Patents

Literature

265 results about "Current clamp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

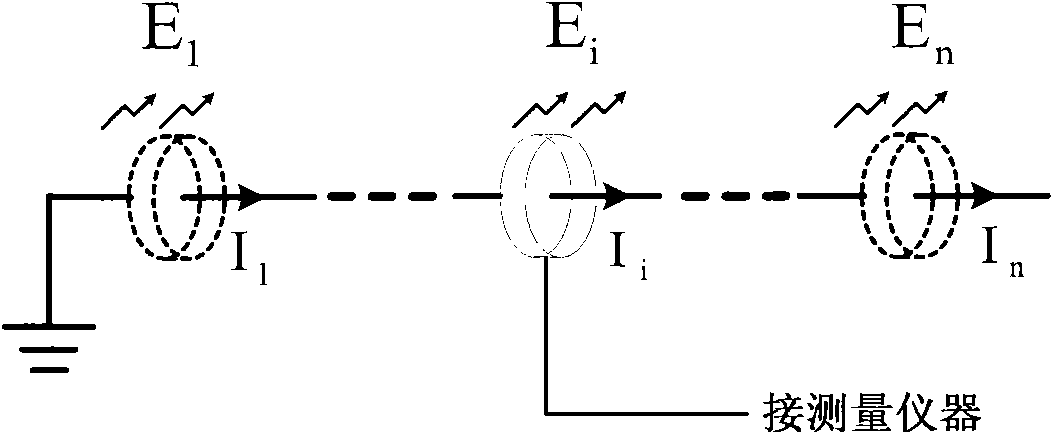

In electrical and electronic engineering, a current clamp or current probe is an electrical device with jaws which open to allow clamping around an electrical conductor. This allows measurement of the current in a conductor without the need to make physical contact with it, or to disconnect it for insertion through the probe. Current clamps are typically used to read the magnitude of alternating current (AC) and, with additional instrumentation, the phase and waveform can also be measured. Some clamp meters can measure currents of 1000 A and more. Hall effect and vane type clamps can also measure direct current (DC).

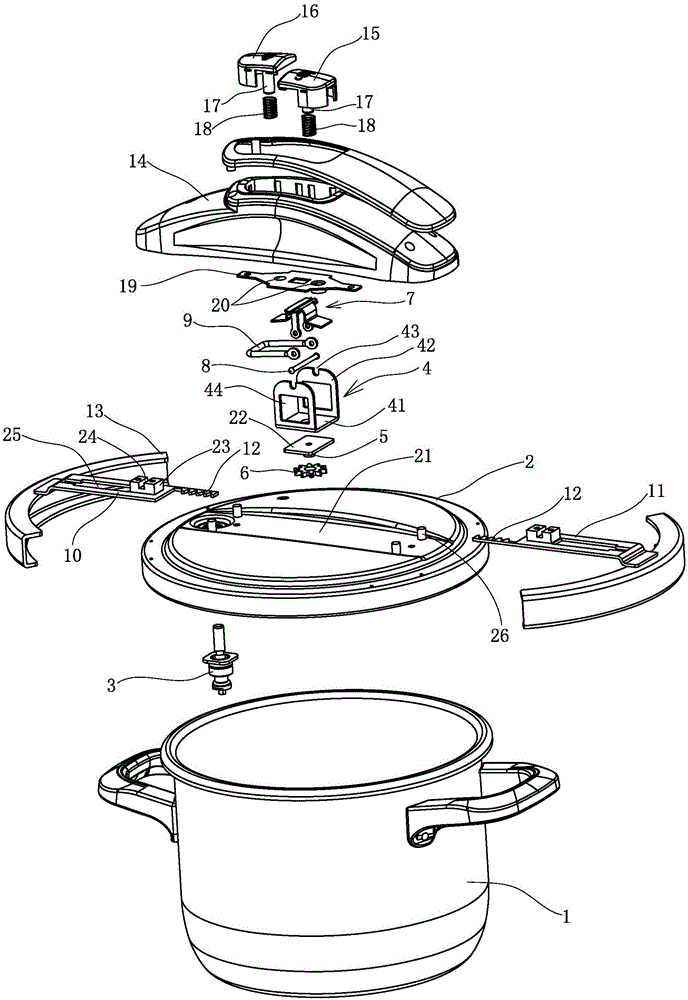

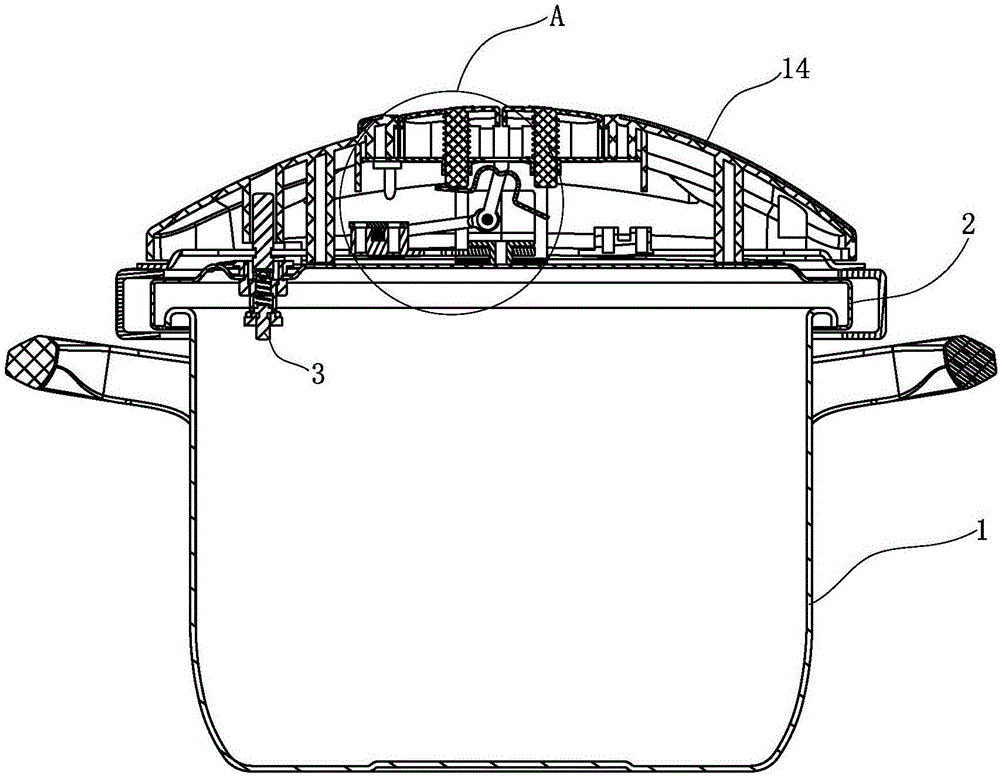

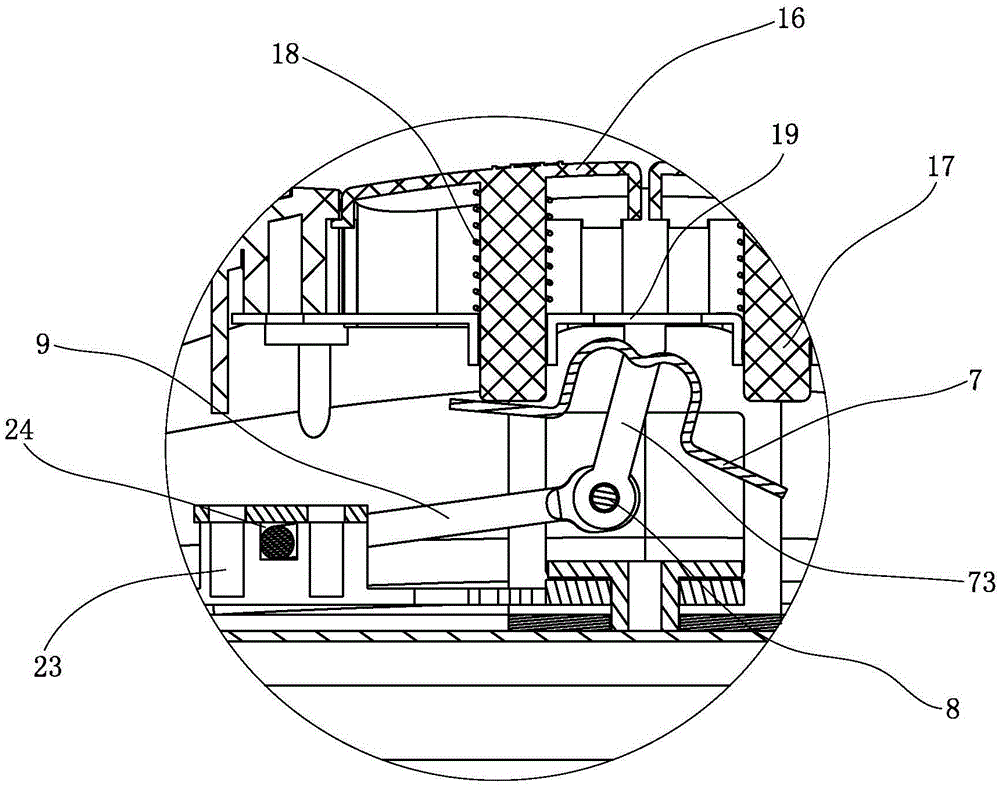

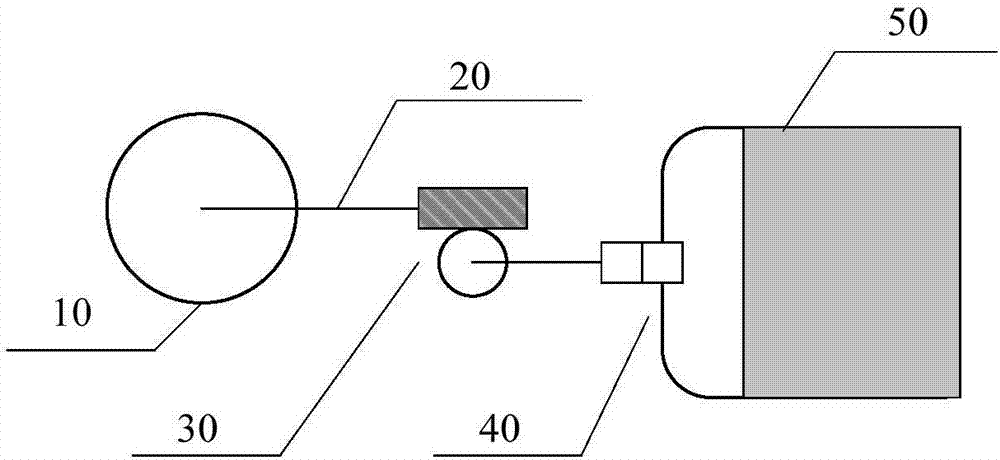

Improved opening-closing structure of clamp pressure cooker

The invention discloses an improved opening-closing structure of a clamp pressure cooker. A current clamp type pressure cooker has the problem that a clamp is prone to being self-reset commonly, the pressure cooker can exert pressure under the condition that a cooker body and a cooker cover are not completely buckled by the clamp, and a danger exists in case of improper usage. The improved opening-closing structure of the clamp pressure cooker is characterized in that a rack is fixedly connected to the center of the upper surface of the cooker cover and is provided with a bottom plate and two side plates; a gear shaft is fixedly connected to the bottom plate or the cooker cover and is sleeved by a gear; a swing piece is arranged at the tops of the two side plates of the rack and swings left and right by taking the upper part of the swing piece as a fulcrum; the lower part of the swing piece is connected with a transmission rod through a central shaft; the bottom end of an opening button and the bottom end of a closing button cooperate with the swing piece. According to the improved opening-closing structure of the clamp pressure cooker, the clamp is prevented from being self-reset, the pressure cooker can exert the pressure under the condition that the cooker body and the cooker cover are not completely buckled by the clamp, and the safety of the pressure cooker in the using process is improved.

Owner:ZHEJIANG AISHIDA ELECTRIC CO LTD

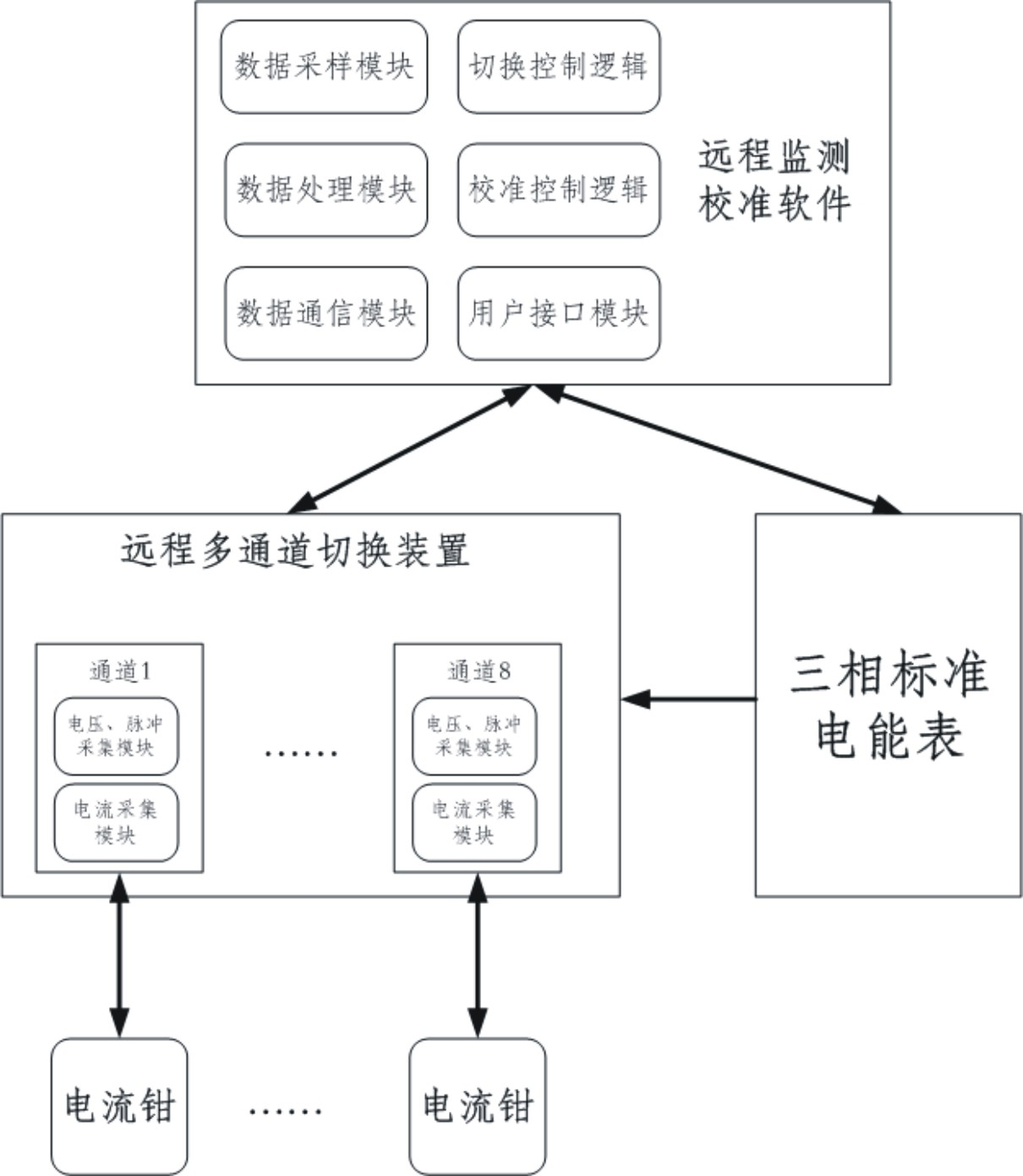

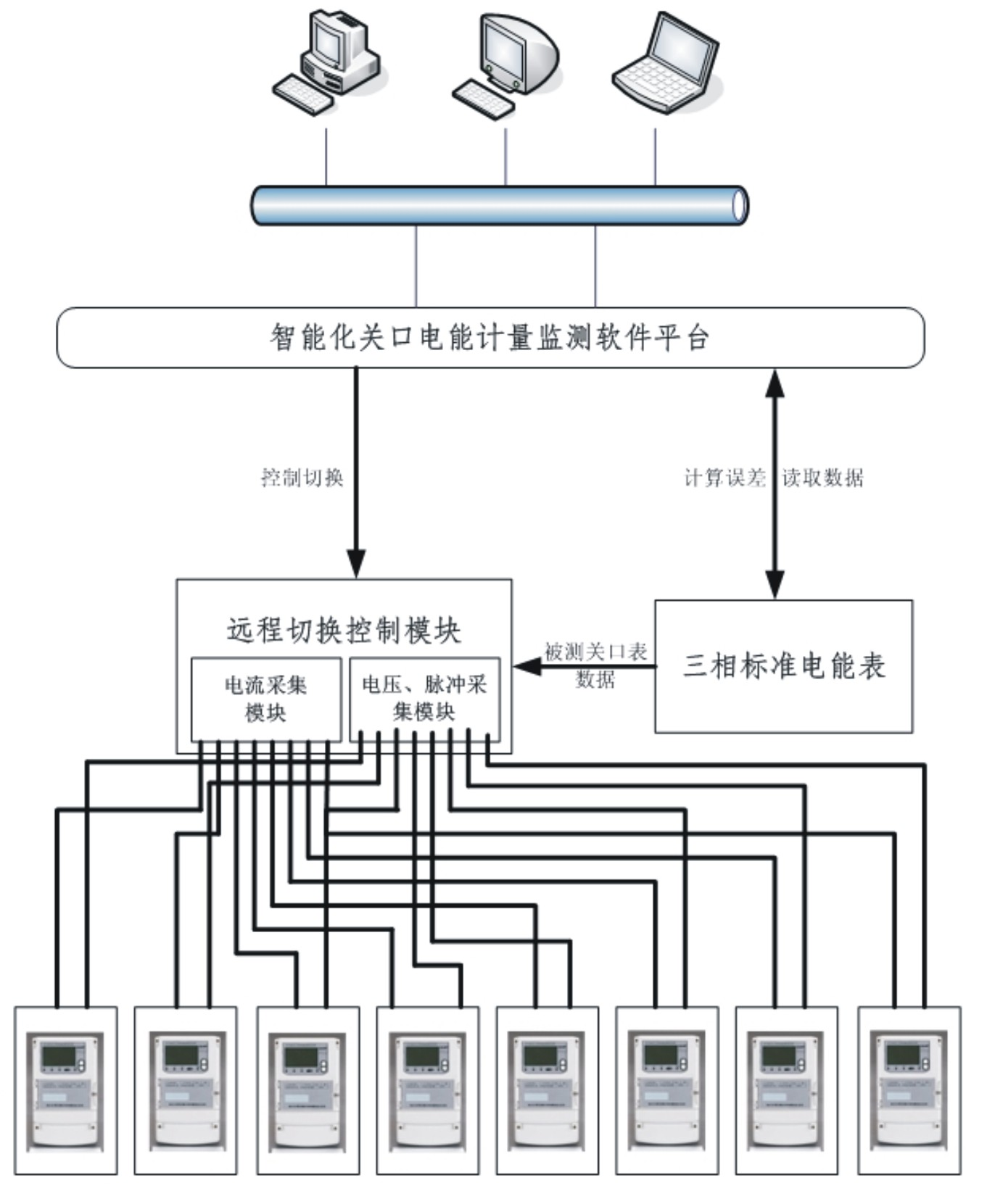

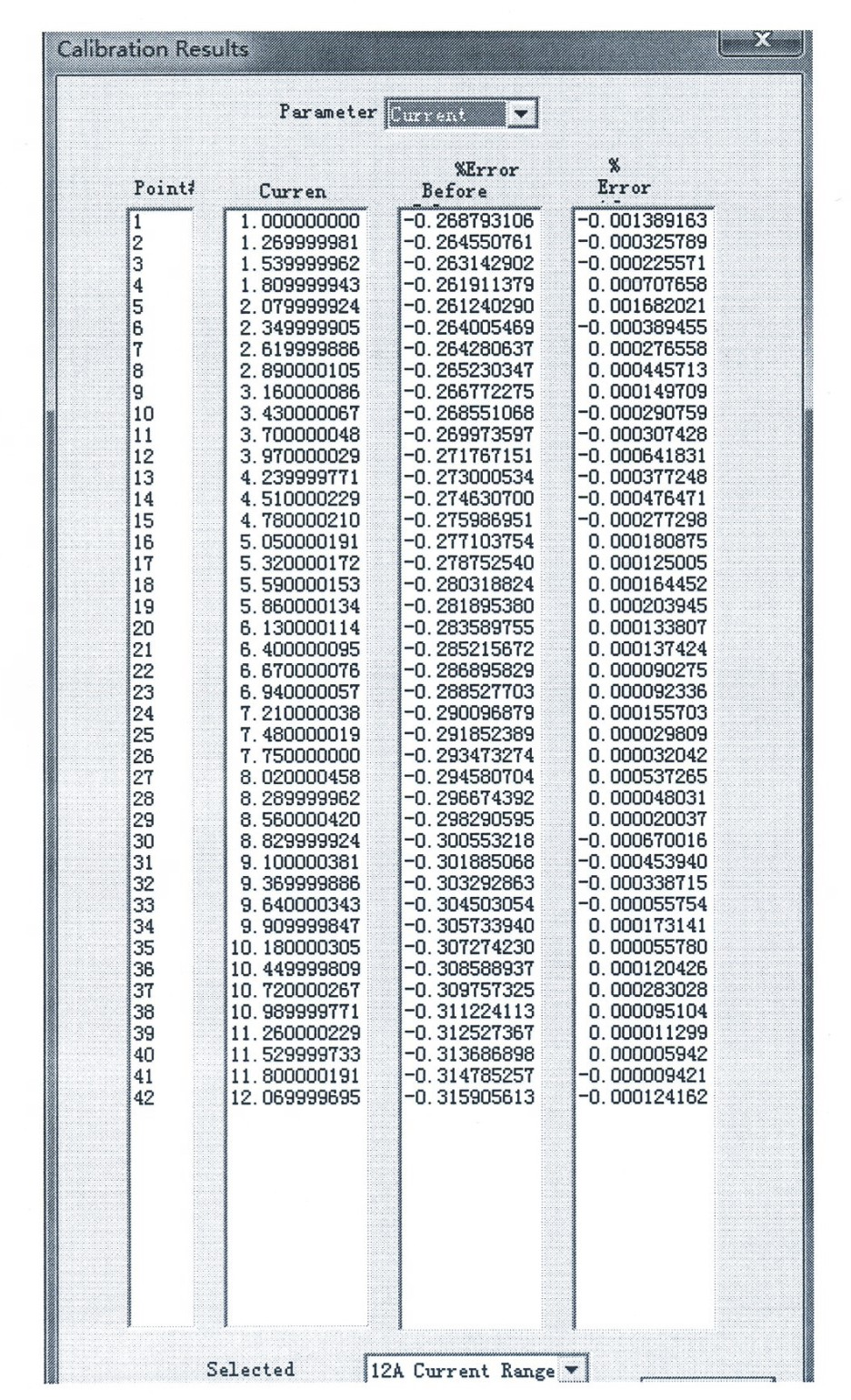

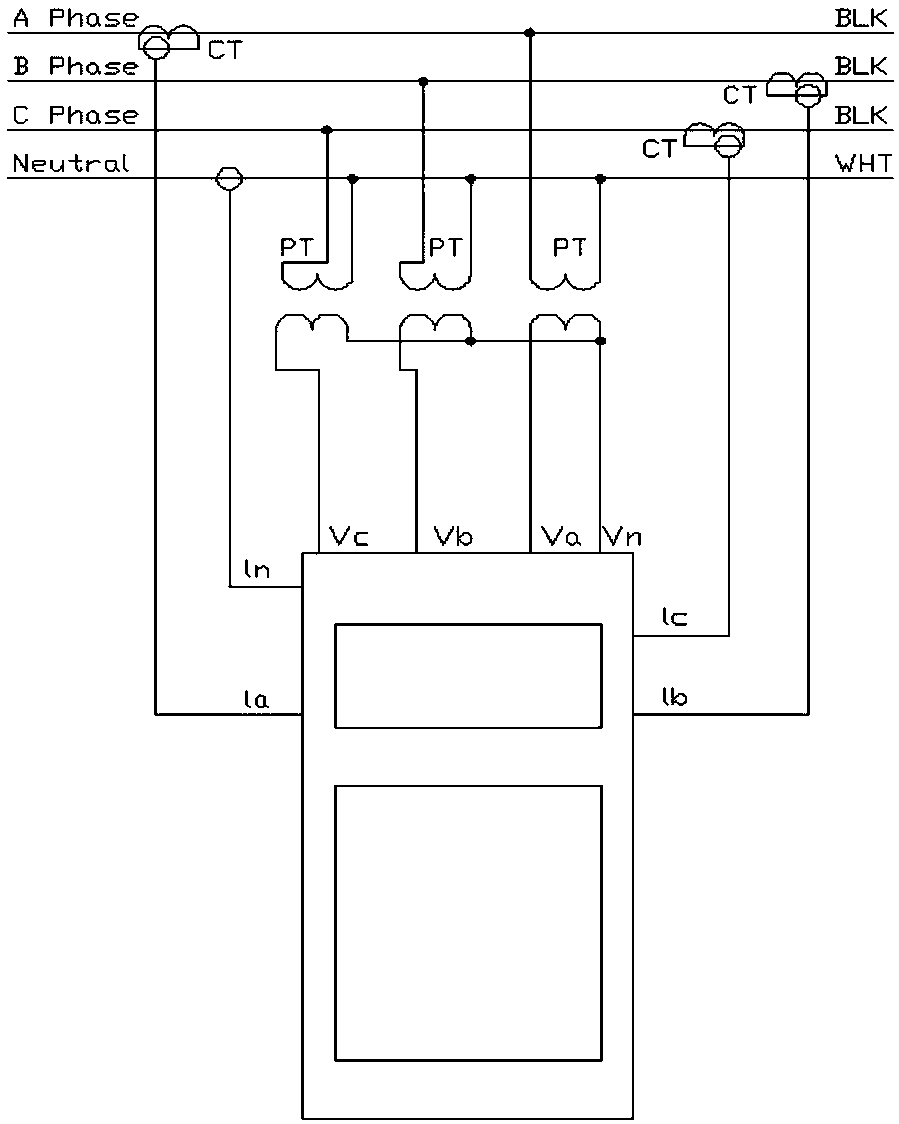

Electric energy metering and monitoring system of intelligent gateway

InactiveCN102135608AImprove Metering AutomationImprove modern management levelElectrical measurementsTime errorCurrent clamp

The invention relates to an electric energy metering and monitoring system of an intelligent gateway, which mainly comprises a three-phase standard ammeter and a built-in computer thereof, a remote switching control device, contactless intelligent open-loop current pincers, a detected meter switching control unit, an error verification unit and the like, wherein the remote switching control device comprises an MPU (Micro Processor Unit) chip control circuit and a relay switching circuit which are arranged in a switching box; 8 paths of input ends for connecting a detected meter are arranged on the switching box; the current signals of the detected meter, which are taken out by the current pincers, and the voltage signals and pulse signals of the detected meter, which are taken out by a voltage and pulse sampling circuit of the detected meter, are accessed to the standard ammeter through the switching box; and the error verification of the detected meter is realized through a software platform. The electric energy metering and monitoring system provided by the invention has the characteristics of simple integral design, real-time error verification and high safety, and is convenient to install.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST

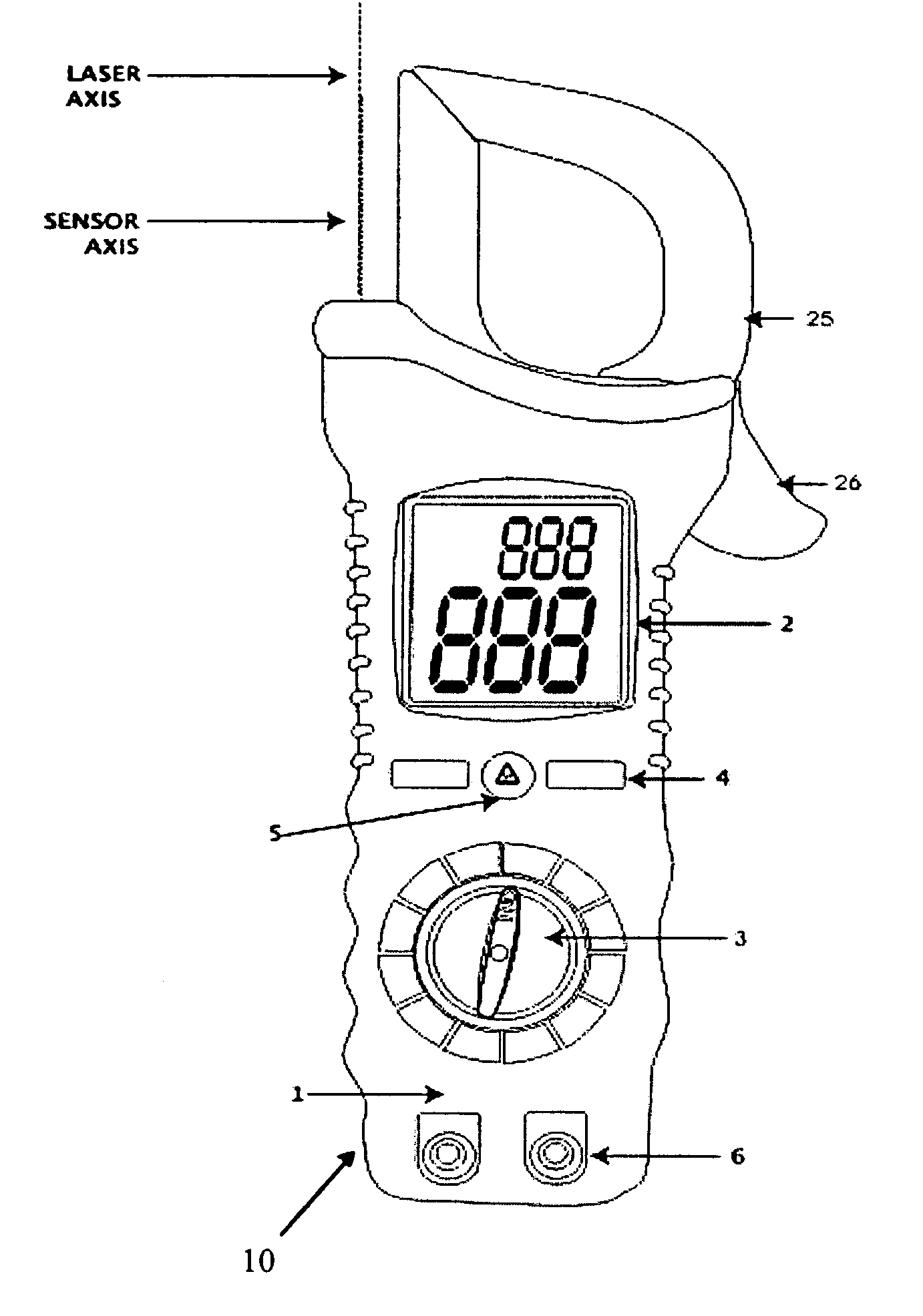

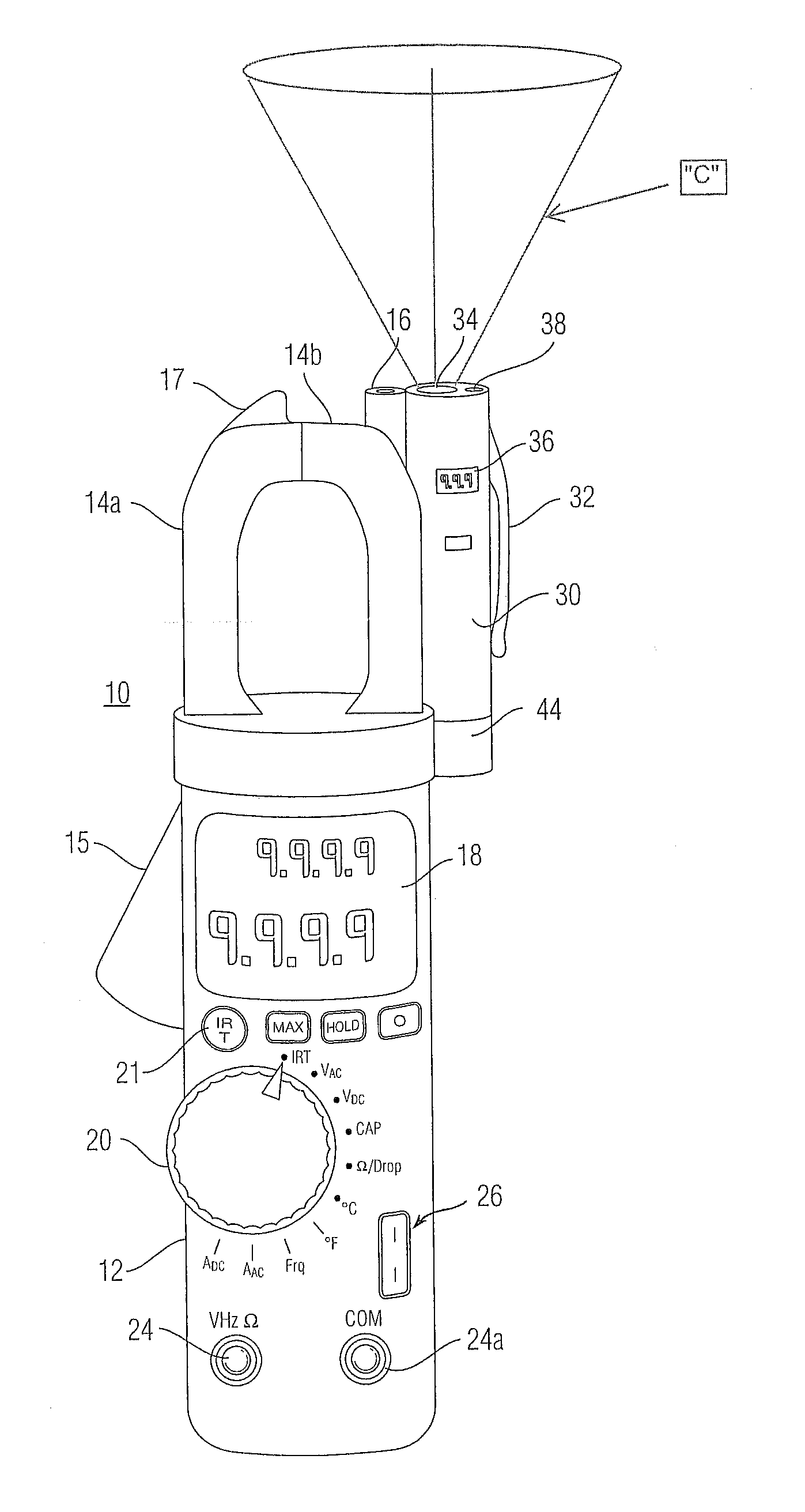

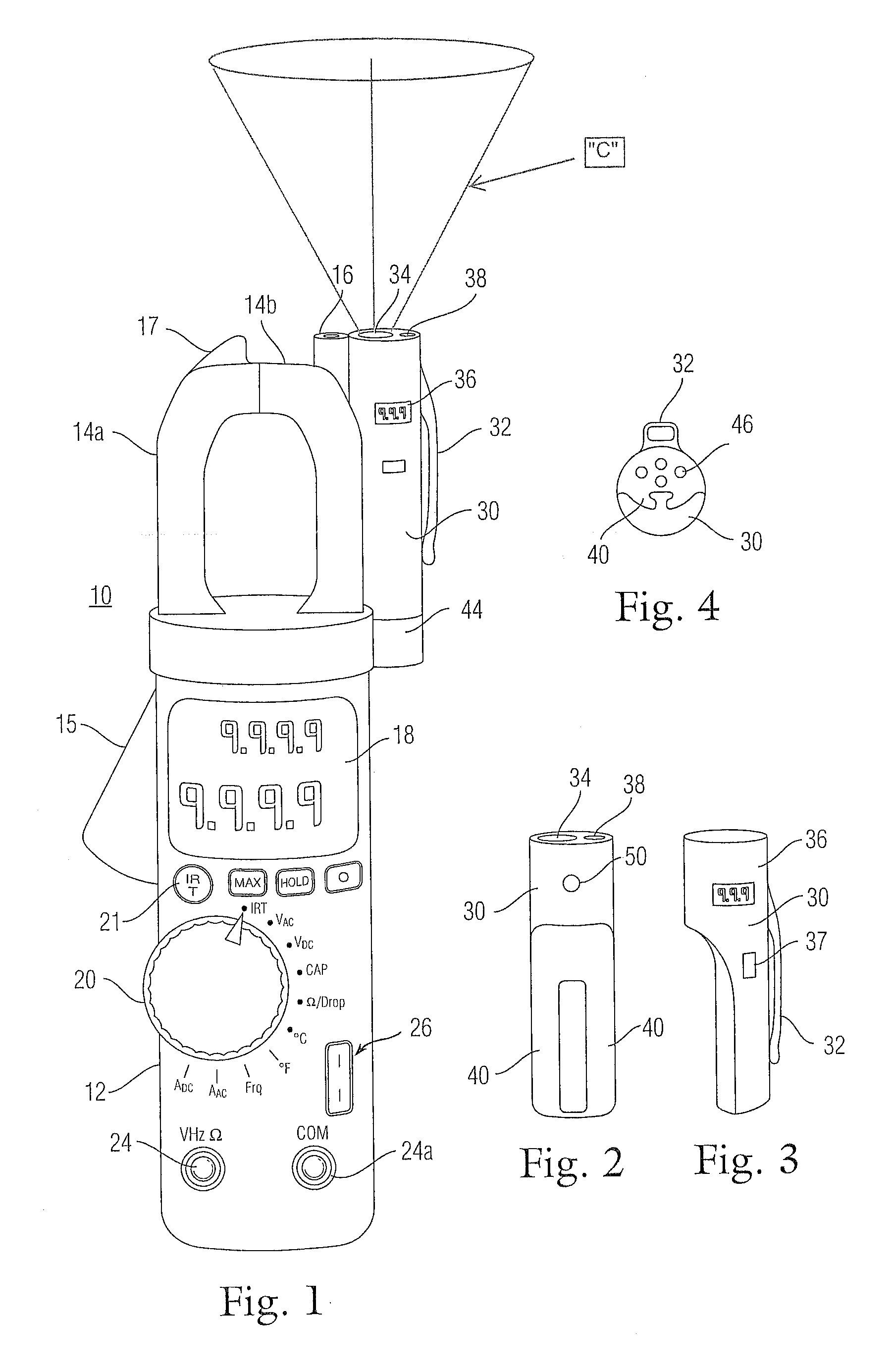

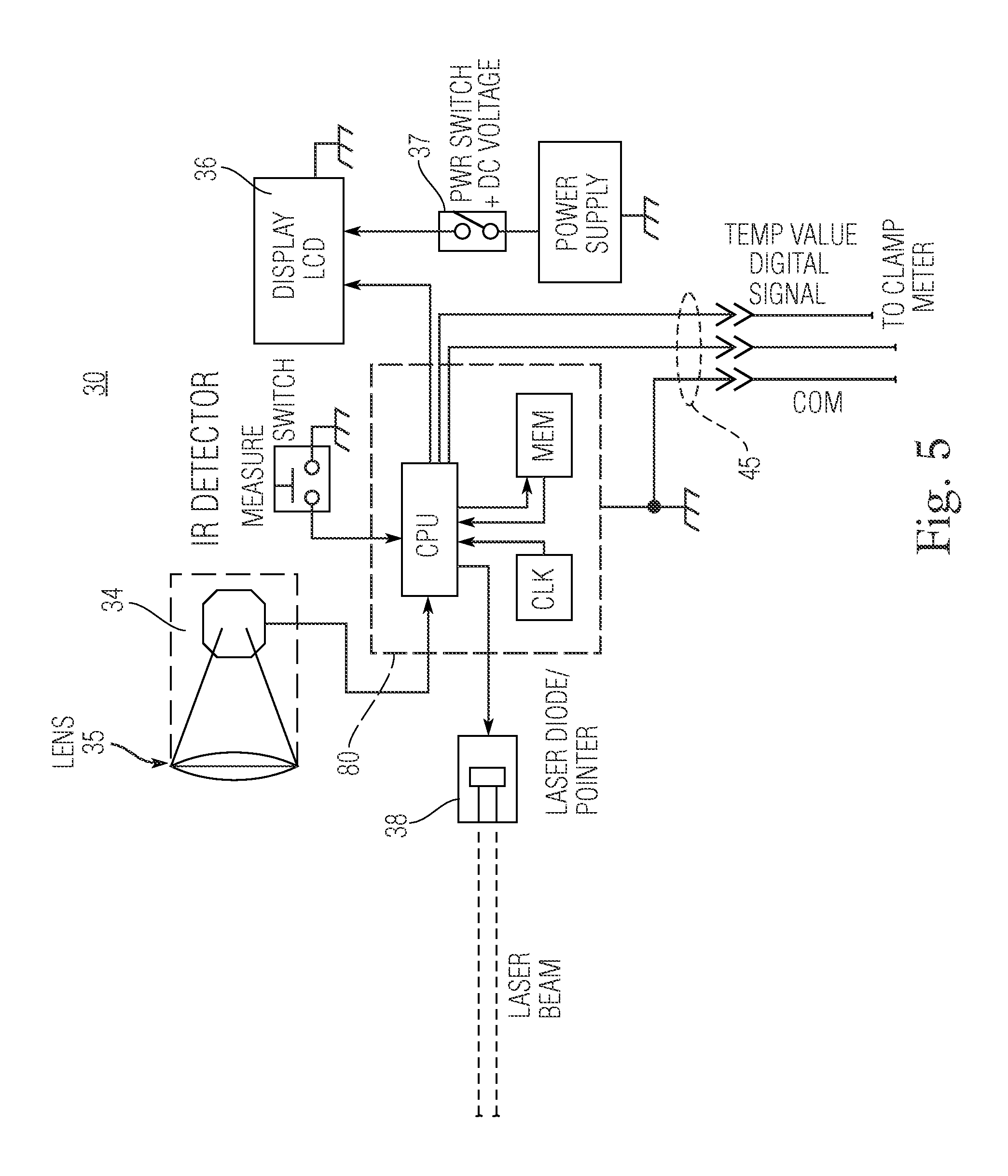

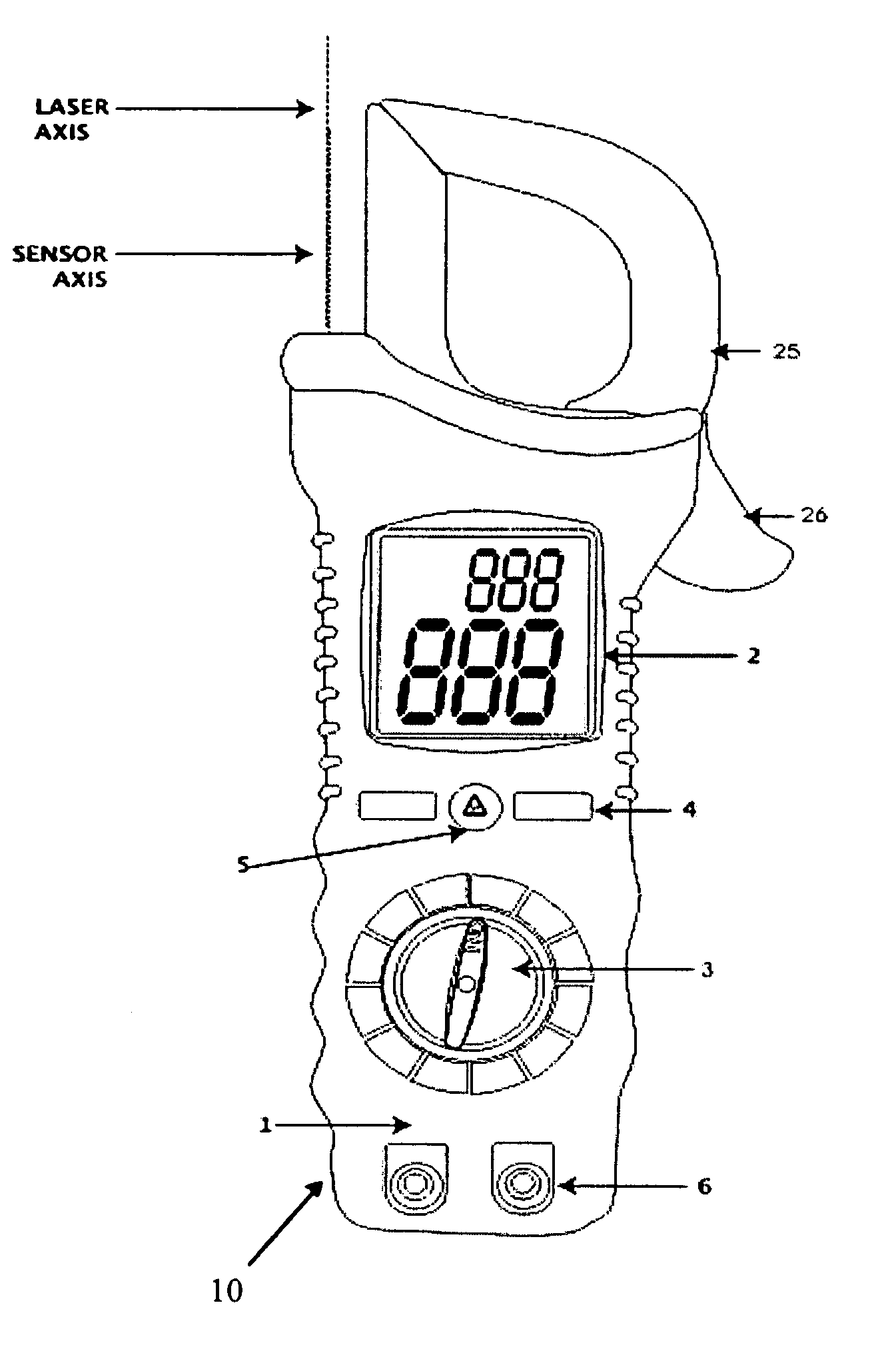

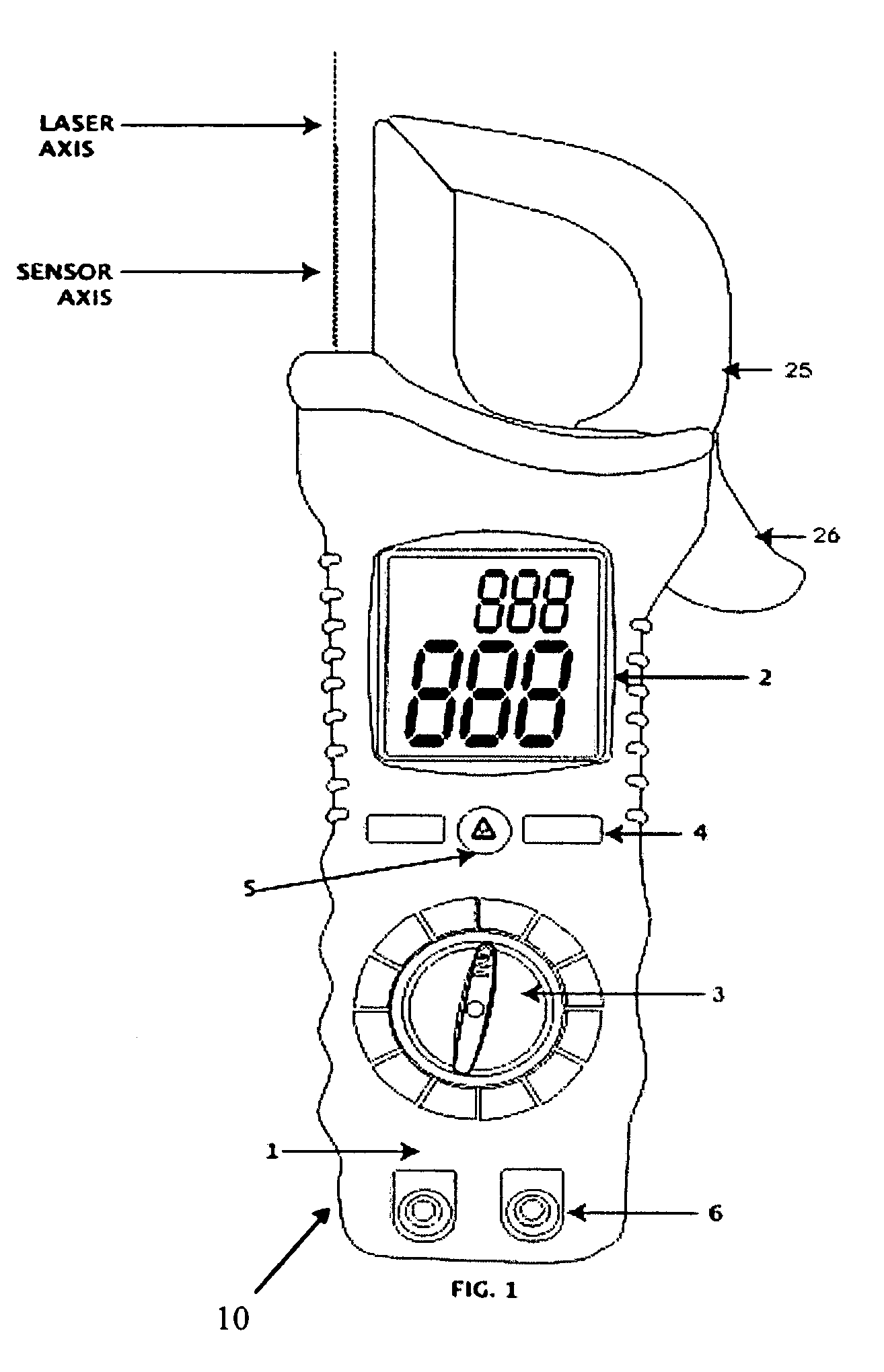

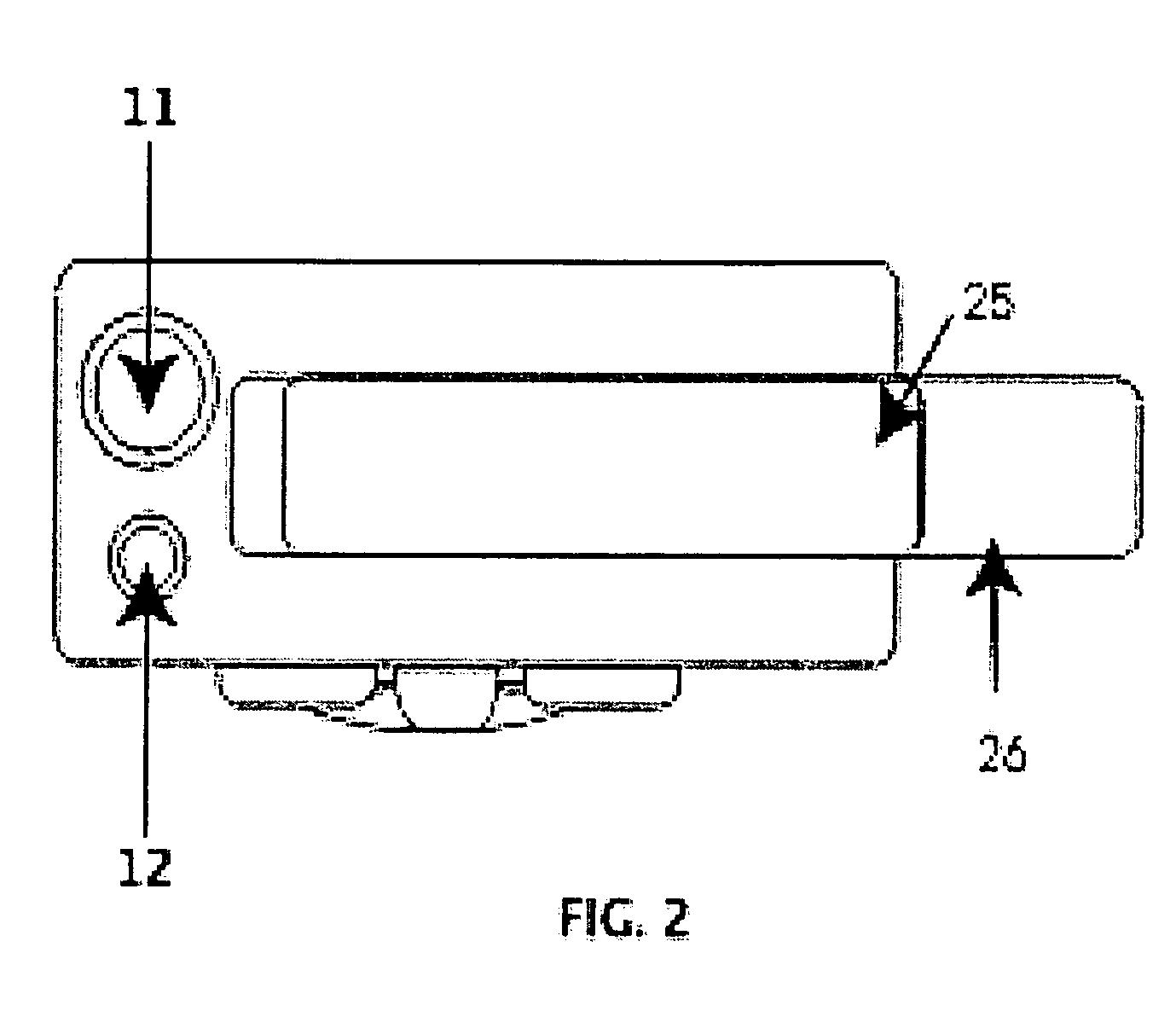

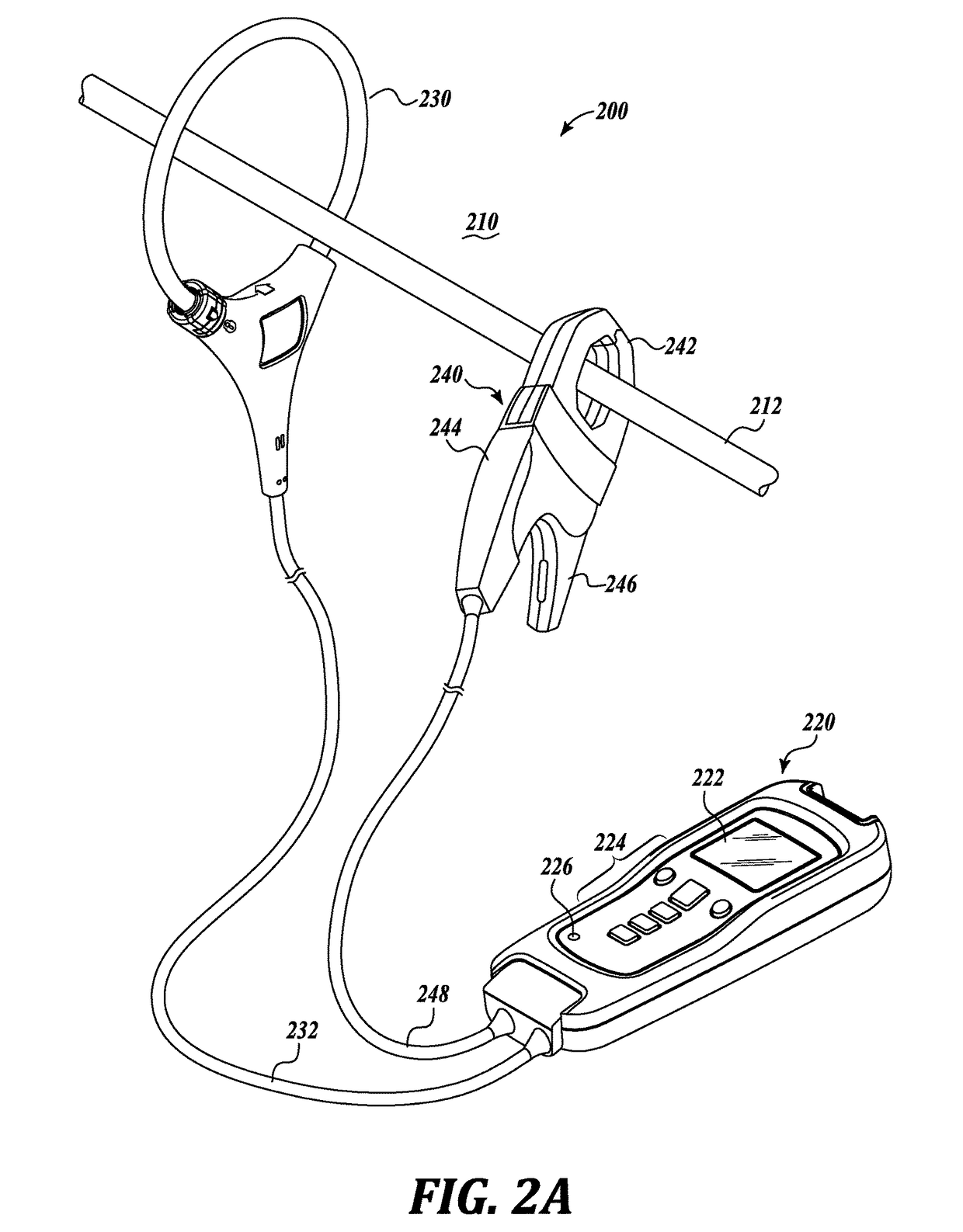

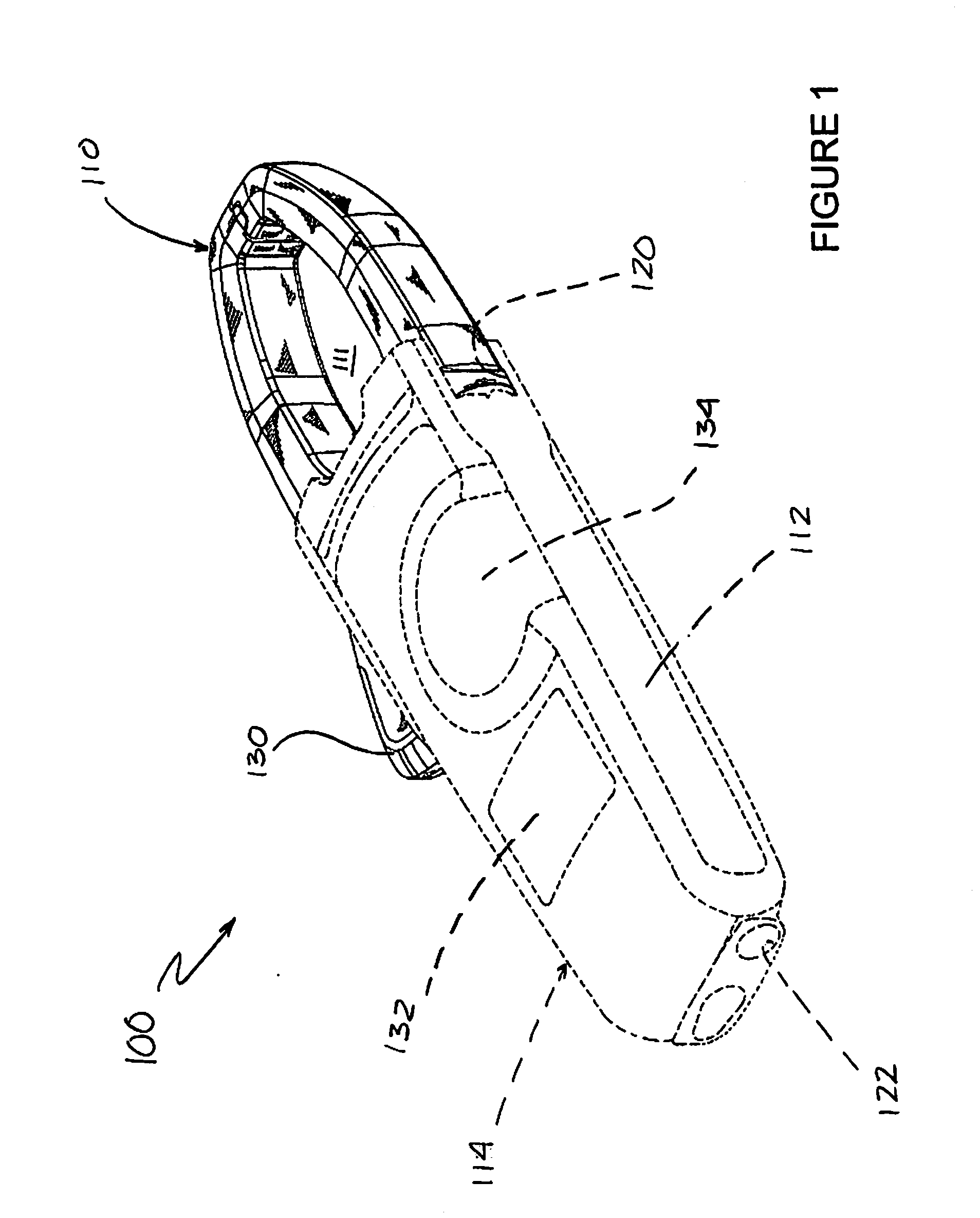

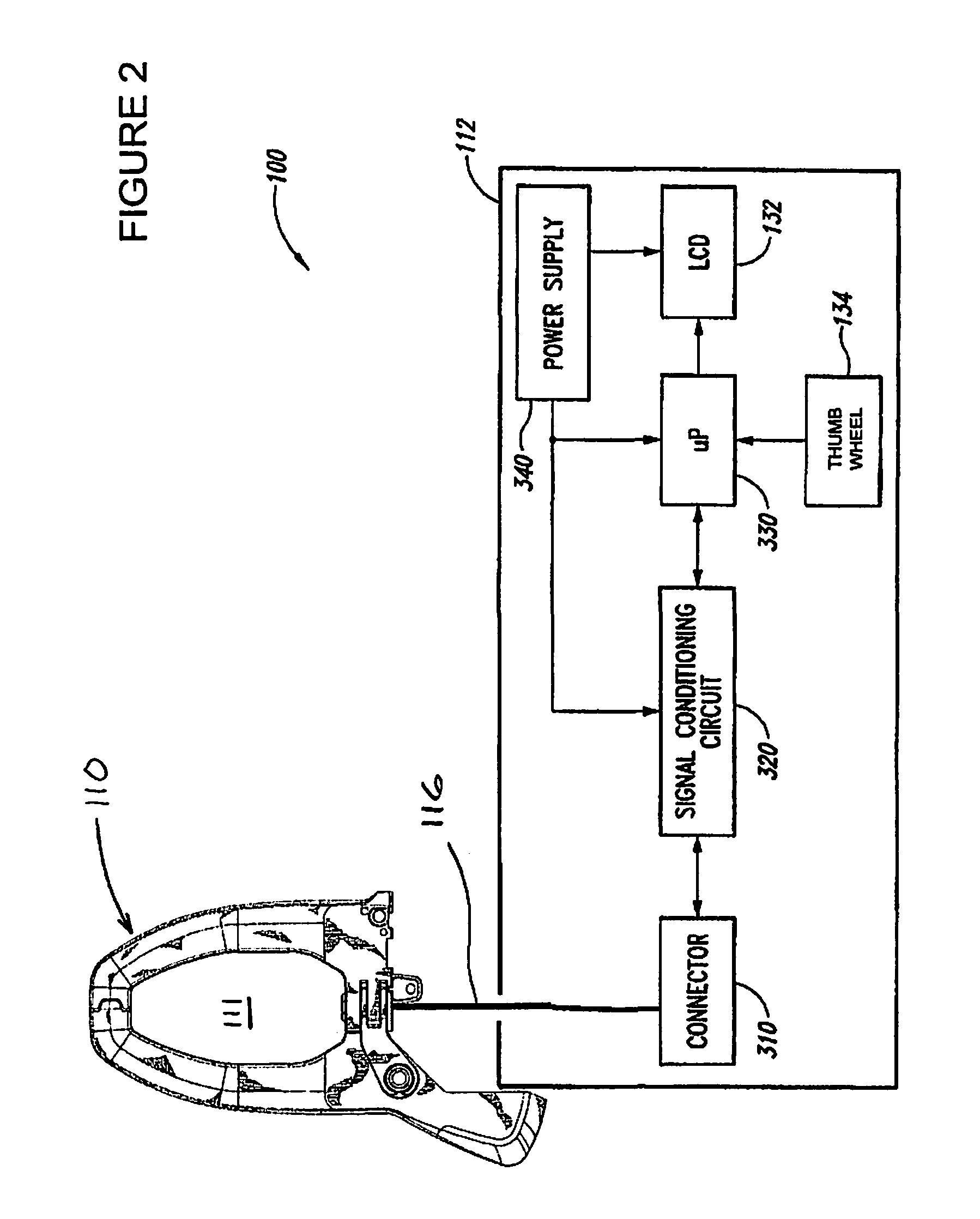

Instrument for non-contact infrared temperature measurement having current clamp meter functions

ActiveUS7163336B2Convenience setThermometer detailsRadiation pyrometryElectrical conductorDisplay device

A handheld instrument that accomplishes infrared (IR) temperature measurement and non-contact electrical current measurement. The instrument has a case, a current-sensing device coupled to the case and operable to be placed around a conductor, for generating an output signal based on the current flowing through the conductor, and an IR detector carried by the case, for sensing IR energy emitted from a surface being measured along a sensing axis that extends from the case, and generating an IR output signal. Sensed IR energy is converted to a temperature value, and the output signal from the current-sensing device is converted to at least a measured current value. There is a display device in the case, for displaying instrument measurements to the user.

Owner:FLIR SYST INC

Electrical measuring instrument having detachable current clamp

ActiveUS7312603B2Measurement using dc-ac conversionBase element modificationsElectricityCurrent meter

Owner:JOHN FLUKE MFG CO INC

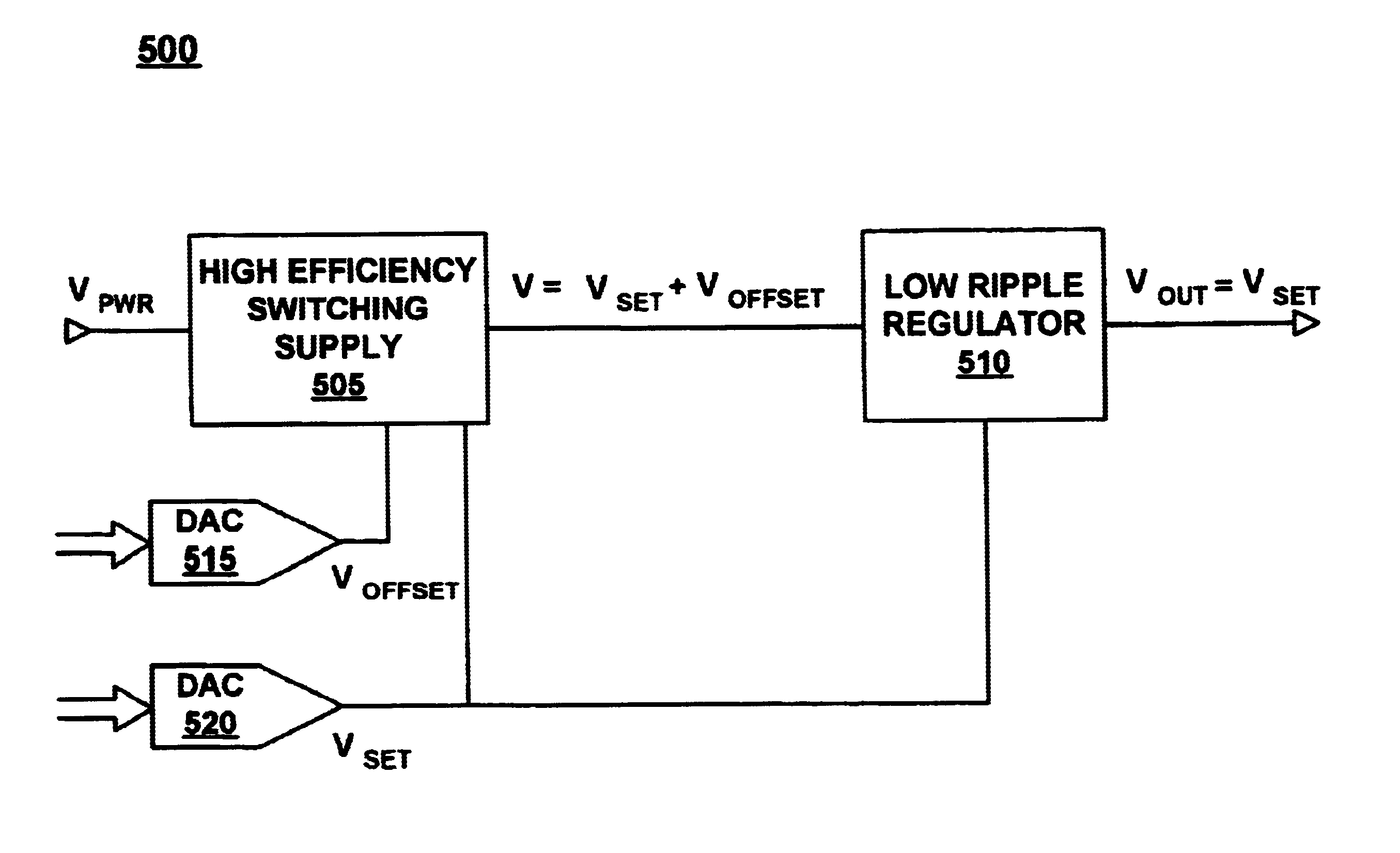

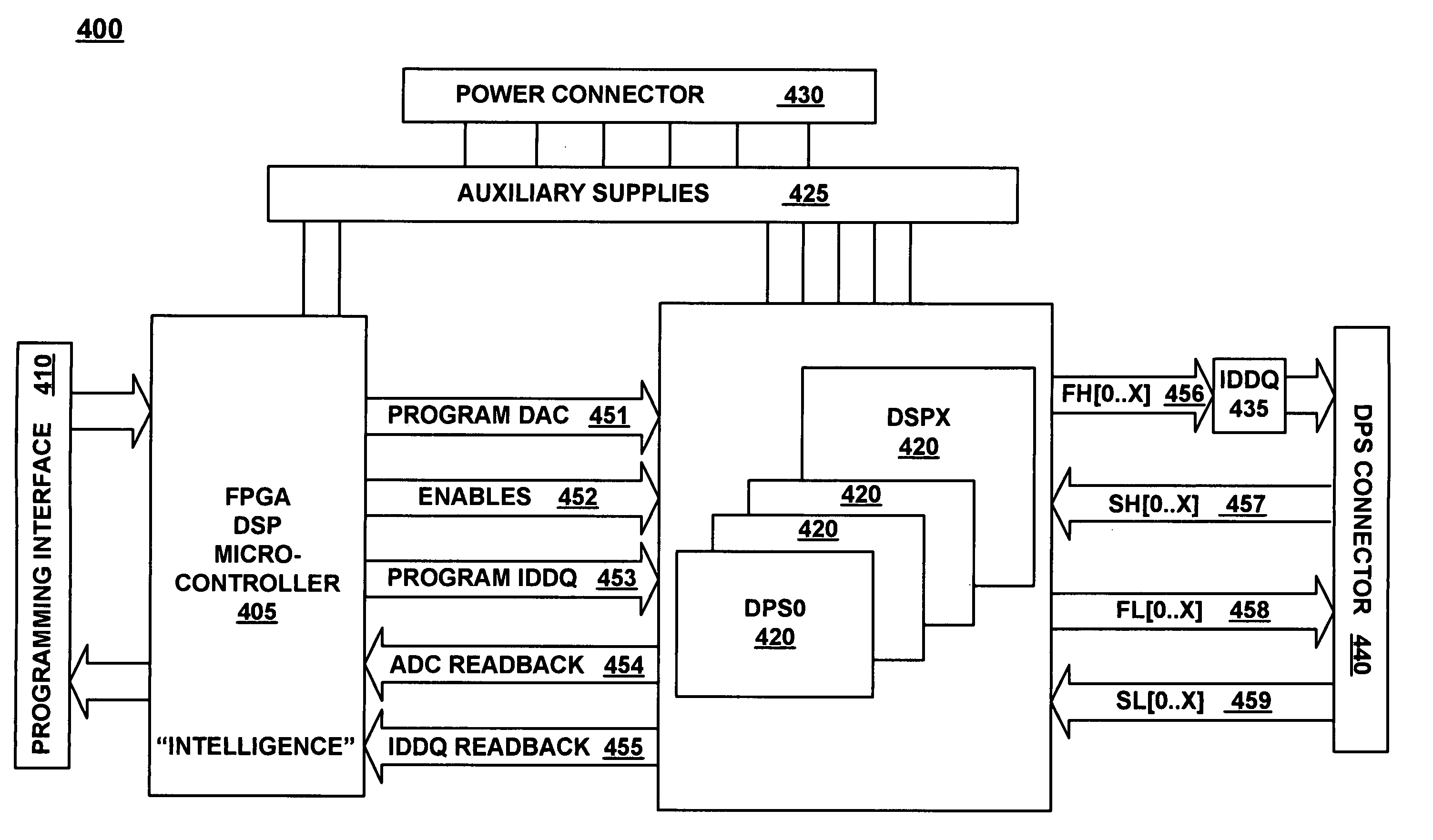

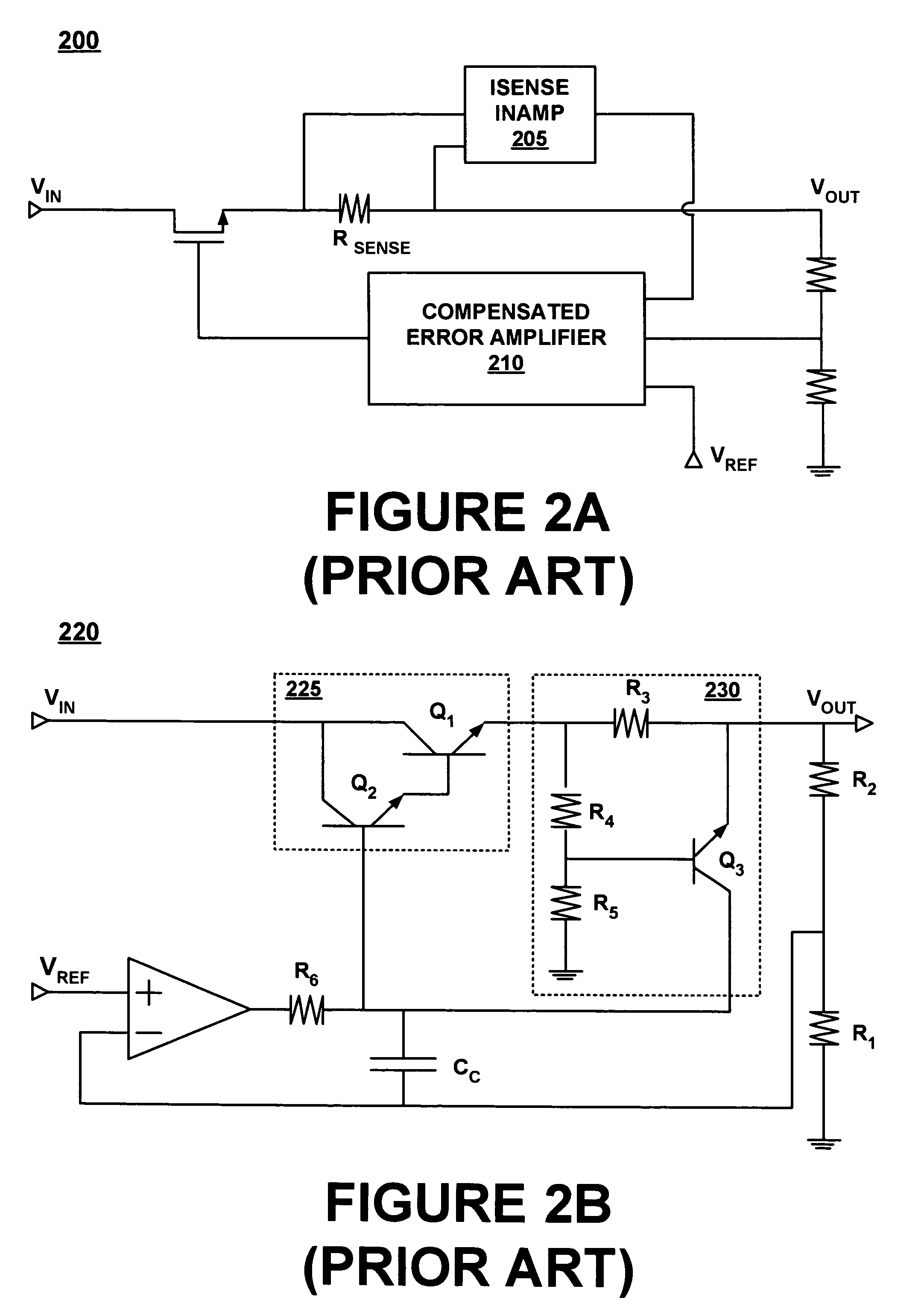

Digitally controlled modular power supply for automated test equipment

InactiveUS6900621B1Increase supplyProvide flexibilityDc network circuit arrangementsIgnition automatic controlMicrocontrollerLinear regulator

A digitally controlled hybrid power module is controlled by a programmable controller. The hybrid power module includes a digitally controlled switching supply with an output coupled to an input of a digitally controlled linear voltage regulator. Independent control of switching supply and the linear regulator is provided by the programmable controller, which may be a field programmable gate array (FPGA), microcontroller, or digital signal processor (DSP). The programmable controller may independently control one or more power modules. Each power module may also include enable switching and an associated current clamp for capacitive loads. An output voltage transient suppressor may also be used to control transients, such as those produced under fast switching conditions.

Owner:ADVANTEST CORP

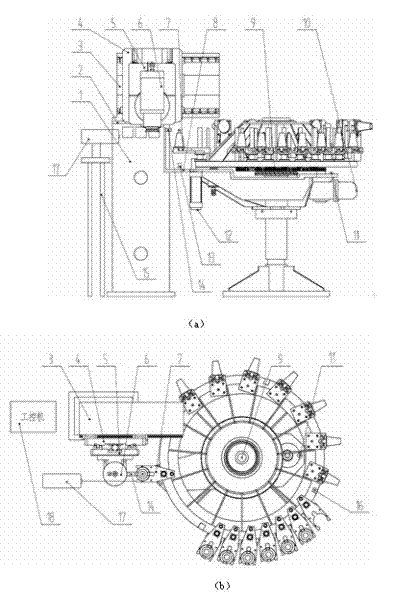

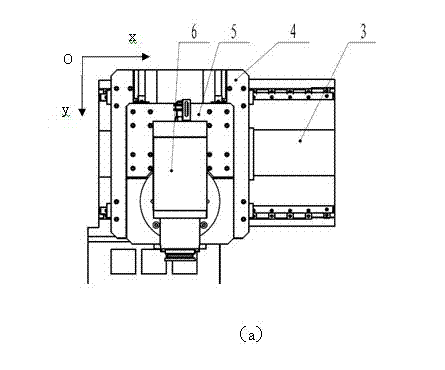

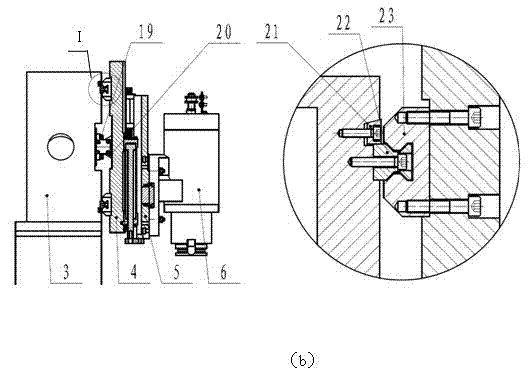

Disc tool magazine reliability testing device and method

ActiveCN102507228AImprove product qualityReliable mechanical positioningStructural/machines measurementNoise monitoringComputer module

The invention discloses a disc tool magazine reliability testing device and method. The disc tool magazine reliability testing device comprises a supporting assembly, a sliding module, a simulation main shaft, a measuring module and an industrial personal computer. The supporting assembly comprises a base, an adjusting shim plate, a transverse beam, a bench and a support. The measuring assembly comprises a photoelectric proximity switch, a displacement sensor, an acceleration sensor, a vibration tester, a current clamp, a pressure transmitter and a noise monitoring system. After the sensors of the measuring assembly complete the parameter measurement of a disc tool magazine and a manipulator, signals are respectively transmitted to the industrial personal computer. By using the device and method, the actual working conditions can be simulated, the parameters can be comprehensively detected and a basis can be provided for the analysis, assessment and improvement of the running reliability of the disc tool magazine and the tool changing reliability of the manipulator.

Owner:NANJING UNIV OF SCI & TECH

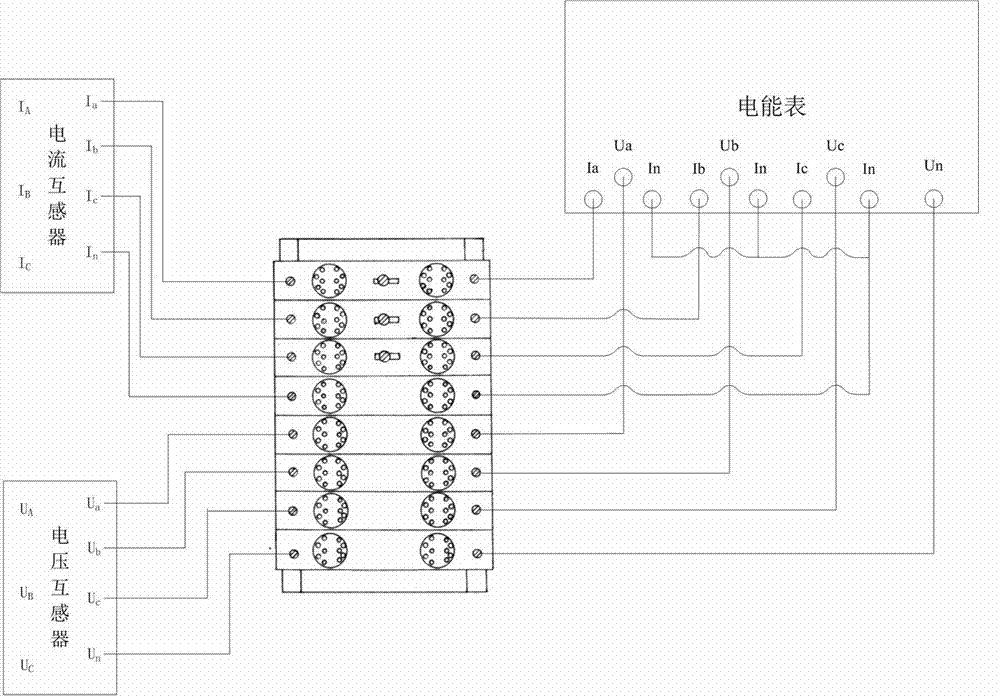

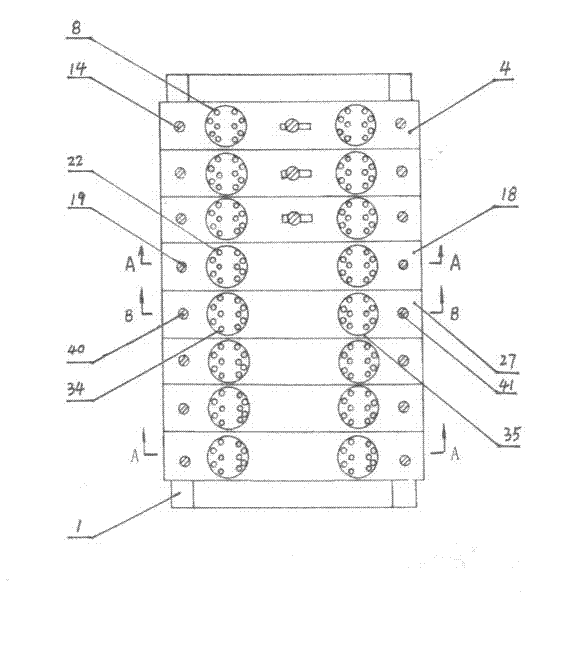

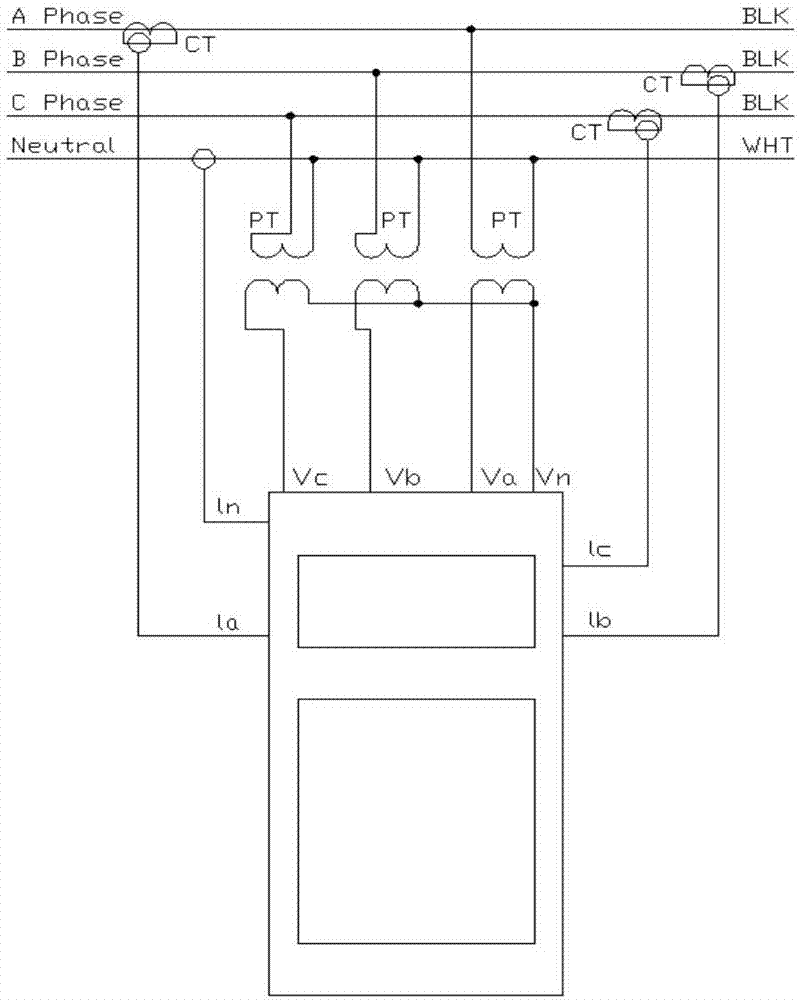

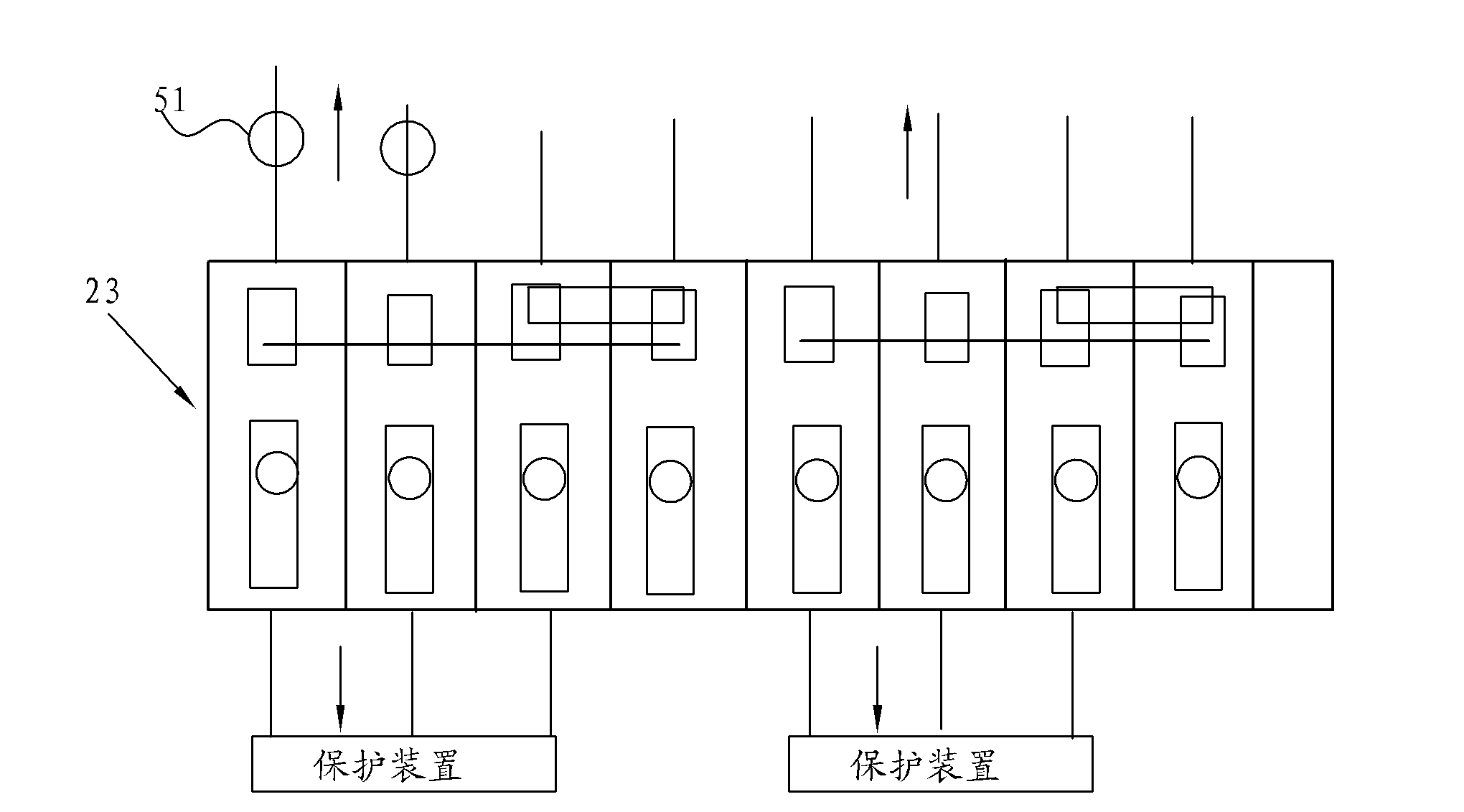

Test wiring terminal component for metering electric energy

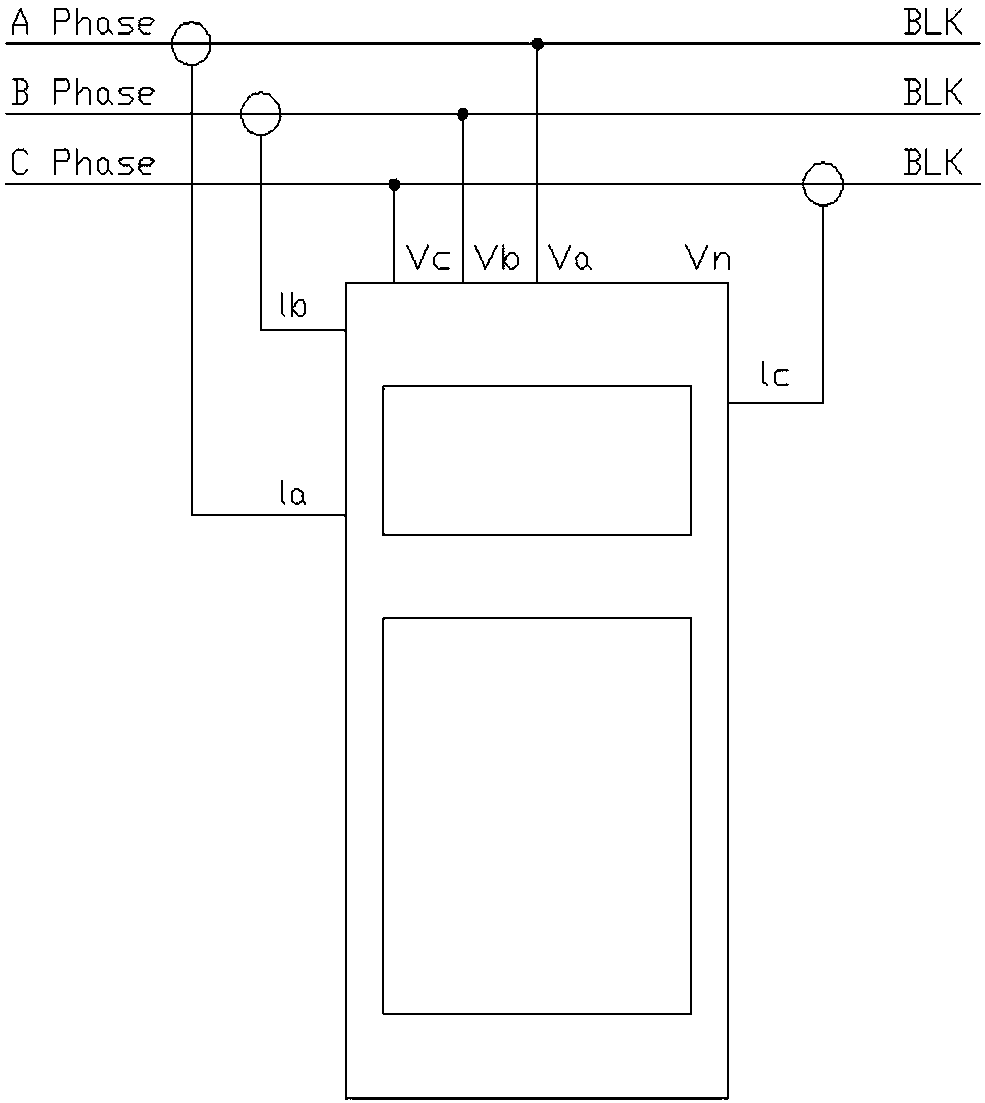

ActiveCN103698733AImprove work efficiencyReduce in quantityTime integral measurementPhase currentsEngineering

The invention relates to a test wiring terminal component for metering electric energy. The test wiring terminal component comprises a support plate with guide rails on the left side and the right side, A-C phase current wiring terminals, a zero-phase current wiring terminal, A-C phase voltage wiring terminals, a zero-phase voltage wiring terminal, a first plug and a second plug, wherein the various wiring terminals are installed on the guide rails of the support plate in sequence. The test wiring terminal component for metering electric energy has the benefits that the work efficiency when a meter is changed is improved; an open circuit of a current secondary circuit, a short-circuit of a voltage secondary circuit or a grounding accident are prevented effectively; the workload of infrastructure construction workers is reduced; the wire checking time when a metering circuit fails is also shortened; the voltage loss of a voltage secondary circuit caused by working is avoided, so that the electricity retroactive work is reduced; voltage short-circuit or grounding accidents are prevented effectively during work; the disadvantages caused by the current measurement by using a current clamp are overcome; the process of changing the socket of the wiring terminal is simple.

Owner:STATE GRID CORP OF CHINA +3

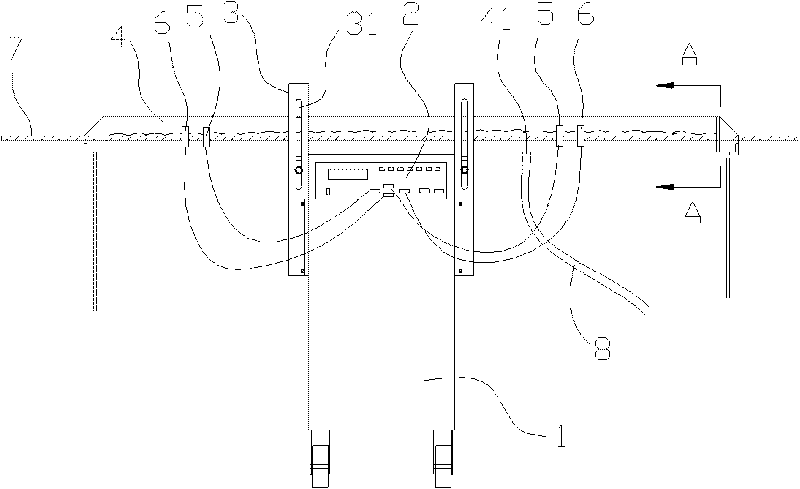

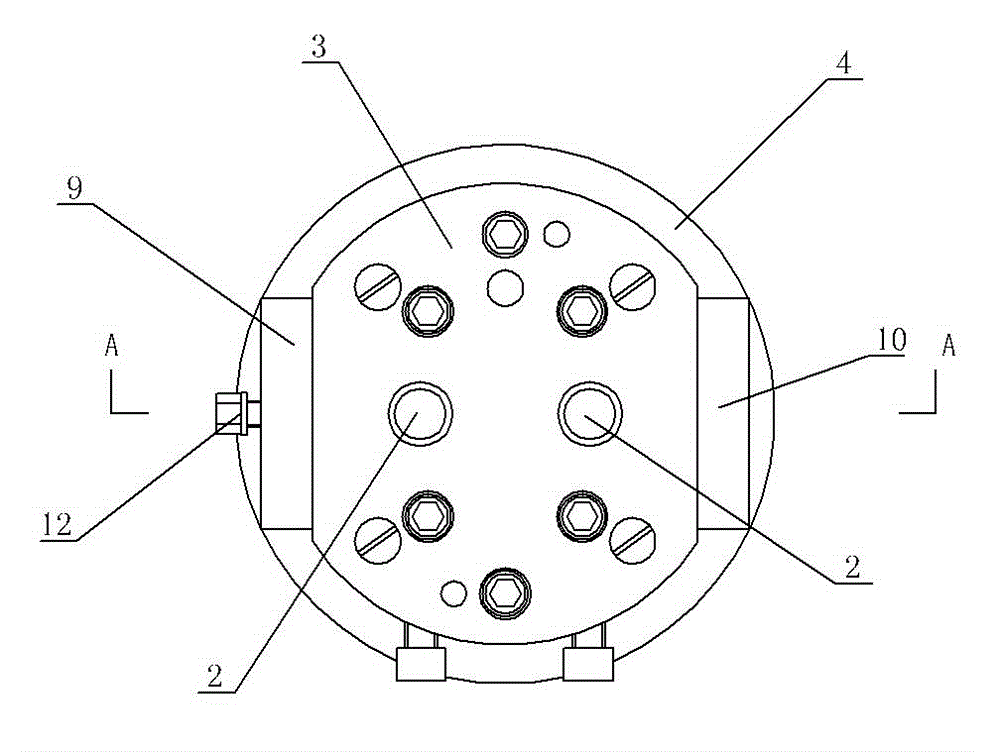

Cable conductor DC resistance on-line detection device and method thereof

InactiveCN101706530AImprove accuracyEasy to useResistance/reactance/impedencePotential clampElectrical conductor

The invention relates to a cable conductor DC resistance on-line detection device and a method thereof, aiming at solving the problems of the prior art that detection to a cable conductor needs to cut a section of the cable conductor, which brings inconvenience to operation and causes material waste; the detection is apt to be influenced by air humidity, air temperature and sample temperature and other factors; and the accuracy of detection results is low. The cable conductor DC resistance on-line detection device comprises a resistance tester, a mobile trolley, a potential clamp and a current clamp, wherein the resistance tester is arranged on the mobile trolley; a water tank for containing cables is arranged on the top end of the mobile trolley; the potential clamp and the current clamp are used for clamping cables and connected on the resistance tester through wires. The invention has the advantages of optional movement, convenient use, waster reduction and high detection structure accuracy.

Owner:浙江万马股份有限公司

Two-way low-voltage punch-through transient voltage suppression diode and manufacturing method thereof

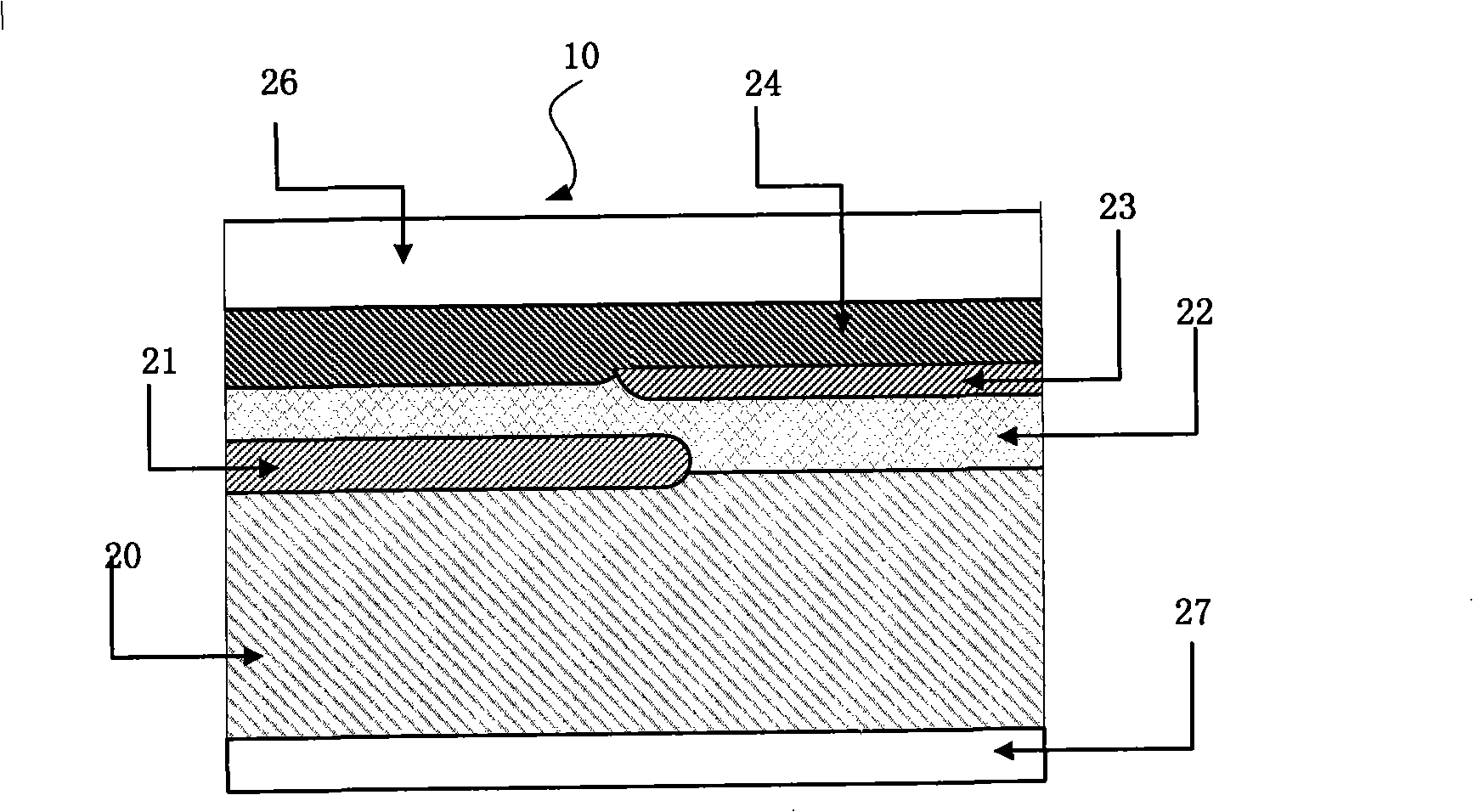

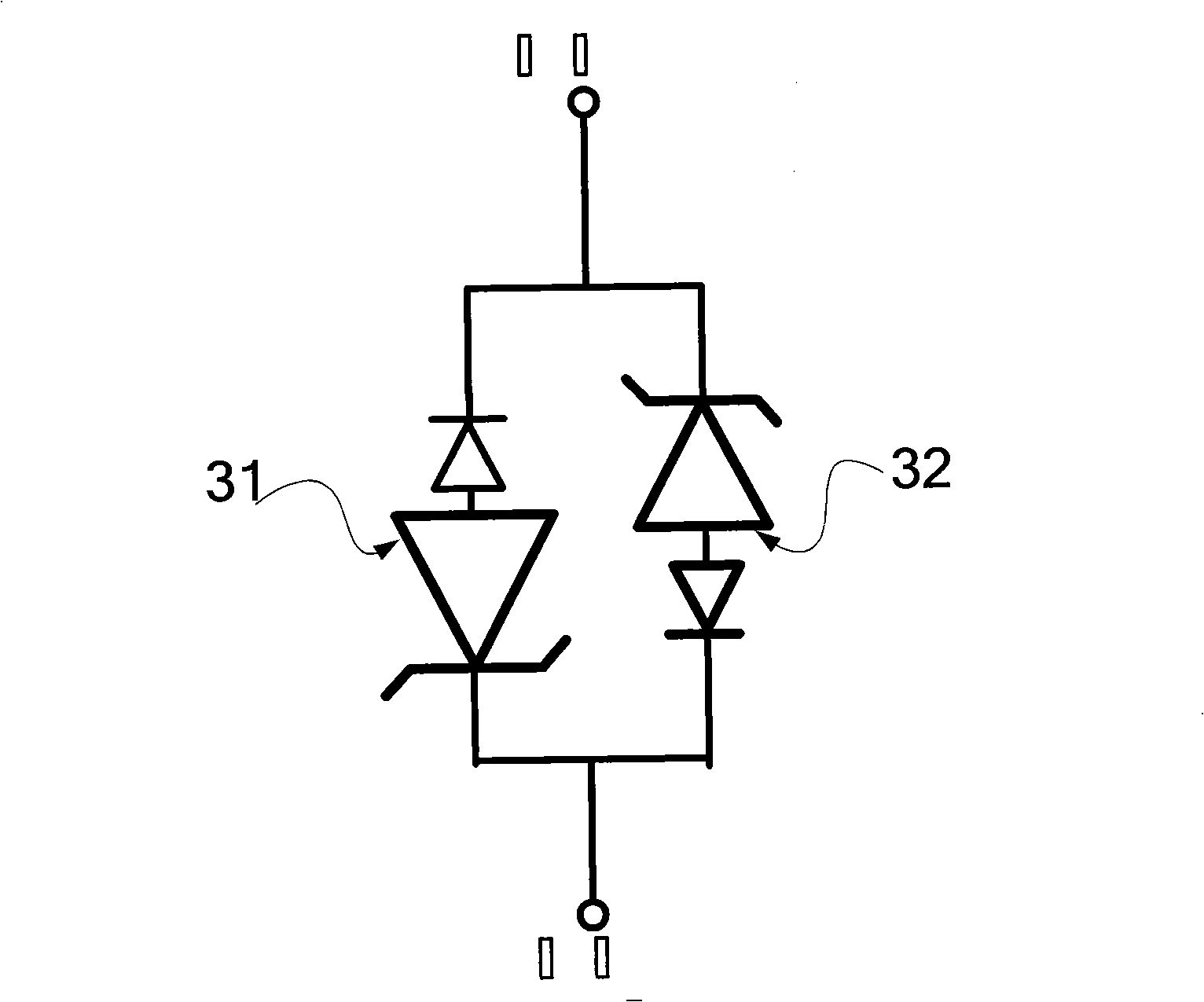

ActiveCN101527324AReduce leakage currentExcellent high current clamping characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceLow voltage

The invention relates to a two-way low-voltage punch-through transient voltage suppression diode which comprises a silicon chip consisting of five areas from bottom to top, wherein metal electrodes are formed at both the front and the back of the silicon chip, and the five areas comprise a first area which is an n+ underlay with the doping of n type, a second area which is a p+ buried layer with the doping of p type, a third area which is a p- epitaxial layer with the doping of p type, a fourth area which is a p+ emitting area with the doping of p type, and a fifth area which is an n+ emitting area with the doping of n type, wherein the second area horizontally overlaps half of the first area; half of the third area is arranged on the first area and the other half of the third area is arranged on the second area; the fourth area horizontally overlaps half of the third area and is opposite to the position of the second area; and half of the fifth area is arranged on the third area and the other half of the fifth area is arranged on the fourth area. The diode has the advantages of low punch-through, voltage and capacitance, large current, excellent clamping performance, surface punch-through resistance and uniform forward and inverse electrical characteristics.

Owner:SHANGHAI CHANGYUAN WAYON MICROELECTRONICS

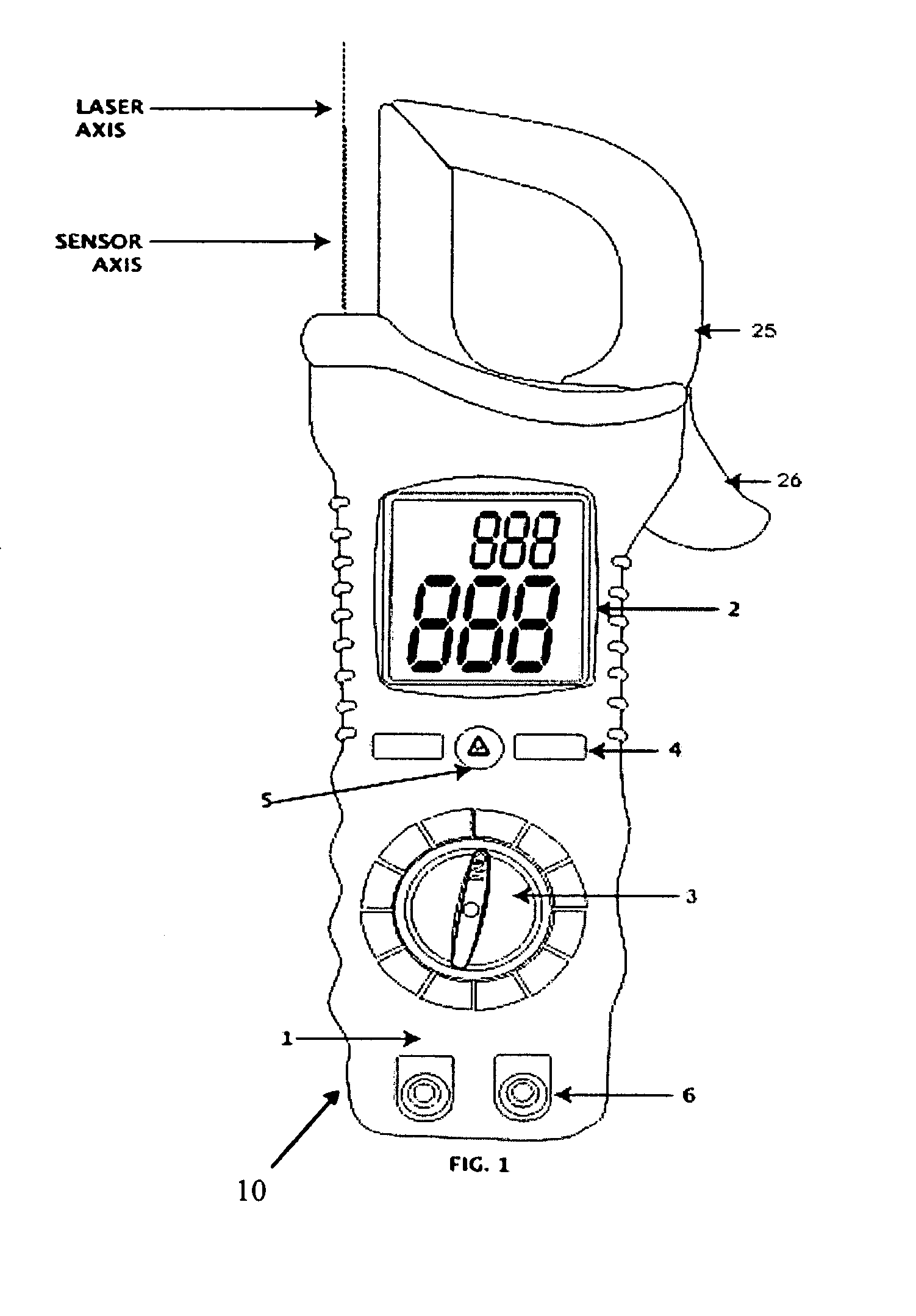

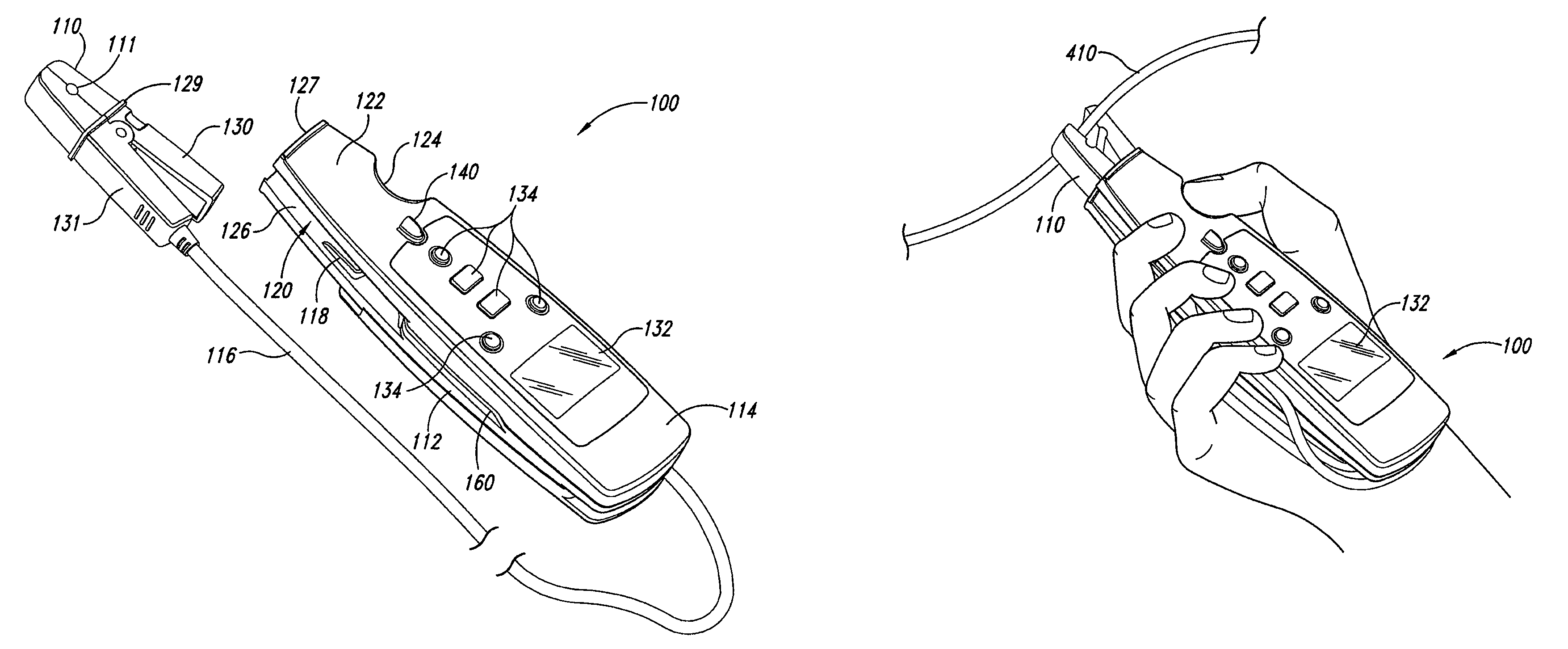

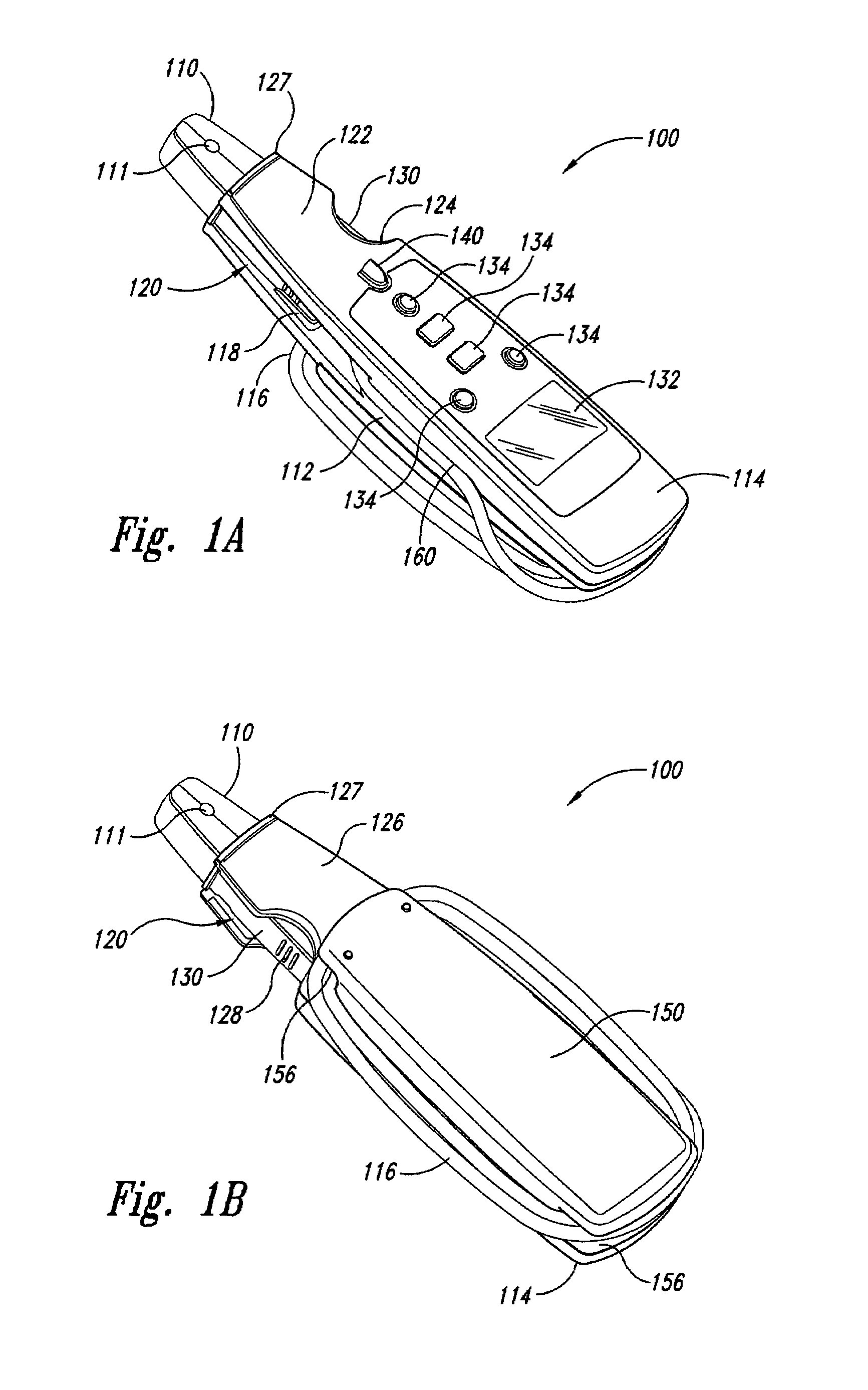

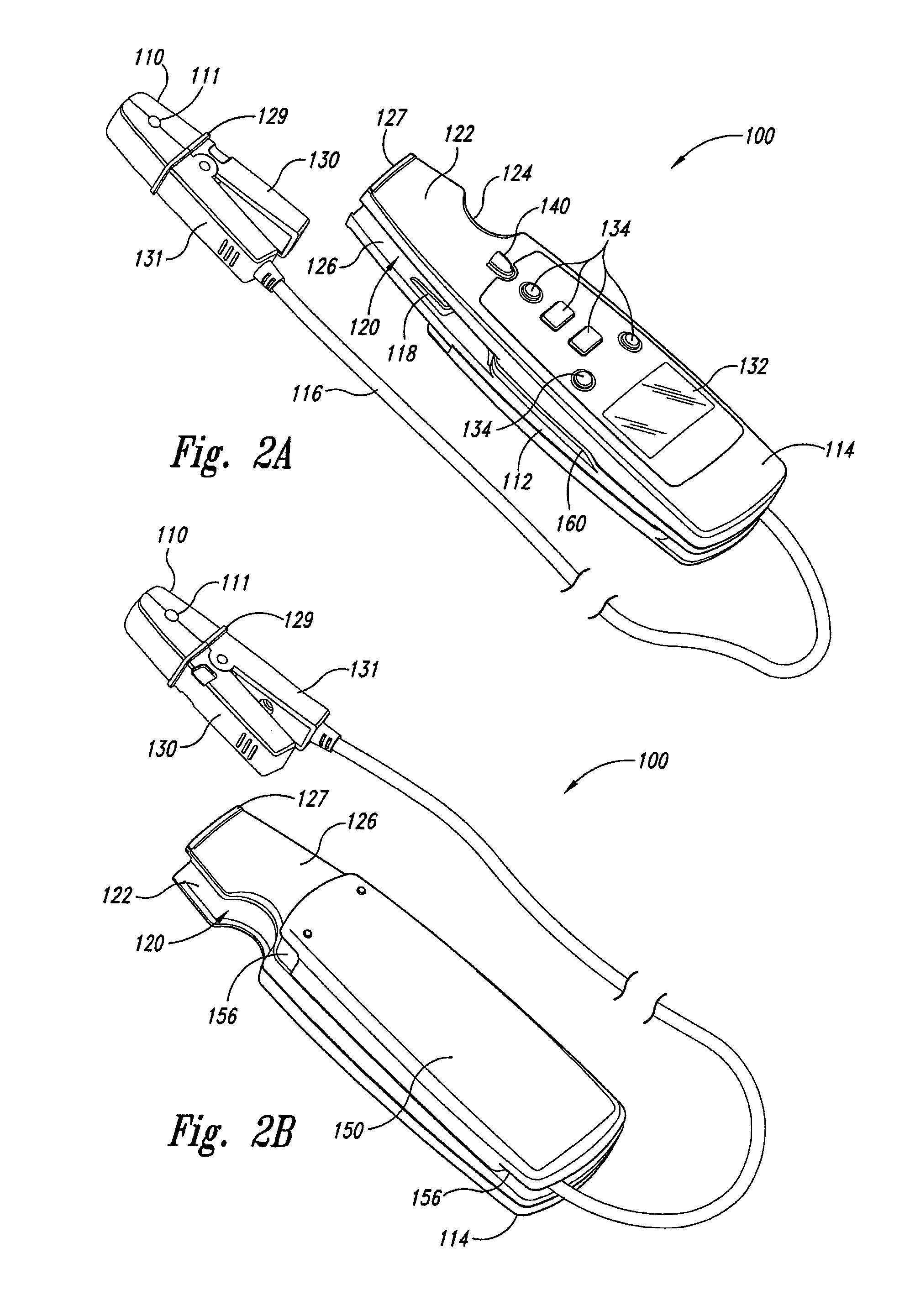

Instrument with Non-contact Infrared Temperature Measurement and Current Clamp

InactiveUS20130208761A1Easy to aimRadiation pyrometryCurrent/voltage measurementMeasuring instrumentDisplay device

A multi-meter performs multiple measurement functions and includes a housing with a longitudinal axis and a measurement display. The multi-meter further includes a clamp arm type current measuring instrument. The clamp arms are generally aligned with the longitudinal axis of the multi-meter housing. The multi-meter also includes a non-contact infrared temperature measurement device contained in a module attached to the stationary clamp arm of the current measuring instrument. The module is arranged so that the non-contact infrared temperature measurement instrument receives a cone of infrared energy along the longitudinal axis and the cone of infrared energy is not obstructed by the housing or clamp arms.

Owner:GEN TOOLS & INSTR

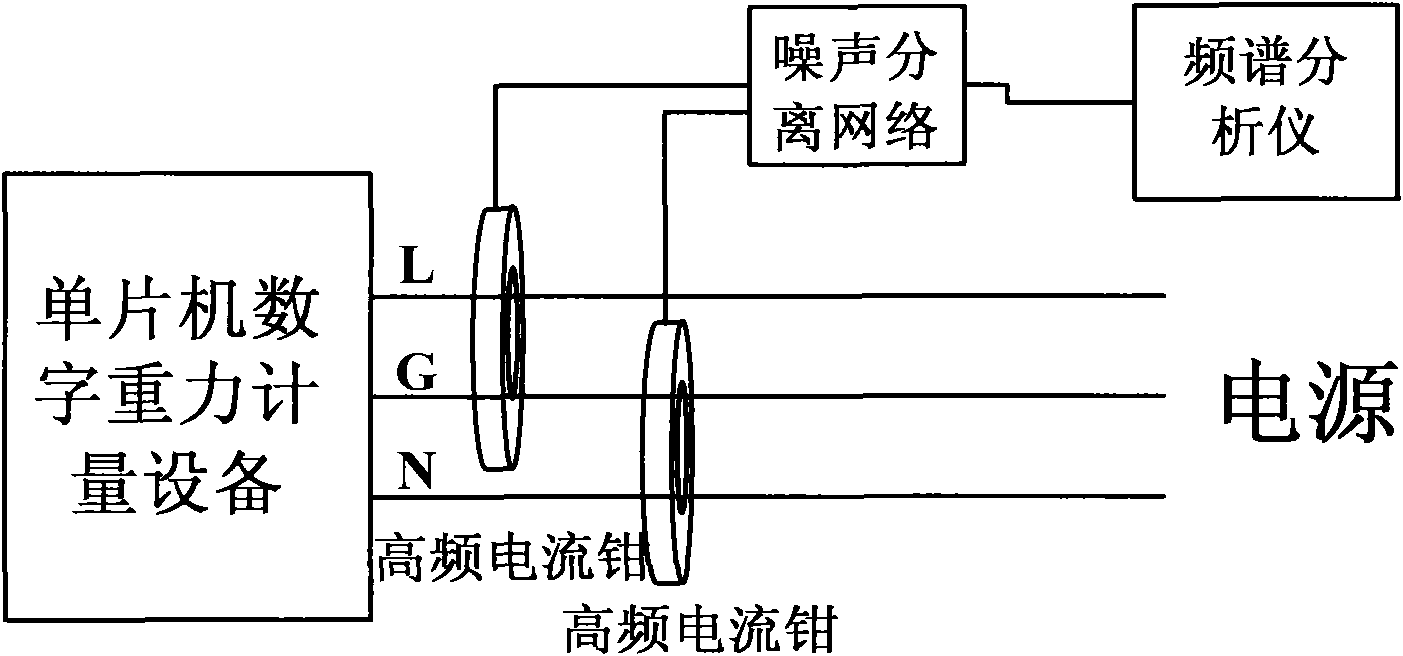

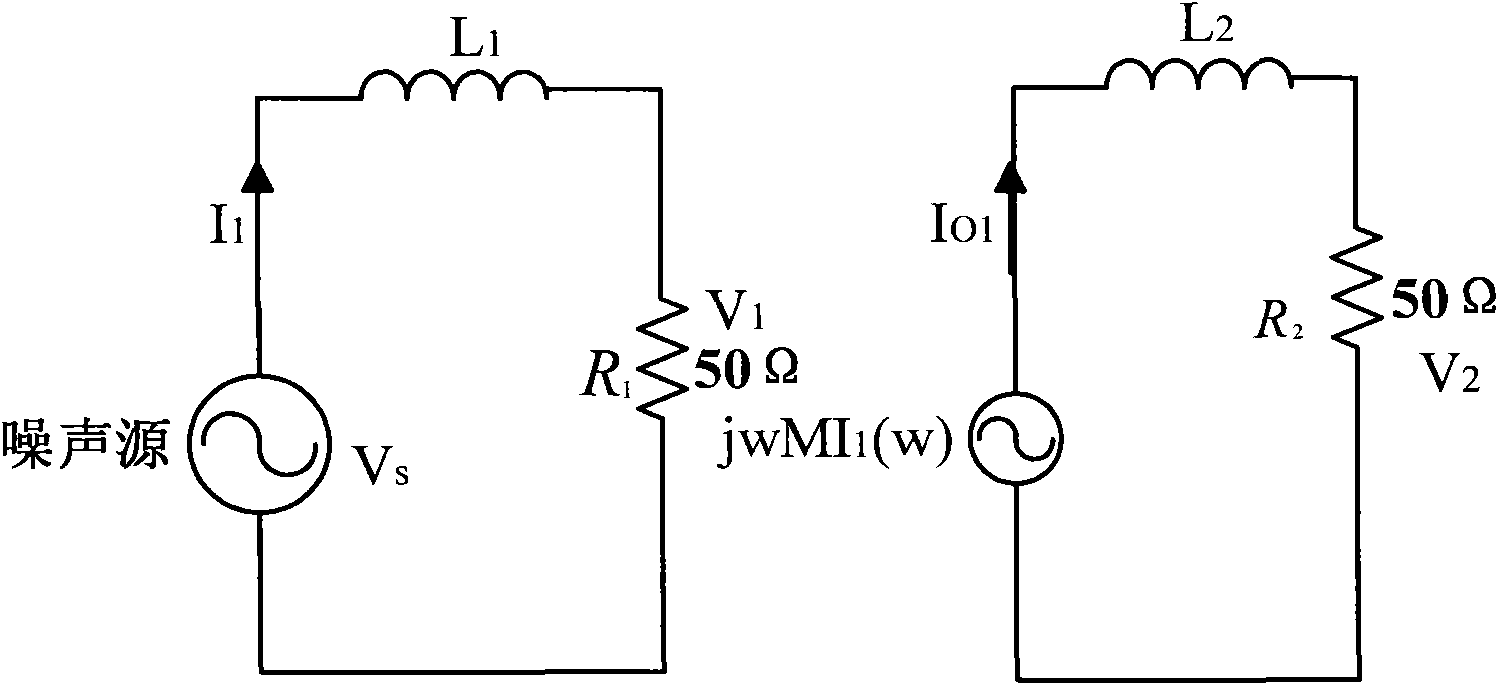

Method for testing radiated noises of digital gravity metering device

ActiveCN101887095ALow cost of measurementSuppress radiated noiseNoise figure or signal-to-noise ratio measurementElectrical testingEngineeringCurrent clamp

The invention discloses a method for testing radiated noises of a digital gravity metering device, which comprises the following steps of: calculating corresponding transfer impedance according to a high-frequency current clamp structure; putting a measuring loop in the high-frequency current clamp on a power cord of the digital gravity metering device so as to extract a first noise voltage and a second noise voltage in the power cord; performing a vector operation and a vector difference operation on the first noise voltage and the second noise voltage by using a noise separation network so as to obtain a difference mode conducted noise voltage and a common mode conducted noise voltage; performing operation on the difference mode conducted noise voltage, the common mode conducted noise voltage and the transfer impedance of the high-frequency current clamp to obtain a difference mode conducted noise current and a common mode conducted noise current; and acquiring an electric field which emits the radiation noises in a free space according to a common mode noise current formula. In the method, the common mode noise current of a single-chip digital gravity metering device is measured by using the high-frequency current clamp and the noise separation network, and the radiated noises are predicted through the common mode noise current.

Owner:苏州泰思特电子科技有限公司

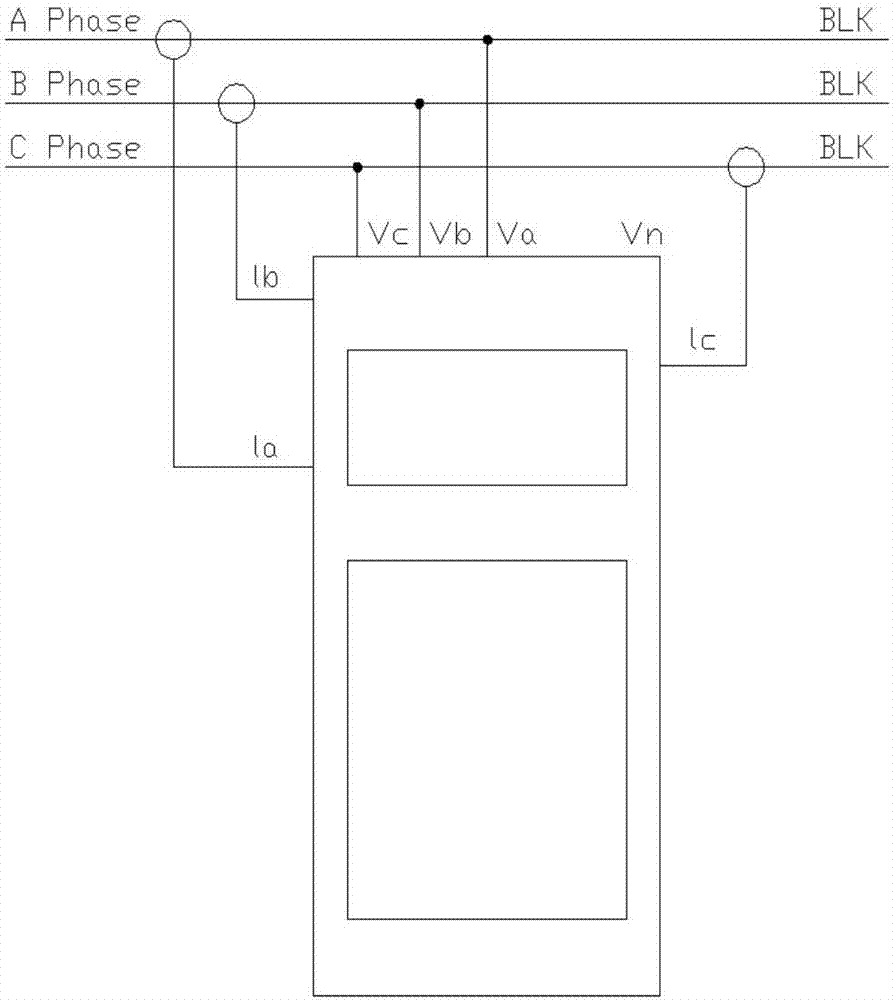

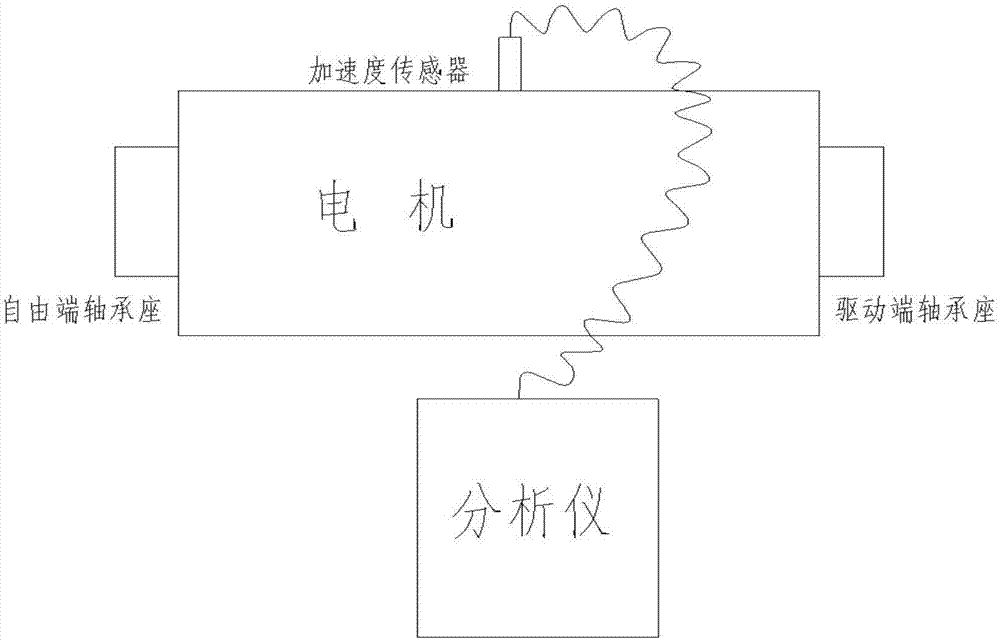

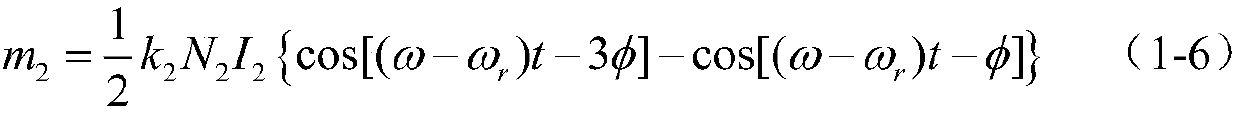

Asynchronous motor rotor broken bar fault judgment method with electric signals and vibration signals integrated

InactiveCN107544025ANot lostPrecise electrical signatureMachine part testingDynamo-electric machine testingFrequency spectrumVibratory signal

The invention discloses an asynchronous motor rotor broken bar fault judgment method with electric signals and vibration signals integrated, which belongs to the field of motor fault judgment. The method comprises the following steps: an acquisition instrument acquires voltage and current data through a current clamp and a voltage clamp, current spectrum analysis is carried out, if the current signals are normal, no broken bar fault happens to the motor rotor, and if the current signals are abnormal and when one side band appears at each position with a twice slip frequency difference from a power frequency, the next step is carried out; voltage spectrum analysis is carried out, if the voltage signals are normal, no broken bar fault happens to the motor rotor, if the voltage signals are abnormal and when one side band appears at each position with a twice slip frequency difference from the power frequency, vibration signal analysis is carried out, and whether broken bar fault happens to the motor is judged. In view of the problem that error judgment exists in a motor current signal analysis method in the asynchronous motor rotor broken bar fault in the prior art, a mode of sequentially judging the stator current, the stator voltage and the vibration signals is adopted, the rotor broken bar fault is detected, and the error judgment rate is reduced.

Owner:马鞍山马钢华阳设备诊断工程有限公司

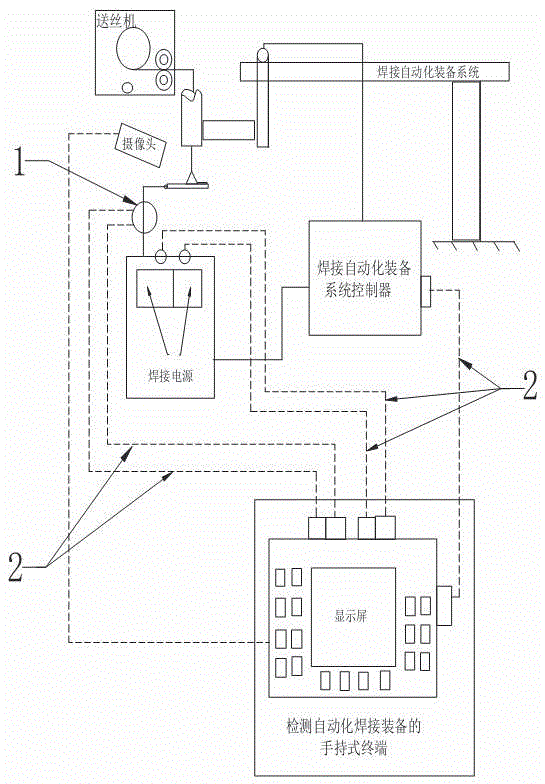

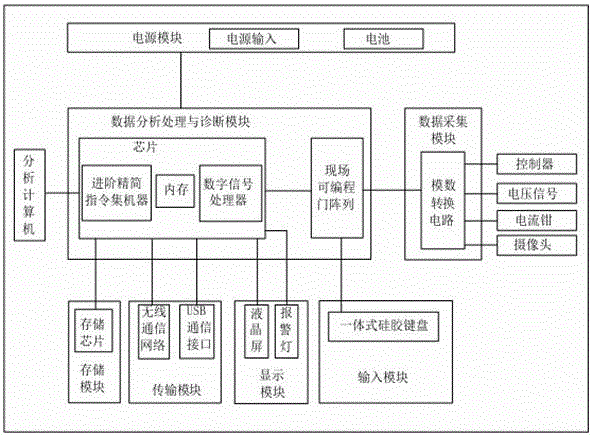

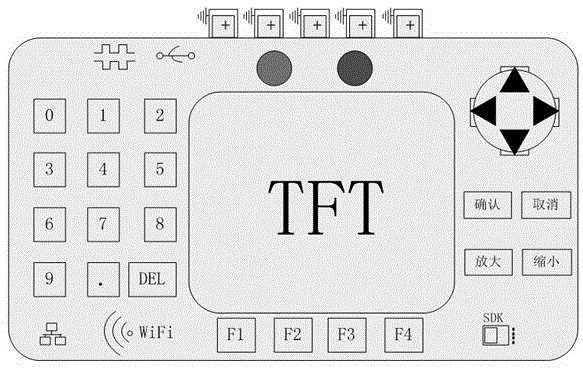

Handheld terminal for detecting automatic welding equipment and detection method for handheld terminal

ActiveCN103331506AAchieve upgradeThe detection method is simple and reliableArc welding apparatusPower supply testingRemote monitoring and controlCurrent clamp

The invention discloses a detection method of the handheld terminal for detecting automatic welding equipment. The handheld terminal is provided with a data analysis and diagnosis module and a data collection module, wherein the data analysis and diagnosis module comprises a processing chip and a field-programmable gate array, the data collection module is provided with an analog-to-digital conversion circuit, the analog-to-digital circuit is respectively connected with an automatic welding equipment controller, a current clamp, a mutual inductor and a camera through signal lines, the handheld terminal is provided with a remote monitoring module, a storage module, and a communication module and a display module. The method adopting the terminal for detecting the welding equipment comprises the steps including terminal self inspection, equipment connection, parameter setting, signal processing, result display, remote detection, system upgrading and the like. The terminal has the characteristics that the size is small, the functions are rich, and the response speed is high. The detection method can be used for fast and precisely detecting the power supply quality of the automatic welding equipment and the operation quality in the welding process.

Owner:TANGSHAN KAIYUAN WELDING AUTOMATION TECH INST

Instrument for non-contact infrared temperature measurement having current clamp meter functions

ActiveUS20050031013A1Convenience setThermometer detailsRadiation pyrometryElectrical conductorDisplay device

A handheld instrument that accomplishes infrared (IR) temperature measurement and non-contact electrical current measurement. The instrument has a case, a current-sensing device coupled to the case and operable to be placed around a conductor, for generating an output signal based on the current flowing through the conductor, and an IR detector carried by the case, for sensing IR energy emitted from a surface being measured along a sensing axis that extends from the case, and generating an IR output signal. Sensed IR energy is converted to a temperature value, and the output signal from the current-sensing device is converted to at least a measured current value. There is a display device in the case, for displaying instrument measurements to the user.

Owner:FLIR SYST INC

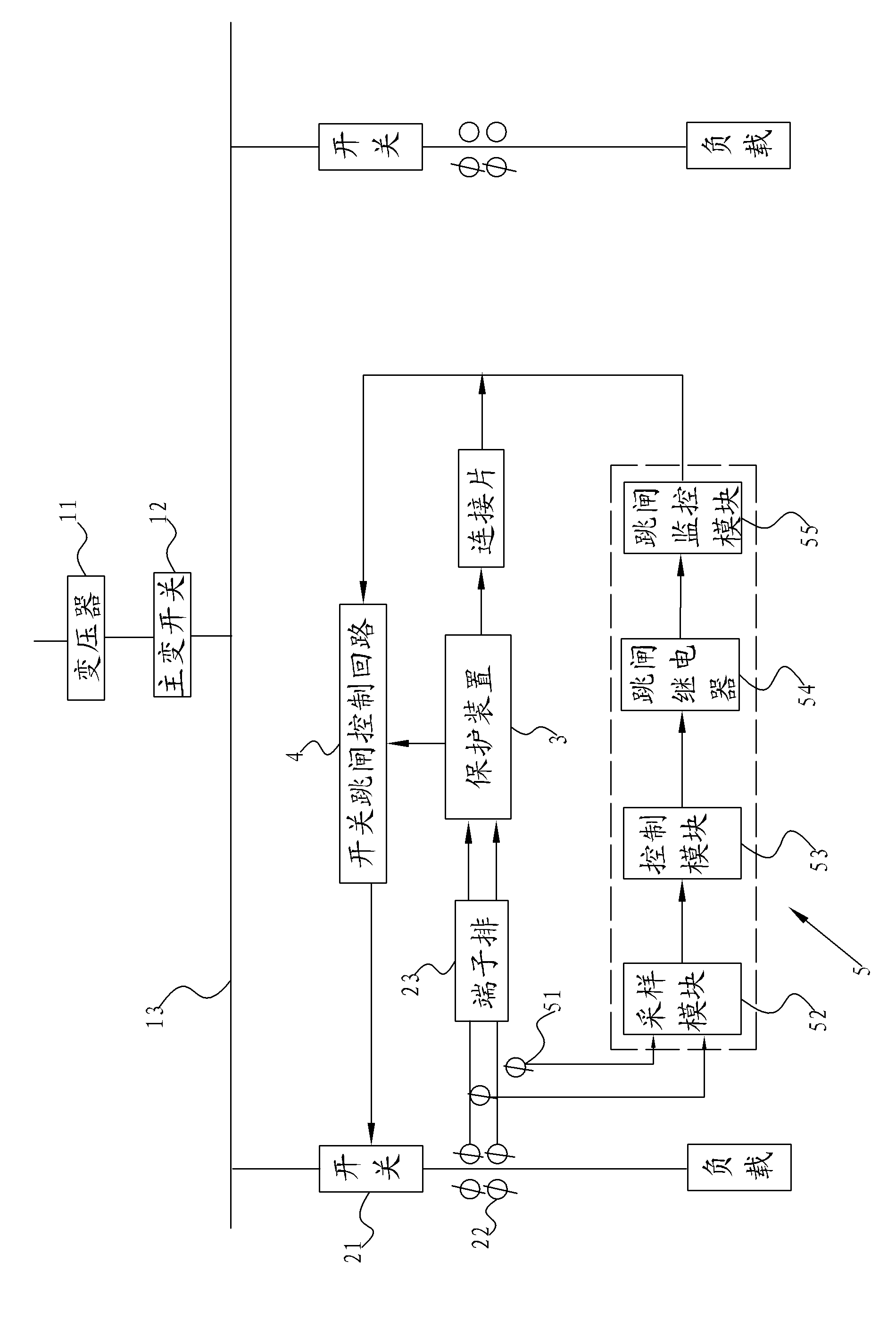

Live processing method and portable protection device after failure of protection device of distribution network system

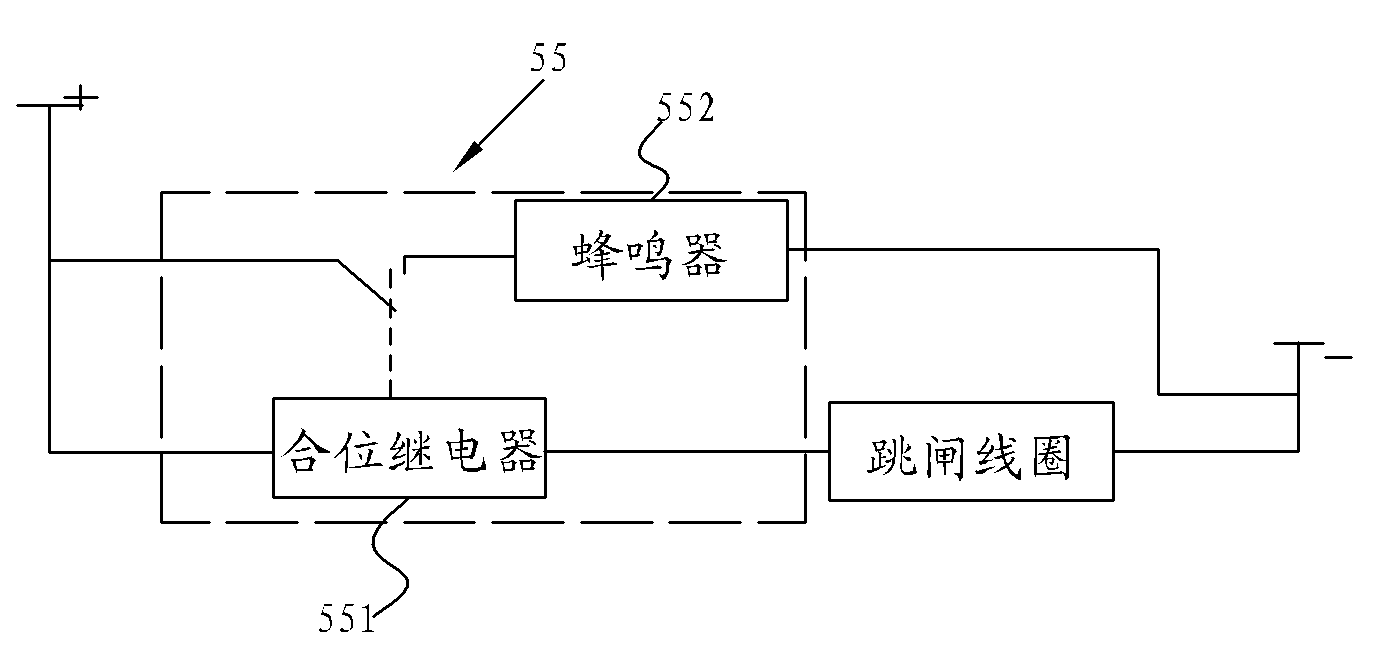

ActiveCN102280864AThe level of safe operation is not affectedSimple working processEmergency protective circuit arrangementsPower gridSystem protection

The invention relates to a portable protection device for post-failure live treatment of a protection device of a distribution network system and a live treatment method thereof, and the portable protection device comprises a current clamp clamped on the connection line between the secondary side of a current transformer and a terminal block, a sampling module for collecting current on the current lamp, a control module connected with the output end of the sampling module and a tripping relay connected with the output end of the control module, wherein the tripping relay is used for connecting with a switch tripping control loop, when failure occurs in the protection device, the tripping relay is put into the connection with the switch tripping control loop under drive of the control module so as to enable the portable protection device to replace the protection device for being put into operation temporarily. As live working treatment is adopted during one equipment interval corresponding to the failure protection device, the workflow is simplified, the working efficiency is improved and the safe operation level of a power grid is not affected.

Owner:SUZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +1

Digitally controlled modular power supply for automated test equipment

InactiveUS7154253B1Increase supplyProvide flexibilityDC motor speed/torque controlAC motor controlMicrocontrollerLinear regulator

A digitally controlled hybrid power module is controlled by a programmable controller. The hybrid power module includes a digitally controlled switching supply with an output coupled to an input of a digitally controlled linear voltage regulator. Independent control of switching supply and the linear regulator is provided by the programmable controller, which may be a field programmable gate array (FPGA), microcontroller, or digital signal processor (DSP). The programmable controller may independently control one or more power modules. Each power module may also include enable switching and an associated current clamp for capacitive loads. An output voltage transient suppressor may also be used to control transients, such as those produced under fast switching conditions.

Owner:ADVANTEST CORP

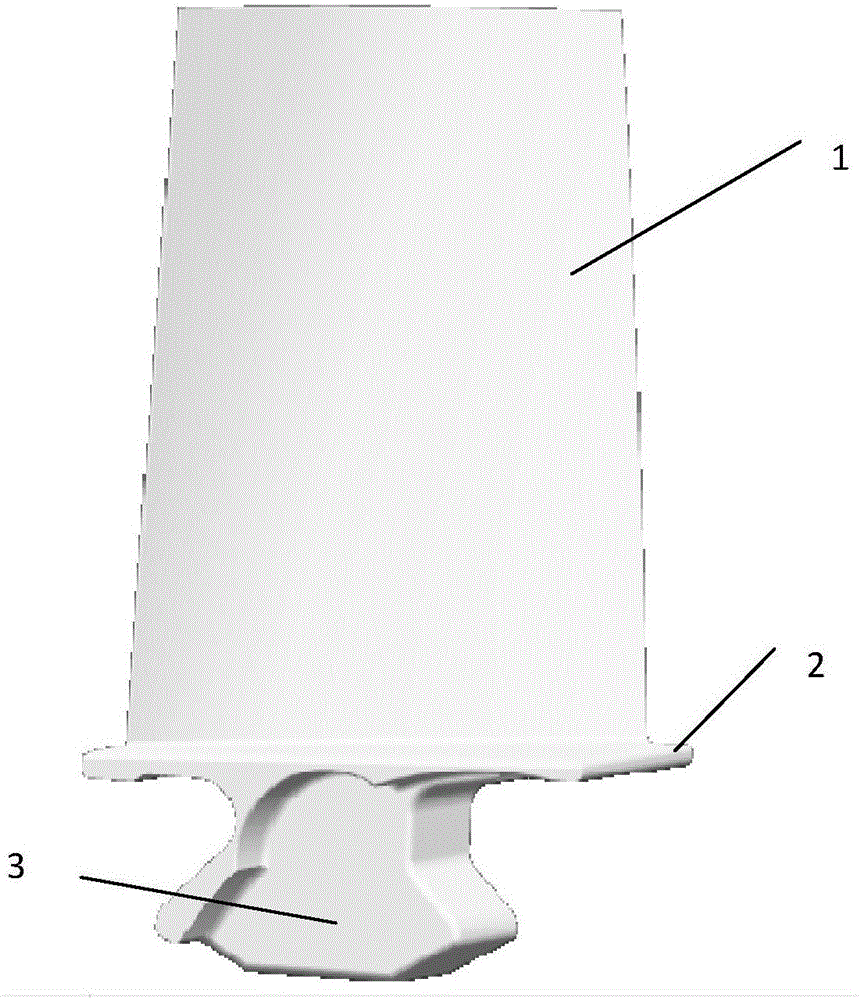

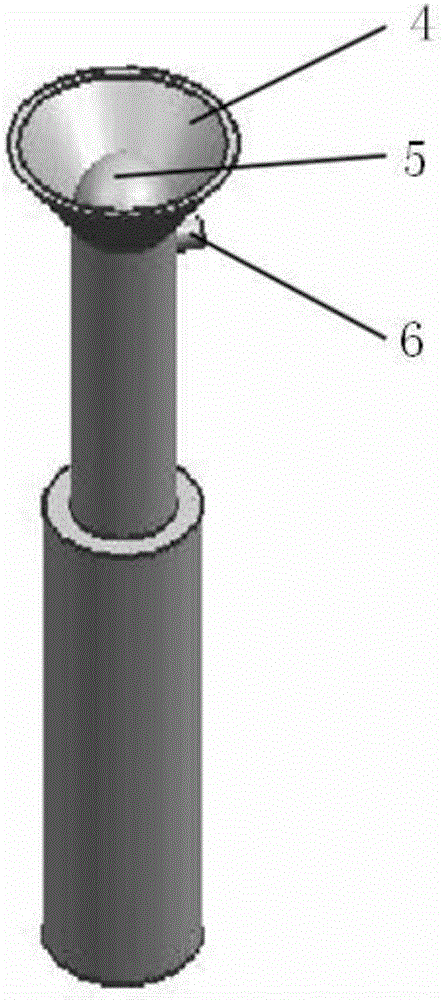

Flexible clamp used for aviation blade

The invention provides a flexible clamp, which aims at overcoming the disadvantages of the existing clamps, which are too large to be suitable for clamping small aviation blades, complex in system, easy to cause deformation and errors, etc.; the flexible clamp of the present invention includes blade body support mechanism, The clamping mechanism, the rotary height adjustment mechanism and the angle tilting mechanism, by adjusting the working angle of the angle tilting mechanism, the flexible clamp can adjust the tilt angle of the blade. The flexible clamp of the present invention can clamp and support the blade body to a certain extent, prevent the blade body from being deformed during processing and cause errors, is universal, flexible and adjustable, and is suitable for different blades with large differences in blade body and different curved surface shapes.

Owner:GUANGDONG UNIV OF TECH

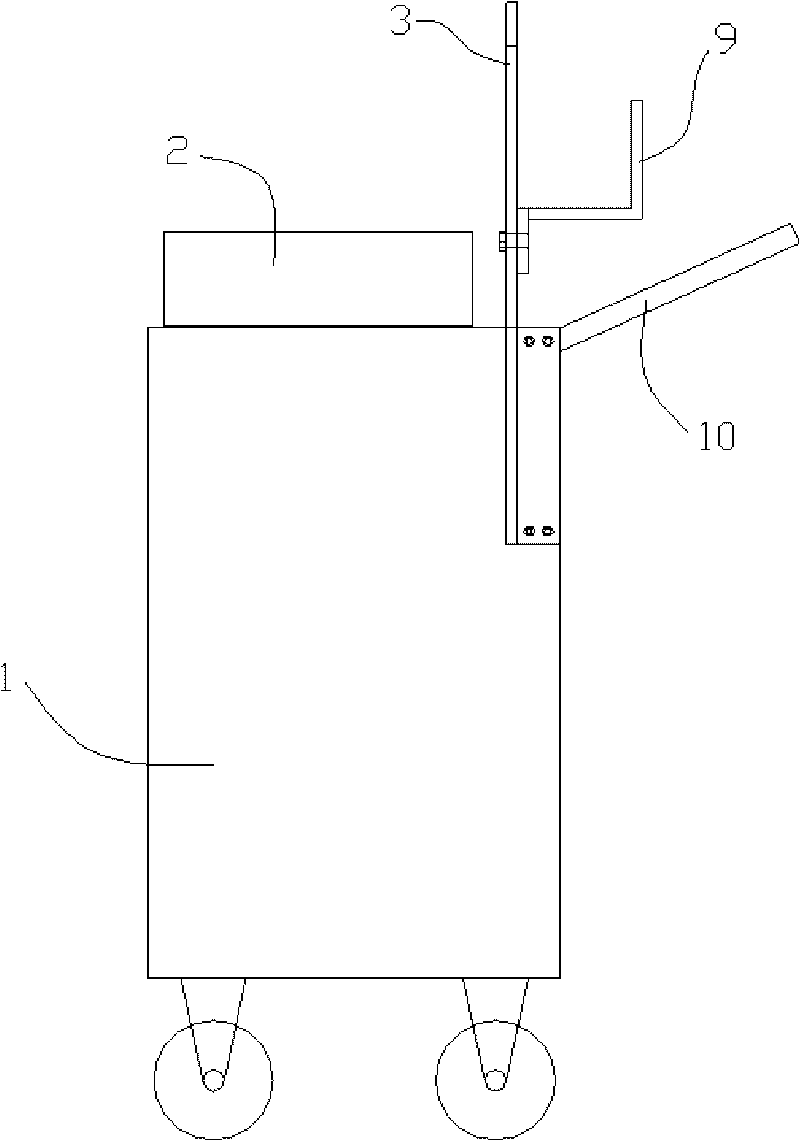

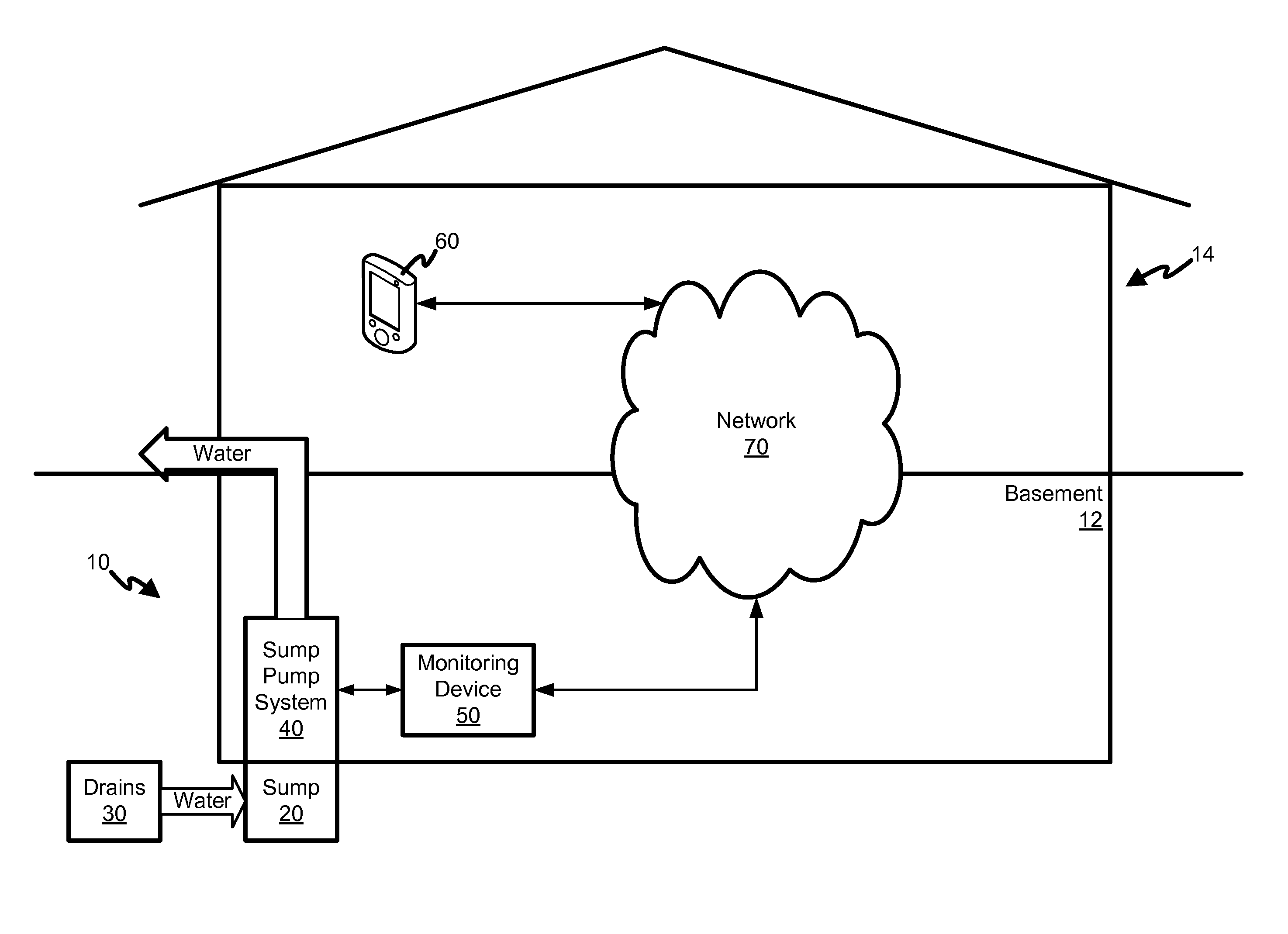

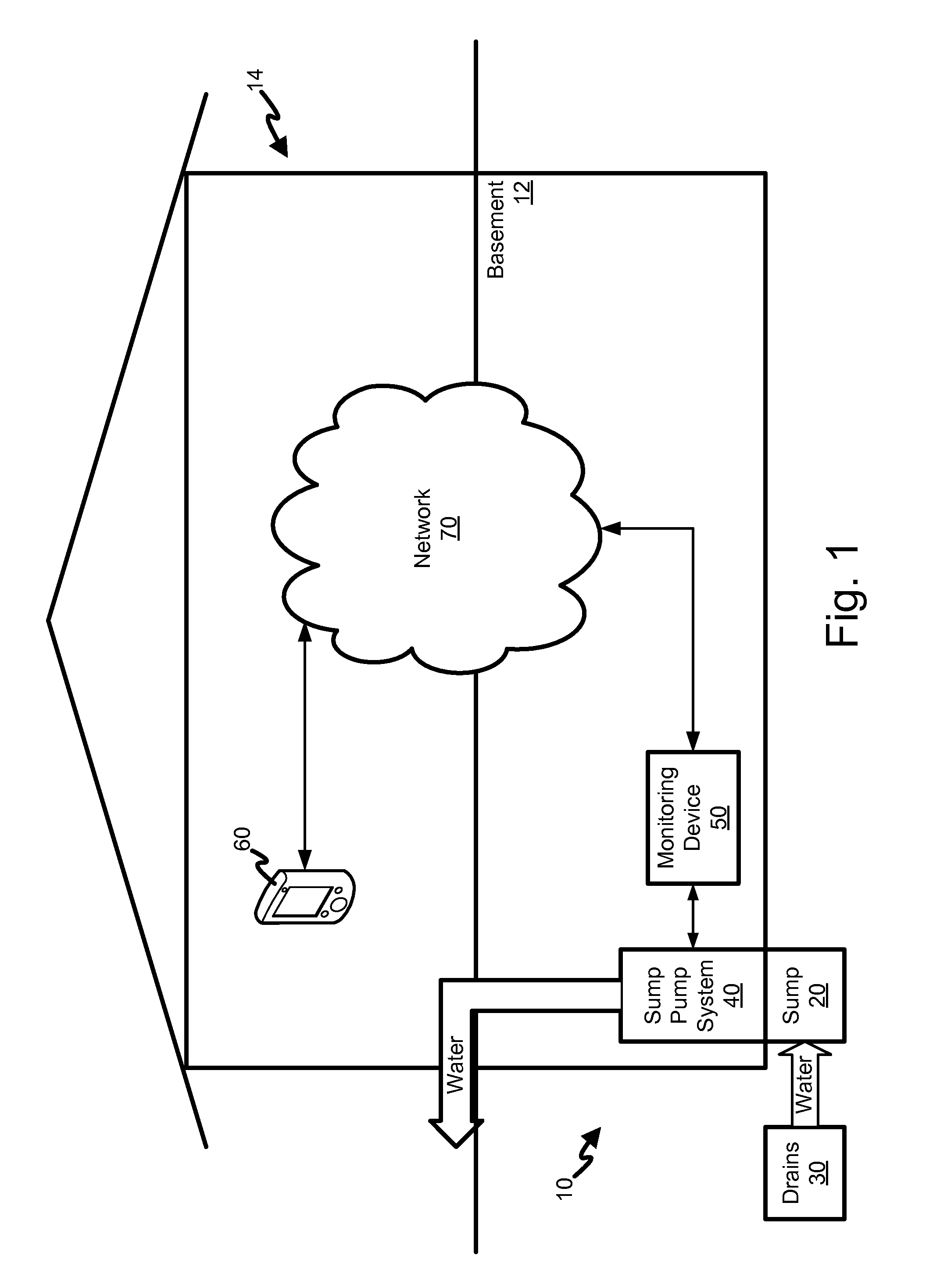

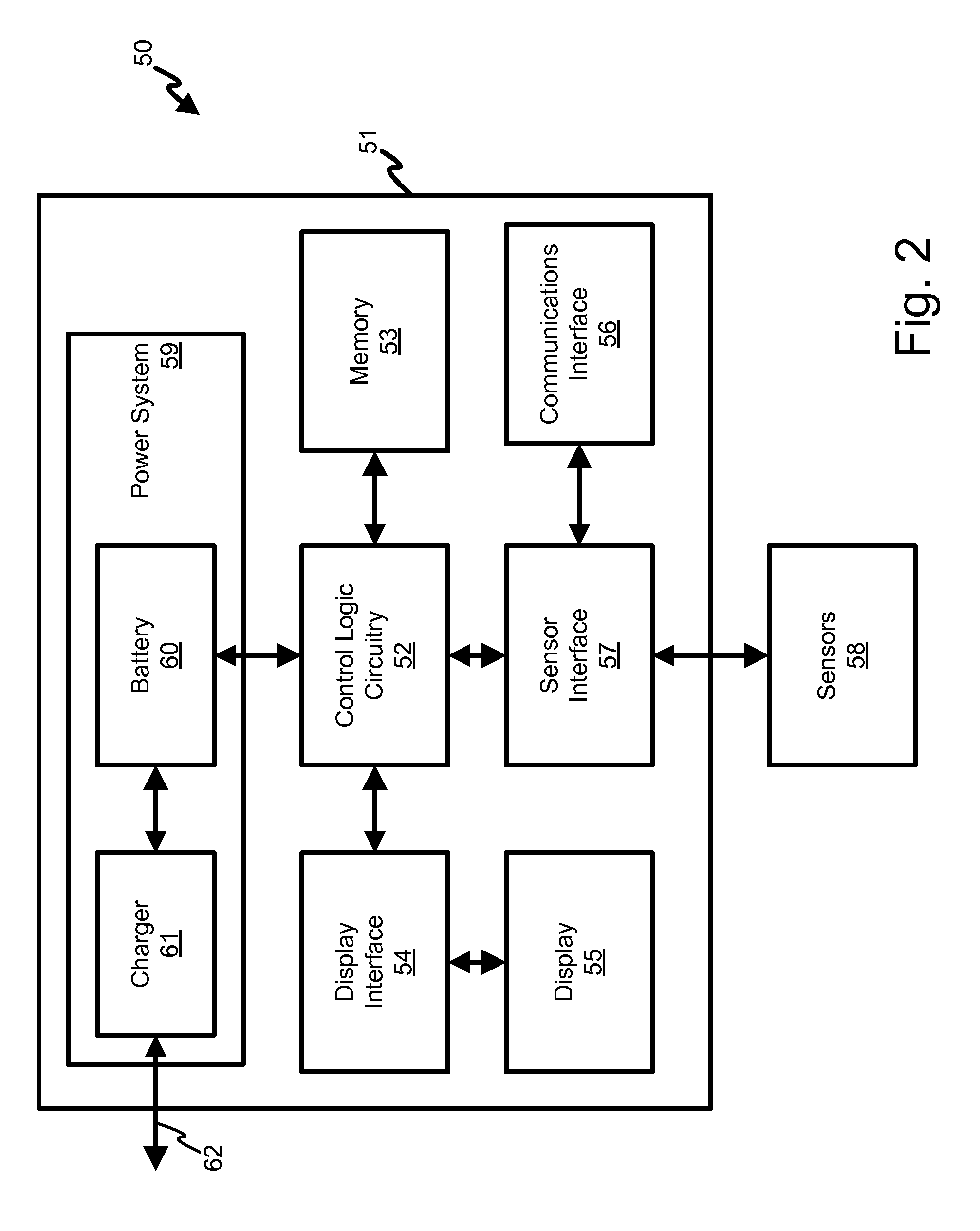

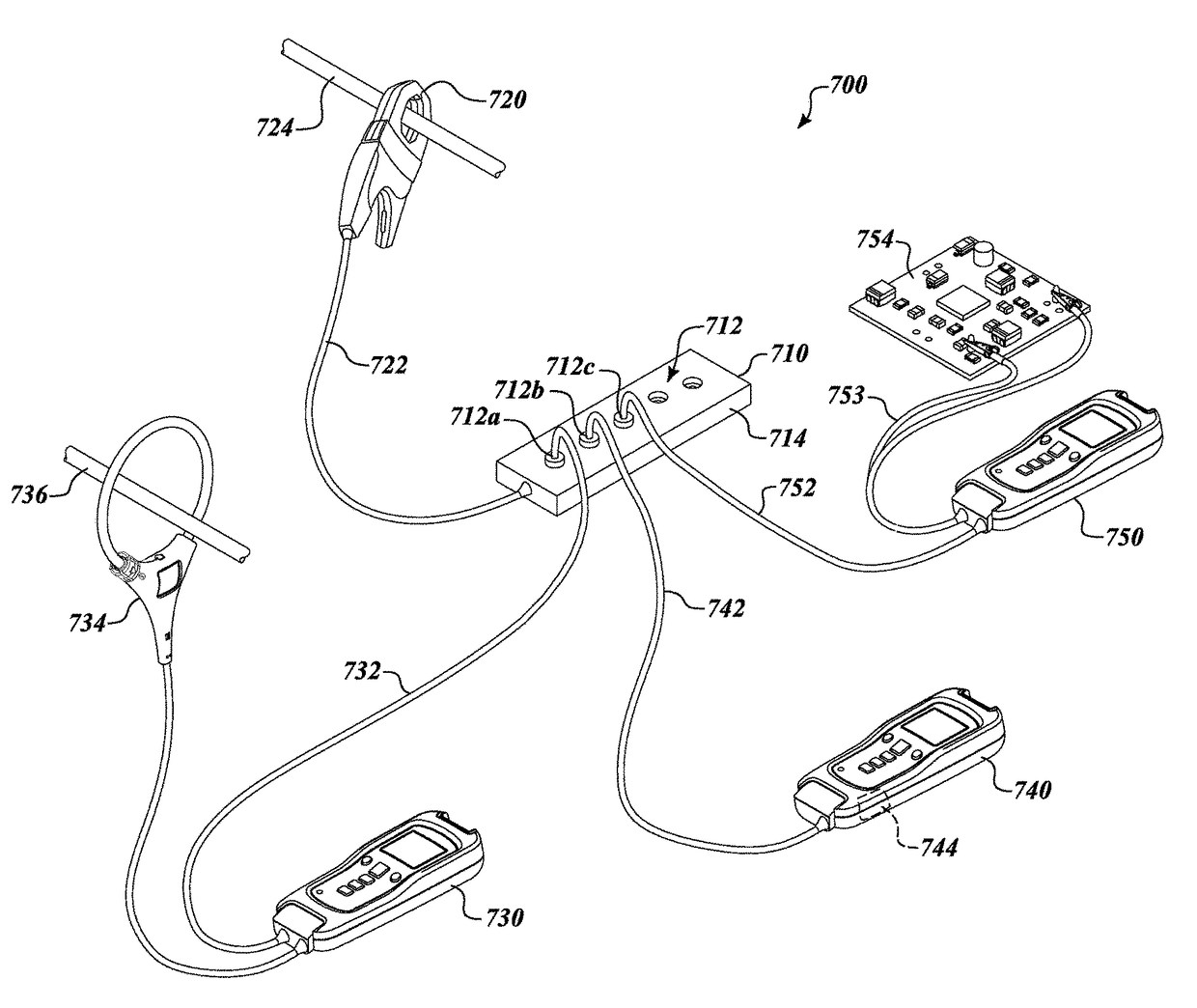

Sump pump monitoring device and method

A method and device are disclosed for monitoring a sump pump system. The monitoring device may include electrical sensors to sense electrical characteristics of the sump pump system. The sensors may include one or more current clamps which may be clamped around an electrical lead or wire of the sump pump system. The monitoring device may further include control logic circuitry configured to monitor sensed electrical characteristics of the sump pump system and deduce an operating status based on the sensed electrical characteristics. The monitoring device may further include a communications interface configured to report the deduced operating status to an interested party via a communications device.

Owner:SEARS BRANDS

Power source system with multiple electrical outputs

ActiveUS9735588B2Ac-dc conversion without reversalMeasurement apparatus componentsElectrical conductorTransformer

Owner:JOHN FLUKE MFG CO INC

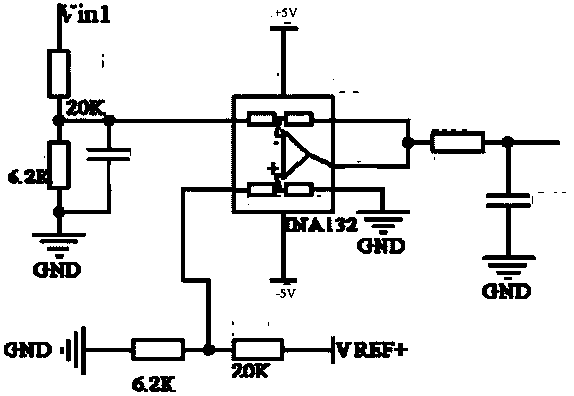

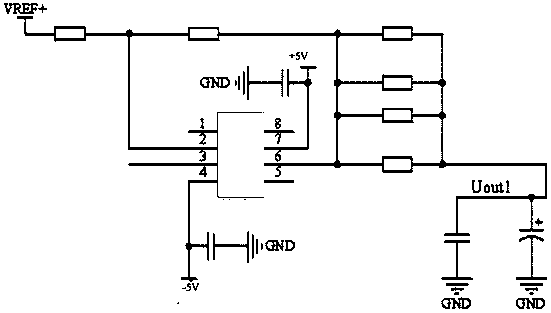

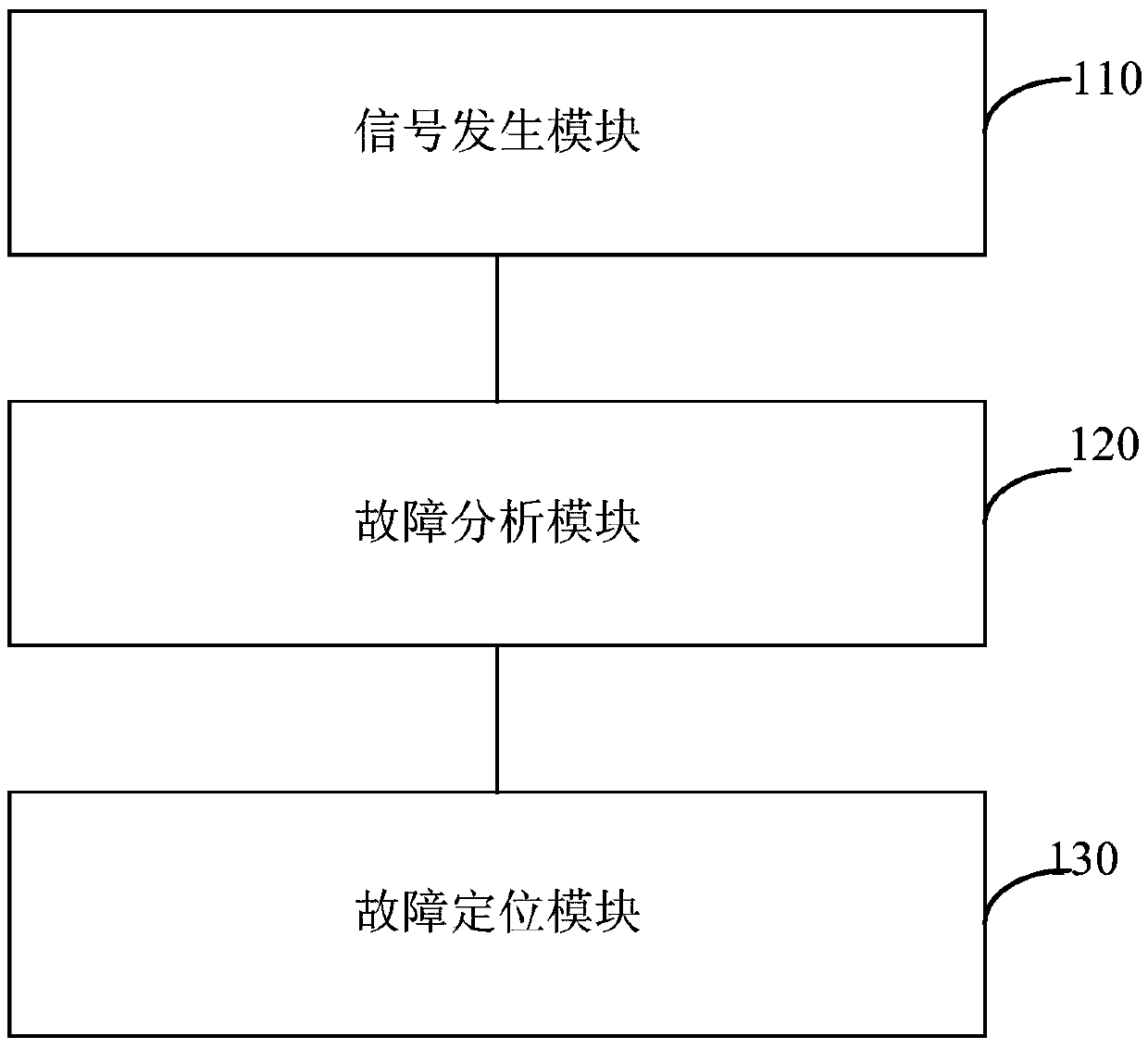

Earth fault detection device for direct current system

The invention discloses an earth fault detection device for a direct current system. The device comprises a signal generating module, a fault analyzing module and a fault positioning module; the signal generating module is used for setting a working mode of the fault analyzing module, generating a current signal which is matched with the working mode and has the set frequency and amplitude and injecting the current signal into the direct current system; the fault analyzing module is used for sampling varying voltage of a bus of the direct current system, judging whether an earth fault exists in the direct current system and synchronously transmitting the sampled voltage and the current signal which has the set frequency and amplitude to the fault positioning module; the fault positioning module is used for sampling a branch circuit leakage current in the direct current system through a direct-current current clamp meter or alternating-current current clamp meter and performing fault positioning processing according to a sampling result and the data synchronized by the fault analyzing module. According to the earth fault detection device for the direct current system, a user can conveniently perform switching using between a direct current mode and an alternating current mode according to the self demand, and therefore the earth fault in the direct current system can be accurately and reliably detected out.

Owner:GUANGZHOU PREFECT SERVICE ELECTRONICS TECH

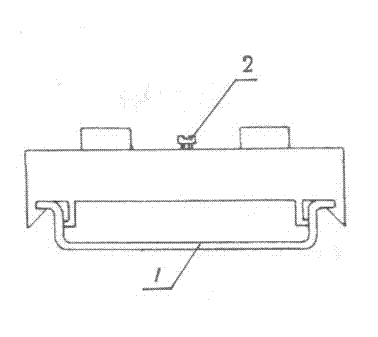

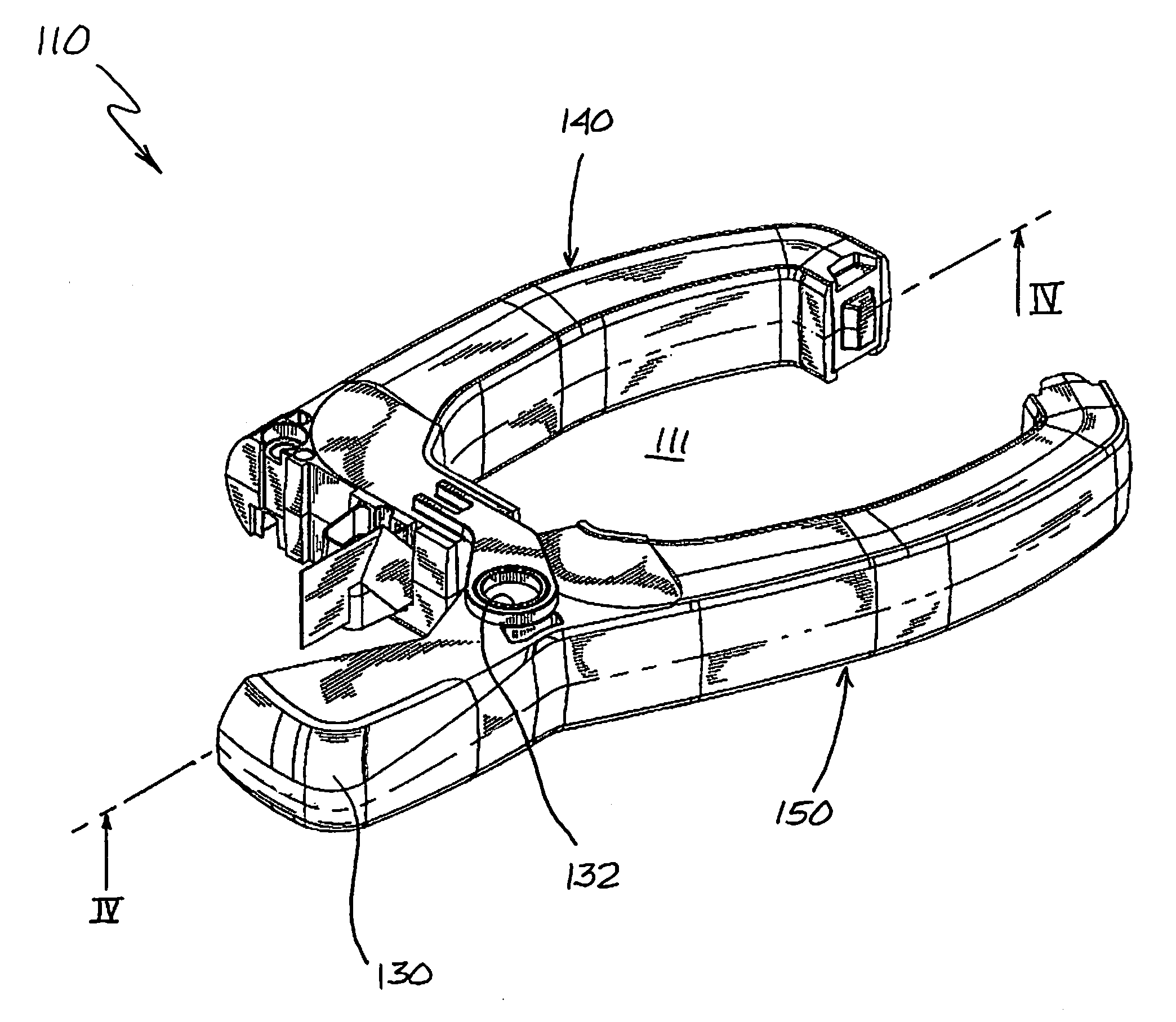

Simplified jaw assembly for a clamp meter

A current clamp meter includes a current meter body and a jaw assembly. The jaw assembly is configured so that the current clamp meter may be used to reach and readily single-out a desired wire from amongst adjacent wires.

Owner:JOHN FLUKE MFG CO INC

Double tip rotary mill clamp

ActiveCN102975049AClamp firmlyImprove versatilityTailstocks/centresPositioning apparatusNumerical controlEngineering

The invention provides a double tip rotary mill clamp which solves the problem that the blade is clamped unstably due to the fact that the extending length of a single tip for the current clamp cannot be adjusted, so as to ensure the profile machining quality of the blade and improve the machining speed as well as solve the problem of poor universality and high tool cost. The double tip rotary mill clamp comprises a tip base and two positioning tips. The two positioning tips are installed on the tip base in parallel. The tip base is installed on a numerically-controlled machine tool. The double tip rotary mill clamp is characterized in that the tip base is integral, and the two positioning tips are installed on the integral tip base through a tip support plate. The integral tip base is internally provided with an adjusting mechanism which adjusts the extending lengths of the two positioning tips simultaneously, wherein the two positioning tips are connected with the adjusting mechanism.

Owner:WUXI TURBINE BLADE

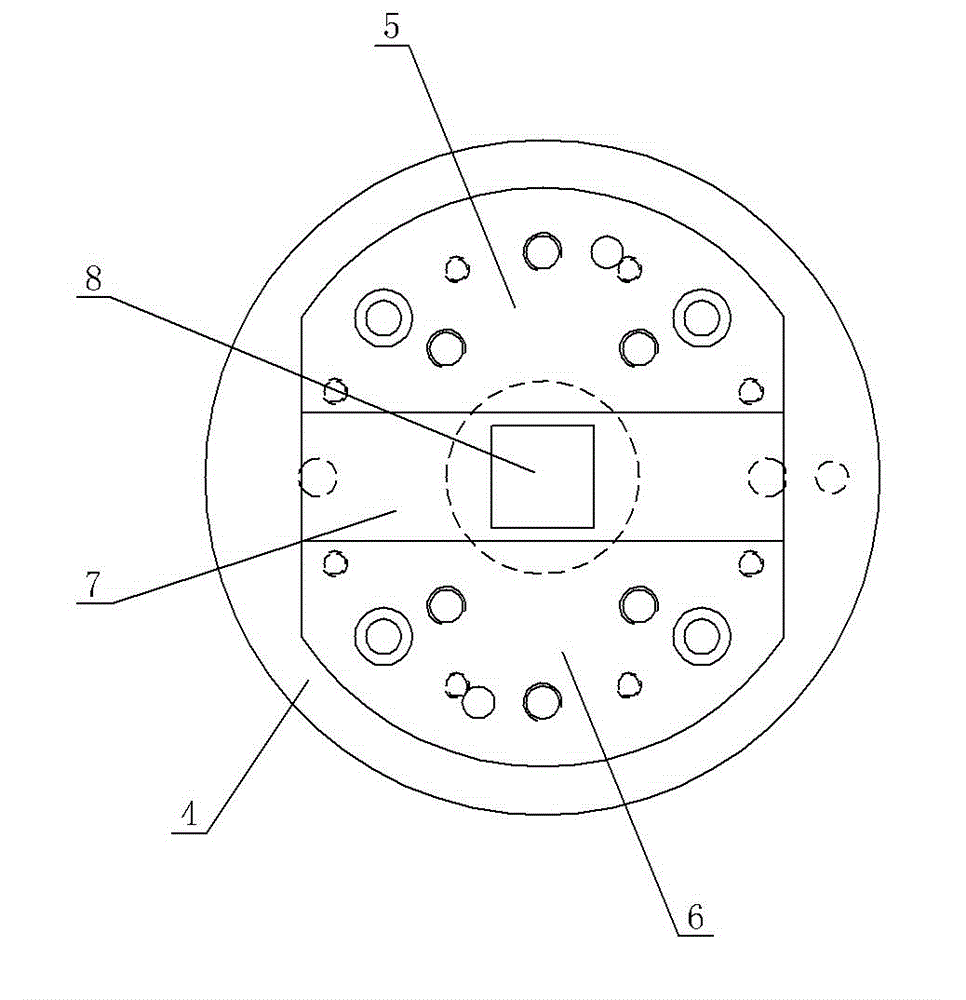

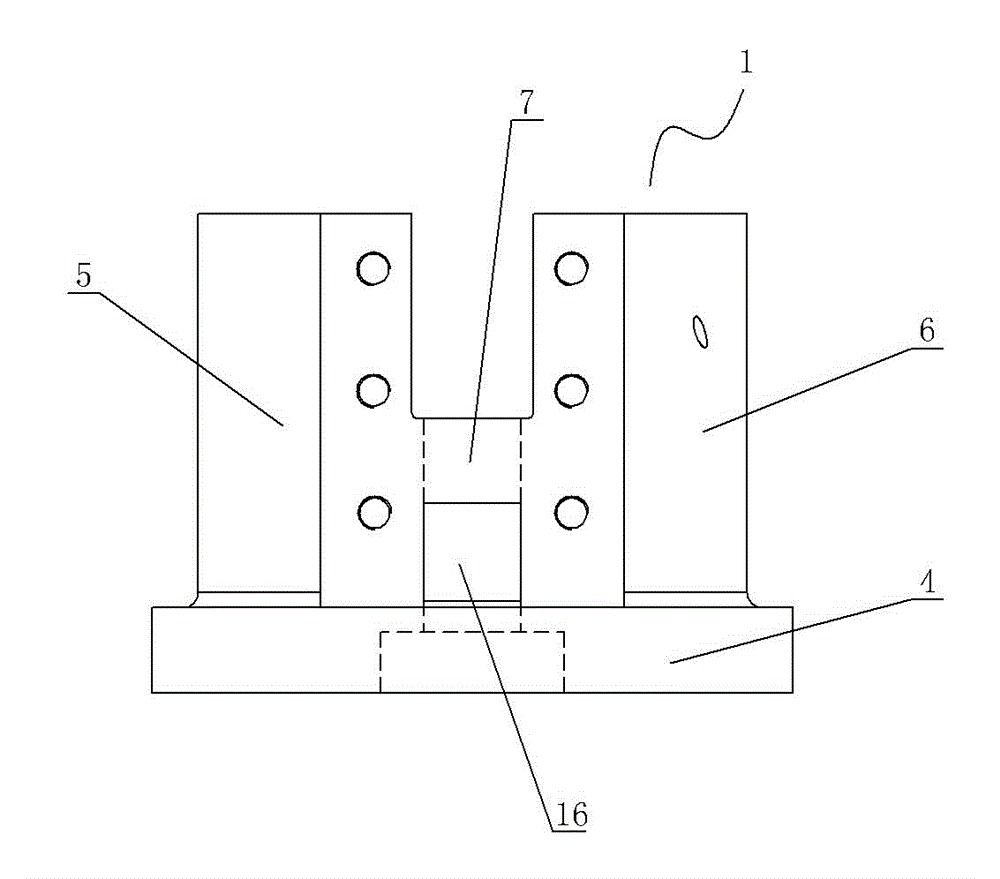

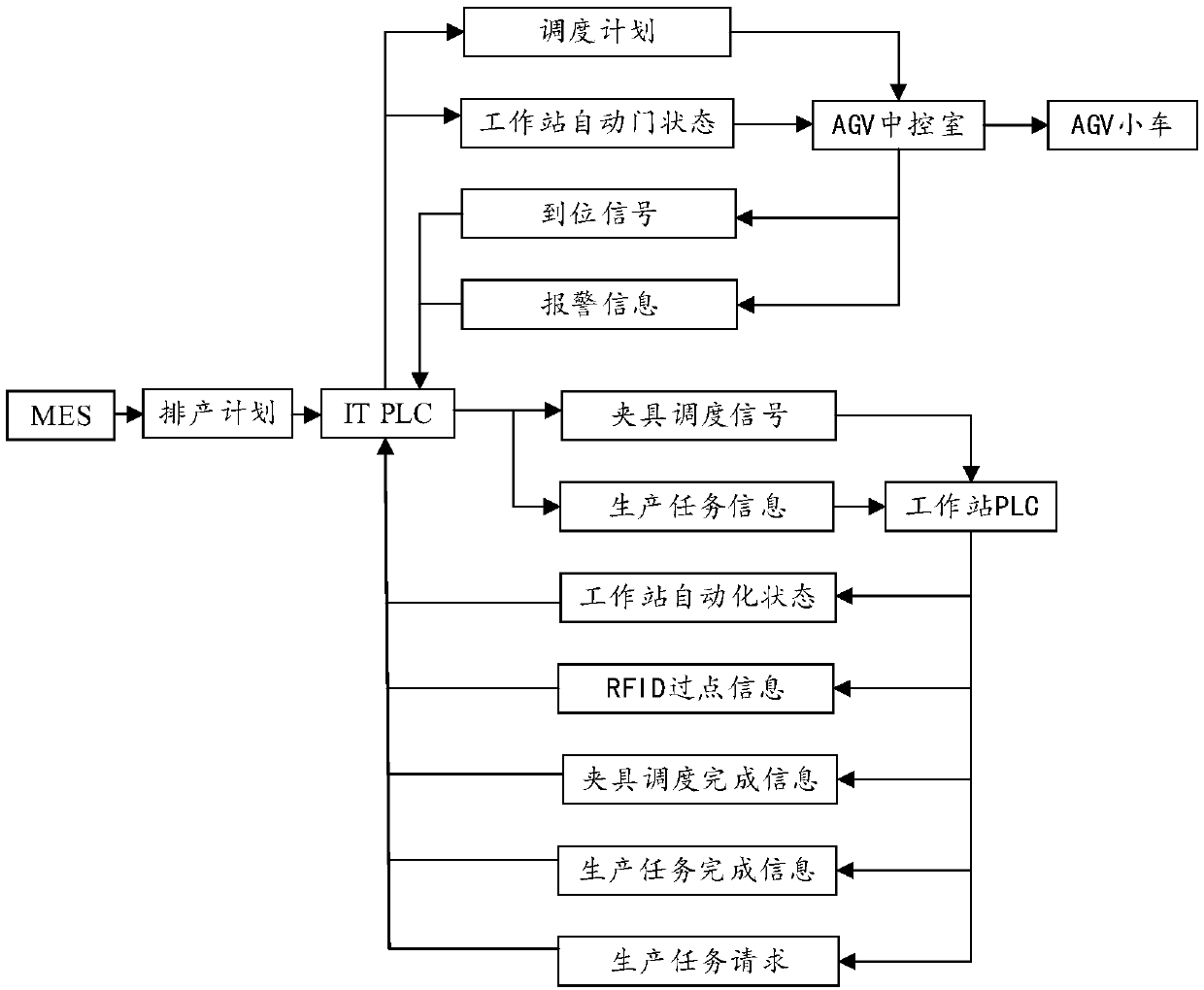

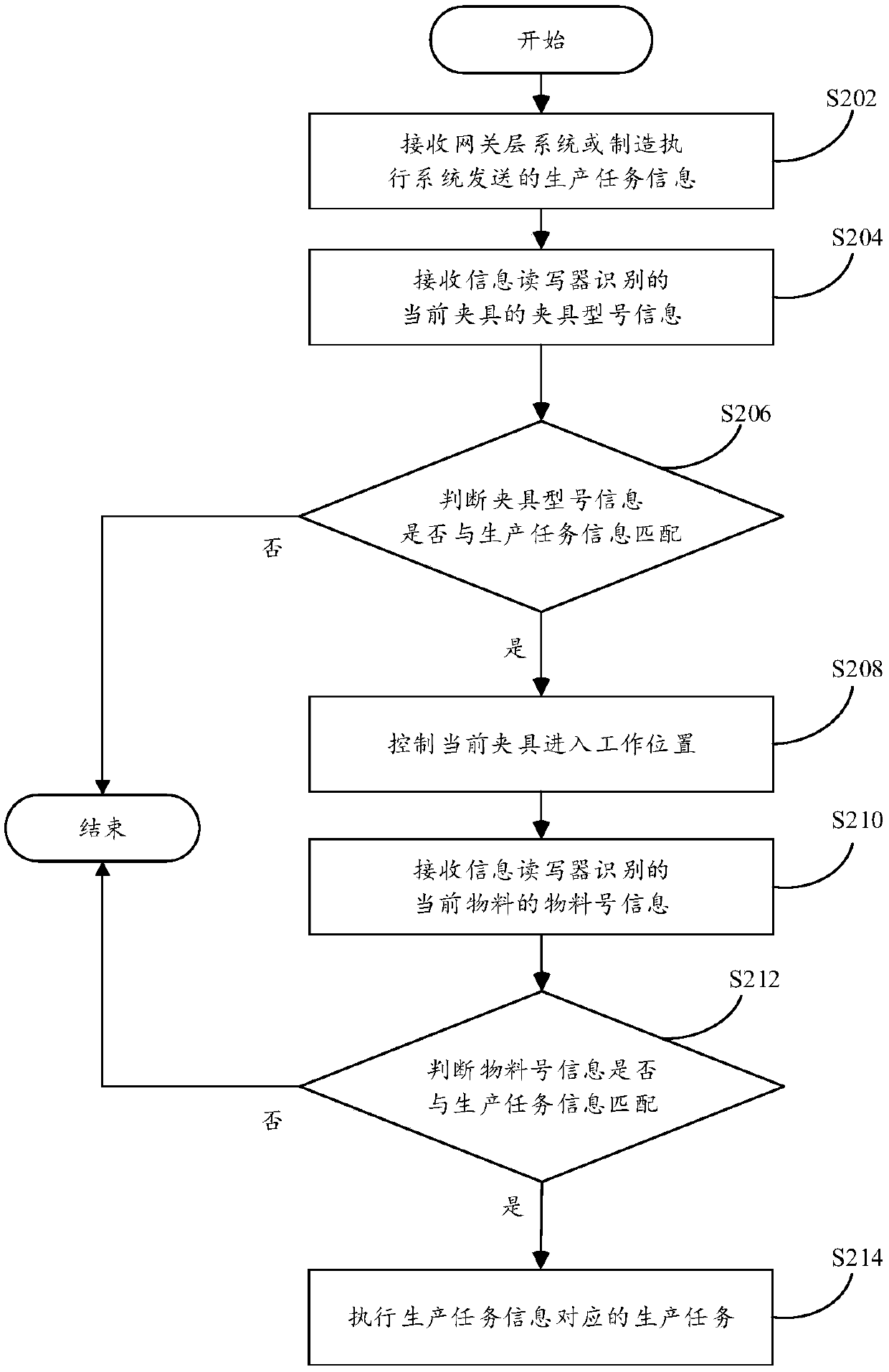

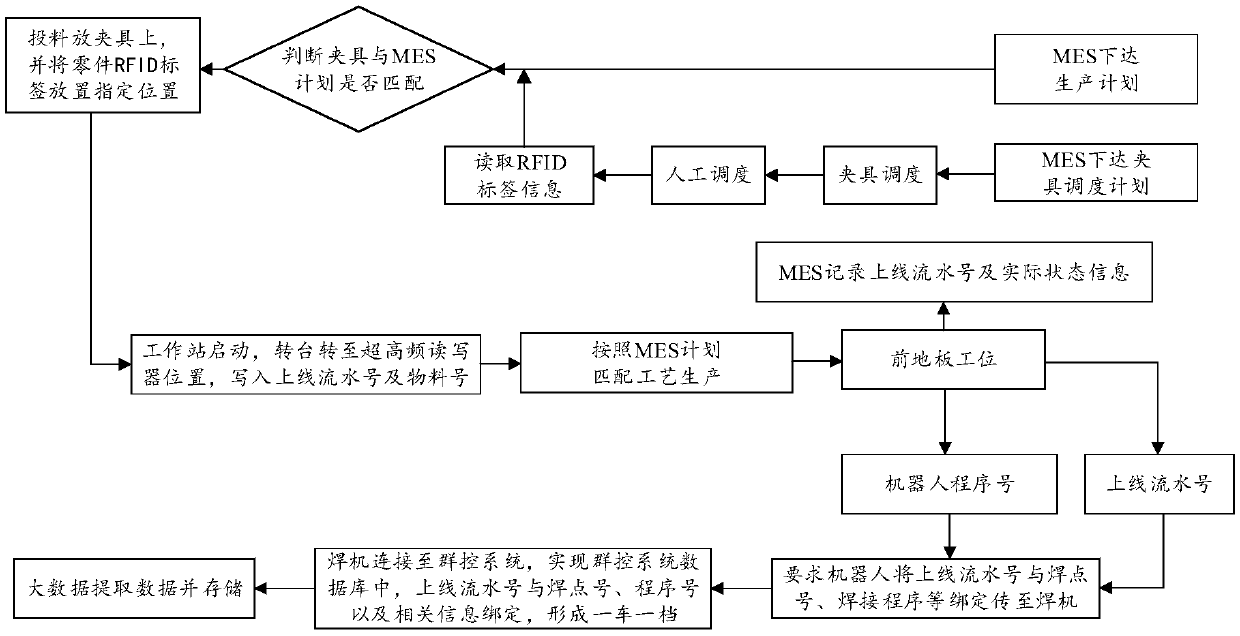

Multi-vehicle-type flexible manufacturing method and device

InactiveCN109676279ALow costShorten the production cycleWelding/cutting auxillary devicesAuxillary welding devicesManufacturing technologyModel Number

The embodiment of the invention provides a multi-vehicle-type flexible manufacturing method and device, and relates to the technical field of multi-vehicle-type vehicle body manufacturing. The methodcomprises the steps that production task information sent by a gateway layer system or a manufacturing executing system is received; clamp type information, recognized by an information reader-writer,of a current clamp is received, and whether the clamp type information is matched with the production task information or not is judged; if the clamp type information is matched with the production task information, the current clamp is controlled to enter the work position; material number information, recognized by the information reader-writer, of the current material is received, and whetherthe material number information is matched with the production task information or not is judged; and if the material number information is matched with the production task information, the productiontask corresponding to the production task information is executed. According to the embodiment, the corresponding production task is executed according to the fact about whether the received currentclamp type, the received online serial number and the received material number recognized by the information reader-writer are matched with the production task information or not, the production period is shortened, and the production cost is reduced.

Owner:NINGBO GEELY AUTOMOBILE RES & DEV CO LTD +1

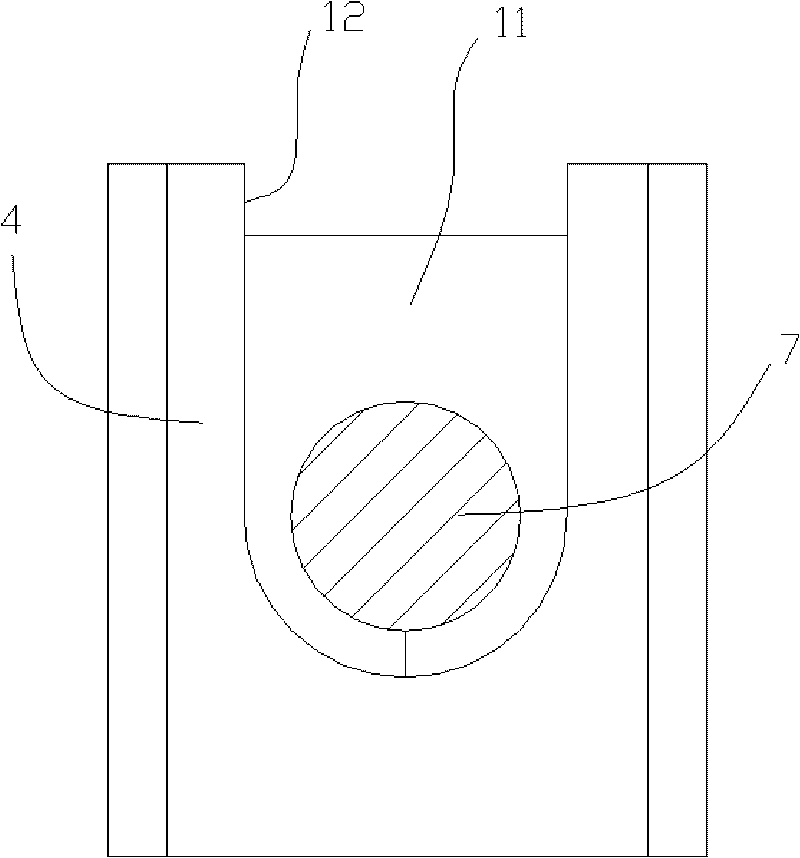

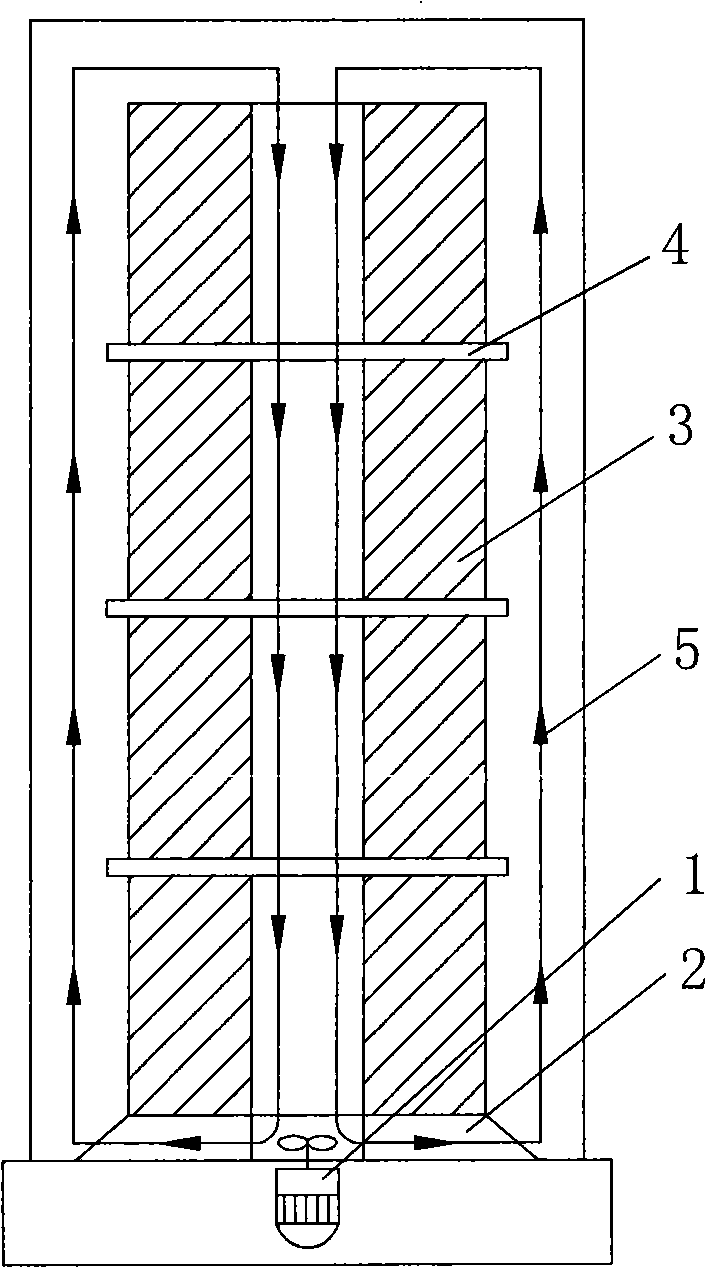

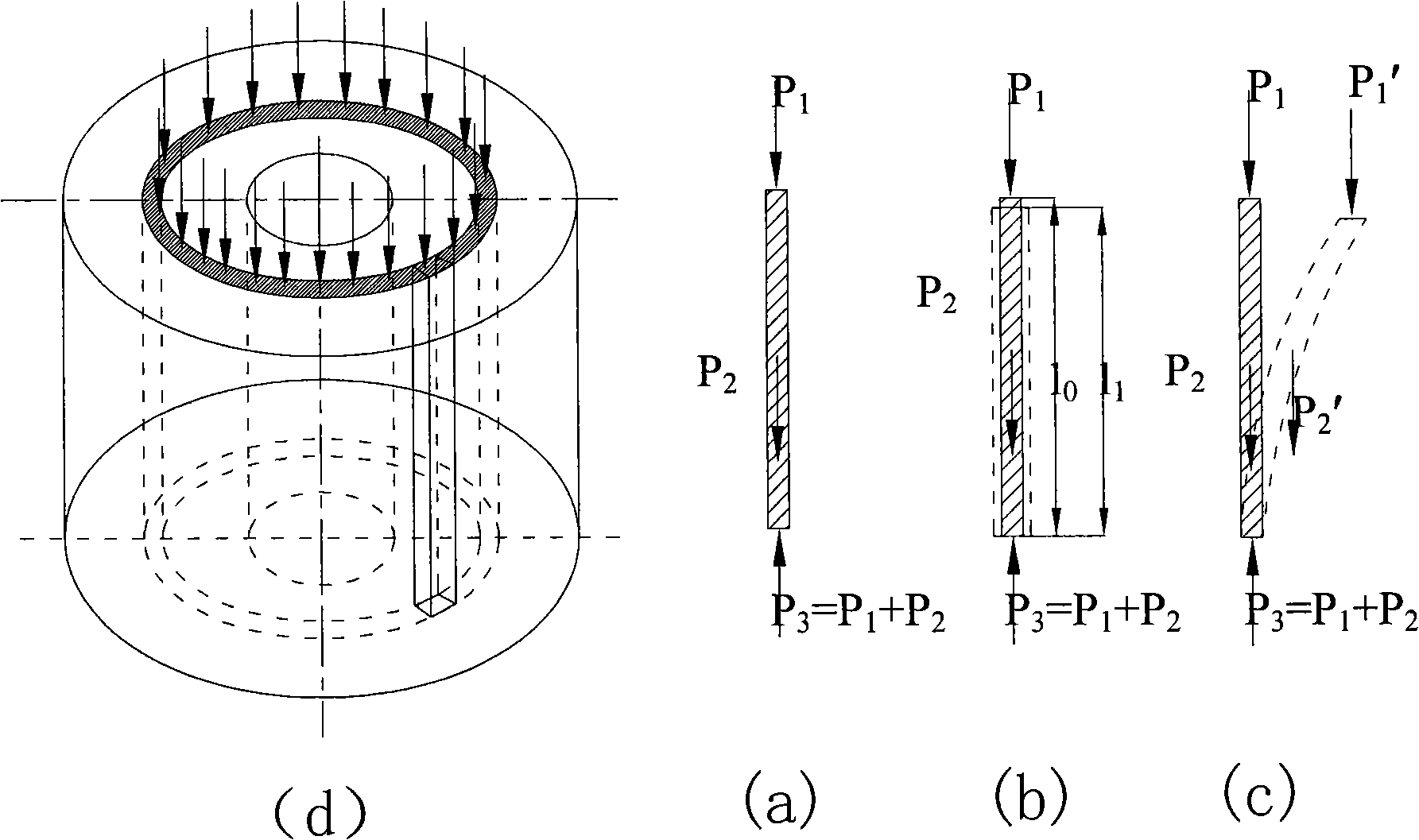

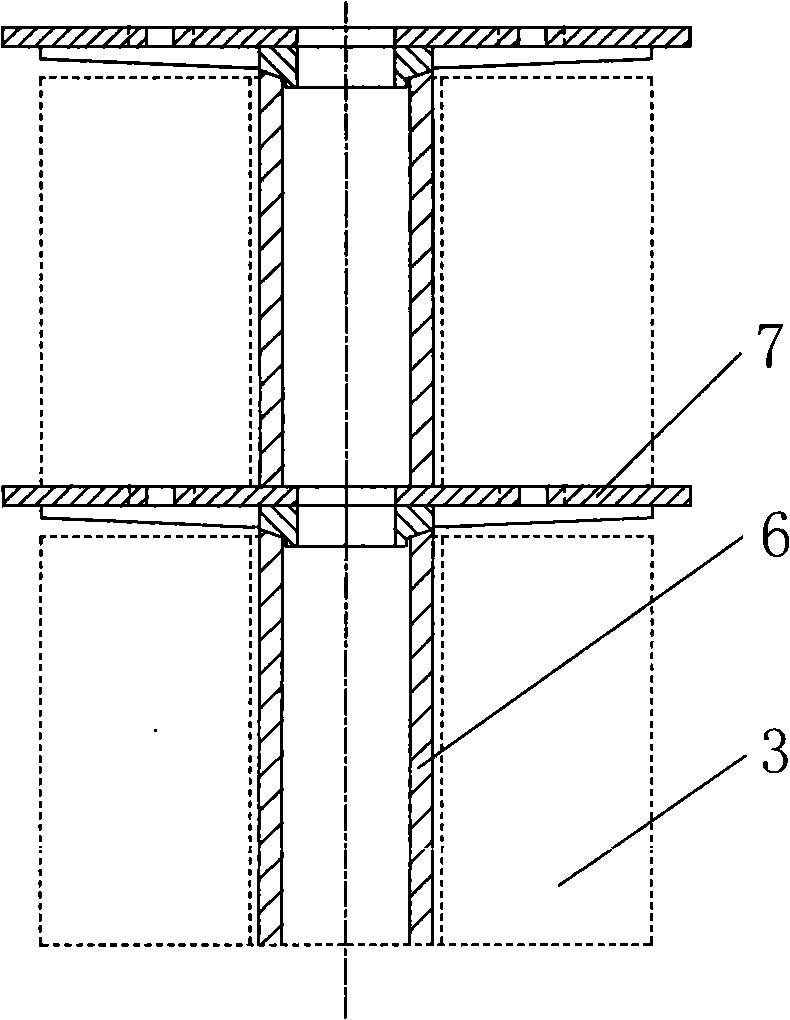

Suspending type convection current clamp method for bell type annealing furnace

InactiveCN101294241AReduce the chance of vertical foldingSolve the problem of vertical compressionBell type furnacesMetallurgyCurrent clamp

The invention relates to a convective stacking method of a hood-type annealing furnace, in particular to a suspended-type convective stacking method used on the hood-type annealing furnace. The method is characterized in that: first, the inner rings of steel strip rolls are attached with sleeves; second, one steel strip roll is stacked on a charging floor of the annealing furnace, a convective plate is arranged above the steel strip roll in an overlapping manner, the bottom of the convective plate is matched with the sleeve in the steel strip roll, the sleeve supports the convective plate, and the upper surface of the steel strip roll is not contacted with the convective plate; third, the steel strip roll is put on the convective plate in an overlapping manner, the lower surface of the steel strip roll is contacted with the convective plate, and the sleeve in the steel strip roll is positioned on the upper part of the convective plate, so that all the steel strip rolls are installed layer upon layer in an overlapping manner. The convective stacking method can lead only the lower surfaces of the relative steel strip rolls to be contacted with the convective plate, and lead the upper surfaces thereof to be not contacted with the convective plate, thereby solving the problem that the lower layer steel strip rolls are pressed lengthways in traditional equipment; therefore, the bonding incidence rate of the lower layer steel strip rolls is greatly reduced, in addition, the lengthways folding occurrence probability of the steel strip rolls is also reduced correspondingly.

Owner:BAOSHAN IRON & STEEL CO LTD

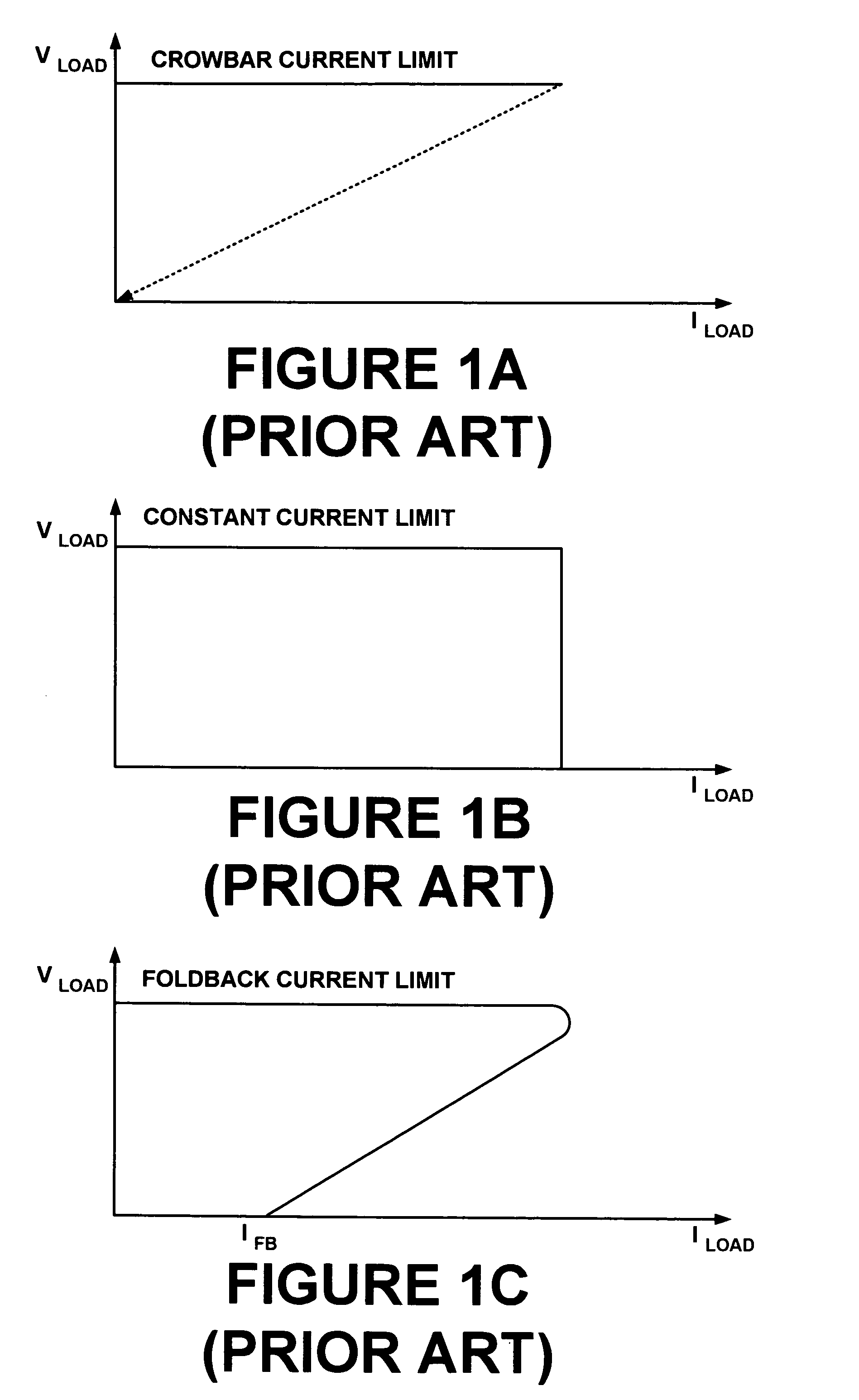

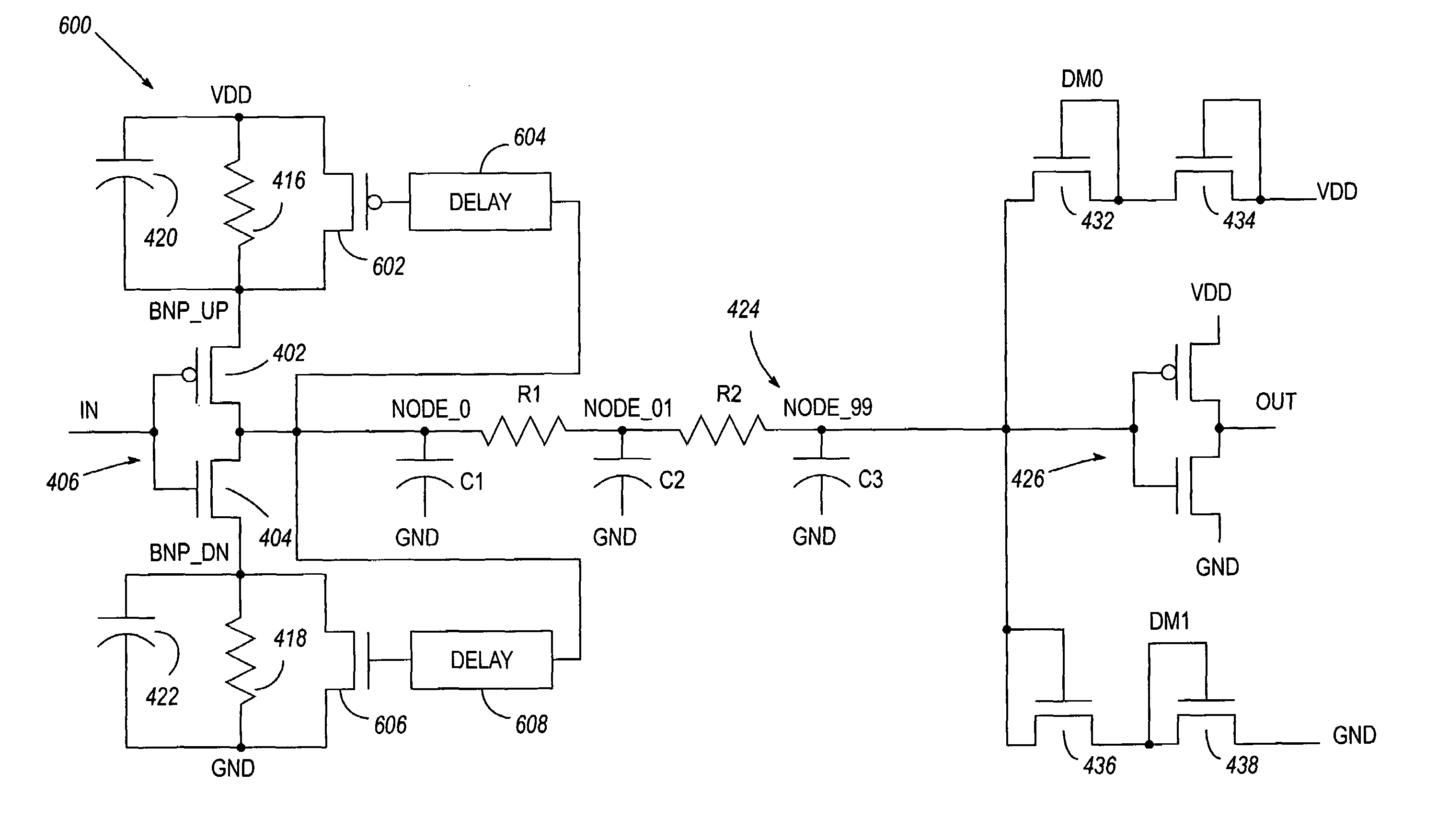

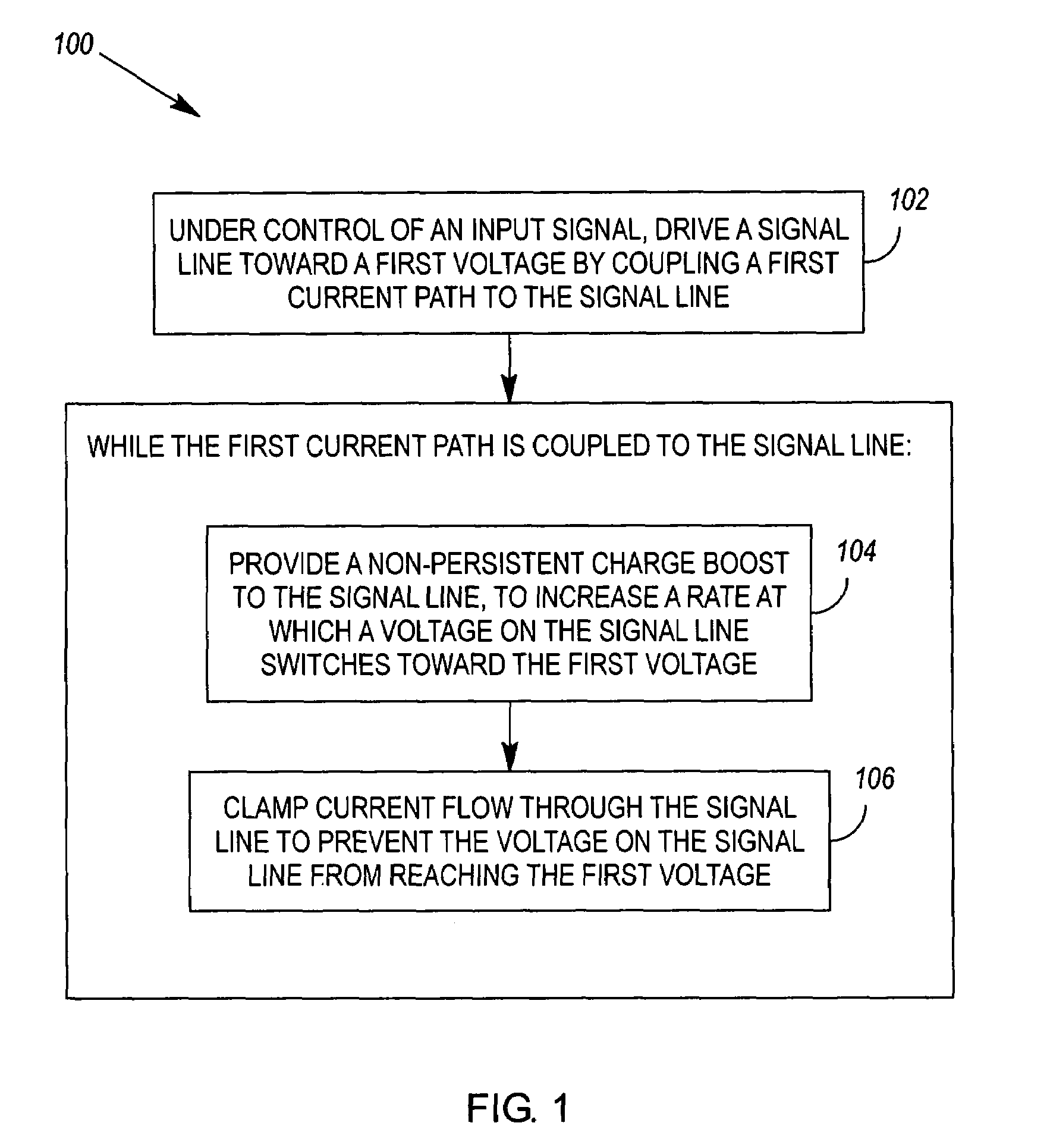

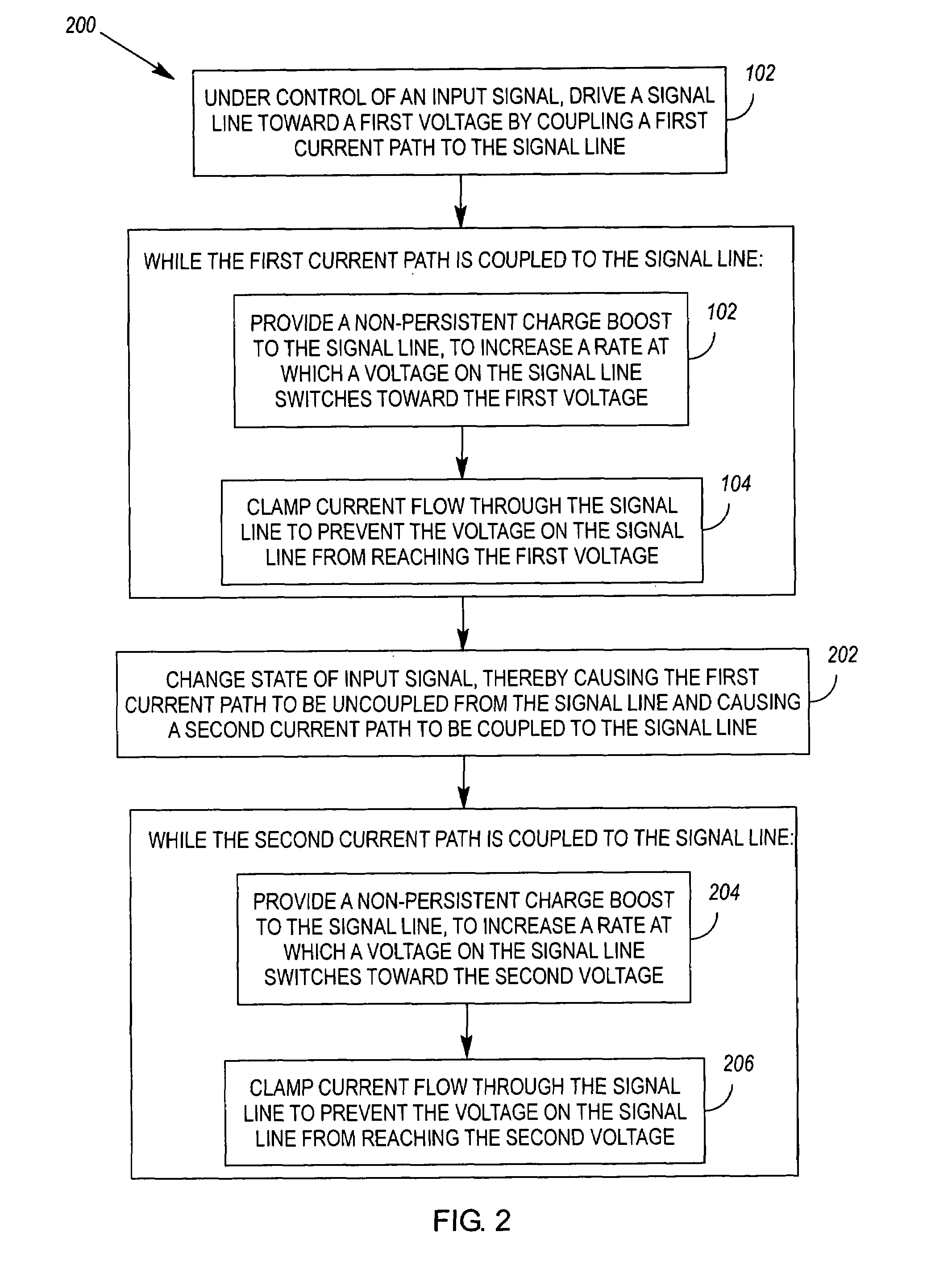

Driver-side current clamping with non-persistent charge boost

ActiveUS7088150B2Increase ratingsSwitching accelaration modificationsElectric pulse generatorCapacitorResistor

Under control of an input signal, a signal line is driven toward a first voltage by coupling a first current path to the signal line. While the first current path is coupled to the signal line, 1) a charge boost is provided to the signal line to increase the rate at which a voltage on the signal line switches toward the first voltage, and 2) current flow through the signal line is clamped to prevent a voltage on the signal line from reaching the first voltage. The current flow may be clamped by means of a resistor in the first current path, and the charge boost may be provided by a capacitor that is coupled in parallel with the resistor.

Owner:AVAGO TECH INT SALES PTE LTD

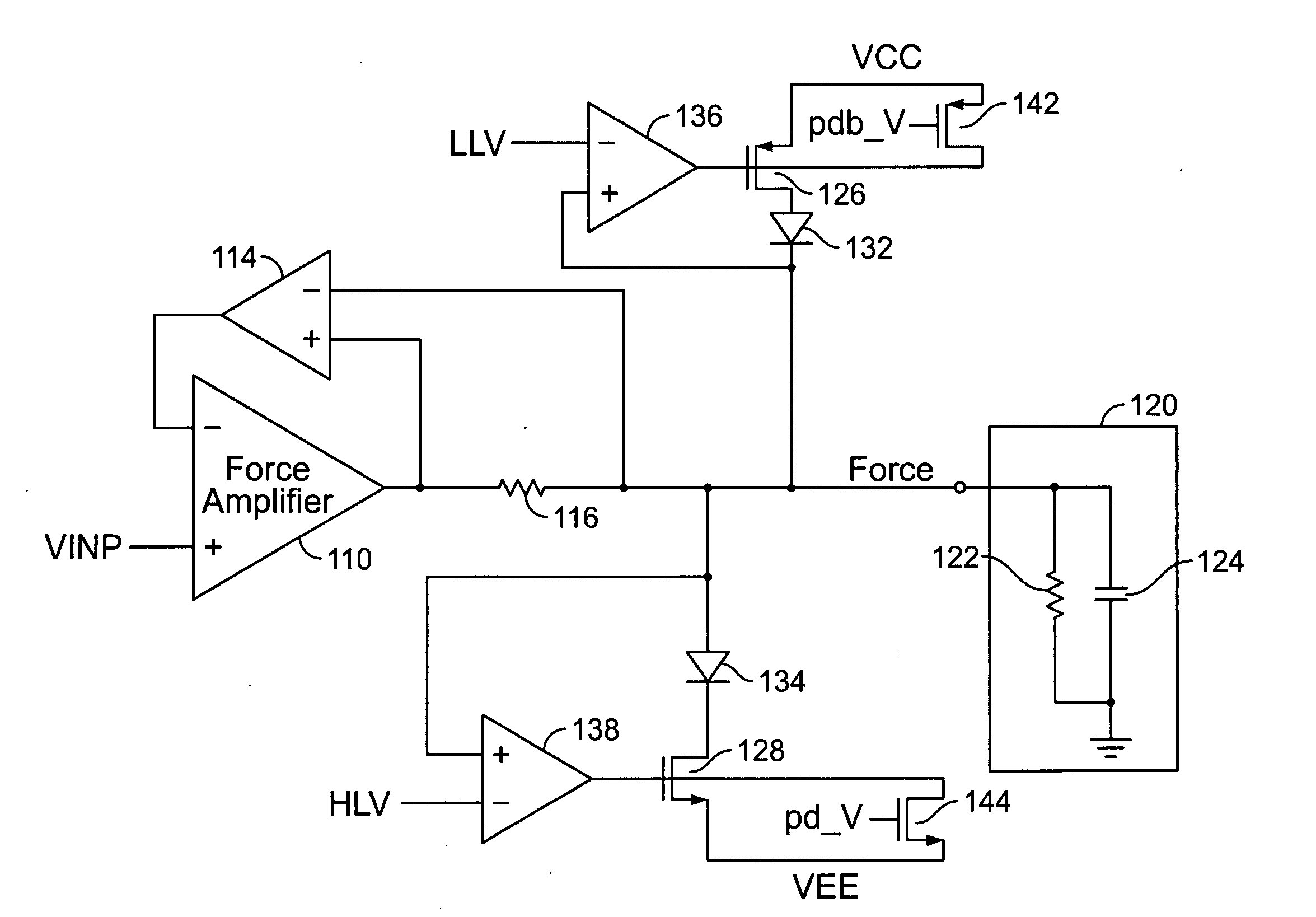

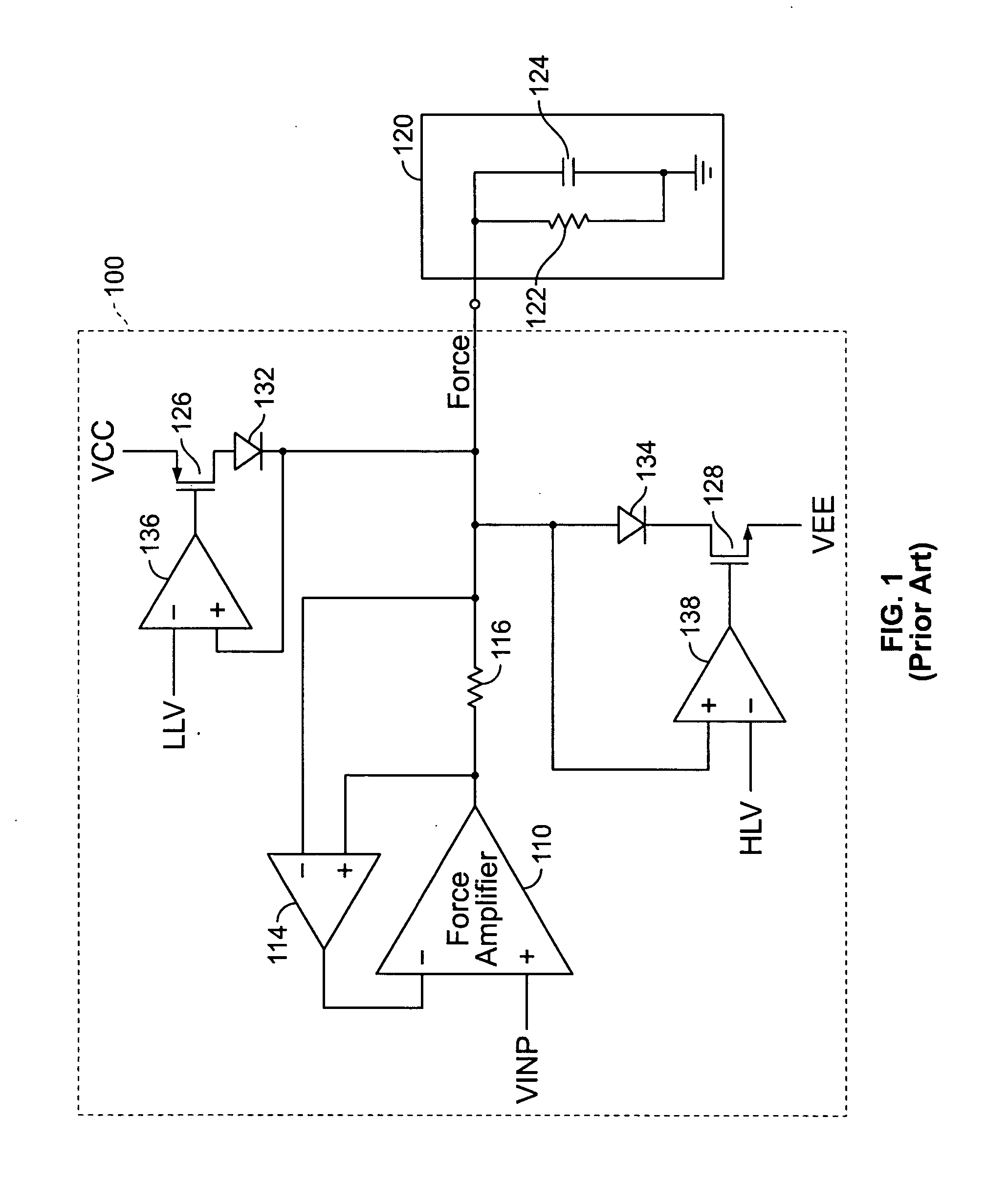

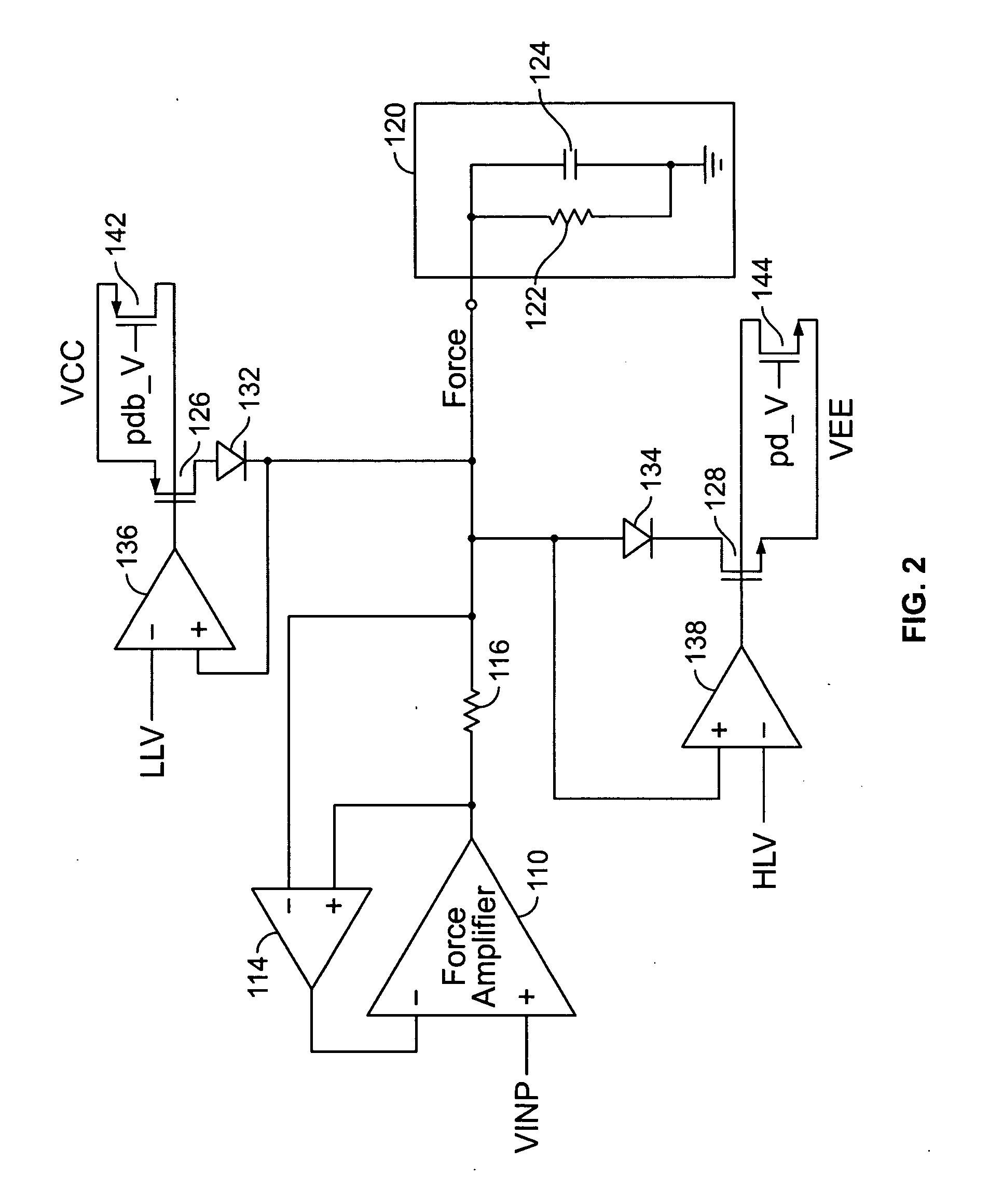

Precision measurement unit having voltage and/or current clamp power down upon setting reversal

InactiveUS20060082359A1Overcomes drawbackCurrent/voltage measurementElectronic circuit testingLower limitAudio power amplifier

A precision measurement unit (PMU) includes a force amplifier selectively providing either a forcing voltage or a forcing current to a device under test via an output force terminal. A low limit voltage clamp and a high limit voltage clamp are operatively coupled to the output force terminal. The low and high limit voltage clamps are each responsive to user programming to define respective low and high voltage limits at the output force terminal. Upon detection of a reversal of said user programming, the operation of the low and high limit voltage clamps is disabled. More particularly, a comparator is adapted to compare the low and high voltage limits and provide a corresponding disabling signal if the high voltage limit is lower than the low voltage limit.

Owner:SEMTECH CORP

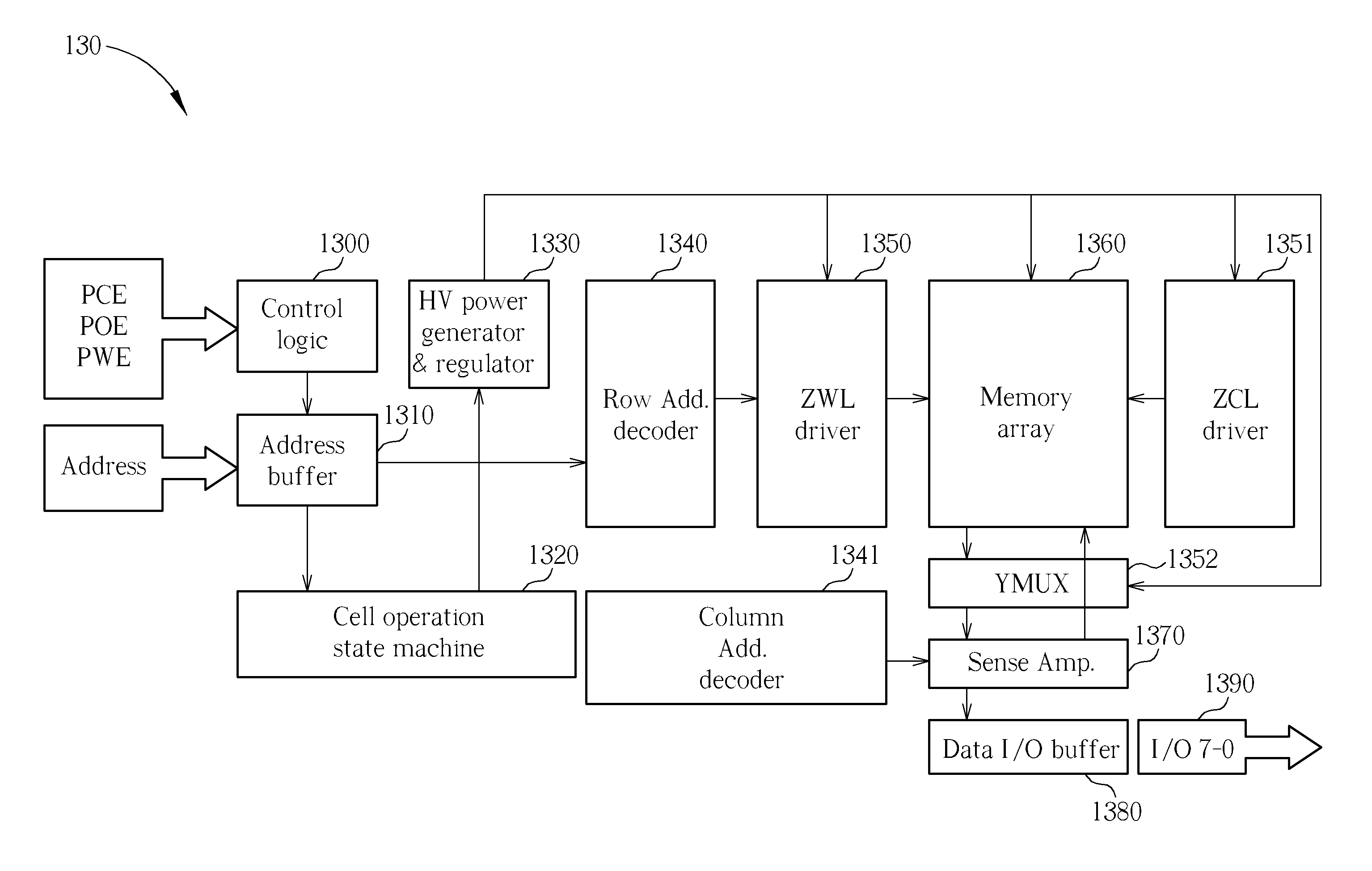

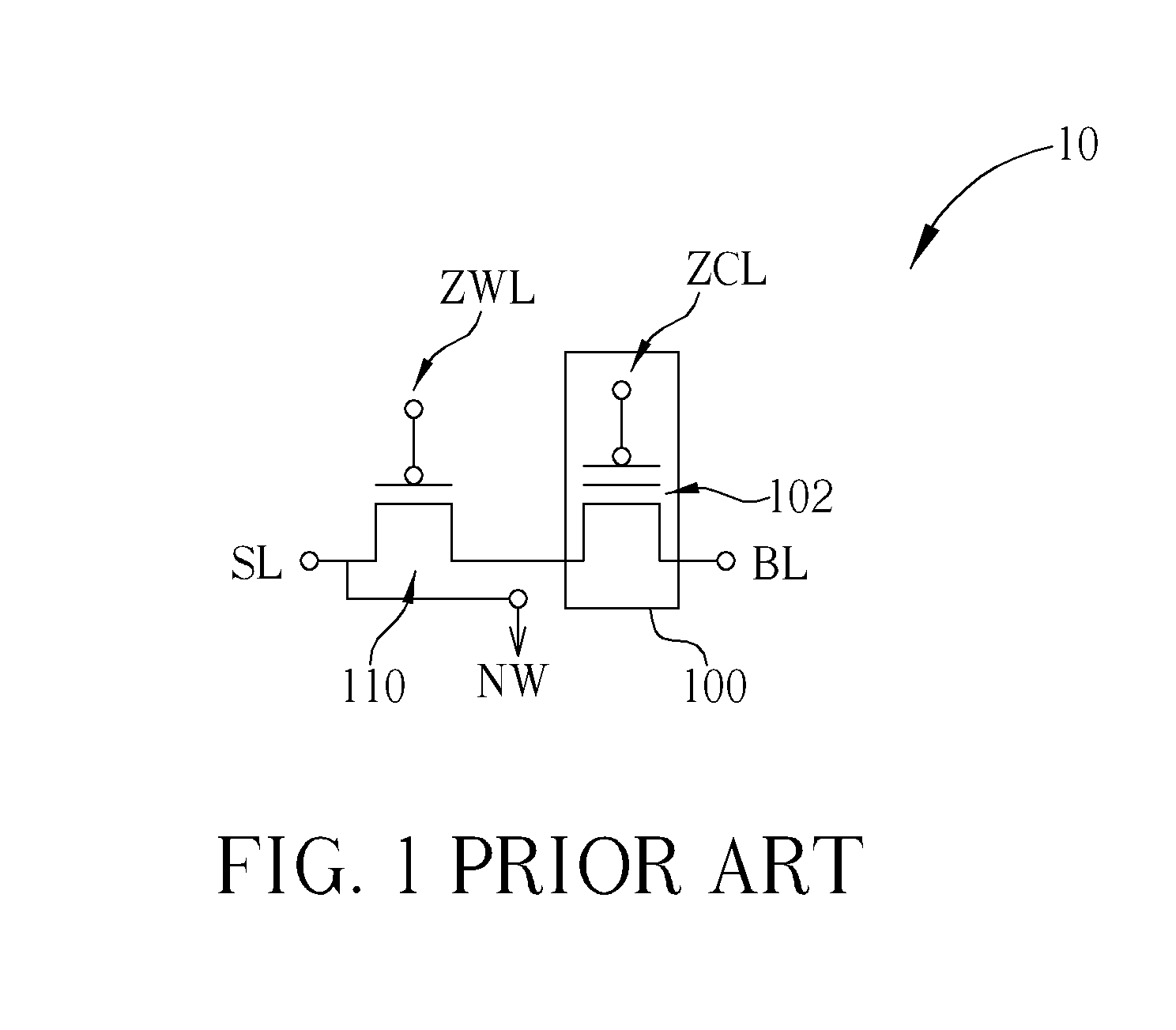

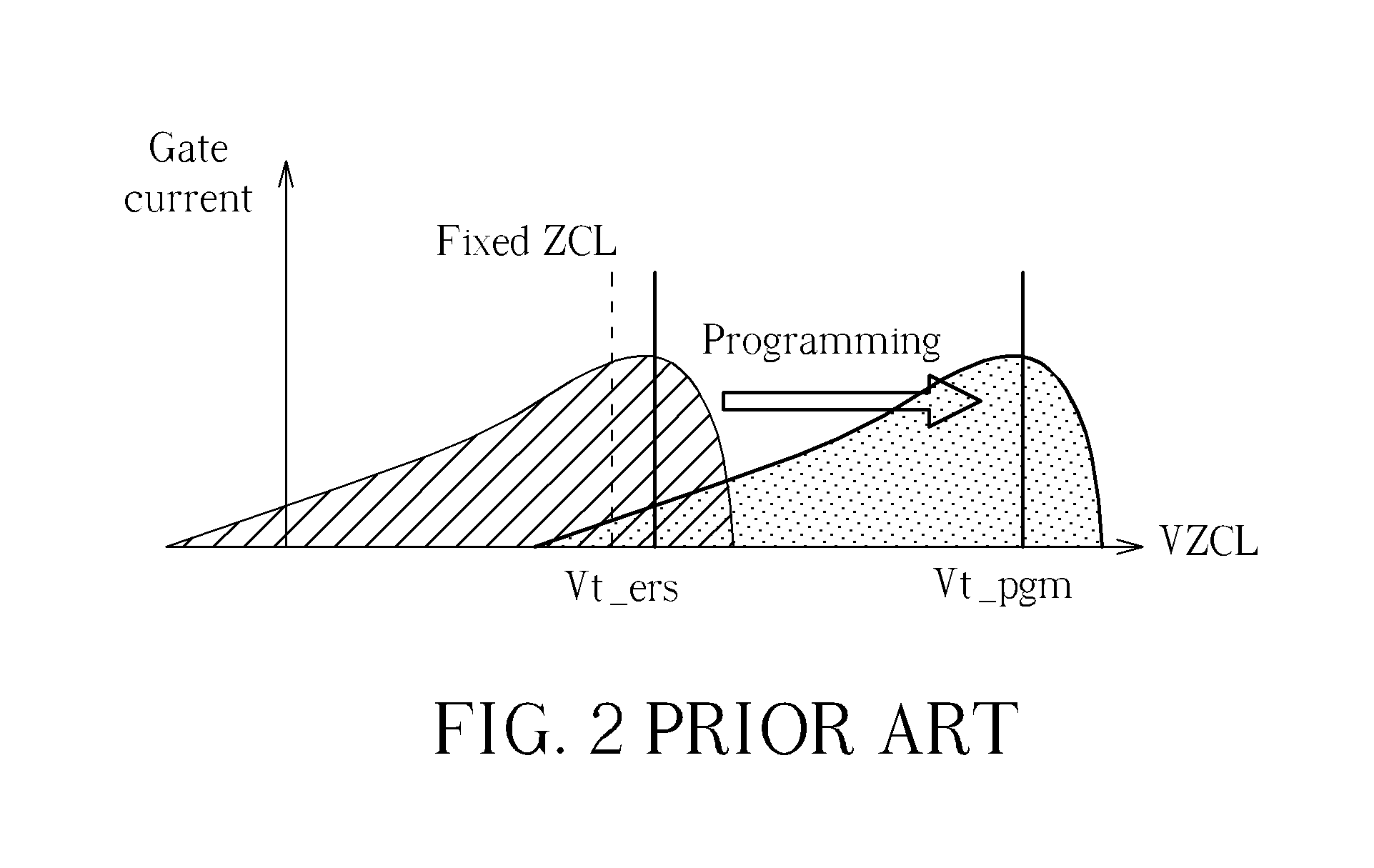

Non-Volatile Memory Device with Program Current Clamp and Related Method

A method of programming a nonvolatile memory cell which comprises a select transistor and a memory transistor includes applying a preset limit current to a first input of the memory cell, applying a limit voltage to a current limiting circuit electrically connected to a second input of the memory cell, applying a limit voltage to stabilize a voltage drop of the memory cell, and applying a ramped gate voltage to the memory cell to program the memory cell with a preset limited current determined by the current limiting circuit.

Owner:EMEMORY TECH INC

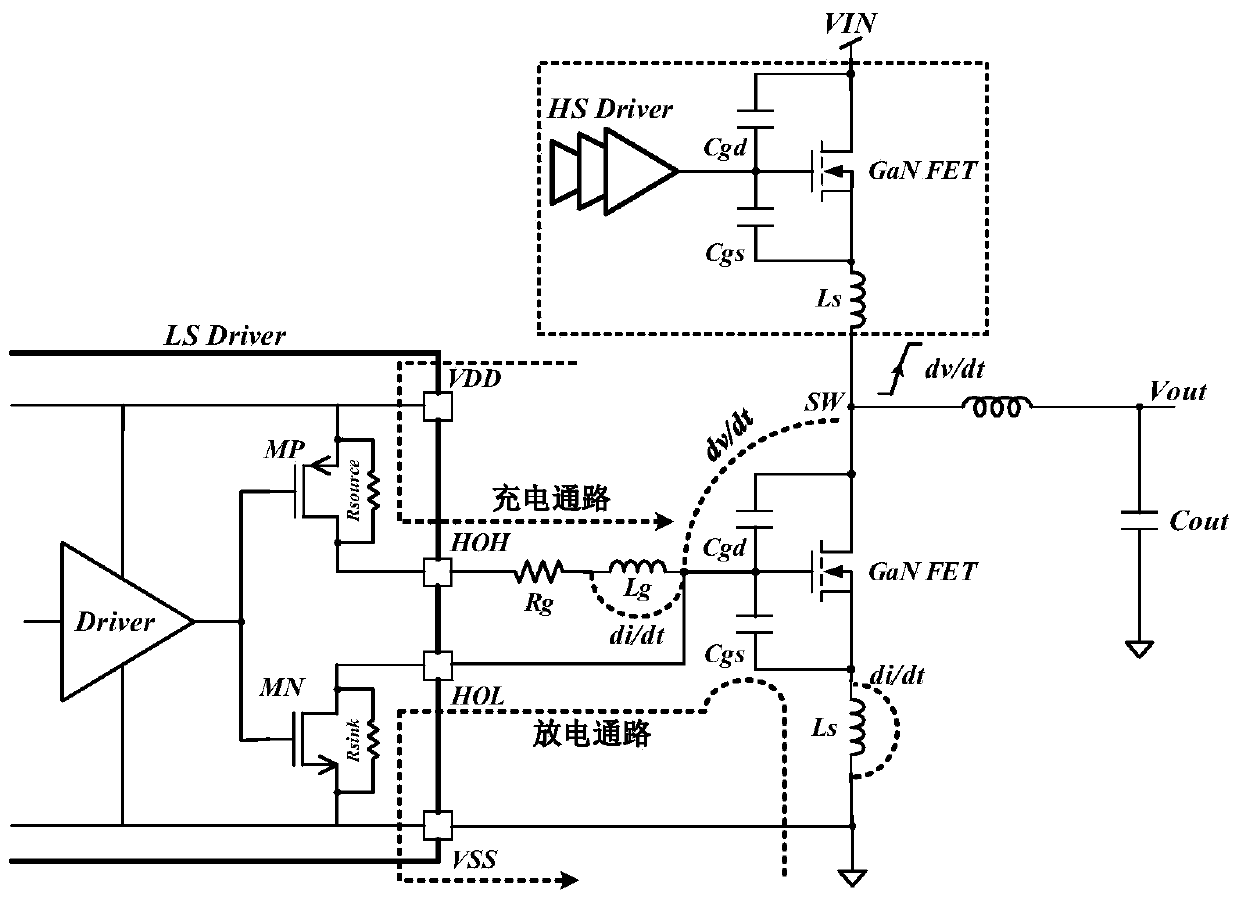

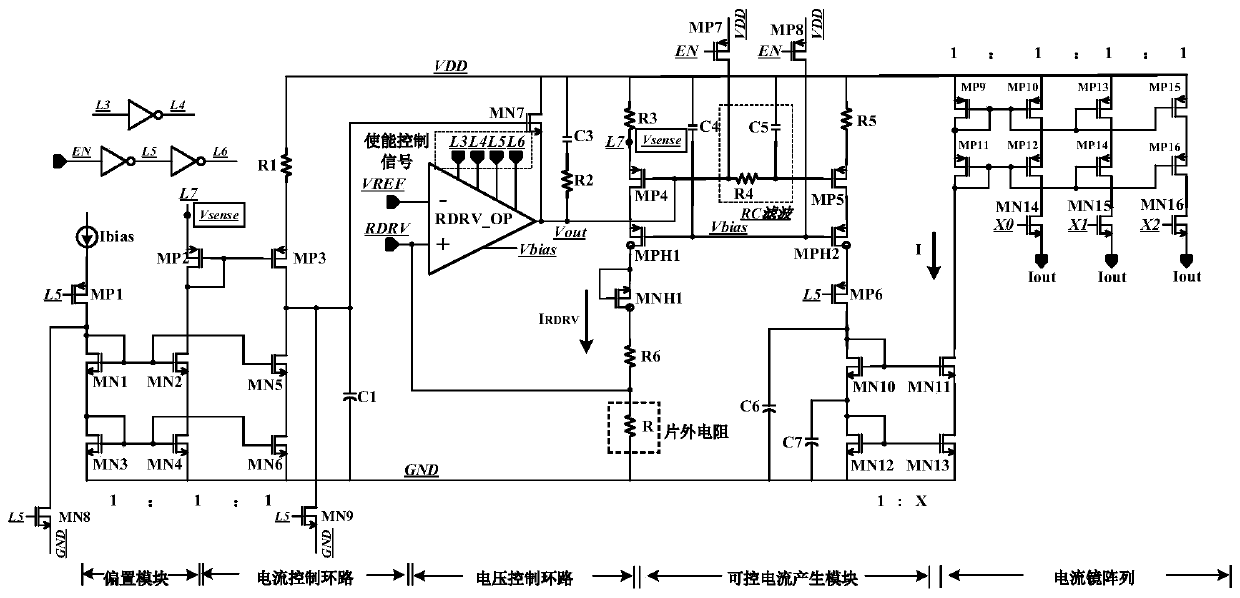

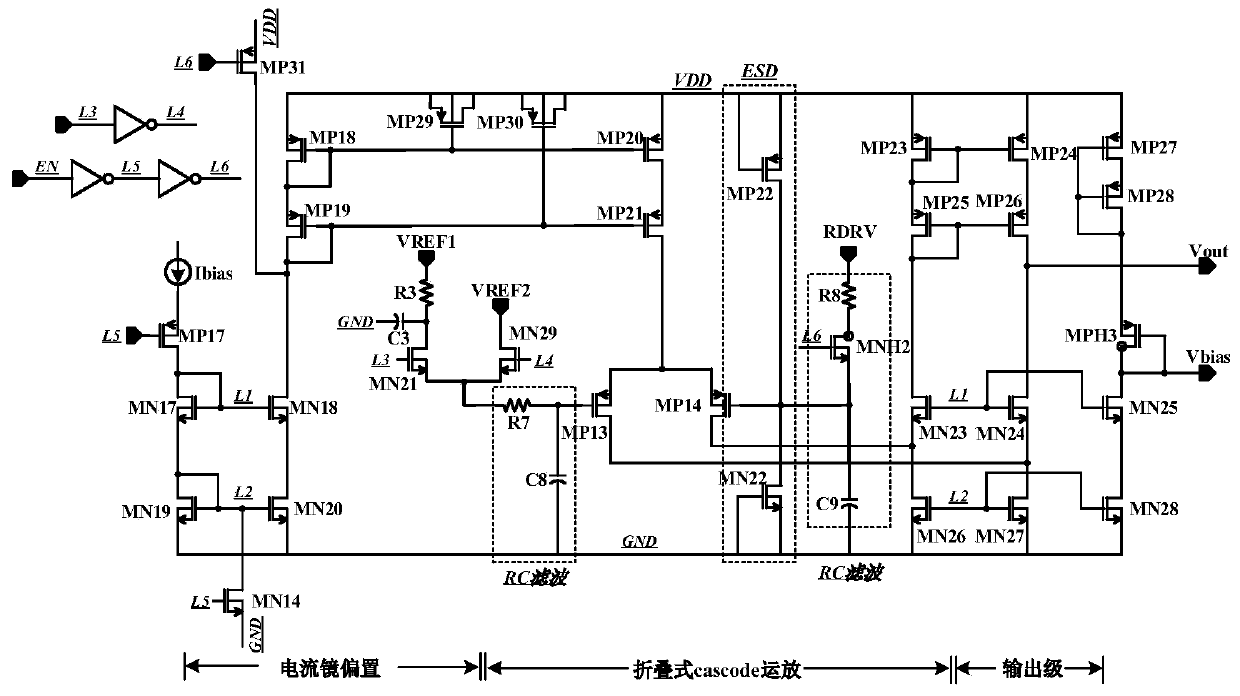

Gate drive current charging circuit and gate drive control circuit of power device

ActiveCN110244813AFlexible and accurate controlReduce the effects of noiseElectric variable regulationControl mannerEngineering

The invention provides a gate drive current charging circuit of a power device and a gate drive control circuit of the power device. The gate drive control circuit separates charge and discharge paths, and uses an adjustable current source to provide charging current for the power device, with more flexible and reliable control mode, which can be applicable to integrated package applications of the power device, especially for depletion-type GaN power transistors. The gate drive current charging circuit is an on-chip adjustable current source with maximum current clamp, and the generated charging current is adjusted by adjusting the voltage value of the reference voltage, the resistance value of the off-chip resistor and the number of strobe current mirror units, so as to ensure more flexible and accurate control of the charging current of the power device. A current control loop is used to realize the maximum current clamping, and a filtering structure is set to eliminate the influence of noise, so as to improve the system reliability. At the same time, when the gate voltage of the power device reaches the logic high level of the gate drive control circuit, the generation of the charging current is stopped, and no additional power consumption is generated. No series resistance is used, so that no gate parasitic inductance is introduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

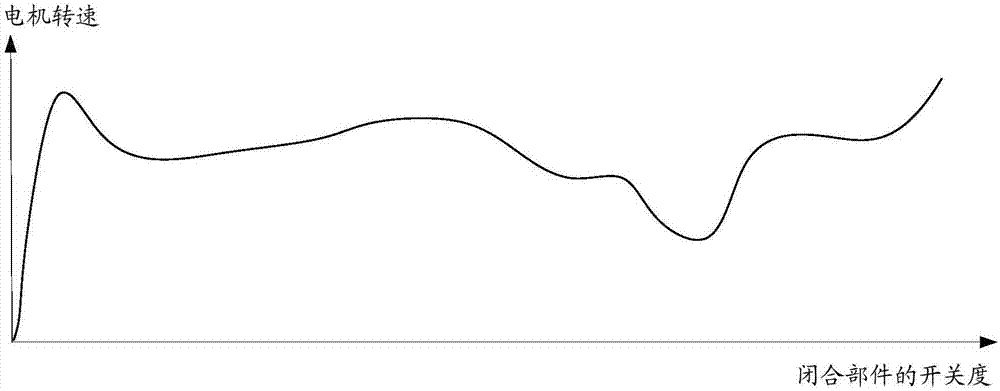

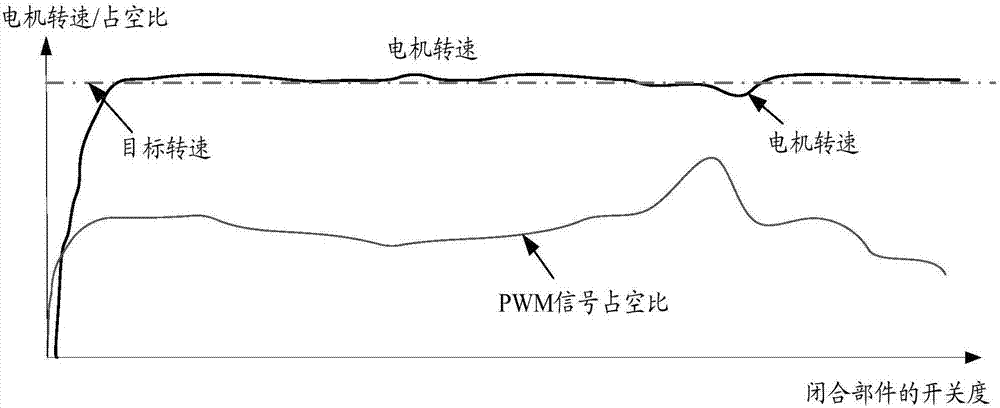

Clamp proof detection method and apparatus of closed part

ActiveCN106899254AAvoid pinchingLow costElectric motor controlPower-operated mechanismElectric machineEngineering

The invention discloses a clamp proof detection method of a closed part. The clamp proof detection method of a closed part includes the steps: acquiring the current duty ratio of a PWM (Pulse-Width Modulation) signal which is used for controlling rotation of a motor so as to drive the closed part to take action; according to the current duty ratio and a pre-obtained barrier-free duty ratio, obtaining the current clamp proof force of the closed part; comparing the current clamp proof force with a pre-obtained clamp proof force threshold; and when the current clamp proof force is greater than the clamp proof force threshold, sending a clamp proof signal which is used for controlling the motor to stop or counter-rotate. The clamp proof detection method of a closed part takes the PWM duty ratio signal as a basis for determining resistance change of the closed part, and does not need adding an extra current sampling circuit to determine whether the closed part is obstructed by a barrier, thus reducing the hardware cost.

Owner:BEIJING JINGWEI HIRAIN TECH CO INC

Asynchronous motor rotor broken bar fault determination method

InactiveCN107589373APrecise electrical signatureAvoid safety hazardsDynamo-electric machine testingStator voltageFrequency spectrum

The invention discloses an asynchronous motor rotor broken bar fault determination method, and belongs to the motor fault determination field. The asynchronous motor rotor broken bar fault determination method includes the steps: an acquisition instrument acquires the voltage and current data through a current clamp and a voltage clamp, and performs spectrum analysis on current; if the current signal is normal, a motor rotor has no broken bar faults, and if the current signal is abnormal, one sideband appears at each of the positions that the power frequency differs from the slip frequency bytwo times, and then the text step is performed; and spectrum analysis is performed on voltage, and if the voltage signal is normal, the motor rotor has no broken bar faults, and if the voltage signalis abnormal and when one sideband appears at each of the positions that the power frequency differs from the slip frequency by two times, a broken bar fault exists in the motor rotor. For solving theproblem that the motor current signal analysis method in the rotor broken bar fault of an asynchronous motor in the prior art may encounter error determination, the asynchronous motor rotor broken barfault determination method uses the mode of using the stator current and the stator voltage to determine successively to detect the rotor broken bar fault, thus reducing the error determination rate.

Owner:马鞍山马钢华阳设备诊断工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com