Disc tool magazine reliability testing device and method

A test device and reliability technology, which is applied in the field of disc-type tool magazine reliability test device, can solve the problems of single data, inability to obtain detection data such as position accuracy, speed, torque, etc., and it is difficult to analyze the reasons in depth, so as to improve the manufacturing quality , Reduce the effect of tool change failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

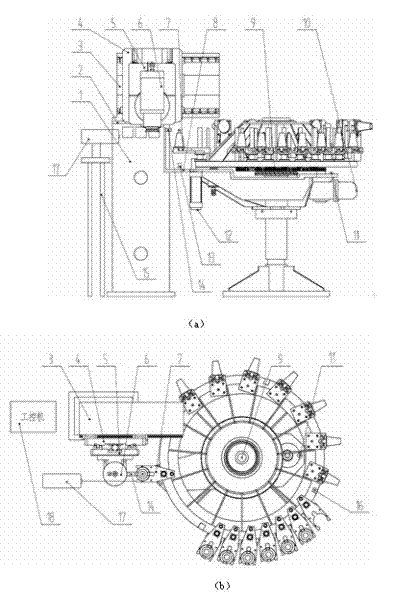

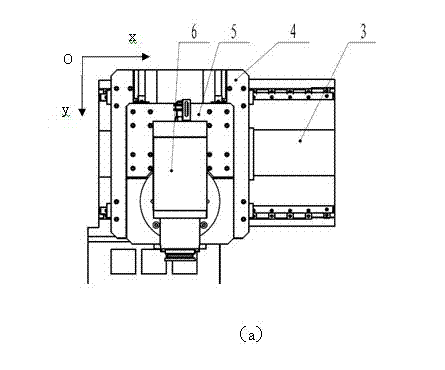

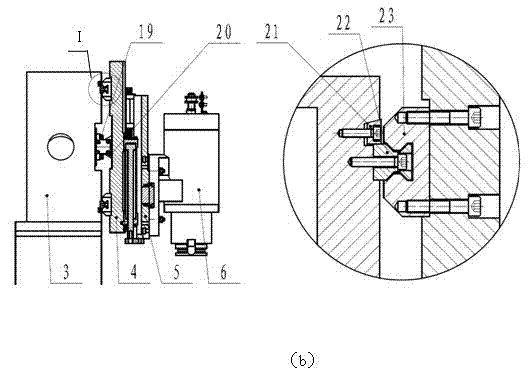

[0015] See attached figure 1 , the disk tool magazine reliability test device invented, the test object is the disc tool magazine 9. The test device includes a supporting component, a sliding module, a simulated spindle 6 , a measuring component and an industrial computer 18 . The supporting component includes a base 1, an adjustment backing plate 2, a beam 3, a stand 15 and a bracket 8; the measuring component includes a photoelectric proximity switch 13, a displacement sensor 14, an acceleration sensor 16, a vibration tester 17, a current clamp 10, and a pressure transmitter 12 and the noise monitoring system 11; the crossbeam 3, the adjustment backing plate 2, and the base 1 are connected together by bolts, the adjustment backing plate 2 is located between the crossbeam 3 and the base 1, and the crossbeam 3 can be adjusted by selecting an adjustment backing plate 2 of different thickness the height of the sliding module; the sliding module is erected on the beam 3; the ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com