Solid-liquid separation toilet bowl and solid-liquid separation treatment system

A solid-liquid separation and treatment system technology, applied in separation methods, dispersed particle separation, gravity filters, etc., can solve problems such as inability to recycle feces and urine, separate recovery, and difficulty in fecal and urine mixture entering the soil, etc. Achieving the effect of fully resource processing and improving the separation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below. All other implementations obtained below fall within the protection scope of the present invention.

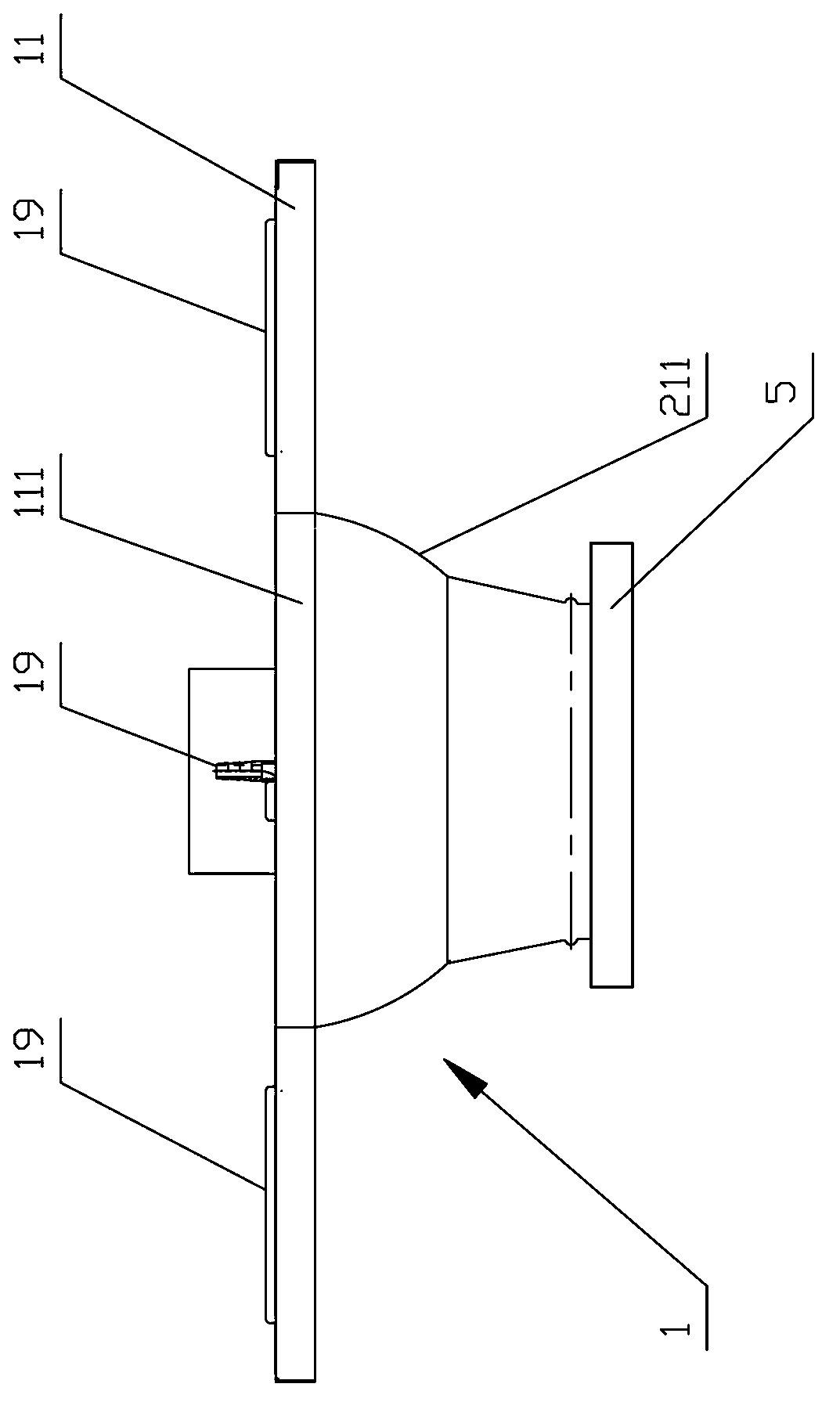

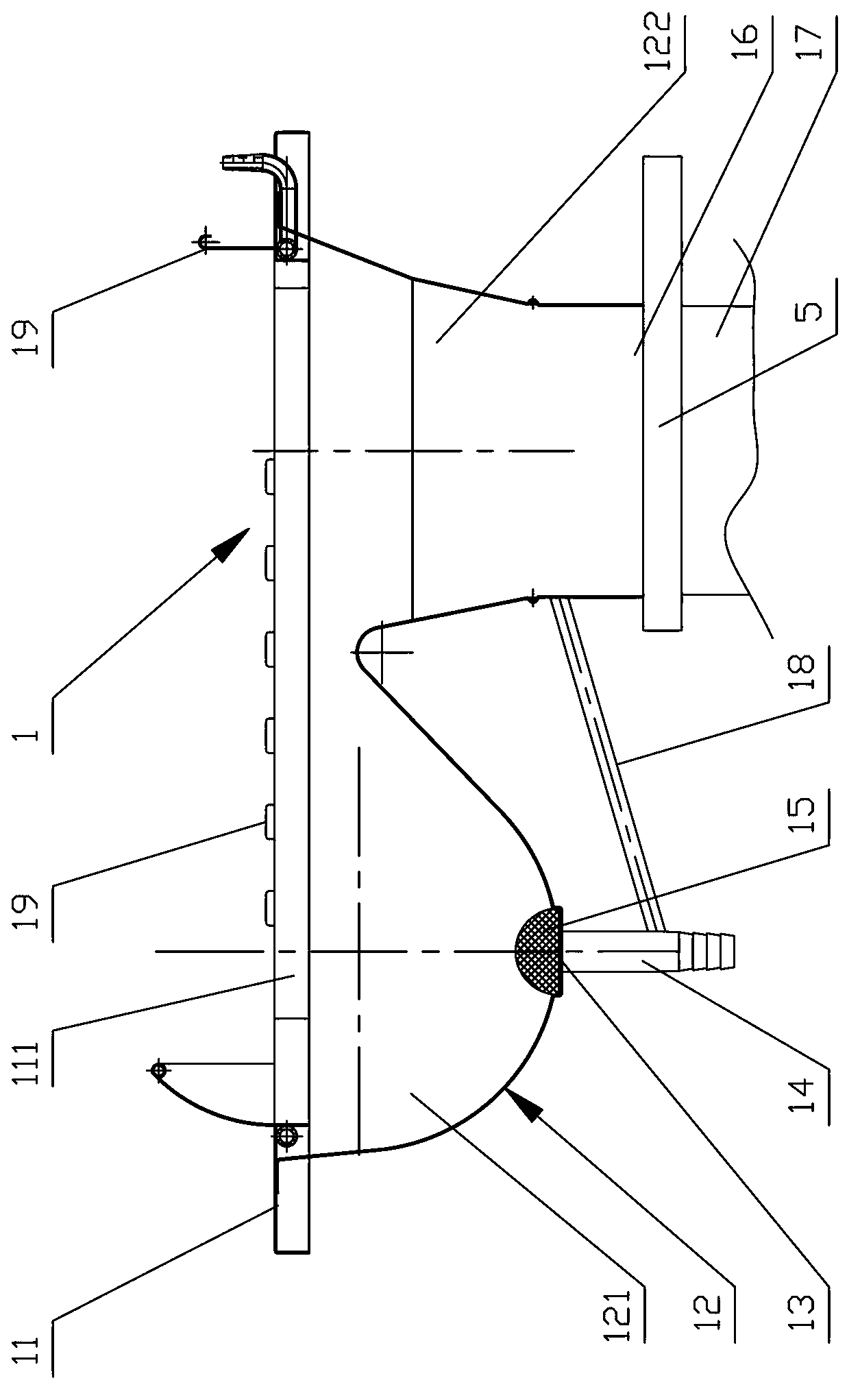

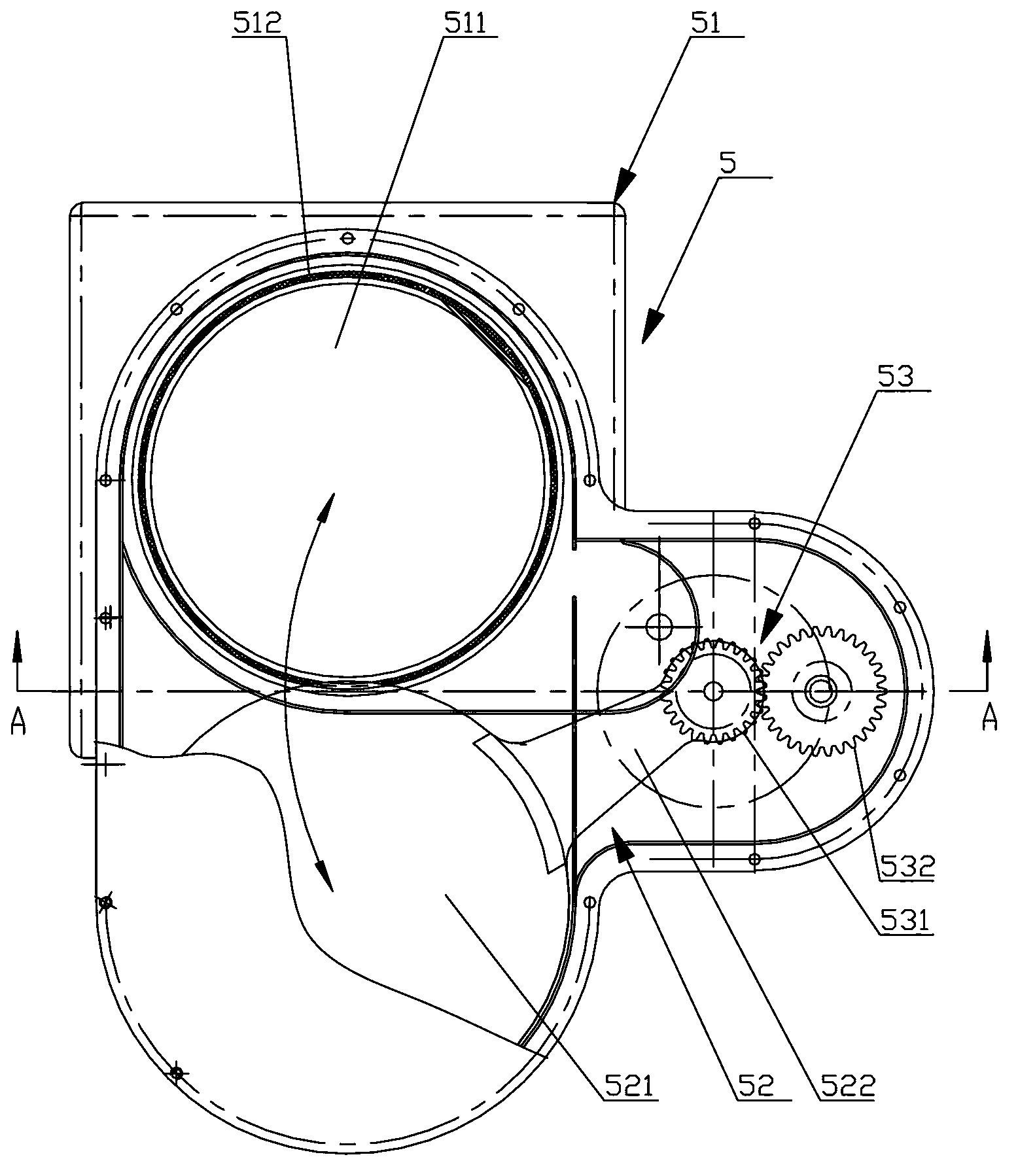

[0100] like figure 1 and figure 2As shown, the solid-liquid separation toilet provided by the embodiment of the present invention includes a panel 11 and a toilet body 12. The middle part of the panel 11 is provided with a toilet position hole 111. The toilet body 12 forms a urine collection chamber 121 and a feces collection chamber 122. The urine collection The cavity 121 and the feces collection cavity 122 are arranged forward and backward along the longitudinal direction of the panel 11 ;

[0101] Wherein, the urine collection cavity 121 and the feces collection cavity 122 formed by the toilet body 12 are arranged forward and backward along the longitudinal direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com