Suspending type convection current clamp method for bell type annealing furnace

A bell-type annealing furnace and suspension technology, applied in the field of suspension convection stacking for bell-type annealing furnaces, can solve problems such as accidental roll changes, scratches on the roll surface, and economic losses of the enterprise, and reduce the occurrence of sticking rate, reducing vertical folding, and reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

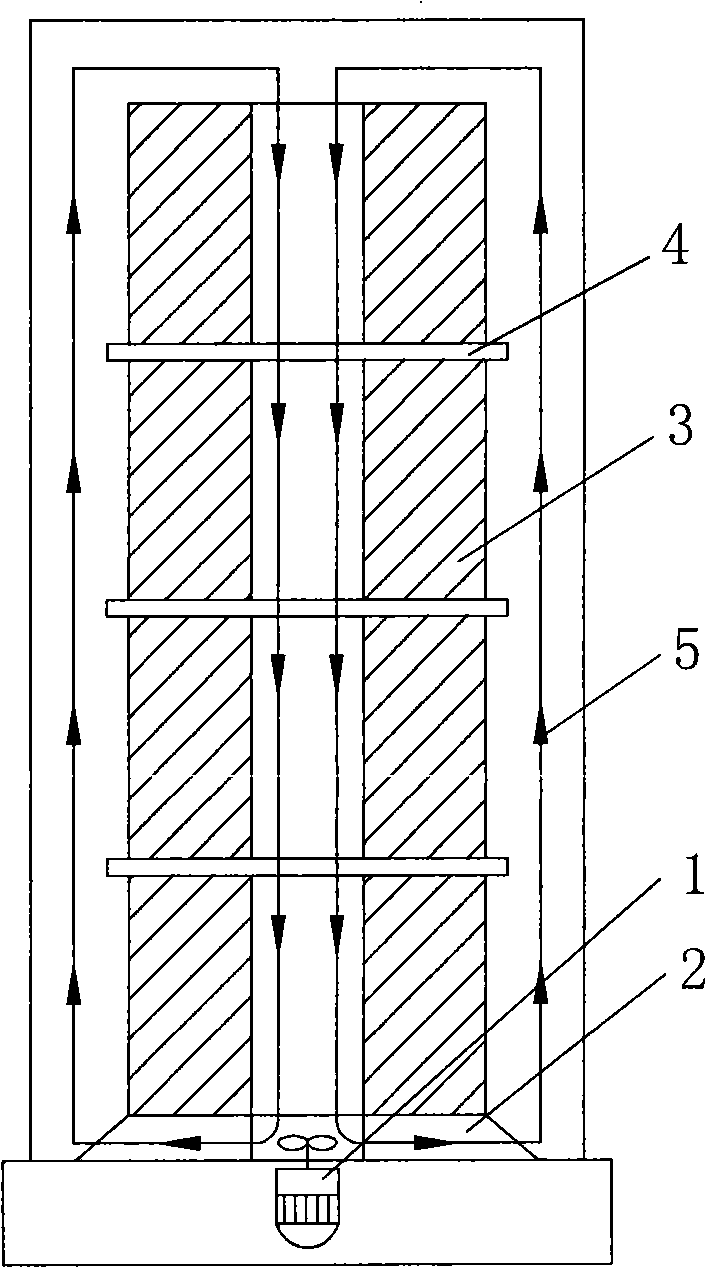

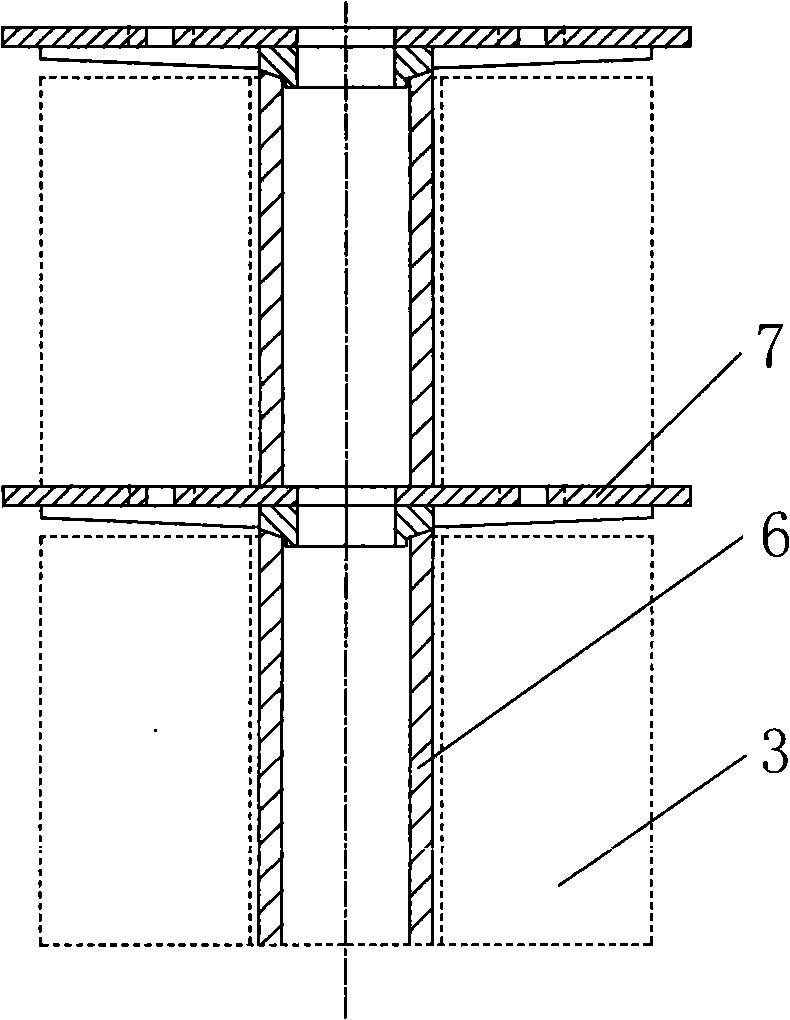

[0016] see image 3 , a suspension convective stacking method for bell annealing furnaces, first attach a sleeve 6 to the inner ring of the steel coil 3, and the sleeve 6 can directly wrap the steel coil when the steel coil is coiled in the upstream process Take it on the sleeve 6; then stack the steel coil 3 on the annealing furnace platform, stack the convection plate 7 above the steel coil 3, the bottom of the convection plate 7 matches the inner sleeve 6 of the steel coil 3, and the sleeve 6 Support the convection plate 7 so that the upper surface of the steel coil 3 is not in contact with the convection plate 7; Tube 6 sits on the top of convection plate 7, so that steel coils 3 are stacked one on top of the other. The circulation blower 1 installed under the hearth 2 keeps the protective gas in the annealing furnace circulating.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com