Powder bagging weight sorting and shaping all-in-one machine

A weight-separating, all-in-one machine technology, applied in packaging, sorting, etc., can solve the problems of large volume, large space occupation, and complex structure, and achieve the effect of small volume, reduced space occupation, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

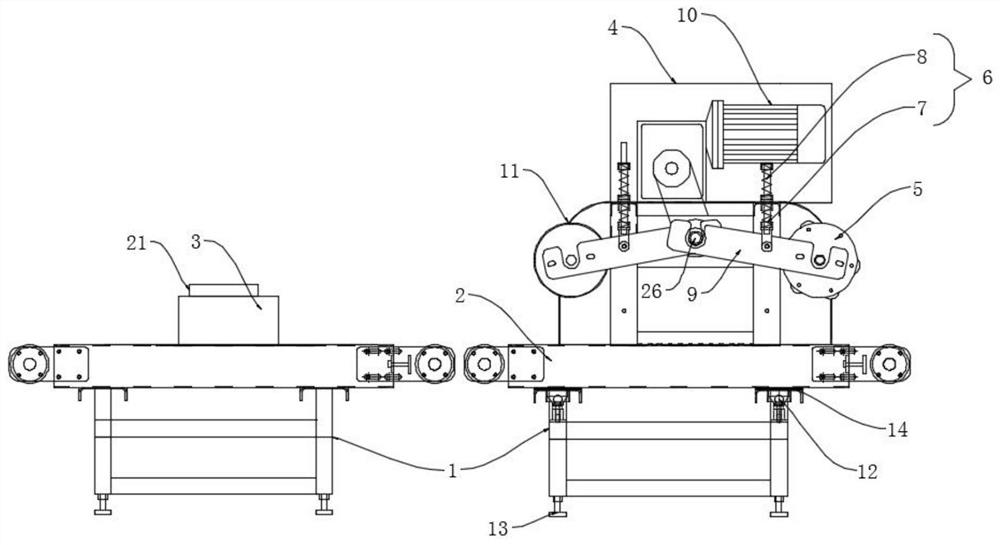

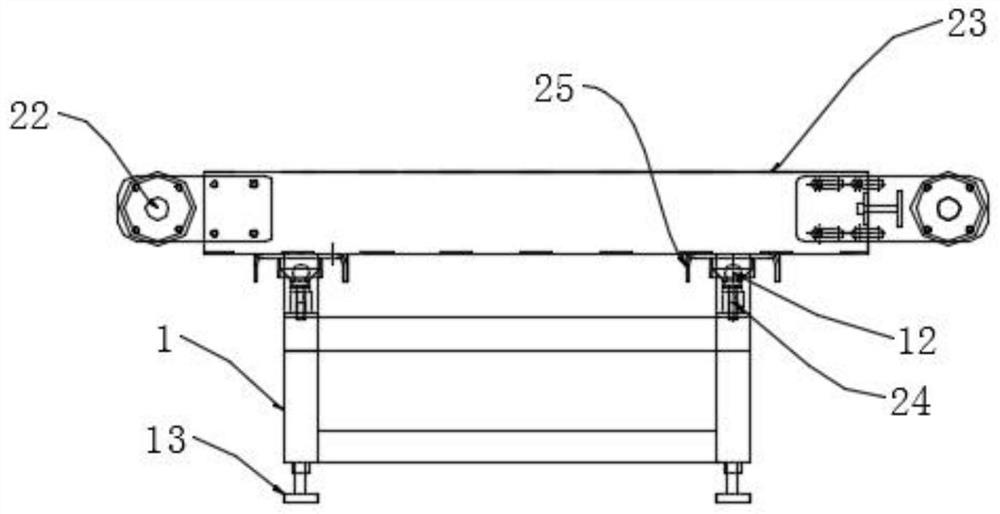

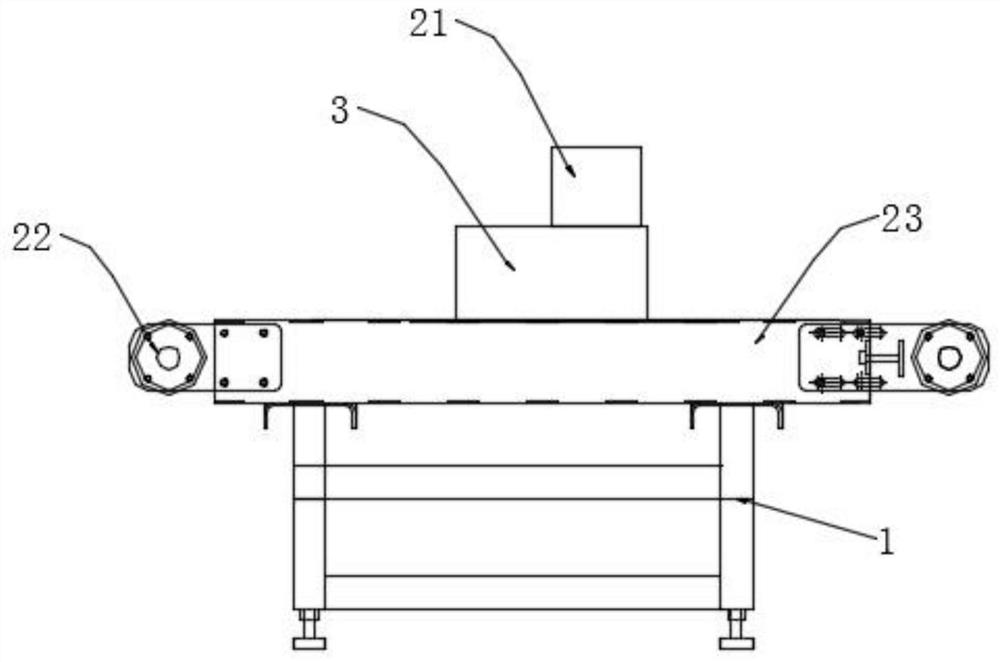

[0028] see figure 1 , in an embodiment of the present invention, a powder bag weight sorting and shaping machine includes two supporting frames 1, a shaping mechanism and two conveyors 2 respectively arranged on the supporting frames 1, one of the supporting frames A support plate 25 is arranged between the frame 1 and the conveyor 2 installed thereon, and a ball sensor 12 and a weight sensor 24 are arranged between the support plate 25 and each support frame 1 push rod. The mechanism is arranged on the supporting frame 1 on which the ball sensor 12 and the weight sensor 24 are installed, and the rejecting mechanism 3 is installed on the other supporting frame 1, and the controller 21 for electrically controlling its work is arranged on the rejecting mechanism 3 , the controller 21 is also connected to the ball sensor 12 and the weight sensor 24 through wires. The weight of the upper support changes to transmit a signal to the controller 21. Generally, the weight of the powde...

Embodiment 2

[0033] see figure 1 , the difference between the embodiment of the present invention and embodiment 1 is that: the ends of the two pole brackets 9 are hinged to the fastening shaft 26 arranged on the side wall of the mounting frame 4, and the mounting frame 4 is also provided with The pressure regulating assembly 6, the pressure regulating assembly 6 includes a push rod 7 and a spring 8, the spring 8 is arranged on the top of the push rod 7 and connected to the side wall of the mounting frame 4, the bottom end of the push rod 7 is hinged on the pole frame 9, because The setting of the pressure regulating assembly 6 can realize the automatic adjustment of the flat pressure of the support rod frame 9;

[0034] The bottom end of the pole column of the support frame 1 is equipped with a horizontal adjustment foot 13 so as to adjust the level of the whole device, and a shock absorber 14 is also arranged between the support plate 25 and each support frame 1 push rod. , The setting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com