Circular gravure printing and embossing production line

A technology of printing embossing and production line, which is applied in the field of circular concave printing embossing production line. It can solve the problems of shrinkage of printing materials, time-consuming and material, wrinkles, etc., and achieve full and real printing effect, stable and adjustable tension, and stable tension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

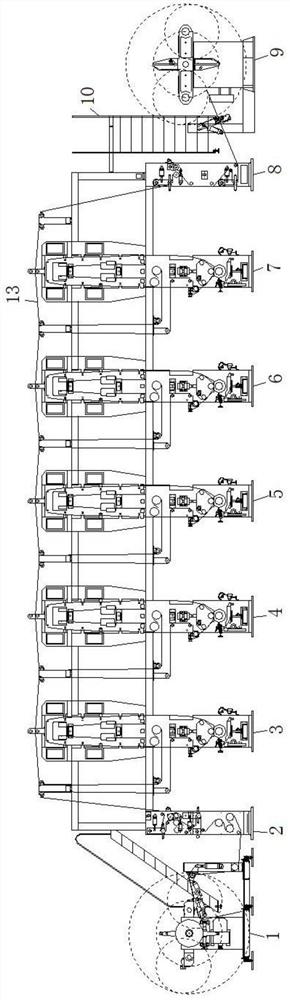

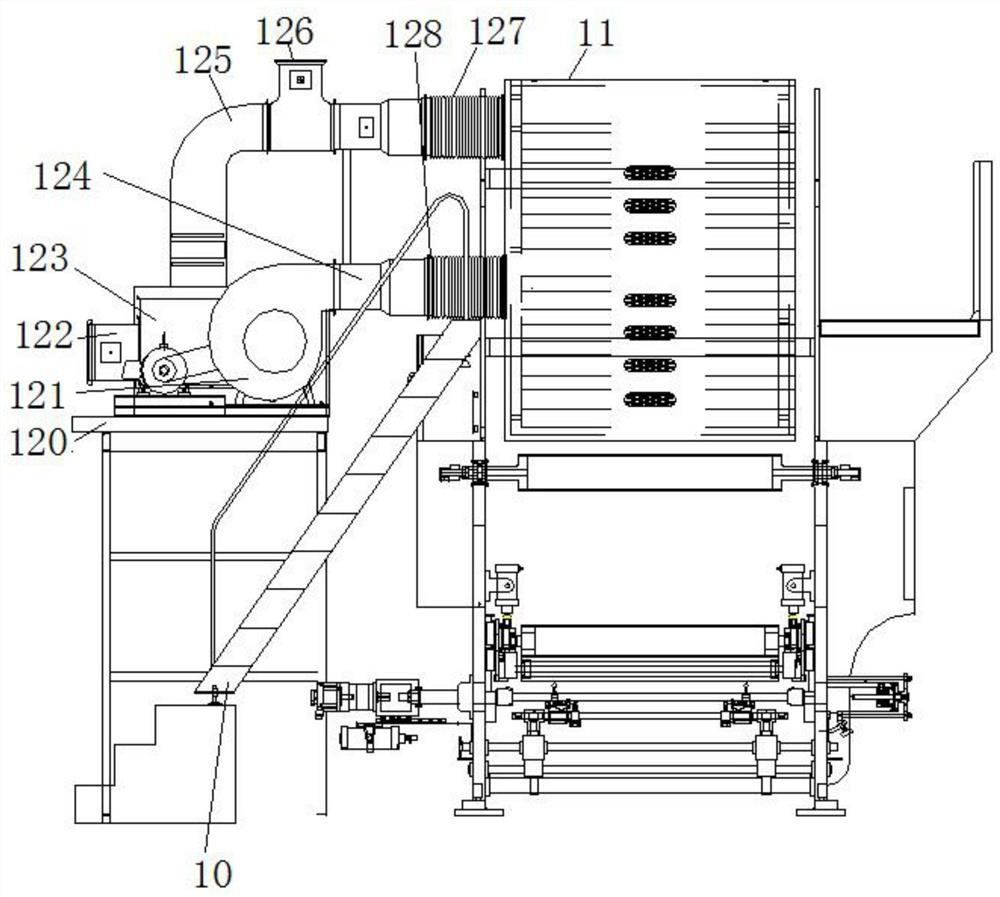

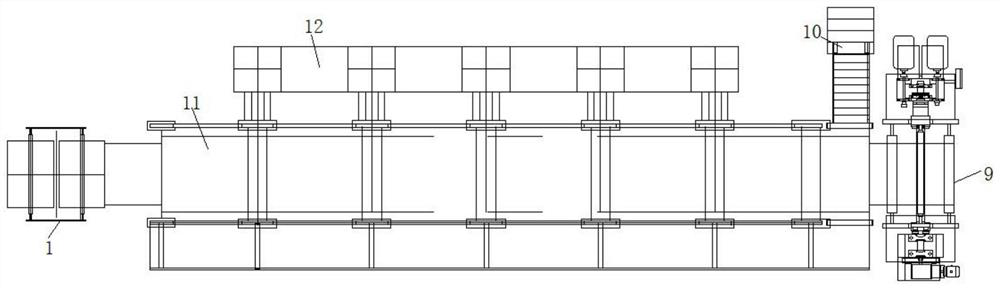

[0030] Specific implementation mode one, refer to Figure 1-5 , the present invention provides a technical solution: a circular concave printing and embossing production line, including a material discharging mechanism 1, a material receiving mechanism 9, a printing unit 11, a hot air drying mechanism 12 and a material 13, and the left side of the printing unit 11 is arranged There is a discharge mechanism 1, and a material receiving mechanism 9 is arranged on the right side of the printing unit 11, a hot air drying mechanism 12 is installed on the rear side of the printing unit 11, and materials 13 are printed on the printing unit 11, and the conveying of the materials 13 The direction is conveyed to the material receiving mechanism 9 by the discharging mechanism 1. A ladder 10 is provided on the rear side of the right end of the printing unit 11, and an introduction mechanism 2 is provided on the left end of the printing unit 11, and an export mechanism 8 is provided on the r...

specific Embodiment approach 2

[0034] Embodiment 2. This embodiment is a further limitation of Embodiment 1. In the present invention, multiple groups of guide rollers provided on the lower body of the first printing mechanism 3 guide the material 13 and guide the material 13 to the embossing rubber roller 302. And between the printing plate cylinder 301, and the transportation between the left guide roller 321, the third guide roller 312, the second guide roller 311 and the first guide roller 310 is from top to bottom, which is convenient for embossing the material 13 deal with.

specific Embodiment approach 3

[0035] Embodiment 3. This embodiment is a further limitation of Embodiment 1. The bottom of the trough mechanism 300 in the present invention is provided with a stroke limit cylinder, and an ink trough is placed on the top of the cylinder, which is convenient for straight lifting, so that the printing plate cylinder The lower part of 301 can be immersed in the feed tank for dipping ink for printing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com