Two-way low-voltage punch-through transient voltage suppression diode and manufacturing method thereof

A technology of transient voltage suppression and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as increased cost, and achieve the effects of low leakage current, excellent clamping characteristics, and low capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] See Figure 3.1~3.6 As shown, in order to realize the structure diagram of the manufacturing process of the bidirectional low-voltage punch-through transient voltage suppression diode of the present invention, it specifically includes the following steps:

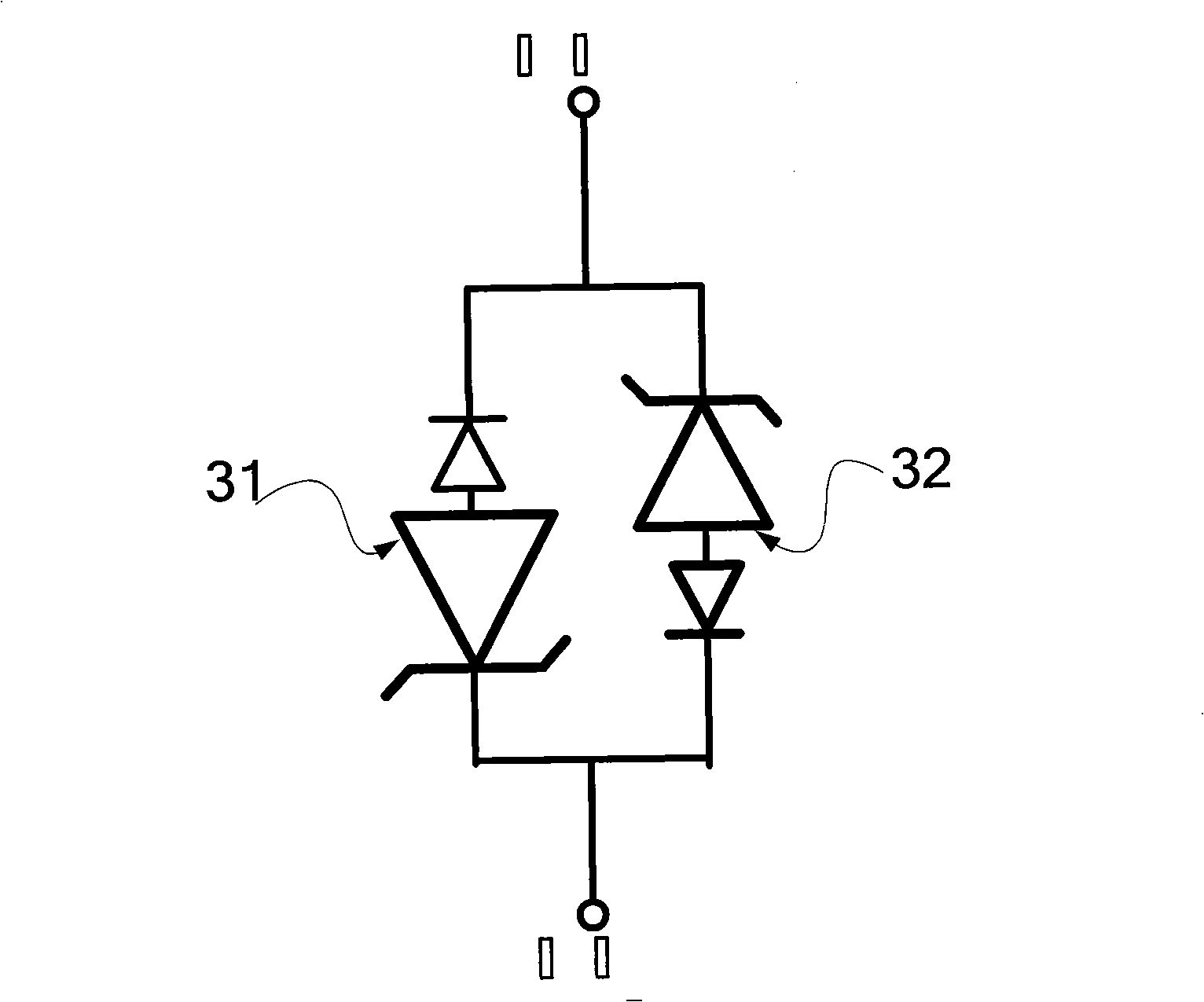

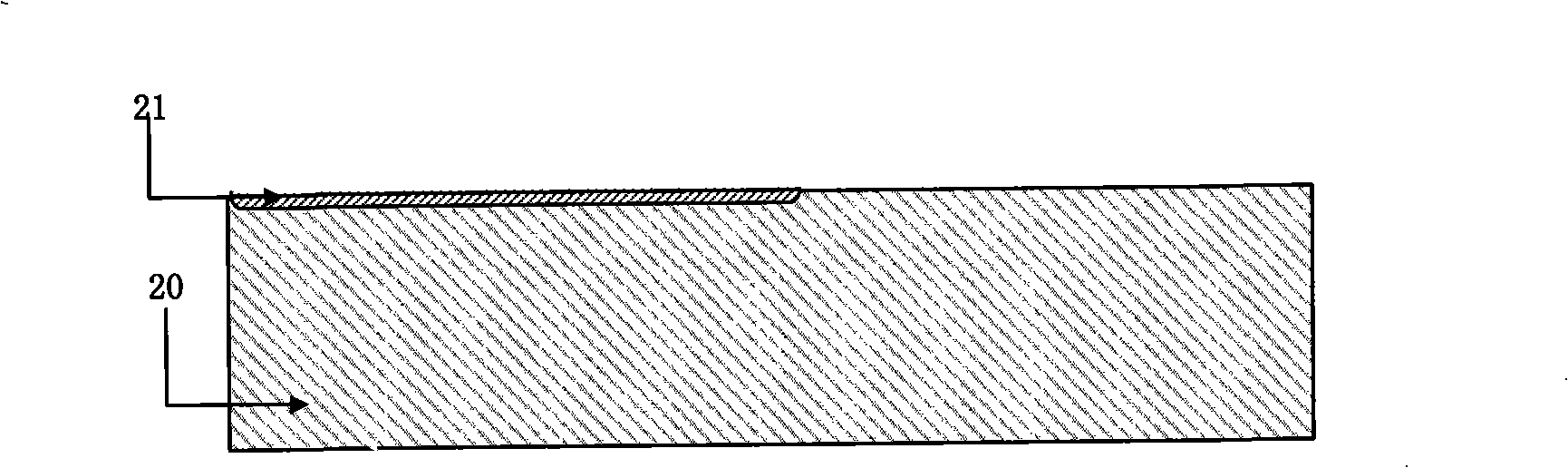

[0086] The first step: such as Figure 3.1 , The p+ buried layer 21 is formed by boron implantation and annealing in half of the n+ substrate 20. The p+ buried layer 21 laterally covers half of the n+ substrate 20. This p-type buried layer serves as the heavily doped base region of the reverse punch through diode. The n-type substrate serves as the emitter area of the reverse protection low-voltage punch-through diode 31 and the collector area of the forward protection low-voltage punch-through diode 32;

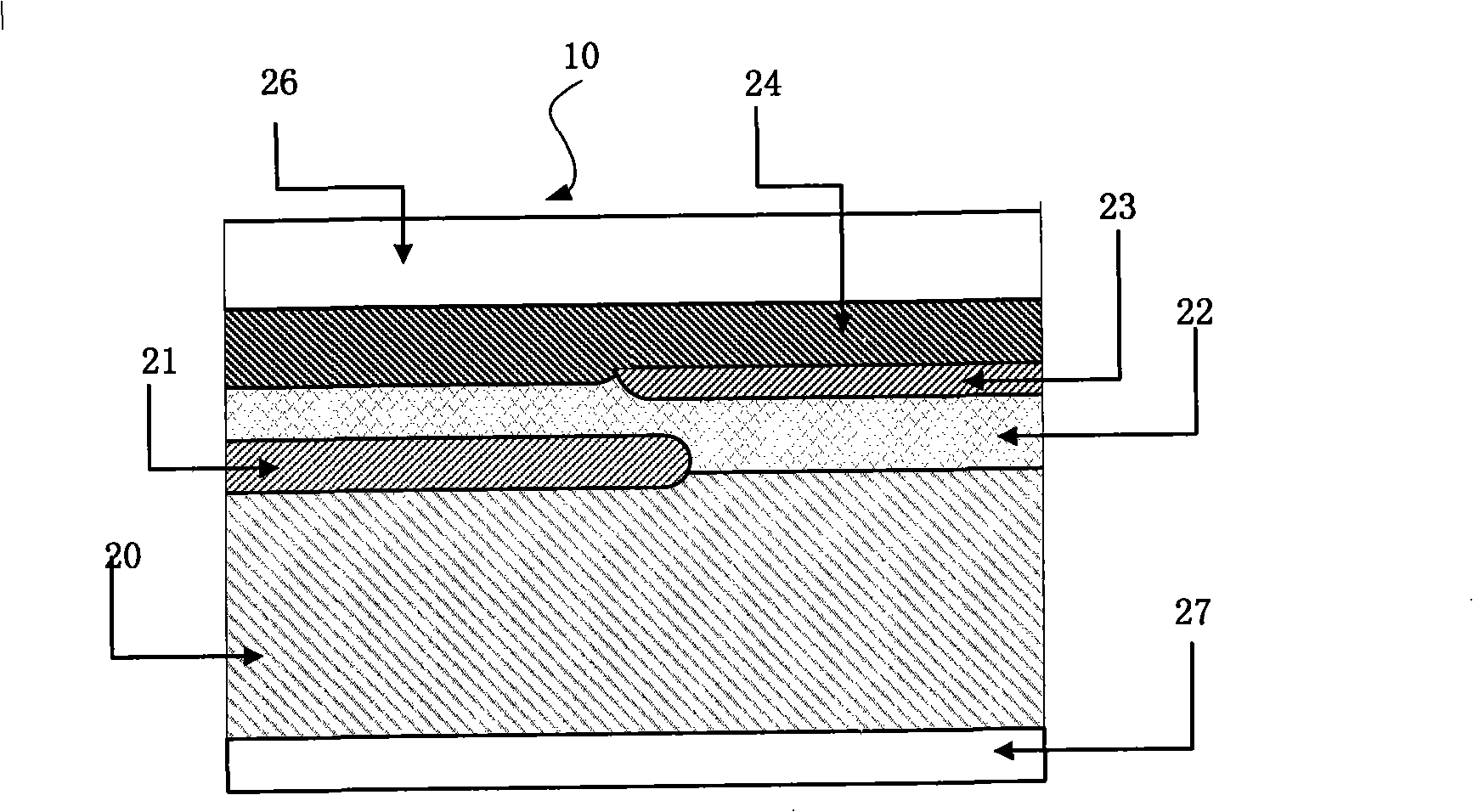

[0087] The second step: such as Figure 3.2 , Grow a lightly doped p- epitaxial layer 22 on the n+ substrate 20 with the p+ buried layer 21, half of the p- epitaxial layer 22 is on the n+ substrate 20, and the othe...

Embodiment 2

[0093] See Figure 4.1~4.7 As shown, in order to realize the structure diagram of the manufacturing process of the bidirectional low-voltage punch-through transient voltage suppression diode of the present invention, it specifically includes the following steps:

[0094] The first step: such as Figure 4.1 , The p+ buried layer 21 is formed by boron implantation and annealing in half of the n+ substrate 20. The p+ buried layer 21 laterally covers half of the n+ substrate 20. This p-type buried layer serves as the heavily doped base region of the reverse punch through diode. The n-type substrate serves as the emitter area of the reverse protection low-voltage punch-through diode 31 and the collector area of the forward protection low-voltage punch-through diode 32;

[0095] The second step: such as Figure 4.2 , Grow a lightly doped p- epitaxial layer 22 on the n+ substrate 20 with the p+ buried layer 21, half of the p- epitaxial layer 22 is on the n+ substrate 20, and the othe...

Embodiment 3

[0102] See Figure 5.1~5.6 As shown, in order to realize the structure diagram of the manufacturing process of the bidirectional low-voltage punch-through transient voltage suppression diode of the present invention, it specifically includes the following steps:

[0103] The first step: such as Figure 5.1 , The p+ buried layer 21 is formed by boron implantation and annealing in half of the n+ substrate 20. The p+ buried layer 21 laterally covers half of the n+ substrate 20. This p-type buried layer serves as the heavily doped base region of the reverse punch through diode. The n-type substrate serves as the emitter area of the reverse protection low-voltage punch-through diode 31 and the collector area of the forward protection low-voltage punch-through diode 32;

[0104] The second step: such as Figure 5.2 , Grow a lightly doped p- epitaxial layer 22 on the n+ substrate 20 with the p+ buried layer 21, half of the p- epitaxial layer 22 is on the n+ substrate 20, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com