Control device for split nose main drive and impact protection of flat knitting machine

A protection control, flat knitting machine technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of affecting machine work, loss, and the inability of front and rear machine heads to move synchronously, and achieve simple structure, convenient assembly and operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

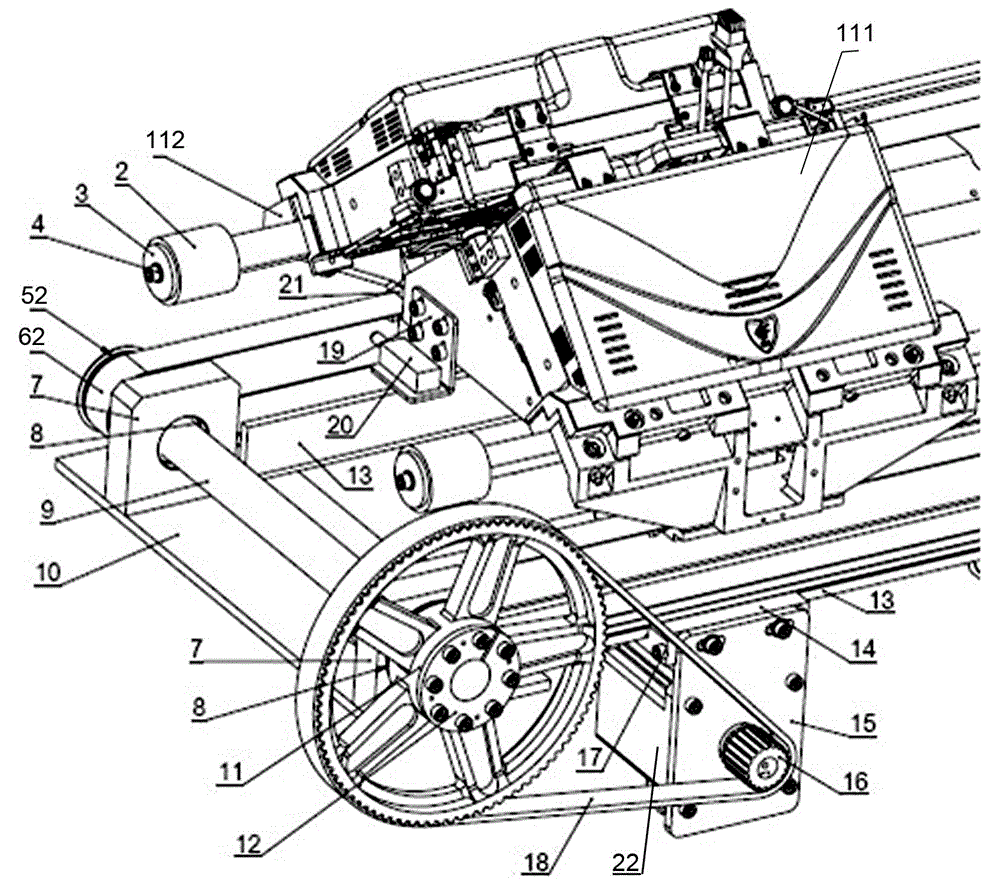

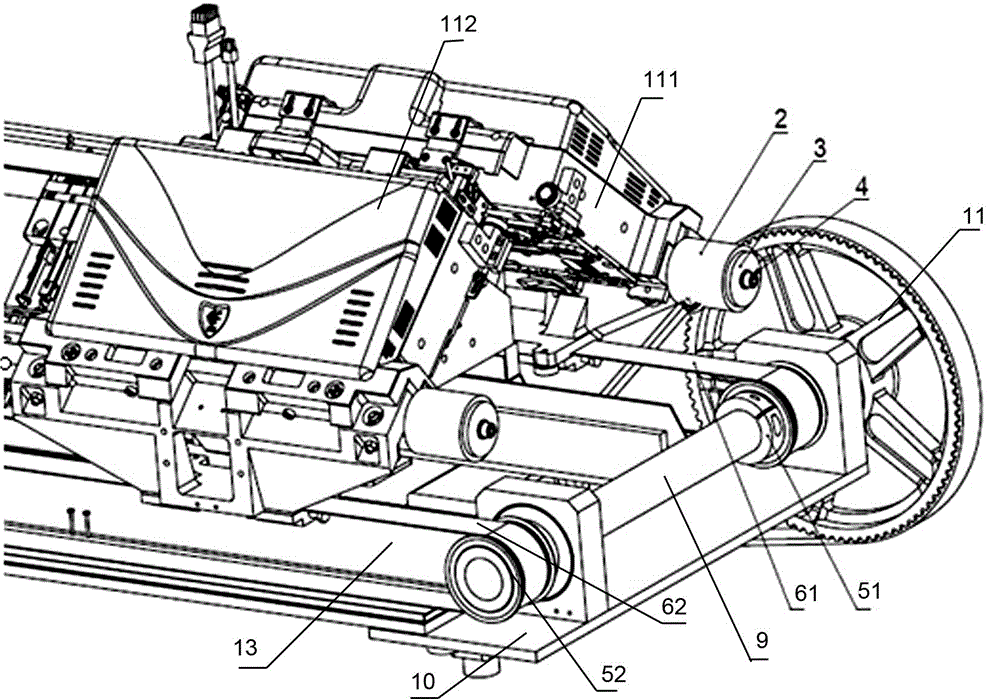

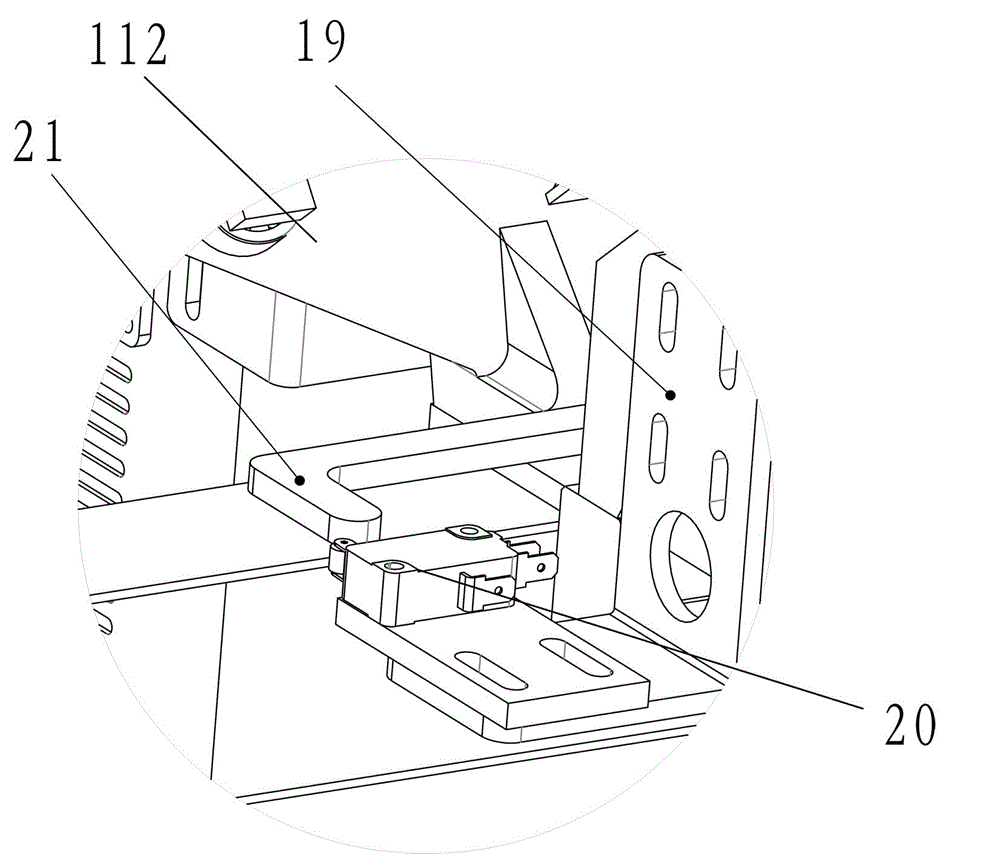

[0012] See attached picture. This embodiment includes a main transmission control device and an impact protection control device; the main transmission control device includes a fixed plate 13, a motor seat fixed plate 14, a motor seat 15, a main motor 22, a driving pulley 16, a passive pulley 11, and a transmission belt 18 , connecting shaft 9, bearing seat 7, bearing seat bottom plate 10, front pulley 51, front synchronous belt 61, rear pulley 52 and rear synchronous belt 62; The fixed plate 14 is fixed on the fixed plate 13; the main motor 22 is fixed on the motor seat fixed plate 14 through the motor seat 15; the motor seat fixed plate 14 has an adjusting screw 17; the bearing seat bottom plate 10 connects the front and rear Two fixing plates 13, bearing housings 7 are fixed on the two ends of the bearing base plate 10, the bearing housings 7 have built-in bearings 8; the two ends of the connecting shaft 9 pass through the two bearing housings 7 respectively; the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com