Cement kiln capable of realizing waste gasification outside same and gasification method thereof

A cement kiln and garbage technology, applied in the direction of gasification process, combustion method, fixed bed gasification, etc., can solve the problems of high moisture content and complex composition of domestic garbage, and achieve the goal of overcoming high moisture content, expanding scale, and simplifying pretreatment Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

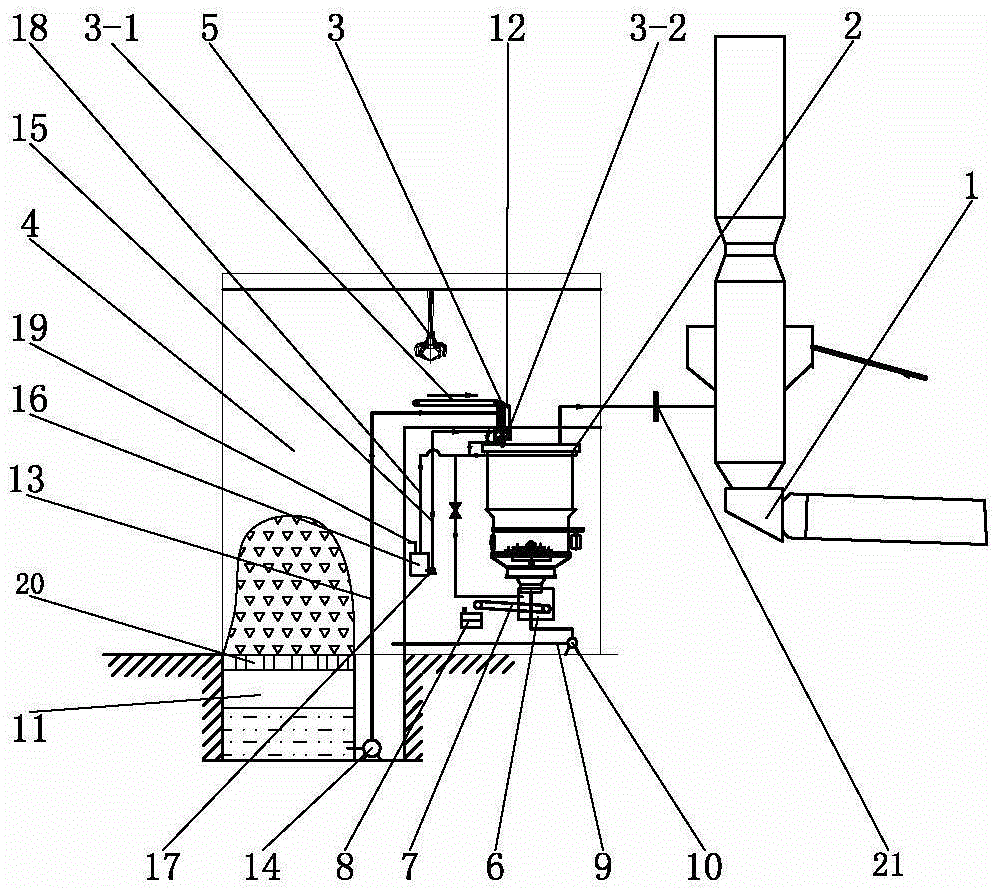

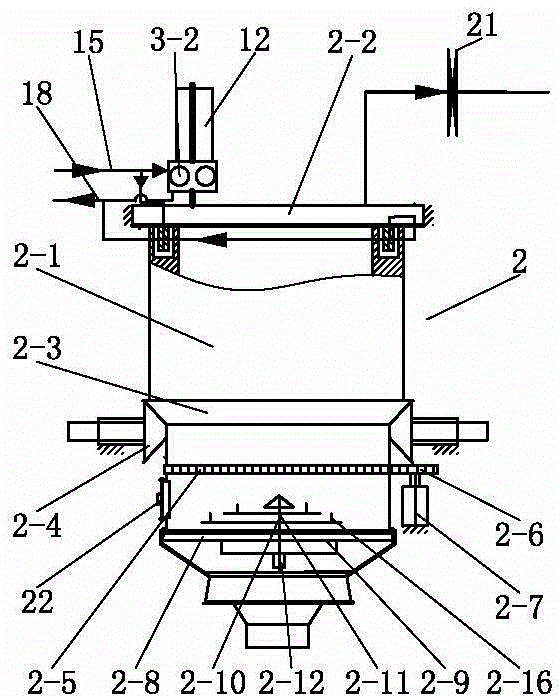

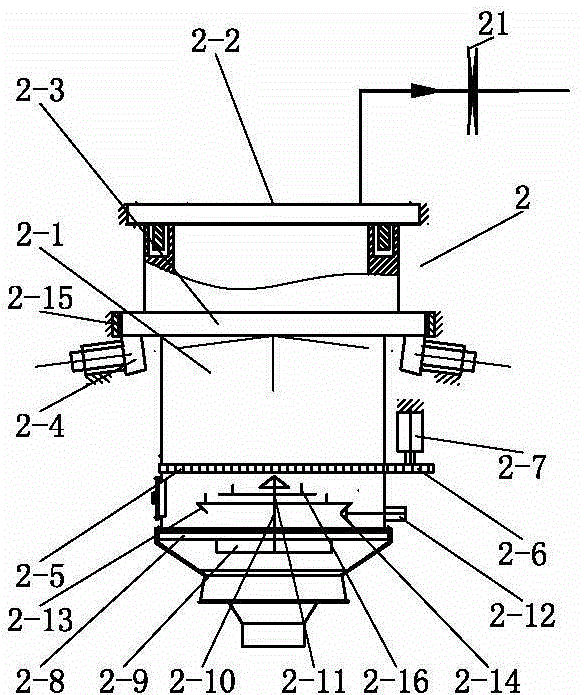

[0033] like Figure 1 to Figure 3 As shown, the present embodiment provides a cement kiln capable of gasifying waste outside the kiln, including a cement kiln 1, the air inlet of the cement kiln 1 is communicated with the air outlet of the waste gasifier 2, and the waste The feeding port of the gasifier 2 is located below the outlet of the garbage conveying device 3 , and the inlet of the garbage conveying device 3 is located in the garbage shed 4 , and a garbage grab device 5 is arranged in the garbage shed 4 .

[0034] In this embodiment, because the air inlet of the cement kiln is connected with the air outlet of the garbage gasifier, the feed inlet of the garbage gasifier is located below the outlet of the garbage conveying device, and the inlet of the garbage conveying device is located at In the garbage shed, the technical means of the garbage grab device are installed in the garbage shed, so the defects of high moisture content and complex composition of domestic garbag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com