Patents

Literature

124 results about "Motor block" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The engine block - also known as a cylinder block - contains all of the major components that make up the bottom end of a motor. This is where the crankshaft spins, and the pistons move up and down in the cylinder bores, fired by the fuel combusting.

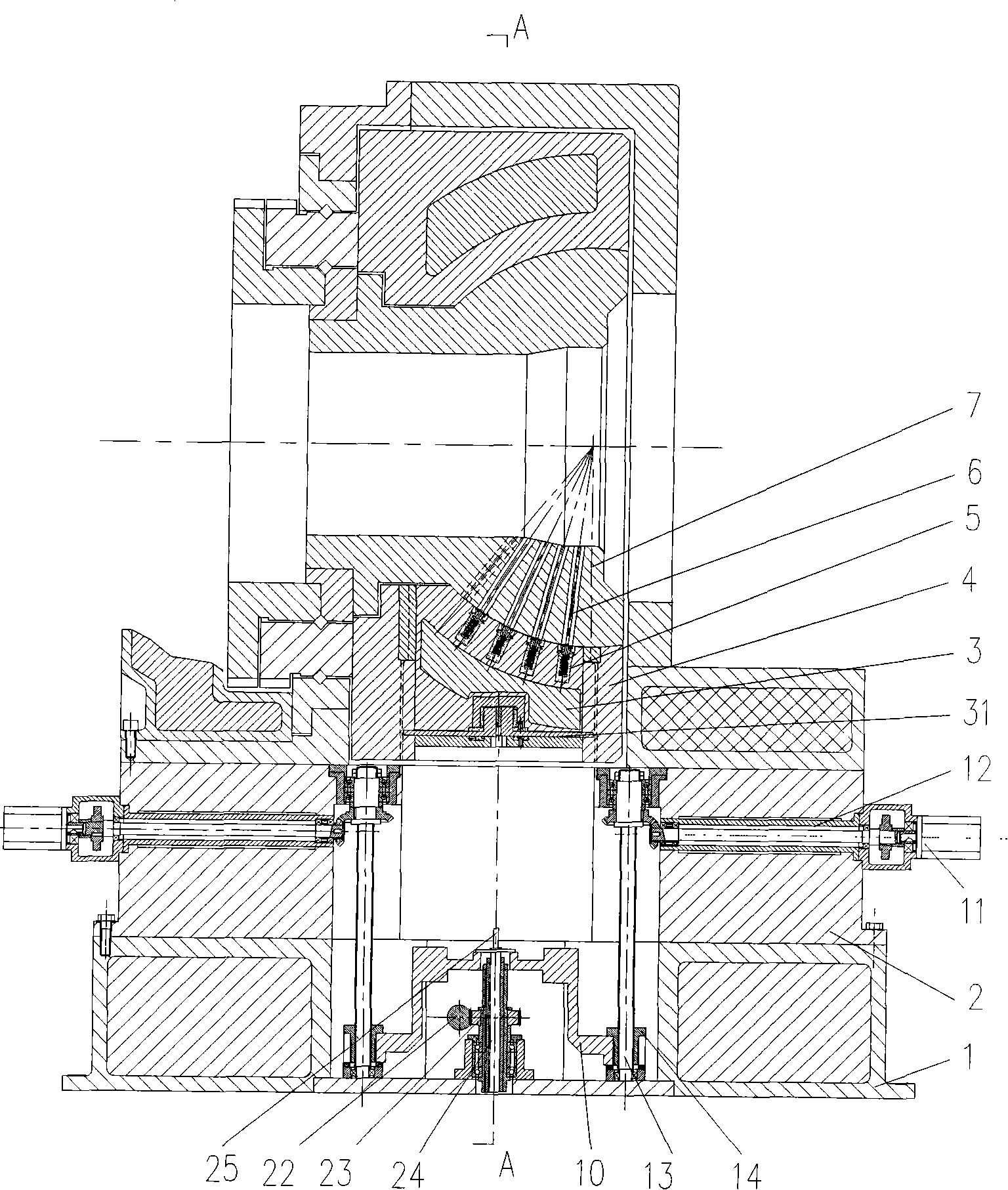

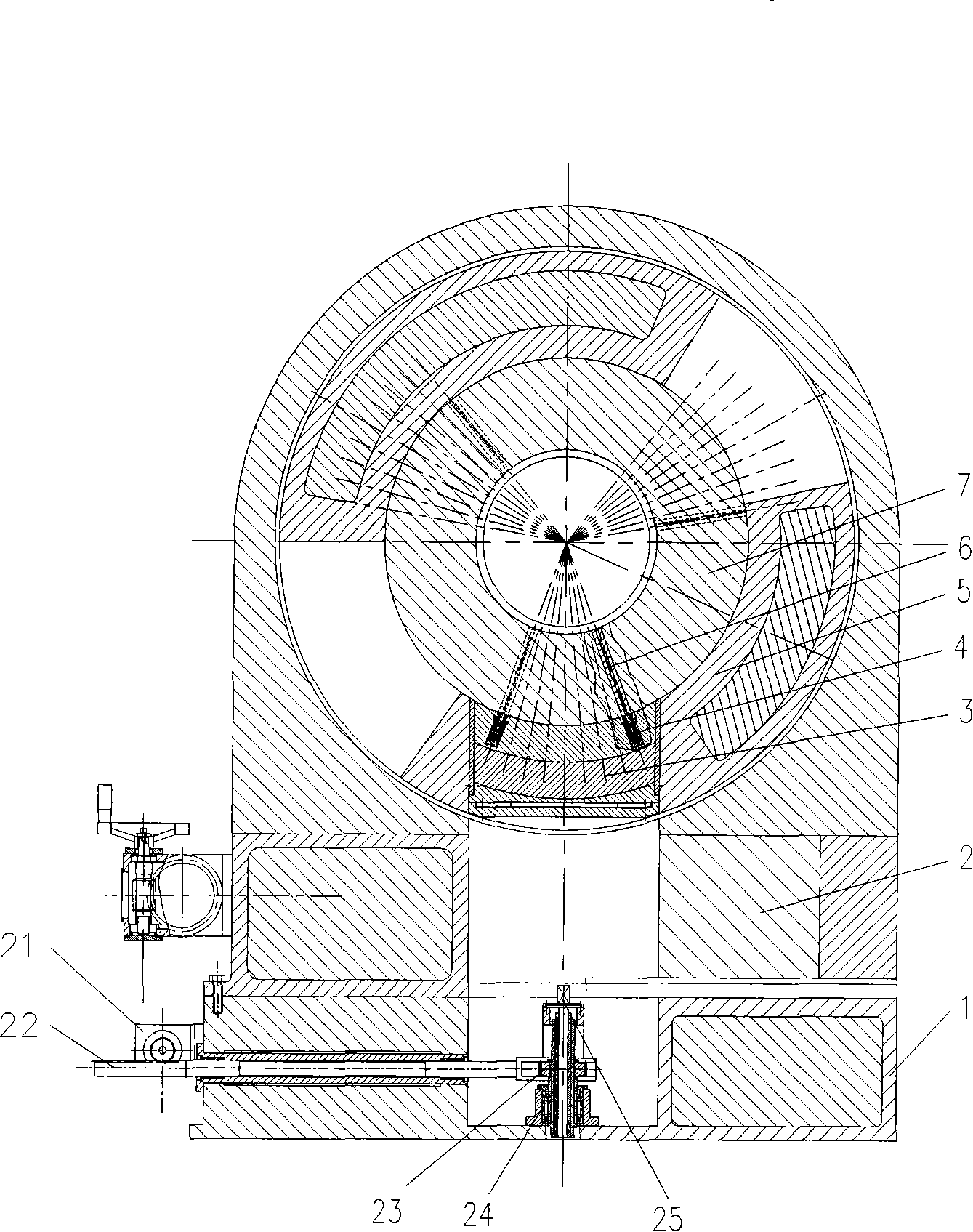

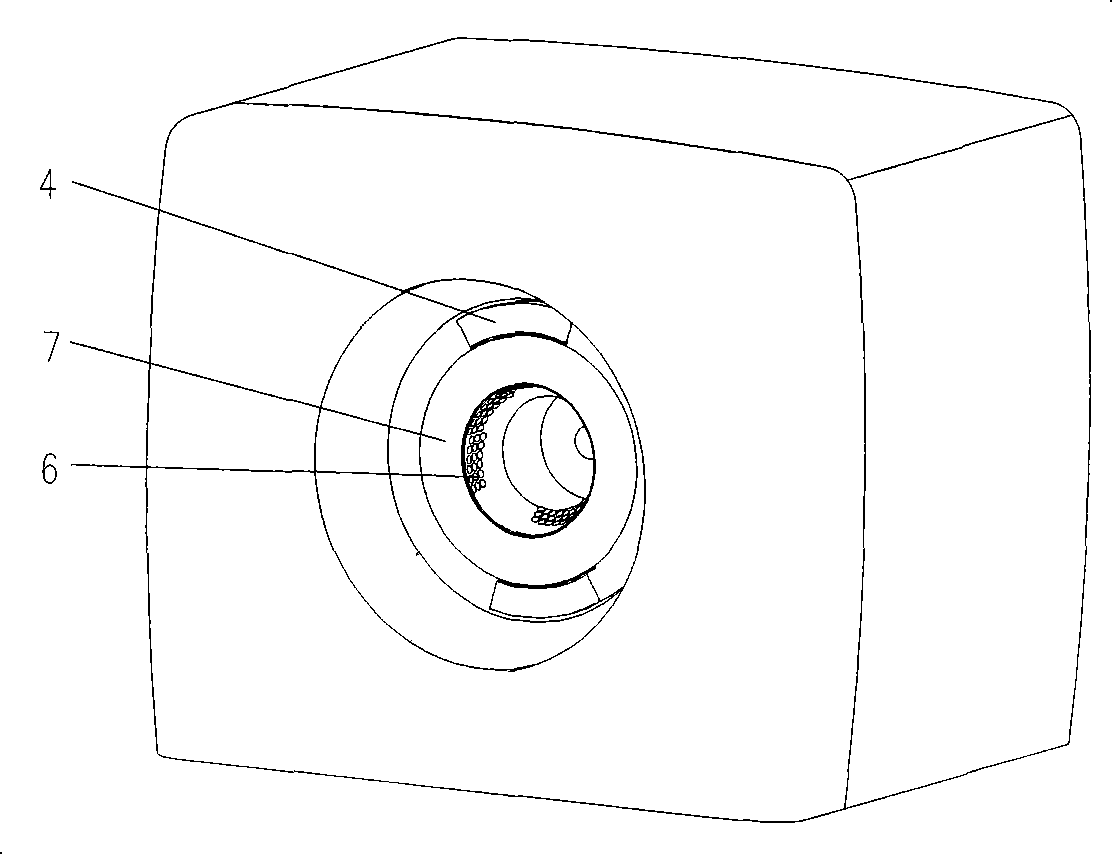

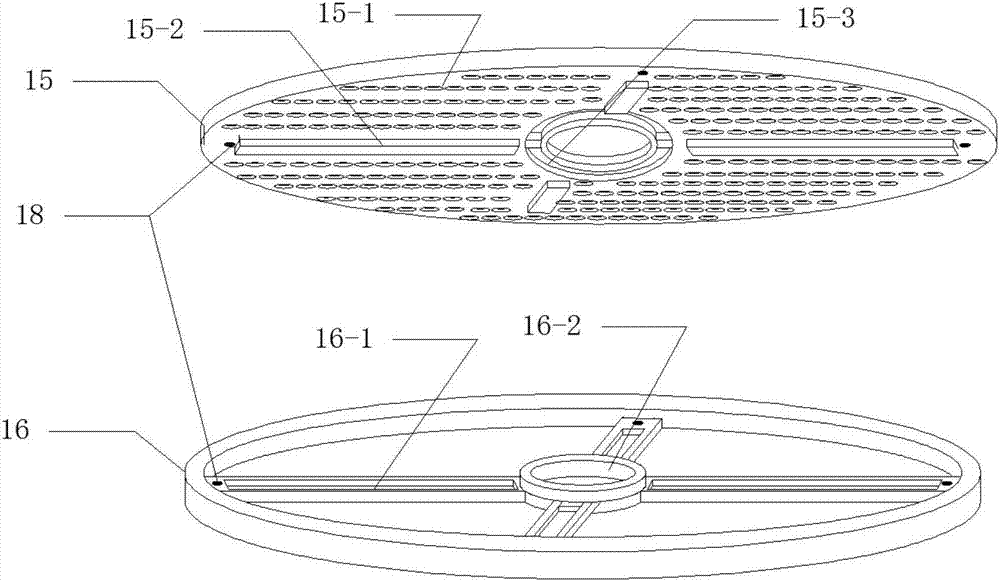

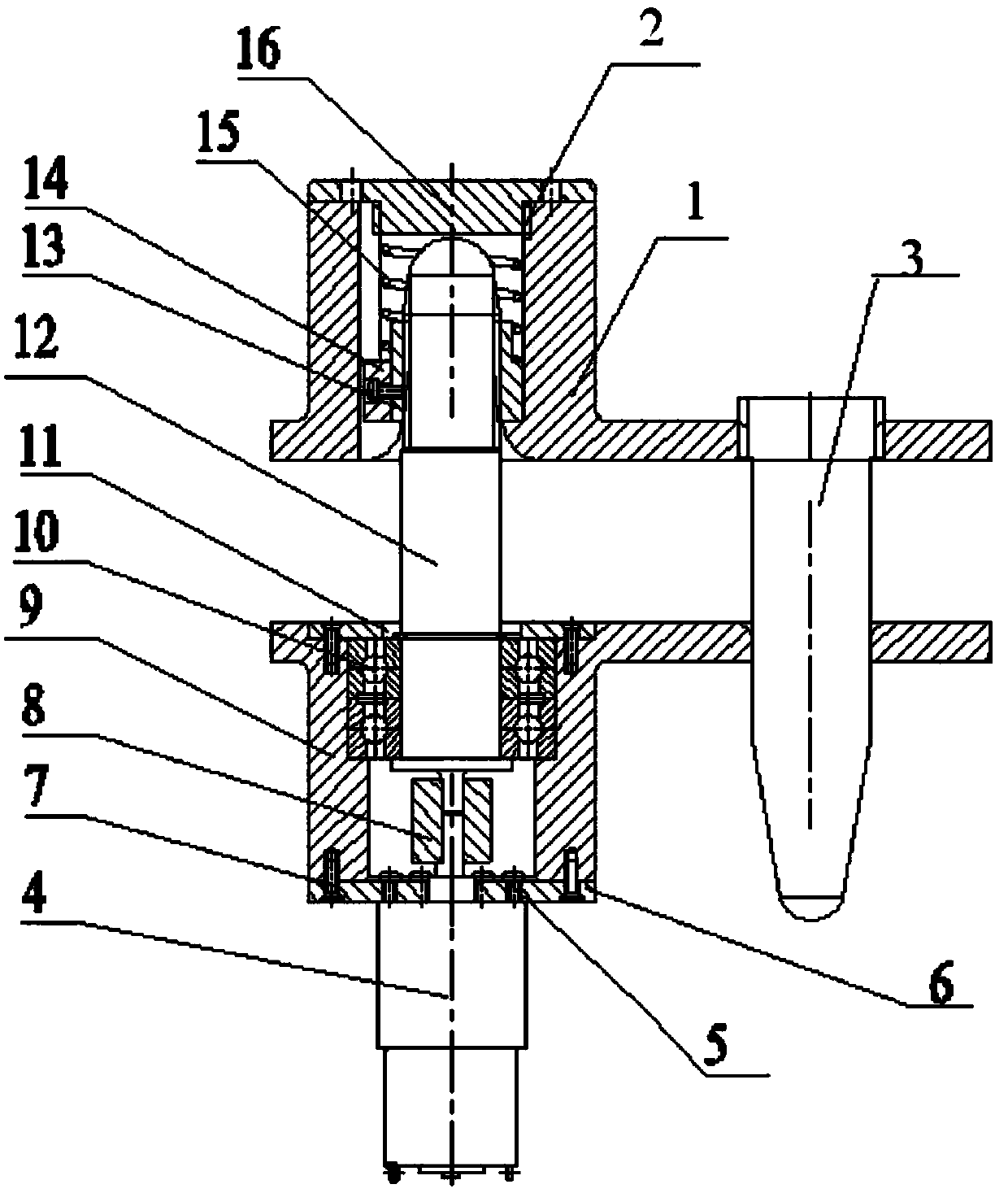

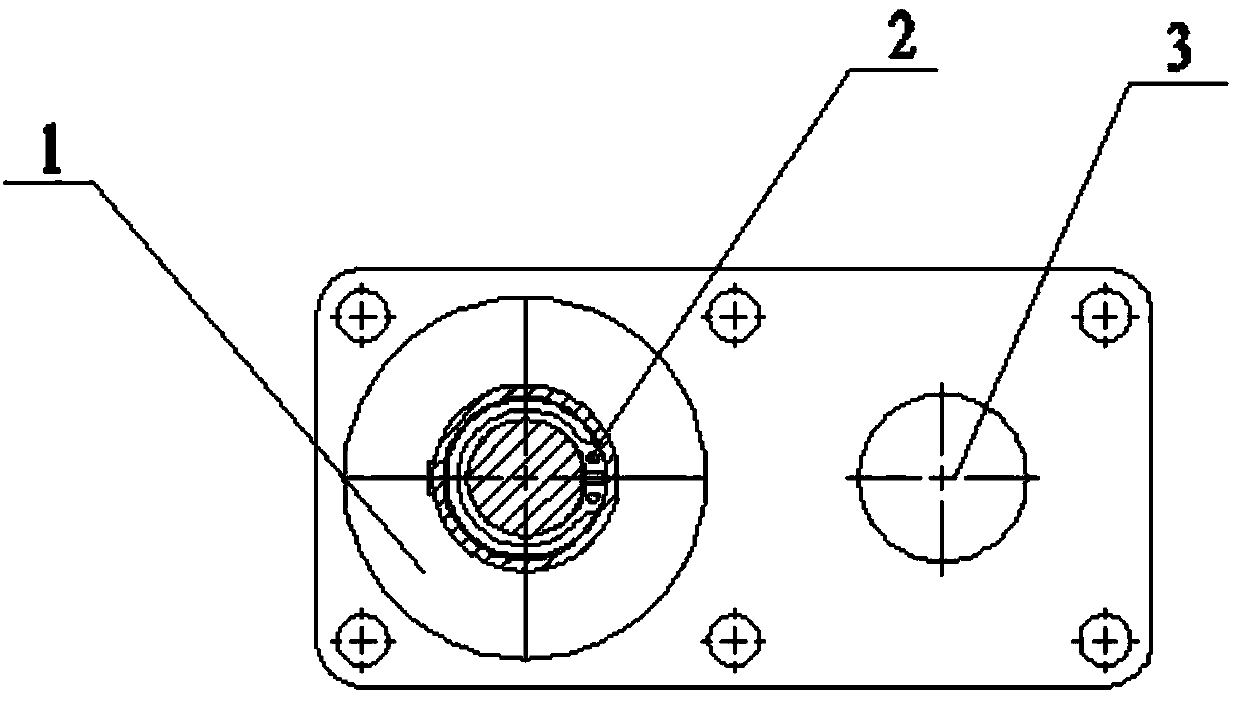

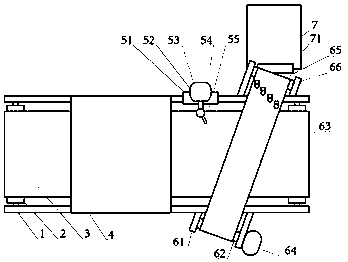

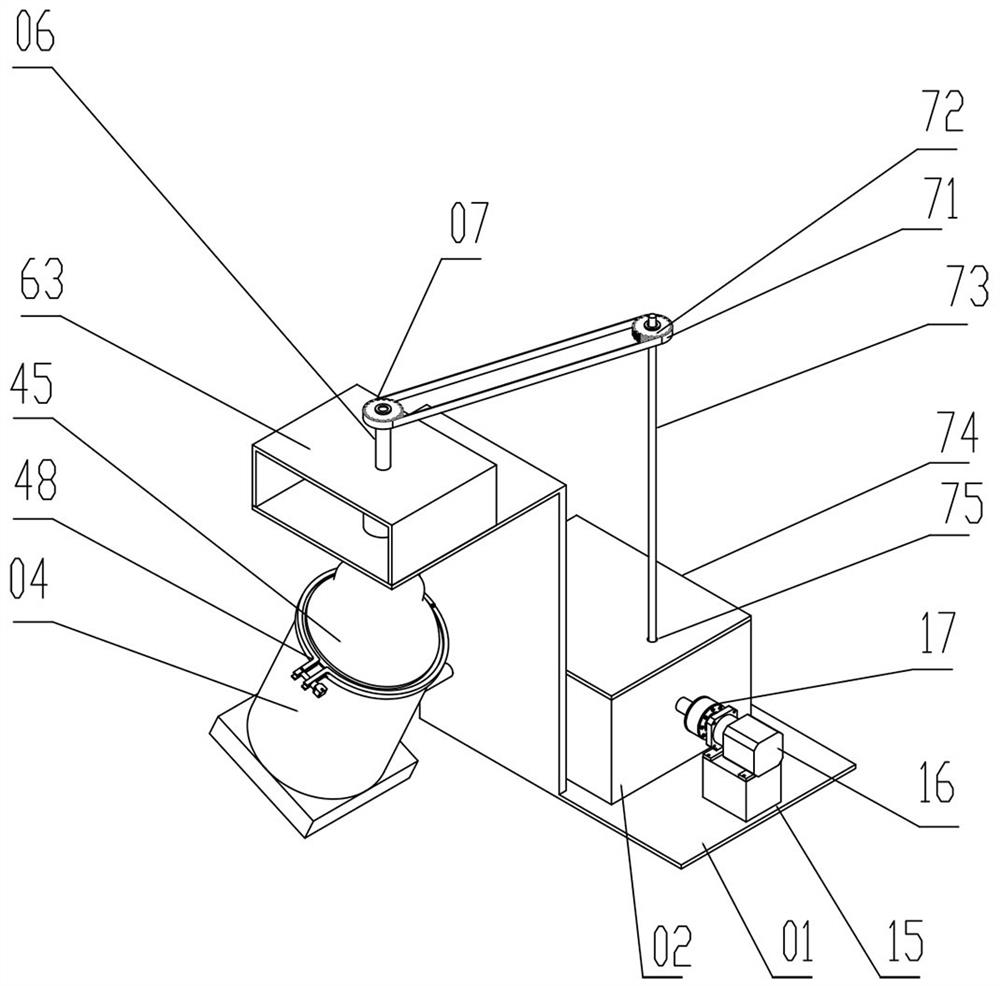

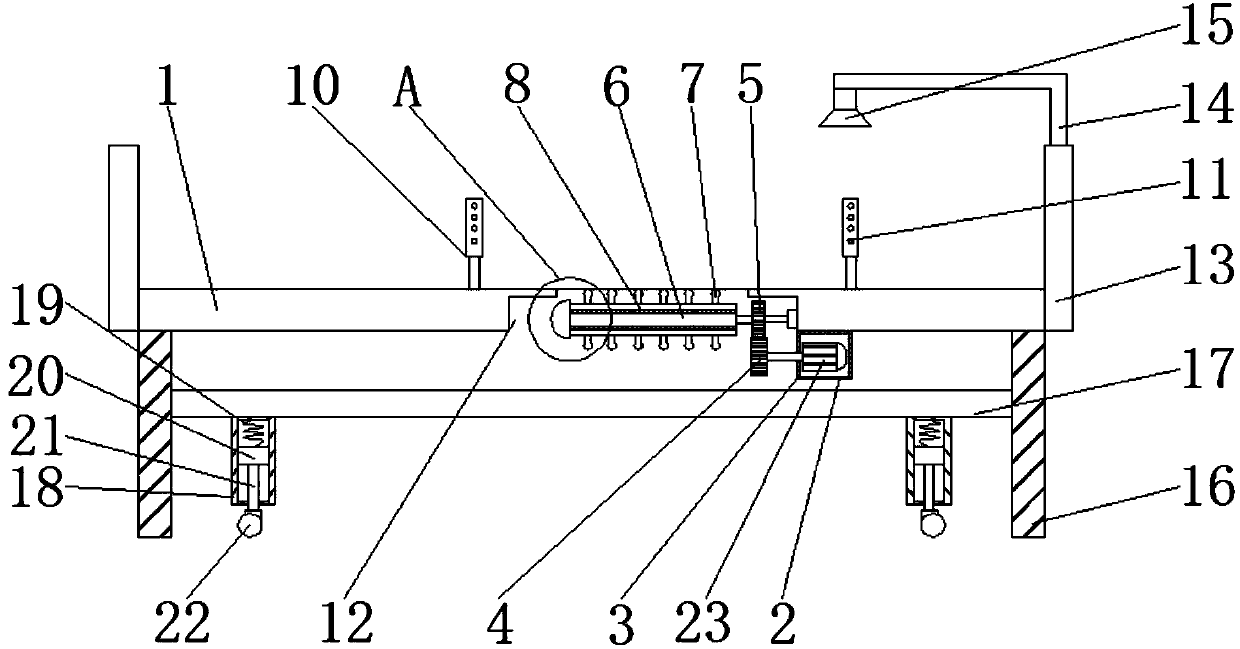

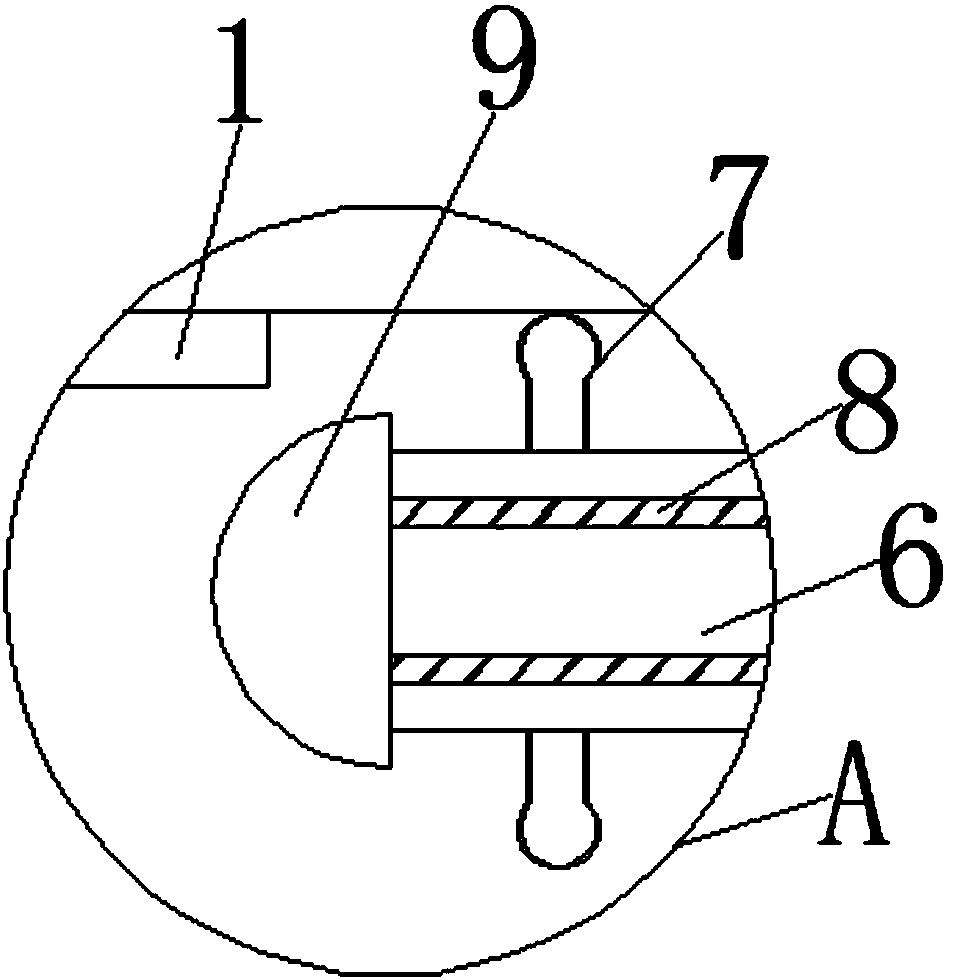

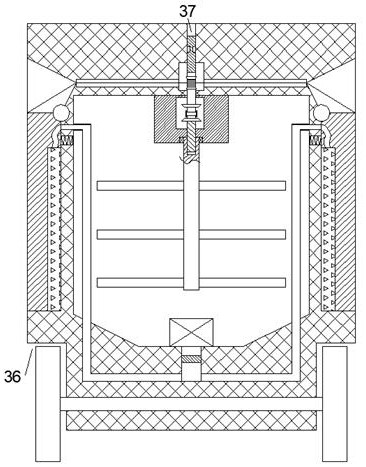

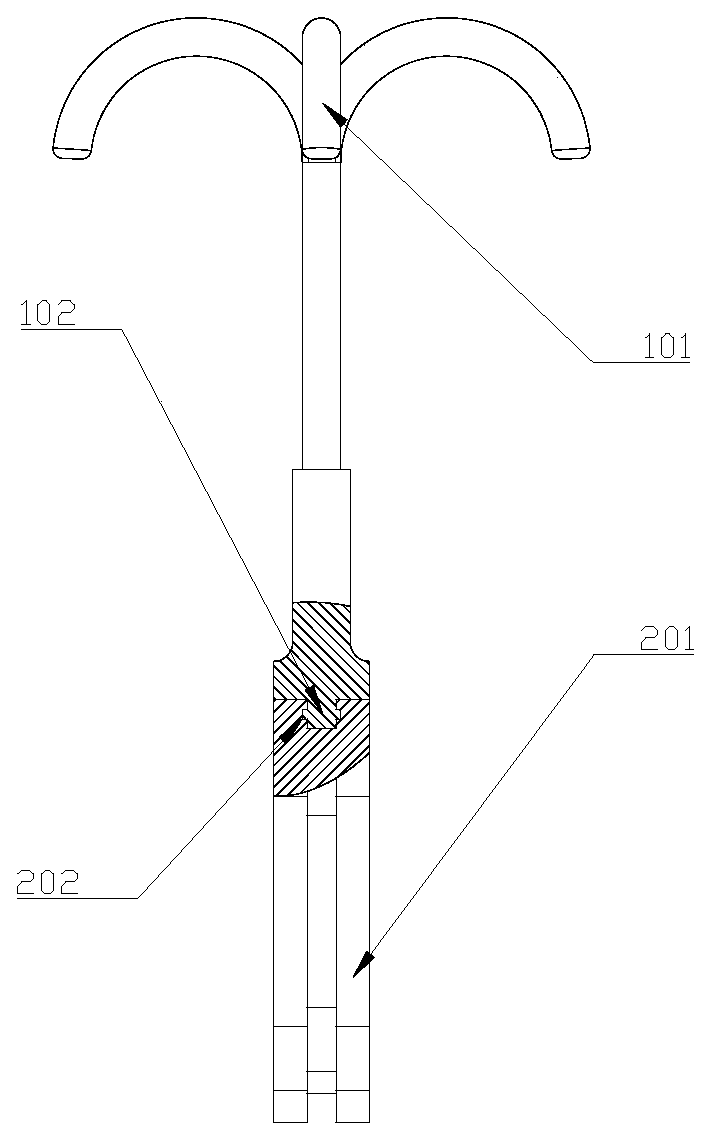

Radiation therapy driving device

ActiveCN101239224AReduce protection requirementsSimple structureRadiation applicationsPretreated surfacesEngineeringRadioactive source

The present invention relates to a radiotherapy driving device which includes: shield, source body, radioactive source, source deck, driving device of source deck. The radioactive source is in the source deck inner, the shield and source body have space for containing the source box, the driving device of the source box can be separated installed on down part of the source box, and the source box is drived to up-and-down movement between the shield and source box. The shield and source box are in the down part of the source body, which can save the shield material, reduce the whole device weight and occupied space; the driving device of the source box can be separated drive the source box up-and-down movement when treating, the source box is fixed on radiation device of the radiotherapy system by lock board, and rotary irradiate with the radiation device. The radiotherapy driving device reduces protective request of the radiation device, prevents motor block of the source box efficiently, simplifies the radiotherapy system structure, reduces processing difficuites and saves cost.

Owner:SHEN ZHEN HYPER TECH SHENZHEN

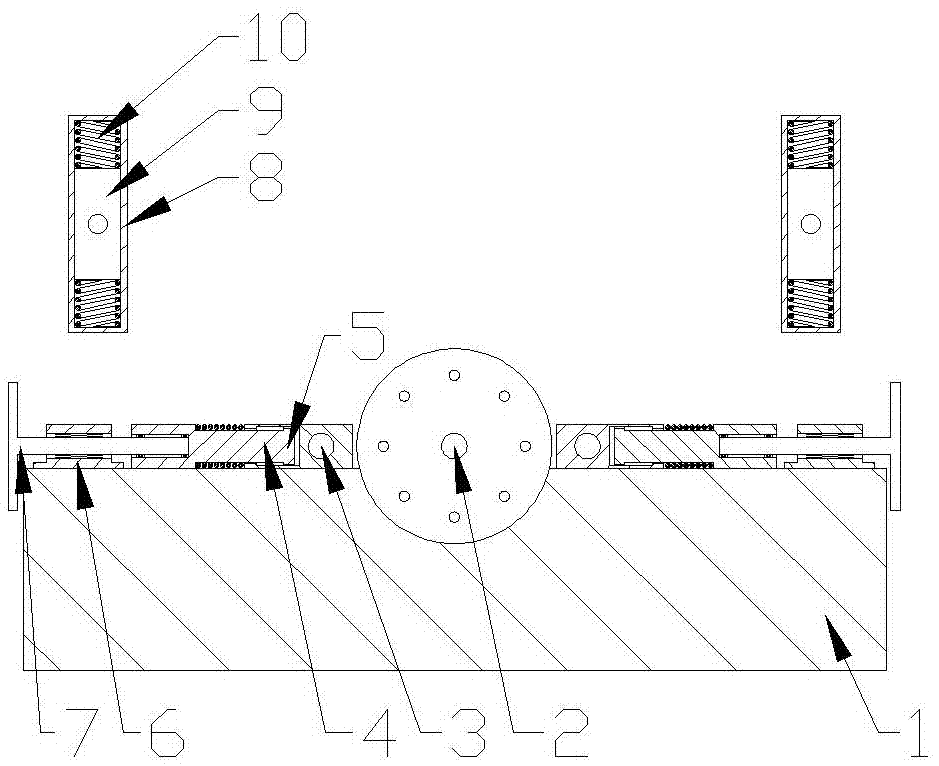

Ground dirt cleaning device

InactiveCN107569185AAchieve cleaningIncrease frictionCarpet cleanersFloor cleanersDrive shaftEngineering

The invention discloses a ground dirt cleaning device, and relates to the technical field of cleaning equipment. The device comprises a support platform, a driving mechanism, an adjusting mechanism and a cleaning device, the support platform is supported through supporting legs arranged at the lower end of the support platform, mobile casters are arranged at the lower ends of the supporting legs,a through groove is formed in the center of the support platform, the adjusting mechanism comprises a lifting pump vertically installed at the upper end of the support platform, the lifting pump is located on the periphery of the through groove, a supporting plate is arranged on the top of the lifting pump, the driving mechanism comprises a rotating motor and a driving shaft arranged at the driving end of the rotating motor, a motor base of the rotating motor is installed on the lower end face of the supporting plate, and the cleaning device comprises a detergent box and a cleaning mechanism.Accordingly, by conducting mechanical cleaning on oil dirt and dirt on the ground, the ground cleaning efficiency is improved, the manpower is saved, the structure is simple, all parts can be maintained and replaced conveniently, and the cost is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

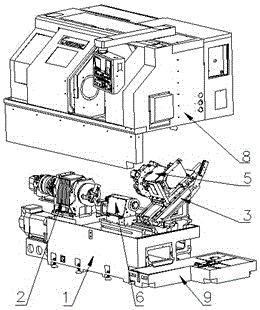

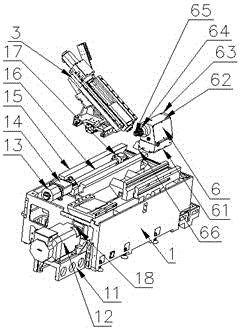

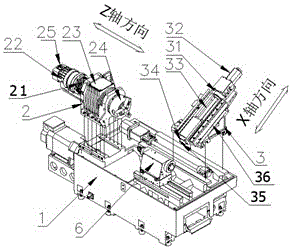

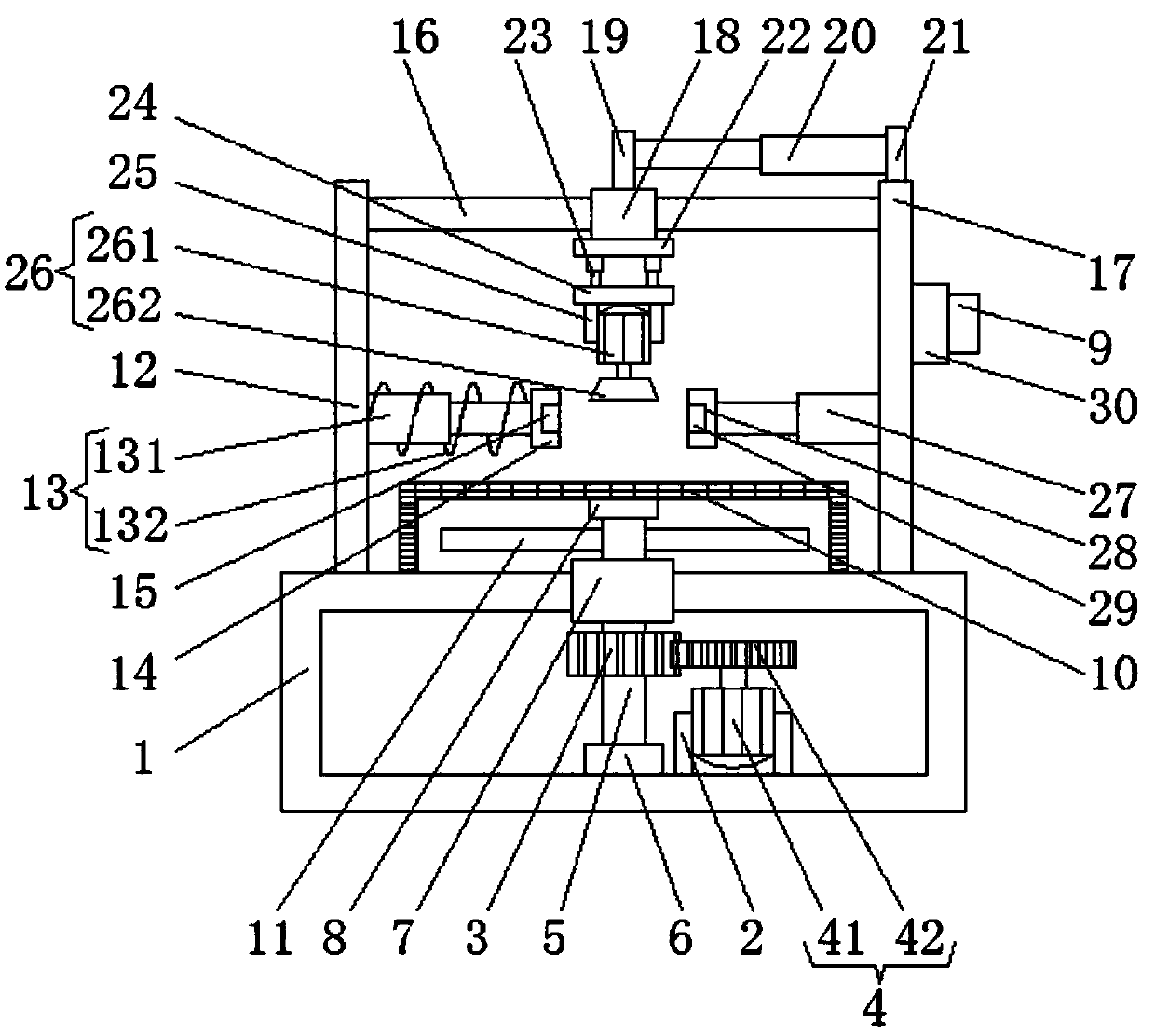

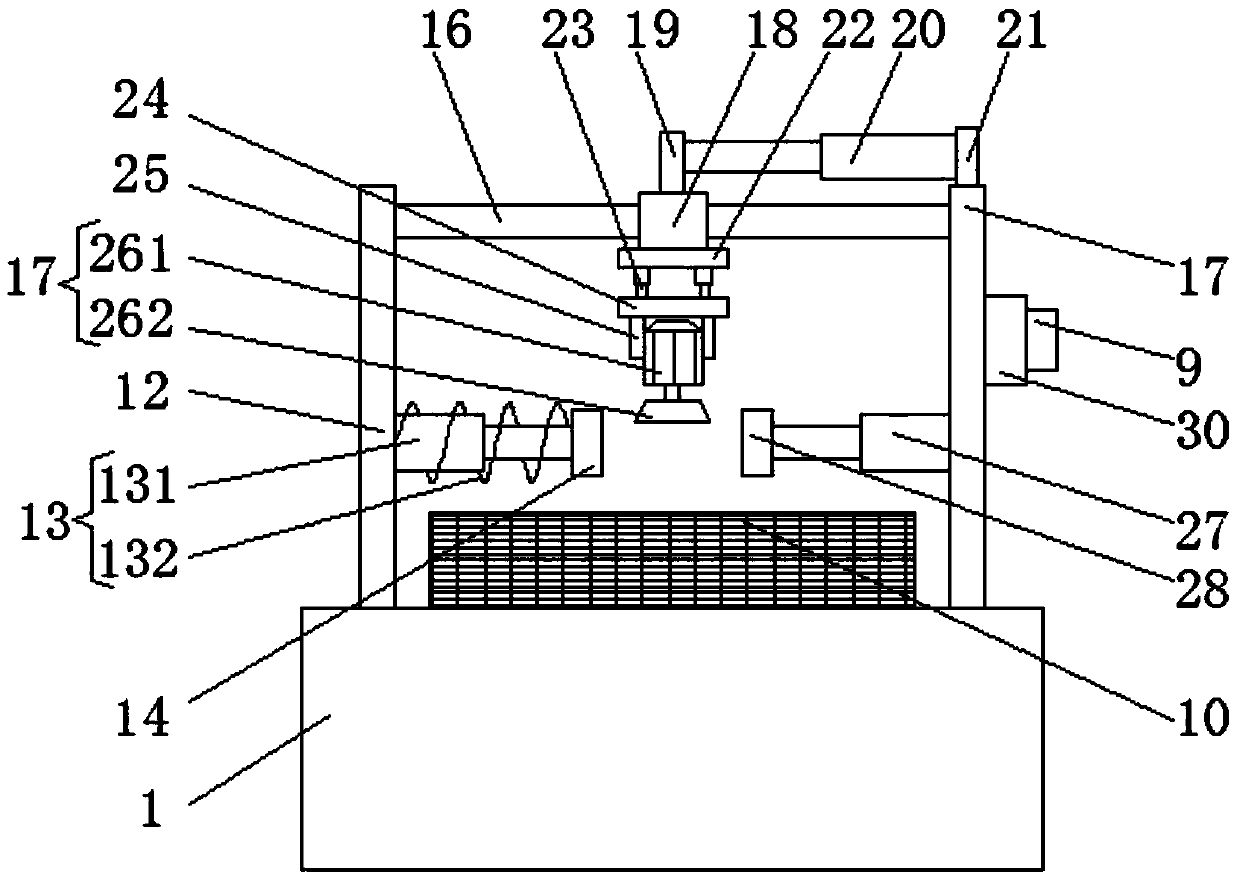

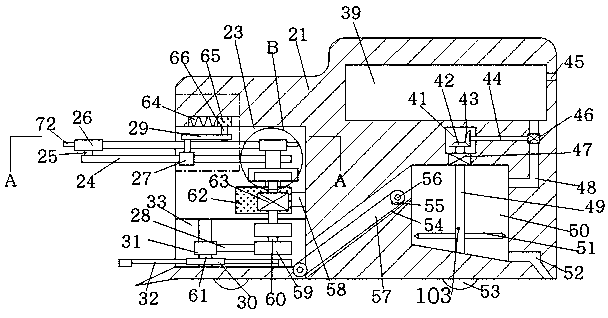

Hard rail numerical control lathe

ActiveCN105817654AIncrease powerIncrease torqueTailstocks/centresLarge fixed membersNumerical controlEngineering

The invention provides a hard rail numerical control lathe. The hard rail numerical control lathe comprises a base module. The base module comprises a motor base, a spindle motor, a Z-axis motor, a Z-axis motor base, a base body, a Z-axis lead screw, a bearing block and a motor belt wheel. The spindle motor is fixed to the side edge of the base body through the motor base. The motor belt wheel is fixed to the spindle motor. The Z-axis motor base is fixed to the base body. One end of the Z-axis lead screw is connected with the Z-axis motor base, and the other end of the Z-axis lead screw is connected with the bearing block. The problems that when a traditional machine tool is used for machining a larger workpiece, the cutting strength of a spindle is insufficient, feed horsepower of all shafts is weak, the strength of a base is not high enough, and machining feed is excessively large, and consequently tool abrading, jamming, servo alarming and even burning-out of a spindle bearing are caused are solved, and the phenomenon of instable transmission caused by the fact that a certain part of a pipeline is not lubricated in place due to the long use cycle and the phenomenon of burning-out of a rail due to the fact that the rail makes contact with overheat are avoided.

Owner:GOODWAY MACHINE WUJIANG CORP

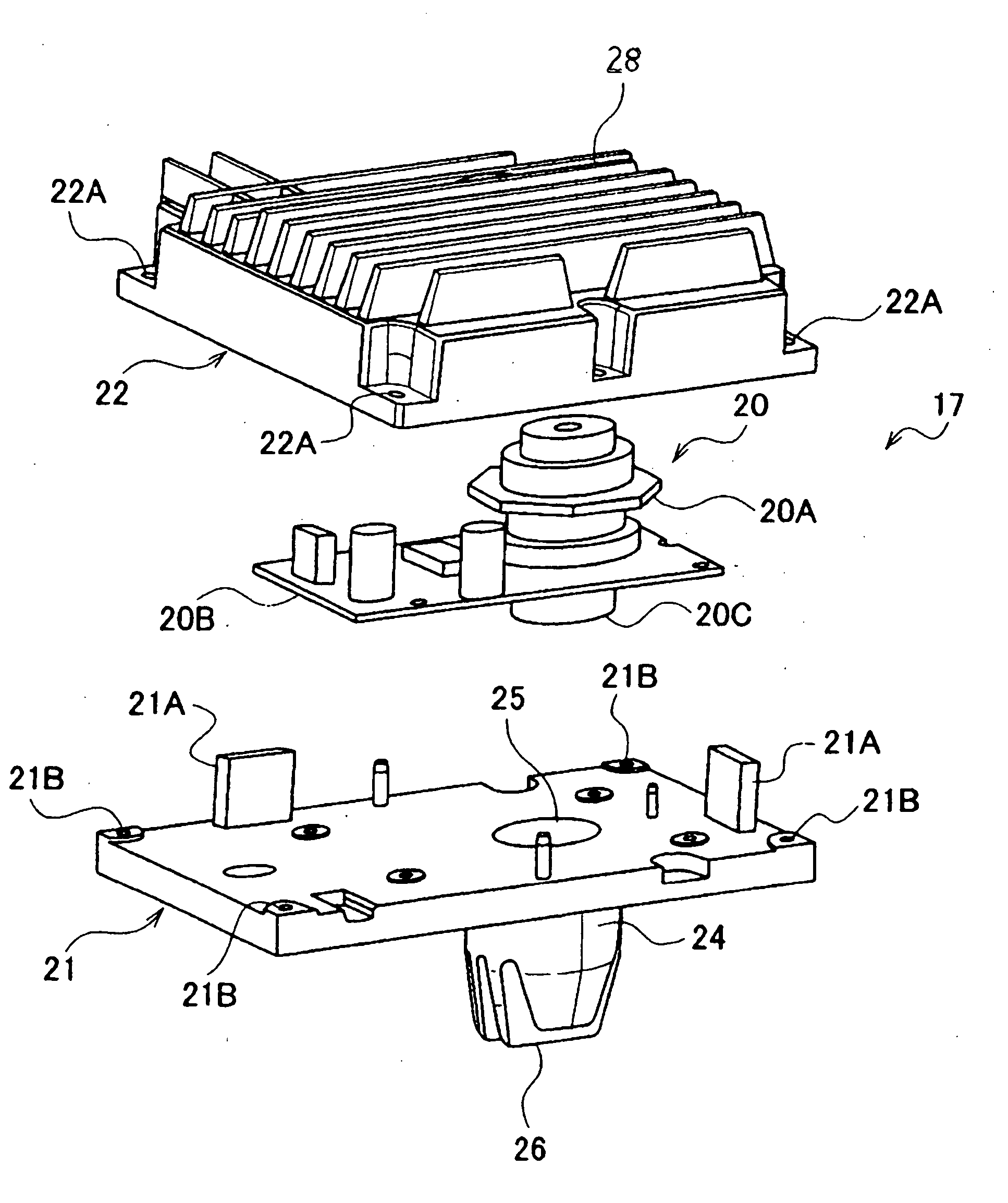

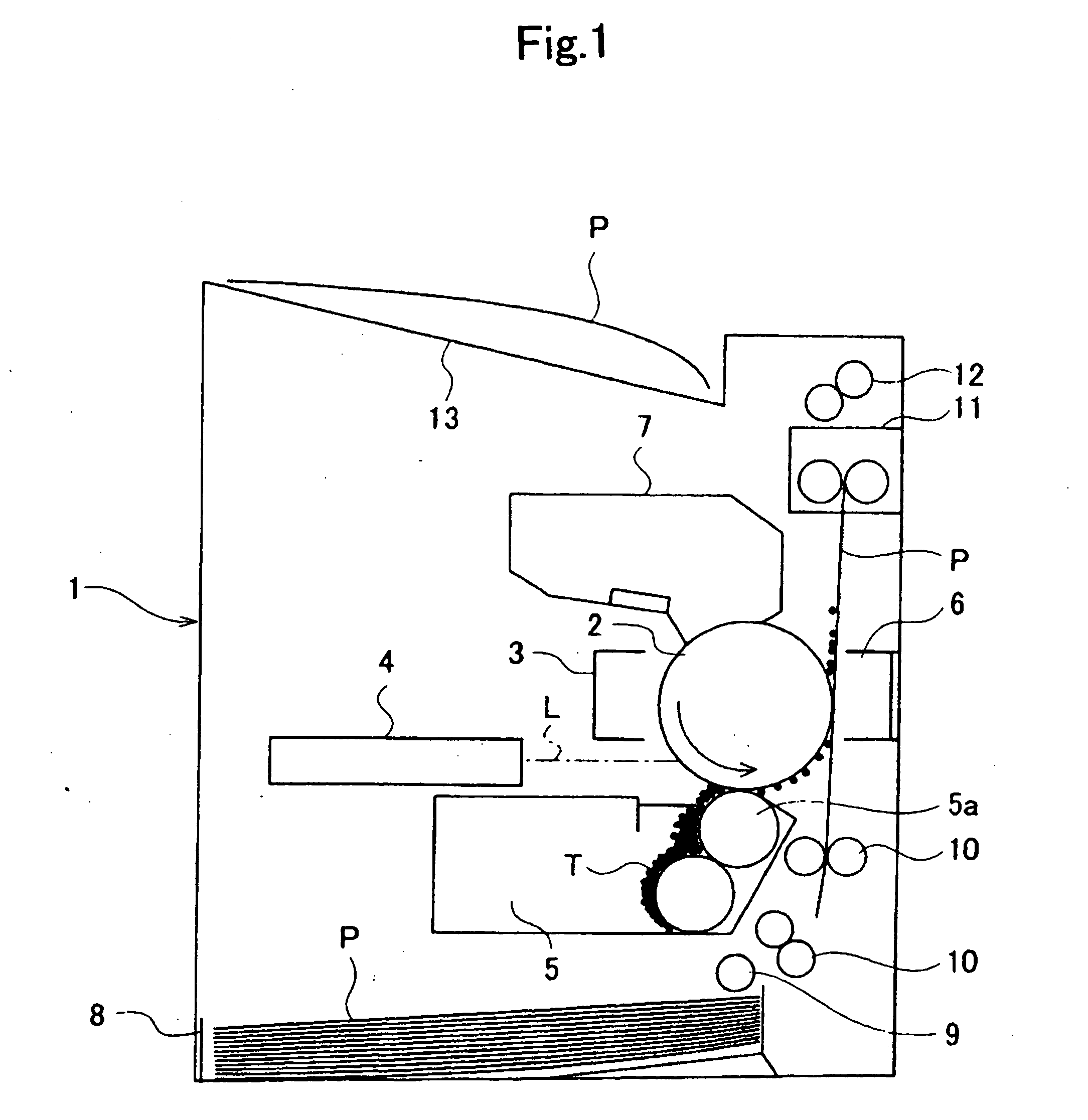

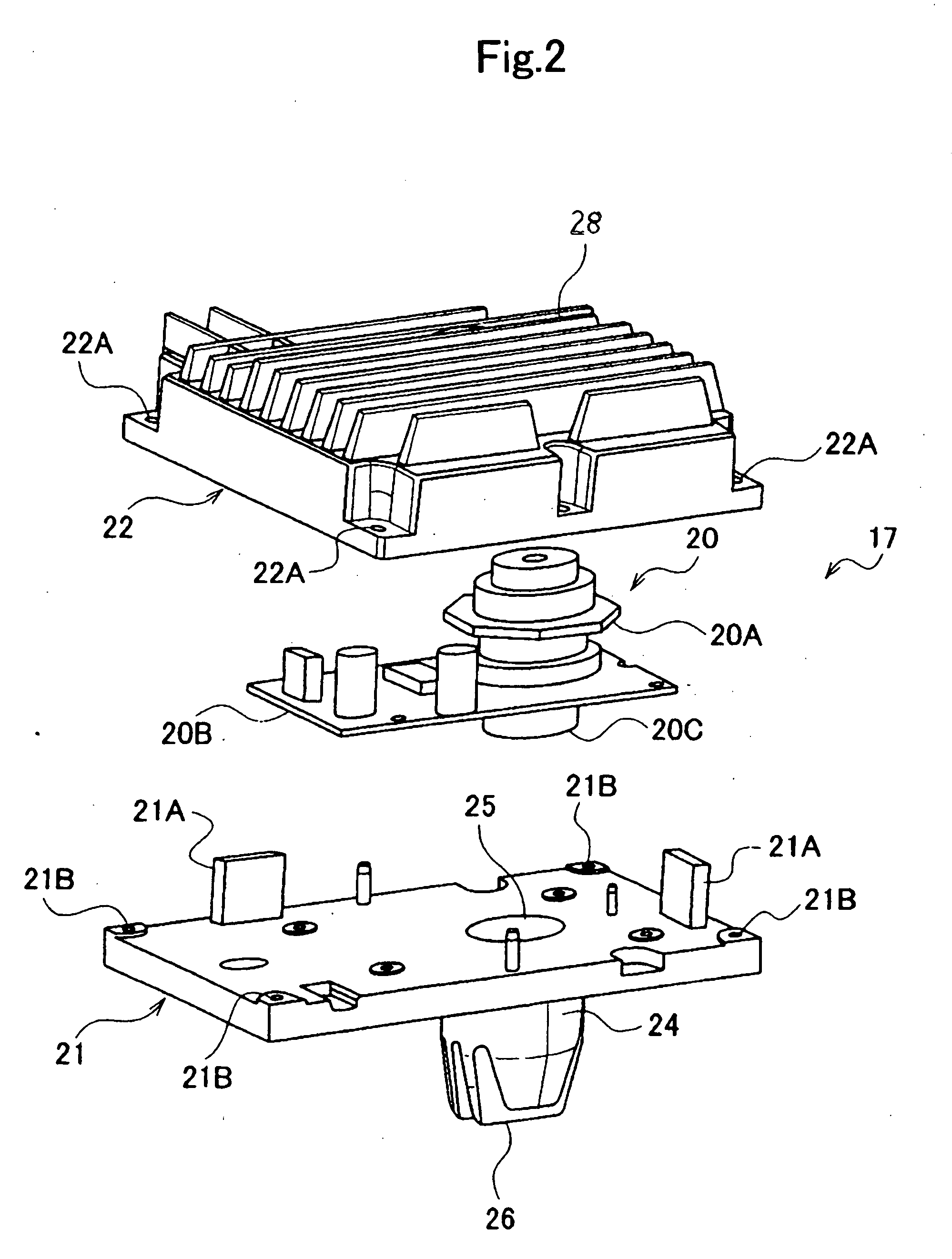

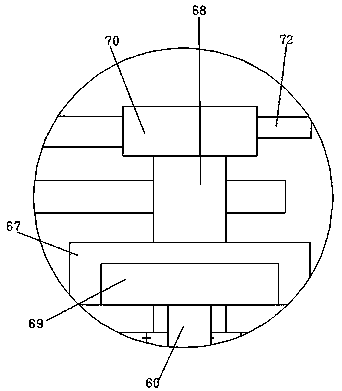

Light scanning unit

A light scanning unit according to the present invention has a polygon motor that scans a laser beam emitted from a laser source, a plate that supports the polygon motor, and a cover that is fixed to the plate and covers the polygon motor. The polygon motor, plate, and cover constitute a motor block. The motor block is housed in a housing. The housing is made of synthetic resin. The plate and cover are made of metal. When a polygon mirror is attached to a circuit board and the base end of a motor shaft is inserted into a fix hole of the plate, the entire surface of the circuit board directly comes into contact with the plate surface.

Owner:KK TOSHIBA +1

Washing machine with air drying and drum drying program

ActiveCN1807747AShort runtimeReduce running timeControl devices for washing apparatusWashing machine with receptaclesDrum dryingPulp and paper industry

This invention relates to a washing machine with airing and barrel drying programme, during the airing in the washing machine, the motor is changed to interrupted running from continuous running, which can reduce the rising temperature and heating quantum that result from long continuous working hours and heavier load, and this invention add the fuzzy detecting clothes quantum function during the airing, when the clothes are overweight in barrel, the wave wheel is not running, then canceling wave wheel stir to avoid the motor blocking to achieve the aim of protecting motor and prolonging the motor longevity.

Owner:HAIER GRP CORP +1

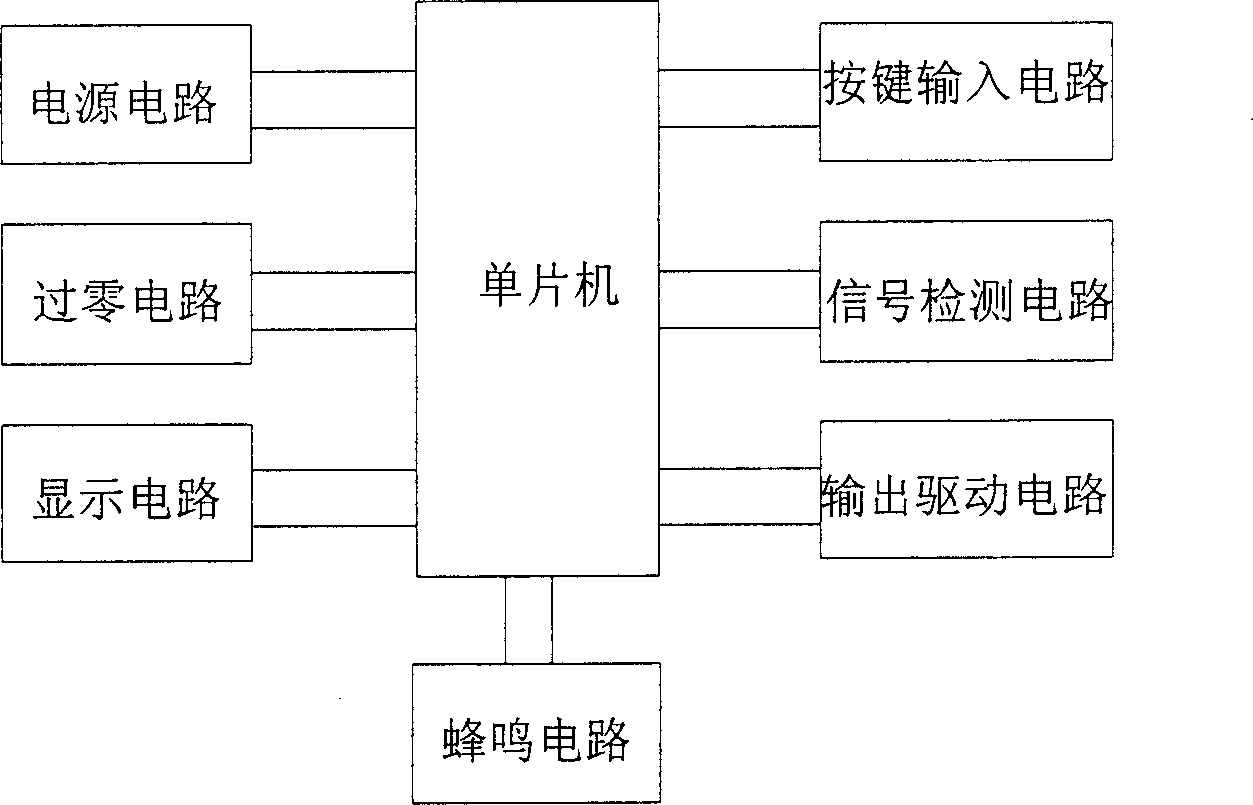

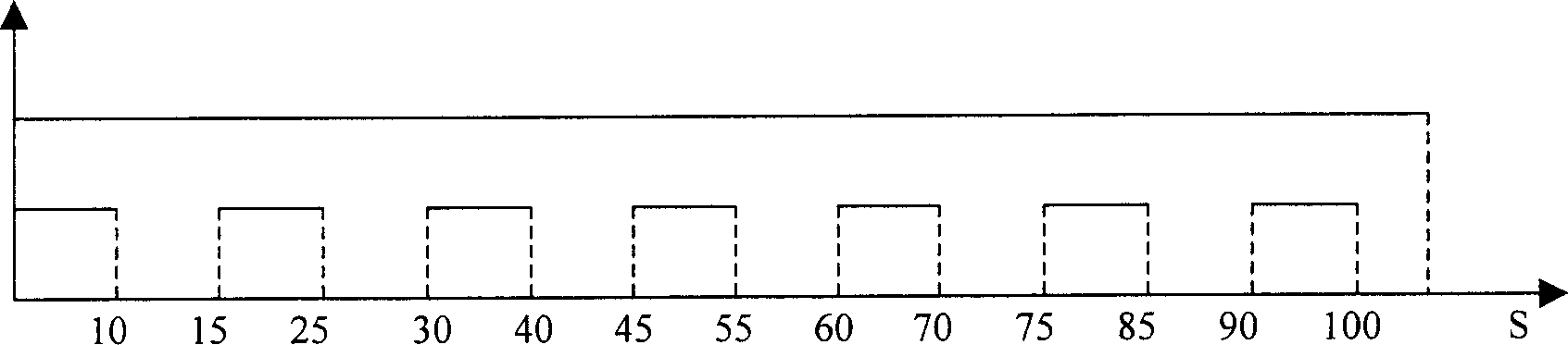

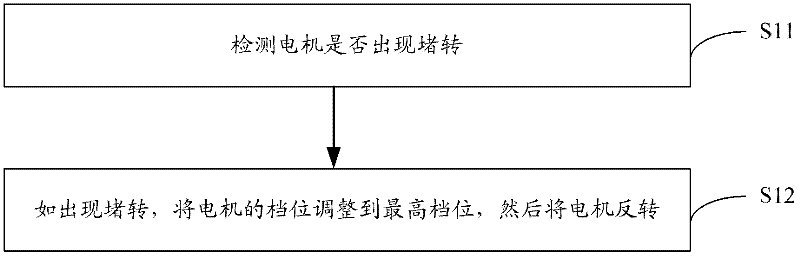

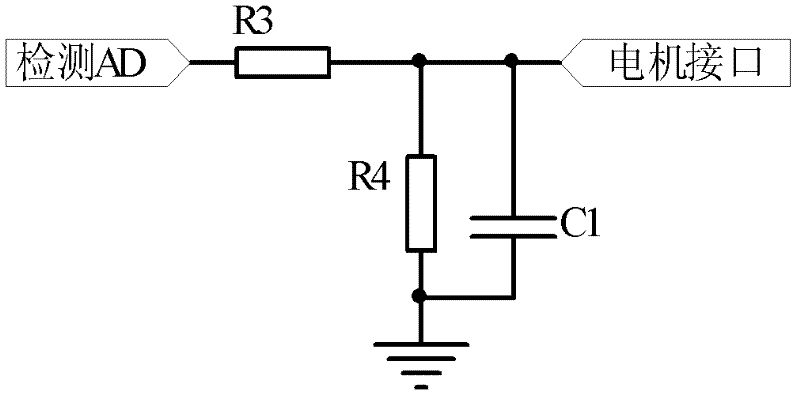

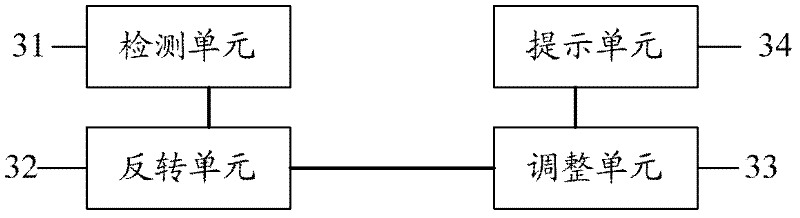

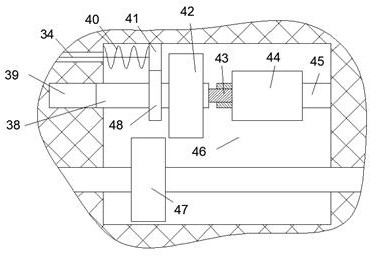

Motor blocking method of massager and massager

ActiveCN102641204AImprove reliabilityEmergency protective circuit arrangementsVibration massageMassageEngineering

The invention is suitable for the electronic field, providing a motor blocking method of a massage and the massager; the method comprises the following steps: the massager detects whether a motor is blocked; if so, the massager regulates gears of the motor to the highest gear, and then enables the motor to rotate reversely. The technical proposal provided by the invention has the advantages that reliability of the massager is increased.

Owner:SHENZHEN BREO TECH CO LTD

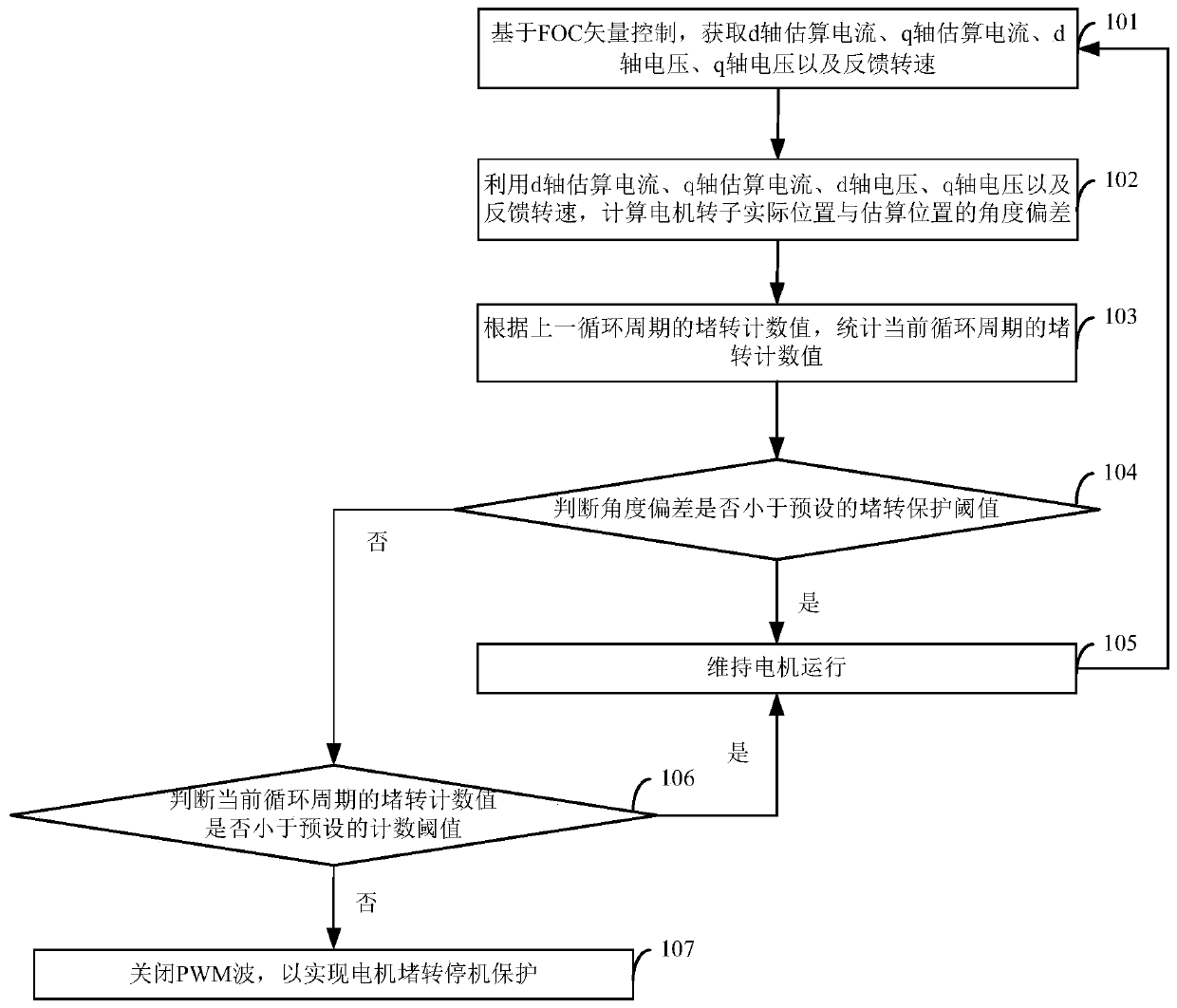

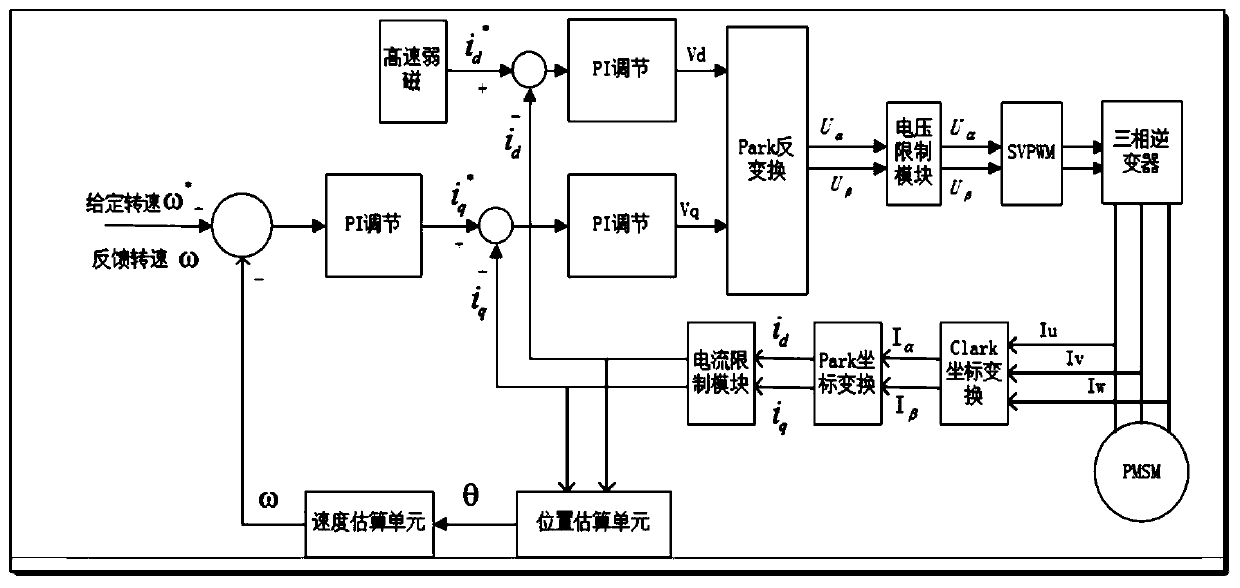

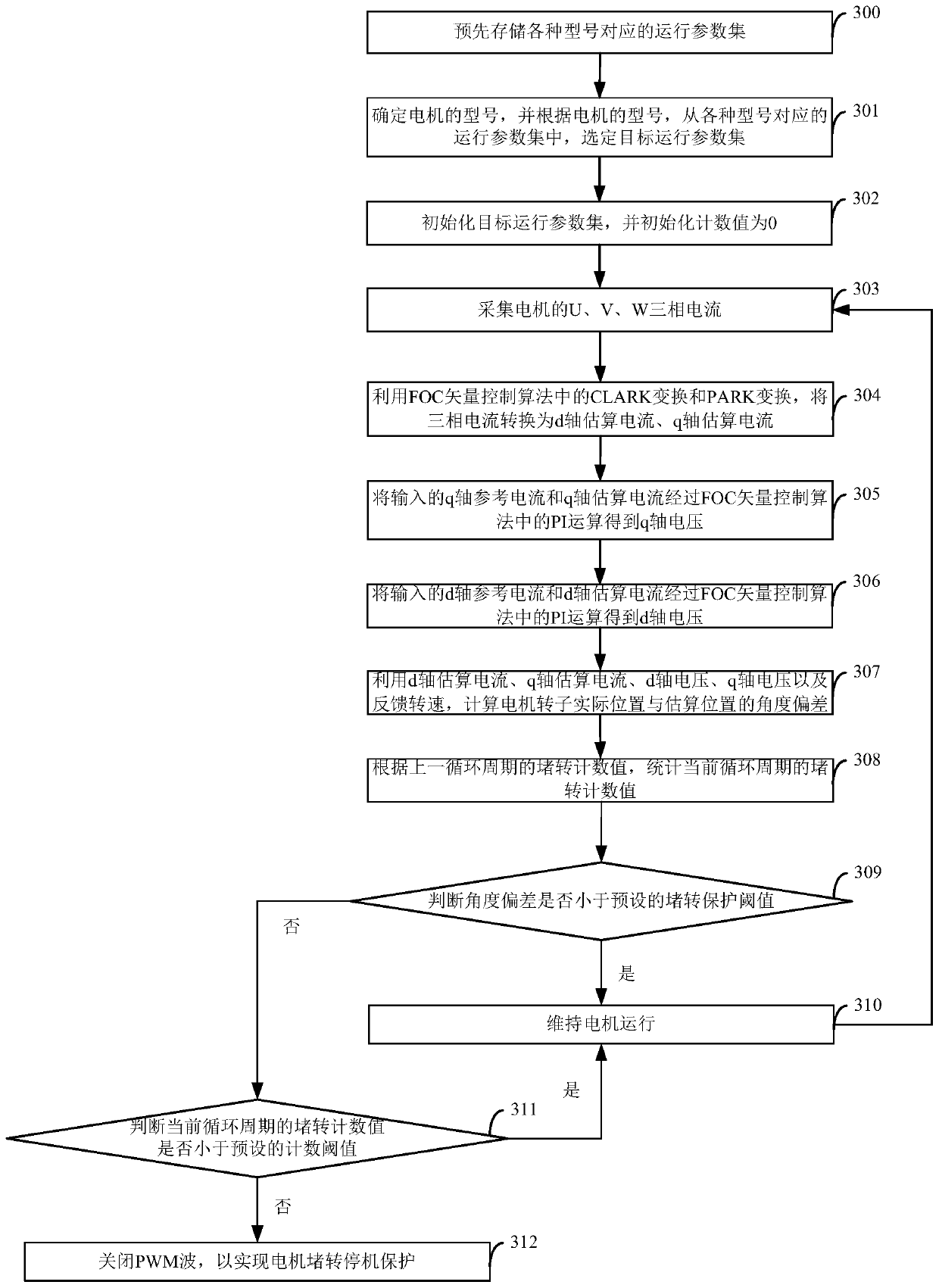

Motor block running protection method and device

ActiveCN110350482AStall protection is effectiveAccurately reflectEmergency protective circuit arrangementsPower flowControl vector

The invention provides a motor block running protection method and device. The motor block running protection method comprises the following steps: circularly executing the following N1 to N4 until the motor stops running; N1: obtaining d-axis estimated current, q-axis estimated current, d-axis voltage, q-axis voltage and feedback speed based on FOC vector control; N2: calculating the angle deviation between the actual position and the estimated position of the motor rotor by using the d-axis estimated current, the q-axis estimated current, the d-axis voltage, the q-axis voltage and the feedback speed; N3: counting the block running count value of the current cycle according to the block running count value of the previous cycle; and N4: turning off the PWM wave when the angle deviation isnot less than the preset block running protection threshold and the block running count value of the current cycle period is not less than the preset count threshold so as to realize the block running shutdown protection of the motor. The scheme can perform more effective block running protection of the motor.

Owner:SICHUAN HONGMEI INTELLIGENT TECH CO LTD

Connecting lock for spacecraft docking

ActiveCN104192323ASimple structureEasy to implementCosmonautic component separationBall bearingCoupling

Owner:HARBIN INST OF TECH

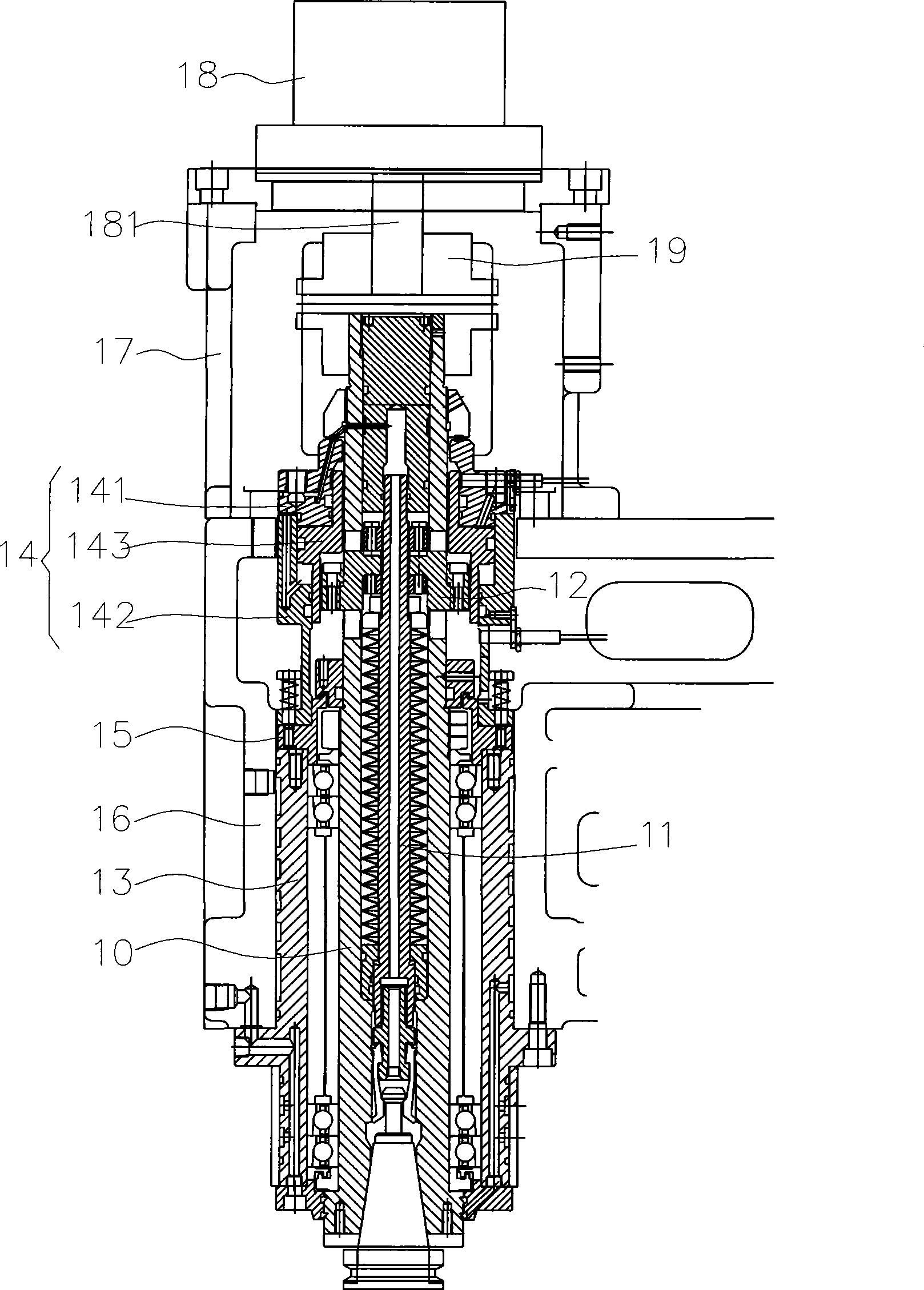

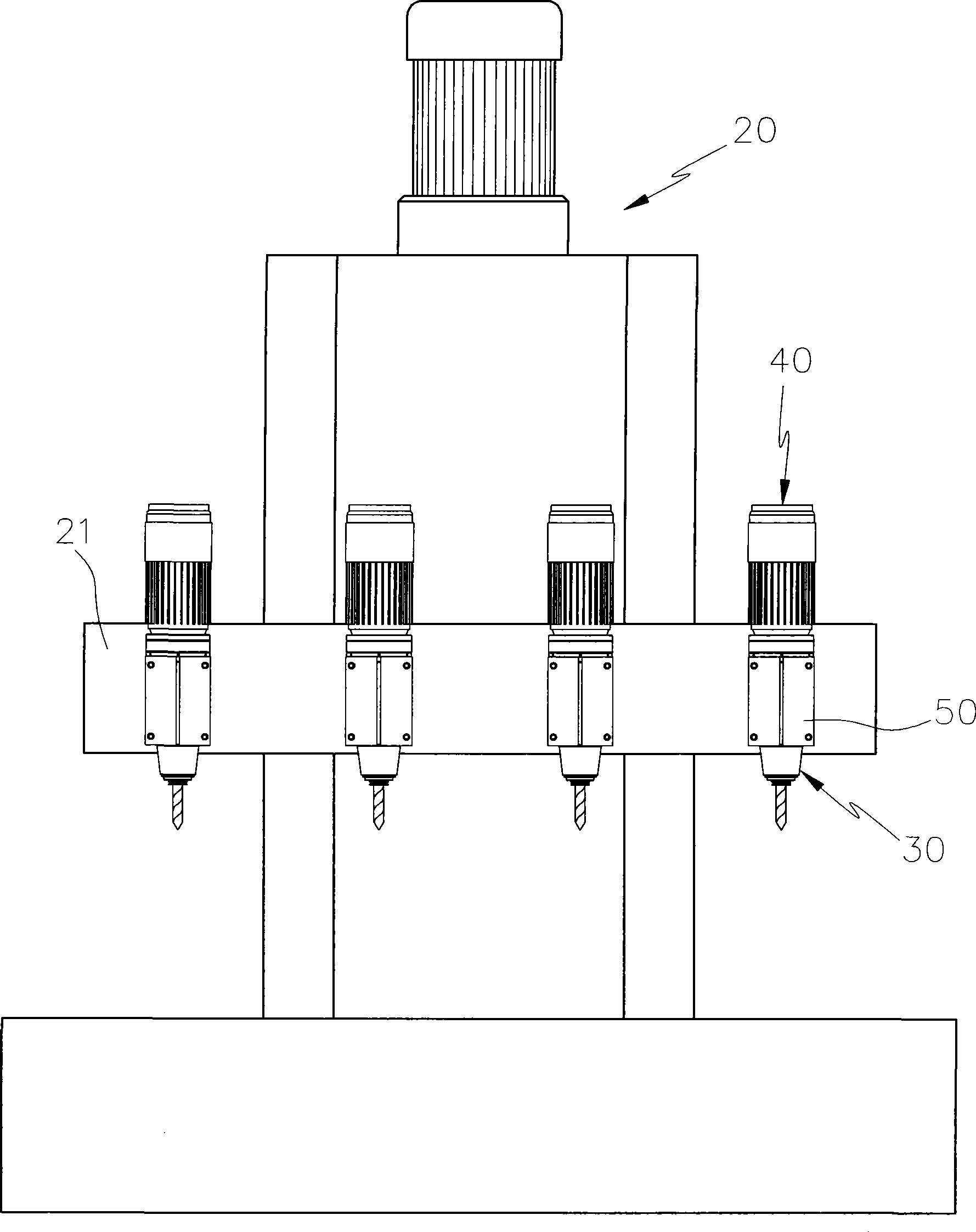

Direct-connecting main spindle for multiple-spindle processor

InactiveCN101468400AReduce volumeLow costPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention relates to a vertical junction main shaft used in a multishaft processing machine, wherein a plurality of the vertical junction main shafts are fixed on a lifting actuated load-bearing frame of the multishaft processing machine; the inside and outside of a rotating shaft of each main shaft are provided with coupled pull rods used to forge a knife and a brake piece; moreover, a sleeve outside each rotating shaft is taken as a pressure cylinder body, and the inside of the sleeve is provided with a piston used to press the brake piece for actuation; a motor seat fixed on the top of the sleeve is taken as a pressure cylinder cover, thereby forming an integral pressure cylinder outside the rotating shaft to drive the pull rod to carry out knife forging and grasping operations; the motor seat can be taken as a hydraulic adapter or an air-pressure adapter for assembling a tube body; in addition, a rotary shaft of the motor is provided with a shaft sleeve to connect the rotating shaft of each main shaft. Thus, the volume of vertical junction main shafts assembled on the multishaft processing machine can be reduced to save cost, and the rotating shaft of each main shaft can realize smooth rotation and actuation to improve processing quality; moreover, the motor seat has different use efficiencies to improve use convenience.

Owner:SPINDER TECH

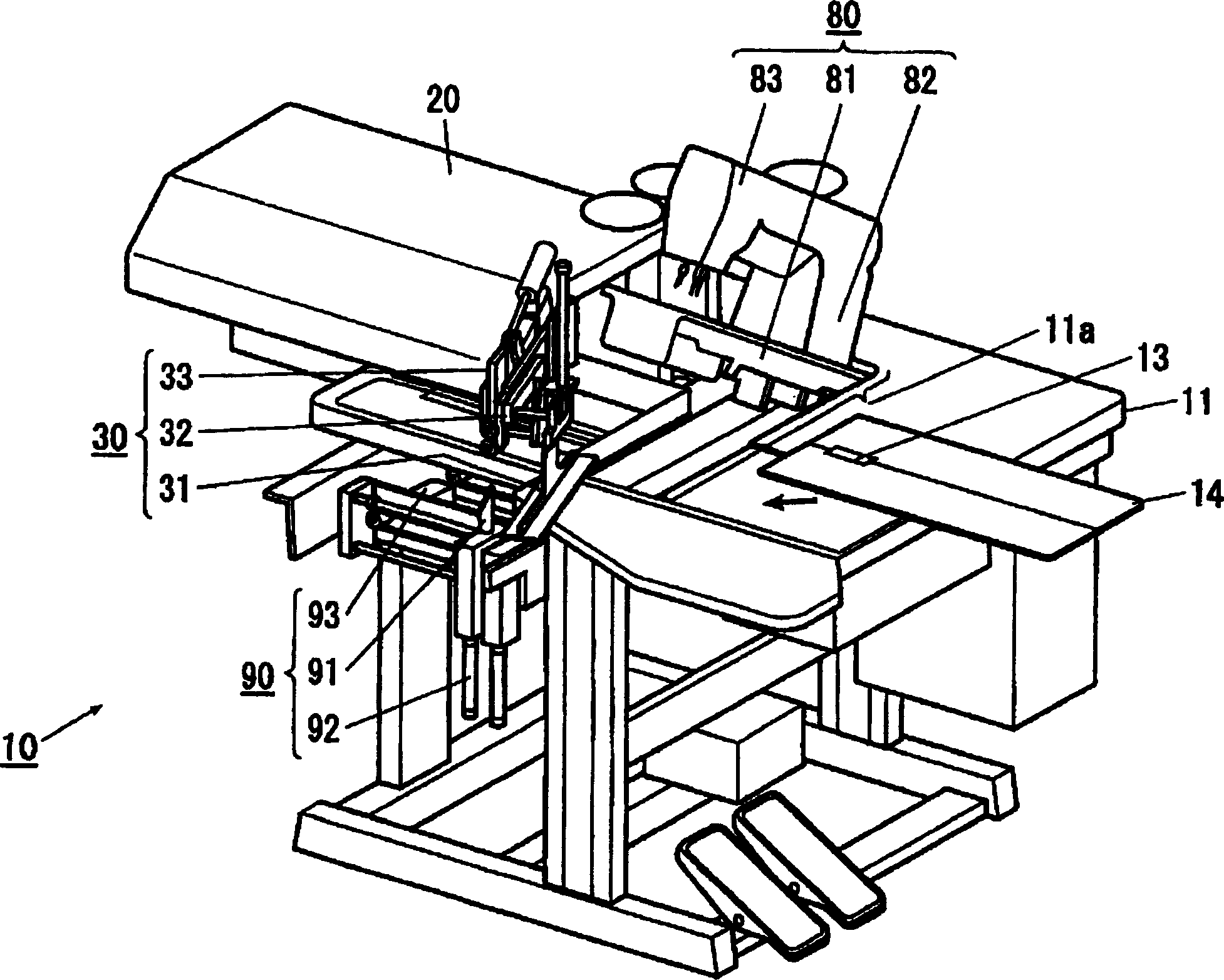

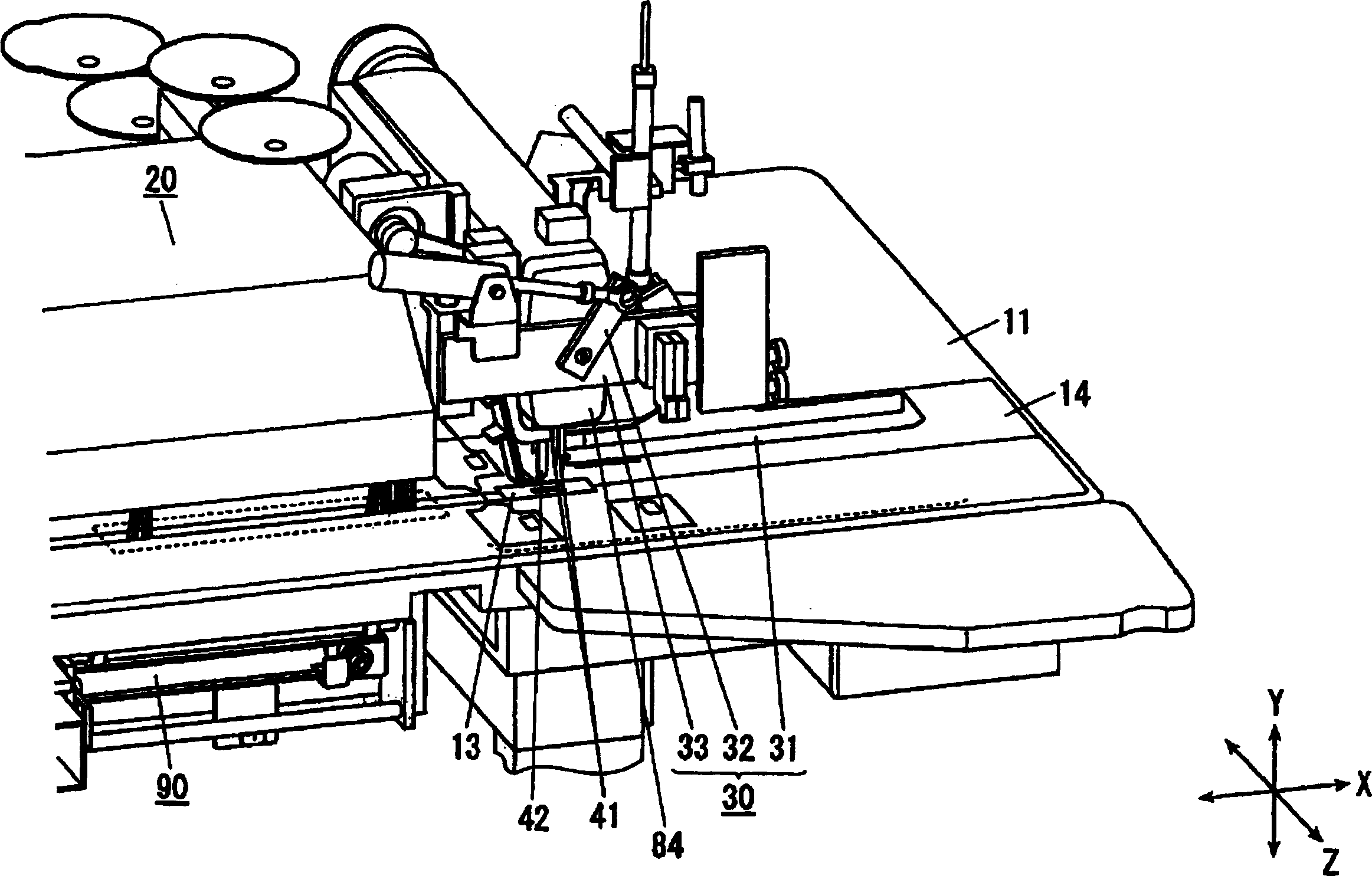

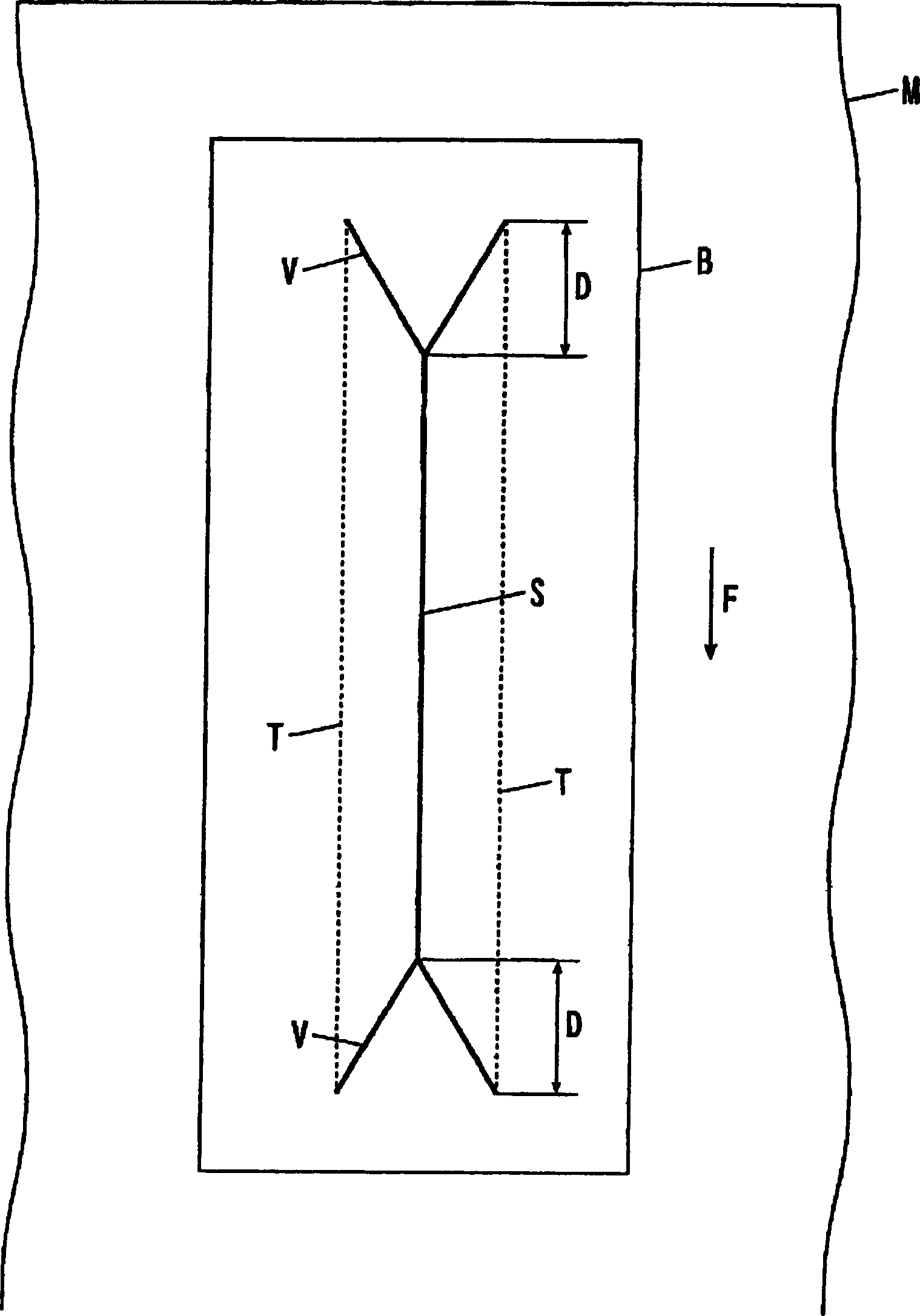

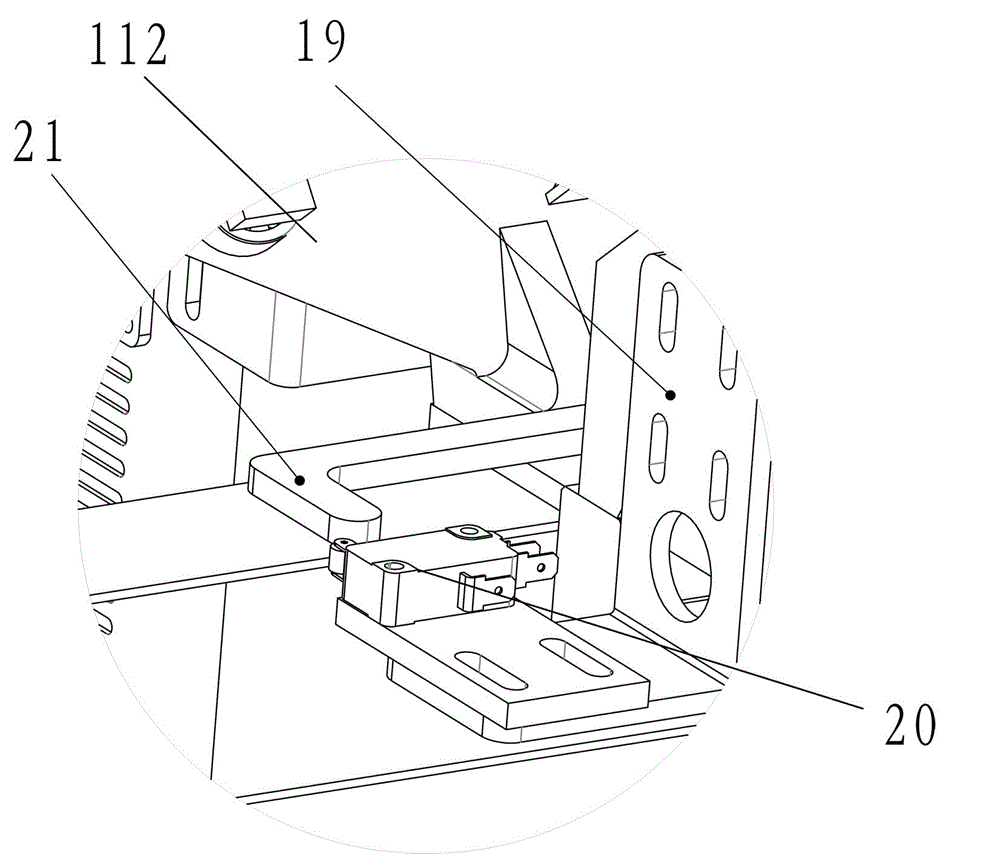

Inserting strip sewing machine

ActiveCN1800476AEliminates restrictions on tipping directionMiniaturizationWorkpiece carriersWork-feeding meansBobbinEngineering

To restrain a bad effect of throwing down a sewing machine frame forward. This binding sewing machine comprises: a needle vertical motion mechanism for moving up and down a sewing needle 41; a shuttle mechanism for entangling a sewing thread passed through the sewing needle in a bobbin thread; a driving motor 15 serving as a driving source of the needle vertical motion mechanism and the shuttle mechanism; a sewing machine frame 80 holding the respective components; and a table 11 holding the sewing machine frame in its placed state, wherein an output shaft of the driving motor is directly connected to one end part of a lower shaft, a motor block 85 holding the driving motor is fixed and mounted on the lower side of the end of a vertical cylinder part 82 side of the sewing machine frame, and the motor block 85 is provided with a support shaft 86 rockably supporting the sewing needle side end part of the sewing machine frame to move up and down.

Owner:JUKI CORP

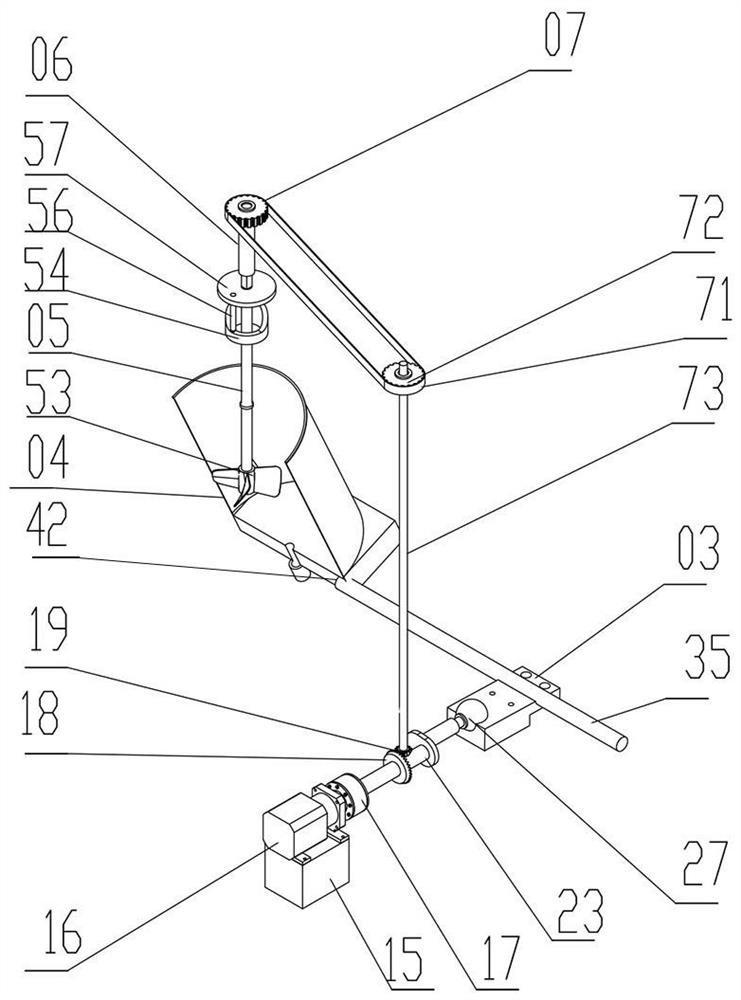

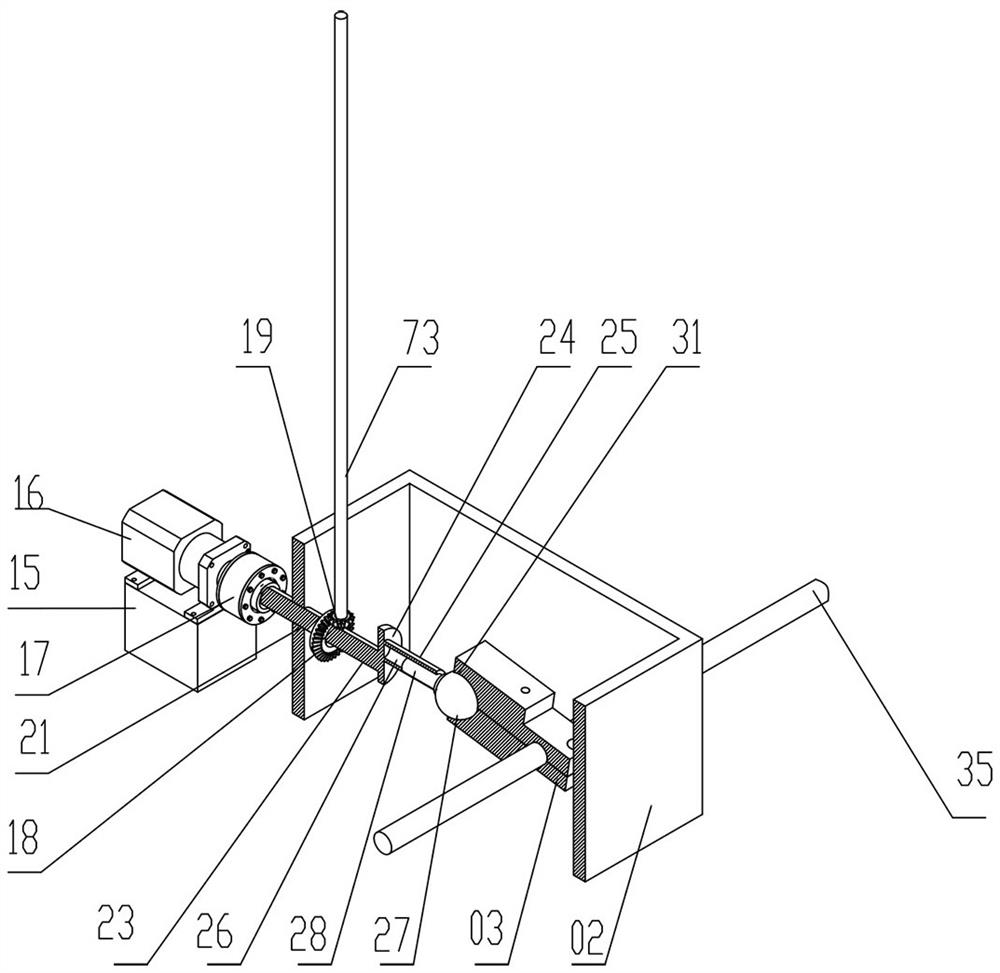

Rotary speed and opening degree double-adjustment device for fertilizer discharging shaft of variable fertilizer applicator

InactiveCN104380897AIncrease or decrease effective working lengthReduce the effective working lengthFertiliser distributersAgriculture gas emission reductionAgricultural engineeringControl theory

The invention relates to a rotary speed and opening degree double-adjustment device for a fertilizer discharging shaft of a variable fertilizer applicator. The rotary speed and opening degree double-adjustment device comprises a rack, a rotary speed adjusting mechanism, an opening degree adjusting mechanism and fertilizer discharging devices, and is characterized in that the rotary speed adjusting mechanism is arranged at the right side of the rack; the opening degree adjusting mechanism is arranged at the left side of the rack; and the fertilizer discharging devices are uniformly distributed between the rotary speed adjusting mechanism and the opening degree adjusting mechanism according to specific farmland plant planting line spacing and the width of the variable fertilizer applicator. The rotary speed adjusting mechanism is composed of a rotary speed motor, a rotary speed motor seat, a rotary speed sleeve, a rotary speed shaft coupler, a supporting bearing, a rotary speed connection piece and a spline; the opening degree adjusting mechanism is composed of an opening degree motor, an opening degree motor seat, an opening degree sleeve, an opening degree shaft coupler, an opening degree connection piece and a rotary bearing; and each fertilizer discharging device is composed of a fertilizer discharging box, a groove wheel, a fertilizer discharging stopping shaft, a clamping device and a follow-up baffle. The adjustment device can be used for adjusting the rotary speed and the opening degree of a fertilizer discharging main shaft at the same time so that the working efficiency is improved, and the influences in fertilization uniformity, caused by fertilizer discharging pulsatility in a fertilizer discharging process are reduced.

Owner:SHIHEZI BOLI ELECTROMECHANICAL TECH

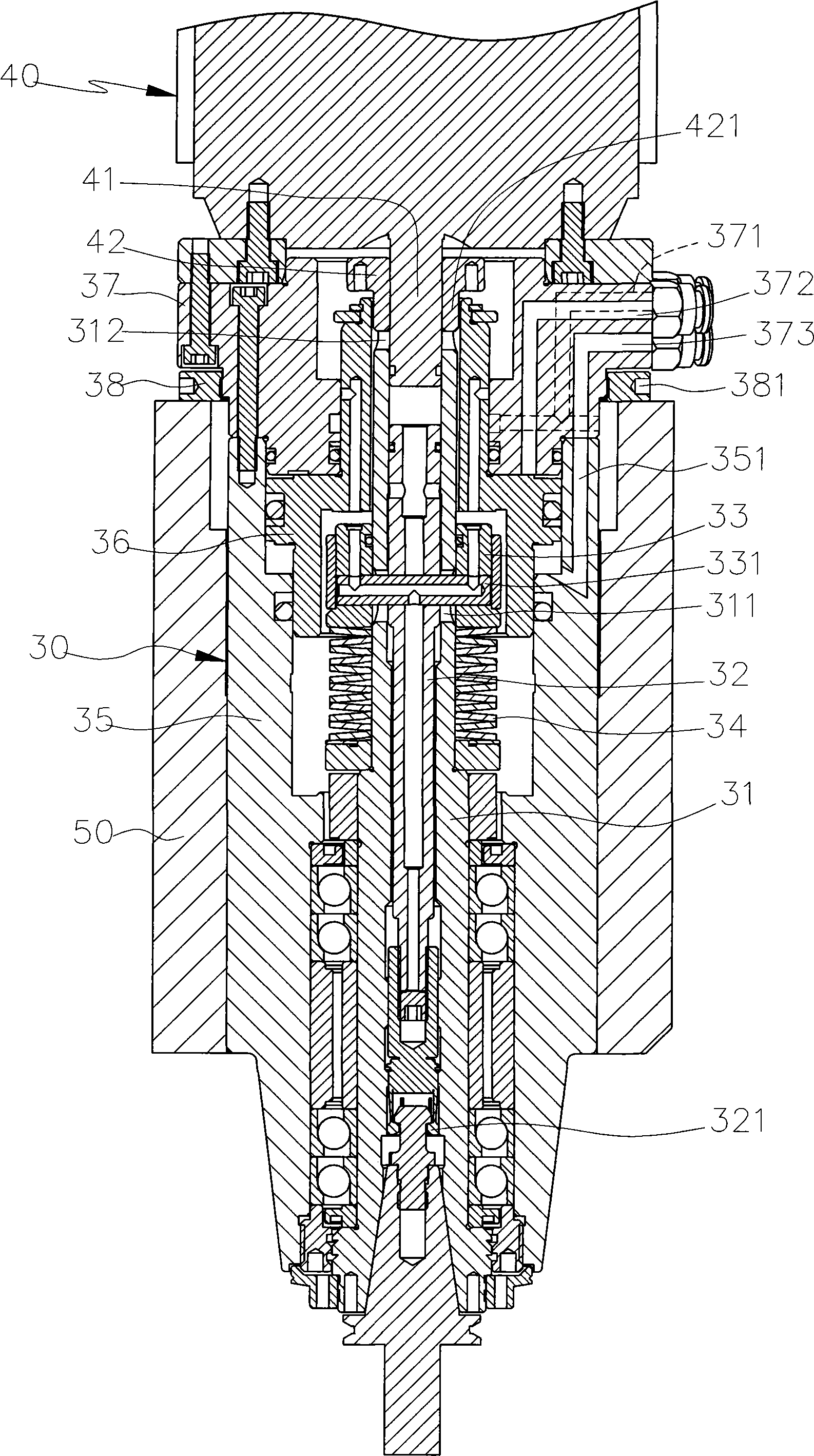

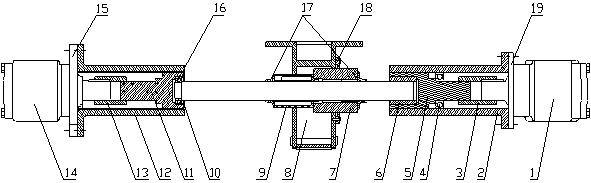

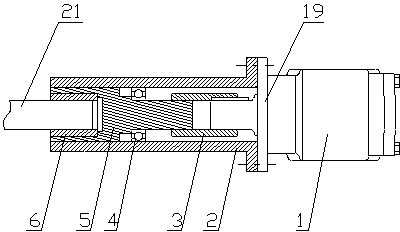

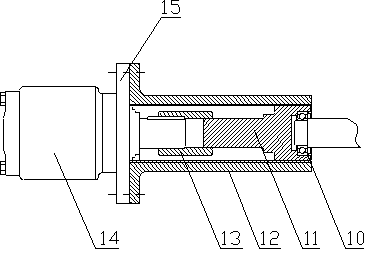

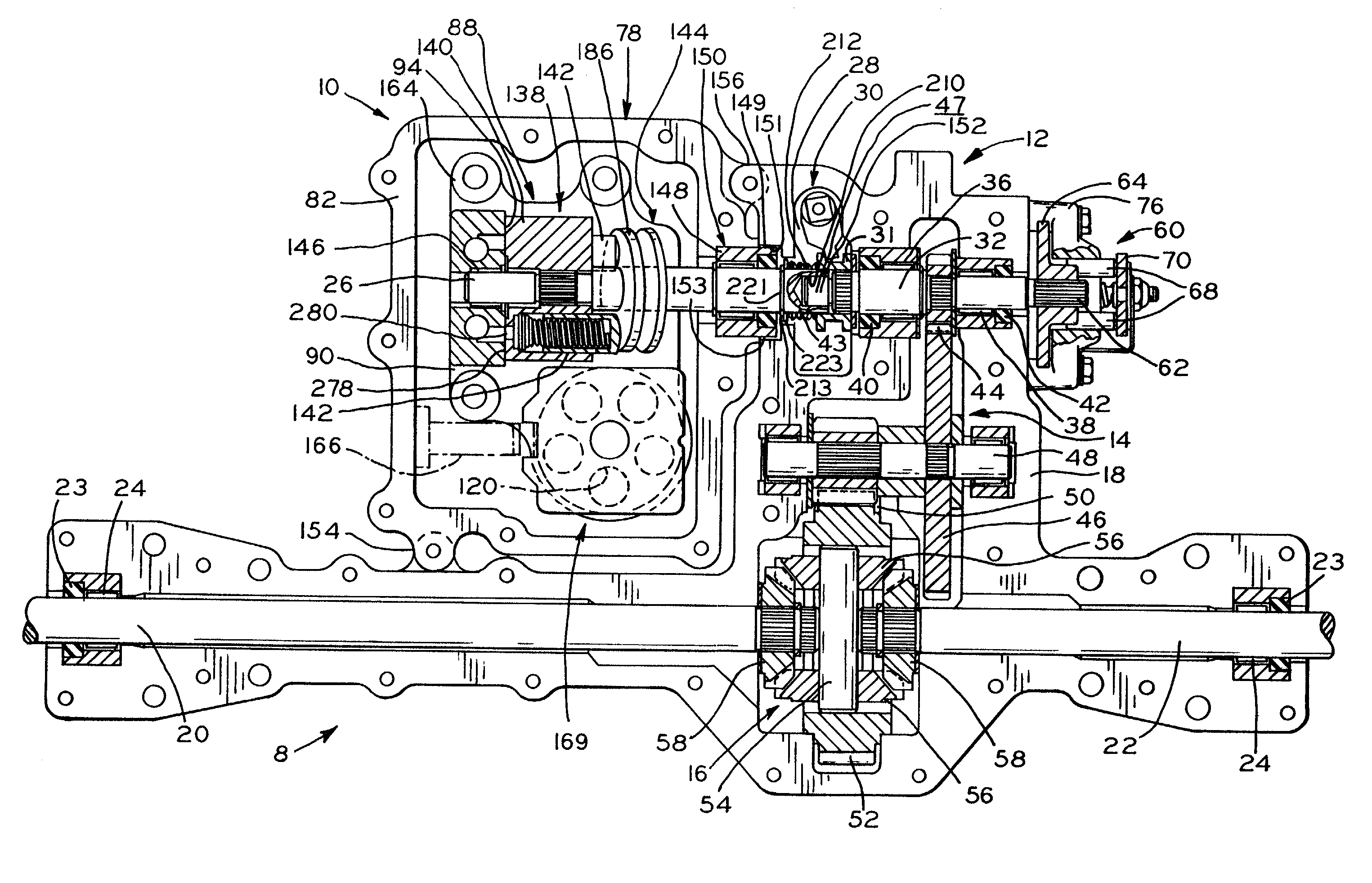

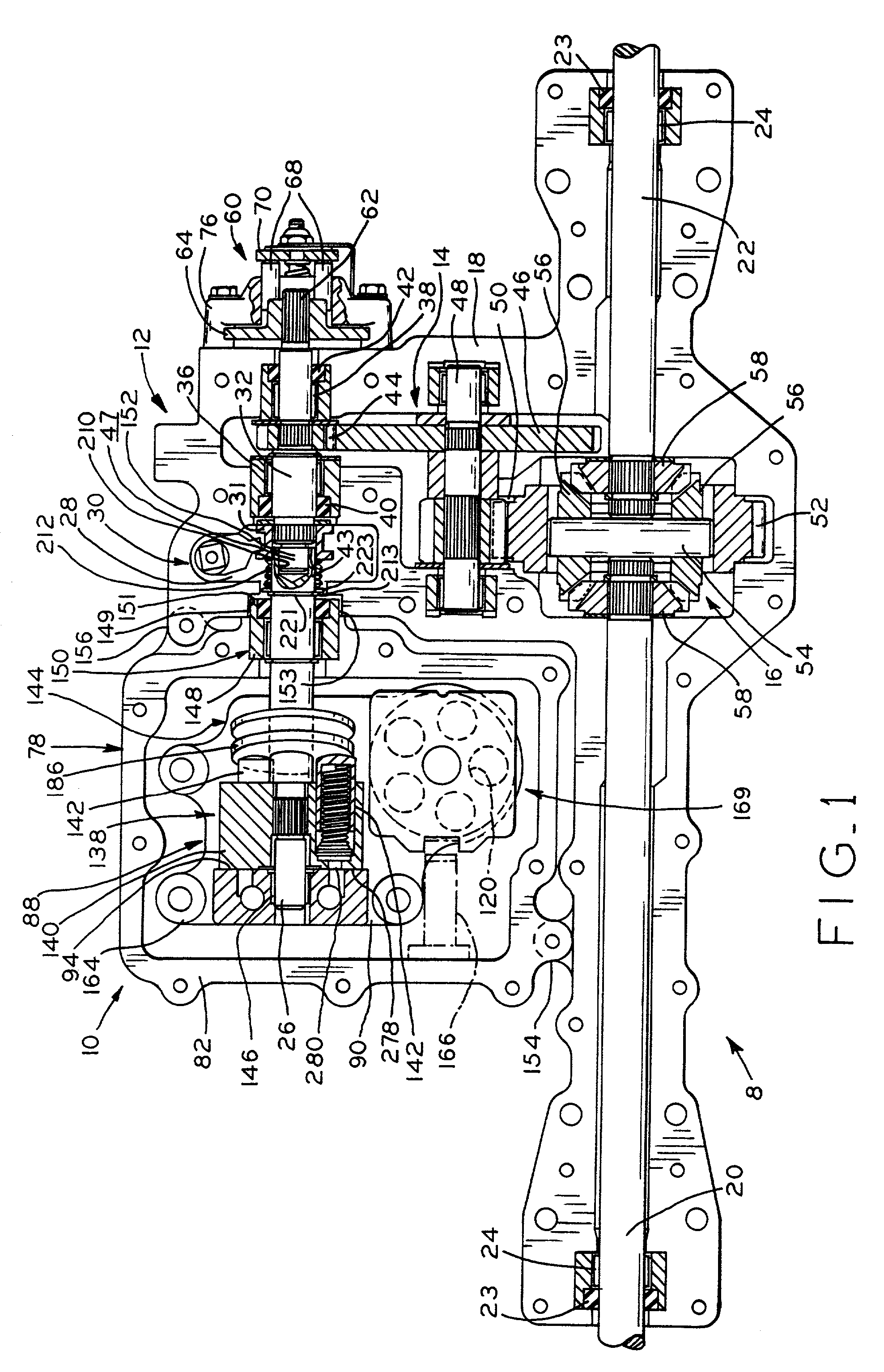

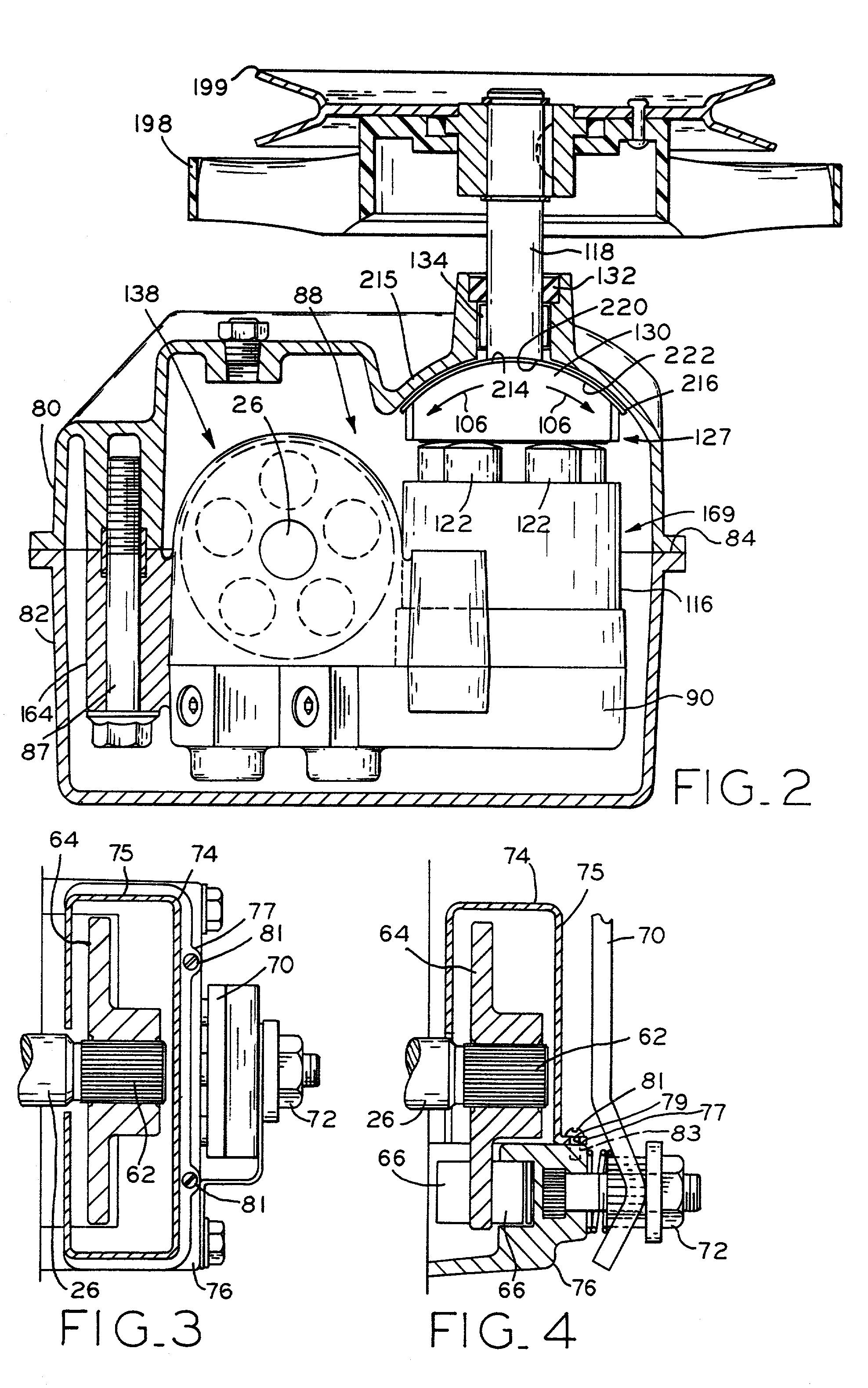

Hydrostatic transaxle having axial piston motor and method for manufacturing transaxles

InactiveUS20020128108A1Minimal downtimeEasy to removeGearboxesGear lubrication/coolingThrust bearingEngineering

A modular hydrostatic transaxle includes an axle module removably connected to a hydrostatic transmission module. The axle module includes a differential connected to a reduction gear train and disposed in an axle casing. A pair of axles are connected to the differential and supported within the axle casing. The hydrostatic transmission module comprises a transmission casing separate from the axle casing and hydraulically connected pump and motor disposed in the transmission casing. The motor output connection includes a shaft piloted to an input drive of the reduction gear train, which constitutes the alignment mechanism of the transmission and axle modules. The pump and motor cylinder barrels are hydraulically connected through the pump and motor block at 90.degree. orientation, and a portion of the pump and motor block forms an inclined surface which supports a face of a thrust bearing. At least one homogeneous low friction bearing strip is confined between the swash plate and the interior portion of the casing. A disconnect mechanism includes a spring that urges a sleeve to engage the output and input shafts. The brake disc is disposed on a distal end of the output shaft and a brake cover is fastened to the outer portion of the axle casing and substantially encloses the brake disc.

Owner:HUSQVARNA AB

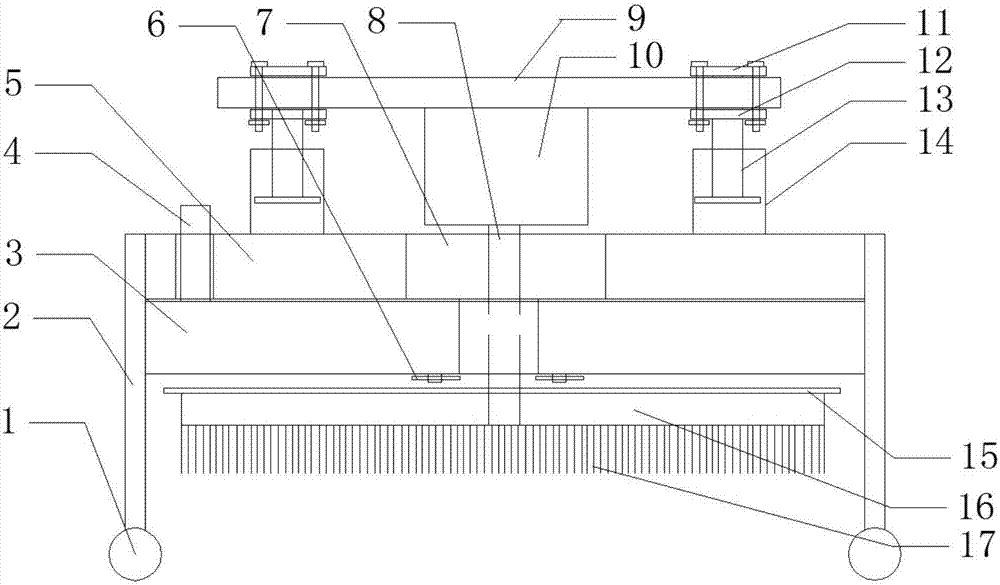

Defective board sorting device

InactiveCN107716347AGuaranteed vertical forceWon't touch by mistakeOther workshop equipmentSortingEngineeringConveyor belt

The invention provides a defective board sorting device which comprises a rack, a delivery mechanism, a detecting mechanism and a sorting mechanism. The detecting mechanism is arranged on the deliverymechanism, and the sorting mechanism is arranged on the upstream position of the detecting mechanism and horizontally arranged on a conveyor belt in a crossing mode; the sorting mechanism further comprises delivery wheels which are arranged on supports, the delivery wheels on one side are connected with a motor, and a belt is arranged between the delivery wheels on the two sides; a sorting push block is arranged on the surface of the belt, and an interval between the bottom of the sorting push block and the delivery mechanism is smaller than the thicknesses of boards; and when the belt is driven by the motor to move, the sorting push block can push the boards below the sorting mechanism from the side face, and the boards can be removed from the delivery mechanism. Compared with the priorart, the defective board sorting device has the remarkable advantages and the beneficial effects that when the defective boards are sorted from the delivery mechanism, it can be ensured that the boards are perpendicularly stressed, and the adjacent boards cannot be collided mistakenly; and the sorting mechanism is obliquely arranged, the pushing block can move along with the boards, and the defective board sorting device is suitable for high-speed conveyor belts.

Owner:湖州市新庭吉家居科技有限公司

Cleaning and maintenance device for computer hardware

InactiveCN107661875AConvenience to workReduce work intensityCleaning using toolsCleaning using gasesGear wheelDetent

The invention discloses a cleaning and maintenance device for computer hardware. The device comprises a case body, two first fixing rods are fixedly connected to the upper surface of the inner wall ofthe case body, and the opposite surfaces of the two first fixing rods are fixedly connected with the left surface and the right surface of a first driving device respectively; the first driving device is meshed with a second gear, a rotation shaft is clamped to the inner surface of the second gear, and a first bearing, a second bearing and a third bearing are in sleeving connection with the surface of the rotation shaft; the first bearing is clamped to the upper surface of the inner wall of the case body, and the second bearing is clamped to the upper surface of the case body. According to the cleaning and maintenance device for computer hardware, through cooperation of a third electric push rod, a first extruding plate, a second extruding plate, a telescopic rod, a spring, a second electric push rod, a second motor and a wiping block, work of workers is facilitated, the working intensity of the workers is lowered, and the working efficiency of the workers is improved.

Owner:成都吉尼尔斯科技有限公司

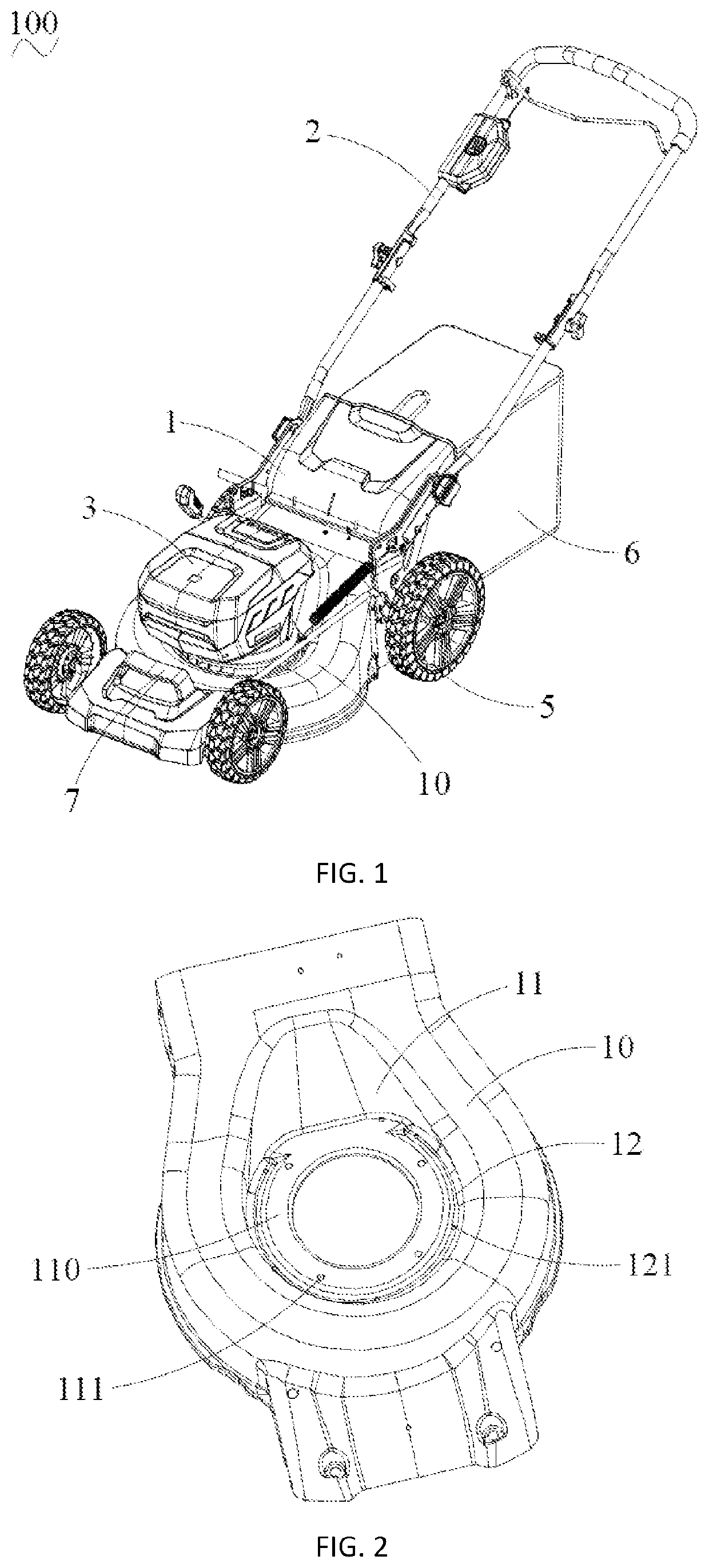

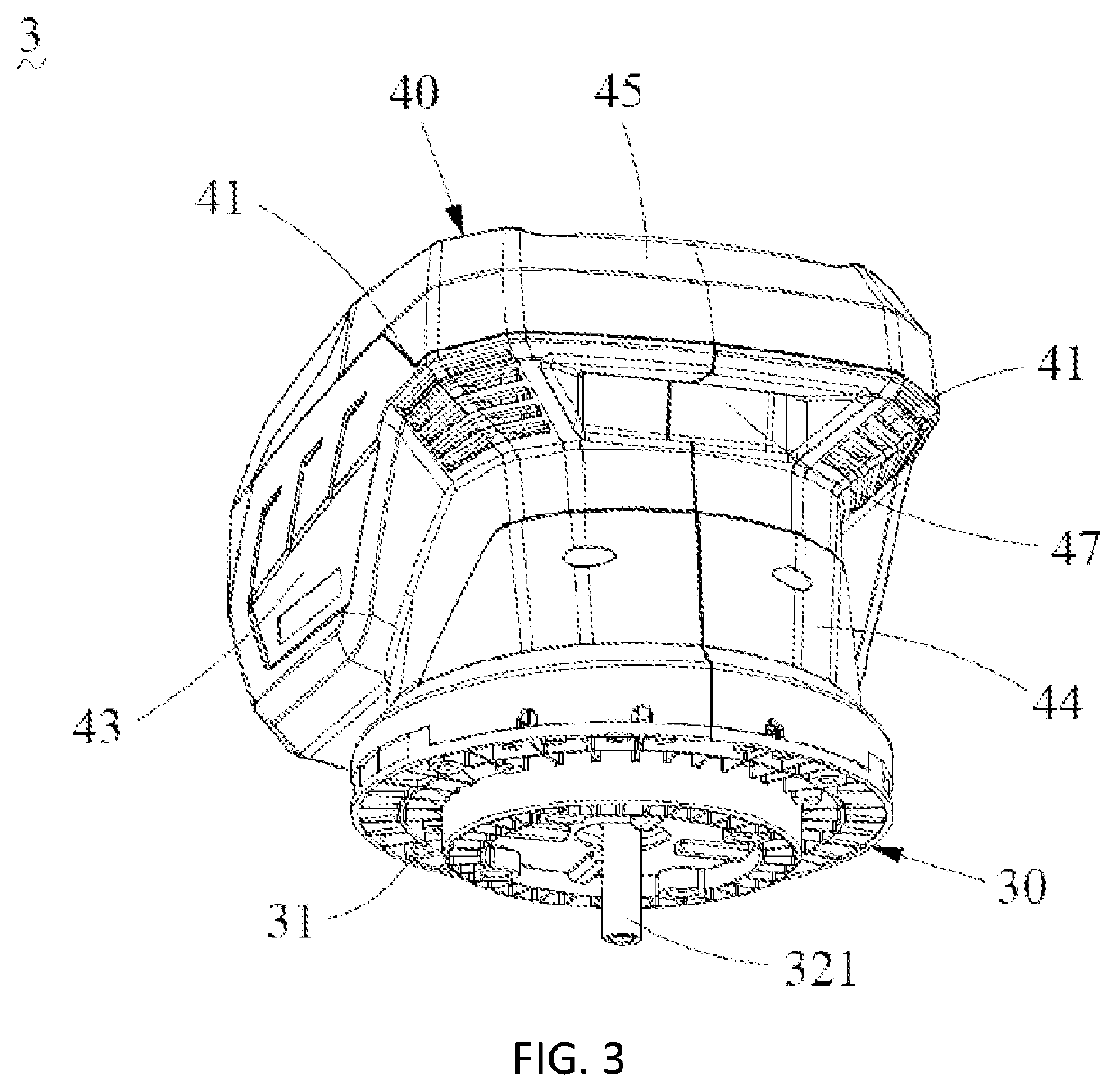

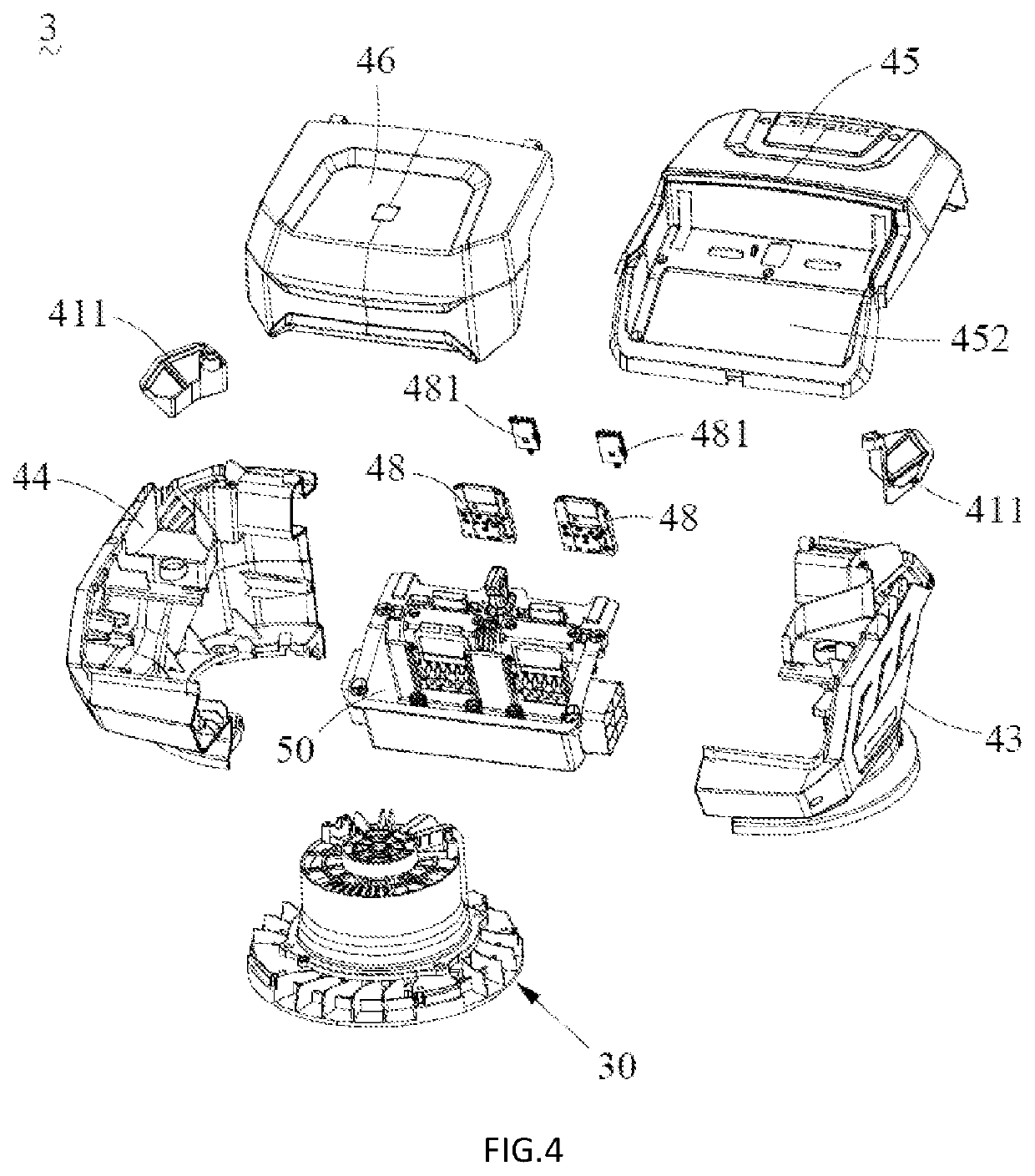

Power head and lawn mower

The invention provides a power head and a lawn mower. The power head comprises a motor assembly, an energy device and a housing. The motor assembly comprises a motor base and a motor fixed on the motor base. The housing assembly comprises a casing that is assembled with the motor base. The top of the casing is provided with an air inlet that is inclined backward and downward and an air inlet cavity connected to the air inlet. The air inlet and the air inlet cavity are provided with two. The air inlet cavity is a U-shaped structure with an upper opening, and the casing covers the top of the air inlet cavity to form a sealed airflow passage.

Owner:GLOBE (JIANGSU) CO LTD

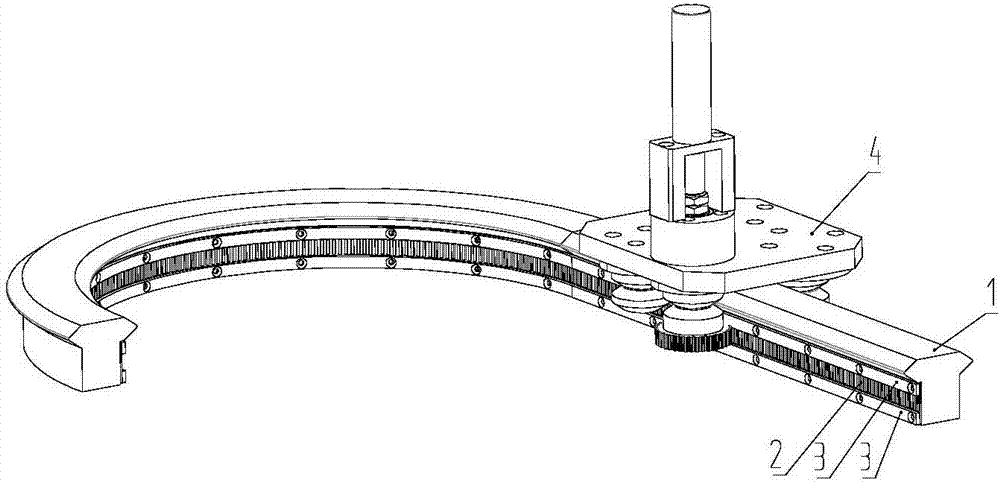

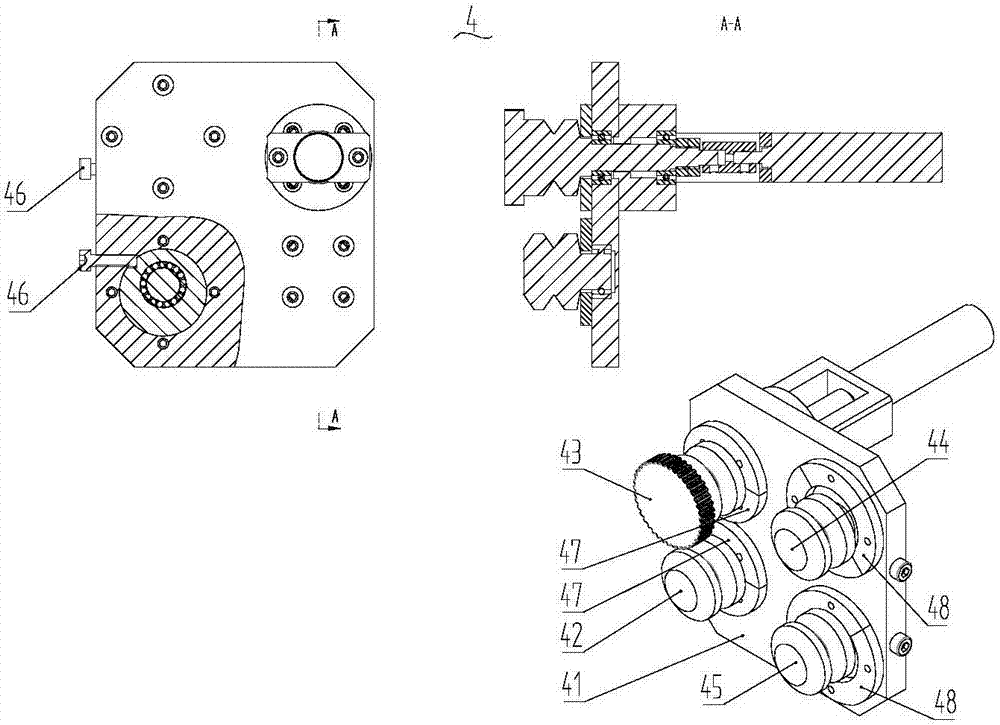

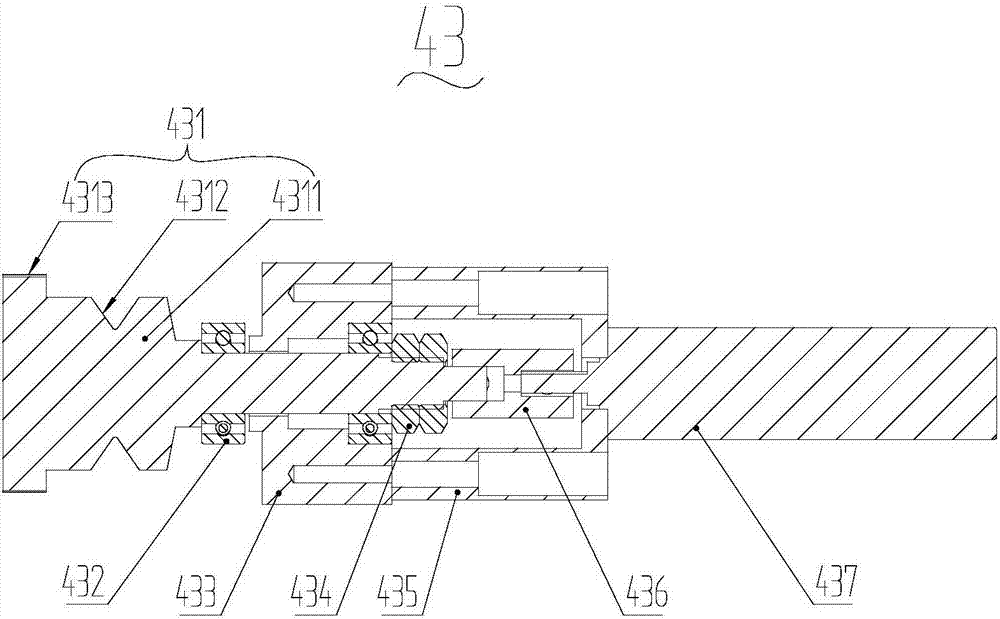

Curve orbit system with sliding blocks having independent driving force

Owner:FOSHAN GONGXIN PRECISION MACHINERY CO LTD

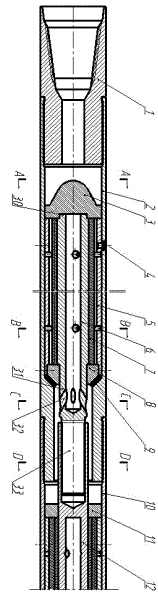

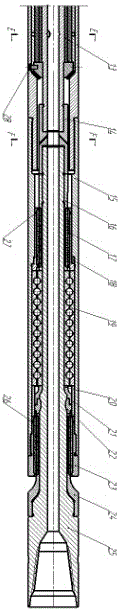

Coaxial all-metal cam stator and rotor underground dynamical drilling tool

Owner:XI'AN PETROLEUM UNIVERSITY

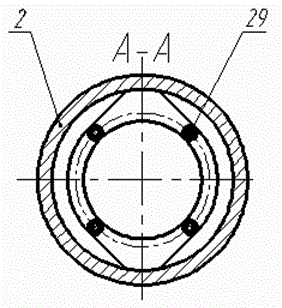

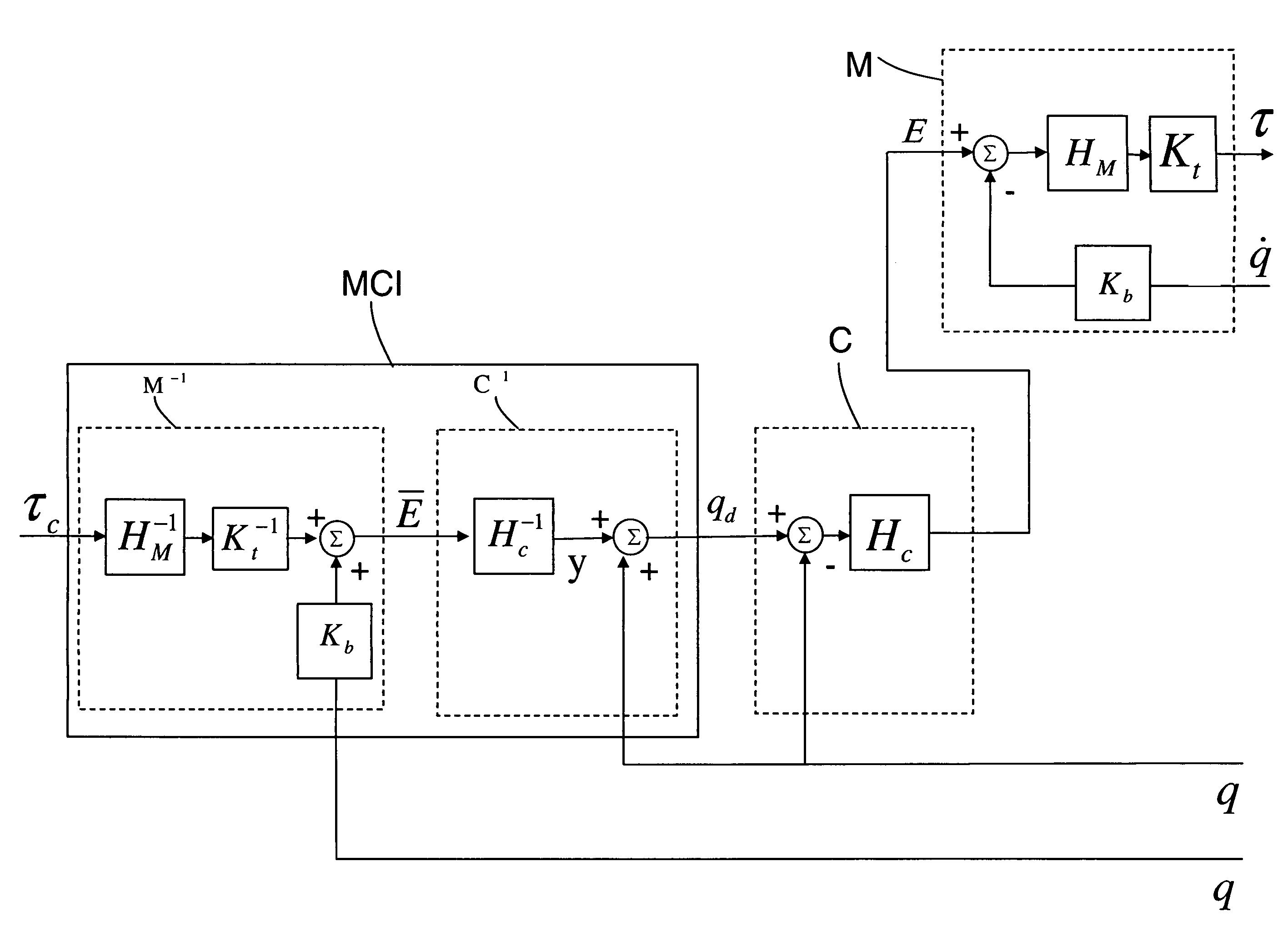

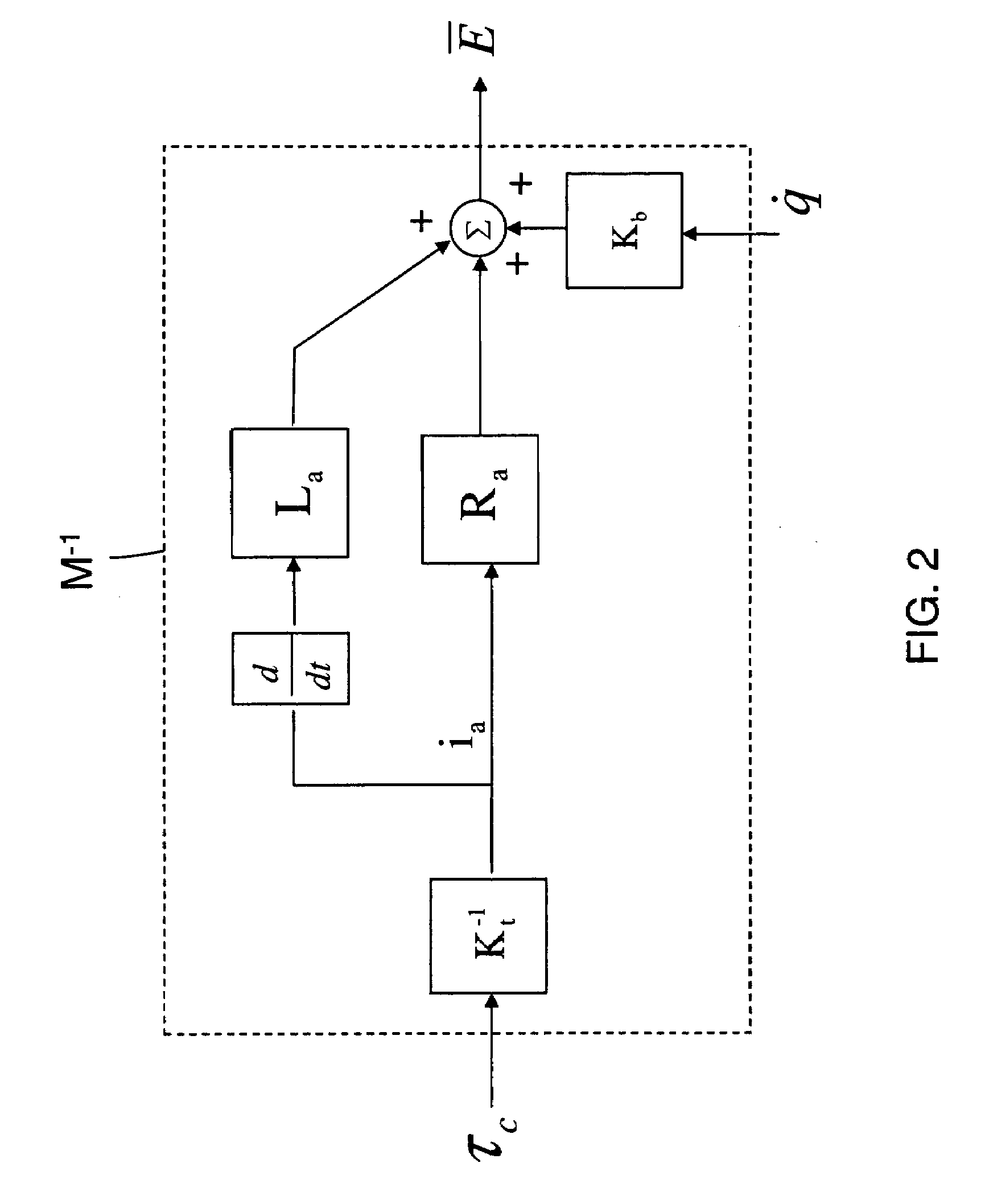

Motor and controller inversion: commanding torque to position-controlled robots

ActiveUS7355364B2Cancellation effectProgramme controlProgramme-controlled manipulatorRobotic systemsMeasuring output

Systems and methods are presented that cancel the dynamics of a motor and a joint controller in the presence of communication time delays, measurement noise, and controller parameter uncertainties inherent in a robot system. A cancellation system includes feedback of the measured output Ê of a controller block C. A first summing node (Σ1) subtracts Ê from the desired voltage Ed to determine a voltage error, which is fed into a G(s) block. A second summing node (Σ2) adds the output of the G(s) block to the desired voltage Ed to generate the signal Ē, which is fed into a non-robust controller inversion block C−1. The block C−1 outputs a value μ, which is fed into the block C. The block C outputs the actual voltage E, which is input into a motor block M. Under perfect conditions, the voltage error is zero, in which case the input to block G(s) is zero.

Owner:HONDA MOTOR CO LTD

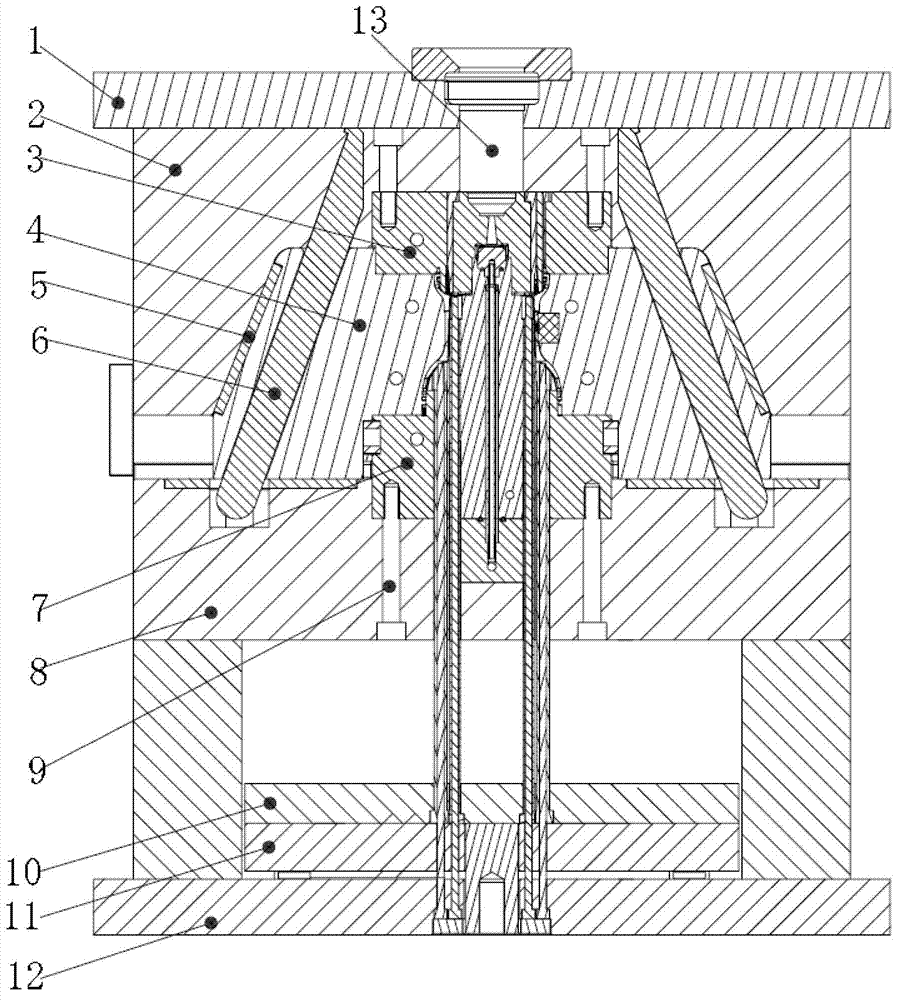

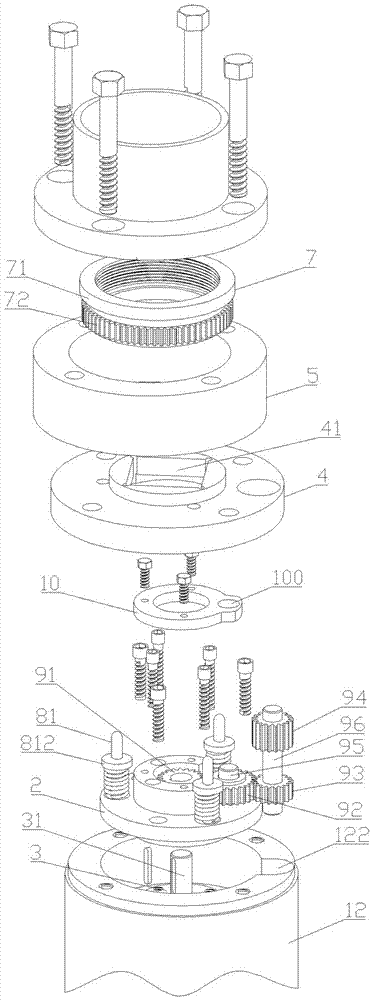

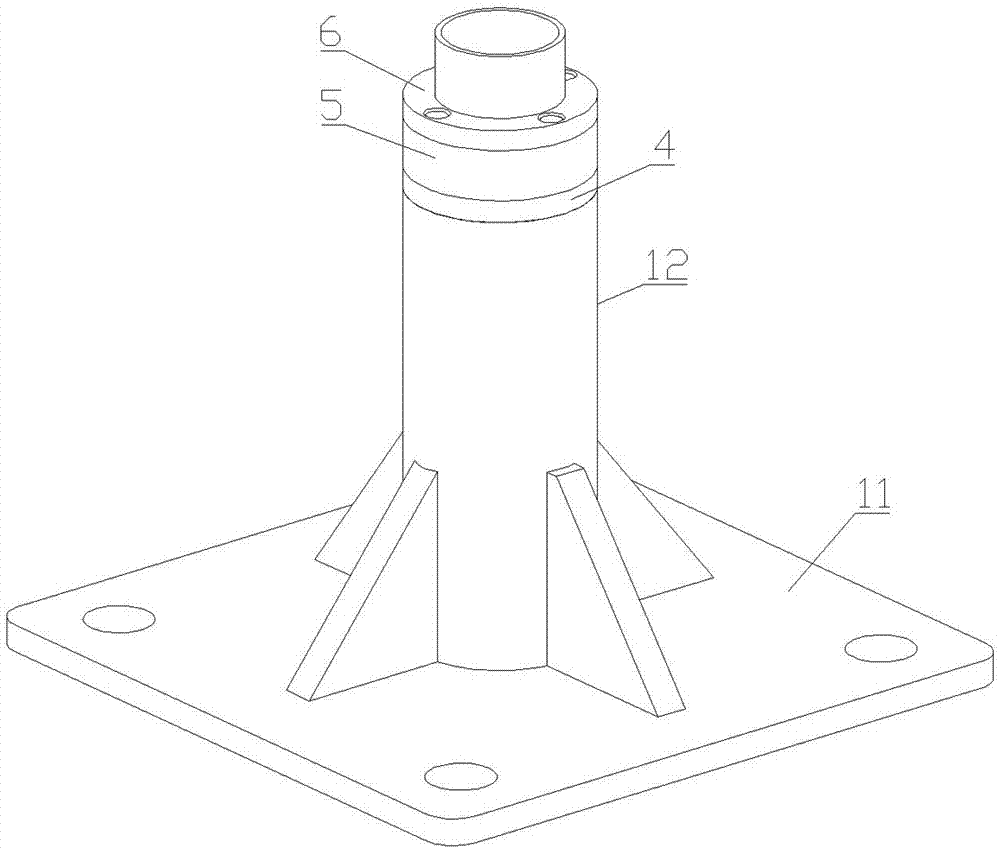

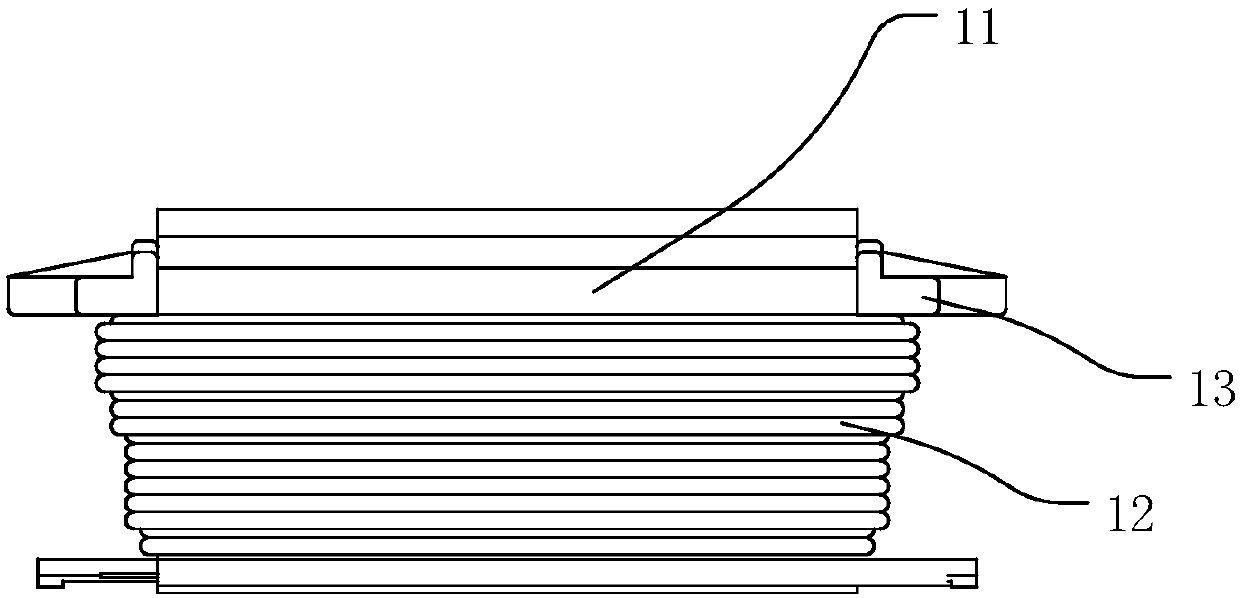

Motor seat mould of electric tool

The invention relates to a motor seat mould of an electric tool, comprising fixing plates, moulds, guide columns, thimble plates and a nozzle, wherein a lower thimble plate (11) and an upper thimble plate (10) are arranged above a lower fixing plate (12) from bottom to top; a male mould (8) is arranged above the upper thimble plate (10) and a female mould (2) is arranged on the male mould (8); an upper fixing plate (1) is arranged on the female mould (2); inclined guide columns (6) are arranged in cavities of the female mould (2) and the male mould (8) in a bilateral symmetry manner; slide blocks (4) are mounted on the inclined guide columns (6) and a male mould core (7) is mounted in a cavity formed below the slide blocks (4) by the male mould (8); a female mould core embedding piece (3) is mounted in a cavity formed above the slide blocks (4) by the female mould (2); and the central position of the upper end of the female mould core embedding piece (3) is communicated with a hot nozzle (13) on the upper fixing plate (1). According to the motor seat mould of the electric tool, the accuracy of the size, and the concentricity and the roundness of a stator can be guaranteed.

Owner:KUSN TUOAN PLASTIC PRODS

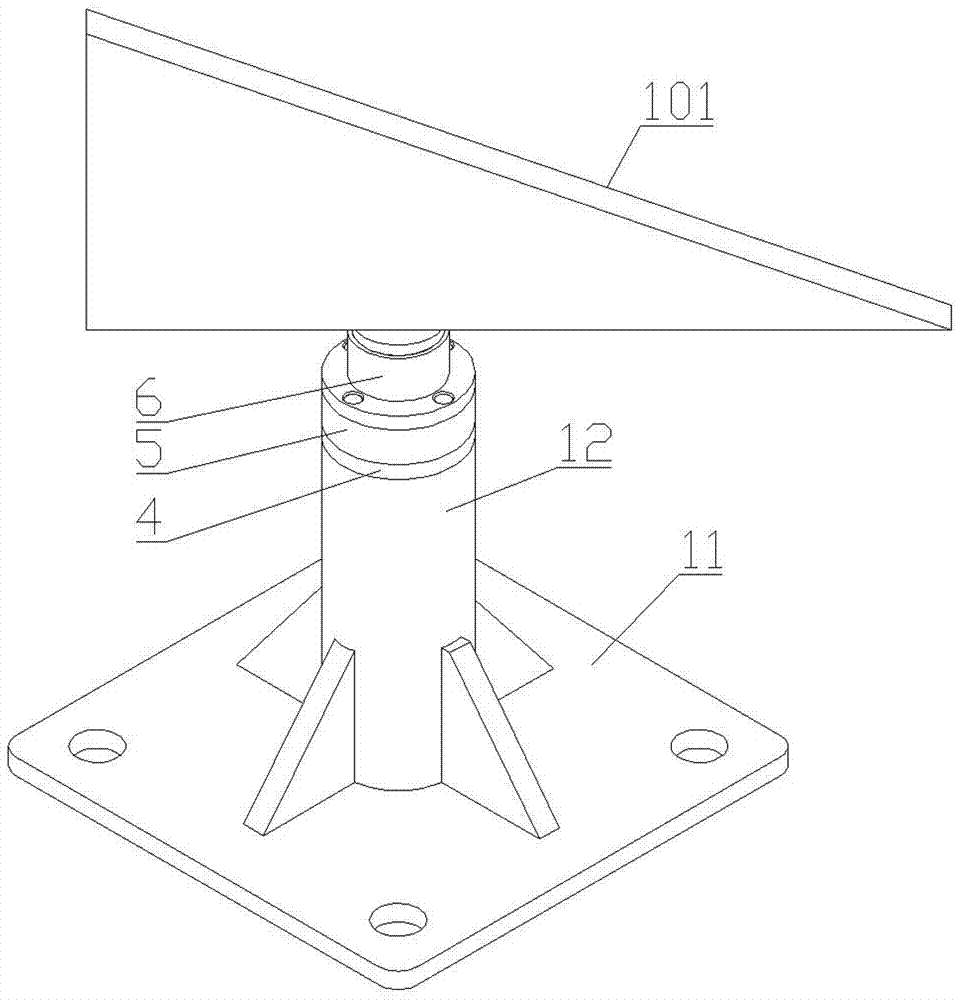

Automatic clamping clamp for aerial rudder grinding machining

The invention relates to an automatic clamping clamp for aerial rudder grinding machining. The automatic clamping clamp comprises a base, a step base, a motor, an outer positioning cover, a sleeve, an inlet sleeve, a locking nut, an elasticity pushing assembly and a transmission assembly; the base comprises a base plate and a motor base; the step base is fixedly installed on the motor base, and a center hole is formed in the step base; the motor is installed in a step hole of the motor base and is fixedly connected with the step base; the outer positioning cover is fixedly connected to the position of an opening in the upper end of the motor base, and a square hole is formed in the center position of the outer positioning cover; the sleeve is fixedly connected to the upper end of the outer positioning cover; the inlet sleeve is fixedly connected to the upper end of the sleeve; the locking nut is movably installed in the inner hole of the sleeve, the lower end of the locking nut is supported and borne by the elasticity pushing assembly, a contact face is arranged at the upper end of the outer wall of the locking nut, and a transmission structure is arranged at the lower end of the outer wall of the locking nut; the lower end of the elasticity pushing assembly is related to the step base, the upper end of the elasticity pushing assembly extends into the inner hole of the sleeve to be in contact with the lower end face of the locking nut, and therefore elastic bearing is provided for the locking nut; and the transmission assembly is arranged between the motor and the locking nut, and is used for transmitting power of the motor to the locking nut.

Owner:NANHUA UNIV

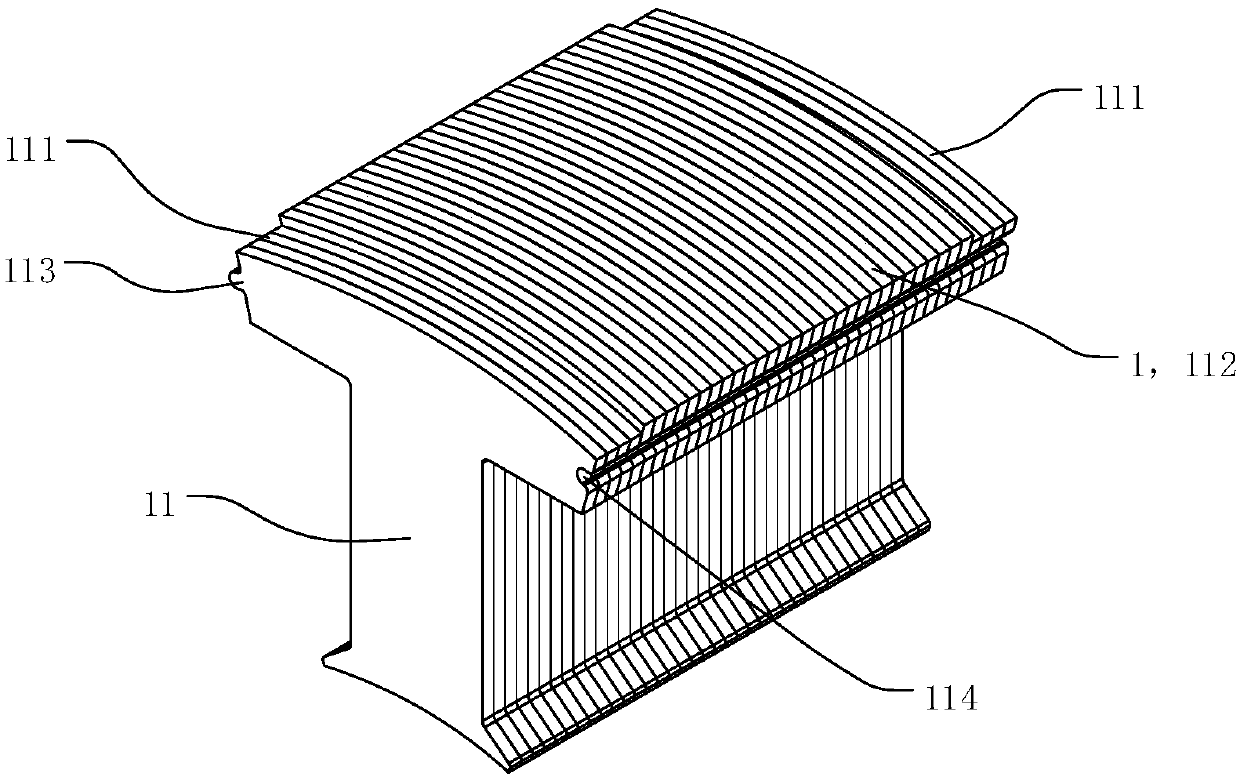

Motor blocking stator structure, motor stator and motor

PendingCN107919747AReduce iron lossReduce temperature riseWindings insulation shape/form/constructionMagnetic circuit stationary partsPunchingControl theory

The invention discloses a motor blocking stator structure, a motor stator with the motor blocking stator structure and a motor. The motor blocking stator structure includes a plurality of mutually independent stator punching sheets which are stacked together, wherein the plurality of stator punching sheets are fixed together through coiling. In the motor blocking stator structure, the plurality ofstacked stator punching sheets are fixed together through coiling; no other fixed structures are arranged among the plurality of stator punching sheets; and the stacked stator punching sheets are fixed together only through winding of coiling; and the plurality of blocking stator structures are fastened and fixed through fastening rings to realize firm fixing of the overall motor stator. The motor blocking stator structure can effectively reduce the iron core loss of the stator core, can improve efficiency of the motor and can reduce temperature rise of the motor.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Computer case paint mixing and stirring device and operation method

ActiveCN112705085AReduce shockFlexible rotationShaking/oscillating/vibrating mixersTransportation and packagingDrive shaftCrank

The invention discloses a computer case paint mixing and stirring device and an operation method. The computer case paint mixing and stirring device comprises a base, a motor, a coupling, a first bevel gear, a second bevel gear, a case, a right pillow block, a ball head, ball head seats, an output shaft, a paint bucket, a bucket cover, a hoop, a stirring shaft, blades, a cam, a transmission shaft, a first synchronous wheel, a synchronous belt, a second synchronous wheel and a transmission shaft. The right side of the base is fixedly connected with a motor block, the motor is fixedly connected to the upper portion of the motor block and fixedly connected with a crankshaft through the coupling, the case is arranged on the outer side of the crankshaft, a crankshaft hole is formed in the left side of the case, the crankshaft hole is rotatably connected with the crankshaft, the crankshaft rotates in the crankshaft hole, the crankshaft penetrates through the crankshaft hole and is fixedly connected with the first bevel gear, the first bevel gear is meshed with the second bevel gear, the middle of the second bevel gear is fixedly connected with the lower part of the transmission shaft, a crank is arranged on the right side of the crankshaft, and the right pillow block is arranged on the right side of the crank.

Owner:重庆化工职业学院

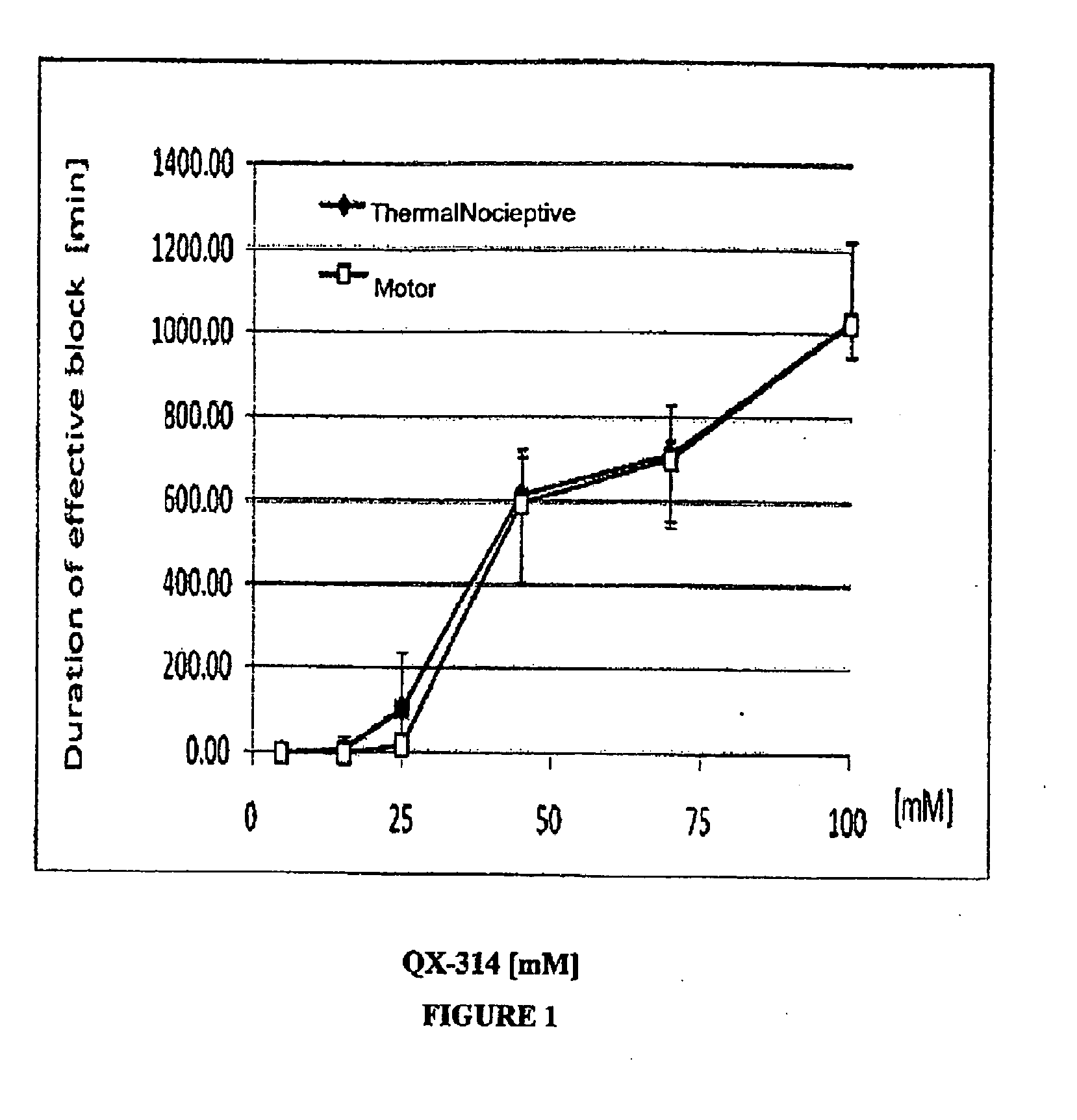

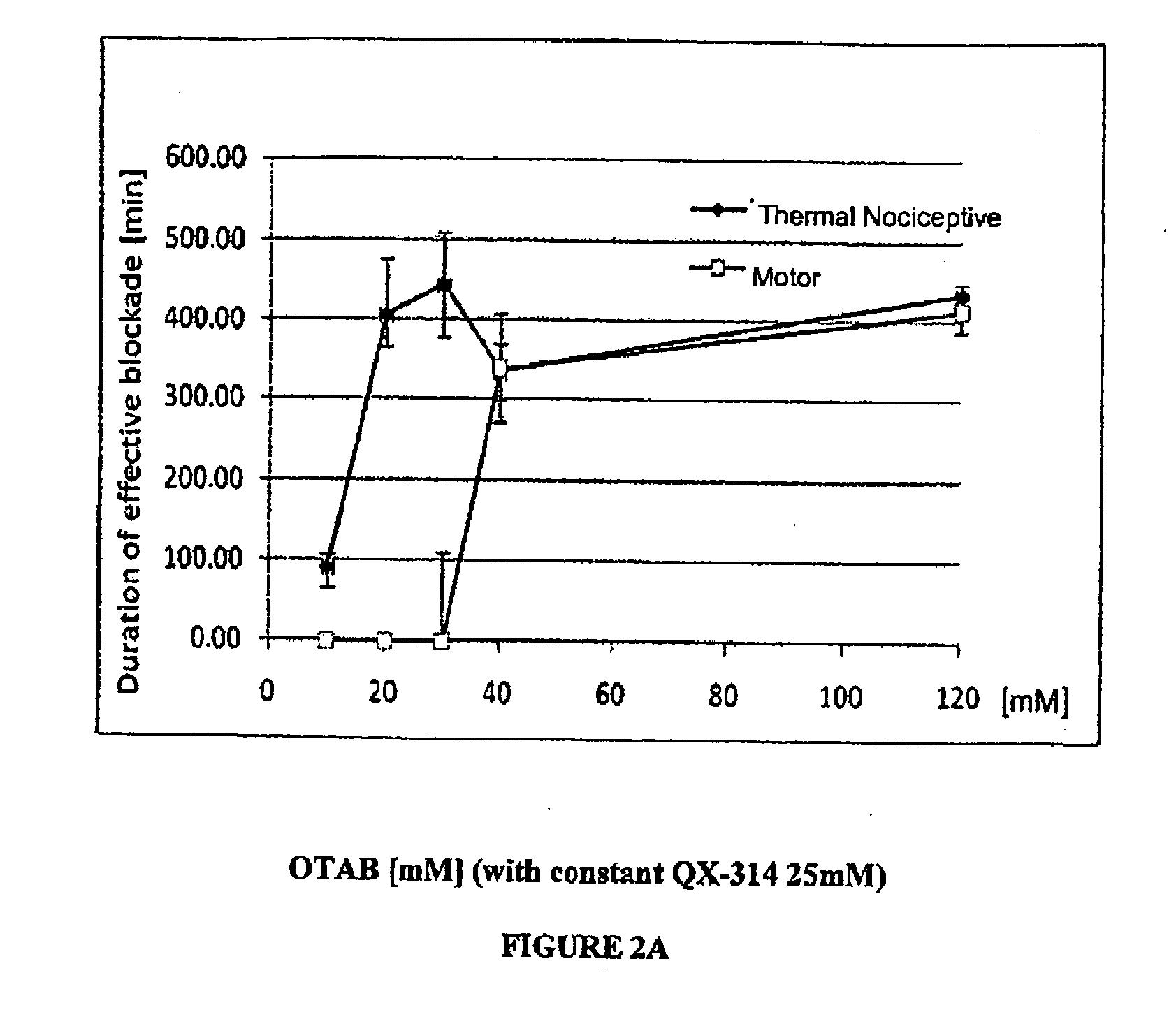

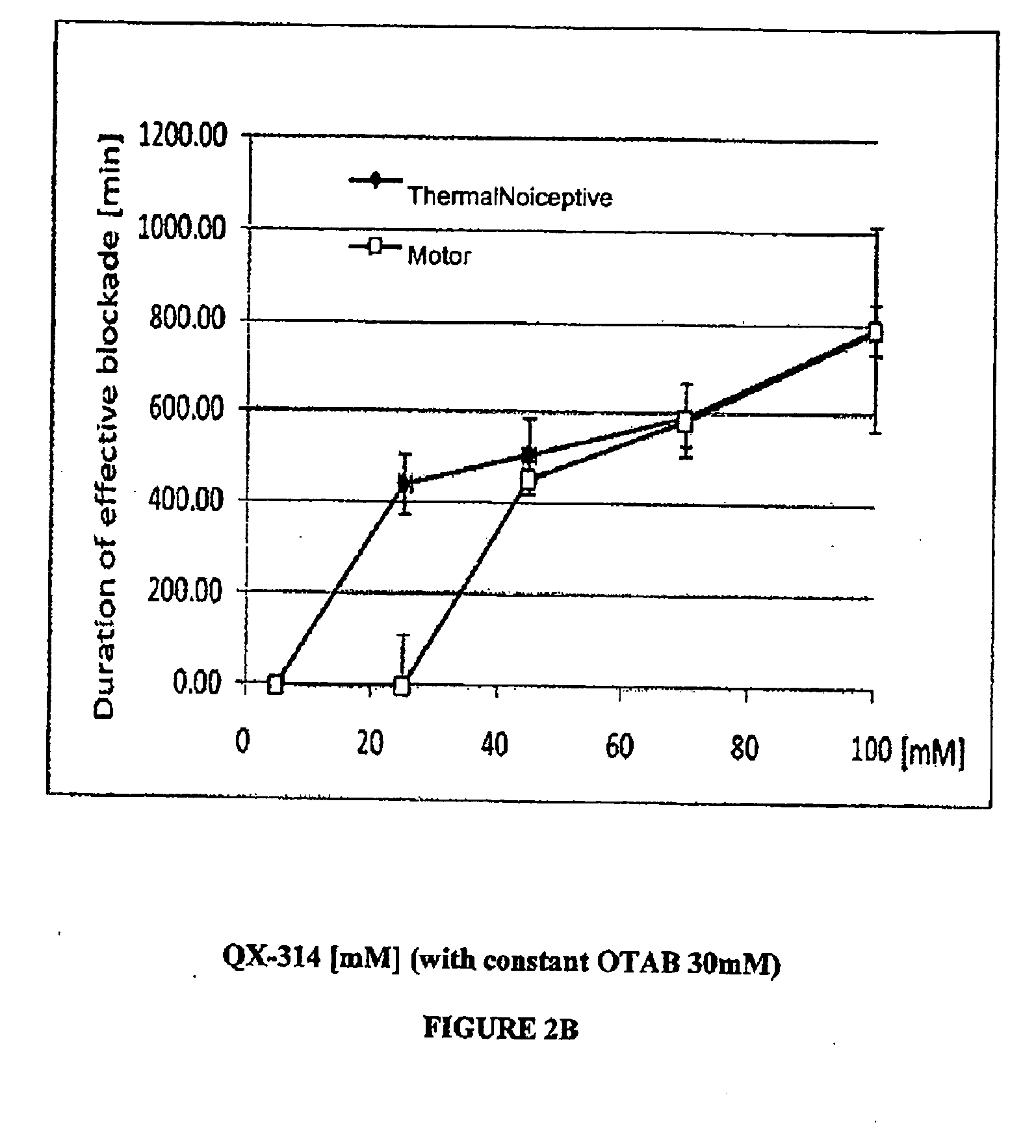

Sensory-specific local anesthesia and prolonged duration local anesthesia

ActiveUS20110086922A1Extended durationProlong duration of blockBiocideOrganic chemistryPrimary motor neuronLocal anesthesia

Combinations of charged local anesthetics with chemical permeation enhancers have been developed to give long duration block which is selective for sensory block over motor block. The duration of block is greatly prolonged by combining the local anesthetic with a permeation enhancer. The selectivity of sensory over motor block is provided by selecting the concentration of the local anesthetic and the permeation enhancer to provide selective permeability of the sensory and motor neurons to the enhancer.

Owner:MASSACHUSETTS INST OF TECH +1

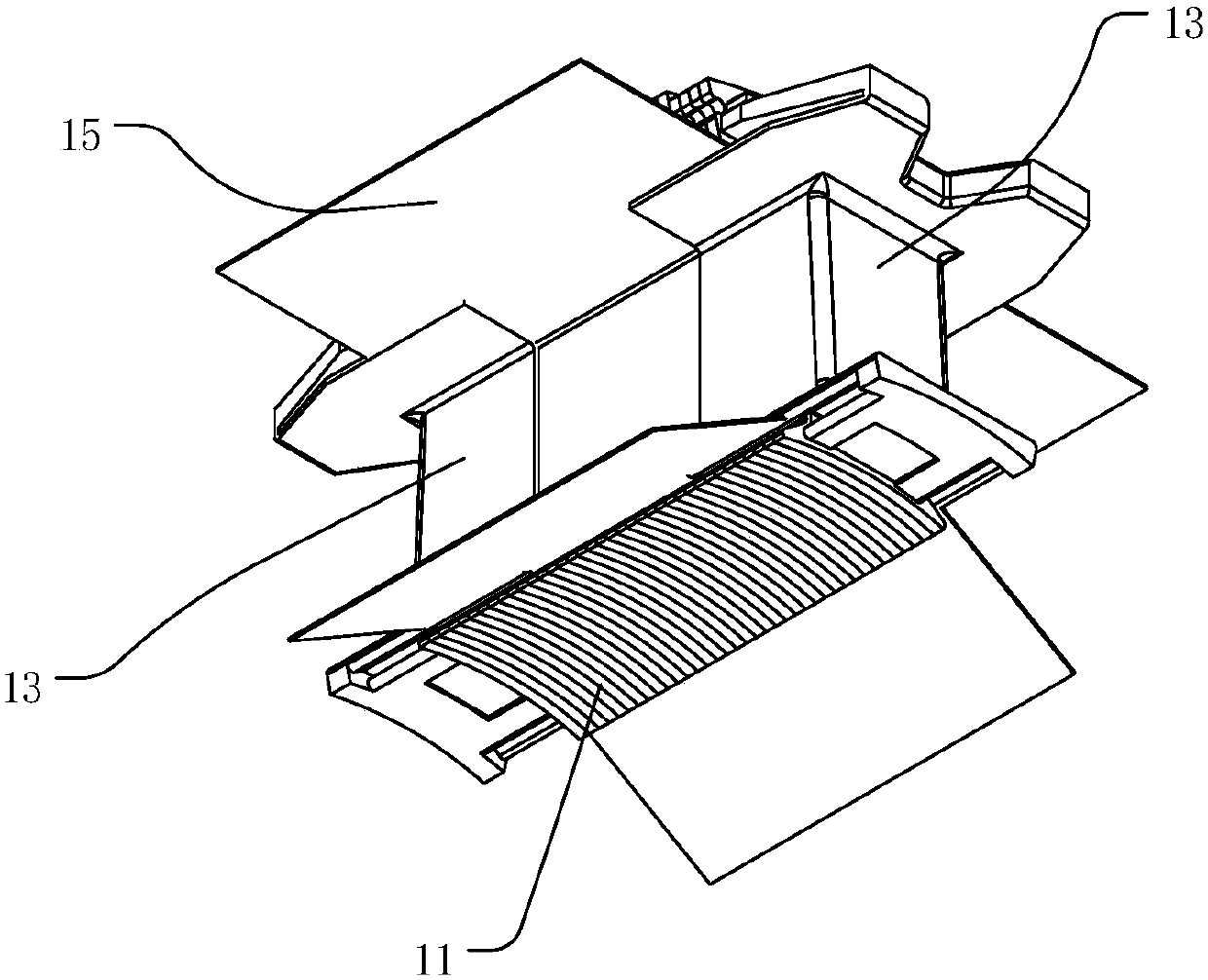

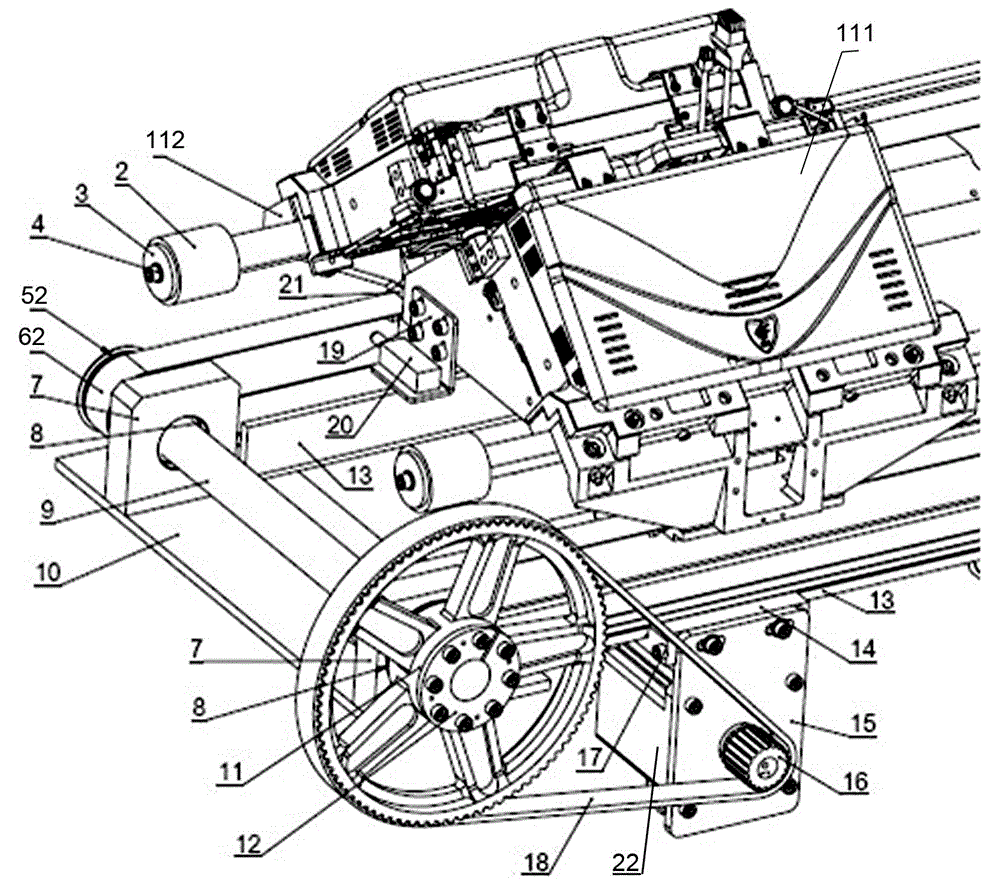

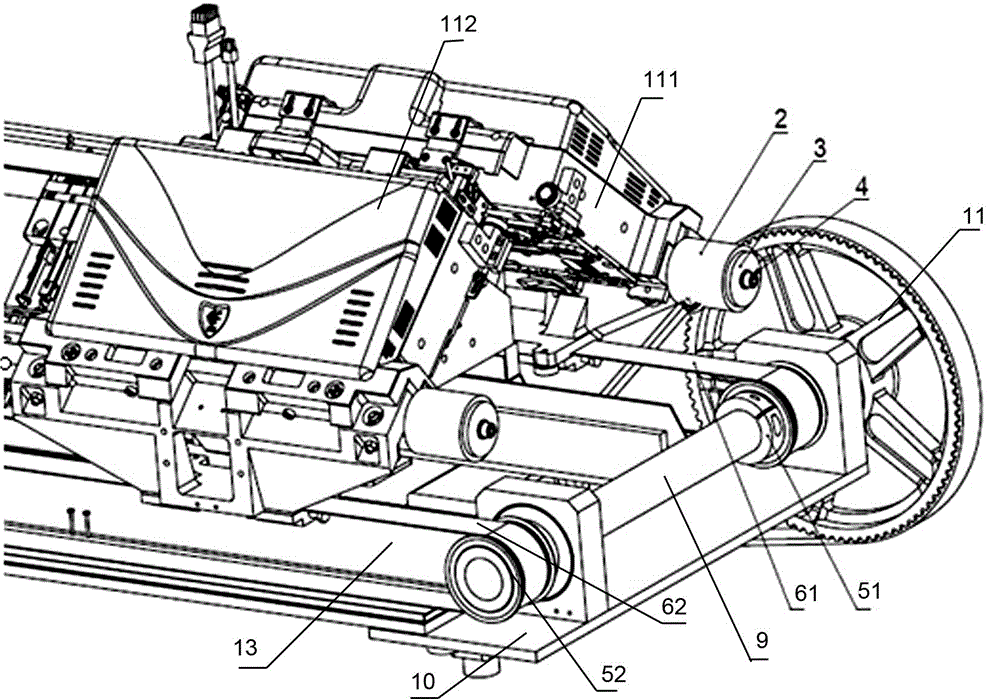

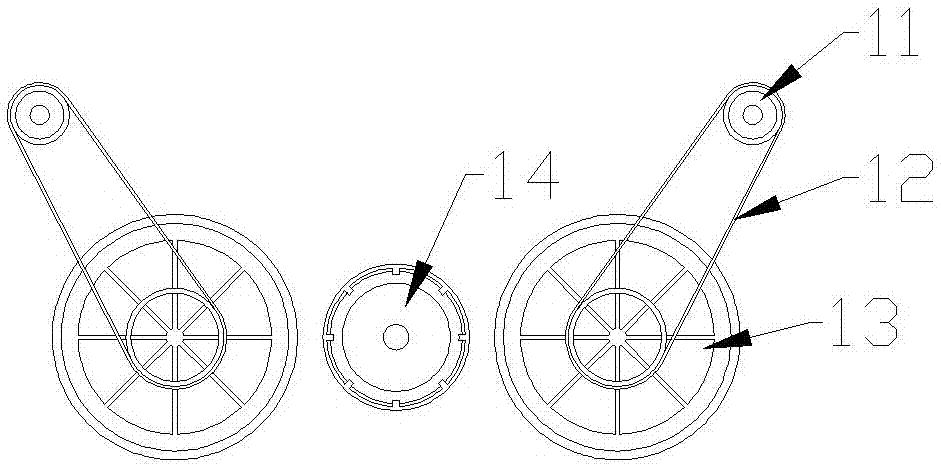

Control device for split nose main drive and impact protection of flat knitting machine

ActiveCN103603132AEasy to disassemblePrevent slipping outWeft knittingTransmission beltAgricultural engineering

The invention discloses a control device for split nose main drive and impact protection of flat knitting machine. The control device for split nose main drive and impact protection of flat knitting machine comprises main drive control device and impact protection control device; the main drive control device comprises a fixed plate, a fixed plate of motor metal, a motor metal, a main motor, a driving pulley, a driven pulley, transmission belt, a connecting shaft, bearing seats and a bearing plate; the fixed plate is fixed on both sides of the front and rear of car wall and the fixed plate of motor metal is fixed on the fixed plate; the motor is fixed on the fixed plate of motor metal through the motor; the bearing seats are fixed at both ends of the bearing plate; both ends of the connecting shaft are penetrated respectively by two bearing seats; a rear pulley is fixed at the rear end of the connecting shaft and a front pulley and the driven pulley are fixed at the front end; the driving pulley is connected with the shaft of motor and the transmission belt is connected with the driving pulley and the driven pulley; the front pulley is connected with the front nose through the front synchronous belt and the rear pulley is connected with the rear nose through rear synchronous belt.

Owner:NINGBO CIXING

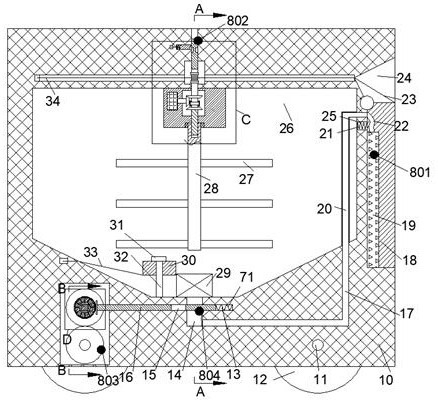

Surgical physiotherapy bed

The invention relates to the technical field of physiotherapy equipment, and discloses a physiotherapy bed for surgery, which includes a bed board, a motor frame fixedly connected to the bottom of the bed board, a sponge block fixedly connected to the inner wall of the motor frame, and a motor arranged inside the motor frame. The output end is fixedly connected with a driving gear, the top of the driving gear is meshed with a driven gear, one side of the driven gear is fixedly connected with a drug cartridge, the outer surface of the drug cartridge is fixedly connected with a massage head, and the inside of the drug cartridge is provided with a heating wire. In the present invention, through the motor, driving gear, driven gear, drug cartridge, massage head, heating wire, fixing belt and air outlet, the effect of physiotherapy can be achieved on the waist suffering from lumbar disc herniation. On the one hand, the heating wire can make the drug The effect is better. On the other hand, it can improve the patient's comfort when it is cold, making the physical therapy effect more obvious. The massage head can slow down the pain caused by the lumbar disc herniation to the patient.

Owner:林孝振

Pesticide spraying vehicle capable of automatically adjusting liquid spraying flow according to vehicle speed

InactiveCN111838118AEasy to useLiquid spraying apparatusInsect catchers and killersAgricultural engineeringElectric machinery

The invention discloses a pesticide spraying vehicle capable of automatically adjusting the liquid spraying flow according to the vehicle speed. The pesticide spraying vehicle comprises a vehicle body, rotating cavities are formed in the front side surface, the rear side surface and the right side surface of the vehicle body, a spraying mechanism used for being rotatably stretched is arranged in each rotating cavity, a storage cavity is formed in the vehicle body, a motor block is fixedly arranged on the top wall of the storage cavity, a motor is arranged in the motor block, and a motor shaftis in power connection with the right side of the motor. By starting the motor, the states of rotating starting of a rotating plate, stirring of a stirring rod and switching of the flow can be achieved, meanwhile, after liquid pesticide is sprayed, the vehicle can be automatically switched back to the initial state, and the pesticide spraying vehicle is quite convenient to use; meanwhile, the flowis constantly increased along with increasing of the vehicle speed; and by stirring, the liquid pesticide in the vehicle body is kept in the state of uniform concentration all the time, and then it can be guaranteed that the spraying amounts of the liquid pesticide in the unit area are close to be equal at different vehicle speeds.

Owner:绍兴息德科技有限公司

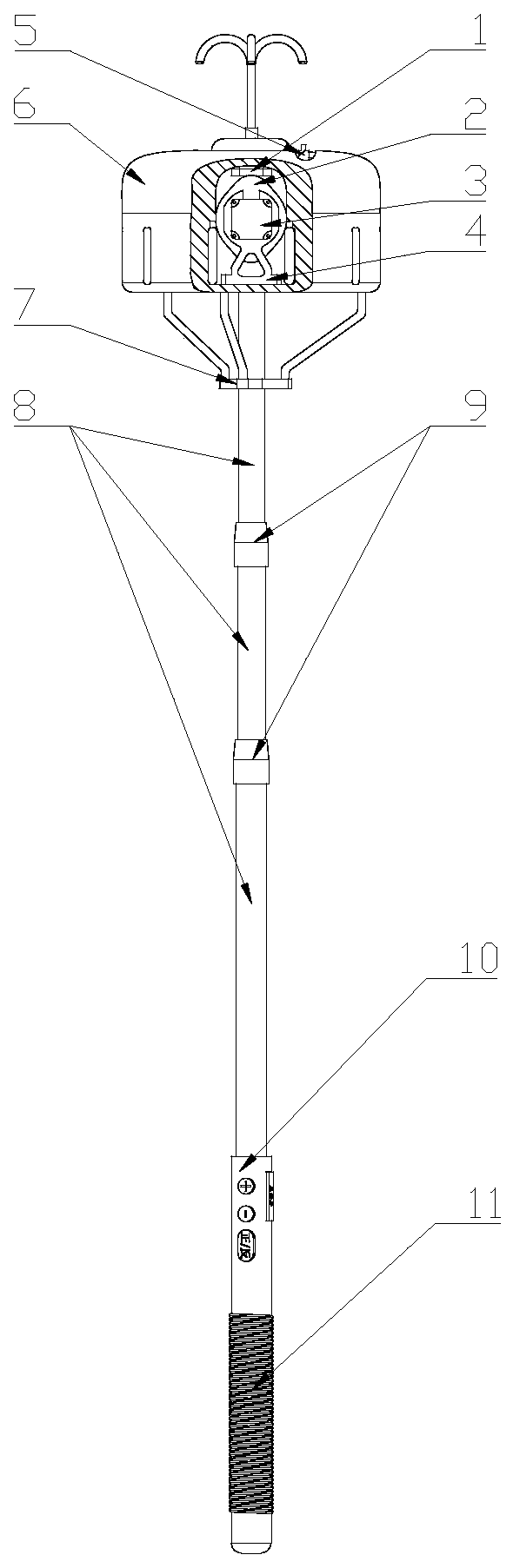

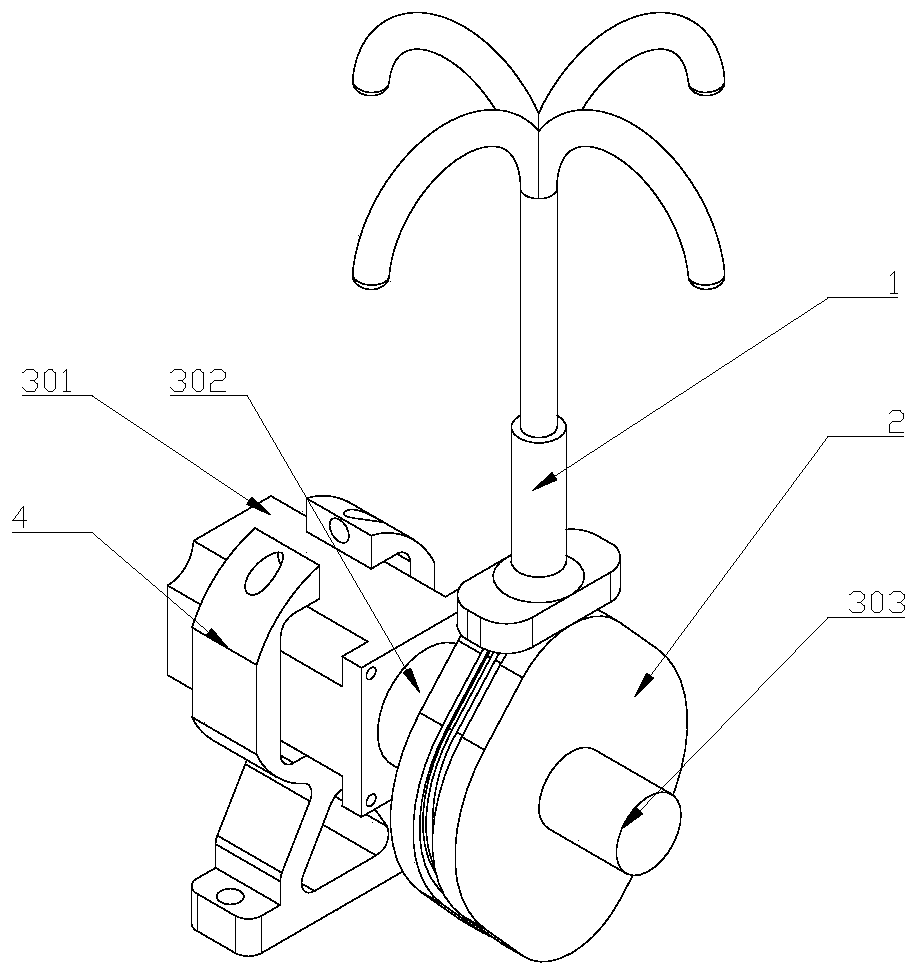

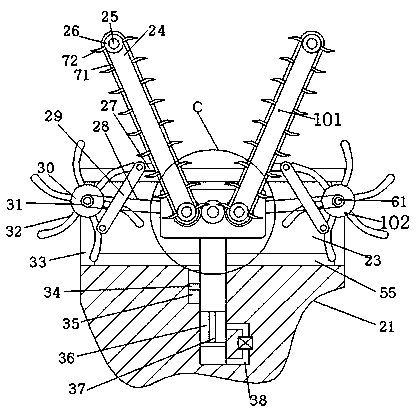

Hand-held telescopic chestnut vibrating picking device

InactiveCN111567220ALight and firm structureImprove reliabilityPicking devicesLiquid-crystal displayElectric machinery

The invention relates to a hand-held telescopic chestnut vibrating picking device. A motor bracket is arranged in a stop cover; a miniature camera is arranged at the upper end of the stop cover; a motor block is arranged on the motor bracket; a miniature motor is arranged on the motor block; a cam groove is formed in the center of a grooved cam along a contour line; sliding rails are arranged at two sides of the cam groove along the contour line; the grooved cam sleeves a motor output shaft of the miniature motor; a push rod slider is in sliding fit with the cam groove through a roller; a liquid crystal display screen arranged on a handle is connected to the miniature camera through an electric wire; and a 51 single chip microcomputer and a control button are connected to the miniature motor through the electric wires. The hand-held telescopic chestnut vibrating picking device is scientific and reasonable in structural design, light and firm in structure and high in reliability; the weight of the picking device is effectively reduced; and through automatic operation of a telescopic rod, the miniature camera and the miniature motor, automatic picking of chestnuts can be achieved, and a person can complete the operation without climbing up a tree, so that manpower is saved, the problems of difficulty in high altitude picking, high cost and the like can be solved and the chestnutpicking efficiency is improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Bearing pressure load test equipment

Owner:WUXI SIBORUI ELECTROMECHANICAL CO LTD

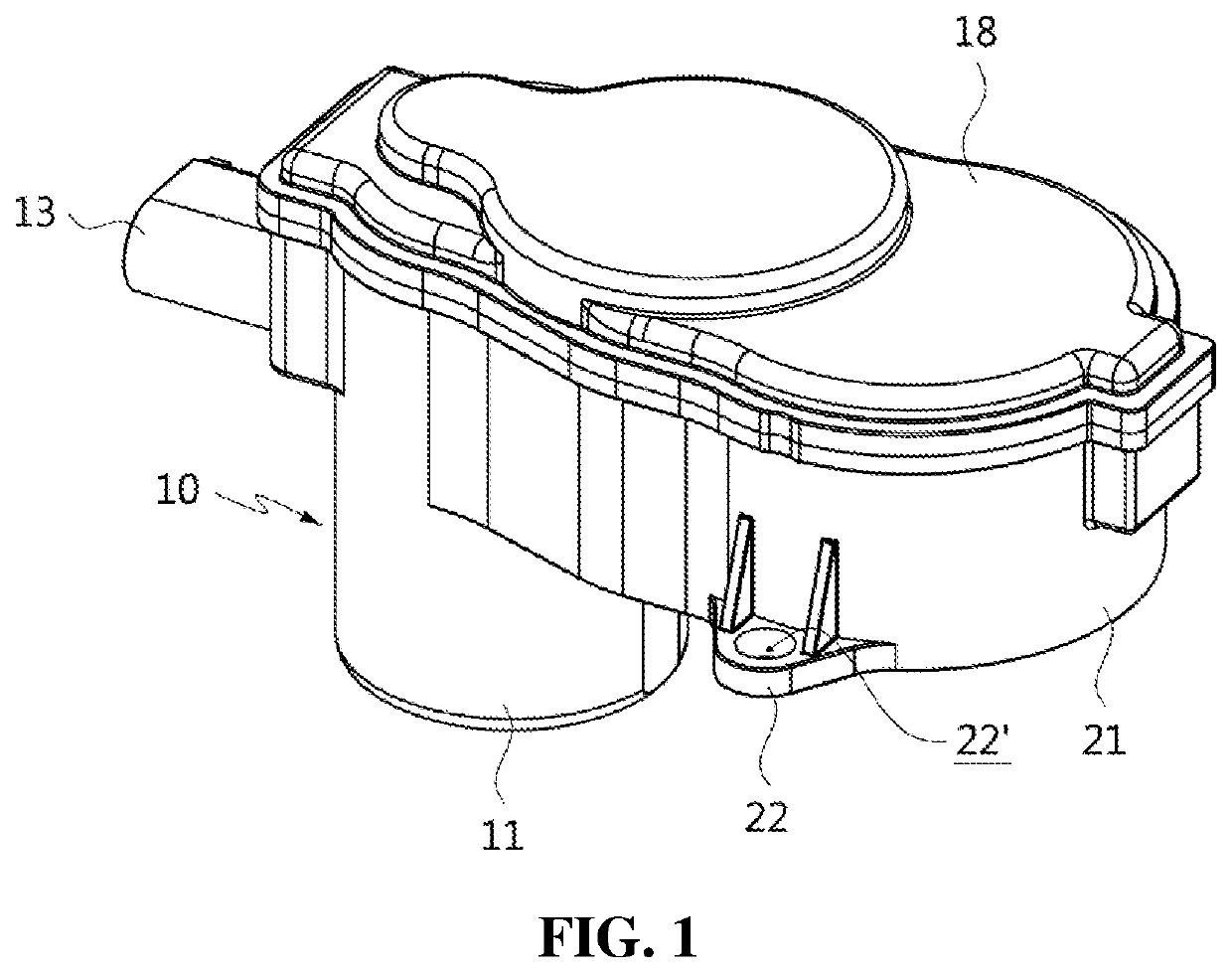

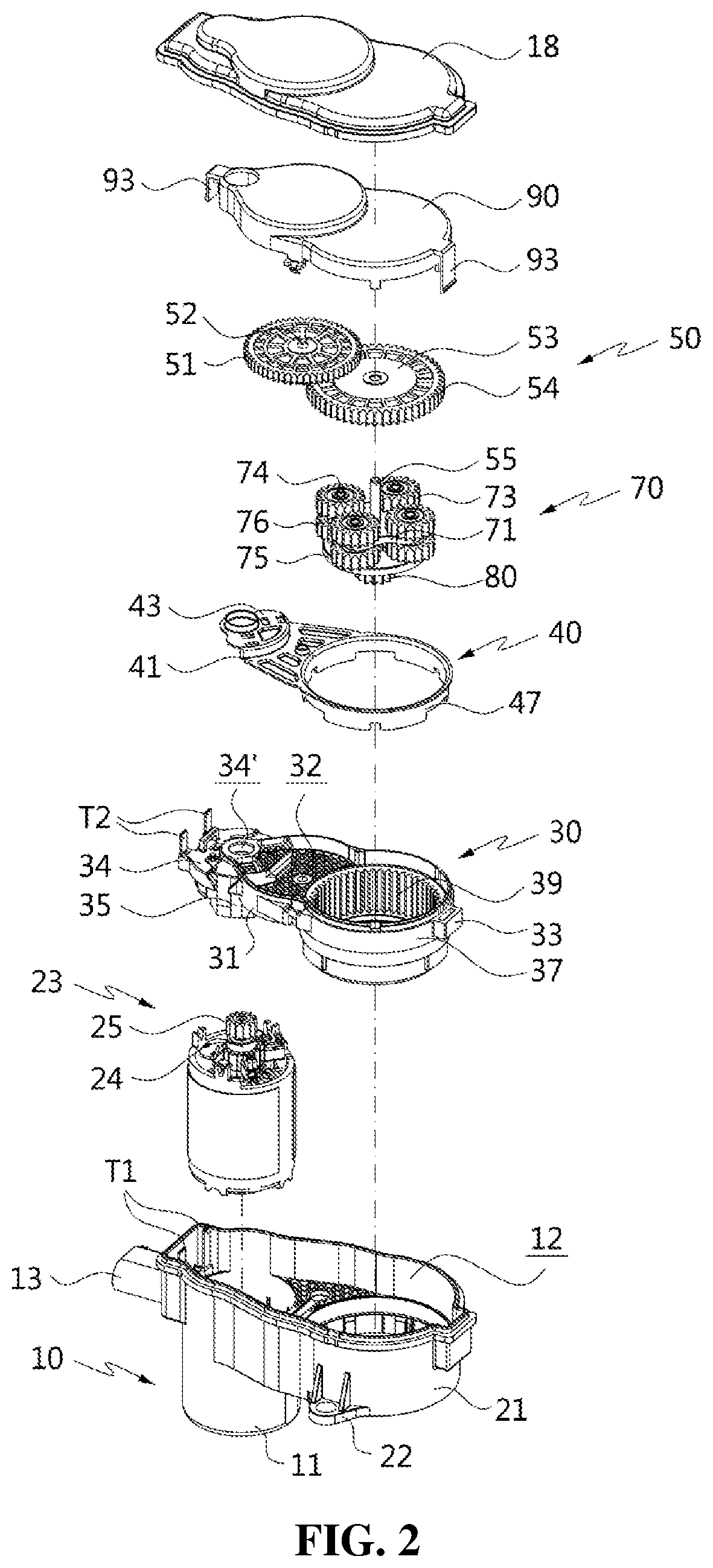

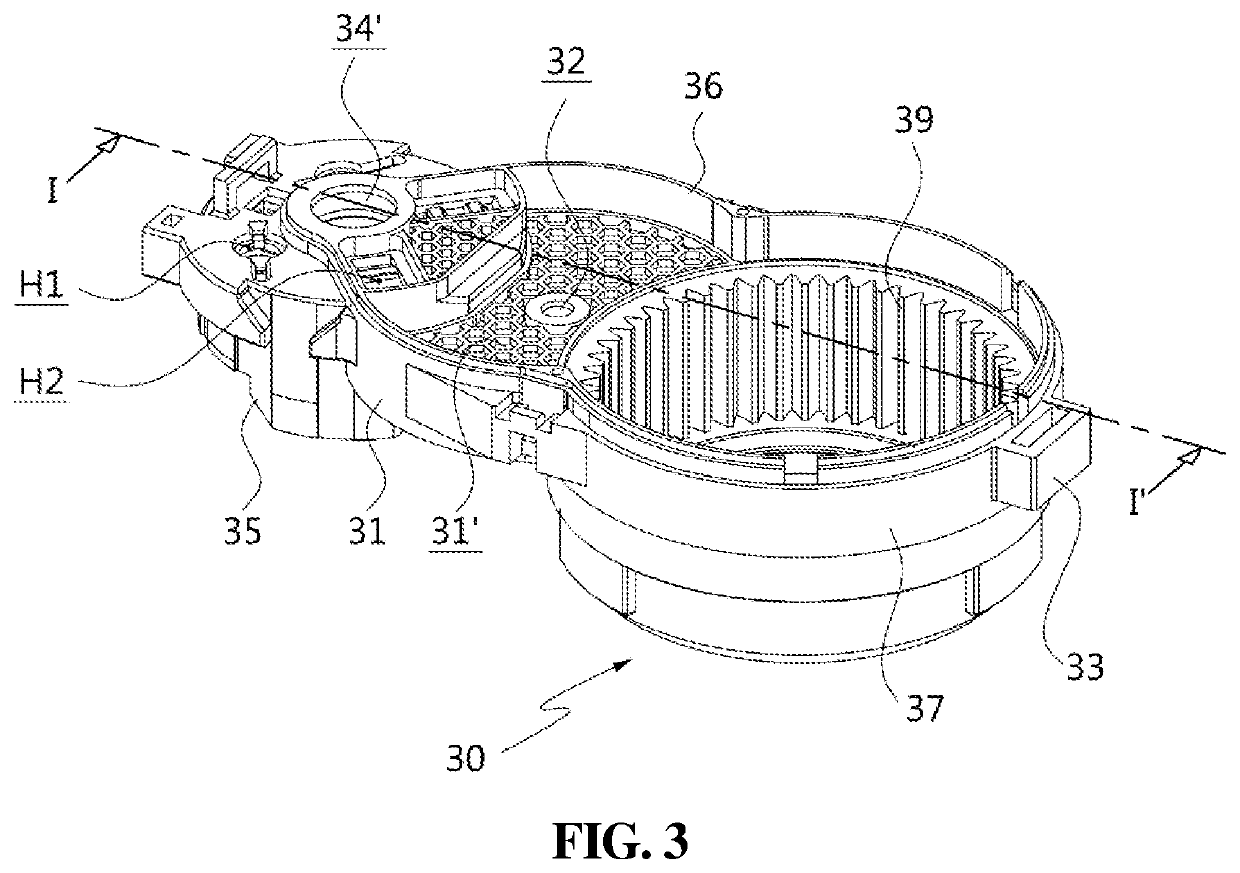

Actuator for electromechanical parking brake having housing with brush card assembly

ActiveUS10843675B2Improve convenienceImprove performanceAxially engaging brakesBraking action transmissionElectric machineGear wheel

An actuator for an electromechanical parking brake having a housing with a brush card assembly is provided, which includes: a main housing having a motor seat and a gear seat; a motor assembly disposed in the motor seat and providing torque; a gear assembly rotated by torque from the motor assembly and performing a reduction function through a plurality of gears; and an inner housing. The inner housing is combined with the main housing and fixes the gear assembly, and integrally has a ring gear operating in mesh with a planetary gear seat of the gear assembly and a brush card electrically connected to the motor assembly. A ring gear operating with the planetary gear set and a brush card electrically connected to the motor assembly are integrally formed at the inner housing.

Owner:KEYANG ELECTRIC MACHINERY

Environment-friendly weeding machine applicable to farmland

The invention discloses an environment-friendly weeding machine applicable to farmlands. The environment-friendly weeding machine comprises a trolley body, wherein a work cavity is formed in the trolley body; open grooves are formed in the front and back side walls of the work cavity; the front and back parts of the top wall of the work cavity are symmetrically provided with sliding grooves; a hydraulic cavity is formed in the right side wall of the work cavity; a weeding device is arranged in the hydraulic cavity and the work cavity; firstly, a catalytic solution is added into a water box from a water adding opening; then, the trolley body is driven to forwards move through wheels; then, a hydraulic valve is opened, so that a motor block is driven to move; long plates are driven to move,so that an included angle between the long plates is controlled through fixing rods, a hinging rod, a connecting rod and a slide block mechanism. The environment-friendly weeding machine has the advantages that the structure is simple; the operation is convenient; eugonic weeds can be cut in a mechanical mode; compared with manual cutting and small-sized weeding machines, the environment-friendlyweeding machine is higher in work efficiency; meanwhile, the one-step grass cutting area can be automatically regulated by the device.

Owner:SHENGZHOU PANCHEN MASCH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com