Patents

Literature

38results about How to "Guaranteed vertical force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weighing module

ActiveCN101078649ADoes not affect accuracyHigh precisionWeighing apparatus detailsAgricultural engineeringNeck parts

Owner:METTLER TOLEDO CHANGZHOU PRECISION INSTR +2

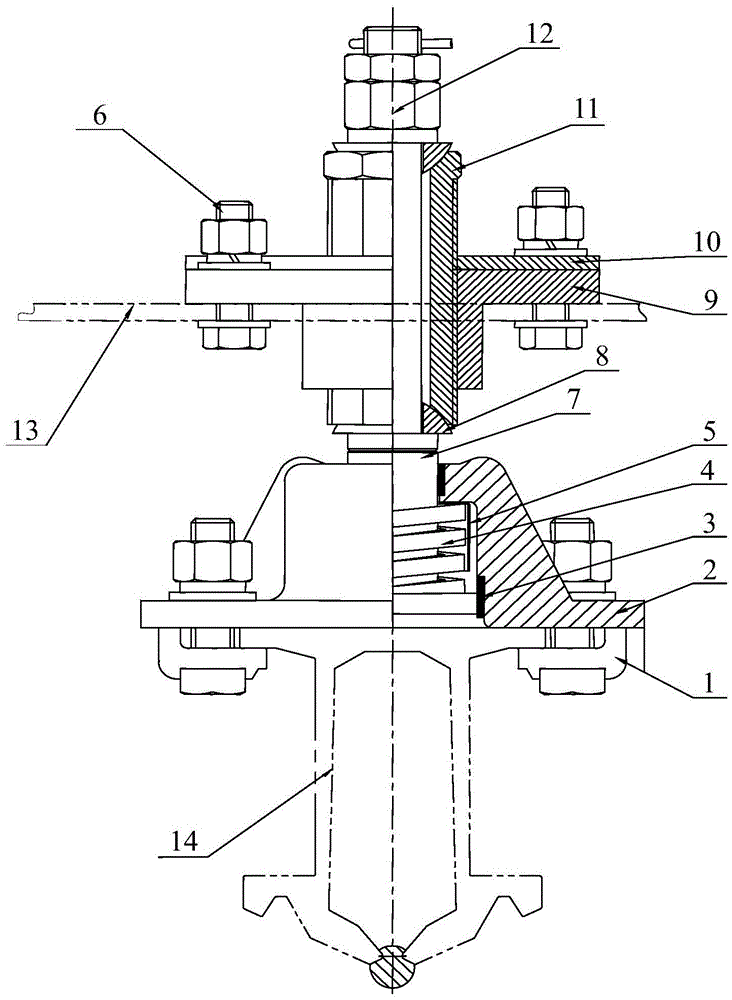

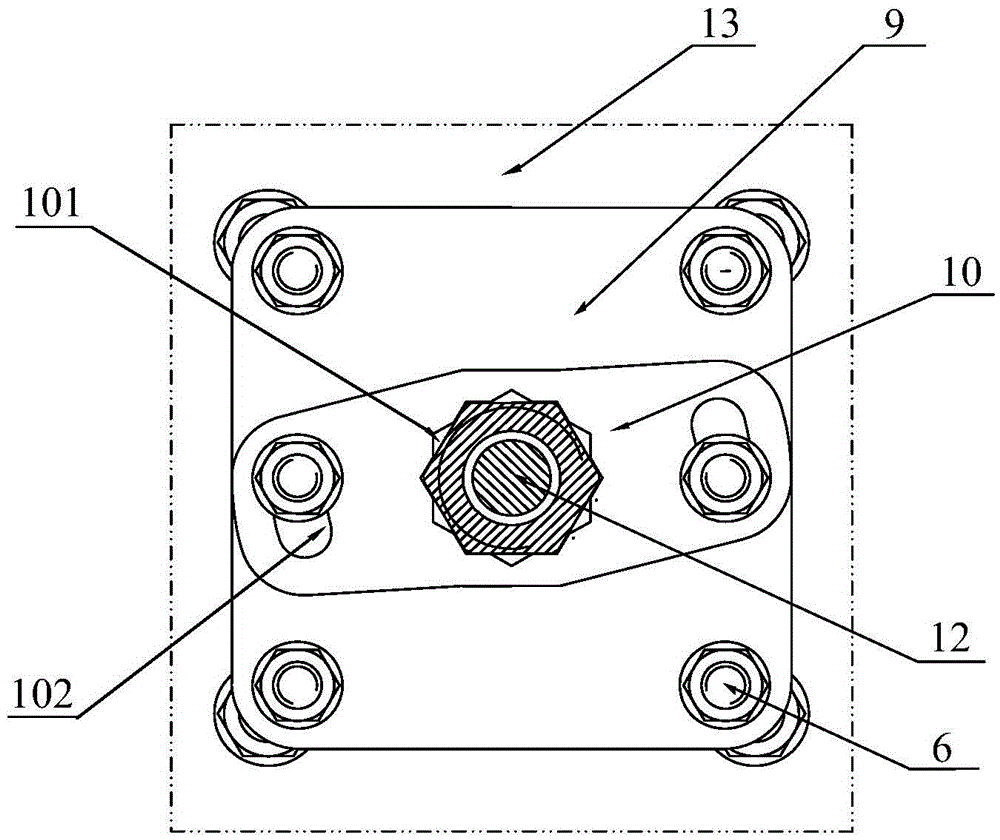

Weighing module

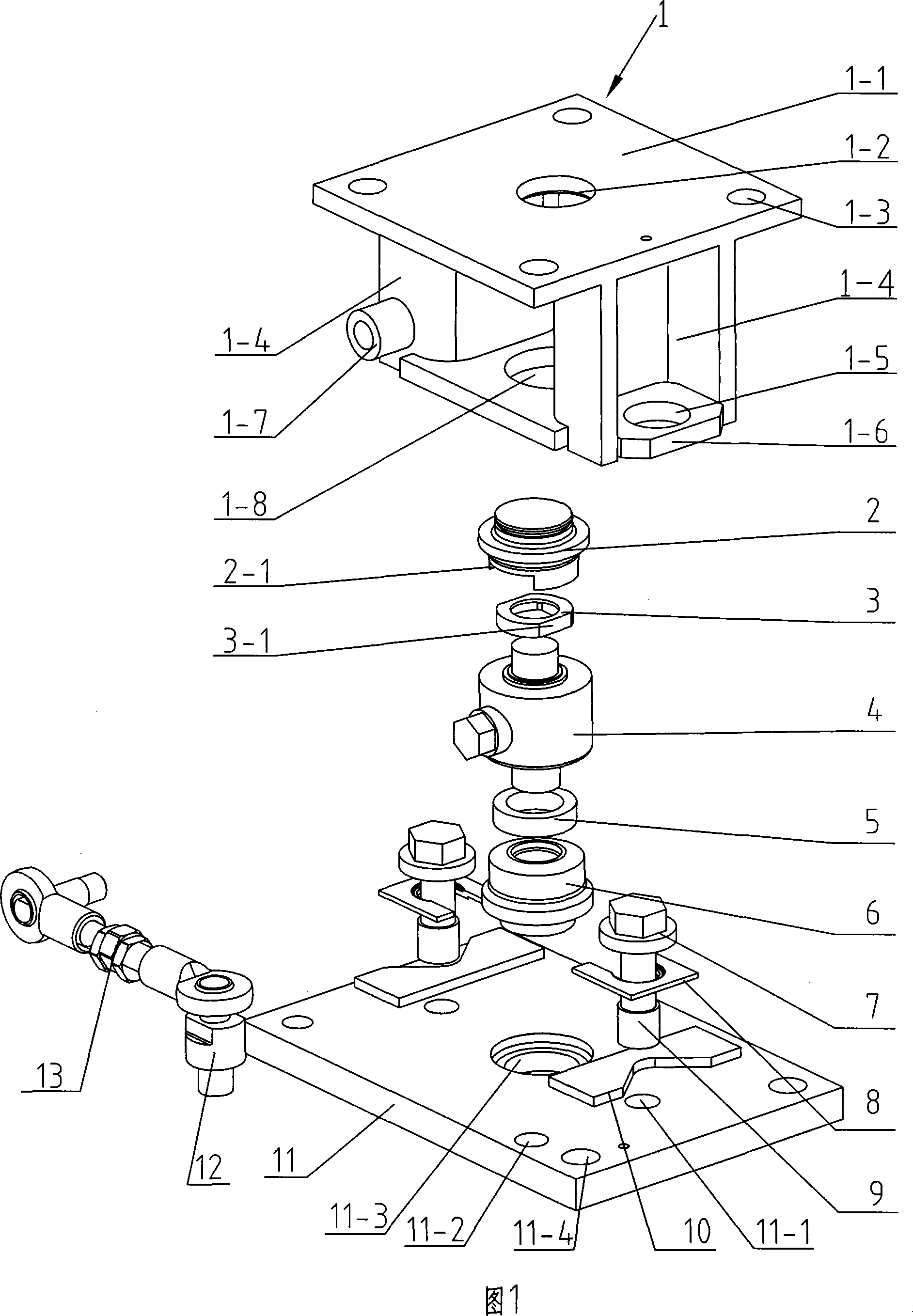

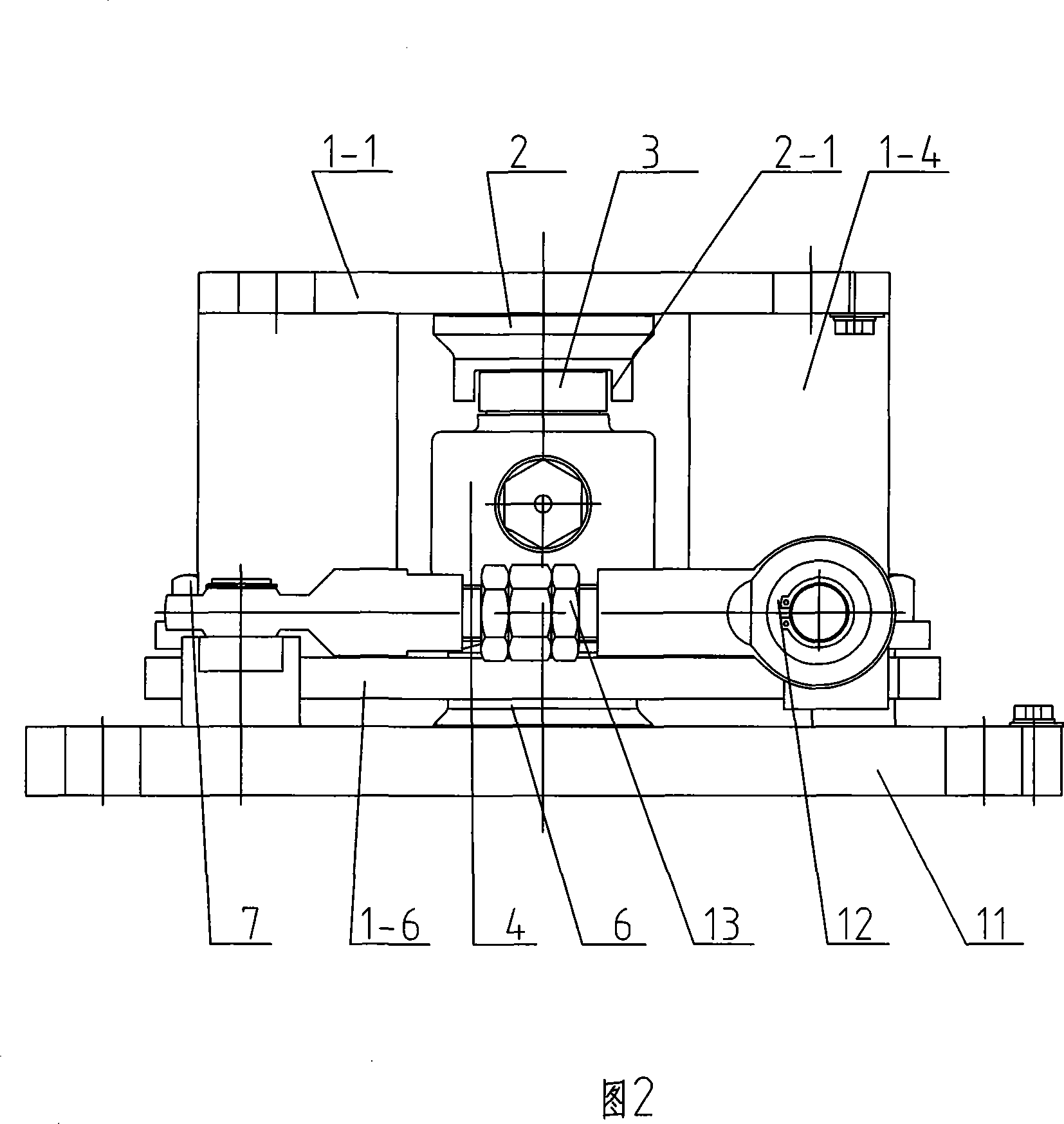

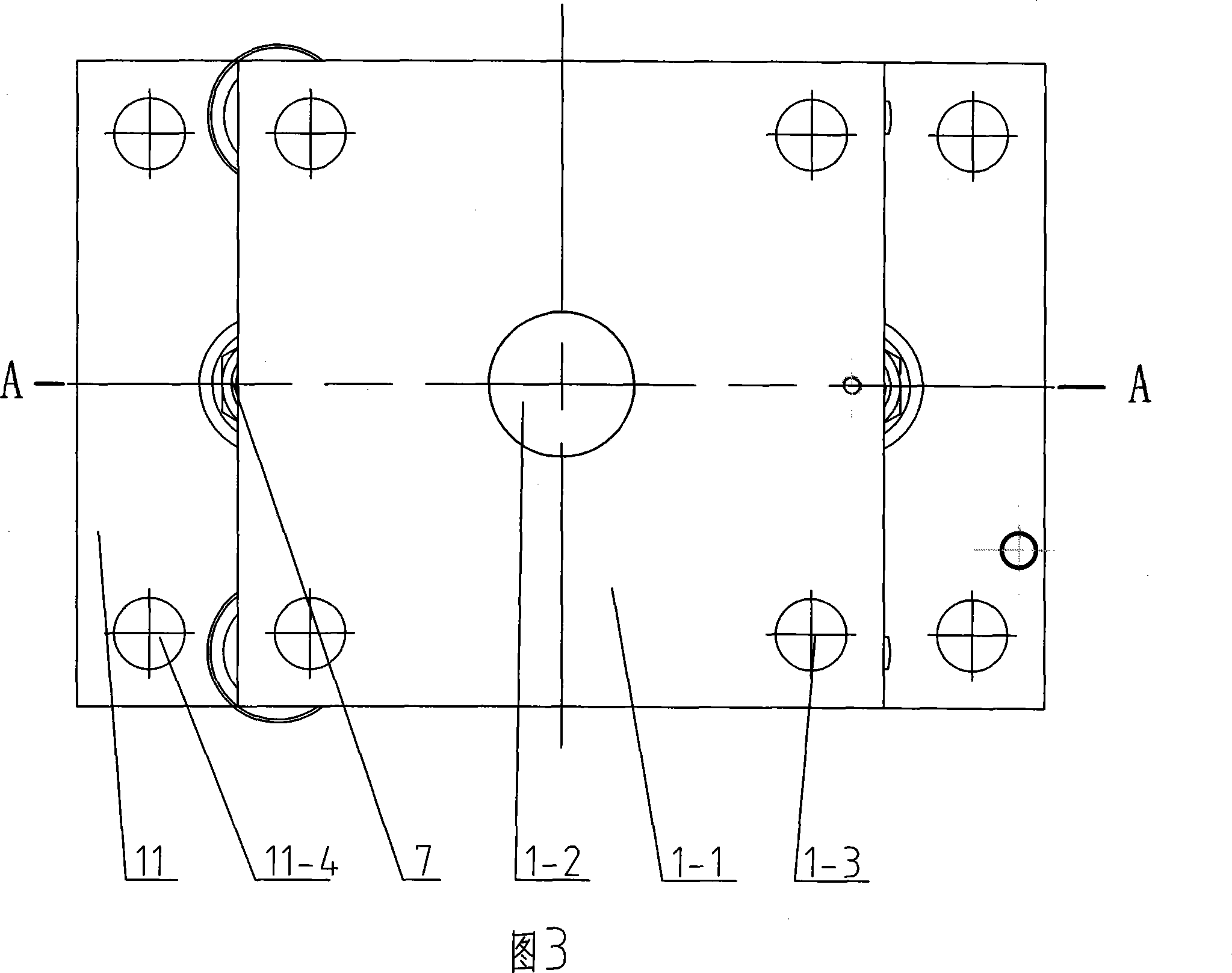

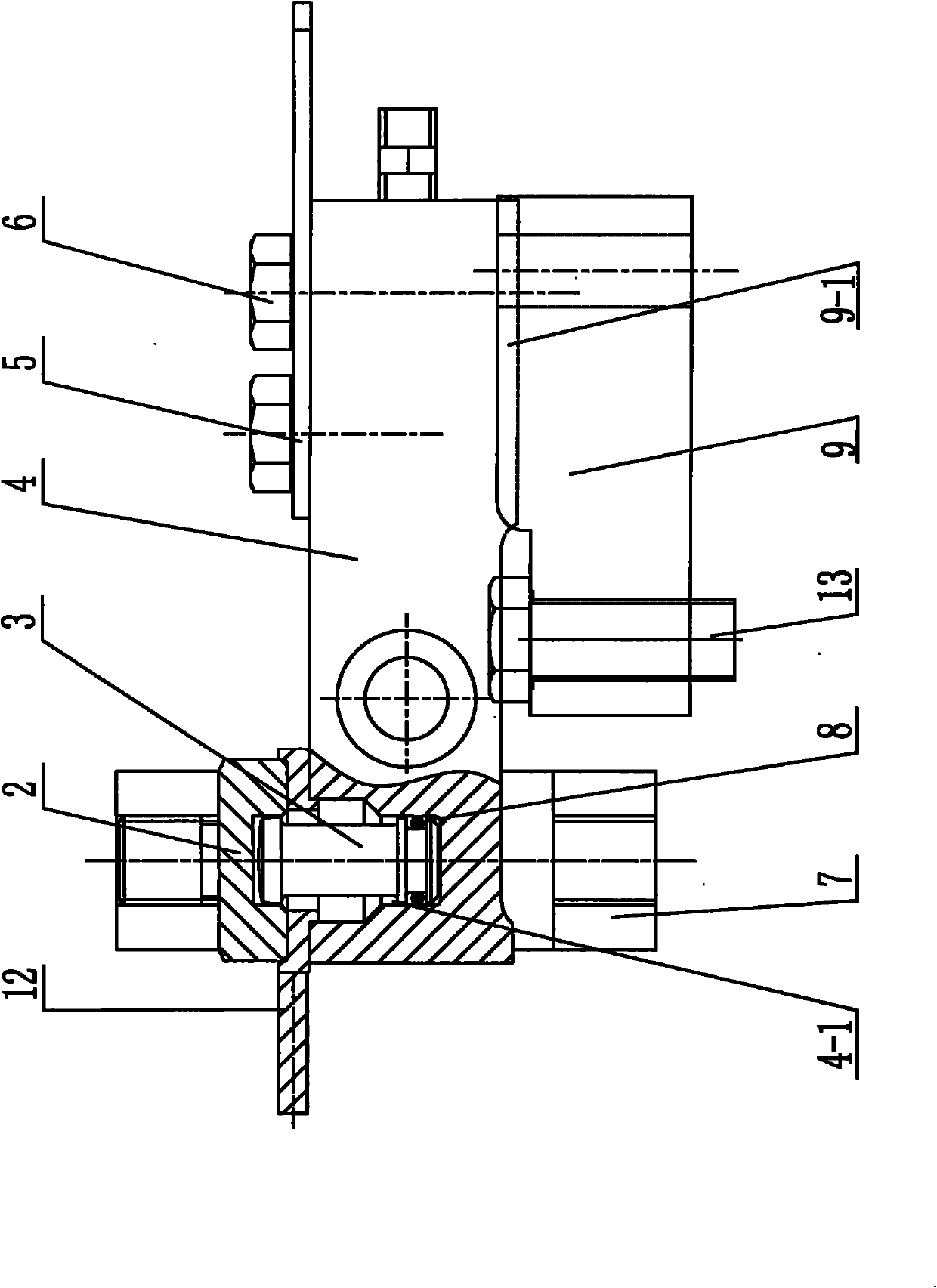

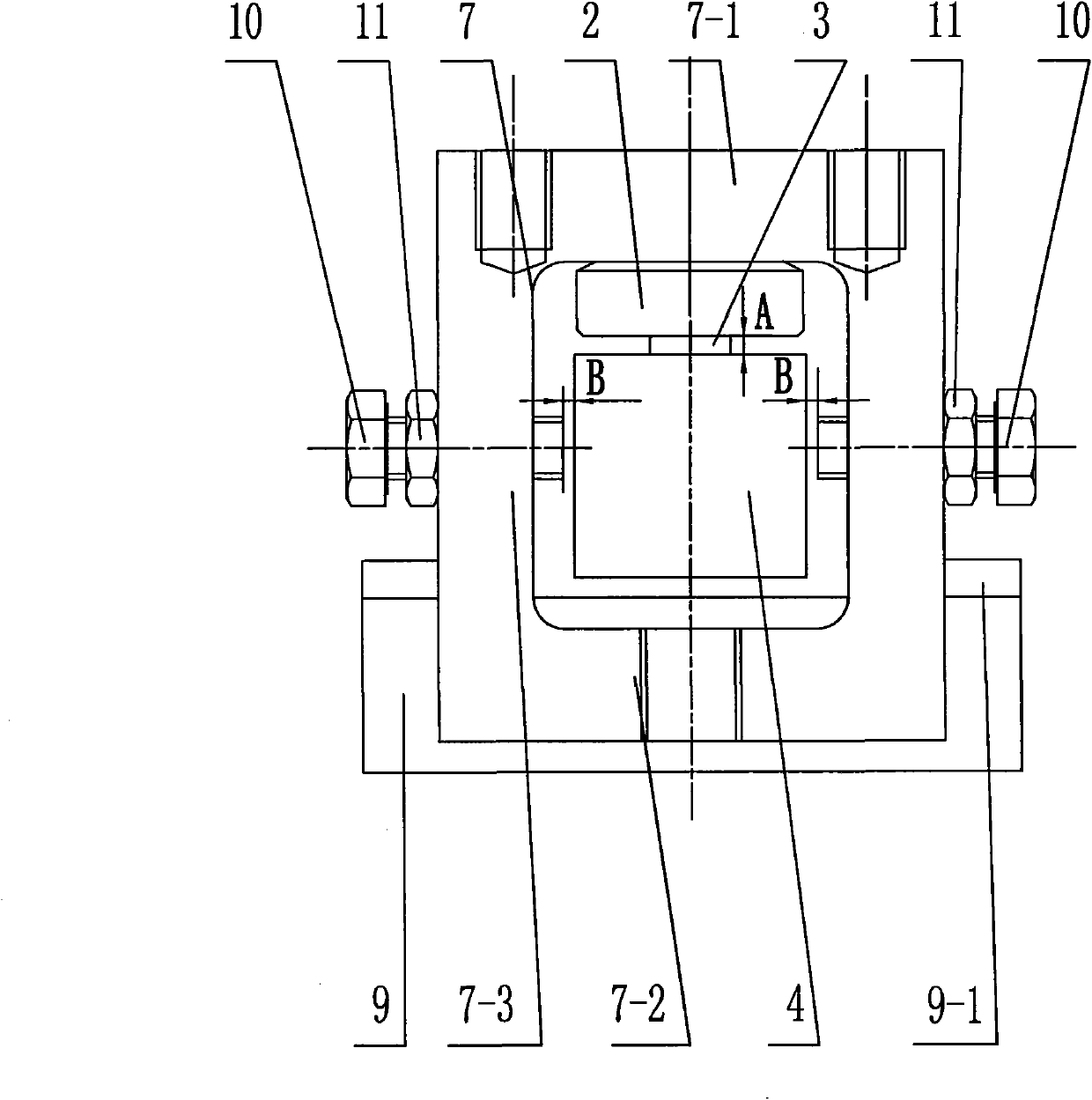

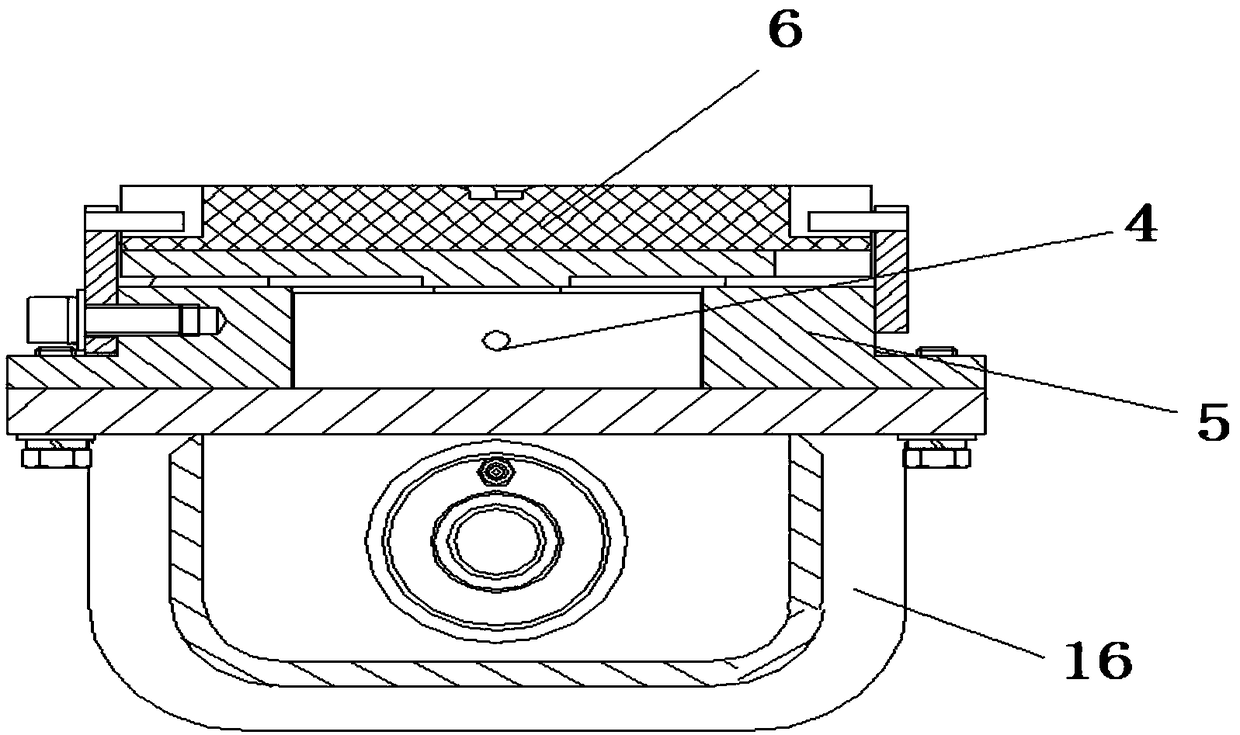

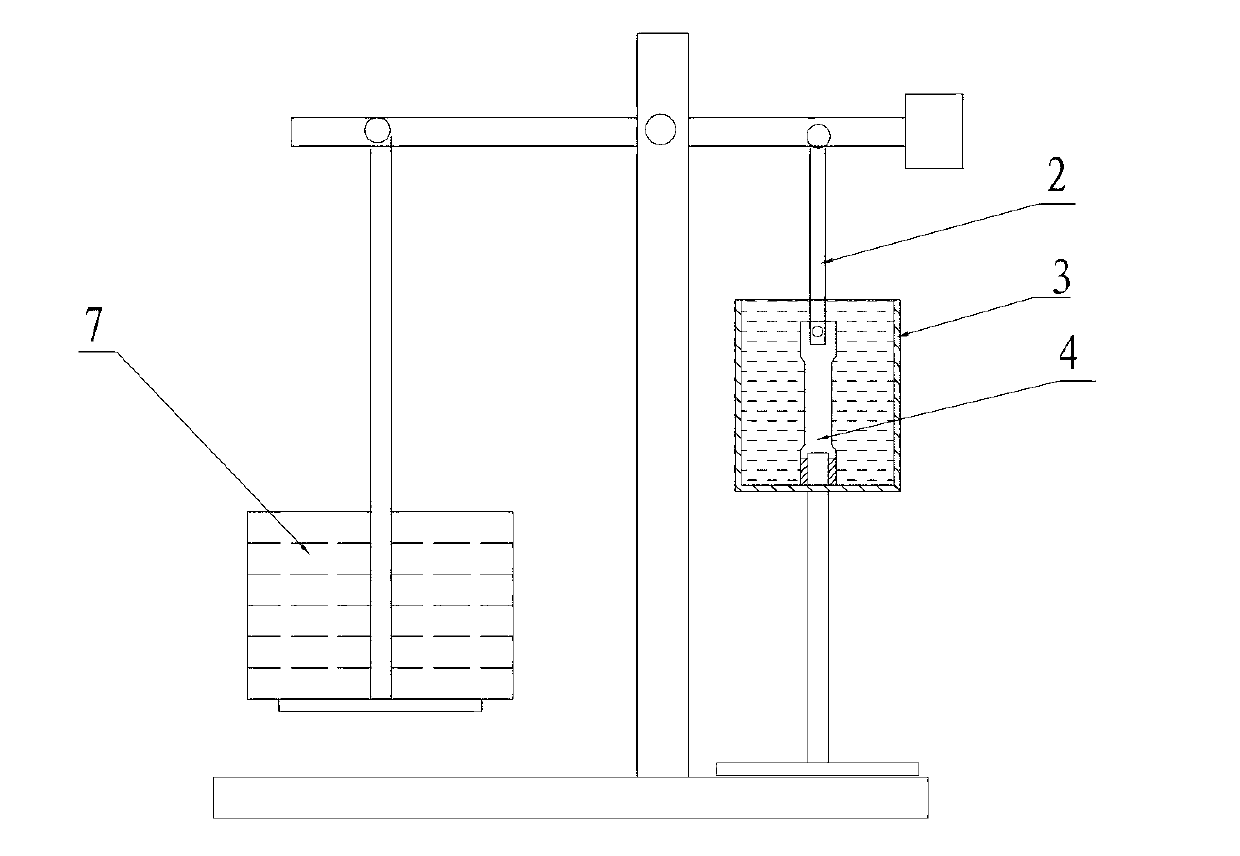

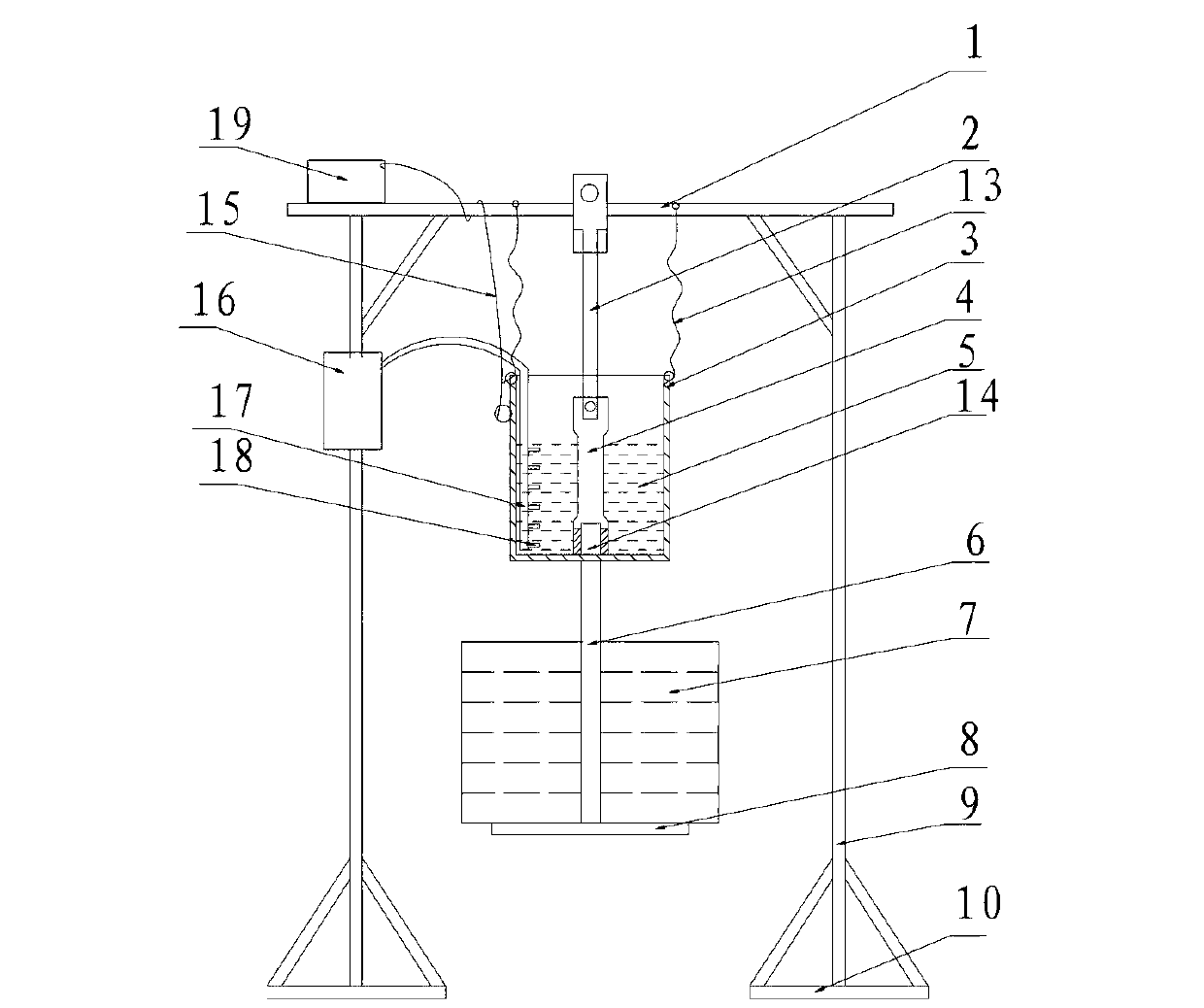

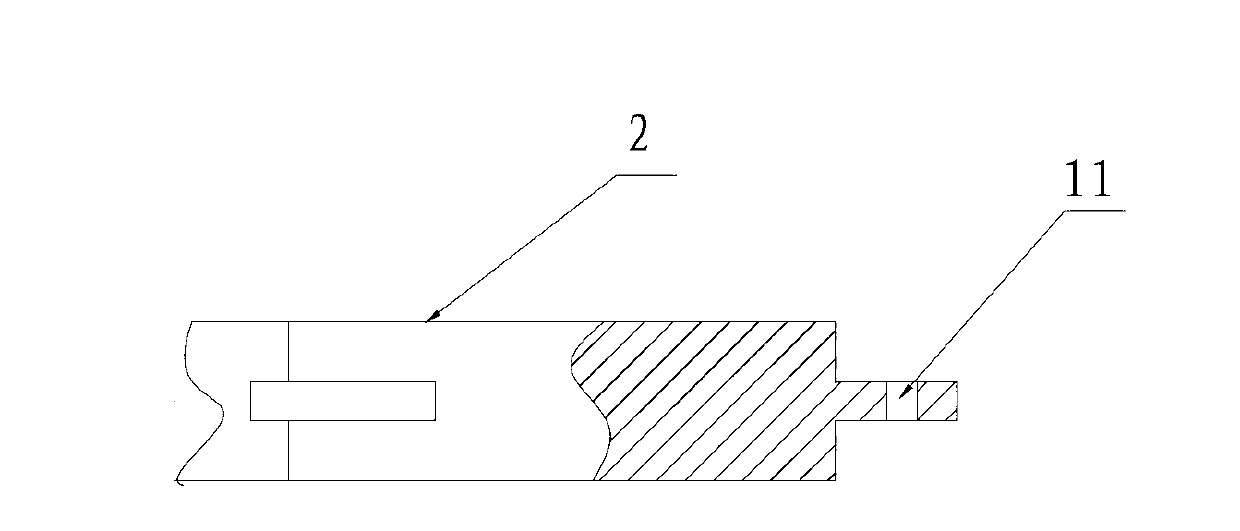

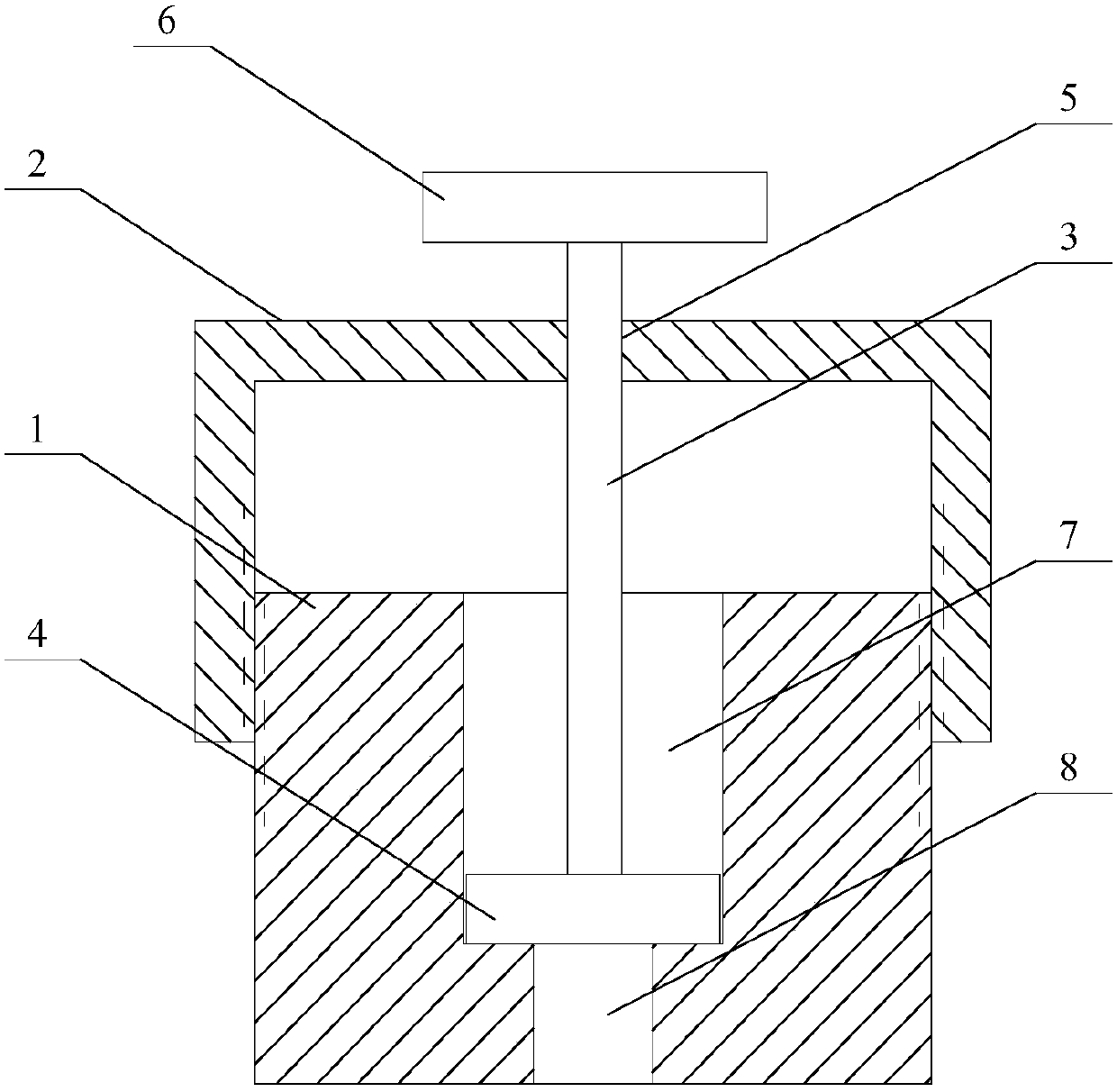

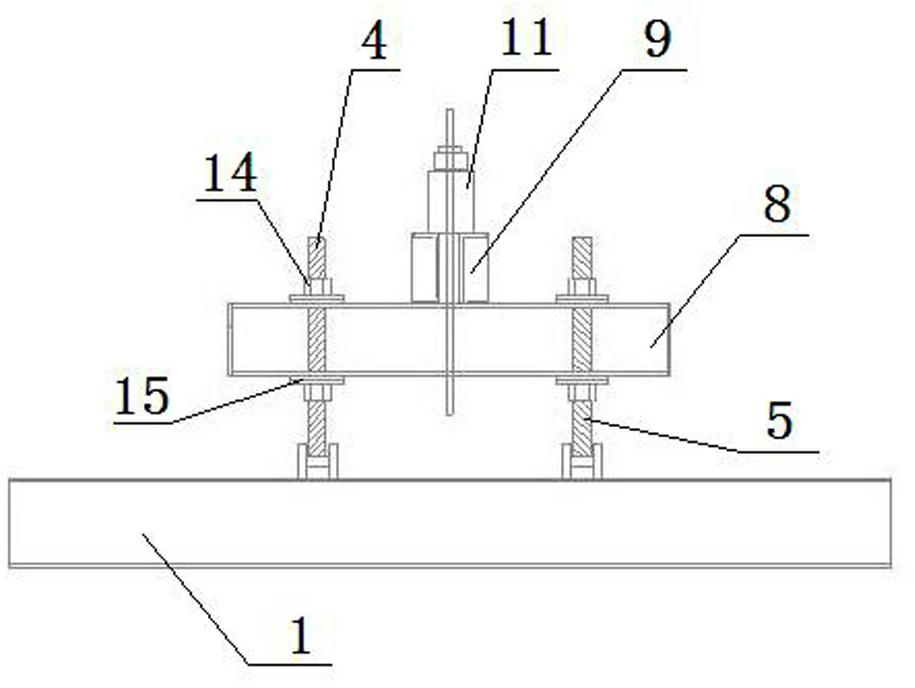

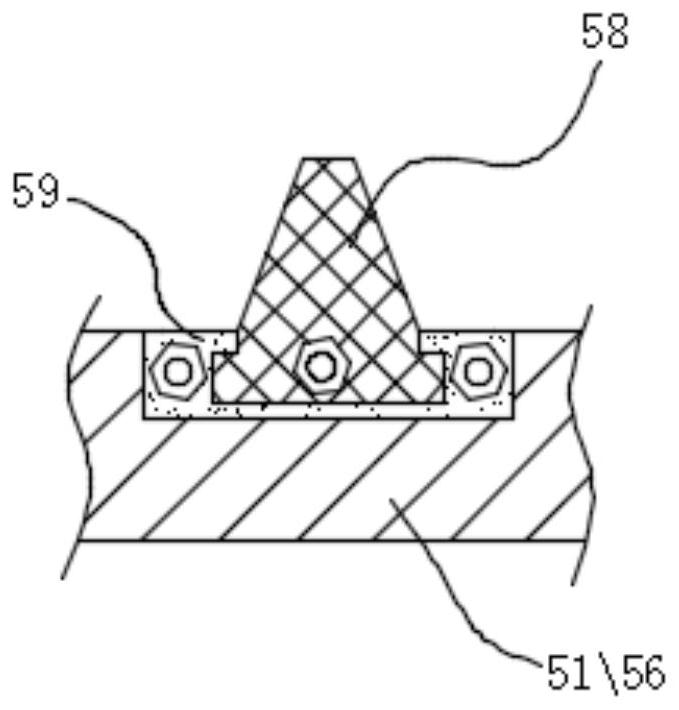

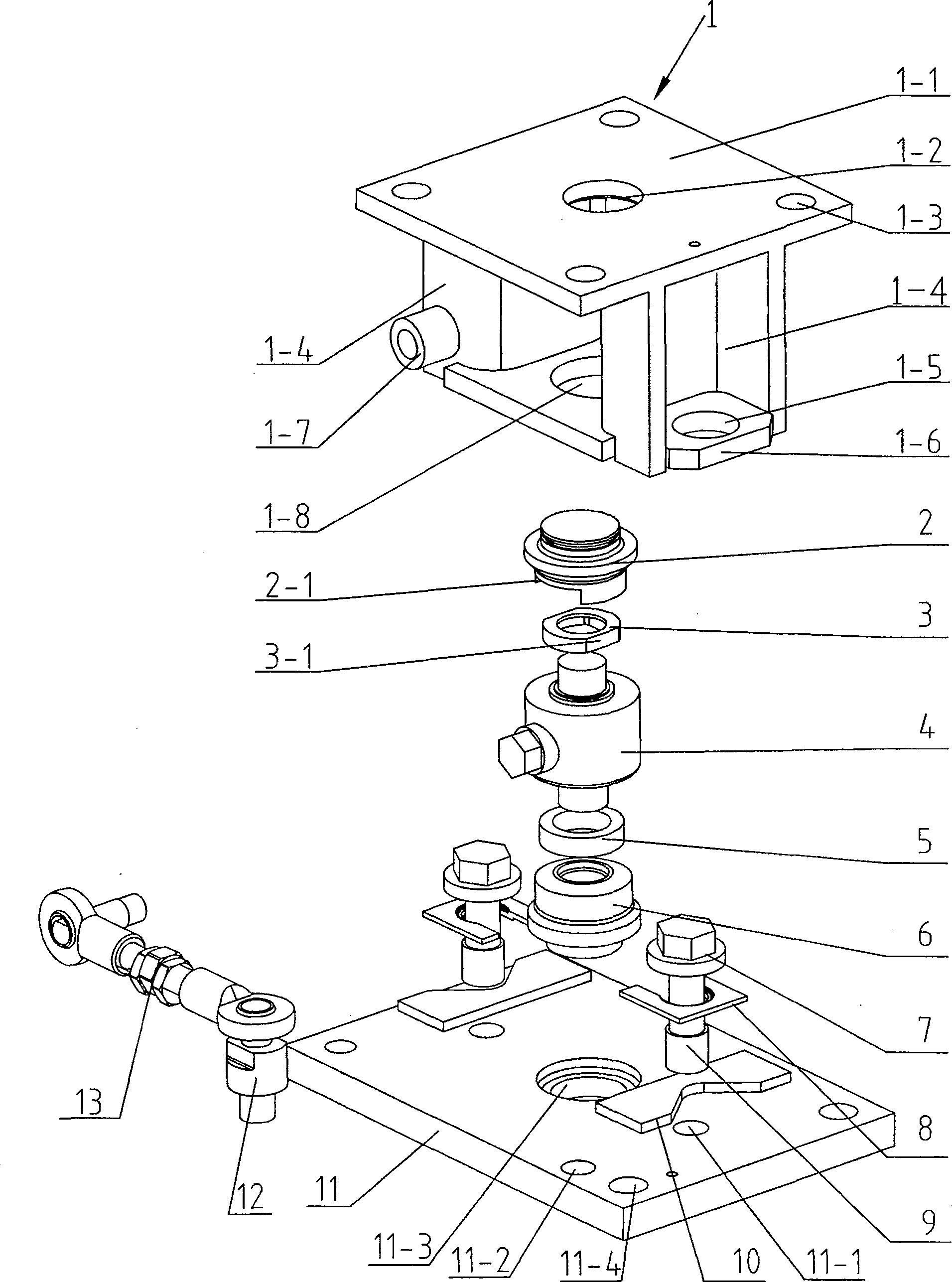

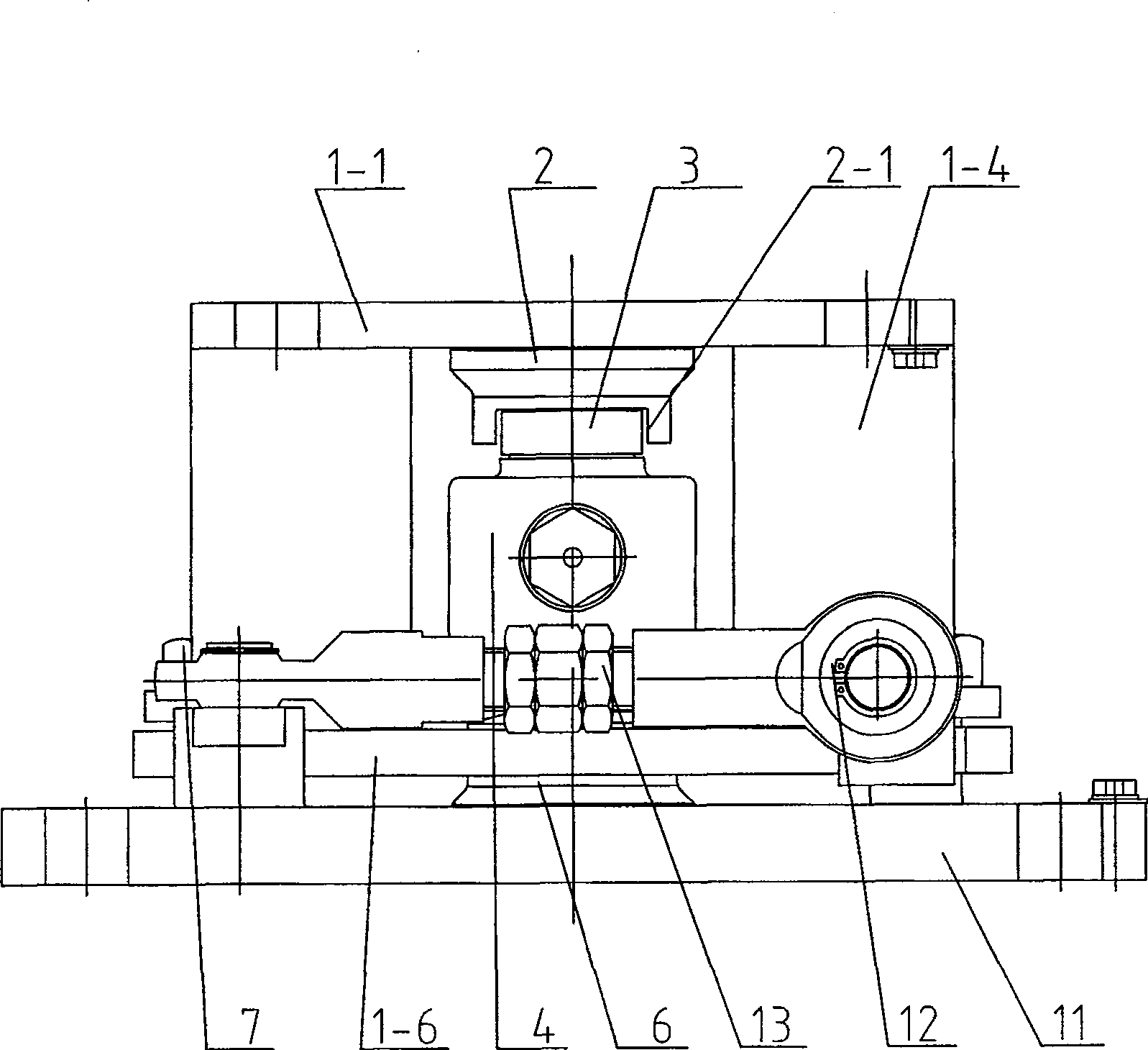

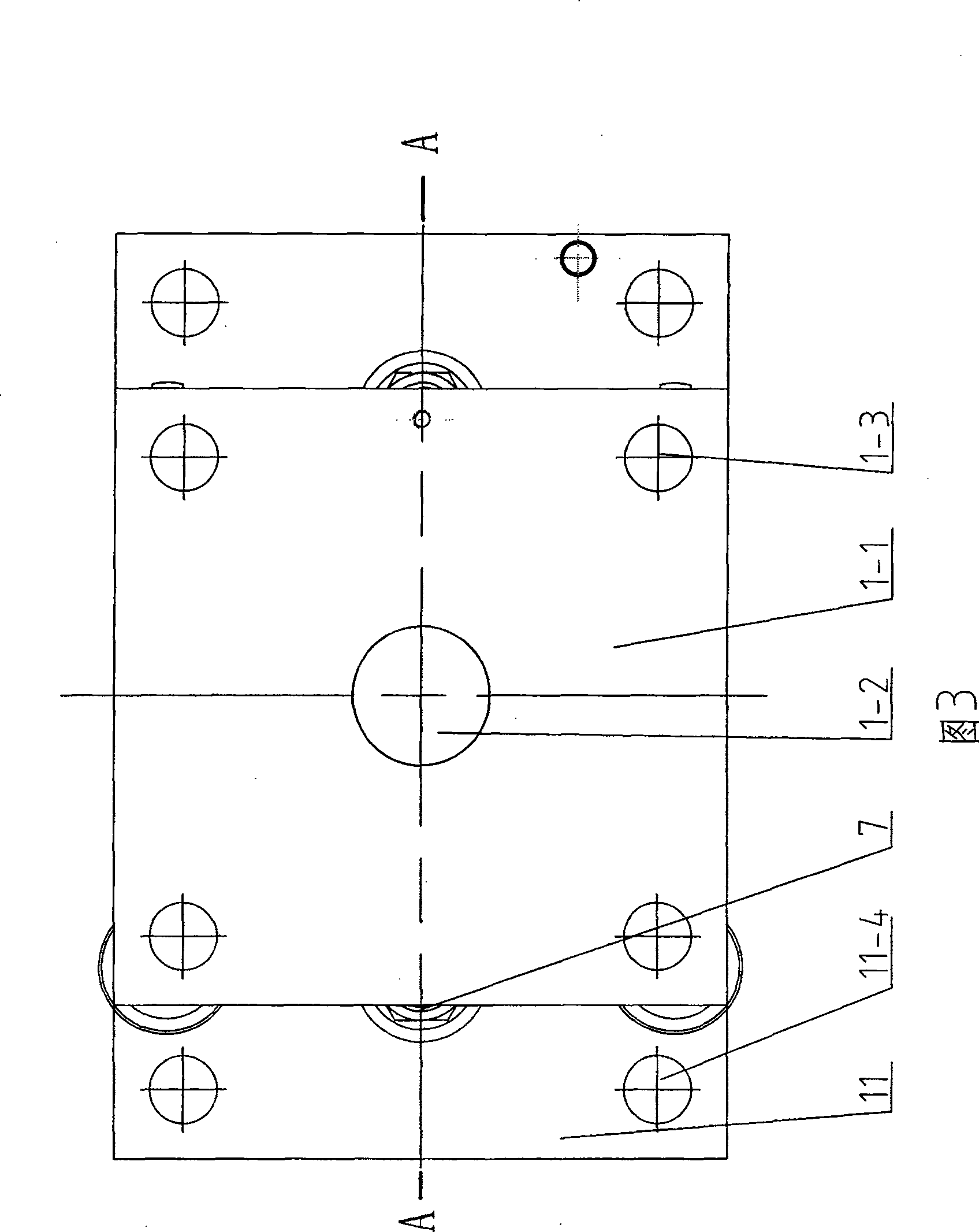

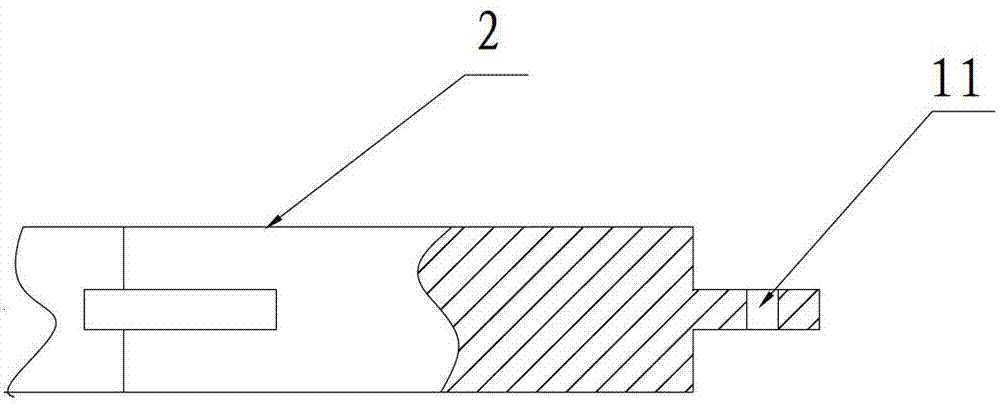

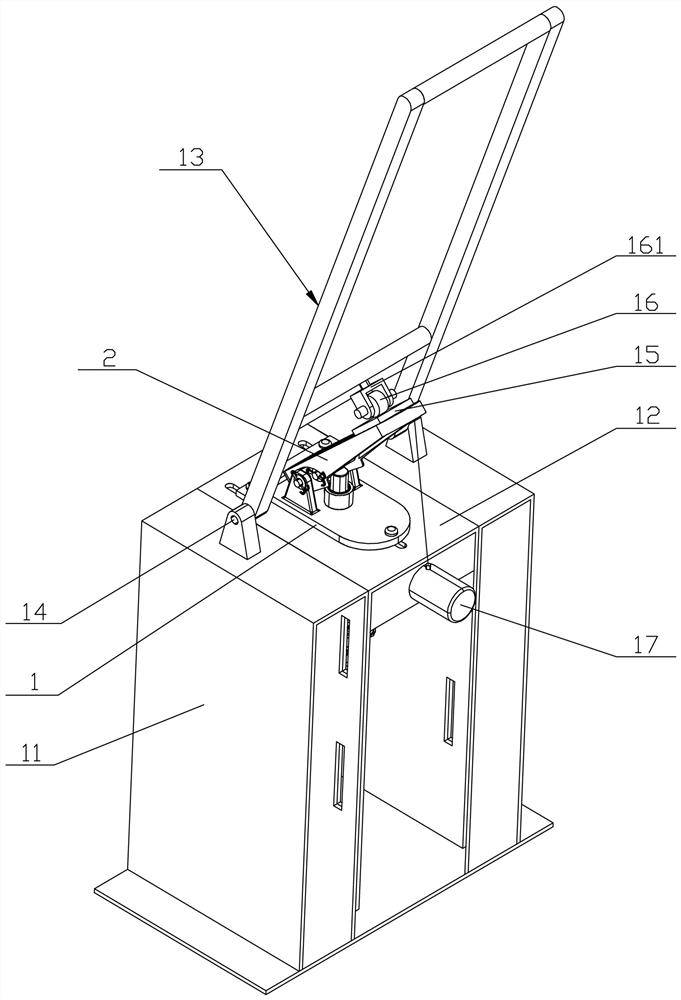

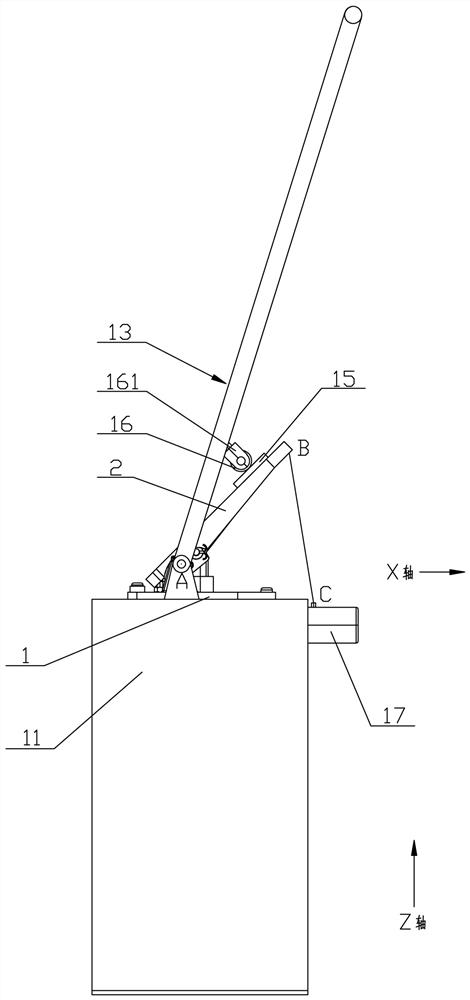

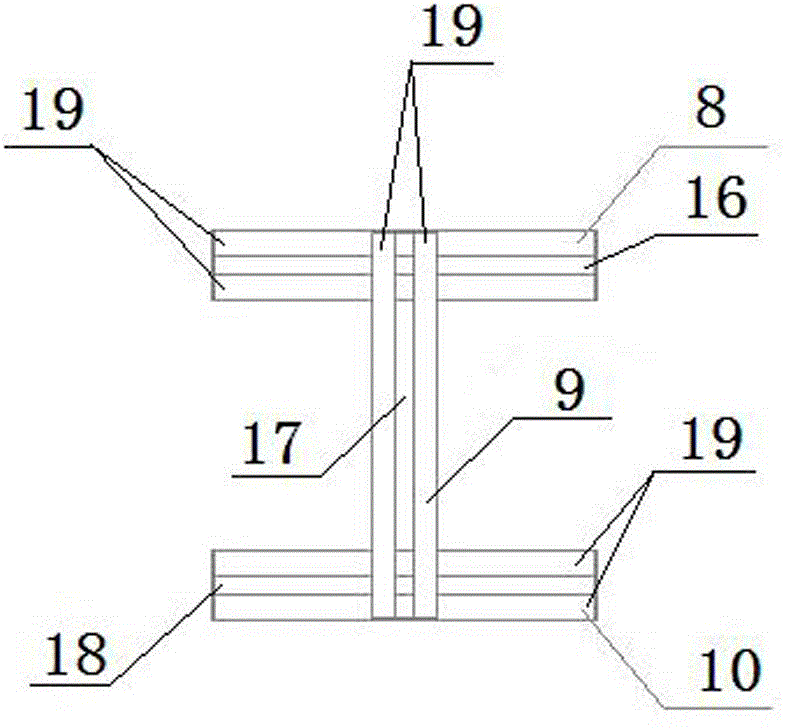

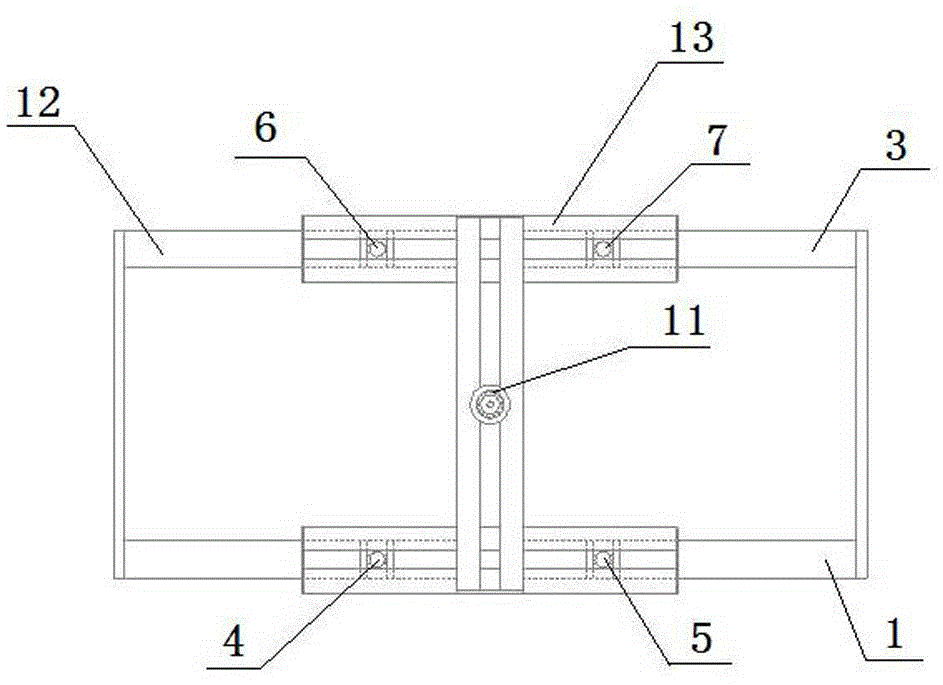

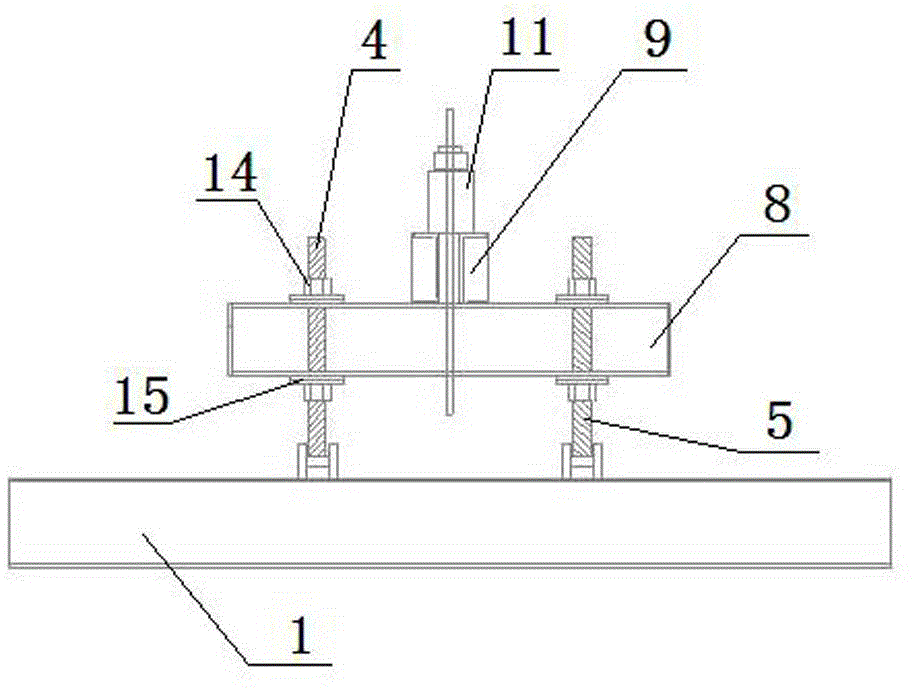

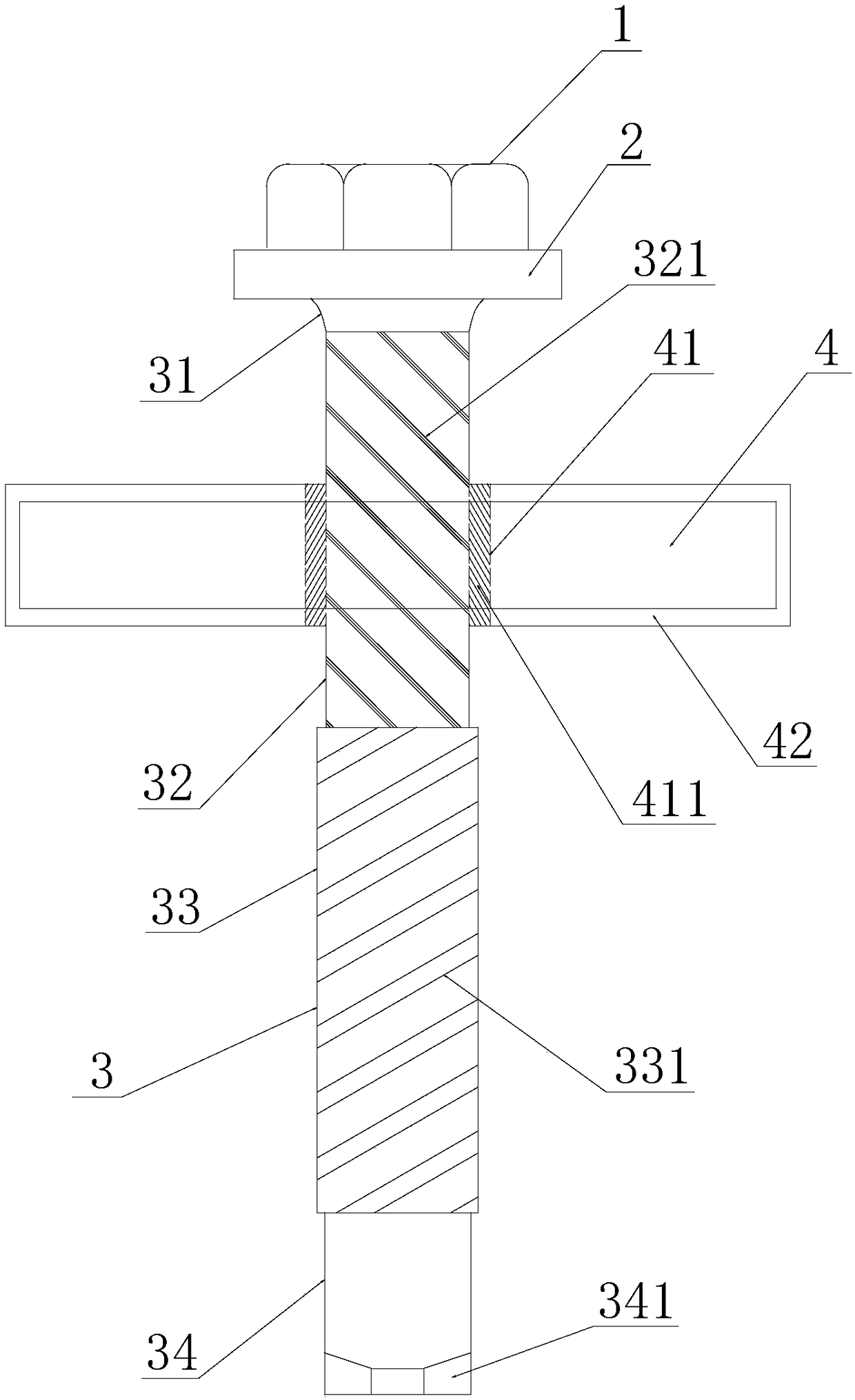

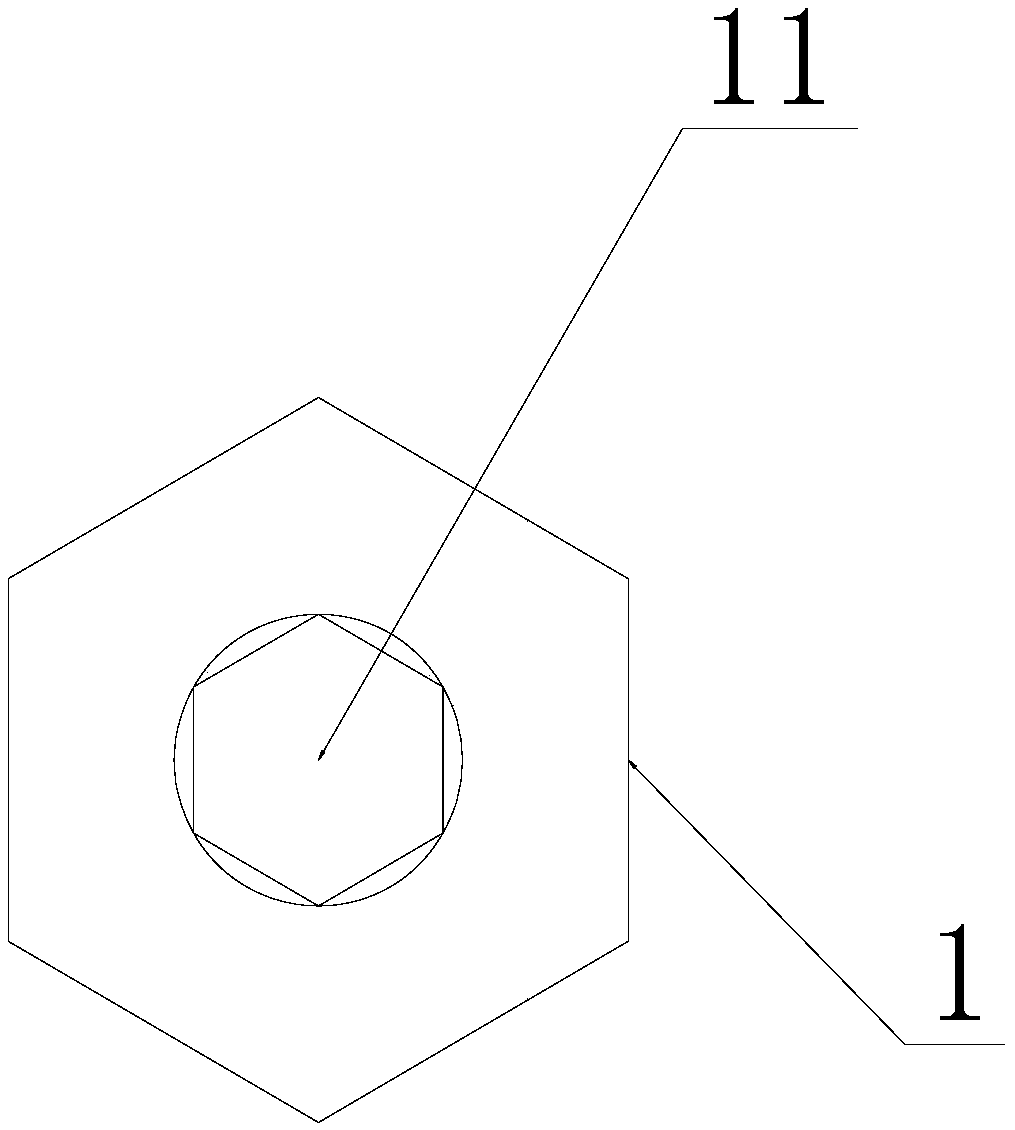

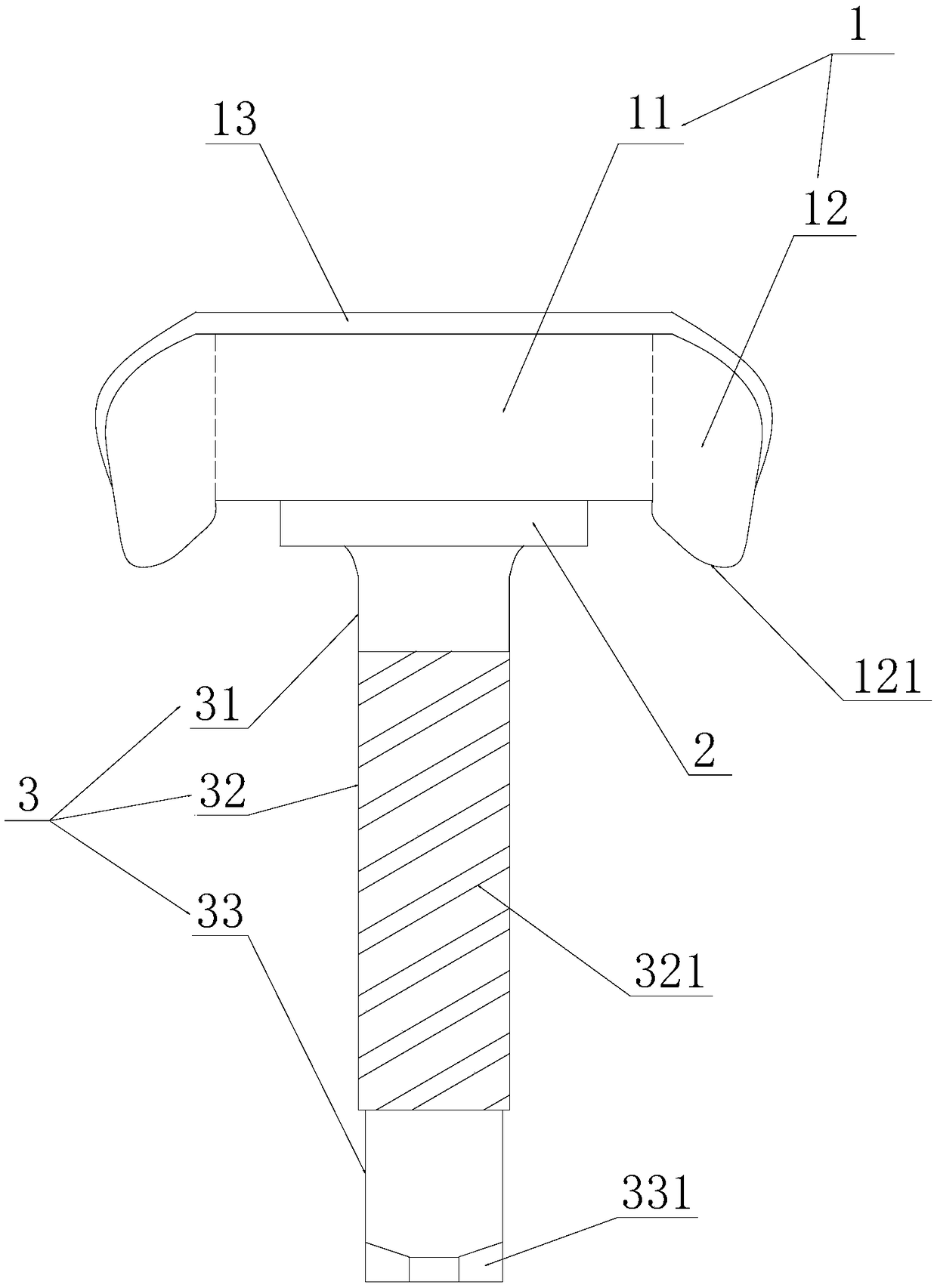

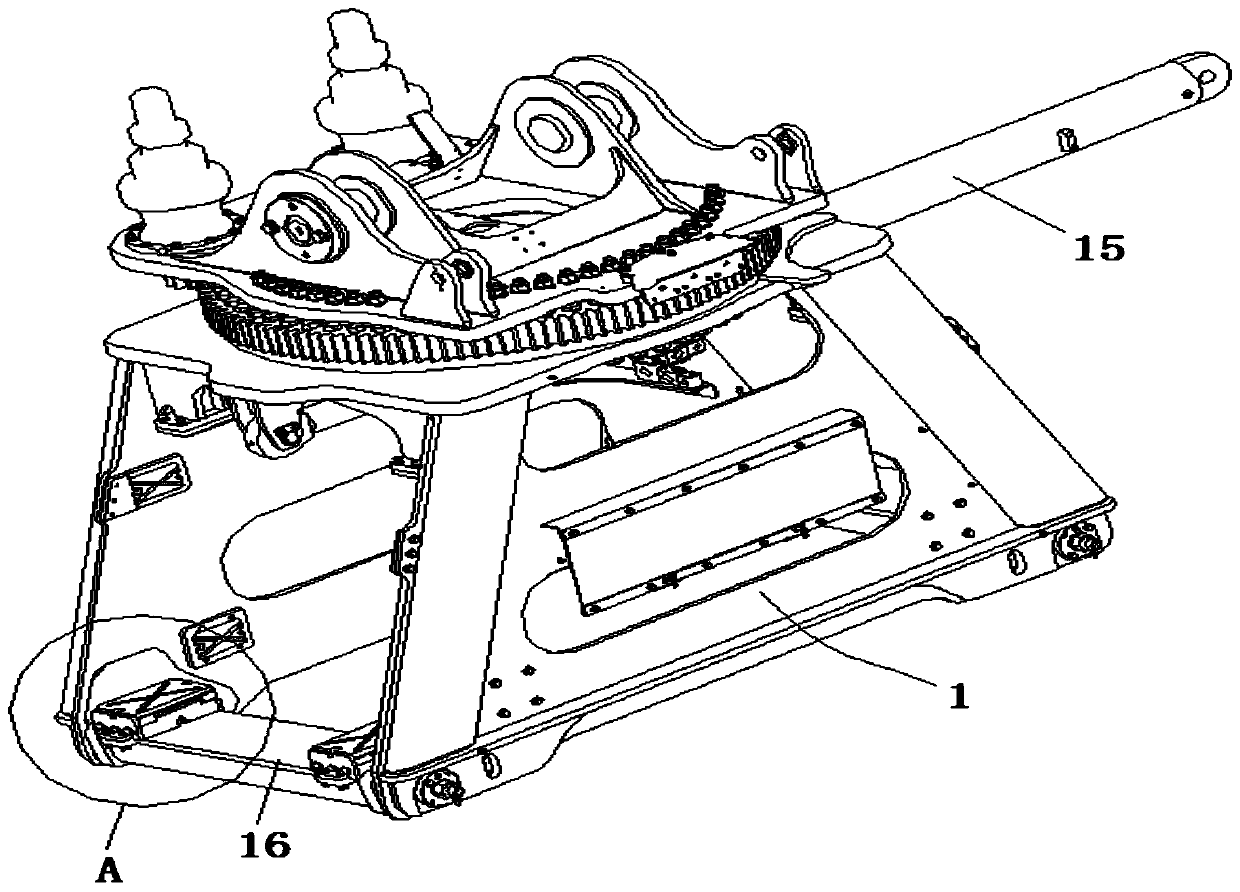

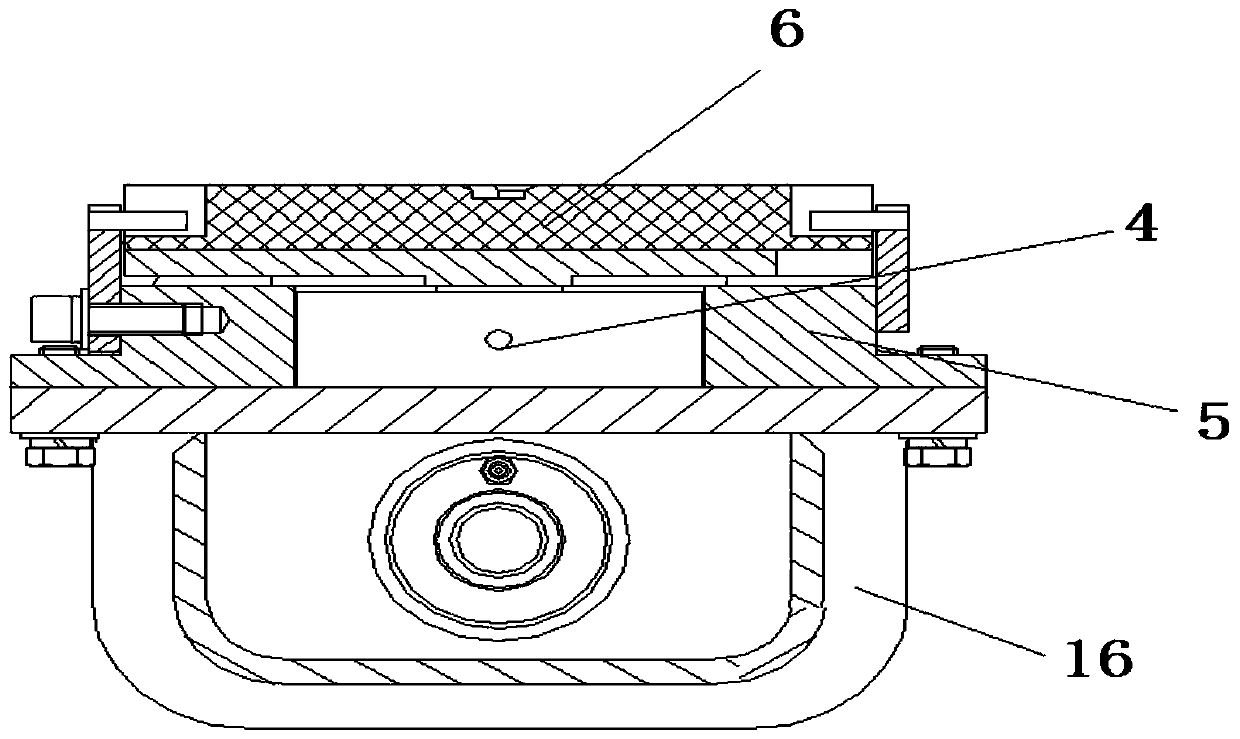

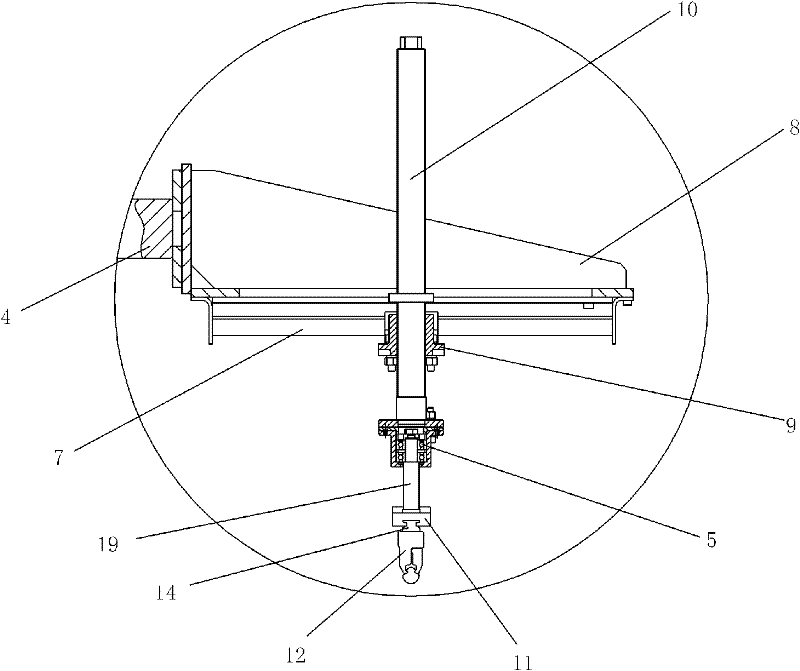

InactiveCN101949730AGuaranteed vertical forceEasy to adjustWeighing apparatus detailsSpecial purpose weighing apparatusComputer moduleLoad cell

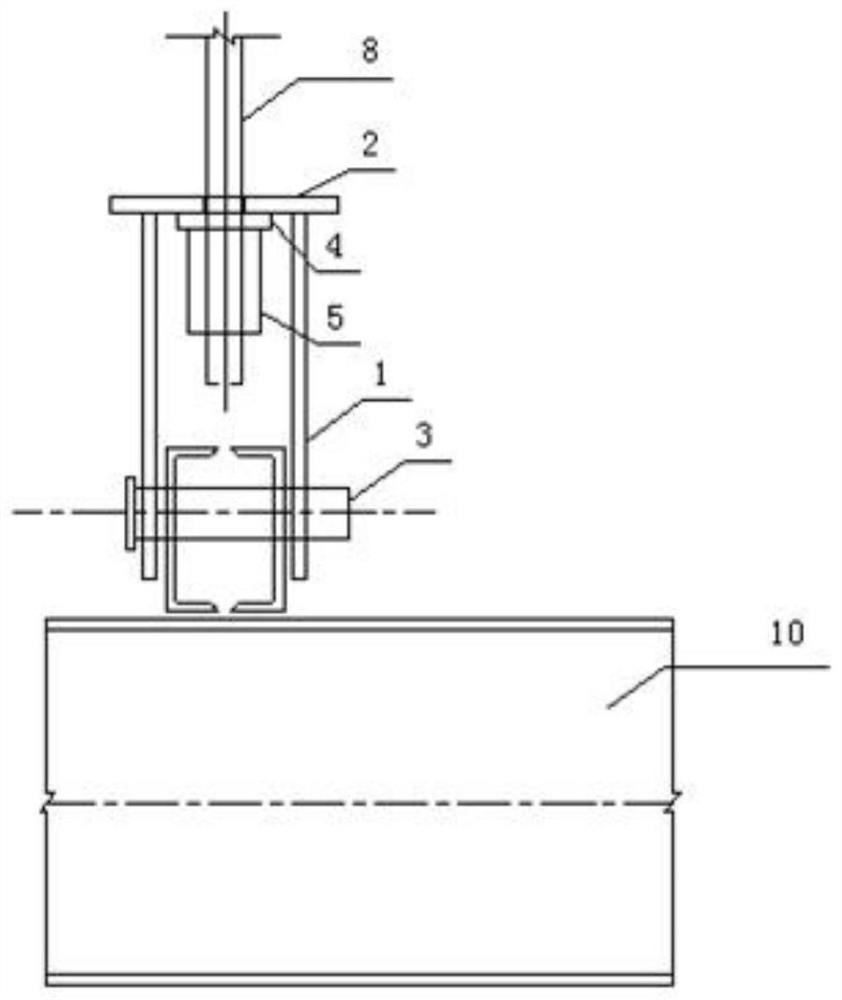

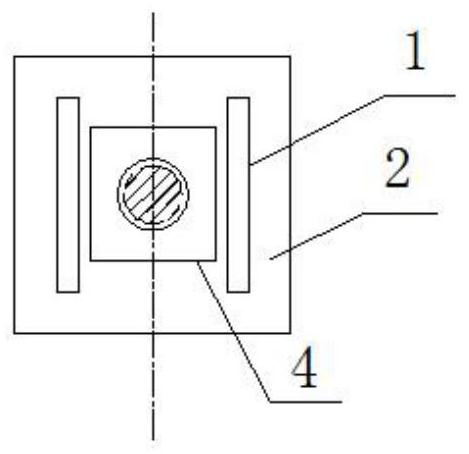

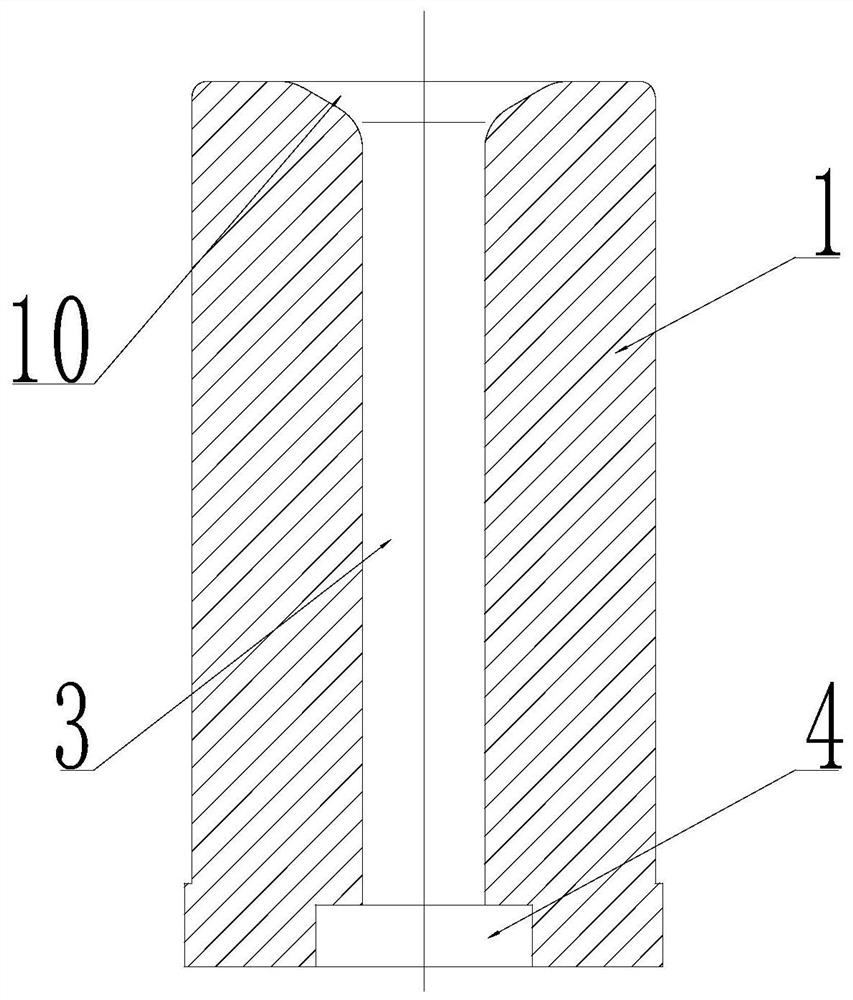

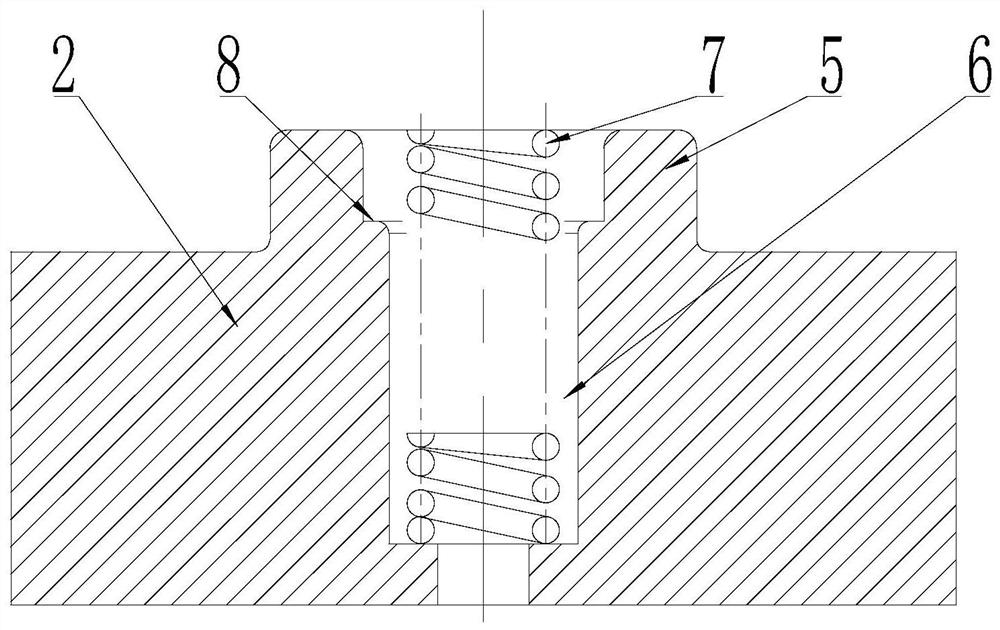

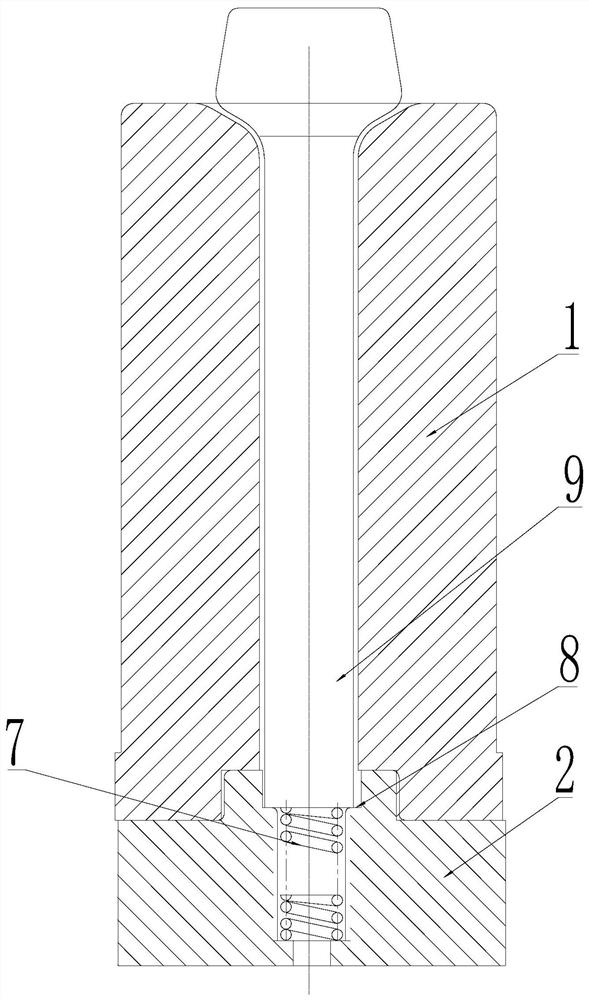

The invention relates to a weighing module which comprises a base and a weighing sensor, wherein the connecting side of the weighing sensor is installed on the base by a fastener; the base is provided with more than two installation holes; both side faces of the weighing sensor are connected with the wall of a spacing groove; the bearing side of the weighing sensor is provided with blind holes in a vertical direction; a top board or / and a bottom board of a frame-shaped rack is provided with installation holes; a bearing piece with spacing holes at the bottom is screwed on the top board of the frame-shaped rack and is fixed with the top board by a fastening bolt; both end surfaces of a rocking column respectively come into contact with the bottom surfaces of the blind holes and the top surfaces of the spacing holes; protective space A is arranged between the upper end surface of the weighing sensor and the bottom surface of the bearing piece; two horizontal spacing bolts are respectively installed on two side boards and positioned on both sides of the weighing sensor; and protective space B is arranged between the end surfaces of the horizontal spacing bolts and both side faces of the weighing sensor. The weighing module has the characteristics of high weighing precision, safety, reliability, convenient installation and maintenance, stable operation, low manufacturing cost and wide application range.

Owner:METTLER TOLEDO (CHANGZHOU) MEASUREMENT TECH CO LTD +2

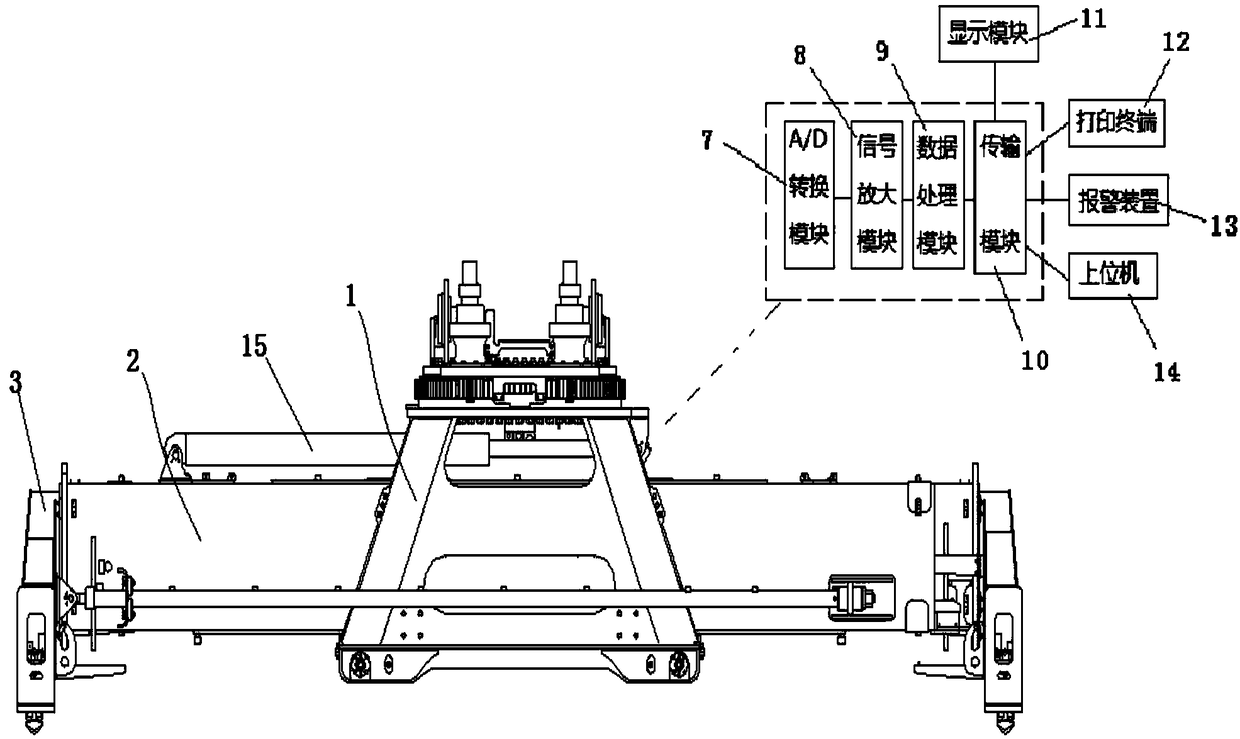

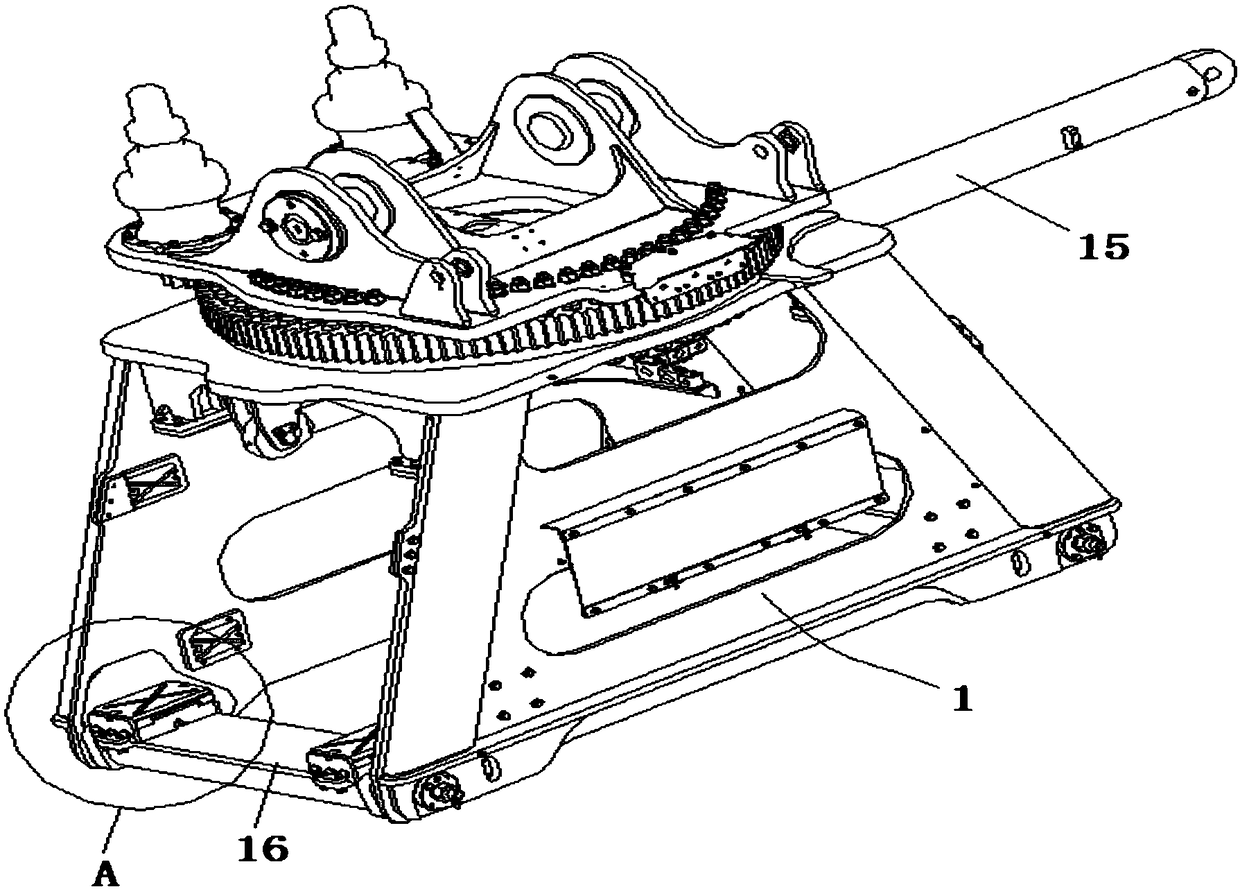

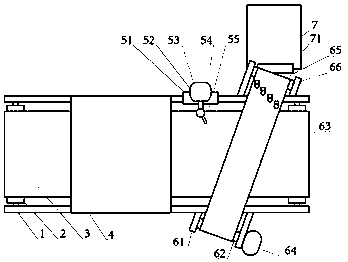

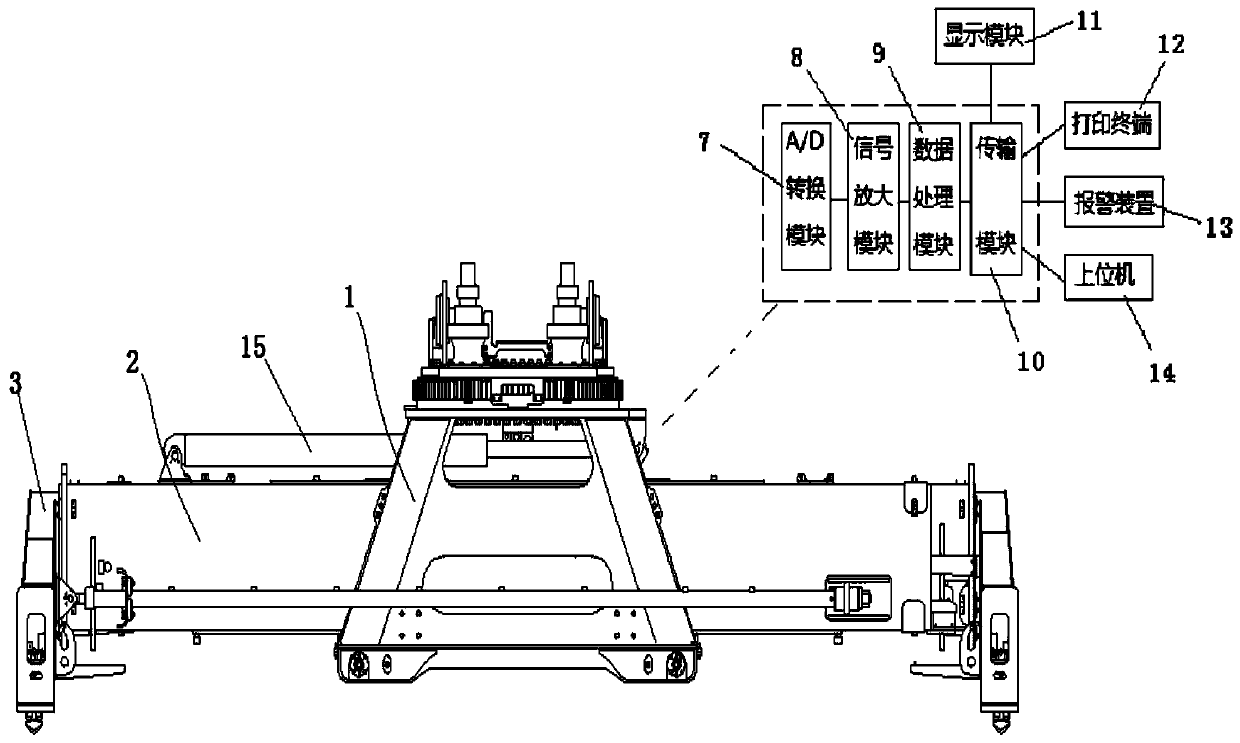

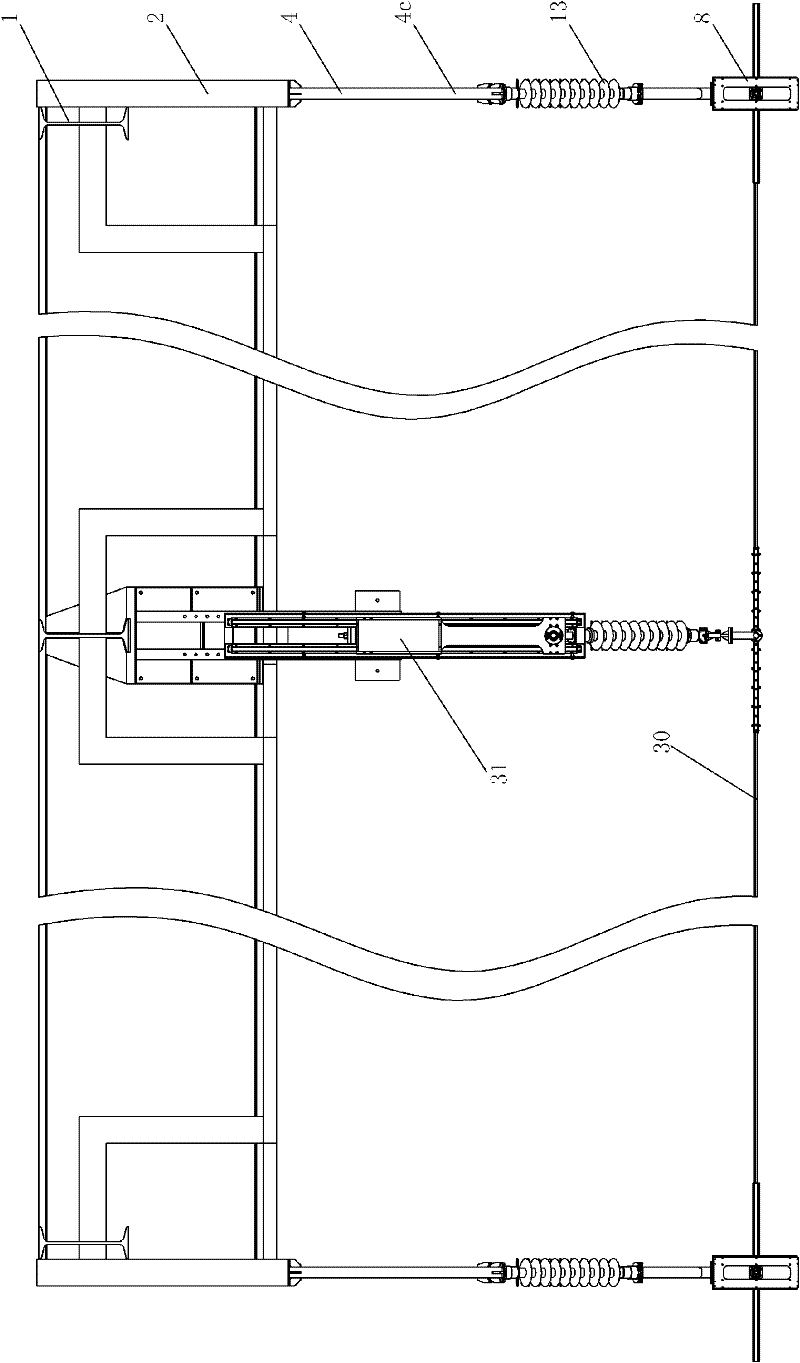

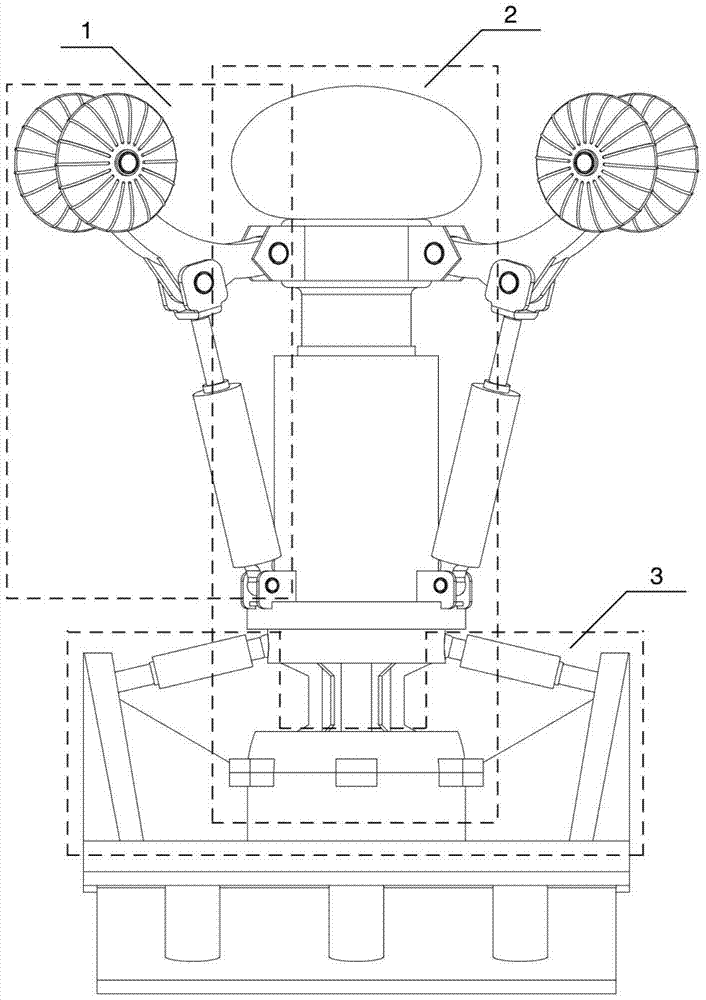

Container overloading and unbalanced loading detection and protection system and method, and reach stacker

ActiveCN108862036AGuaranteed vertical forceGuaranteed weighing accuracyWeighing auxillary devicesSafety gearComputer moduleComputer terminal

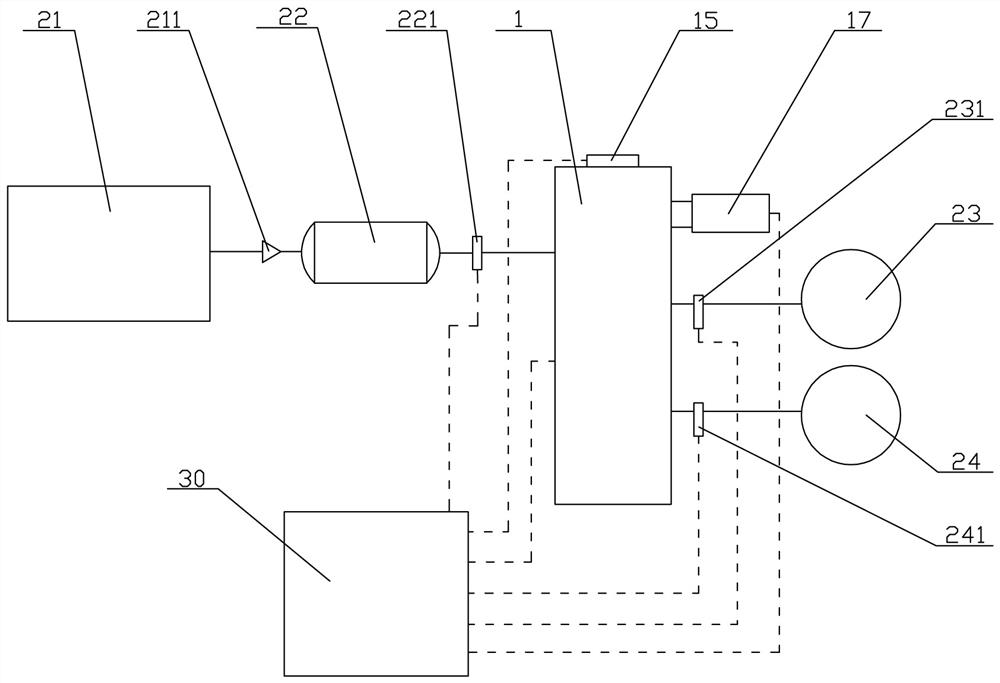

The invention discloses a container overloading and unbalanced loading detection and protection system and method, and a reach stacker, and relates to the field of container overloading and unbalancedloading detection and protection devices and methods. The container overloading and unbalanced loading detection and protection system comprises four weighing sensors mounted in a main body crossbeam, an electric control cabinet, a display module, a printing terminal, an alarming device and an upper computer, wherein the electric control cabinet is integrated with an A / D conversion module, a signal amplification module, a data processing module and a transmission module, and the display module, the printing terminal, the alarming device and the upper computer are mounted in a cab. Weight signals collected by the weighing sensors are sent to the electric control cabinet, result data processed by the electric control cabinet are sent to the display module through the transmission module tobe displayed, sent to the printing terminal to be printed, sent to the alarming device for pre-warning and sent to the upper computer to be shared. In order to overcome the defects of inconvenience and inaccuracy during overloading and unbalanced loading weighing of a container in the prior art, the rapid and accurate container overloading and unbalanced loading detection and protection system andmethod, and the reach stacker are provided, and the container overloading and unbalanced loading limiting case can be alarmed, displayed and recorded in real time.

Owner:上海亿锤机械科技有限公司

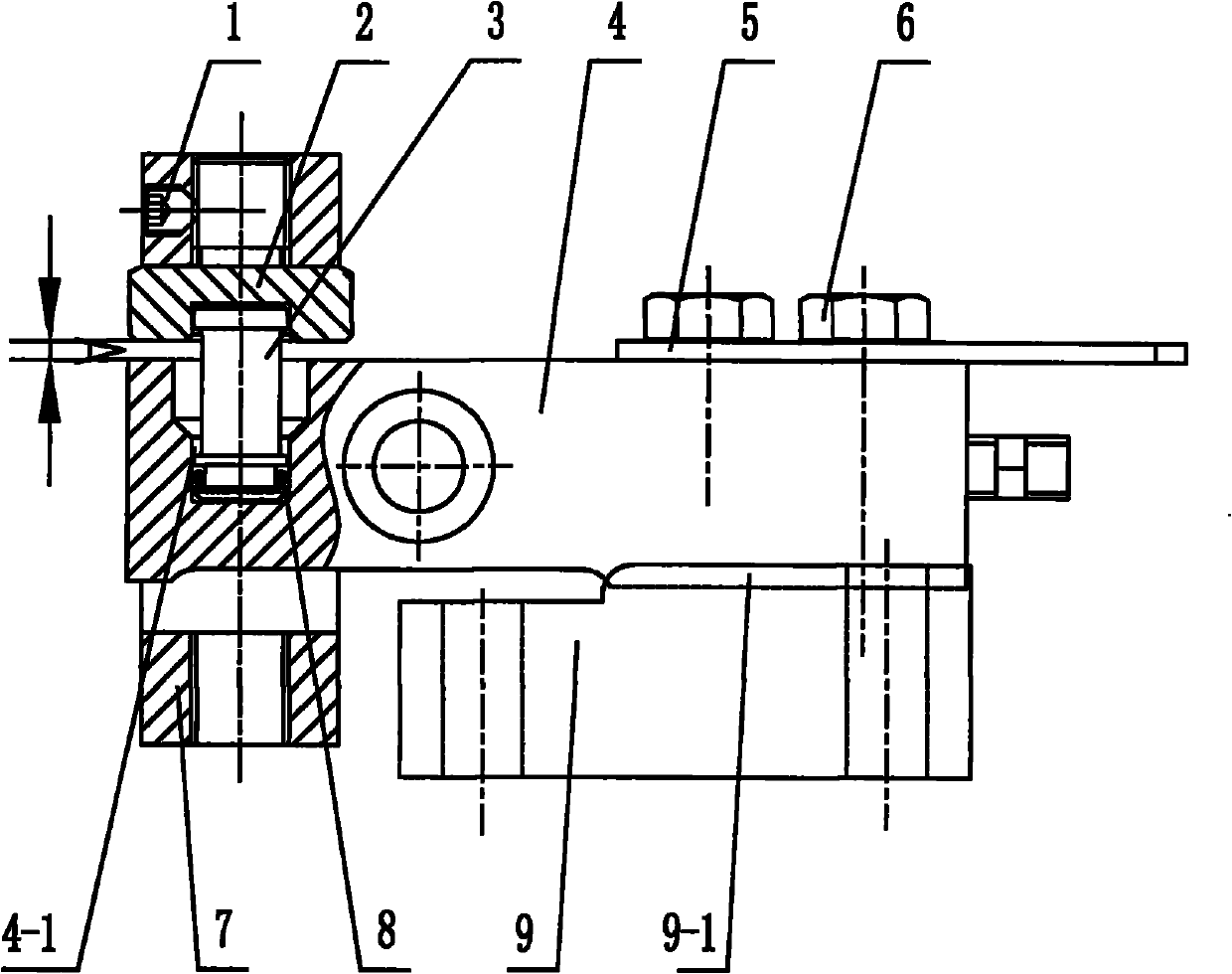

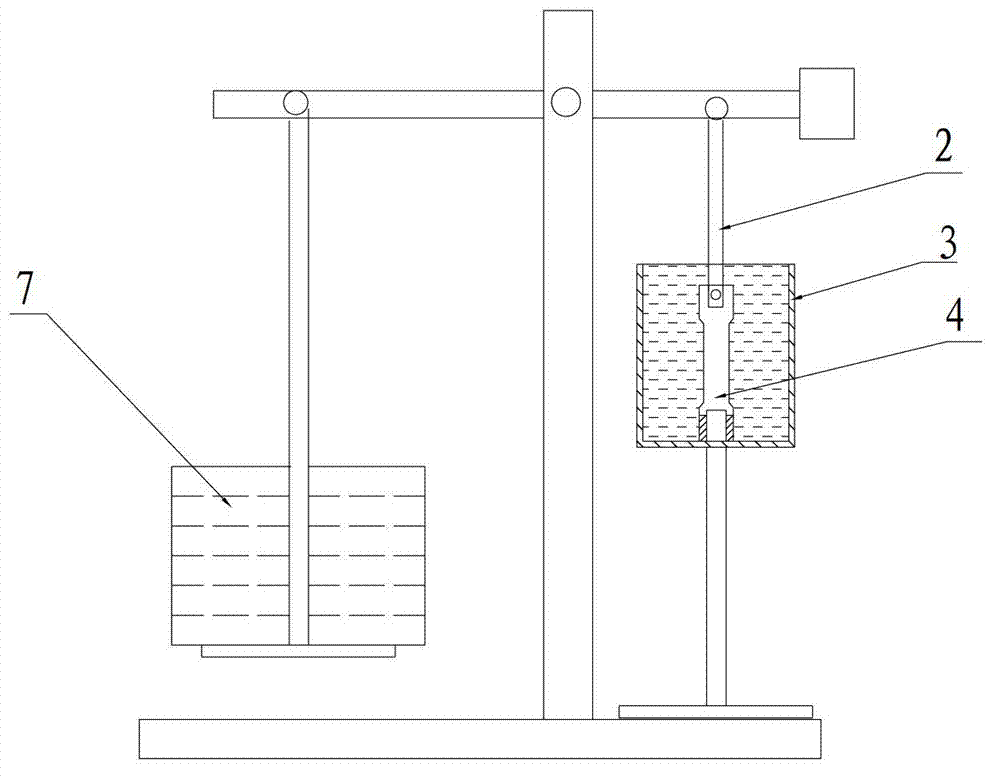

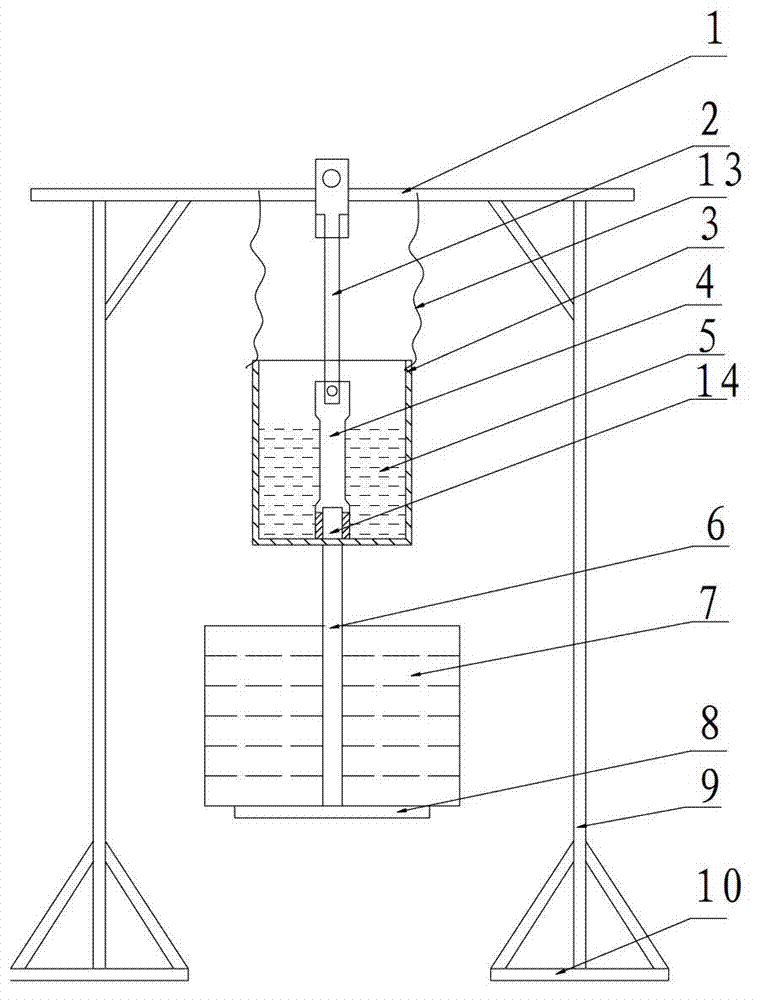

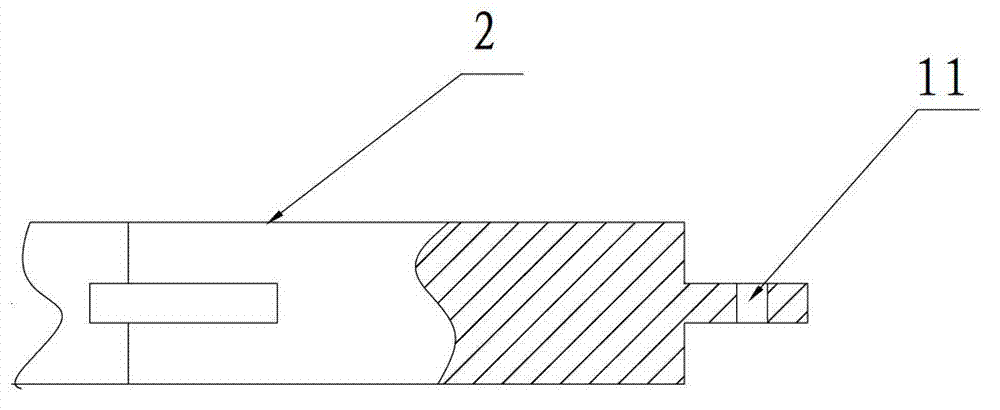

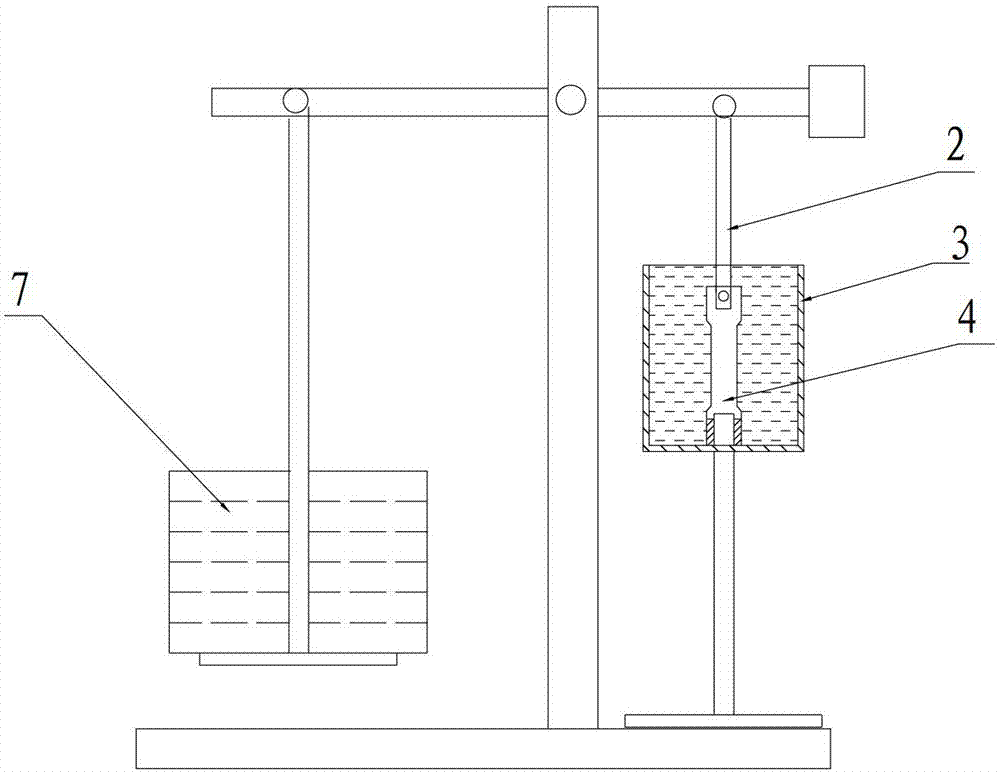

Sample pull stress corrosion tester

InactiveCN103091235AThe detection data is accurateDetection data is reliableWeather/light/corrosion resistanceEngineeringAlloy

The invention relates to a sample pull stress corrosion tester comprising a bracket, a corrosion cup, weights, an upper traction rod and a lower traction rod. The sample pull stress corrosion tester is characterized in that the bracket comprises a transverse beam; the upper end of the upper traction rod is connected with the transverse beam and the lower end of the upper traction rod is connected with a sample; the upper end of the lower traction rod is fixedly connected with the bottom end of the corrosion cup and the lower end of the lower traction rod is provided with a weight base; the weights are stacked on the weight base; and a sample clamping device is arranged at the bottom of the corrosion cup. The upper part of the corrosion cup is further provided with safety ropes which are fixedly connected with the transverse beam. The sample pull stress corrosion tester has the beneficial effects that the structure is simple; detected data is accurate and reliable; and different alloy samples can be adjusted by the weights and the utilization is convenient.

Owner:龙口市丛林铝材有限公司

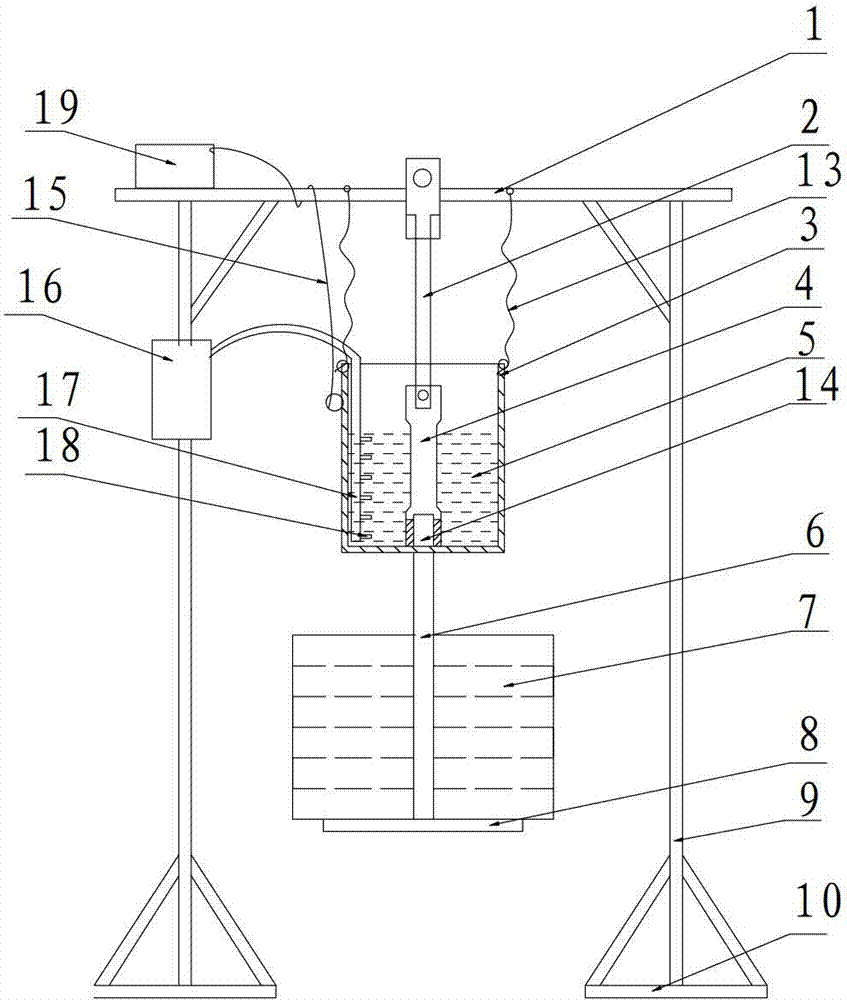

Rapid test sample tensile stress corrosion tester

ActiveCN103105354ASpeed up the experiment cycleTimely replacementWeather/light/corrosion resistanceTest sampleAir pump

The invention relates to a rapid test sample tensile stress corrosion tester which comprises a corrosive cup and a corrosive liquid timing stirring device, wherein the corrosive liquid timing stirring device comprises a main air tube which is inserted into the corrosive cup, branch air tubes connected with the main air tube and an air pump connected with the main air tube; the tester further comprises a bracket, weights, an upper traction rod and a lower traction rod, wherein the bracket comprises a transverse beam; the upper end of the upper traction rod is connected with the transverse beam; the lower end of the upper traction rod is connected with a test sample; the upper end of the lower traction rod is fixedly connected with the bottom end of the corrosive cup; a weight base is arranged at the lower end of the lower traction rod; the weights are stacked on the weight base; a safety rope which is fixedly connected with the transverse beam is further arranged at the upper part of the corrosive cup; and the tester further comprises a test sample breakage timing alarm device. The tester has the beneficial effects that the structure is simple, the detection data are accurate and reliable, and different alloy test samples can be adjusted by the weights, with convenience in use.

Owner:龙口市丛林铝材有限公司

A device used for testing interlaminar interfacial shear strength of a fiber composite material bar

ActiveCN108037020AWide range of applicationsAvoid eccentric forceMaterial strength using steady shearing forcesFibrous compositesInterfacial shear

The invention provides a device used for testing interlaminar interfacial shear strength of a fiber composite material bar, and belongs to the technical field of devices used for testing interlaminarinterfacial shear strength of fiber composite material bars. The center of a bearing pedestal is provided with a cavity for a bar to be tested. The bearing pedestal below the cavity for the bar to betested is provided with a through hole. A fixing top cover is threaded to the bearing pedestal. The center of the fixing top cover is provided with a pressing bar hole. A force bearing pressing bar isconnected to the pressing bar hole in the fixing top cover in an up-down sliding manner. The top end of the force bearing pressing bar is fixed to a force bearing bar top disc. The inner hole diameter of the bearing pedestal and the height of the cavity can be designed according to different fiber bar diameters and testing heights, and shear strength of different cross sections can be obtained byadopting different pressing bar diameters, and therefore the application range of the device is wide. The fixing top cover firmly fixes the force bearing pressing bar to the bearing pedestal throughthreaded connection, thus ensuring vertical forcing applying on a fiber bar in a testing process of the device, and avoiding eccentric force applying.

Owner:HARBIN INST OF TECH

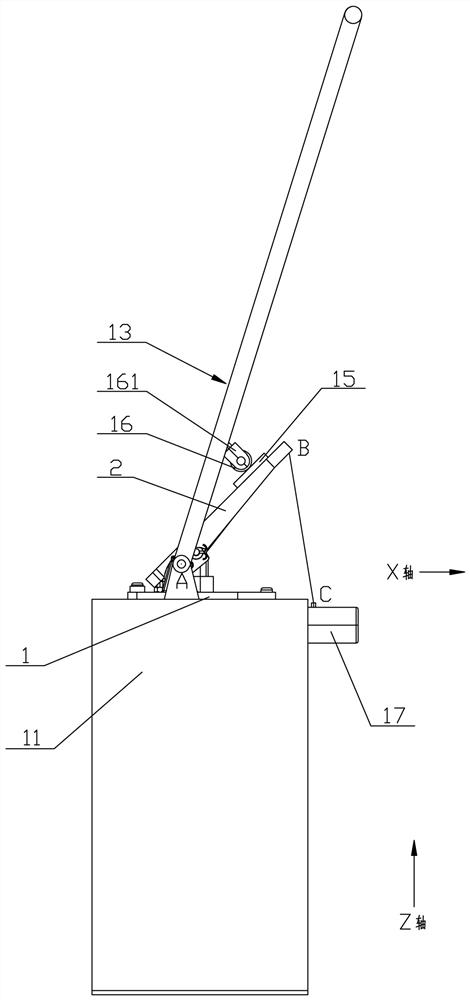

Reaction frame testing method for earth nail drawing tests

ActiveCN102677710AGuaranteed vertical forceSolve the detection speed is slowFoundation testingExcavationsSoil nailingBearing surface

The invention discloses a reaction frame testing method for earth nail drawing tests. The reaction frame testing method is realized through a reaction frame consisting of a base and a stress support. The base is connected with the stress support through screws, and a bearing surface of the stress support can be guaranteed to be coaxial with an earth nail by adjusting the screws. A jack is mounted on the stress support to form a jack reaction system. During testing, the earth nail can be fixed with the jack after being lengthened, and perpendicular stress is guaranteed by adjusting the screws. By adjusting the screws between the stress support and the support, stress surface on the wall at any gradient can be adjusted optionally, the perpendicular stress of the earth nail can be guaranteed, and testing speed and testing quality of the earth nail can be improved greatly.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

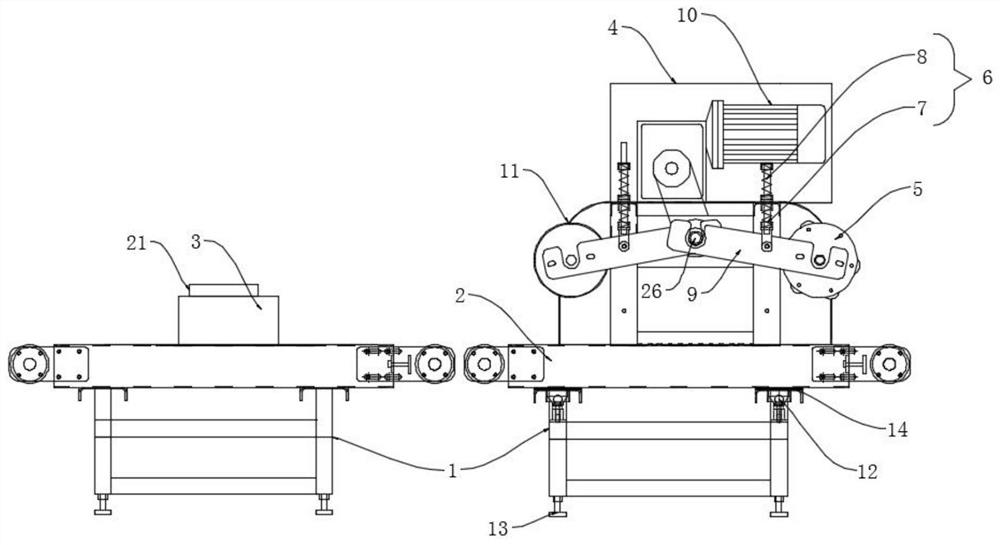

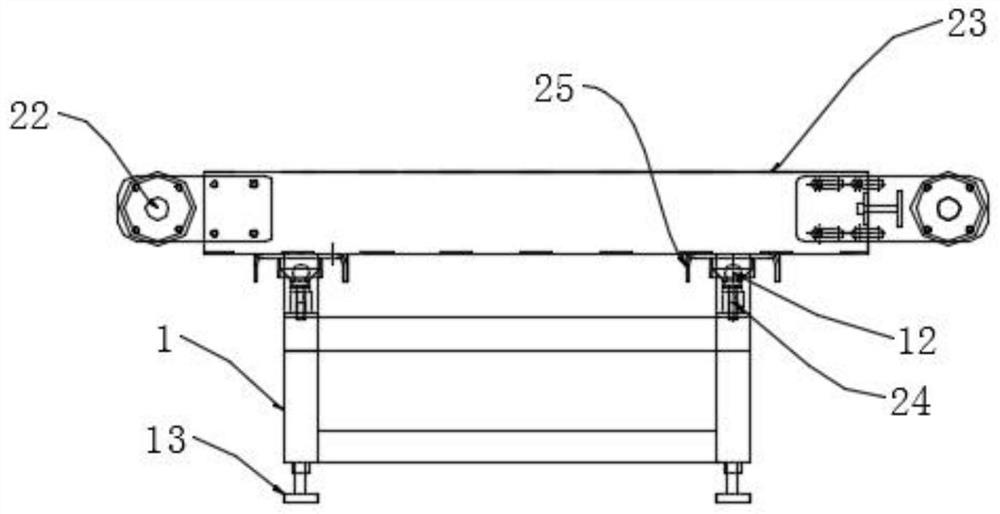

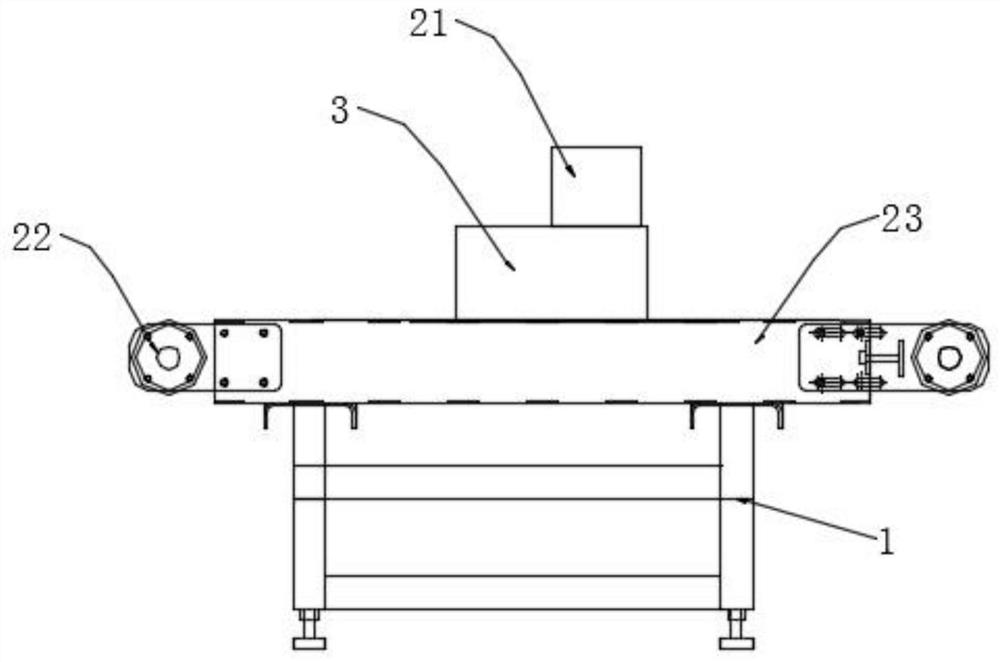

Defective board sorting device

InactiveCN107716347AGuaranteed vertical forceWon't touch by mistakeOther workshop equipmentSortingEngineeringConveyor belt

The invention provides a defective board sorting device which comprises a rack, a delivery mechanism, a detecting mechanism and a sorting mechanism. The detecting mechanism is arranged on the deliverymechanism, and the sorting mechanism is arranged on the upstream position of the detecting mechanism and horizontally arranged on a conveyor belt in a crossing mode; the sorting mechanism further comprises delivery wheels which are arranged on supports, the delivery wheels on one side are connected with a motor, and a belt is arranged between the delivery wheels on the two sides; a sorting push block is arranged on the surface of the belt, and an interval between the bottom of the sorting push block and the delivery mechanism is smaller than the thicknesses of boards; and when the belt is driven by the motor to move, the sorting push block can push the boards below the sorting mechanism from the side face, and the boards can be removed from the delivery mechanism. Compared with the priorart, the defective board sorting device has the remarkable advantages and the beneficial effects that when the defective boards are sorted from the delivery mechanism, it can be ensured that the boards are perpendicularly stressed, and the adjacent boards cannot be collided mistakenly; and the sorting mechanism is obliquely arranged, the pushing block can move along with the boards, and the defective board sorting device is suitable for high-speed conveyor belts.

Owner:湖州市新庭吉家居科技有限公司

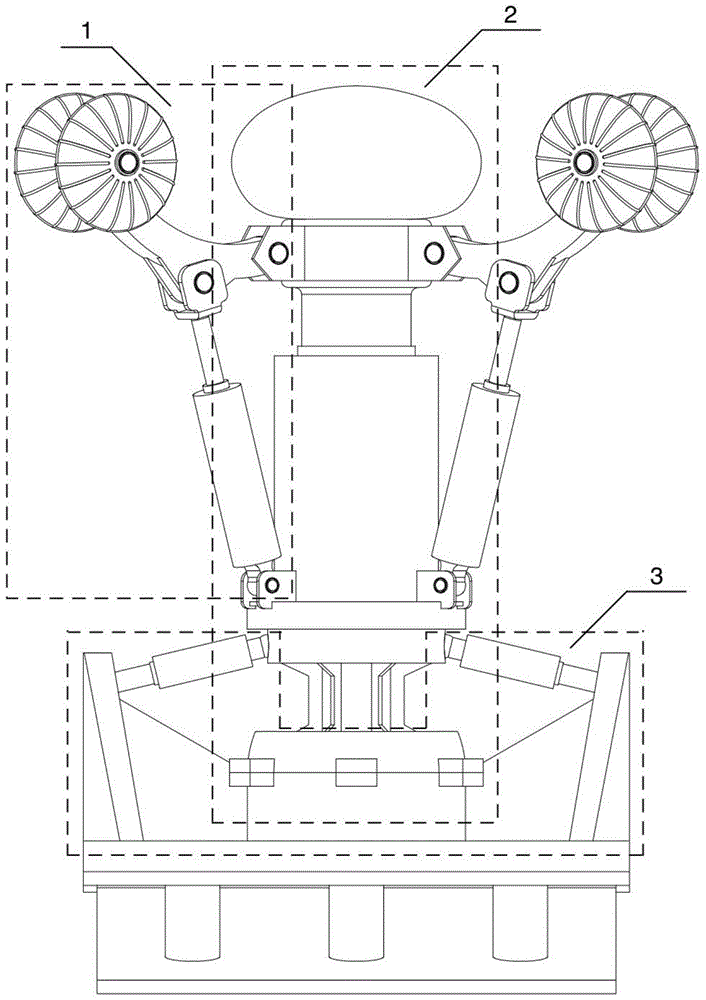

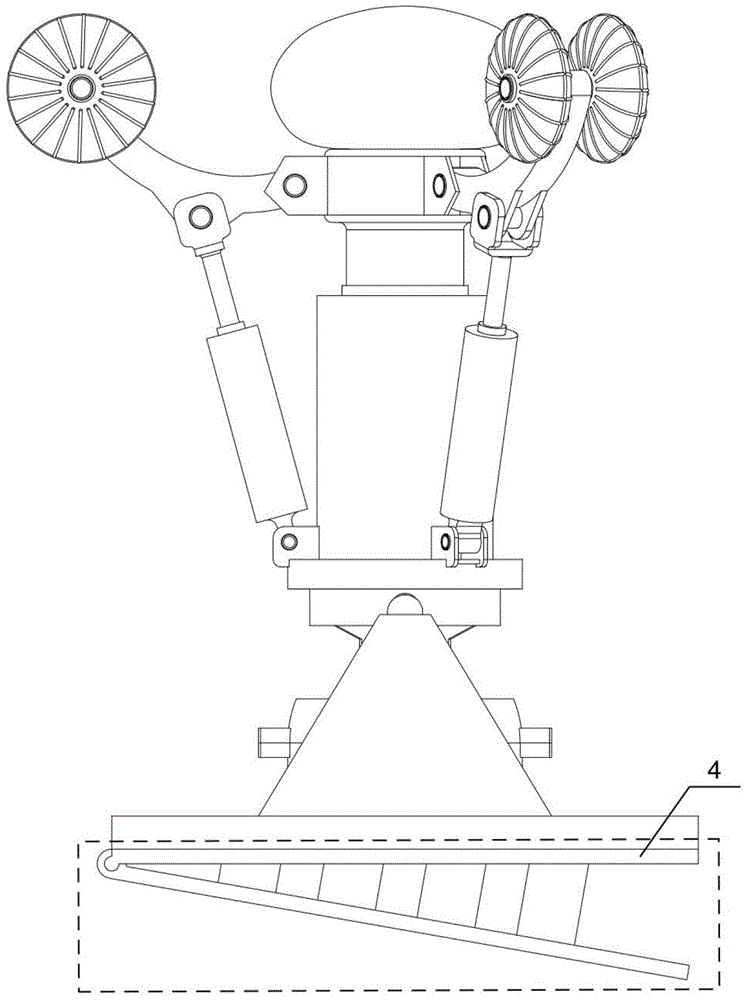

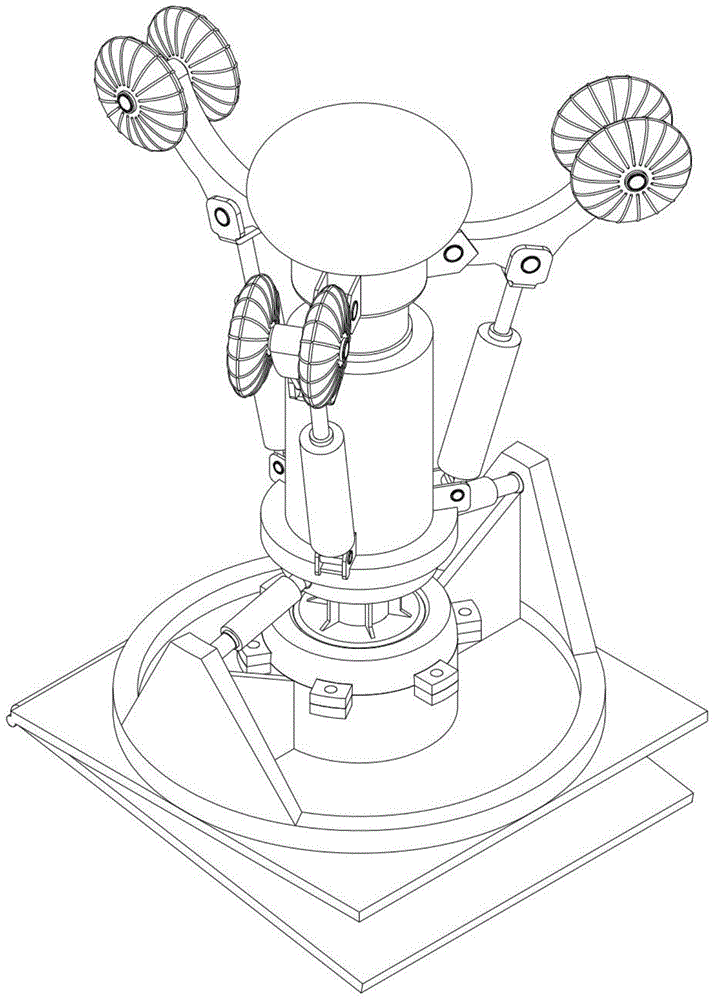

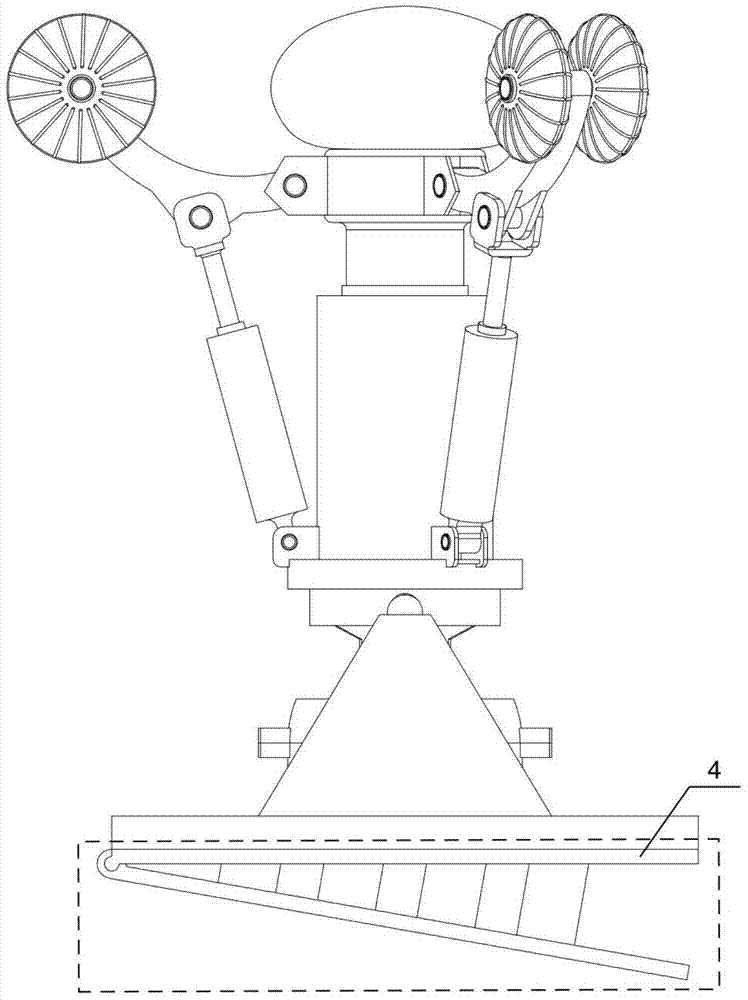

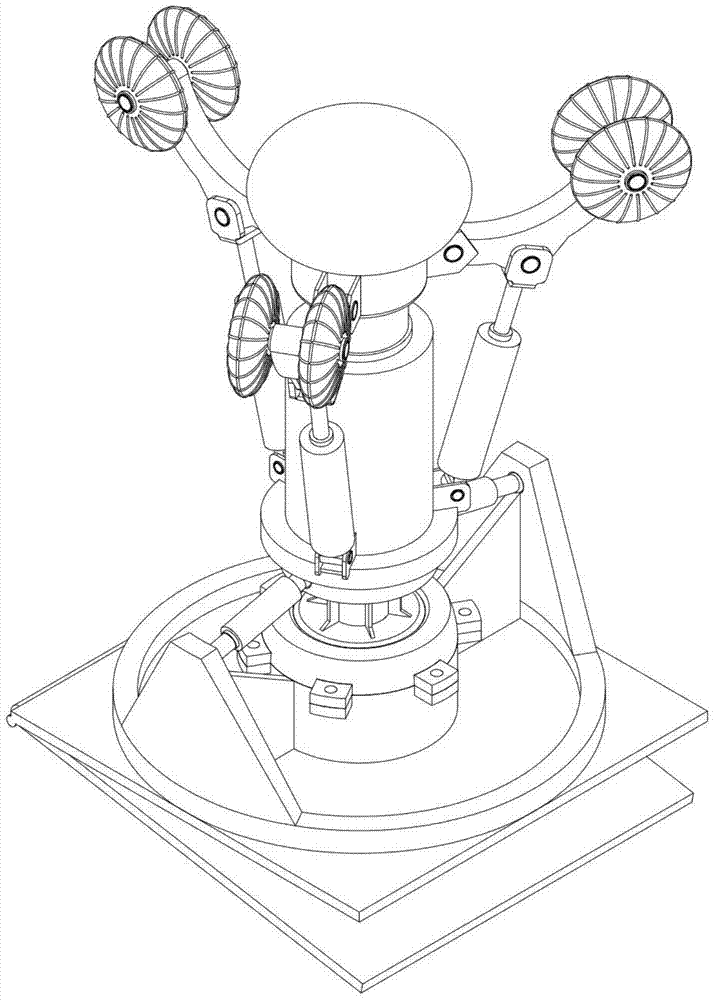

Angle-adjustable wharf berthing buffering device

ActiveCN105714742ABig impactExtended service lifeClimate change adaptationShipping equipmentComputer scienceShore

The invention provides an angle-adjustable wharf berthing buffering device and belongs to the field of harbor machinery. The angle-adjustable wharf berthing buffering device comprises pre-buffering modules, a main buffering module, a supporting module and a base module. The base module is fixed to the ground of a wharf. The supporting module is arranged on the base module. The main buffering module is connected with the supporting module through a spherical hinge. The pre-buffering modules are connected with the main buffering module and the supporting module through bolts. The angle-adjustable wharf berthing buffering device can achieve effective buffering when ships are pulled into shore.

Owner:SHANGHAI JIAO TONG UNIV +1

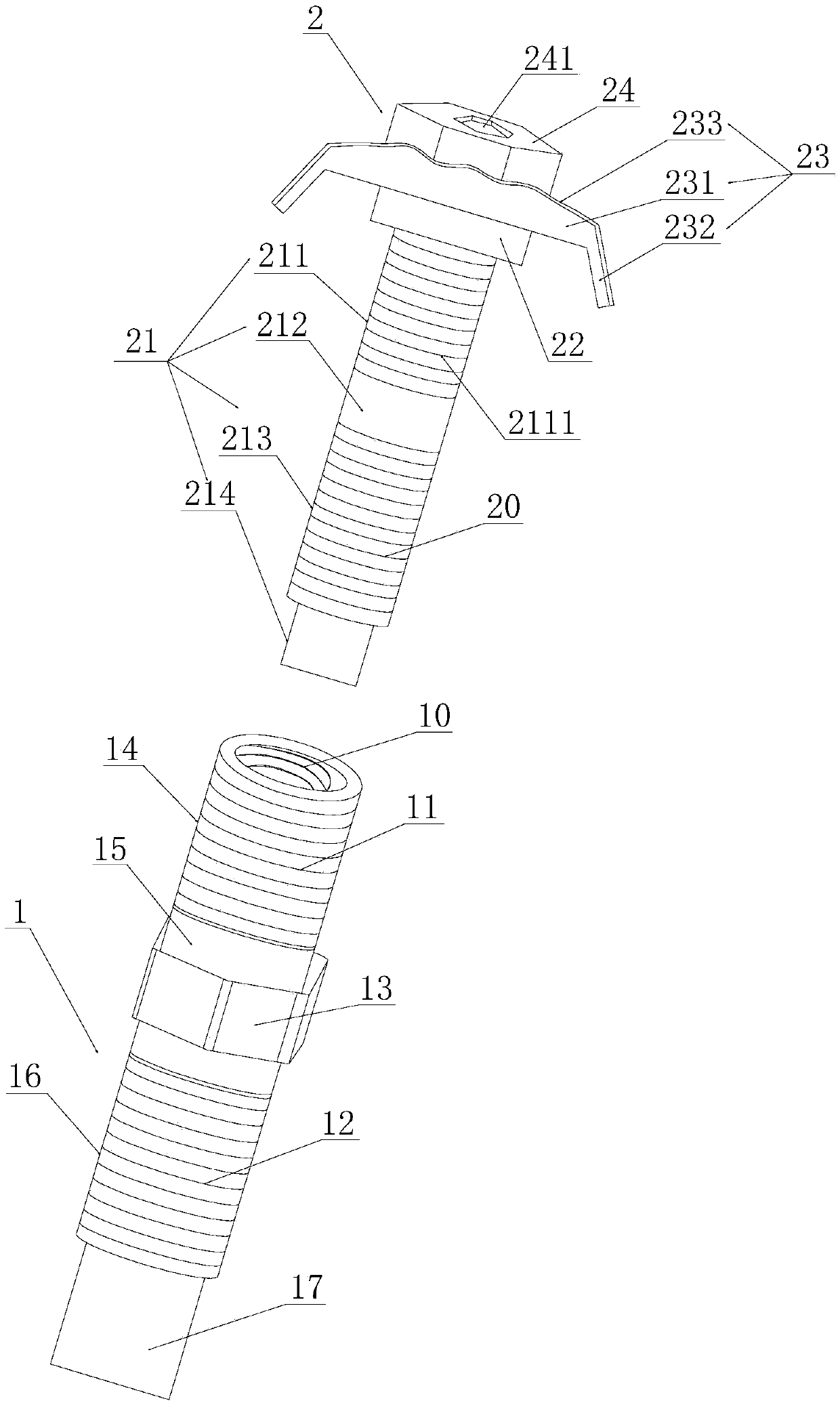

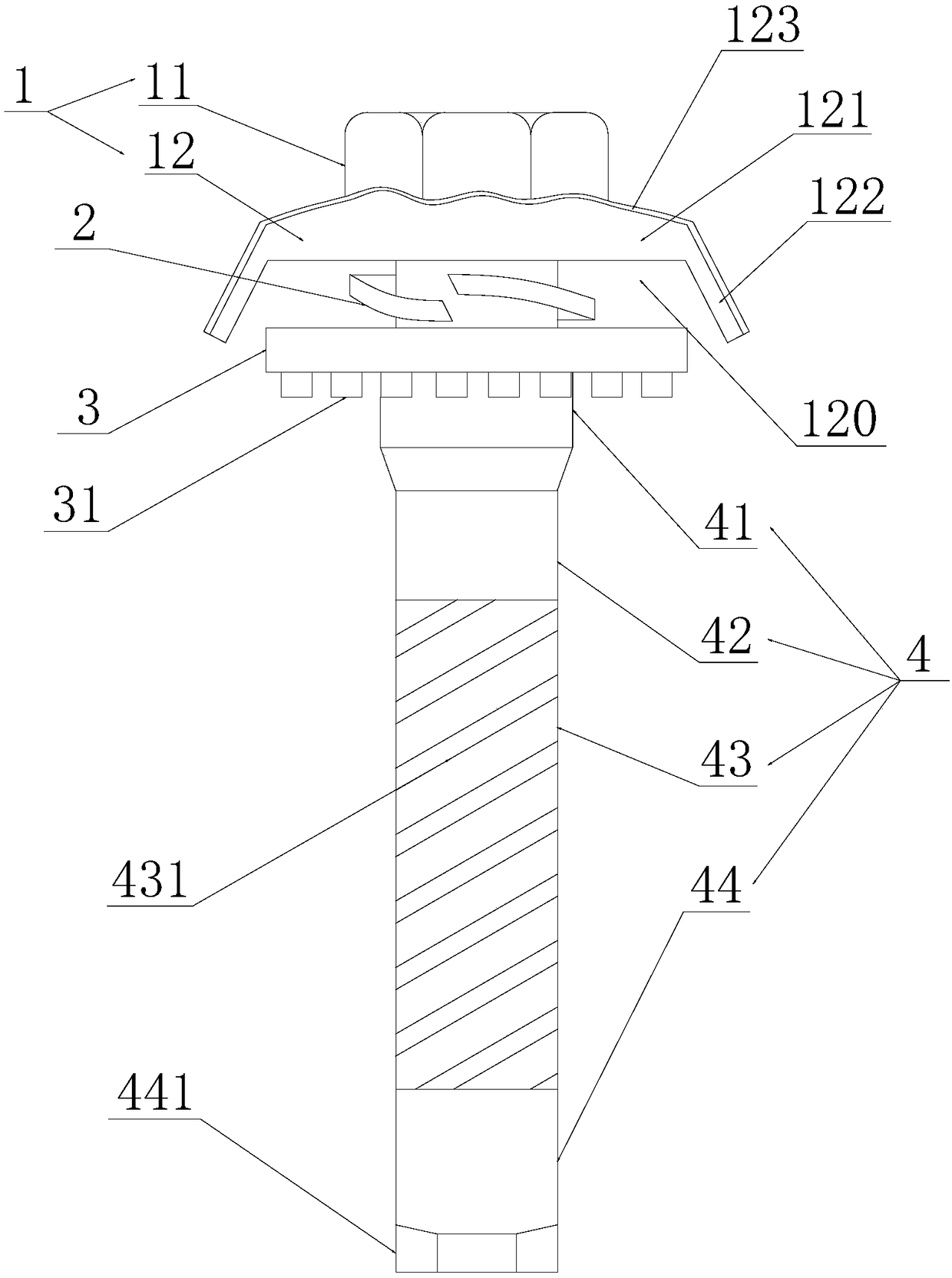

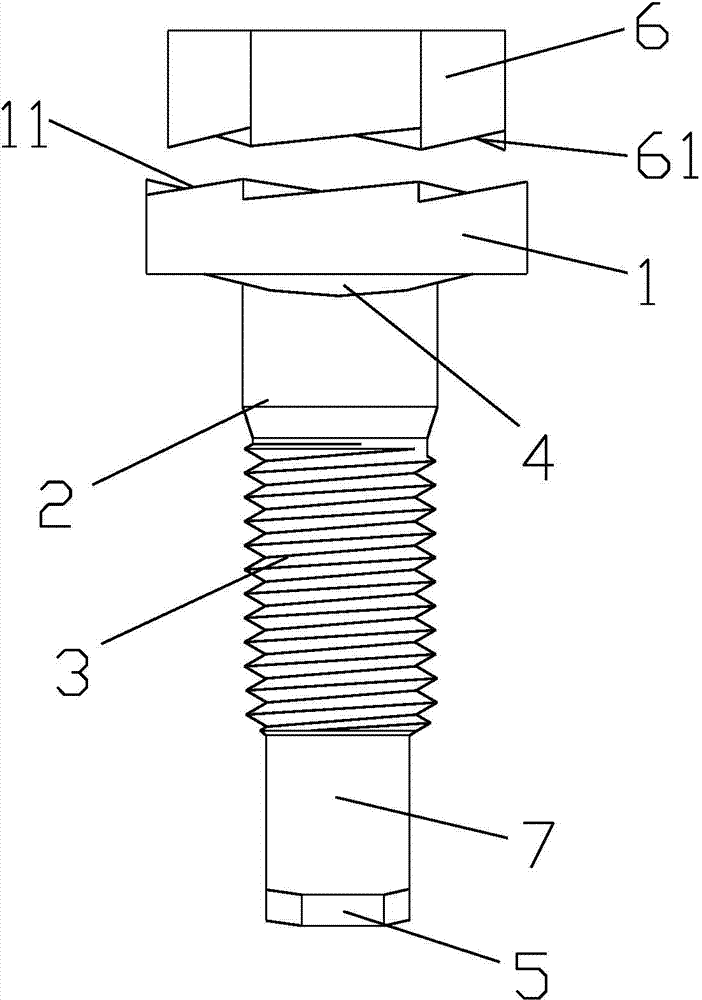

Combined type bolt for car hub

The invention discloses a combined type bolt for a car hub. The bolt comprises a lower bolt part and an upper bolt part; a connecting inner thread is arranged on the inner wall of the lower bolt part,a connecting outer thread is arranged on the upper bolt part, the upper bolt part and the lower bolt part are detachably connected, the lower bolt part is provided with a mounting nut, the upper boltpart comprises a screw, a connecting block, a fender and a hexagonal bolt head, the lower bolt part and the upper bolt part are detachably connected through cooperation of the connecting inner threadand the connecting outer thread, the lower bolt part can be independently used as a dual-head bolt to be used, a first guide polish rod segment smaller than the outer diameter of a lower bolt secondsegment is arranged below the lower bolt second segment, and the probability of thread wire sliding is reduced; due to the fender, rain water and mud are prevented from permeating into a screw hole along the bolt, and the service life of the bolt can be prolonged; through an inner hexagon bolt hole formed in the middle of the hexagon bolt head, the lower bolt part is provided with the mounting nut, and mounting and dismounting of the bolt are more labor-saving.

Owner:嘉兴同辉汽配有限公司

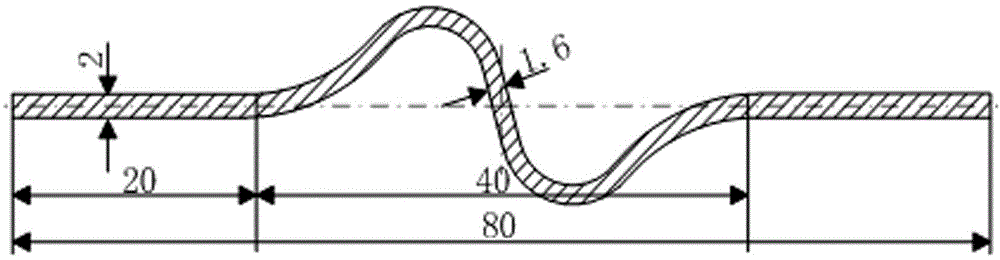

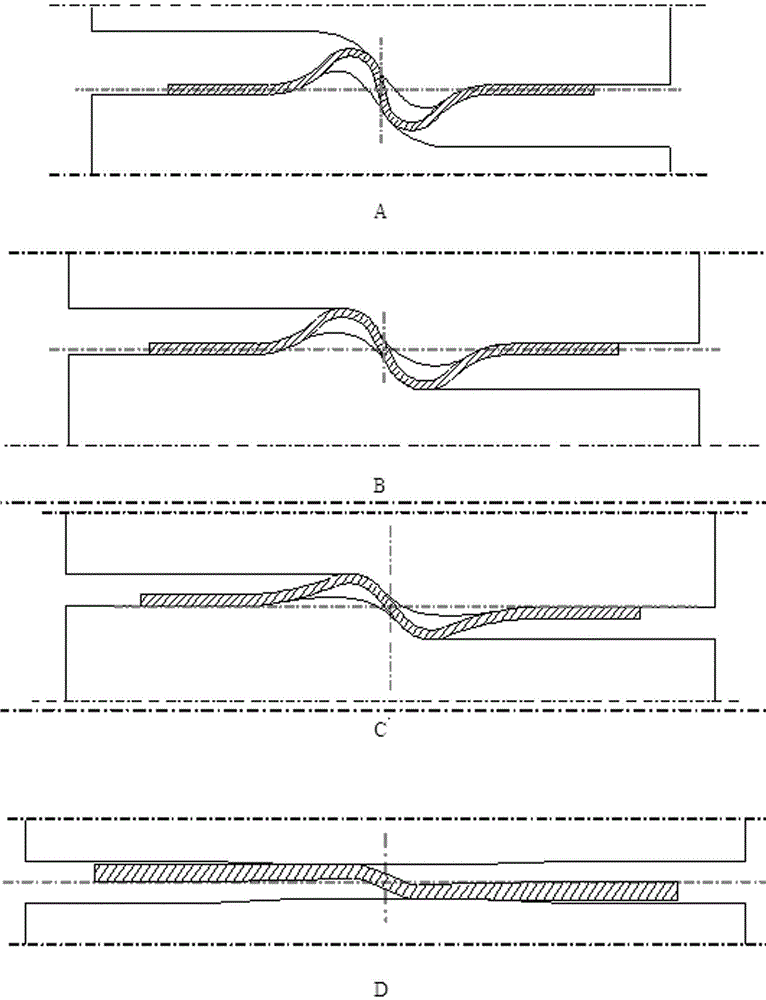

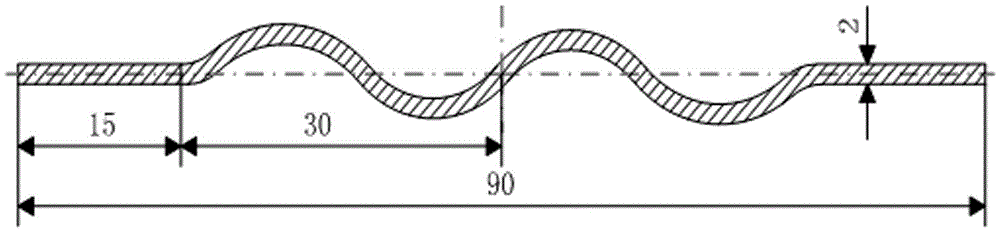

Mill roll system for flattening irregular metal part and flattening rolling method

ActiveCN105268744AGuaranteed vertical forceAccurate locationRollsAuxillary arrangementsCurve lineSurface mass

The invention provides a mill roll system for flattening an irregular metal part and a flattening rolling method. The roll system is characterized in that an upper working roll and a lower working roll each comprises at least one curved line part and two straight line parts, wherein two ends in the length direction of each roll body are the straight line parts, and the straight line parts of the two ends are 1 to 5mm in length; included angles between tangent lines at a front end point and a rear end point of each curved line part and the horizontal line range from 0 to 75 degrees; the curved line parts are in smooth connection with each other, or the curved line parts are in smooth connection with the straight line parts. The flattening method comprises the following steps: (1) performing the roll bending rolling process for the irregular metal part, and flattening at one to ten times; (2) flattening in a finishing pass manner. With the adoption of the roll system and the flattening rolling method, the irregular metal parts with equal thickness or different thicknesses and being 0.2 to 10mm in thickness can be efficiently flattened; in addition, the damage, caused by the structural diversity, of the irregular part can be effectively avoided; a flattened board is high in surface quality, and the board can remain the original thickness.

Owner:NORTHEASTERN UNIV

Inner hexagon bolt used on automobile hub

The invention discloses an inner hexagon bolt used on an automobile hub. The inner hexagon bolt comprises a bolt head mechanism, an elastic ring, a flange face and a screw mechanism. The bolt head mechanism comprises a hexagon bolt head and a waterproof tabletop. An inner hexagon bolt hole is formed in the middle portion of the hexagon bolt head. The screw mechanism comprises an installation section, a smooth-surface screw section, a threaded section and a guide polished rod section. Multiple tooth ripple grooves are formed in the lower surface of the flange face. According to the inner hexagon bolt, by arranging the elastic ring, certain tensile force can be kept between two connected parts all the time by the inner hexagon bolt through deformation of the elastic ring, and connection stability is ensured; the guide polished rod conducts perpendicular guiding before the bolt and a threaded hole are engaged, perpendicular stress of the bolt is ensured, and the probability of thread sliding is lowered; by arranging the waterproof tabletop above the flange face, it is avoided that because of erosion of rainwater, the bolt rusts and is damaged; and by forming the tooth ripple grooves in the lower surface of the flange face, the connection stability between the two connected parts is further ensured.

Owner:嘉兴同辉汽配有限公司

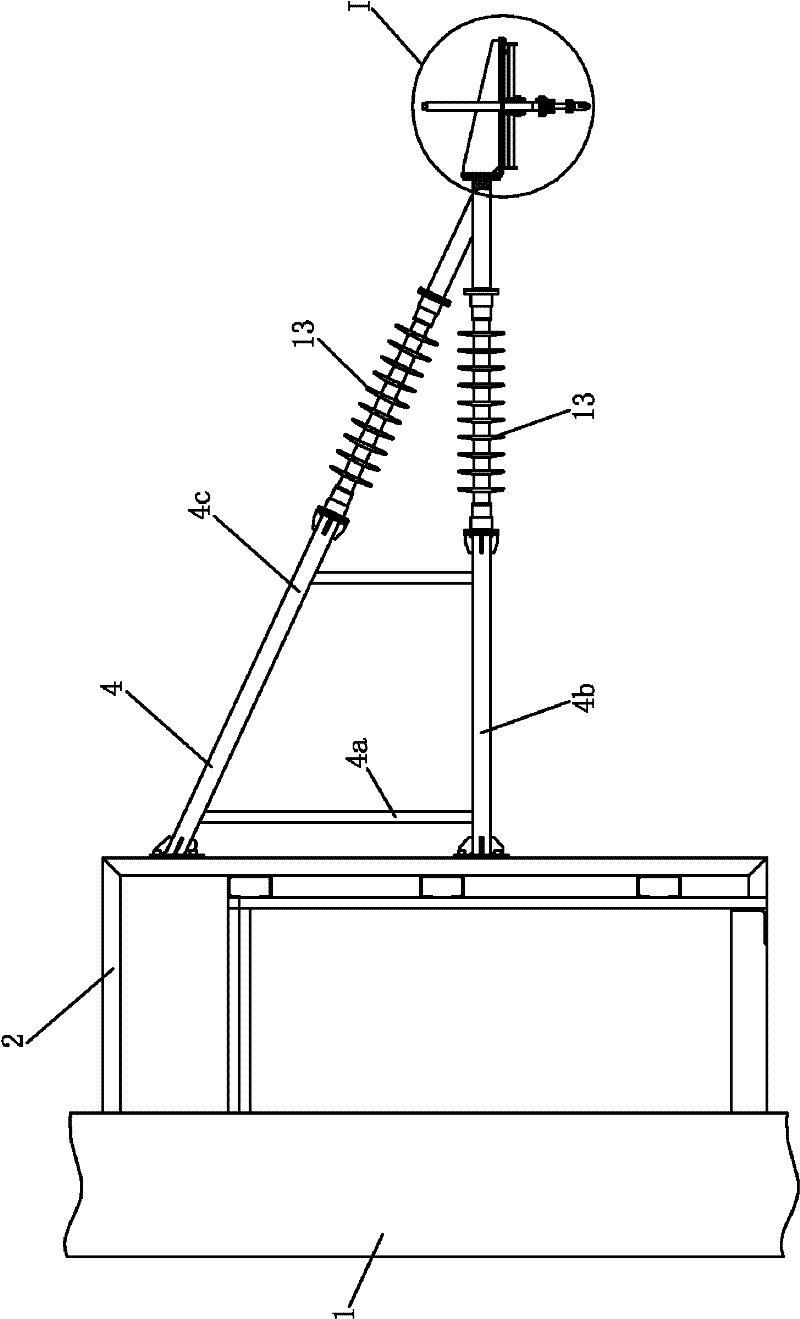

Bridge construction hanging basket front hanging system

PendingCN112813851AGuaranteed vertical forceReasonable forceBridge erection/assemblyConvertersArchitectural engineering

The invention discloses a bridge construction hanging basket front hanging system which comprises a hanging basket hanging rod, the hanging basket hanging rod is a straight rod and is provided with a top threaded section and a bottom threaded section, the top threaded section of the hanging basket hanging rod is in threaded connection with a first fastener, and the upper portion of the hanging basket hanging rod is used for penetrating through and being hung on a front upper cross beam and an upper distribution beam of a hanging basket; the bottom threaded section is in threaded connection with a second fastener, a suspender converter is hung on the second fastener, and the bottom of the suspender converter is hinged to the lower distribution beam. When the front hanging system of the hanging basket is used, the hanging basket suspender penetrates through the first fastener, the upper end of the hanging basket suspender is locked through the fastener, the lower end of the hanging basket suspender is hinged to the hanging bracket through the suspender converter and the pin, it can be effectively guaranteed that the hanging basket suspender is stressed vertically all the time, the hanging basket suspender is stressed more reasonably, and installation and operation are more convenient; the problem of potential safety and quality hazards occurring in the construction process of a traditional front hanging basket hanging rod is successfully solved, and the working efficiency of hanging basket construction is remarkably improved.

Owner:CCCC THIRD HIGHWAY ENG

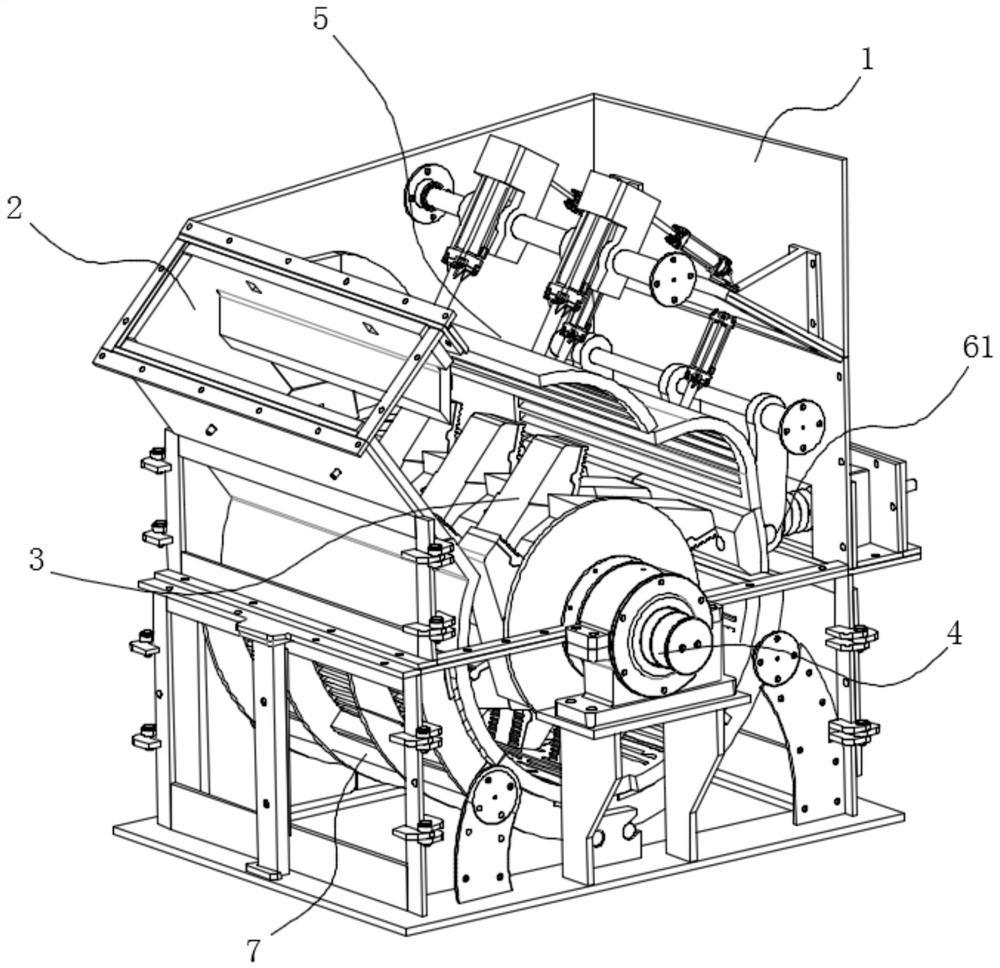

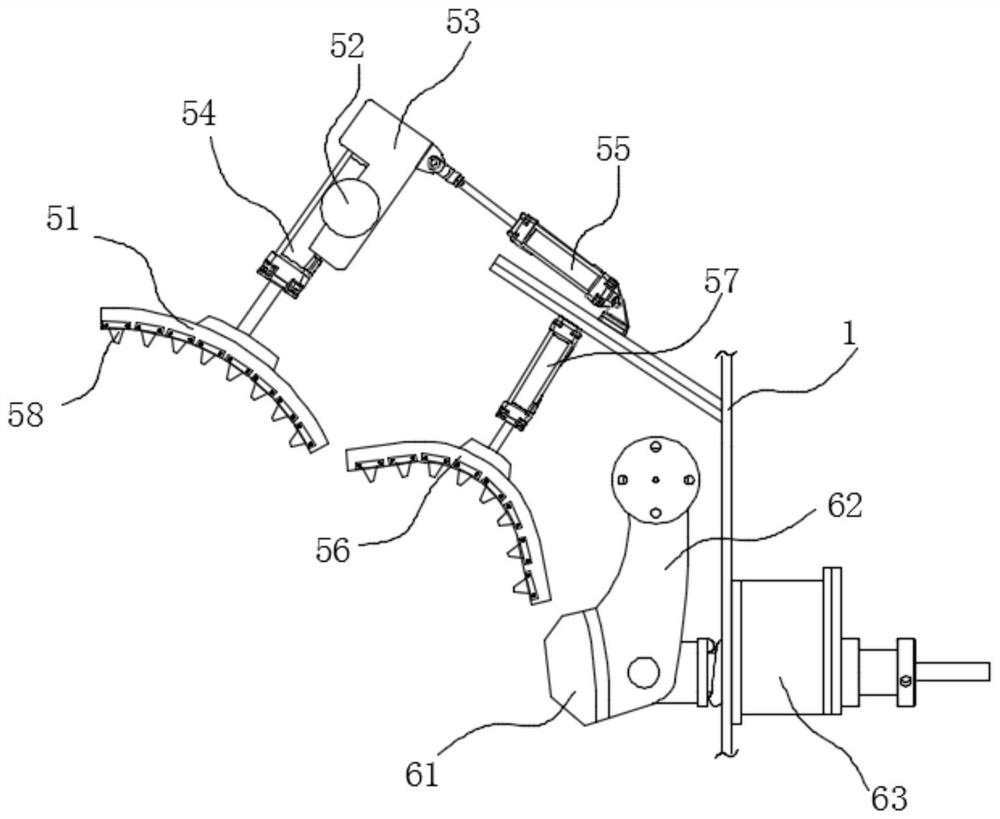

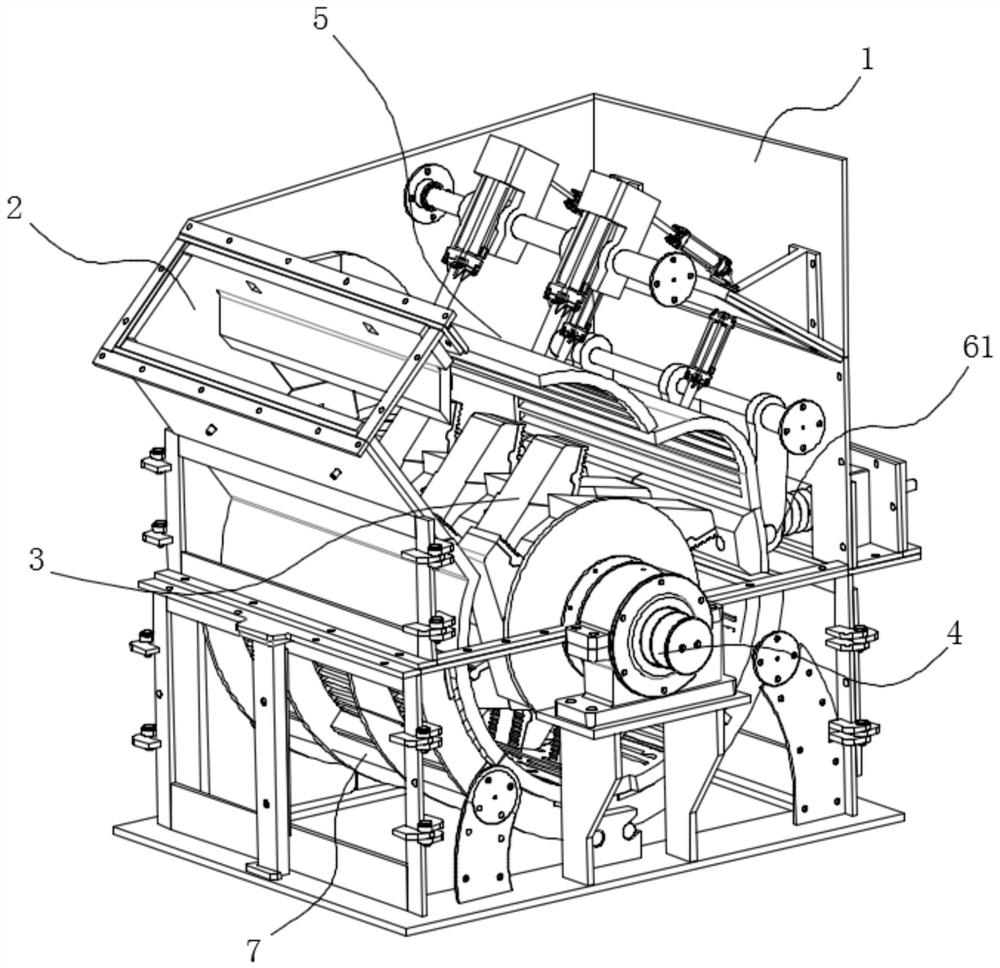

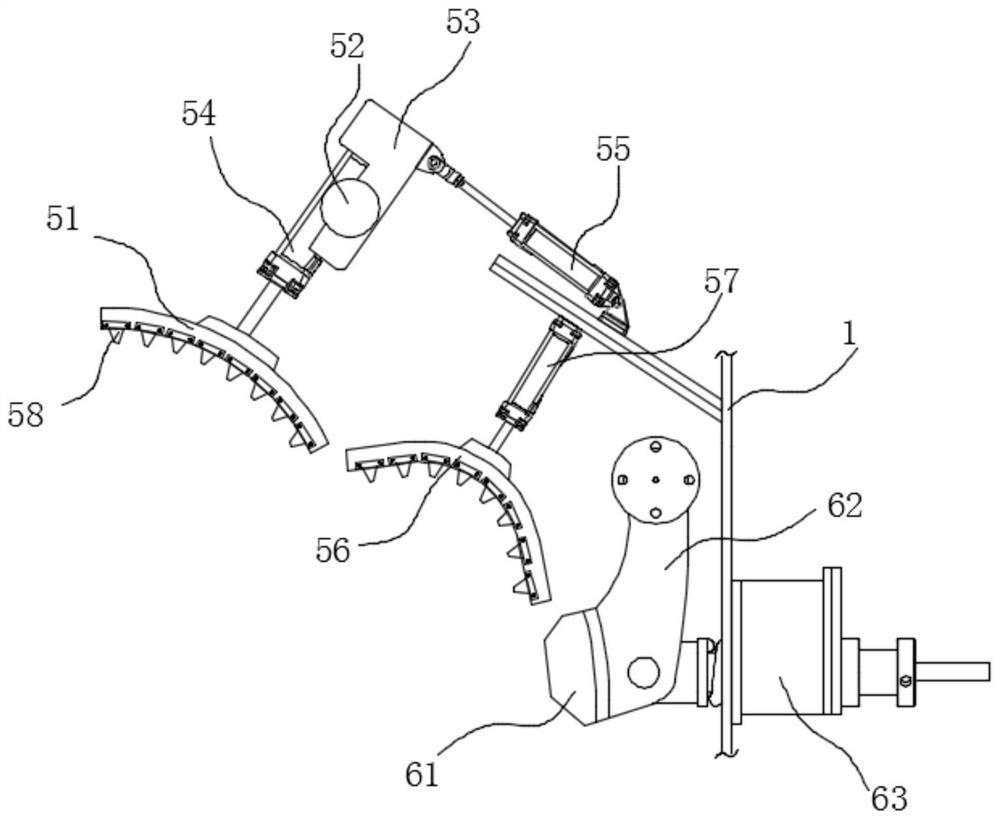

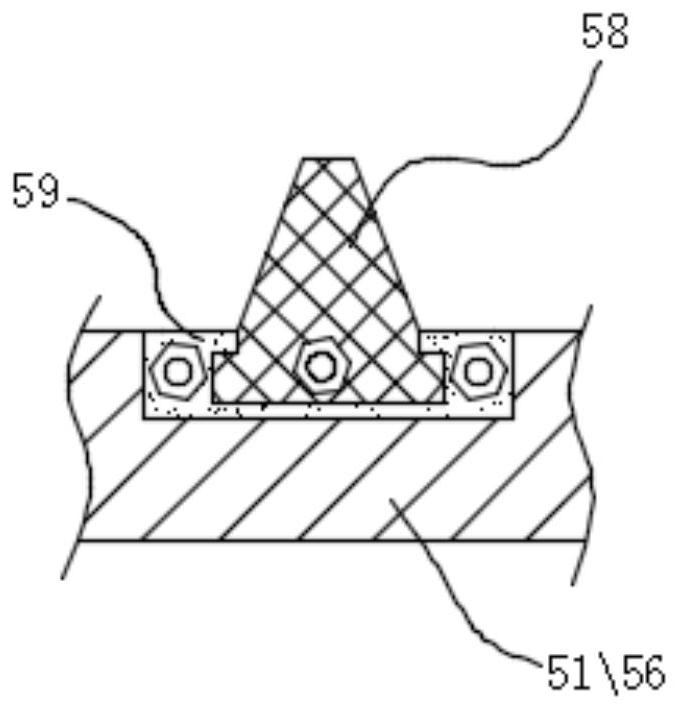

Automatic crushing equipment used for production of sulphate-resistant cement

ActiveCN112791794AImprove general performanceGuaranteed stabilityGrain treatmentsStructural engineeringMechanical engineering

The invention discloses automatic crushing equipment used for production of sulphate-resistant cement. The automatic crushing equipment used for production of the sulphate-resistant cement comprises a rack, rotating hammer assemblies and an impact plate assembly, wherein a feeding opening is formed in the upper portion of the rack, a semi-cylindrical hollowed-out discharging cage is below the feeding opening, the multiple rotating hammer assemblies are arranged in the discharging cage and coaxial with the discharging cage, the adjacent rotating hammer assemblies are connected in a staggered mode through a spindle in series, one end of the spindle is connected with one side of the rack through a bearing, and the other end of the spindle is connected with the rack through a power-receiving axial assembly; the impact plate assembly is arranged at the side, away from the feeding opening, above the rotating hammer assemblies; and a batten is arranged below the impact plate assembly, and the batten and an edge of each rotating hammer assembly are at a certain distance. Compared with the prior art, the automatic crushing equipment used for production of the sulphate-resistant cement is suitable for putting of different materials so that a stable discharging shape can be ensured.

Owner:山东山铝环境新材料有限公司

Weighing module

ActiveCN100498245CDoes not affect accuracyHigh precisionWeighing apparatus detailsAgricultural engineeringNeck parts

Owner:METTLER TOLEDO (CHANGZHOU) PRECISION INSTR CO LTD +2

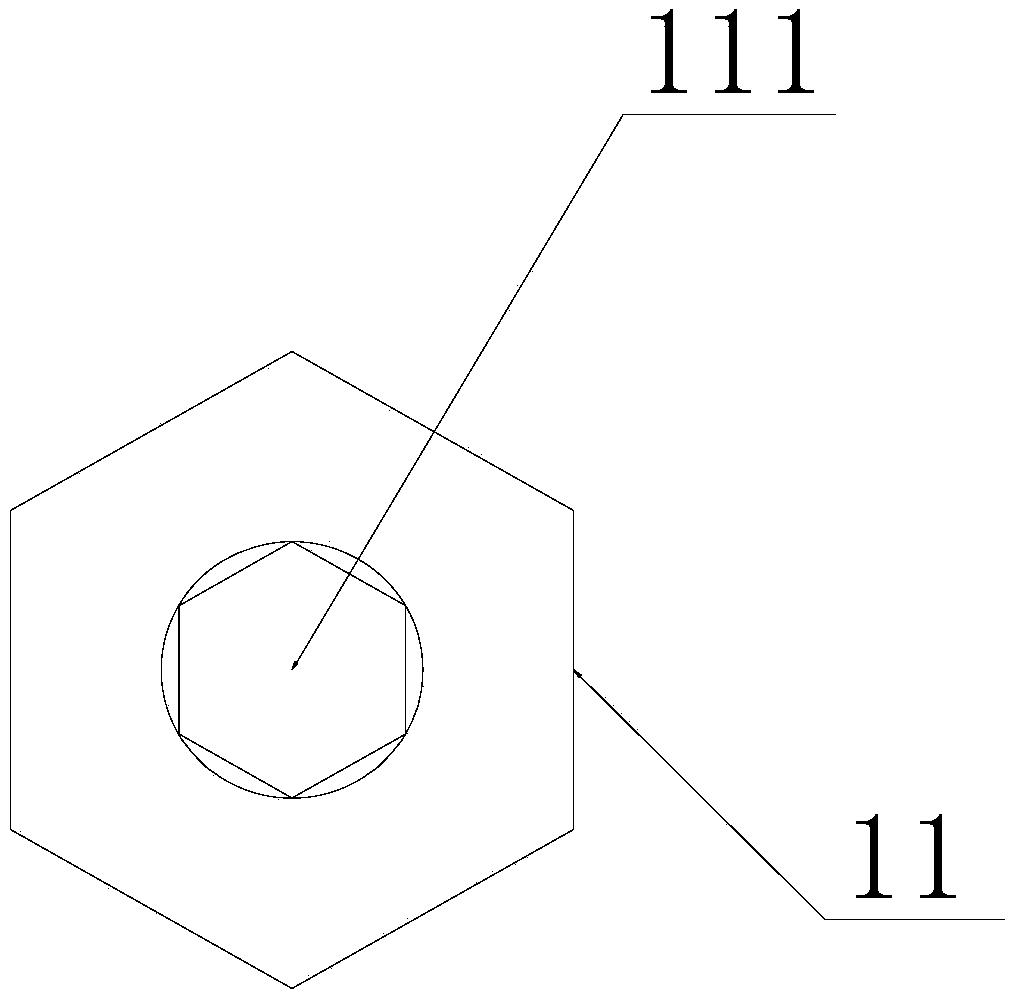

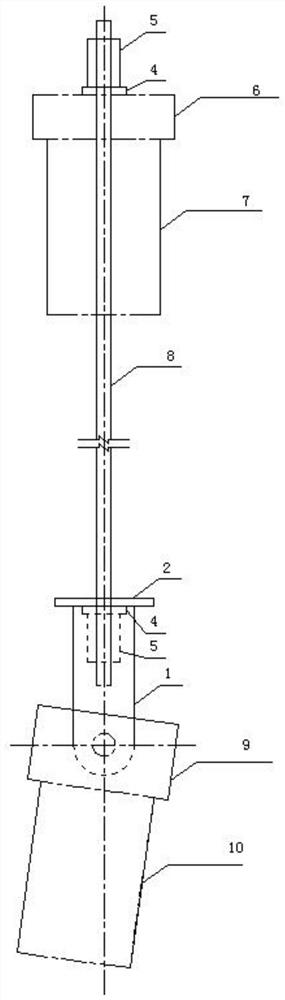

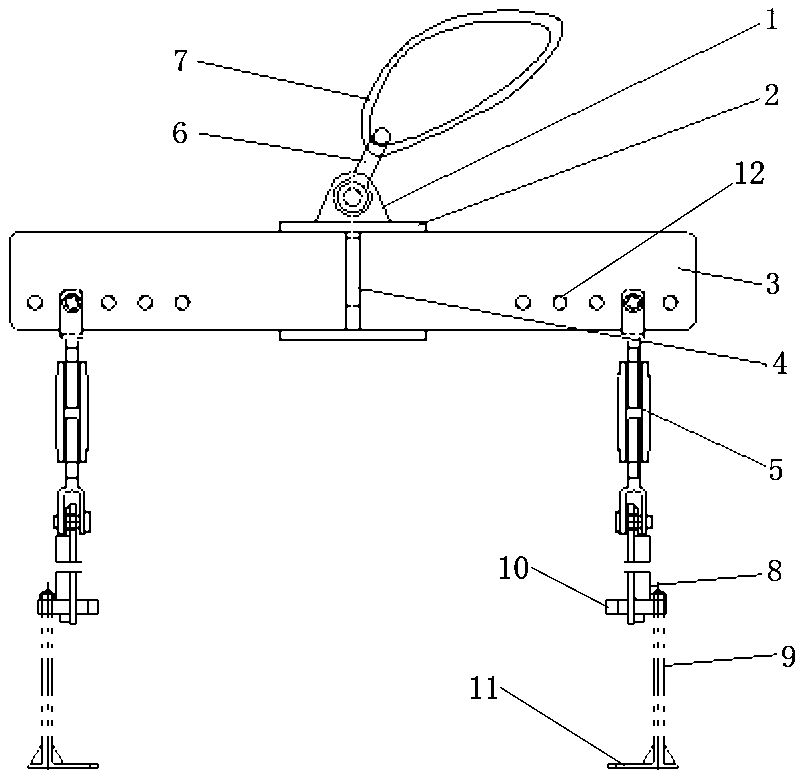

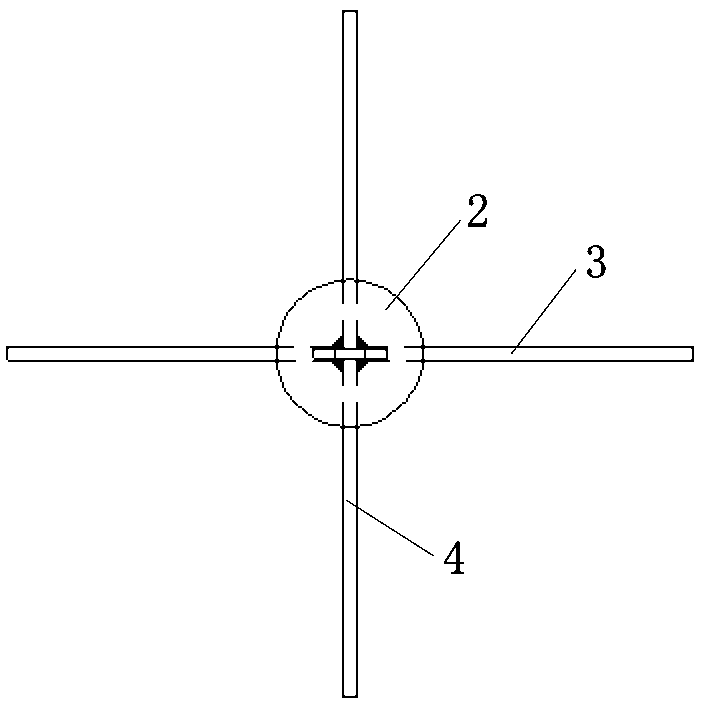

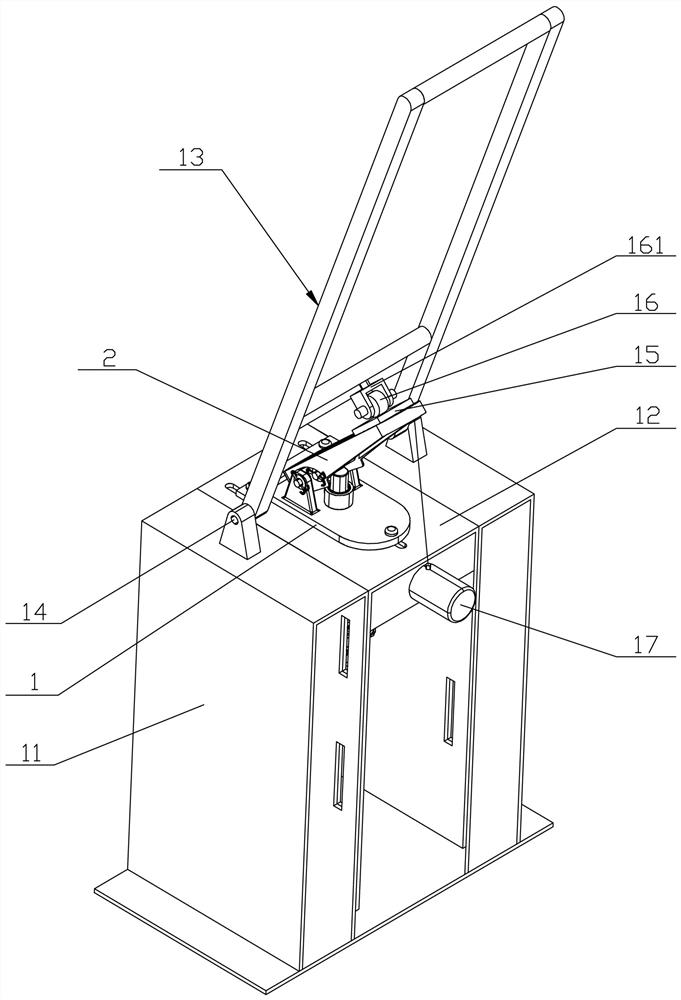

Novel electric reactor iron core pillar mounting method and tool

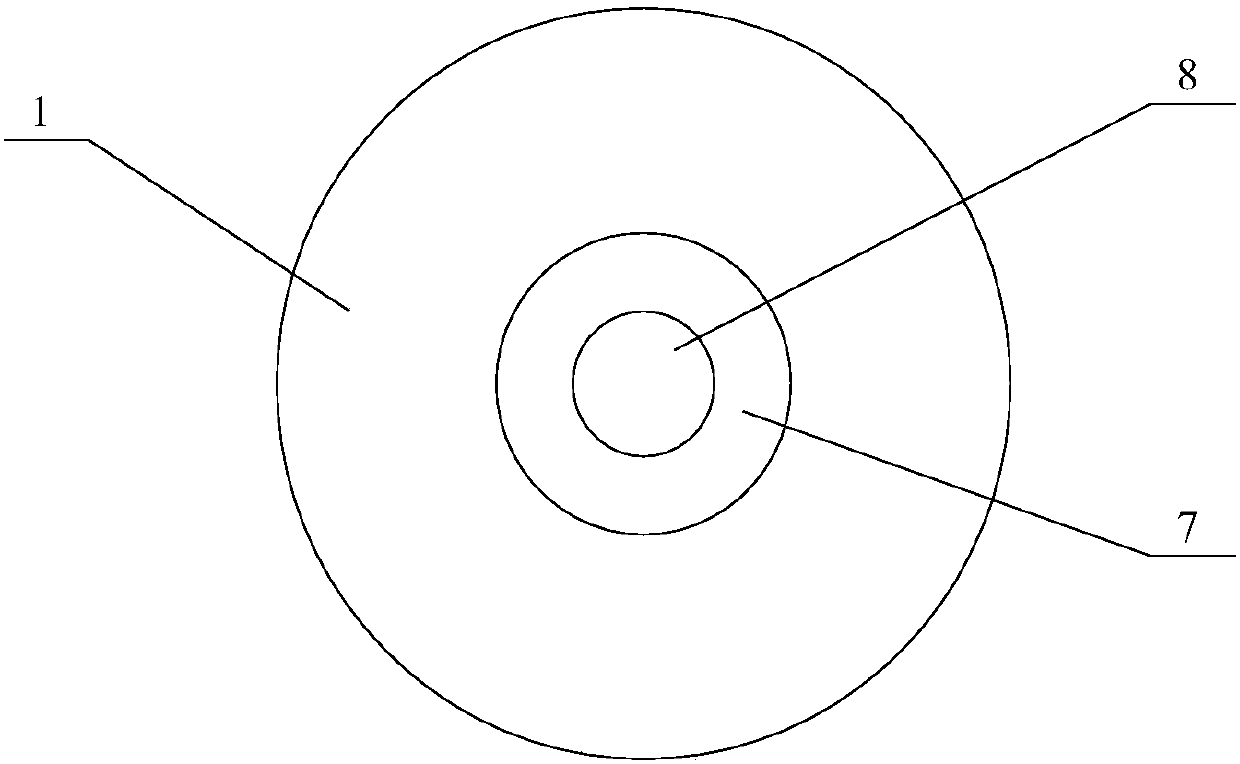

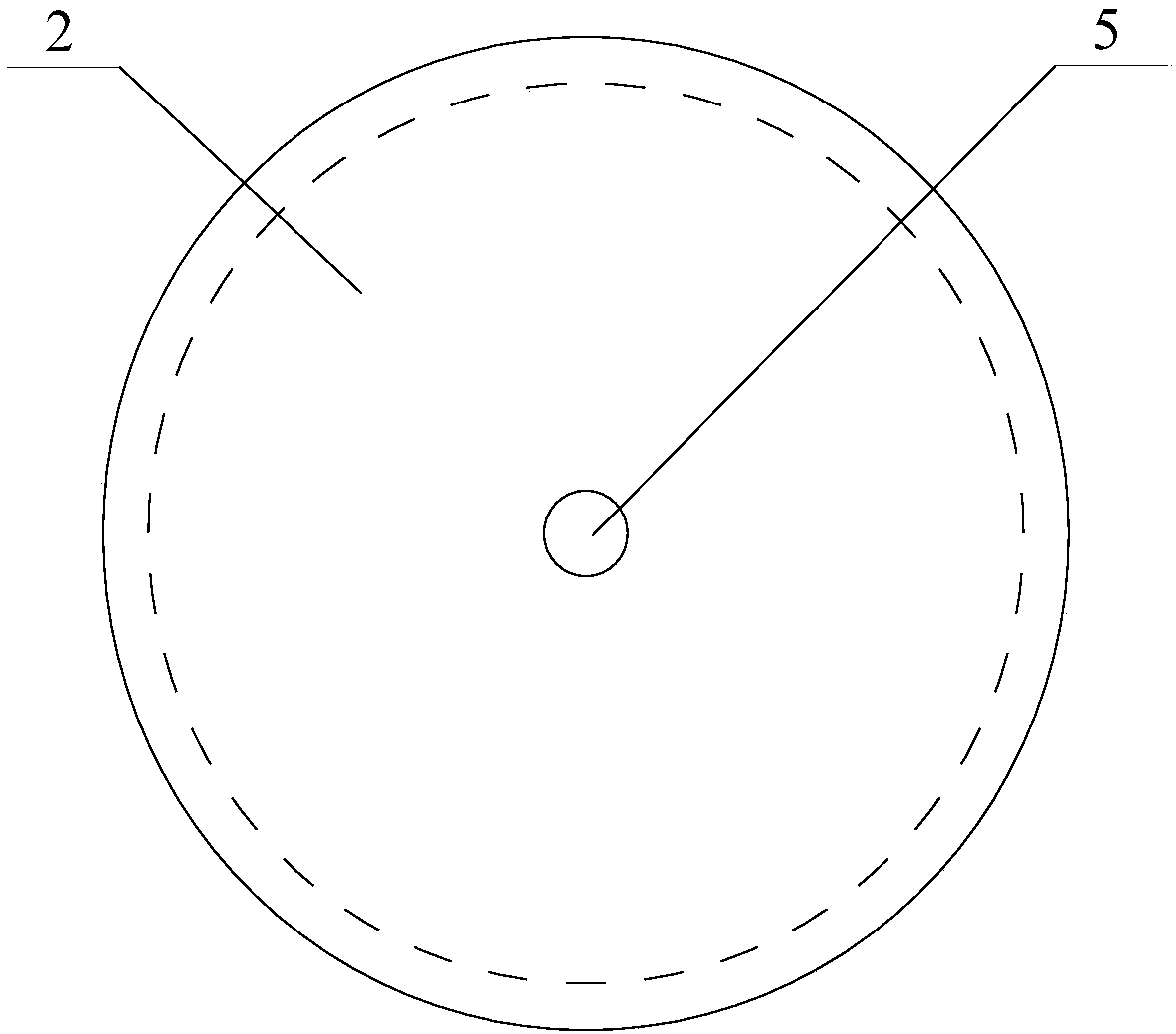

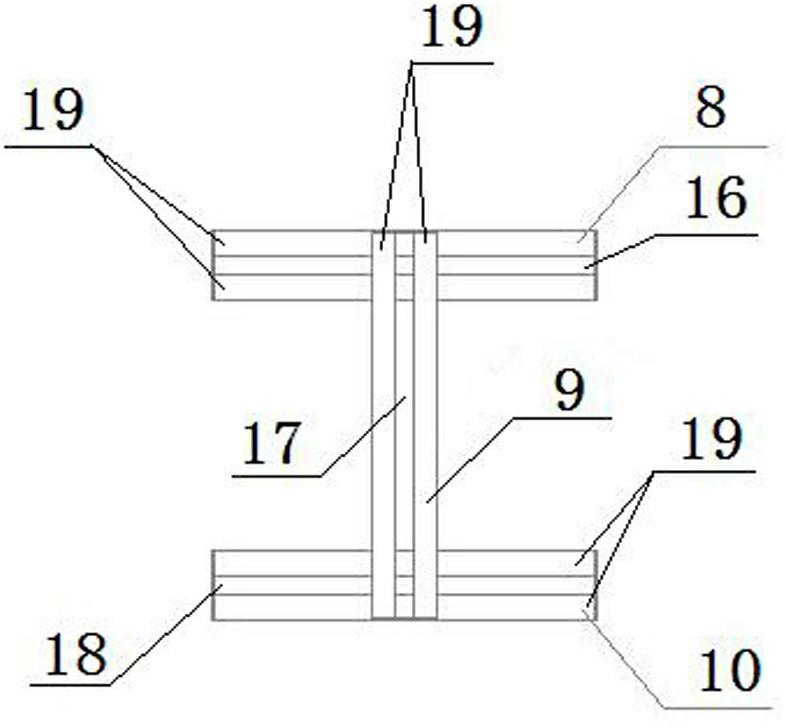

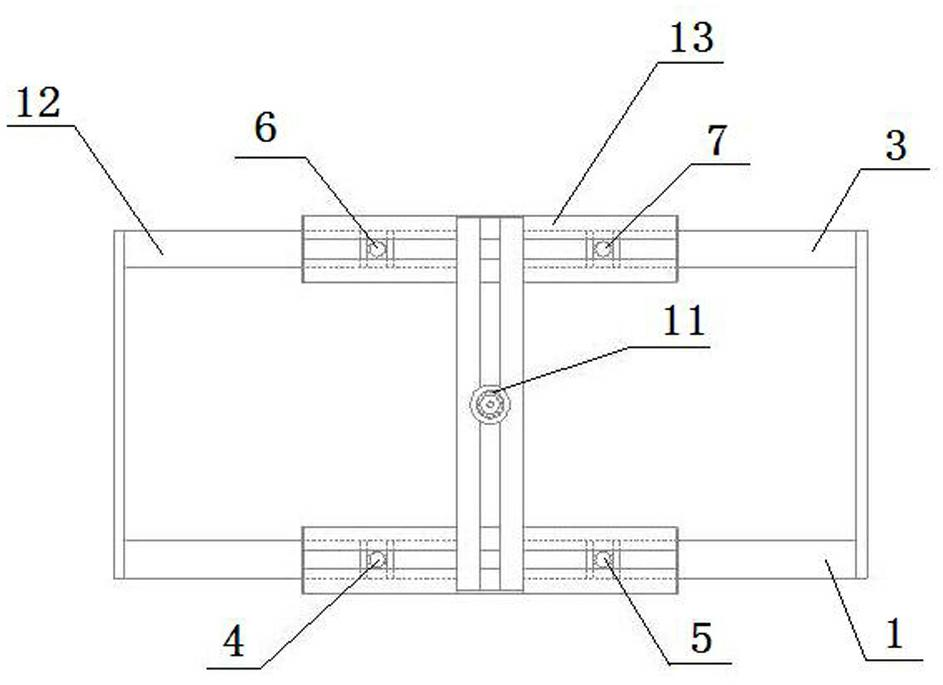

PendingCN107720530AGuaranteed vertical forceSimple and safe installationLoad-engaging elementsMagnetic core manufactureCircular discTransformer

The invention relates to a novel electric reactor iron core pillar mounting method and tool, and belongs to the technical field of transformer mounting equipment. According to the technical scheme, hanging legs (8) are connected with the end of a cross hanging beam through turnbuckles (5), the center of the cross hanging beam is connected with a disc (2), a hanging pate (1) is installed on the upper surface of the disc (2), and a steel wire rope (7) is connected with the hanging plate (1) through a shackle (6); supporting plates (10) are arranged at the inner sides at the bottoms of the hanging legs, screw holes are formed in the outer sides of the bottoms of the hanging legs, the top of auxiliary hanging legs are of screw structures, the screw structures are matched with the screw holes of the outer sides of the bottoms of the hanging legs, and the bottoms of the hanging legs (8) are connected with the tops of the auxiliary hanging legs (9); auxiliary supporting plates (11) are arranged at the inner sides of the bottoms of the auxiliary hanging legs. The novel electric reactor iron core pillar mounting method and tool have the advantages that it can be guaranteed that hanging tools are vertically stressed, an electric reactor core pillar is safely and simply installed, the design is novel in structure, the operation is simple and reliable, and the safety is high.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

A tensile stress rapid corrosion test machine for samples

ActiveCN103105354BGuaranteed comparabilityThe detection data is accurateWeather/light/corrosion resistanceTest sampleAlloy

The invention relates to a rapid test sample tensile stress corrosion tester which comprises a corrosive cup and a corrosive liquid timing stirring device, wherein the corrosive liquid timing stirring device comprises a main air tube which is inserted into the corrosive cup, branch air tubes connected with the main air tube and an air pump connected with the main air tube; the tester further comprises a bracket, weights, an upper traction rod and a lower traction rod, wherein the bracket comprises a transverse beam; the upper end of the upper traction rod is connected with the transverse beam; the lower end of the upper traction rod is connected with a test sample; the upper end of the lower traction rod is fixedly connected with the bottom end of the corrosive cup; a weight base is arranged at the lower end of the lower traction rod; the weights are stacked on the weight base; a safety rope which is fixedly connected with the transverse beam is further arranged at the upper part of the corrosive cup; and the tester further comprises a test sample breakage timing alarm device. The tester has the beneficial effects that the structure is simple, the detection data are accurate and reliable, and different alloy test samples can be adjusted by the weights, with convenience in use.

Owner:龙口市丛林铝材有限公司

An automatic crushing equipment for the production of sulfate-resistant cement

ActiveCN112791794BImprove general performanceGuaranteed stabilityGrain treatmentsStructural engineeringMechanical engineering

Owner:山东山铝环境新材料有限公司

Novel spline shaft upsetting forging die structure

PendingCN113500162AGuaranteed vertical forceImprove reclaiming efficiencyForging/hammering/pressing machinesEngine componentsMechanical engineeringIndustrial engineering

The invention discloses a novel spline shaft upsetting forging die structure and relates to the field of spline shaft machining. The novel spline shaft upsetting forging die structure comprises an upsetting upper die and an upsetting lower die, a blank channel is arranged in the upsetting upper die in a penetrating mode, the inner diameter of the bottom of the blank channel is expanded to form a concave connector, a convex connector is arranged at the position, corresponding to the concave connector, of the top of the upsetting lower die, the convex connector is matched with the concave connector in an embedded manner, and the upsetting upper die is supported on the upsetting lower die. A spring groove is formed in the convex connector and used for containing a spring, a step face is arranged on the inner wall of the top end of the spring groove, the rod part of a blank is inserted into the blank channel and abuts against the step face, and the upsetting portion of the blank is exposed out of the upper portion of the blank channel. One end of the spring abuts against the bottom of the spring groove, and the other end of the spring abuts against the end face of the rod part, so that the blank moves up and down along the blank channel. The novel spline shaft upsetting forging die structure has the beneficial effects that the ejection vertical force is guaranteed, the material taking efficiency is improved, and the overall spline shaft upsetting efficiency is doubled.

Owner:WANXIANG QIANCHAO TRANSMISSION SHAFT +1

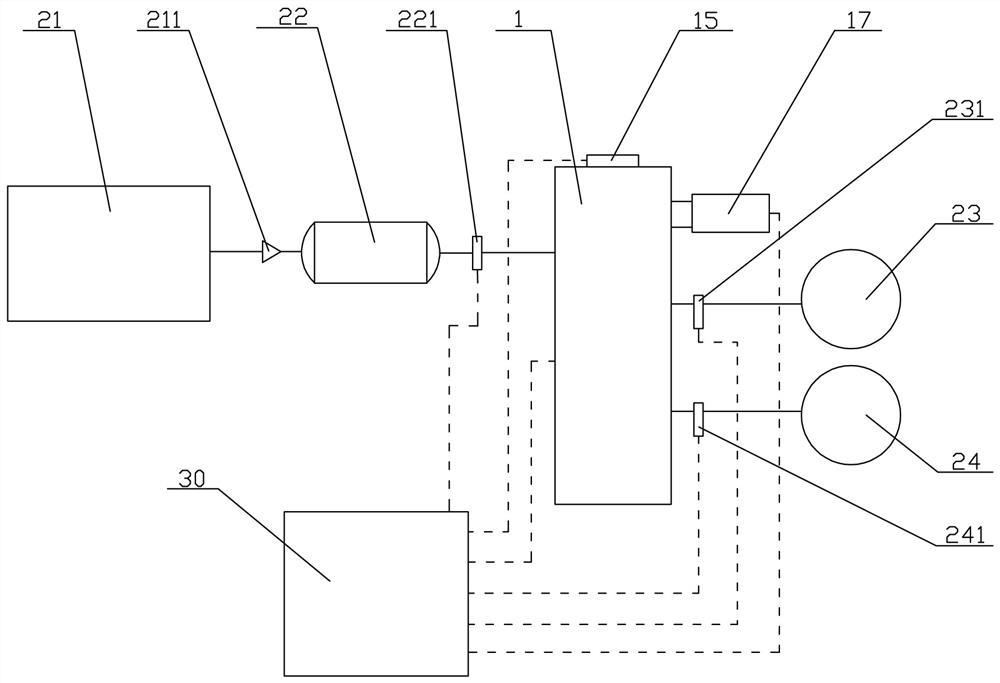

Floor type brake master cylinder performance test device and method

ActiveCN111824108AGuaranteed vertical forceGuaranteed accuracyBrake safety systemsMaster cylinderMechanical engineering

The invention discloses a floor type brake master cylinder performance test device. The device comprises an air source system, a fixed base, an adjustable support and a pressing rod mechanism; the adjustable support is arranged on the fixed base; a brake master cylinder is mounted on the adjustable support; the pressing rod mechanism is rotatably mounted on the top surface of the fixed base; the rotating shaft center is overlapped with the pedal rotating shaft center of the brake master cylinder; a pedal force sensor is arranged at the position, 160 mm away from the pedal rotating shaft of thebrake master cylinder, of the upper surface of the pedal; the pressing rod mechanism is provided with a roller abutting against the pedal force sensor through a support hanging rod, the central axisof the support hanging rod is perpendicular to the upper surface of the pedal force sensor, and a displacement sensor is fixed to the side face of the adjustable support and connected with the end ofthe pedal through a pull wire. The invention further discloses a floor type brake master cylinder performance test method, the pedal angle advancing amount can be accurately calculated through testingand calculation of the displacement sensor, the pedal angle advancing amount is not directly related to the starting point of the pull wire of the displacement sensor, and high applicability is achieved.

Owner:XIAMEN KING LONG UNITED AUTOMOTIVE IND CO LTD

Reaction frame testing method for earth nail drawing tests

ActiveCN102677710BGuaranteed vertical forceSolve the detection speed is slowFoundation testingExcavationsEngineeringBearing surface

The invention discloses a reaction frame testing method for earth nail drawing tests. The reaction frame testing method is realized through a reaction frame consisting of a base and a stress support. The base is connected with the stress support through screws, and a bearing surface of the stress support can be guaranteed to be coaxial with an earth nail by adjusting the screws. A jack is mounted on the stress support to form a jack reaction system. During testing, the earth nail can be fixed with the jack after being lengthened, and perpendicular stress is guaranteed by adjusting the screws. By adjusting the screws between the stress support and the support, stress surface on the wall at any gradient can be adjusted optionally, the perpendicular stress of the earth nail can be guaranteed, and testing speed and testing quality of the earth nail can be improved greatly.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

Rust-proof bolt for automobile hub

PendingCN108757685AReduce the chance of thread slippageExtended service lifePinsNutsEngineeringMechanical engineering

The invention discloses a rust-proof bolt for an automobile hub. The rust-proof bolt comprises a bolt head mechanism, a connecting block, a screw mechanism and a fender, the bolt head mechanism and the connecting block below are stamped and riveted through a stamping machine, the connecting block and the screw mechanism below are stamped and riveted through the stamping machine, the screw mechanism comprises a transition section, a first threaded section, a second threaded section and a guide polished rod section, and the fender can be installed on the first threaded section in an up-and-downadjustable manner. According to the rust-proof bolt, the guide polished rod section is arranged below the screw mechanism, vertical stress of the bolt in the fastening process is guaranteed, and the thread slipping rate is reduced; the fender is matched with the connecting block and the screw mechanism, rainwater, mud and the like are prevented from seeping into a screw hole along a gap of a screwor a bolt head, and the service life of the bolt is prolonged; and an inside hexagonal bolt hole is formed in the middle portion of the bolt head mechanism, even though a hexagon bolt head outsides deforms, bolt quick demounting can be carried out through a hexagonal socket still, and the service life of the bolt is prolonged.

Owner:嘉兴同辉汽配有限公司

Rotation-prevention-type hub bolt

The invention discloses a rotation-prevention-type hub bolt. The rotation-prevention-type hub bolt comprises a bolt head mechanism, a connection block and a screw rod mechanism; the bolt head mechanism comprises a bolt head base and bolt head rotation-prevention parts; the bolt head rotation-prevention parts are arranged on the left and right ends of the bolt head base; a stabilization part is arranged on each bolt head rotation-prevention part; and each stabilization part is an arc surface and the radian of each stabilization part is matched with the arc surface of a hub which is in contact with the stabilization part. According to the rotation-prevention-type hub bolt, through the arc structures of the stabilization parts on the rotation-prevention parts of the bolt head, the bolt head can be well matched with the arc surface of the hub; a guiding unthreaded rod section of which the diameter is smaller than that of the outer thread of the bolt is arranged below the screw rod mechanism, and the guiding unthreaded rod perform vertical guiding before the bolt is engaged with a threaded hole, so that vertical stressing of the bolt is ensured, and the probability thread slippery is reduced; the bolt head base is matched with the bolt head rotation-prevention parts, so that an umbrella-shaped shielding zone is formed above the connection block and shields the connection block and the screw rod mechanism; and rainwater is prevented from permeating, and the bolt is prevented from being rusted and corroded by rainwater.

Owner:嘉兴同辉汽配有限公司

Powder bagging weight sorting and shaping all-in-one machine

InactiveCN112124715AThe device is compactReduce volumePackagingSortingProcess engineeringControl engineering

The invention discloses a powder bagging weight sorting and shaping all-in-one machine, and relates to the technical field of bagging. The powder bagging weight sorting and shaping all-in-one machinemainly aims to solve the problems that a traditional powder bagging weight sorting and shaping split body is complex in structure, and large in size and occupied site. The powder bagging weight sorting and shaping all-in-one machine comprises two supporting racks, a shaping mechanism and two conveyors arranged on the supporting racks respectively. A supporting plate is arranged between one supporting rack and the conveyor installed on the supporting rack. A spherical sensor and a weight sensor are arranged between the supporting plate and an ejector rod of each supporting rack. A removing mechanism is installed on the other supporting rack and provided with a controller which electrically controls the removing mechanism to work. The controller is further connected with the spherical sensors and the weight sensors through wires. The powder bagging weight sorting and shaping all-in-one machine is simple and compact in structure, capable of effectively reducing the occupied space and achieving automatic sorting and shaping, easy, convenient and fast to operate, accurate in detection and high in practicability.

Owner:湖北信美智能设备有限公司

Container overload detection and protection system, method and front stacker

ActiveCN108862036BGuaranteed vertical forceGuaranteed weighing accuracyWeighing auxillary devicesSafety gearElectric controlLoad cell

Owner:上海亿锤机械科技有限公司

Thread-slipping-resistant check bolt

InactiveCN103775470ATo achieve the purpose of anti-theftGuaranteed vertical forcePinsNutsEngineeringScrew thread

The invention relates to a thread-slipping-resistant check bolt which comprises a bolt head, a screw and threads. The bolt head is cylindrical, end face ratchets are arranged on the upper end face of the bolt head, and the check direction of the end face ratchets is identical to the heading direction of the threads; an outer hexagon bolt connector is further arranged at the upper end of the bolt head and auxiliary end face ratchets meshed with the end face ratchets are arranged on the lower end face of the bolt head. After the bolt is installed in a device, the outer hexagon bolt connector is screwed through a hexagon spanner, the auxiliary end face ratchets drive the end face ratchets meshed with the auxiliary end face ratchets to rotate, and therefore the bolt is driven to be screwed. After the bolt is screwed tightly, the outer hexagon bolt connector is taken out, the bolt can not be detached from the outer end through a common measure and a common tool any more, and therefore the anti-theft purpose is achieved. Meanwhile, a guide polish rod with the diameter smaller than that of outer threads of the bolt is designed at the end, far away from the bolt head, of a thread screwing portion, the guide polish rod conducts perpendicular guidance before the bolt and a threaded hole are meshed, the perpendicular stress of the bolt is guaranteed, and the probability of thread slipping is reduced.

Owner:ZHEJIANG COWIN FASTECH

Double-bow cut-off device for detecting pantograph pressure of engine

ActiveCN101782448BAvoid the effects of superimposed vertical (lifting) forcesGuaranteed vertical forceApparatus for force/torque/work measurementElectricityContact network

The invention relates to a double-bow cut-off device for detecting pantograph pressure of an engine. An installation rack is fixed at the inner side of a stand column at the outer side of a track, and is fixedly connected with the cut-off device through an insulative connecting rack. The concrete structure of the cut-off device is that: a working platform is fixedly connected with the connecting rack, the bottom of the working platform is fixedly provided with a transverse sliding rail; a transverse sliding seat is sleeved on the transverse sliding rail, a screw at the middle lower part of a vertical lifting rod is connected in a screw nut of the transverse sliding seat, the lower end of the lifting rod is connected with the outer ring of a bearing through a flange, the inner ring of the bearing is fixedly connected with the upper end part of a connecting rod; and the lower end of the connecting rod is connected with a longitudinal slide block, and a longitudinal slide block at the upper part of a contact network clip is sleeved on the longitudinal slide block. When contact pressure detection is carried out on more than two pantographs, the double-bow cut-off device can be utilized to eliminate the mutual interference between adjacent pantographs, thereby enabling the detection result to be more reliable and more accurate.

Owner:CHENGDU LEAD SCI TECH CO LMT +6

A floor-standing brake master cylinder performance test device and method

ActiveCN111824108BGuaranteed vertical forceGuaranteed accuracyBrake safety systemsPower sensorMaster cylinder

Owner:XIAMEN KING LONG UNITED AUTOMOTIVE IND CO LTD

An adjustable elastic support wire clip

ActiveCN104085316BStress state is normalFirmly adjust the positioningTrolley linesEngineeringCushion

The invention relates to an adjustable and elastic supporting wire clamp, and relates to the field of rigid suspension systems of electrified railways. A connecting shaft is connected with an adjusting sleeve and a wire clamp body in a vertically penetrating mode. An elastic element is arranged on the portion, located inside the wire clamp body, of the connecting shaft in a sleeved mode. The two sides of the bottom of the wire clamp body are respectively provided with an anti-rotation clamping plate. The adjusting sleeve is provided with a supporting thread sleeve and an anti-rotation blocking board in a sleeved mode, wherein the anti-rotation blocking board is arranged on the supporting thread sleeve in an overlaid mode. A spherical cushion block is arranged between the connecting shaft and each end opening of the adjusting sleeve. The adjustable and elastic supporting wire clamp is accurate in positioning, solid in connection and capable of adjusting the deflection angle.

Owner:CHINA RAILWAY HIGH SPEED ELECTRIFICATION EQUIP CORP LTD

An adjustable angle docking buffer device

ActiveCN105714742BBig impactGuaranteed vertical forceClimate change adaptationShipping equipmentComputer scienceShore

The invention provides an angle-adjustable wharf berthing buffering device and belongs to the field of harbor machinery. The angle-adjustable wharf berthing buffering device comprises pre-buffering modules, a main buffering module, a supporting module and a base module. The base module is fixed to the ground of a wharf. The supporting module is arranged on the base module. The main buffering module is connected with the supporting module through a spherical hinge. The pre-buffering modules are connected with the main buffering module and the supporting module through bolts. The angle-adjustable wharf berthing buffering device can achieve effective buffering when ships are pulled into shore.

Owner:SHANGHAI JIAO TONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com