Handheld terminal for detecting automatic welding equipment and detection method for handheld terminal

A hand-held terminal and automatic welding technology, which is applied in the direction of welding equipment, arc welding equipment, power supply testing, etc., can solve the problems of inability to quickly detect, diagnose and evaluate, inconvenient to carry, and reduce practicability, and achieve simple and reliable detection methods. The effect of improving production efficiency, improving detection efficiency and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

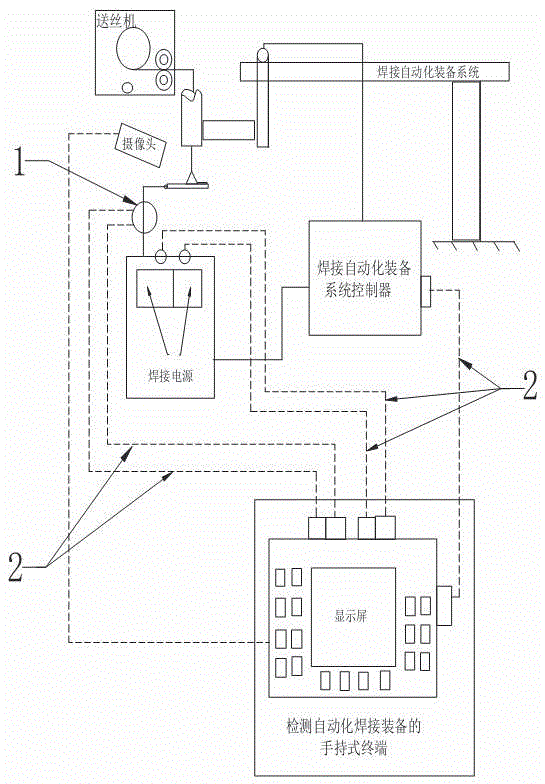

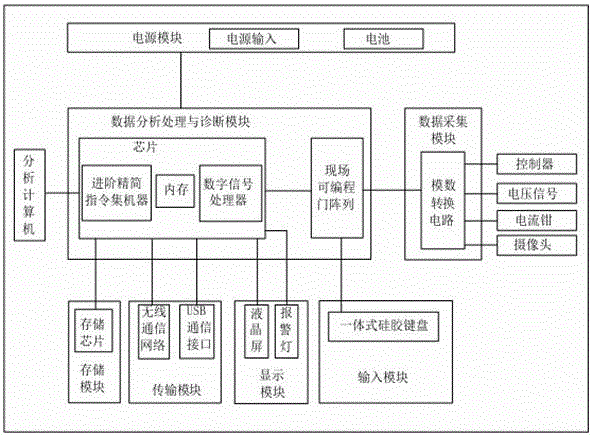

[0029] Such as figure 1 , figure 2 and image 3 As shown, the technical solution adopted by the present invention is a hand-held terminal for detecting automatic welding equipment. The hand-held terminal is provided with a data analysis and diagnosis module and a data acquisition module. The data analysis and diagnosis module includes a processing chip and a device connected to the processing chip. Field programmable gate array; the data acquisition module is provided with an analog-to-digital conversion circuit connected to the field programmable gate array through a data line, and the signal port of the analog-to-digital conversion circuit is respectively connected to the controller of the automatic welding equipment through the signal line 2 for Current clamp for detecting welding current 1, transformer for detecting welding power supply voltage, camera connection for real-time monitoring of automatic welding equipment; the handheld terminal is equipped with a remote moni...

Embodiment 2

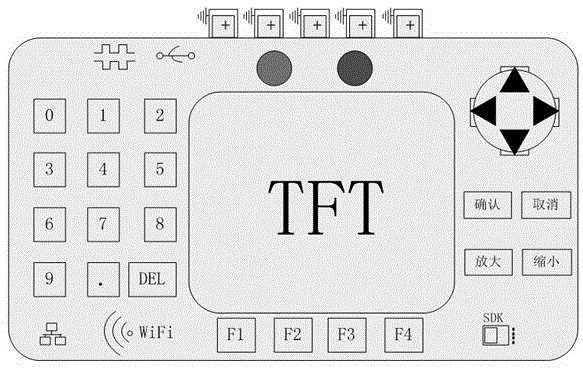

[0031] On the basis of Embodiment 1, in order to realize the detection and regulation of the handheld terminal and quickly process the detection information in the present invention, a preferred embodiment is that the handheld terminal is also provided with an input module connected to a field programmable gate array, and the input The module is equipped with an input panel for detecting and controlling the automatic welding equipment; the processing chip is equipped with a digital signal processor, an advanced reduced instruction set machine and a memory; in order to realize the remote detection of the automatic welding equipment, the communication module is equipped with a remote monitoring The wireless communication network and the USB communication interface connected by the modules are completely the same as those in Embodiment 1.

Embodiment 3

[0033] On the basis of Embodiment 2, in order to realize the rapid and clear display of detection results and faults on the handheld terminal, a preferred embodiment of the present invention also includes a display module for displaying real-time detection data and human-computer interaction to set the operating parameters of automatic welding equipment The liquid crystal display screen has a resolution of 600×800, and the display module is also equipped with an alarm light for displaying the failure of the welding equipment; in order to realize the real-time storage of the test results, the storage module is equipped with a storage module for storing welding parameters and test result data The memory chip is provided with a 12-bit analog-to-digital conversion chip in the analog-to-digital conversion circuit, and other parts are exactly the same as in embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com