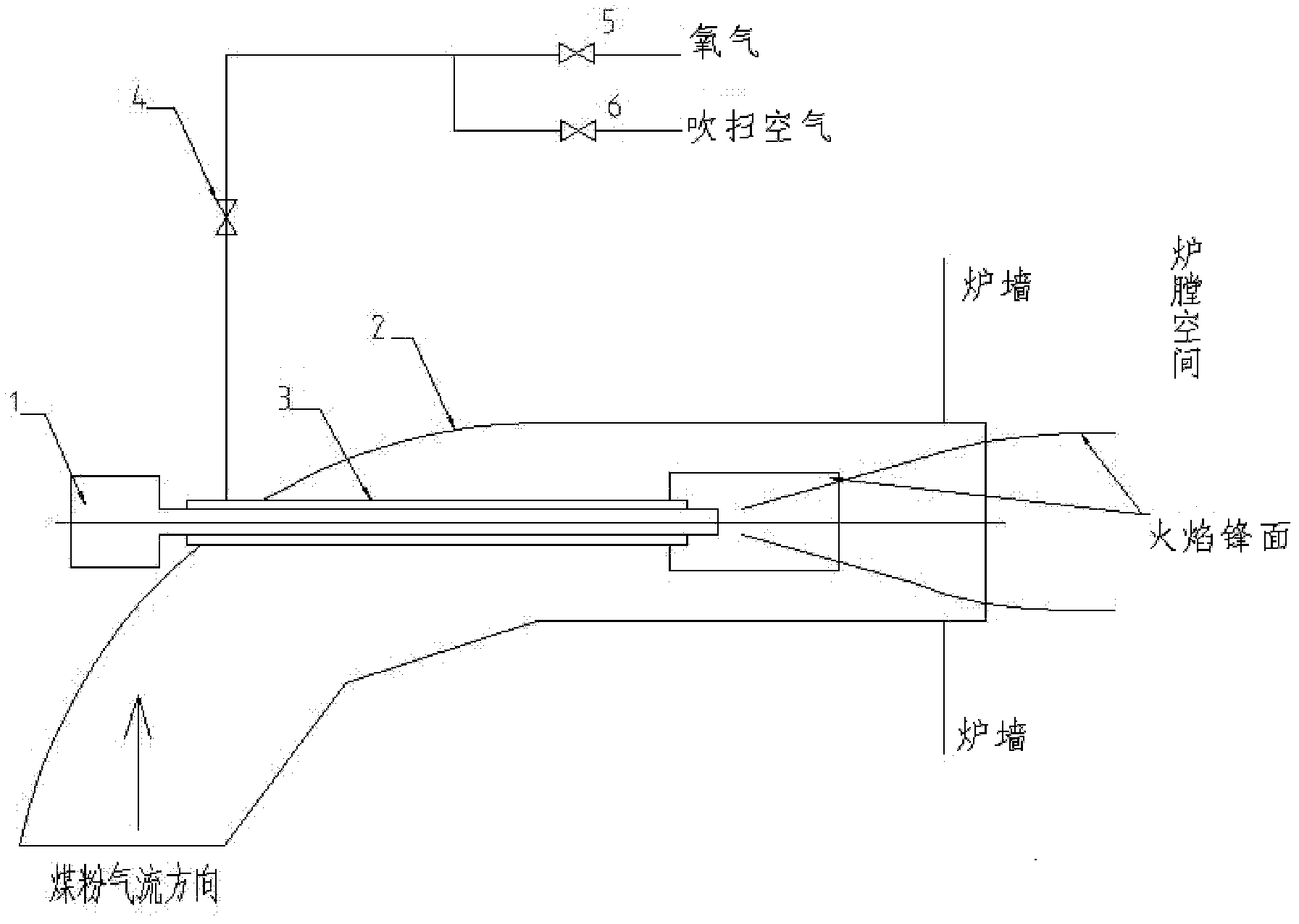

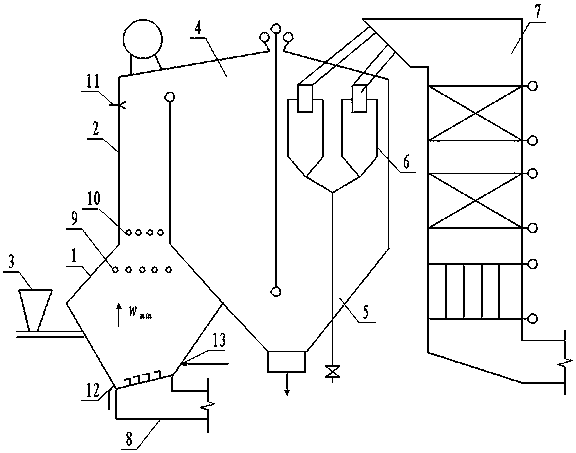

Method and system thereof for oxygen-enriched flameless combustion of coal powder

ActiveCN103615713AIncrease temperatureImprove heat utilization efficiencyDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationFlue gasInjection point

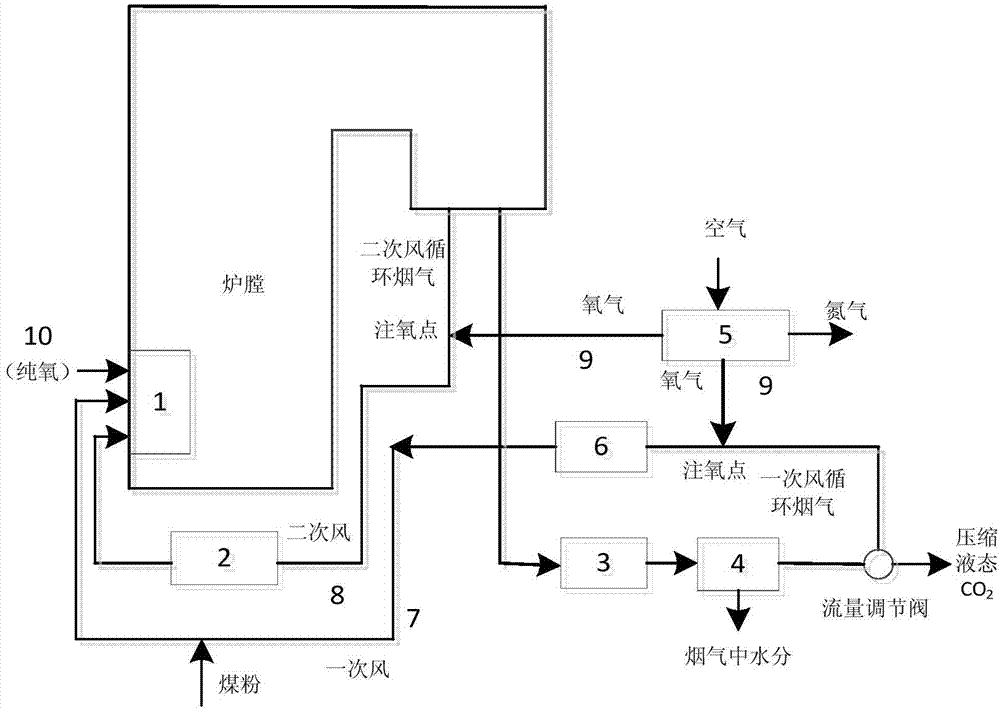

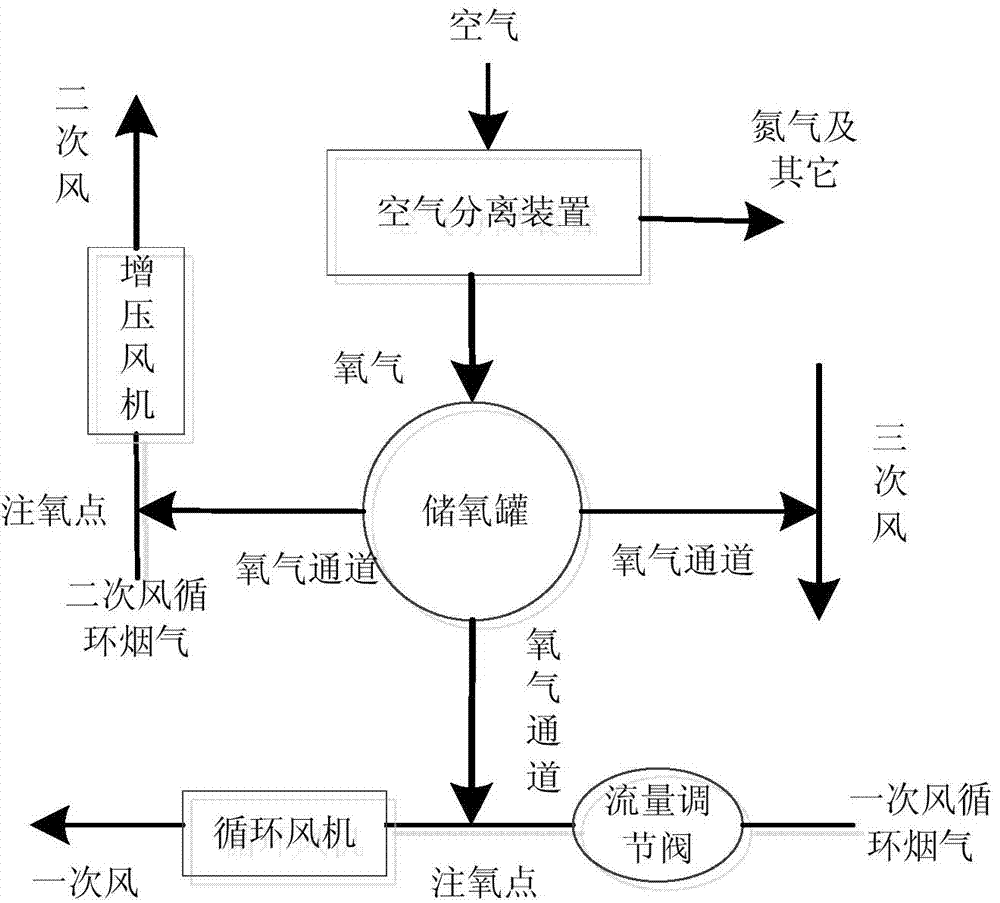

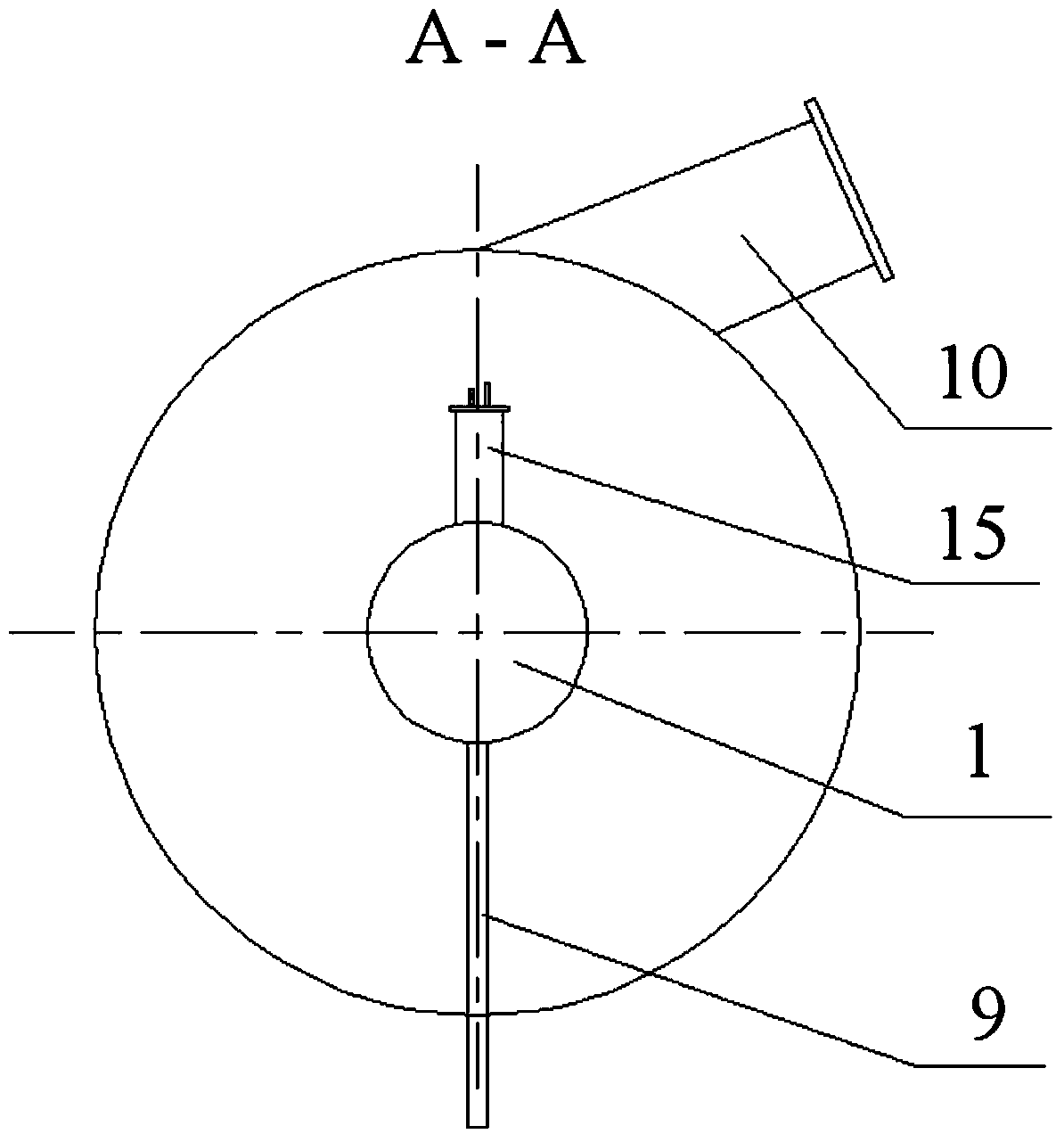

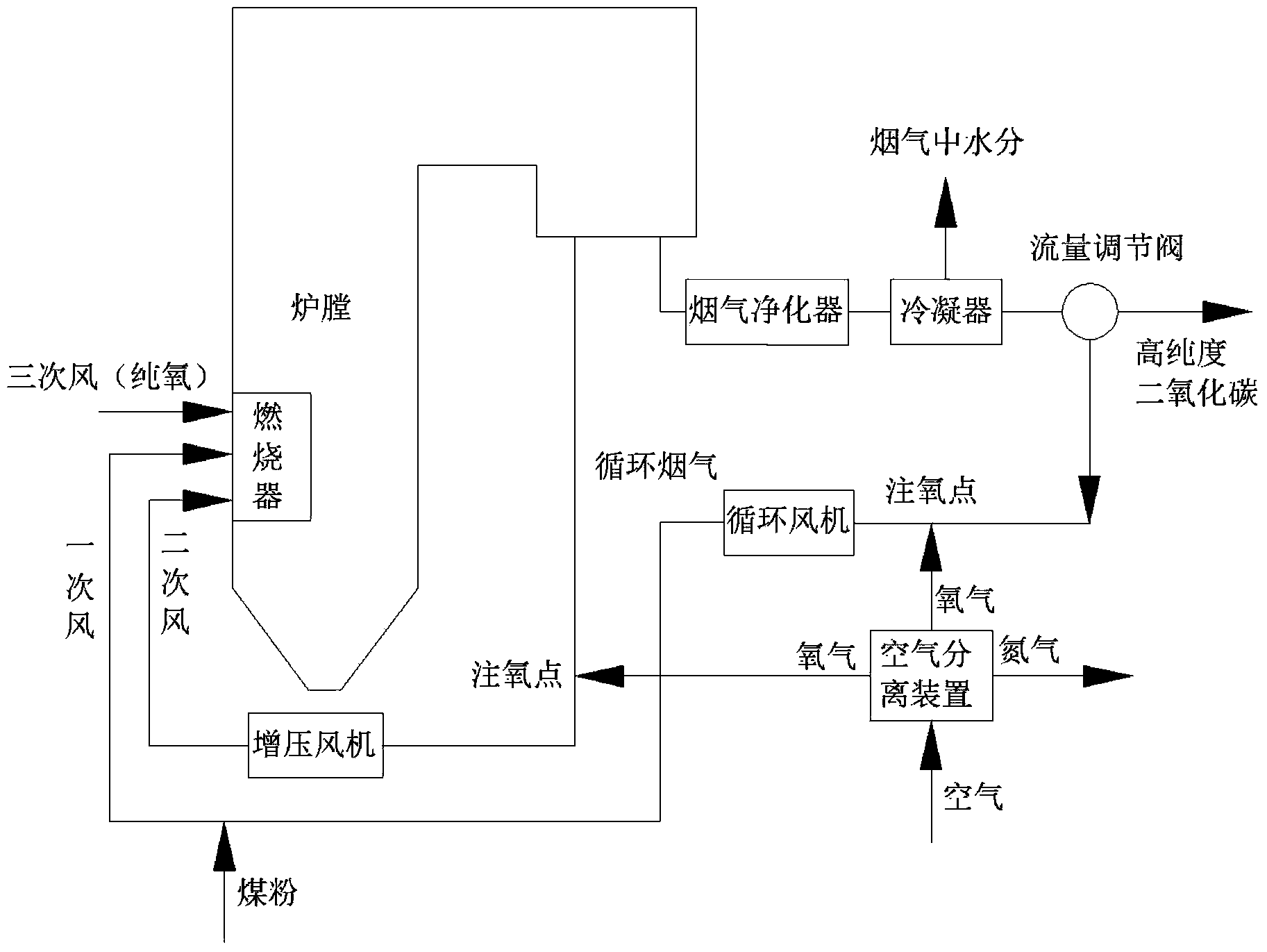

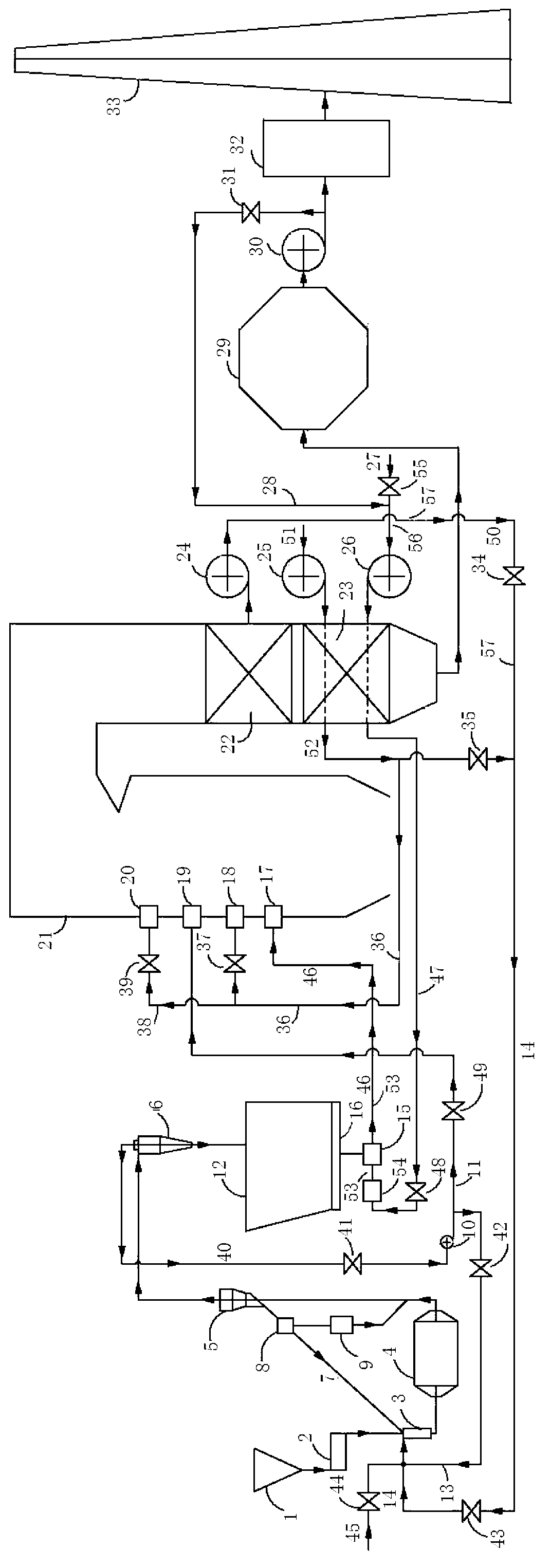

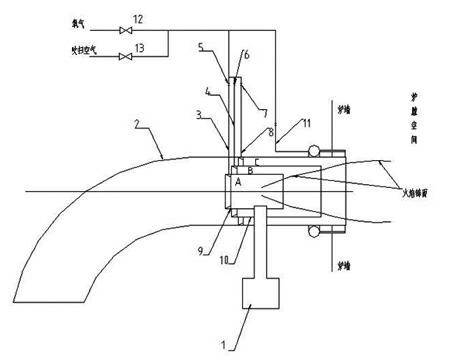

The invention discloses a method and a system thereof for oxygen-enriched flameless combustion of coal powder. By adopting the method, the stability, burn-off rate and radiative heat transfer of combustion can be improved through flameless combustion on the basis of enriching CO2 during oxygen-enriched combustion. High-temperature flue gas generated by the oxygen-enriched combustion is injected into a hearth in the form of high-speed jet flow through a direct-current flameless burner, and quick and uniform mixing of heat and quality in the hearth can be realized through high-speed jet flow entrainment. The system comprises an oxygen injection system, and a primary air oxygen-injection point is positioned between a circulating fan and a flow regulating valve; a secondary air oxygen-injection point is positioned between a booster fan and a hearth outlet; a primary air pipe of the direct-current flameless burner is positioned in the center, and a secondary air pipe is parallel to the primary air pipe and is circularly arranged around the primary air pipe; the booster fan with a high-pressure head is arranged on a secondary air duct, and secondary air is boosted and speeded up and then enters the hearth in the form of the high-speed jet flow. The heat utilization ratio of the method and the system can be improved by 10-25%, and the generation of NOX can be reduced by 15-40%.

Owner:HUAZHONG UNIV OF SCI & TECH

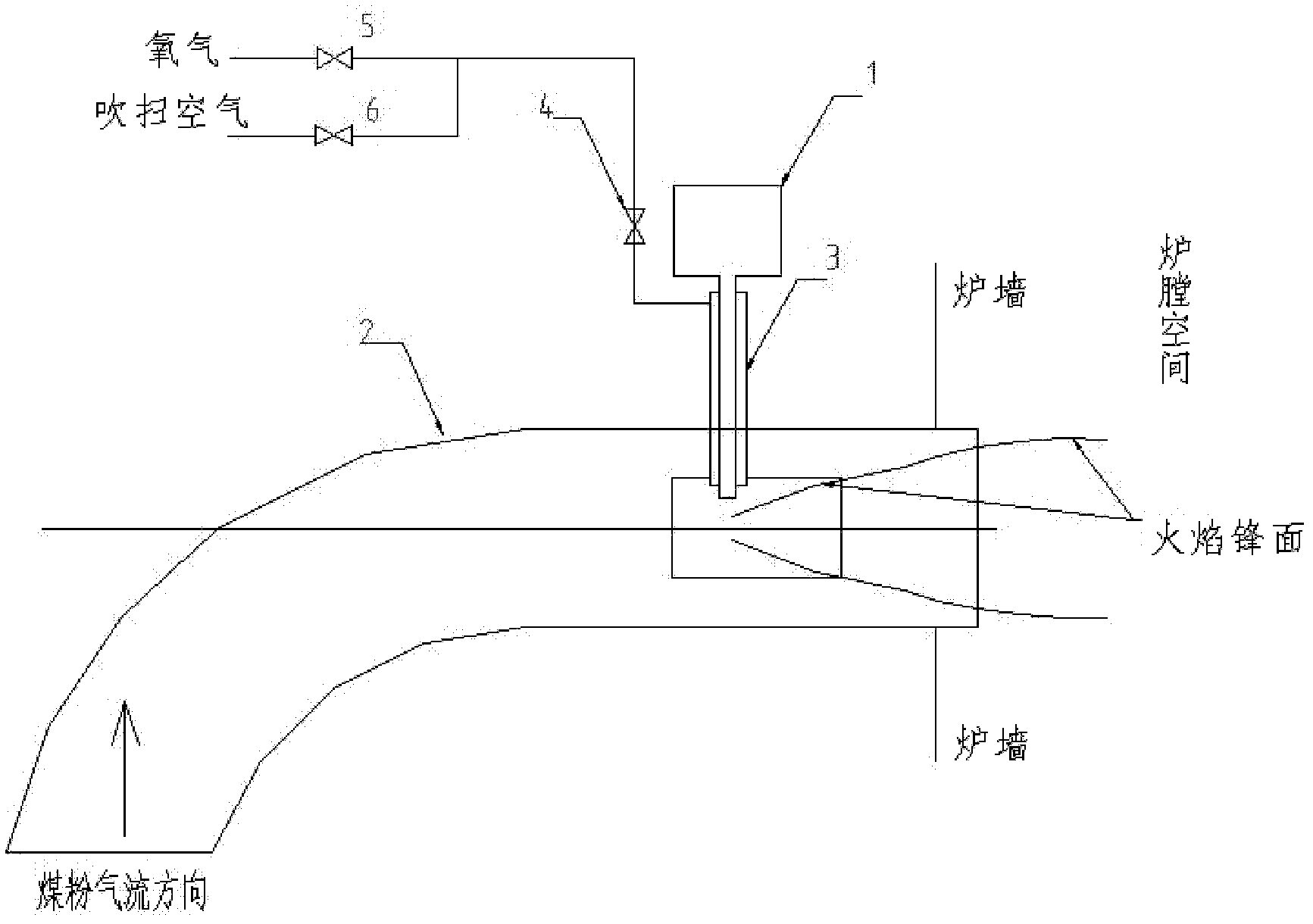

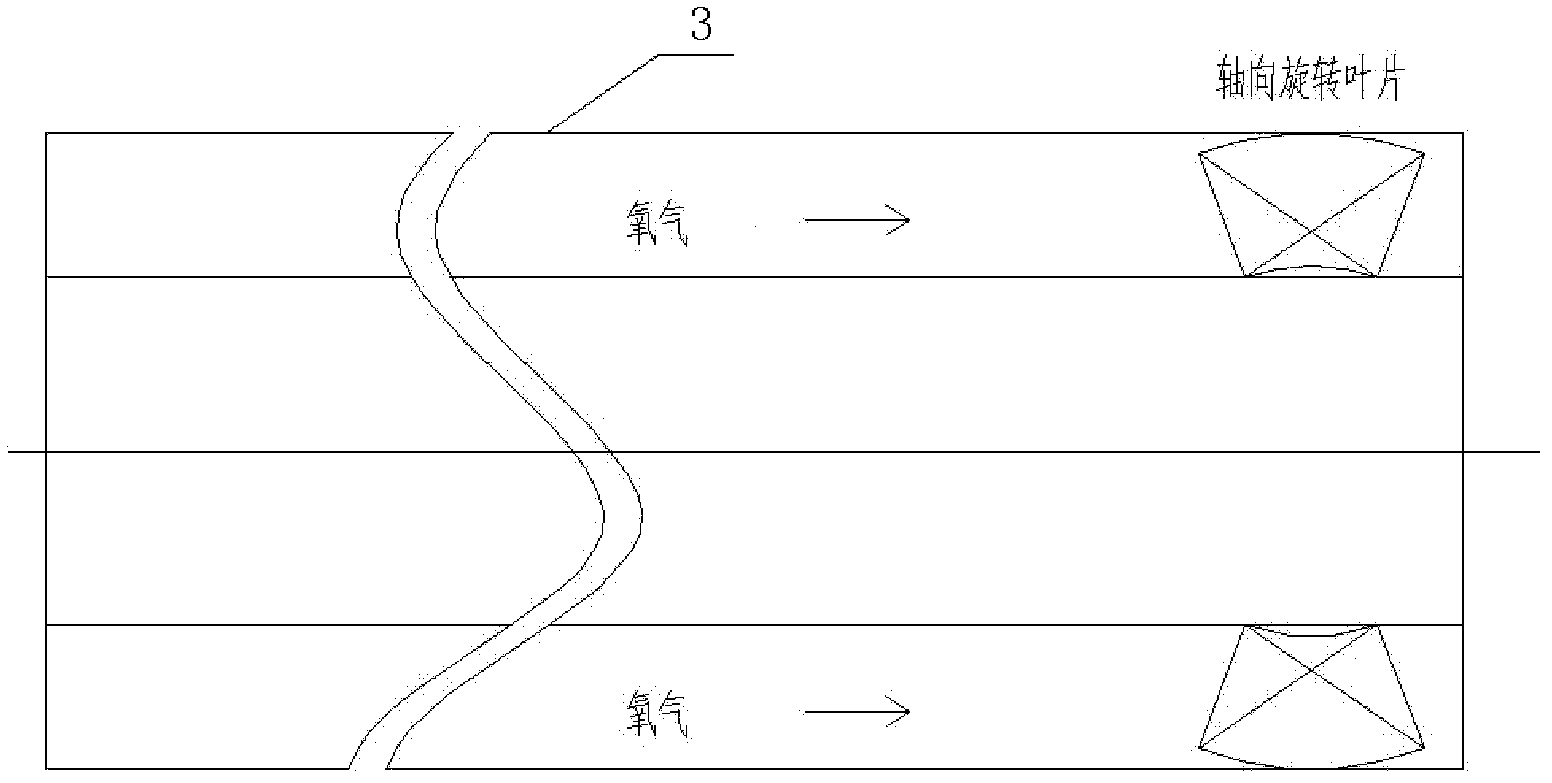

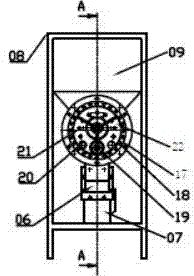

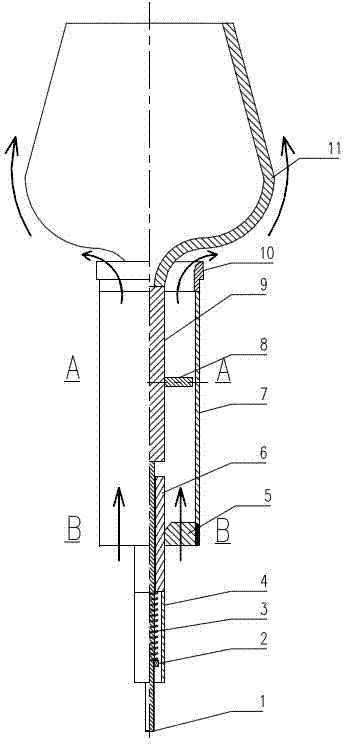

Novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor

ActiveCN103615717AWith low load stable combustion functionProvide in timePilot flame ignitersPulverulent fuel combustion burnersCombustion chamberCombustor

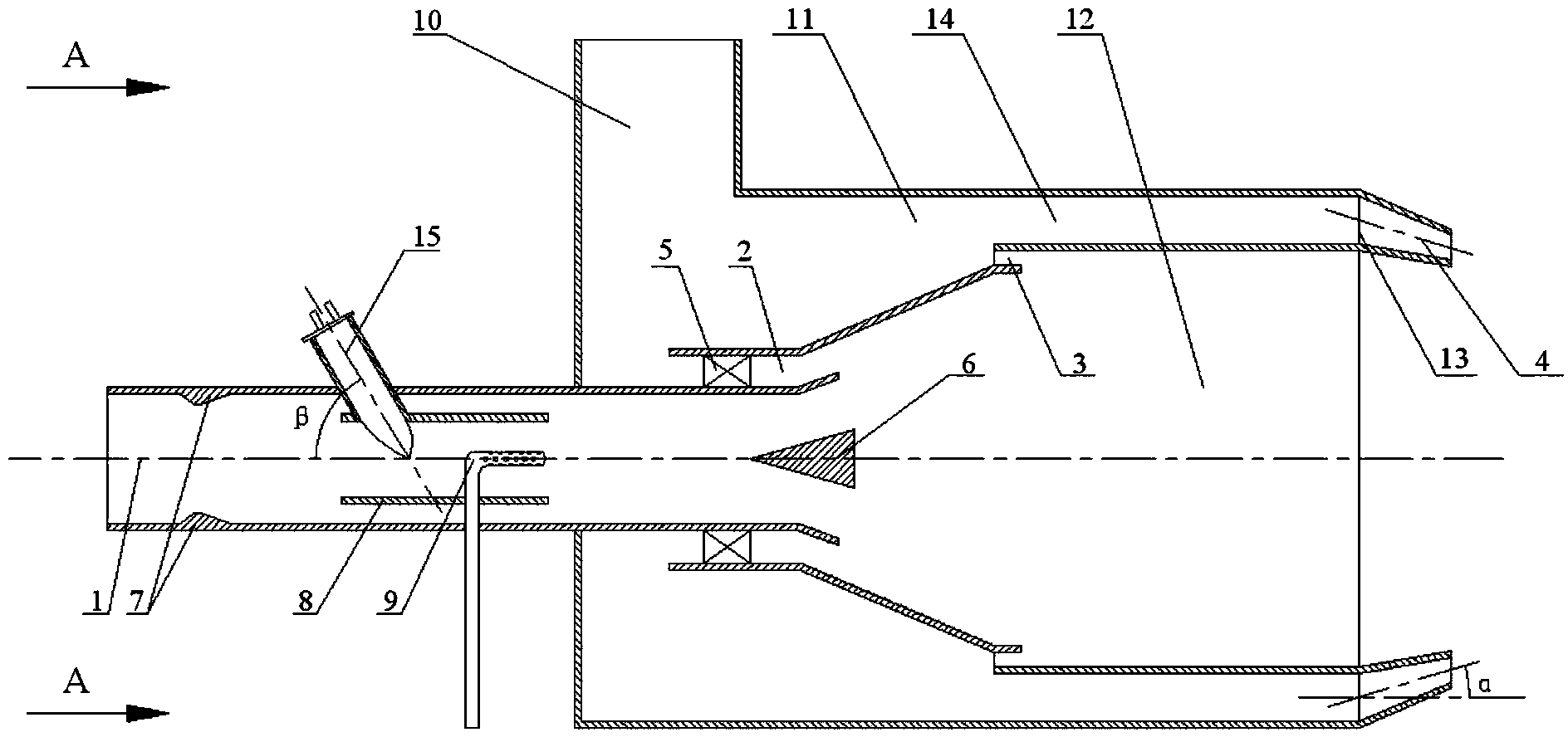

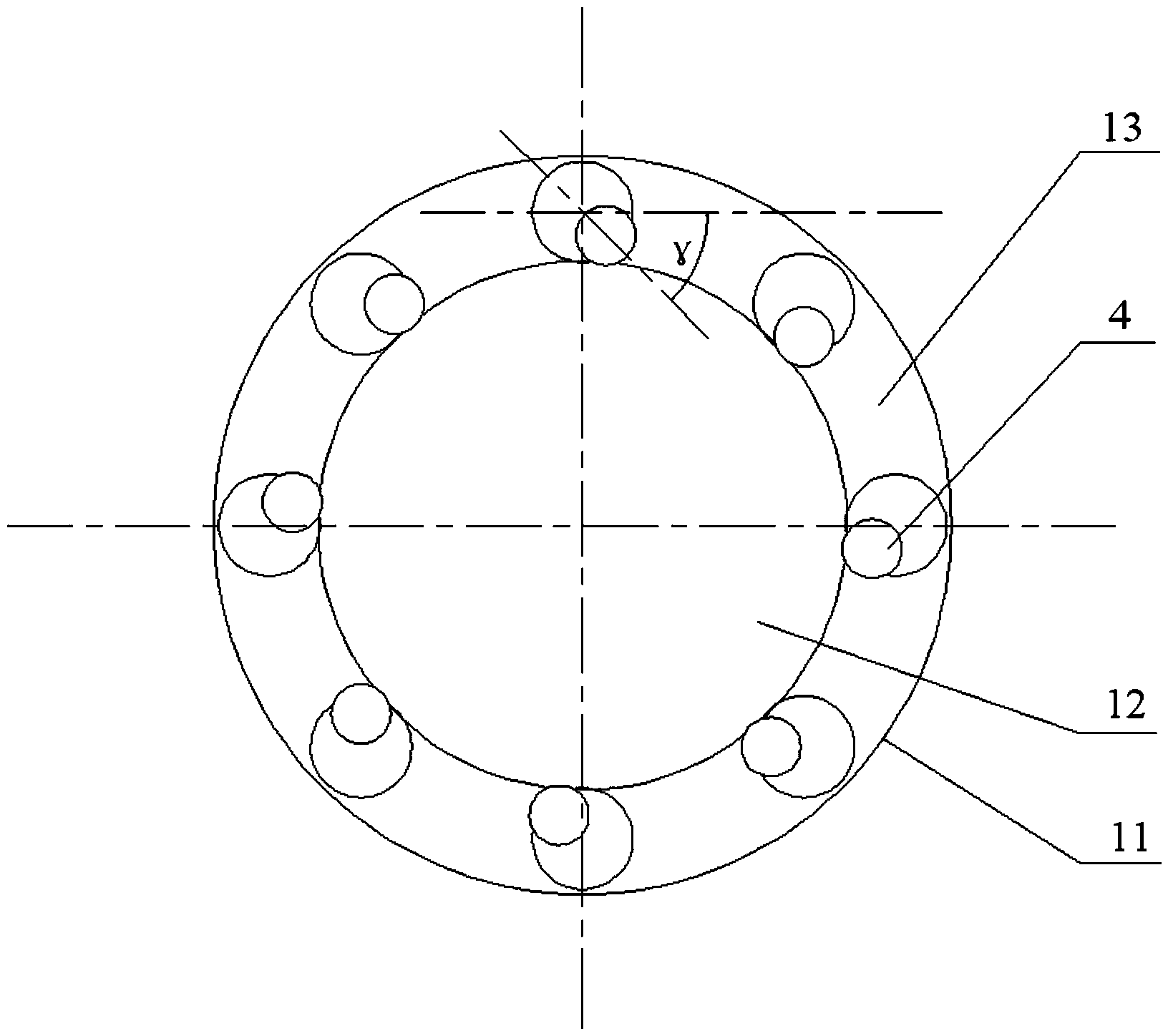

The invention discloses a novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor. The novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor comprises an oxygen enrichment guide pipe, a primary air pipe, a cylindrical oil-coal mixed combustion chamber, a secondary air pipe, a secondary air box and a pre-combustion chamber, wherein the central axes of the primary air pipe, the cylindrical oil-coal mixed combustion chamber, the secondary air pipe, the secondary air box and the pre-combustion chamber coincide. A secondary air inlet inclining in the circumferential direction is formed in the pipe wall of the secondary air box; the primary air pipe penetrates through the secondary air box in the axial direction, the oil-coal mixed combustion chamber is coaxially arranged in the primary air pipe, and a high-energy tiny-oil ignition oil gun and the oxygen enrichment guide pipe are arranged in the oil-coal mixed combustion chamber; the secondary air pipe with a rotational flow impeller is coaxially arranged outside the primary air pipe in a sleeved mode and an outlet end is provided with a bluff body; the pre-combustion chamber is arranged in the secondary air box, the inlet end of the pre-combustion chamber is provided with a graded air duct, and a plurality of disturbance air nozzles are installed in an outlet of the combustor. The ignition fuel saving ratio reaches over 90% and the novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor has the function of low load stable combustion and the function of ultralow load stable combustion; the technologies of oxygen enrichment, coal dust concentration, graded air feeding and the like are adopted, so that the novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor has the advantages of being high in coal dust burn-off rate, low in NOx discharge and the like.

Owner:CHINA JILIANG UNIV

Pulverized coal oxygen-rich combustion method and system

InactiveCN103968373AEasy to captureEfficient use ofDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationCombustion systemAir volume

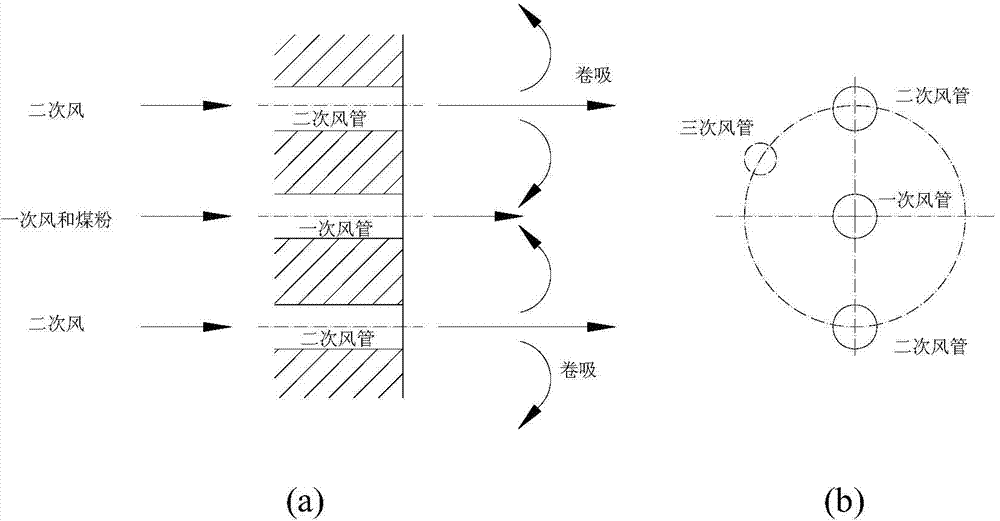

The invention discloses a pulverized coal oxygen-rich combustion method. According to the method, based on traditional oxygen-rich combustion CO2 enrichment, oxygen proportions in a primary air and a secondary air are adjusted to ensure that the oxygen concentration of the primary air is higher than the oxygen concentration of the secondary air, wherein the oxygen content of the primary air is about 30-50 %, the oxygen content of the secondary air is 10-25 % and a third air is pure oxygen; oxygen volume flow entering a furnace chamber takes up 25-35 % of total furnace chamber air volume flow; the pulverized coal is carried by the primary air; the proportion of the primary air to the secondary air is (5 %-25 % ) to (95 % - 75 %); the oxygen excess air coefficient is 1.0-1.2. The invention further provides a corresponding pulverized coal oxygen-rich combustion system. According to the pulverized coal oxygen-rich combustion method, the stability of combustion is improved, the temperature distribution in combustion process is changed and the NOX generation is reduced eventually; after the improvement, the thermal utilization efficiency can be increased by 5-15% and generated NOX can be reduced by 15-45 %.

Owner:HUAZHONG UNIV OF SCI & TECH

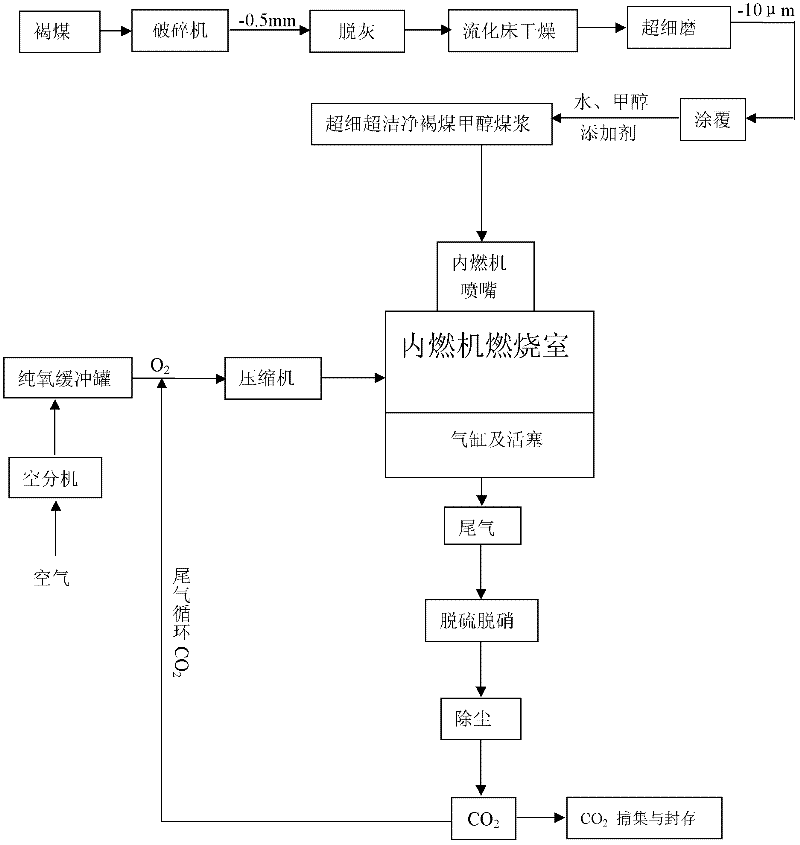

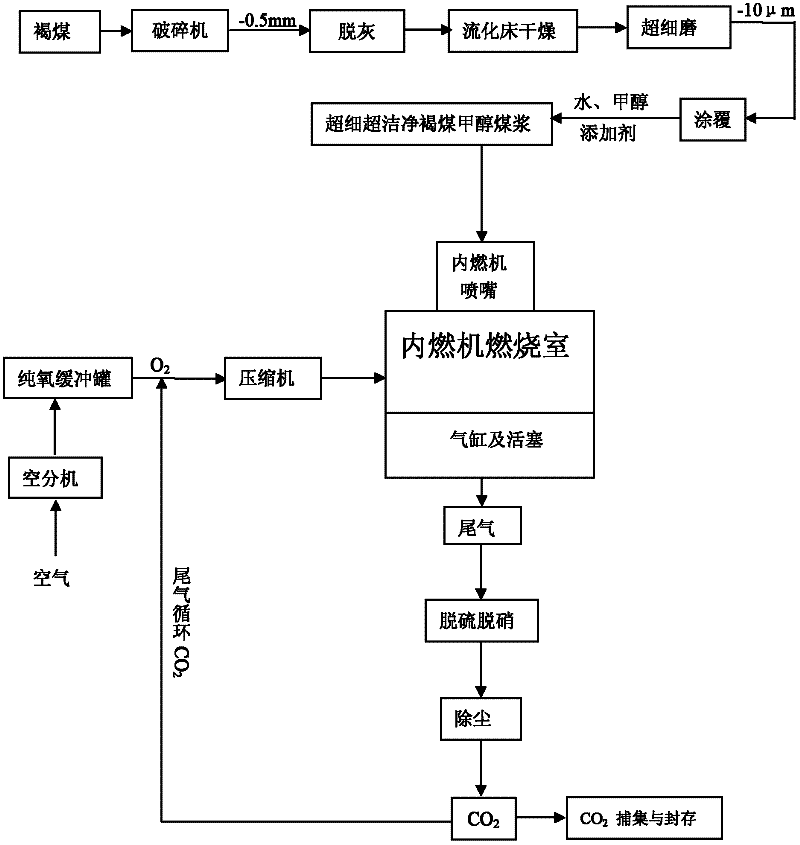

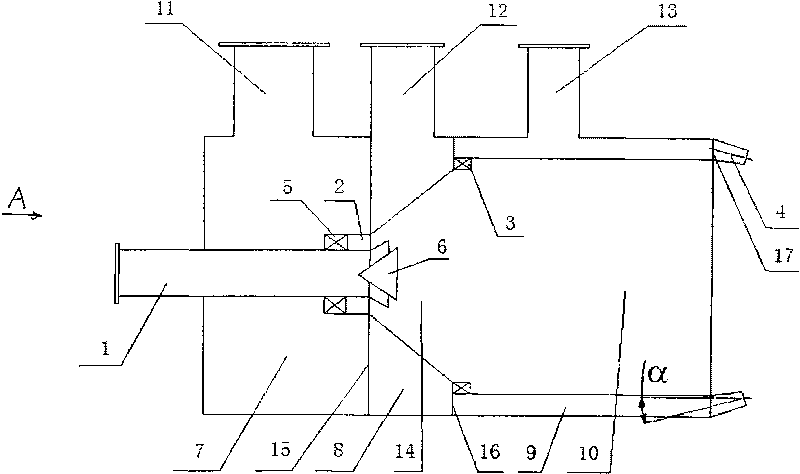

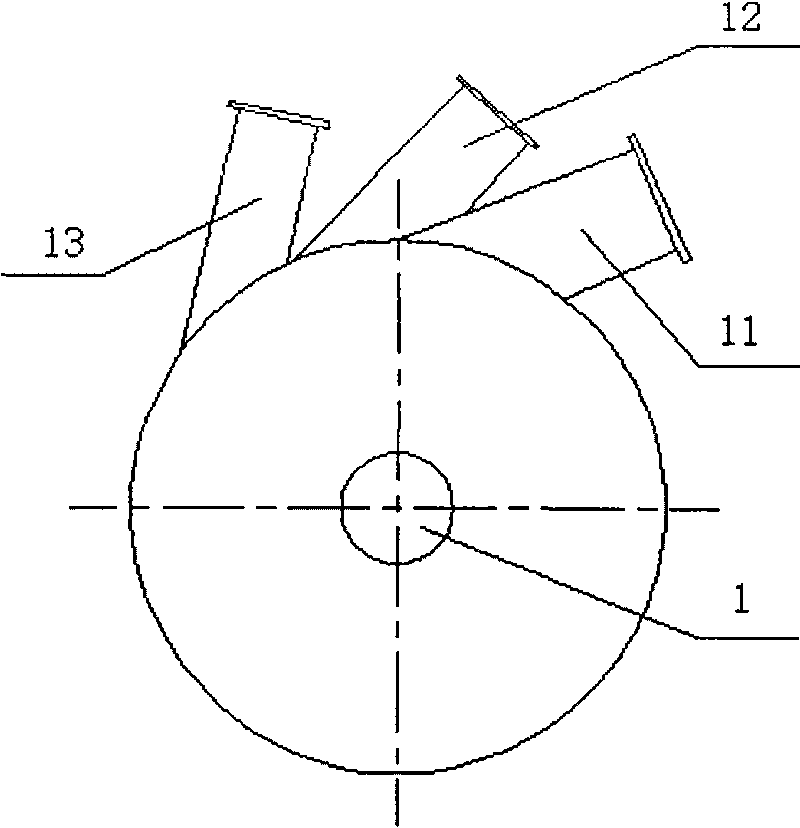

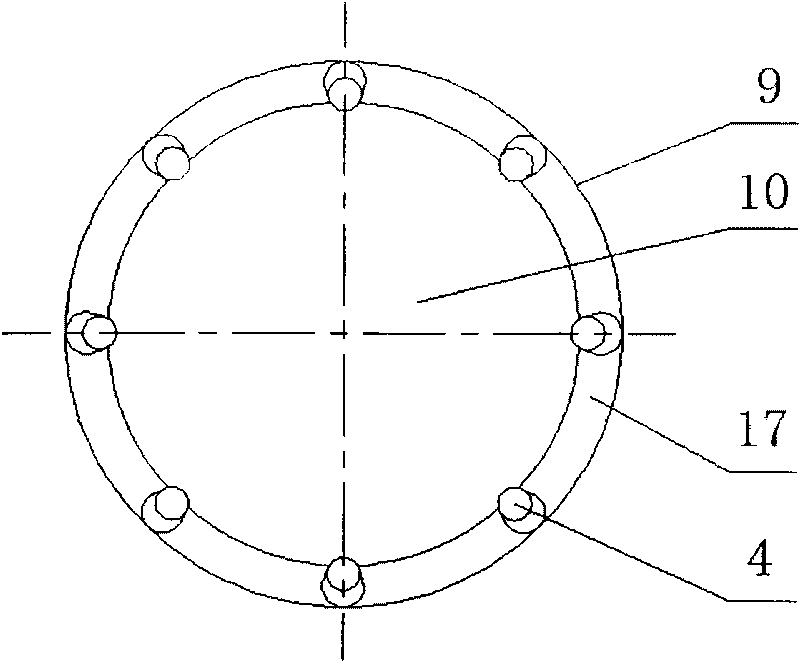

Oxygen-enriched combustion method of lignite methyl alcohol coal slurry fuel material in compression-type internal combustion engine

InactiveCN102434343AObvious beneficial effectImprove pressure and wear resistanceInternal combustion piston enginesNon-fuel substance addition to fuelHigh concentrationExternal combustion engine

The invention discloses an oxygen-enriched combustion method of a lignite methyl alcohol coal slurry fuel material in a compression-type internal combustion engine. The problem of difficulty in ignition of the traditional water coal slurry in the internal combustion engine is solved by utilizing the methyl alcohol coal slurry and oxygen-enriched combustion technology; and zero carbon emission of the whole system is realized through collecting CO2 generated by tail gas, and the pollution to environment is eliminated. The method provided by the invention adopts the following technical scheme which comprises the following steps of: taking ultra-fine ultra-clean ignite methyl alcohol coal slurry as a fuel material; taking pure oxygen and CO2 mixed gas with high concentration in recycled tail gas as a combustion-supporting gas; and carrying out enriched-oxygen combustion in the compression-type internal combustion engine, and generating a driving force by the compression-type internal combustion engine. Combustion is carried out by adopting pure oxygen and the recycled CO2 in the tail gas of the internal combustion engine as the combustion-supporting gas, the formation of NOX in the tail gas is reduced effectively, the concentration of CO2 in the tail gas is improved, the tail gas treatment expense is reduced, and the treated tail gas is easy to compress and store. The combustion method is suitable for a distribution-type power generation system and a large ship motive power system.

Owner:UNIV OF SCI & TECH LIAONING

Low-NOx pulverized coal burner

The invention discloses a low-NOx pulverized coal burner, which comprises an inner secondary air box, a hierarchical air box and a disturbed air box. The inner secondary air box, the hierarchical air box and the disturbed air box are separated by a first clapboard and a second clapboard sequentially; the centers of the first clapboard and the second clapboard are provided with circular holes; each pipe wall of each of the three air boxes is correspondingly provided with an air inlet which inclines towards the circumferential direction; a primary air pipe axially passes through the inner secondary air box; an inner secondary air pipe with a swirl vane is coaxially sleeved outside the primary air pipe; the inner secondary air pipe is hermetically connected with the first clapboard; the inner secondary air pipe expands conicity and extends outwards to form a conical cylinder at the circular hole of the first clapboard; the conical cylinder is arranged in the hierarchical air box; the disturbed air box is coaxially provided with a precombustion chamber with two open ends; an annular channel is formed between the wall of the disturbed air box and the wall of the precombustion chamber; an annular end face is arranged at an outlet of the annular channel; a disturbed air nozzle is fixed at an opening of the annular end face; the inlet end of the precombustion chamber is hermetically connected with the second clapboard; an annular hierarchical air channel is formed at the root of the inlet of the precombustion chamber; and the conical cylinder is hermetically fixed with the inner wall of the hierarchical air channel.

Owner:ZHEJIANG JINGUO BOILER

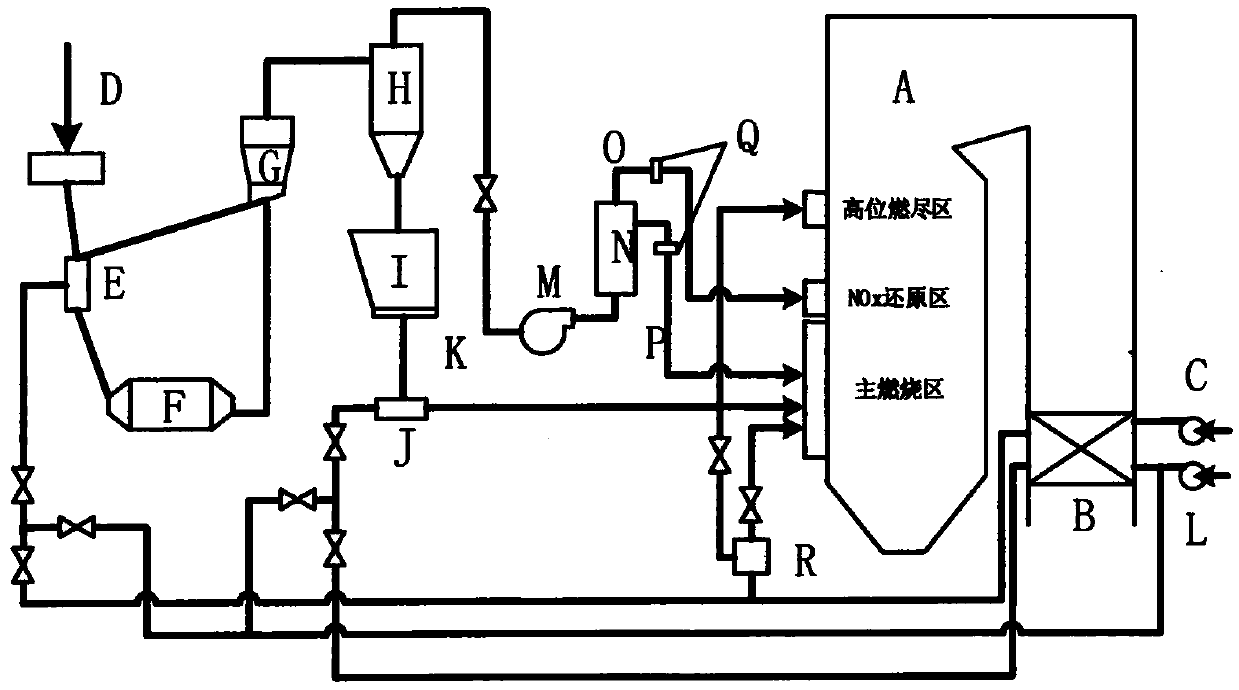

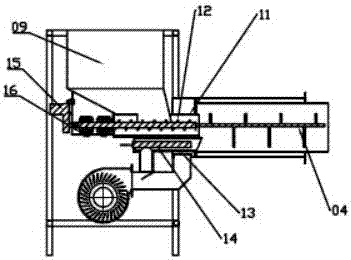

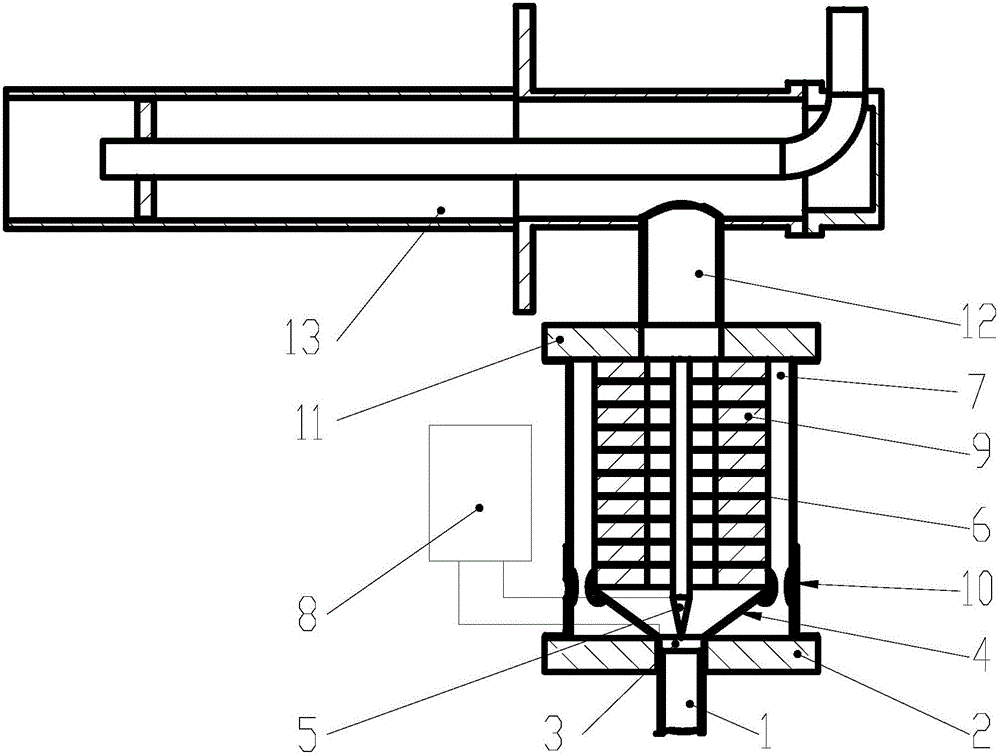

Storage-type super-low nitric oxide system in coal fired boiler coal mill

ActiveCN103216840ANot easy to explodeIncrease delivery temperatureLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationPowder mixtureNitric oxide

The invention relates to a storage-type super-low nitric oxide system in a coal fired boiler coal mill. On the basis of the existing low-nitrogen burning technology, the superfine coal powder preparation technology and the smoke circulating technology are adopted. The smoke circulating technology adopts cold furnace smoke to be mixed with primary air to be supercharged by a primary fan, the heating and powder feeding technology of an air preheater and the hot air and high-temperature furnace smoke drying technology of the powder production system are adopted, i.e. superfine coal powder can be prepared, the hot furnace smoke enters a primary air large air bellow, the hot furnace smoke is mixed with superfine coal powder prepared by a superfine coal powder preparation device in a coal powder blender and supplied by a powder supply machine from a coal powder cabin to be heated, and the air-powder mixture is fed into a low-nitrogen burner through a primary air pipe. In the main burning area of the boiler, since the air content of the furnace smoke is little, a lower residual air coefficient can be realized, the emission of the nitric oxide can be reduced.

Owner:南京佛莱斯特环保科技有限公司

Fire coal efficient catalysis combustion-supporting agent and preparation method and use method thereof

InactiveCN102061212AImprove combustion performanceImprove burnout rateSolid fuelsBasic copper carbonateUrea

The invention provides a fire coal efficient catalysis combustion-supporting agent and a preparation method and use method thereof. The combustion-supporting agent provided by the invention comprises the following components in parts by weight: 20-40 parts of basic copper carbonate, 10-25 parts of calcium oxide, 5-20 parts of citric acid, 5-10 parts of ammonium metavanadate, 5-10 parts of urea, 5-10 parts of potassium carbonate and 5-10 parts of borax. The combustion-supporting agent can also contain 5-10 parts of lanthanide oxide, 5-15 parts of magnesium powder and 0-10 parts of iron nitrate. The invention has the following beneficial effects: the components of the combined combustion-supporting agent release or transfer active oxygen at the high temperature; the macromolecular structures of coal are damaged to break the bridge bonds between the connecting structure units, improve the combustibility of fire coal and increase the burn-off rate of coal, thus fire coal can be fully utilized and the aim of energy saving can be achieved; and the combustion-supporting agent performs combination reactions with the combustion products of coal such as SO2 and the generated solids which are difficult to volatilize enter ash, thus the emissions of gaseous pollutants can be reduced.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Pulse-combustion control method of steel rolling heating furnace

InactiveCN102221220AEven workloadImprove heat transfer efficiencyFurnace typesHeat treatment furnacesFurnace temperaturePulse cycle

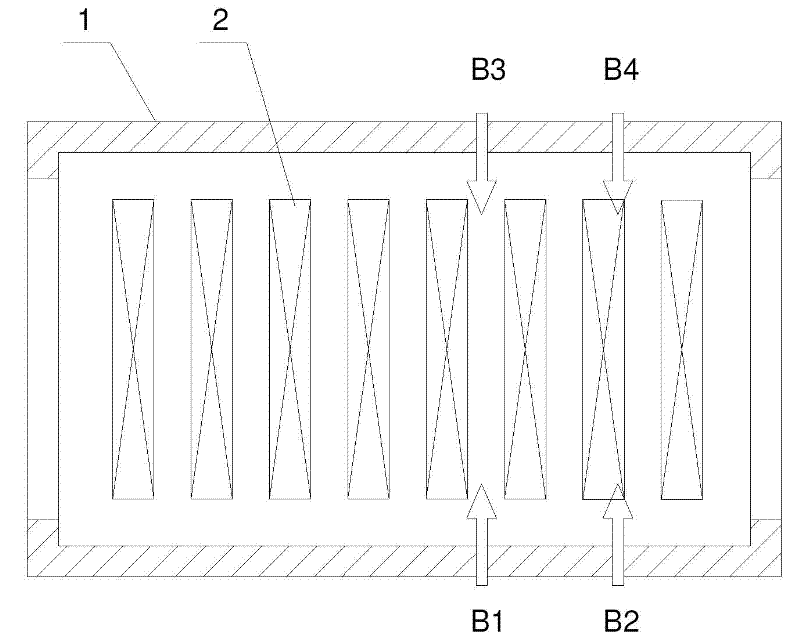

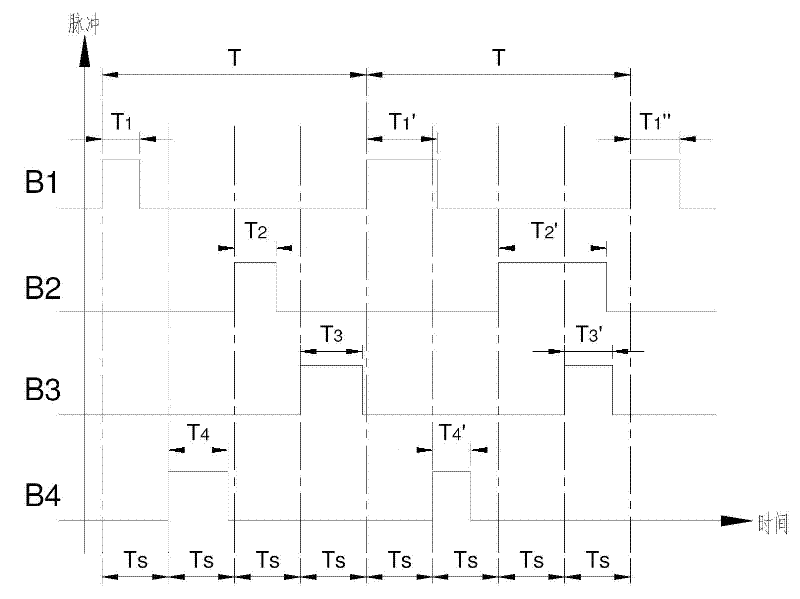

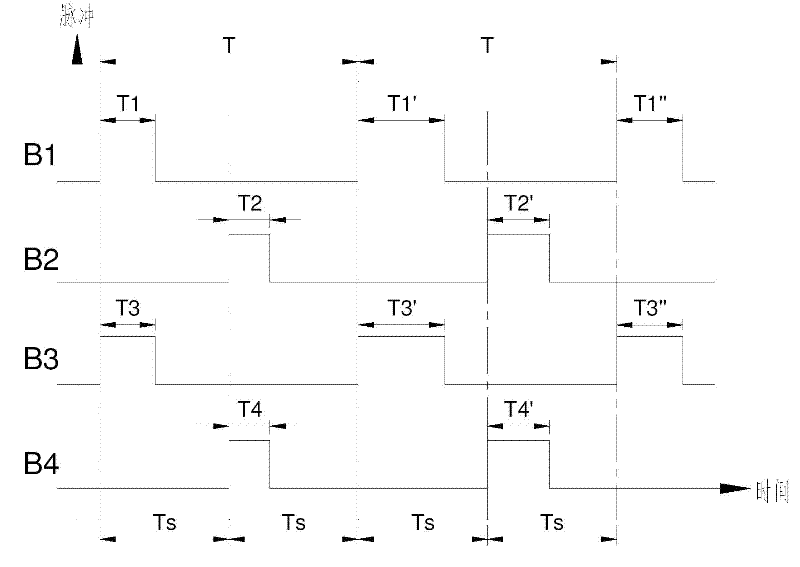

The invention discloses a pulse-combustion control method of a steel rolling heating furnace, namely at least four gas nozzles are arranged at the two sides of the heating furnace and located at the upper and lower parts of blanks in the blank along the length direction of the oven, thus whole-side-burning is formed for the heating furnace, the pulse of opening and closing of the whole gas nozzles is finished in T time and T is taken as a cycle period, each gas nozzle is opened at Ts interval successively, the quantity of the gas nozzles is N, thus in a pulse cycle period Ts=T / N, each gas nozzle open pulse order is set as required and opened by rated heating efficiency, each gas nozzle open pulse time is T1, T2...TQ, and the each gas nozzle open pulse time T1, T2... and TQ are calculated by the PID controller of the heating furnace control system according to the set value and the measured value of the furnace temperature. The pulse-combustion control method provided by the invention has the advantages of improving the furnace-shape, balancing the workload of the gas nozzle, improving fuel burn-off rate, strengthening the heat transfer efficiency of the blank, saving the fuel loss and improving control accuracy and flexibility of the furnace temperature, and is convenient in maintain and operation.

Owner:BAOSTEEL IND FURNACE ENG TECH

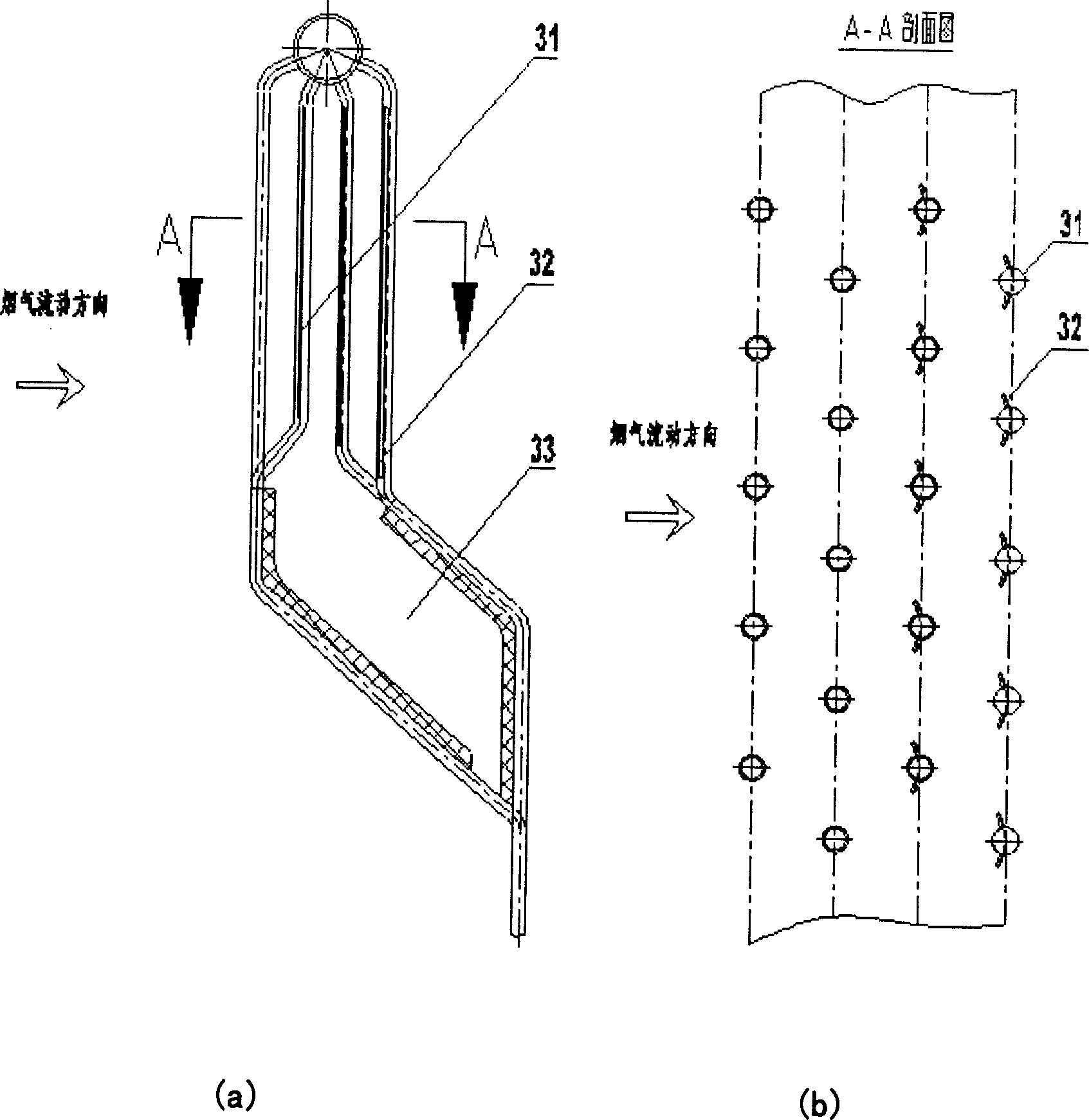

System and method for reducing boiler NOx emission by tertiary air concentrated-diluted separation

ActiveCN105509085AImprove reducibilityEmission reductionFuel feeding arrangementsSolid fuel pretreatmentEngineeringLower upper

The invention provides a system for reducing boiler NOx emission by tertiary air concentrated-diluted separation. An outlet of a tertiary air powder exhaust fan is connected with a coal powder concentrated-diluted separator; a separation blade for adjusting a separation quantity of concentrated-diluted coal powder is arranged on an inlet section of the coal powder concentrated-diluted separator, and a concentrated coal powder pipe and a diluted coal powder pipe are arranged on an outlet section; the concentrated coal powder pipe is connected with at least one layer of hearth main combustion area middle lower nozzles; and the diluted coal powder pipe is connected with at least one layer of hearth main combustion area upper nozzles. The invention further provides a method for reducing boiler NOx emission by tertiary air concentrated-diluted separation; tertiary air containing thin coal powder is separated as concentrated and diluted two parts of coal powder air currents; and the concentrated and diluted two parts of coal powder air currents are respectively sprayed into the middle lower part and the upper part of a hearth main combustion area. The concentrated coal powder current replaces one part of secondary air to form an oxygen debt environment in the main combustion area so as to enhance the reducibility of the main combustion area; the diluted coal powder current is quickly burnt to consume oxygen so as to enhance the reducibility of NOx in a boiler; and the secondary air quantity reduced in the main combustion area is replenished to high-level burnt air so as to guarantee the burn-off rate of the coal powder in the boiler.

Owner:SHANGHAI BOILER WORKS

Biomass moulded coal and preparation method thereof

InactiveCN101985575ALow calorific valueLow volatileBiofuelsSolid fuelsFixation agentSodium hydroxide

The invention provides a method for preparing biomass moulded coal by using biomass and inferior smokeless pulverized coal as raw materials. The biomass moulded coal is prepared by uniformly mixing the biomass, the inferior smokeless pulverized coal and additives (a sulfur fixation agent, a biomass binder, an oxidant and a waterproofing agent), and performing low-pressure compression moulding by a wet method, wherein the sulfur fixation agent is calcined lime CaO; the biomass binder is light yellow dope prepared by treating bagasse by using 1 to 2 percent sodium hydroxide solution; the oxidant is potassium permanganate; and the waterproofing agent is tar or a binder. The biomass moulded coal comprises following raw materials in part by mass: 40 to 65 parts of inferior smokeless pulverized coal, 25 to 55 parts of biomass and 5 to 10 parts of additive. The biomass moulded coal has the advantages of low cost, low ignition point, high burn-off rate and integrative desulfurization and water proofing performance, and has great significance of energy conservation and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

Resource utilization method of paint slag

ActiveCN105880261ASimple processing methodProcess method safetySolid waste disposalTransportation and packagingCombustionLiquid state

A resource utilization method of paint slag includes the following steps that (1) pretreatment and separation are conducted, specifically, the wet paint slag is pretreated through a grinding modified spray drying method and separated into two components which are powdery or granular slag and organic matter waster liquid, or the wet paint slag is pretreated and separated into two components which are solid slag and organic matter waster liquid through an acid-modified baking hardening treatment technology; and (2) the water-containing organic matter waster liquid obtained in the step (1) is placed in a stirring tank, an emulsifying agent and a modifier are sequentially added into the water-containing organic matter waster liquid with constant stirring, uniform stirring is conducted, and a product is obtained. According to component characteristics of the wet paint slag, the wet paint slag is pretreated and separated into the two components which are the solid slag raw material convenient to use and the organic matter waster liquid containing volatile matter, namely water, and then the water-containing organic matter waster liquid is made into the liquid-state coal clean combustion improver; and the process method is simple, safe and free of secondary pollution, takes effect rapidly, is low in treatment or utilization cost, and is good in economical efficiency.

Owner:湖南省小尹无忌环境能源科技开发有限公司 +1

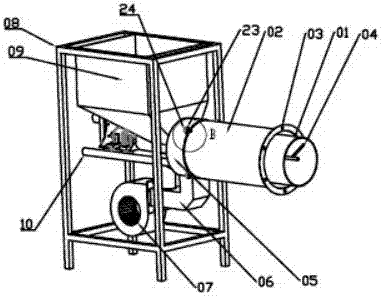

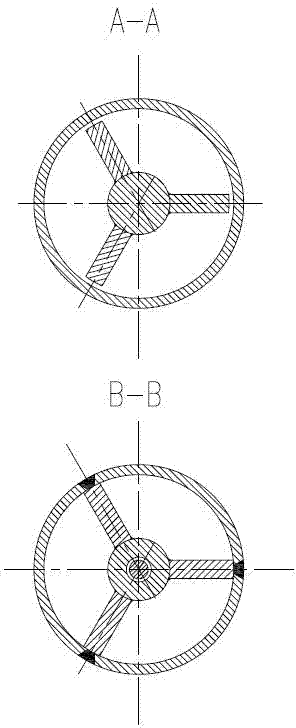

Plasma oil-free ignition combustor

ActiveCN102519037AAdapt to wideImprove burnout rateIncandescent ignitionPulverulent fuel combustion burnersCombustorPlasma generator

The invention discloses a plasma oil-free ignition combustor. The plasma oil-free ignition combustor comprises a plasma generator and a combustor, wherein an annular oxygen sleeve for supplementing oxygen to support combustion is arranged outside the plasma generator; the plasma generator and the sleeve are arranged coaxially; and the annular oxygen sleeve is connected with an oxygen pipeline. Because the annular oxygen sleeve is connected with the oxygen pipeline, the oxygen can enter the combustor through the annular oxygen sleeve, a local oxygen-enriched area is formed in the combustor and in a space of flowing pulverized coal airflow in a boiler, and combustion of the pulverized coal airflow can be intensified.

Owner:SHANGHAI BOILER WORKS

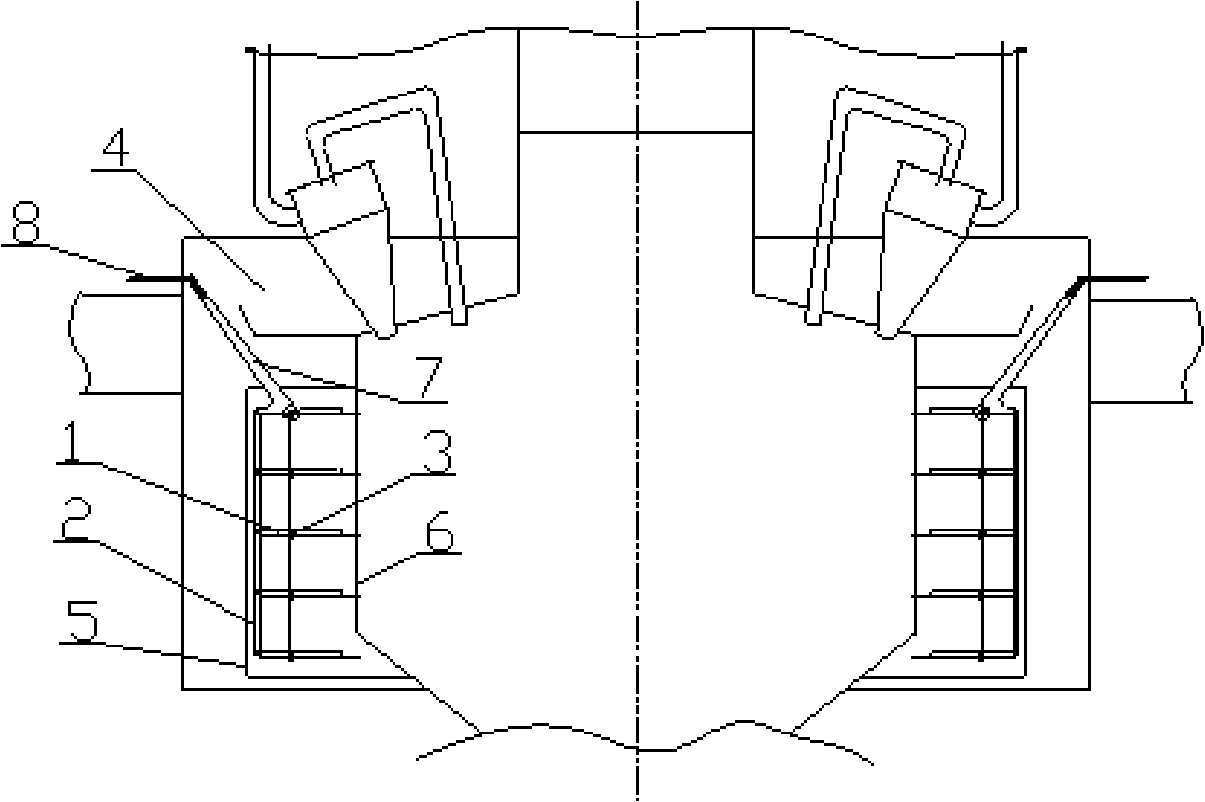

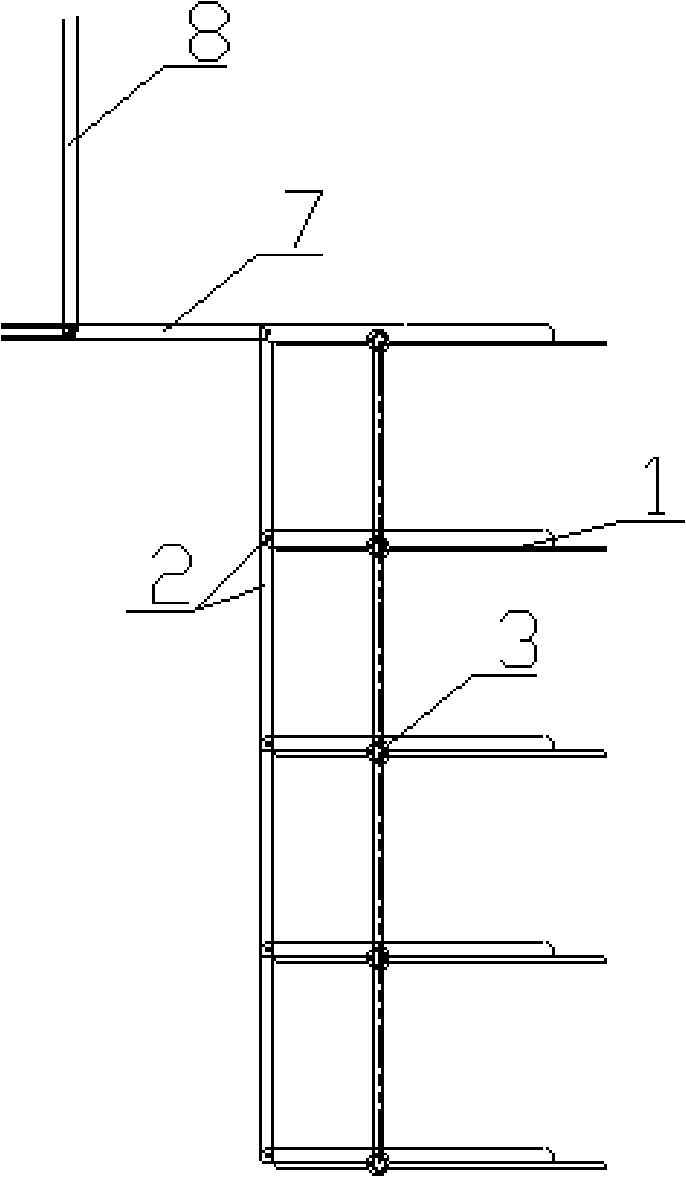

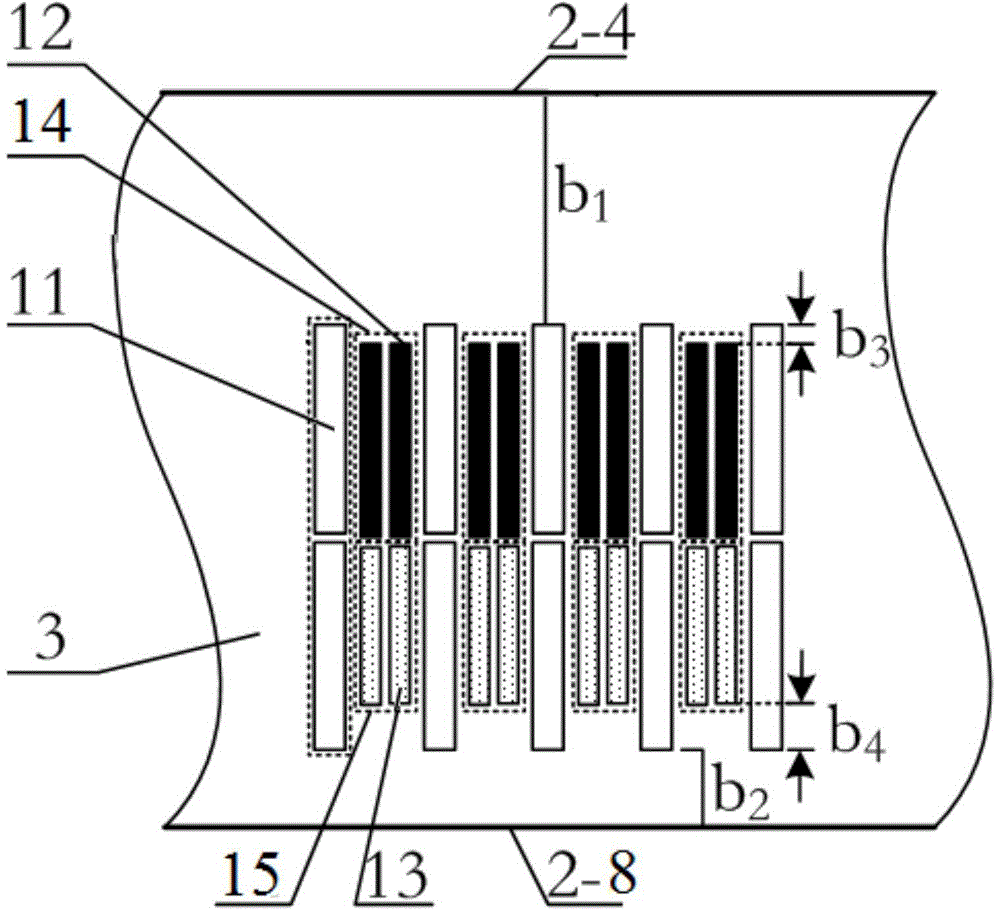

Apparatus for adjusting secondary wind direction under W type flame oven arch

InactiveCN101324340AImprove burnout rateReduce generationAir supply regulationCombustion apparatusRetention timeEngineering

The invention discloses a device for adjusting the direction of under-arch secondary air of a W-shaped flame furnace. More than two guide blades (1) are connected with each other through a connection hinge (2), a rotation shaft (3) is arranged on each guide blade (1), the guide blades (1) are arranged between an orifice plate (5) and a water-cooling wall pipe (6) of an under-arch secondary air chamber (4) of the W-shaped flame furnace, an adjusting arm (7) is arranged on one of the guide blades (1), and a pull rod (8) is connected with the adjusting arm (7). The device can set different under-arch secondary air inclination angle according to different conditions of each burner and can adjust the under-arch secondary air inclination angle to adapt to different areas (altitudes) and different coal qualities. Under proper lower inclination angle of the under-arch secondary air, the undershoot stroke of the flame and the coal retention time are increased remarkably, and the flame filling degree and uniformity in the lower furnace are improved remarkably, thus effectively improving the burn-out rate of pulverized coal and saving energy resource by about 30 to 50%.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

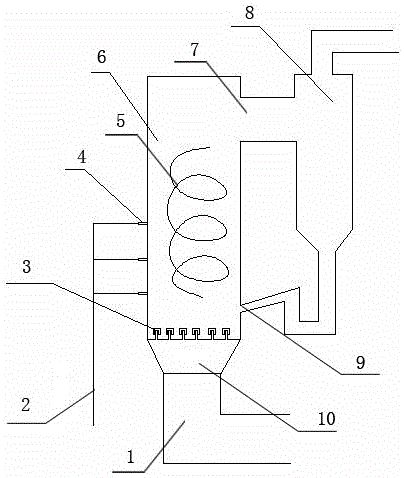

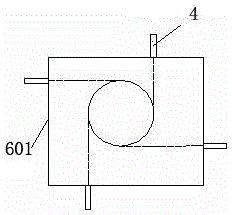

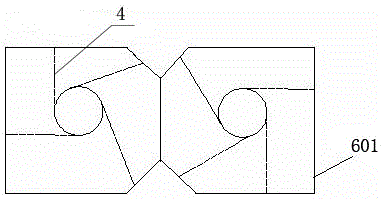

Multi-layer reciprocating type gasified combustion furnace

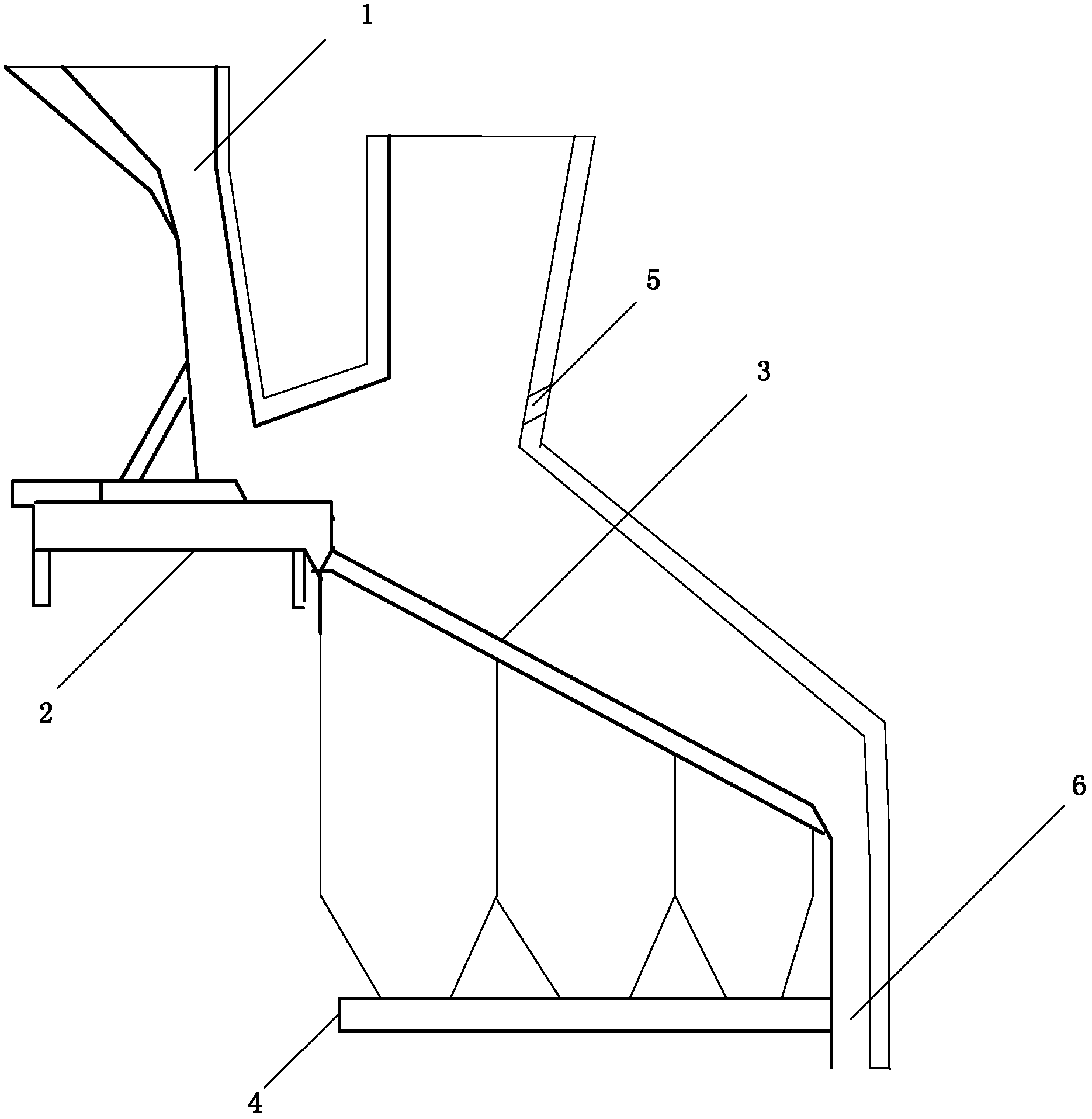

PendingCN107131503ASmall sizeLarge amount of disposalInclined grateIncinerator apparatusCombustionSlag

The invention discloses a multi-layer reciprocating type gasified combustion furnace comprising a combustion furnace body. A gasified fume discharging outlet and a gasified raw material garbage feeding inlet are formed in the upper end of the combustion furnace body, and a combustion gas inlet and a slag tapping outlet after combustion of gasified raw material garbage are formed in the lower end side of the combustion furnace body; a hearth in the furnace body is vertically provided with multiple layers of furnace rows from top to bottom; each layer of furnace row is arranged in a downward-inclining mode; the high end sides of the furnace rows at the lower layers stretch out of the low end sides of the furnace rows at the upper layers to enable the gasified raw material garbage on the furnace rows at the upper layers to fall into the high end sides of the furnace rows at the lower layers from the low end sides of the upper layers along the inclining gradient; and dust receiving funnels are arranged on the bottom face of the furnace row at each layer and connected with a dust discharging pipeline to output dust from the bottom side of the combustion furnace body. Because the garbage is fully dried and dehydrated through the multiple layers of furnace rows in the hearth, the heat value is increased, the combustion effect is more full, the structure is simple, the size of the combustion furnace is decreased greatly, investment is reduced, thermal decomposition gasified combustion of the furnace row at each layer can be achieved, and the application range of raw materials is wide.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

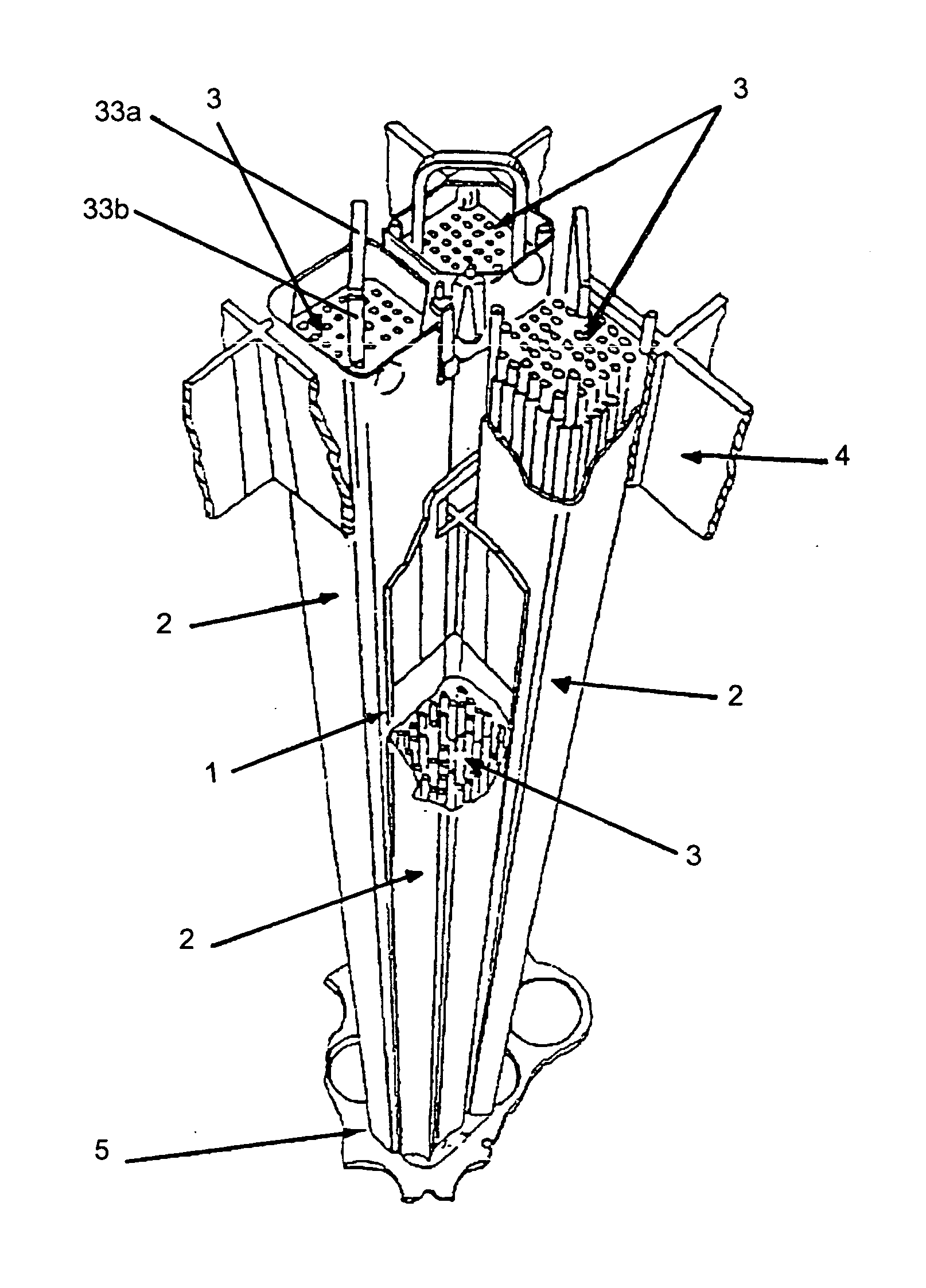

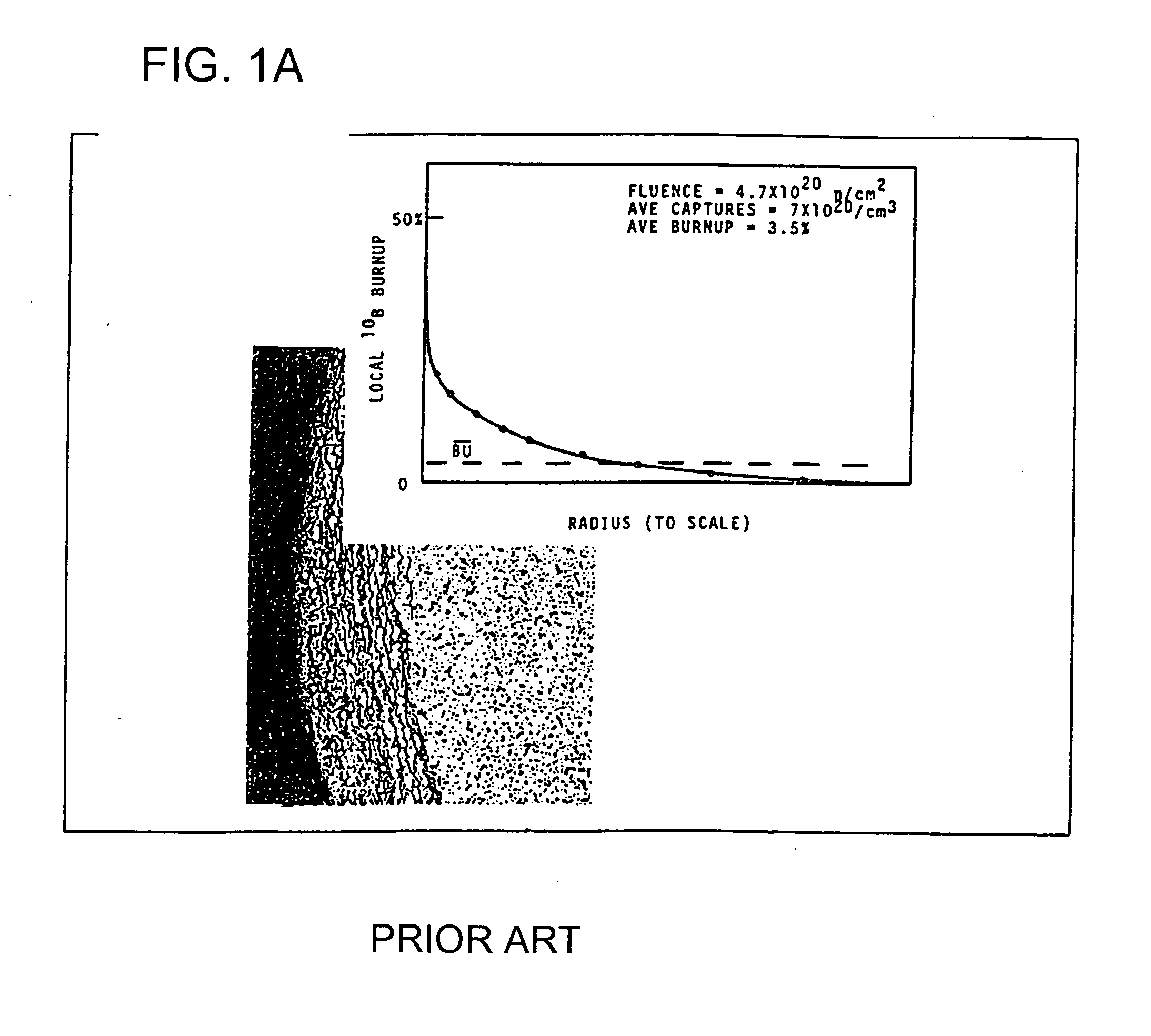

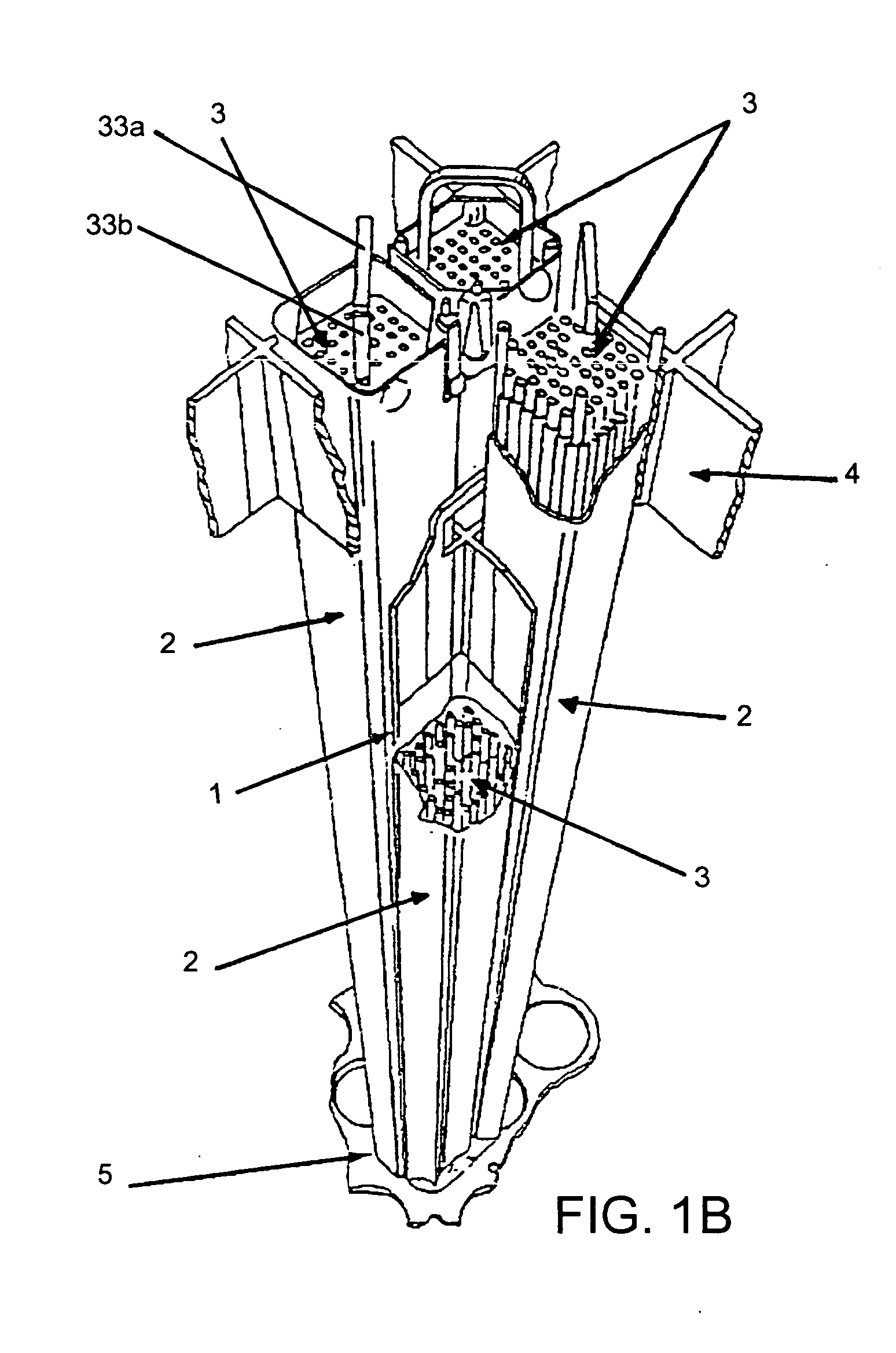

Control element for a nuclear reactor

InactiveUS20050135547A1Improve burnout rateEasy to controlNuclear energy generationNuclear engineering problemsNuclear reactorMechanical resistance

A control element for a nuclear reactor includes an absorber or absorber material and at least three absorber enclosures for receiving the absorber. The absorber enclosure is constructed in such a way that the received absorber can be subjected to local relative burn up of more than 90% without the burnt-off absorber material getting into the reactor coolant. The control element is constructed in such a way that there are at least three absorber enclosures and a predetermined spacing between the enclosures, so that each absorber enclosure forms a mechanical resistance for the absorber and is removable from the starting position in the event of expansion of the absorber.

Owner:SCHULZ WOLFGANG

Vaporizing combustion turbulence incinerator

PendingCN108758643AReduce dust contentImprove qualityIncinerator apparatusNon-combustible gases/liquids supplyCombustion chamberCombustor

A vaporizing combustion turbulence incinerator comprises a vaporizing combustor, a burning-out section, a cooling section, a separator, a tail smoke flue and a feeding device, wherein the vaporizing combustor communicates with the upper portion of the burning-out section, the burning-out section communicates with the bottom of the cooling section to form a steering separation chamber, the upper portion of the cooling section is connected with an inlet of the separator, and a smoke outlet of the separator communicates with the tail smoke flue. The vaporizing combustor comprises a variable-section vaporizing section and a constant-section combustion section which are integrally arranged. The vaporizing section is provided with a gradually-expanding area and a gradually-contracting area in sequence from bottom to top, and the top of the gradually-contracting area is connected with the combustion section. A slag discharge channel is arranged on one side of the bottom of the vaporizing section. A plurality of secondary air ports and / or a plurality of tertiary air ports are arranged in the middle of the vaporizing combustor, the multiple secondary air ports are evenly arranged in the topof the vaporizing section in a surrounding mode, and the multiple tertiary air ports are evenly arranged in the bottom of the combustion section in a surrounding mode. The vaporizing combustion turbulence incinerator has the advantages of good fuel adaptability, good initial discharging property and high burning-out rate.

Owner:BEIJING ONE A HI TECH ENERGY TECH CO LTD

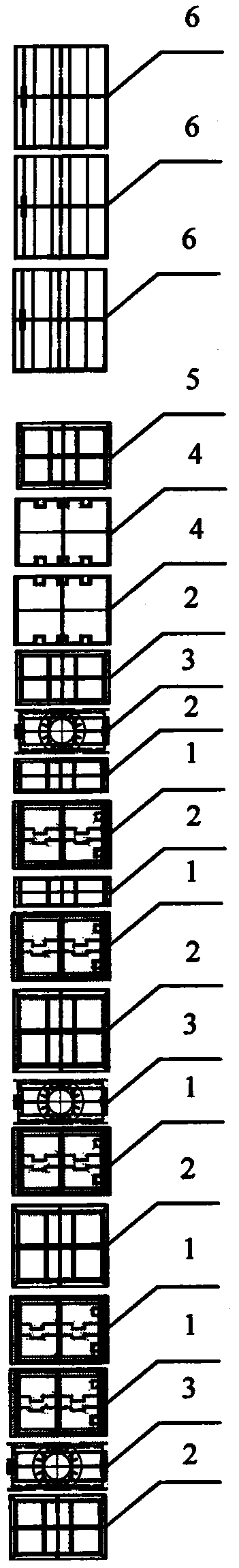

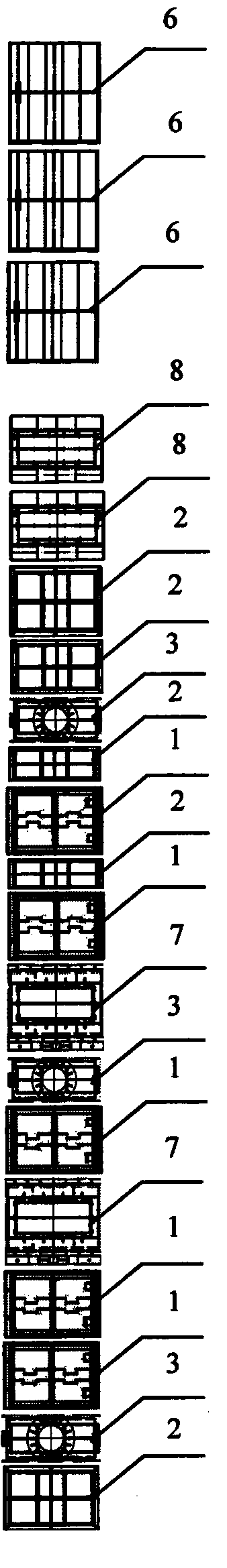

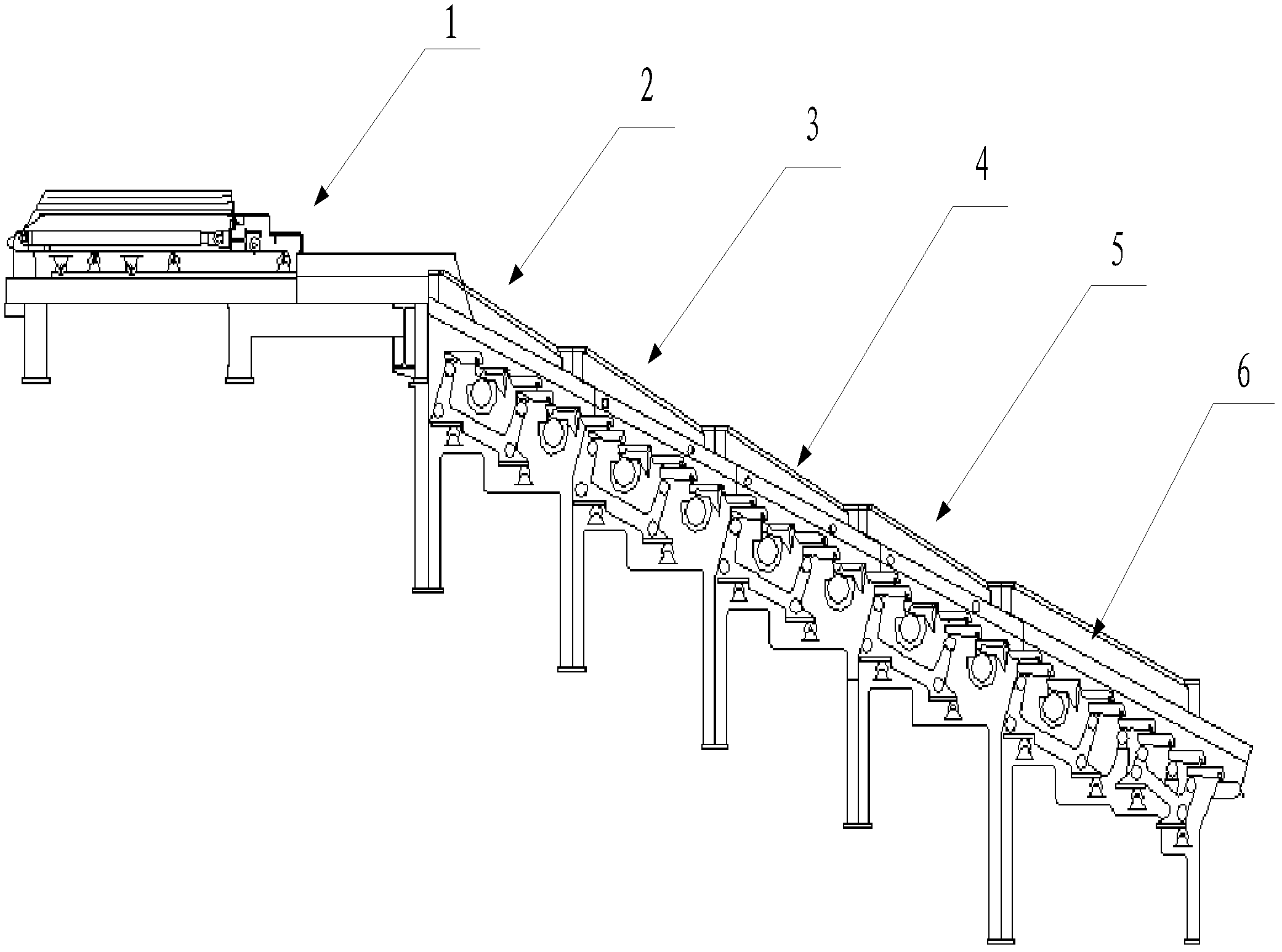

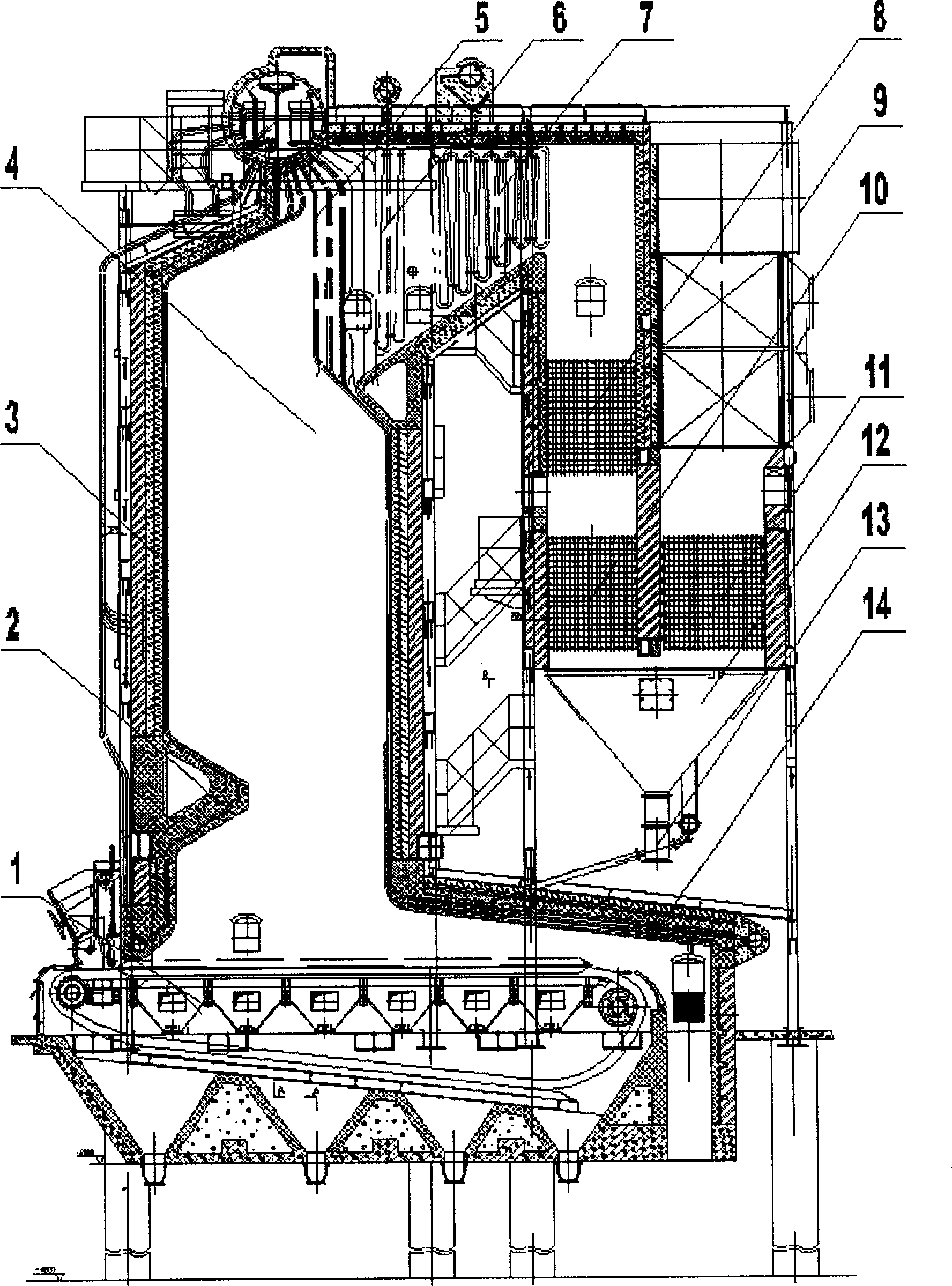

Multistage hydraulic mechanical garbage incinerator and control method for same

ActiveCN102607037AImprove combustionImprove burnout rateHollow bar grateInclined grateHydraulic machinerySteel frame

The invention provides a multistage hydraulic mechanical garbage incinerator and a control method for the same. The multistage hydraulic mechanical garbage incinerator comprises a feeding port, a feeding fire grate, an incinerating fire grate, a primary air supply system and a secondary air supply system. The incinerating fire grate is longitudinally divided into five units, wherein the first unit, the second unit, the third unit and the fourth unit are standard units, the fifth unit is a tail end lengthened unit, each unit comprises a plurality of sliding fire grate segments, turning fire grate segments and fixed fire grate segments, and the incinerating fire grate is integrally and longitudinally divided into a drying section, a burning section and a burnout section by the five units. The multistage hydraulic mechanical garbage incinerator is characterized in that the fire grate segments in each row of the incinerating fire grate are transversely driven by a shaft and transversely supported by a steel frame at three positions at the least. By the aid of the multistage hydraulic mechanical garbage incinerator, the shortcomings of an existing garbage incinerator are improved, and burnout ratio of garbage incineration is increased.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +1

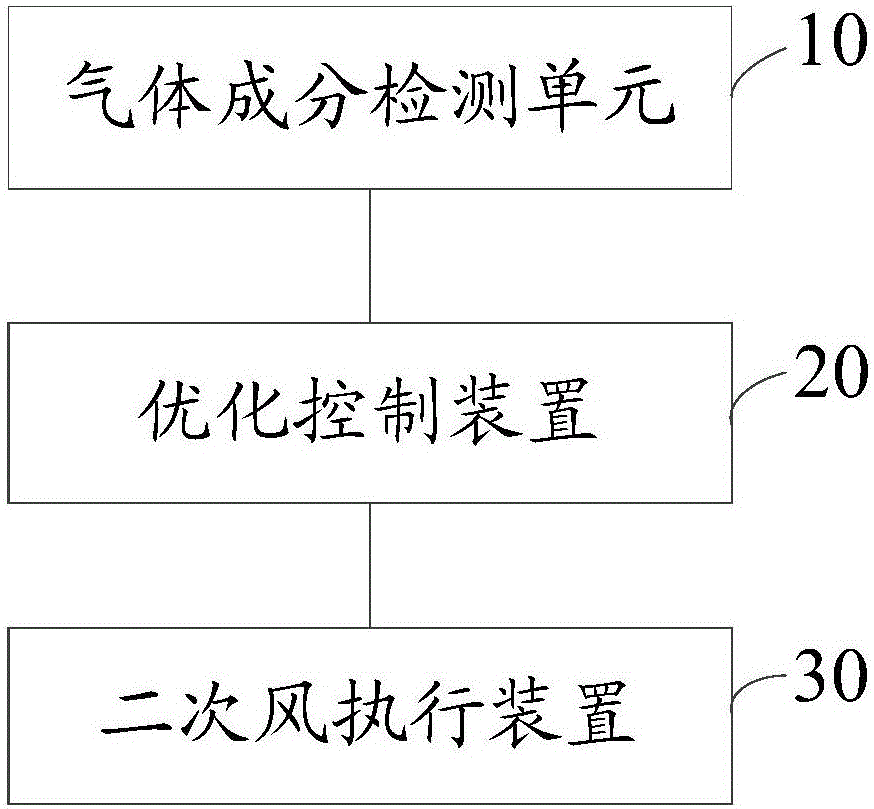

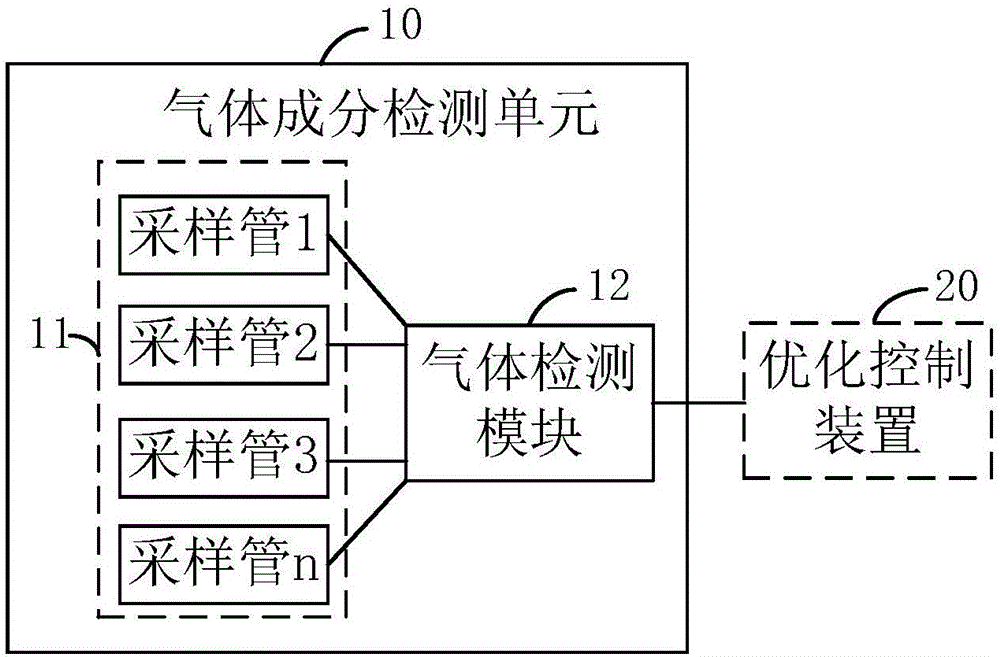

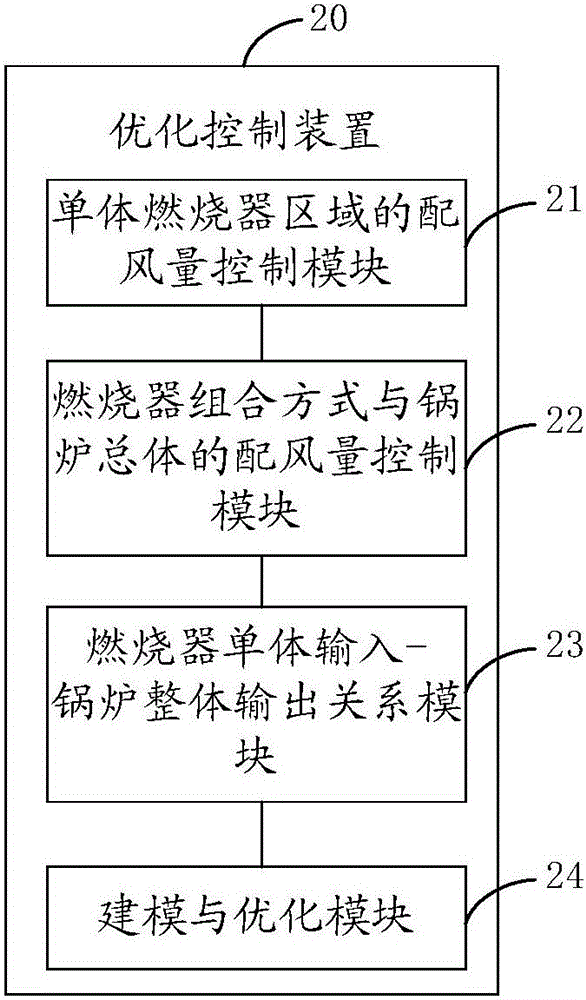

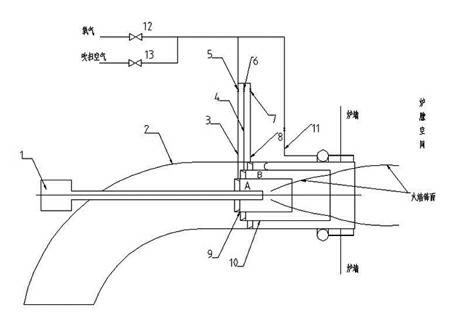

Control system for optimized combustion of combustor

ActiveCN106247396AReduce reducing atmosphereAchieve combustion optimization controlNon-combustible gases/liquids supplyCombustion regulationAir volumeCombustor

The application discloses a control system for optimized combustion of a combustor. The system comprises a gas component detection unit, an optimized control device and a secondary air executing device, wherein the gas component detection unit is used for detecting smoke component numerical values of a region where the combustor is and of a region of a rear flue of a boiler and sending the detection result to the optimized control device; the optimized control device is connected to the gas component detection unit for receiving the smoke component numerical values detected by the gas component detection unit and generating a control command according to the smoke component numerical values; the secondary air executing device is connected to the optimized control device for receiving the control command sent by the optimized control device and controlling a second air baffle plate executing mechanism according to the control command. According to the technical scheme disclosed by the invention, operation under a relatively low excessive air coefficient is guaranteed by controlling the air supply amount of the combustor, so that the burnout efficiency of fuels is effectively improved, the reducing atmosphere of the boiler is reduced and coking and corroding phenomena are improved while the heat loss due to exhaust gas is reduced, and the combustion process is safe, efficient and low in pollution.

Owner:河北思路科技有限公司

Plasma oil-free ignition system in oxygen-enriched environments

ActiveCN102305415AImprove burnout rateGood value for moneyIncandescent ignitionBurner ignition devicsCombustorPlasma generator

The invention relates to a plasma oil-free ignition system in oxygen-enriched environments. The system comprises a plasma generator, a combustor, and a sleeve set, wherein the sleeve set and the combustor are coaxially arranged; the sleeve set comprises a plurality of coaxially-arranged sleeves, an annular space is respectively formed between two adjacent sleeves and between the sleeves and the combustor, an oxygen guide tube is arranged on each sleeve, and the combustor is provided with an oxygen guide tube; plasmas spouted out from the plasma generator are formed into a localized high-temperature area, and the localized high-temperature area is filled with high-temperature plasmas and pulverized coal airflows. Through supplementing a certain amount of oxygen to the inside of the combustor by the oxygen guide tube in the combustor, and a localized oxygen-enriched area is respectively formed in the annular space and a subsequent adjacent space through which an airflow flows, thereby realizing the oxygen-enriched combustion of volatile matters or cokes or a mixture of the volatile matters and the cokes, so that the pulverized coal airflows is combusted more severely and releases more heats, and finally, a primary air pulverized coal airflow is rapidly ignited and combusted stably. The plasma oil-free ignition system in oxygen-enriched environments provided by the invention is simple in structure, wide in coal applicability, and especially suitable for low-volatile coals.

Owner:SHANGHAI BOILER WORKS

Fire coal liquid oxidizer for cement production and preparation method thereof

ActiveCN103320196AImprove combustion effectIncrease burn rateSolid fuelsSocial benefitsMetal catalyst

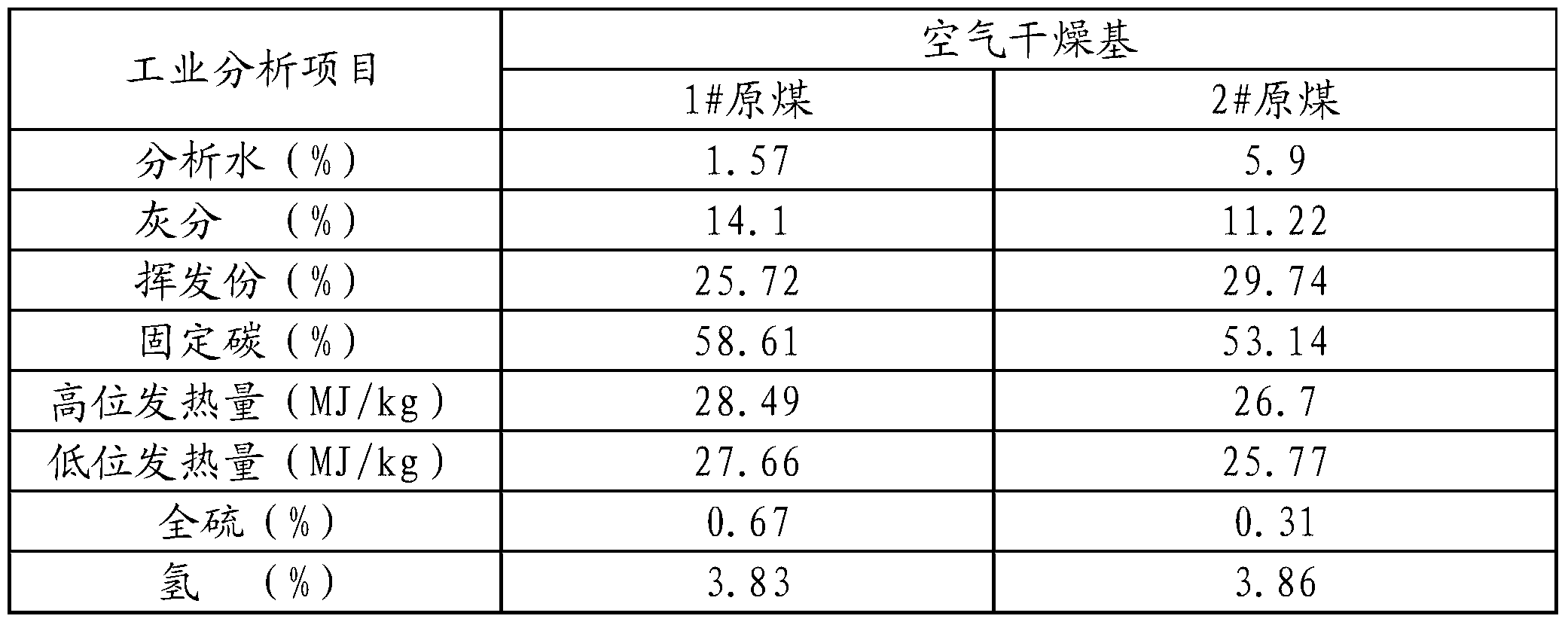

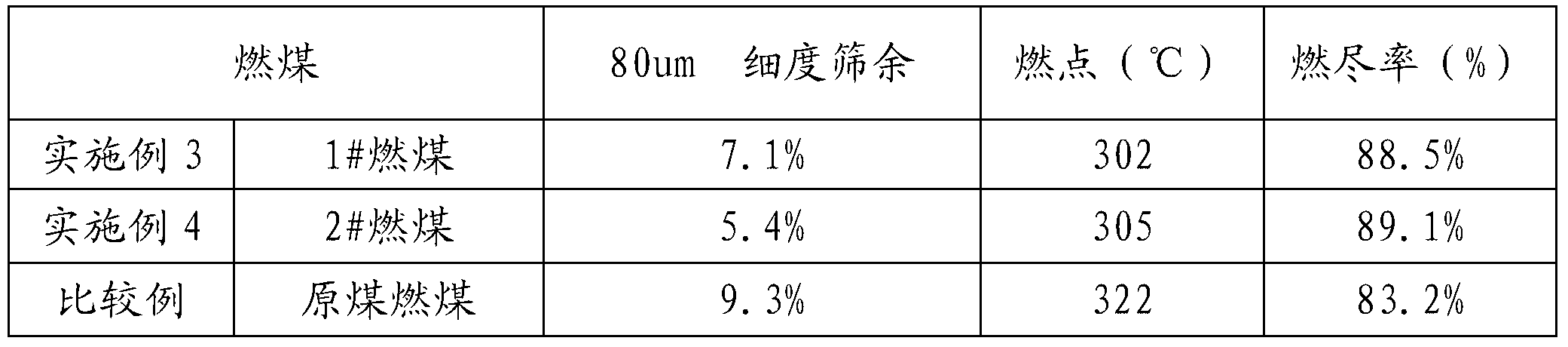

The invention provides a fire coal liquid oxidizer for cement production. The fire coal liquid oxidizer comprises the following ingredients: by weight, 20-40% of mineral oil, 25-35% of plant oil, 6-16% of an emulsifier, 4-8% of metal catalyst salt, and the balance water. In comparison with the prior art, the fire coal liquid oxidizer for cement production has the following beneficial effects: on the basis of not changing original equipment and technology, burning point of prepared coal dust is reduced, burning rate is raised and burnout rate is improved; coal consumption per cement clinker is decreased, discharge capacity is minimized, energy is greatly saved, sintering of cement clinker is promoted, quality of cement clinker is raised, and economic and social benefits of cement clinker production are enhanced; and the fire coal liquid oxidizer is beneficial to environmental protection. The invention also provides a preparation method of the fire coal liquid oxidizer.

Owner:北京金隅节能科技有限公司

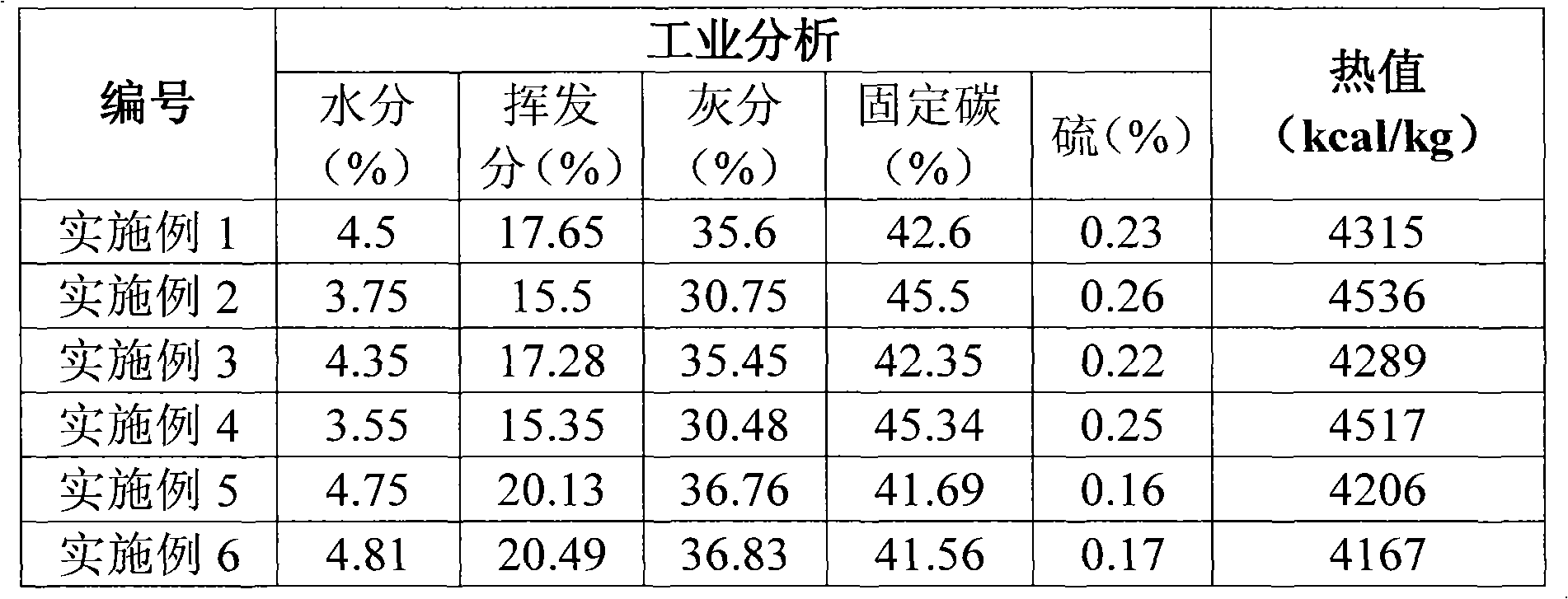

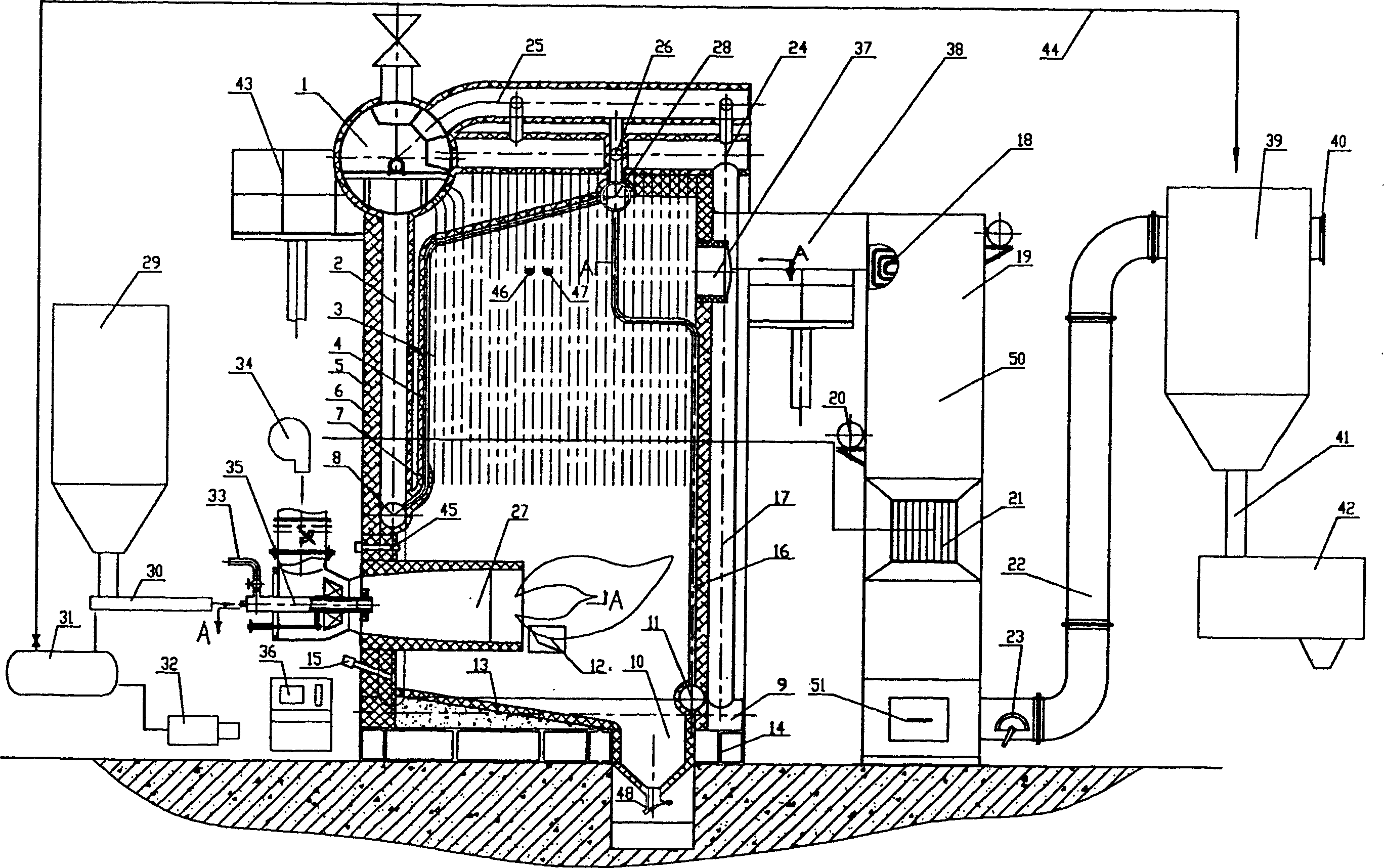

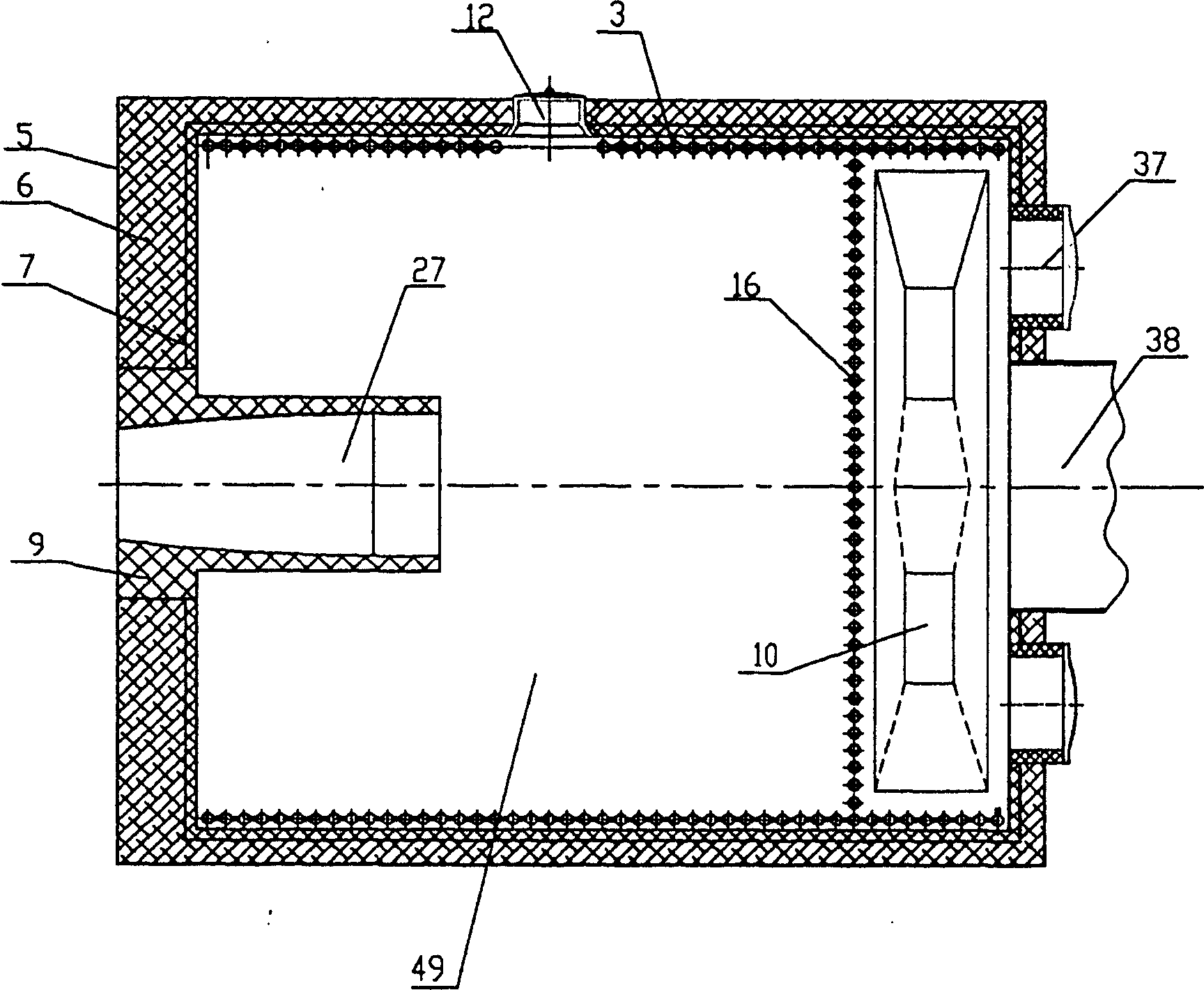

Industrial boiler of multi-fuel burning using ultrafine coal dust as main fuel

InactiveCN1724928AImprove burnout rateFully mixed combustionBurnersCombustion using multiple fuelsMultifuelCoal dust

The invention discloses an industrial boiler fired by multiple mixed fuels with superfine powder coal(water coal slurry) as the primary and natural gas or oil products as the auxiliary, and it is an industrial boiler with the advantages of high firing efficiency, low cost, auto control and reduction of environmental pollution, especially applied to middle-small scale industrial boilers.

Owner:姜政华

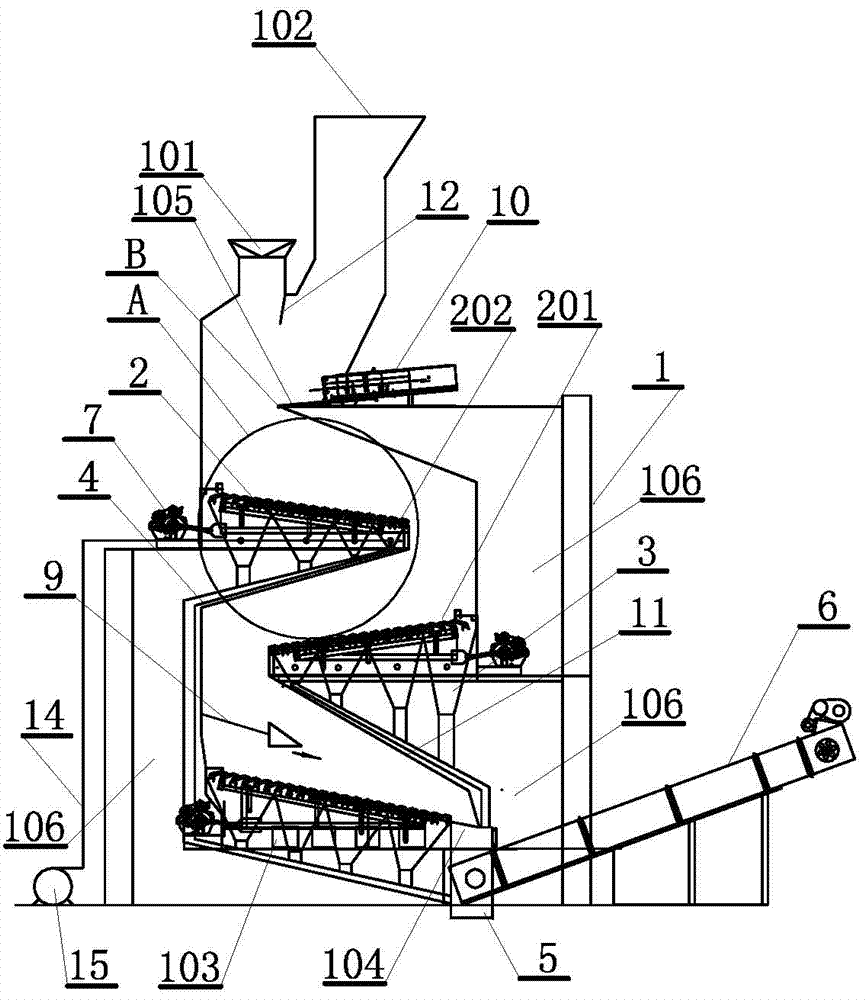

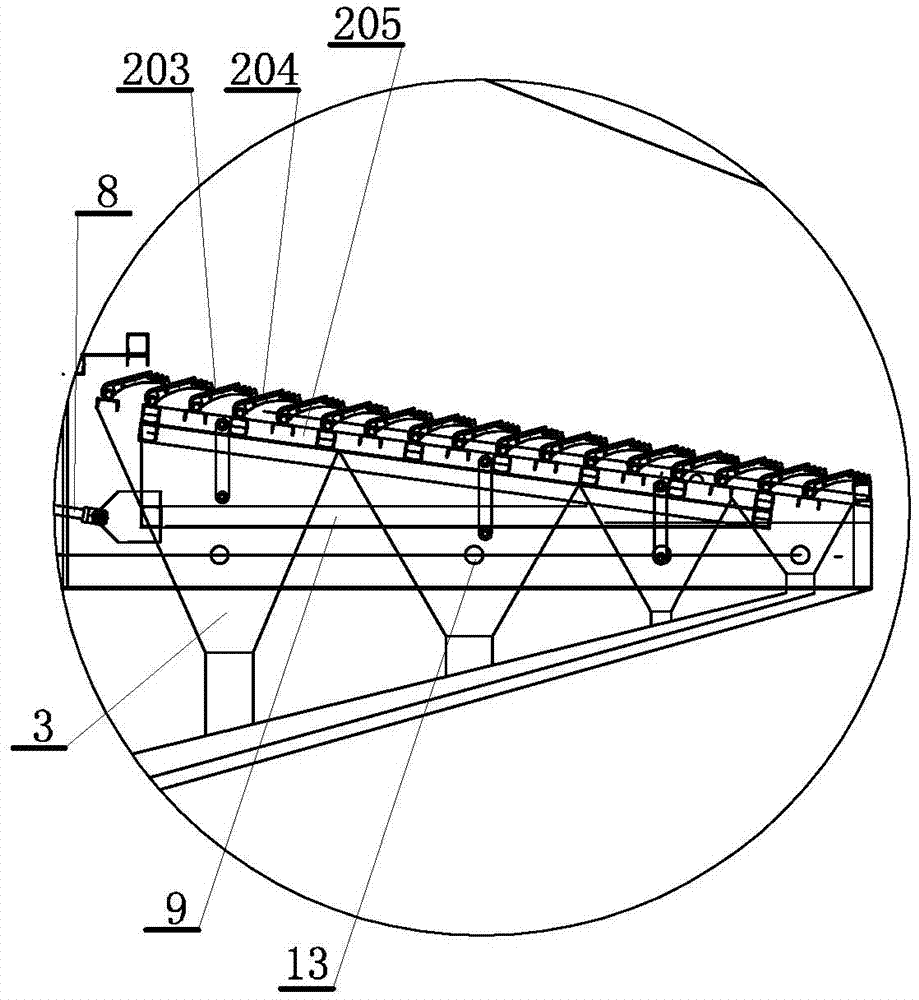

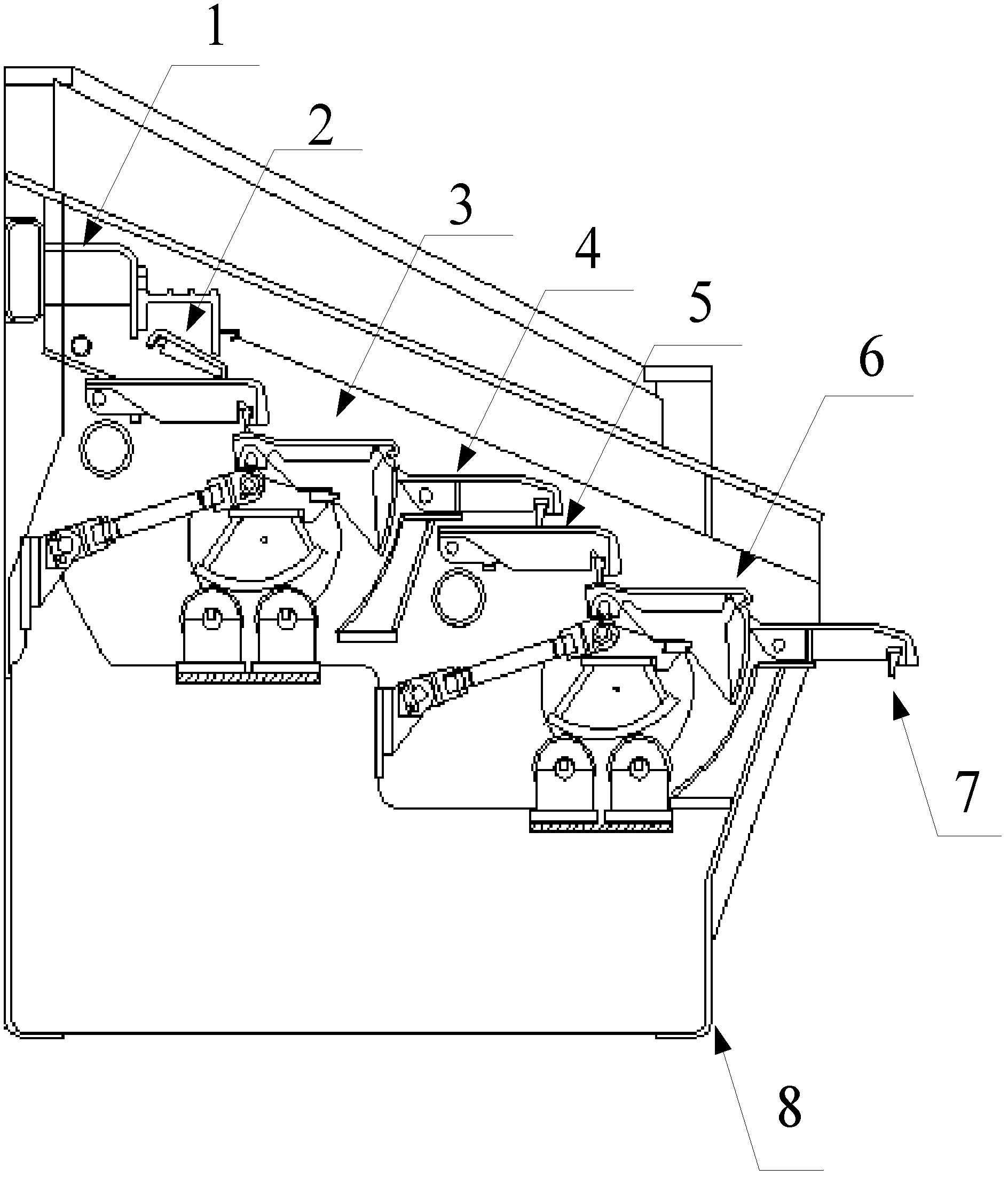

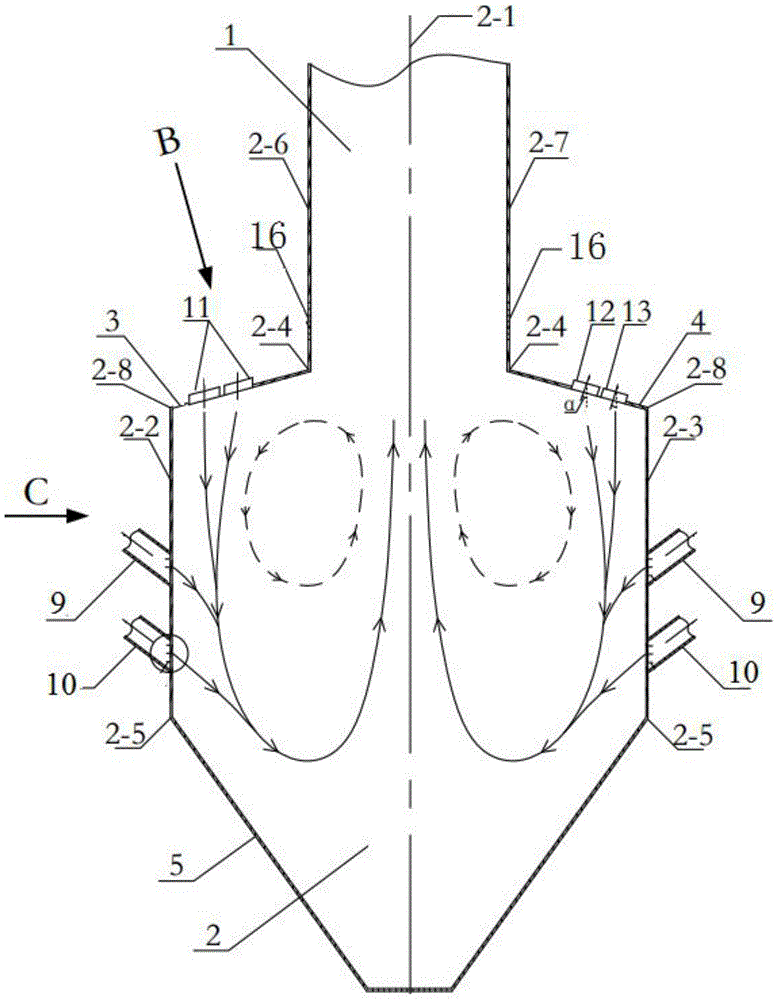

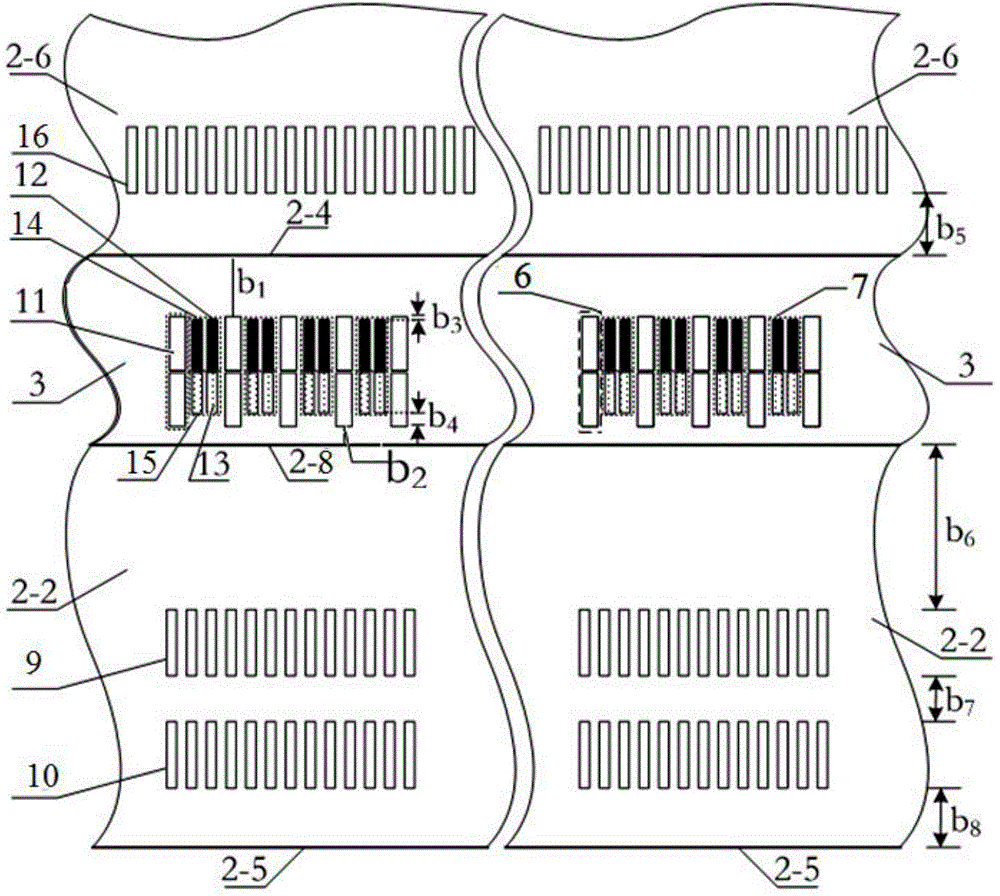

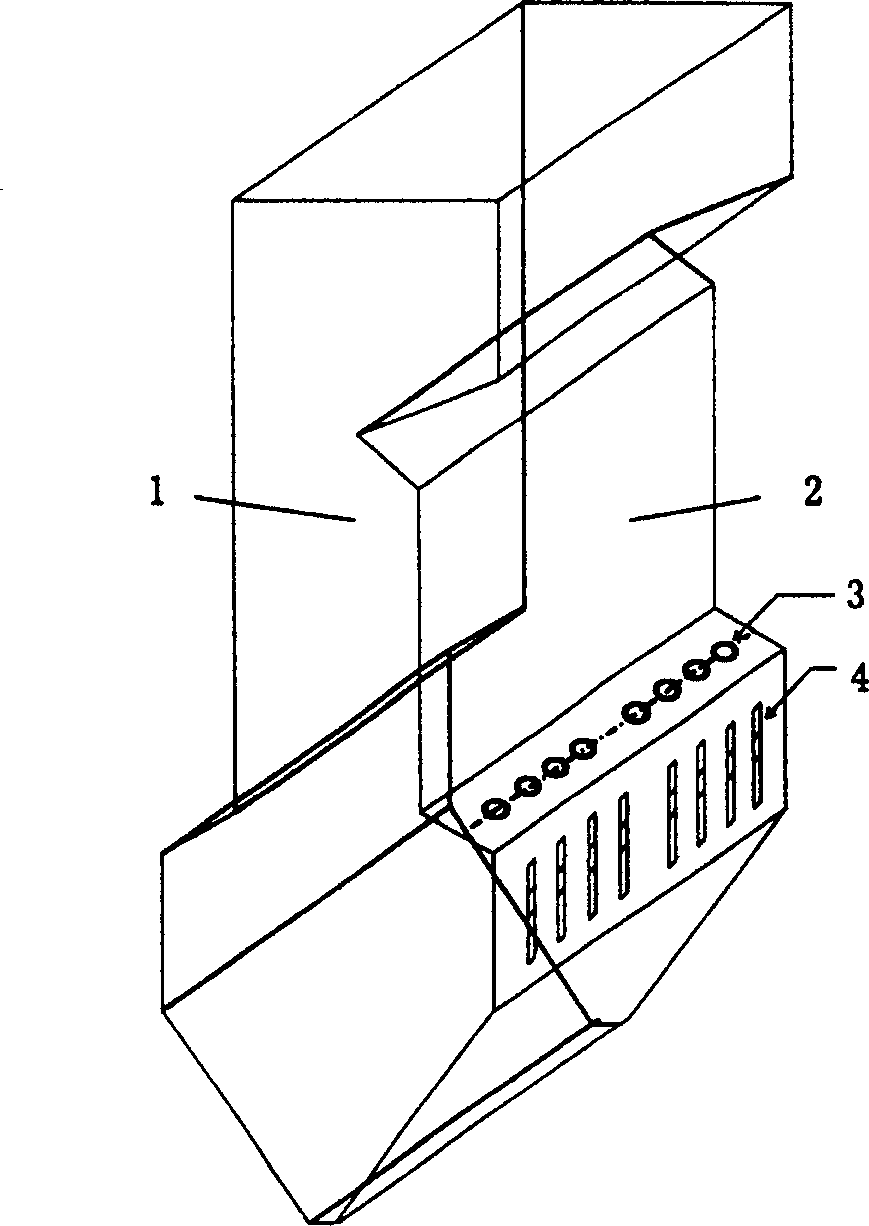

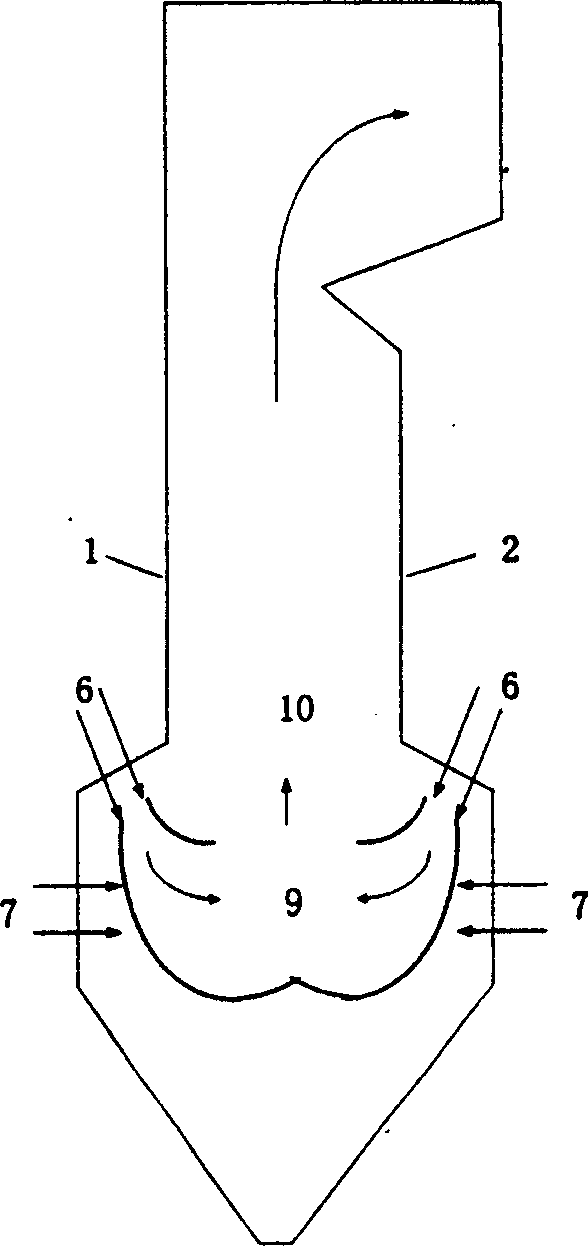

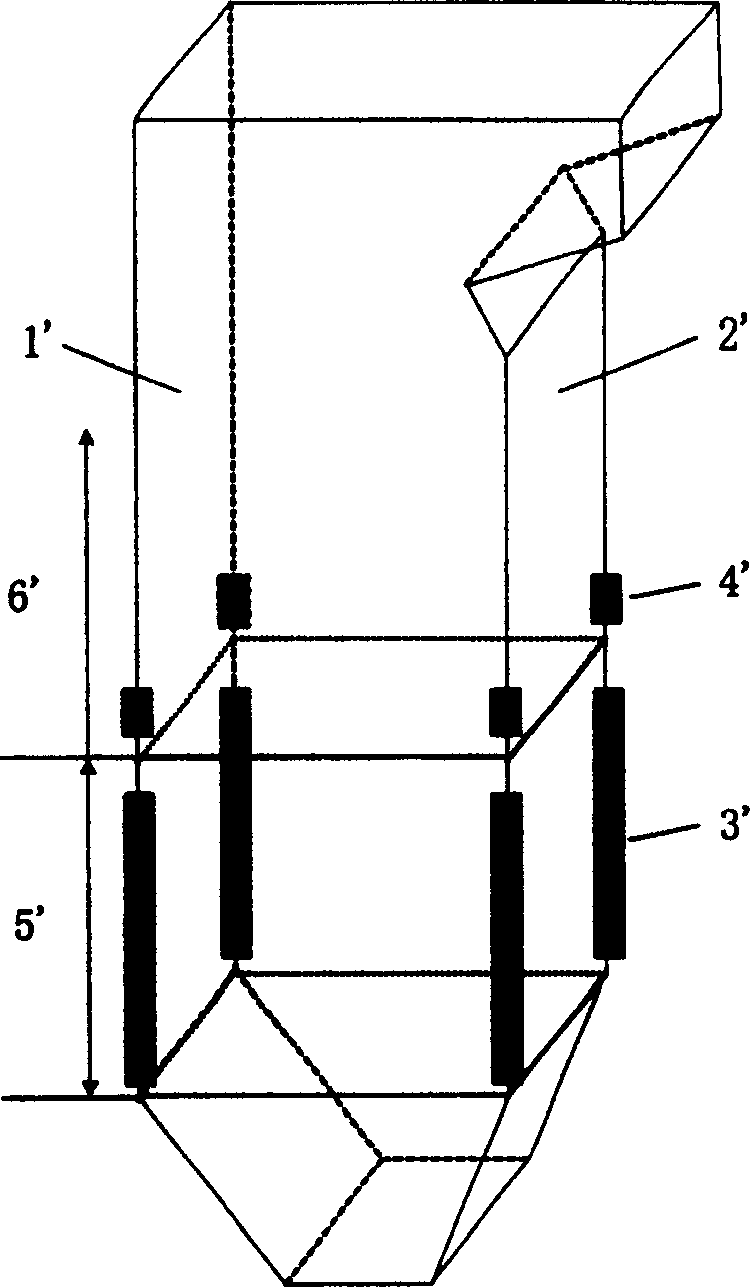

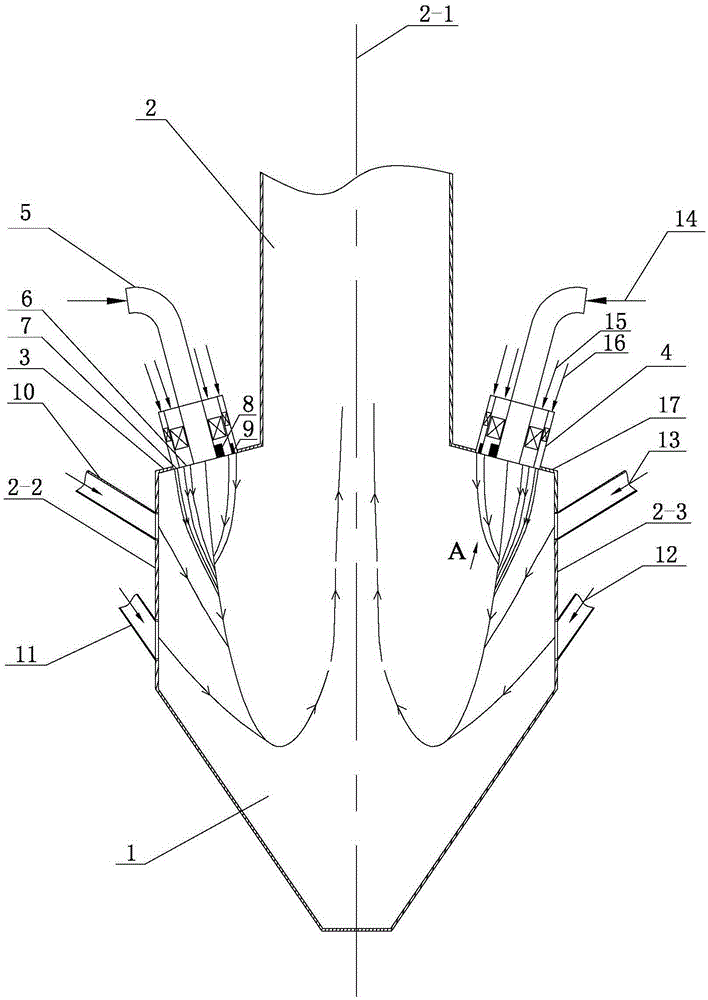

Ejecting staged combustion W flame boiler for improving ignition and combustion of pulverized coal

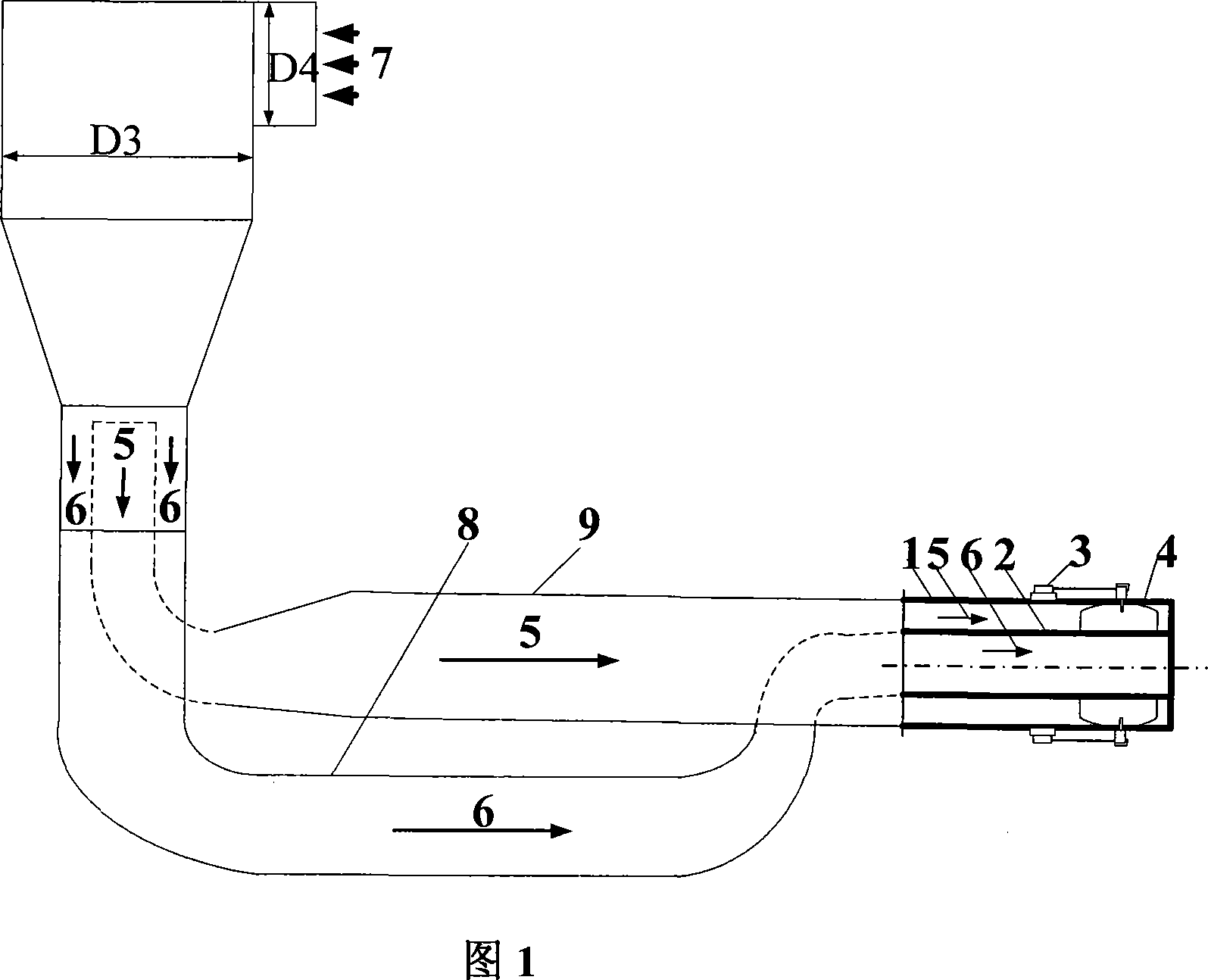

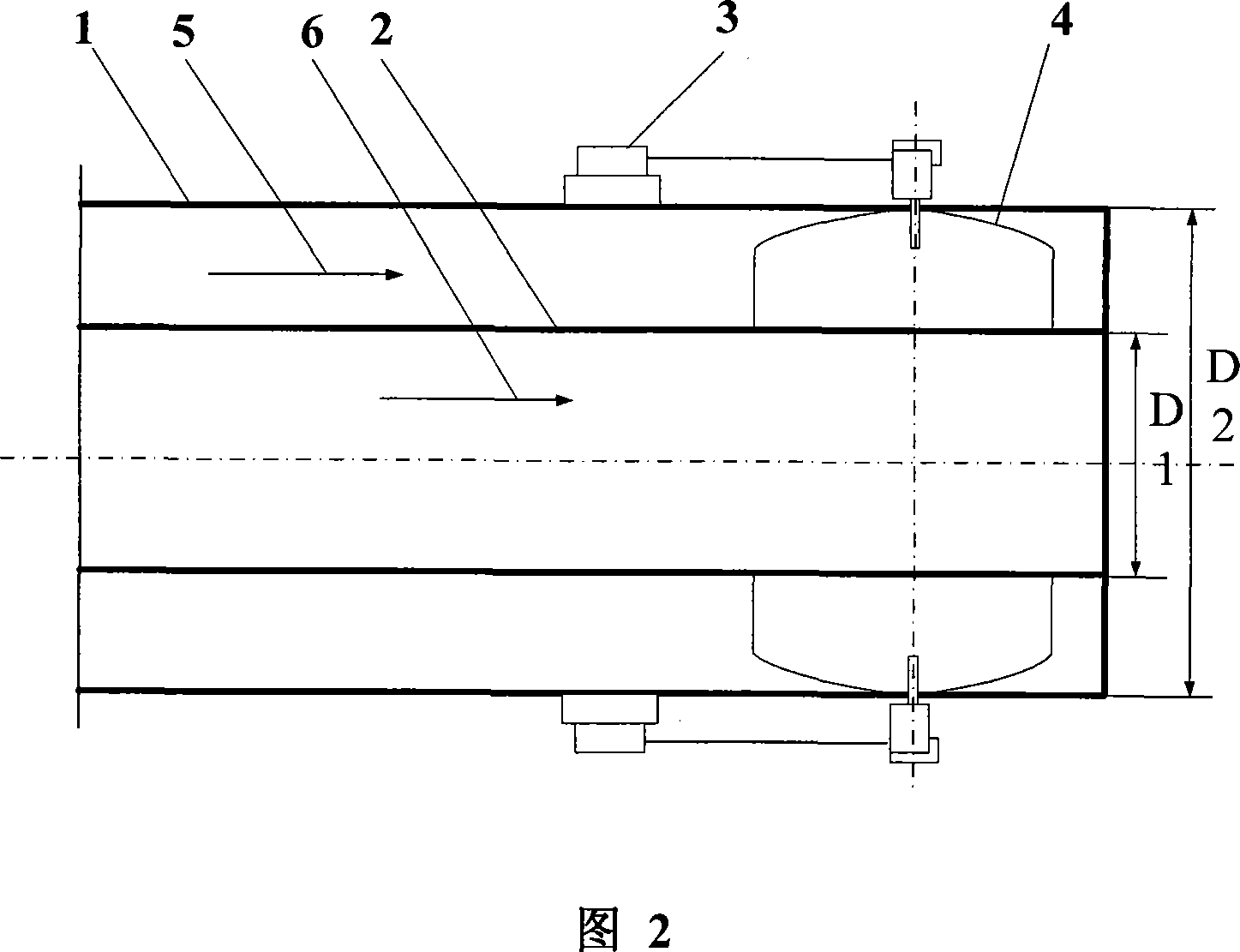

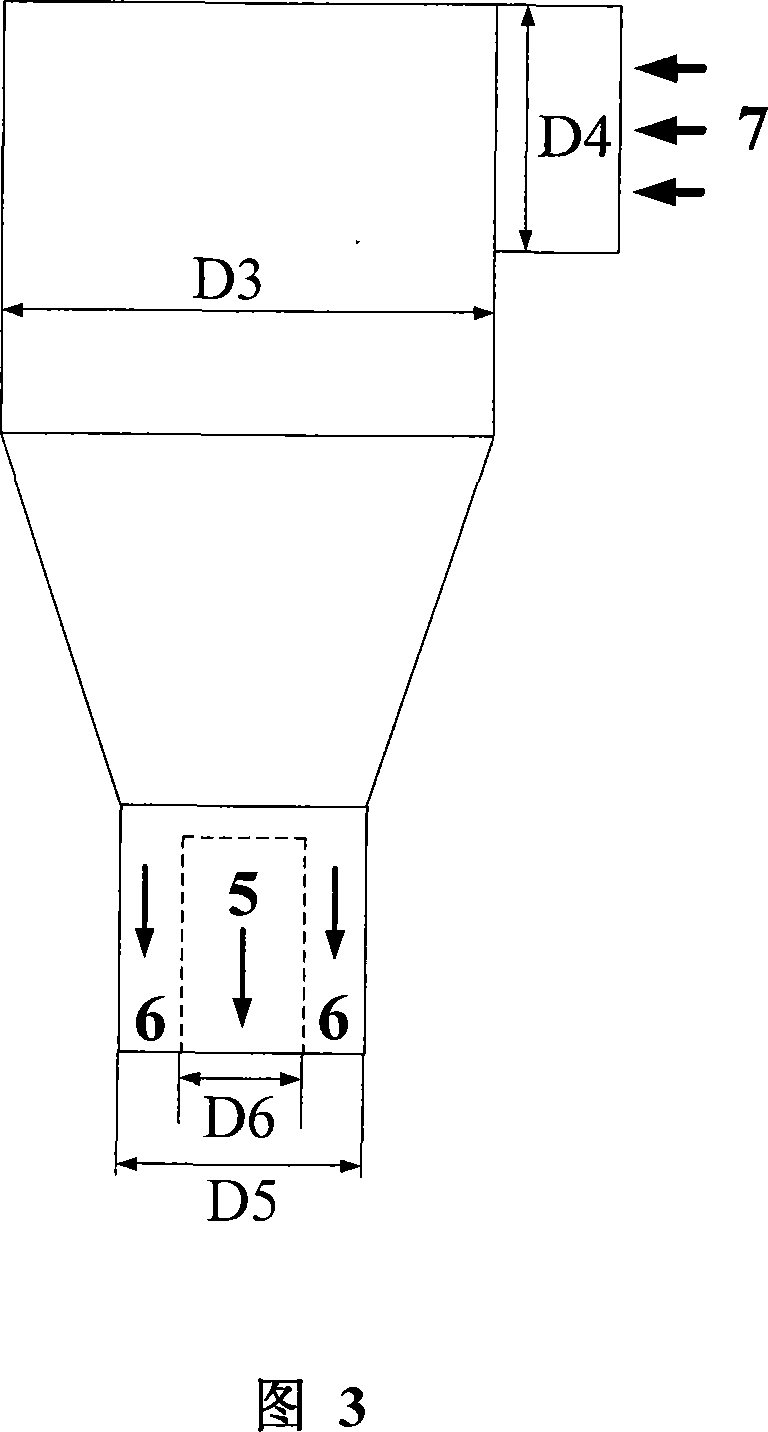

ActiveCN104595892AImprove combustion stabilityImprove burnout rateCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberSlag

The invention relates to an ejecting staged combustion W flame boiler for improving ignition and combustion of pulverized coal. The W flame boiler comprises a furnace hearth which is formed by an upper furnace hearth, a lower furnace hearth, a front furnace arch and a rear furnace arch, a plurality of secondary air nozzle groups which are arranged on the front furnace arch and the rear furnace arch, and a plurality of pulverized coal airflow nozzle groups, wherein the plurality of secondary air nozzle groups and the plurality of pulverized coal airflow nozzle groups are arranged side by side linearly, equidistantly and abreast along a width direction of a furnace, the plurality of pulverized coal airflow nozzle groups can be arranged on the furnace arches at fixed angles, an incident angle of secondary air can be adjusted, a plurality of over-fire air nozzles with adjustable incident angles can be formed in the upper furnace hearth, and two layers of tertiary air nozzles with the adjustable incident angles can be formed in water-cooled walls of front and rear walls of each furnace hearth. By adopting the W flame boiler disclosed by the invention, the combustion of the pulverized coal in the furnace can be effectively improved, the adaptive capacity of the boiler to coal types can be improved, the heat and reheat steam temperature can be effectively adjusted to reach a design value, the emission of NOx and the flue gas temperature can be reduced, slag bonding of the front and rear walls can be prevented, and the thermal fatigue existing in water-cooled walls of a combustion chamber hopper can be avoided.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Device and method for w shape flame boiler completely burning

Owner:HUAZHONG UNIV OF SCI & TECH

Spiral-flow type fluidized bed incinerator

ActiveCN105090980AEnhanced lateral mixingReduce carbon contentIncinerator apparatusCombustionFluidized bed

The invention discloses a spiral-flow type fluidized bed incinerator which comprises an incinerator body and a cyclone separator. The incinerator body is used for providing combustion space for a fluidized bed, and the cyclone separator is used for recycling insufficiently-combusted ingredients for secondary combustion. At least three layers of secondary air jet orifices are further formed in the walls of the incinerator body and located in a transition zone between a dense-phase zone and a lean-phase zone. The other ends of the secondary air jet orifices are communicated with a secondary air source. The secondary air jet orifices on the same layer are distributed in the walls of the incinerator body. The air flow is spiral so as to enhance transverse mixing of particles and air in the incinerator body and prolong the residence time of the particles in the incinerator body. High-speed secondary air is jetted into the lean-phase zone on the upper portion of an air distribution plate of the circulation fluidized bed incinerator body in a classified manner through wall type tangential firing, so that transverse mixing of particles and air is enhanced, temperature distribution in different areas in the dense-phase zone is more uniform, the combustion efficiency and the desulphurization efficiency are improved, NOx emissions are lowered, the heat transferring is enhanced, and the equipment size is reduced.

Owner:潍坊联荣环保设备有限公司

Compact anti-coking nozzle type biomass burner

InactiveCN107143870ACompact designOverall small sizeSolid fuel combustionLump/pulverulent fuel feeder/distributionThree levelSocial benefits

The invention discloses a compact anti-coking nozzle type biomass burner. The biomass burner mainly comprises a front replaceable sleeve nozzle, a rear feeding comprehensive device and a bottom air distribution auxiliary comprehensive device; and a main body adopts a double-layer sleeve structure, an inner sleeve is used for gasifying burning, and an outer sleeve is used for blast cooling protection. According to the burner, an economic and efficient rotary fire rabbling and ash removing device is adopted, in cooperation with a three-level multi-directional three-dimensional air distribution nozzle type structure design, the environment and working condition applicability is high, and the practicability is high; the biomass heat energy application technology is clean, efficient, energy-saving, environment-friendly, stable in operation, simple and convenient to operate, capable of preventing coking and wide in fuel applicability; and a feasible popularization scheme can be provided for new type urbanization, agricultural modernization and transformation of clean energy of various medium-and-small-sized coal-fired boilers in China, and remarkable economic and social benefits can be expected.

Owner:联合优发生物质能源徐州有限公司

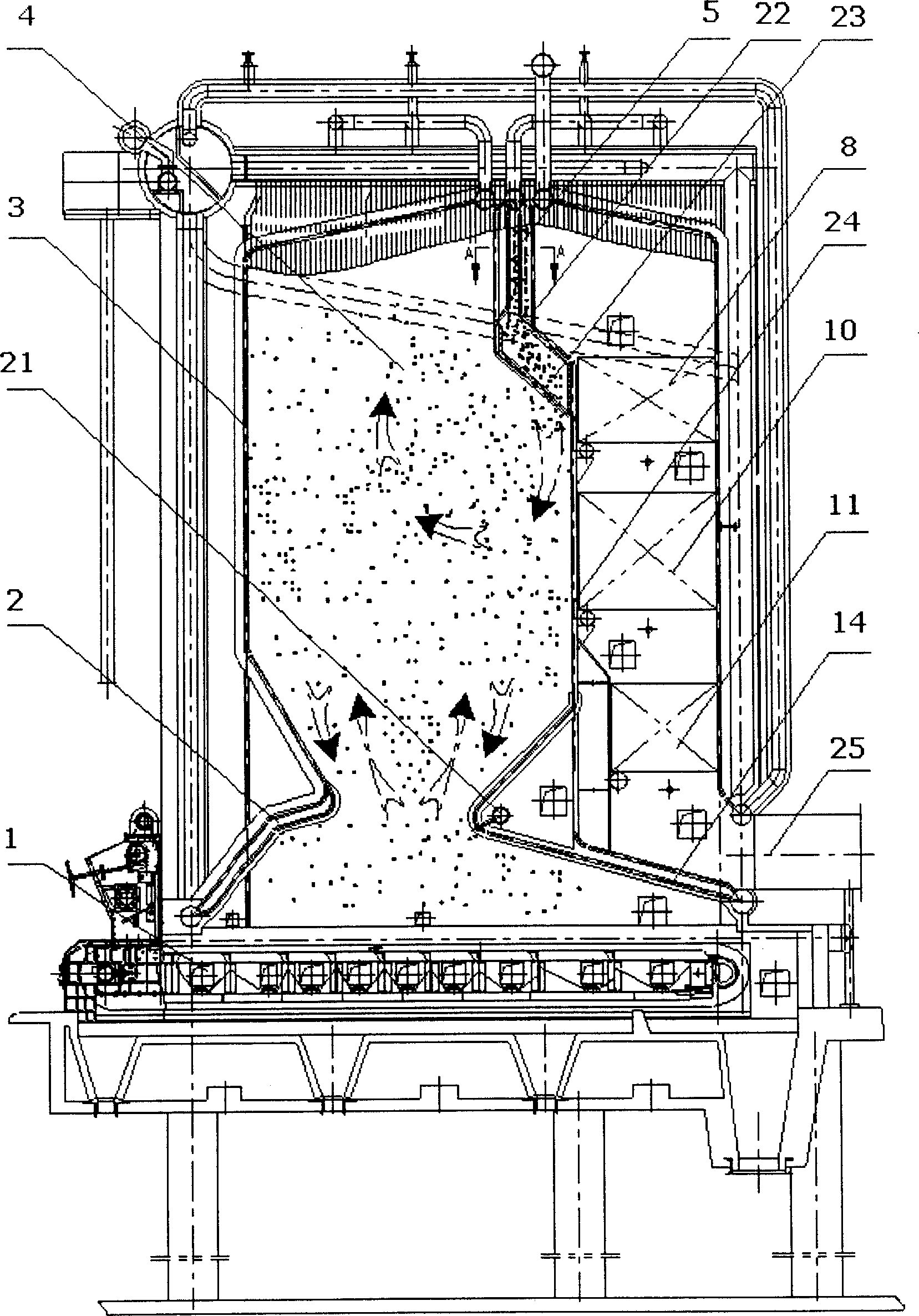

Internally circulating fluidized reburning device for fly ash based on high temperature separation

InactiveCN1884909AReduce carbon contentWith slagFluidized bed combustionApparatus for fluidised bed combustionSlagWater cooling

The invention relates to an ash internal cycle fluid afterburning device, based on high-temperature separation, wherein the invention uses furnace and secondary wind to realize initial high-temperature separation and sets high-temperature combined water cooling separator at the heated surface of water condense slag tube beam at the outlet of high-temperature smoke to realize ash high-temperature separation; and the separated ash is feedback to the high-temperature area to be cycle fluidized burnt, to meet the burning conditions as temperature, time, and disturbing mixing, to improve the burning rate and reduce the pollution. The invention can improve the burnt rate and the burning efficiency of coal.

Owner:XI AN JIAOTONG UNIV

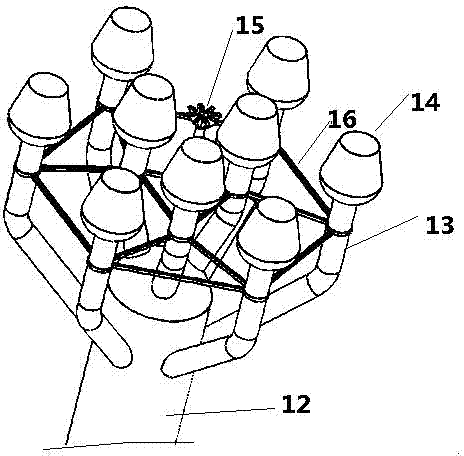

Torch combustion system with automatically adjustable sound speed

ActiveCN103486588AEmission reductionReduce usageIncinerator apparatusGaseous fuel burnerVibration attenuationCombustion system

The invention discloses a torch combustion system with automatically adjustable sound speed. The torch combustion system comprises a torch combustor (14), a torch header pipe (12), torch branch pipes (13), a quincuncial flame holder (15) and a vibration attenuation support (16), wherein the torch combustor (14) is installed on the torch branch pipes (13), air inlets of the torch branch pipes (13) are all connected with the torch header pipe (12), the quincuncial flame holder (15) and the torch branch pipes (13) are connected to form an integral structure through the vibration attenuation support (16). The torch combustion system is characterized in that the torch combustor (14) comprises a flow guide cover (11), an external sleeve (7) and a supporting bar (9), the flow guide cover is installed at the upper end of the supporting bar, the external sleeve is sleeved on the supporting bar, and the lower end of the supporting bar is connected with a device for automatically adjusting the height of the flow guide cover (11). According to the torch combustion system, the structure is simple, the size of an air outlet can be automatically adjusted according to the pressure of flare gas, the combustion effect can be obviously improved and the combustion efficiency is high.

Owner:JIANGSU SUNPOWER TECH

Crude and fine coal powder separation and burn method and device

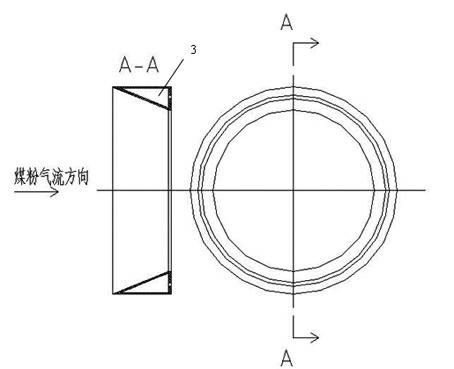

InactiveCN101055077AImprove combustion stabilityPromote fireCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorJet flow

A coal powder thickness separation burning method and a device thereof belong to coal powder burning technology field and are adapted to coal powder burning boiler. The method includes: (1) separating step, separating the conventional coal powder to fine coal powder and thick coal powder; (2) flow lead burning step, setting the thick coal powder to the middle part of the burning jet flow, leading the fine coal powder to the external of the thick coal powder air flow to burn, forming a stable fire source around the thick coal powder air flow to strength the fire and stable burning for the thick coal powder air flow. The device of the invention is mounted with a cyclone separation apparatus on the front part of the main burner, the outlet of the cyclone separation apparatus is disposed with a double layer circular bushing, the inner pipe of the double layer circular bushing is connected to a hypo-wind circular tube outside of the main burner by a connection device, the outer pipe of the double layer circular bushing is connected to a hypo-wind circular tube in the main burner by a connection device. The invention has good fire characteristic, strong stable fire ability, high coal burnt rate, low NOx exhaust amount, strong adaptability for load and coal kinds and realizes high efficiency low-pollution combustion for coal powder.

Owner:HUAZHONG UNIV OF SCI & TECH

Magnetic electrode small-particle-size hydroxide ion generator

The invention relates to a magnetic electrode small-particle-size hydroxide ion generator. The magnetic electrode small-particle-size hydroxide ion generator comprises a raw material air supply channel, a cathode insulation fixation plate, a tunnel cylinder and an anode insulation fixation plate, wherein the cathode insulation fixation plate, the tunnel cylinder and the anode insulation fixation plate form a sealing cavity, the raw material air supply channel passes through the cathode insulation fixation plate and communicates with a cathode selection network inside the tunnel cylinder through a cathode conductive ring, the other end of the cathode selection network is connected with one end of an anode selection network, the other end of the anode selection network is fixed on the anode insulation fixation plate, an anode discharge needle is also fixed on the anode insulation fixation plate, the anode discharge needle is connected with a pulse high-frequency discharger, and the top portion of the tunnel cylinder is provided with a hydroxide ion air channel. Small-particle-size air negative ions prepared by use of the generator are widely applied, and since a prepared gas contains numerous negative hydrogen, oxygen ions and free electrons and is segmented and magnetized into small particle sizes, the magnetic electrode small-particle-size hydroxide ion generator can be widely applied to a health care industry, a medical industry and industrial combustion and machine combustion industries.

Owner:ZIBO S & N MAGNET MFG

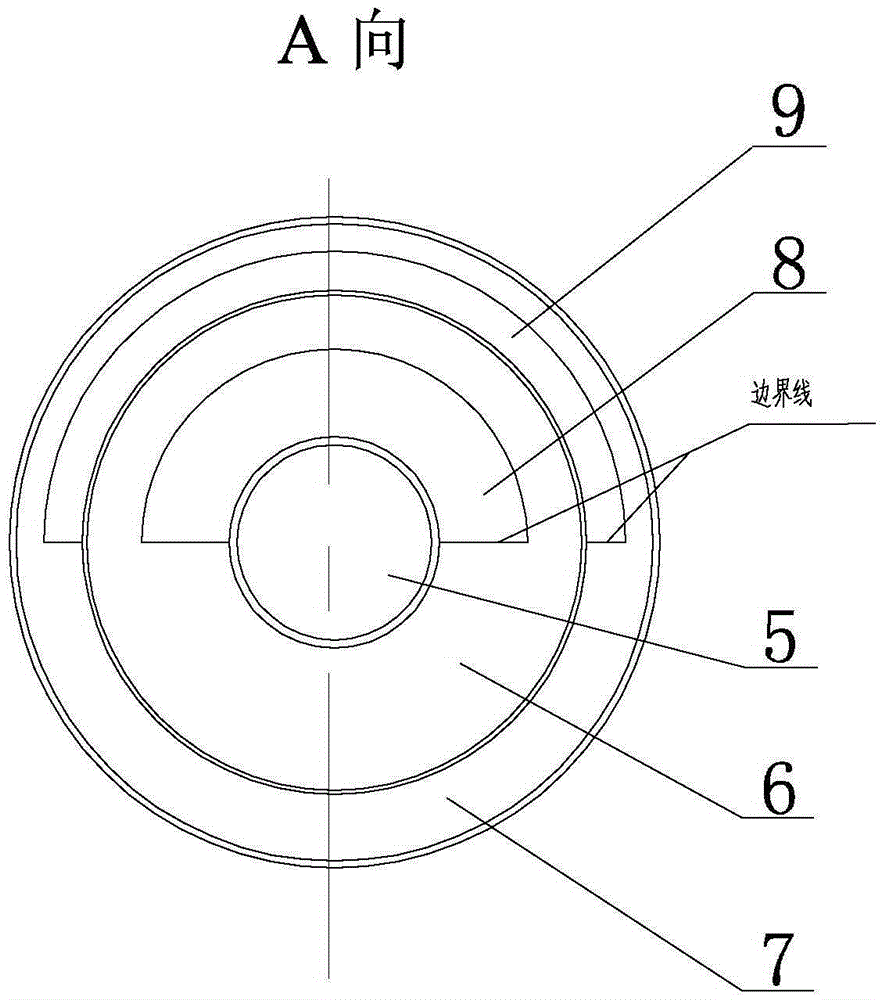

Secondary air offset whirl pulverized coal burner for W flame boiler

ActiveCN105423294AGood for early ignitionImprove flame stabilityPulverulent fuel combustion burnersCombustion apparatusCombustion chamberSlag

Disclosed is a secondary air offset whirl pulverized coal burner for a W flame boiler. The problems of high NOx discharge amount, high fly ash combustible matter content, slag-bonding to water walls of front and back walls of a lower combustion chamber and high temperature corrosion of the W flame boiler which is provided with an existing whirl pulverized coal burner on an arch are solved. A circular ring inner secondary air stop block in the circumferential direction is added in inner secondary air on a dividing cylinder of primary air and inner secondary air of the whirl pulverized coal burner; the angle of the circular ring inner secondary air stop block in the circumferential direction is 180 degrees; a circular ring outer secondary air stop block in the circumferential direction is added in outer secondary air on a dividing cylinder of the inner secondary air and the outer secondary air; the angle of the circular ring outer secondary air stop block in the circumferential direction is 180 degrees; the boundary line in the diameter direction of the circular ring inner secondary air stop block and the circular ring outer secondary air stop block is parallel to the front and back walls of the boiler; the circular ring inner secondary air stop block and the circular ring outer secondary air stop block are mounted on one side close to the center of a combustion chamber. The secondary air offset whirl pulverized coal burner is used for the W flame boiler.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com