Patents

Literature

2124results about How to "Avoid blockage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

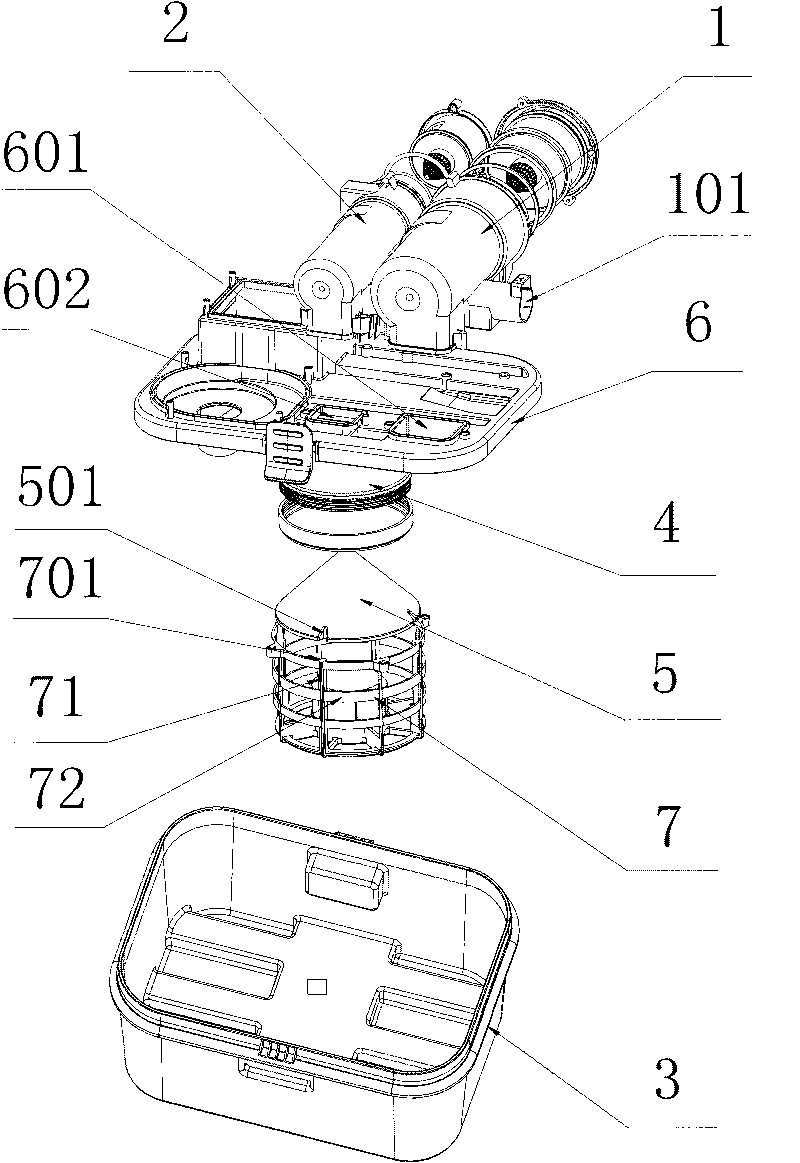

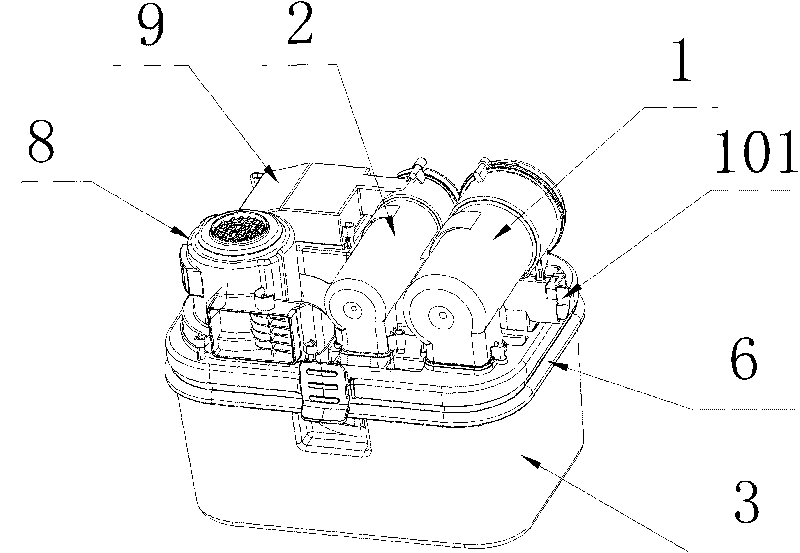

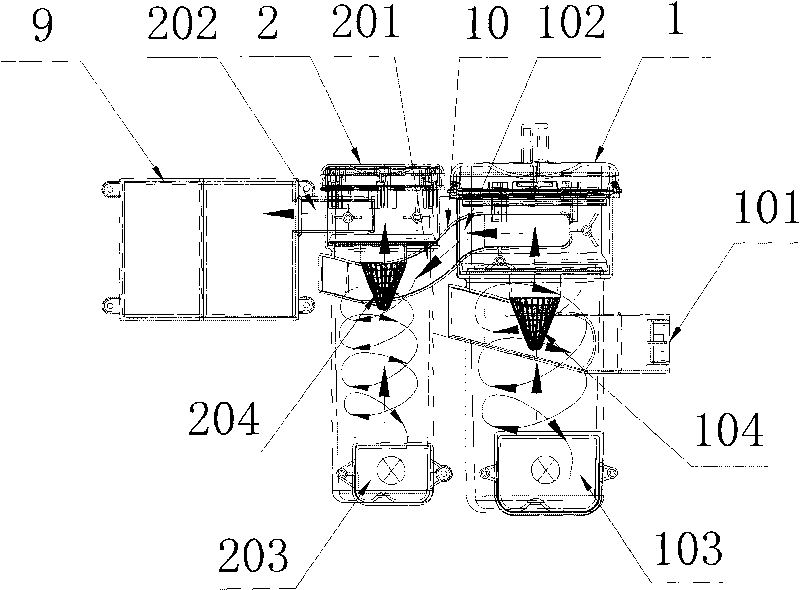

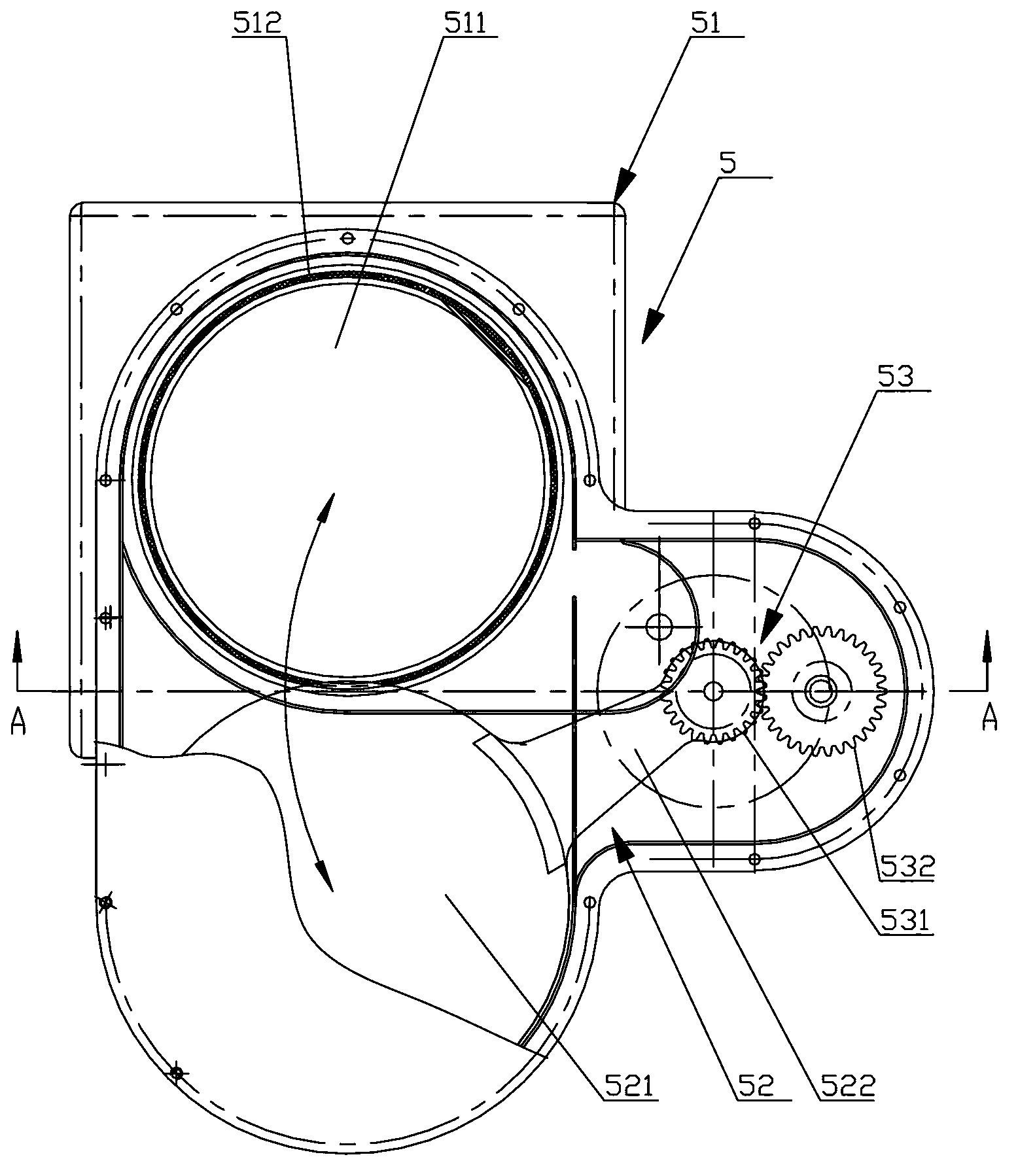

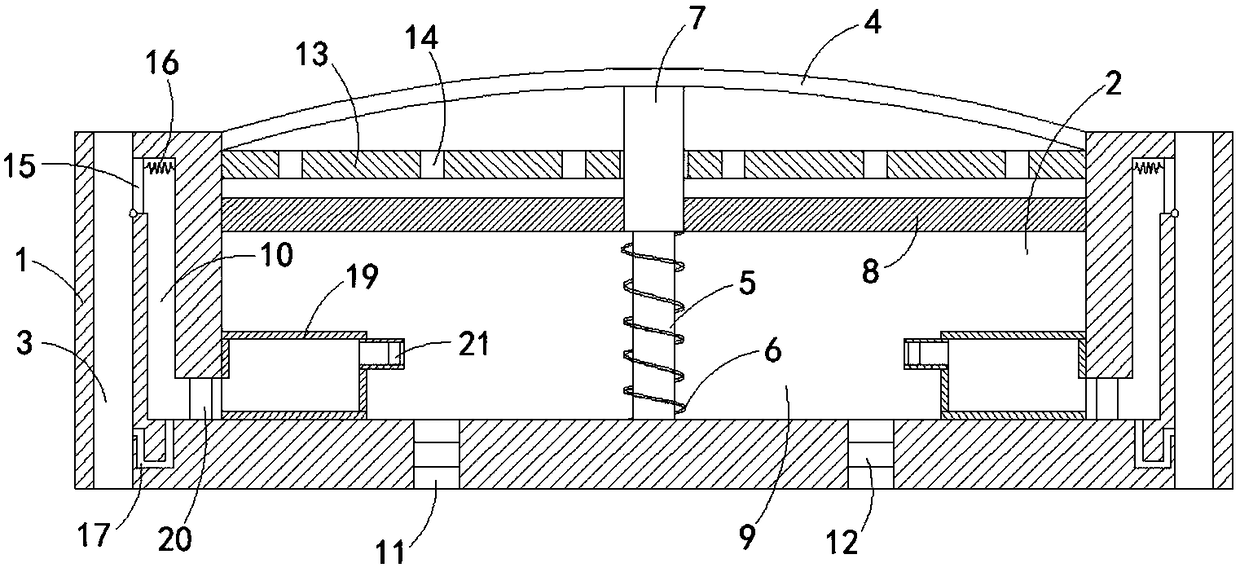

Cyclone dust collecting device of dust collector

ActiveCN101700180AIncreased Cyclone Separation CapacityAvoid being blockedSuction filtersReversed direction vortexPhencycloneCyclone

The invention discloses a cyclone dust collecting device of a dust collector, comprising a primary cyclone separator, a secondary cyclone separator, a primary dust collecting barrel and a secondary dust collecting barrel, wherein the primary cyclone separator and the secondary cyclone separator are connected in series; the primary dust collecting barrel and the secondary collecting barrel are respectively connected with the first dust outlet and the second dust outlet of the primary and the secondary cyclone separator; the secondary dust collecting barrel is arranged in the primary dust collecting barrel and is provided with a detachable bottom cover at the bottom part thereof; when the dust collector works, the bottom cover and the barrel body are actuated to store dust, when the dust collector is free of work, the bottom cover and the barrel body are separated to lead the dust to fall into the primary dust collecting barrel. In the cyclone dust collecting device of dust collector provided by the invention, the secondary dust collecting barrel can automatically dump dust to the primary dust collecting barrel, thus facilitating cleaning of users and simplifying cleaning operation for users; as the installation of the primary cyclone separator and the cyclone secondary separator which are connected in series, gas containing dust can be fully filtered, thus greatly improving dust collecting efficiency and effect of the dust collector.

Owner:KINGCLEAN ELECTRIC

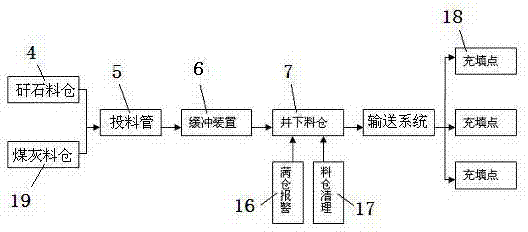

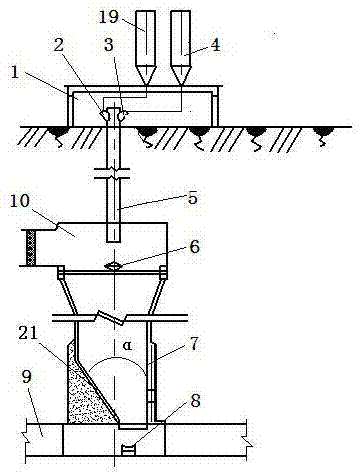

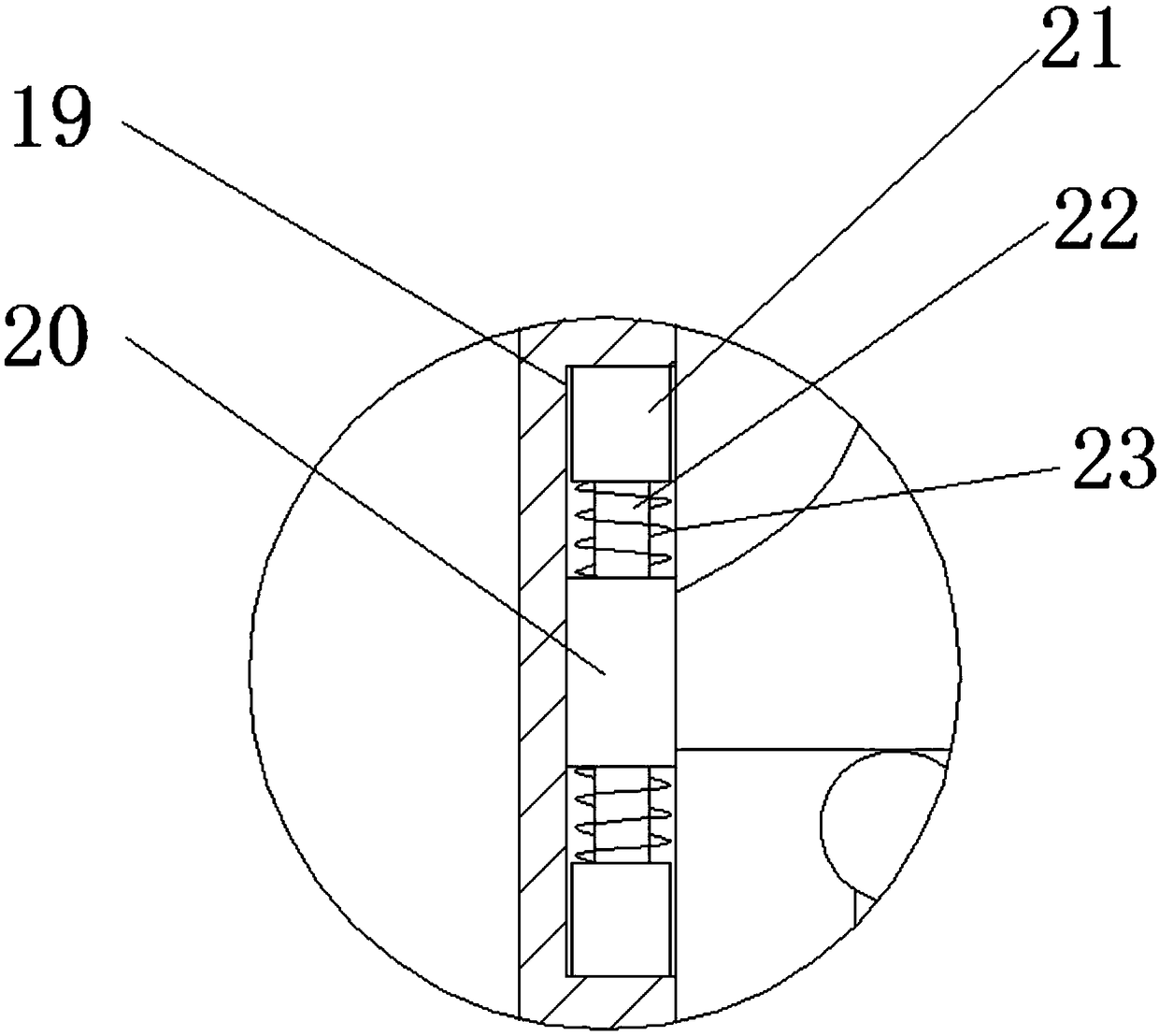

System for feeding coal mine solid filling material

InactiveCN102889097AImprove delivery capabilitiesAvoid cloggingMaterial fill-upFilling materialsClosed chamber

The invention relates to a system for feeding a coal mine solid filling material. The system comprises a filling control chamber, a gangue material bin, a coal ash material bin, a feeding pipe, an underground closed chamber, an impact resistance buffering device, an underground material bin and an underground conveying system, wherein the impact resistance buffering device is positioned at the bottom of the underground closed chamber; the feeding pipe is connected with the underground material bin through the underground closed chamber; the underground material bin is connected with the underground conveying system; the underground conveying system comprises a conveying passage and a conveyer; the conveyer is connected to a filling point; the feeding pipe consists of a protection hole wall steel pipe and a double-layer anti-abrasion pipe; a ceramic anti-abrasion pipe is sleeved on a shrinkage wall at the bottom of the underground material bin; and an outwards discharging type air guide hose is arranged at the upper opening of the underground material bin. According to the system, a large-aperture perpendicular feeding pipe is used for feeding the material, so that the feeding capacity of the filling material is improved, and a filling effect and the safety are improved; by the umbrella-shaped impact resistance buffering device, falling impact force of the filling material can be relieved; the compactness of the filling material in the bin can be reduced; and the bins can be prevented from being plugged.

Owner:HEBEI COAL SCI RES INST

Solid-liquid separation toilet bowl and solid-liquid separation treatment system

InactiveCN102836866AReduce the possibility of mixingIncrease the amount of separationSolid waste disposalExcrement fertilisersUrine collectionEngineering

The invention provides a solid-liquid separation toilet bowl and a solid-liquid separation treatment system comprising the solid-liquid separation toilet bowl. The solid-liquid separation toilet bowl comprises a panel and a toilet bowl body, wherein the middle part of the panel is provided with a seat hole; the toilet bowl body is provided with a urine collection cavity and an excrement collection cavity; and the urine collection cavity and the excrement collection cavity are arranged with one in front of the other in longitudinal direction of the panel, are positioned below the seat hole and are opposite to the seat hole. Through the urine collection cavity and the excrement collection cavity formed in the toilet bowl body and by arranging the urine collection cavity and the excrement collection cavity with one in front of the other in the longitudinal direction of the panel, the urine collection cavity arranged at the front end is used for collecting urine, the excrement collection cavity arranged at the rear end is used for collecting the excrement, so that the urine and the excrement are effectively prevented from being mixed in the toilet bowl body; and thus, separation and recovery of the urine and the excrement are realized, further recycling of the excrement and the urine is realized respectively, and premise is provided for realizing the value of full utilization of the excrement and the urine.

Owner:张少岩 +2

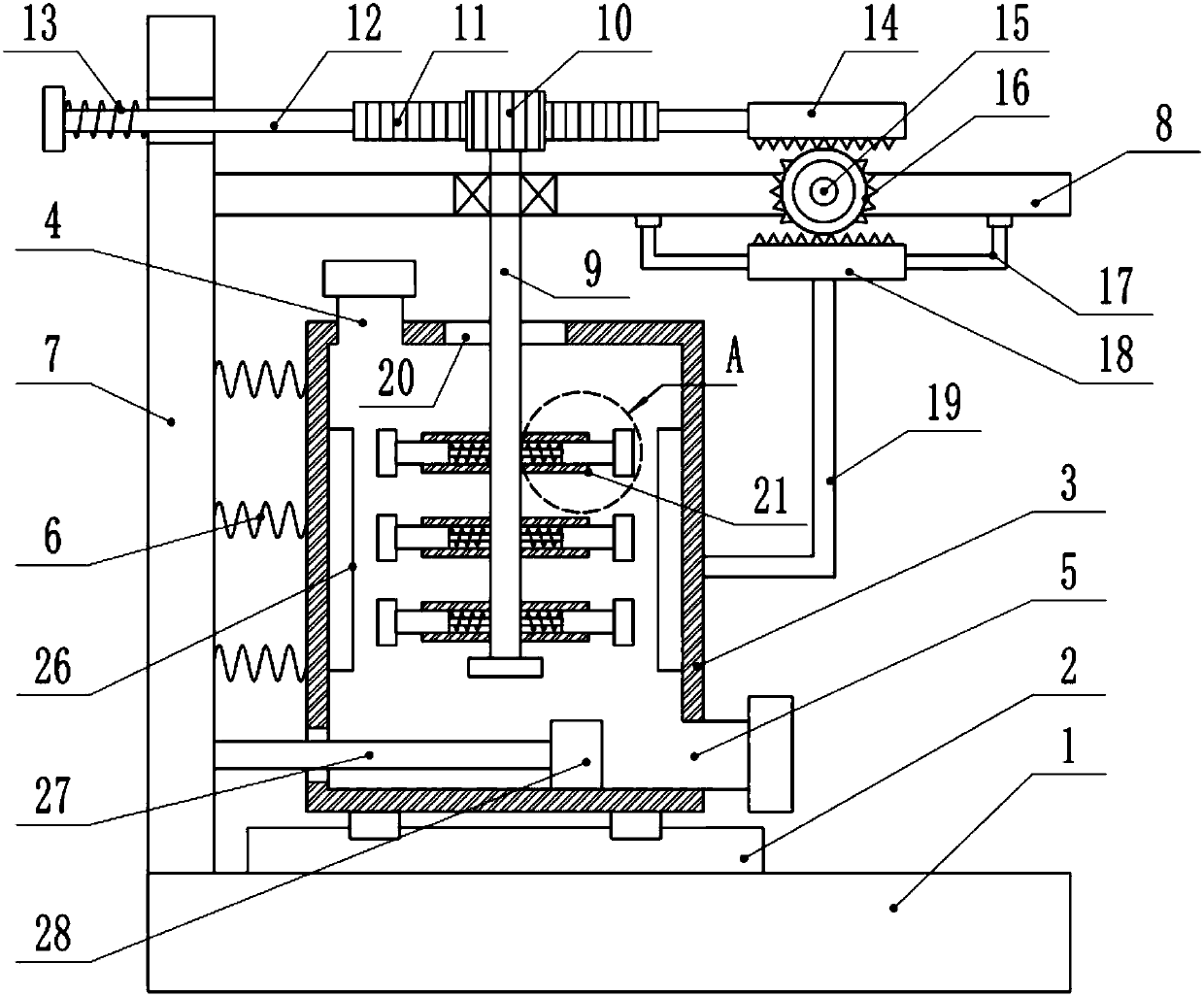

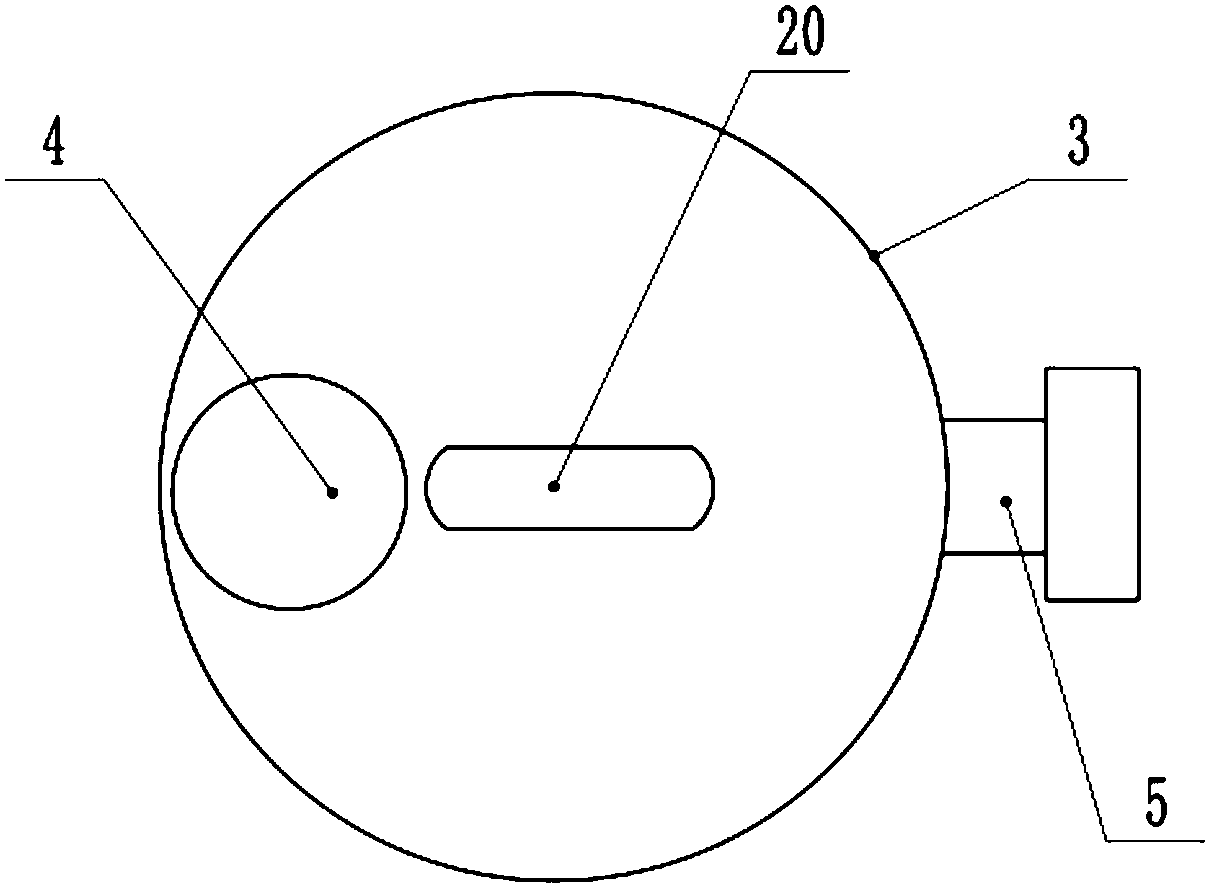

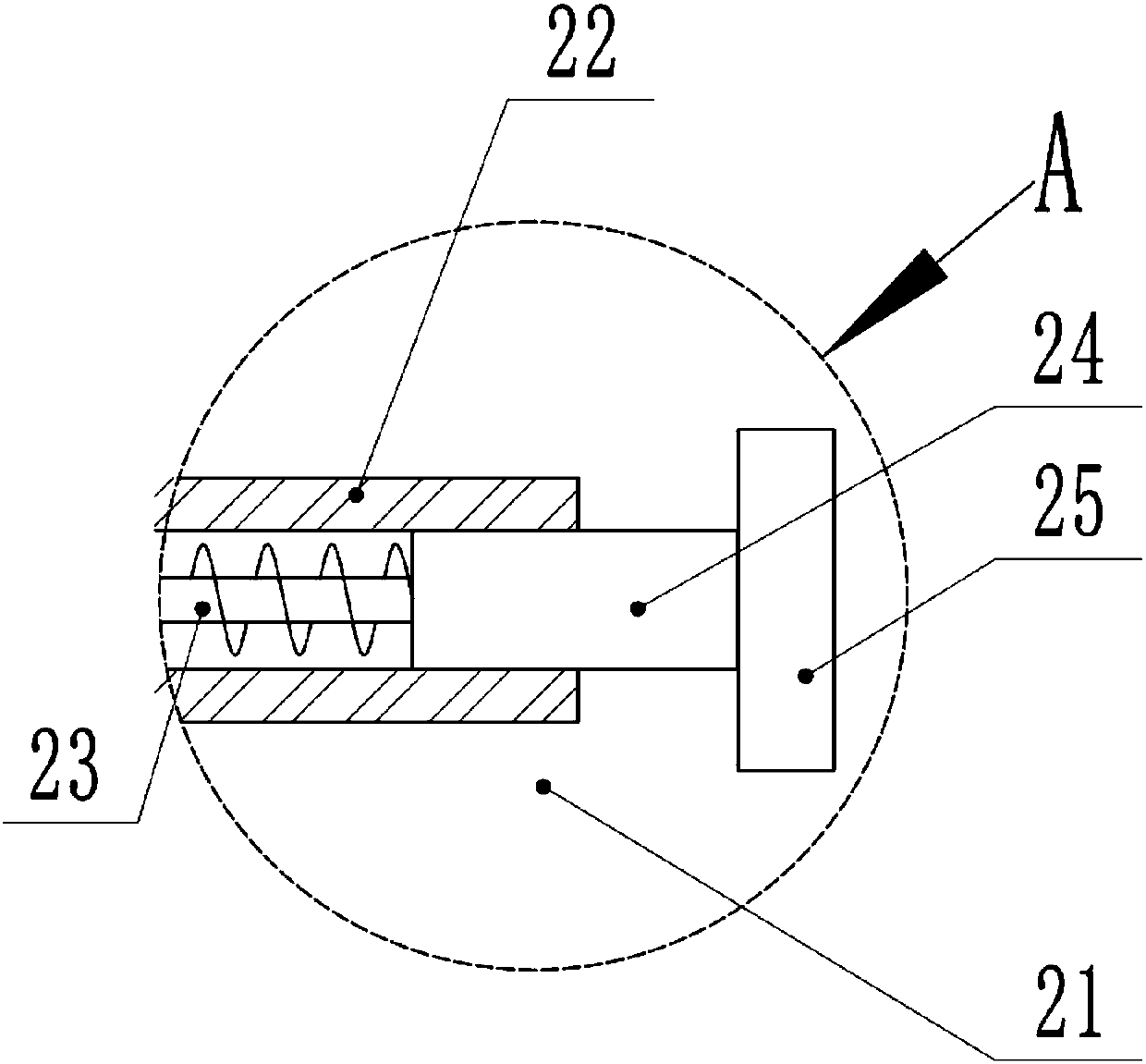

Colloid mixing and stirring device for producing lead-acid battery

InactiveCN107670563AStir wellImprove turnoverShaking/oscillating/vibrating mixersTransportation and packagingDrive motorEngineering

The invention discloses a colloid mixing and stirring device for producing a lead-acid battery. The colloid mixing and stirring device comprises a colloid mixing box, a driving motor, a special-shapedgear, stirring devices, a magnet A and a push rod. The colloid mixing box is slidably mounted on a slide rail, a stirring shaft is rotatably mounted on a horizontal plate through a bearing, groups ofstirring devices are fixedly mounted on the stirring shaft, the magnet A is arranged on the outer side of a stirring blade, and a magnet B is further arranged on the inner wall of the colloid mixingbox. The colloid stirring device can stir the colloid in the colloid mixing box more fully through alternate clockwise and counterclockwise rotation of the stirring devices to increase the flow rate of the colloid in the colloid mixing box and prevent coagulation; moreover, the magnet A and the magnet B on the stirring blade have same polarity, so that the stirring blade shrinks toward the stirring shaft, the change of the stirring range can be realized on the one hand and the colloid mixing box can be prevented from being broken after the stirring blade collides with the inner wall of the colloid mixing box during movement on the other hand.

Owner:高明飞

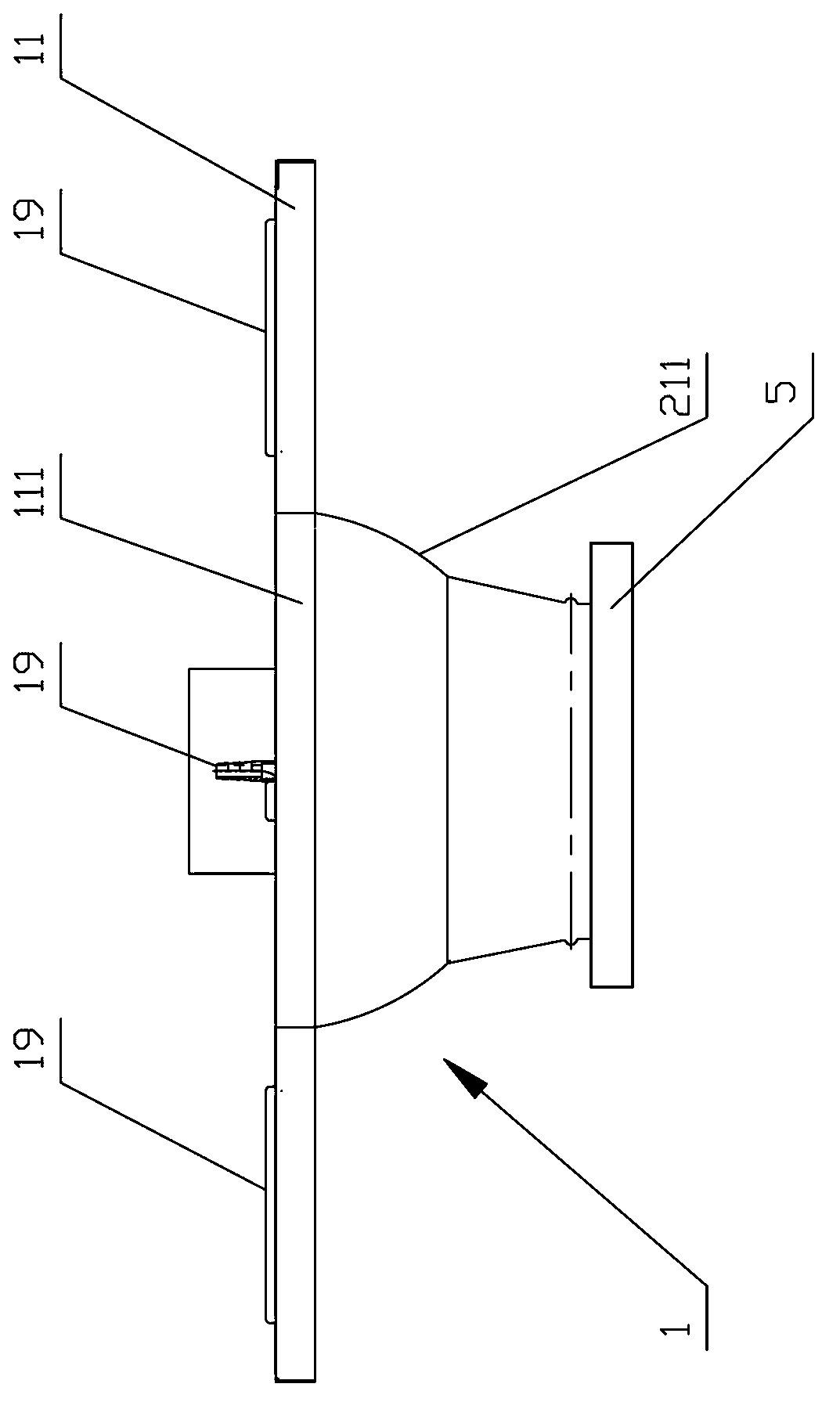

Display control apparatus, computer-implemented method, storage medium, and projection apparatus

ActiveUS20150097866A1Avoid blockageAvoid cloggingCathode-ray tube indicatorsClosed circuit television systemsComputer visionComputer graphics (images)

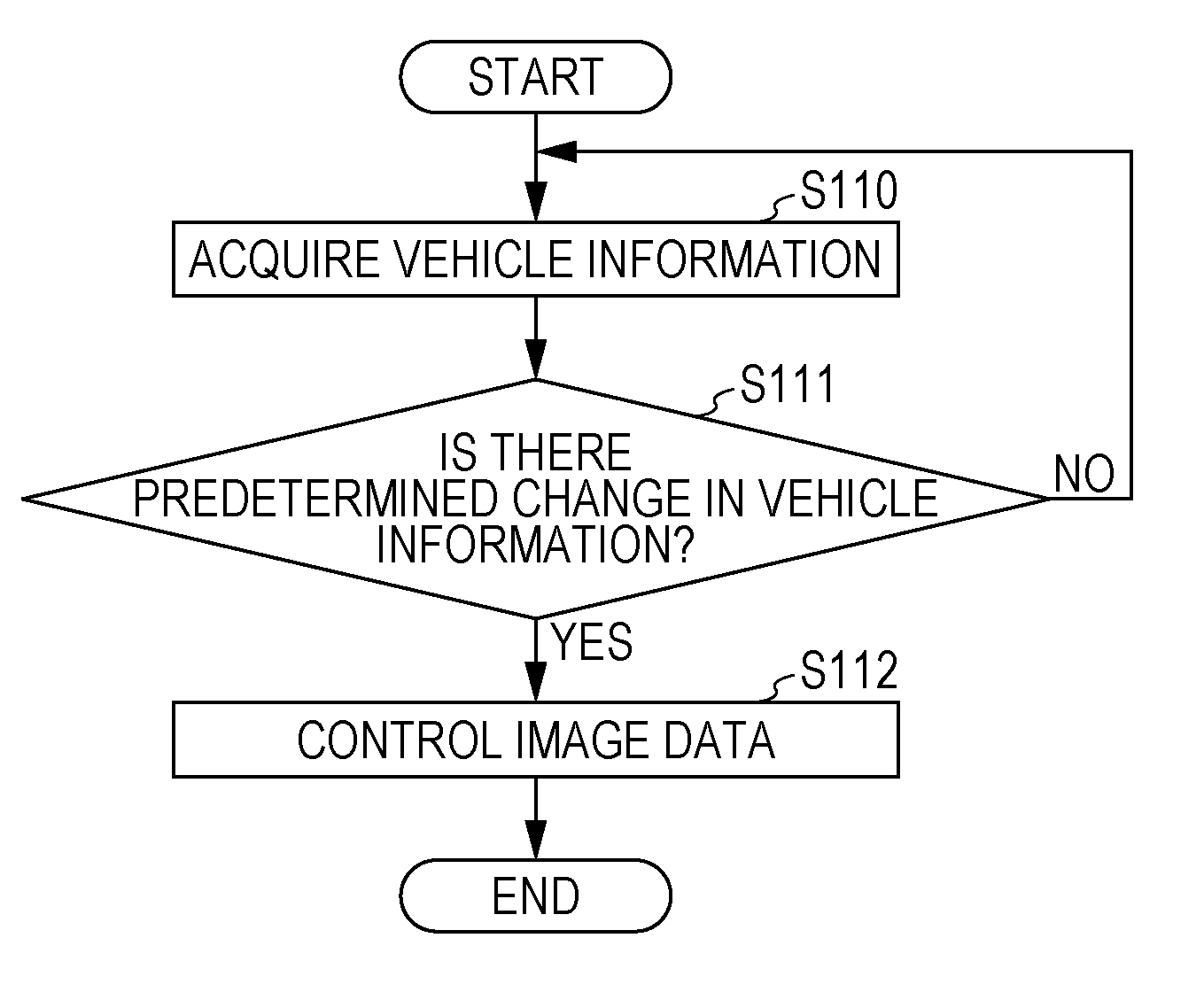

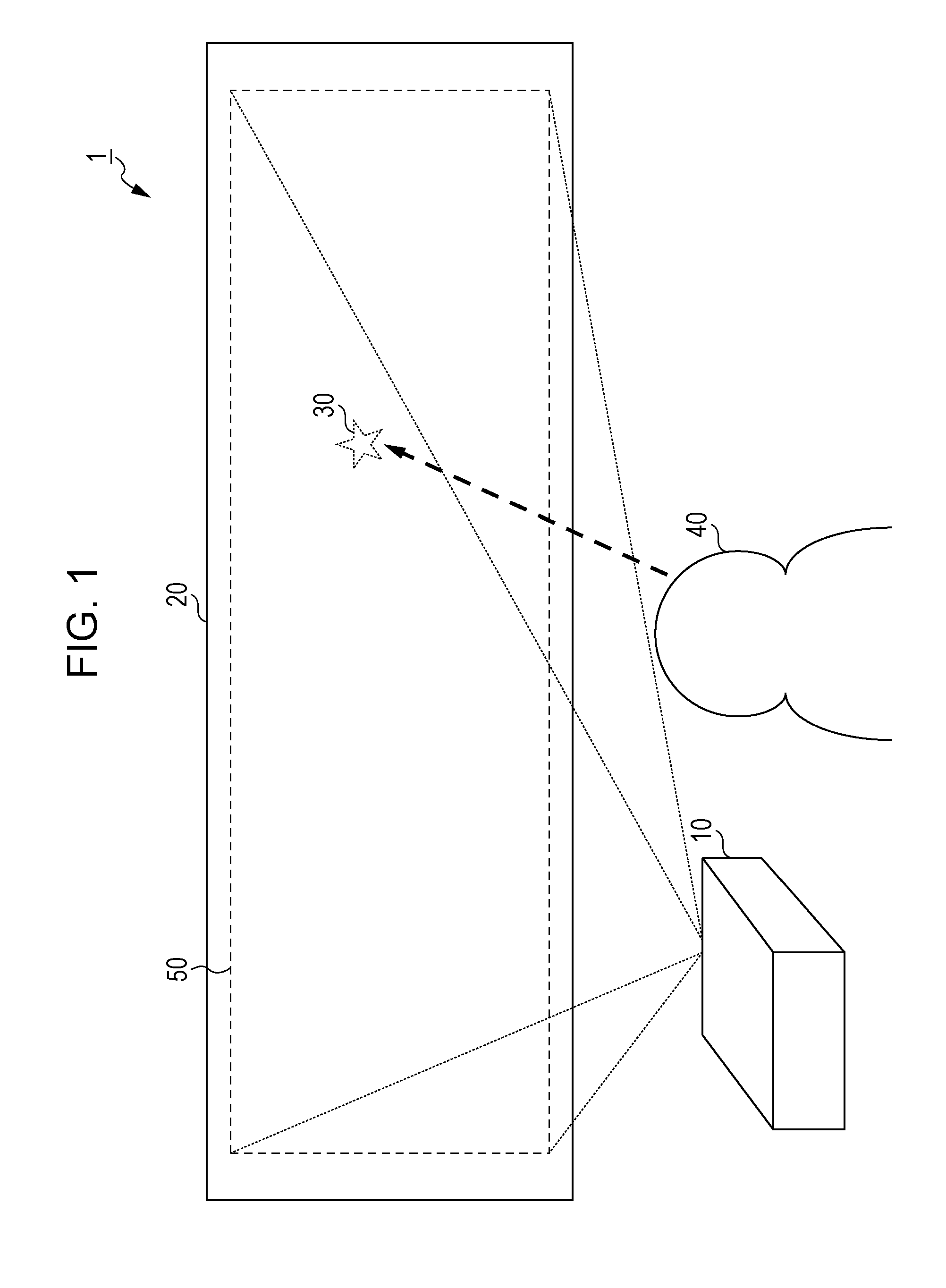

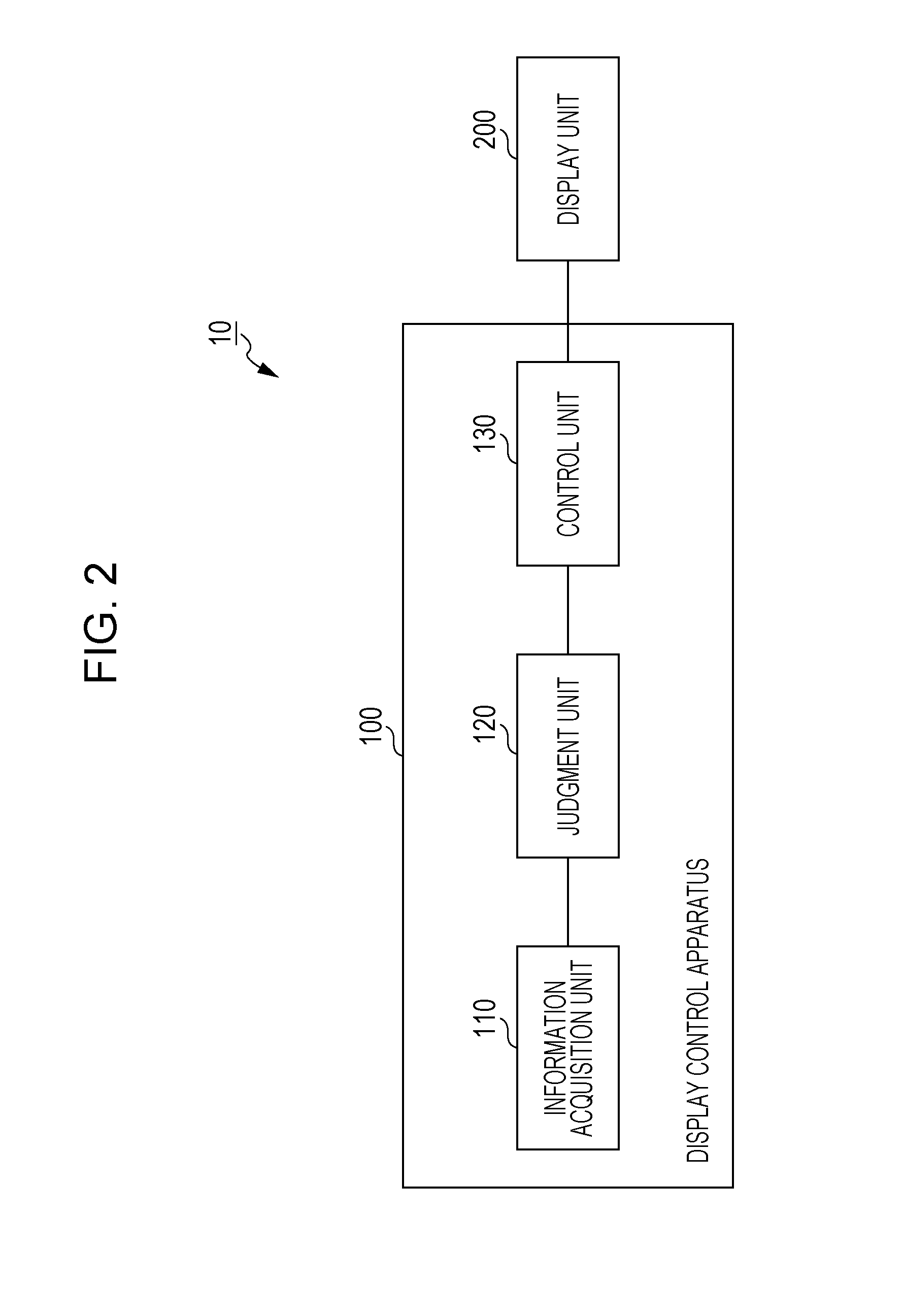

In a display control apparatus configured to control image data displayed on a predetermined display medium, an information acquisition unit acquires a first information associated with the predetermined matter at a first time and acquire a second information associated with the predetermined matter at a second time after the first time. A determination unit judges whether there is a predetermined change between the first information and the second information. A control unit controls the image data such that in a case where a predetermined change is detected, at least one of parameters including a location, a size, and a shape of a restricted area, in which the displaying of display information including in the image data is limited, is changed so as to achieve the parameter defined in relation to the second information.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

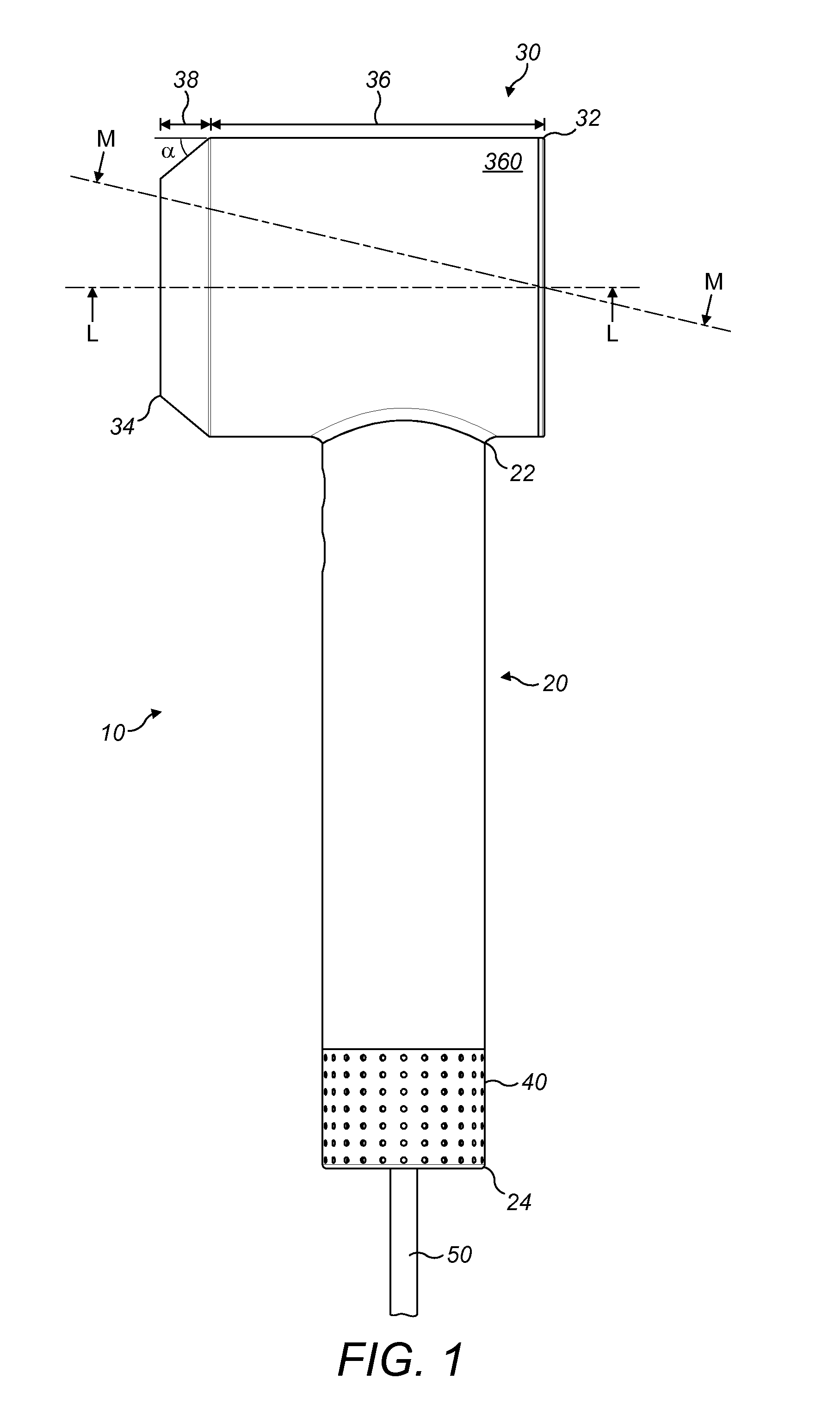

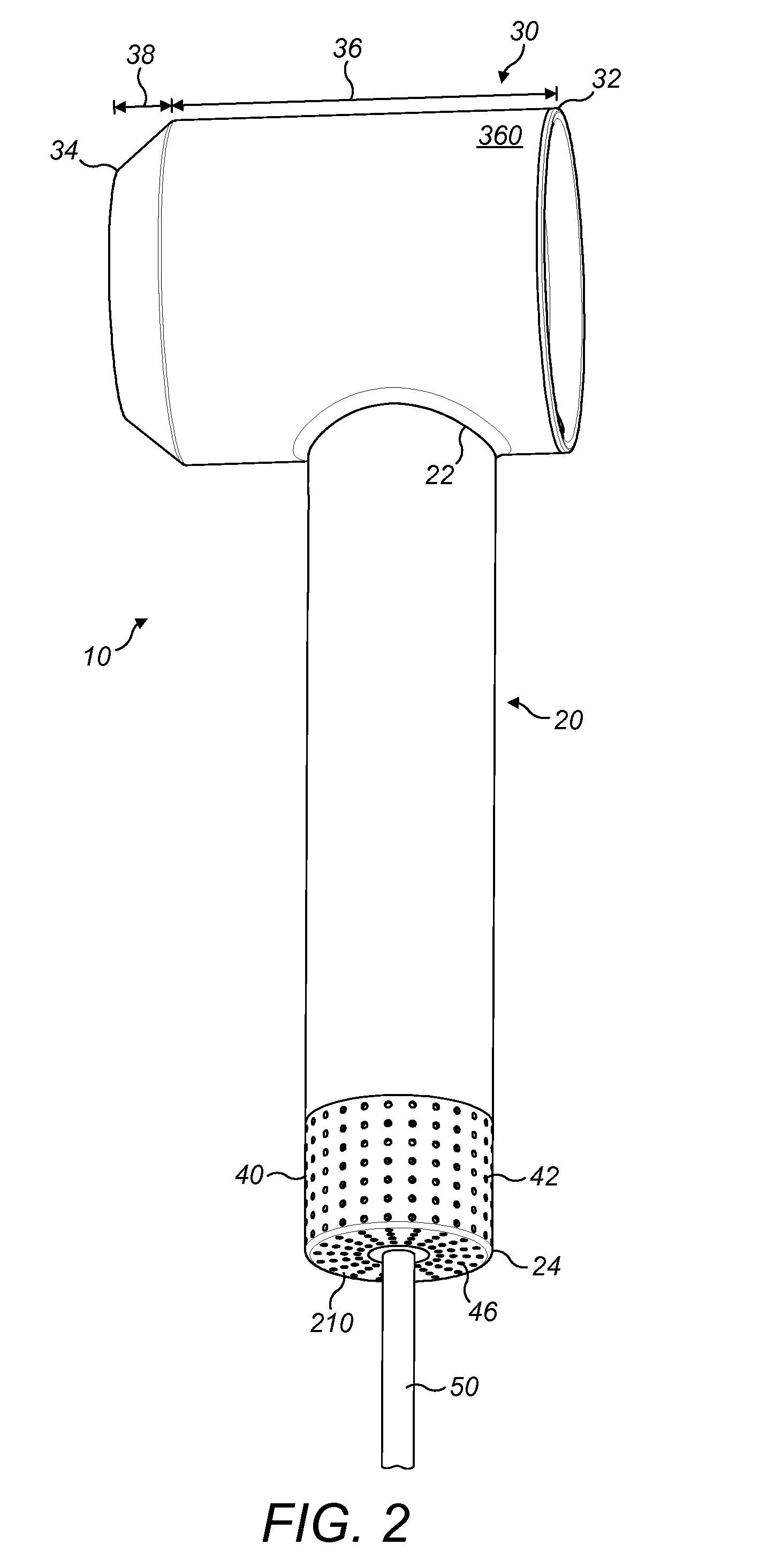

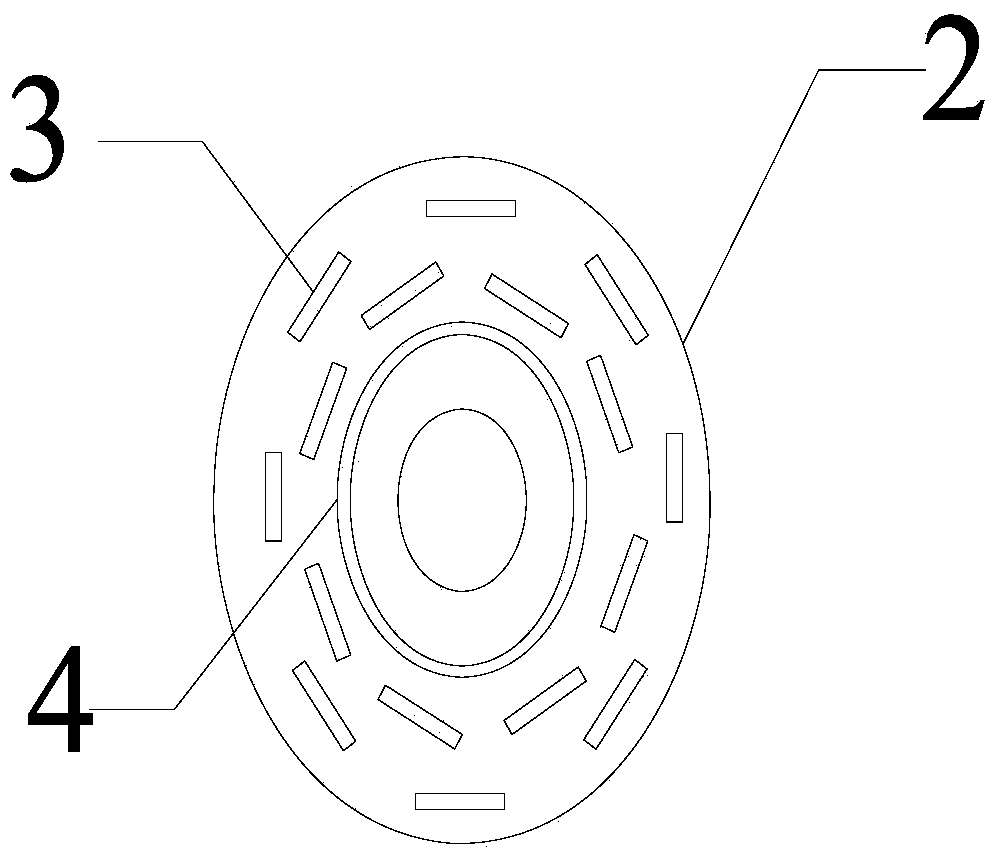

Hand held appliance

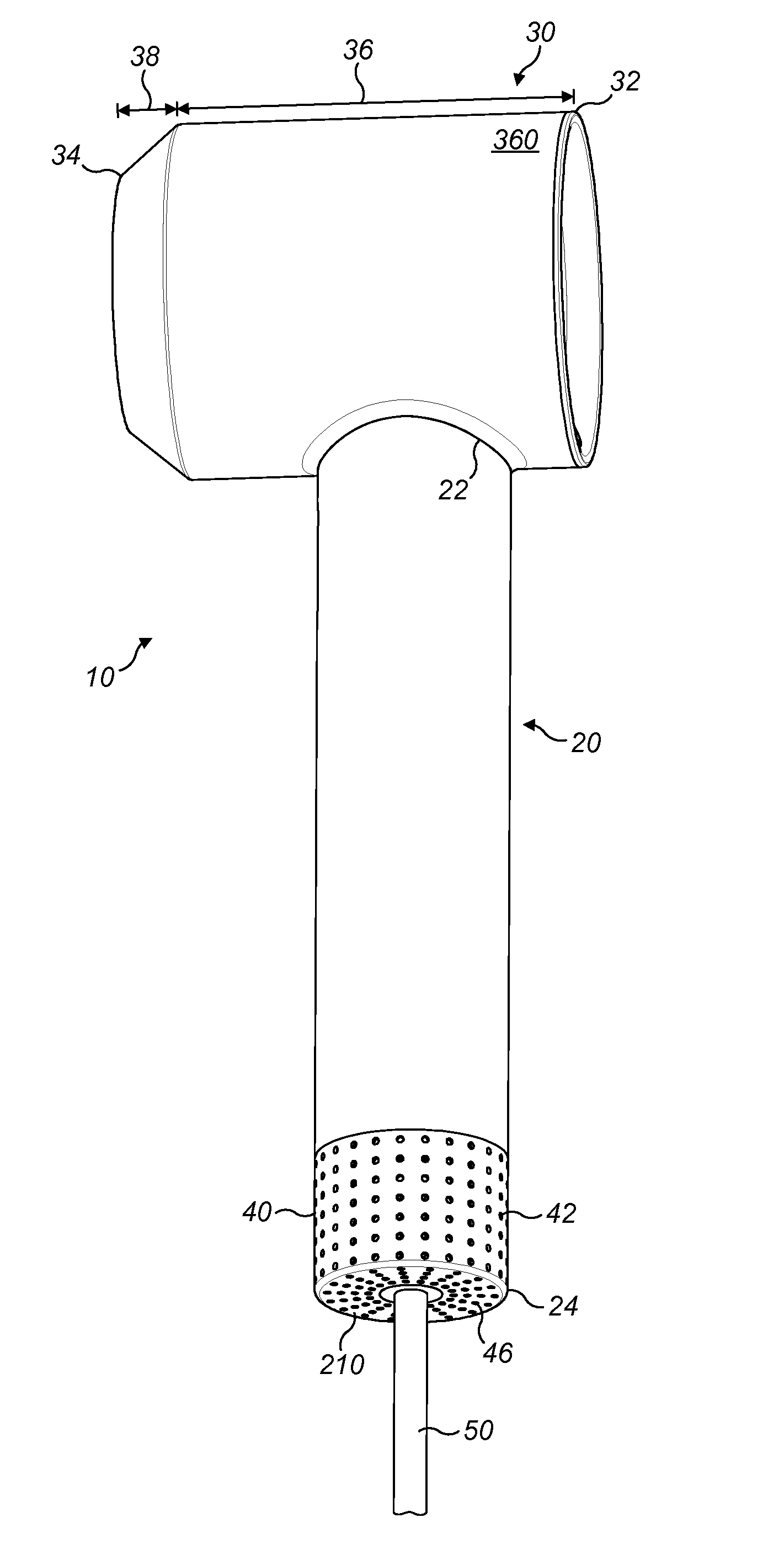

Disclosed is a hair care appliance comprising a body, a fluid flow path extending through the body from a fluid inlet to a fluid outlet and a PCB extending about the fluid flow path. The PCB may be annular. The PCB may be isolated from the fluid flow path. The PCB may comprise a first layer and a second layer. The first layer may extend substantially continuously about the fluid flow path and the second layer may extend partially about the fluid flow path. The second layer may be adjacent the first layer and may be downstream of the first layer. The body may comprise a duct and the fluid flow path extends through the duct. The PCB may extend about the duct. The body may comprise a primary fluid flow path extending about the duct which may be in fluid communication with the PCB.

Owner:DYSON TECH LTD

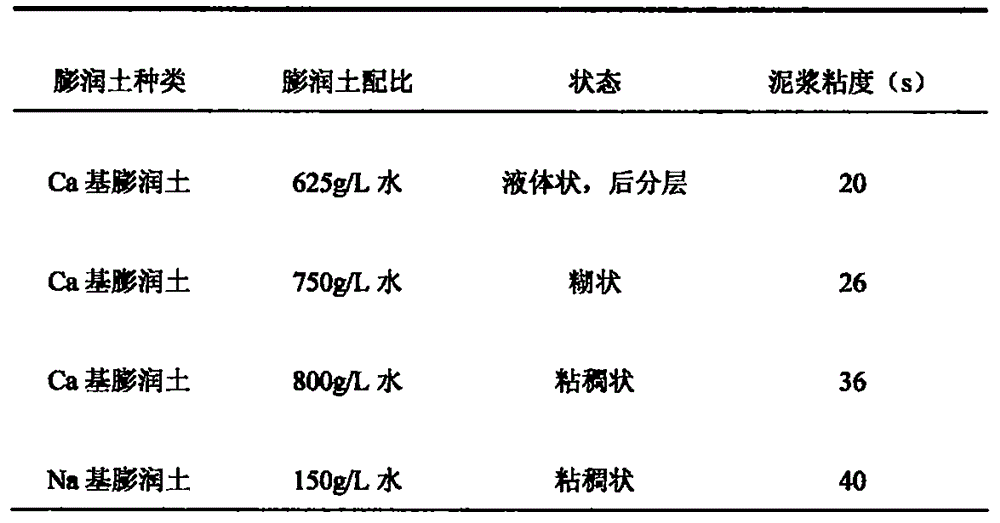

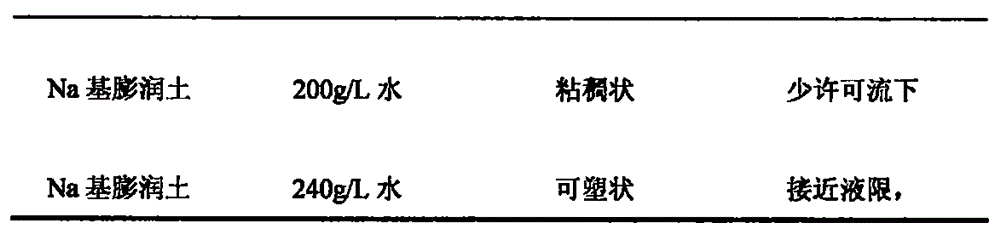

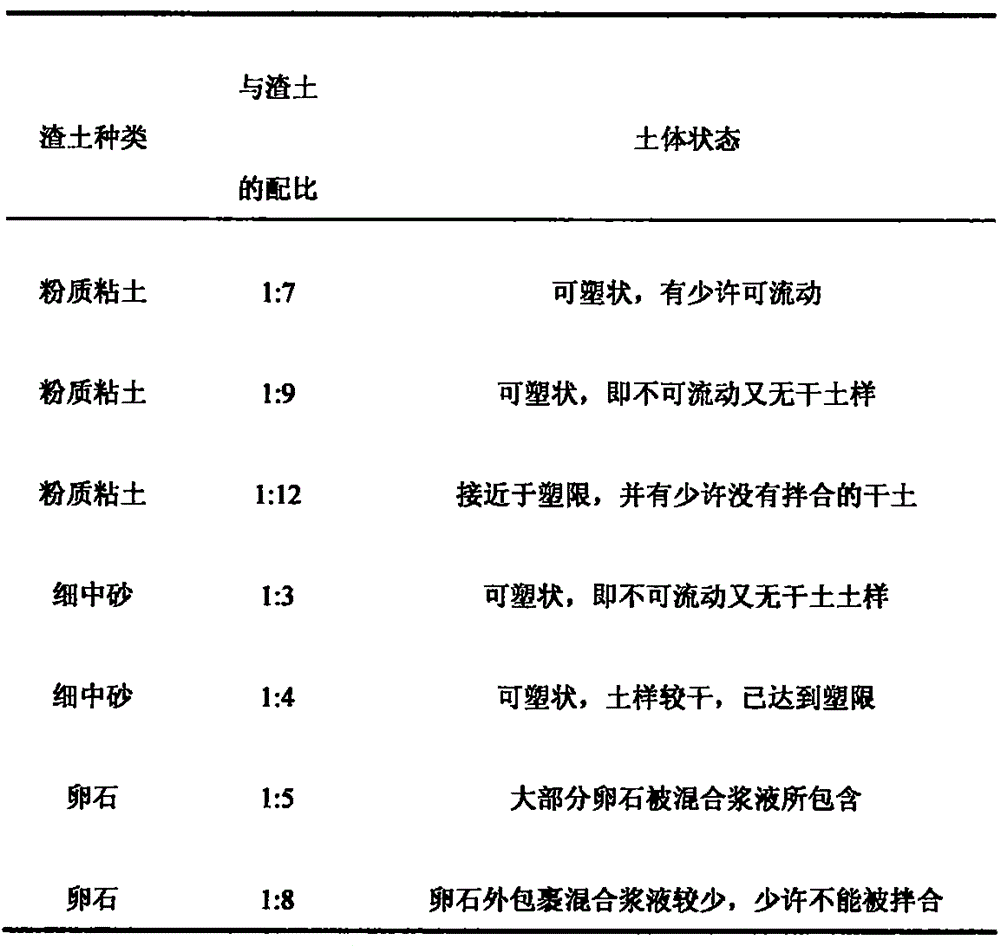

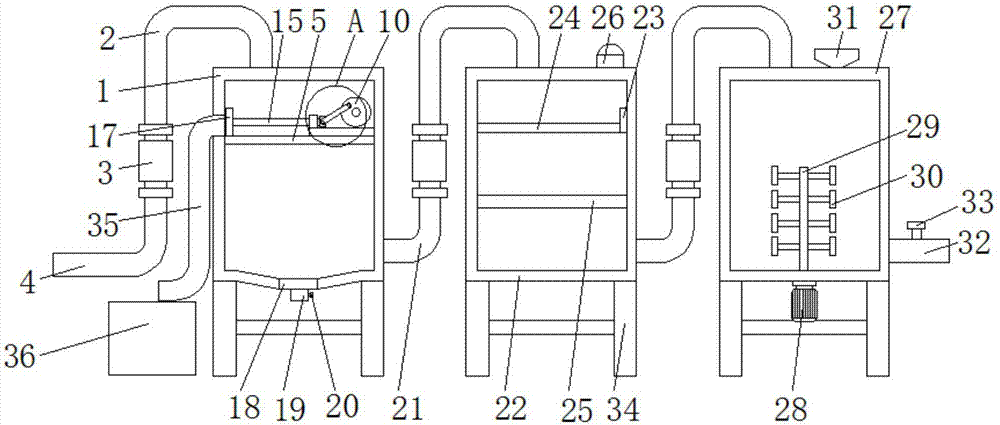

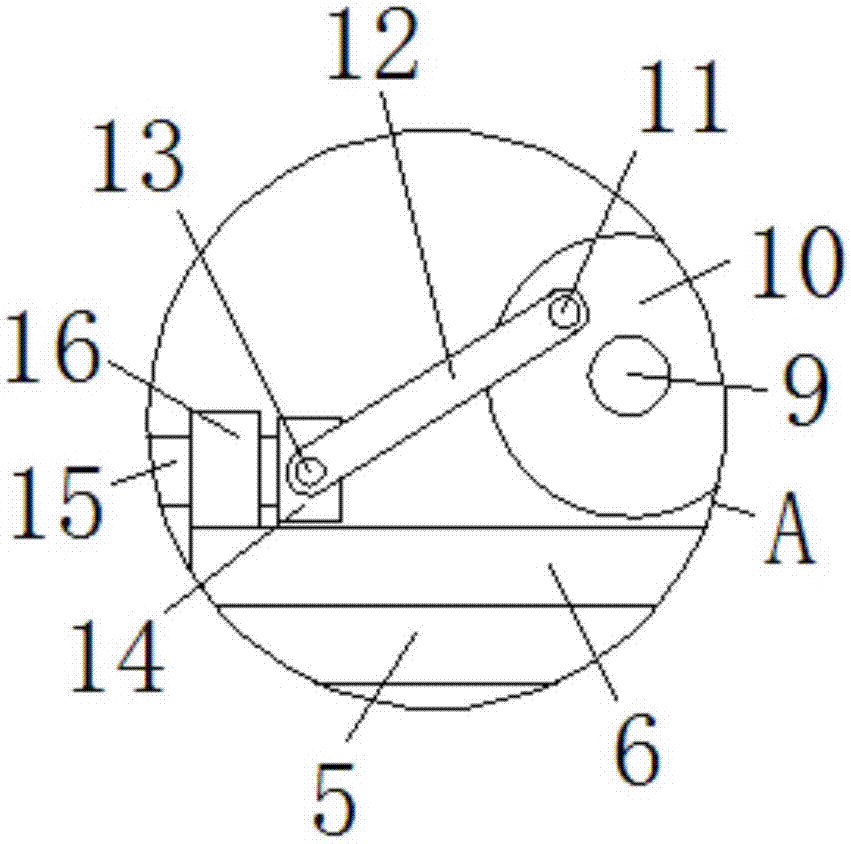

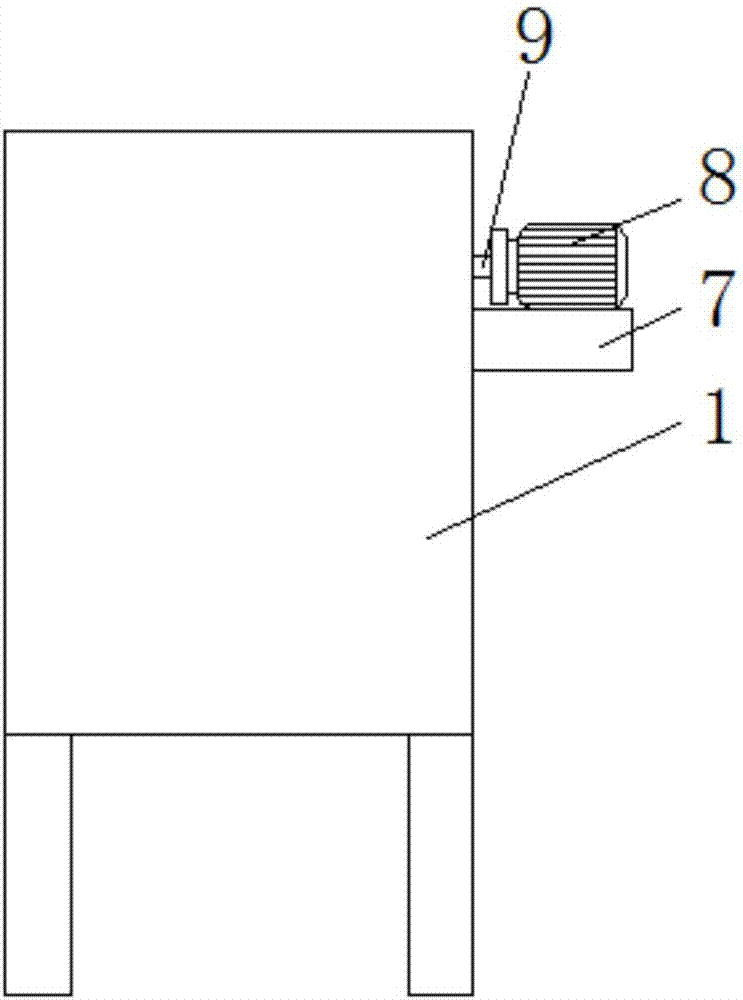

Muck improvement technology for earth pressure balance shield construction in sandy cobble stratum

The invention discloses a muck improvement technology for earth pressure balance shield construction in a sandy cobble stratum and relates to the technical field of stratum shield construction. The improvement technology comprises the following steps: 1, selection of a land improver; 2, land improvement; 3, construction quality control; 4, a soil mass improvement effect and analysis. The improvement technology is simple, and after improvement, muck can be prevented from forming mud cakes on a cutter head, being accumulated in an earth bin, blocking the bin and causing blocking, spewing, wear of the cutter head and a tool and the like at a screw conveyor.

Owner:BEIJING NO 4 MUNICIPAL CONSTR ENG +1

Dyeing and printing sewage treatment device

InactiveCN107337300AAvoid blockageEfficient collectionSpecific water treatment objectivesTreatment involving filtrationFiltrationToxic material

The invention discloses a dyeing and printing sewage treatment device which comprises a settler, wherein a first connecting tube is communicated with the top of the settler; a first water pump is communicated with one end far away from the settler, of the first connecting tube; a first water inlet tube is communicated with the other end of the first water pump; a filtering plate is fixedly mounted inside the settler; a support plate is fixedly connected with the top of the filtering plate. By adopting the dyeing and printing sewage treatment device, the situation of blocking caused by too much accumulated waste on the filtering plate is effectively avoided, wastes can be effectively collected, convenience is brought to later recycling treatment, sewage can be effectively further purified, dyes after adsorption can be collected, fine impurities in the sewage can be effectively filtered through an activated carbon adsorption plate, toxic substances in filtered water can be sterilized, and the problems of low biodegradability, high treatment difficulties and relatively poor treatment effects of an independent conventional biochemical treatment process are solved.

Owner:姚飞

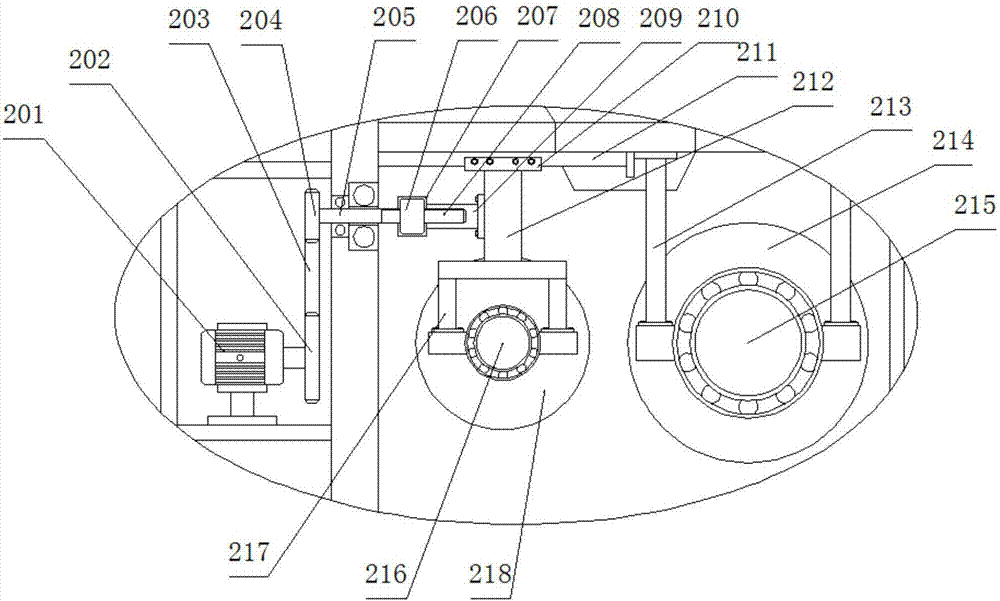

Construction waste separating and crushing treatment device

ActiveCN107486388AAvoid secondary crushingAvoid blockageSievingScreeningHydraulic cylinderEngineering

The invention discloses a construction waste separating and crushing treatment device and relates to a construction waste treatment device and facility. The construction waste separating and crushing treatment device comprises a screening box, a smashing box and a collecting box; the screening box and the smashing box are connected through a smashing pipeline; the screening box is connected with the collecting box through a discharging pipe; the collecting box is connected with the smashing box through a connecting pipe; the top of the screening box is connected with an adding-in port; a screen plate is arranged in the screening box; the left end and the right end of the screen plate are connected with a vibrating device and a downwards-pressing device correspondingly; the smashing box comprises a guiding-in chamber, a machine chamber, an air compressor, a hydraulic machine, a hydraulic cylinder and a smashing device; according to the device, separating and smashing are combined together, separating of materials can be completed on the device, it is avoided that qualified waste is subjected to secondary smashing, unqualified waste can also be smashed, and convenience is brought to a user; and the screen plate in the separating device of the device can move up and down, and the blockage condition in the long time using process can be effectively avoided in the separating process.

Owner:孙勇

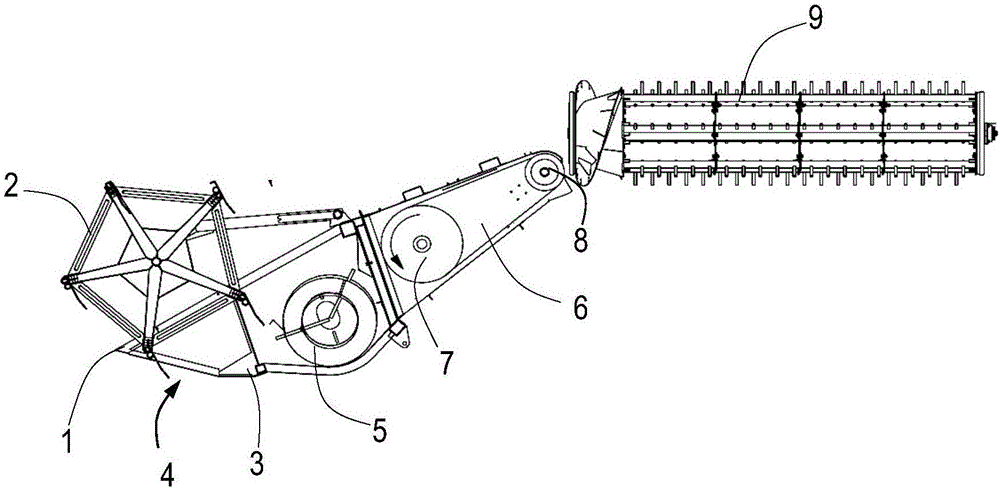

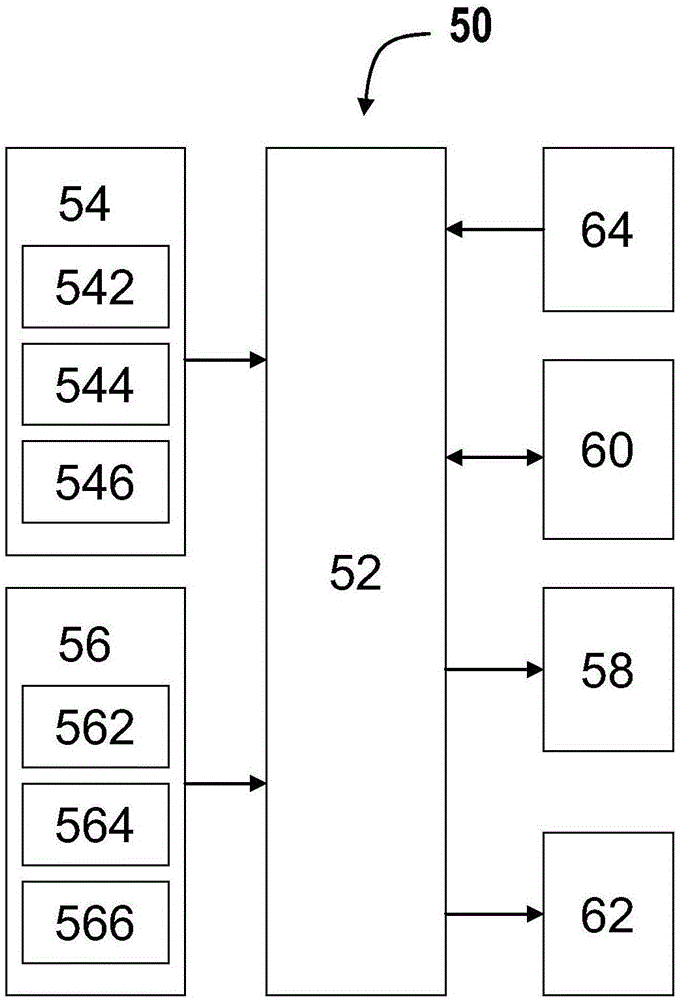

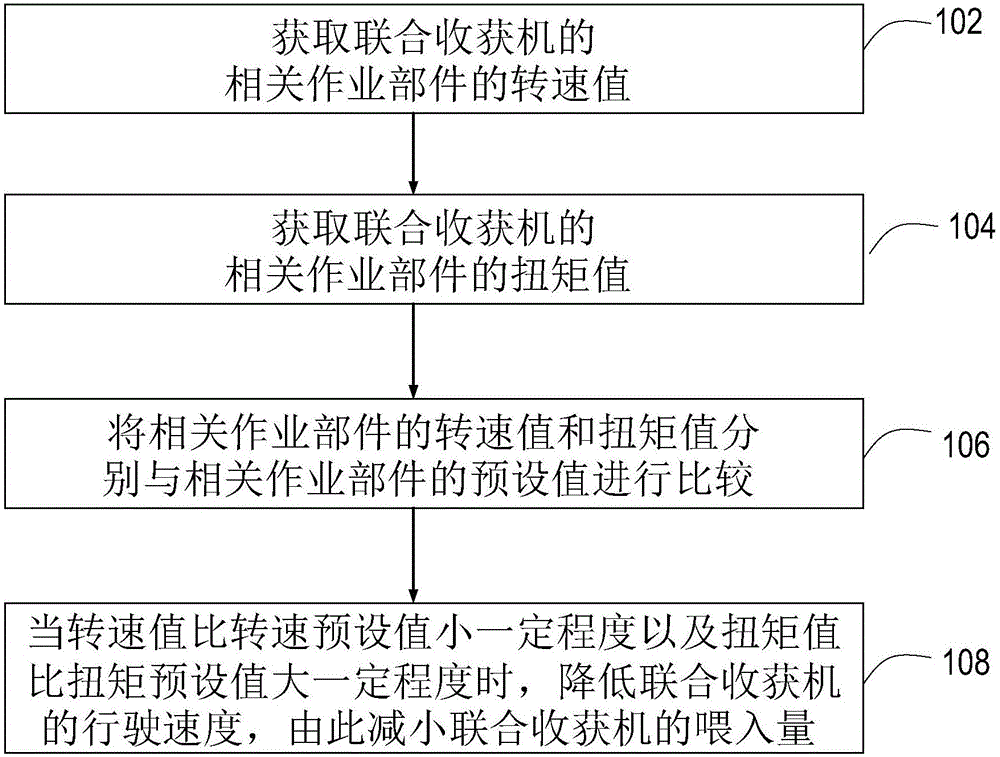

Anti-blocking system and anti-blocking method of combined harvester, and combined harvester

ActiveCN106576580ARealize automatic anti-blocking controlImprove work efficiencyMowersControl theoryOperating speed

The invention relates to an anti-blocking system of a combined harvester. The anti-blocking system of the combined harvester comprises a central processing unit, a rotate speed sensor assembly connected to the central processing unit in a communication way, a torque sensor assembly connected to the central processing unit in a communication way, and a walking control device connected to the central processing unit in a communication way. The central processing unit is used for comparing a rotate speed value from the rotate speed sensor assembly with a corresponding rotate speed preset value, and comparing a torque value of the torque sensor assembly with a corresponding torque preset value; and when the rotate speed value is less than the rotate speed preset value to a certain extent, and the torque value is larger than the torque preset value to a certain extent, the walking control device is used for reducing the running speed of the combined harvester, so that the feed quantity of the combined harvester is reduced. The automatic anti-blocking control of the combined harvester is realized according to the anti-blocking system provided by the invention, so that the operation efficiency of the combined harvester is greatly improved. The invention further relates to the combined harvester comprising the anti-blocking system, and a corresponding anti-blocking method.

Owner:ZOOMLION HEAVY MASCH CO LTD

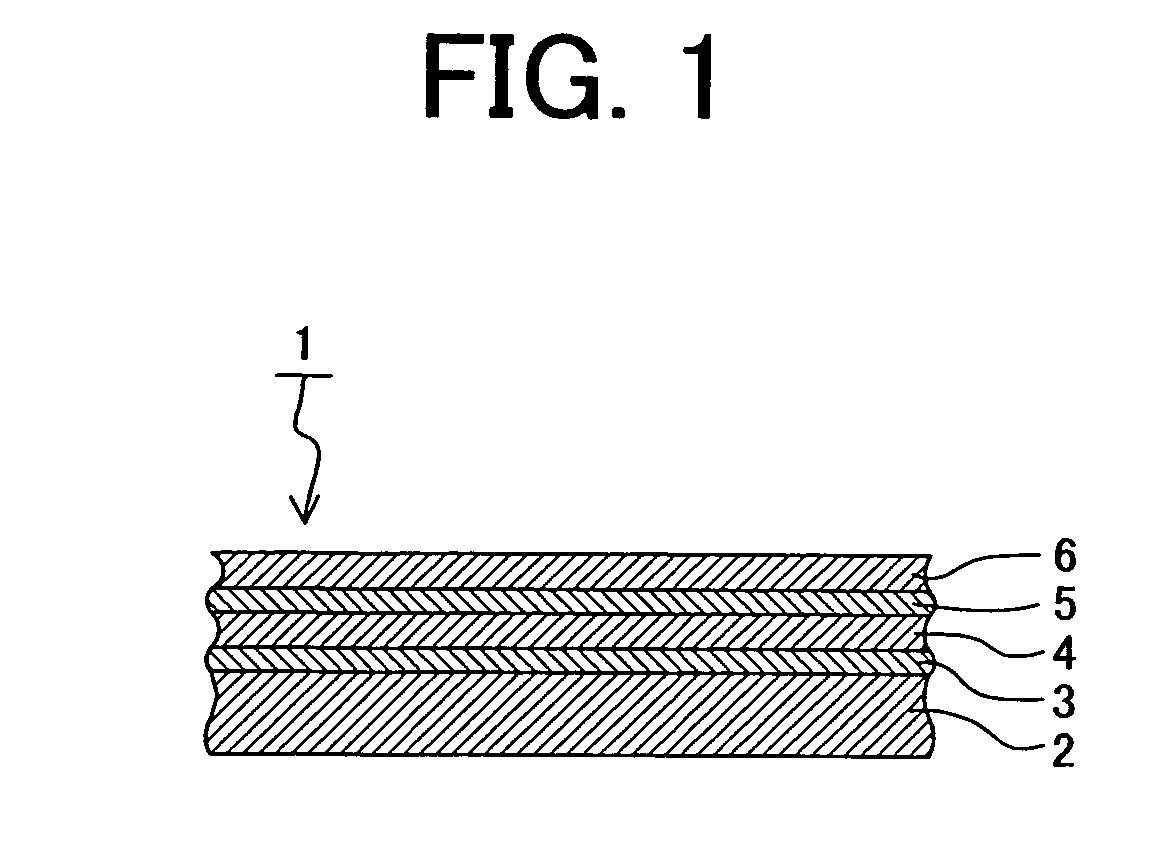

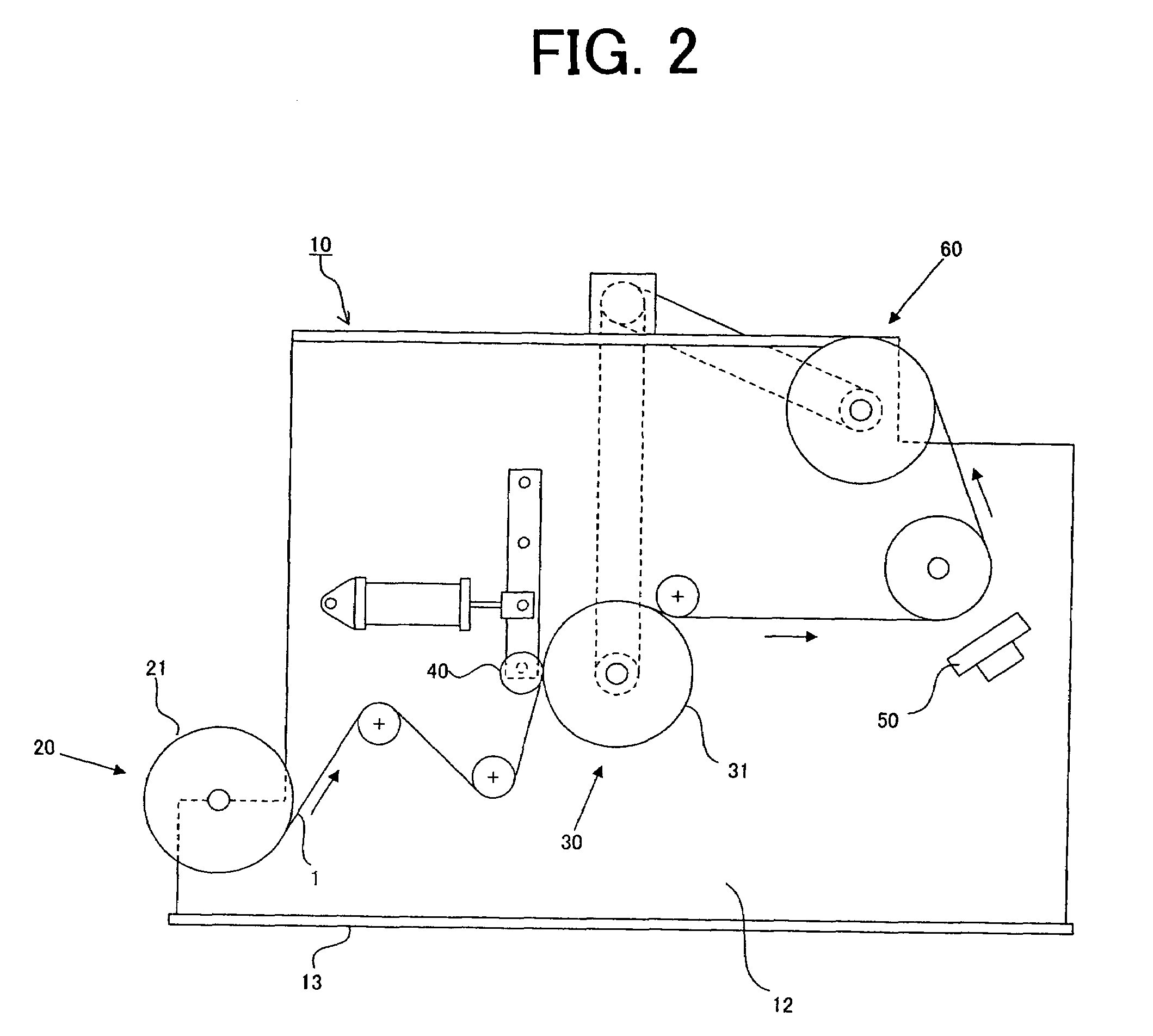

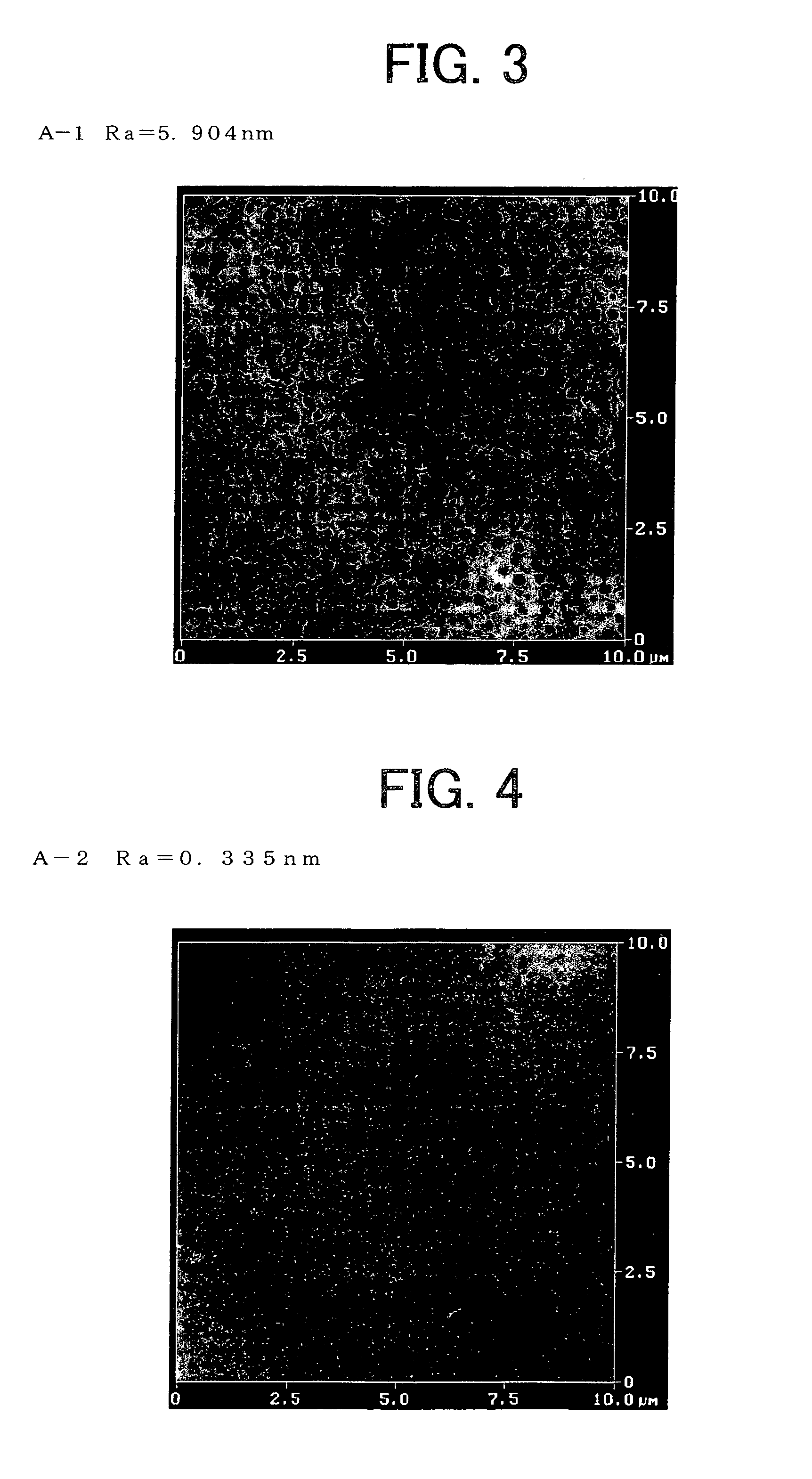

Photocurable resin composition, finely embossed pattern-forming sheet, finely embossed transfer sheet, optical article, stamper and method of forming finely embossed pattern

InactiveUS7420005B2Accurate layeringKeep shapeImpression capsRecord carriersPolyesterSilica particle

The photocurable resin composition in the first aspect of the invention comprises, as essential components, (A) a binder resin having photopolymerizable functional groups and (B) inorganic superfine particles in the order of sub-micron which can be dispersed in a colloidal form; the photocurable resin composition in the second aspect comprises, as essential components, (C) a binder resin containing photopolymerizable functional groups and (D) hydrophobic fine silica particles; and the photocurable resin composition in the third aspect comprises, as essential components, (E) a binder resin containing acrylic resin and urethane acrylate resin and / or polyester acrylate having photopolymerizable functional groups and (F) an organometallic coupling agent. These photocurable resin compositions are excellent not only in fitting to the shape of a cavity in a stamper complementary to a finely embossed pattern on an optical article, thus enabling rapidly and accurately shaping a finely embossed pattern, but also in form retention after shaping and resistance to blocking, thus enabling exposure to light after removal of the stamper and storage in a rolled form to achieve excellent successive producibility.

Owner:DAI NIPPON PRINTING CO LTD

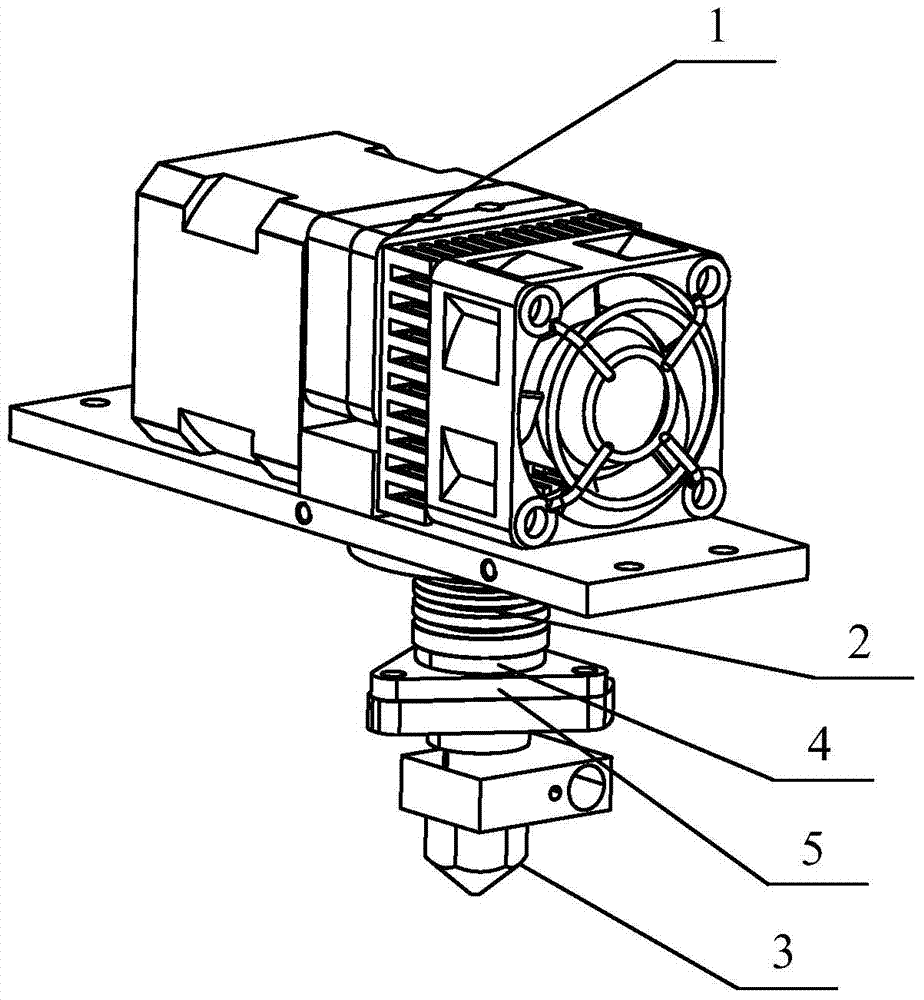

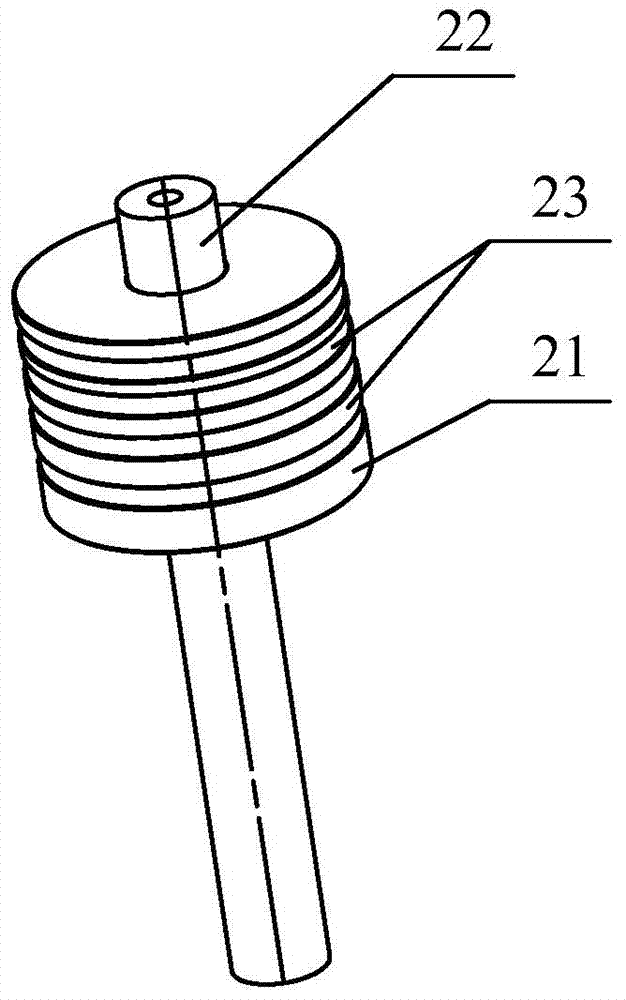

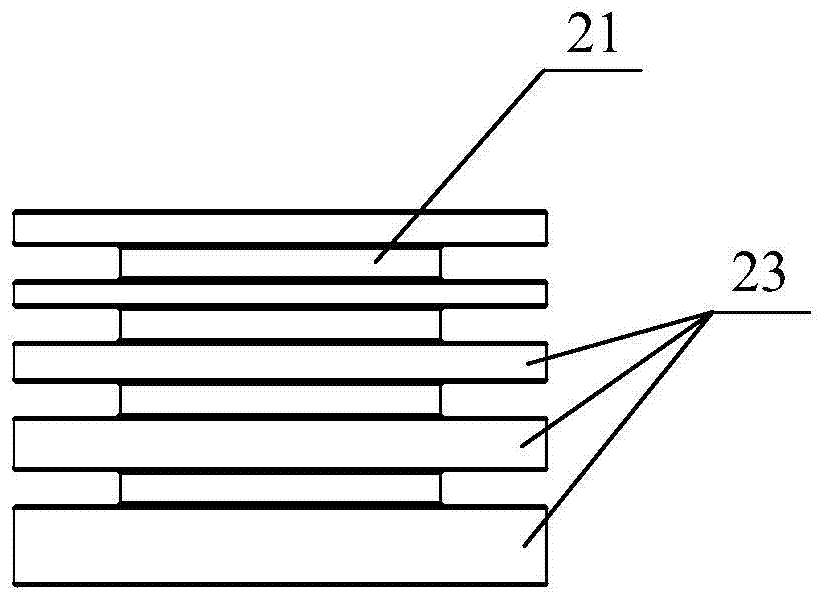

Feeding venturi and feeding structure for 3D printer

The invention provides a feeding venturi for a 3D (three-dimensional) printer. The feeding venturi comprises a radiating outer tube and a polytetrafluoroethylene inner tube embedded in the radiating outer tube; a feeding passage for enabling a printing material to pass through is formed in the polytetrafluoroethylene inner tube. According to the feeding venturi, by the polytetrafluoroethylene inner tube, the condition that the PLA (Poly Lactic Acid) printing material is blocked in the venturi is prevented and stability and smoothness of wire output of a heating printing head, so that surface quality of a printed model is improved; a feeding structure is simple and reliable, is low in cost and is suitable for popularization and application.

Owner:SHANGHAI MEDDO MEDICAL DEVICE

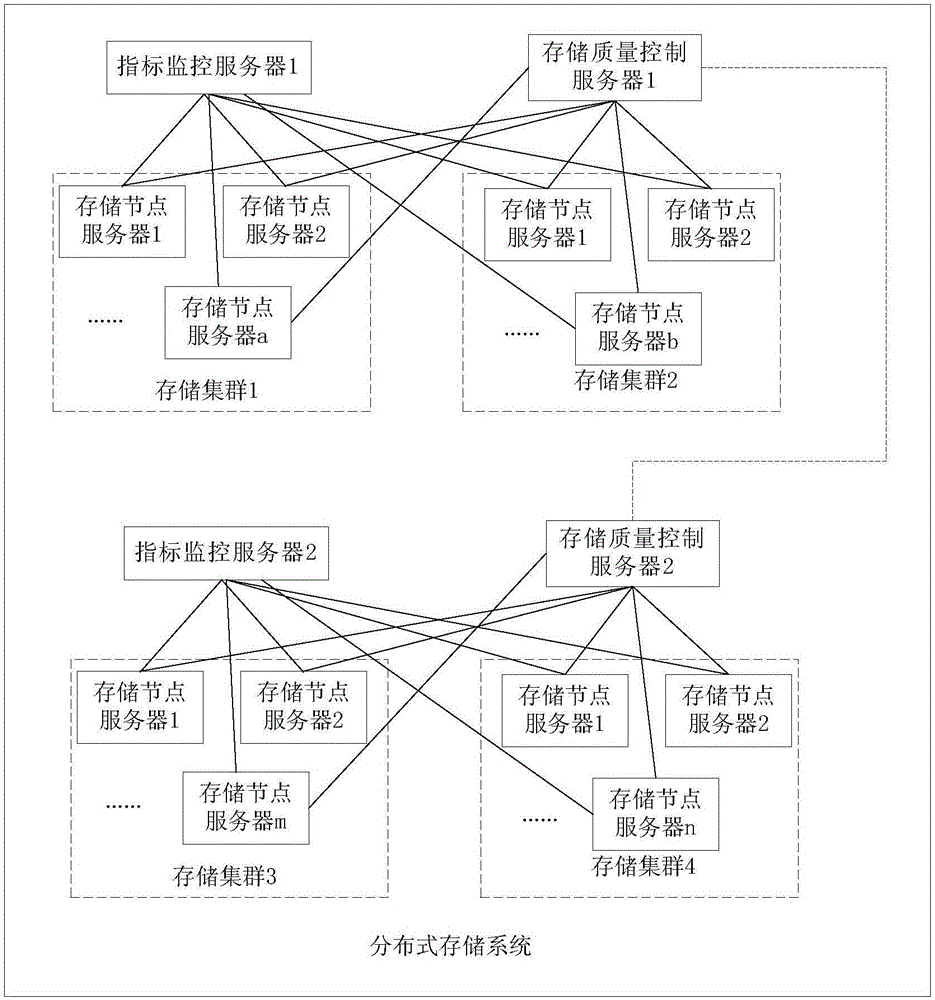

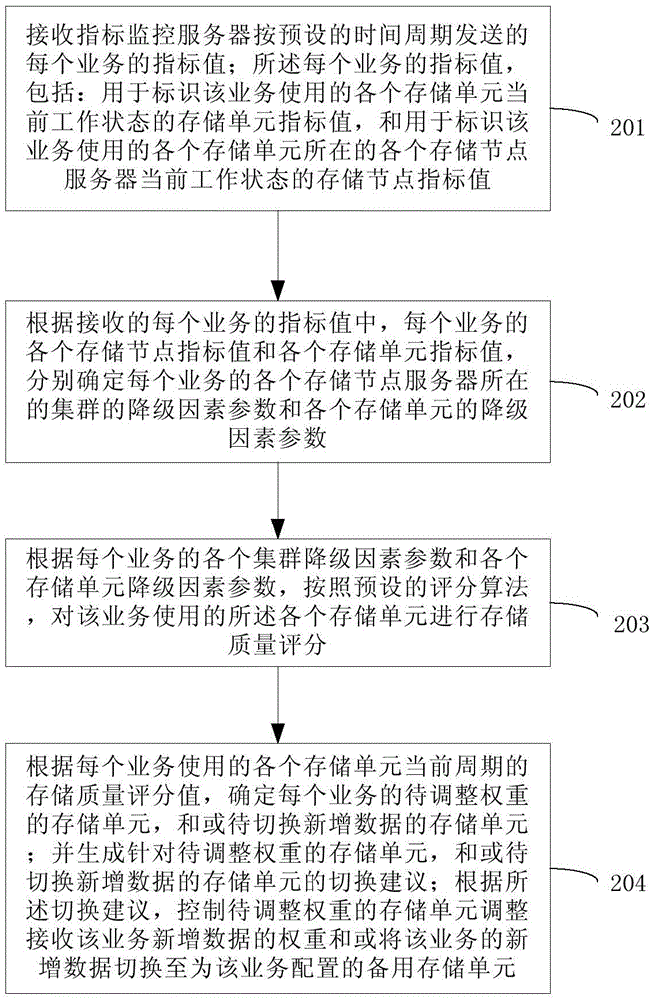

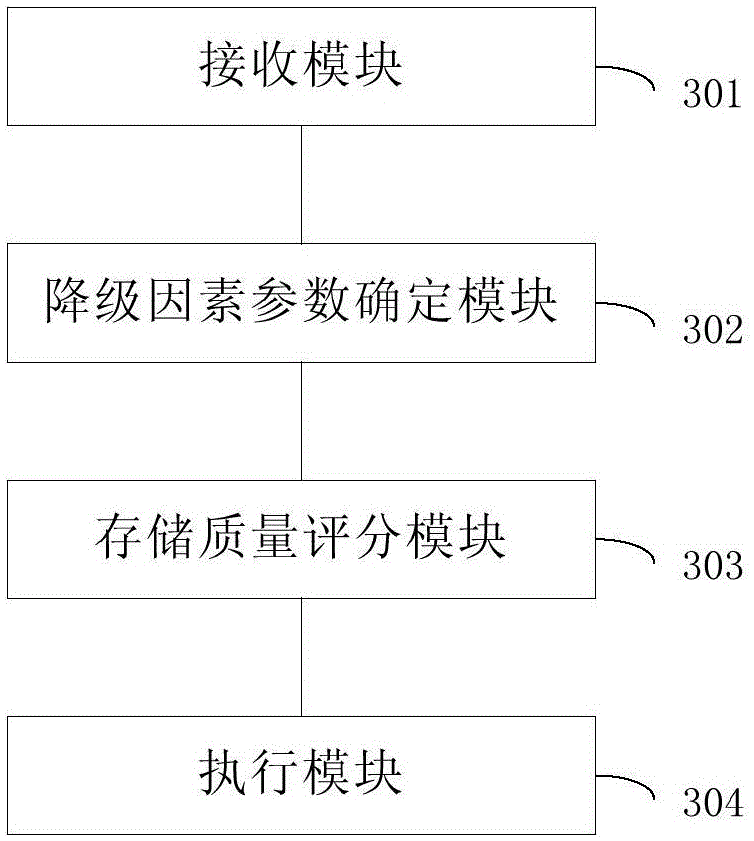

Distributed storage system and storage quality control method and device thereof

ActiveCN105072201AAvoid blockageRealize automatic switchingTransmissionQuality of serviceQuality control

The invention discloses a distributed storage system and a storage quality control method and device thereof in an embodiment. The system, by use of an index monitoring server, performs index monitoring on each storage unit used by each service and each storage node server of the storage unit to obtain the index values of each service for sending to a storage quality control server; the storage quality control server determines a degrading factor parameter of a cluster of each storage node server of each service and the degrading factor parameter of each storage unit according to each storage node index value and each storage unit index value of each service in the received index values of each service, respectively; the storage quality of each storage unit used by the service is scored according to the degrading factor parameters, and the storage unit is switched according to the score. The distributed storage system is capable of realizing automatic switching of the storage units and guaranteeing the quality of the storage service.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

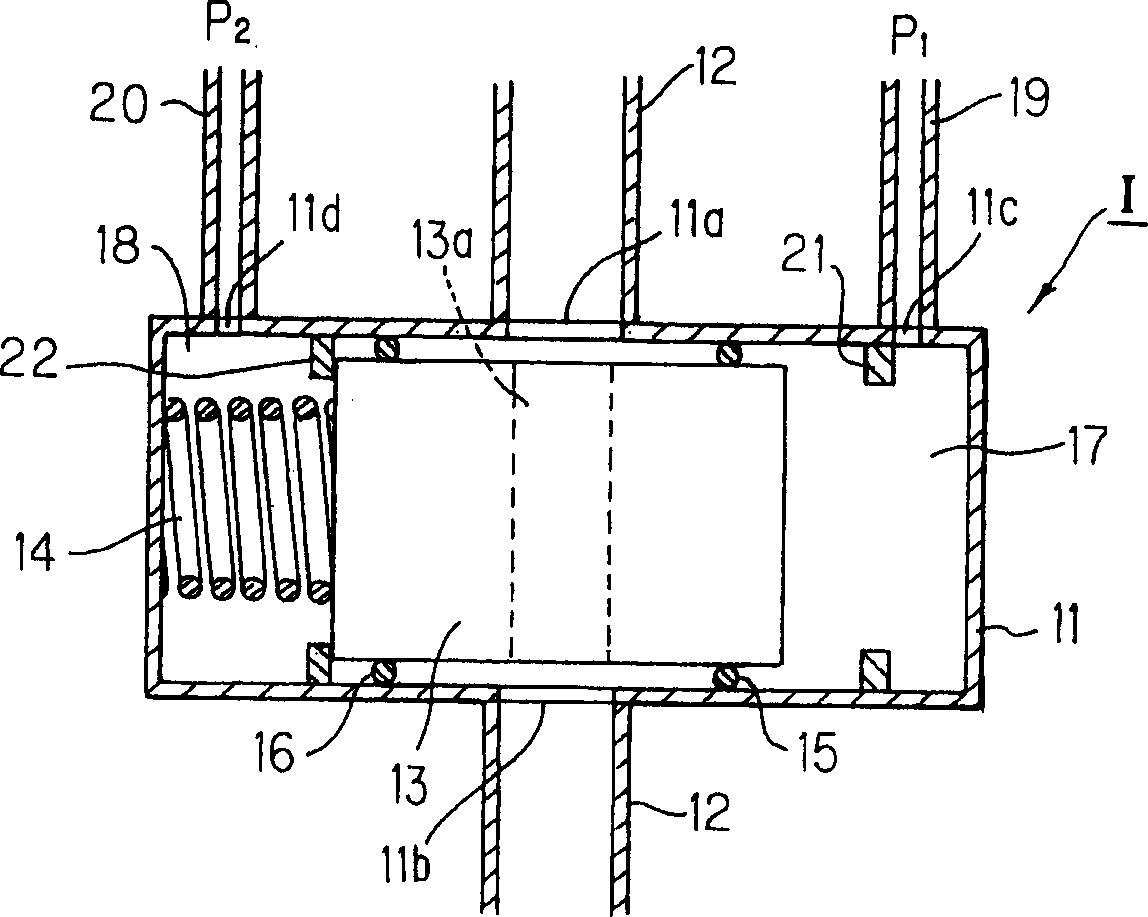

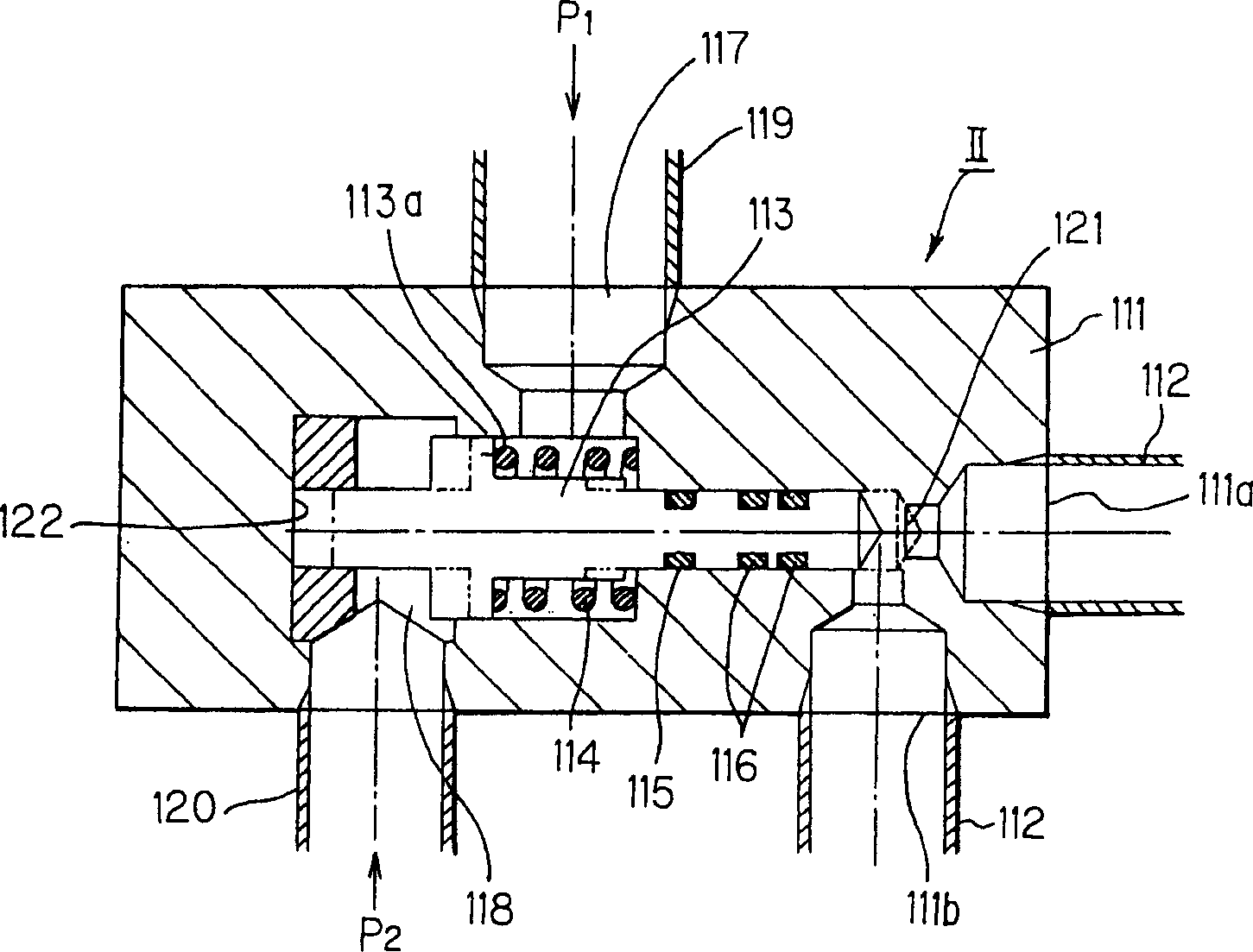

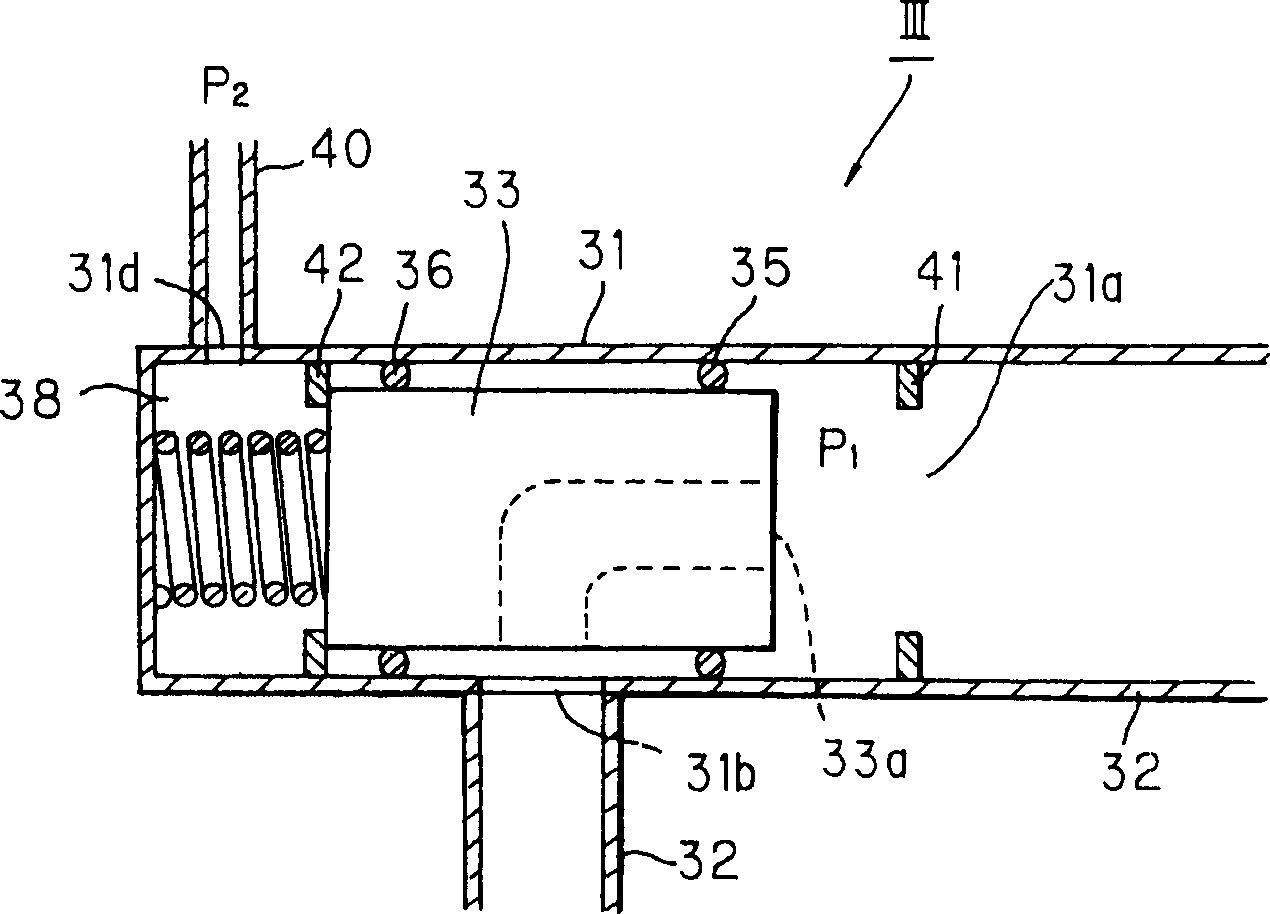

Self-contained regulating valve, and compression type refrigerating machine having the same

InactiveCN1422367ASimple structureLow priceOperating means/releasing devices for valvesCompression machines with non-reversible cycleInterior spaceDifferential pressure

A self-contained regulating valve having a spool, axially movable in the internal space of a cylindrical valve main body, wherein one pressure (P1) is applied to one end surface of the spool while the other pressure (P2) is applied to the other end surface, the spool being formed with a through-hole, so that when the difference between one pressure (P1) and the other present (P2) exceeds a set value, the through-hole communicates with a pipe line connected to the valve main body, thus establishing the open state.

Owner:MITSUBISHI HEAVY IND LTD

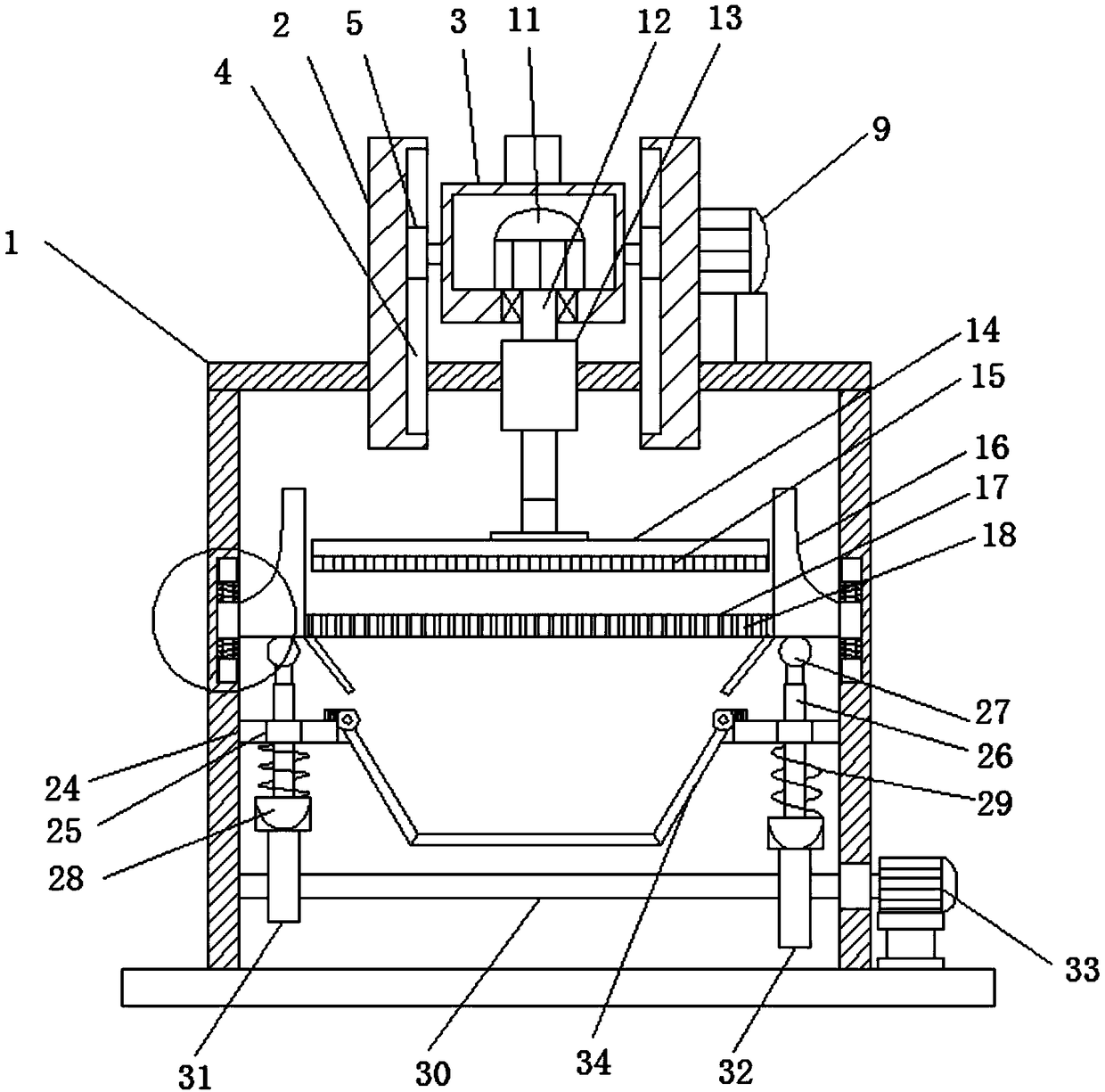

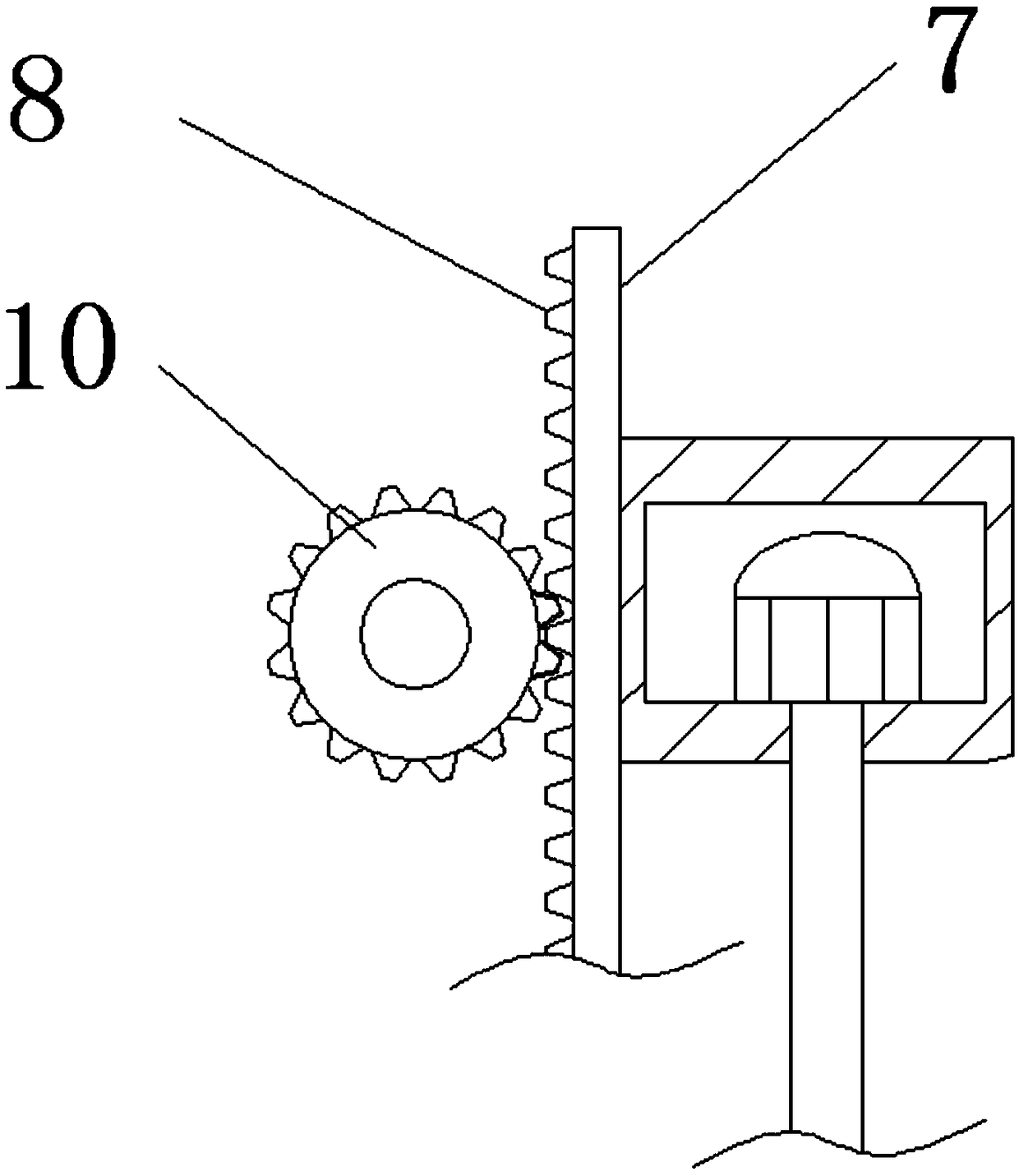

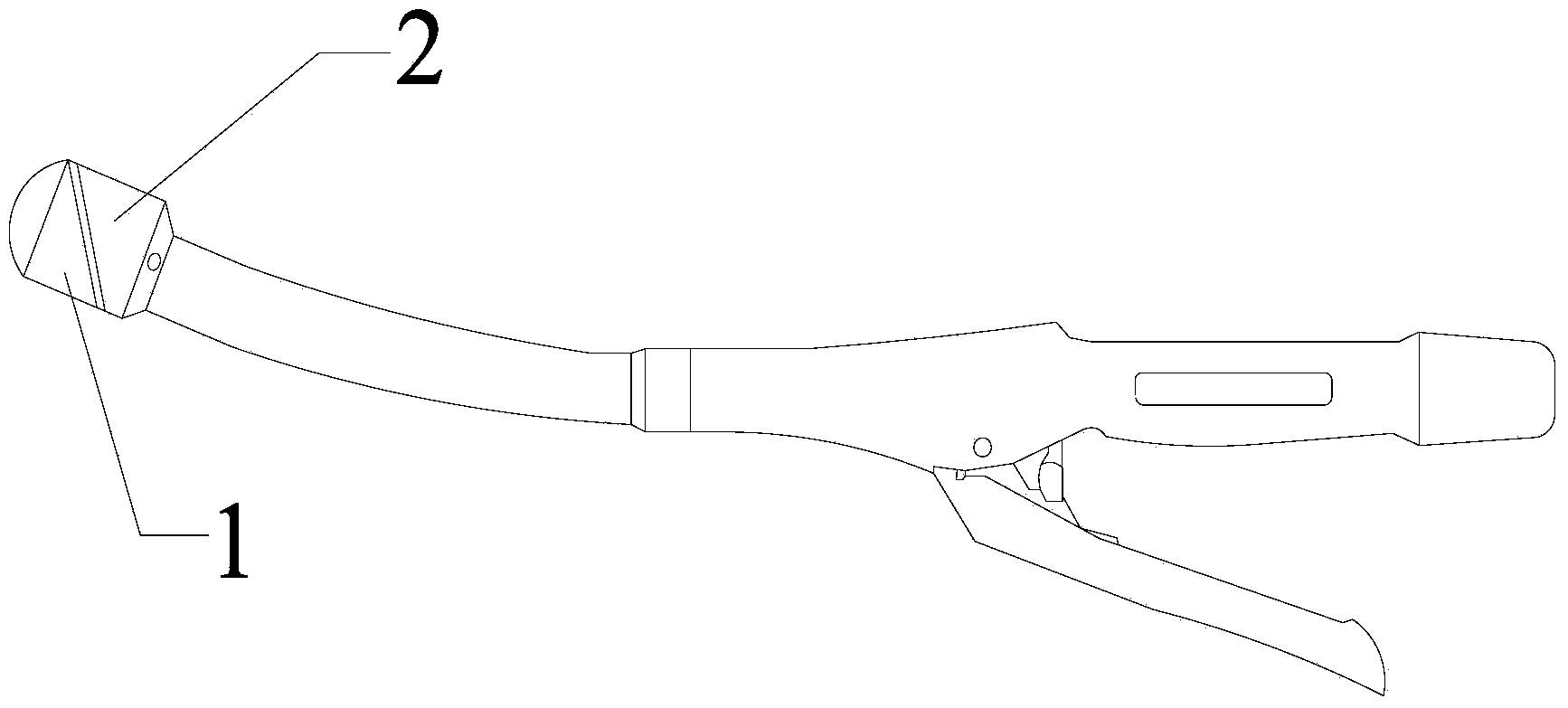

Grinding device for flour processing

The invention discloses a grinding device for flour processing. The grinding device for the flour processing comprises a grinding box. Grinding disks are mounted on the inner wall of the grinding box.Grinding grooves are formed in the grinding disks. A transmission frame is mounted at the top of the grinding box. A motor box is mounted in the transmission frame. Sliding blocks are mounted on theleft side and right side of the motor box through connection blocks. Sliding grooves are formed on the left side and the right side of the transmission frame correspondingly. Both the sliding blocks are mounted in corresponding sliding grooves. A movable plate is mounted on the rear side of the motor box. Racks are mounted on the movable plate. A transmission motor is mounted on the rear wall of the transmission frame. A transmission gear is mounted at the front end of the transmission motor through a rotary shaft. The transmission gear is meshed with the racks. A plurality of material sievingholes are formed in a base plate of each grinding disk. According to the grinding device for the flour processing, through rack transmission, materials in the grinding grooves reduce; meanwhile, a grinding plate declines along with the materials; the grinding plate is laminated with the materials from beginning to end; and thus high-quality grinding effect is continuously guaranteed.

Owner:临泉县生产力促进中心

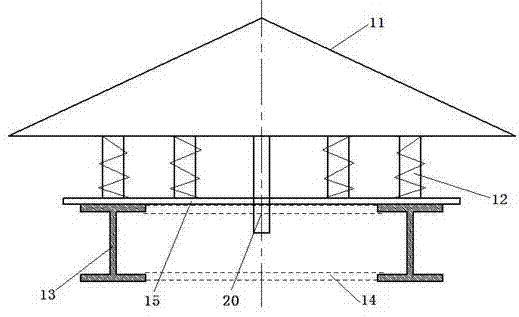

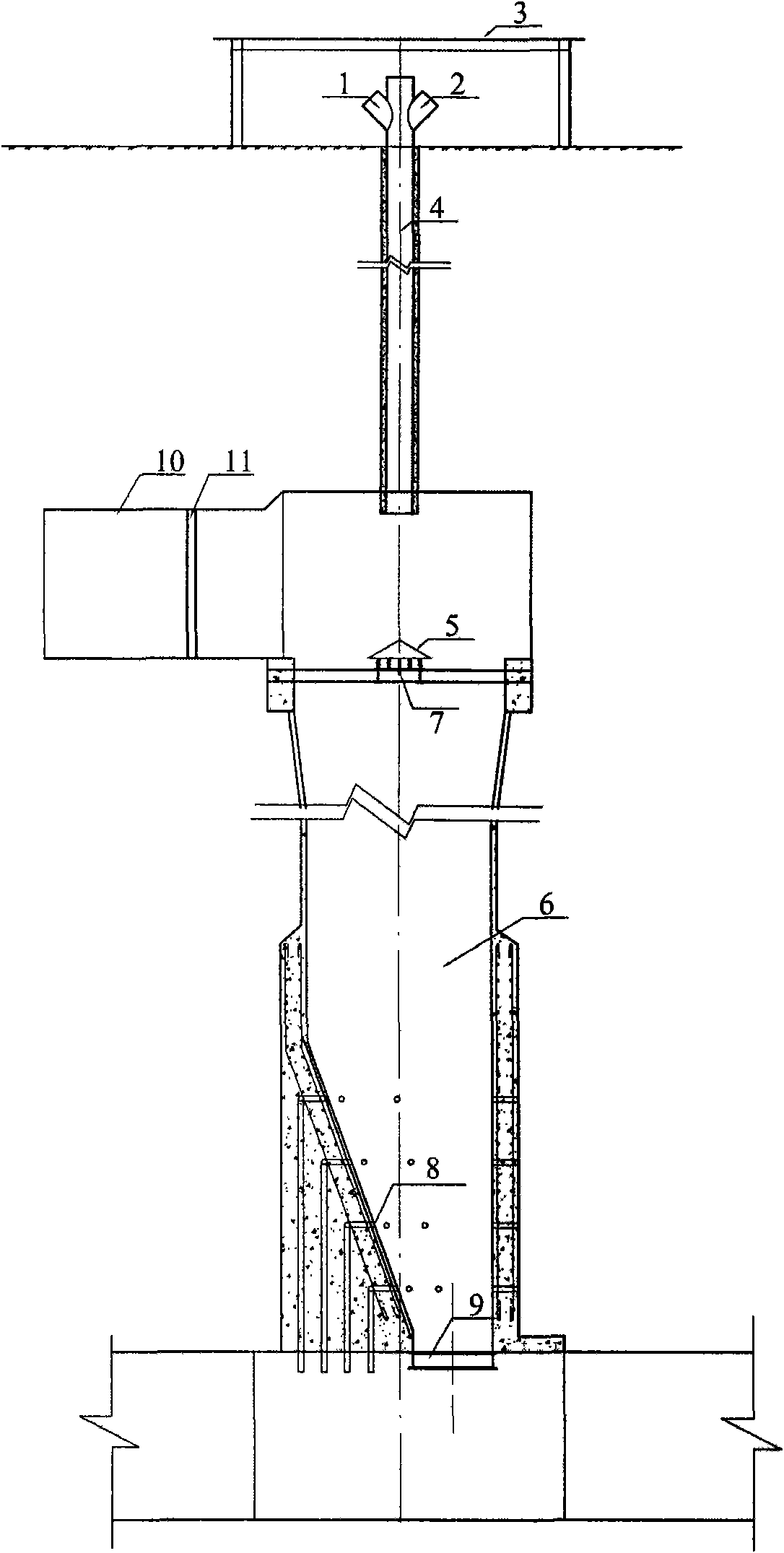

Large vertical depth solid feeding system and large vertical depth solid feeding process for filling extracted coal

InactiveCN101566072AReduce impactSafe and efficient deliveryMaterial fill-upFilling materialsMain channel

The invention relates to a large vertical depth solid feeding system and a large vertical depth solid feeding process for filling extracted coal. The system comprises a ground control console, a feeding pipeline and a well-type storage bin, wherein the upper part of the storage bin is provided with an underground observation chamber which is communicated with a crossheading and also provided with a conical buffer for reducing the impact force; the bottom of the conical buffer is provided with a signal sensor for monitoring the bulk height of monitored materials; the lower part of the well-type storage bin has the shape of a semi-oblique cone; a well wall cleaning device is arranged on the well-type storage bin; and the bottom of the well-type storage bin is provided with a bottom bin feeder which is communicated with a material conveying roadway. Solid filling materials with different compositions are continuously fed into a main channel from a branch pipe through the ground control console, mixed materials are subjected to pressure reduction through the conical buffer on the upper part of the well-type storage bin first, enter the well-type storage bin with the shape of the semi-oblique cone, slide off and are stacked, and feeding is stopped by the ground control console after the bin is full. The invention has the advantages of simple structure, convenient and fast process, convenient implementation, time and labor conservation, and high efficiency and safety.

Owner:CHINA UNIV OF MINING & TECH +1

Anti-blocking coating for pressure sensitive adhesives using cellulose acetate butyrate

InactiveUS6083630AEasily appliedAvoid blockageSynthetic resin layered productsCellulosic plastic layered productsPressure sensitiveHot-melt adhesive

A composition comprising a hot melt adhesive; and a coating for the adhesive comprising cellulose acetate butyrate, wherein the cellulose acetate butyrate is coated on the hot melt adhesive, and a method to prevent blocking of hot melt adhesives comprising coating cellulose acetate butyrate on at least a portion of the surface of a hot melt adhesive.

Owner:EASTMAN CHEM CO

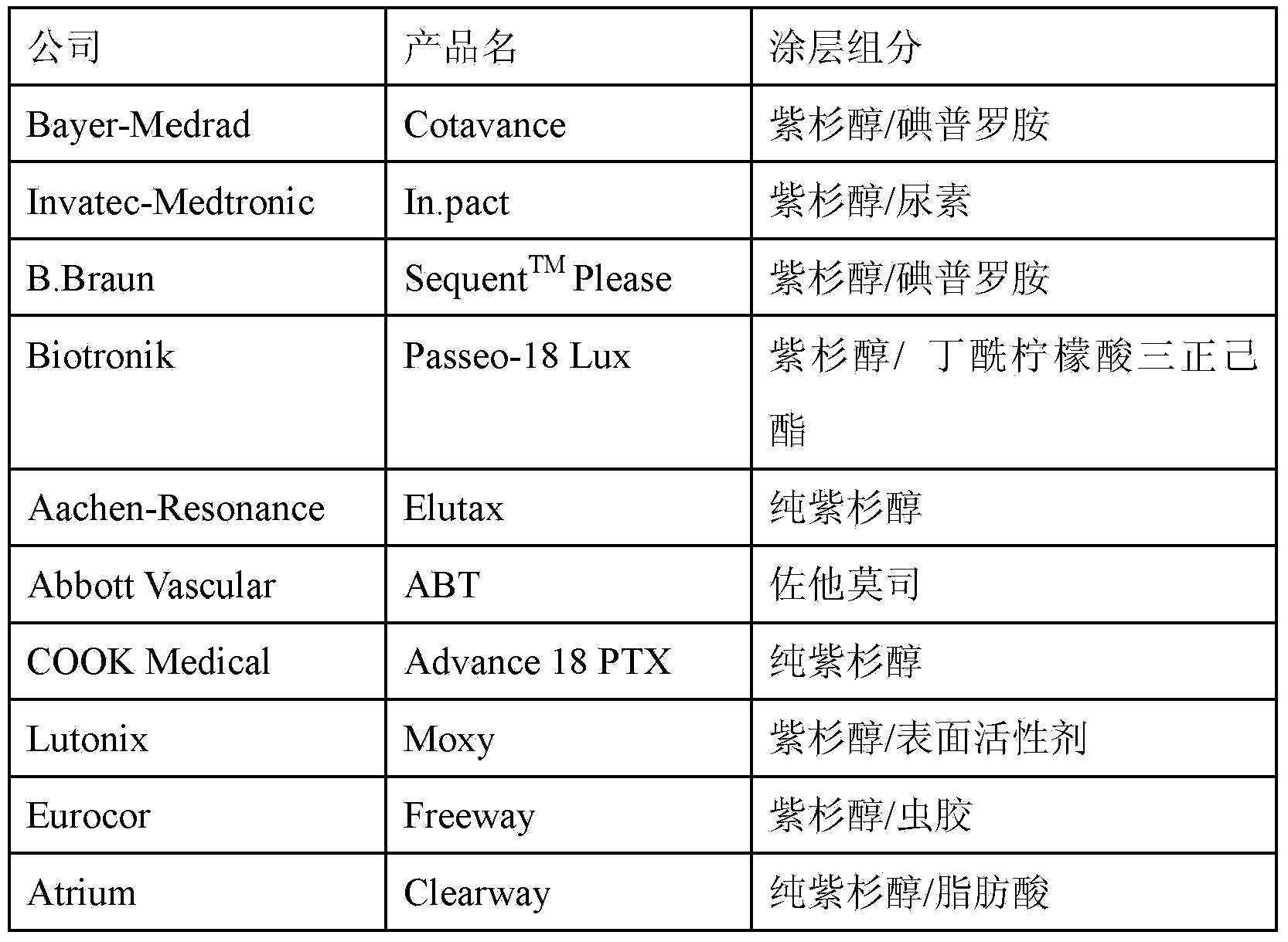

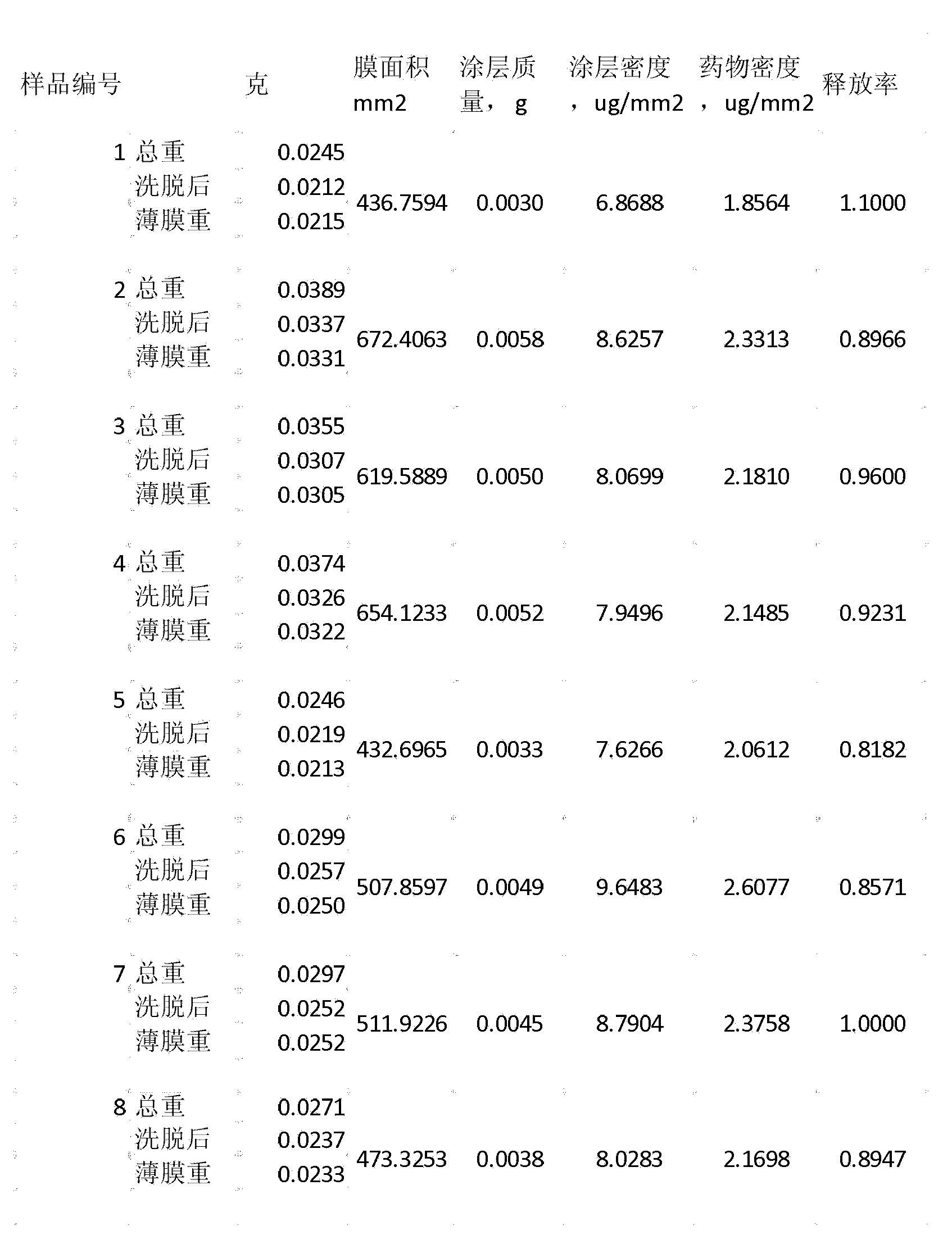

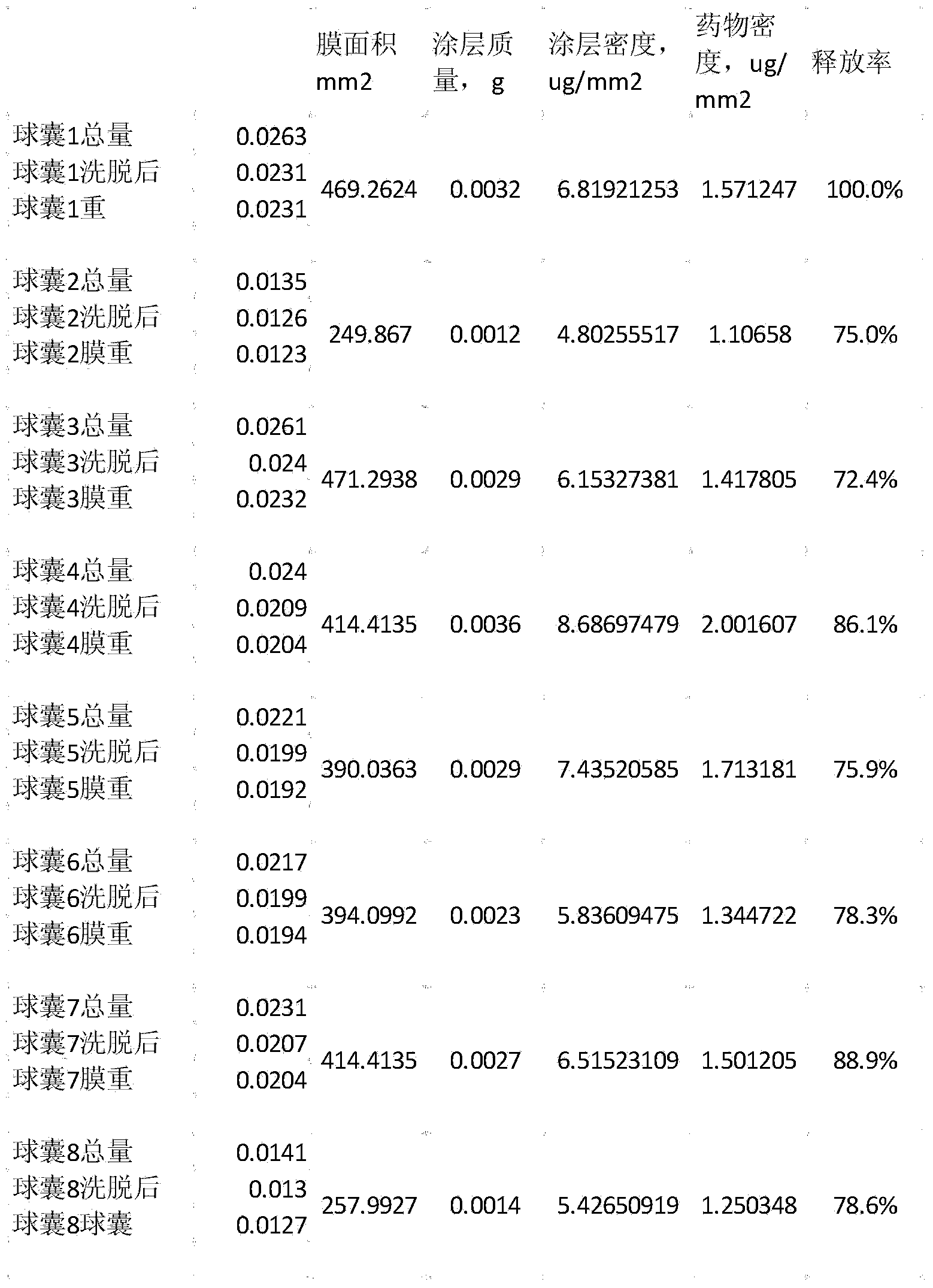

Medicine coating composition as well as preparation method thereof and an implanting or intervention medical apparatus made thereof

The invention belongs to the technical field of medical appliances, and particularly relates to a medicine coating composition as well as a preparation method thereof and an implanting or intervention medical apparatus made thereof. The medicine coating composition for being coated on the surface of an implanting or intervention medical apparatus comprises the following components: a hydrophilic polymer as the first component, a medicine for treating blood vessel hyperplasia as the second component, an inorganic substance as the third component which is one or more than two compositions selected from inorganic simple substances, water soluble inorganic salts or amphiphilic small molecule compounds, and a solvent system as the fourth component, and the solvent system comprises corresponding solvents for the first component, the second component and the third component. The medicine balloon coating made of the medicine coating composition has good compatibility with balloons and little coating falling rate when folded, and does not form large medicine crystal particles while quickly disintegrating after immersing blood or distilled water, thereby avoiding the occurrence of thrombosis and angiemphraxis.

Owner:杭州瑞维特医疗科技有限公司

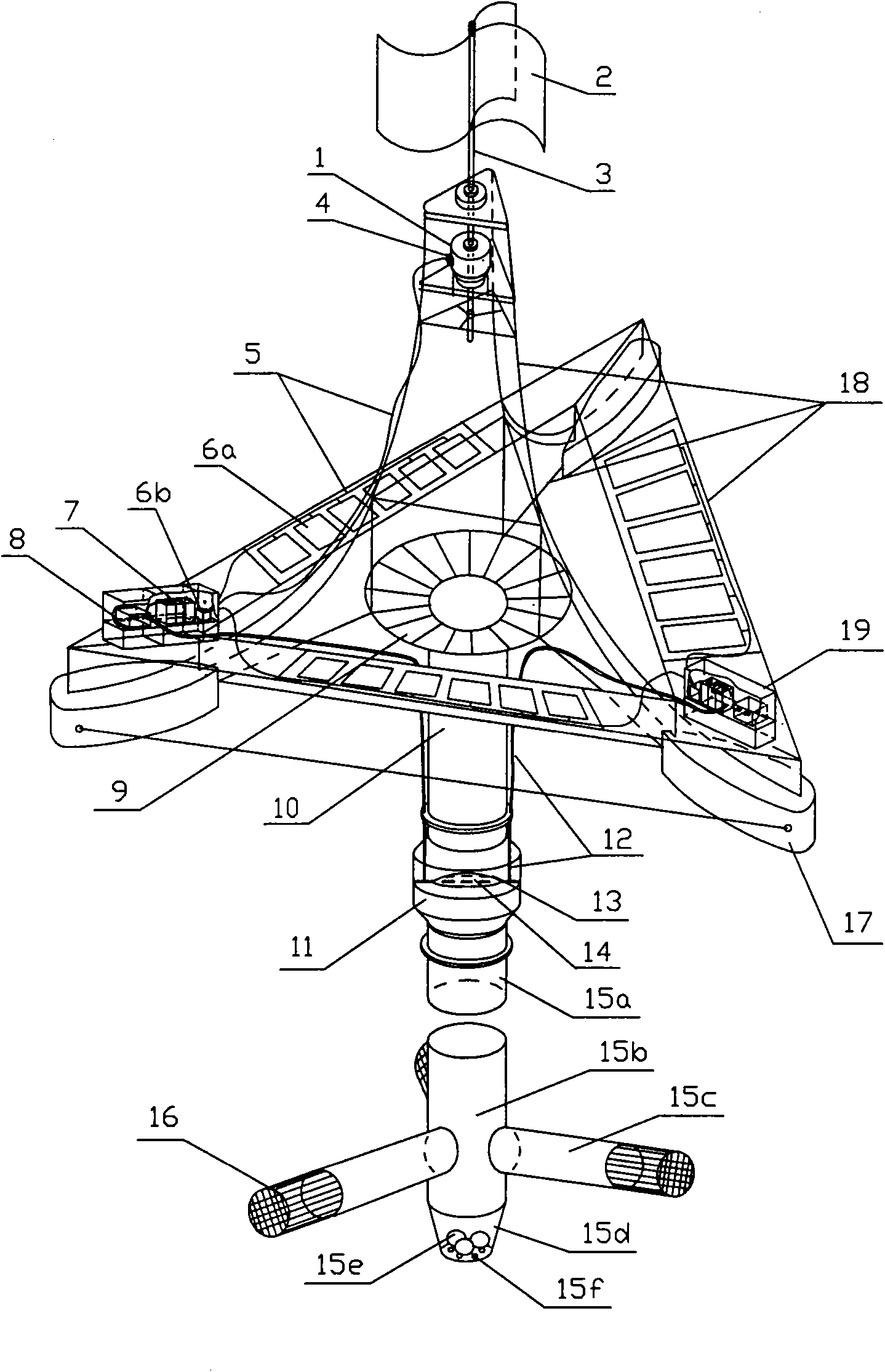

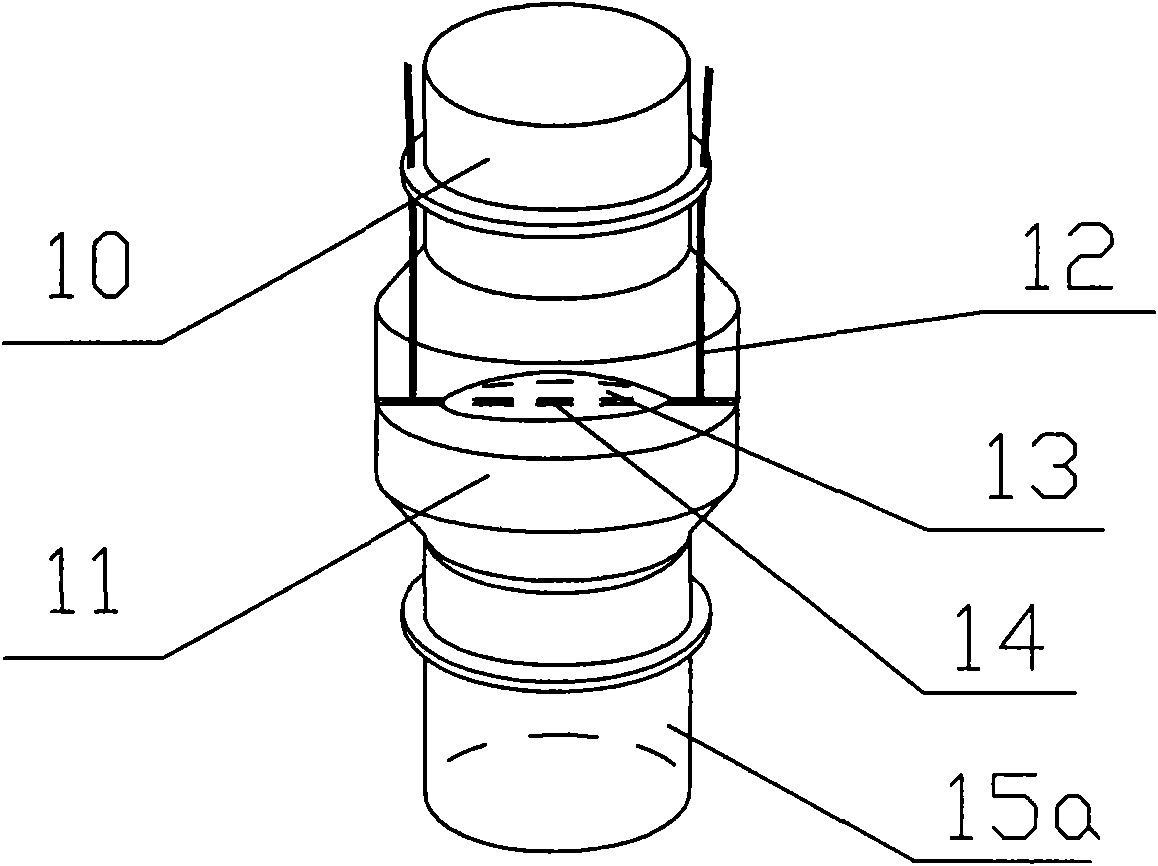

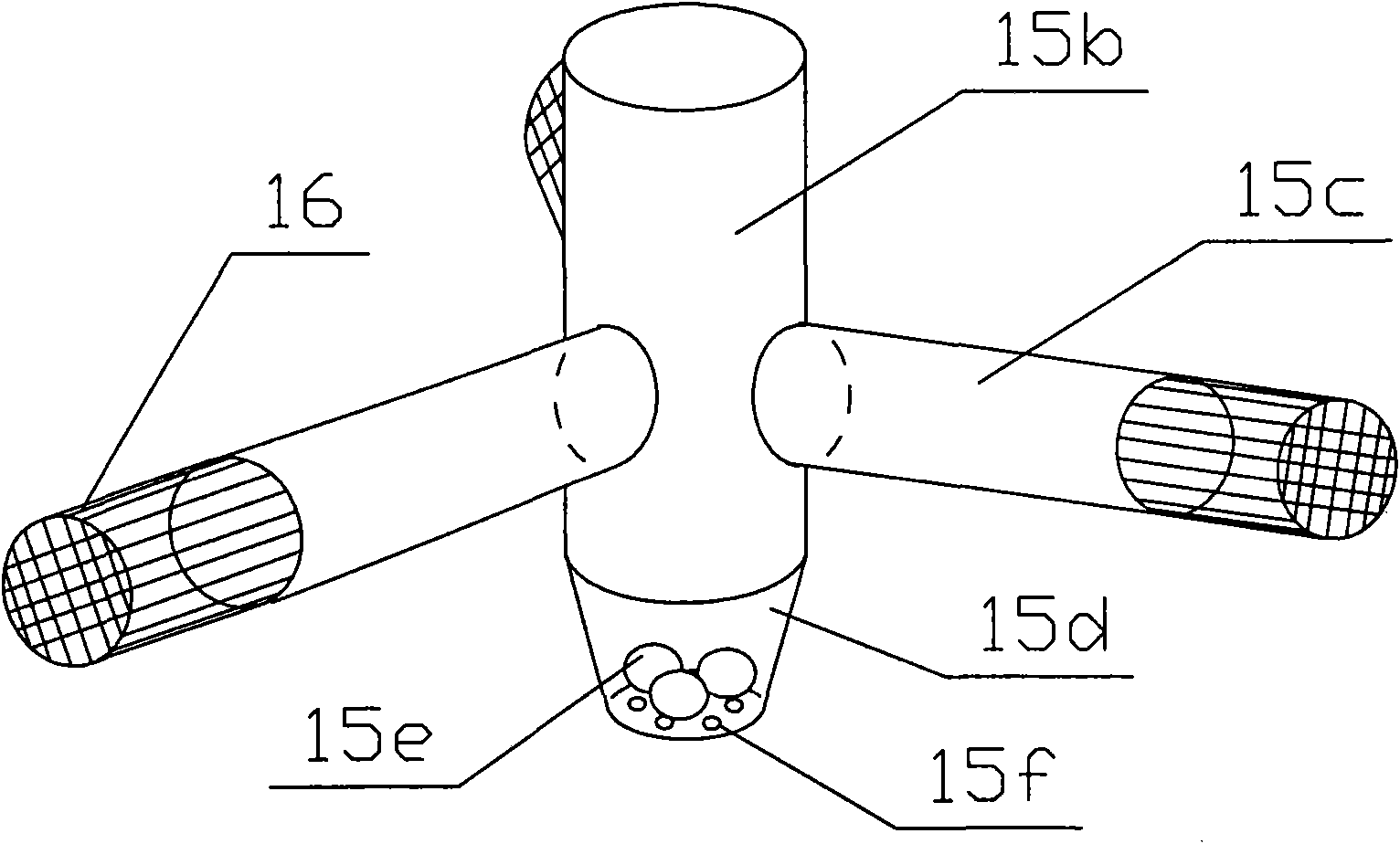

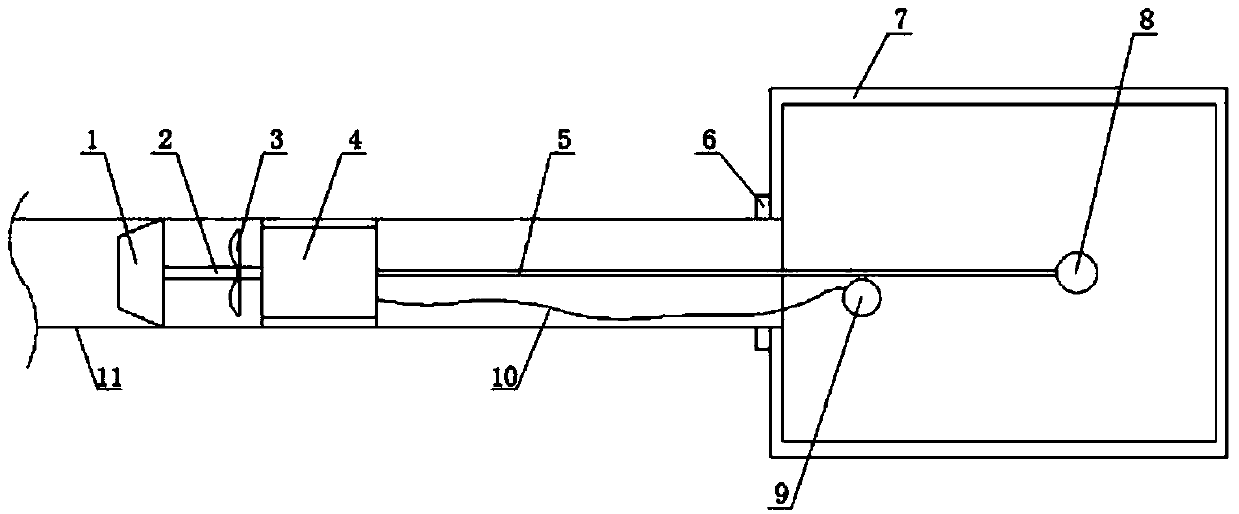

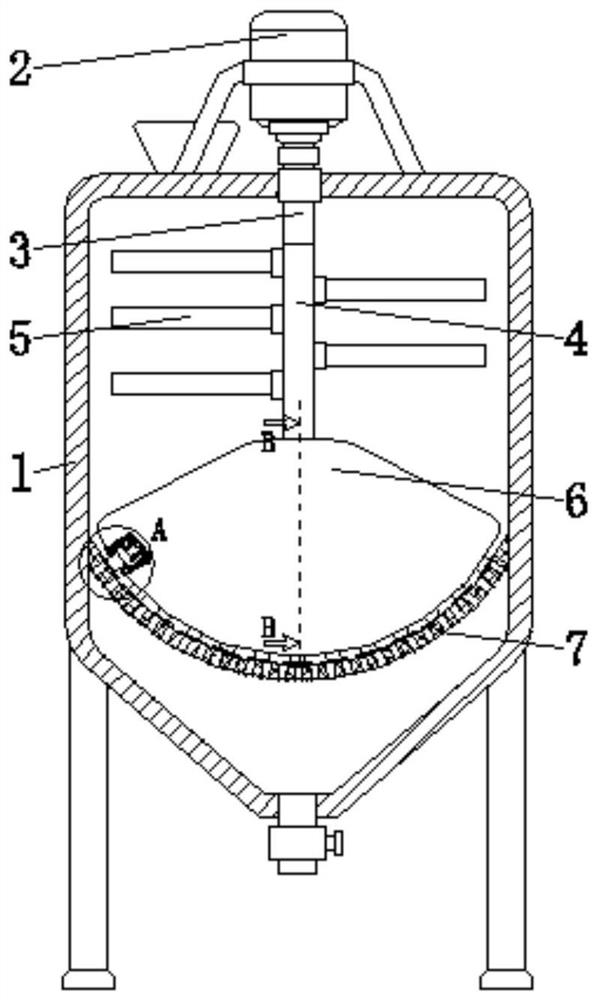

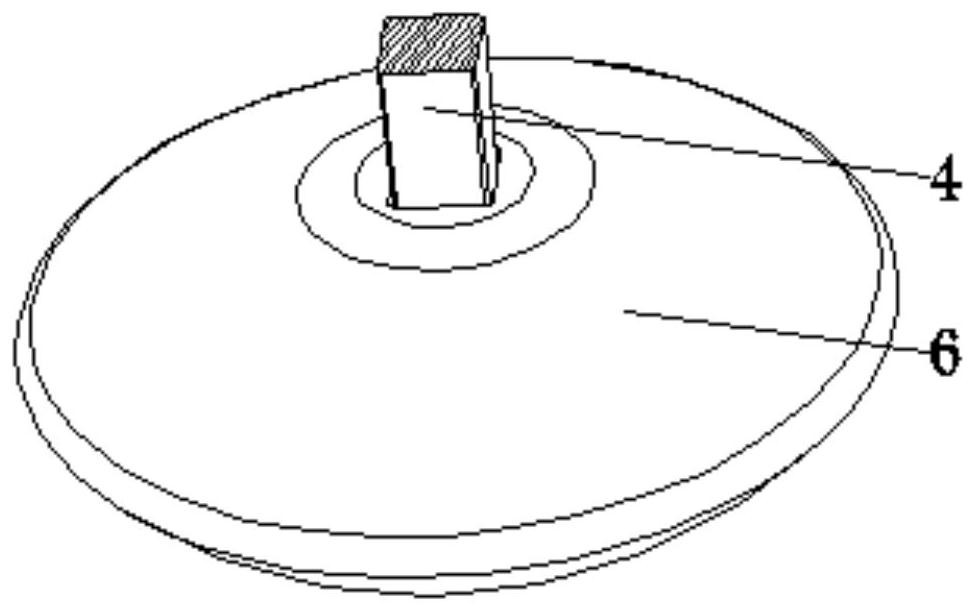

Three-dimensional waterbody circular oxygenation purification plant and method

InactiveCN101676226AEfficient use ofIncrease water delivery areaWater aerationSustainable biological treatmentMicro bubbleGas supply

The invention discloses a three-dimensional waterbody circular oxygenation purification plant and a method in waterbody control and restoration field, realizing circular oxygenation purification function for water body in mass flow in big water areas. The circular oxygenation purification plant comprises a power supply, an aeration plant, a water-output vectoring nozzle, a work pipe section, a micro-bubble generator, a water-input vectoring nozzle, a gas supply pipe, a floating body and a floating body support. The method comprises the following steps: pressure gas generated by the aeration plant in water area is fed into the micro-bubble generator fixed in the work pipe section to generate micro-bubble flow flowing upwards; in the water-output vectoring nozzle, micro-bubble flow pushes waterbody to flow upwards to the top, and simultaneously the waterbody at the bottom of the water-input vectoring nozzle enters the vectoring nozzle and then quickly flows to the top of the vectoring nozzle for spraying and then sprays all around, therefore, the purpose of circular oxygenation purification by waterbody exchange is realized by the way that waterbody flows back to the bottom of the vectoring nozzle downwards from a far end for circular flow after surface reoxygenation.

Owner:北京市水利科学研究所 +1

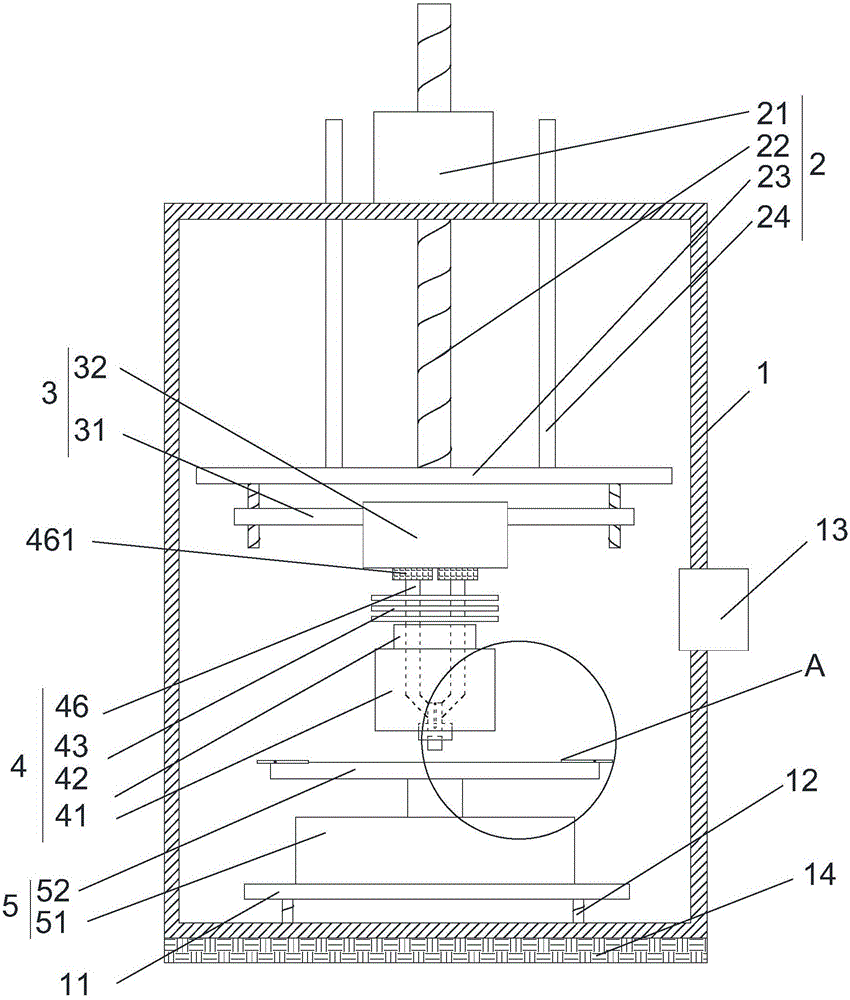

3D printing equipment with multiple feeding tubes

InactiveCN105128330AReduce vibrationIncrease manufacturing costAdditive manufacturing apparatusColor printingSpray nozzle

The invention discloses 3D printing equipment with multiple feeding tubes. The 3D printing equipment comprises a mounting rack, a vertical moving mechanism, a horizontal moving mechanism, a printing head and a printing supporting mechanism, wherein the vertical moving mechanism comprises a first drive device, a lifting rod, a mounting plate and a positioning rod; the horizontal moving mechanism comprises a horizontal moving rod and a second drive mechanism; the printing head comprises a plurality of heating devices, a heat insulating device, a radiating device, a spray head, a spray nozzle and a plurality of feeding tubes; the heat insulating device is mounted above the heating devices; the radiating device is mounted above the heat insulating device; a feeding device is mounted at the upper ends of the feeding tubes; a closing valve is arranged on positions, corresponding to communication positions of the feeding tubes and the spray head, in the spray nozzle; the spray nozzle is detachably mounted at the lower end of the spray nozzle; and the printing supporting mechanism comprises a third drive device and a printing base. The 3D practical equipment with multiple feeding tubes can reduce vibration in a printing process, and can carry out color printing.

Owner:WUHU SIRUIDI THREE DIMENSIONAL TECH CO LTD

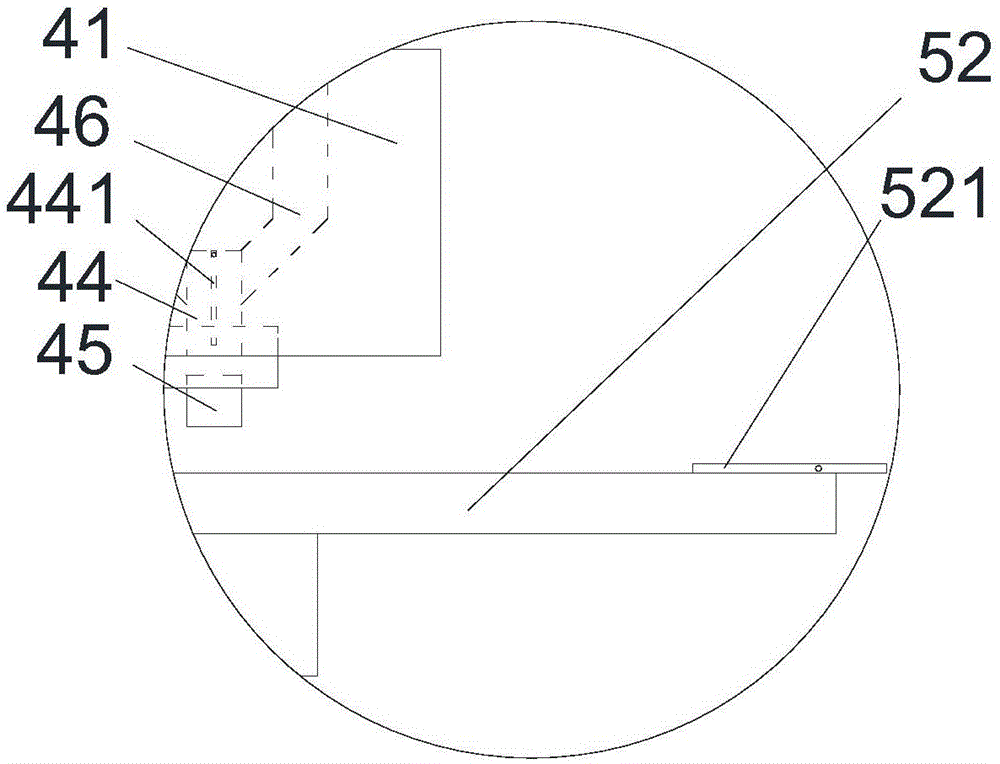

Pipe-type oblique-angle digestive tract anastomat

The invention relates to the field of medical treatment instruments and equipment, and particularly relates to a pipe-type oblique-angle digestive tract anastomat. The pipe-type oblique-angle digestive tract anastomat comprises a nail supporting seat and a nail bin which are provided with oblique surfaces fit mutually; the nail bin is internally provided with suturing nails and an annular tool which are in flush with the oblique surface of the nail bin. According to the pipe-type oblique-angle digestive tract anastomat provided by the invention, the fit surfaces of the nail pushing seat and the nail bin are oblique surfaces, and after the pipe-type oblique-angle digestive tract anastomat is used, scars on the intestinal canal are changed to be oblique, so that each cross section of the intestinal canal is only provided with two scar points rather than a circle of scar, thereby guaranteeing the original elasticity of the intestinal canal and preventing the unsmoothness and the blocking of the intestinal canal. As the suturing surface is an oblique surface, a large enough fit lip can be reserved by the operation instrument design and cutting, and the problem of mutual contradiction of the cutting inner diameter and the lip is solved, and the problems of small lip, poor blood supply and fistula existence are solved.

Owner:聂保江

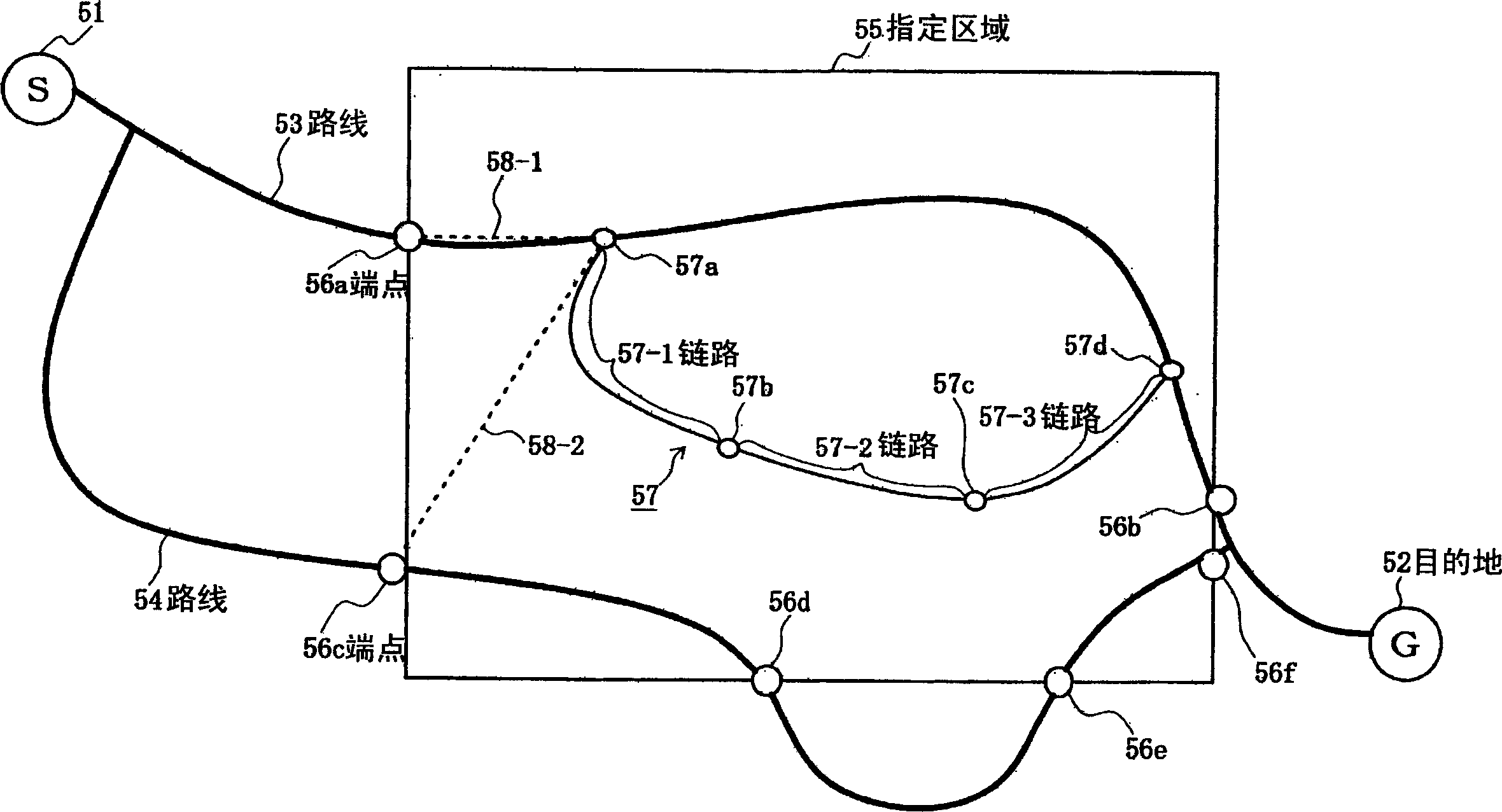

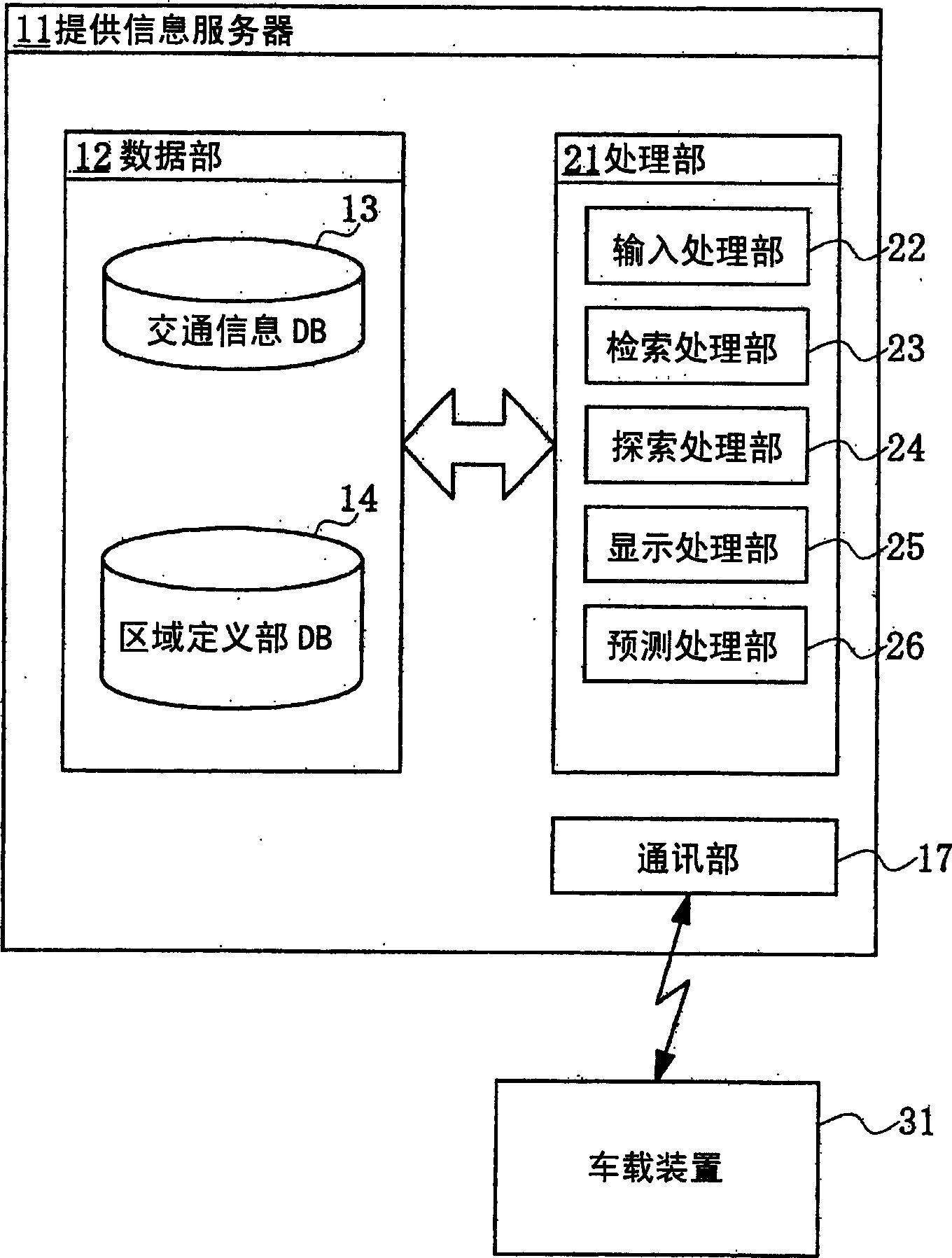

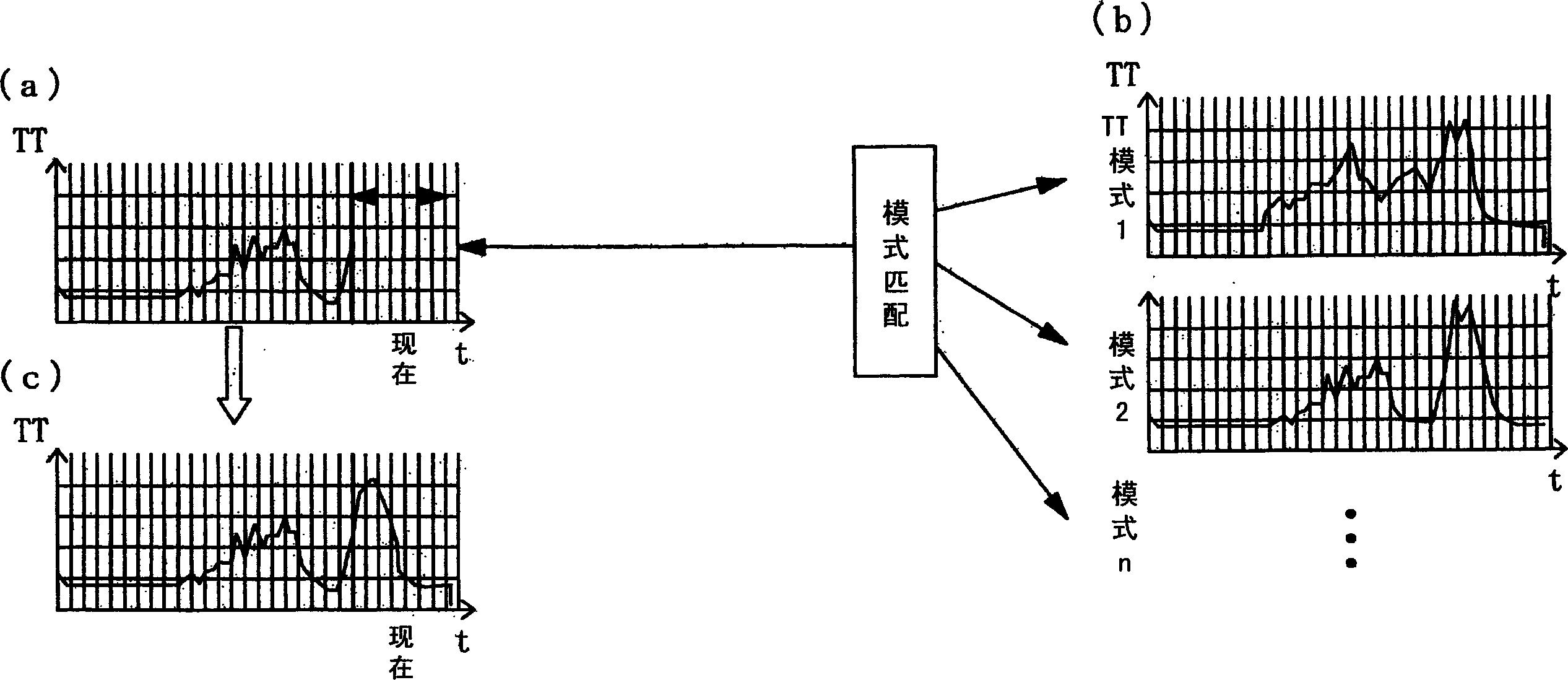

Navigation system

InactiveCN1715835AAvoid blockageInstruments for road network navigationRoad vehicles traffic controlTraffic predictionNavigation system

A navigation system, traffic prediction method, and traffic prediction program search for a plurality of routes to a destination. The system, method, and program calculate, if any of the plurality of routes passes through a predetermined area (55), a predicted time at which a link within the predetermined (55) area will be passed through. The system, method, and program generate predicted traffic information for the link at the predicted time at which the link will be passed through based on the stored traffic information.

Owner:AISIN AW CO LTD

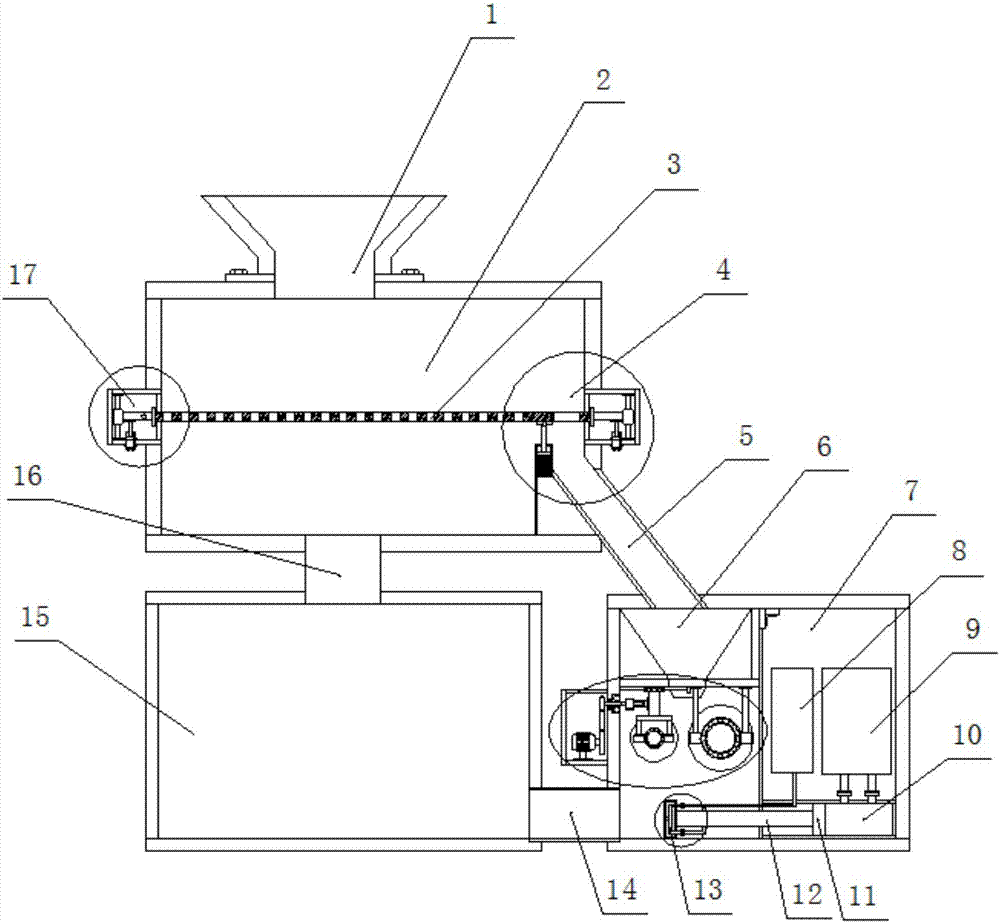

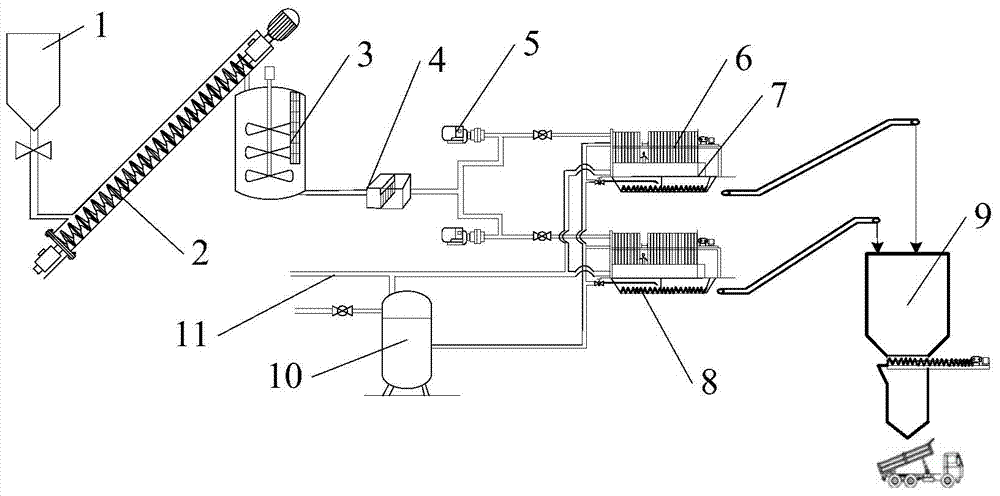

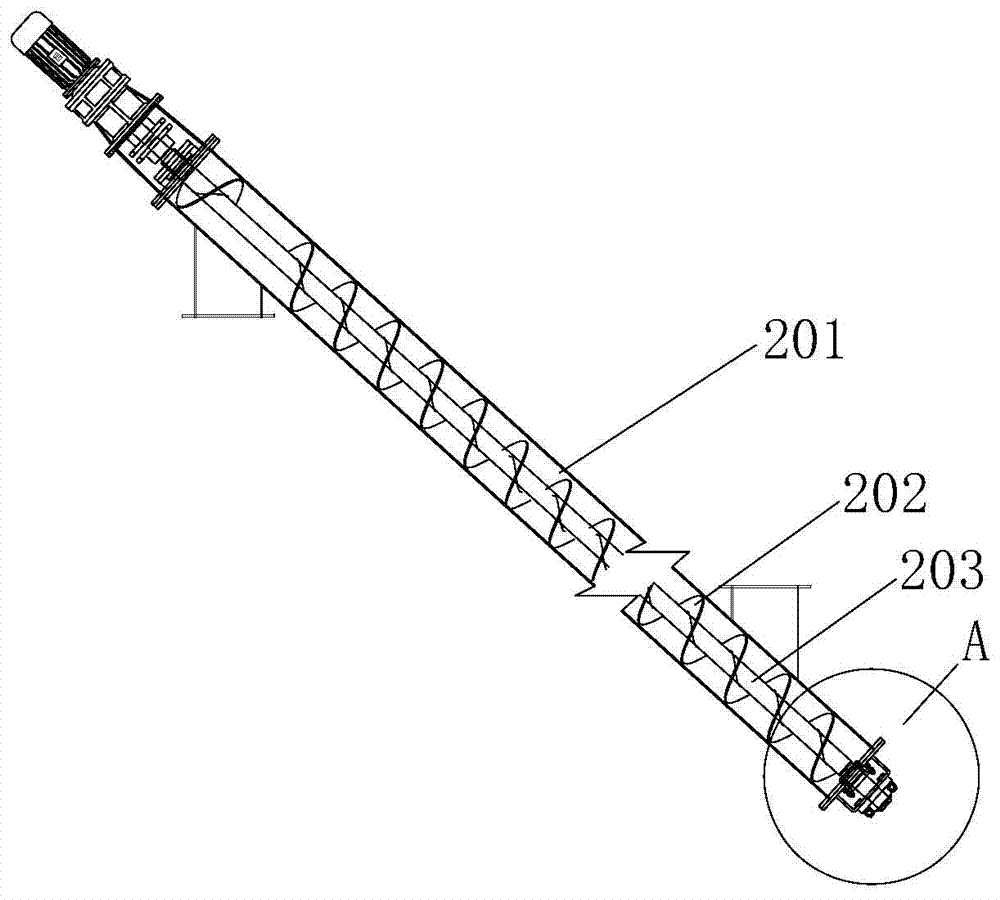

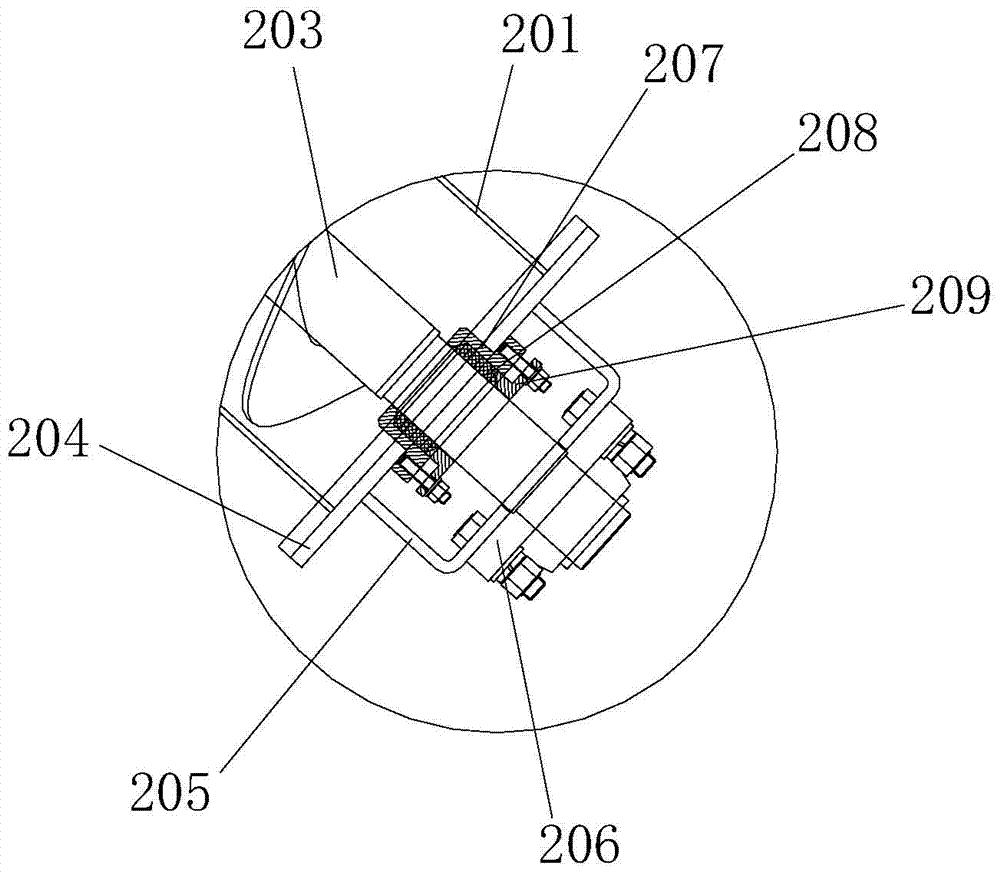

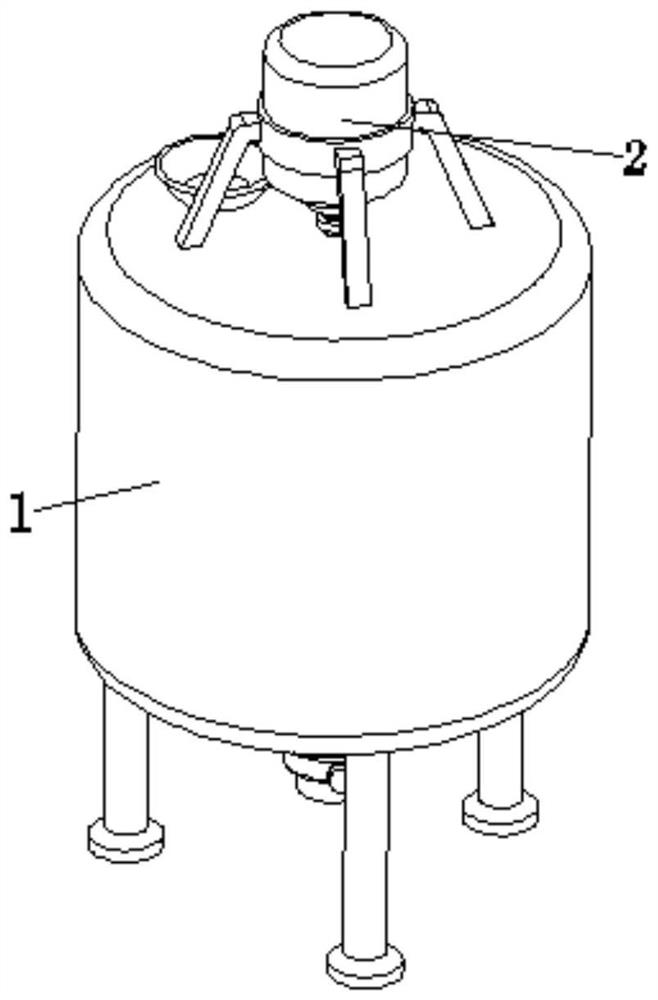

Method and system for deep dehydration of sludge

ActiveCN103693841AFacilitate deep dehydrationHigh economic valueSludge treatment by de-watering/drying/thickeningSludgeFilter press

The invention relates to a method and a system for deep dehydration of sludge. The method comprises the following steps: S1, adding sludge and a modifier to a sludge conditioning tank; S2, fully stirring the sludge and the modifier in the sludge conditioning tank, so that the sludge is subjected to flocculating modification; S3, carrying out second-level filtering on the sludge flowing out from the sludge conditioning tank, and then conveying to a high-pressure diaphragm plate-and-frame filter press to carry out filter pressing through a high-pressure pump, extruding the moisture in the sludge and forming a mud cake; S4, conveying the mud cake to a mud cake discharge bin to store through screw conveying equipment. The system comprises a modifier storage bin (1), a modifier conveyer (2), a sludge conditioning tank (3), a second-level filtering device (4), a high-pressure pump (5), a high-pressure diaphragm plate-and-frame filter press (6), screw conveying equipment (8) and a mud cake discharge bin (9). The method and the system are high in automatic degree, the sludge treatment efficiency is improved, the sludge is conveyed in the sealed equipment, and secondary pollution to the environment is not generated.

Owner:华新环境工程有限公司 +1

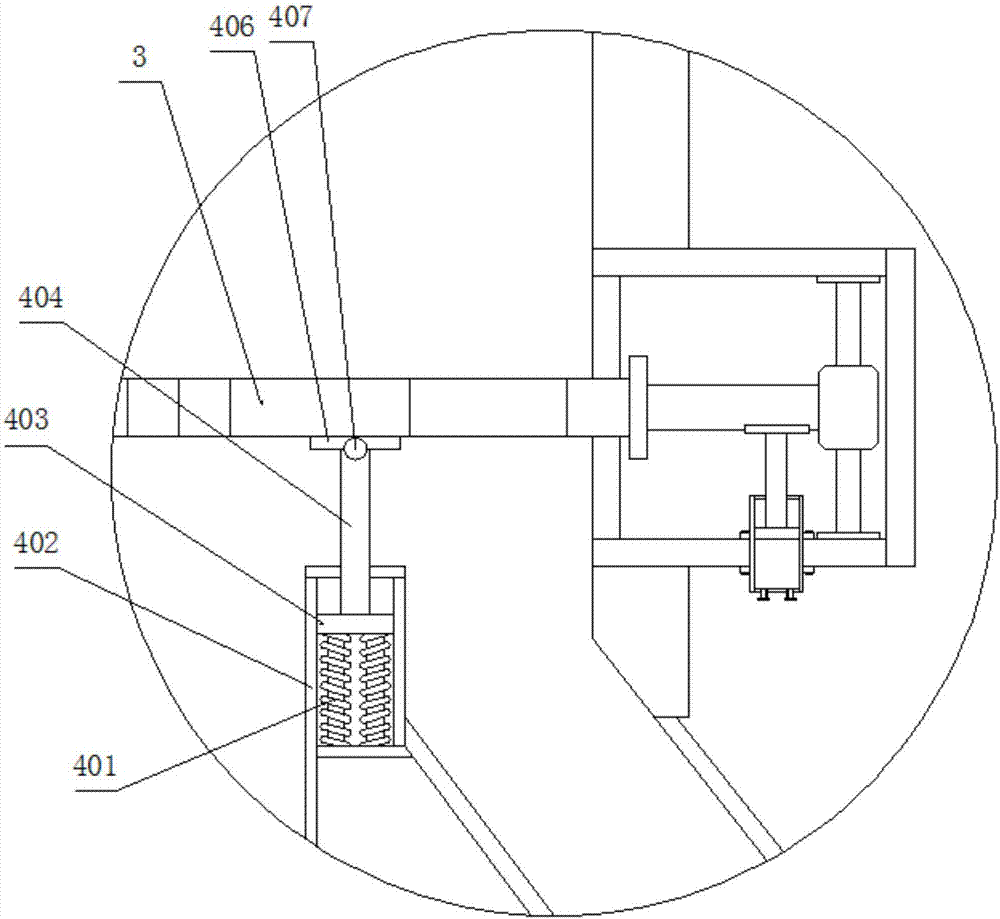

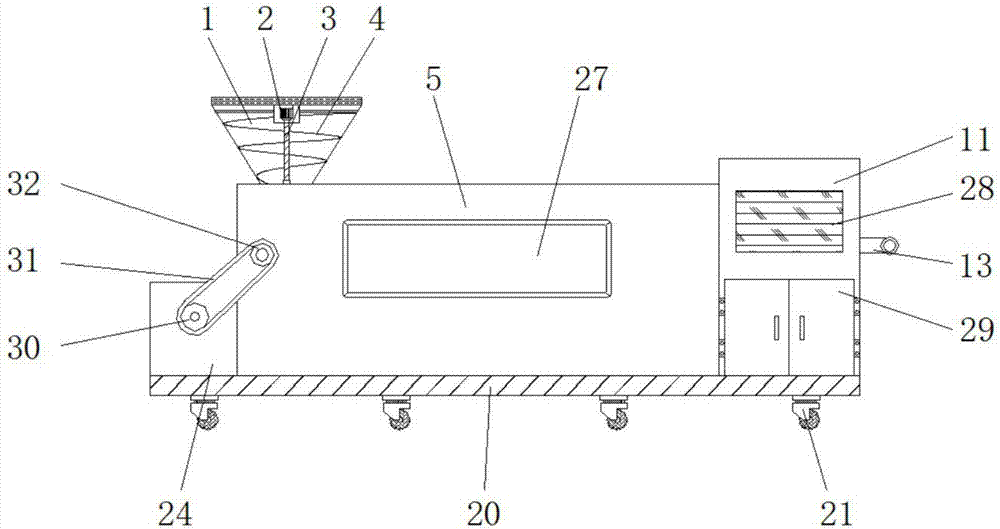

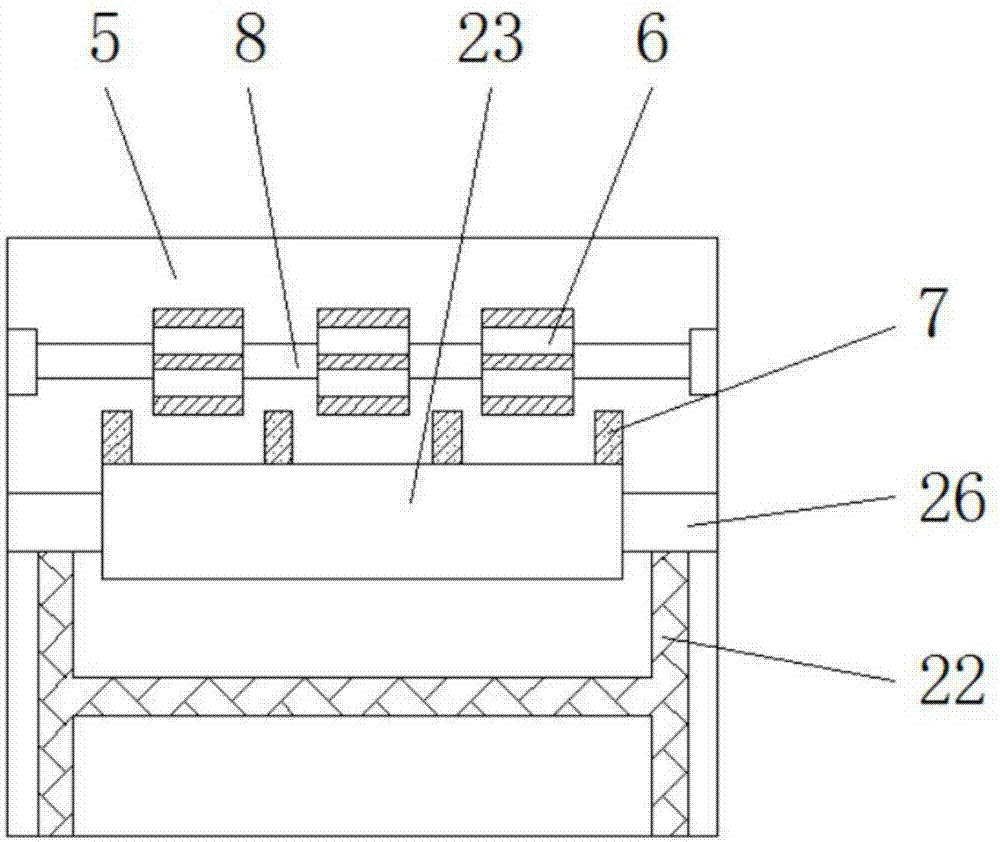

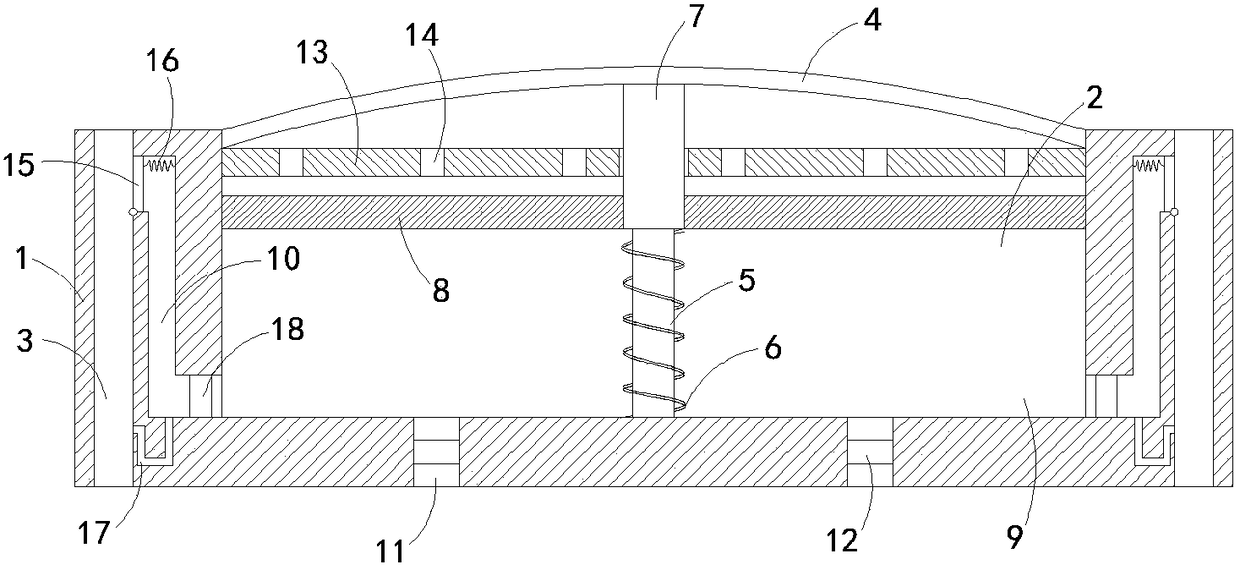

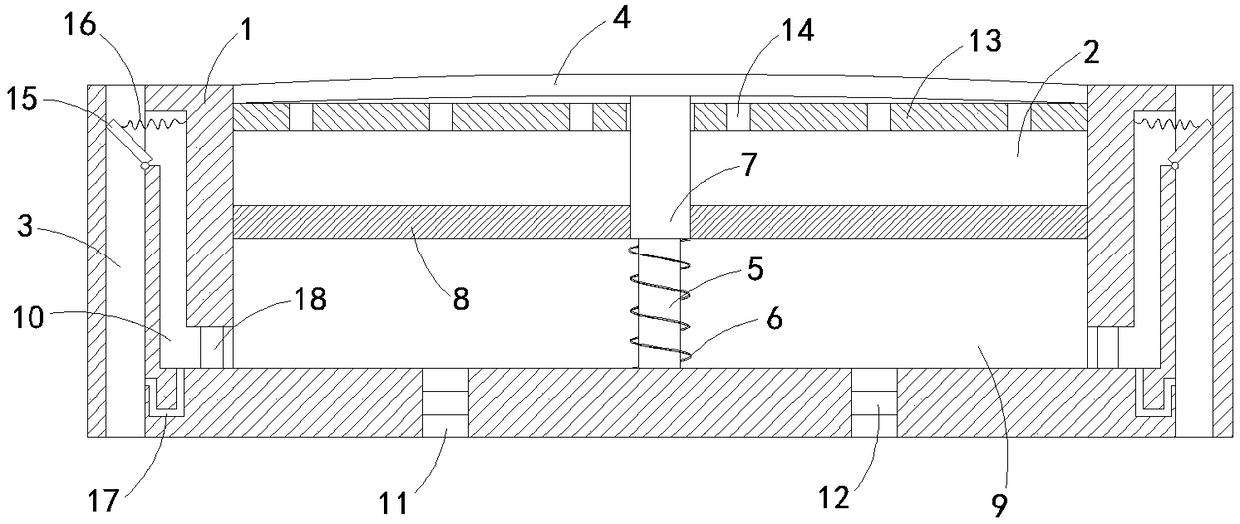

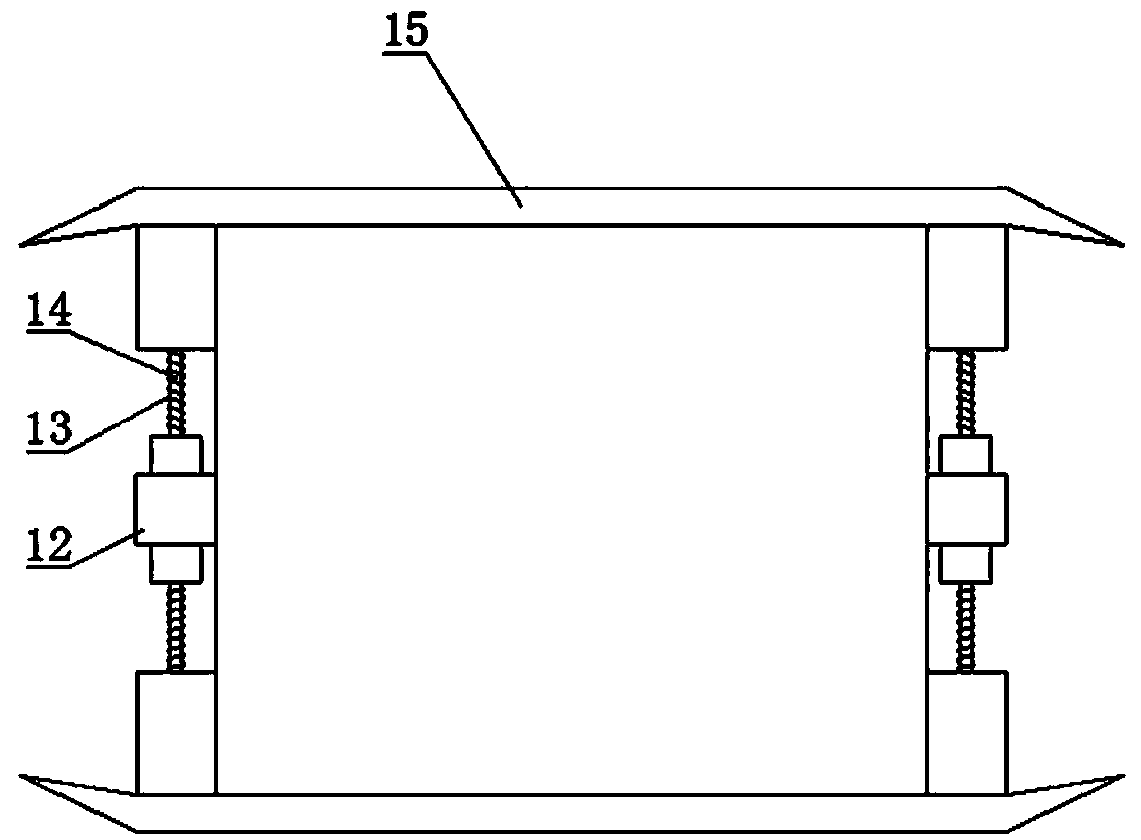

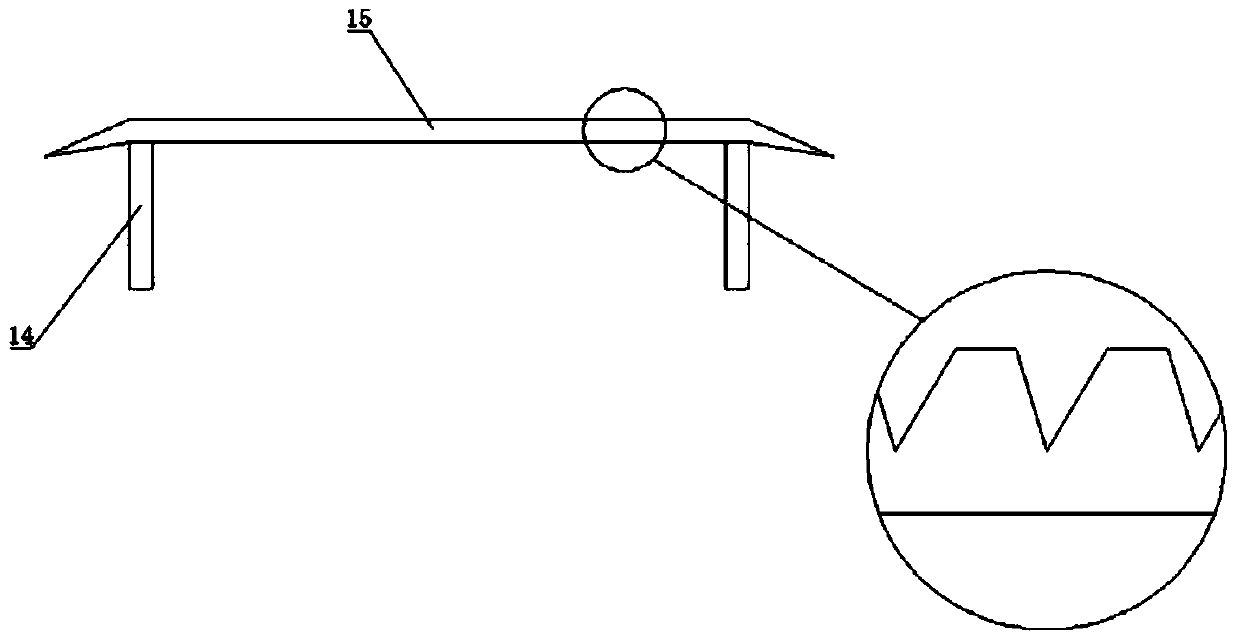

Slicing device special for processing traditional Chinese medicine decoction pieces of rhizoma gastrodiae

InactiveCN107351147AEasy to separate by groupAvoid accumulationSievingScreeningEngineeringChinese herbology

The invention relates to a special slicing device for the processing of Chinese herbal decoction pieces Gastrodia elata, comprising a hopper, a leveling box, a slicing box and a base, wheels are evenly installed on both sides of the bottom of the base, a leveling box is installed on the top of the base, and A hopper is installed on the top of the leveling box, a motor is installed on the top inside the hopper, and a rotating shaft is installed on the bottom of the motor, an auger is installed on the rotating shaft, and a support frame is installed on the bottom of the inside of the leveling box , and both sides of the top of the support frame are equipped with drive rollers. In the present invention, a hopper is installed, an auger is installed in the hopper, and the auger is driven to rotate by a motor, so that Gastrodia elata can enter the leveling box evenly and orderly for flattening, which is convenient for cutting and avoids clogging when feeding. According to the situation, the device is installed with partitions, which makes it easy to separate Gastrodia elata in groups, and is convenient for leveling transportation and slicing.

Owner:蒋涛

Blockage-preventing inspection well lid

The invention belongs to the field of urban construction and particularly relates to a blockage-preventing inspection well lid. The blockage-preventing inspection well lid comprises a well lid body, wherein the upper end of the well lid body is provided with a round groove, vertically communicated water draining channels are uniformly formed around the round groove, an arc-shaped elastic plate isarranged at the upper end of the round groove, a fixing rod is fixedly connected to the bottom side wall of the round groove and is sleeved with a first spring and a sleeve, the upper end and the lower end of the first spring are fixedly connected with the sleeve and the bottom side wall of the round groove, the upper end of the sleeve is fixedly connected with the lower end of the arc-shaped elastic plate, the sleeve is externally in sleeved connection with a compressing plate matched with the rough groove, an air compressing chamber is formed between the compressing plate and the round groove, an air exhausting channel communicated with the water draining channels is formed in the side wall of the round groove, a control mechanism is arranged in the air exhausting channel, multiple air inlet channels are arranged at the bottom of the round groove, and a first one-way valve is arranged in each air inlet channel. The blockage-preventing inspection well lid can automatically clean the water draining channels in the inspection well lid and prevent the blockage situation of the inspection well lid.

Owner:浙江汉宇设计有限公司

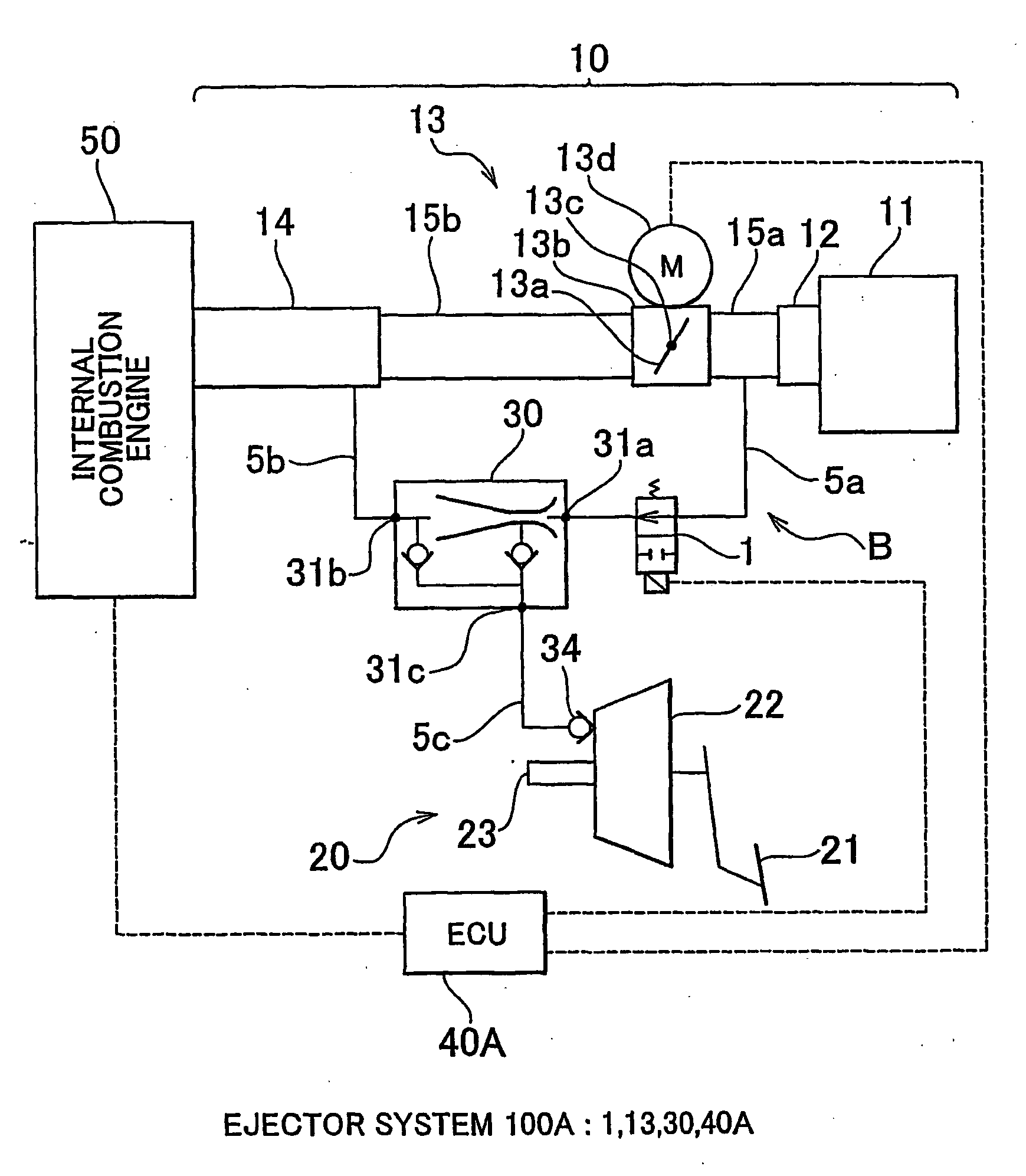

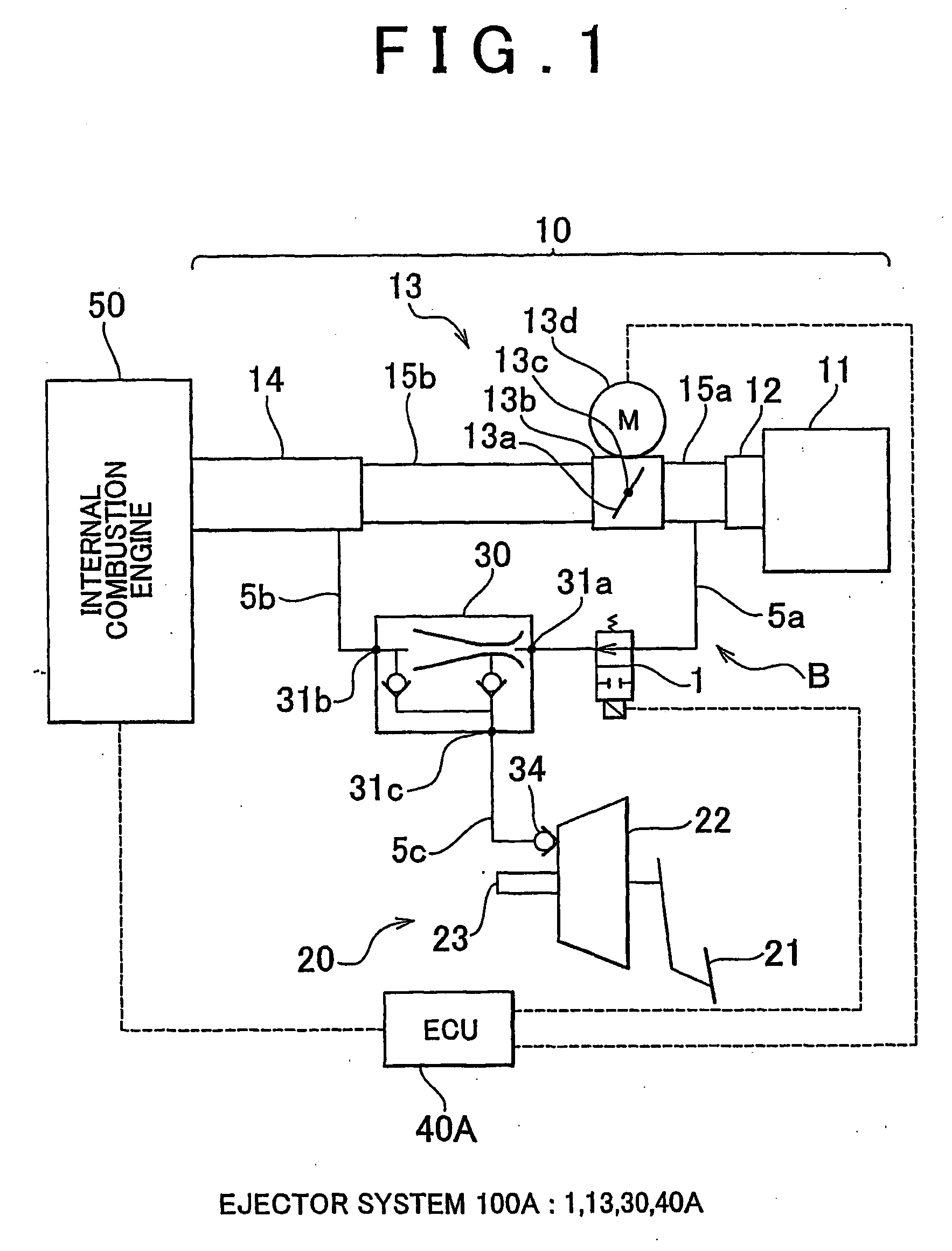

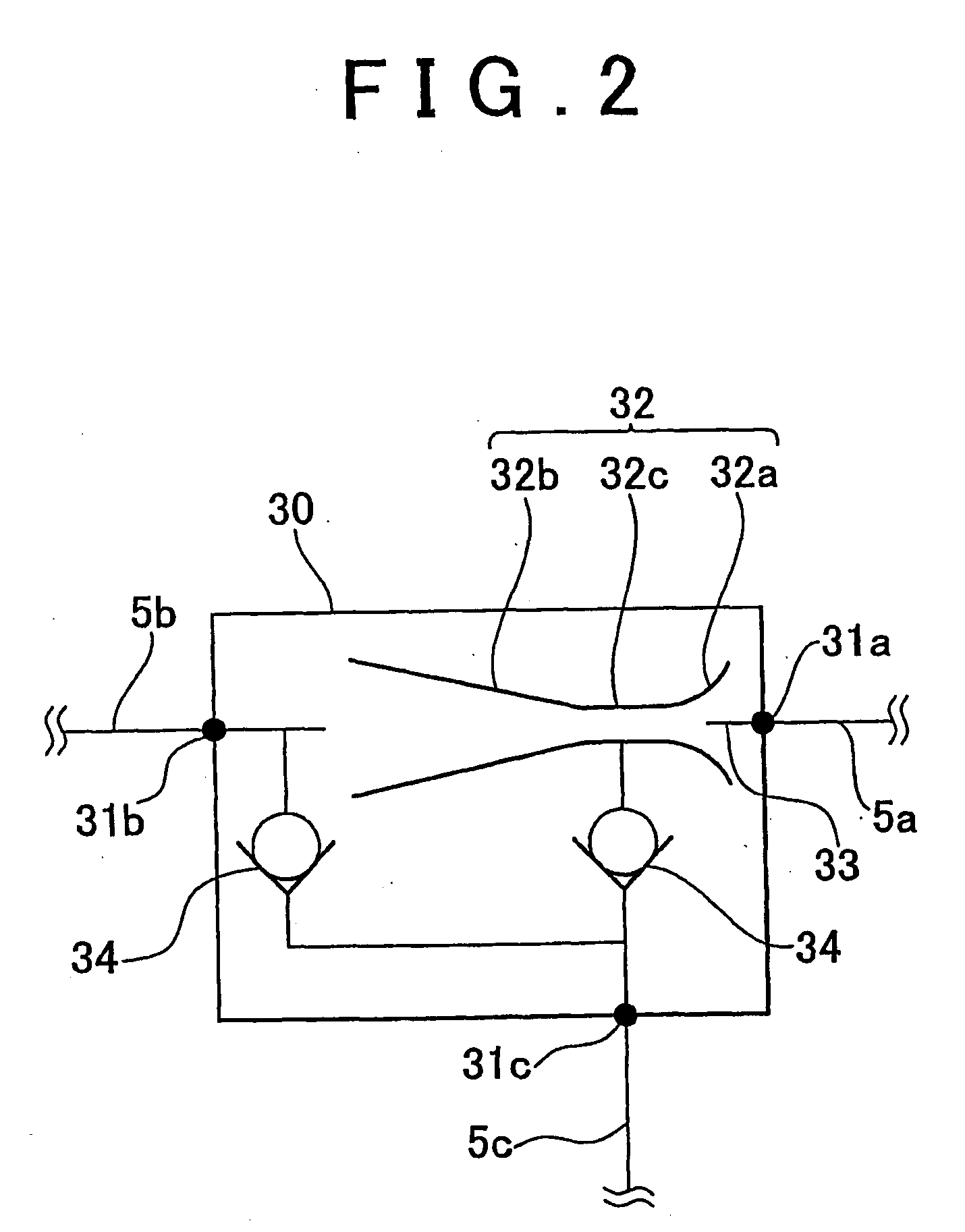

Ejector system for a vehicle and ejector system controller

InactiveUS20090132149A1Avoid blockageMinimal additional costElectrical controlDigital data processing detailsInjectorThrottle

A vehicle ejector system (100A) has an in-flow port (31a) and an out-flow port (31b) connected in the intake passage of an intake system (10) of an internal combustion engine (50), which provides communication between the atmosphere and each cylinder of the internal combustion engine, so as to include a throttle valve (13a) between the in-flow port (31a) and the out-flow port (31b). The ejector system (100A) also includes an ejector (30) that supplies negative pressure generated by the intake air passing between in-flow port (31a) and the out-flow port (31b) to a brake booster (22), a VSV (1) that allows the ejector (30) to operate and stop, and an ECU (40A) that controls the VSV (1), wherein in the combustion cycle of the internal combustion engine (50) the ECU (40A) controls the VSV (1) to operate the ejector (30).

Owner:TOYOTA JIDOSHA KK

Guiding structure of pipeline washing device

ActiveCN103736699AAvoid breakingTo achieve the purpose of cleaning the pipelineHollow article cleaningFiberElastic fiber

A guiding structure of a pipeline washing device is characterized in that the guiding structure is mounted on one side of a pipeline washing device body and comprises support legs and a regular-pentagon-shaped support, five support sleeve pipes are evenly distributed on the same plane of the support in the circumferential direction, a plurality of grooves are formed at the ends, in contact with pipe walls, of the supporting legs, supporting leg spring columns used for being inserted to the corresponding support sleeve pipes are arranged on the opposite sides of the supporting legs, and an elastic structure is arranged between each support sleeve pipe and the corresponding supporting leg spring column. The supporting legs with the grooves are mounted on the side wall of the pipeline washing device body, spring elastic fibers in the support extend into the supporting legs, the supporting legs with elastic supporting is fixed on the inner wall of a pipeline, the groove structure avoids the problems that an original pulley structure is not stable in operation, not stable in supporting and prone to block, the effect of secondary wall scraping washing is achieved, and the washing efficiency is improved.

Owner:科恩工业(大连)有限公司

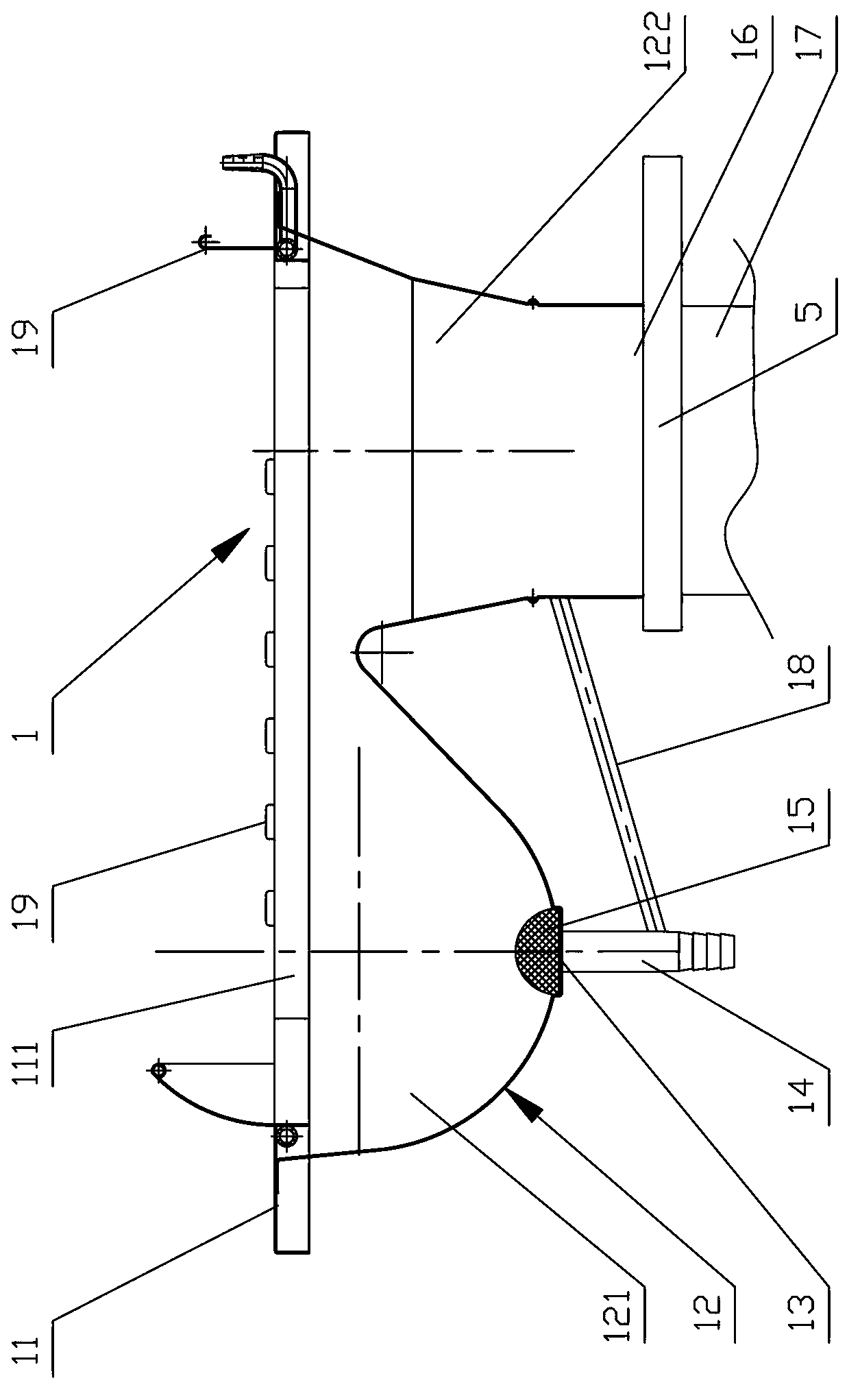

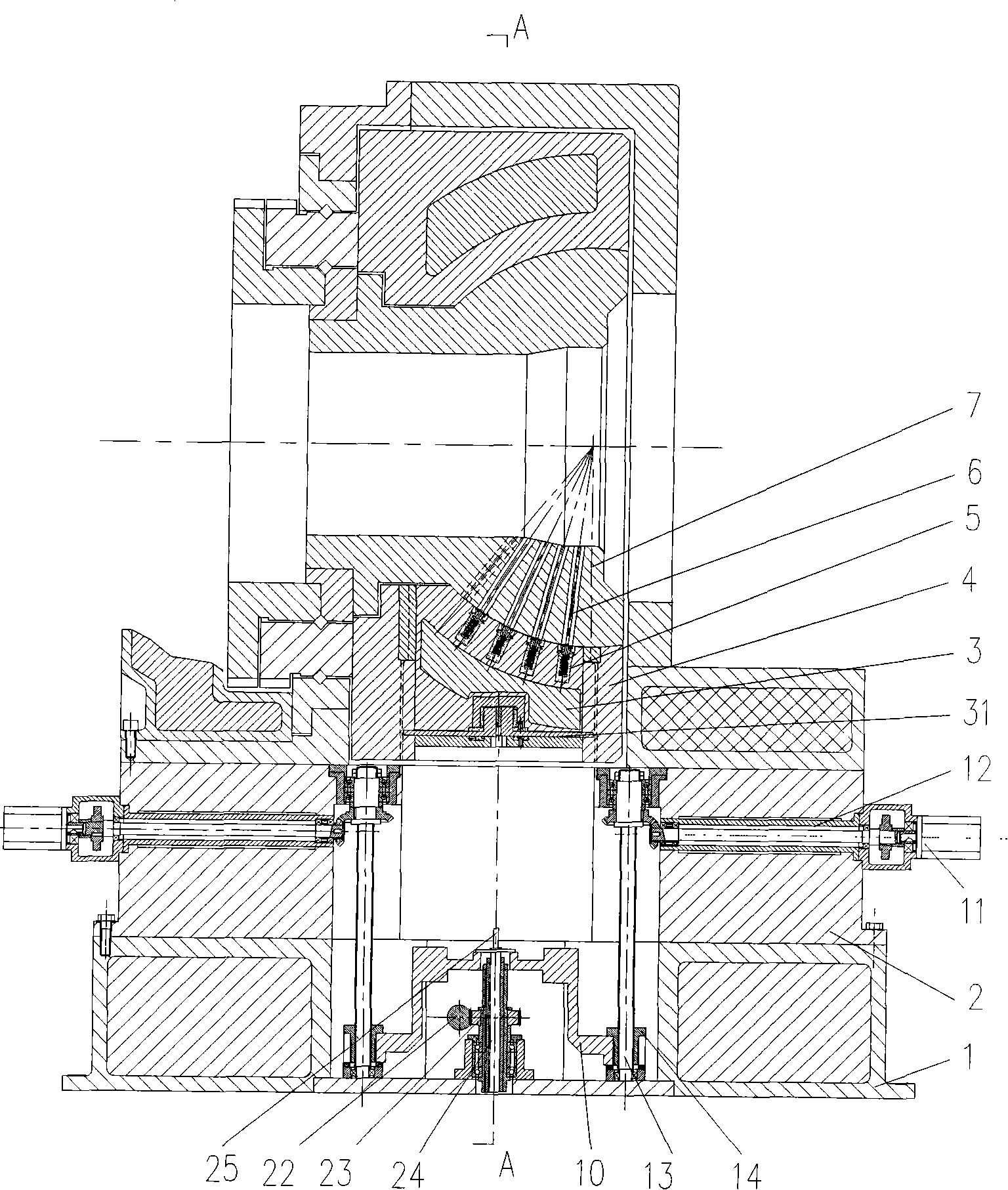

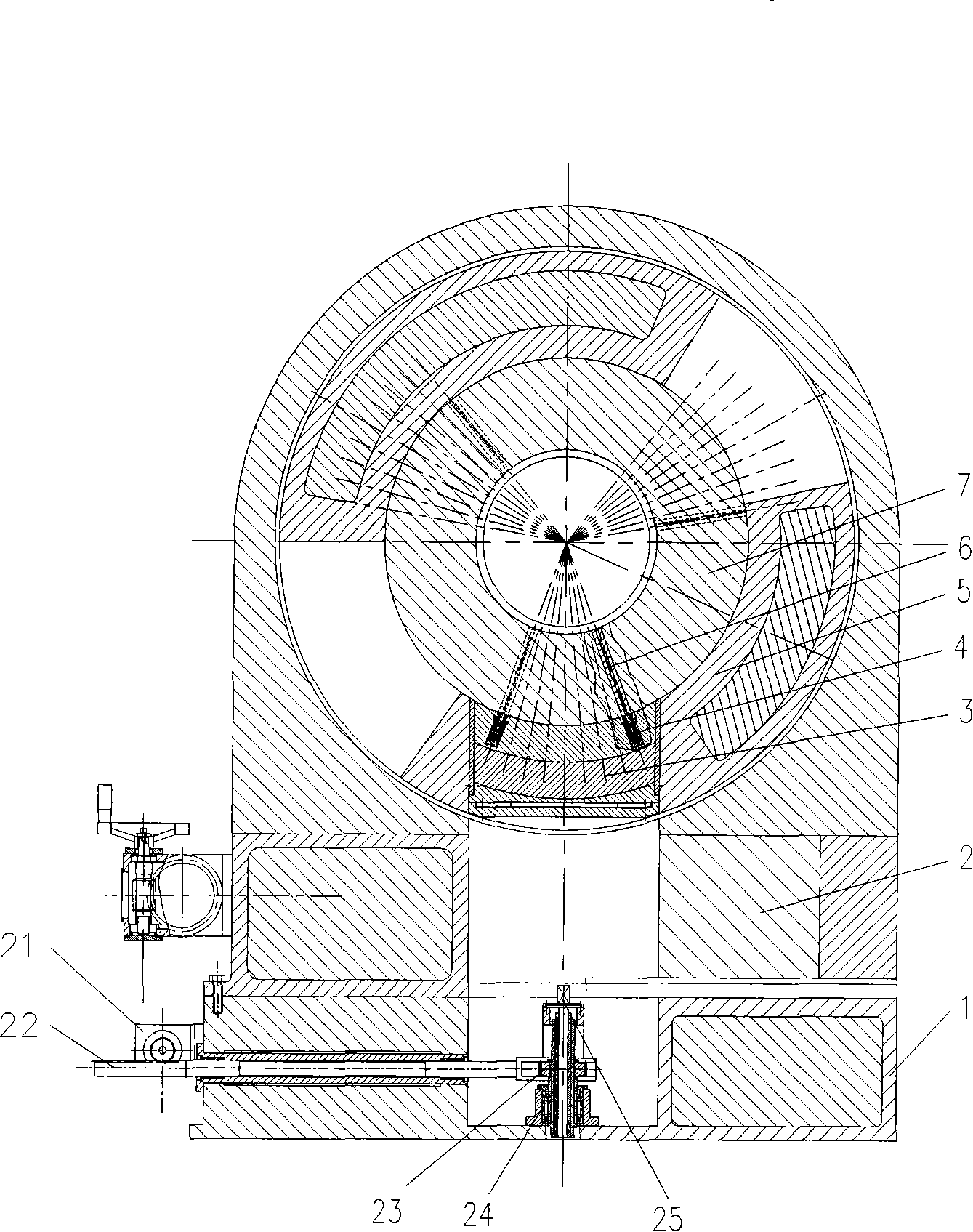

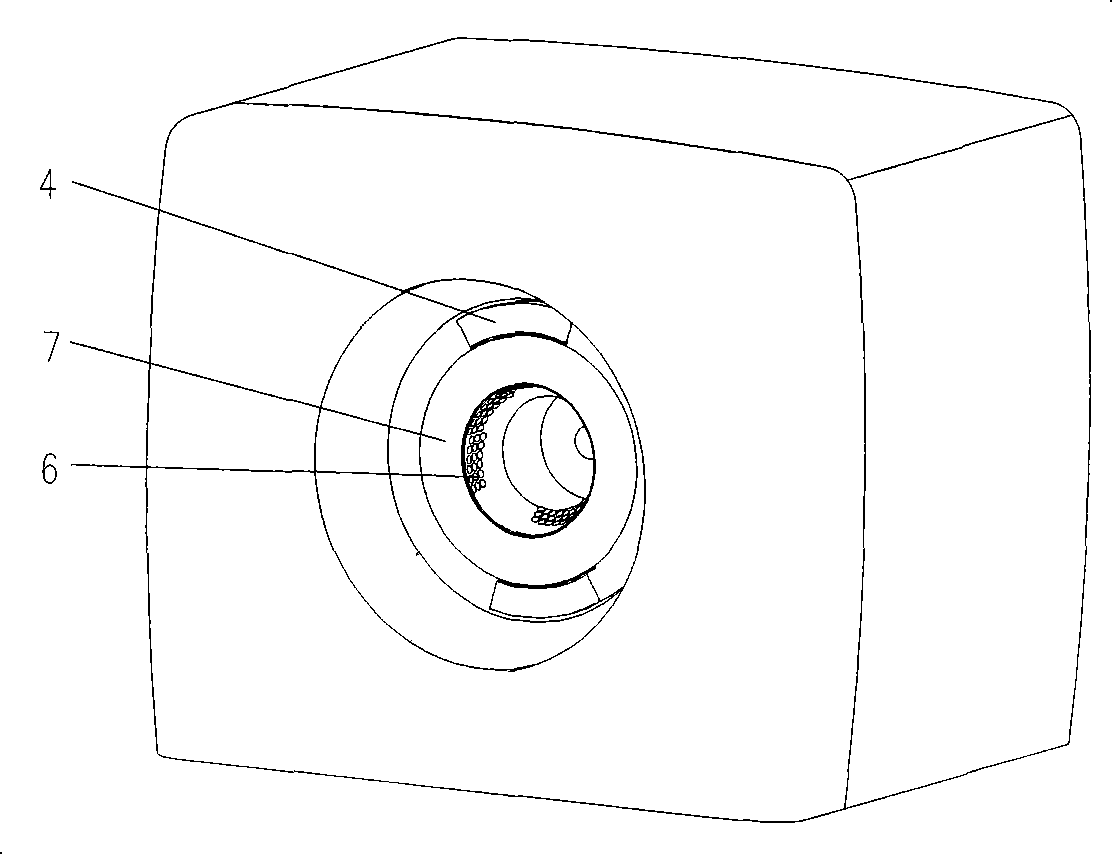

Radiation therapy driving device

ActiveCN101239224AReduce protection requirementsSimple structureRadiation applicationsPretreated surfacesEngineeringRadioactive source

The present invention relates to a radiotherapy driving device which includes: shield, source body, radioactive source, source deck, driving device of source deck. The radioactive source is in the source deck inner, the shield and source body have space for containing the source box, the driving device of the source box can be separated installed on down part of the source box, and the source box is drived to up-and-down movement between the shield and source box. The shield and source box are in the down part of the source body, which can save the shield material, reduce the whole device weight and occupied space; the driving device of the source box can be separated drive the source box up-and-down movement when treating, the source box is fixed on radiation device of the radiotherapy system by lock board, and rotary irradiate with the radiation device. The radiotherapy driving device reduces protective request of the radiation device, prevents motor block of the source box efficiently, simplifies the radiotherapy system structure, reduces processing difficuites and saves cost.

Owner:SHEN ZHEN HYPER TECH SHENZHEN

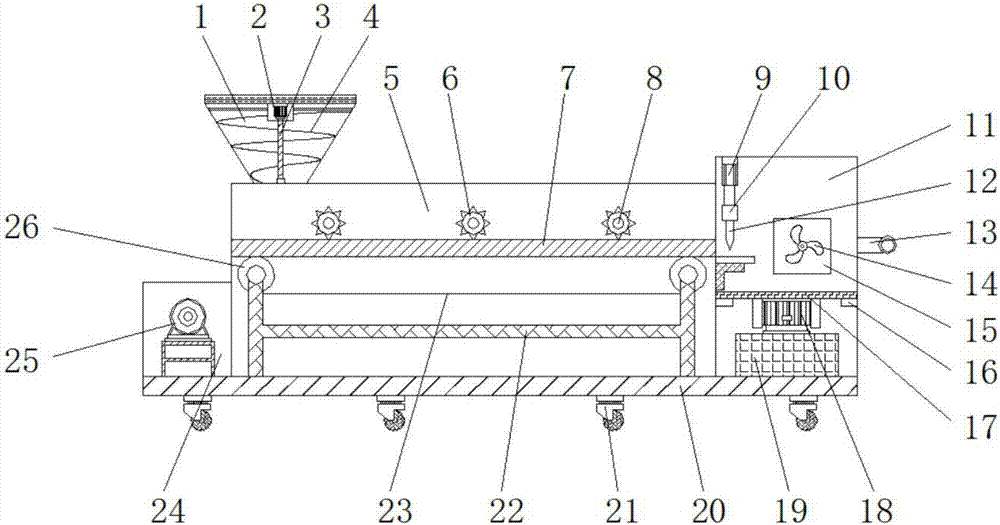

Feed processing equipment

The invention discloses feed processing equipment. The feed processing equipment comprises a grinding tank and a driving motor, wherein a rotating shaft is rotatably connected to the center of the topof the grinding tank; the top end of the rotating shaft is fixedly connected with an output shaft of the driving motor through a coupling; a square connecting rod is fixed to the bottom end of the rotating shaft and located in the center of the interior of the rotating shaft; deflector rods are fixed to the surface of the square connecting rod; a grinding device is arranged at the bottom end of the square connecting rod, the grinding device is in sliding connection with the square connecting rod; and a sieve plate is fixed to the position, close to the bottom of the grinding device, in the grinding tank. The invention relates to the technical field of feed processing. According to the feed processing equipment, the effects of uniform grinding and adhesion prevention are achieved; elasticpressing can be carried out, and the grinding space is automatically and moderately increased, so that large and small granular materials uniformly leak, and grinding is rapid and uniform; and meanwhile, sticky materials on the inner wall can be automatically scraped off, so that the working efficiency and the use performance are improved.

Owner:莱阳和美华饲料有限公司

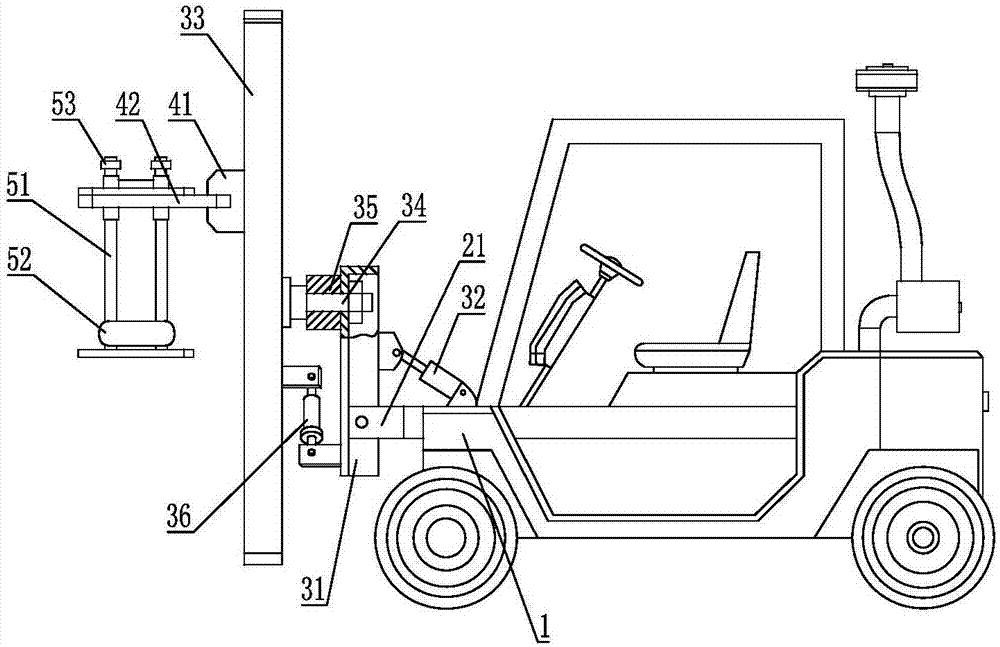

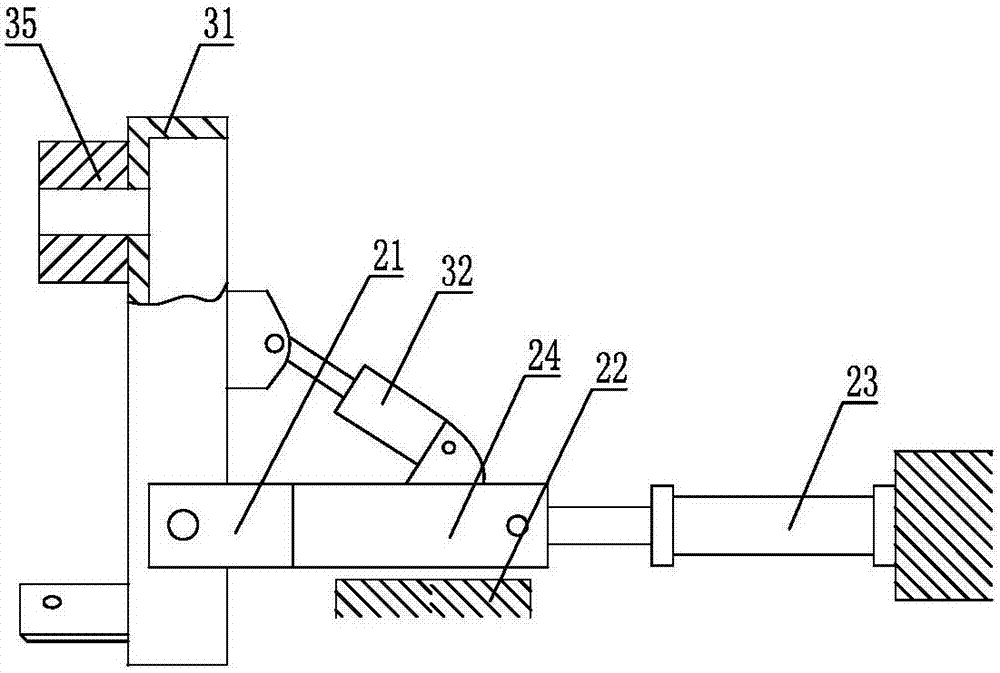

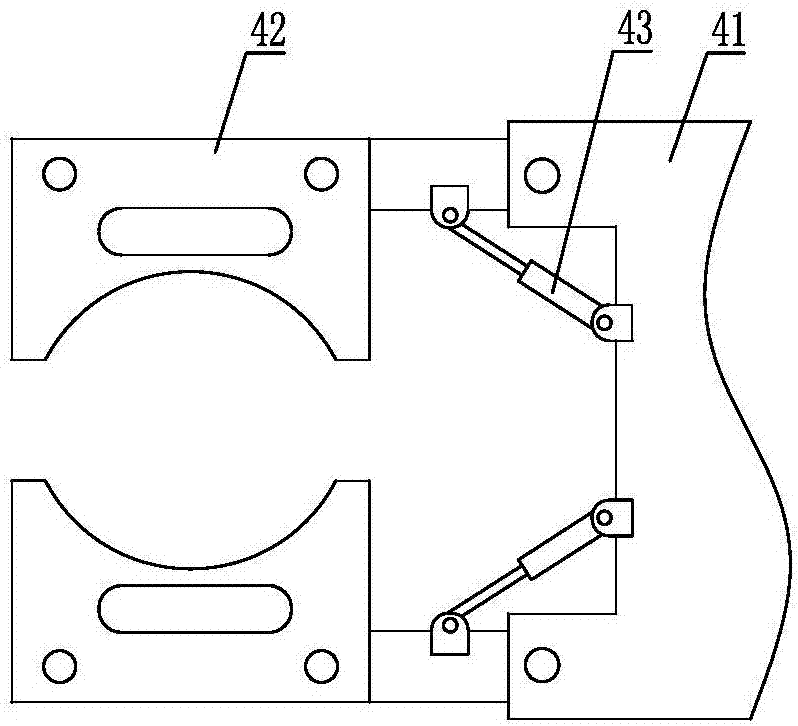

Hydraulic high-speed power pole base tamper

ActiveCN107035216AAvoid blockageSave moneyTowersSoil preservationControl theoryMechanical engineering

The invention discloses a hydraulic high-speed power pole base tamper. The hydraulic high-speed power pole base tamper is mounted on a loading haulage motor body, and comprises a retractable frame mounted on the loading haulage motor body, a multi-azimuth adjusting frame is mounted on the retractable frame, a power pole clamping holding device is mounted on the multi-azimuth adjusting frame, and a tamping work head arranged surround a power pole is mounted on the power pole clamping holding device; and when working, the power pole clamping holding device tightly holds the power pole, and after the angle is adjusted by utilizing the retractable frame and the multi-azimuth adjusting frame, the tamping work head is started to work and tamps a power pole base. The hydraulic high-speed power pole base tamper can automatically correct and hold the power pole to prevent retardation in the tamping process; and the hydraulic high-speed power pole base tamper can replace onerous and dangerous labor work, saves fund and enhances efficiency.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO WUDI COUNTY POWER SUPPLY CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com