Colloid mixing and stirring device for producing lead-acid battery

A lead-acid battery, mixing and stirring technology, which is used in mixers, shaking/oscillating/vibrating mixers, transportation and packaging, etc., can solve the problems of insufficient mixing, clogging of the discharge port, and difficulty in discharging, so as to improve the mixing effect, clogging prevention, flow rate improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

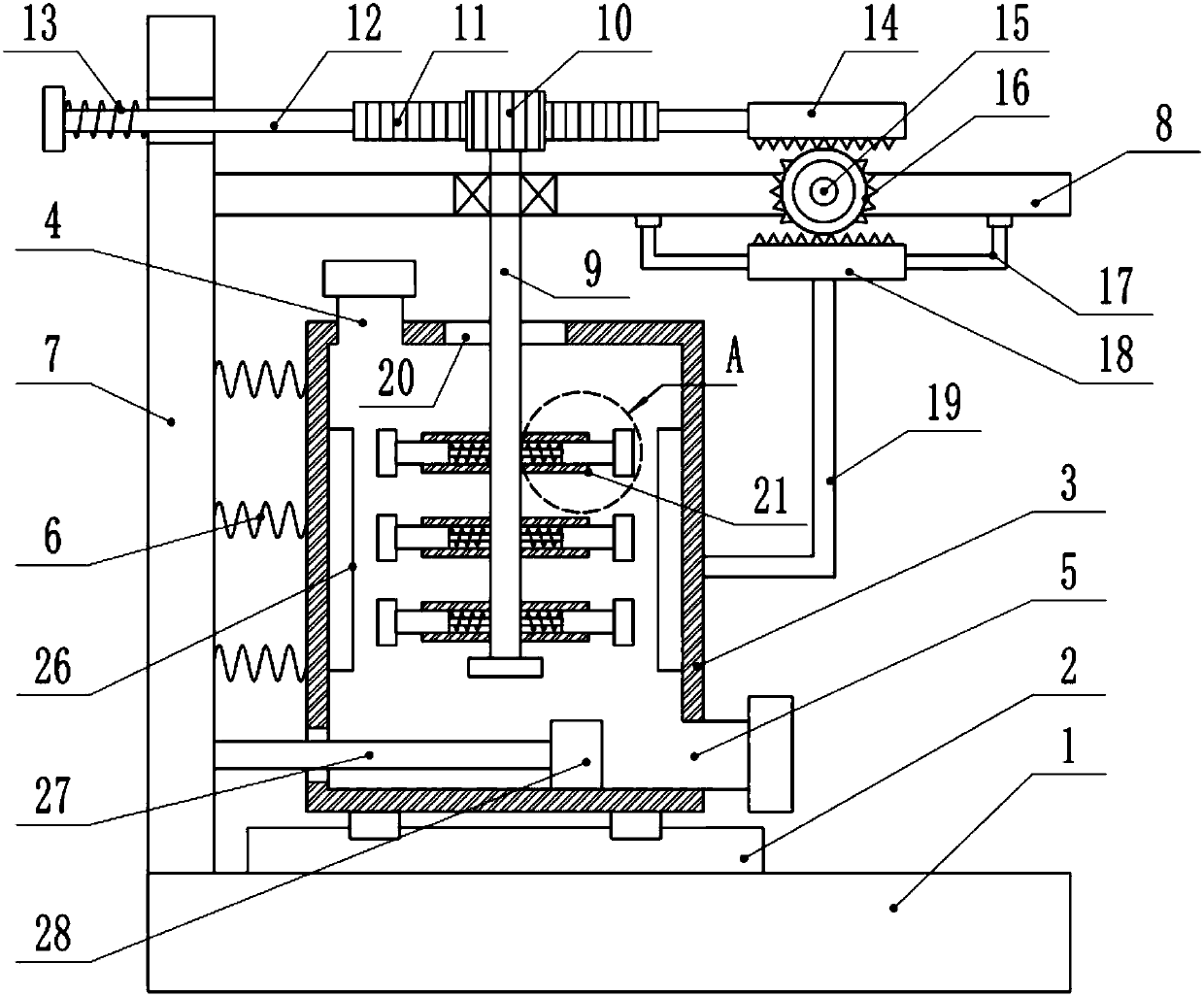

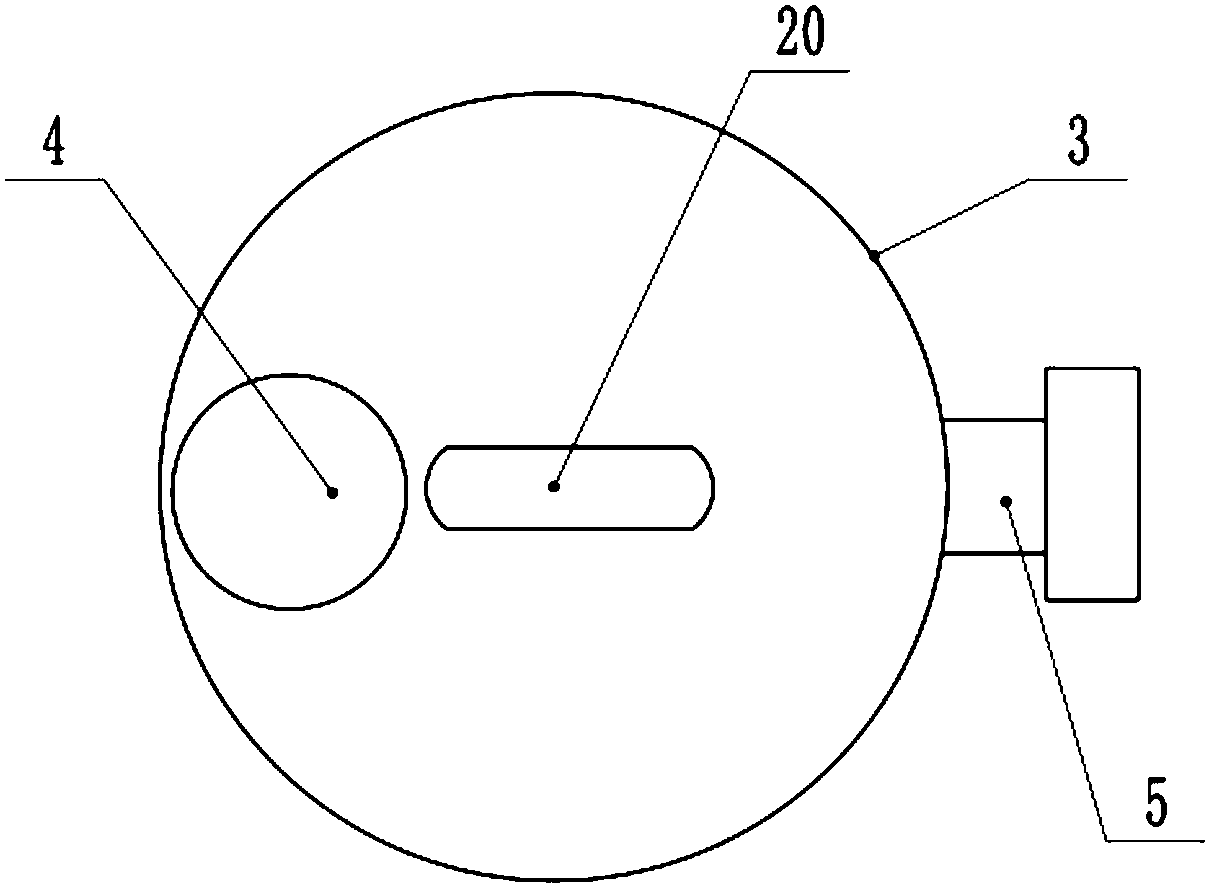

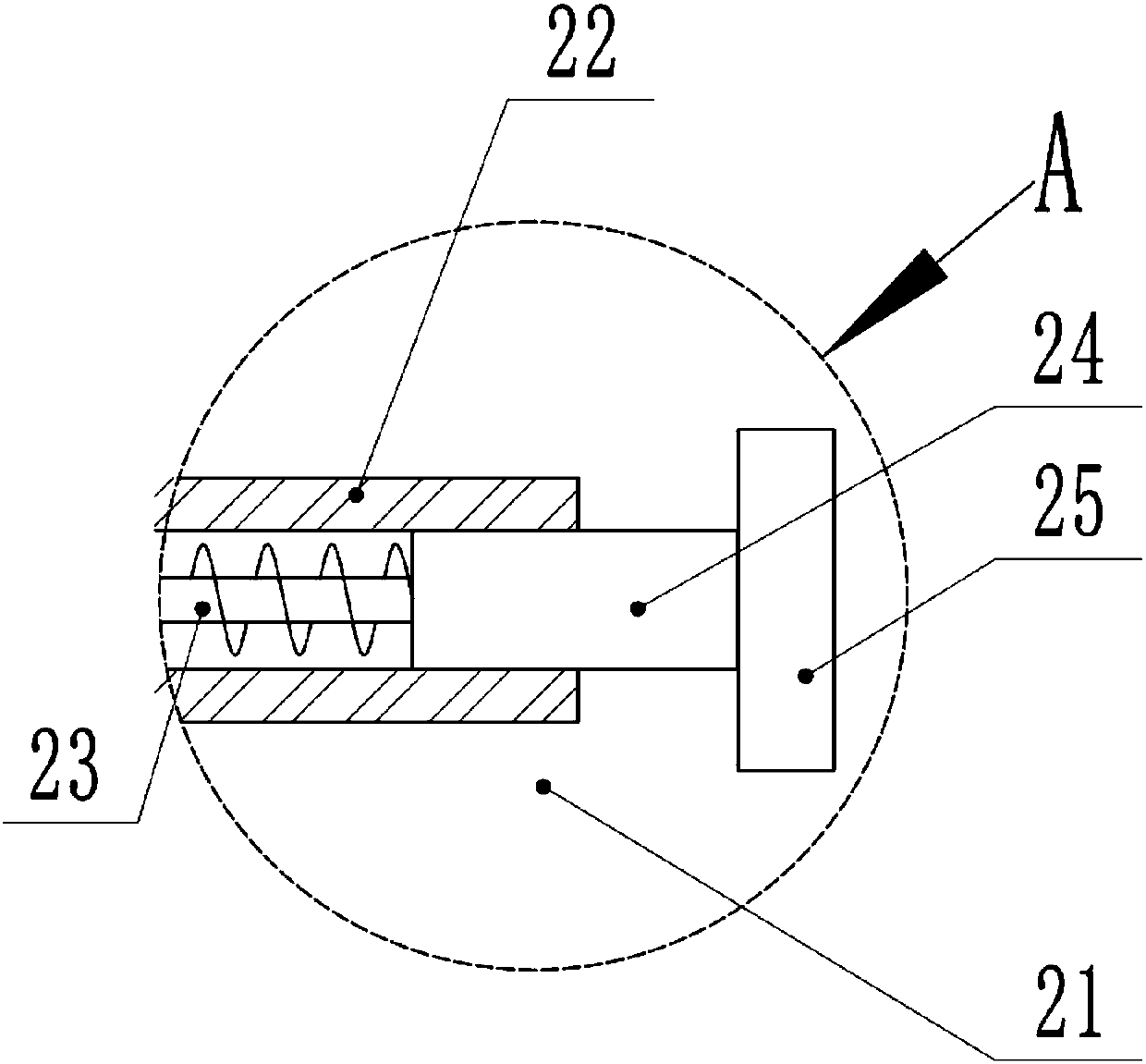

[0020] see Figure 1-3 , a colloid mixing and stirring device for lead-acid battery production, comprising a colloid mixing box 3, a drive motor 15, a special-shaped gear 16, a stirring device 21, a magnet A25 and a push rod 27, and the upper surface of the base 1 is provided with a slide rail 2, The base 1 and the slide rail 2 are fixedly connected by screws, and a colloid mixing box 3 is slidingly installed on the slide rail 2. The feed port 4 and the discharge port 5, the feed port 4 and the discharge port 5 are all screwed with a sealing cover, and the left side of the upper surface of the base 1 is also provided with a riser 7, between the base 1 and the riser 7 Fixedly connected by screws, the first spring 6 is connected between the colloid mixing box 3 and the vertical plate 7, the vertical plate 7 is also provided with a horizontal plate 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com