Patents

Literature

30results about How to "Large amount of disposal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

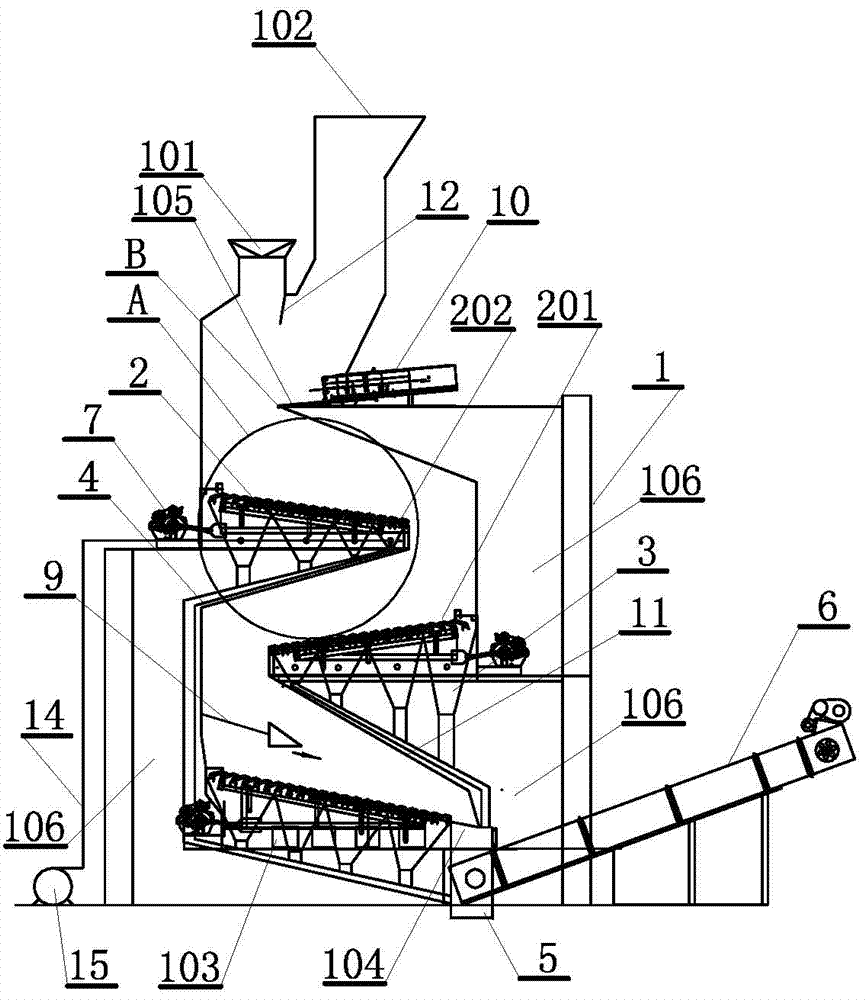

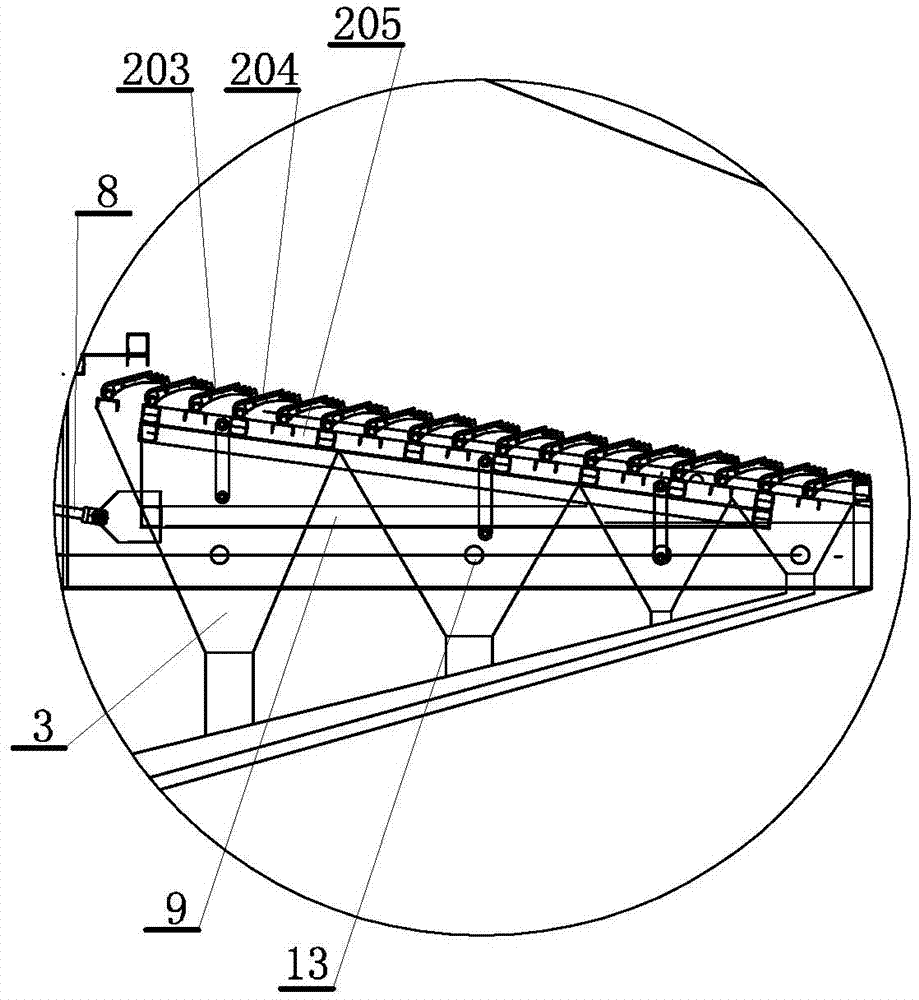

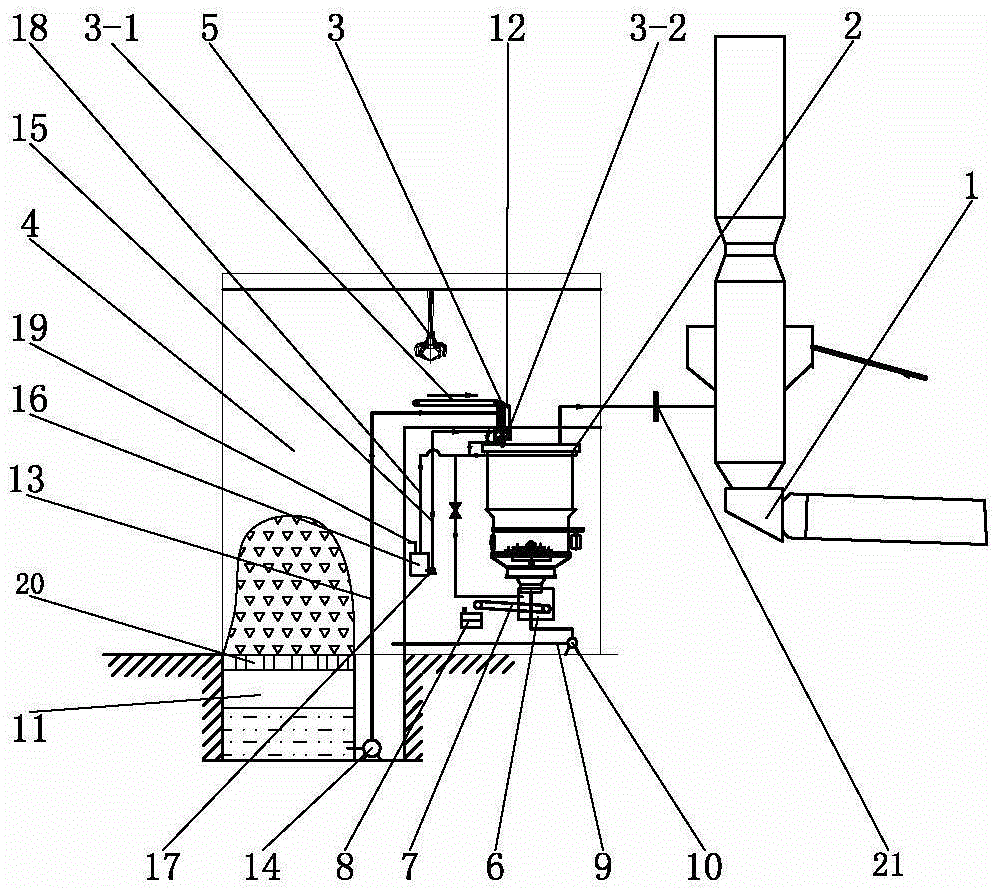

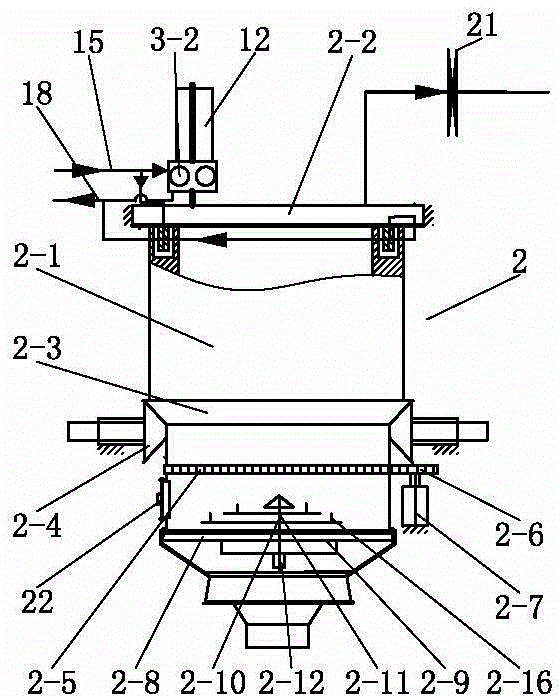

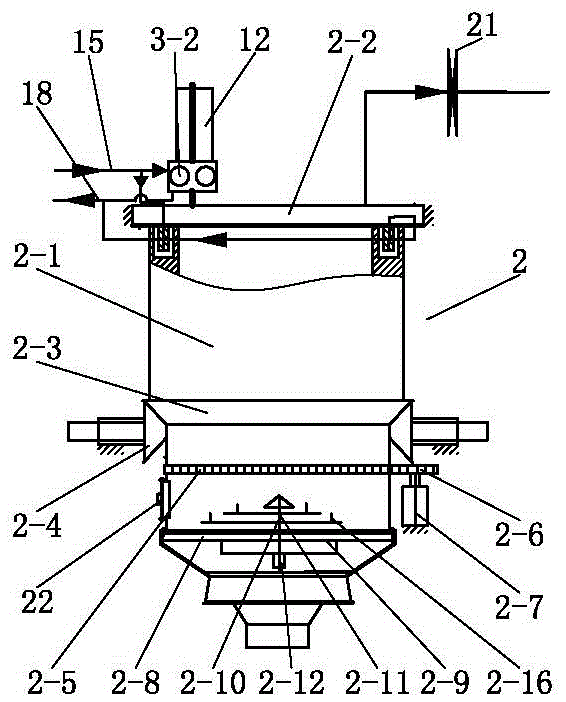

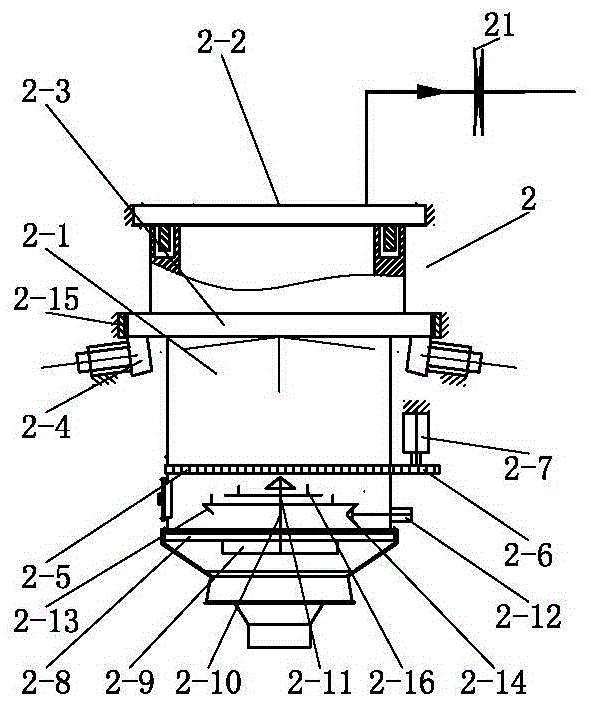

Multi-layer reciprocating type gasified combustion furnace

PendingCN107131503ASmall sizeLarge amount of disposalInclined grateIncinerator apparatusCombustionSlag

The invention discloses a multi-layer reciprocating type gasified combustion furnace comprising a combustion furnace body. A gasified fume discharging outlet and a gasified raw material garbage feeding inlet are formed in the upper end of the combustion furnace body, and a combustion gas inlet and a slag tapping outlet after combustion of gasified raw material garbage are formed in the lower end side of the combustion furnace body; a hearth in the furnace body is vertically provided with multiple layers of furnace rows from top to bottom; each layer of furnace row is arranged in a downward-inclining mode; the high end sides of the furnace rows at the lower layers stretch out of the low end sides of the furnace rows at the upper layers to enable the gasified raw material garbage on the furnace rows at the upper layers to fall into the high end sides of the furnace rows at the lower layers from the low end sides of the upper layers along the inclining gradient; and dust receiving funnels are arranged on the bottom face of the furnace row at each layer and connected with a dust discharging pipeline to output dust from the bottom side of the combustion furnace body. Because the garbage is fully dried and dehydrated through the multiple layers of furnace rows in the hearth, the heat value is increased, the combustion effect is more full, the structure is simple, the size of the combustion furnace is decreased greatly, investment is reduced, thermal decomposition gasified combustion of the furnace row at each layer can be achieved, and the application range of raw materials is wide.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

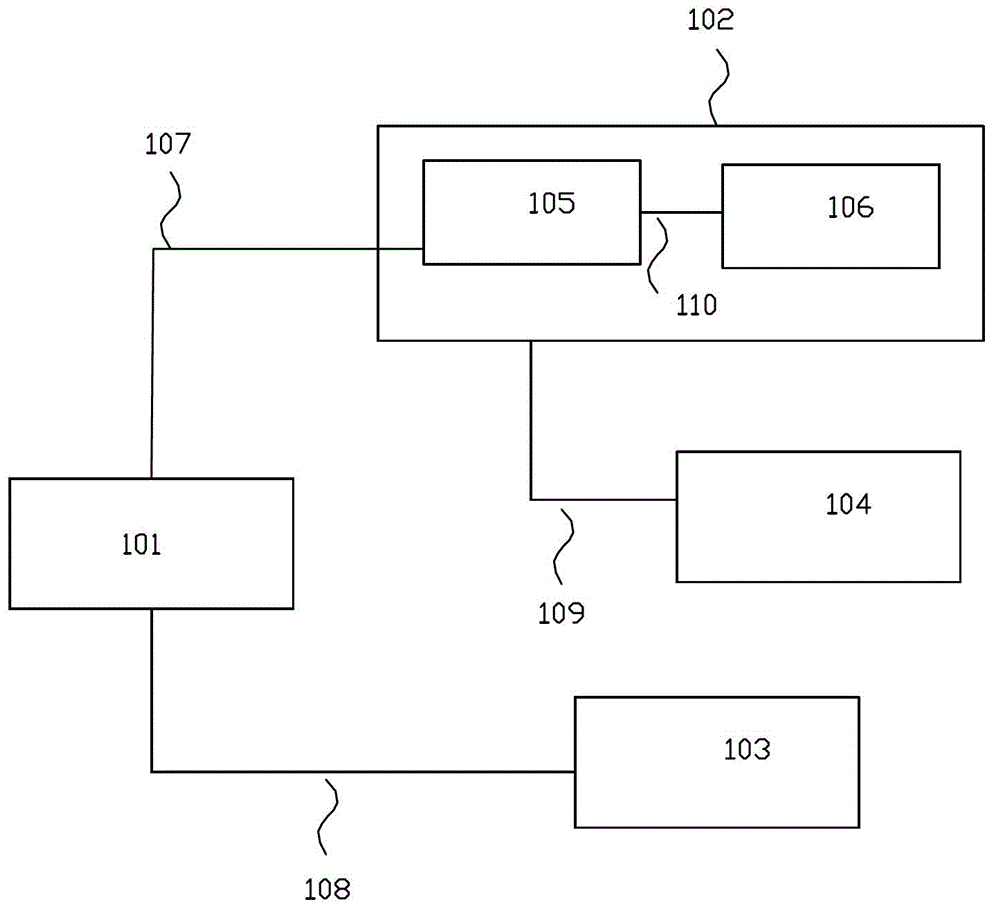

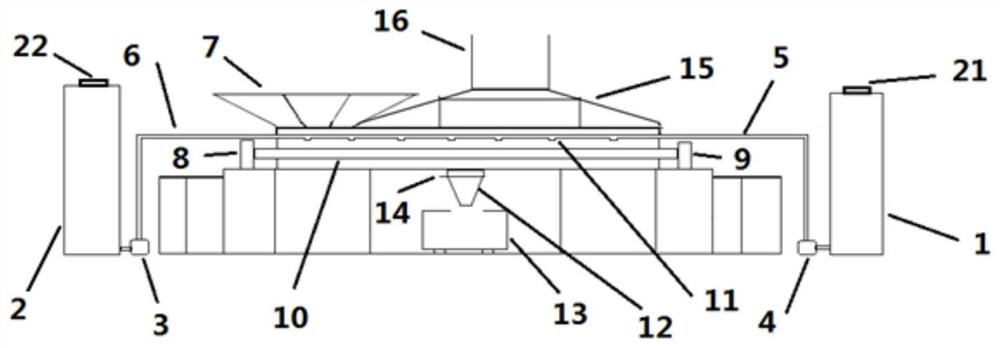

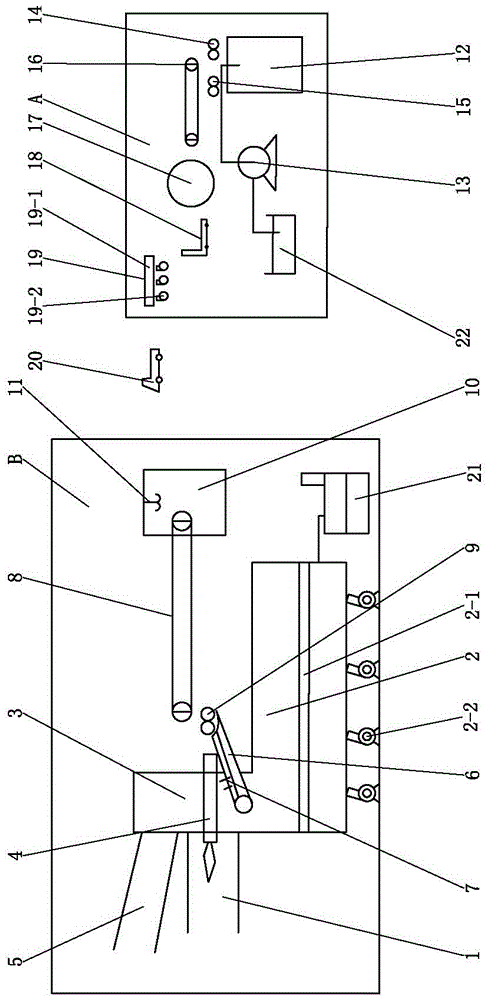

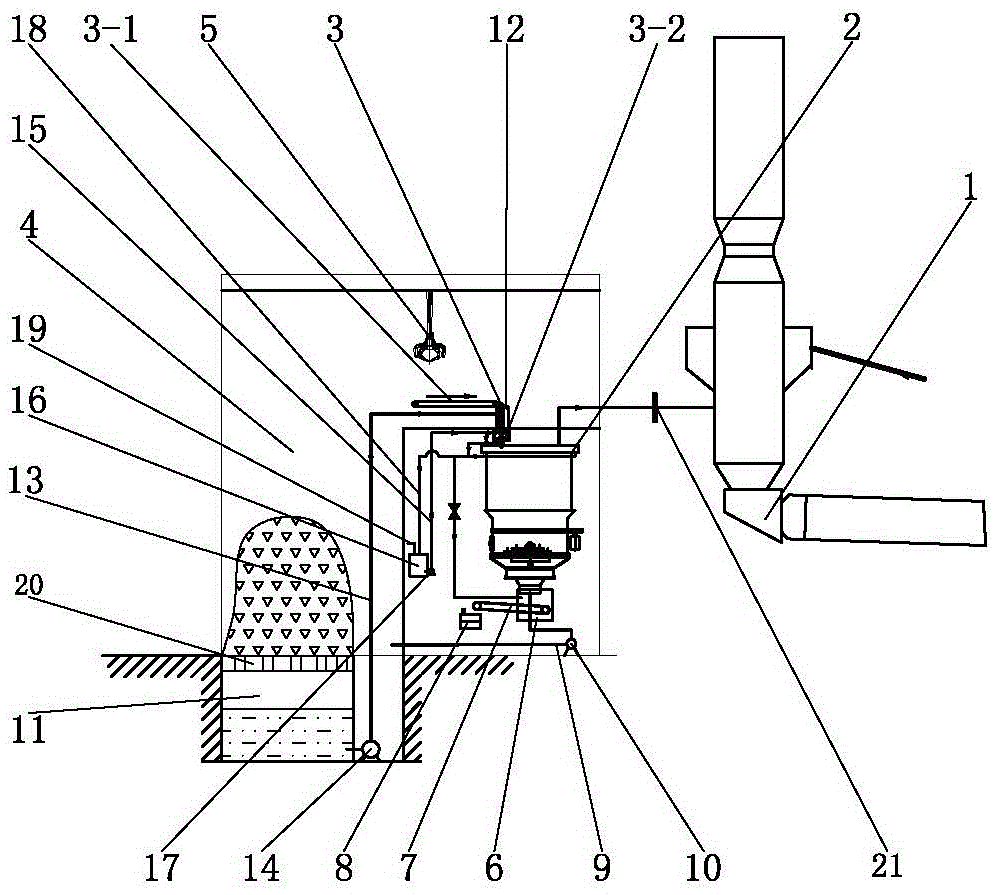

Sludge treatment system and method in cement kiln

InactiveCN102976575ALarge amount of disposalRelieve pressureSludge treatment by de-watering/drying/thickeningDispersed particle separationLimit valueCement kiln

The invention discloses a sludge treatment system in a cement kiln, which is characterized by comprising a sludge drying device, a sludge incineration device, a sludge drying waste gas treatment device, a waste water treatment device, a first delivery mechanism for delivering dried sludge to the sludge incineration device, a second delivery mechanism for delivering sludge drying waste gas to the sludge drying waste gas treatment device, and a third delivery mechanism for delivering waste water generated by the sludge drying waste gas treatment device to the waste water treatment device, wherein the sludge drying device is connected with the sludge incineration device through the first delivery mechanism; the sludge drying device is connected with the sludge drying waste gas treatment device through the second delivery mechanism; and the sludge drying waste gas treatment device is connected with the waste water treatment device through the third delivery mechanism. The overall system achieves zero discharge of waste residue and waste water, and the waste gas discharge is lower than the limit value in the national discharge standard, thereby achieving the goal of converting sludge into resources and harmless substances.

Owner:广州市越堡水泥有限公司

Biodegradation-based sludge brick-making technology

InactiveCN102390913AIncrease the addition ratioReduce moisture contentSludge treatment by de-watering/drying/thickeningSolid waste managementBrickFilter press

The invention relates to a biodegradation-based sludge brick-making technology. Compared with a traditional technology, the biodegradation-based sludge brick-making technology is characterized in that a step of anaerobic treatment is added. Fermentation is carried out and then filter-pressing dehydration treatment is performed, so that the content of organic matters in sludge is reduced to below 10% and the content of water is reduced to 20%-30%, thereby obtaining brick-making sludge suitable for being added to a brick-making material, such as shale and the like. According to the traditional technology, the filter-pressing dehydration treatment is directly performed, so that the content of water in the sludge is only reduced to about 80% and the content of organic volatile matters is above 20%. Generally, the total added weight of the sludge, which contains 80% of water and more than 20% of organic matters and is added for making a brick, is only 30% of the weight of the brick-making material. In the brick-making sludge which is suitable for being added to the brick-making material and is obtained according to the biodegradation-based sludge brick-making technology, the content of organic matters is reduced to below 10% and the content of water is reduced to 20%-30%, and the total added weight of the sludge used for making the brick can be 40%-60% of the weight of the brick-making material, thereby saving raw materials, lowering cost and greatly promoting the capacity for treating the sludge.

Owner:CHONGQING JUKANG BUILDING MATERIAL

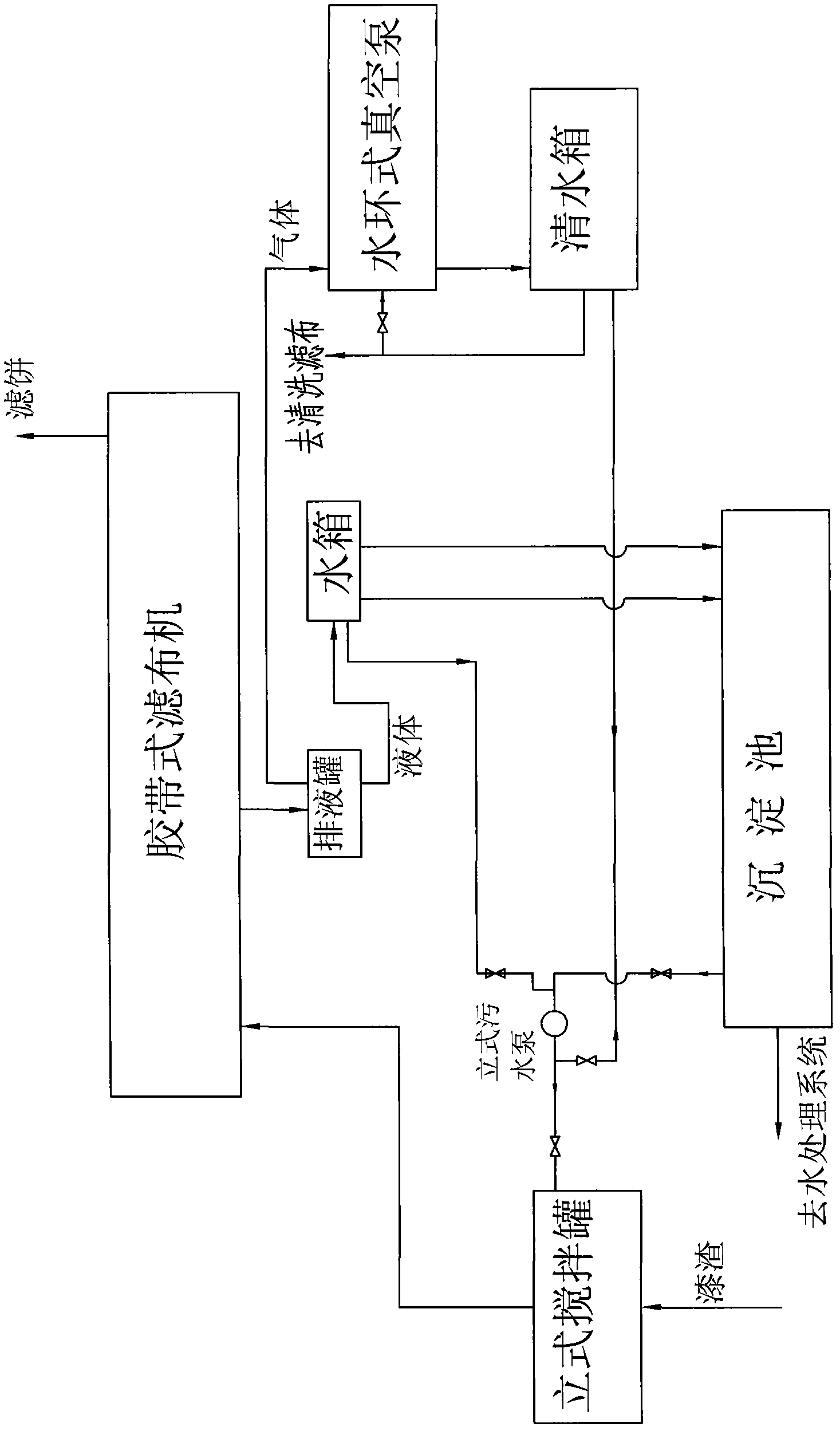

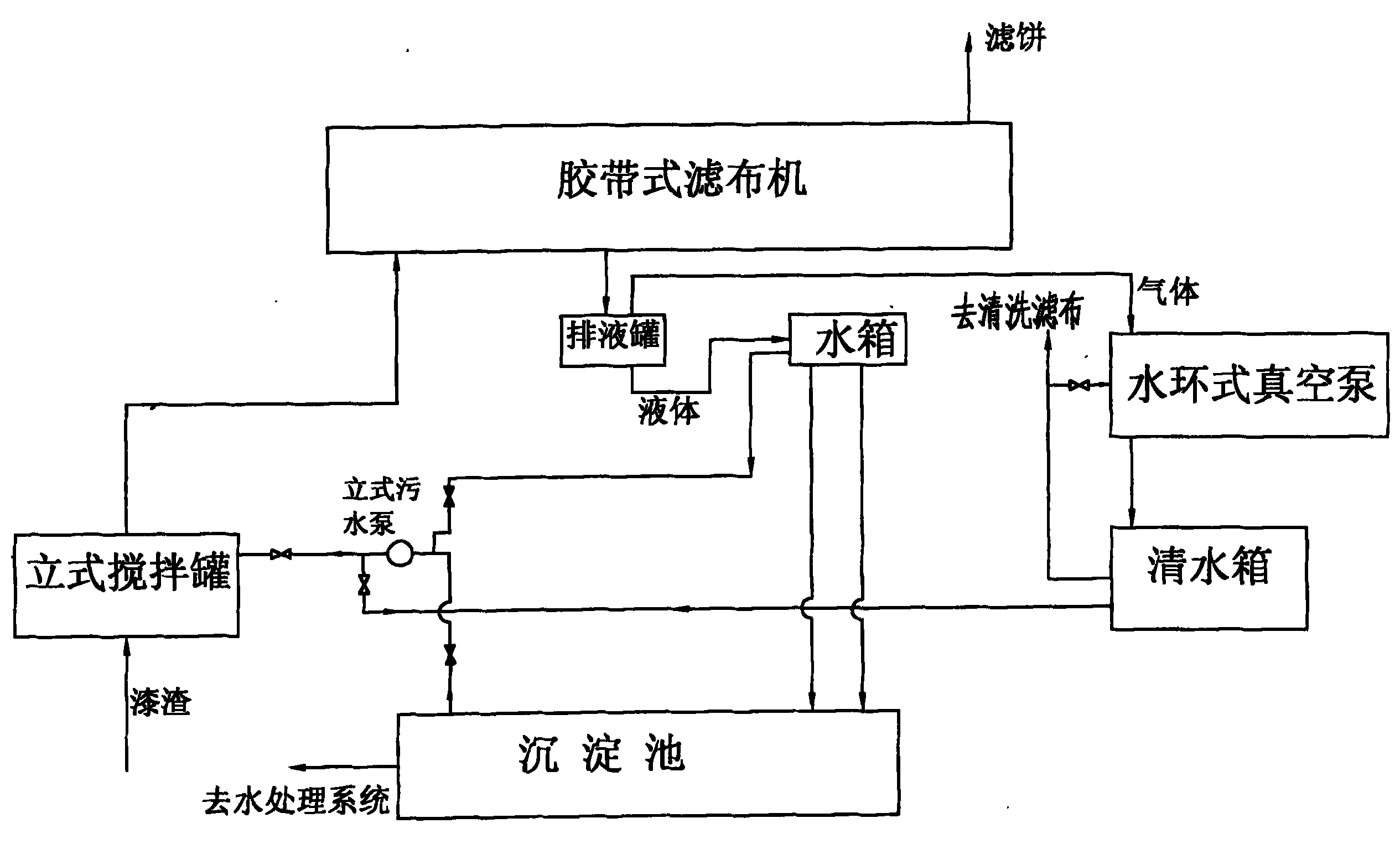

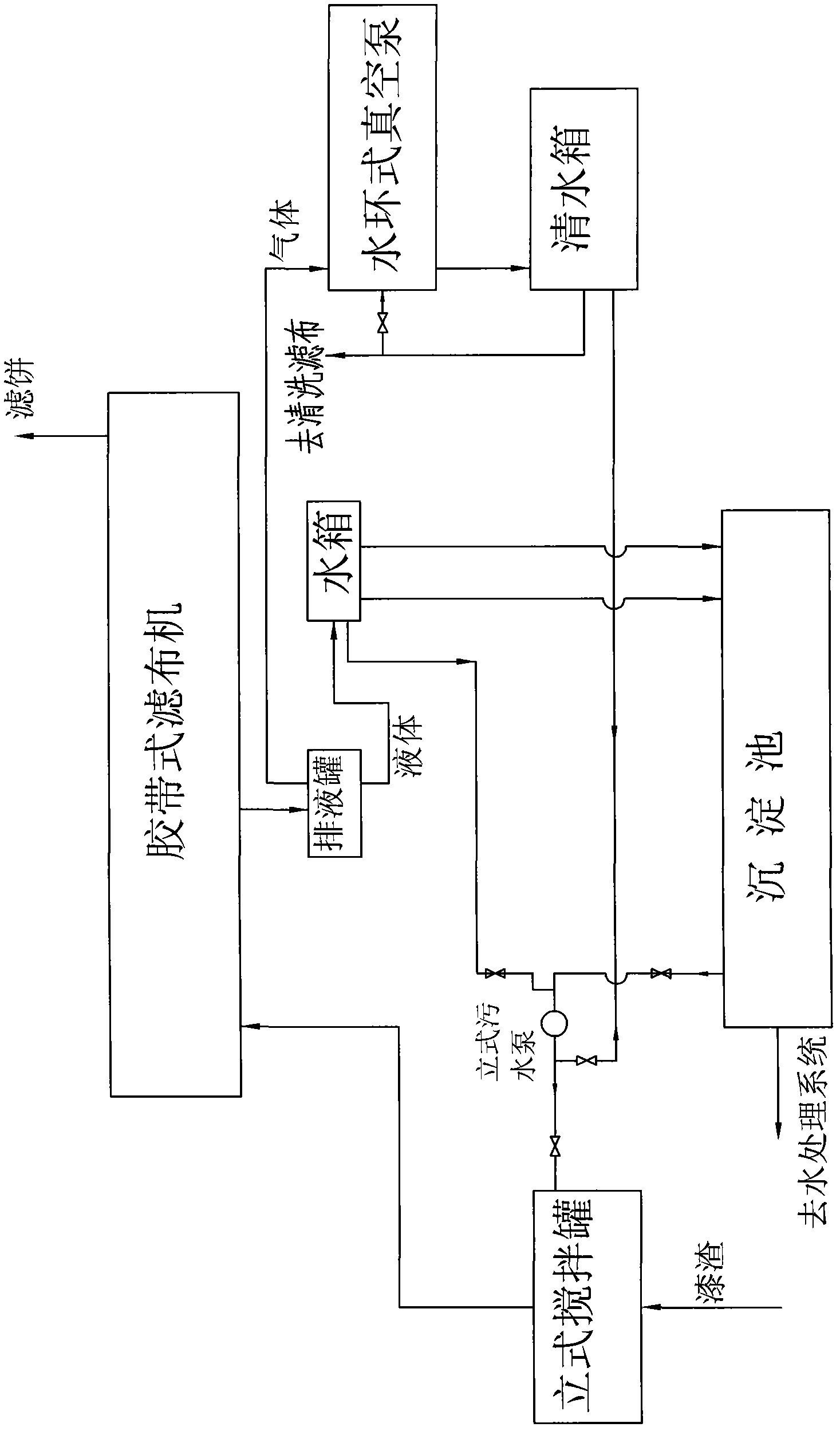

Method for processing paint slag muck by separating slag muck from water

ActiveCN102580389ALarge amount of disposalReduce consumptionMoving filtering element filtersTransverse grooveSlag

The invention relates to a method for processing paint slag muck by separating slag muck from water. The method comprises the steps of: pouring water-containing paint slag muck into an upright agitating tank to uniformly mix and agitate; conveying the water-containing paint slag muck from the tank to filter cloth at one end of a tape type filtering machine; vacuum filtering the water-containing paint slag muck continuously running on the filter cloth; collecting the filtrate by a transverse groove on the tape, wherein the filtrate enters a vacuum box from a center hole at the bottom of the groove and moves into a liquid draining tank from a suction filtering hole on the sidewall of the vacuum box to undergo gas-liquid separation; pumping the gas from the top of the liquid draining tank into a water-ring vacuum pump, and exhausting to a clean water tank through a gas outlet of the vacuum pump; draining the liquid from the bottom of the liquid draining tank into a water tank; moving the liquid into a settling pond through the water tank to suction filter; intercepting the solid particles stayed on the filter cloth caused by filtering to form filter cakes; and discharging the filter cakes. The method for processing paint slag muck by separating slag muck from water provided by the invention has the advantages that the water content in the paint slag muck is reduced, the influence of water content to the working condition in a kiln is reduced, the quantity of processed paint slag muck is increased, the effect of replacing some fuels by the paint slag muck is achieved, and the energy saving and emission reduction in cement production is promoted.

Owner:BEIJING BBMG BEISHUI ENVIROMENTAL TECH CO LTD

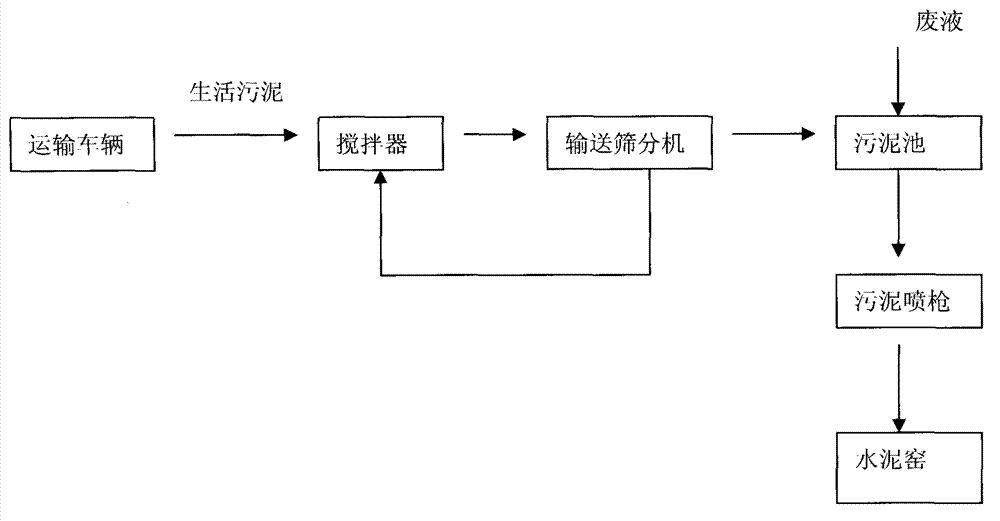

Method for reducing nitric oxides by using disposed sludge

InactiveCN102923923AEmission reductionLow costSludge treatmentIncinerator apparatusSludgeDecomposition

The invention relates to a method for reducing nitric oxides by using disposed sludge. The method comprises the following steps of: conveying domestic sludge from a sewage treatment plant to a plant by using a vehicle, uniformly stirring the domestic sludge in a stirrer, conveying the domestic sludge to a conveying sieving machine, and further scattering large-particle sludge; throwing the scattered sludge out through small holes in the barrel wall of the conveying sieving machine to directly enter into a sludge pond for being disposed, collecting un-scattered sludge and then recycling to enter into the stirrer for being stirred; stirring and mixing the sludge entering into the sludge pond for the second time, directly throwing into a sludge spray gun through a sludge pump, and throwing wet sludge into a kiln tail decomposition furnace for incineration through a scattering function of the spray gun. The method has the advantages that a reducing atmosphere is formed in a cement kiln decomposition furnace while sludge is disposed by using ammonia nitrogen in the sludge, most of nitric oxides can be directly reduced into nitrogen, thus the nitric oxides in the tail gas of a cement kiln can be reduced, and the disposition amount of the sludge is increased.

Owner:BEIJING BBMG BEISHUI ENVIROMENTAL TECH CO LTD

Cement kiln capable of realizing waste gasification outside same and gasification method thereof

ActiveCN104531218AOvercome the defects of high water content and complex compositionScale upGasifier feeding meansGasification processes detailsCement kilnDomestic waste

The invention discloses a cement kiln capable of realizing waste gasification outside the same and a gasification method thereof. The cement kiln capable of realizing waste gasification outside the same comprises a cement kiln, wherein a gas inlet of the cement kiln is communicated with a gas outlet of a waste gasification furnace; a feed port of the waste gasification furnace is positioned below an outlet of a waste conveying device; an inlet of the waste conveying device is positioned in a waste material shed; and a waste grabbing device is arranged in the waste material shed. An operating method of the cement kiln capable of realizing waste gasification outside the same is characterized in that heat generated by burning part of waste in the waste gasification furnace is used to heat the rest of the waste in the waste gasification furnace, so that the rest of the waste can be gasified. According to the invention, the defect that domestic waste is high in water content and contains complicated components is overcome, the pretreatment procedure can be greatly simplified, the treatment cost is greatly lowered, and the domestic waste treatment scale is expanded; and furthermore, no auxiliary fuel is needed. Besides, the waste feeding uniformity can be ensured, thereby being beneficial to uniform distribution in the waste gasification furnace.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

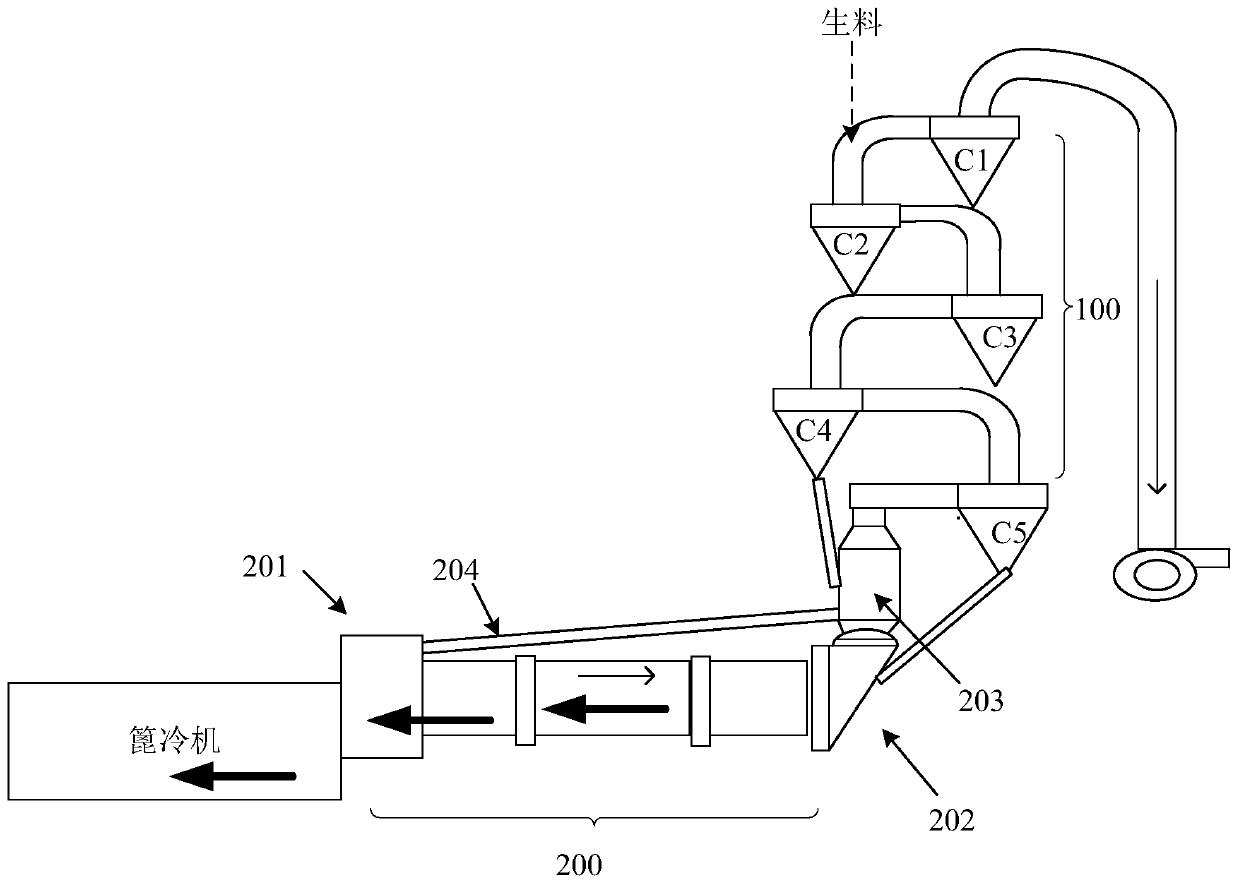

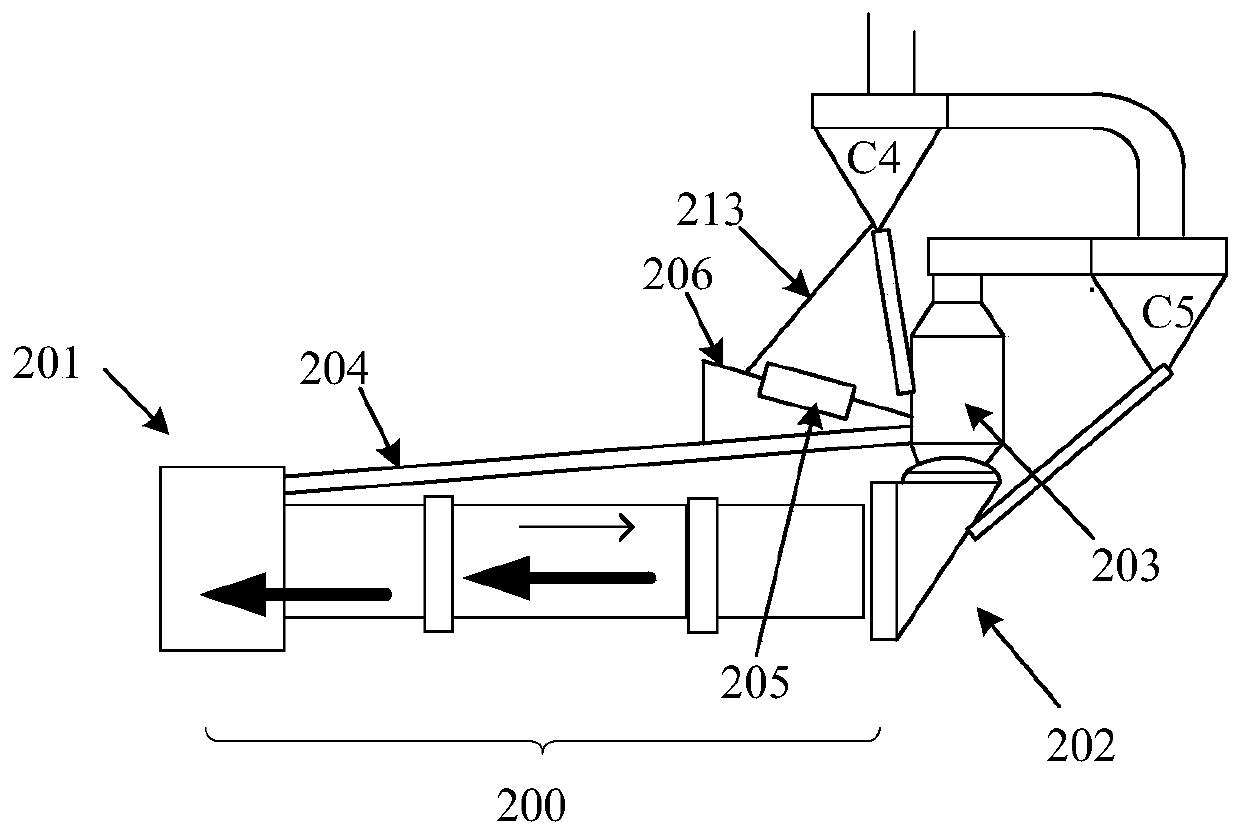

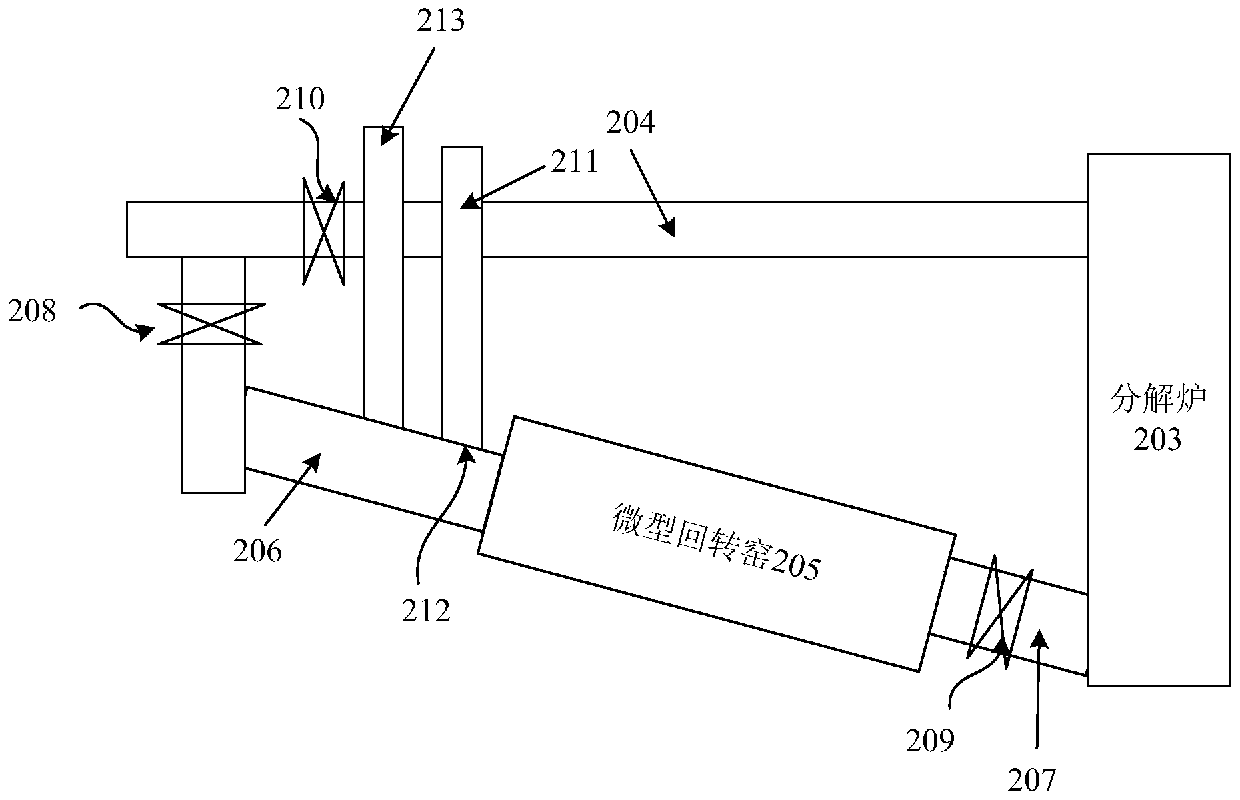

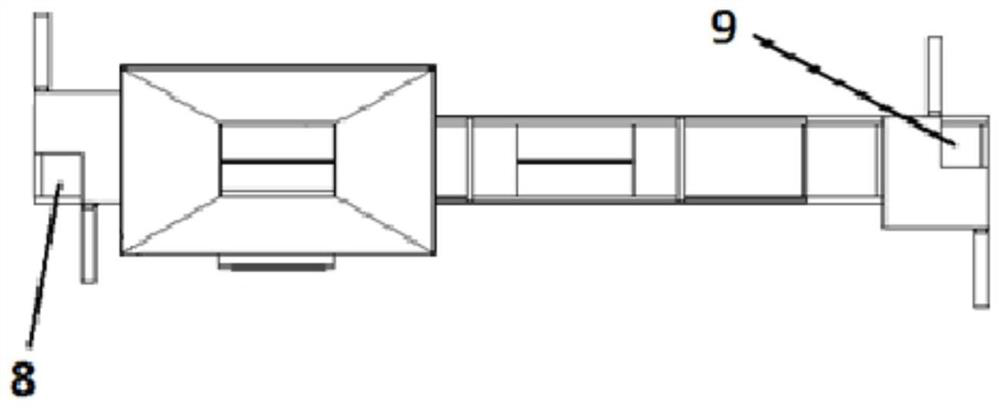

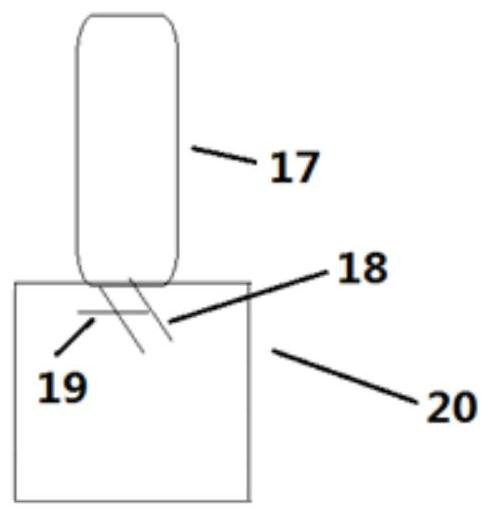

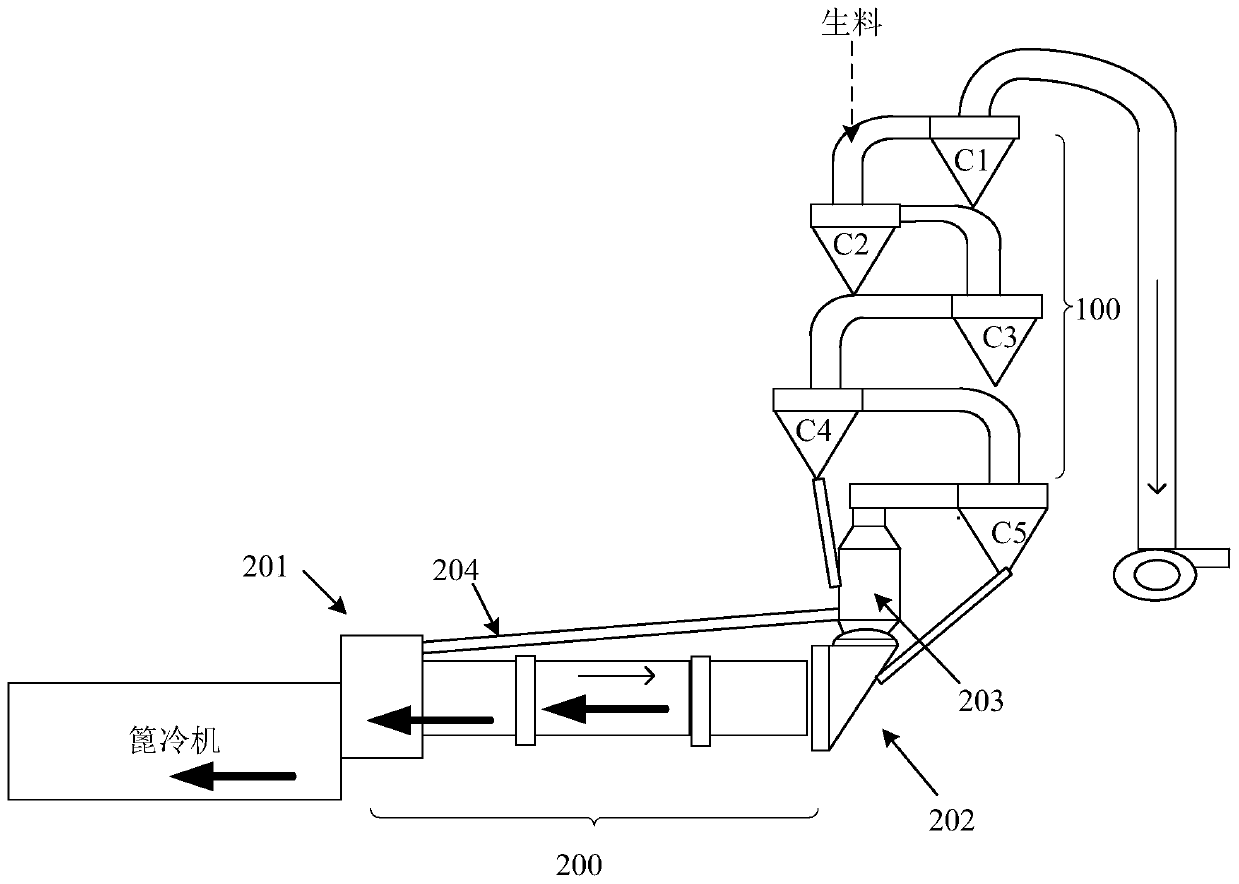

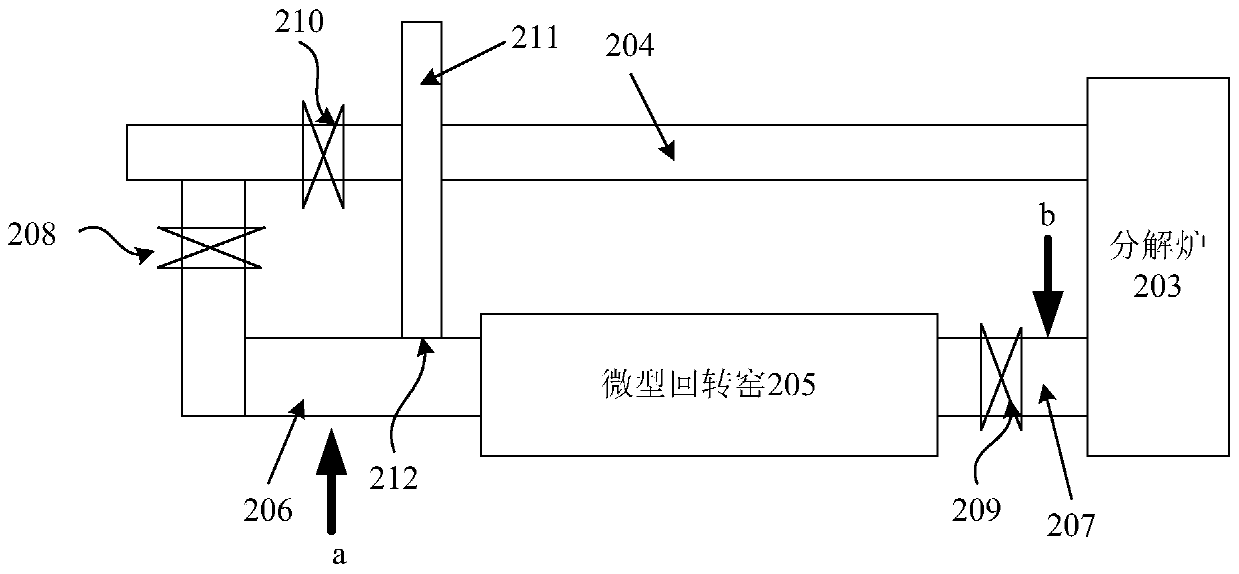

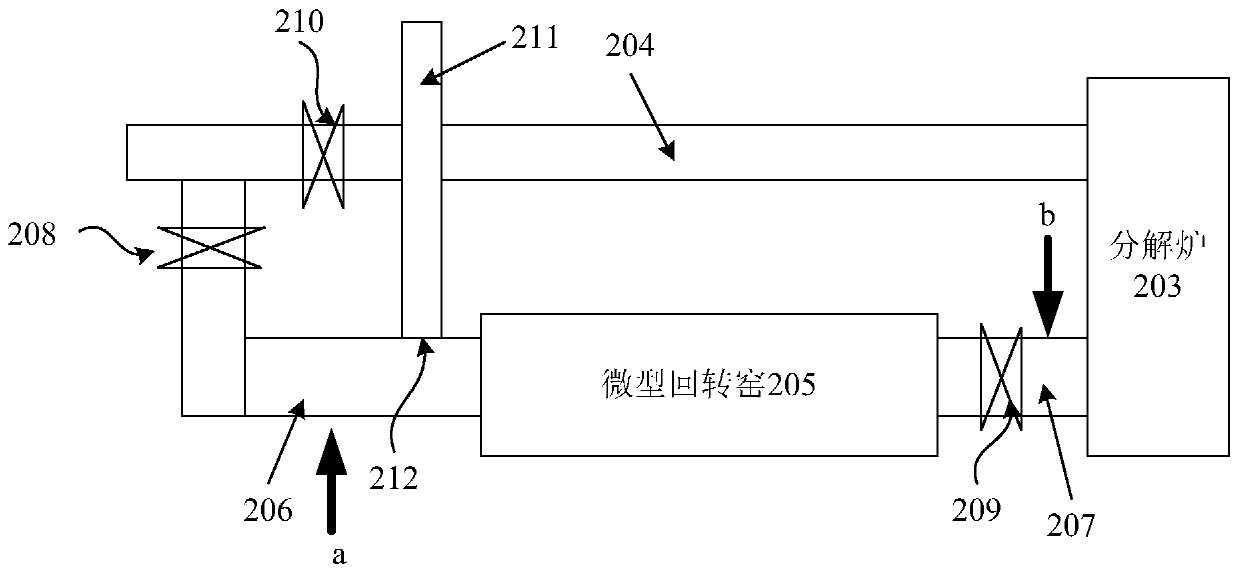

Device and method for disposing waste by preheating raw materials through rotary kiln

PendingCN110006246AIncrease filling volumeLittle impact on operationRotary drum furnacesIncinerator apparatusCause blockageRaw material

The invention provides a device for disposing waste by preheating raw materials through a rotary kiln. The device comprises a decomposing furnace, the rotary kiln, a tertiary air pipe and a minisize rotary kiln, wherein the tertiary air pipe is connected with a kiln head of the rotary kiln and the decomposing furnace, and the minisize rotary kiln and the tertiary air pipe are arranged to form an inclination angle. One end of the minisize rotary kiln communicates with the tertiary air pipe through a first pipe, and the other end of the minisize rotary kiln communicates with the decomposing furnace through a second pipe. The end, communicating with the tertiary air pipe, of the minisize rotary kiln is higher than the end, communicating with the decomposing furnace, of the minisize rotary kiln. The first pipe communicating with the tertiary air pipe is provided with a waste charging opening. The first pipe communicates with a preheater through a third pipe, and the hot raw materials in the preheater are distributed into the minisize rotary kiln through the third pipe. By means of the device, the harmless disposal process of the solid waste is achieved while cement clinker is produced;the charging amount of the waste is increased; and in addition, the problem that coking occurs in the minisize rotary kiln and the pipes to cause blockage can be avoided.

Owner:北京科太亚洲生态科技股份有限公司

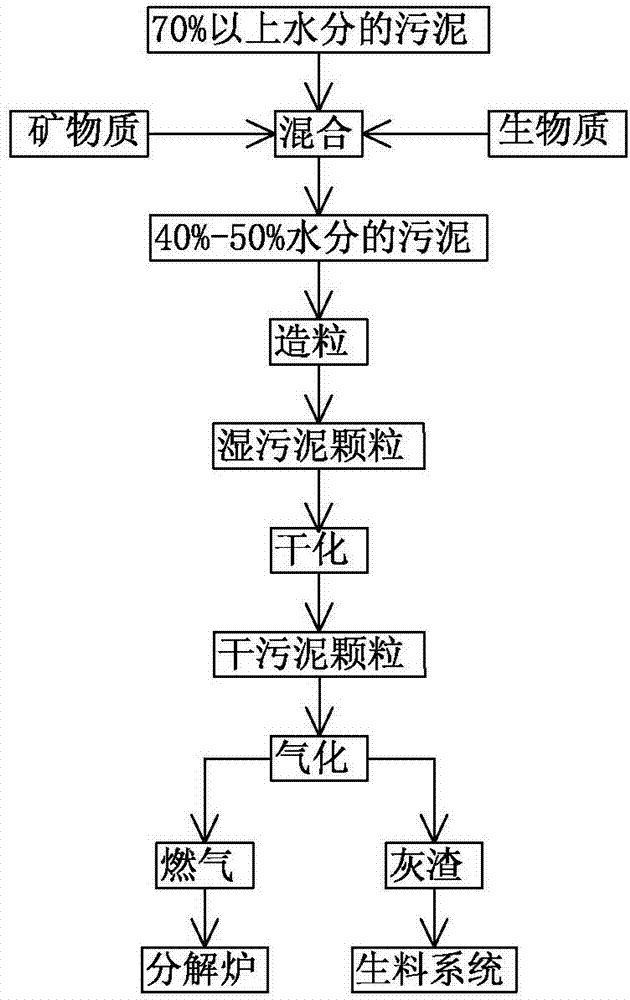

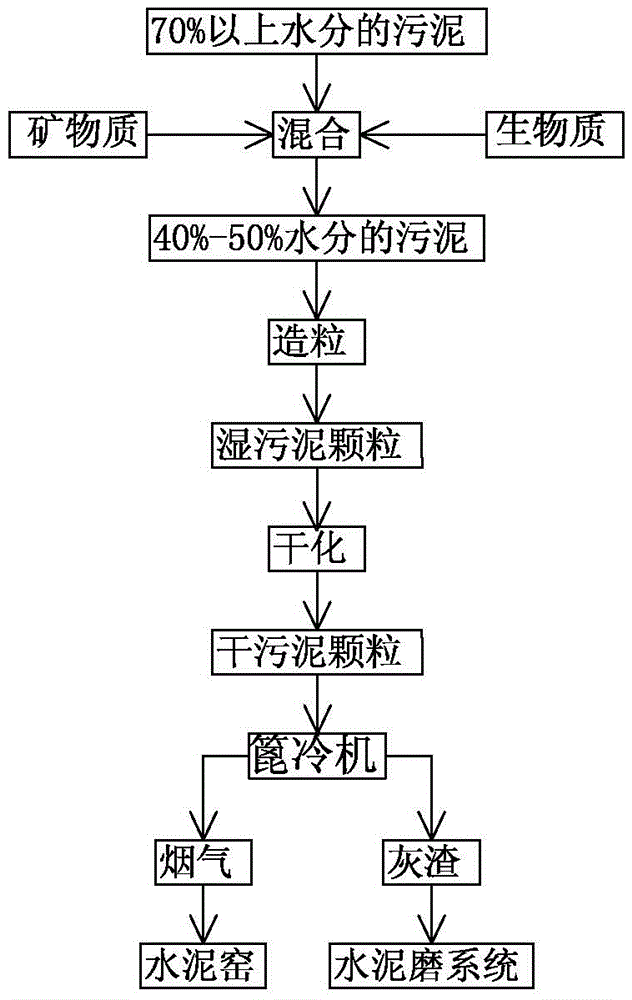

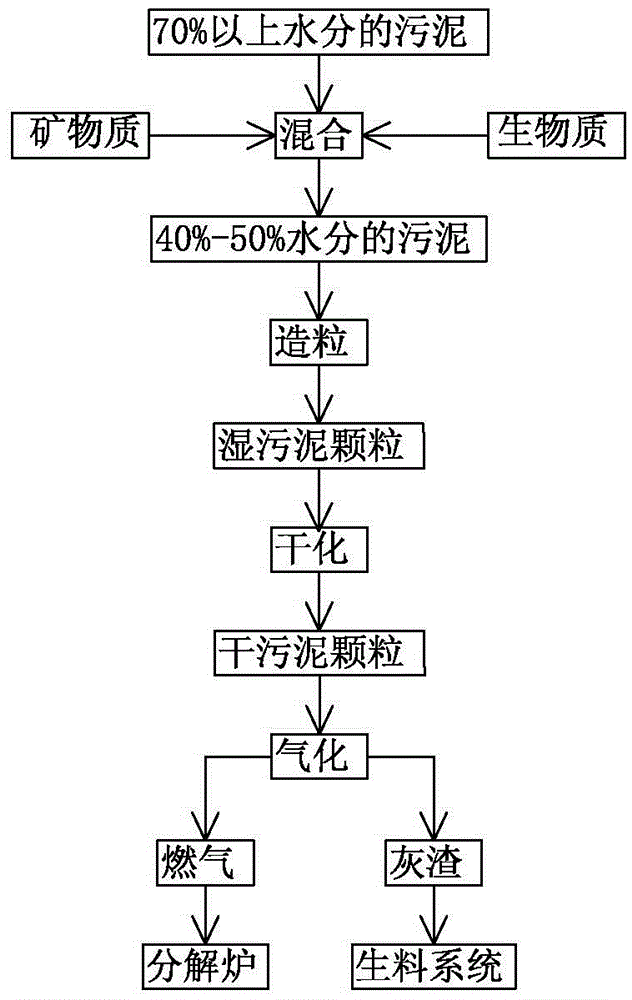

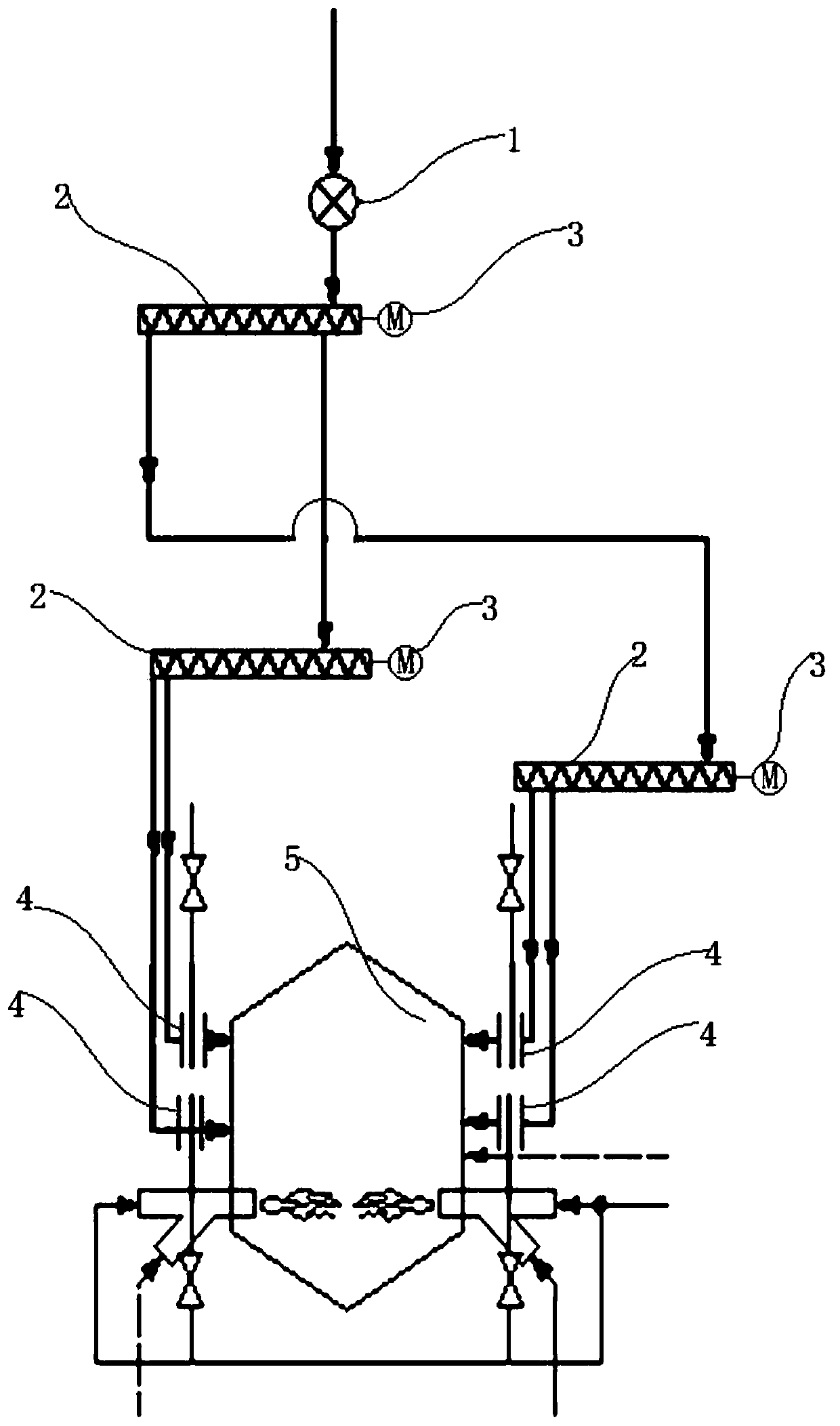

Method for treating sludge by using cement kiln, and sludge gasifying cement kiln system

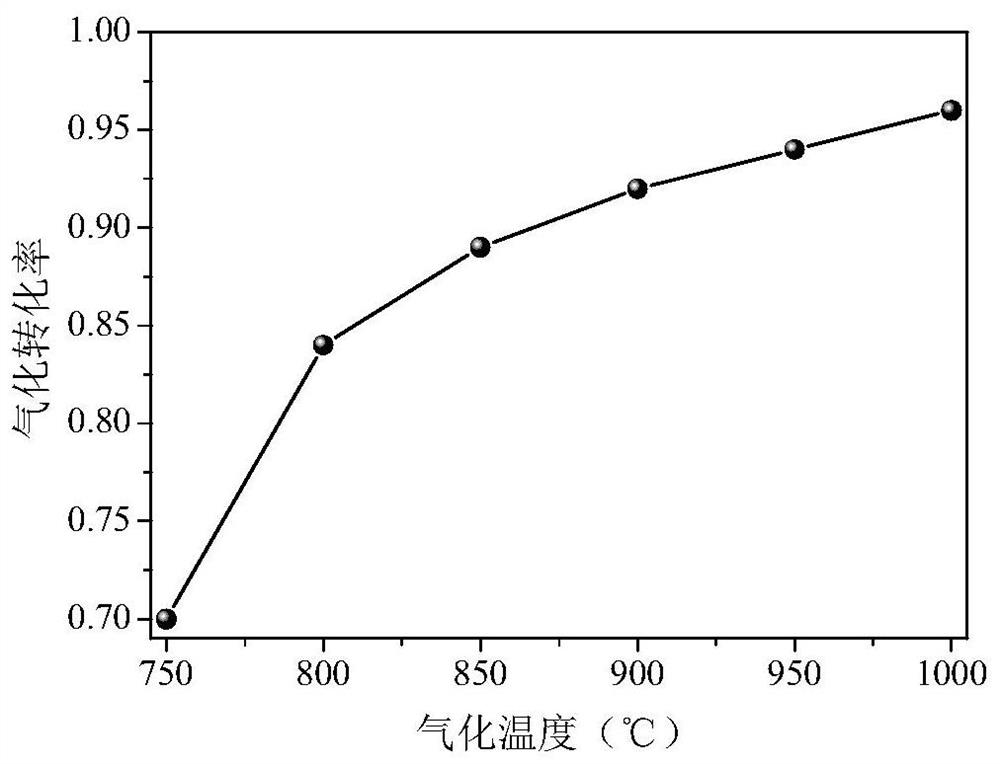

ActiveCN104496135AReduce moistureTransportSludge treatment by de-watering/drying/thickeningClinker productionSludgeSlag

The invention discloses a method for treating sludge by using a cement kiln, and a sludge gasifying cement kiln system. The method for treating sludge by using the cement kiln comprises the following steps: making wet sludge into dry sludge particles, then gasifying the dry sludge particles, sending the fuel gas obtained after gasification into a decomposing furnace, and sending ash obtained after gasification into a crude material system. The sludge gasifying cement kiln system comprises a cement kiln and a decomposing furnace, wherein an inlet of the cement kiln is communicated with an outlet of the decomposing furnace, and a gas inlet of the decomposing furnace is communicated with a gas outlet of a gasifying furnace through a fuel gas pipeline; a feed opening of the gasifying furnace is communicated with a warehouse through a conveying system, and a slag outlet of the gasifying furnace is communicated with the crude material system through a slagging system. According to the method and the sludge gasifying cement kiln system provided by the invention, the treatment scale of sludge can be greatly improved; the difference between the form of solid sludge directly sent to the kiln and the fineness of coal dust as well as a cement raw material is reduced, and the mass and heat transfer effect is increased.

Owner:BBMG CORP +2

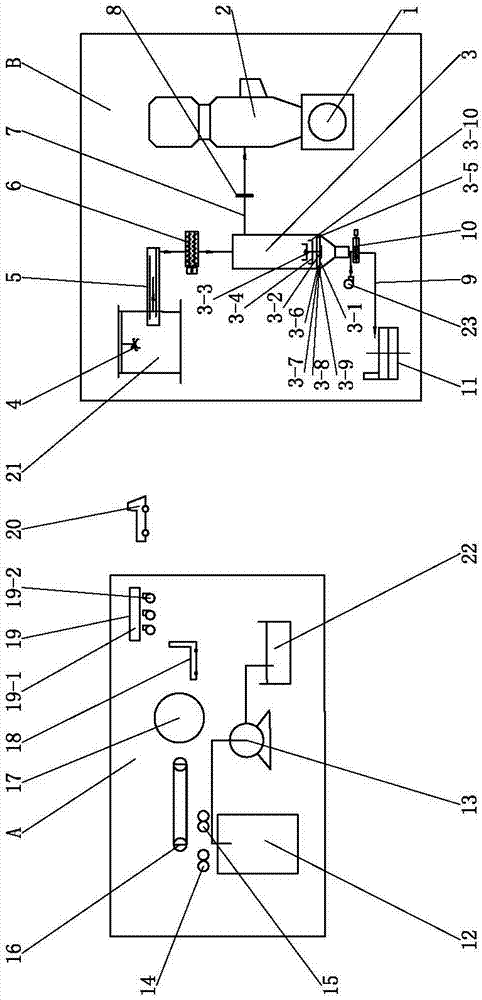

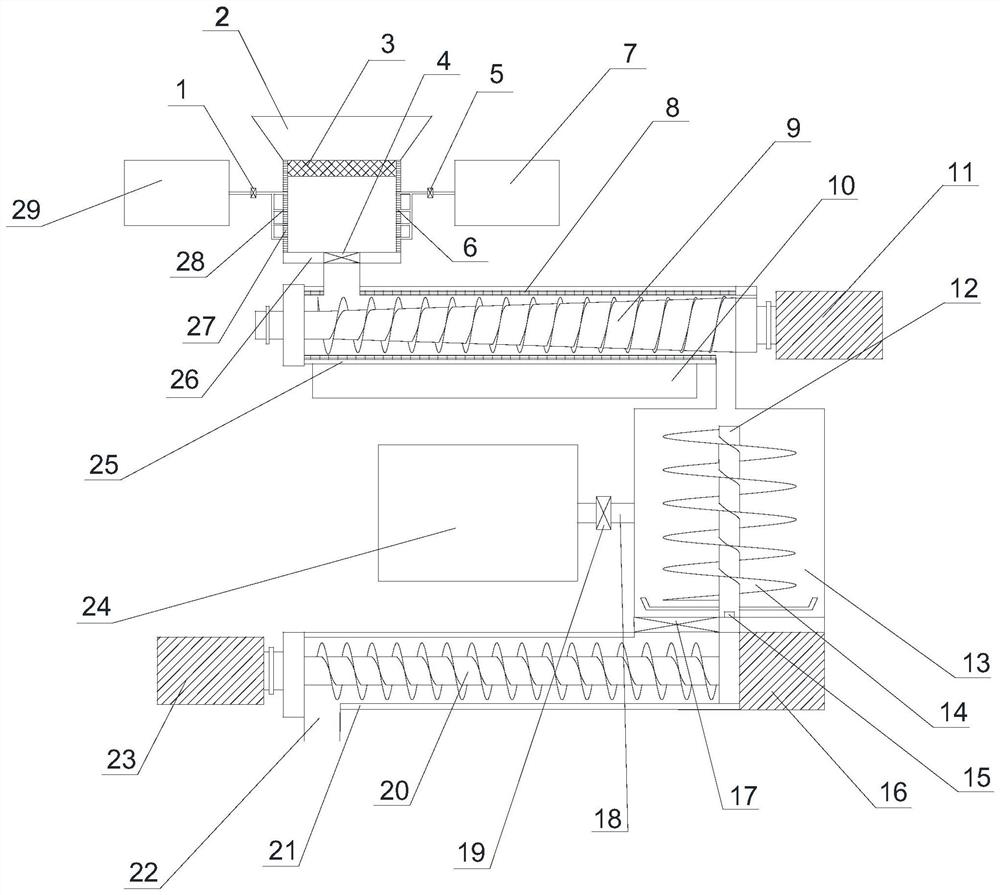

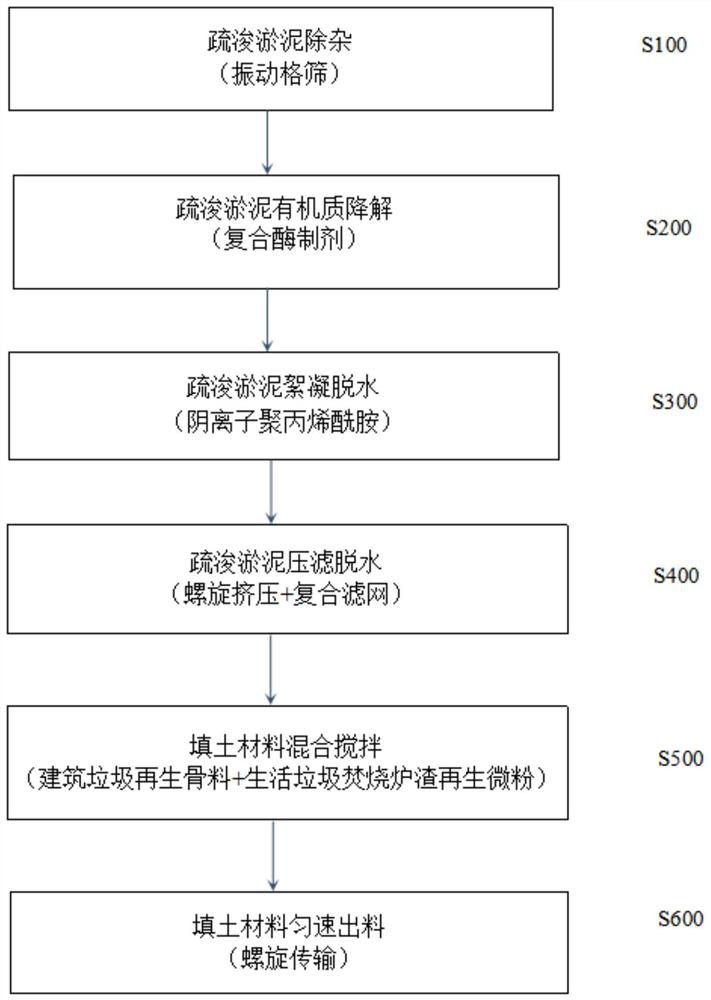

Device and method for regenerating filling material by using solid waste

PendingCN114057441AAchieving processing powerImplement resourcesSludge treatment by de-watering/drying/thickeningSolid waste managementSludgeSlag

Owner:ZHEJIANG SCI-TECH UNIV

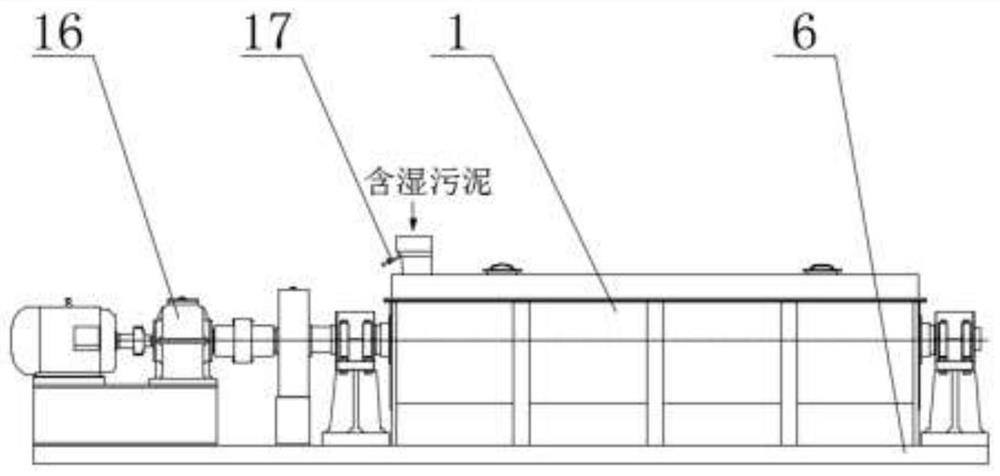

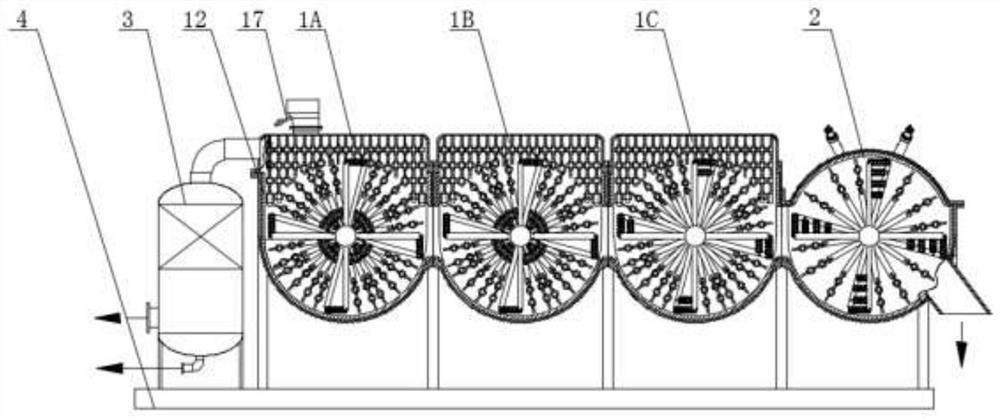

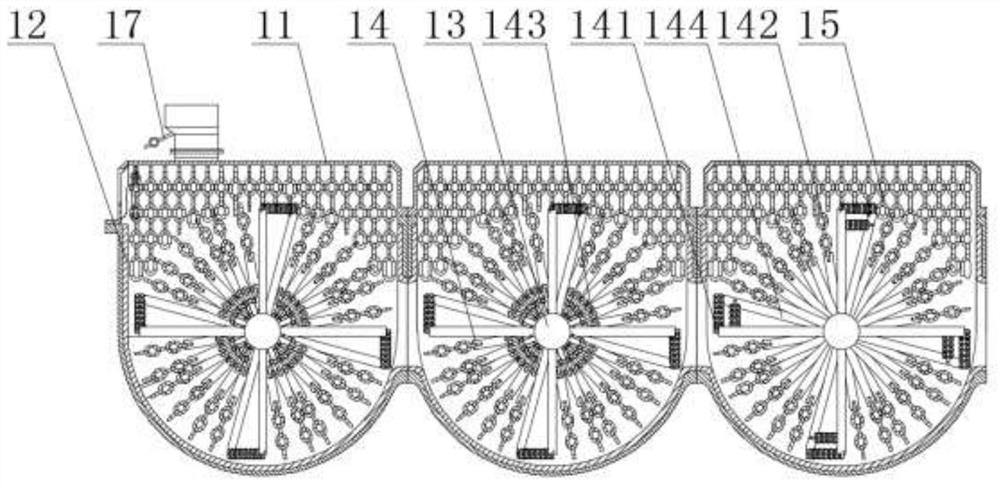

Municipal sludge chain rolling suspension drying clean incineration equipment and incineration method

PendingCN112777903ALarge amount of disposalSimple processSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesExhaust fumesDry heat

The invention discloses municipal sludge chain rolling suspension drying clean incineration equipment and an incineration method, and the municipal sludge chain rolling suspension drying clean incineration equipment comprises more than two stages of horizontal sludge rod chain rolling suspension drying devices, plasma flame suspension incineration devices and waste gas purification devices which are communicated in sequence.Municipal sludge chain rolling suspension drying clean incineration can be integrated, the treatment process is simple, the heat utilization efficiency is high, the energy consumption is low, operation is continuous and reliable, the sludge treatment amount is large, the occupied area is small, and the operation cost is lower. The invention further provides the incineration method, the technology that wet sludge and hot air are rolled, hung, suspended and dried in a relatively closed space through a multi-stage rod chain is utilized, moisture in the sludge can be rapidly removed, the retention time of a sludge viscous area is effectively shortened, the sludge dewatering and drying efficiency is effectively improved, and the drying heat consumption is reduced.

Owner:长沙紫宸科技开发有限公司

Liquid hazardous waste pre-treatment and exhaust gas collection device

PendingCN111678138AEasy to collectHazardous waste high efficiencyIncinerator apparatusLiquid wasteReclaimed water

The invention provides a liquid hazardous waste pre-treatment and exhaust gas collection device. One end of a spray pipe of the device is connected to a reuse reclaimed water storage tank while the other end of the spray pipe is connected to a hazardous liquid waste storage tank, waste liquor in the hazardous liquid waste storage tank is sucked into the spray pipe through a first self-priming pump, reuse reclaimed water in the reuse reclaimed water storage tank is sucked into the spray pipe through a second self-priming pump, a mixing and stirring device is mounted below the spray pipe, a hopper is mounted on one side above the mixing and stirring device, a feeding device is mounted on the hopper side, an unloading device is mounted at the bottom of the mixing and stirring device, a firstvalve is mounted on the unloading device, a seal cover is mounted on the other side above the mixing and stirring device, and a gas collecting pipeline is mounted above the seal cover. The liquid hazardous waste pre-treatment and exhaust gas collection device solves the problem of feeding liquid hazardous wastes treated by way of pump spraying into a rotary kiln to incinerate. The liquid hazardouswaste pre-treatment and exhaust gas collection device which pre-treats the liquid hazardous wastes is safer and more stable by adopting liquid waste neutralizing and stirring equipment and a device of collecting harmful gas generated during stirring, so that the treatment progress of the liquid wastes is improved.

Owner:黑龙江云水环境技术服务有限公司

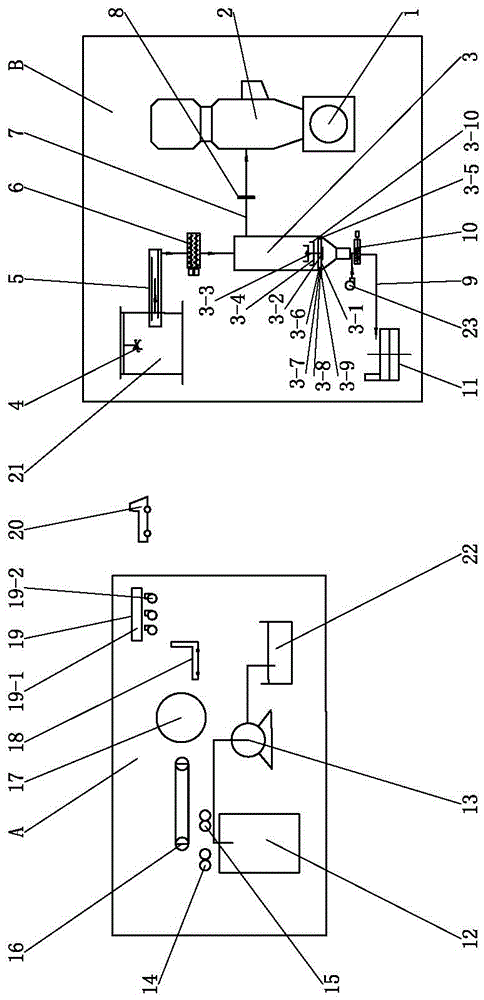

Method for treating sludge with cement kiln and cement kiln system for treating sludge with grate cooler

ActiveCN104478243BLarge amount of disposalSize DisposalCement productionIncinerator apparatusCombustionSludge

The invention discloses a method for treating sludge by a cement kiln and a cement kiln system for treating sludge by a grate cooler. The method comprises the steps: preparing dry sludge particles through wet sludge; heating the dry sludge particles through high temperature clinkers discharged from the cement kiln to prompt the combustion of the dry sludge particles; then feeding smoke into a third air system of the cement kiln; and feeding the combusted sludge particles and heated clinker into a cement grinding mill system. The cement kiln system comprises the cement kiln, and the grate cooler which communicates with the cement kiln through a head cover; the head cover communicates with the cement kiln through a third air pipeline; and a sludge feeding opening is formed in the head cover and communicates with a dry sludge particle storage through a dry sludge particle conveying device. With the adoption of the method and cement kiln system, the sludge can be treated massively, and the daily treatment capacity reaches 200t / d.

Owner:BBMG CORP +2

A method of treating sludge with a cement kiln and a sludge gasification cement kiln system

ActiveCN104496135BReduce moistureTransportSludge treatment by de-watering/drying/thickeningClinker productionSludgeSlag

The invention discloses a method for treating sludge by using a cement kiln, and a sludge gasifying cement kiln system. The method for treating sludge by using the cement kiln comprises the following steps: making wet sludge into dry sludge particles, then gasifying the dry sludge particles, sending the fuel gas obtained after gasification into a decomposing furnace, and sending ash obtained after gasification into a crude material system. The sludge gasifying cement kiln system comprises a cement kiln and a decomposing furnace, wherein an inlet of the cement kiln is communicated with an outlet of the decomposing furnace, and a gas inlet of the decomposing furnace is communicated with a gas outlet of a gasifying furnace through a fuel gas pipeline; a feed opening of the gasifying furnace is communicated with a warehouse through a conveying system, and a slag outlet of the gasifying furnace is communicated with the crude material system through a slagging system. According to the method and the sludge gasifying cement kiln system provided by the invention, the treatment scale of sludge can be greatly improved; the difference between the form of solid sludge directly sent to the kiln and the fineness of coal dust as well as a cement raw material is reduced, and the mass and heat transfer effect is increased.

Owner:BBMG CORP +2

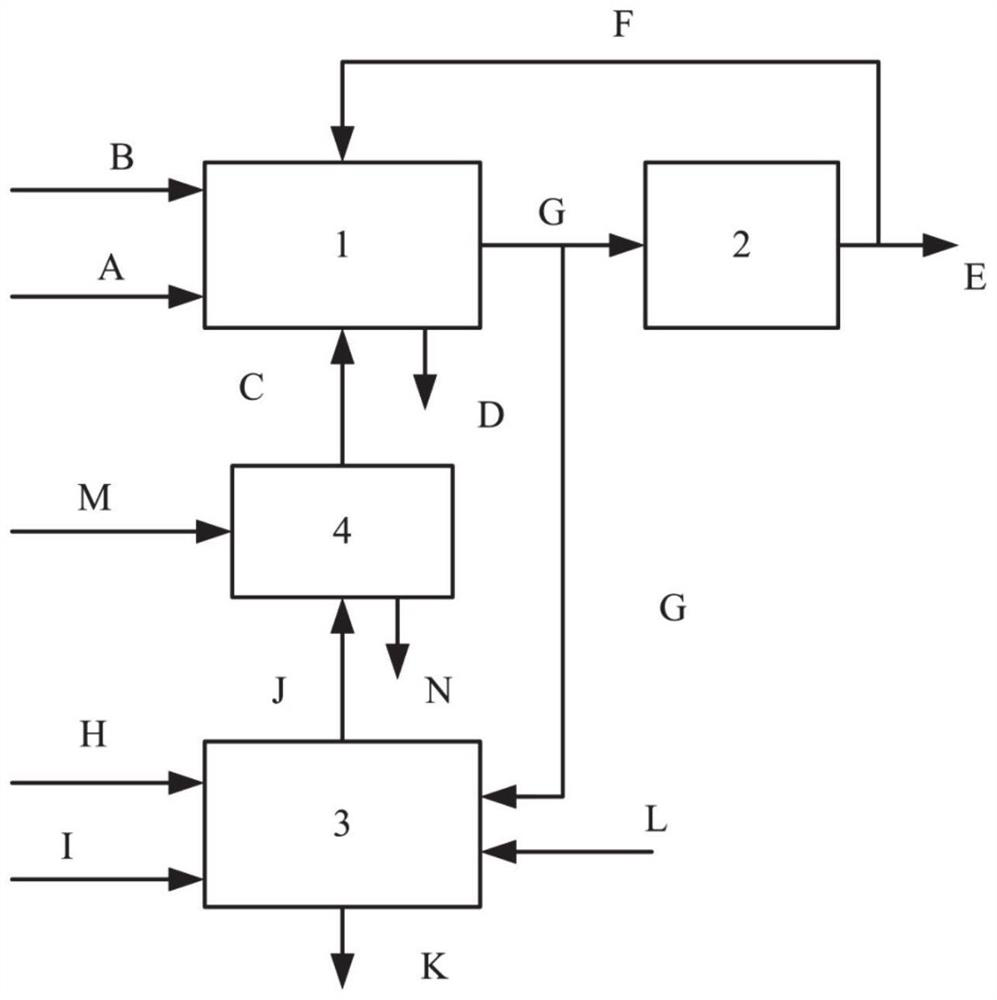

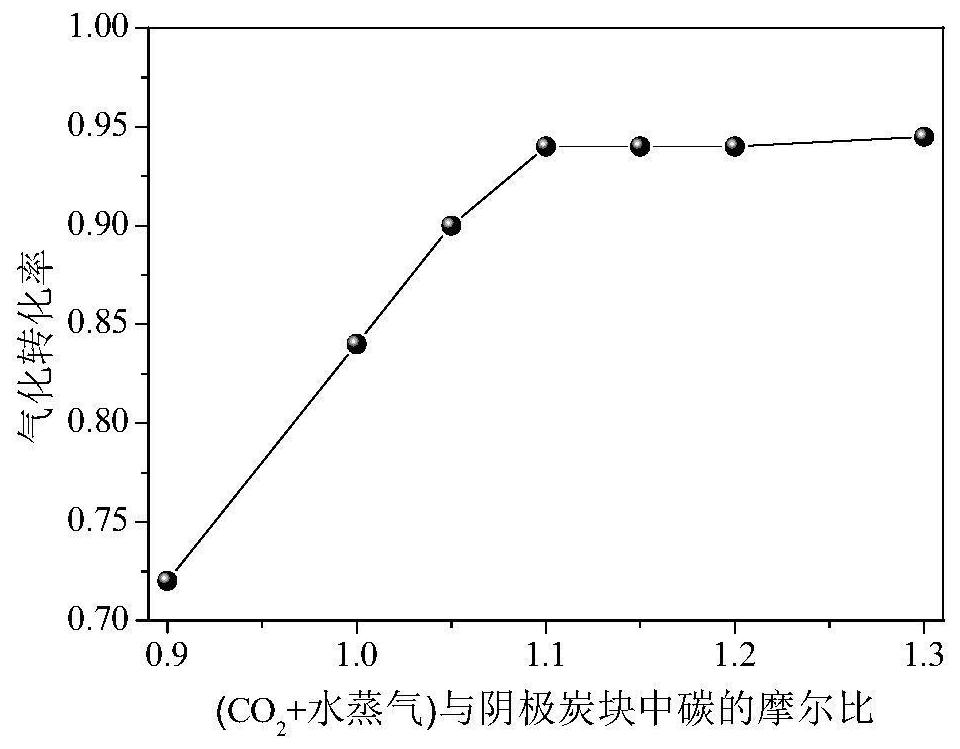

System and method for gasification treatment of waste cathode carbon blocks of aluminum electrolysis cell in cooperation with oxygen-enriched combustion of coal, and application of system

InactiveCN111909728AEasy to igniteReduce usageIndirect carbon-dioxide mitigationGranular/pulverulent flues gasificationHydrogen fluorideAluminum fluoride

The invention relates to a system and a method for gasification treatment of waste cathode carbon blocks of an aluminum electrolysis cell in cooperation with oxygen-enriched combustion of coal, and application of the system. The method comprises the following steps: feeding part of high-temperature flue gas generated by oxygen-enriched combustion of a pulverized coal furnace into a circulating fluidized bed gasification furnace, and performing a gasification reaction on waste cathode carbon blocks of an aluminum electrolysis cell and the high-temperature flue gas in the gasification furnace togenerate gasified gas; adding a calcium-based absorbent into the gasification furnace, wherein hydrogen fluoride is removed, calcium fluoride is generated, and primary fluorine fixing is achieved; feeding the gasified gas containing a small amount of hydrogen fluoride into a circulating fluidized bed secondary fluorine-fixing reactor, adding aluminum oxide particles into the reactor to remove hydrogen fluoride in the gasified gas so as to generate aluminum fluoride, wherein secondary fluorine fixing is achieved; and making the purified gasified gas enter the pulverized coal furnace to be subjected to oxygen-enriched combustion together with pulverized coal to form flue gas containing high-concentration CO2, so that the flue gas can be sealed or recycled. According to the method, waste cathode carbon blocks of an aluminum electrolysis cell are converted into combustible gas, CO2 capture and synergistic removal of various pollutants such as hydrogen fluoride are achieved, coal consumption is reduced, and the method has good application prospects.

Owner:山东魏桥铝电有限公司

Rapid separation method of petroleum oil mud-water mixed liquor

InactiveCN107188342AHigh clarityFast solid-liquid separationTreatment involving filtrationMultistage water/sewage treatmentFlocculationAfter treatment

The invention discloses a rapid separation method of petroleum oil mud-water mixed liquor. The method includes the following steps that acid is added into petroleum oil mud-water mixed liquor at the room temperature to regulate the pH to be acidic, then flocculant is added, stirring is conducted for a reaction, and standing and filtering are conducted. Acidification and flocculation are adopted to achieve automatic solid-liquid separation of the petroleum oil mud-water mixed liquor, and the method has the advantages that solid-liquid separation is fast, treatment agents are cheap and easy to obtain, the disposal capacity is large, the technological process is simple, operability is high, and liquid clarity is high after treatment; besides, some waste acid can be recycled to deal with waste by waste, and thus the treatment concepts of resource conservation and energy conservation and environment protection are realized.

Owner:云南大地绿坤环保科技有限公司

Method for cooperatively treating electrolytic manganese residue by dry method rotary kiln cement plant production line

InactiveCN110986577AReduce the temperatureReduce crustRotary drum furnacesCement productionCement factoryManganese

The invention provides a method for cooperatively treating electrolytic manganese residue by a dry method rotary kiln cement plant production line. The method comprises the steps that in the dry method rotary kiln cement plant production line which operates normally, the electrolytic manganese residue is continuously fed into a kiln tail smoke chamber of dry method rotary kiln production line equipment, meanwhile, oxidizing atmosphere calcinaiton in a rotary kiln and kiln tail draught fan breezing are controlled, and normal calcinaiton of clinkers in the kiln and the stable operation of the rotary kiln cement plant production line are maintained. The method is simple to operate, the investment in technological upgrading is small, the disposal quantity of the manganese residue is greater, no second pollution generates, resource utilization of protogenetic electrolytic manganese residue and stocked or discarded electrolytic manganese residue can be fully achieved, and the protection of asocial ecological environment and a natural environment is facilitated.

Owner:湖南省小尹无忌环境能源科技开发有限公司

Oxygenating device and oxygenating method for increasing waste treatment capacity of rotary kiln

PendingCN109970374AIncrease thermal decomposition exchange timeImprove disposal efficiencyDecompositionOxygen content

The invention provides an oxygenating device for increasing the waste treatment capacity of a rotary kiln. The device comprises a decomposition furnace, the rotary kiln, a tertiary air duct for connecting the head of the rotary kiln with the decomposition furnace, and a miniature rotary kiln arranged in parallel with the tertiary air duct, one end of the miniature rotary kiln is communicated withthe tertiary air duct through a first pipeline, the other end is communicated with the decomposition furnace through a second pipeline, and the first pipeline and / or the second pipeline are / is provided with an oxygen injection inlet; and the first pipeline, communicated with the tertiary air duct of the miniature rotary kiln is provided with a waste filling port. The device realizes the harmless treatment process of solid wastes while producing a cement clinker, improves the filling amount of the wastes, prolongs the heat exchange time, increases the treatment efficiency of the wastes, and canensure the total oxygen content of tertiary hot air of the decomposition furnace.

Owner:北京科太亚洲生态科技股份有限公司

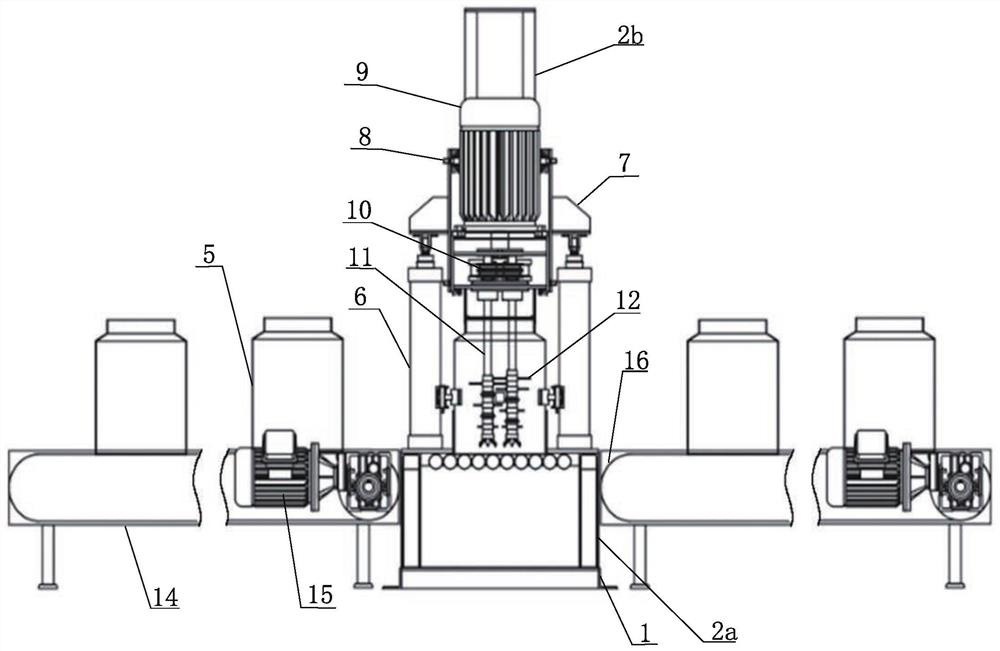

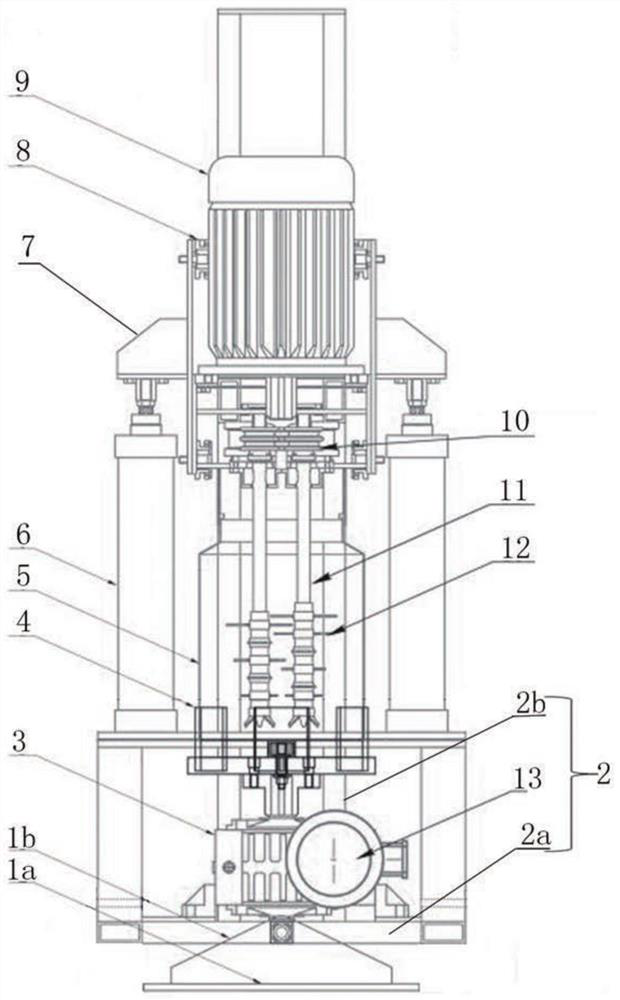

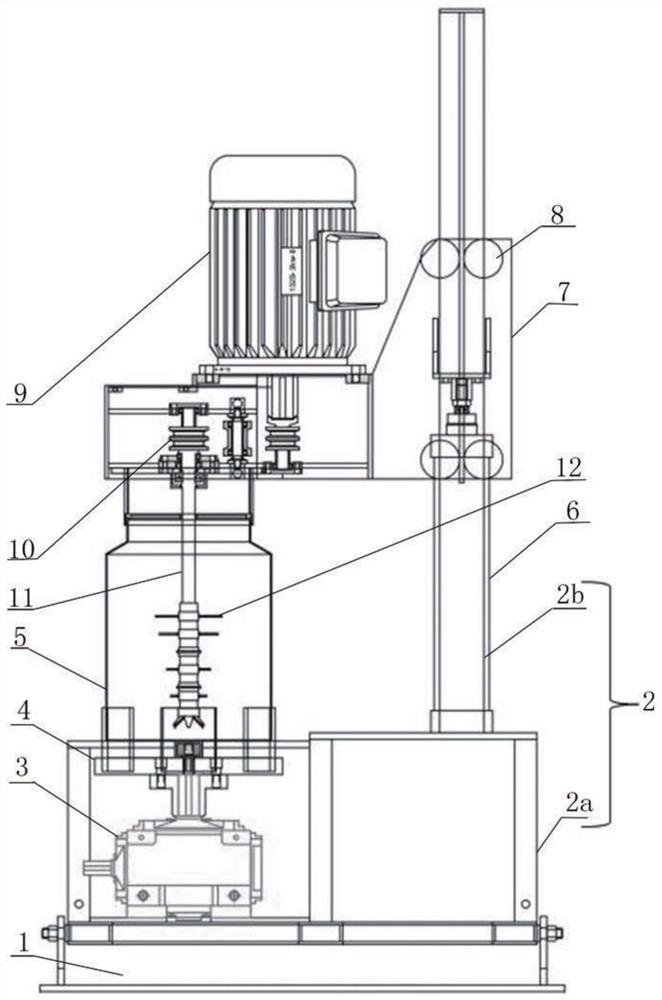

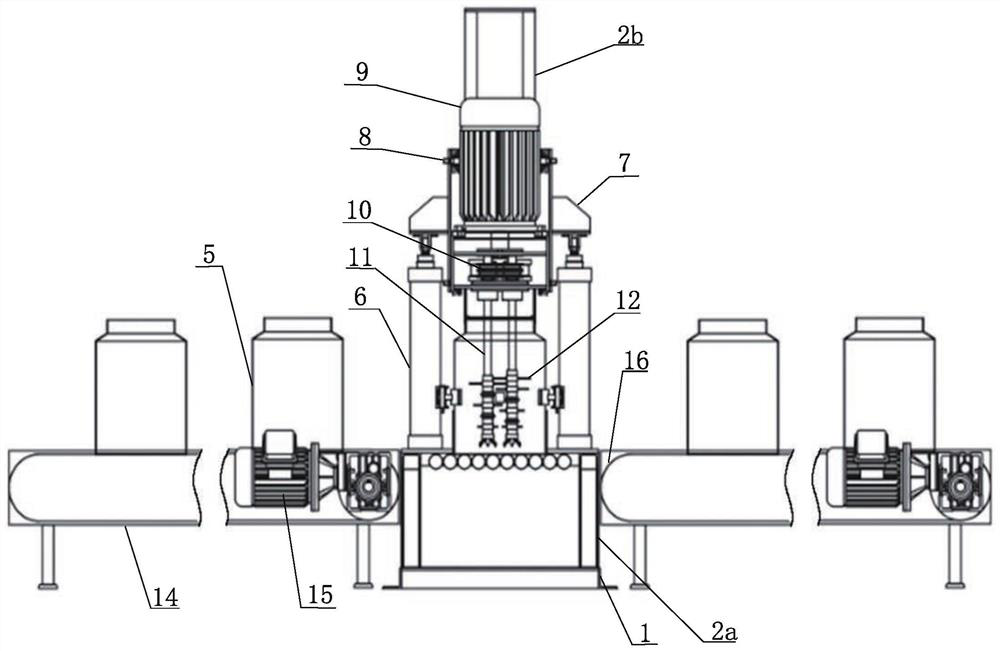

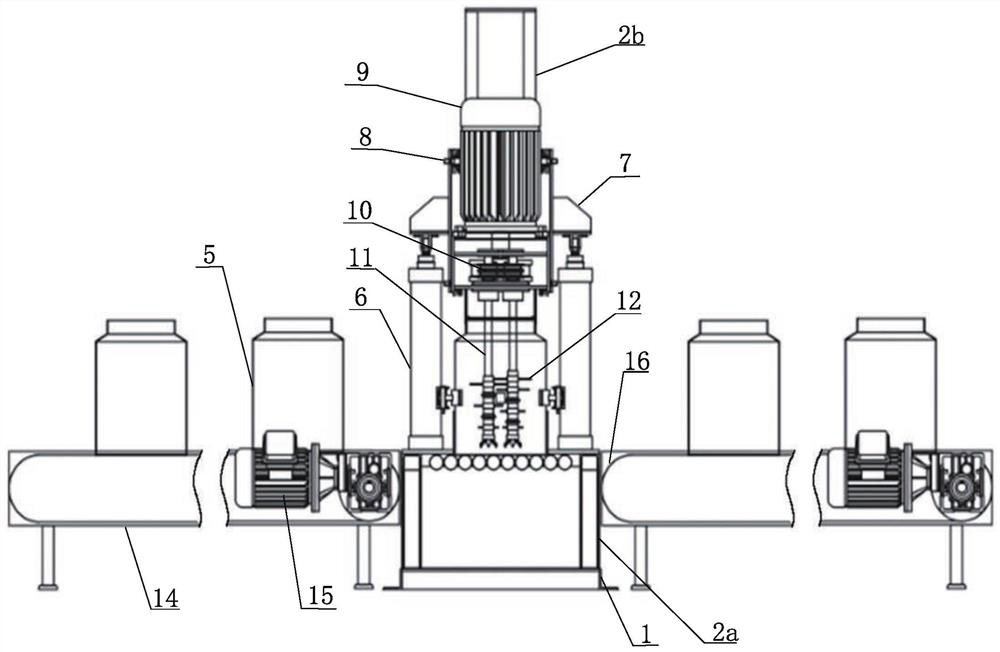

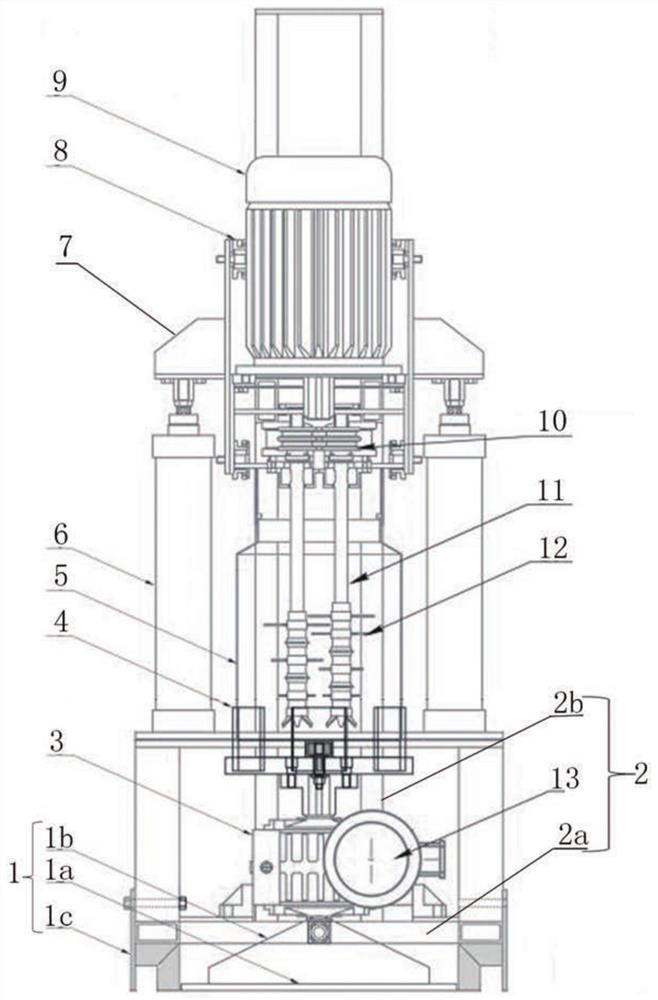

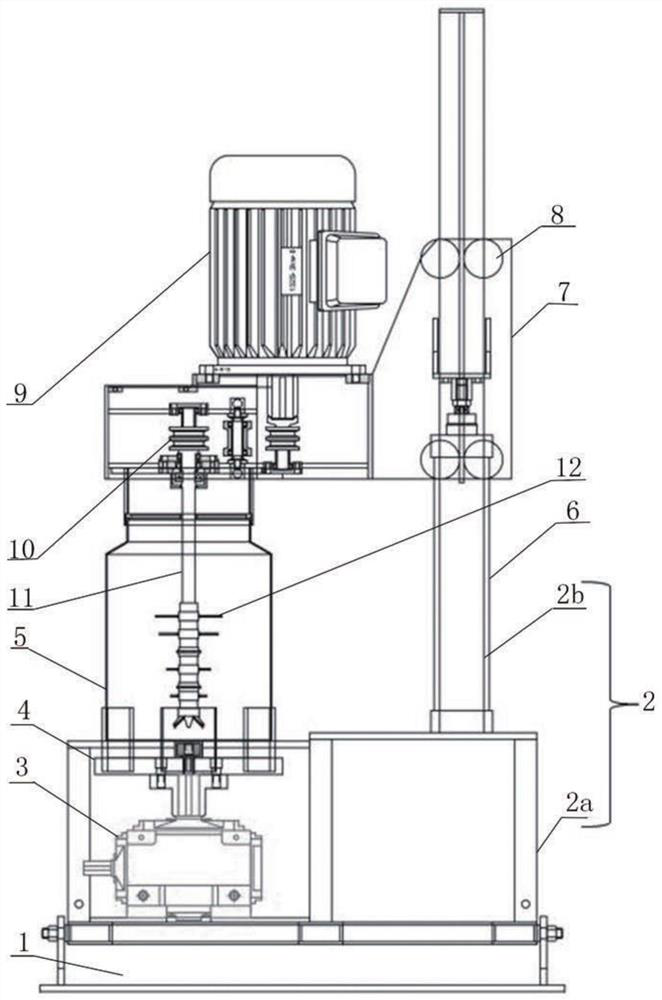

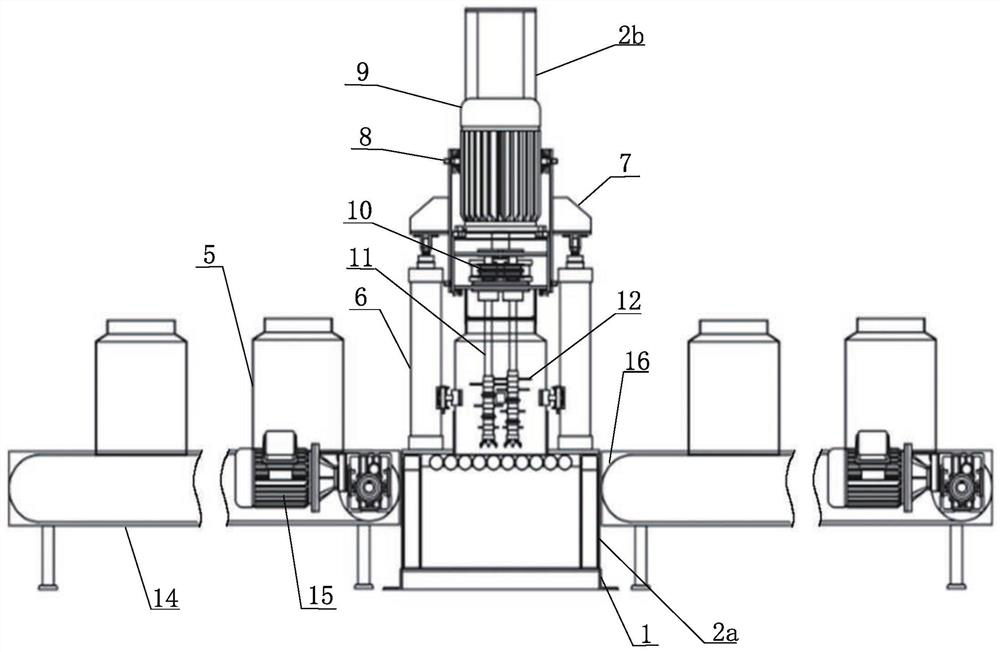

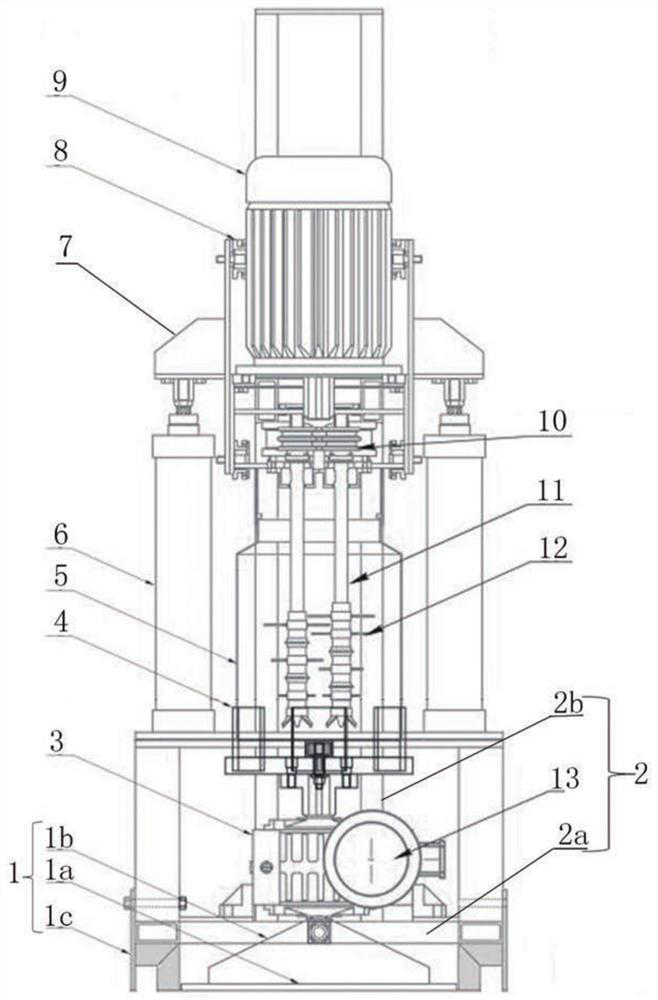

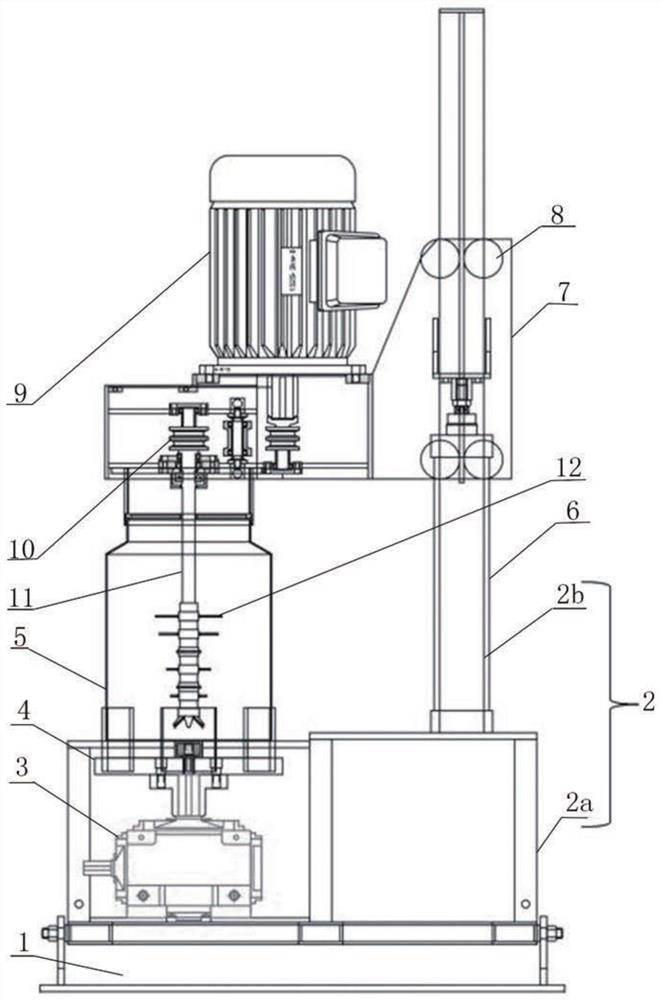

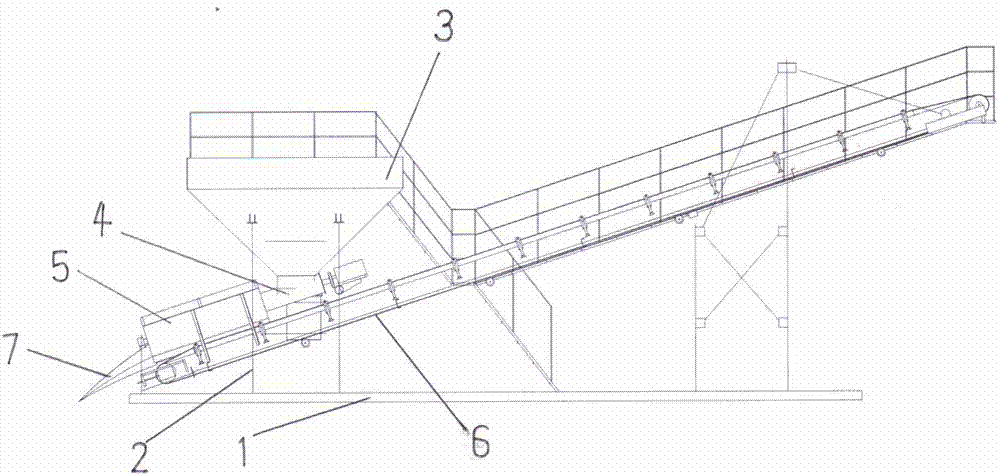

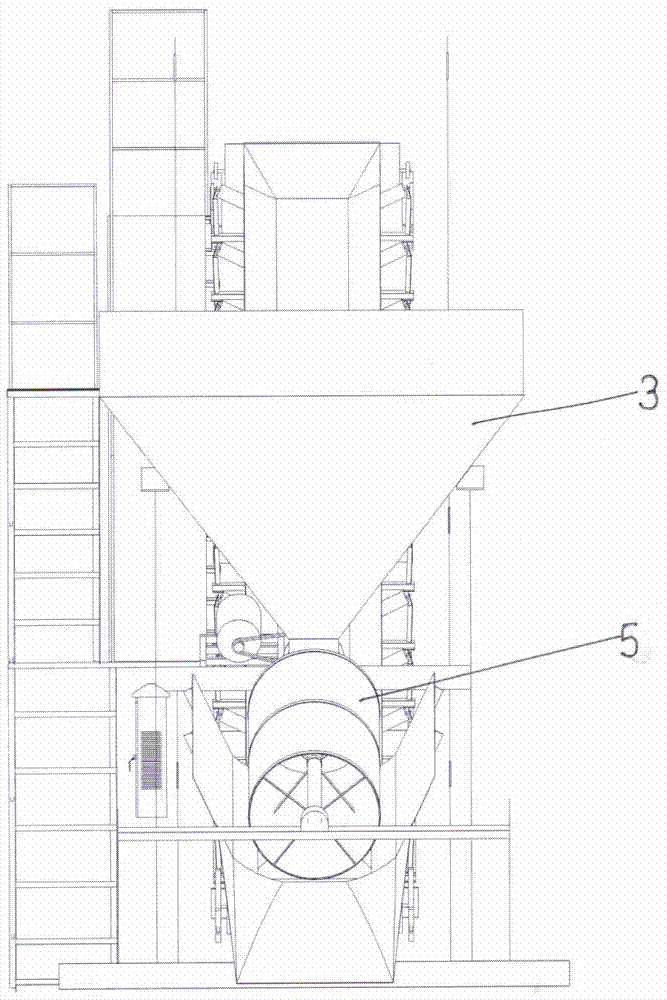

Automatic crushing and slurrying process for kitchen garbage

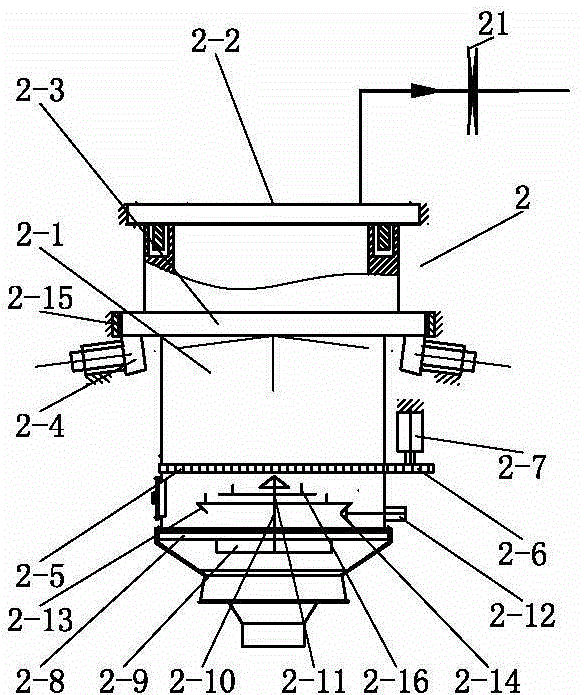

ActiveCN112108245AImprove late shippingImprove efficiencyGrain treatmentsFiberStructural engineering

The invention provides an automatic crushing and slurrying process for kitchen garbage. The process is realized through an automatic kitchen garbage crushing and slurrying system. The system comprisesa first conveying mechanism, a second conveying mechanism and a kitchen garbage crushing and slurrying device, wherein the device comprises a support, a container fixing mechanism, a crushing and slurrying mechanism and a lifting mechanism, and the support comprises a horizontally-arranged support body and a vertical rail; the container fixing mechanism is arranged on the support body to fix a container, and the crushing and slurrying mechanism comprises a fixing frame, a power component and two groups of slurrying cutter shaft assemblies; the fixing frame is arranged on the support body in parallel and is in sliding connection with the rail; the two groups of pulping cutter shaft assemblies are arranged in parallel and can axially rotate relative to the fixing frame, and the power component drives the pulping cutter shaft assemblies to rotate; the lifting mechanism drives the fixing frame to move up and down to crush garbage in the container; and the first conveying mechanism and thesecond conveying mechanism are used for conveying the container. The process has the advantages of assembly line work, large treatment capacity, difficulty in winding of garbage fibers and the like.

Owner:四川省环境政策研究与规划院

A cement kiln capable of gasifying waste outside the kiln and its gasification method

ActiveCN104531218BScale upEasy pretreatmentGasifier feeding meansGasification processes detailsLitterCement kiln

The invention discloses a cement kiln capable of realizing waste gasification outside the same and a gasification method thereof. The cement kiln capable of realizing waste gasification outside the same comprises a cement kiln, wherein a gas inlet of the cement kiln is communicated with a gas outlet of a waste gasification furnace; a feed port of the waste gasification furnace is positioned below an outlet of a waste conveying device; an inlet of the waste conveying device is positioned in a waste material shed; and a waste grabbing device is arranged in the waste material shed. An operating method of the cement kiln capable of realizing waste gasification outside the same is characterized in that heat generated by burning part of waste in the waste gasification furnace is used to heat the rest of the waste in the waste gasification furnace, so that the rest of the waste can be gasified. According to the invention, the defect that domestic waste is high in water content and contains complicated components is overcome, the pretreatment procedure can be greatly simplified, the treatment cost is greatly lowered, and the domestic waste treatment scale is expanded; and furthermore, no auxiliary fuel is needed. Besides, the waste feeding uniformity can be ensured, thereby being beneficial to uniform distribution in the waste gasification furnace.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

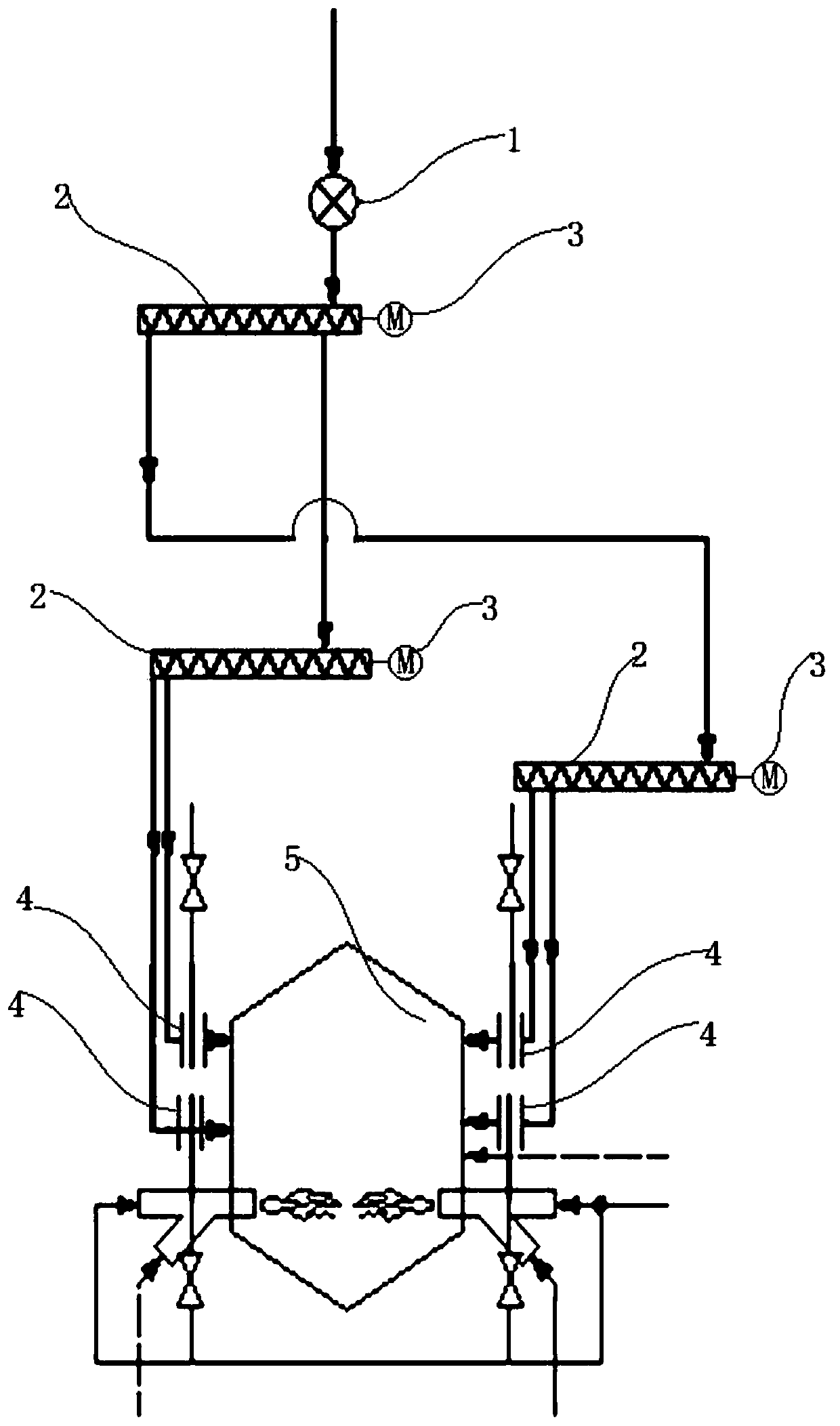

Multi-point feeding system for co-processing rdf in cement kiln

ActiveCN109780559BRealize the function of material distributionLarge amount of disposalIncinerator apparatusRefuse-derived fuelProcess engineering

The invention relates to a multi-point feeding system for coordinated disposal of refuse derived fuel (RDF) by a cement kiln. The multi-point feeding system comprises two or more stages of shaftless screw conveyors; an inlet of only one shaftless screw conveyor of the first stage communicates with a main pipeline, and one or more rotary wind locking valves are arranged on the main pipeline; each shaftless screw conveyor of the previous stage communicates with inlets of two or more corresponding shaftless screw conveyors of the next stage through branch pipelines; each shaftless screw conveyorof the last stage is divided into two or more ways through branch pipelines, and each way is provided with a gate plate valve and communicates with a kiln system; and inlets of the branch pipelines communicate with the shaftless screw conveyors through shell lateral openings connected into the shaftless screw conveyors. According to the multi-point feeding system, an RDF distributing function is achieved, multi-point adjusting feeding is achieved, stable operation of the kiln system is guaranteed, the disposal amount of the RDF is increased, and feeding wind locking is achieved.

Owner:华新环境工程有限公司 +1

A kitchen waste automatic crushing and pulping process

ActiveCN112108245BImprove efficiencyPulping is easy and sufficientGrain treatmentsProcess engineeringMechanical engineering

The invention provides an automatic crushing and pulping process of kitchen waste. The process is realized by an automatic kitchen waste crushing and pulping system, and the system includes a first conveying mechanism, a second conveying mechanism and a kitchen waste crushing and pulping device. The device includes a support, a container fixing mechanism, a crushing and pulping mechanism and a lifting mechanism. The bracket includes a horizontal bracket body and a vertical track; the container fixing mechanism is set on the bracket body to fix the container; the crushing and pulping mechanism includes a fixing bracket, a power part, and two sets of pulping knife shaft assemblies; the fixing bracket is arranged in parallel on the bracket It is above the body and is slidingly connected with the track; two sets of pulping knife shaft assemblies are arranged side by side and can rotate axially relative to the fixed frame, and the power part drives the pulping knife shaft assembly to rotate; the lifting mechanism drives the fixed frame to move up and down to crush the garbage in the container . The first and second conveying mechanisms are used for conveying containers. The invention has the advantages of assembly line operation, large processing capacity, and difficult entanglement of garbage fibers.

Owner:四川省环境政策研究与规划院

Multi-point feeding system for coordinated disposal of refuse derived fuel (RDF) by cement kiln

ActiveCN109780559ARealize the function of material distributionLarge amount of disposalIncinerator apparatusRefuse-derived fuelCement kiln

The invention relates to a multi-point feeding system for coordinated disposal of refuse derived fuel (RDF) by a cement kiln. The multi-point feeding system comprises two or more stages of shaftless screw conveyors; an inlet of only one shaftless screw conveyor of the first stage communicates with a main pipeline, and one or more rotary wind locking valves are arranged on the main pipeline; each shaftless screw conveyor of the previous stage communicates with inlets of two or more corresponding shaftless screw conveyors of the next stage through branch pipelines; each shaftless screw conveyorof the last stage is divided into two or more ways through branch pipelines, and each way is provided with a gate plate valve and communicates with a kiln system; and inlets of the branch pipelines communicate with the shaftless screw conveyors through shell lateral openings connected into the shaftless screw conveyors. According to the multi-point feeding system, an RDF distributing function is achieved, multi-point adjusting feeding is achieved, stable operation of the kiln system is guaranteed, the disposal amount of the RDF is increased, and feeding wind locking is achieved.

Owner:华新环境工程有限公司 +1

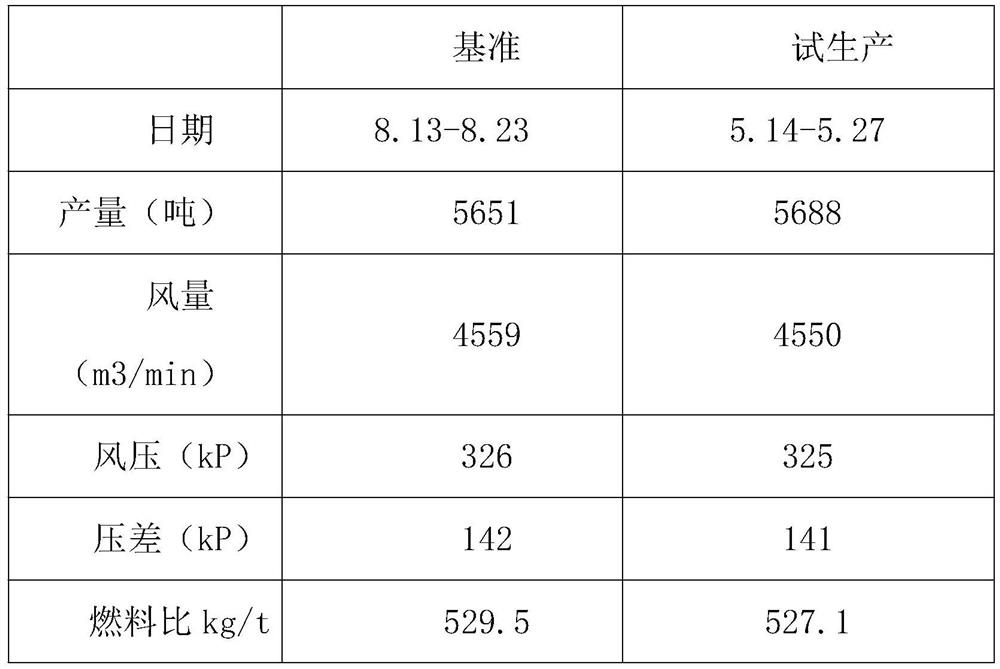

Novel process method of co-processing iron hazardous waste briquettes by blast furnace

InactiveCN113881821ALarge amount of disposalReduce investmentBlast furnace detailsProcess efficiency improvementProcess engineeringBriquette

The invention discloses a novel process method of co-processing iron hazardous waste briquettes by a blast furnace. The novel process method comprises the following steps of: firstly, pretreating iron hazardous wastes hw49, hw08 and hw09, and mixing and briquetting the iron hazardous wastes hw49, hw08 and hw09 to enable the iron hazardous wastes meet the use requirements; and secondly, mixing the pretreated iron hazardous wastes hw49, hw08 and hw09 with ironmaking raw materials, and finally enabling a mixture to enter the blast furnace. According to the novel process method of co-processing the iron hazardous waste briquettes by the blast furnace, an original blast furnace process does not need to be changed, the treatment process technology and operation requirements are simple, and the novel process method has the advantages of thorough combustion and processing, low processing cost and simple process and operation.

Owner:浙江省工业设计研究院有限公司

Method for processing paint slag muck by separating slag muck from water

ActiveCN102580389BLarge amount of disposalReduce consumptionMoving filtering element filtersLacquerTransverse groove

Owner:BEIJING BBMG BEISHUI ENVIROMENTAL TECH CO LTD

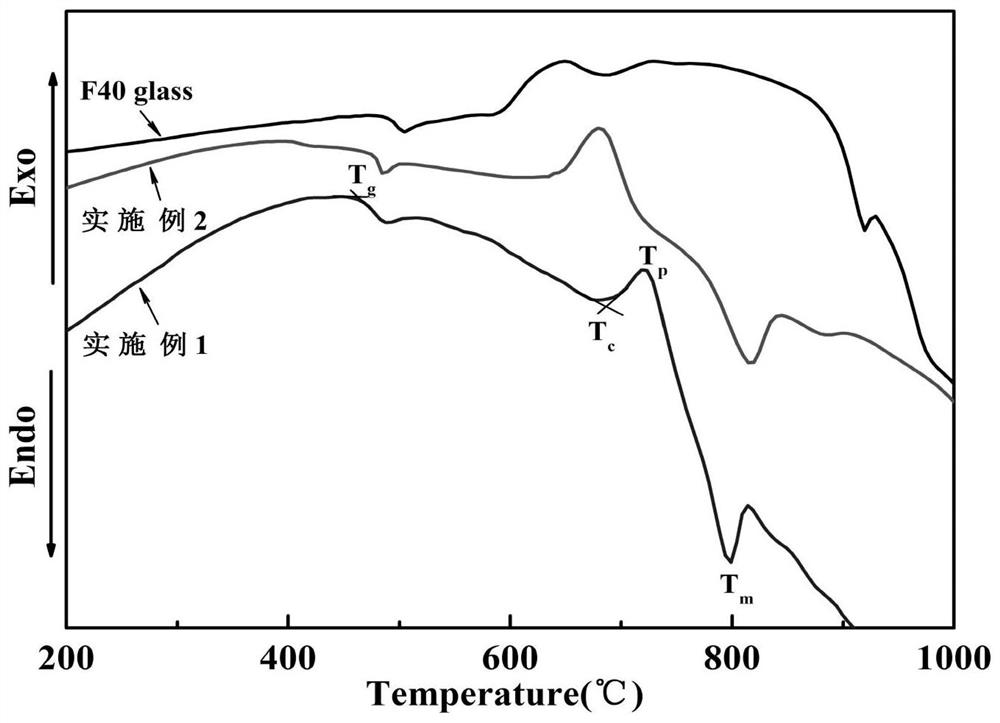

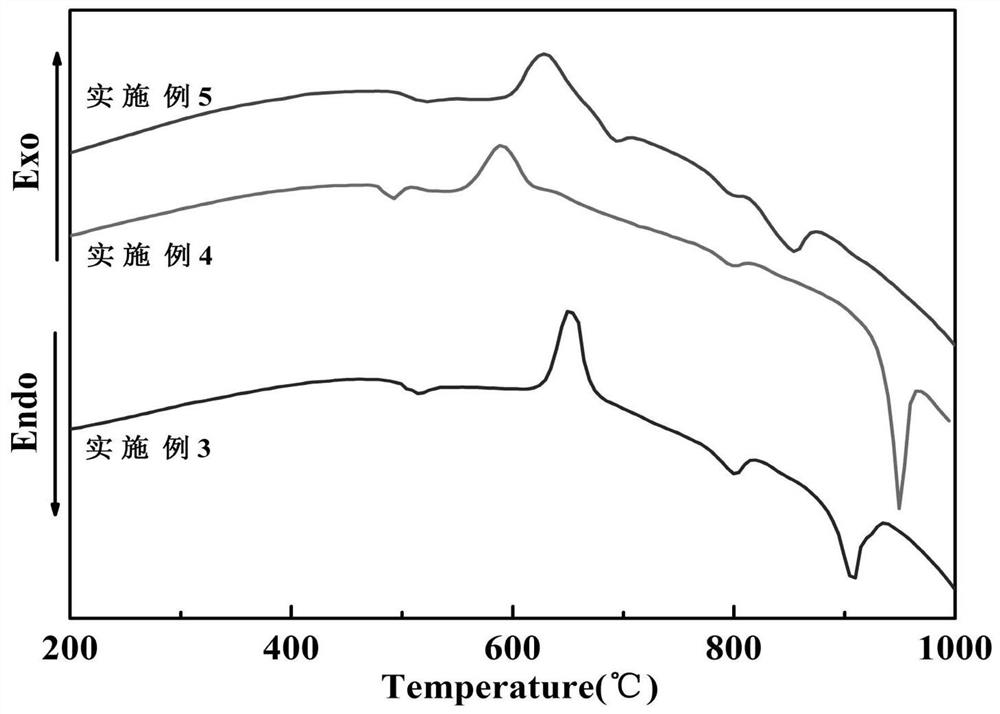

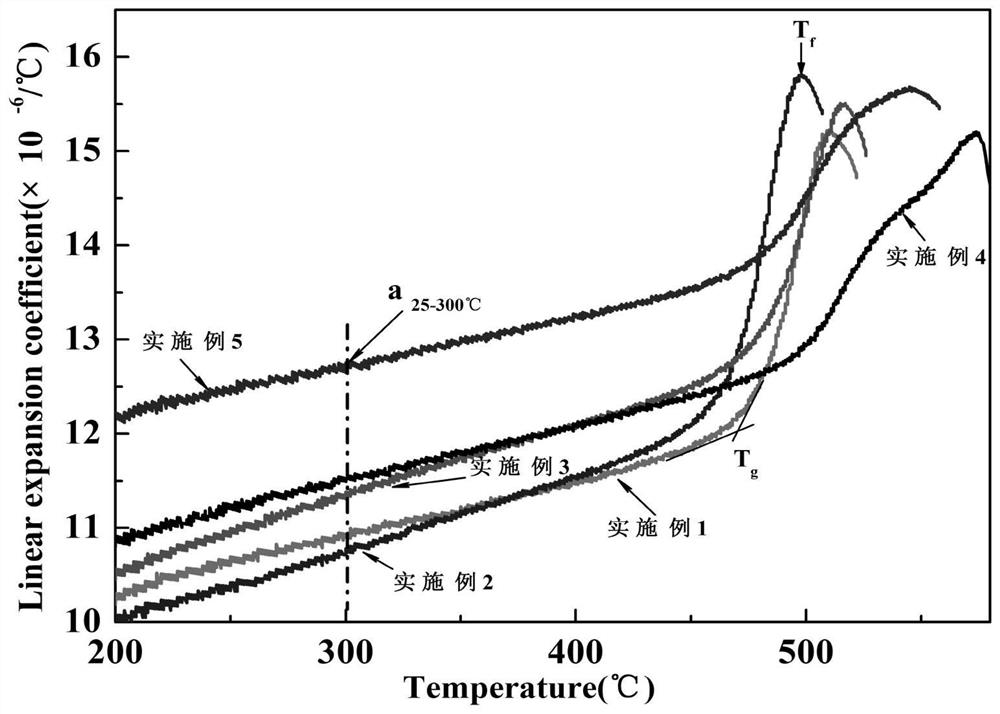

Glass solidified body synergistically solidifying SrF2 and high-sodium high-iron waste and preparation method thereof

ActiveCN111916246AGood chemical stabilityImprove thermal stabilityRadioactive decontaminationWaste treatmentWaste material

The invention belongs to the technical field of solid waste treatment, and particularly relates to a synergistic solidifying method for SrF2 solid waste and high-sodium high-iron solid waste. The method includes mixing SrF2 solid waste and high-sodium high-iron solid waste, melting, forming and annealing to obtain a glass solidified body. In the high-sodium high-iron solid waste, the sum of mole percentages of the Na2O and Fe2O3 components is in the range of 58-79 mol%. The invention provides an innovative idea of combined treatment of the SrF2 solid waste and the high-sodium high-iron solid waste for the first time, and finds that the combined treatment of the SrF2 solid waste and the high-sodium high-iron solid waste can generate a synergistic effect, the solid waste treatment capacity can be improved, the chemical and thermal stability of the glass solidified body can be improved, and in addition, F can be synchronously solidified. According to the technical scheme, waste is treatedwith waste, and in addition, unexpected effects of improving the chemical and thermal stability of a solidified body, achieving F synchronous curing which is difficult to achieve in the industry andthe like can be achieved synergistically. The technical scheme provided by the invention can be applied to combined treatment of SrF2 and high-sodium high-iron radioactive solid waste.

Owner:JINGDEZHEN CERAMIC INSTITUTE

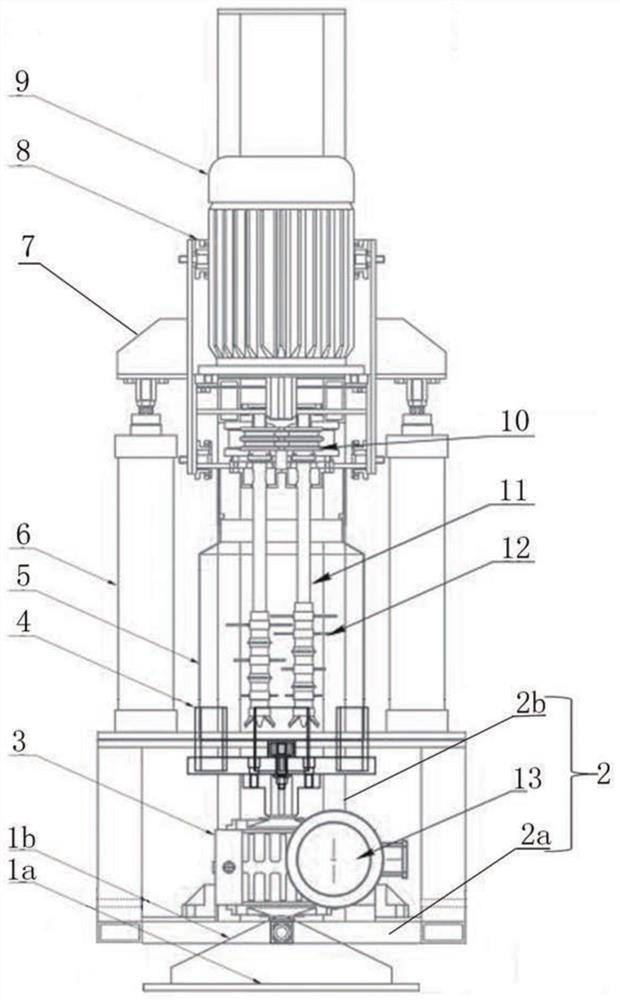

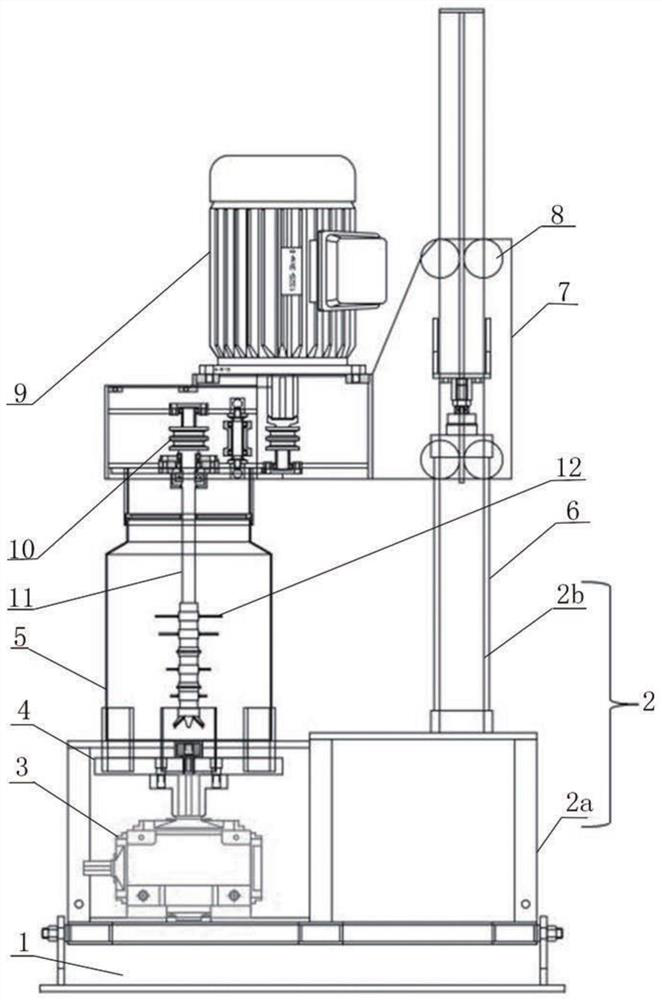

Automatic crushing and pulping system for kitchen waste

ActiveCN112090548BImprove efficiencyPulping is easy and sufficientGrain treatmentsStructural engineeringTransfer mechanism

The invention provides an automatic crushing and pulping system for kitchen waste. The system includes a first transmission mechanism, a second transmission mechanism and a food waste crushing and pulping device. The device includes a support, a container fixing mechanism, a crushing and pulping mechanism and a lifting mechanism. The bracket includes a horizontal bracket body and a vertical track; the container fixing mechanism is arranged on the bracket body to fix the container; the crushing and pulping mechanism includes a fixing frame, a power part, and two sets of pulping knife shaft assemblies; the fixing frame is arranged in parallel On the bracket body and slidingly connected with the track; two sets of pulping knife shaft assemblies are arranged side by side and can rotate axially relative to the fixed frame, and the power part drives the pulping knife shaft assembly to rotate; the lifting mechanism drives the fixed frame to move up and down to the container Garbage is shredded. The first and second conveying mechanisms are capable of transporting the containers to the container holding mechanism and transported away after processing. The invention has the advantages of assembly line operation, large processing capacity, and difficult entanglement of garbage fibers.

Owner:四川省环境政策研究与规划院

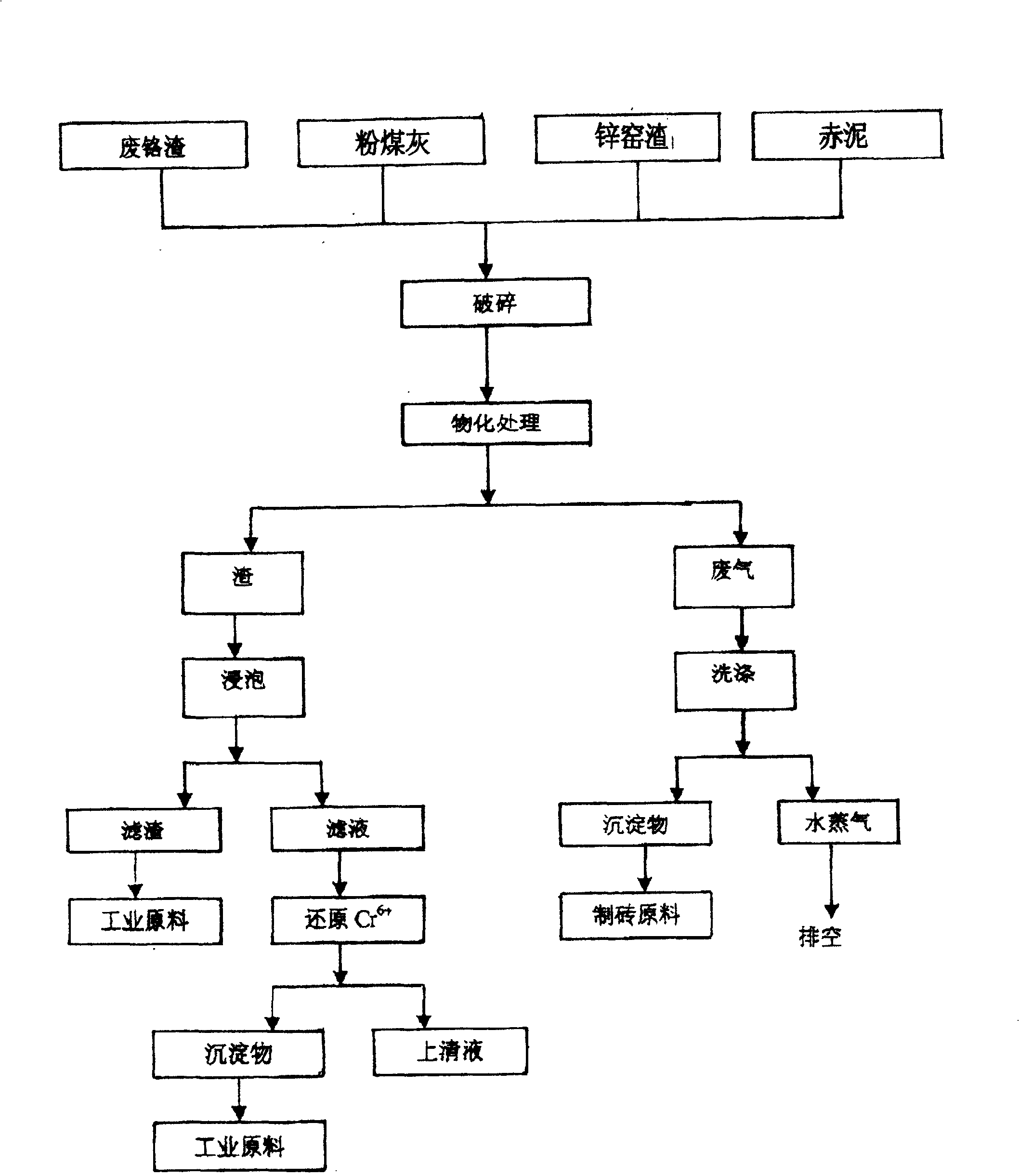

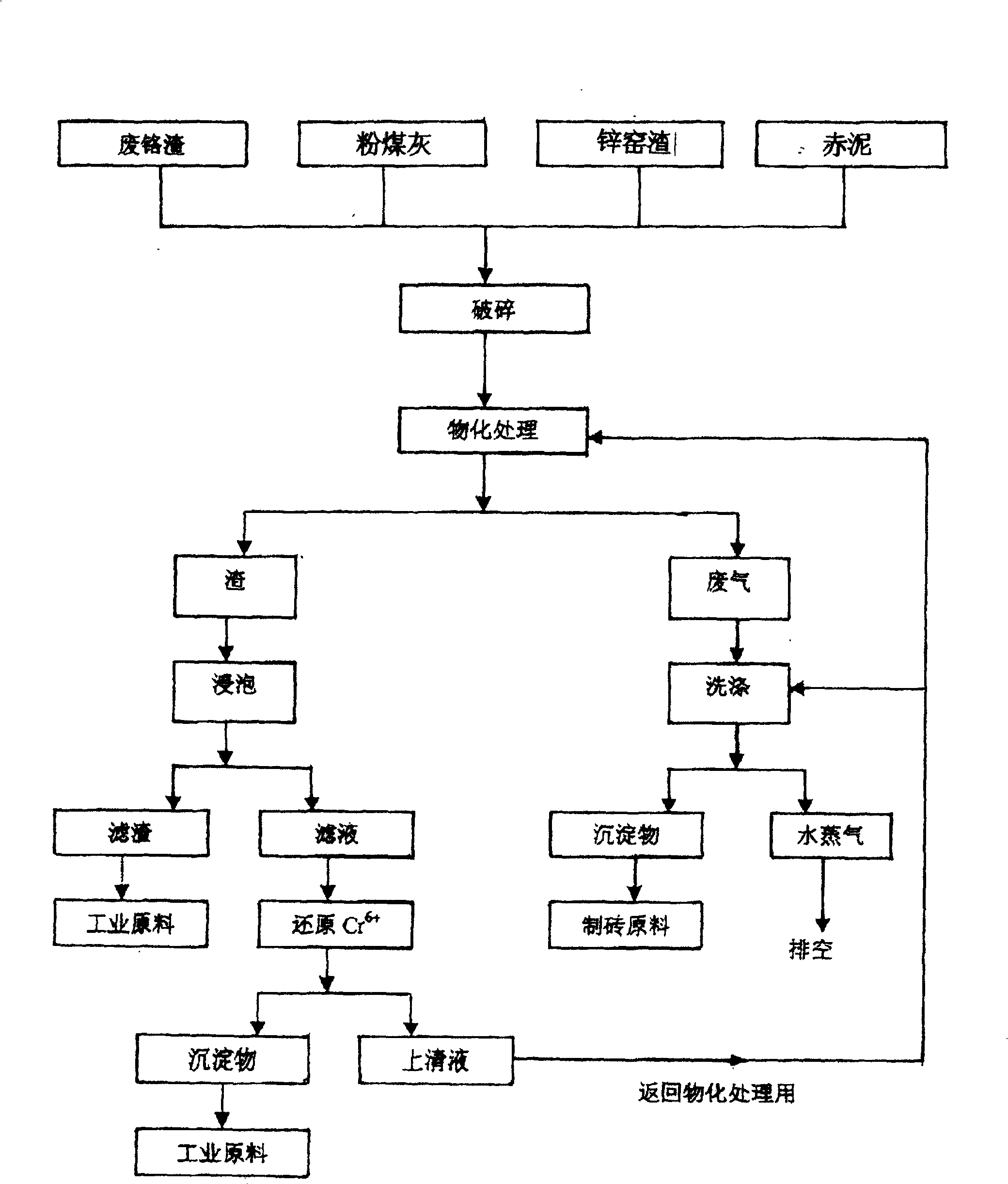

Harmless treatment process for waste chromium slag

InactiveCN100413607CNo emissionsSafe and environmentally friendly entrySolid waste disposalPresent methodWater vapor

The invention relates to an innocent treatment method of waste chromic slag, which comprises: mixing the waste chromic slag, coal ash, zinc stove slag, and red mud at the weight percents of waste chromic slag in 40-45%, the coal ash in 10-15%, the zinc stove slag in 10-15% and the red mud in 28-30% to be broken into 50-80 items and deoxidized sintered in the sintering furnace at the temperature of 1000-1100Deg. C; the sintered mixture after cooled for 2-3 hours is dipped for 20-26 hours to filter the slag via filter cloth, while the filter solution uses FeSO4 as reducing agent whose amount is 14-16 times of Cr6+ of waste chromic slag, therefore, the filter solution can process reducing reaction at the pH valve of 8-8.5; the waste gas generated in sintering is fed into washing tower to be washed, and the generated water vapor is all discharged. The invention can overcome the defect of present method which can not process innocent treatment, to reduce the nocuous elements of waste chromic slag and avoid the environment pollution.

Owner:赵建国

Automatic crushing and slurrying system for kitchen garbage

ActiveCN112090548AImprove efficiencyPulping is easy and sufficientGrain treatmentsAgricultural engineeringStructural engineering

The invention provides an automatic crushing and slurrying system for kitchen garbage. The automatic crushing and slurrying system comprises a first conveying mechanism, a second conveying mechanism and a kitchen waste crushing and slurrying device, the kitchen waste crushing and slurrying device comprises a support, a container fixing mechanism, a crushing and slurrying mechanism and a lifting mechanism, the support comprises a horizontally-arranged support body and a vertical rail, the container fixing mechanism is arranged on the support body so as to carry out fixation on containers, the crushing and slurrying mechanism comprises a fixing frame, a power part and two groups of slurrying cutter shaft assemblies, the fixing frame is arranged on the support body in parallel and is connected with the rail in a sliding mode, the two groups of slurrying cutter shaft assemblies are arranged in parallel and can axially rotate relative to the fixing frame, the power part drives the slurryingcutter shaft assemblies to rotate, the lifting mechanism drives the fixing frame to move up and down to crush garbage in the containers, and the first conveying mechanism and the second conveying mechanism can convey the containers to the container fixing mechanism and carry away the containers after treatment. The automatic crushing and slurrying system has the advantages of assembly line work,large treatment capacity, difficulty in winding of garbage fibers and the like.

Owner:四川省环境政策研究与规划院

Method for using aluminum ash as fuel, correction material and sintering aid for dry cement production

ActiveCN114524630ALarge amount of disposalPromote solid wasteCement productionCombustorClinker (waste)

A method for using aluminum ash as fuel, correction material and sintering aid for dry-process cement production comprises the following steps: mixing aluminum ash and a catalytic combustion accelerant in a conveying pipeline or a combustor, spraying the mixture into a kiln tail decomposing furnace and / or a kiln head rotary kiln of a dry-process cement production line through an injection pipe or the combustor, under the catalytic activation action of a catalytic combustion accelerant, the raw materials are quickly burnt out in a high-temperature environment and under a suspension condition, heat energy generated by combustion is directly supplied to decomposition of calcium carbonate and / or sintering of clinker, and activated aluminum oxide generated by combustion is directly used as an aluminum correction raw material of a raw material; halides contained in the aluminum ash, other raw materials and catalytic elements after acting directly form a sintering aid for raw material calcination and / or clinker calcination. By utilizing the method, the aluminum ash can be effectively and comprehensively utilized, so that the cost for producing original combustion materials from cement can be reduced, and hazardous wastes can be co-processed by utilizing a cement kiln to protect the ecological environment; the method is simple and convenient to operate, easy to implement and low in investment, and various aluminum ashes can be consumed in a large-scale manner.

Owner:长沙紫宸科技开发有限公司

Electric intelligentized sand-stone separator

The invention discloses an electric intelligentized sand-stone separator. A bracket is installed on a movable base, an aggregate collecting bin is installed on the bracket, an outlet of the aggregate collecting bin communicates with an inlet of an aggregate separator under the aggregate collecting bin, the aggregate separator adopts spiral blades to stir and push materials, an outlet of the aggregate separator is connected with a bucket type filter screen, a conveying belt is arranged below a filter screen body of the bucket type filter screen, and a discharging plate is arranged at the rear end of the bucket type filter screen. The electric intelligentized sand-stone separator can effectively separate out aggregate exceeding the granular composition requirement and meanwhile has the advantages of being large in processed volume, convenient and fast in granular composition selection, high in overall mobility and the like, and the requirements of a pre-mixed mortar production base for aggregate good in granular composition are greatly met. Through the electric intelligentized sand-stone separator, the separation efficiency of the aggregate, good in granular composition, of to-be-separated aggregate is improved, the large-volume processing capacity is high, the sand-stone separator is convenient, quick and safe, sand and stone are thoroughly separated in one time, and the quality of the separated aggregate is fully ensured.

Owner:NANTONG DONGTENG SPECIAL SYNTHETIC RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com