Blockage-preventing inspection well lid

A manhole cover and anti-clogging technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of slippage, large damage to wheels, uncertainty, and the possibility that the wheels will be directly rolled on the end surface of the rotating wheel body And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

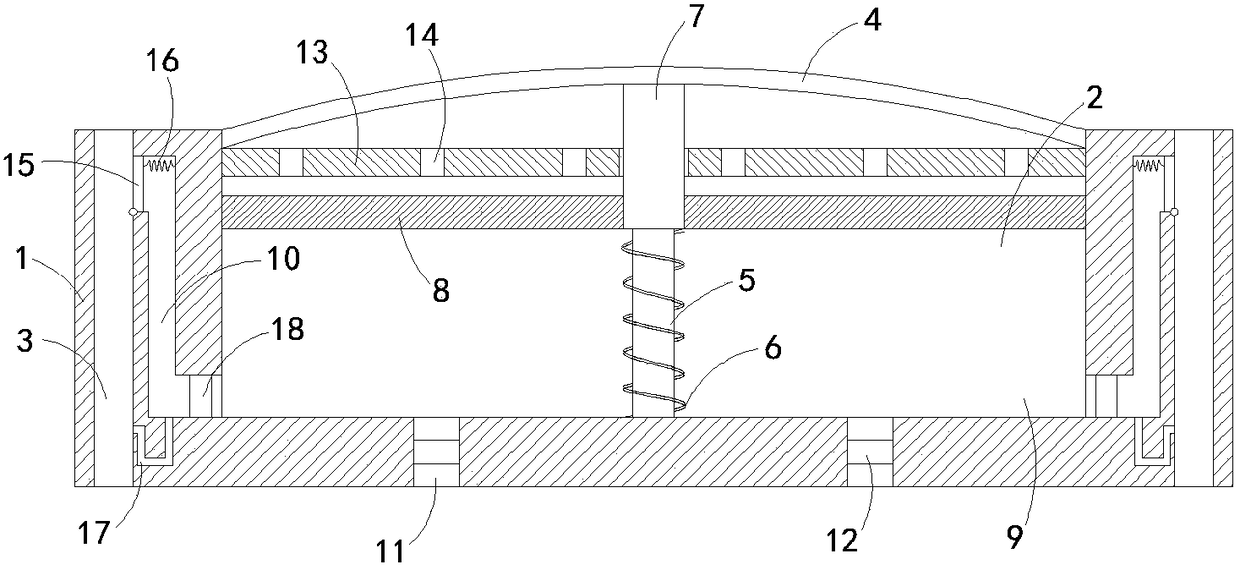

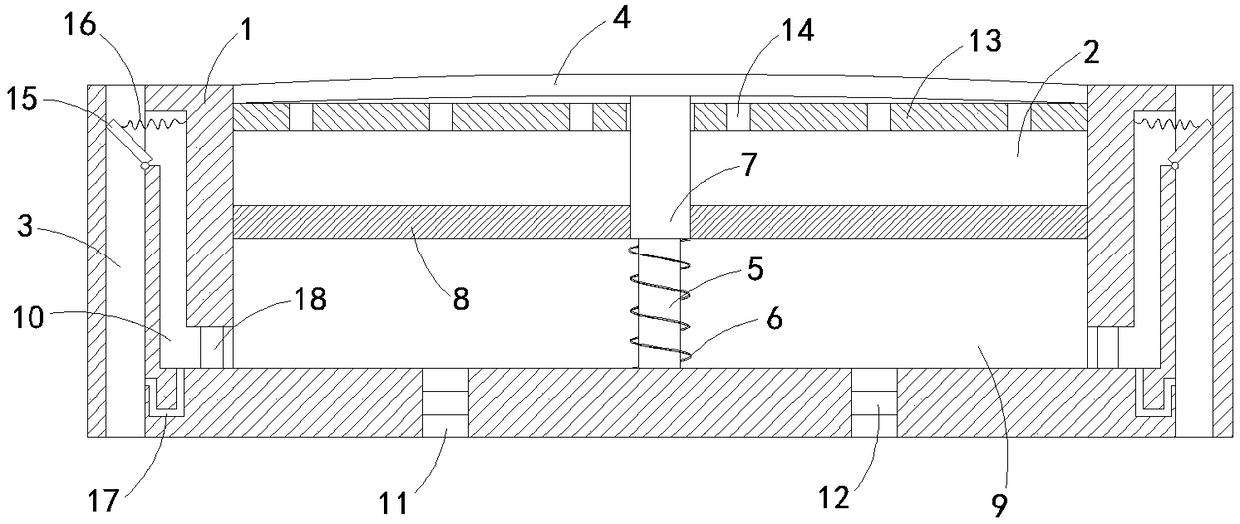

[0024] Such as Figure 1-2 As shown, an anti-clogging inspection well cover includes a well cover 1. It should be noted that the well cover 1 is a circular well cover, and the upper end of the well cover 1 is provided with a circular groove 2, and the circumference of the circular groove 2 is evenly provided with up and down communication The drainage channel 3, a plurality of drainage channels 3 are evenly arranged along the circumference of the circular groove 2, and the upper end of the circular groove 2 is provided with an arc-shaped elastic plate 4. It is worth mentioning that, under the action of no external force, the arc Shaped elastic plate 4 is in a raised state, and the edge of arc-shaped elastic plate 4 is flush with the upper end of well cover 1, which improves the smoothness of automobile driving. The bottom side wall of circular groove 2 is fixedly connected with fixed rod 5, fixed The rod 5 is sleeved with a first spring 6 and a sleeve 7, the upper and lower en...

Embodiment 2

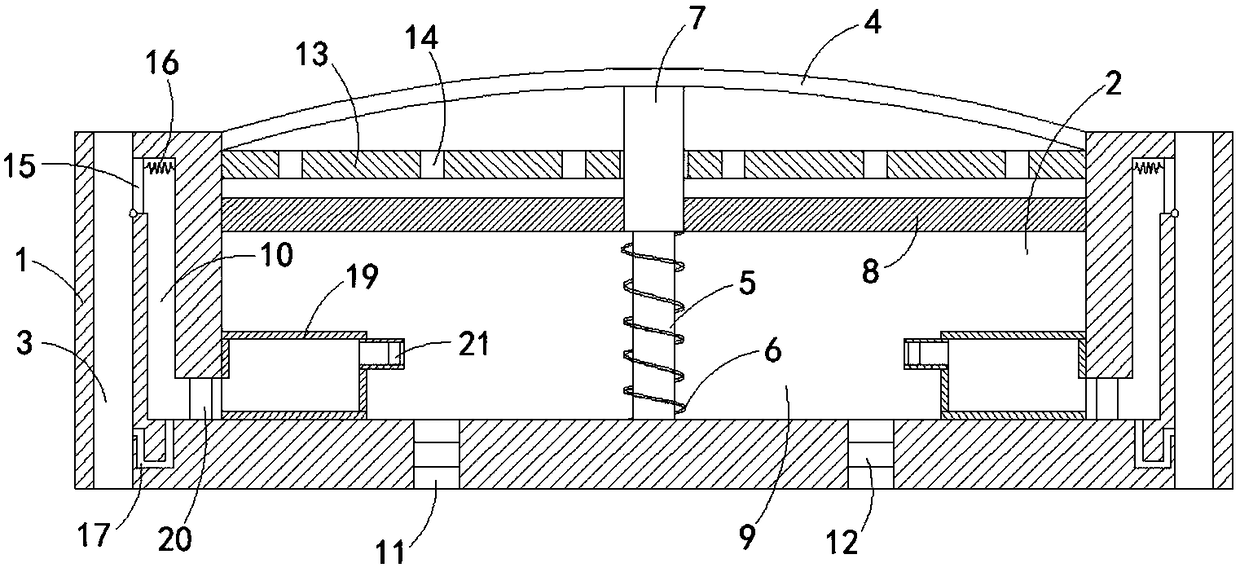

[0033] In this embodiment, the control mechanism includes a pressurized chamber 19 connected to the air inlet of the exhaust passage 10, a pressure valve 20 is installed in the exhaust passage 10, and a third check valve is installed in the air inlet of the pressurized chamber 19. twenty one.

[0034] In this embodiment, when the pressure plate 8 presses the compression chamber 9, the compression chamber 9 will discharge the gas into the pressurization chamber 19 through the third one-way valve 21, the gas will gradually accumulate in the pressurization chamber 19, and the air pressure will gradually increase. When the air pressure in the pressurization chamber 19 exceeds the critical pressure value of the pressure valve 20, the pressure valve 20 is opened, the high-pressure gas in the pressurization chamber 19 is ejected at a high speed, and the high-speed air flow is discharged from the air inlet of the drainage channel 3, and the Dust or sundries on the water inlet of drainag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com