Construction method of bidirectional inclined v-shaped bridge tower of cable-stayed bridge without backstays

A construction method and two-way tilting technology, which is applied to cable-stayed bridges, bridges, bridge materials, etc., can solve the problems of difficult control of pouring quality and line shape, high load-bearing capacity requirements, and large consumption of support formwork, etc., to improve construction quality , Simplify the construction process and ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

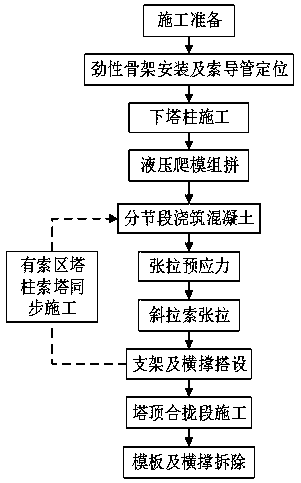

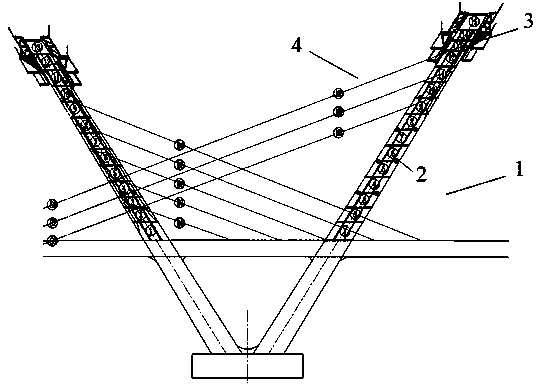

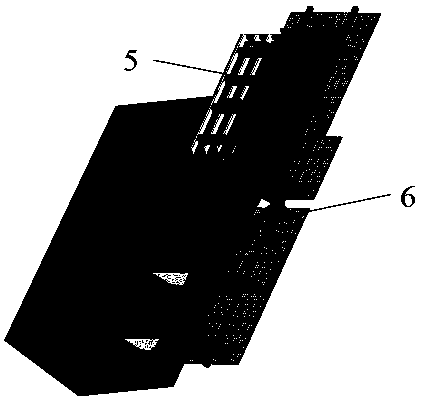

[0036] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. like Figure 1 to Figure 7 Shown: a construction method of a two-way inclined V-shaped bridge tower of a cable-stayed bridge without back cables, which is carried out in sequence according to the following steps: construction preparation, installation of rigid skeleton and positioning of cable guides, construction of lower tower columns, assembly of hydraulic climbing modules, and Simultaneous construction of tower columns and towers in the cable area, construction of the closing section of the tower top and removal of formwork and cross braces,

[0037] The synchronous construction steps of the tower column and cable tower in the cable area are composed of four steps: pouring concrete in sections, tensioning prestress, tensioning cable stays, and erecting brackets and cross braces.

[0038] The construction preparation steps are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com