Melt refiner

A purification device and melt technology, applied in stirring devices, charge manipulation, lighting and heating equipment, etc., can solve problems such as product defects, achieve the effects of improving internal quality, preventing temperature drop, improving internal quality and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

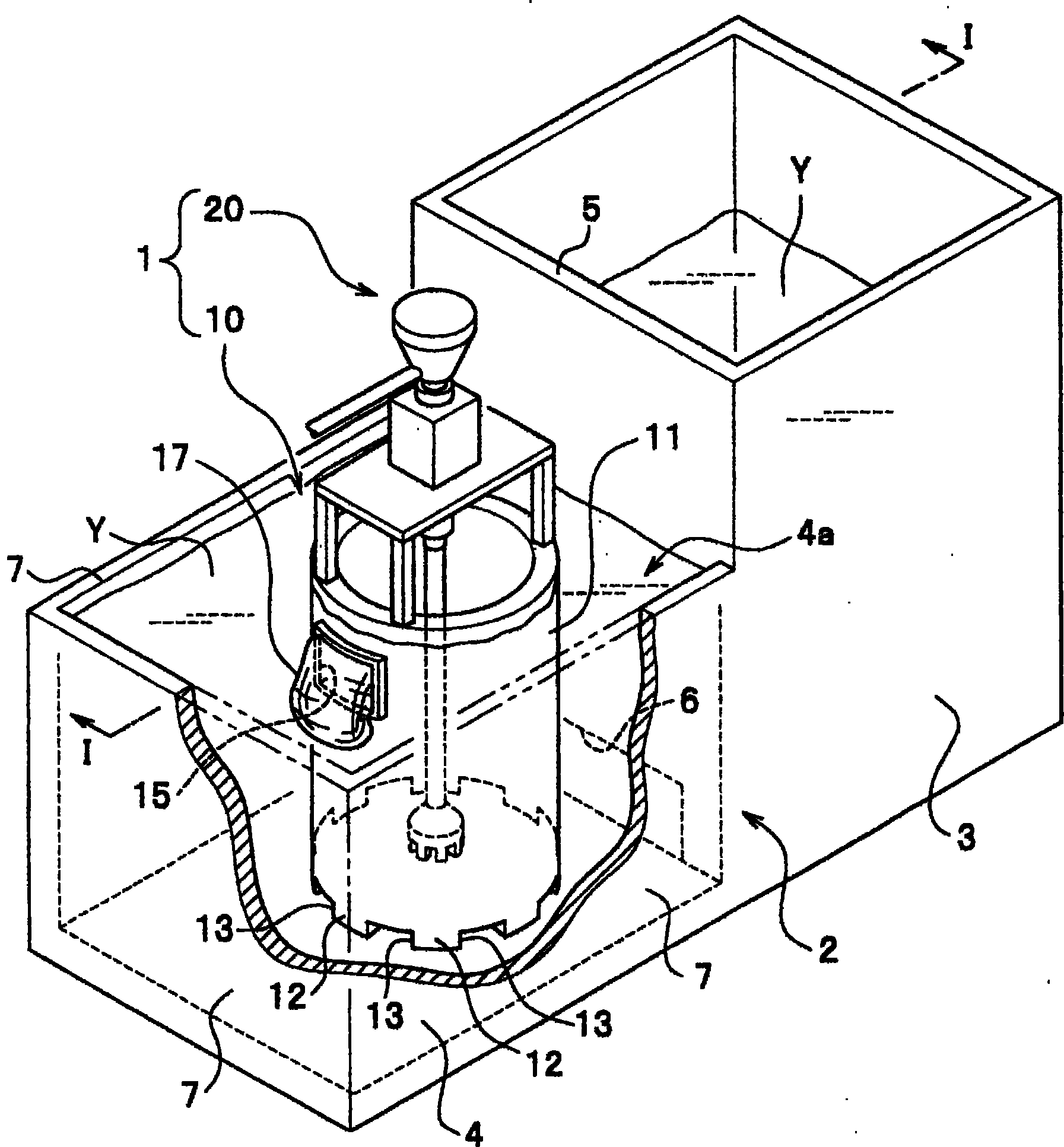

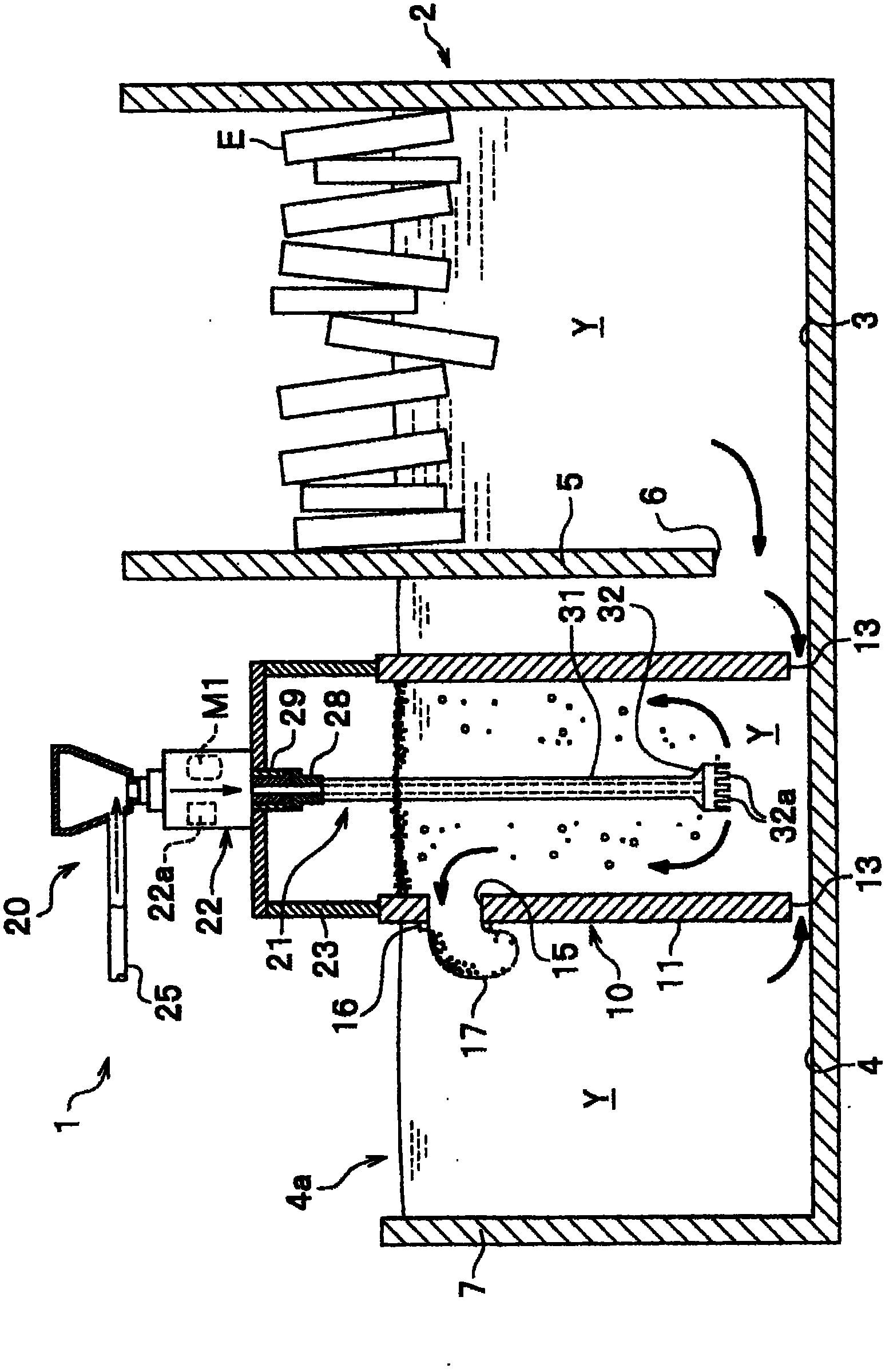

[0036] Embodiments of the present invention will be described in detail with reference to the drawings. Such as figure 1 and figure 2 As shown, in the first embodiment, the case of using the melt purification device 1 in the continuous processing furnace 2 will be described as an example.

[0037] Such as figure 1 and figure 2 As shown, the continuous processing furnace 2 has: a melting furnace 3 for melting an aluminum ingot E, for example; The melting furnace 3 includes a burner (furnace) not shown in the figure, and is heated to 720° C. to 900° C. to melt the aluminum ingot E to generate a molten metal Y.

[0038] The pumping chamber 4 is arranged side by side with the melting furnace 3 via the furnace wall 5 , is provided with a molten metal purification device 1 described later, and holds purified molten metal Y. The pumping chamber 4 corresponds to a "holding chamber" in the claims. Such as figure 2 As shown, a liquid outlet 6 is provided through the lower part...

no. 2 approach

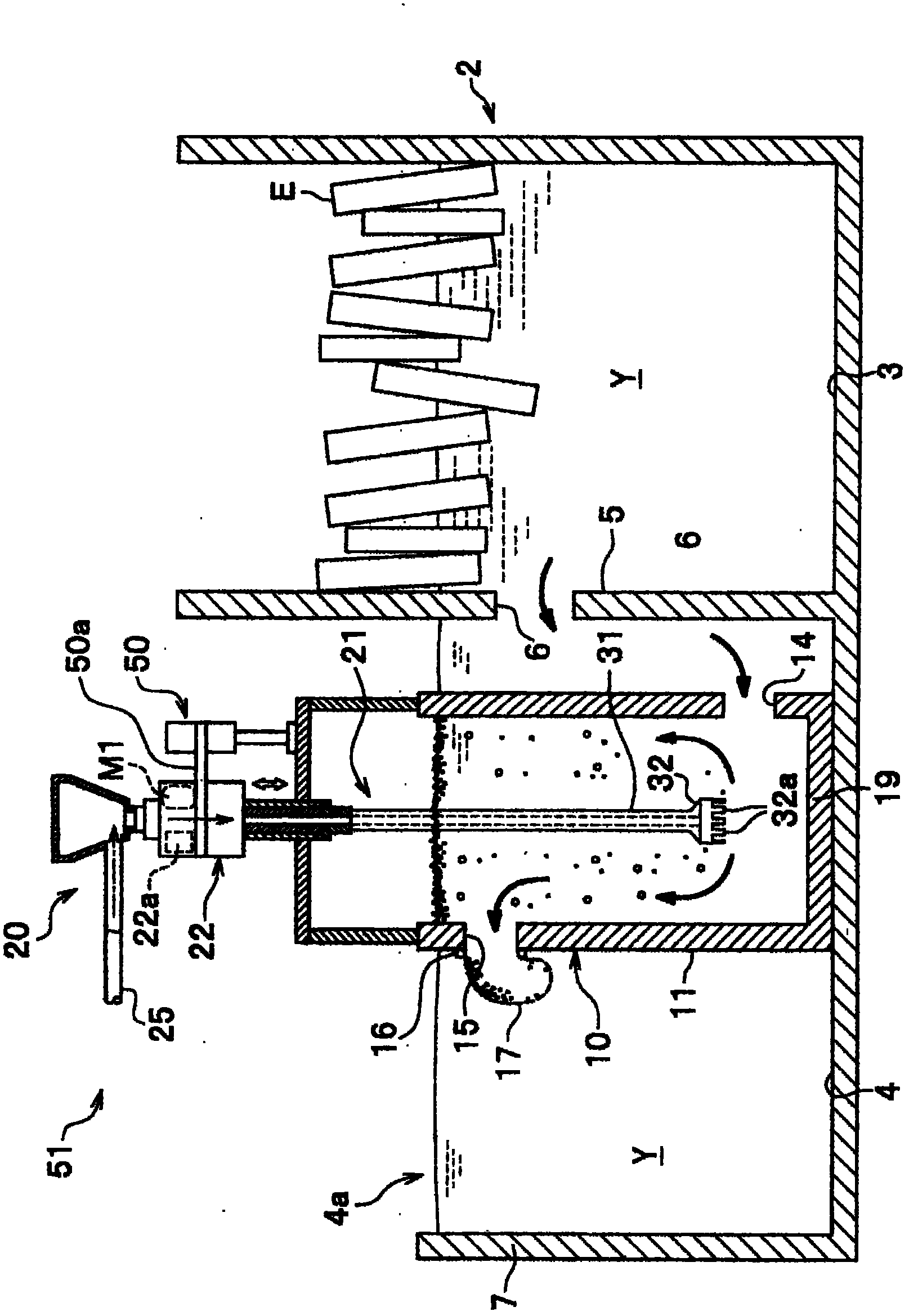

[0064] Next, a second embodiment of the present invention will be described. image 3 It is a cross-sectional view showing the melt purification device and the continuous processing furnace in the second embodiment. Such as image 3 As shown, the melt purification device 51 of the second embodiment differs from the first embodiment in that the bottom 19 is formed on the processing cylinder 10 and that an elevating mechanism 50 for elevating the rotor 21 is provided. In addition, the same code|symbol is attached|subjected to the part common (common) with 1st Embodiment, and description is abbreviate|omitted.

[0065] The melt purification device 51 of the second embodiment mainly includes the processing cylinder unit 10 and the refining device 20 . The processing cylinder 10 has: a circular cylinder 11 in plan view, a bottom 19 formed at the lower end of the cylinder 11, an inlet hole 14 penetrating through the lower part of the cylinder 11, and an outlet penetrating through ...

no. 3 approach

[0073] Figure 4 It is a sectional view showing the melt purification device and the crucible boiler in the third embodiment. In the first and second embodiments, the case where the melt purification device is installed in the continuous processing furnace 2 has been described, but the present invention is not limited to this, and the crucible boiler 82 may be installed as described in the third embodiment. Purification device.

[0074] As described in the third embodiment, in the crucible 82 , the molten metal purifying device 1 may be installed in the holding furnace 84 that melts the ingot and holds the molten metal Y. Thus, the target for installing the molten metal purifying device of the present invention is not limited to the pumping chamber 4 of the continuous processing furnace 2, but may also be the holding furnace 82 that heats and holds the molten metal Y when the molten metal Y is drawn out with a ladle or the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com