Asynchronous motor rotor broken bar fault determination method

A technology for asynchronous motors and rotor broken bars, which is applied in the direction of motor generator testing, etc., can solve the problems of misjudgment and missed judgment, misjudgment, current detection method is easily affected by load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] A method for judging a broken bar fault of an asynchronous motor rotor, the steps of which are:

[0097] A. Construct a fault detection system for rotor broken bar of asynchronous motor;

[0098] B. Connect the Ia, Ib, and Ic current clamps to the A, B, and C phase cables one by one, pay attention to the connection direction of the current clamps, and make the direction of the arrow on the current clamps point to the direction of the motor;

[0099] C. Put the voltage clips of Va, Vb, and Vc on the terminals of A, B, and C phases in one-to-one correspondence;

[0100] D. The phase sequence of the detection current, if the display sequence is Ia, Ib, Ic and the phase angle is 120 degrees, the connection is correct.

[0101] E. The phase sequence of the detection voltage, if the displayed sequence is Vab, Vbc, Vca and the phase angle is 120 degrees, the connection is correct;

[0102] F. Detect the phase lag angle so that the three-phase lag angle matches, indicating th...

Embodiment 2

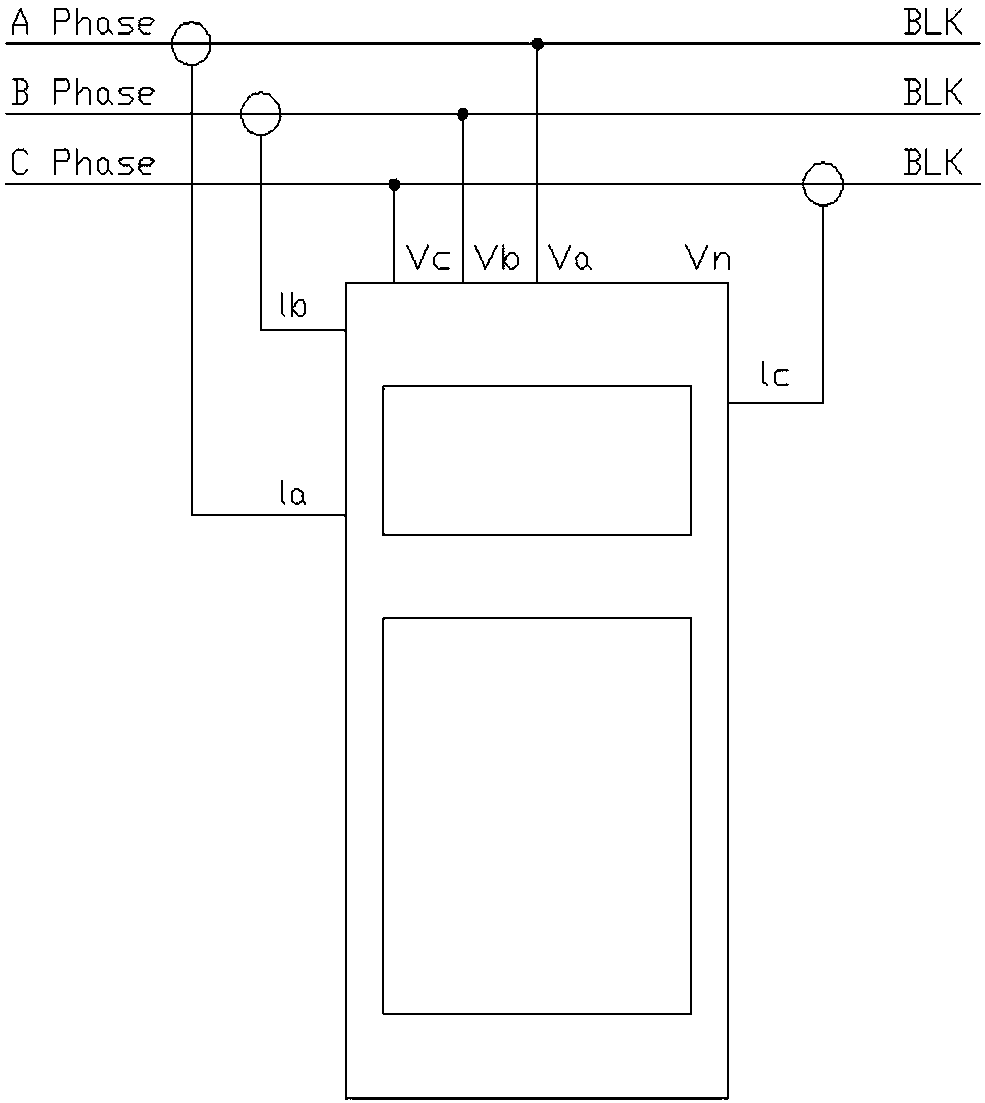

[0106] Such as figure 2 As shown, the asynchronous motor rotor broken bar fault detection system of this embodiment includes a power analyzer and a collector, and the current clamps of the power analyzer are respectively connected to the A, B and C phase cables one by one. The voltage clamps are respectively clamped on the A, B, and C phase terminals in one-to-one correspondence; the power analyzer is connected to the collector.

Embodiment 3

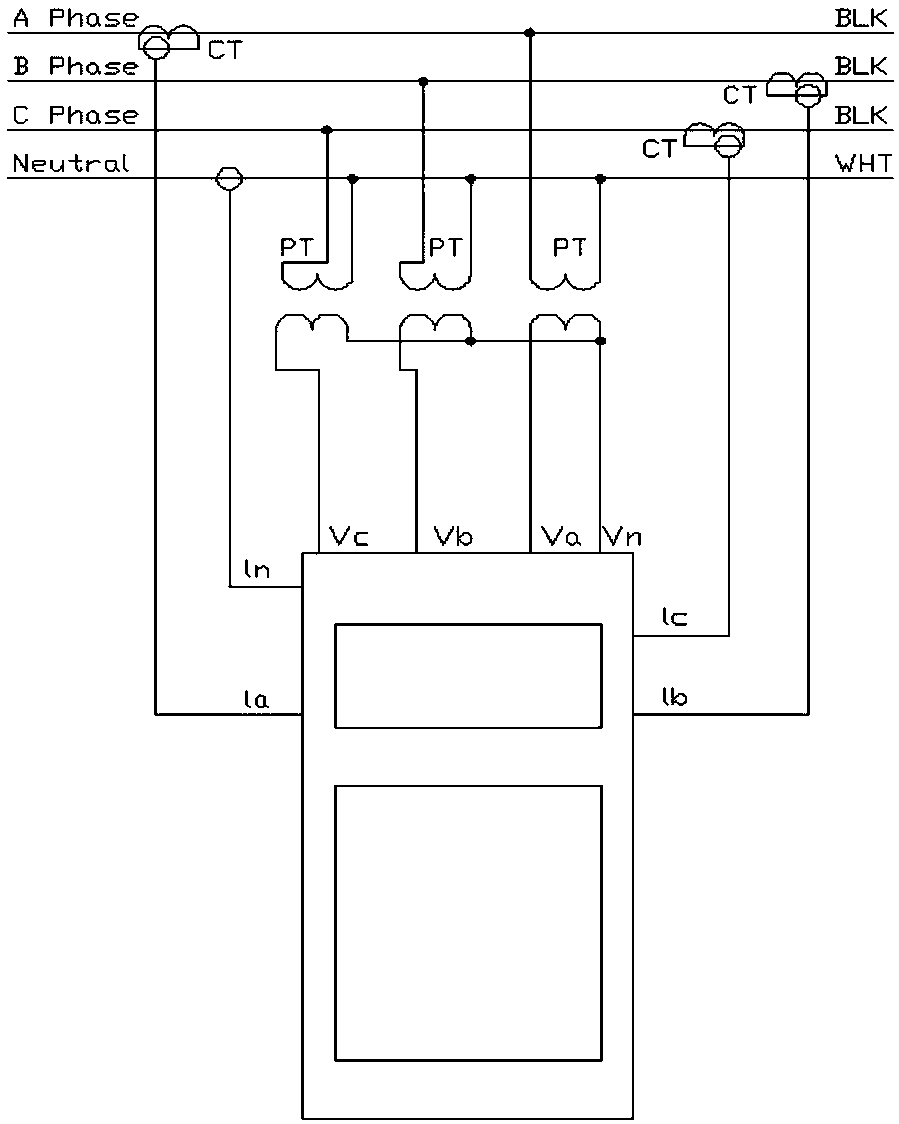

[0108] Such as figure 1 As shown, when the motor is a high-voltage motor, a broken rotor bar fault detection system of an asynchronous motor in this embodiment includes a voltage transformer and a current transformer, and the current transformer passes through the A, B, and C phase cables. The output end is connected to the power analyzer, the primary end of the voltage transformer is connected to the A, B, and C phase terminals, the secondary end of the voltage transformer is connected to the power analyzer, and the power analyzer is connected to the collector. The multiplier setting of the voltage and current of the acquisition instrument corresponds to the transformation ratio of the voltage transformer and the current transformer respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com