Three-dimensional waterbody circular oxygenation purification plant and method

A purification device and water body technology, which is applied in chemical instruments and methods, water aeration, water/sludge/sewage treatment, etc., can solve the problems of equipment work efficiency drop, work efficiency drop, and device structure complexity, etc., and achieve water body dissolution Increased oxygen rate, improved work efficiency, and expanded contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

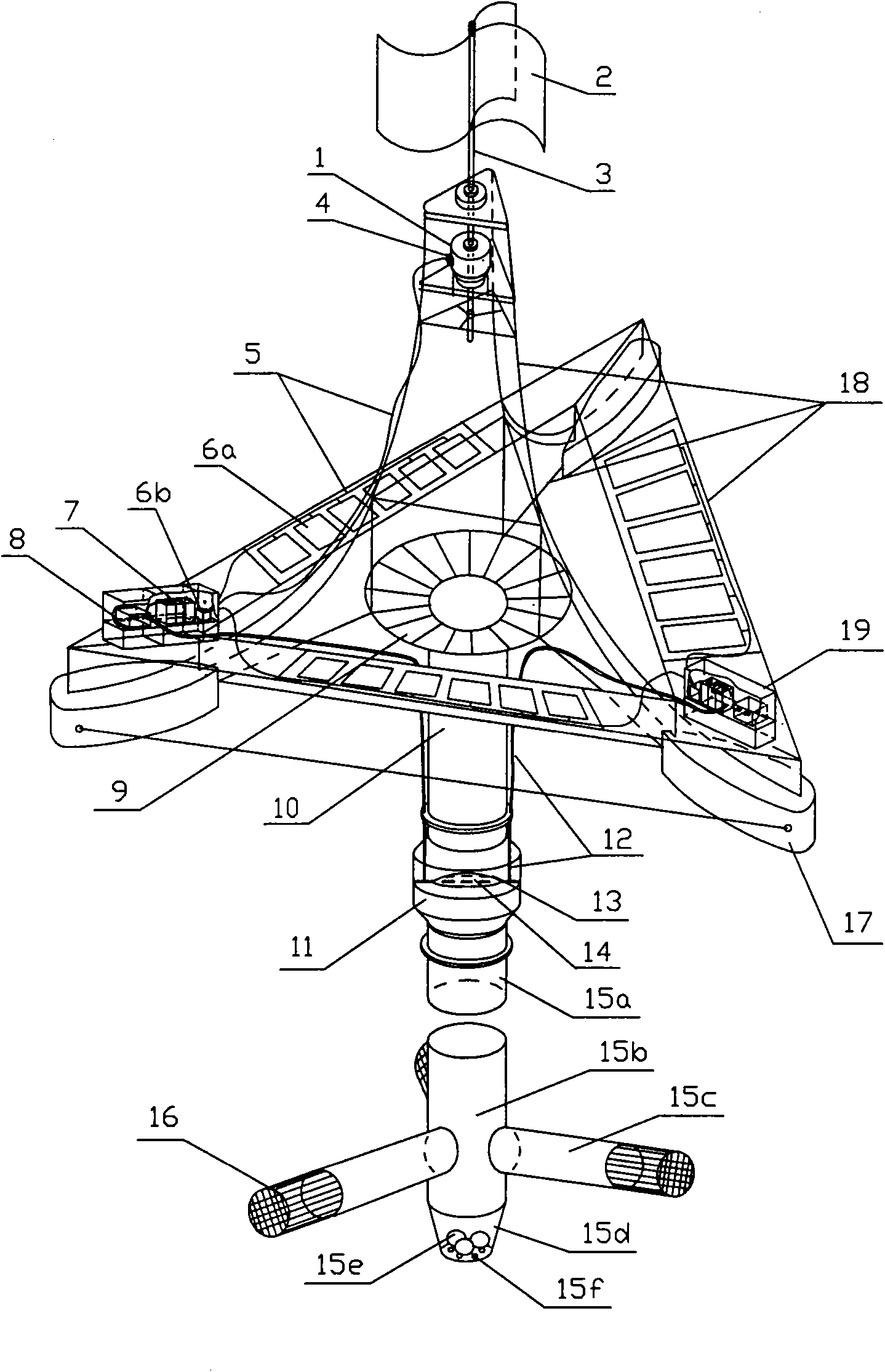

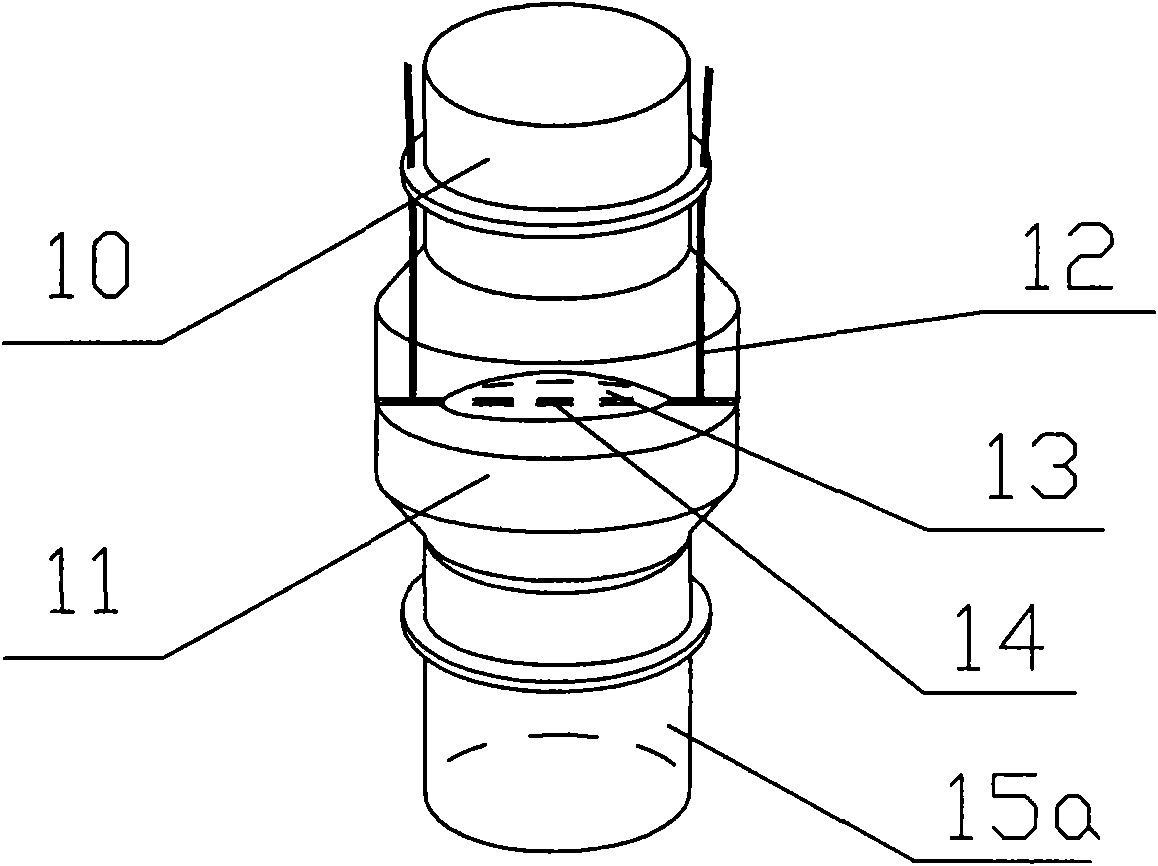

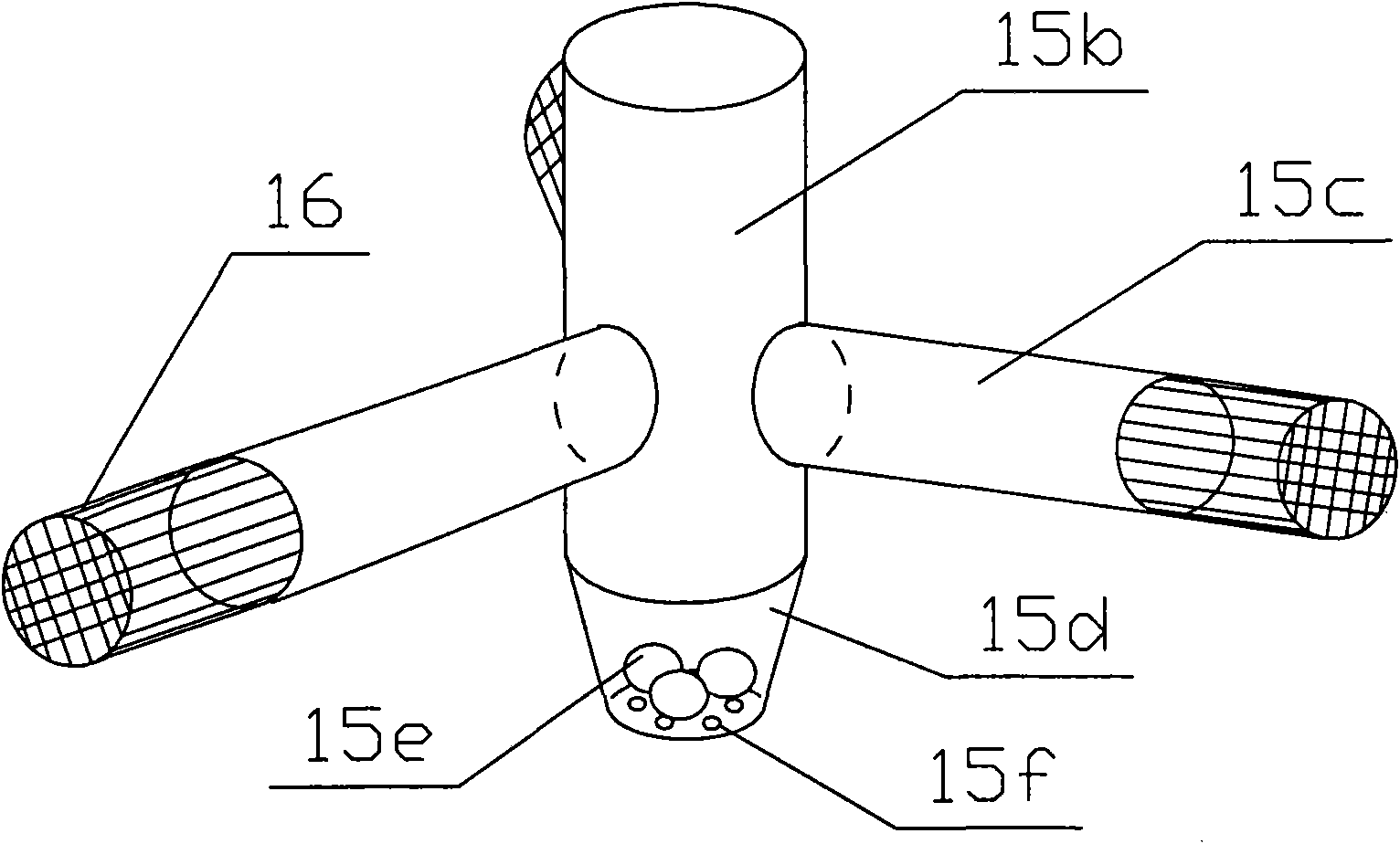

[0032] figure 1 Shown is an embodiment of the wind-solar complementary three-dimensional water circulation oxygenation purification device of the present invention, which includes:

[0033]Wind power generation device, which is a vertical axial windmill device, wherein the upper end of the windmill shaft 3 is connected to the windmill blade 2, and the lower end of the windmill shaft 3 is connected to the wind turbine 1; the junction box 4 is fixed outside the wind turbine 1, and the circuit The cable 5 is connected to the junction box 4; the electricity generated by the wind turbine 1 is input into the battery pack 7 through the circuit cable 5 and the controller 6b for storage and utilization;

[0034] The solar power generation device is composed of a solar panel 6a, a controller 6b and a storage battery pack 7, and multiple sets of solar panels 6a are horizontally fixed on the floating support 18, and the electricity sent by the solar panel 6a is input through the circuit c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com