Organic EL face-board and making method thereof

An organic and panel technology, applied in semiconductor/solid-state device manufacturing, vacuum evaporation plating, coating, etc., can solve problems such as resistance reduction, performance deterioration, and current increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

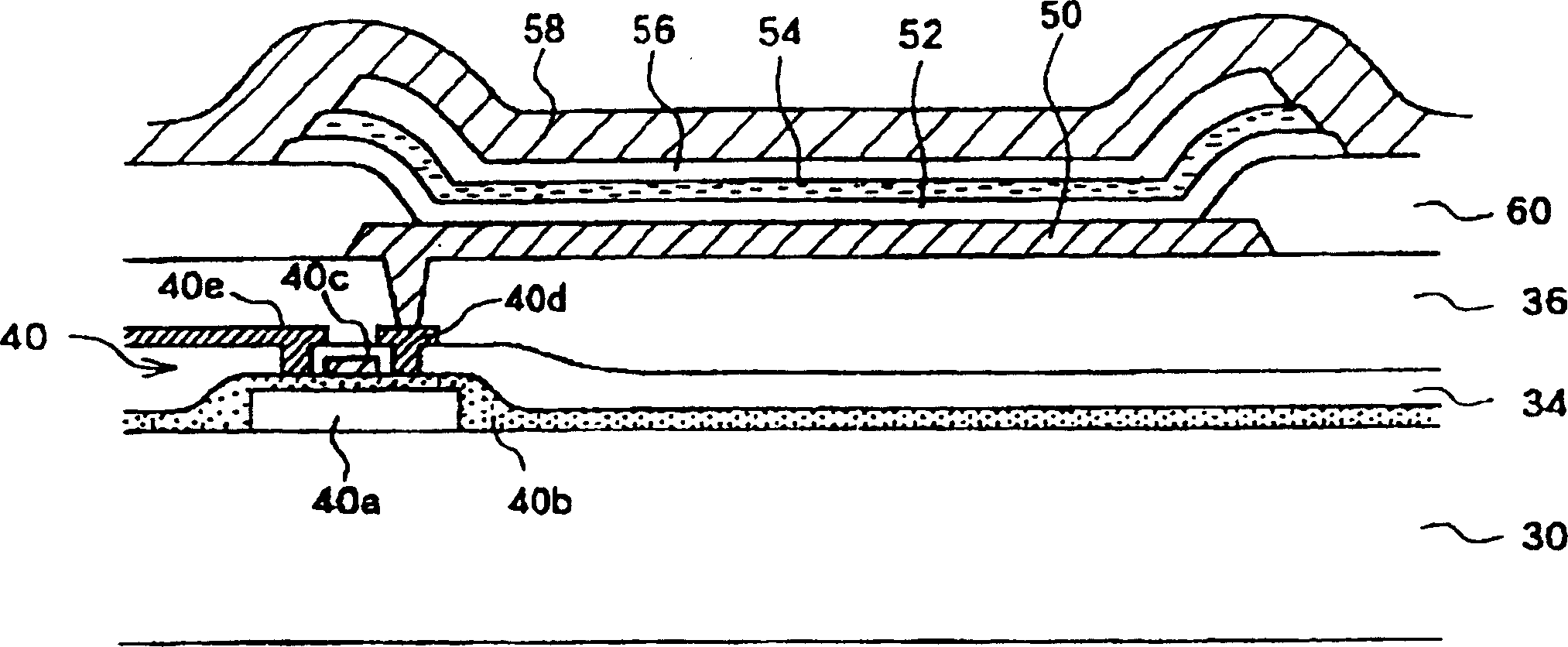

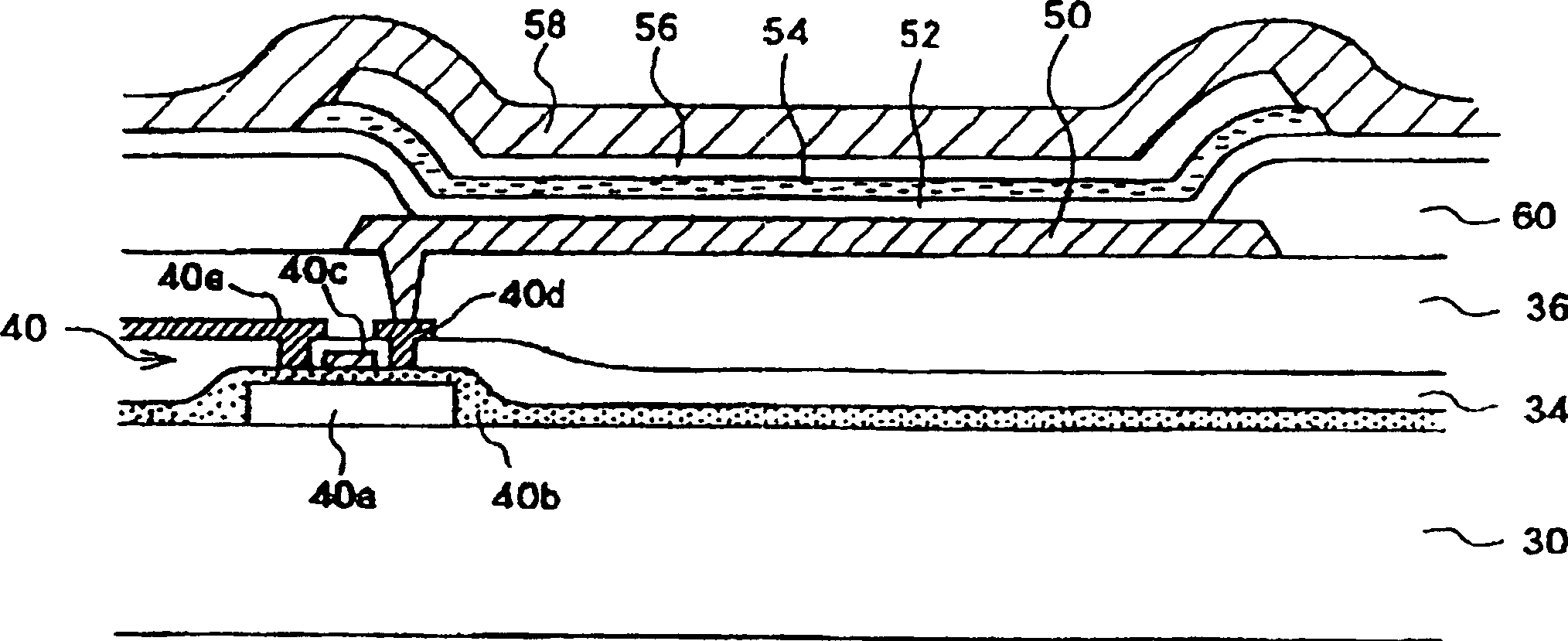

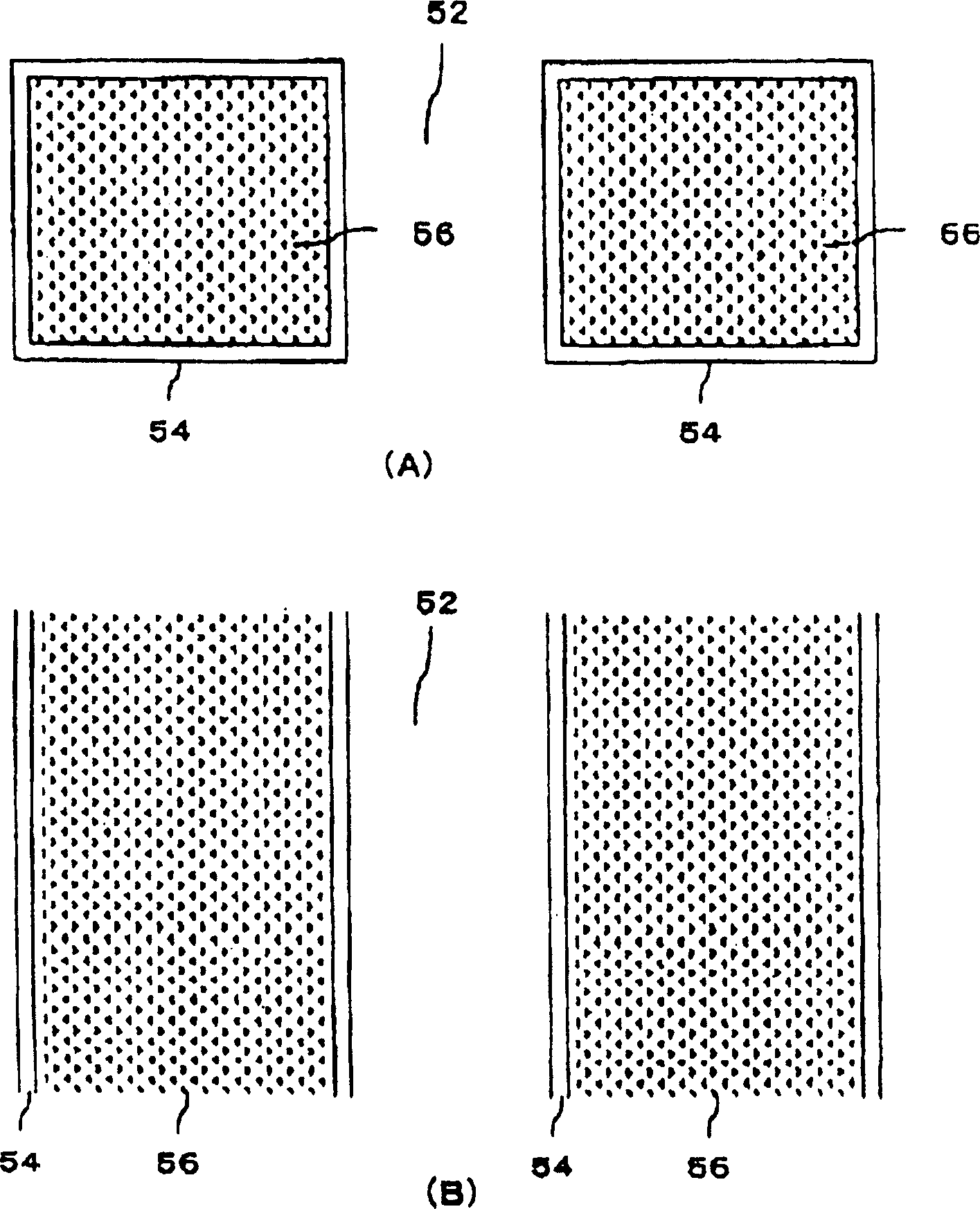

[0021] Embodiments of the present invention will be described below with reference to the drawings.

[0022] figure 1 Represents the composition of pixels. Here, two TFTs, one capacitor, and one organic EL element EL are formed in one pixel on the active matrix element substrate, but only the driving TFT 40 and the organic EL element EL are shown in this figure.

[0023] In the drawing, the element substrate has a driving TFT 40 formed on a glass substrate 30 . An organic EL element is connected to this driving TFT 40 .

[0024] The driving TFT 40 is formed on the glass substrate 30 with an active layer 40a formed of low temperature polysilicon. Both ends of the active layer 40 a are source regions and drain regions doped with impurities, and the center of these regions is a channel region. A gate electrode 40c is formed above the channel region via a gate insulating film 40b made of silicon oxide. The gate insulating film 40b and the gate electrode 40c are covered by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com