Patents

Literature

33results about How to "Easy to preheat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

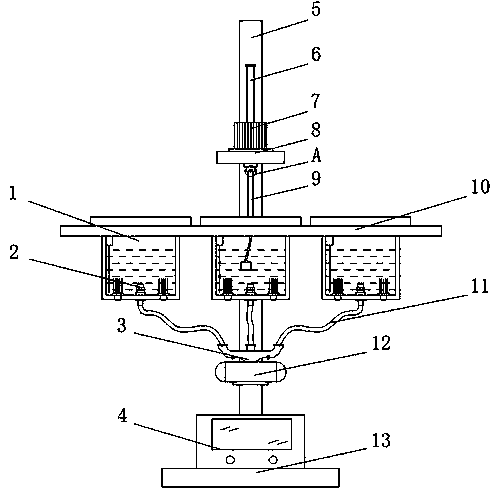

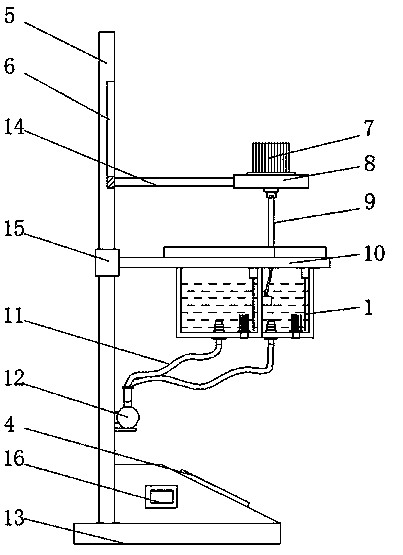

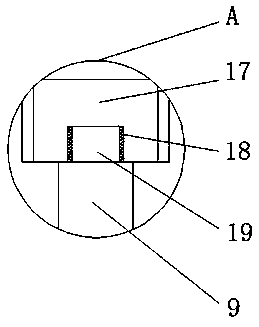

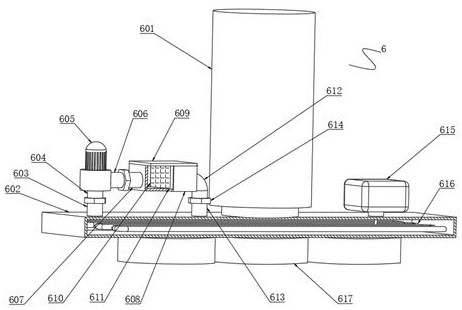

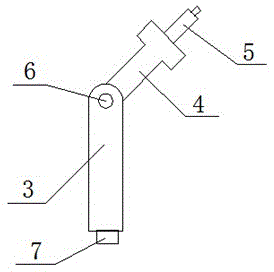

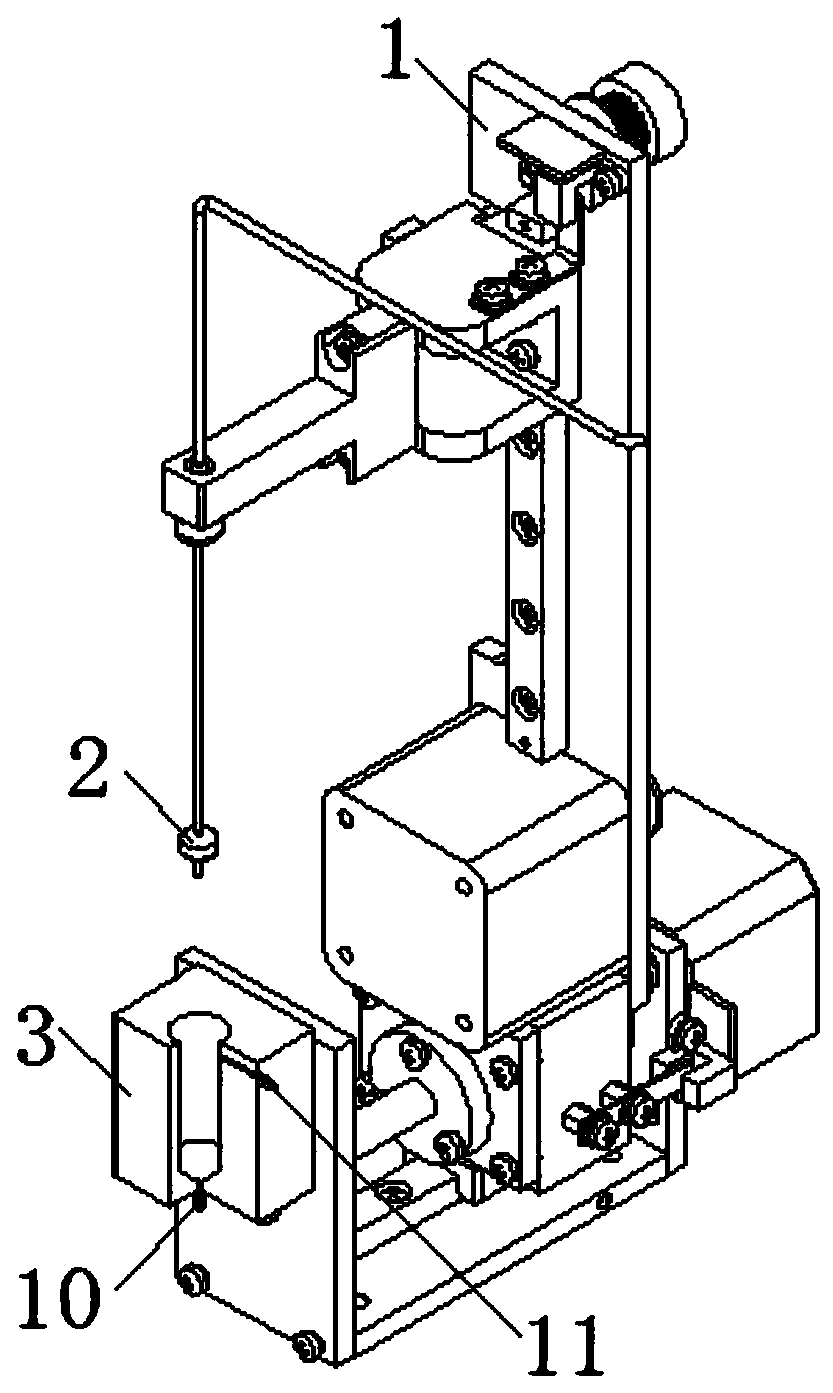

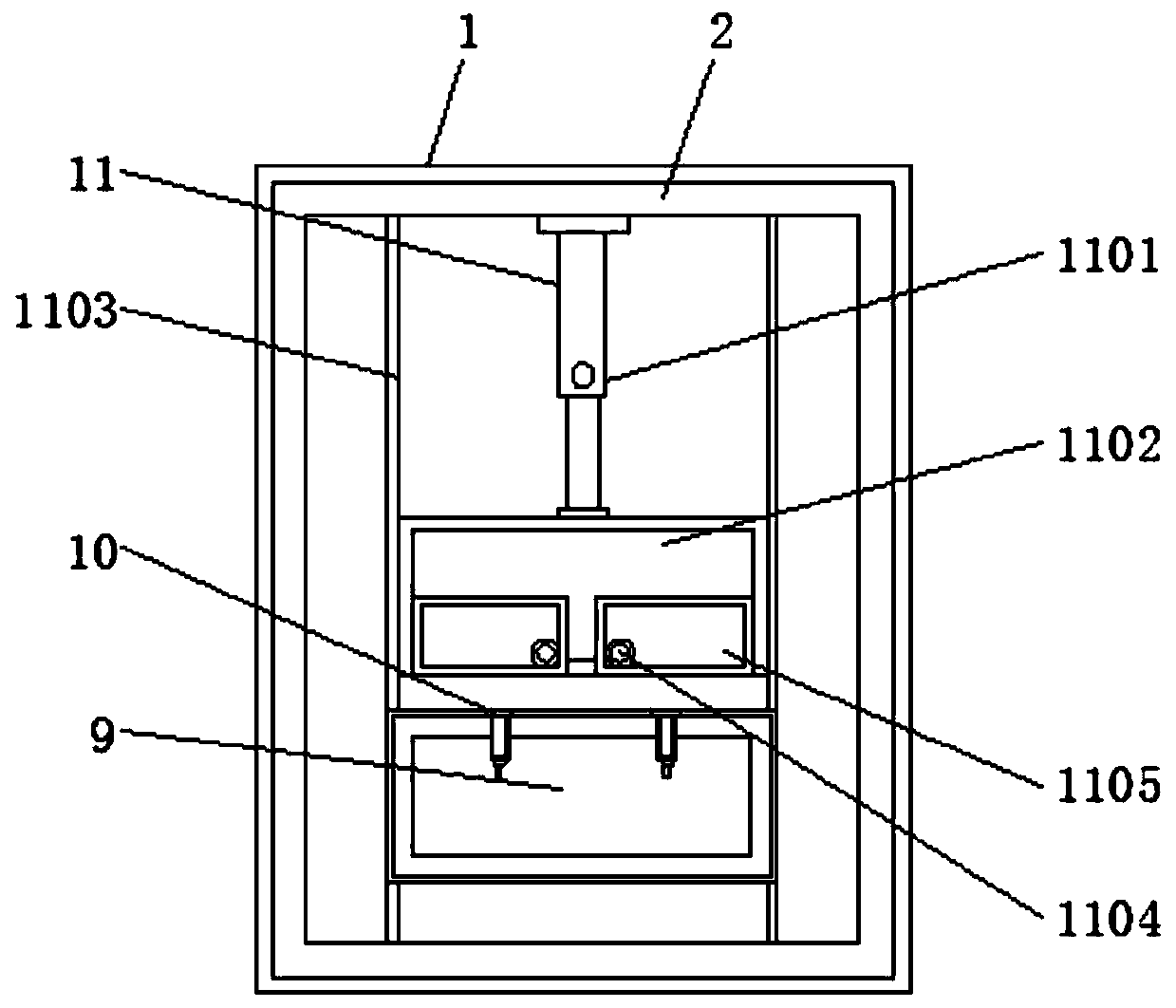

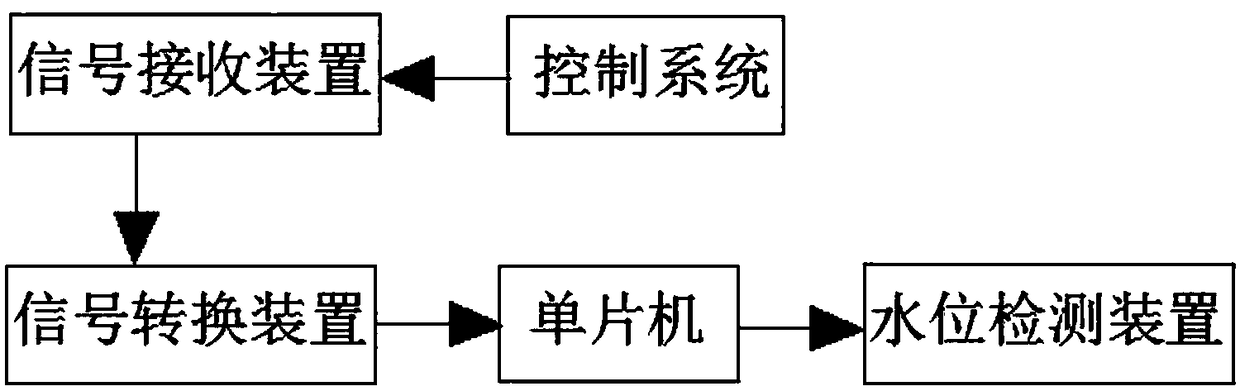

Valve cleaning device

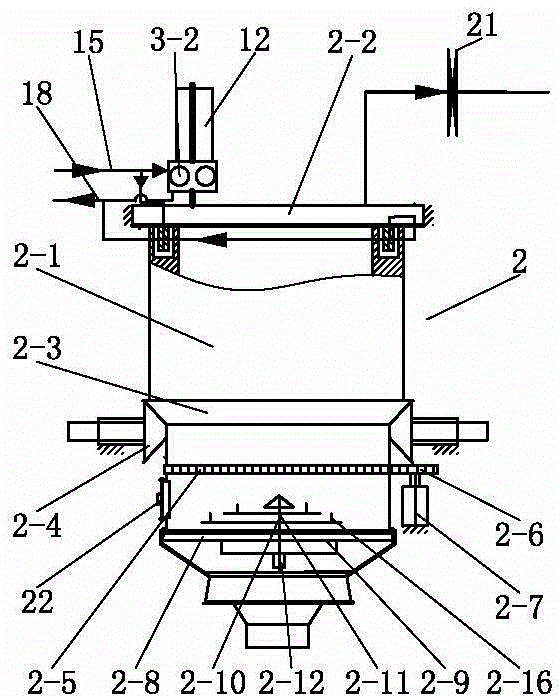

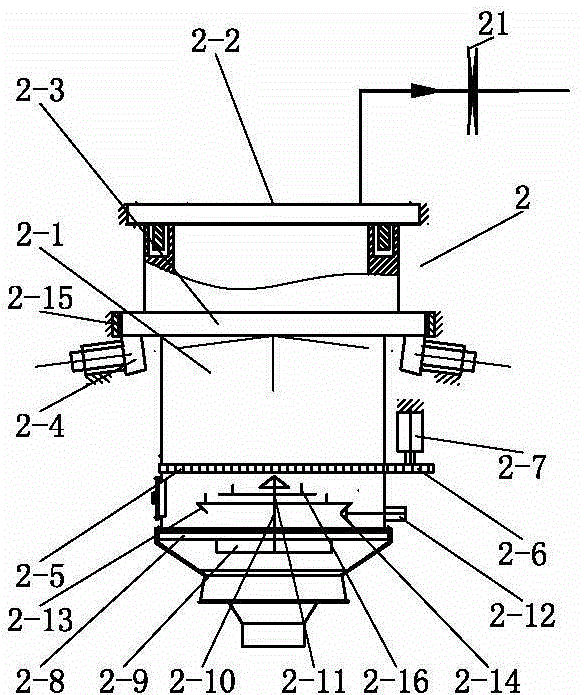

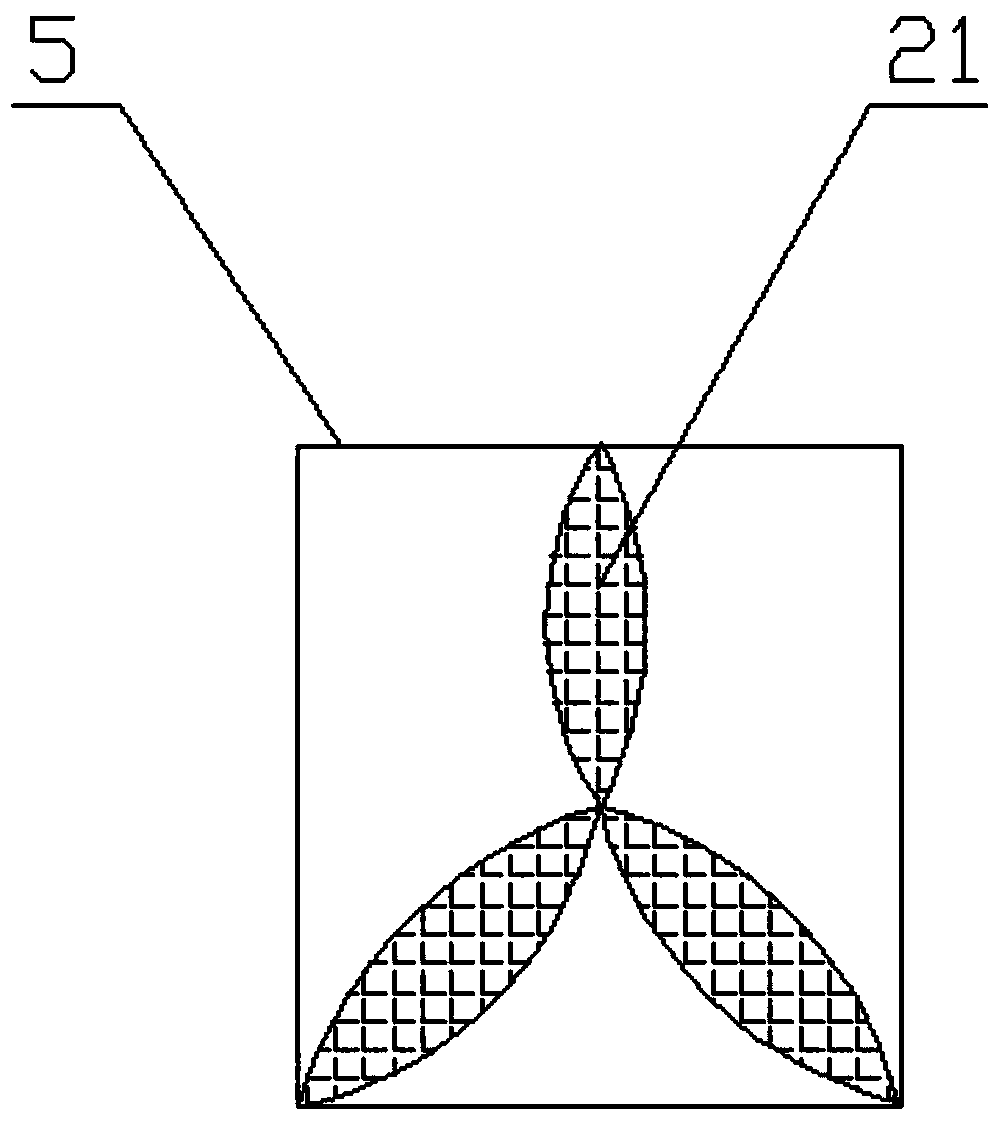

PendingCN109806030ASmooth rotationEasy to cleanHeart valvesCleaning using liquidsMicrocomputerBioprosthetic valve

The invention discloses a valve cleaning device which comprises cleaning basins, a bottom plate and a valve holding device; a supporting rod is vertically fixed to one end of the top of the bottom plate; a control table is mounted at the other end of the top of the supporting rod; a single chip microcomputer is arranged inside the control table; a motor is mounted at the top end of a supporting plate; a locating block is fixed to the bottom end of the motor by means of a rotating shaft; a reserving groove is formed in the bottom end of the locating block; the valve holding device is fixed to the bottom end of the locating block; and an output end of the single chip microcomputer is electrically connected with input ends of an electric slide rail, the motor and an air pump through a wire. The motor is arranged, the locating block is fixed to the output end of the motor by means of the rotating shaft, the valve holding device is fixed to the bottom end of the locating block, the bottom end of the valve holding device is spirally connected with a bioprosthetic valve, and when the motor works, the valve holding device is conveniently driven to rotate, so that the bioprosthetic valve isfavorably cleaned, preserving fluid on the surface of the bioprosthetic valve is favorably cleared away, and the personnel cost is favorably reduced.

Owner:韦秋英

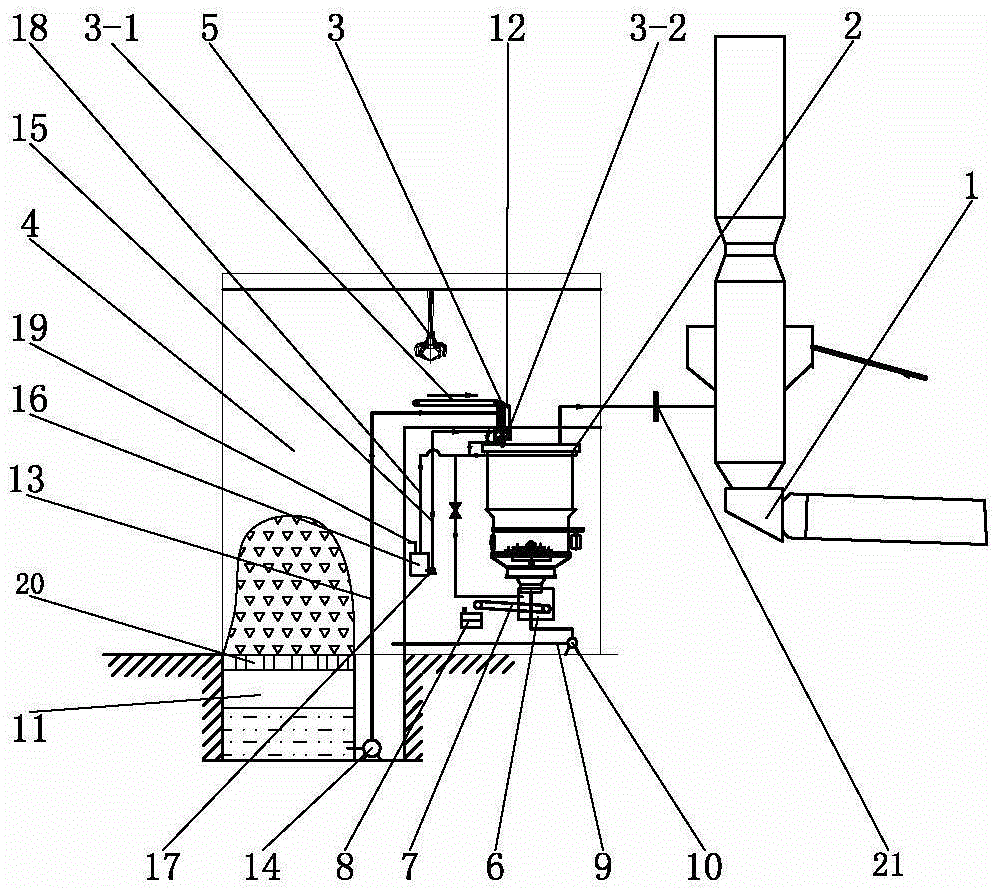

Cement kiln capable of realizing waste gasification outside same and gasification method thereof

ActiveCN104531218AOvercome the defects of high water content and complex compositionScale upGasifier feeding meansGasification processes detailsCement kilnDomestic waste

The invention discloses a cement kiln capable of realizing waste gasification outside the same and a gasification method thereof. The cement kiln capable of realizing waste gasification outside the same comprises a cement kiln, wherein a gas inlet of the cement kiln is communicated with a gas outlet of a waste gasification furnace; a feed port of the waste gasification furnace is positioned below an outlet of a waste conveying device; an inlet of the waste conveying device is positioned in a waste material shed; and a waste grabbing device is arranged in the waste material shed. An operating method of the cement kiln capable of realizing waste gasification outside the same is characterized in that heat generated by burning part of waste in the waste gasification furnace is used to heat the rest of the waste in the waste gasification furnace, so that the rest of the waste can be gasified. According to the invention, the defect that domestic waste is high in water content and contains complicated components is overcome, the pretreatment procedure can be greatly simplified, the treatment cost is greatly lowered, and the domestic waste treatment scale is expanded; and furthermore, no auxiliary fuel is needed. Besides, the waste feeding uniformity can be ensured, thereby being beneficial to uniform distribution in the waste gasification furnace.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

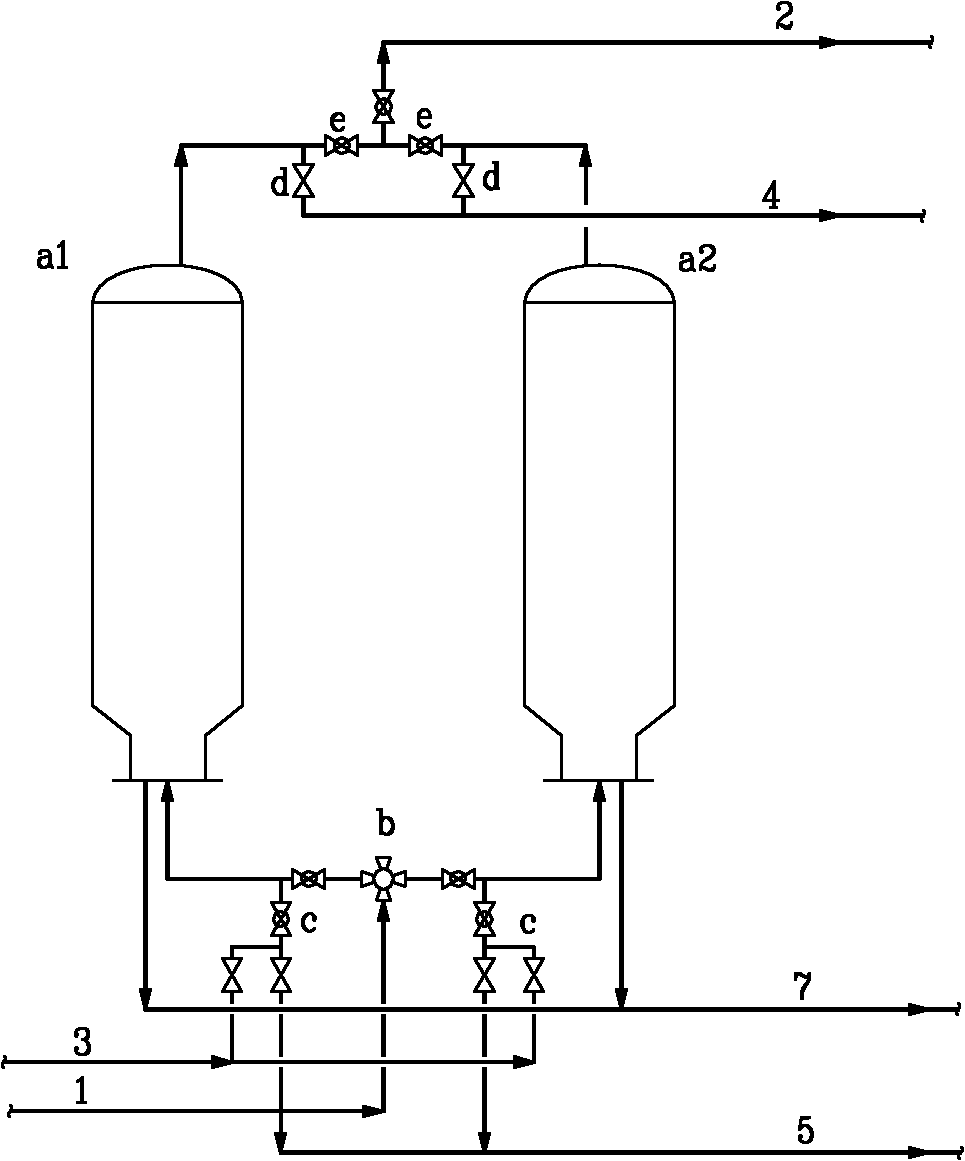

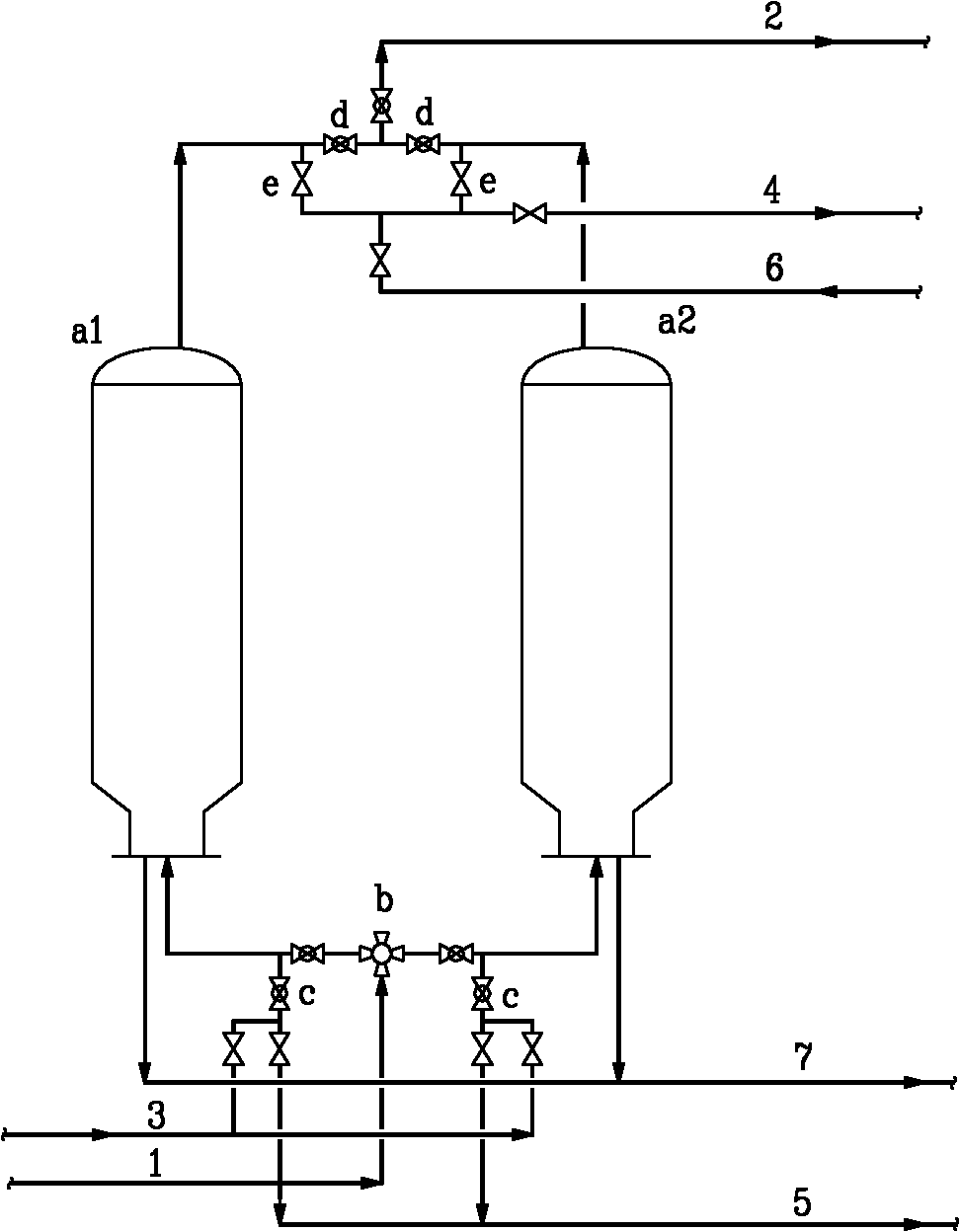

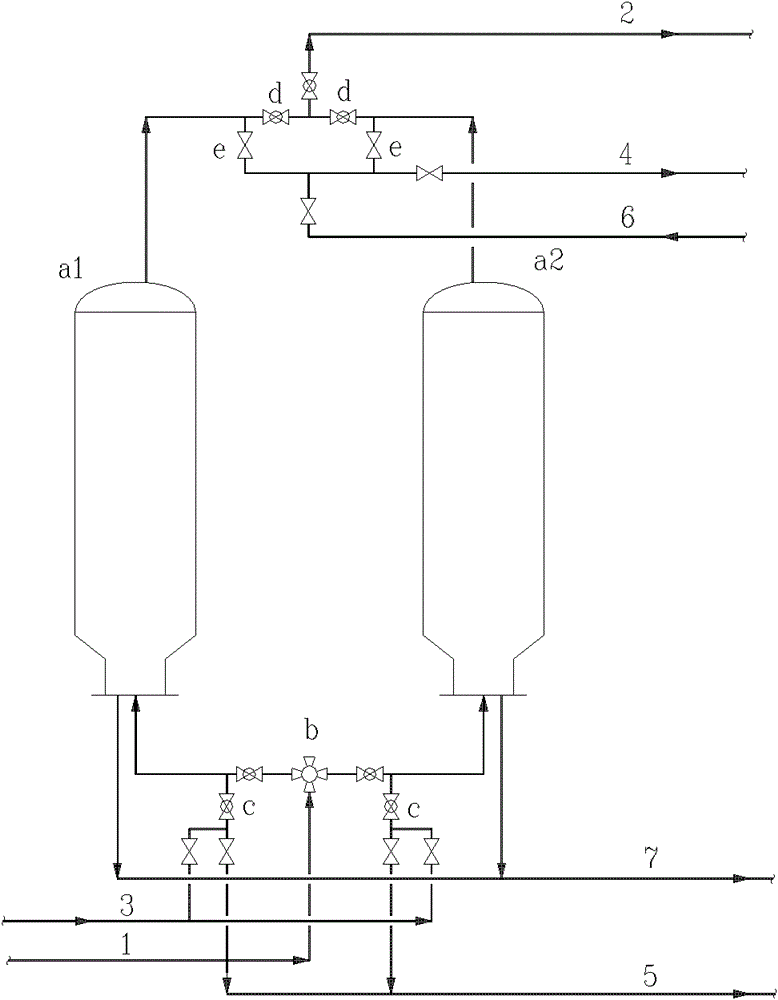

Delayed coking device and counterflow steam pressure testing method for coke tower

The invention discloses a delayed coking device and a counterflow steam pressure testing method for a coke tower. The device comprises blowing and pressure testing pipelines which are arranged at the top of a first coke tower and a second coke tower and is connected with the first coke tower and the second coke tower respectively or connected with the large oil and gas pipelines disposed at the top of the first coke tower and the second coke tower. The method comprises the steps of introducing pressure testing steam into the coke tower from the top of the coke tower, and replacing air in the coke tower from the bottom of the coke tower by flowing in the coke tower from top to bottom. With the device and the method provided by the invention, disadvantages in a conventional flow are overcome, and the operation is simple, flexible and reliable.

Owner:CHINA PETROCHEMICAL CORP +1

Manufacturing method for scale breaking tension leveler working roll

ActiveCN103589850AImprove toughnessIncreasing the thicknessFurnace typesHeat treatment furnacesStress distributionMedium frequency

The invention discloses a manufacturing method for a scale breaking tension leveler working roll. By adopting Cr12MoVCo die steel as the material, the manufacturing method includes the steps of: rough turning, hardening and tempering, semi-finish turning, shaping treatment, coarse grinding of roll surface, preheating, medium frequency spray quenching, isothermal treatment, tempering, and finish machining, thus obtaining a finished product. Specifically, the preheating temperature is 400-450DEG C, the medium frequency spray quenching temperature is 1100-1200DEG C, the isothermal temperature is 200-250DEG C, and the tempering temperature is 500-550DEG C. In the invention, by changing the thermal treatment process, under the circumstance of obtaining quenched martensite on the surface, a transition layer is mainly based on bainite, high hardness and high wear resistance of the surface are retained, toughness of the transition layer and the core is increased, the occurrence of microcracking is reduced, and the fracture risk in use is avoided. The thickness of the transition layer is increased, the overall strength of the roll is increased, the stress distribution is more reasonable, and the grinding performance of the roll is improved.

Owner:宜兴市鑫源辊业有限公司

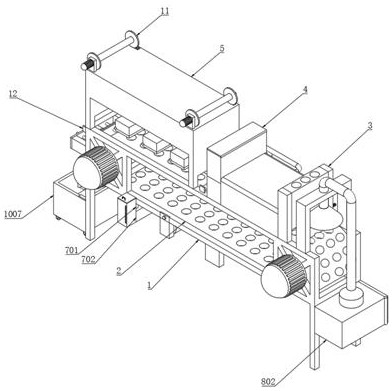

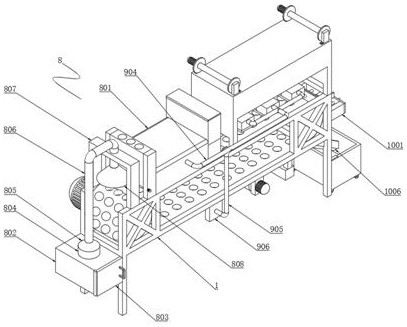

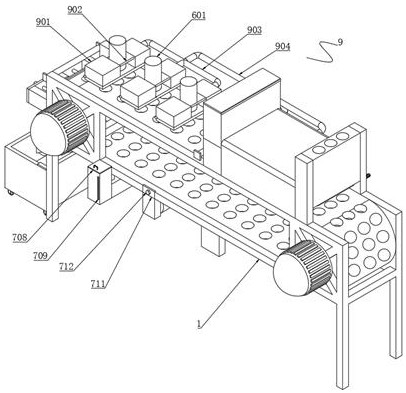

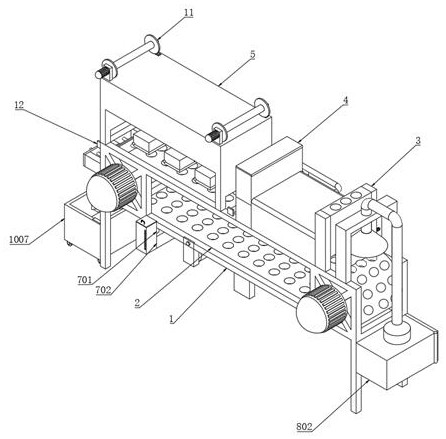

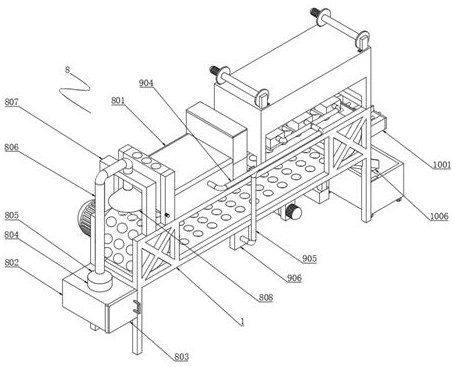

Uniform heat conduction system for jelly sealing machine and temperature control method

ActiveCN111846318AEasy extractionEasy to filterCleaningPackaging protectionTemperature controlHydraulic cylinder

The invention discloses a uniform heat conduction system for a jelly sealing machine and a temperature control method. The uniform heat conduction system comprises a fixing frame. A conveying belt isfixedly arranged on one side of the fixing frame. The edge portion of the top end of the fixing frame is provided with a shell placing block. A feeding groove is formed in a position, corresponding toone side of the shell placing block, of the top end of the fixing frame. The edge portion of top end of the fixing frame is provided with a sealing block. A heat conducting mechanism is fixedly arranged at the bottom end of the sealing block and comprises a hydraulic cylinder, a pressing plate, an oil outlet pipe, an oil via pipe, an oil pump, a through pipe, an oil pipe and a filtering box. According to the uniform heat conduction system for the jelly sealing machine and the temperature control method, through cooperation of the heat conducting mechanism, a cleaning mechanism, a dustproof mechanism and an energy-saving mechanism, optimization is conducted on the pressing plate and pressing block uniform heat conducting process, the heat recycling process and the sterilization process; and meanwhile, through a material collecting mechanism, the difficulty of collecting jelly products by workers is reduced, the sealing efficiency of the jelly sealing machine is effectively improved, and the jelly sealing machine is more efficient and energy-saving.

Owner:LABIXIAOXIN (FUJIAN) FOOD INDUSTRY CO LTD

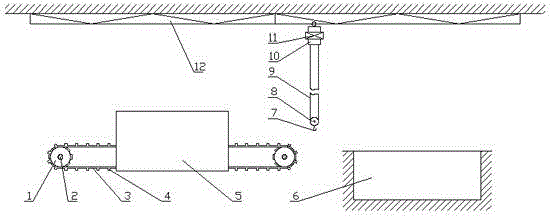

Blowout type spraying device

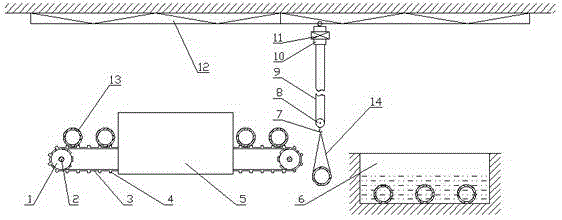

InactiveCN104307705AEasy to transportEasy to installLiquid surface applicatorsCoatingsDrive wheelTower

The invention discloses a blowout type spraying device. The device comprises a driving wheel (1), a driving belt (3), a pre-heating storeroom (5) and a spraying well (6), and is characterized in that the driving wheel (1) is arranged on an actuating shaft (2), the driving wheel (1) is matched with the driving belt (3), the driving belt (3) penetrates through the pre-heating storeroom (5), and the output side of the driving belt (3) is provided with the spraying well (6), and a hoisting component (11) is arranged above the driving belt (3) and the spraying well (6); the hoisting component (11) comprises a fixed tower (12), a connecting piece (10), a rope (9) and a hook (7); the connecting piece is movably mounted on the fixed tower (12), the lower end of the connecting piece (10) is provided with the rope (9), the rope (9) is connected with a pulley (8), and the hook (7) is arranged on the pulley (8). The spraying device disclosed by the invention is uniform in spraying, efficient and convenient, economical and environment-friendly.

Owner:六枝特区华兴管业制品有限公司

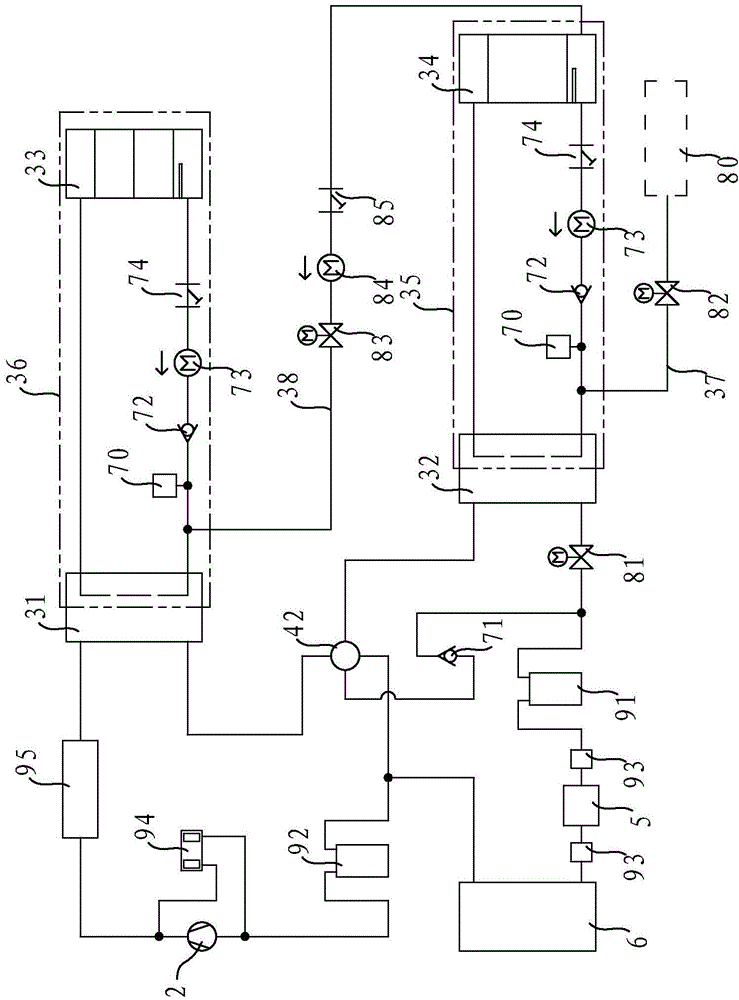

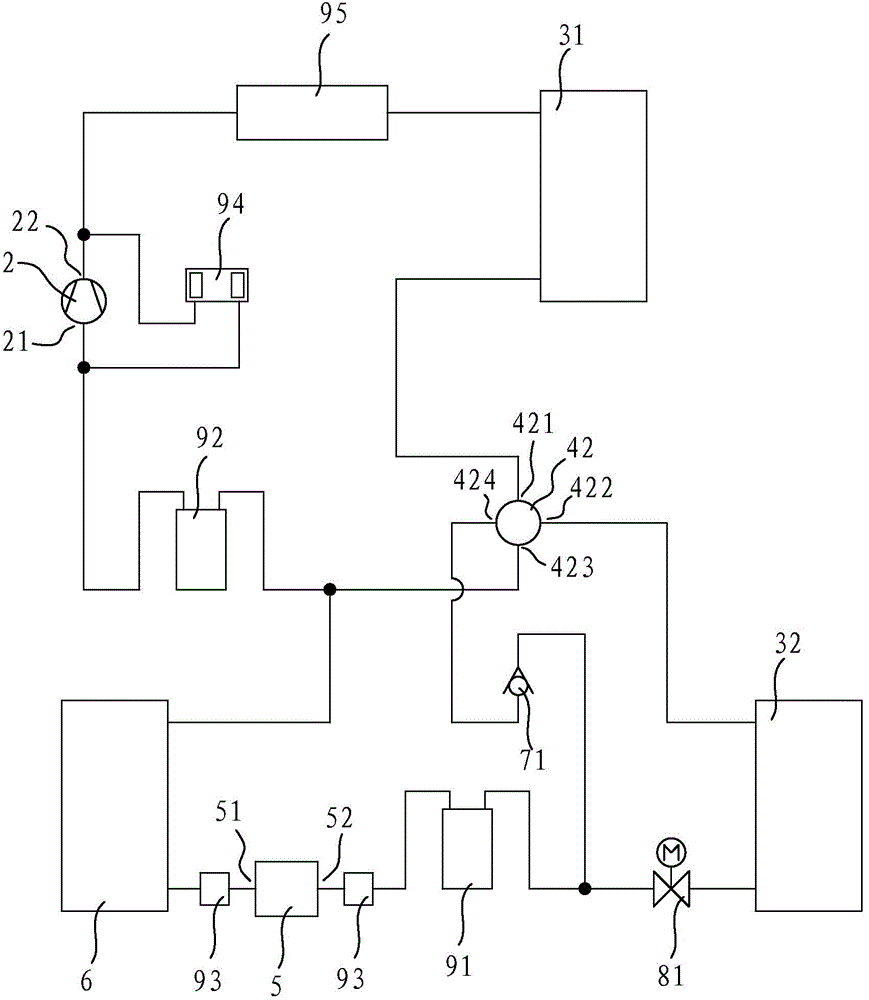

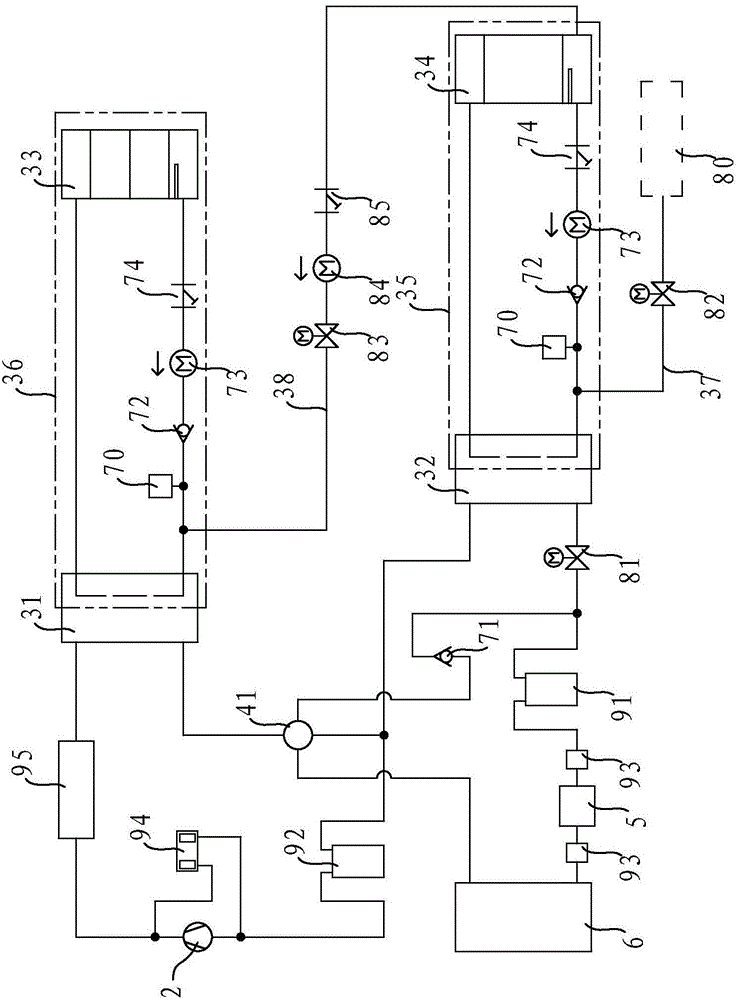

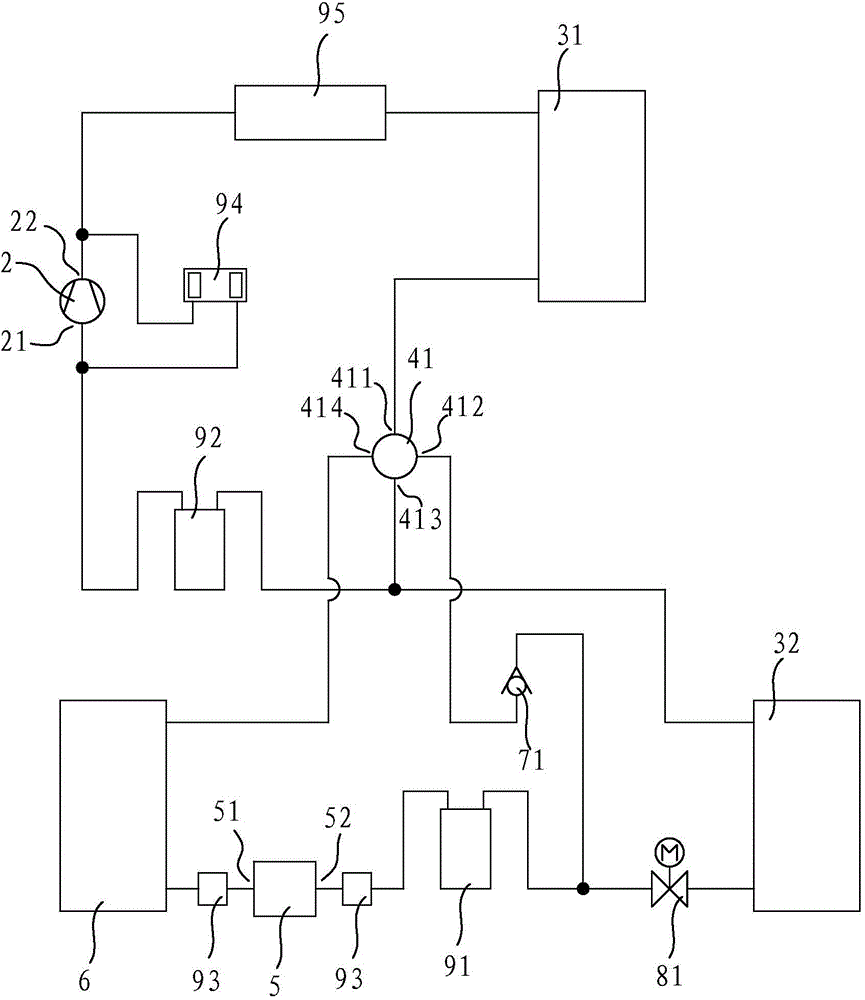

Efficient heat pump system

InactiveCN104567066AImprove heating energy efficiencyExtended service lifeFluid heatersMechanical apparatusFour-way valveEngineering

The invention discloses an efficient heat pump system, which comprises a compressor, a four-way valve, a first condenser, a second condenser, a throttling device and an evaporator, wherein the first condenser is connected in series between the compressor and the four-way valve. The heat pump system can be switched between a low-temperature heating mode and a high-temperature heating mode. The efficient heat pump system has the advantages that the heating efficiency is high, the water temperature fluctuation range is small, the compressor and the four-way valve are effectively protected, and the like.

Owner:江门市凯立信电气科技有限公司

Jelly sealing machine with heat recycling function and jelly filling and sealing process thereof

ActiveCN114684400AScientific and reasonable structureEasy to usePackaging protectionPackaging machinesThermodynamicsHeat conservation

The invention discloses a jelly sealing machine with a heat recycling function and a jelly filling and sealing process. The jelly sealing machine comprises a fixed frame, a conveying belt, a shell placing block, a feeding groove and a sealing block. A heat conduction mechanism is fixedly arranged at the bottom end of the sealing block, heat preservation covers are symmetrically hinged to the heat conduction mechanism, the two heat preservation covers are fixedly connected through a through-flow pipe, a ventilation pipe is embedded in the top of one side of each heat preservation cover, and one end of each ventilation pipe is fixedly connected with a dustproof cover; a drying pipe is further installed at the bottom end of the ventilation pipe through a flow guide pipe and a heat conduction pipe, and an outlet of the drying pipe faces the conveying belt. Through cooperation of the heat conduction mechanism and the energy-saving mechanism, the uniform heat conduction process of the pressing plate and the pressing block and the heat recycling process, the sealing efficiency of the jelly sealing machine is effectively improved, and the jelly sealing machine is more efficient and saves more energy.

Owner:LABIXIAOXIN (FUJIAN) FOOD INDUSTRY CO LTD

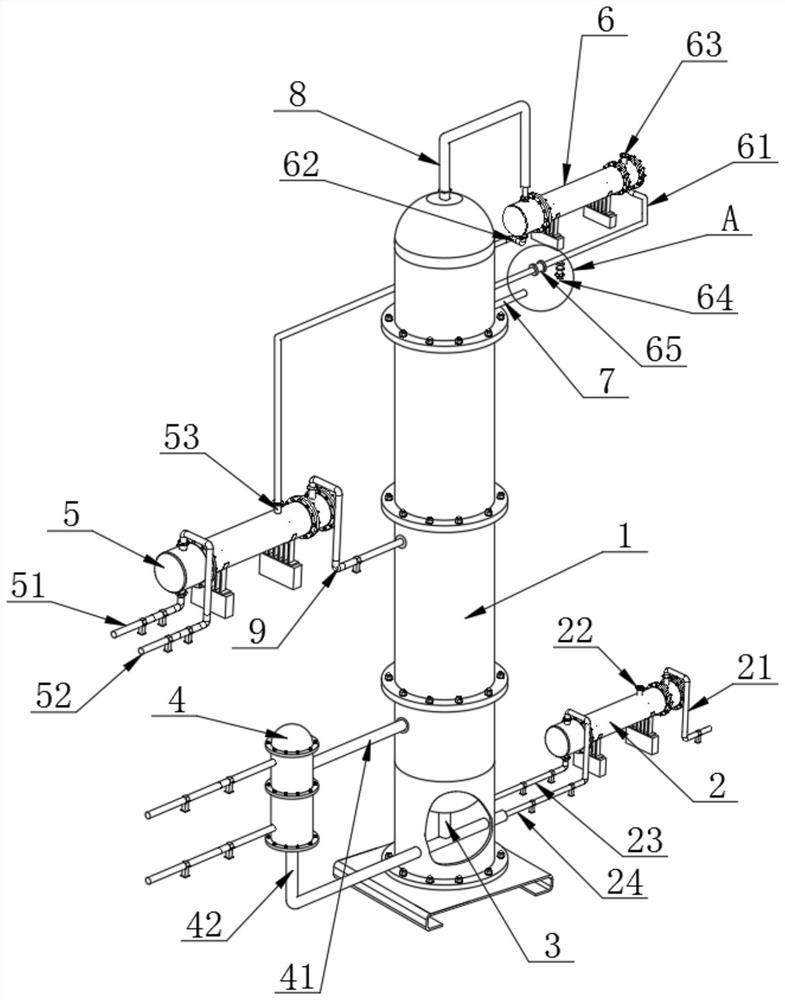

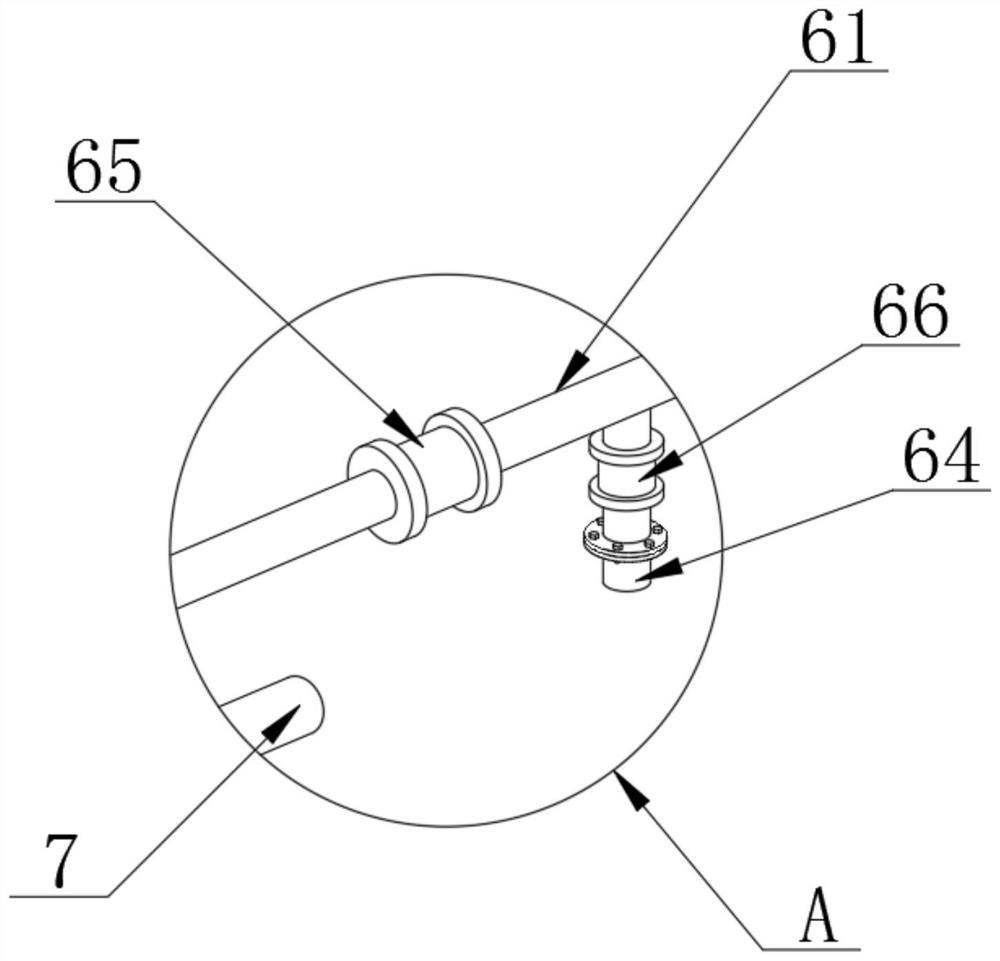

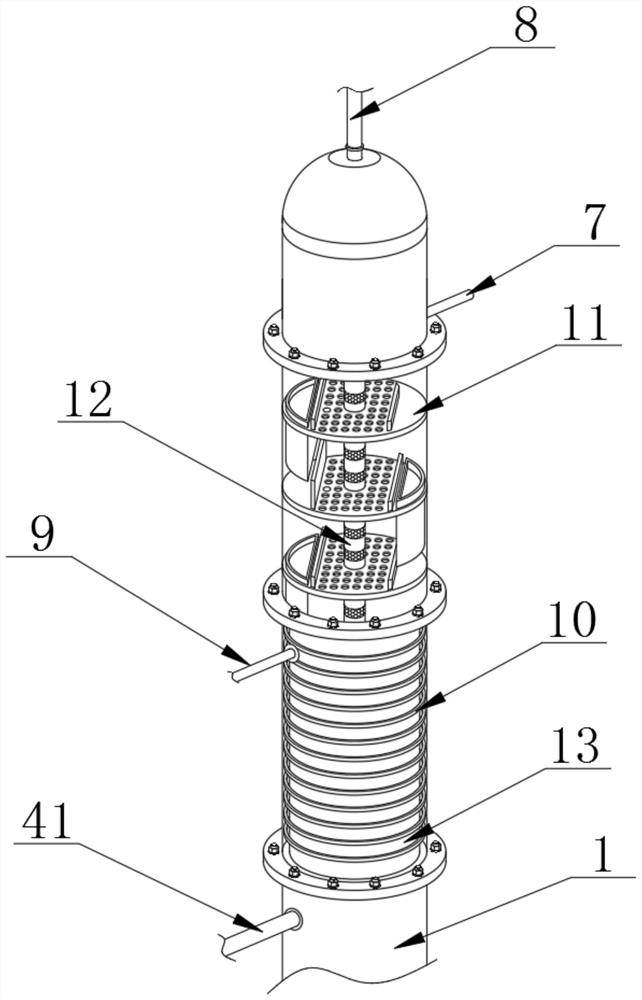

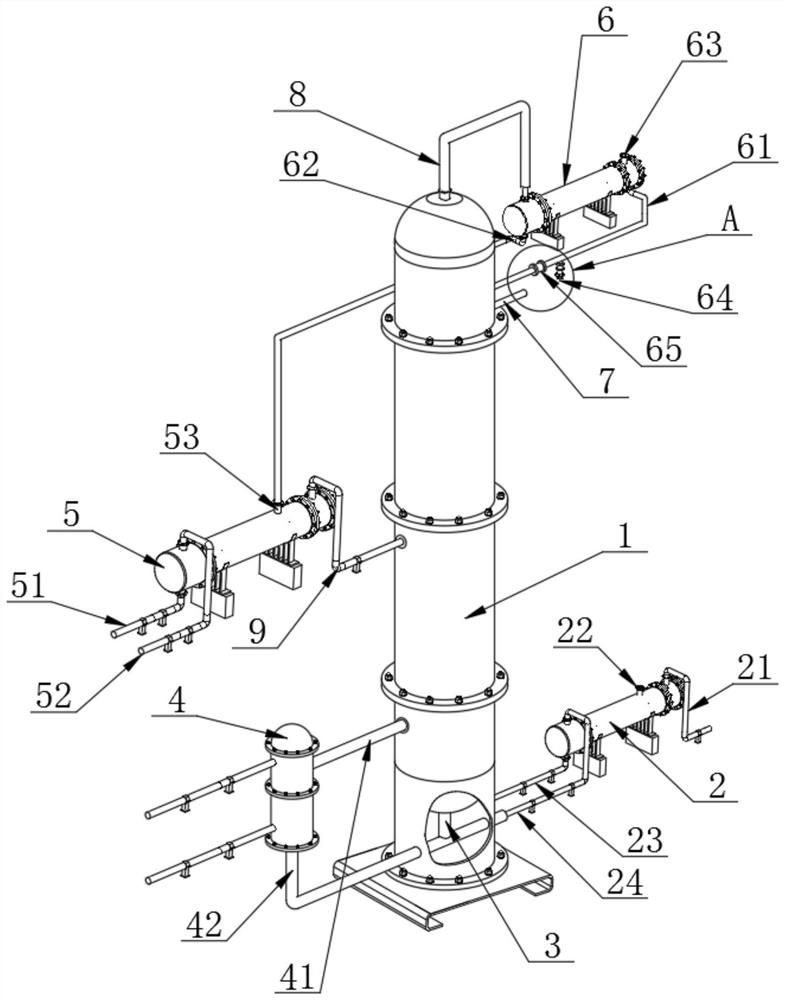

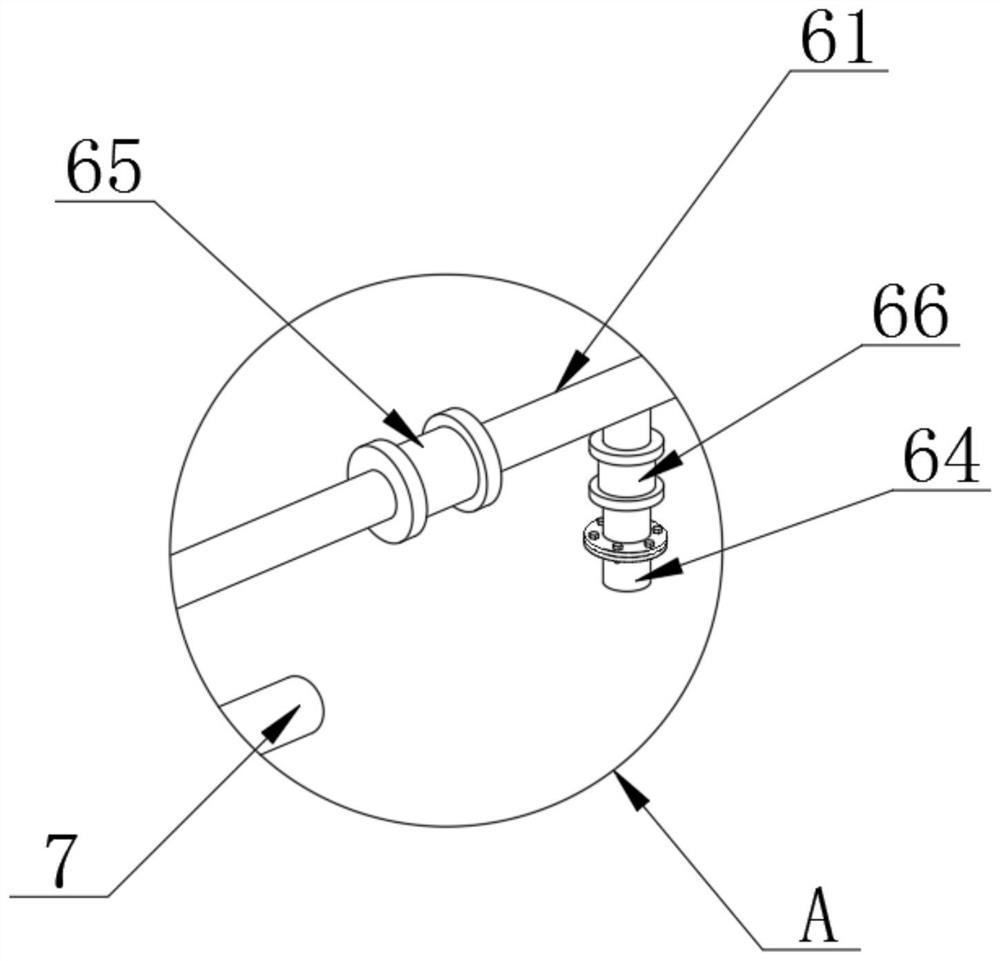

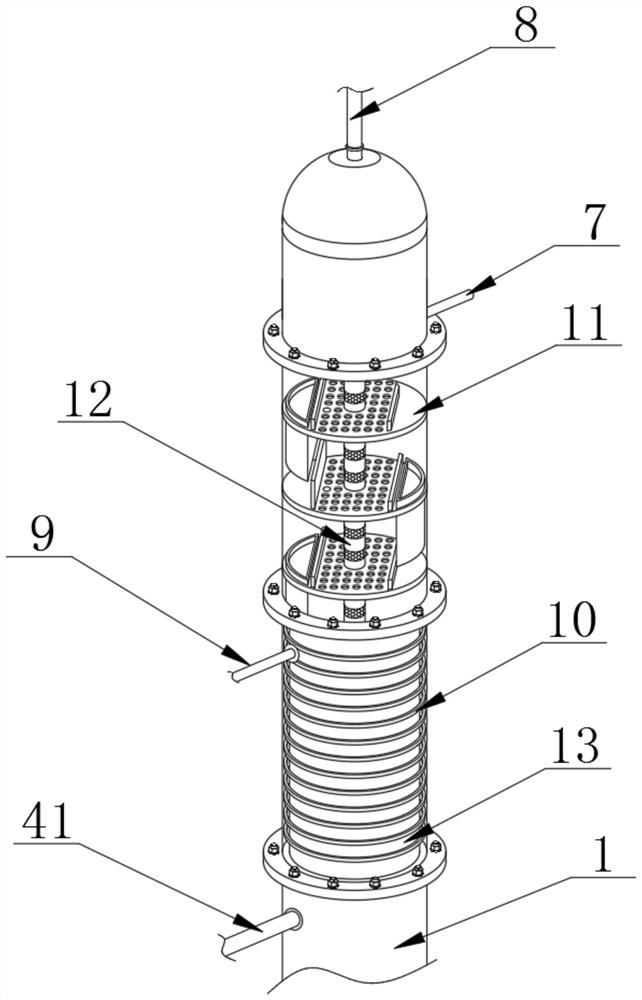

Improved column tray packing type rectifying column for molecular distillation

ActiveCN111803986AEnsuring Distillation EfficiencyImprove distillation efficiencyFractional distillationReboilerGas phase

The invention relates to the technical field of molecular distillation, and discloses an improved column tray packing type rectifying column for molecular distillation. The column comprises a column body, wherein a discharged material heat exchanger is arranged on one side of the bottom end of the column body; a reboiler is arranged on the other side of the bottom end of the column body; a fed material heat exchanger is arranged on the outer side of the middle of the column body; the middle part of the top end of the column body is communicated with a gas-phase matter discharge pipe, the otherend of the gas-phase matter discharge pipe is connected with a column top heat exchanger, an inner cavity is formed in the column body, a first circulating pipe is arranged in the inner cavity in a surrounding manner, a plurality of column plates are distributed in the column body from bottom to top, and a central pipe is arranged in the column body and penetrates through the centers of the column trays. According to the rectifying column, heat recycling is achieved, heat preservation of the column body is facilitated, heat loss of the column body is avoided, materials can be preheated, a plurality of steam layers are conveniently formed in the column body through cooperation of the center pipe and the gas ring, it is guaranteed that steam makes better contact with the materials, and therectifying efficiency of the materials is improved.

Owner:宿迁市盈科新材料有限公司

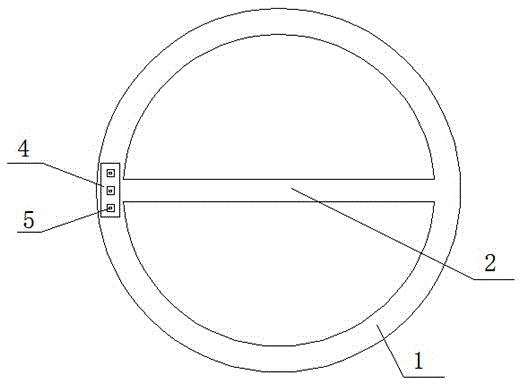

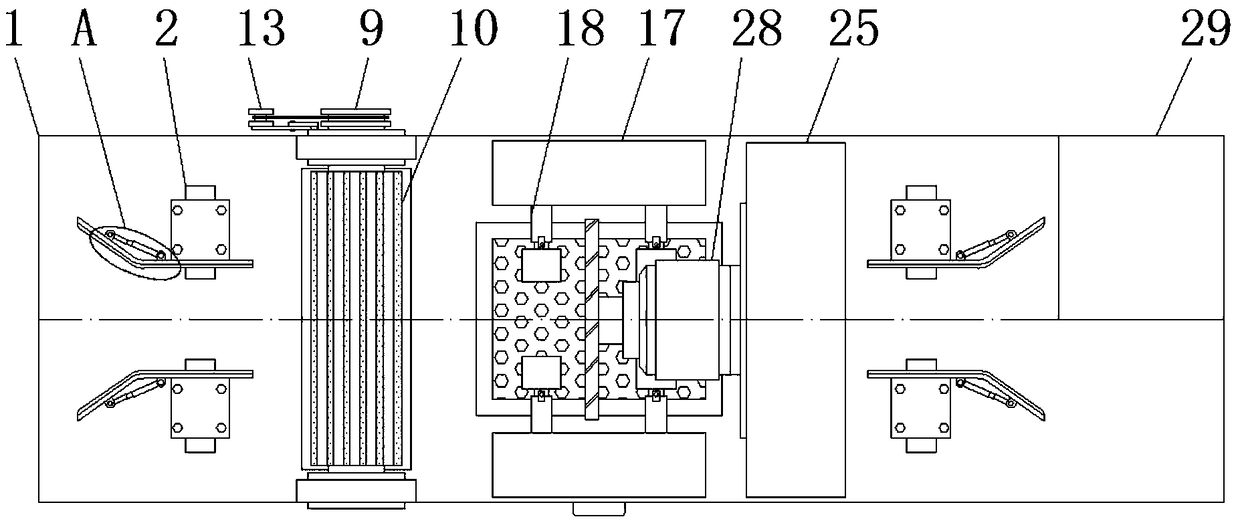

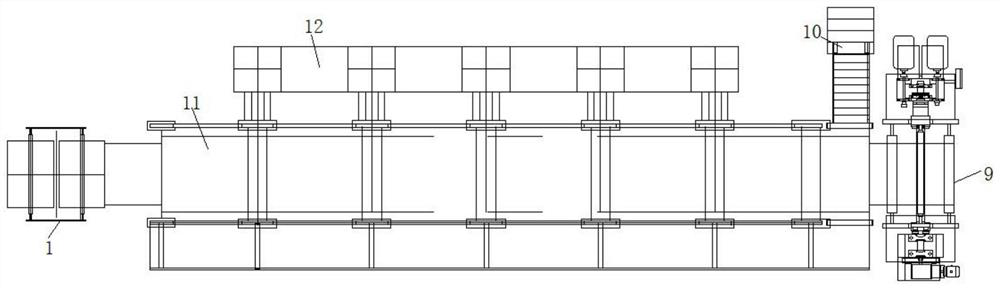

Welding preheating device applicable to steel structures in various shapes

InactiveCN105479050AAvoid safety hazardsEasy to useWelding/cutting auxillary devicesArc welding apparatusEngineeringActual use

The invention discloses a welding preheating device applicable to steel structures in various shapes. The device comprises a walking track, a supporting beam, a rotary positioning beam and a plurality of flame spraying guns, wherein the supporting beam is slidingly arranged on the walking track; the rotary positioning beam is arranged at the top of the supporting beam; the flame spraying guns are fixedly arranged on the rotary positioning beam; the walking track comprises a circular track and a horizontal track arranged inside the circular tack and communicated with the circular track; and the top end of the supporting beam is connected with the rotary positioning beam through a positioning rotating shaft. According to the device, the flame spraying guns used for preheating welding positions can move on the walking track; when an arc-shaped steel structure or a circular steel structure is preheated, the flame spraying guns move on the circular track and preheat the welding positions of the arc-shaped steel structure or the circular steel structure along the track orderly; when a straight steel structure is preheated, the flame spraying guns move on the horizontal track and carry out flame preheating; and the flame spraying guns can be turned over according to actual use requirements. The welding preheating device is suitable for preheating steel-structure materials in various shapes; the application range is wide; and the use is convenient.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

Anti-blood coagulation stirring system

PendingCN110926918AEasy to cleanStir wellPreparing sample for investigationBlood Collection TubeHemolysis

The invention discloses an anti-blood coagulation stirring system, and belongs to the technical field of stirrers. The anti-blood coagulation stirring system comprises a sample injection arm assembly,a stirrer is fixedly connected to the bottom of the front face of the sample injection arm assembly, a hemolysis cleaning pool is fixedly connected to the front face of the bottom of the sample injection arm assembly, and a liquid passing pipe communicates with the right end of the top of an inner cavity of the hemolysis cleaning pool. According to the invention, the sample injection arm assemblyand the stirrer are arranged, the sample injection arm assembly sucks a sample from the blood collection tube and adds the sample into the hemolysis cleaning pool, the stirrer is driven to move up and down, a user can conveniently stir blood at a constant speed, and coagulation and layering of the blood sample are prevented; and, through cooperation of the hemolysis cleaning pool, the cleaning liquid pump and the cleaning liquid bottle, a user can conveniently clean the hemolysis cleaning pool, sample carrying pollution is prevented, the sample detection accuracy is improved, and the problemsthat a traditional anti-blood coagulation stirring system cannot stir samples at a constant speed and cannot clean the samples after the samples are collected are solved.

Owner:JIANGSU AUDICOM MEDICAL TECH

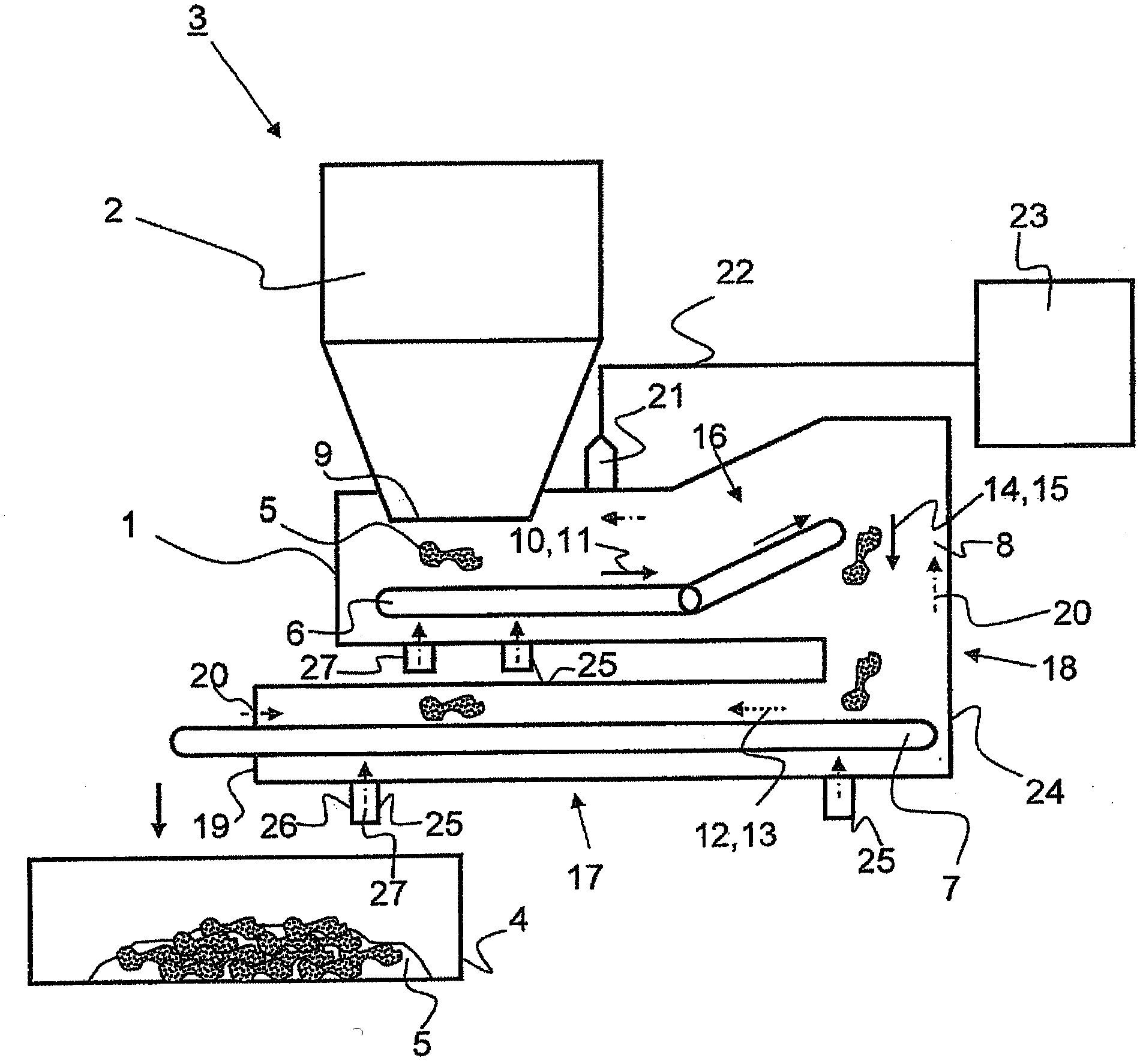

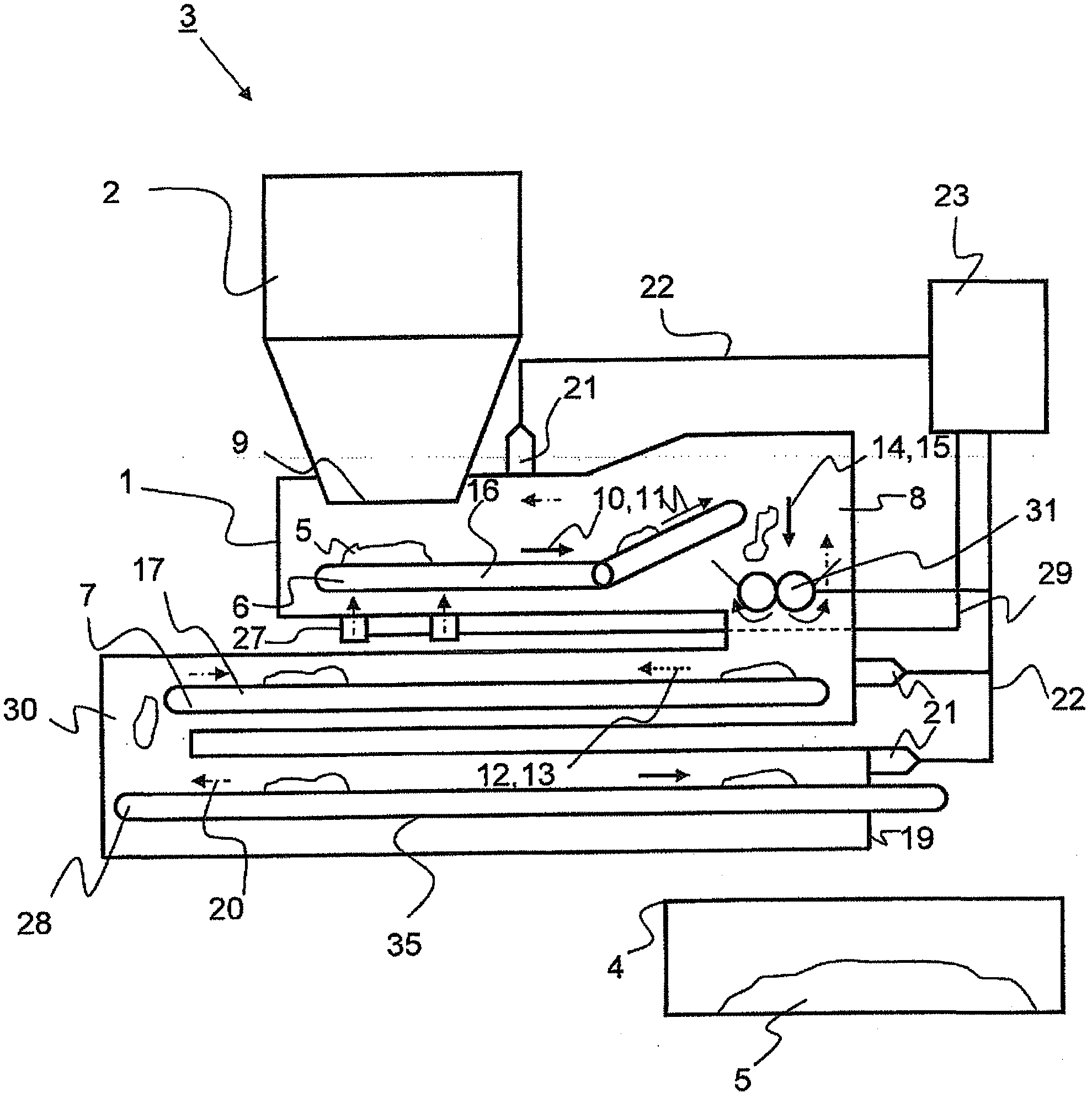

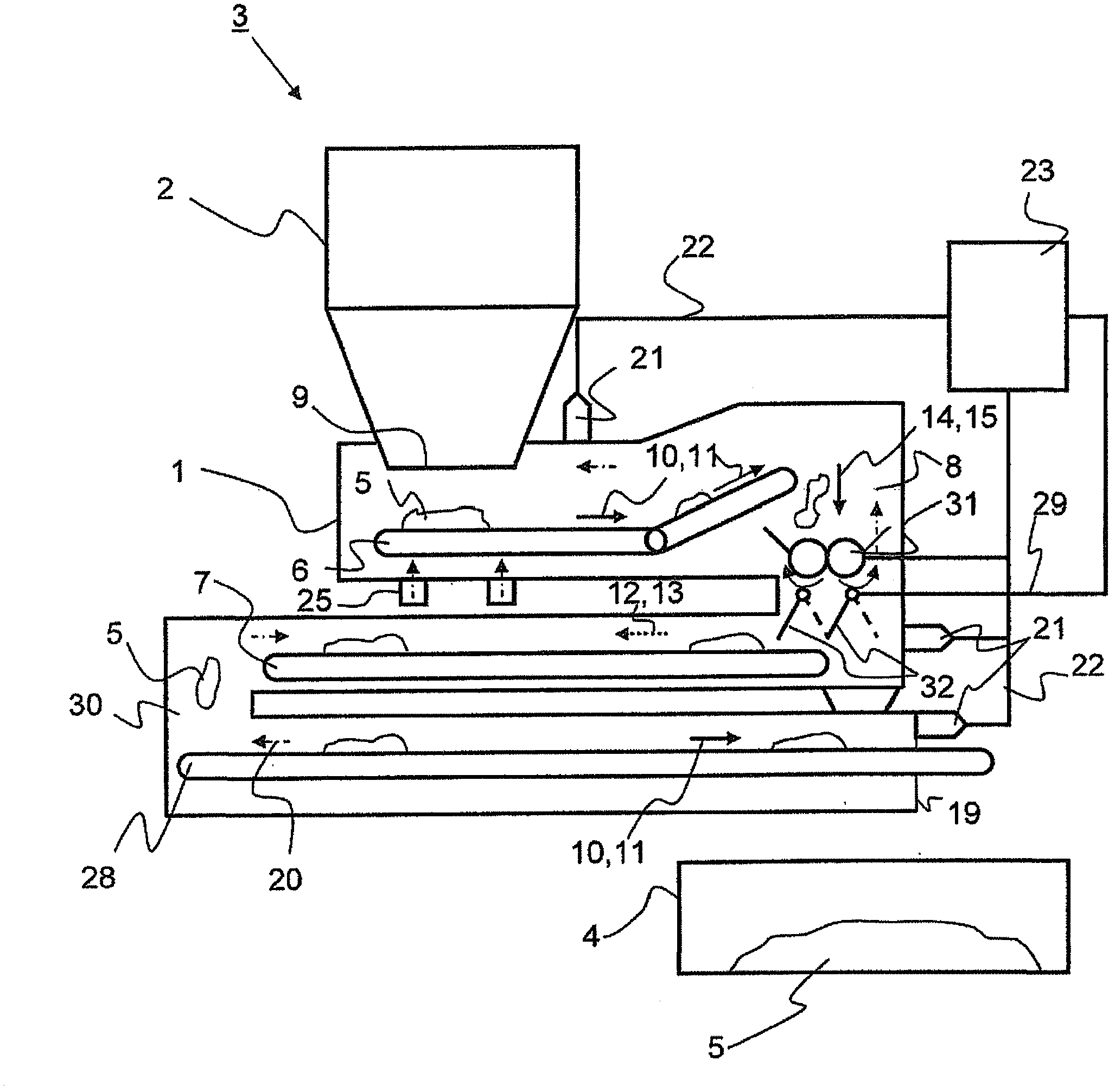

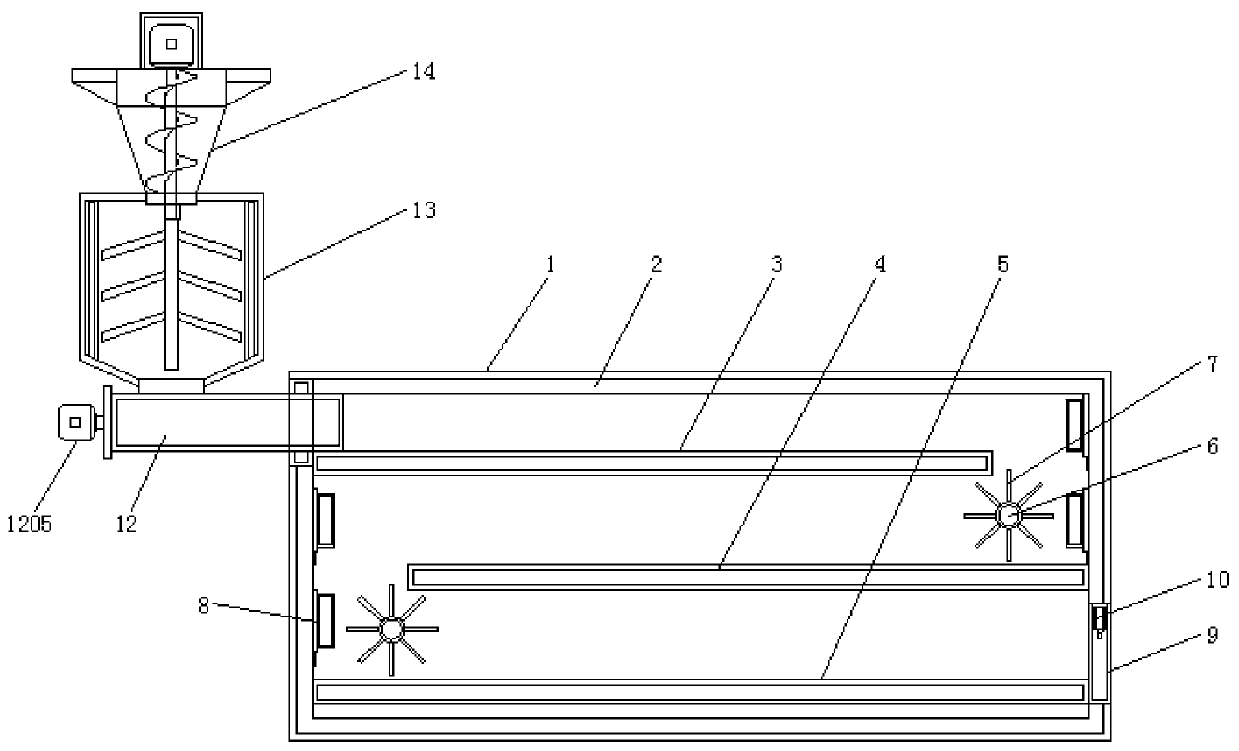

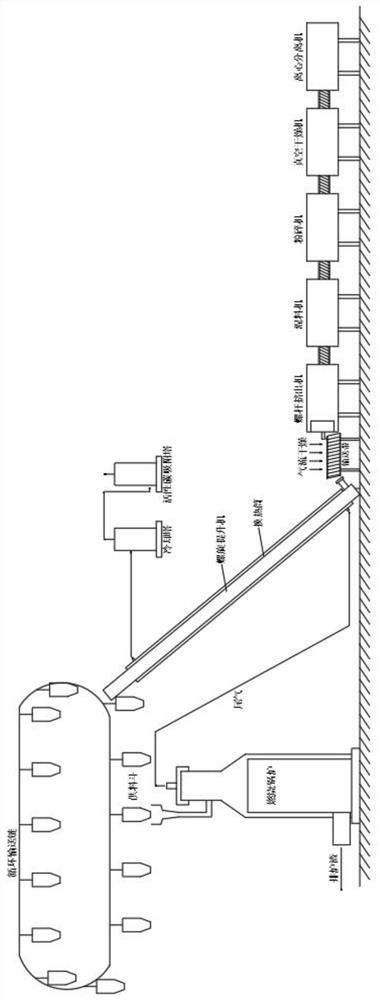

Method and apparatus for conveying material from a combustion boiler

InactiveCN102301184AEasy to preheatEnsure afterburningLighting and heating apparatusCombustionEngineering

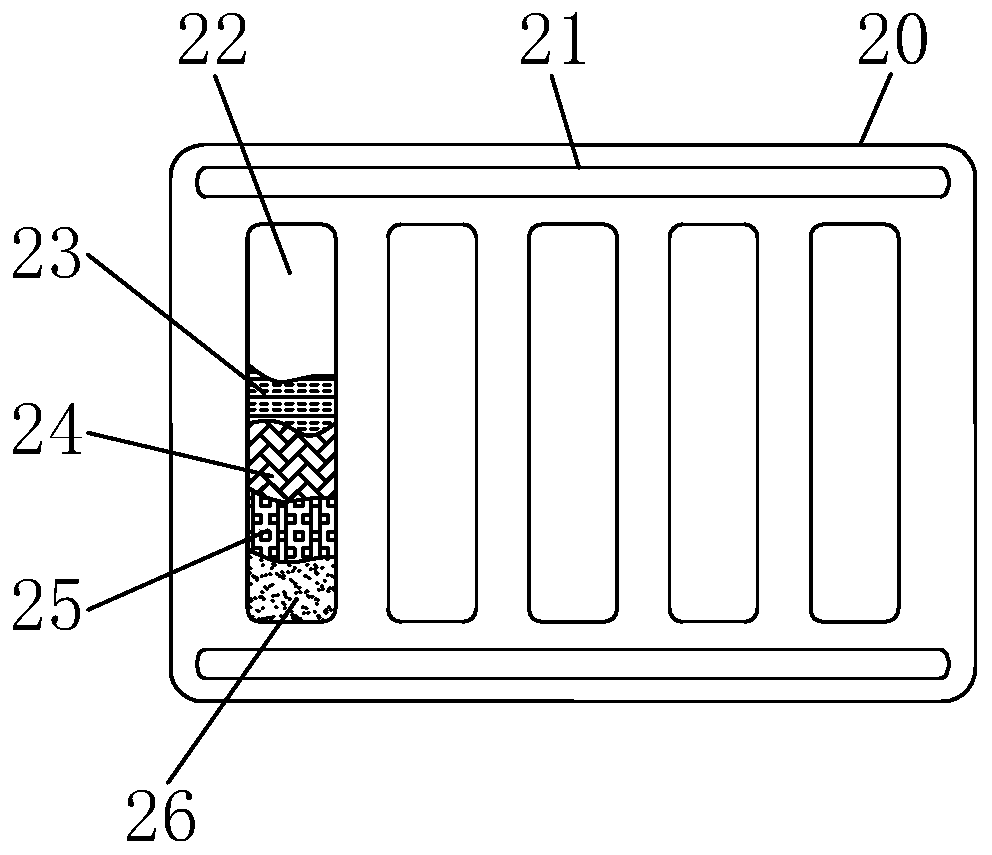

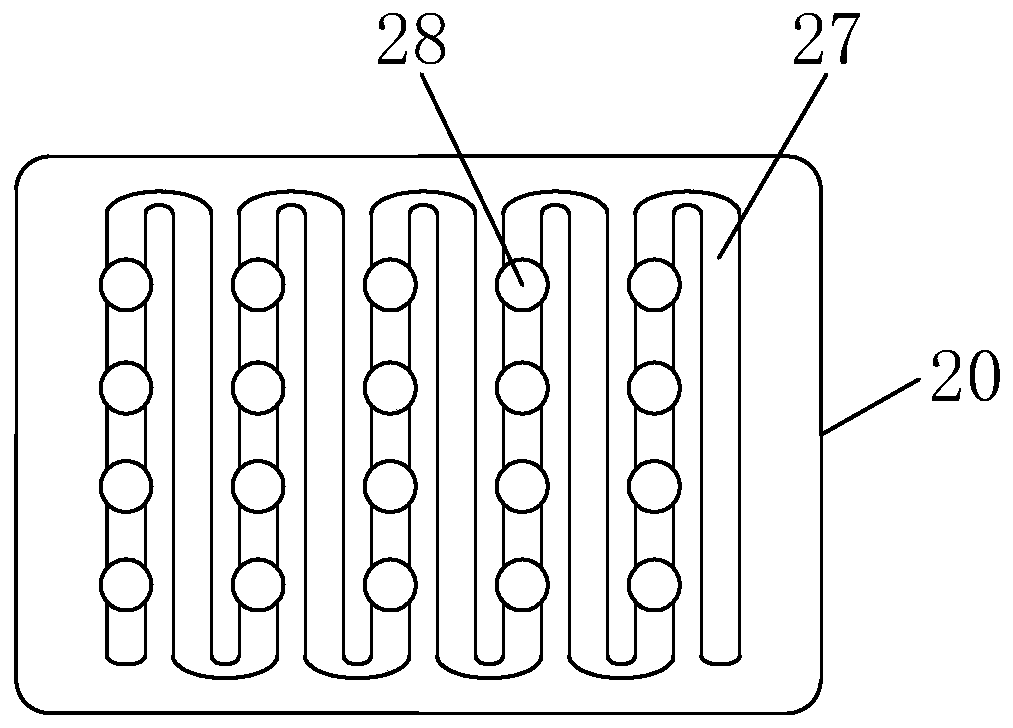

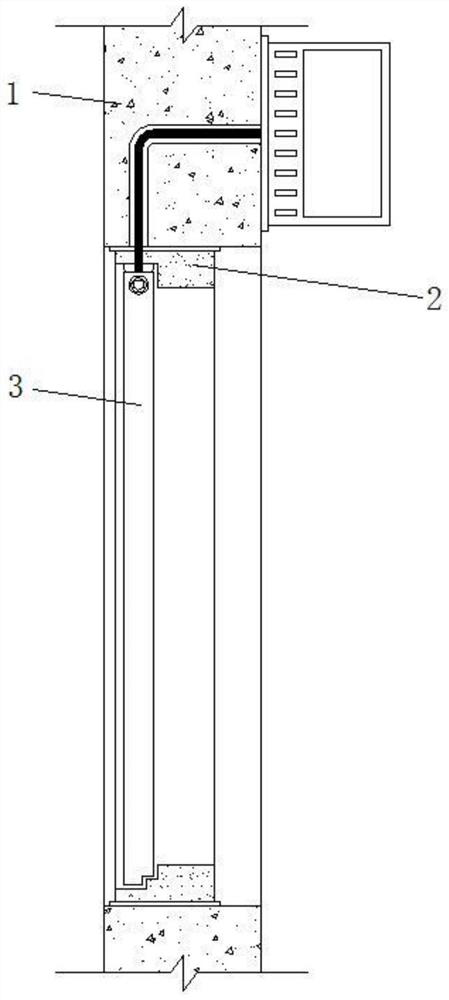

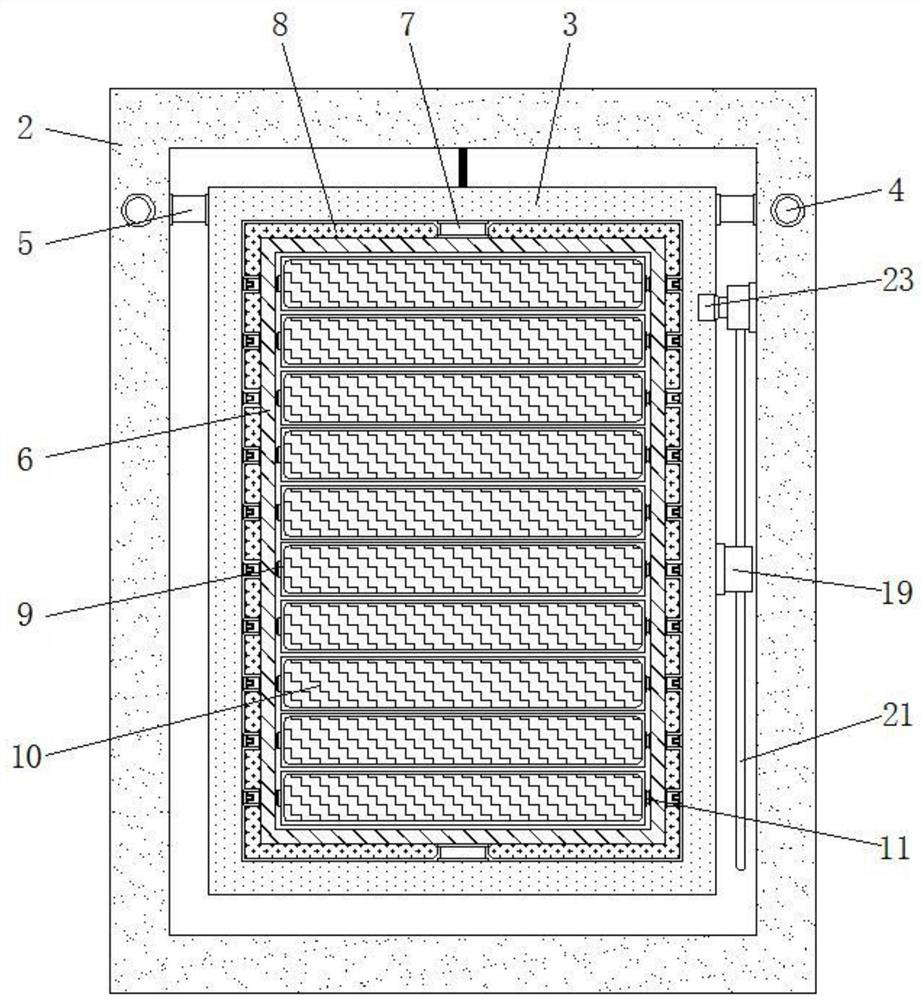

The invention relates to a method and a device (1) for conveying hot material (5) from a combustion boiler (2), said device comprising at least one housing (24), at least one conveyor belt (6) and at least one diverting device (8) wherein at least one conveyor belt (6) conveys the material (5) first in a first horizontal direction component (11) and after passing through a diversion device (8) in at least one second horizontal direction deviating therefrom Component (13) delivery. Furthermore, the material (5) with the first directional component (11) is always separated from the material (5) with the second directional component (13) outside the deflection device (8) by the housing (24), And, said first directional component (11) and said second directional component (13) form an angle (2) of 135° to 180°.

Owner:CLYDE BERGEMANN GMBH

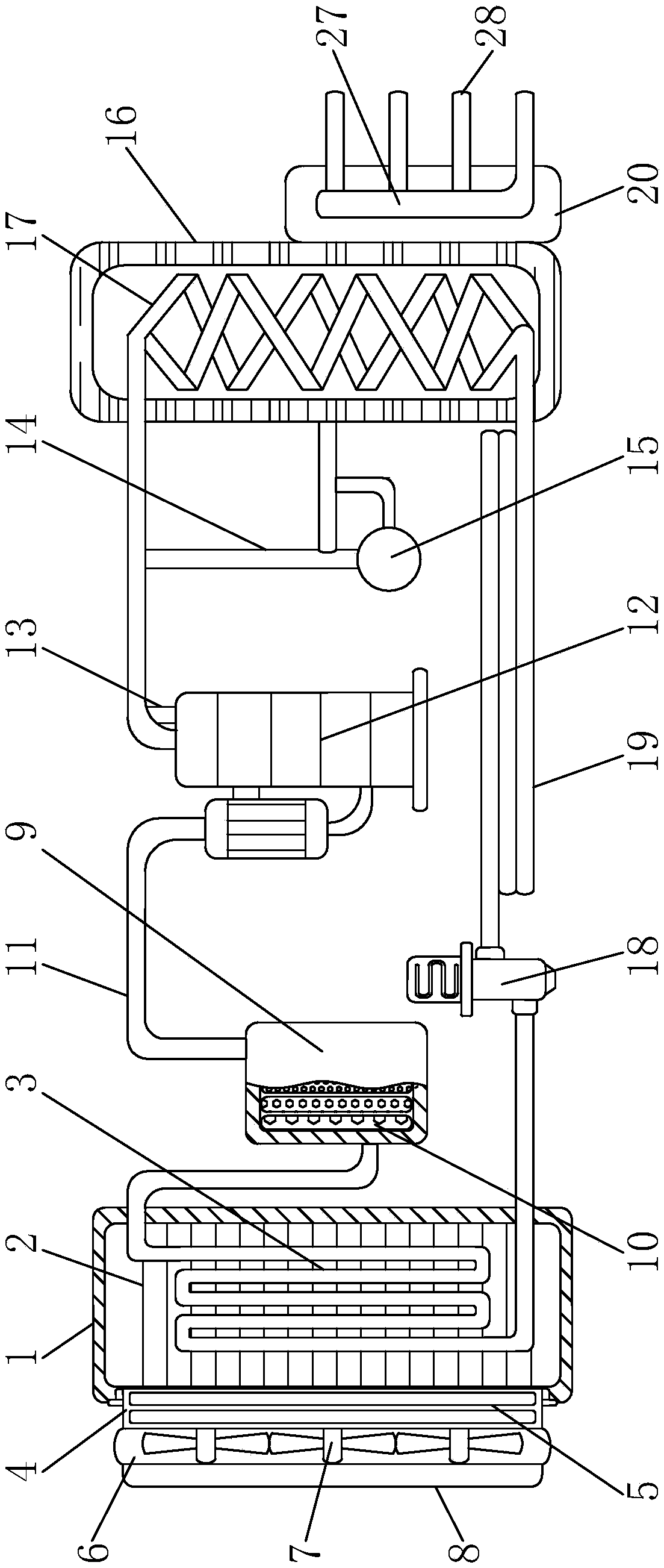

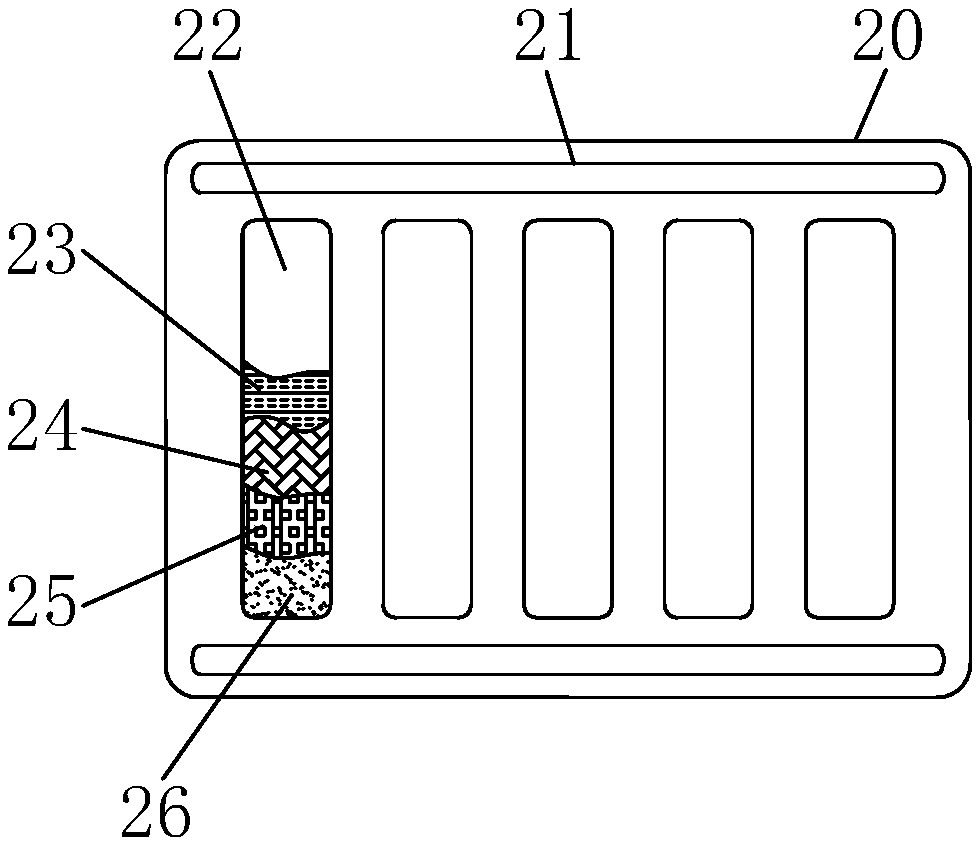

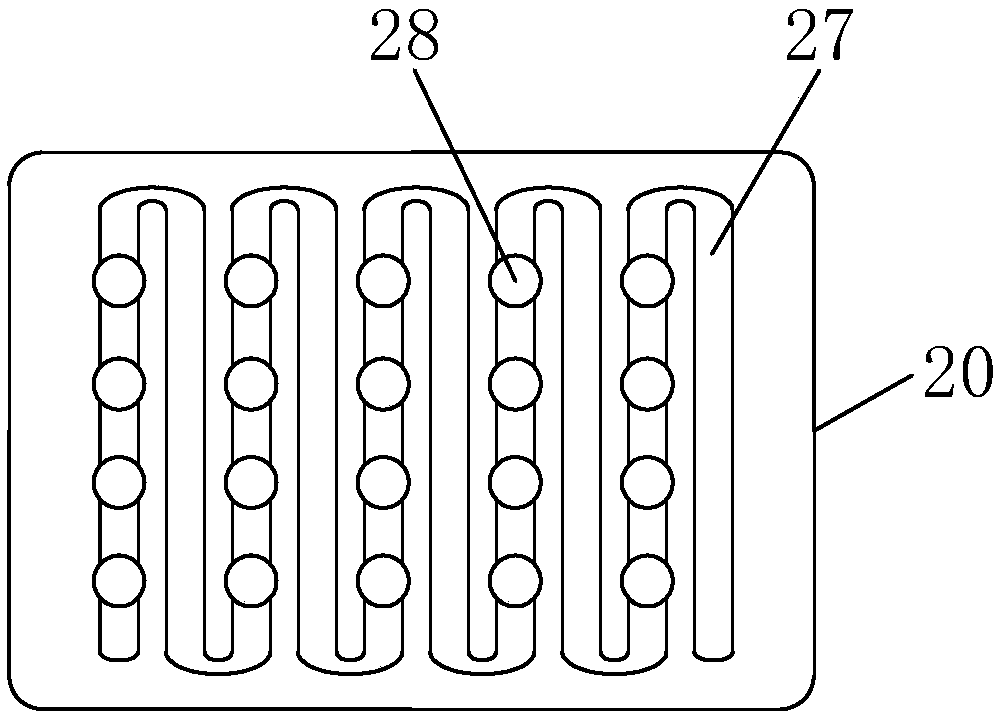

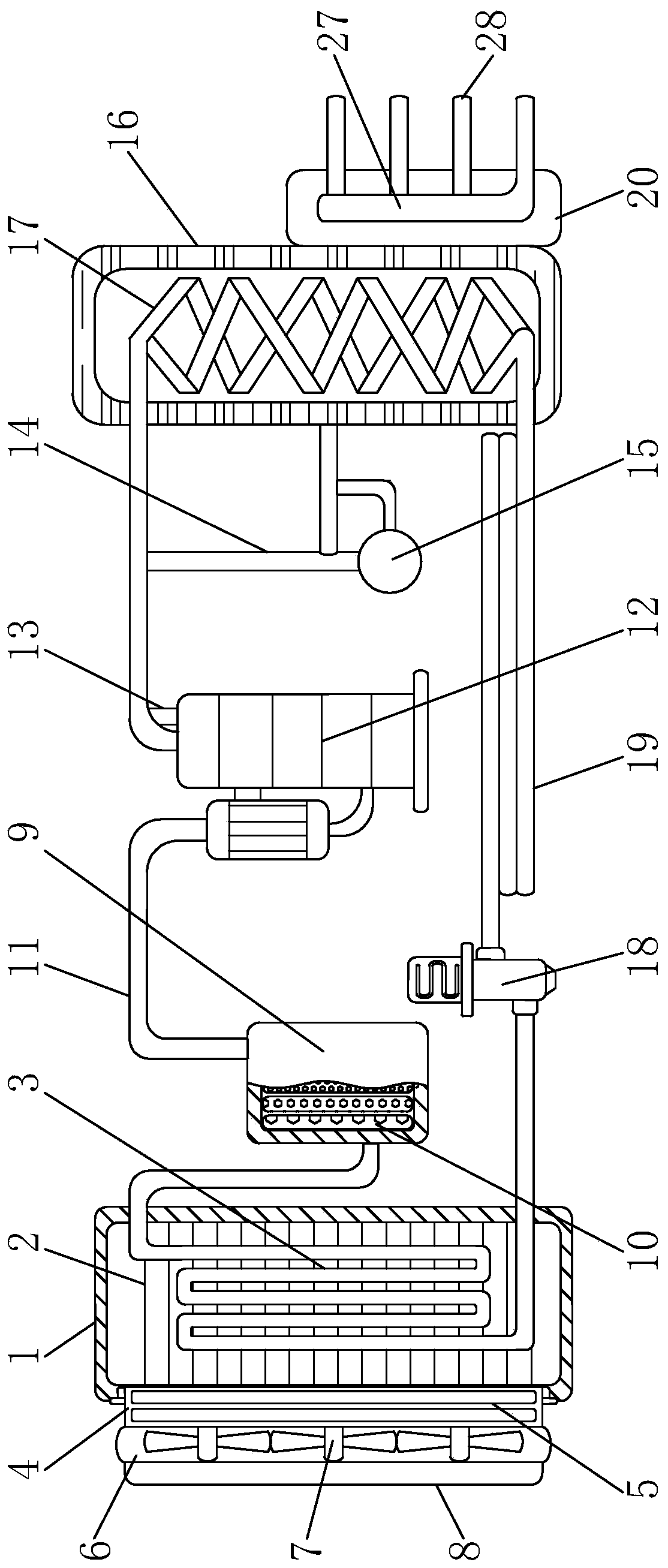

Air-energy water heater

ActiveCN108518862AAffect normal workImprove product performanceFluid heatersPump componentsEvaporationEngineering

The invention discloses an air-energy water heater. The air-energy water heater comprises an evaporator, a drying tank, a heat exchange water tank and a transition water tank, wherein an isolation sealing plate is installed on the inner wall of the evaporator, and the evaporator is connected with the isolation sealing plate in a welding manner; an evaporation contact pipe is arranged at the middleof the evaporator, and a first filter plate is installed at the left side of the evaporator; the first filter plate is installed at the left side of the evaporator in an embedding manner; a filter screen is arranged in the first filter plate, and the first filter plate is fixedly connected with the filter screen; water absorption sponge is arranged in the drying tank, and the drying tank is located at the right side of the evaporator; a heat exchange pipe is installed in the heat exchange water tank, and the heat exchange water tank is located at the right side of a condensation water collection ball; and cutting plates are fixed to the upper side and the lower side of the back surface of the transition water tank, and the transition water tank is located below the right side of the heatexchange water tank. The air-energy water heater can be used in a cold environment, and is rapid in heating and stable in running.

Owner:日照新睿招商发展有限公司

Energy-saving heat pump system

InactiveCN104457005AAvoid melting or deformationExtended service lifeFluid heatersMechanical apparatusEvaporatorEngineering

The invention discloses an energy-saving heat pump system. The energy-saving heat pump system comprises a compressor, a four-way valve, a first condenser, a second condenser, a throttling device and an evaporator, wherein the first condenser is connected between the compressor and the four-way valve in series. The energy-saving heat pump system can work in a heating mode or a defrosting mode as needed. The energy-saving heat pump system has the advantages that energy saving effect is good and the compressor and the four-way valve are effectively protected.

Owner:江门市凯立信电气科技有限公司

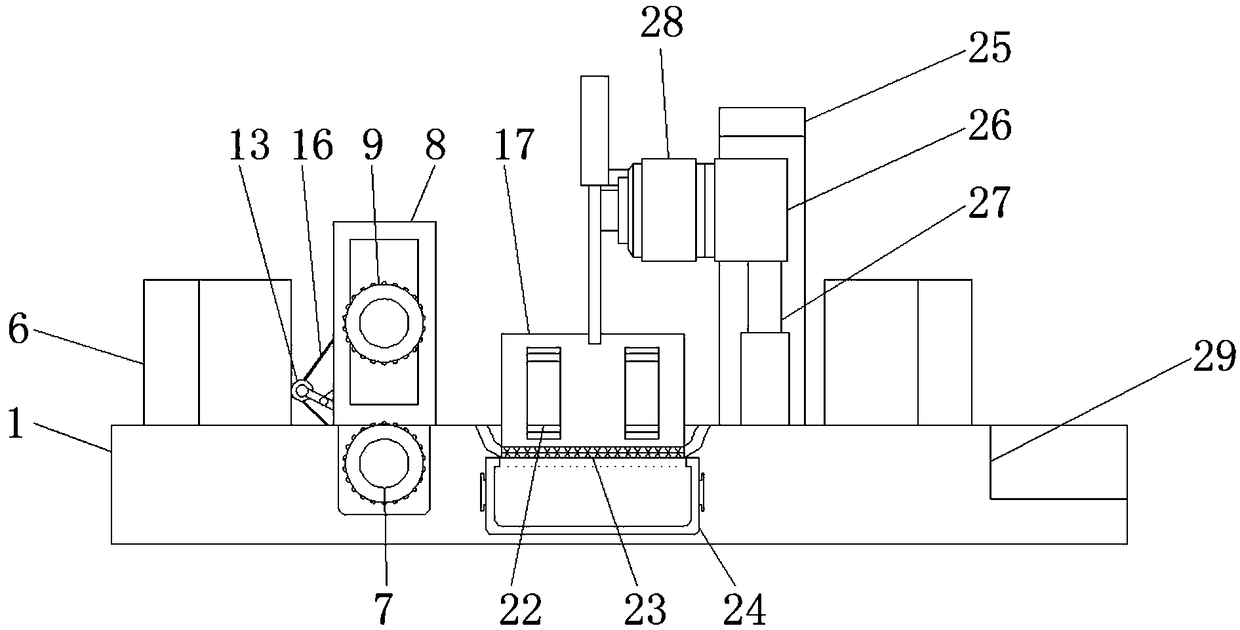

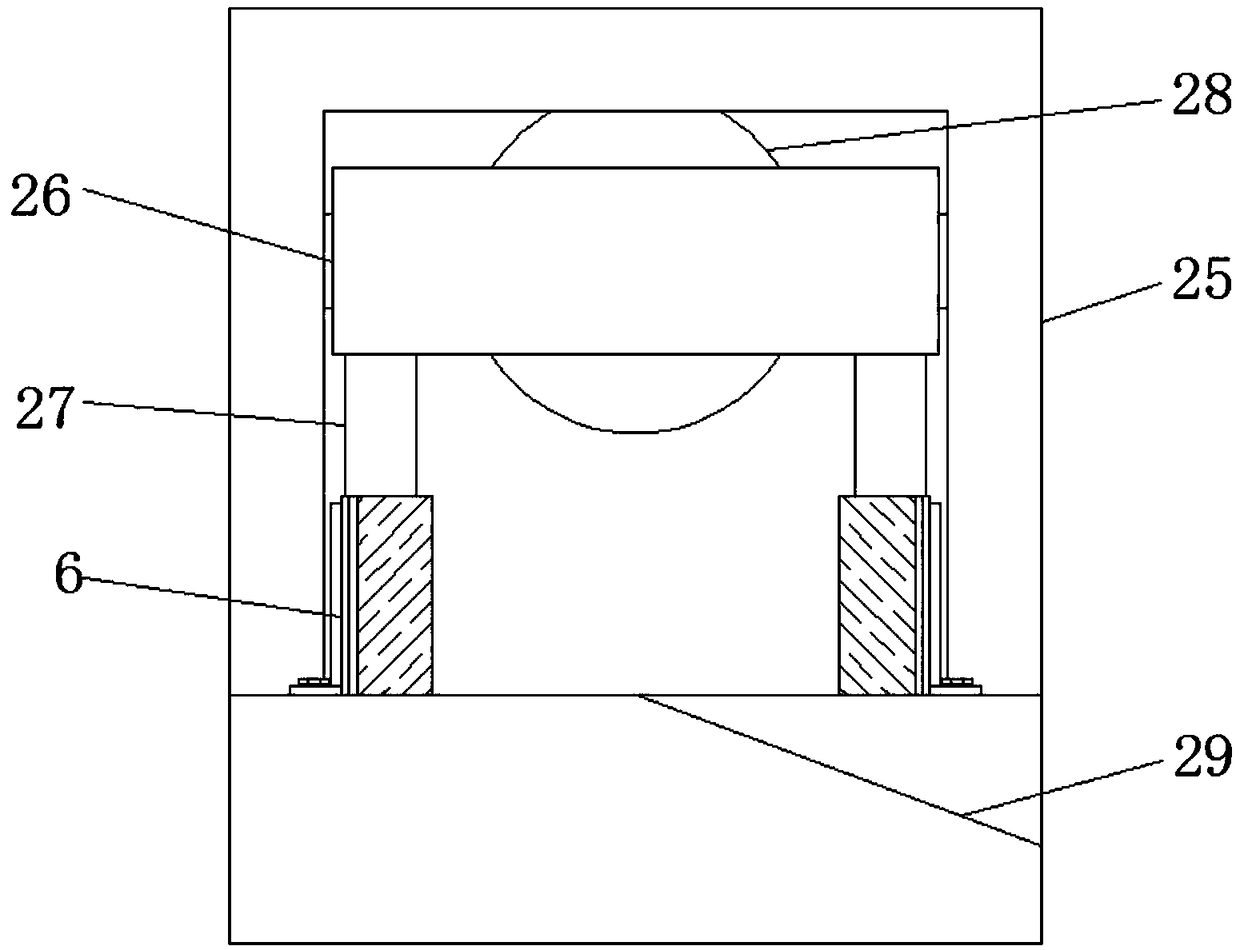

Water pipe cutting device capable of achieving precise guiding and avoiding water pipe brittle failure

InactiveCN108748360AAvoid the phenomenon of brittle fractureEasy to fixMetal working apparatusHydraulic cylinderEngineering

The invention discloses a water pipe cutting device capable of achieving precise guiding and avoiding water pipe brittle failure. The water pipe cutting device comprises a base seat, extending-and-contracting rods, a tightening wheel, a hydraulic cylinder, a gantry and a discharging plate. Sliding grooves are formed inside the left end of the base seat. An adjustment plate is connected to the outer side of each fixing plate, and a lubricating pad is arranged on the outer end face of each adjustment plate. Each extending-and-contracting rod is mounted on the inner end face of the correspondingfixing plate, and a driving roller is arranged at the right sides of the fixing plates. A cutting groove is formed below heat transfer plates, and a collection groove is formed below the cutting groove. Ascending-and-descending rods are arranged below a connecting plate. The discharging plate is arranged above the left portion of the base seat. By means of the water pipe cutting device capable ofachieving precise guiding and avoiding water pipe brittle failure, guiding can be conducted precisely, and a water pipe can be fixed conveniently; the brittle failure phenomenon generated when the water pipe is cut can be avoided; the cutting success rate of the water pipe can be increased conveniently; and the water pipe cutting work can be completed rapidly, efficiently and conveniently.

Owner:芜湖市奥尔特光电科技有限公司

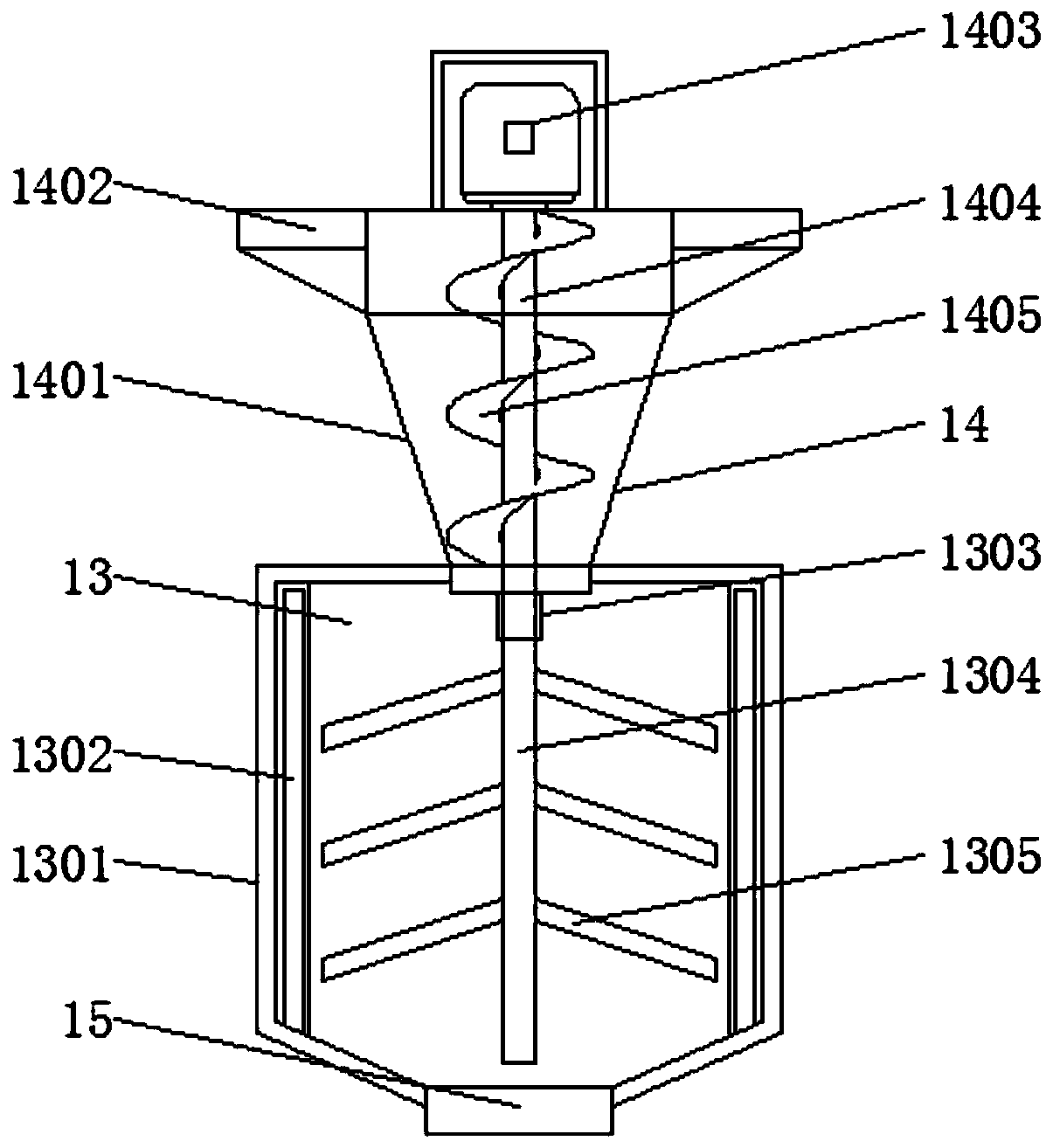

Millet ripening machine

The invention discloses a millet ripening machine. The millet ripening machine comprises a machine body, a conveying assembly and a feeding assembly, a heat preservation layer is arranged on the innerwall of the machine body, a first conveying belt is mounted on the upper part inside the machine body, a second conveying belt is mounted below the first conveying belt, a third conveying belt is mounted below the second conveying belt, rotating shafts are arranged on the lower right part of the first conveying belt, falling plates are fixed to the outer sides of the rotating shafts, microwave magnetrons are mounted on the two sides inside the machine body, a discharging outlet is formed in the lower right part of the machine body, a first temperature sensor is mounted on the upper part inside the discharging outlet, and an adjusting assembly is arranged on the outer side of the discharging outlet. The millet ripening machine is provided with the feeding assembly, thus the feeding speed is convenient to increase, and feeding inlets in the two sides of the upper part of a feeding bin can be used for simultaneous feeding; and a rotating motor is started so that the rotating motor can drive a spiral blade to rotate through a rotary shaft, the falling rate of millet materials is increased accordingly, and the situation of feeding blockage is avoided advantageously.

Owner:湖南志辉知识产权有限公司

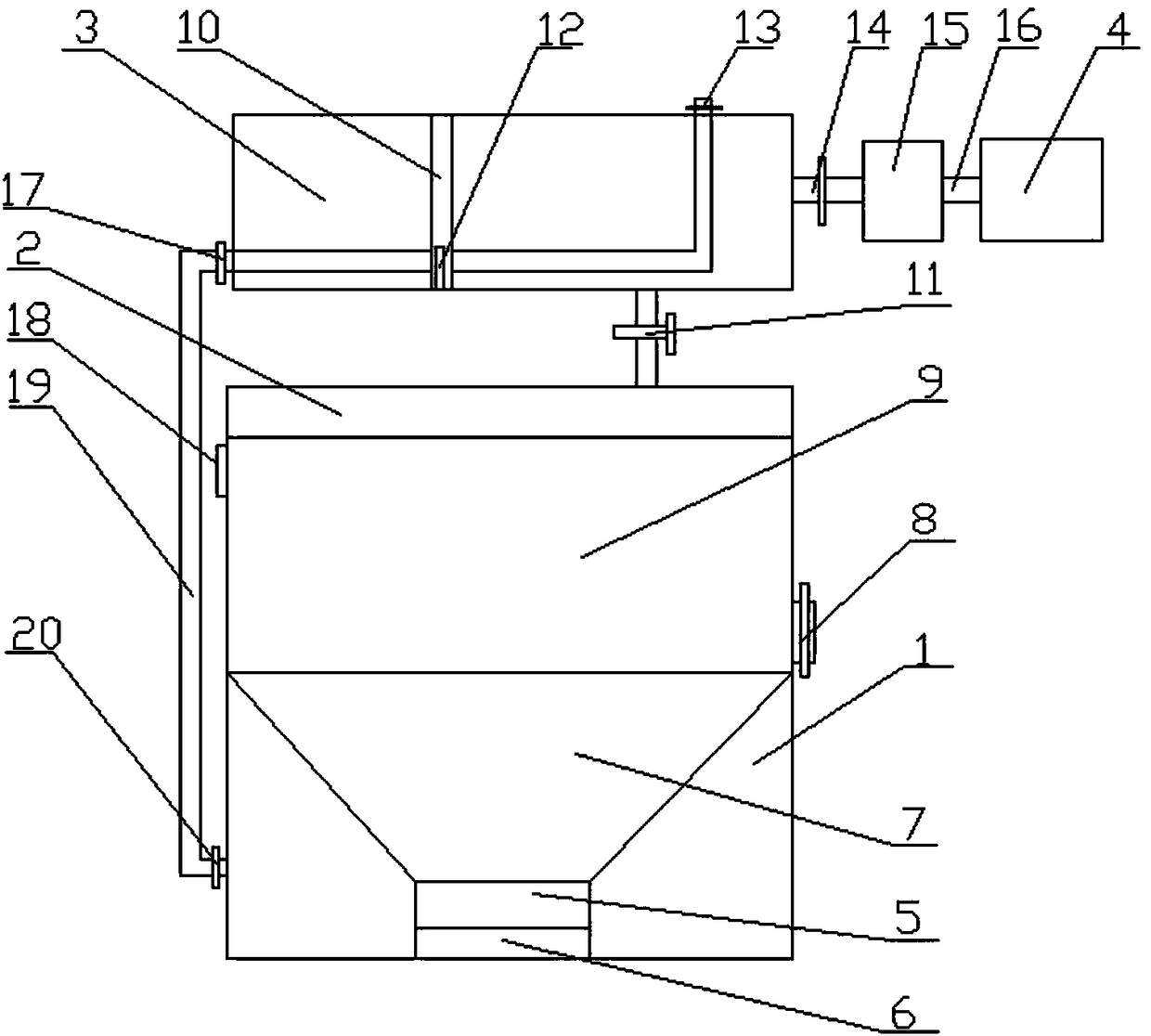

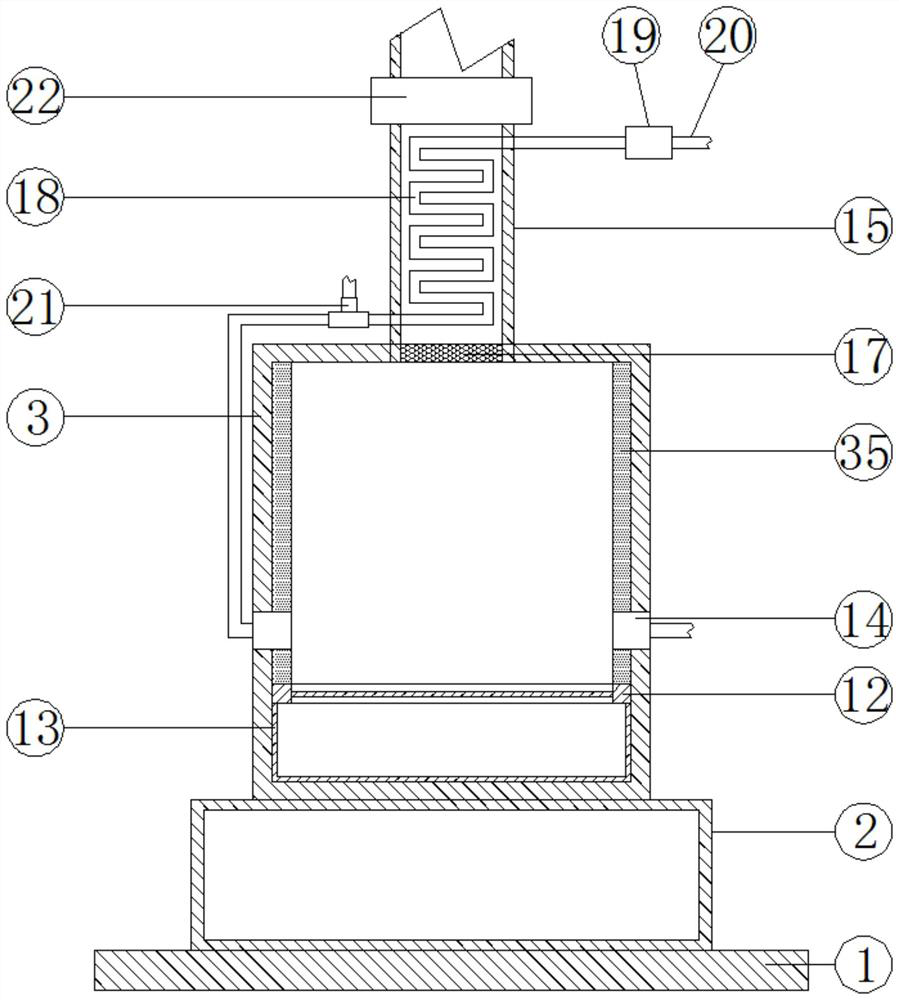

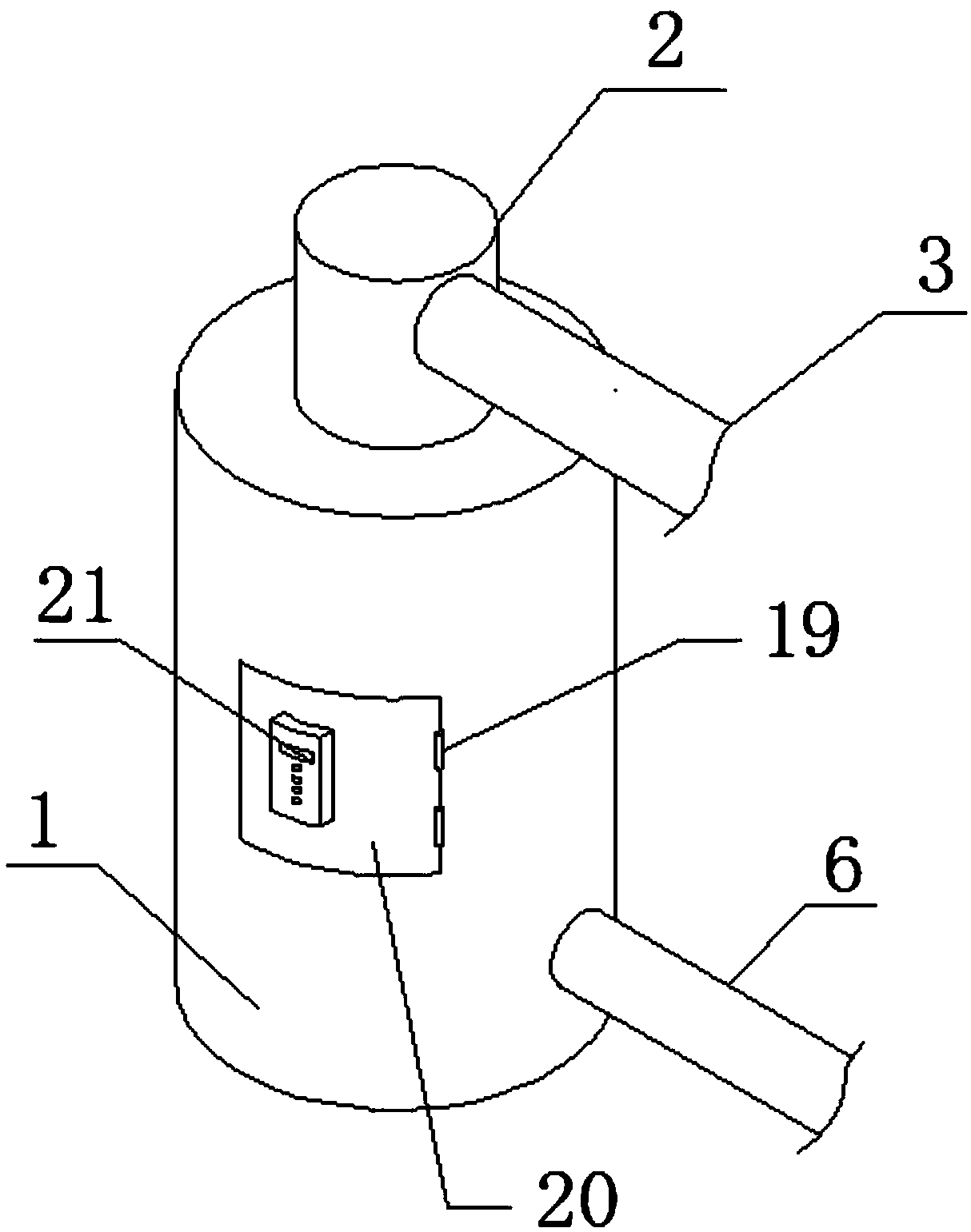

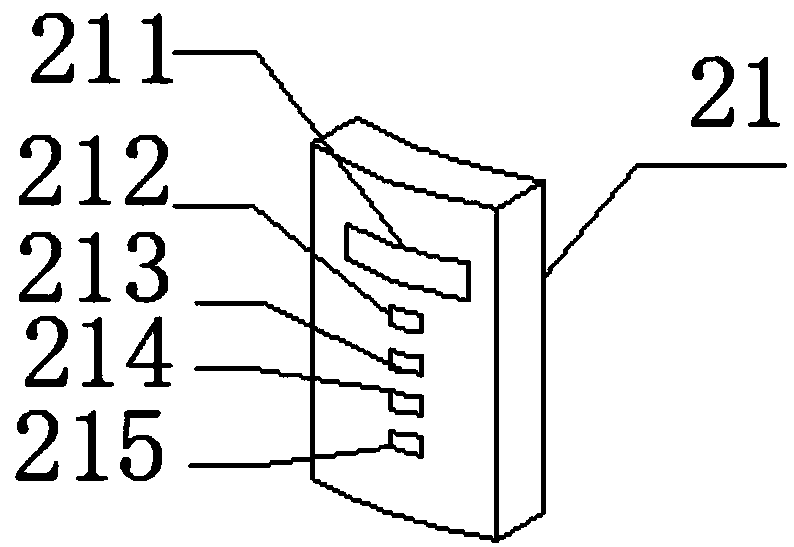

Tail gas energy recycling combustion boiler

InactiveCN109210780AEasy to preheatEfficient use ofCombustion technology mitigationWater heatersCombustorEngineering

The invention belongs to the technical field of combustion boilers, and discloses a tail gas energy recycling combustion boiler. The tail gas energy recycling combustion boiler comprises a combustionboiler body, the combustion boiler body comprises a combustion box, a preheating box and a water pump, a combustor and a water tank are arranged in the combustion box, a water inlet is formed in one side of the preheating box, the water inlet is connected with the water pump through a water pipe, a filtering device is arranged in the water pipe, an air inlet is formed in one side of the preheatingbox, an exhaust port is formed in the upper end of the preheating box, one side of the combustion box is provided with a control panel and an air outlet, the air outlet is connected with the air inlet through an air guide pipe, the preheating box is connected with the combustion box through the water pipe, the water pipe is provided with a valve, and one side of the combustion box is provided with a water outlet. By means of the filtering device in the water pipe, larger impurities in water can be filtered so that the impurities cannot enter the preheating box, and then the combustion rate isprevented from being influenced; and the connection through the air guide pipe is achieved so that waste heat in combustion tail gas can be better utilized to pre-heat the water.

Owner:杨科

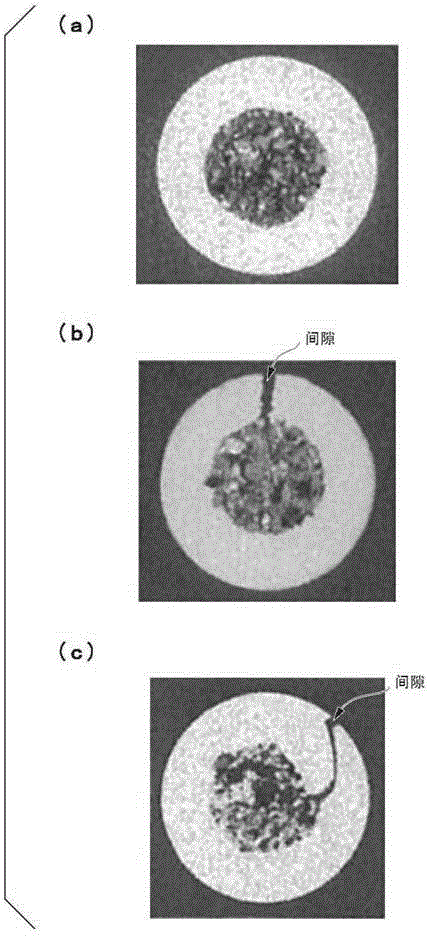

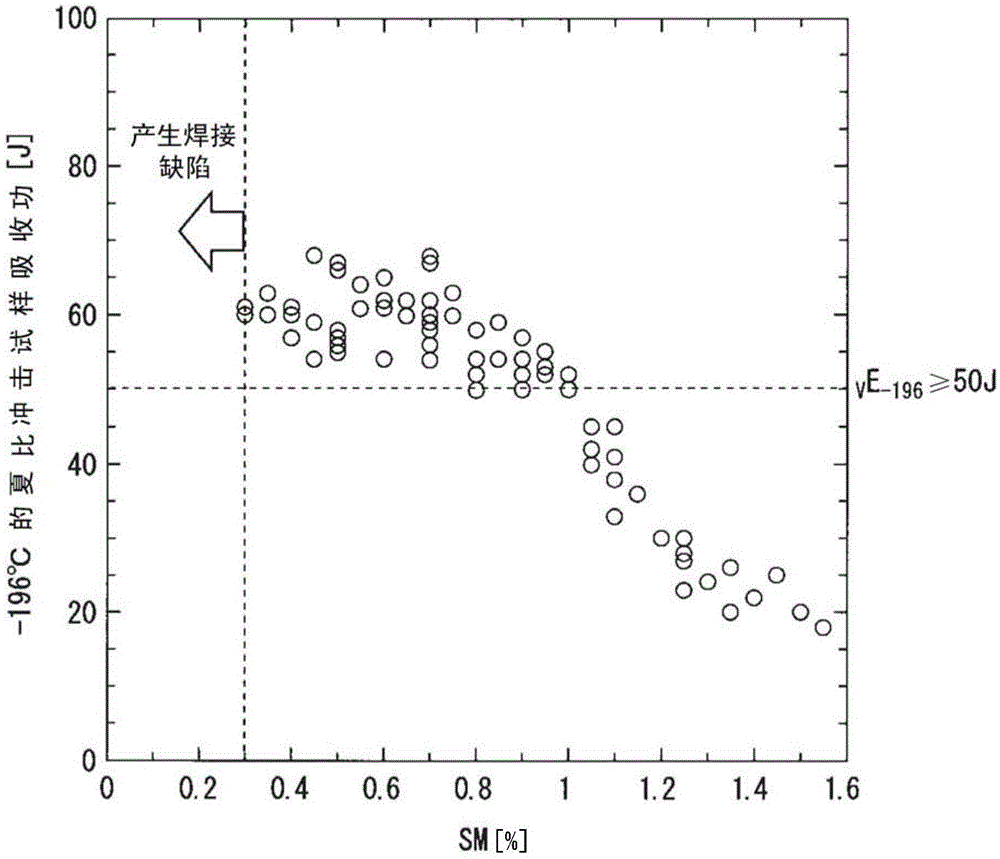

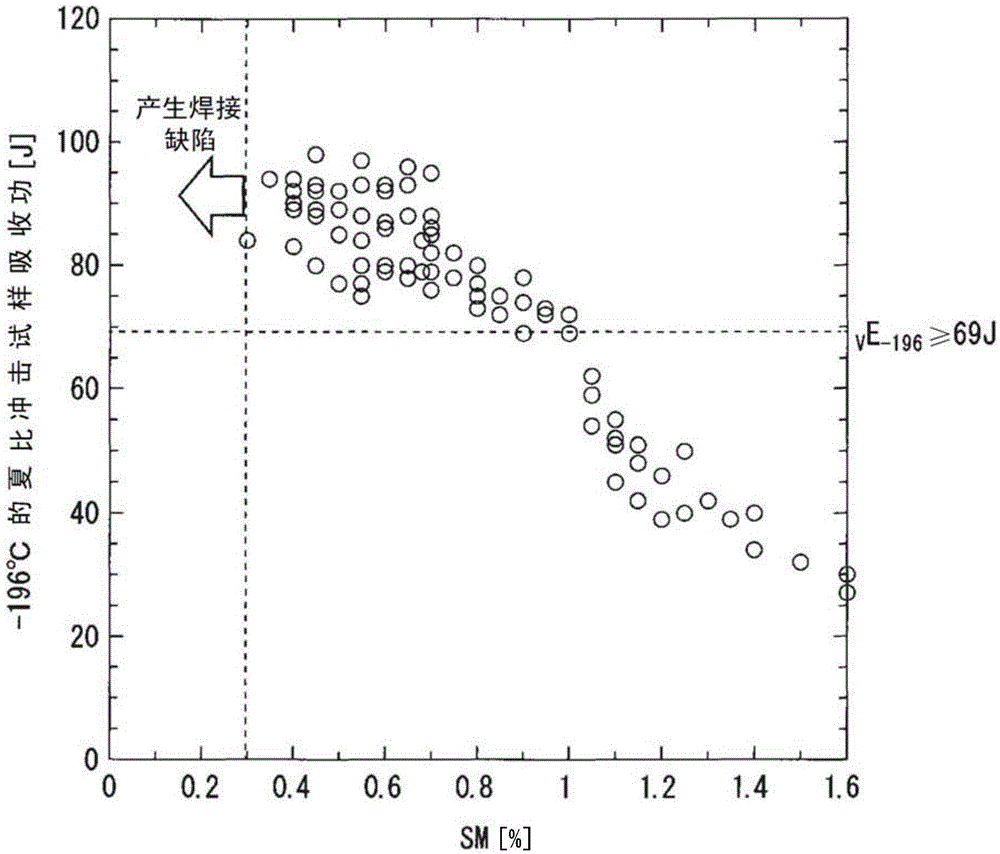

Method for welding flux-filled wire for gas-shielded arc welding and steel for ultra-low temperature, and method for manufacturing welded joint

ActiveCN104625486BImprove low temperature toughnessLow costArc welding apparatusWelding/cutting media/materialsToughnessMetal

Owner:NIPPON STEEL CORP

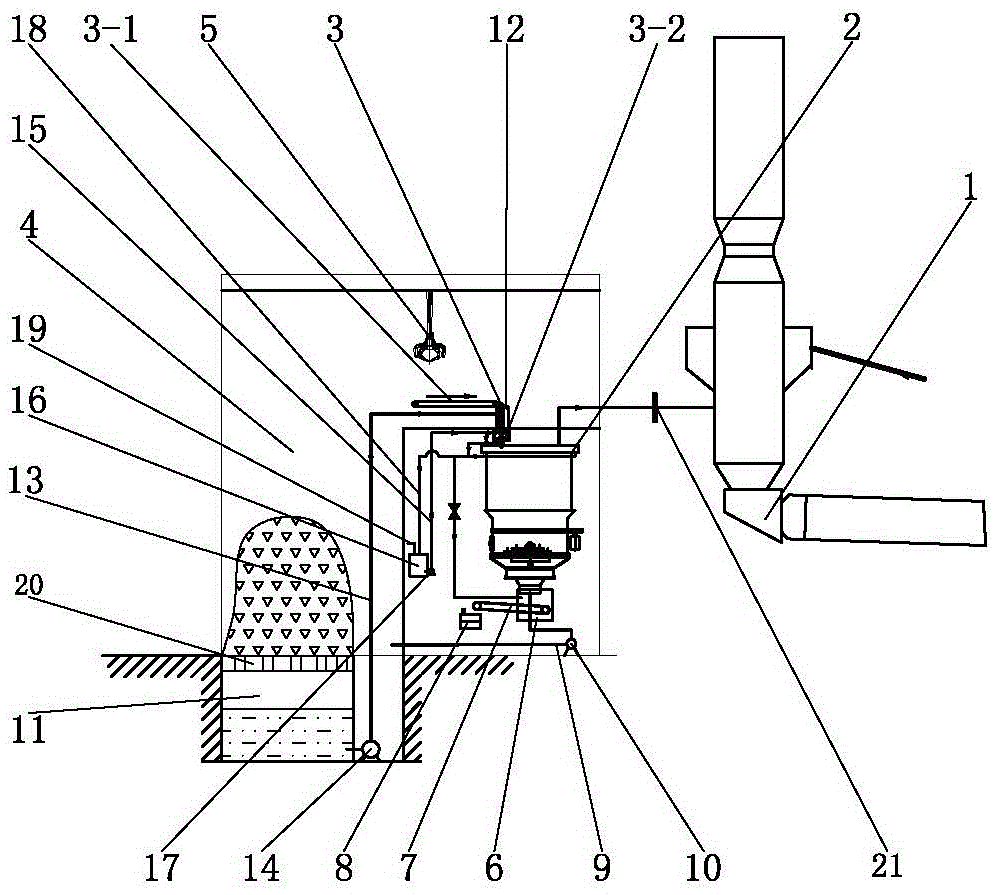

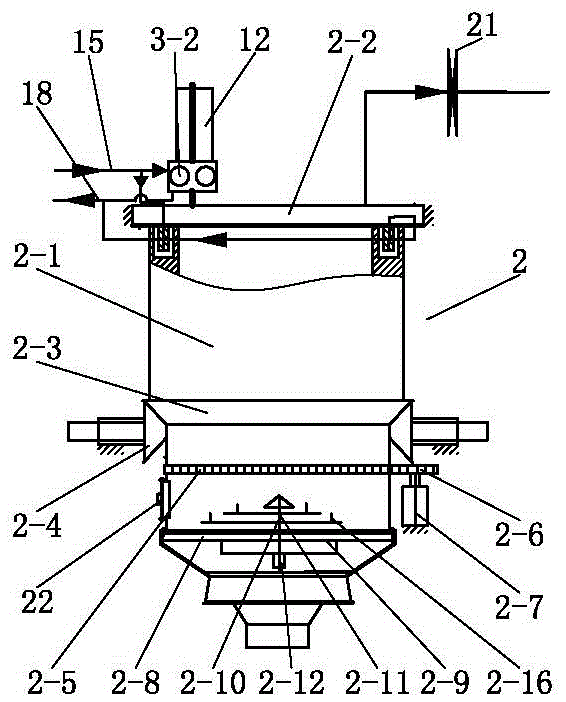

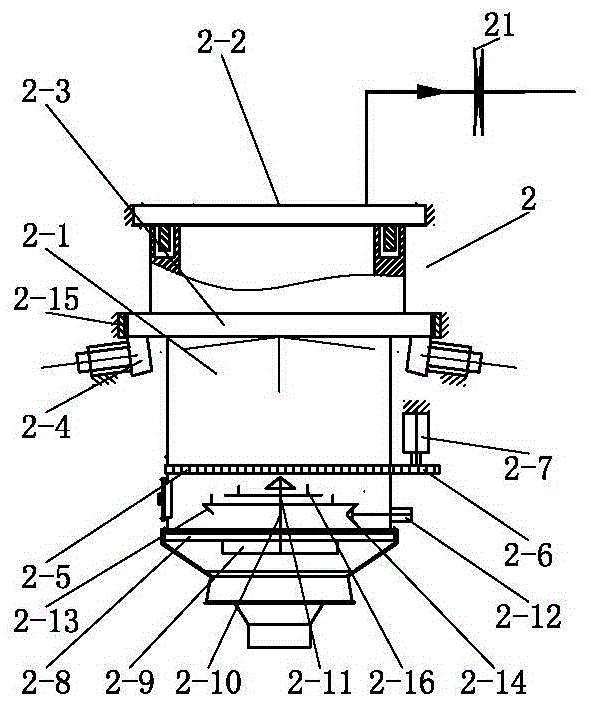

A cement kiln capable of gasifying waste outside the kiln and its gasification method

ActiveCN104531218BScale upEasy pretreatmentGasifier feeding meansGasification processes detailsLitterCement kiln

The invention discloses a cement kiln capable of realizing waste gasification outside the same and a gasification method thereof. The cement kiln capable of realizing waste gasification outside the same comprises a cement kiln, wherein a gas inlet of the cement kiln is communicated with a gas outlet of a waste gasification furnace; a feed port of the waste gasification furnace is positioned below an outlet of a waste conveying device; an inlet of the waste conveying device is positioned in a waste material shed; and a waste grabbing device is arranged in the waste material shed. An operating method of the cement kiln capable of realizing waste gasification outside the same is characterized in that heat generated by burning part of waste in the waste gasification furnace is used to heat the rest of the waste in the waste gasification furnace, so that the rest of the waste can be gasified. According to the invention, the defect that domestic waste is high in water content and contains complicated components is overcome, the pretreatment procedure can be greatly simplified, the treatment cost is greatly lowered, and the domestic waste treatment scale is expanded; and furthermore, no auxiliary fuel is needed. Besides, the waste feeding uniformity can be ensured, thereby being beneficial to uniform distribution in the waste gasification furnace.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

An improved tray-packed rectification column for molecular distillation

ActiveCN111803986BEnsuring Distillation EfficiencyImprove distillation efficiencyFractional distillationReboilerThermal insulation

The invention relates to the technical field of molecular distillation, and discloses an improved tray-packed rectification tower for molecular distillation, which includes a tower body, a discharge heat exchanger is arranged on one side of the bottom end of the tower body, and the bottom of the tower body There is a reboiler on the other side of the end, and a feed heat exchanger is installed outside the middle of the tower body, and the middle part of the top of the tower body is connected with a gas phase discharge pipe, and the other end of the gas phase discharge pipe is connected to a top heat exchanger. , the inside of the tower body is provided with an inner chamber, the inside of the inner chamber is surrounded by a first circulation pipe, the inside of the tower body is distributed from bottom to top with several trays, and the inside of the tower body runs through the center of the trays. central tube. The invention realizes the recovery and utilization of heat, facilitates the heat preservation of the tower body, avoids the heat loss of the tower body, and can preheat the materials, and utilizes the cooperation of the central tube and the gas ring to facilitate the formation of several steam layers in the tower body , to ensure better contact between the steam and the material, and improve the rectification efficiency of the material.

Owner:宿迁市盈科新材料有限公司

air energy water heater

ActiveCN108518862BAffect normal workImprove product performanceFluid heatersPump componentsEngineeringWater collection

The invention discloses an air-energy water heater. The air-energy water heater comprises an evaporator, a drying tank, a heat exchange water tank and a transition water tank, wherein an isolation sealing plate is installed on the inner wall of the evaporator, and the evaporator is connected with the isolation sealing plate in a welding manner; an evaporation contact pipe is arranged at the middleof the evaporator, and a first filter plate is installed at the left side of the evaporator; the first filter plate is installed at the left side of the evaporator in an embedding manner; a filter screen is arranged in the first filter plate, and the first filter plate is fixedly connected with the filter screen; water absorption sponge is arranged in the drying tank, and the drying tank is located at the right side of the evaporator; a heat exchange pipe is installed in the heat exchange water tank, and the heat exchange water tank is located at the right side of a condensation water collection ball; and cutting plates are fixed to the upper side and the lower side of the back surface of the transition water tank, and the transition water tank is located below the right side of the heatexchange water tank. The air-energy water heater can be used in a cold environment, and is rapid in heating and stable in running.

Owner:日照新睿招商发展有限公司

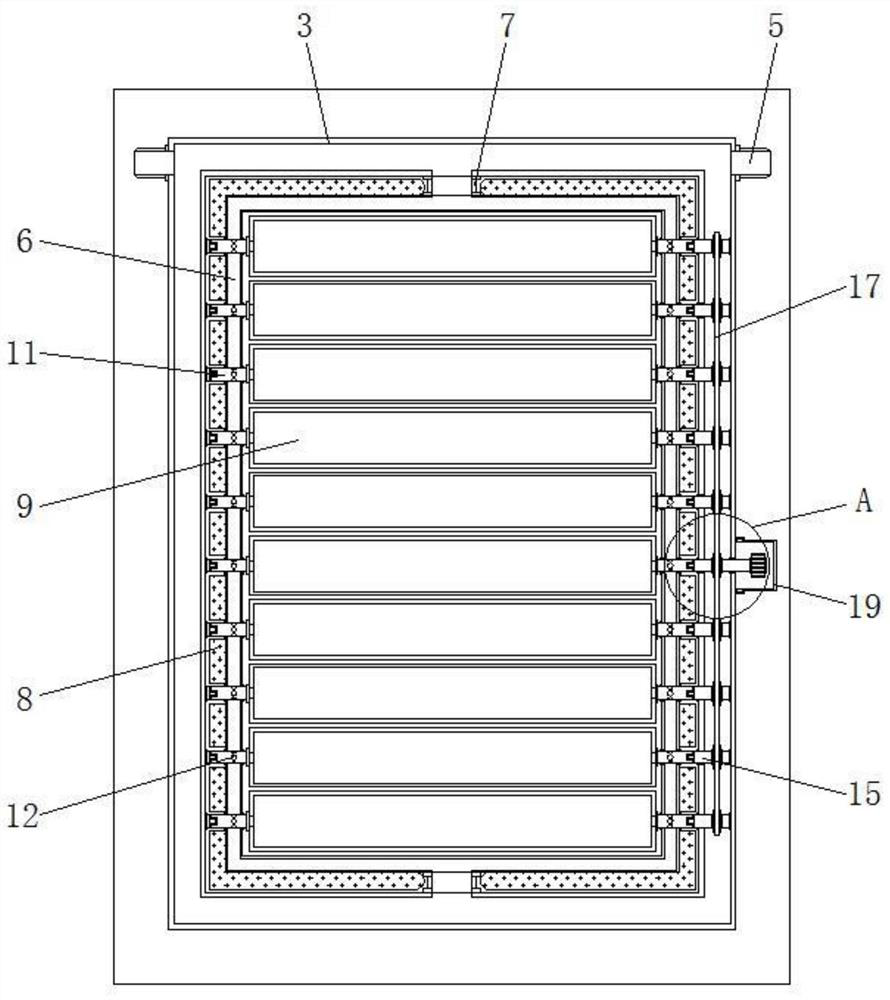

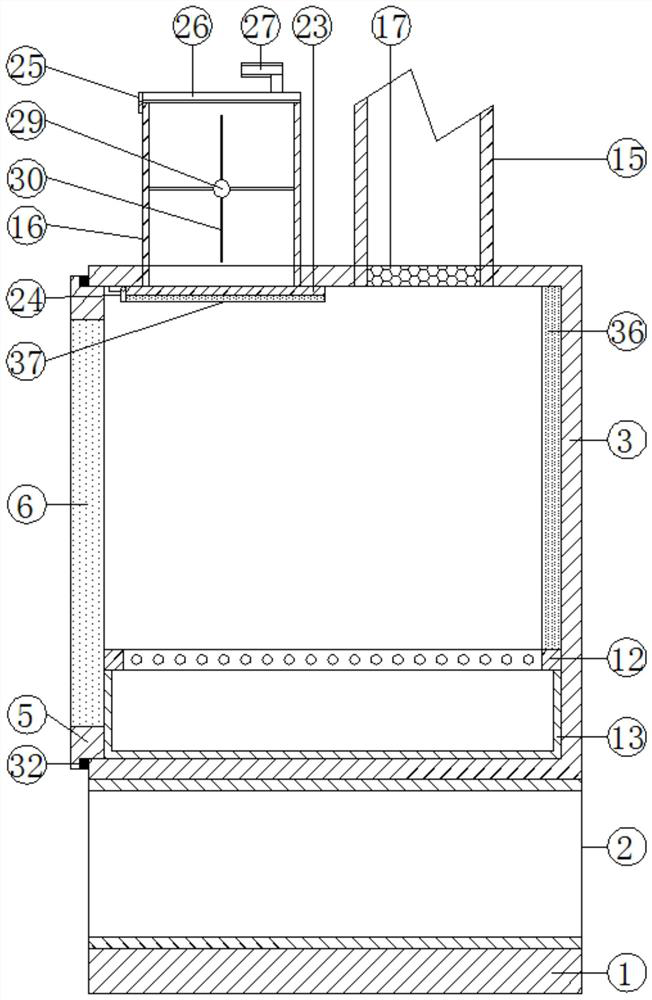

A passive solar energy coordinated and efficient use of flipped building windows

ActiveCN111305703BCoordinated and Efficient UtilizationEasy to preheatPhotovoltaic supportsSolar heating energyEngineeringThermal water

The invention discloses a flip-type building window for coordinated and efficient use of passive solar energy. There is a first frame body, and a docking port is opened on the window frame, the first frame body is connected to the electrical box on the outside of the wall through wires, the upper end of the support rod is connected to the window frame, and the outside of the support rod Set with fastening bolts. The passive solar energy coordinates and efficiently utilizes the overturned building window. When the first frame is rotated and opened from the window frame, the support rod will pull the second gear to rotate through the connecting tooth block. At this time, the second gear can pass through the horizontal The rod and the horizontal axis drive the horizontal tube to rotate and adjust the angle, which is convenient to use solar energy to irradiate the horizontal tube, which is conducive to preheating the water in the horizontal tube, avoiding wasting a lot of water when hot water is needed, and at the same time reduces loss of gas.

Owner:深圳市胜德建筑科技有限公司

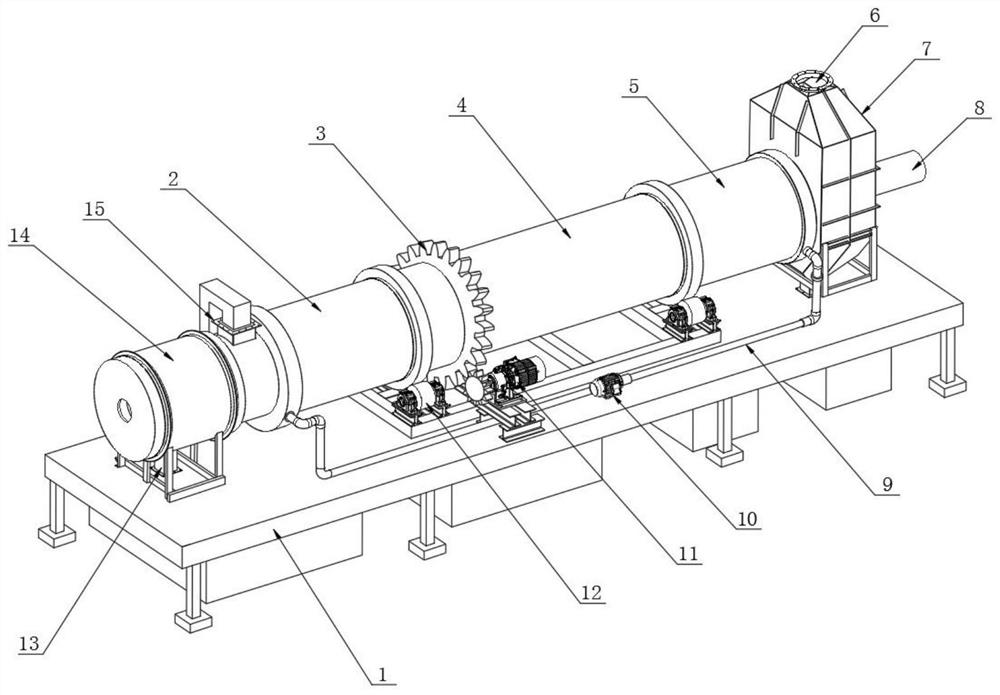

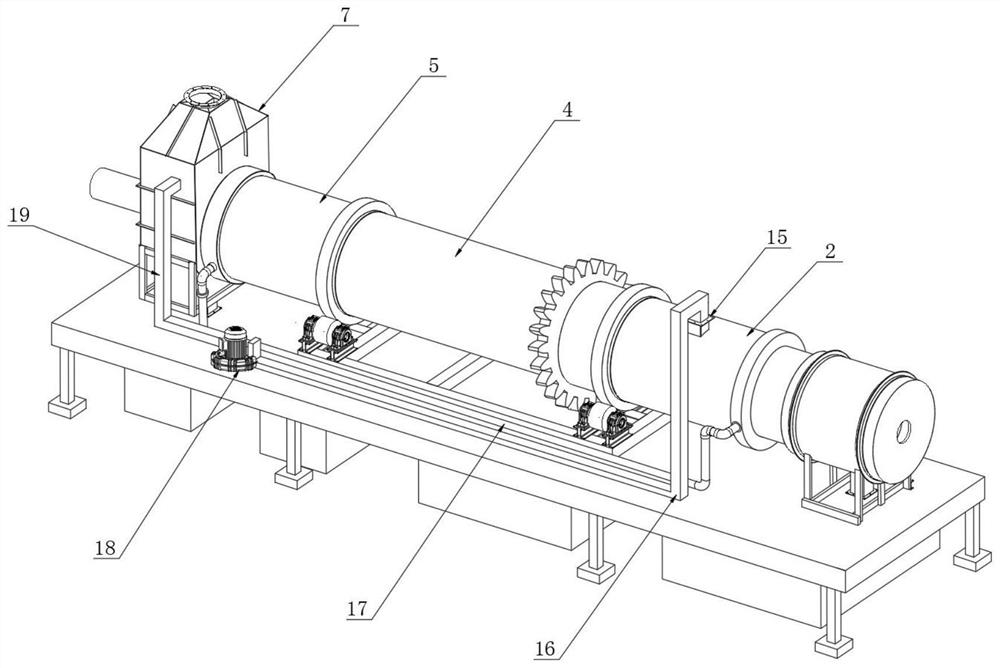

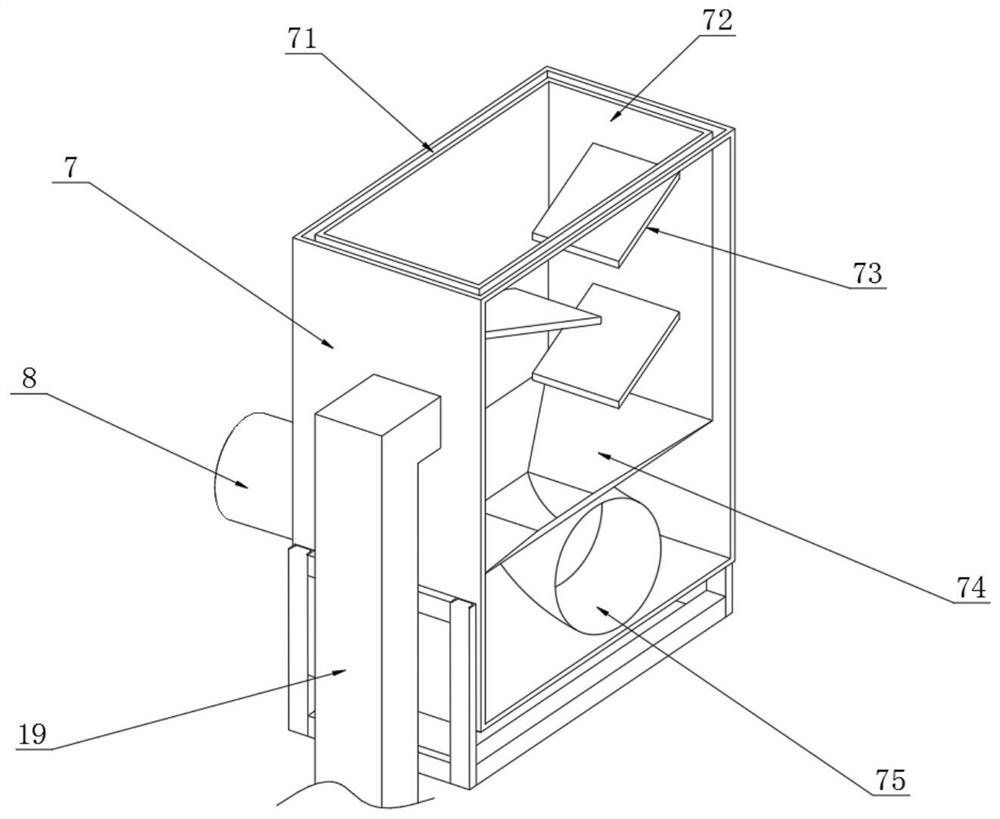

A raw meal calcining device for cement production

ActiveCN111189319BEasy to preheatAchieve initial warm-upRotary drum furnacesThermodynamicsClinker (waste)

The invention relates to the technical field of cement production, and discloses a raw material calcining device for cement production, which includes a frame, a rotary kiln is arranged on the upper end of the frame, and a preheating cylinder is connected to the front end of the rotary kiln, and The rear end of the rotary kiln is connected with a cooling cylinder, the upper end of the cooling cylinder is provided with an air suction port, one end of the preheating cylinder is connected with a preheating box, and the side of one end of the preheating cylinder and the side of one end of the cooling cylinder A liquid return pipe is provided, a compression refrigerator is provided in the middle of the liquid return pipe, a delivery pipe is provided between one end and the other side of the preheating cylinder and the other end side of the cooling cylinder, and one end of the air suction port is connected to There is an exhaust pipe. The invention fully recycles and utilizes the high temperature generated when the raw material is calcined into high-temperature clinker, and uses the recovered high-temperature heat to fully preheat the raw material to improve its calcination efficiency, avoid waste of resources, and simultaneously realize heat efficient recycling.

Owner:内蒙古伊东冀东水泥有限公司

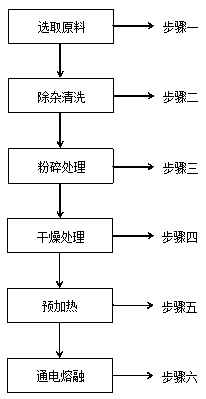

Method for electrically heating glass

InactiveCN109485236AAchieve electrificationEasy to pick and place by handGlass furnace apparatusElectric furnaceHeating effectViscosity

The invention discloses a method for electrically heating glass. The method includes the following steps: (1) raw material selecting: selecting glass with relatively clean surface as a raw material; (2) impurity removal and cleaning: soaking the glass selected in the step (1) in a liquid containing a surfactant, taking out the glass after soaking for 2 to 3 hours, and washing the glass with purified water; (3) pulverizing: adding the glass after impurity removal and cleaning in the step (2) into an ultra-micro pulverizer, and fully pulverizing to prepare glass powder; (4) drying treatment: adding the glass powder prepared in the step (3) into a powder dryer, drying, and continuously drying for 1 hour between 90 and 110 degrees; (5) preheating: introducing the glass powder dried in step (4)into a melting furnace, and heating the glass powder to 600 to 700 degrees by using a heating rod to reduce the viscosity of the glass powder. The method has the characteristics of good heating effect and high purity of the molten liquid.

Owner:贵定县恒伟玻璃制品有限公司

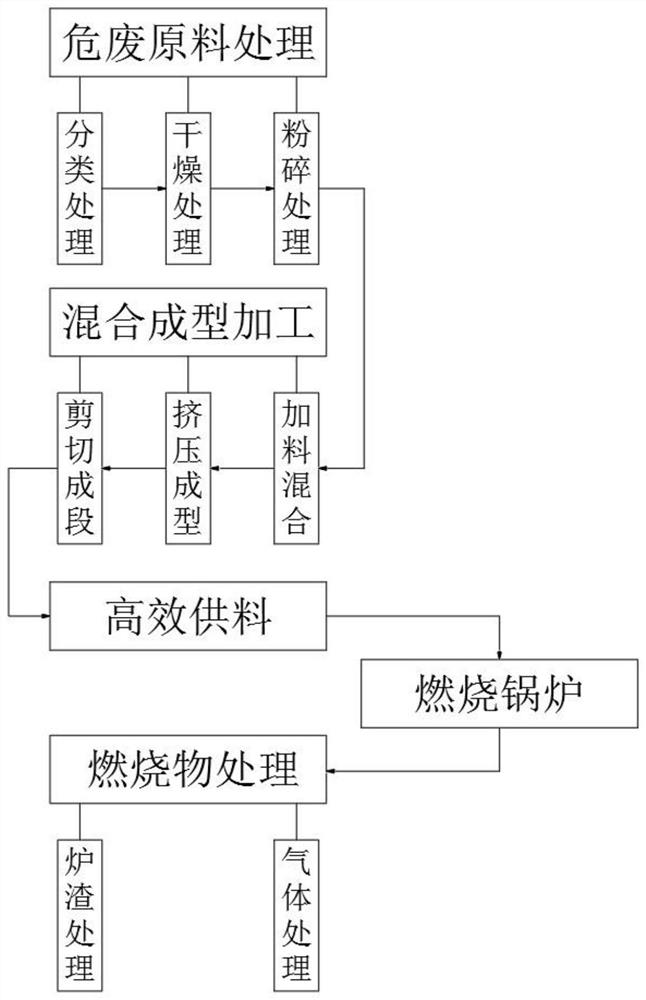

Industrial kiln co-processing method and equipment for hazardous wastes

PendingCN114034046AImprove drying efficiencySolve the problem of not being able to dry effectivelyIncinerator apparatusHazardous substanceEnvironmental engineering

The invention discloses an industrial kiln co-processing method for hazardous wastes. The method comprises the following steps: hazardous waste raw material treating; mixing, molding and processing; efficient feeding; and comburent treating. By classifying, drying and crushing hazardous waste raw materials, mixing and forming the hazardous waste raw materials, and combining an efficient feeding mode, the hazardous waste raw materials have higher combustion efficiency and treatment effect in the actual combustion treatment process, so that the pollution of the hazardous waste raw materials to the environment is reduced, resource loss of a combustion boiler is reduced, production cost of enterprises is reduced, economic and environment-friendly benefits are jointly improved, and the problems that in the prior art, hazardous waste with different water contents cannot be subjected to classified drying treatment, so that hazardous substances are separated out due to the fact that hazardous waste with low water content is heated and dried excessively, secondary harm is caused, and raw materials with high water content cannot be effectively dried, so that the subsequent combustion efficiency is low, and the raw materials cannot be better treated are solved.

Owner:南京希捷环保科技有限公司

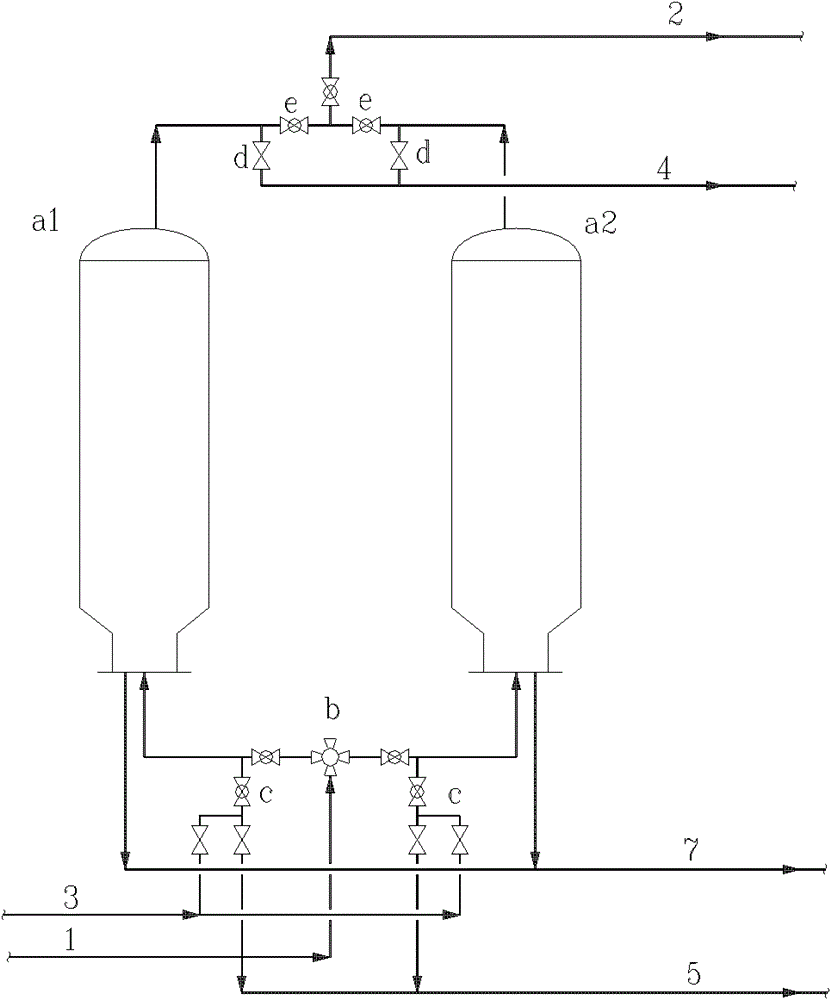

Delayed coking device and counterflow steam pressure testing method for coke tower

ActiveCN103045287BReduce consumptionEfficient use ofThermal non-catalytic crackingSteam pressureTower

The invention discloses a delayed coking device and a counterflow steam pressure testing method for a coke tower. The device comprises blowing and pressure testing pipelines which are arranged at the top of a first coke tower and a second coke tower and is connected with the first coke tower and the second coke tower respectively or connected with the large oil and gas pipelines disposed at the top of the first coke tower and the second coke tower. The method comprises the steps of introducing pressure testing steam into the coke tower from the top of the coke tower, and replacing air in the coke tower from the bottom of the coke tower by flowing in the coke tower from top to bottom. With the device and the method provided by the invention, disadvantages in a conventional flow are overcome, and the operation is simple, flexible and reliable.

Owner:CHINA PETROCHEMICAL CORP +1

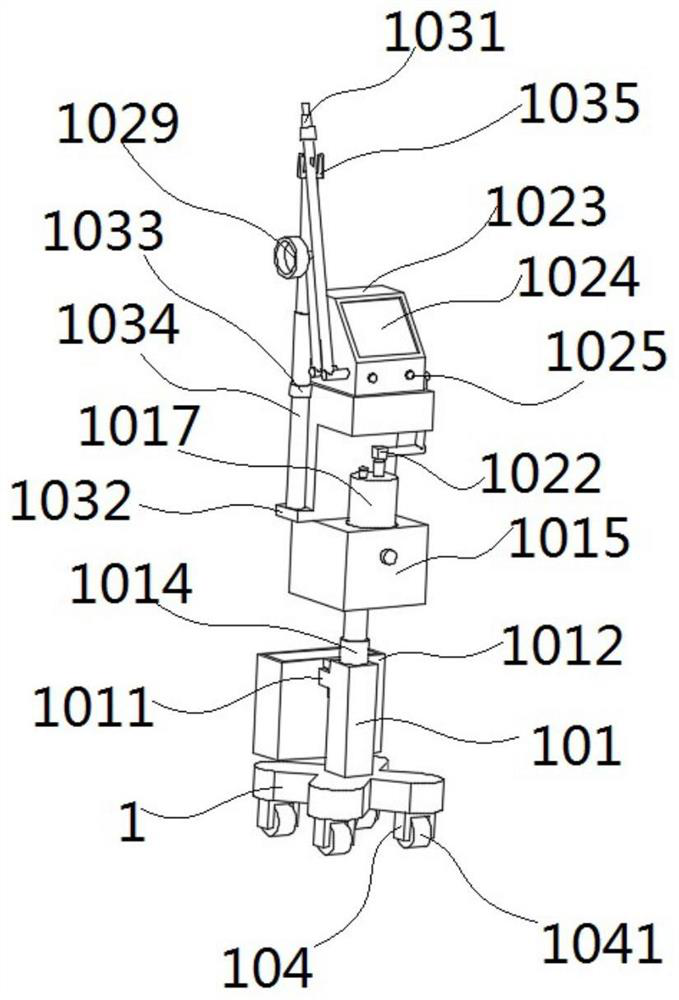

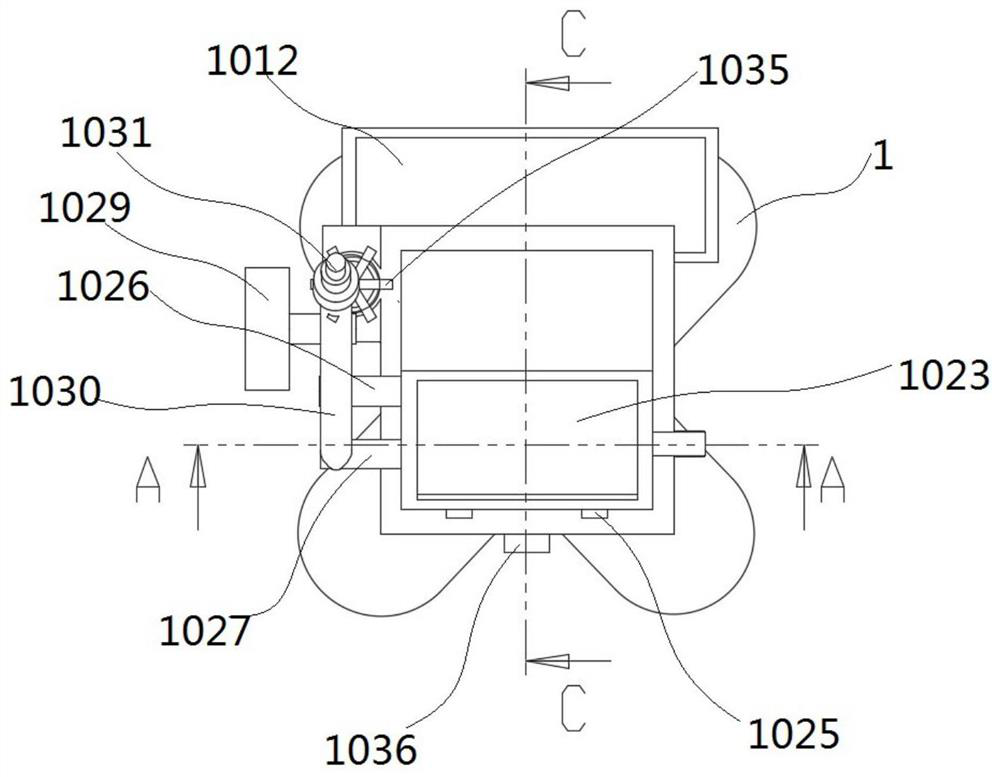

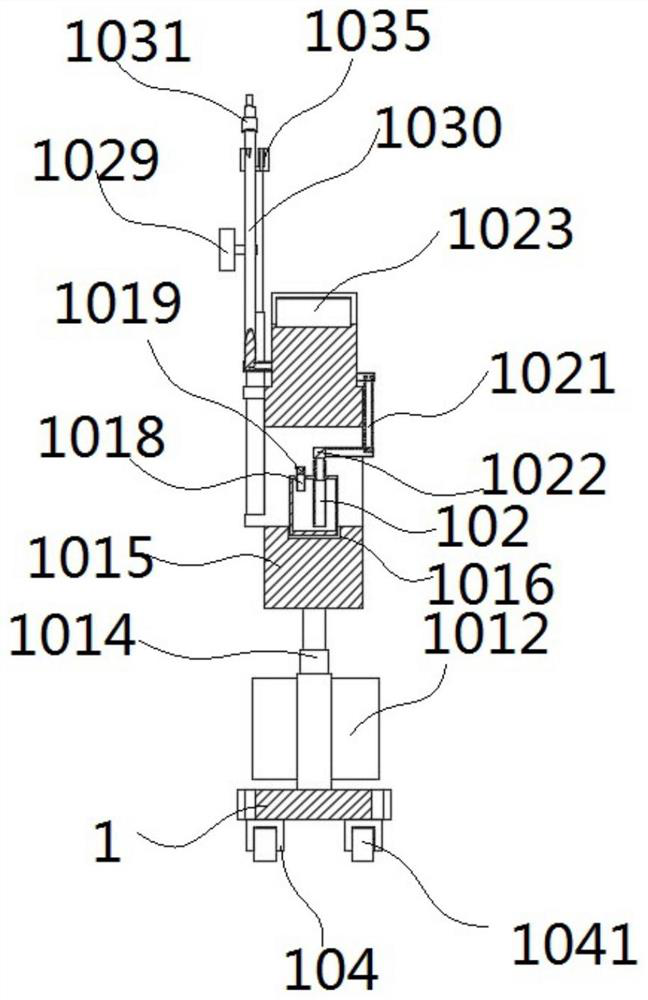

Atomization dosing device driven by invasive ventilator

InactiveCN112426598AEasy to preheatEasy to put inMedical devicesMedical atomisersApparatus instrumentsType ventilator

The invention discloses an atomization dosing device driven by an invasive ventilator, and relates to the technical field of medical instruments. The device comprises a base, a fixing column is arranged on the base, a telescopic column and a storage basket are arranged on the fixing column, a fixing frame is arranged on the telescopic column, a storage barrel and a driving atomizer are arranged onthe fixing frame, and an atomizing mask and an inserting pipe are arranged on the driving atomizer. The telescopic column is arranged on the fixing column so that the height of the dosing device is conveniently adjusted according to the height of a sickbed or the current sitting and lying state of a patient, and the patient feels more comfortable during treatment; the heating plate is arranged below the storage barrel so that liquid medicine is preheated conveniently, and discomfort of a patient due to the fact that the temperature of the liquid medicine is excessively different from the temperature of a human body is avoided; the atomization mask and the cannula are arranged on the driving atomizer so that different atomization dosing modes are conveniently selected according to the physical condition of the patient, and the application range is widened; by arranging the storage basket on the fixing column, medical instruments needed in the dosing process can be conveniently placed in the storage basket, and use is facilitated for medical staff.

Owner:王润丽

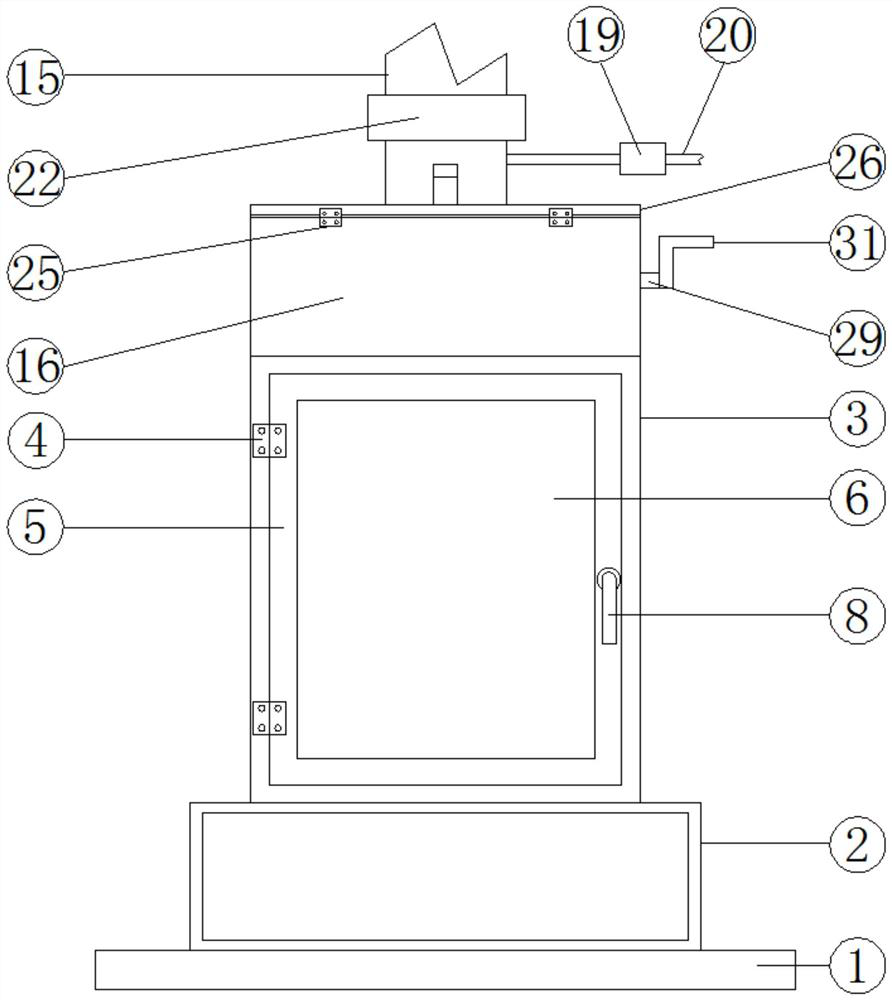

Vacuum fireplace capable of effectively solving backfire problem

InactiveCN111664473APrevent flashbackAvoid burnsDomestic stoves or rangesSolid heating fuelFirewoodFire - disasters

The invention discloses a vacuum fireplace capable of effectively solving a backfire problem. The vacuum fireplace comprises a base. A storage frame is fixedly arranged on the base, a fireplace body is fixedly arranged on the storage frame, a door sheet is movably arranged on the front face of the fireplace body through first hinges, a high-temperature-resistant glass plate is fixedly embedded into the middle of the door sheet, and a locking device is arranged on the side, away from the first hinges, of the door sheet. The locking device comprises a rotary shaft, the rotary shaft is rotationally embedded into the side, away from the first hinges, of the door sheet, and a first handle is fixedly arranged at the outer end of the rotary shaft. The vacuum fireplace has the beneficial effects that the backfire phenomenon generated when firewood is added can be effectively avoided, thus, people can be effectively prevented from being burnt when adding the firewood, the situation that open fire is sprayed when the firewood is added, so that fire disasters exist can be avoided, the safety of the vacuum fireplace can be greatly improved, air fed into the fireplace body and the firewood in the storage frame can be preheated, and therefore burning of the firewood in the fireplace body can be facilitated.

Owner:连云港永喜工贸有限公司

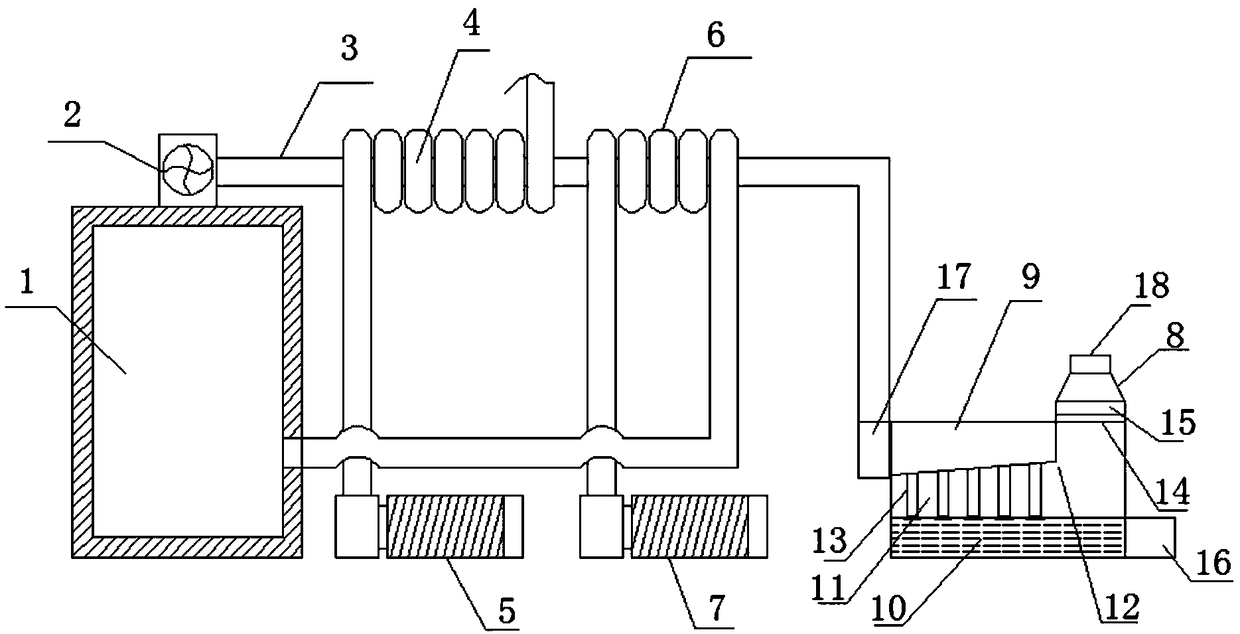

Waste heat recycling equipment used in grain and oil squeezing process

InactiveCN108759516AEasy to preheatThorough treatmentUsing liquid separation agentStationary tubular conduit assembliesCold airCirculating pump

The invention discloses waste heat recycling equipment used in the grain and oil squeezing process. The waste heat recycling equipment comprises a grain and oil squeezing tank. An exhaust fan is welded to the top of the grain and oil squeezing tank. The bottom input end of the exhaust fan communicates with the top input end of the grain and oil squeezing tank. The output end of one side of the exhaust fan is fixedly connected with the input end of an exhaust pipe. Through starting of a circulation pump, cold water is guided into a spiral water pipe, cold water and hot water heat energy exchange is conducted, and the output end of the spiral water pipe can be connected into a domestic water pipeline. An air pump is used for guiding outside air into the spiral air pipe for heat energy exchange, the output end of the spiral air pipe guides the cold air into the bottom of the grain and oil squeezing tank, raw materials at the bottom of the grain and oil squeezing tank can be conveniently preheated, smoke can be thoroughly treated, and the dust removal efficiency is improved. Meanwhile, a smoke distribution chamber and a first smoke treatment chamber are in communication through a plurality of ventilation pipelines, and smoke treatment is more uniform.

Owner:HUIZHOU WULING KANGTAI HEALTH TECH CO LTD

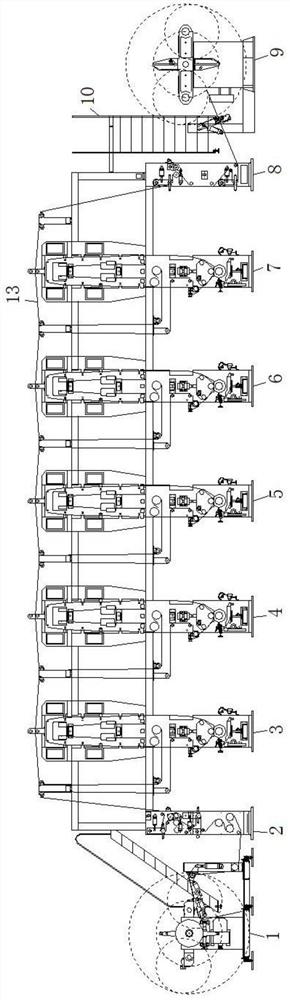

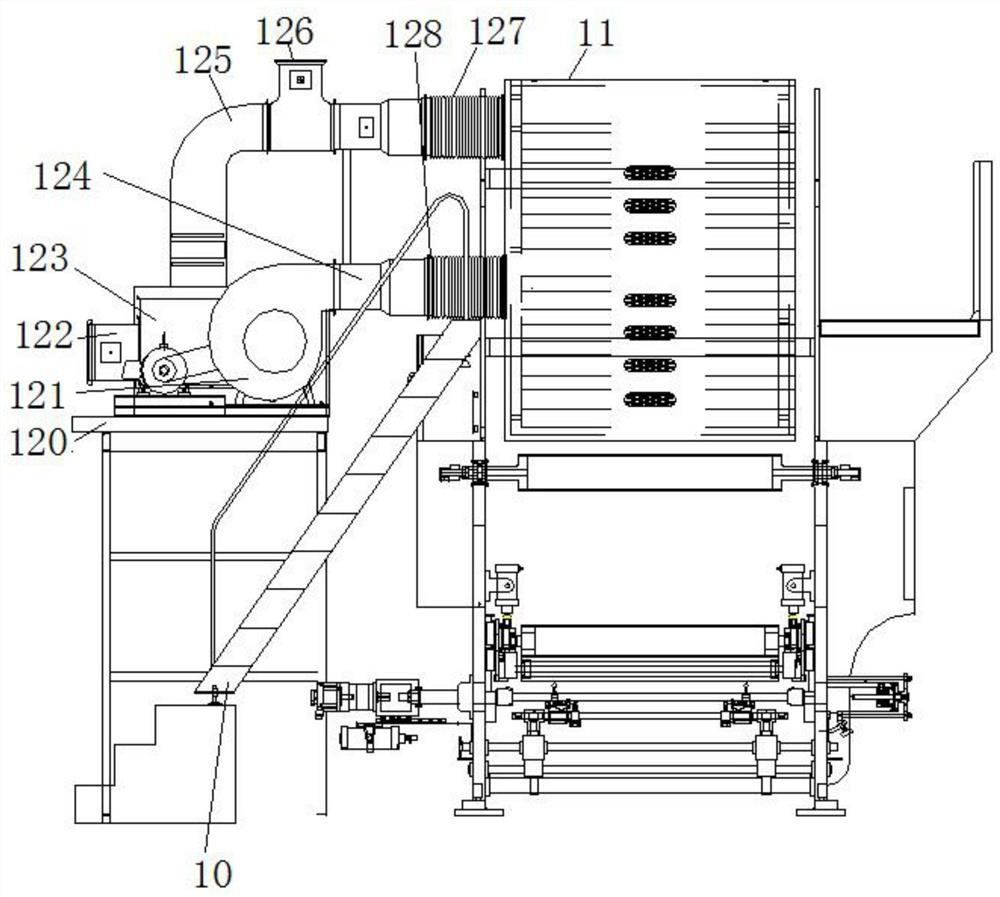

Circular gravure printing and embossing production line

InactiveCN113400774AReduce quality problemsEnsure transfer rateRotary intaglio printing pressPrinting press partsProduction lineThermal deformation

The invention discloses a circular gravure printing and embossing production line which comprises a discharging mechanism, a collecting mechanism, a printing unit, a hot air drying mechanism and a material, wherein the hot air drying mechanism is installed on the rear side surface of the printing unit, the material is printed on the printing unit, the material is conveyed from the discharging mechanism to the collecting mechanism, a leading-in mechanism is arranged at the left end of the printing unit, and a leading-out mechanism is arranged at the right end of the printing unit. According to the circular gravure printing and embossing production line, physical plastic deformation pretreatment is conducted on the printing material through traction preheating so as to reduce the quality problem caused by thermal deformation of the printing material in the printing process, a large-pressure direct pressing mode is adopted for printing and embossing so as to ensure tension stability and the transfer rate of printing dots, the printing effect is full and real, each group of printing is independently driven by a servo motor, the tension between plates is stable and adjustable, the drying effect and the drying speed of water-based ink printing are ensured through the arrangement of a printing and top printing oven structure, and roller sticking and fading are avoided.

Owner:安徽辉盛机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com