Blanking size control method for variable cross-section corrugated steel web box girder web

A corrugated steel web and size control technology, applied in bridges, special data processing applications, geometric CAD, etc., can solve problems such as deviation from the design state, affecting the force and safety of bridge structures, and affecting normal installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

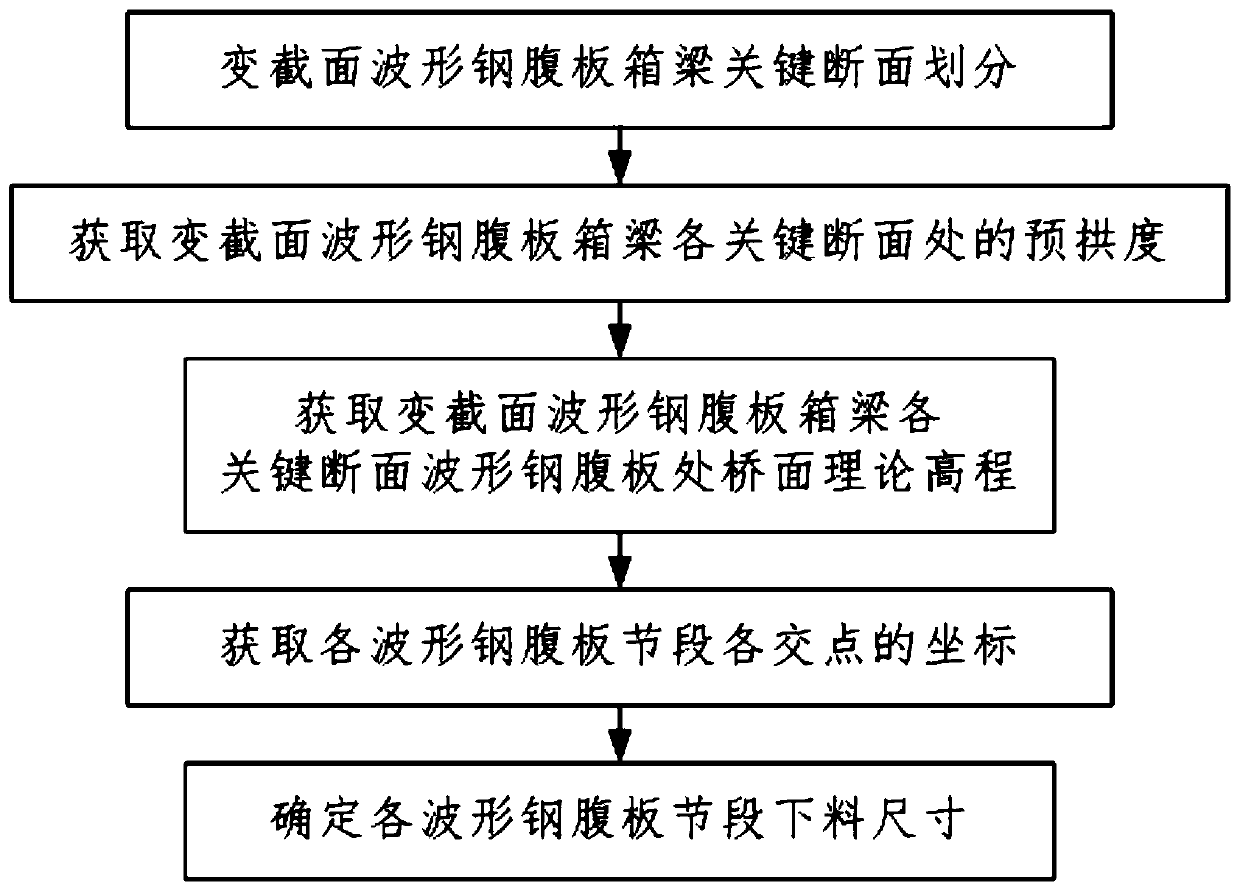

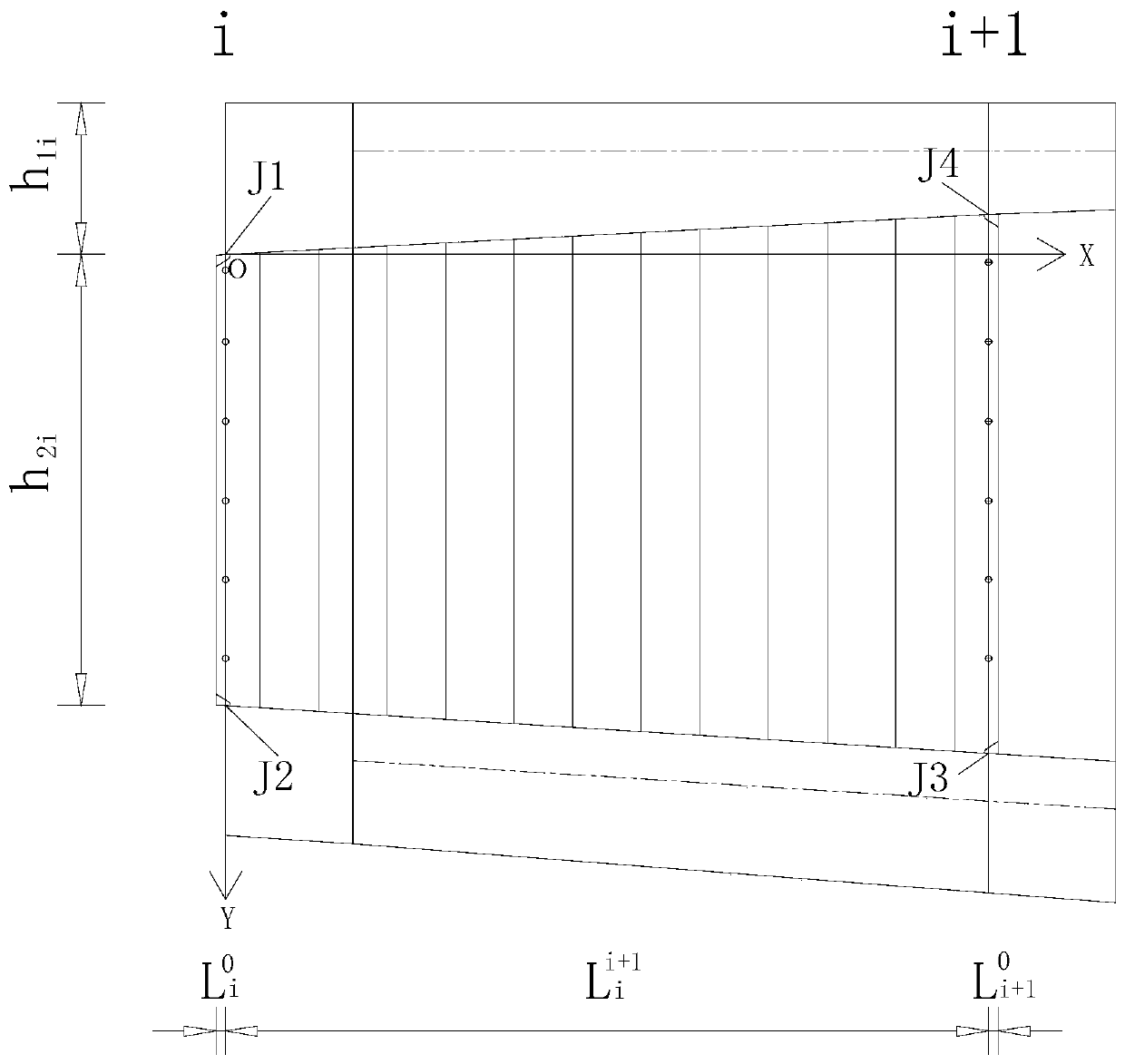

[0041] like Figure 1 to Figure 4 As shown, a method for controlling the blanking size of a box girder web with a variable cross-section corrugated steel web of the present invention includes the following steps:

[0042] Step 1. Divide the key sections of the box girder with corrugated steel webs with variable cross-section: divide the key sections of the box girder with corrugated steel webs with variable cross-sections. The main girder webs of the box girder with corrugated steel webs Steel web hybrid web, segmentally divides the part of the main girder web of the variable cross-section corrugated steel web box girder that is corrugated steel web, and both ends of the corrugated steel web segment are variable cross-section corrugated steel Key section of web box girder;

[0043] Number the key sections of the box girder with variable cross-section corrugated steel webs, and the joint position of the two connected corrugated steel web segments in the continuous corrugated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com