Reaction frame testing method for earth nail drawing tests

A pull-out test and test method technology, applied in the field of steel structural components, can solve the problem of spending a lot of time, and achieve the effect of ensuring vertical force, improving detection speed and detection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] This embodiment relates to a test method for a soil nail pull-out test reaction force frame, and the specific steps are as follows:

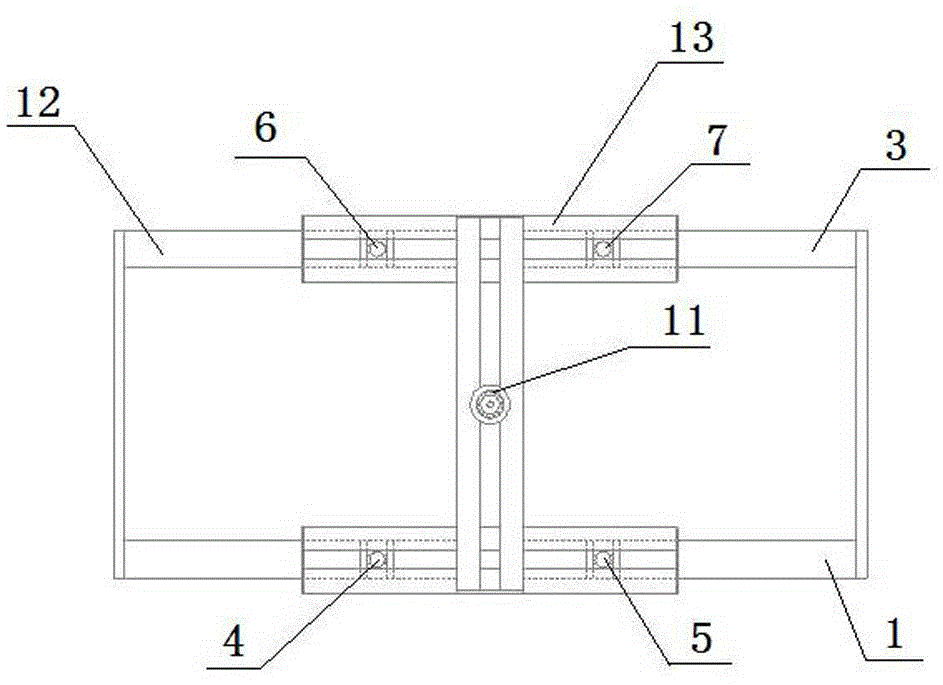

[0024] a) Fix the base 12 on the soil nail wall to ensure that the soil nail is located at the center of the base 12;

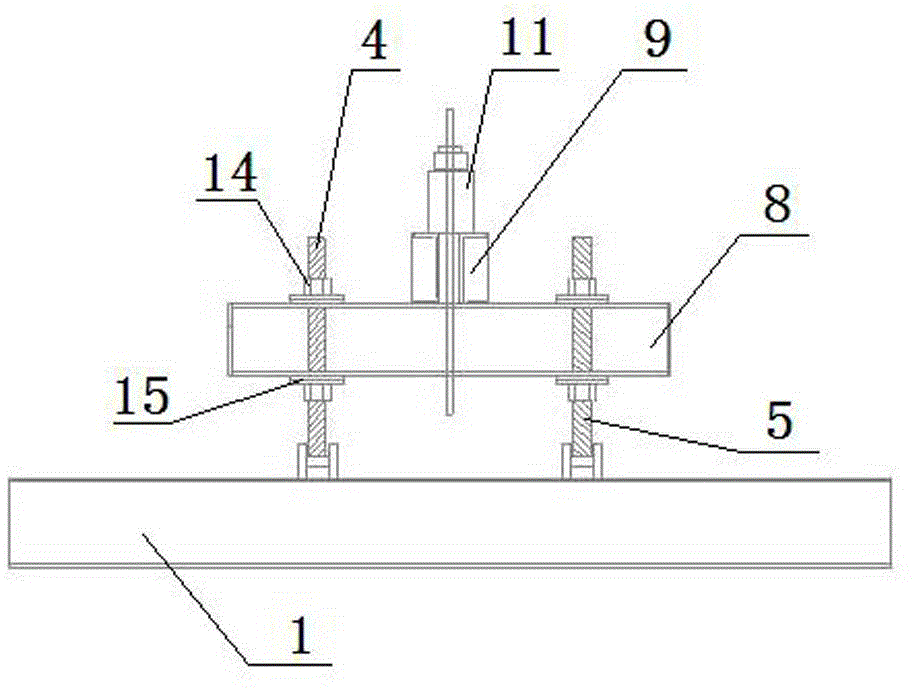

[0025] b) Set the load-bearing bracket 13 on the base 12, and adjust it by screw 4, screw 5, screw 6 and screw 7 to ensure that the load-bearing surface of the load-bearing bracket 13 is perpendicular to the axis of the soil nail;

[0026] c) Install a jack 11 on the longitudinal beam 9 of the force support 13 as a jack reaction system;

[0027] d) Use steel bars with sufficient tensile strength to extend the soil nails to a length that can be in contact with the jack 11, and start the pull-out test.

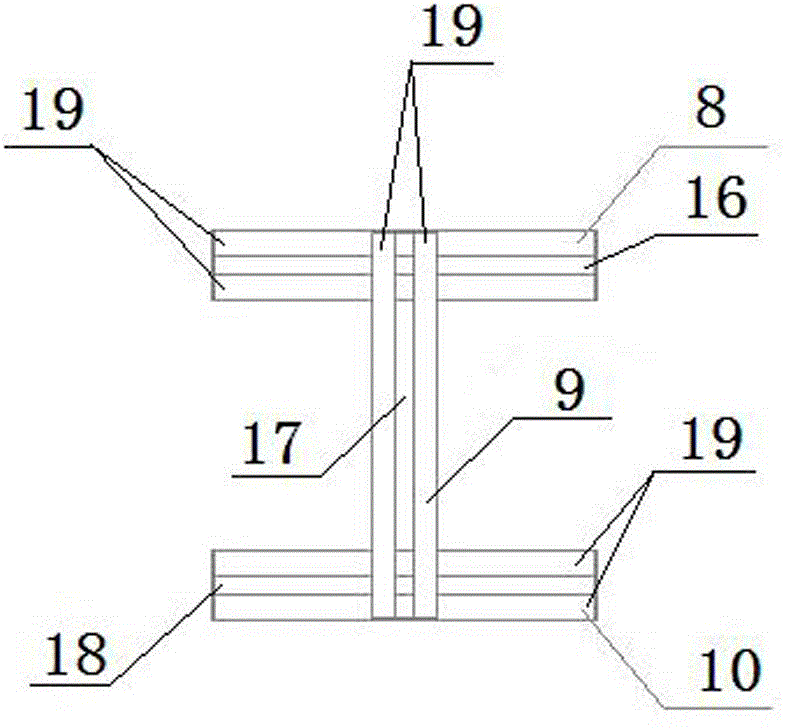

[0028] The facilities of the above test methods are installed as follows: figure 1 As shown, the base 12 is connected by the I-beam 1 and the I-beam 3 through the reinforcement 2, and the screw 4, the screw 5, the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com