System and method for gasification treatment of waste cathode carbon blocks of aluminum electrolysis cell in cooperation with oxygen-enriched combustion of coal, and application of system

The invention relates to a technology for waste and cathode carbon blocks of aluminum electrolysis cells, which is applied in the directions of combustion method, combustion using block fuel and gaseous fuel, chemical instruments and methods, etc., and can solve the problems such as the limitation of the addition amount of waste cathode carbon blocks of aluminum electrolysis cells, etc. To achieve the effect of easy promotion, simple method and improved economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

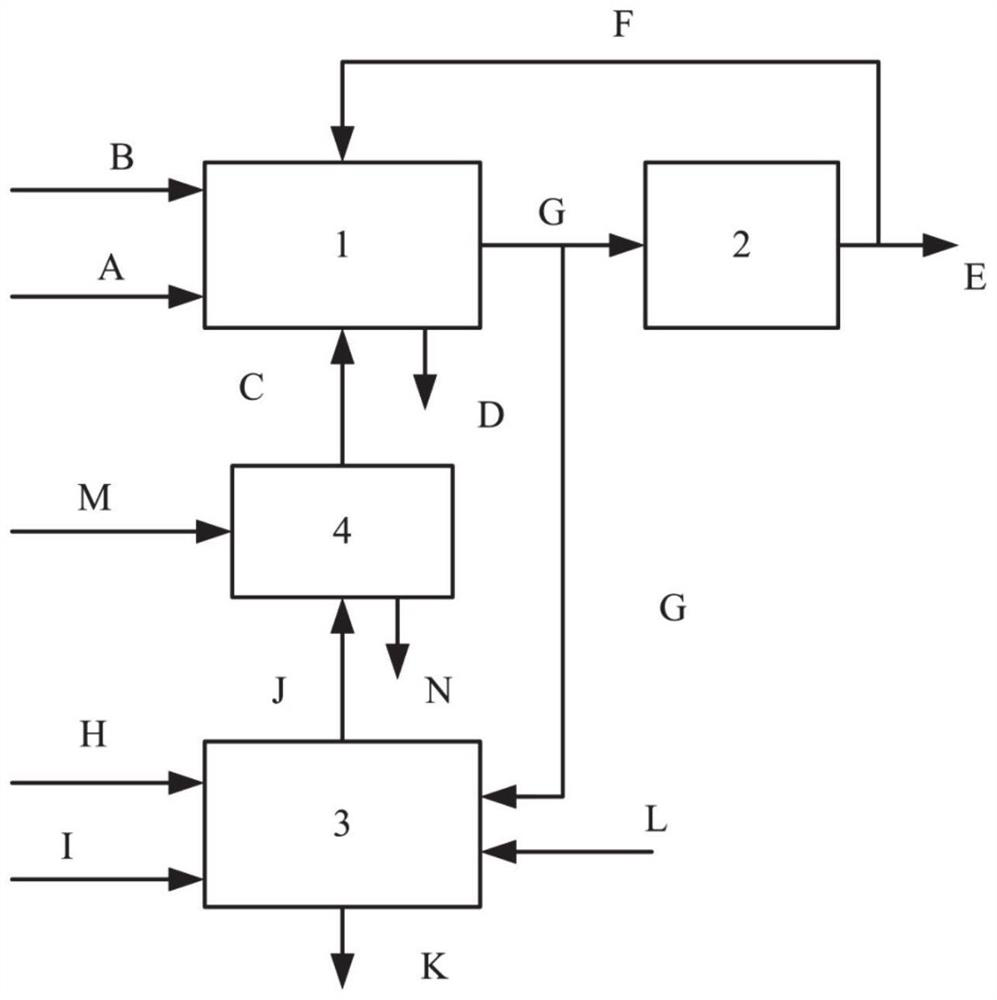

[0051] Such as figure 1 As shown, the system mainly includes the following equipment: pulverized coal furnace 1, denitrification / dust removal / desulfurization treatment device 2 for pulverized coal furnace oxygen-enriched combustion flue gas, circulating fluidized bed gasifier 3 and circulating fluidized bed secondary fluorine fixation Reactor 4. The pulverized coal A first enters the pulverized coal furnace 1, and is combusted with the purified gasification gas C from the circulating fluidized bed secondary fluorine fixation reactor 4 under the combustion support of oxygen B to form a 2 , a small amount of water vapor flue gas, after the flue gas denitrification / dust removal / desulfurization treatment device 2 becomes high concentration CO 2 Flue gas E(CO 2 The volume concentration is greater than 95%), which can be stored or resourced after being condensed and liquefied. In order to reduce the temperature of coal in oxygen-enriched combustion, part of the flue gas E is extr...

Embodiment 2

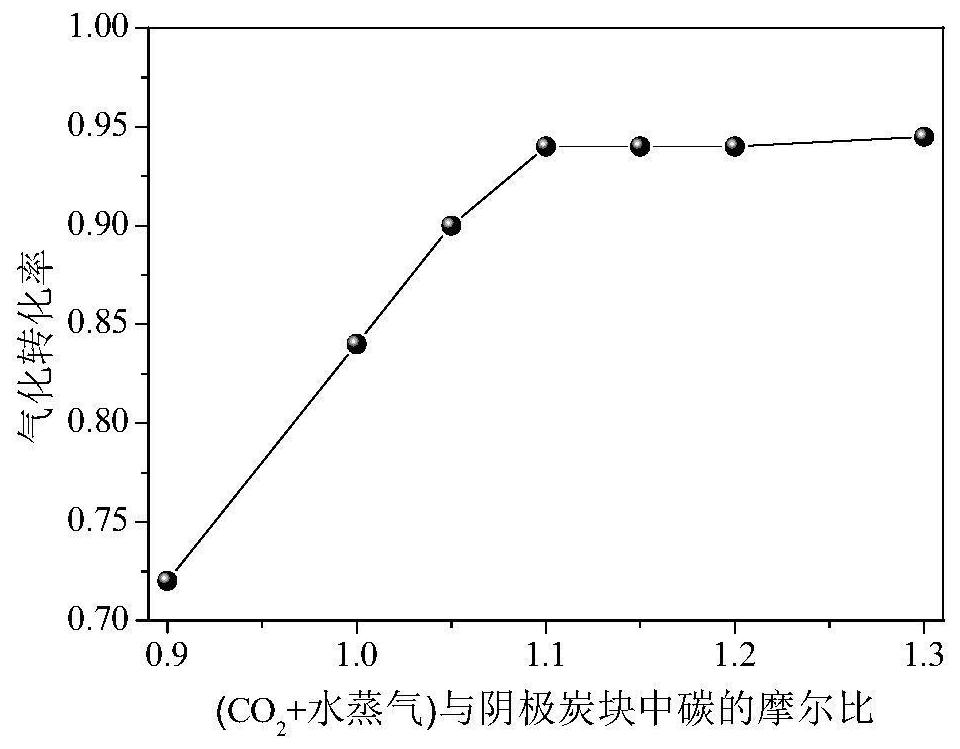

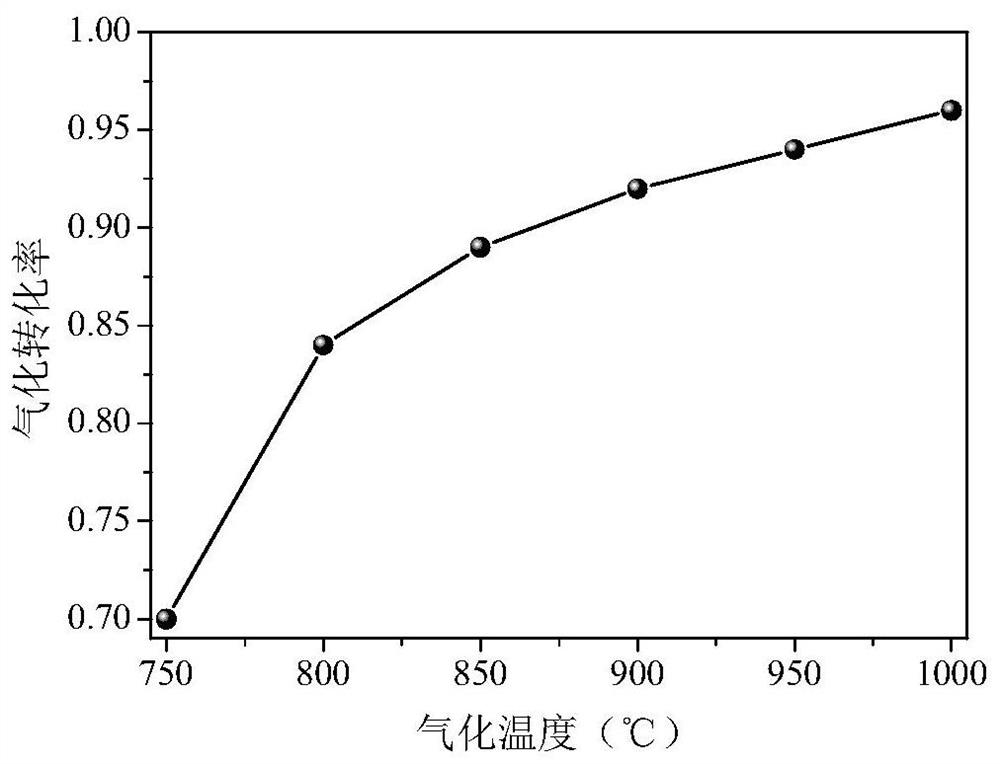

[0058] The gasification characteristics and hydrogen fluoride removal characteristics of waste cathode carbon blocks and oxygen-enriched combustion flue gas of aluminum electrolytic cell were studied experimentally in a bubbling fluidized bed reactor. The fluorine content of the waste cathode carbon block of the aluminum electrolytic cell is about 12.55%, the carbon content is about 47.62%, and the ash content is about 46.33%. The inner diameter of the bubbling fluidized bed reactor is 32 mm, the height is 900 mm, and the length of the constant temperature zone is 200 mm. In simulated flue gas (CO 2 +H 2 The effect of the molar ratio of O) to carbon in the waste cathode carbon block of the electrolyzer on the gasification conversion rate of the waste cathode carbon block. The reaction conditions are as follows: simulated CO in flue gas 2 The volume fraction is 90%, the water vapor is 10%, the total flow of flue gas into the fluidized bed is 2L / min, the reaction time is 20mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com