Multi-vehicle-type flexible manufacturing method and device

A flexible manufacturing and multi-vehicle technology, applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve problems such as high cost, long production cycle time, and unsuitable production conditions, and achieve the effect of shortening the production cycle and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

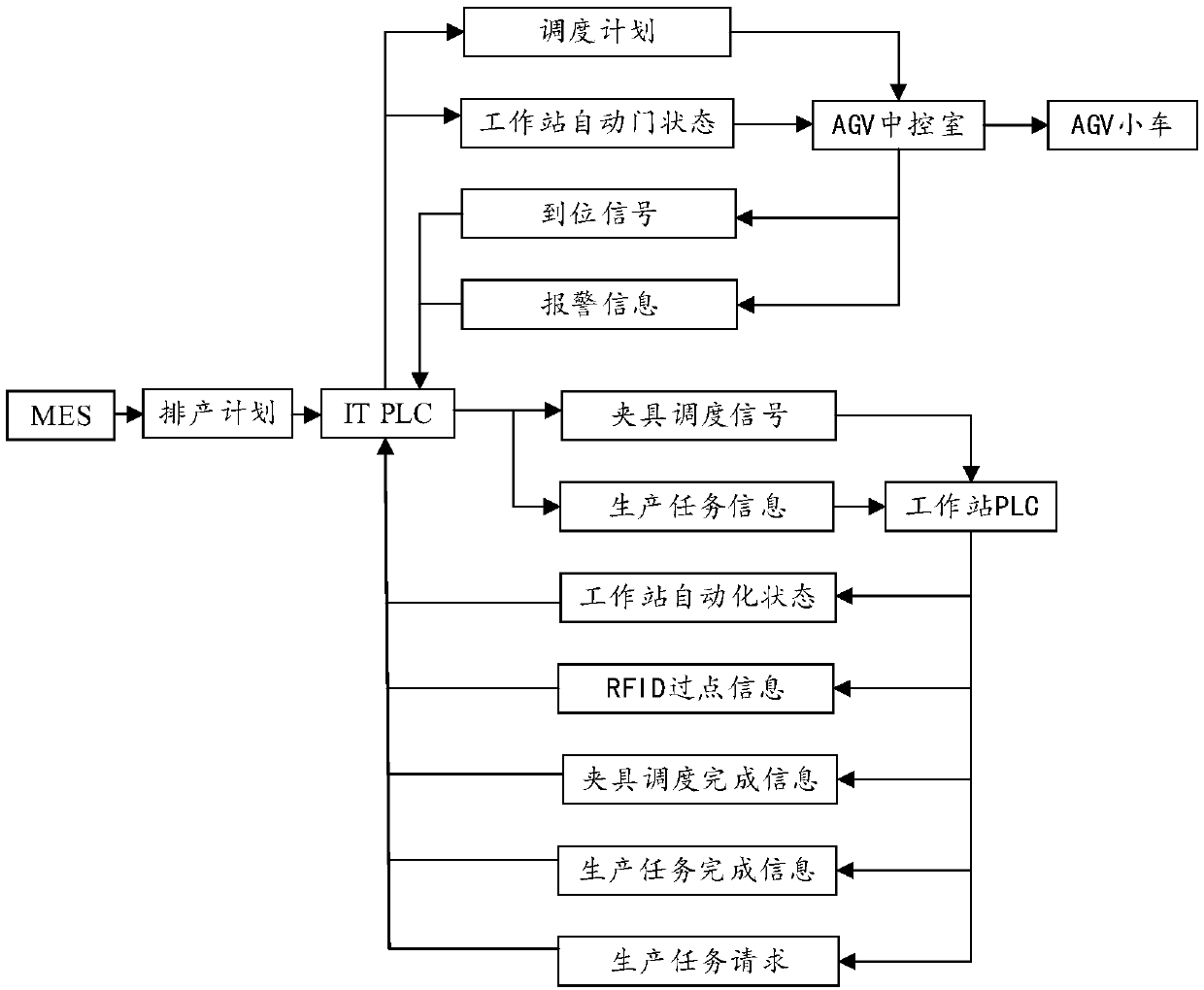

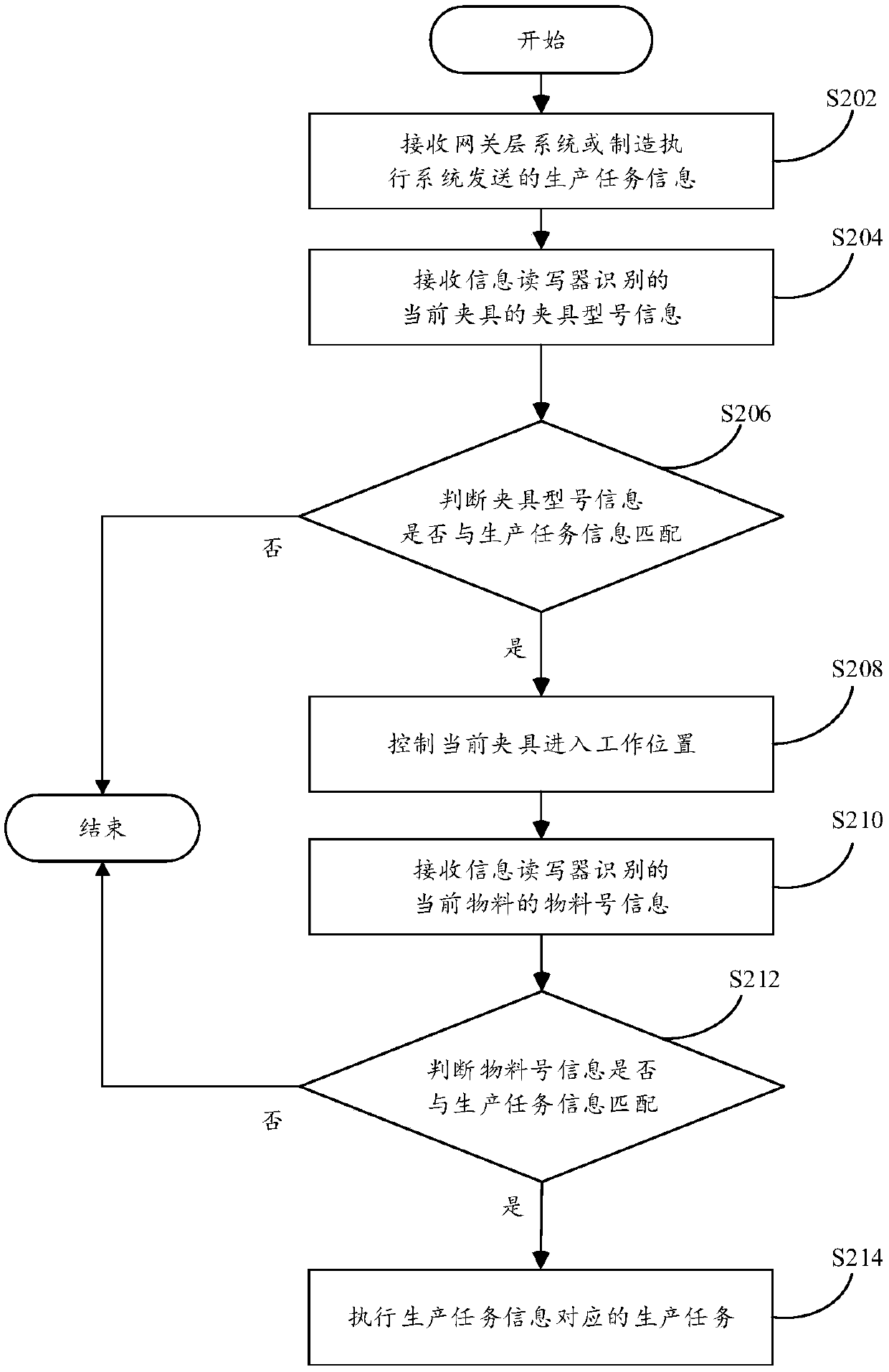

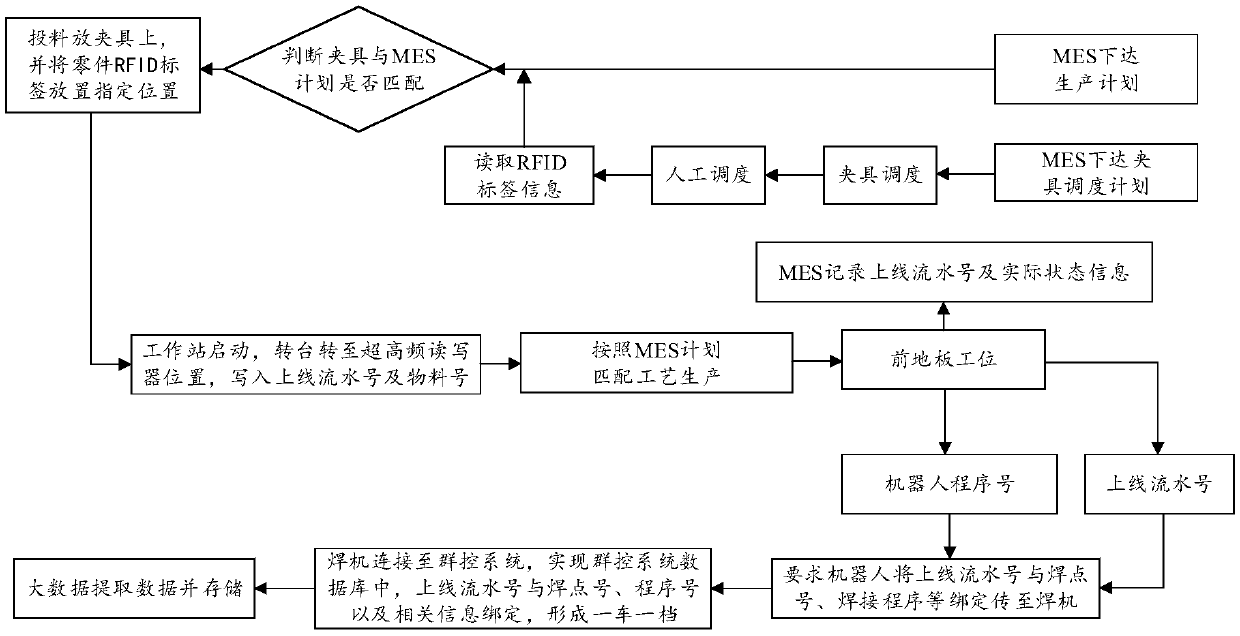

[0043] An embodiment of the present invention provides a multi-vehicle flexible manufacturing method, which is applied to a multi-vehicle line flexible workstation, wherein the multi-vehicle flexible line-through workstation at least includes: an information reader and a workstation PLC; see figure 2 A flow diagram of the multi-vehicle flexible manufacturing method shown, the method includes the following steps:

[0044] Step S202, receiving the production task information sent by the gateway layer system or the manufacturing execution system.

[0045] First, the gateway layer system or the manufacturing execution system sends production task information to the workstation PLC (Programmable Logic Controller, programmable logic controller), wherein the production task information can also include: fixture model information and material material number information, and then the workstation PLC receives the production task information and starts to execute it.

[0046] Step S20...

Embodiment 2

[0083] The embodiment of the present invention provides a multi-vehicle flexible manufacturing method, which is applied to the AGV central control system, see Figure 7 The schematic flow chart of the multi-vehicle flexible manufacturing method is shown, and the method includes:

[0084] Step S702, receiving dispatch plan information sent by the gateway layer system or the manufacturing execution system;

[0085] First, the gateway layer system or the manufacturing execution system sends the scheduling plan information to the AGV central control room, and then the central control room receives the scheduling plan information and starts to execute it.

[0086] Step S704, sending the destination information to the AGV according to the scheduling plan information, so that the AGV drives to the destination.

[0087] Then the central control room sends corresponding destination information to each AGV according to the scheduling plan information. After receiving the relevant infor...

Embodiment 3

[0090] The embodiment of the present invention also provides a multi-vehicle flexible manufacturing device, which is applied to a multi-vehicle line flexible workstation, see Figure 8 The schematic diagram of the structure of the multi-vehicle flexible manufacturing device is shown, wherein the multi-vehicle flexible workstation includes at least: an information reader and a workstation PLC;

[0091] The first receiving module 801 is configured to receive the production task information sent by the gateway layer system or the manufacturing execution system.

[0092] The second receiving module 802 is configured to receive the fixture model information of the current fixture identified by the information reader, and determine whether the fixture model information matches the production task information.

[0093] The control module 803 is configured to, if yes, control the current fixture to enter the working position.

[0094] The third receiving module 804 is configured to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com