An adjustable elastic support wire clip

An elastic support and wire clip technology, applied in the direction of overhead lines, etc., can solve the problems of high installation accuracy, lack of yaw angle, weak connection, etc., to avoid excessive wear, improve stress conditions, and simplify installation. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

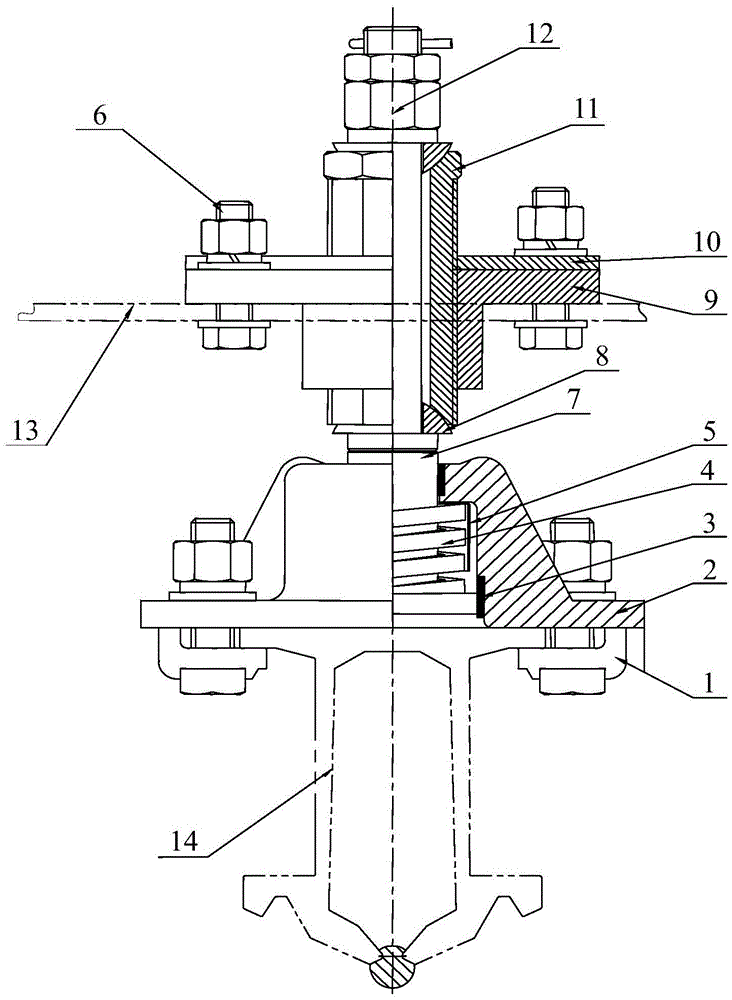

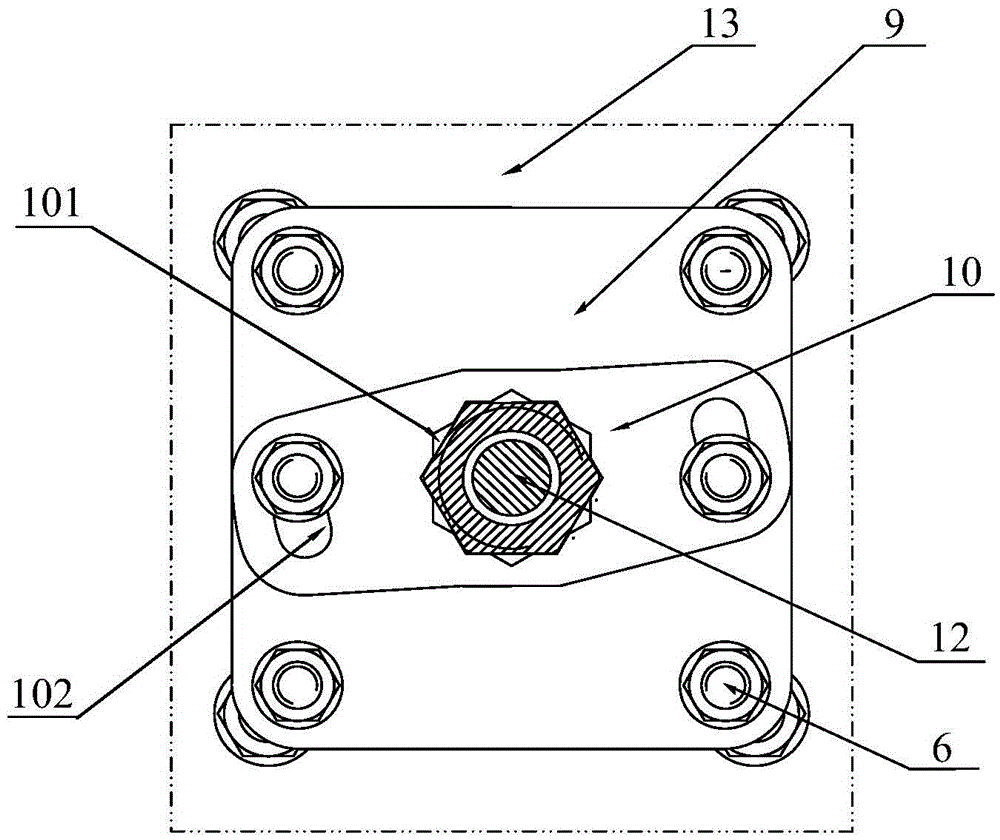

[0022] Such as Figure 1 to Figure 2 As shown, an adjustable elastic support clamp includes an anti-rotation splint 1, a clamp body 2, an elastic element 4, an anti-wear sheath 5, a connecting shaft 7, a spherical pad 8, a support threaded sleeve 9, and an anti-rotation card. The plate 10 and the adjusting sleeve 11, the connecting shaft 7 connects the adjusting sleeve 11 and the clamp body 2 from top to bottom. In this embodiment, the connecting shaft 7 is made of stainless steel machining, and the wire The clamp body 2 is manufactured by an aluminum alloy casting process, and the side of the clamp body 2 is provided with two reinforcing ribs to increase the safety and reliability of the product.

[0023] In the lower part of the supporting wire clamp, the part of the connecting shaft 7 located in the wire clamp body 2 is also sleeved with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com